Page 1

Page 2

Page 3

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

XJR1300 (P) 2002. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

XJR1300 (L) ’99 SERVICE MANUAL: 5EA3-AE1

EAS00000

XJR1300 (P) 2002

SUPPLEMENTARY

SERVICE MANUAL

2001 by Yamaha Motor Co., Ltd.

1st Edition, August 2001

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Page 4

EAS00003

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles

should have a basic understanding of mechanics and the techniques to repair these types of vehicles.

Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard to

performance and emissions. Proper service with the correct tools in necessary to ensure that the vehicle will operate as designed. If there is any question about a service procedure, it is imperative that

you contact a Yamaha dealer for any service information changes that apply to this model. This policy

is intended to provide the customer with the most satisfaction from his vehicle and to conform with federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and

will appear in future editions of this manual where applicable.

NOTE:

S This Service Manual contains information regarding periodic maintenance to the emission control

system. Please read this material carefully.

S Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death

the motorcycle operator, a bystander or a person checking or repairing the motorcycle.

CAUTION:

NOTE: A NOTE provides key information to make procedures easier or clearer.

A CAUTION indicates special precautions that must be taken to avoid damage

to the motorcycle.

to

Page 5

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid

out with the individual steps in sequential order.

1

The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each

page indicate the current chapter.

Refer to “SYMBOLS”.

2

Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(-s) appears.

3

Sub-section titles appear in smaller print than the section title.

4

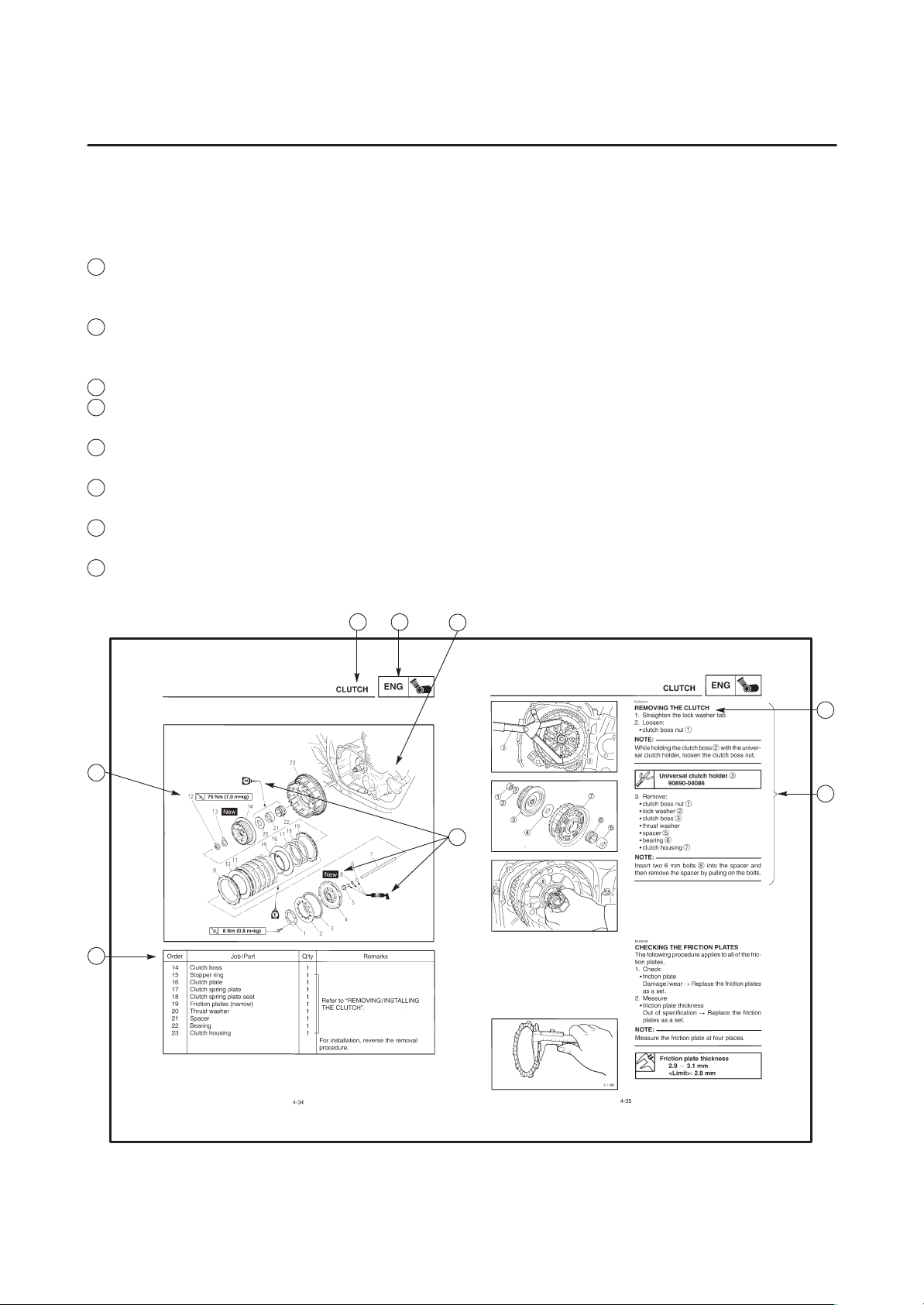

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

5

Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a

disassembly step.

6

Symbols indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

7

A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

8

Jobs requiring more information (such as special tools and technical data) are described sequentially.

12

5

7

4

3

8

6

Page 6

1

GEN

INFO

3

CHK

ADJ

5

CARB

7

2

SPEC

4

ENG

6

CHAS

8

EAS00009

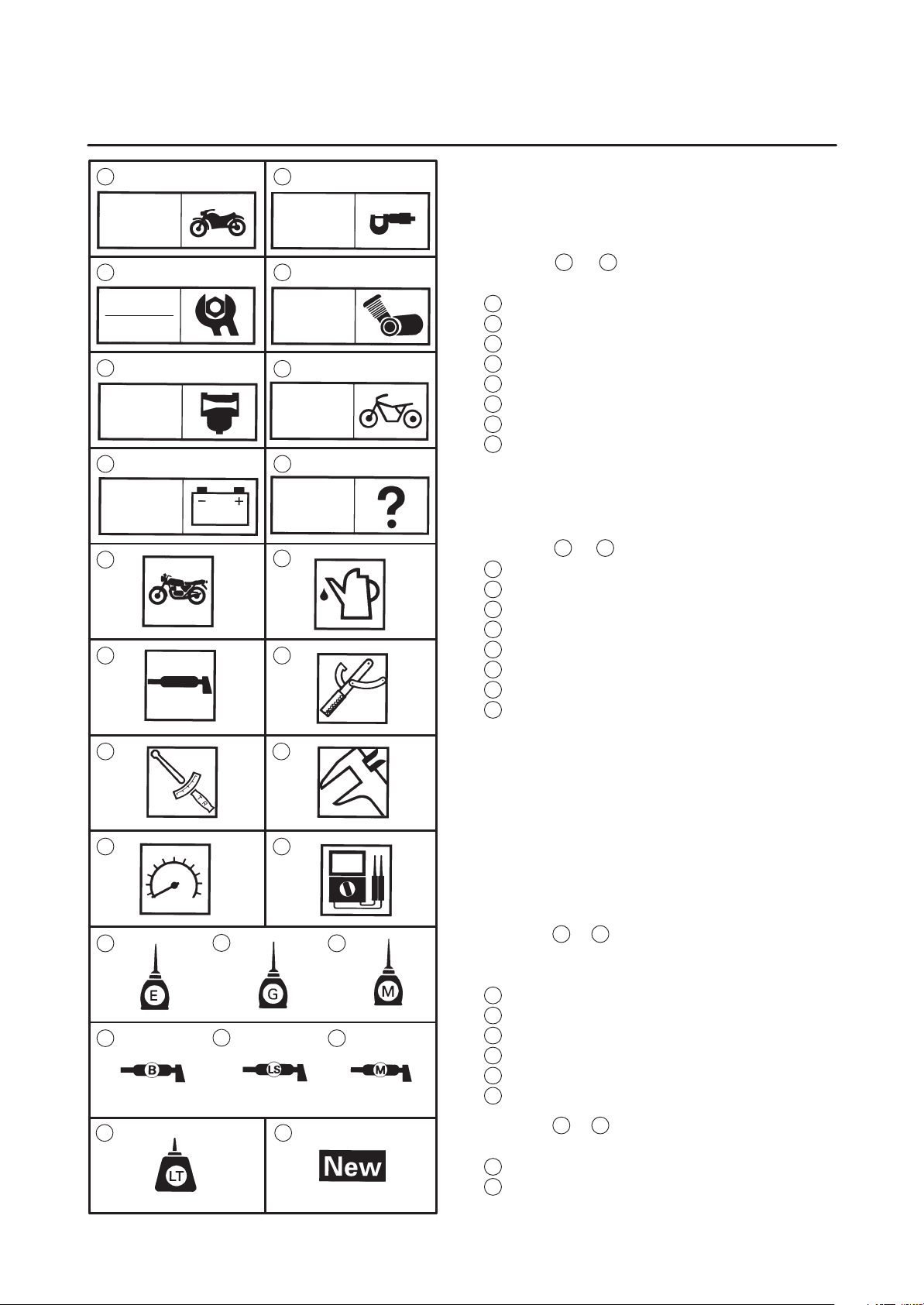

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols

chapter.

General information

1

Specifications

2

Periodic checks and adjustments

3

Engine

4

Carburetor(-s)

5

Chassis

6

Electrical system

7

Troubleshooting

8

1

to 8 indicate the subject of each

ELEC

9

11 12

18 1917

21

10

1413

1615

TRBL

SHTG

2220

Symbols 9 to 16 indicate the following.

Serviceable with engine mounted

9

10

Filling fluid

11

Lubricant

12

Special tool

13

Tightening torque

14

Wear limit, clearance

15

Engine speed

16

Electrical data

Symbols 17 to 22 in the exploded diagrams indicate the types of lubricants and lubrication

points.

17

Engine oil

18

Gear oil

19

Molybdenum disulfide oil

20

Wheel bearing grease

21

Lithium soap base grease

22

Molybdenum disulfide grease

23 24

Symbols 23 to 24 in the exploded diagrams indicate the following:

23

Apply locking agent (LOCTITE)

24

Replace the part

Page 7

CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE SPECIFICATIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CABLE ROUTING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE/LUBRICATION INTERVALS 20. . . . . . .

ENGINE 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING THE CLUTCH LEVER 22. . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING THE FRONT BRAKE 23. . . . . . . . . . . . . . . . . . . . . . . . .

CARBURETORS

AIR INDUCTION SYSTEM 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR INJECTION 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR CUTOFF VALVE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR INDUCTION SYSTEM DIAGRAMS 25. . . . . . . . . . . . . . . . . . . . .

CHECKING THE AIR INDUCTION SYSTEM 26. . . . . . . . . . . . . . . .

CHASSIS

FRONT AND REAR BRAKES 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT BRAKE MASTER CYLINDER 27. . . . . . . . . . . . . . . . . . . . . .

ASSEMBLING AND INSTALLING THE

FRONT BRAKE MASTER CYLINDER 28. . . . . . . . . . . . . . . . . .

REAR BRAKE CALIPER 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL

CARBURETOR HEATING SYSTEM 32. . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XJR1300 2002 WIRING DIAGRAM (for EUR)

XJR1300P 2002 WIRING DIAGRAM (for AUS)

Page 8

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model XJR1300 (P)

Model code: 5EAT/5EAW (EUR)

5EAU/ 5EAX (for D)

5EAV/ 5EAY (for AUS)

Dimensions:

Overall length

Overall width

Overall height

Seat height

Wheelbase

Minimum ground clearance

Minimum turning radius

Basic weight:

With oil and full fuel tank

Carburetor:

Type/ quantity

Manufacturer

2,175 mm

775 mm

1,115 mm

790 mm

1,510 mm

120 mm

2,800 mm

247 kg

BSR37/ 4

MIKUNI

SPEC

Transmission:

Primary reduction system

Primary reduction ratio

Secondary reduction system

Secondary reduction ratio

Transmission type

Operation

Gear ratio 1st

2nd

3rd

4th

5th

Spur gear

98/ 56 (1.750)

Chain drive

39/ 18 (2.167)

Constant mesh 5-speed

Left foot operation

40/ 14 (2.857)

36/ 18 (2.000)

33/ 21 (1.571)

31/ 24 (1.292)

29/ 26 (1.115)

1

Page 9

Model XJR1300 (P)

Tire:

Type

Size front

rear

Manufacturer front

rear

Type front

rear

Tire pressure (cold tire):

Maximum load-except motorcycle

Loading condition A *

front

rear

Loading condition B *

front

rear

High-speed riding

front

rear

GENERAL SPECIFICATIONS

Tubeless

120/ 70ZR17 (58W)/

120/ 70ZR17 M/ C (58W)

180/ 55ZR17 (73W)/

180/ 55ZR17 M/ C (73W)

MICHELIN/ DUNLOP

MICHELIN/ DUNLOP

MACADAM90X E/D220F ST M

MACADAM90X E/D220 ST M

203 kg

0 X 90 kg

250 kPa (2.5 kg/ cm

250 kPa (2.5 kg/ cm

90 X 203 kg

250 kPa (2.5 kg/ cm

290 kPa (2.9 kg/ cm

250 kPa (2.5 kg/ cm

290 kPa (2.9 kg/ cm

2

, 2.5 bar)

2

, 2.5 bar)

2

, 2.5 bar)

2

, 2.9 bar)

2

, 2.5 bar)

2

, 2.9 bar)

SPEC

*Load is the total weight of cargo, rider, passenger, and accessories.

2

Page 10

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

SPEC

Model

Cylinder head:

Warp limit

Cylinder:

Bore size

Taper limit

Out of round limit

Wear limit

Camshaft:

Drive method

Cam cap inside diameter

Camshaft outside diameter

Shaft-to-cap clearance

Cam dimensions

Standard Limit

SSS 0.2 mm

79.00 X 79.01 mm

SSS

SSS

SSS

Chain drive (Center)

25.000 X 25.021 mm

24.967 X 24.980 mm

0.020 X 0.054 mm

SSS

0.05 mm

0.1 mm

79.1 mm

SSS

SSS

SSS

SSS

Intake “A”

“B”

Exhaust “A”

“B”

Camshaft runout limit

35.95 X 36.05 mm

28.058 X 28.158 mm

35.95 X 36.05 mm

28.045 X 28.145 mm

SSS

35.85 mm

27.958 mm

35.85 mm

27.945 mm

0.03 mm

3

Page 11

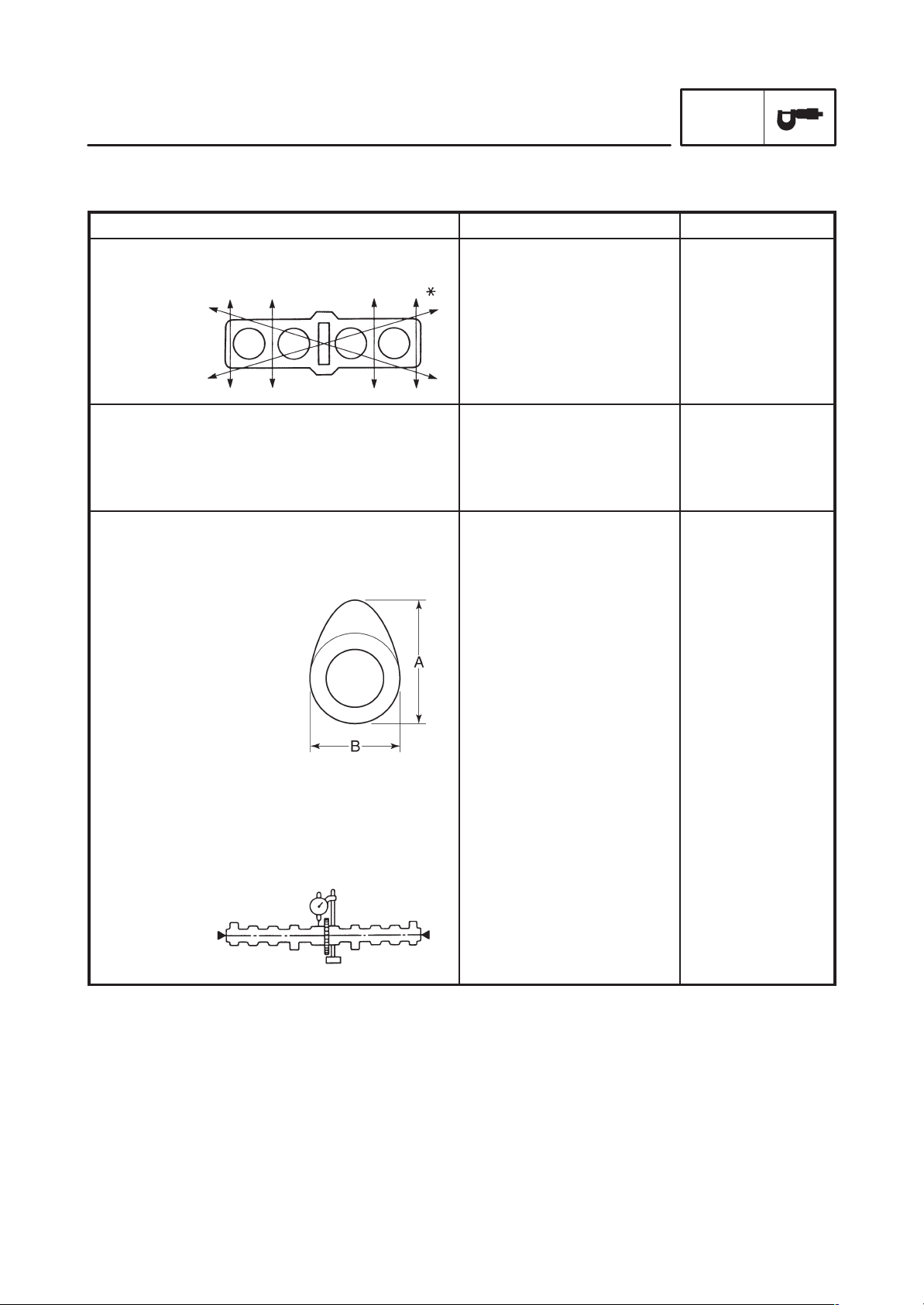

Model Standard Limit

Piston:

Piston to cylinder clearance

Piston size “D”

MAINTENANCE SPECIFICATIONS

0.015 X 0.040 mm

78.970 X 78.985 mm

SPEC

0.15 mm

SSS

Measuring point “H”

Piston off-set

Piston off-set direction

Piston pin bore inside diameter

Piston pin outside diameter

Carburetor:

I.D. mark

Main jet (M.J)

Main air jet (M.A.J)

Jet needle (J.N)

Needle jet (N.J)

Pilot jet (P.A.J.1)

Pilot outlet (P.O)

Pilot jet (P.J)

Bypass 1 (B.P.1)

Bypass 2 (B.P.2)

Bypass 3 (B.P.3)

Pilot screw (P.S)

Valve seat size (V.S)

Starter jet (G.S.1)

Starter jet (G.S.2)

Throttle valve size (Th.V)

Float height (F.H)

Fuel level (using special tool)

Engine idle speed

Intake vacuum

5 mm

1 mm

IN side

18.004 X 18.015 mm

17.991 X 18.000 mm

5EAT 30

#107.5

#80

5D118-53-3

P-0M

#140

ø1.0

#15

0.9

0.9

0.8

2

2.3

#52.5

0.8

#115

33 X 34 mm

3 X 4 mm

950 X 1,150 r/ min

31.3 kPa (235 mmHg)

SSS

SSS

SSS

18.045 mm

17.971 mm

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

4

Page 12

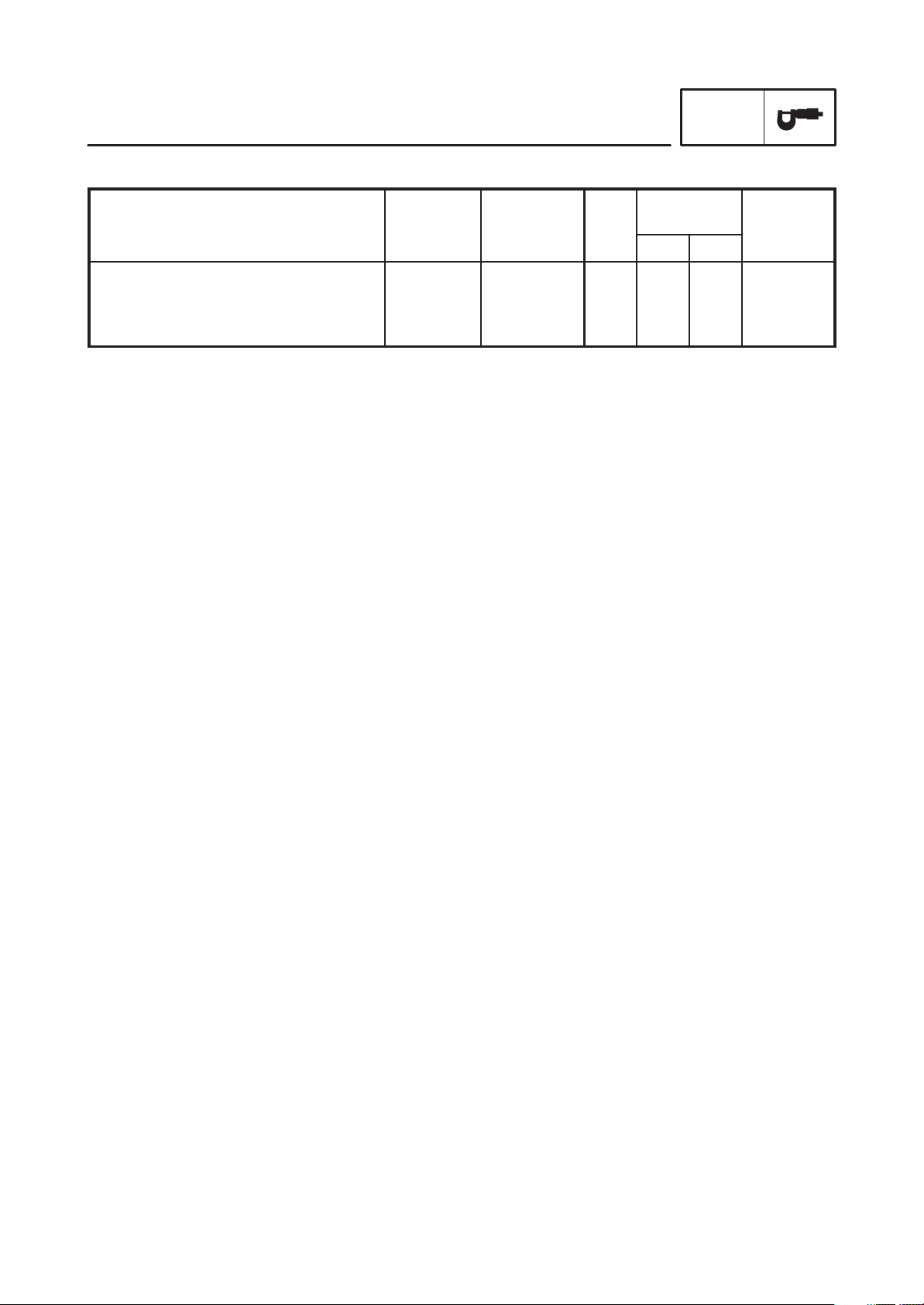

Tightening torques

g

size

y

MAINTENANCE SPECIFICATIONS

SPEC

Part to be tightened

Carburetor joint and carburetor

Carburetor and air filter joint

Air induction system pipe joint

Air induction system

Part name

Band

Clamp

–

Bolt

Thread

M4 0.7

M4 0.7

–

M6 1.0

Q’ty

4

4

4

2

Tightening

torque

Nm mSkg

2.7

2.7

3.7

10

0.27

0.27

0.37

1.0

Remarks

5

Page 13

CHASSIS

MAINTENANCE SPECIFICATIONS

SPEC

Model

Front suspension:

Front fork travel

Fork spring free length

Fitting length

Collar length

Spring rate (K1)

(K2)

Stroke (K1)

(K2)

Optional spring

Oil capacity

Oil level

Oil grade

Rear suspension:

Shock absorber travel

Spring free length

Fitting length

Spring rate (K1)

(K2)

(K3)

(K4)

Stroke (K1)

(K2)

(K3)

(K4)

Standard Limit

130 mm

308.3 mm

287.3 mm

245 mm

6.4 N/ mm (0.65 kg/ mm)

10.8 N/ mm (1.1 kg/ mm)

0 X 85 mm

85 X 130 mm

No

568 cm

118 mm

Fork oil 10W or equivalent

93 mm

230 mm

209 mm

19.4 N/ mm (1.98 kg/ mm)

21.4 N/ mm (2.18 kg/ mm)

26.3 N/ mm (2.68 kg/ mm)

28.2 N/ mm (2.88 kg/ mm)

0 X 13 mm

13 X 50 mm

50 X 67.5 mm

67.5 X 93.0 mm

3

SSS

300 mm

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

225 mm

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

Front wheel:

Type

Rim size

Rim material

Rim runout limit radial

lateral

Rear wheel:

Type

Rim size

Rim material

Rim runout limit radial

lateral

Drive chain:

Type/ manufacturer

No. of links

Chain free play

Brake lever & brake pedal:

Brake pedal position

Cast wheel

17 MT3.50 or

17 M/ C MT3.50

Aluminum

SSS

SSS

Cast wheel

17 MT3.50 or

17 M/ C MT3.50

Aluminum

SSS

SSS

50VA8/ DAIDO

112

20 X 30 mm

40 mm SSS

SSS

SSS

SSS

1 mm

0.5 mm

SSS

SSS

SSS

1 mm

0.5 mm

SSS

SSS

SSS

6

Page 14

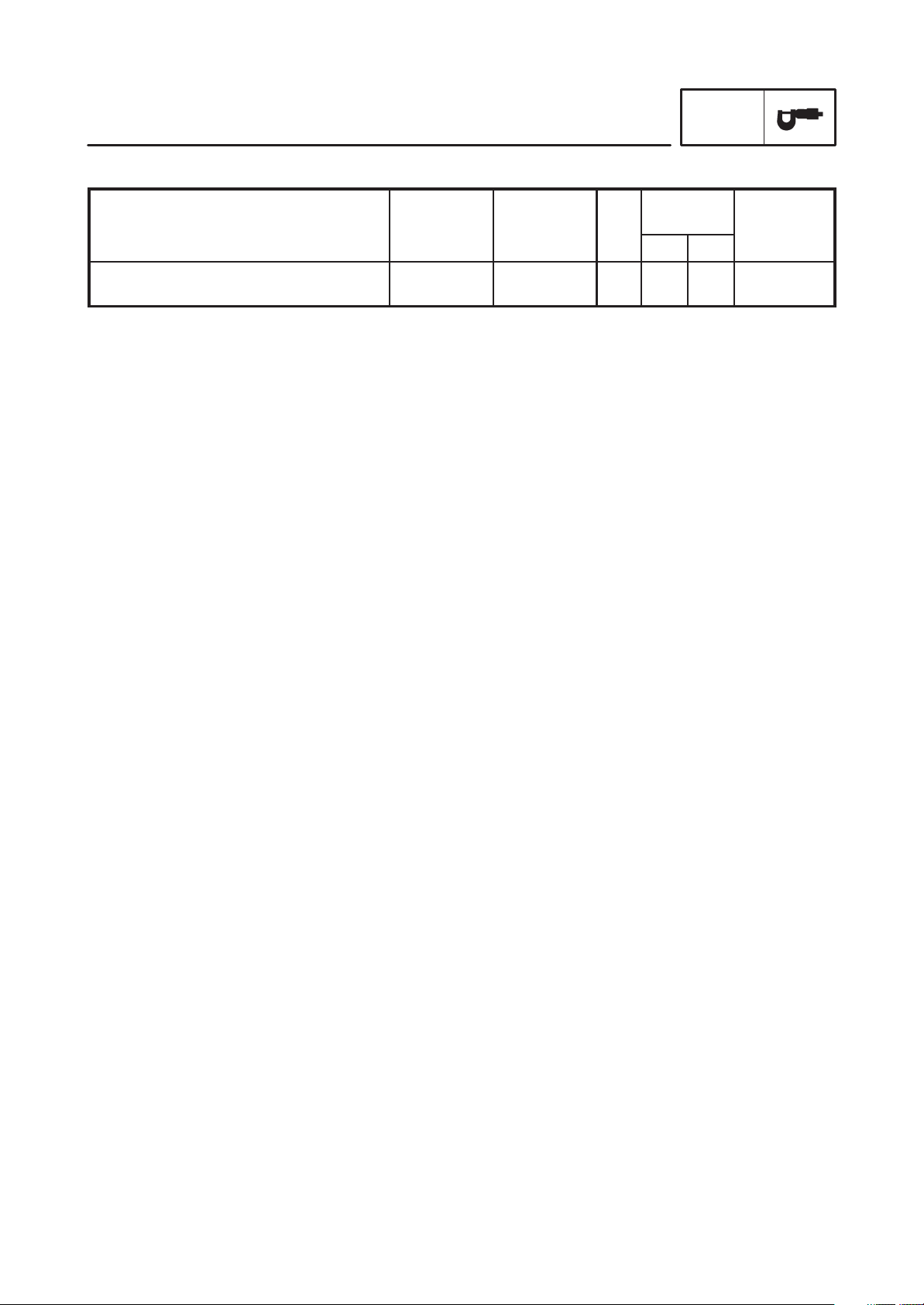

Tightening torques

g

y

Part to be tightened

MAINTENANCE SPECIFICATIONS

Part name Thread size Q’ty

SPEC

Tightening

torque

Nm mSkg

Remarks

Throttle cable and carburetor

Ignition coil

Nut

Nut

M6 1.0

M6 1.0

2

246.5

0.4

0.65

7

Page 15

ELECTRICAL

MAINTENANCE SPECIFICATIONS

SPEC

Model

T.C.I.:

Pickup coil resistance/ color

T.C.I. unit model/ manufacturer

Charging system:

Type

Model/ manufacturer

Normal output

Rotor coil resistance

Stator coil resistance

Brush overall length

Spring force

Voltage regulator:

Type

Model/ manufacturer

No load regulated voltage

Electric starter system:

Type

Starter motor:

Model/ manufacturer

Output

Brush overall length

Spring force

Commutator diameter

Mica undercut

Starter relay:

Model/ manufacturer

Amperage rating

Coil winding resistance

Starting circuit cut-off relay:

Model/ manufacturer

Coil winding resistance

Diode

Standard Limit

248 X 372 Ω/W/R-W/G

TNDF63/ DENSO (except for D)

TNDF64/ DENSO (for D)

A.C. generator

B3G/ DENSO

13.5 V 28 A/ 5,000 r/ min

2.8 X 3.0 Ω

0.19 X 0.21 Ω

13.7 mm

5.10 X 5.69 N (0.52 X 0.58 kg)

Semi-conductor, field control type

B3G/ DENSO

14.2 X 14.8 V

Constant mesh type

SM-13/ MITSUBA

0.65 kW

10 mm

8.82 N (899 kg)

28 mm

0.7 mm

MS5E-491/ JIDECO

180 A

4.2 X 4.6 Ω

G8R-30Y-P/OMRON

162 X 198 Ω

Yes

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

4.7 mm

SSS

SSS

SSS

SSS

SSS

SSS

SSS

5 mm

SSS

27 mm

SSS

SSS

SSS

SSS

SSS

SSS

SSS

Circuit breaker:

Type

Amperage for individual circuit Q’ty

MAIN

HEAD LIGHT

SIGNAL

IGNITION

TURN

Reserve

Fuse

40 A 1

15 A 1

15 A 1

15 A 1

15 A 1

40 A 1

15 A 1

8

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

Page 16

CABLE ROUTING

CABLE ROUTING

SPEC

1 Starter motor cable

2 Battery negative (–) lead wire

3 Carburetor heater plug

4 A.C. generator coupler

5 Rear stop switch coupler

6 Neutral lead wire

7 Pickup lead wire

8 Side stand switch lead wire

9 T.P.S.

10 Tank fitting

11 #1 and #4 ignition coil lead wires

12 Horn lead wire

13 #3 high-tension cord

14 #4 high-tension cord

15 Engine frame ground lead wire

16 Rear stop switch

17 Relay assy

18 Guide wire

19 Fuel tank drain hose

20 Fuel tank breather hose

A Pass the starter motor cable and

the negative (–) lead wire of the

battery through the inside of the

seat rail.

9

Page 17

CABLE ROUTING

SPEC

B Secure the carburetor heater

lead wire, the starter motor

cable, the negative (–) lead wire

of the battery, the A.C. generator

lead wire, the neutral lead wire,

the side stand switch lead wire,

the pickup lead wire, and the rear

stop switch lead wire (total 8

wires), to the fuel tank rail, near

the air cleaner intake port mounting screw, by use of this band.

The front end of the band must

be directed towards the front of

the vehicle.

C Clamp the throttle cables to the

fuel tank rail, on the tank fitting by

use of this band. The front end of

the band must be directed downward.

D Thread this clamp through the

upper hole in the gusset and secure the two throttle cables. The

front end of the clamp must be directed towards the inside of the

vehicle.

E Bundle the #3 and #4 high-ten-

sion cords, on the head cover

mounting bolt at the #3 cord, by

use of this band.

F Do not entangle the lead wires

and the hosing.

Pass the bundle of lead wires

and that of hosing orderly as

shown.

G Pass the air cleaner drain hose,

the fuel tank drain hose, and the

fuel tank breather hose (total 3

hoses) through the guide wire of

the engine.

10

Page 18

CABLE ROUTING

SPEC

H Bundle the A.C. generator lead

wire, the pickup lead wire, the

side stand switch lead wire, the

starter motor cable, and the carburetor heater lead wire (total 5

wires), by use of this clamp.

I Match the marks of the fuel tank

drain hose and fuel tank breather

hose, and arrange the two types

of hose properly.

J Match the paint mark of the air

cleaner drain hose to the lower

end of the guide wire.

K Clamp the wire harness to the

seat rail, at the front end of the

bracket.The front end of the

clamp must be directed downward.

L Clamp the wire harness.

M Pass the wire harness between

the handle standing lug member

and the rear fender.

11

Page 19

CABLE ROUTING

SPEC

1 Gusset

2 Tension pipe 1

3 #2 high-tension cord

4 #1 high-tension cord

5 Wire starter

6 A.C. generator

7 Oil filter cover

8 Side stand switch

9 Side stand switch lead wire

10 Horn lead wire

11 #2 and #3 ignition coil lead wires

12 Frame ground lead wire

13 Flasher relay coupler

14 Oil lamp relay coupler

15 Igniter unit coupler

A Pass the wire harness and the

starter cable through the holder

wire of the gusset.

Pass the starter cable under the

wire harness.

B Secure the lead wire branch of

the main harness to tension pipe

1, at the immediate rear of the

gusset, by use of this band.

The front end of the band must

be directed downward.

C Bundle the four high-tension

cords, the #1 and #2 cords up

and the #3 and #4 cords down,

by use of this band.

Position the leading ends of the

cords near, but not below, the

lower front end of the air induction system assy.

12

Page 20

CABLE ROUTING

SPEC

D Bundle the #1 and #2 high-ten-

sion cords using this clamp.

Clamp these cords above the #2

head cover mounting bolt.

E Route the air cleaner drain hose

through the right side of the vehicle with a clearance above the

starter motor.

F Mount the square fixture of the

clutch hose in parallel with the

cover.

G After securing the side stand

switch lead wire using this

clamp, first route the lead wire

between the pickup cover, the oil

filter cover, the A.C. generator,

and the starter motor. Next, as

with the engine lead wire, route

the lead wire through the right

side of the vehicle.

H Clamp the clutch hose.

I Secure the grommet of the

clutch hose by use of this holder

wire of the gusset.

J Pass the horn lead wire between

the clutch hose and the frame,

then pull the lead wire out to the

front, and connect the lead wire

to the horn.

K Connect the black-coupler-

equipped lead wire to the #1 and

#4 ignition coils.

13

Page 21

CABLE ROUTING

SPEC

L Pass this clamp through the low-

er hole of the gusset and secure

the clutch hose.

The front end of the clamp must

be directed towards the inside of

the vehicle.

M Pass the main harness through

the inside of the clutch hose and

insert the harness into the left of

the headlight lower hole.

N Fasten the frame ground lead

wire together with the igniter unit

mounting screw.

O Clamp the seat lock wire to the

seat rail.

The front end of the clamp must

be directed downward.

14

Page 22

CABLE ROUTING

SPEC

1 Throttle cable

2 #1 and #4 ignition coils

3 T.P.S.

4 Neutral switch coupler

5 Pickup coupler

6 Side stand switch coupler

7 Fuel sender coupler

8 Igniter unit

9 Starter cable

10 #2 and #3 ignition coils

11 Stoppers

12 Negative (–) lead wire of the bat-

tery

13 Relay assy

14 Starter motor cable

15 Thermoswitch

16 Starter relay

17 Rib of the rear fender

18 Seat lock wire

19 Positive (+) lead wire of the bat-

tery

20 Starter relay coupler

21 Fuse box

22 Negative (–) lead wire coupler of

the battery

23 Flasher relay

24 Oil lamp relay

25 Battery band

A Right horn.

Install the HI tone source (with Hmarked label) at the right of the

vehicle.

B Connect the #1-#4 high-tension

cords in order of the cord number.

C Pass the T.P.S. lead wire through

the clamp of the #4 carburetor.

D To fuel sender

15

Page 23

CABLE ROUTING

SPEC

E Clamp the starter motor cable

and the negative (–) lead wire of

the battery to the seat rail, between the air cleaner mounting

bracket and the tank mounting

bracket.

F Connect the fuel sender coupler,

neutral switch coupler, pickup

coupler, and side stand switch

coupler wires above the air

cleaner.

G Thread the wire harness inser-

tion clamp onto the T-stud of the

frame.

H Pass the starter cable through

the front of the throttle cable.

I From left: #1, #2, #3, and #4

high-tension cords.

J Secure the wire harness and the

starter cable, on the harness

positioning tape, by use of this

band. The front end of the band

must be directed downward.

The harness must not deflect between the T-stud and the clamp.

K Connect the starter cable to face

at right angles to the vehicle

body with contact with the stoppers.

L Direct the crimping side of the

battery positive (+) lead wire

downward and connect the lead

wire.

M Connect the starter motor cable

to face outward at an angle of

about 45 degrees.

16

Page 24

CABLE ROUTING

SPEC

N Secure the two positive (+) lead

wires of the battery, the negative(–) lead wire coupler of the

battery, and the wire harness by

use of this battery band.

O Clamp the wire harness to the

seat rail, on the wire harness

positioning tape and at the immediate rear of the side cover

mounting bracket on the seat

rail.

The front end of the clamp must

face downward and be positioned inside the back stay.

P Store the wire harness, the tail-

light lead wire, and the rear left

and right flasher lead wires, into

the space between the taillight

bracket and the rib of the rear

fender.

Q The seat lock wire must not ex-

tend to the outside of the bracket.

R Pass the lead wire leading to the

fuse box under the wire harness.

S After connecting the lead wire of

the thermoswitch, store the lead

wire into the space under the

wire harness.

T Clamp the wire harness to the

seat rail, on the wire harness

positioning tape and at the immediate rear of the side cover

mounting bracket on the seat

rail.

The front end of the clamp must

face downward and be positioned inside the back stay.

17

Page 25

CABLE ROUTING

SPEC

1 Meter lead wire

2 Main switch lead wire

3 Crown handle

4 Starter cable

5 Left handle switch lead wire

6 Clutch hose

7 Front left flasher lead wire

8 Front right flasher lead wire

9 Brake hose 2

10 Brake hose 1

11 Right handle switch lead wire

12 Wire harness

13 Taillight lead wires

14 Taillight bracket

15 Rib of the rear fender

16 Rear fender

17 Rear left flasher lead wire

18 Rear right flasher lead wire

19 Wire harness

A Pass the throttle cable through

the guide wire of the stay headlight.

B Insert the meter lead wire and

the main switch lead wire into the

upper hole of the headlight.

C Bundle the handle switch lead

wire, the clutch hose, and the

starter cable, under the crown

handle, by use of this band.

The handle switch lead wire

must be passed outside the

clutch hose.

The starter cable must be

passed inside the clutch hose.

D Pass the front left and right flash-

er lead wires through the front of

the stay headlight.

Securely mount the cap to face

upward.

18

Page 26

CABLE ROUTING

SPEC

E Insert the left lead wire of the

handle switch and the left lead

wire of the front flasher into the

left of the headlight lower hole.

F Insert the right lead wire of the

handle switch and the right lead

wire of the front flasher into the

right of the headlight lower hole.

G Bundle the handle switch lead

wire and brake hose 2, near the

guide wire of the stay headlight

by use of this band.

H Match the wire harness, the

main switch lead wire, and the

meter lead wire, to the wire harness and main switch lead wire

positioning tapes, and bundle

the harness and the lead wires

by use of the band.

I The lead wires must be clamped

in this area.

J Bundle the front left and right

flasher lead wires by use of the

clamp.

K The wire harness, the taillight

lead wires, and the rear left and

right flasher lead wires must be

arranged below the rib of the rear

fender.

L Clamp the wire harness and the

rear left and right flasher lead

wires.

The front end of the clamp must

be directed forward.

M Pass the rear left and right flash-

er lead wires through the respective holes in the rear fender.

19

Page 27

INTRODUCTION/

NO.ITEM

CHECK OR MAINTENANCE JOB

ppg

5

Air filter element

9*Brake hoses

13*Swingarm

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

CHK

ADJ

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced. This information applies to vehicles already in service as well as new vehicles that are being prepared for sale. All

service technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

NOTE:

D The annual checks must be performed every year, except if a kilometer-based maintenance is per-

formed instead.

D From 50,000 km, repeat the maintenance intervals starting from 10,000 km.

D Items marked with an asterisk should be performed by Yamaha dealer as they require special tools,

data and technical skills.

ODOMETER READING ( 1,000 km)

1 10 20 30 40

1 * Fuel line

2 * Fuel filter S Check condition. √ √

3 Spark plugs

4 * Valves

6 * Clutch

7 * Front brake

8 * Rear brake

*

10 * Wheels S Check runout and for damage. √ √ √ √

11 * Tires

12 * Wheel bearings S Check bearing for looseness or damage. √ √ √ √

*

14 Drive chain

S Check fuel hoses and vacuum hose for

cracks or damage.

S Check condition.

S Clean and regap.

S Replace. √ √

S Check valve clearance.

S Adjust

S Clean. √ √

S Replace. √ √

S Check operation, fluid level and vehicle for

fluid leakage. (See NOTE.)

S Check operation, fluid level and vehicle for

fluid leakage. (See NOTE.)

S Replace brake pads. Whenever worn to the limit

S Check operation, fluid level and vehicle for

fluid leakage. (See NOTE.)

S Replace brake pads. Whenever worn to the limit

S Check for cracks or damage. √ √ √ √ √

S Replace. (See NOTE.) Every 4 years

S Check tread depth and for damage.

S Replace if necessary.

S Check air pressure.

S Correct if necessary.

S Check operation and for excessive play. √ √ √ √

S Lubricate with lithium-soap-based grease. Every 50,000 km

S Check chain slack.

S Make sure that the rear wheel is properly

aligned.

S Clean and lubricate.

√ √ √ √ √

√ √ √ √ √ √

√ √ √ √ √ √

√ √ √ √ √

√ √

Every 20,000 km

√ √ √ √ √

Every 1,000 km and after washing

the motorcycle or riding in the rain

ANNUAL

CHECK

20

Page 28

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

NO.ITEM

CHECK OR MAINTENANCE JOB

gg

CHK

ADJ

ODOMETER READING ( 1,000 km)

1 10 20 30 40

S Check bearing play and steering for

15 * Steering bearings

16 * Chassis fasteners

17

18 * Sidestand switch S Check operation. √ √ √ √ √ √

19 * Front fork S Check operation and for oil leakage. √ √ √ √

20 *

21 * Carburetors

22 Engine oil

23

24 *

25

26 *

Sidestand,

centeratand

Shock absorber

assemblies

Engine oil filter

element

Front and rear

brake switches

Moving parts and

cables

Lights, signals

and switches

roughness.

S Lubricate with lithium-soap-based grease. Every 20,000 km

S Make sure that all nuts, bolts and

screws are properly tightened.

S Check operation.

S Lubricate.

S Check operation and shock absorbers for

oil leakage.

S Check starter (choke) operation.

S Adjust engine idling speed and

synchronization.

S Change.

S Check oil level and vehicle for oil leakage.

S Replace. √ √ √

S Check operation. √ √ √ √ √ √

S Lubricate. √ √ √ √ √

S Check operation.

S Adjust headlight beam.

√ √ √ √ √

√ √ √ √ √

√ √ √ √ √

√ √ √ √

√ √ √ √ √ √

√ √ √ √ √ √

√ √ √ √ √ √

ANNUAL

CHECK

NOTE:

D The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

D Hydraulic brake and clutch service.

S Regularly check and, if necessary, correct the brake and clutch fluid levels.

S Every two years replace the internal components of the brake master cylinders and calipers as

well as clutch master and release cylinders, and change the brake and clutch fluids.

S Replace the brake and clutch hoses every four years and if cracked or damaged.

21

Page 29

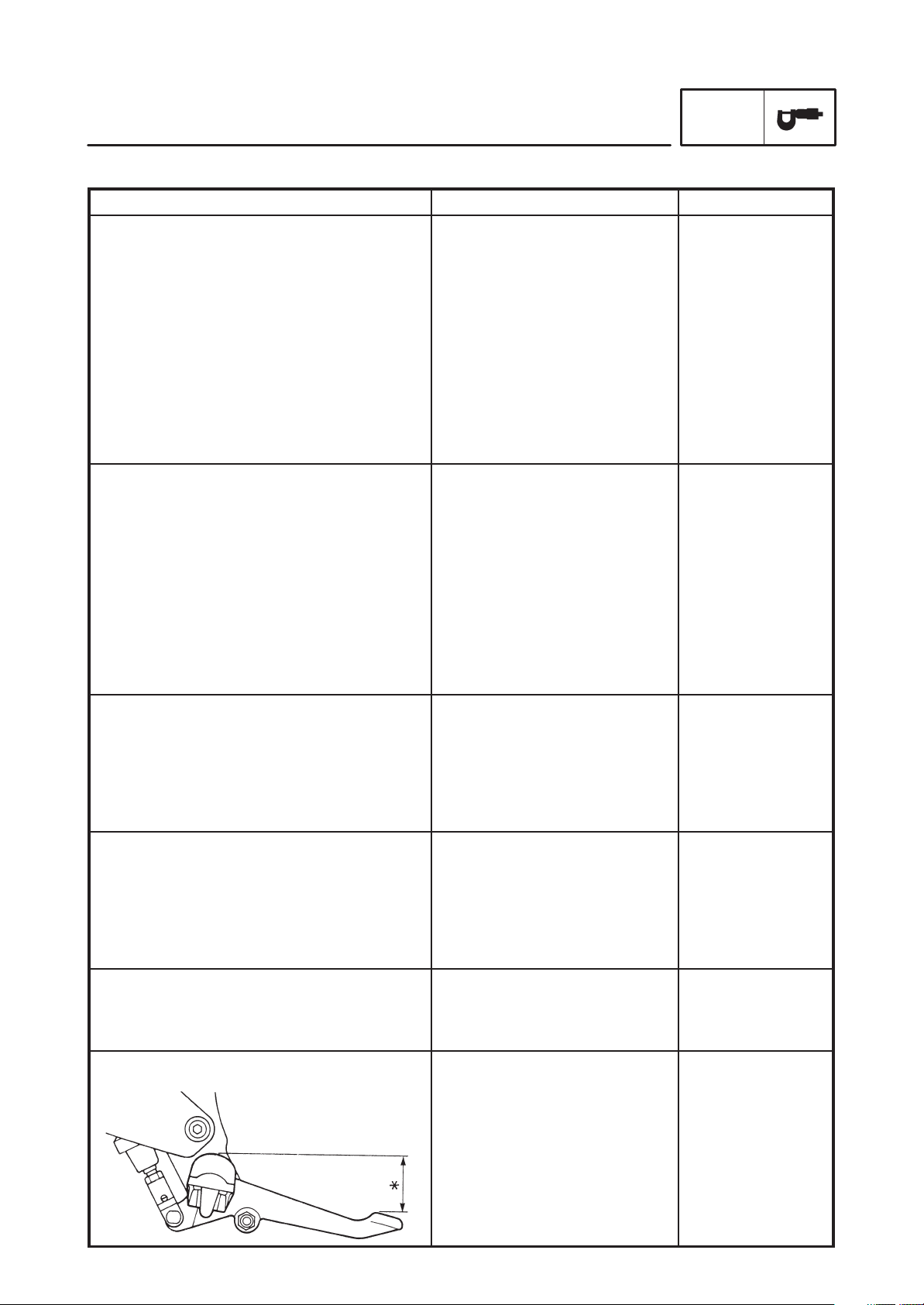

ADJUSTING THE CLUTCH LEVER

ENGINE

EAS00082

ADJUSTING THE CLUTCH LEVER

1. Adjust:

S clutch lever position

(distance

clutch lever)

a. While pushing the clutch lever forward, turn

the adjusting dial

the desired position.

NOTE:

Be sure to align the setting on the adjusting dial

with the arrow mark

er.

a

from the handlebar grip to the

1

2

CHK

ADJ

until the clutch lever is in

on the clutch lever hold-

Position #1

Position #5

Distance is the largest

Distance is the smallest

a

a

22

Page 30

ADJUSTING THE FRONT BRAKE

EAS00107

CHASSIS

ADJUSTING THE FRONT BRAKE

1. Adjust:

S brake lever position

a

(distance

lever)

a. While pushing the brake lever forward, turn

the adjusting dial

the desired position.

NOTE:

Be sure to align the setting on the adjusting dial

with the arrow mark

er.

from the throttle grip to the brake

1

2

CHK

ADJ

until the brake lever is in

on the brake lever hold-

Position #1

Position #5

Distance is the largest.

Distance is the smallest.

a

a

23

Page 31

AIR INDUCTION SYSTEM

CARBURETOR

EAS00507

AIR INDUCTION SYSTEM

AIR INJECTION

The air induction system burns unburned exhaust gases by injecting fresh air (secondary

air) into the exhaust port, reducing the emission

of hydrocarbons.

When there is negative pressure at the exhaust

port, the reed valve opens, allowing secondary

air to flow into the exhaust port. The required

temperature for burning the unburned exhaust

gases is approximately 600 to 700_C.

CARB

VIEW 1. (NO FLOW)

EAS00508

AIR CUTOFF VALVE

The air cutoff valve is operated by the intake gas

pressure through the piston valve diaphragm.

Normally, the air cutoff valve is open to allow

fresh air to flow into the exhaust port. During

sudden deceleration (the throttle valve suddenly closes), negative pressure is generated and

the air cutoff valve is closed in order to prevent

after-burning.

Additionally, at high engine speeds and when

the pressure decreases, the air cutoff valve automatically closes to guard against a loss of performance due to self-EGR.

VIEW 1. (NO FLOW)

When decelerating (the throttle closes), the valve will

close.

VIEW 2. (FLOW)

During normal operation the valve is open.

From the air cleaner

A

To the cylinder

B

To the carburetor joint

C

VIEW 2. (FLOW)

24

Page 32

EAS00509

AIR INDUCTION SYSTEM DIAGRAMS

AIR INDUCTION SYSTEM

CARB

Reed valve

1

Air cleaner

2

Air cutoff valve

3

Vacuum hose (cylinder #3)

4

To the air cutoff valve

A

To cylinder #1

B

To cylinder #2

C

To cylinder #3

D

To cylinder #4

E

25

Page 33

AIR INDUCTION SYSTEM

EAS00510

CHECKING THE AIR INDUCTION SYSTEM

1. Check:

S hoses

Loose connection ! Connect properly.

Cracks/ damage ! Replace.

S pipes

Cracks/ damage ! Replace.

2. Check:

S fibre reed

S fibre reed stopper

S reed valve seat

Cracks/ damage ! Replace the reed valve.

1

CARB

3. Measure:

S fibre reed bending limit

Out of specification ! Replace the reed

valve.

Fibre reed bending limit

0.2 mm

Surface plate

1

4. Check:

S air cutoff valve

Cracks/ damage ! Replace.

a

26

Page 34

FRONT AND REAR BRAKES

EAS00586

FRONT BRAKE MASTER CYLINDER

FRONT AND REAR BRAKES

CHASSIS

CHAS

10 Nm (1.0 mSkg)

30 Nm (3.0 mSkg)

Order Job/ Part Q’ty Remarks

Removing the front brake master

cylinder

Brake fluid

Brake lever

1

Brake switch lead

2

Front brake switch

3

Union bolt

4

Copper washers/ Brake hose

5

Master cylinder bracket

6

Master cylinder

7

Remove the parts in the order listed.

Drain

1

2

1

Refer to “DISASSEMBLING/ ASSEM-

1

3/2

BLING AND INSTALLING THE REAR

BRAKE MASTER CYLINDER” in

1

chapter 6. (Manual No.: 5EA3-AE1)

1

For installation, reverse the removal

procedure.

27

Page 35

FRONT AND REAR BRAKES

EAS00598

ASSEMBLING AND INSTALLING THE

FRONT BRAKE MASTER CYLINDER

WARNING

S Before installation, all internal brake com-

ponents should be cleaned and lubricated

with clean or new brake fluid.

S Never use solvents on internal brake com-

ponents.

Recommended brake fluid

DOT 4

1. Install:

S brake master cylinder

NOTE:

S Install the brake master cylinder holder with

the “UP” mark facing up.

S Align the end of the brake master cylinder hold-

er with the punch mark

S First, tighten the upper bolt, then the lower bolt.

CHAS

1

a

on the handlebar.

Brake master cylinder bolt

10 Nm (1.0 mSkg)

2. Install:

S copper washers (New)

S brake hose 1

S brake hose 2

S union bolt

Union bolt

2

3

4

30 Nm (3.0 mSkg)

1

WARNING

Proper brake hose routing is essential to insure safe motorcycle operation. Refer to

“CABLE ROUTING”.

CAUTION:

S When installing the brake hose 1

the brake master cylinder, make sure that

the brake pipe touches the projection

shown. And install the paint mark

ward the brake master cylinder side.

S Install the brake hose 2

angle as the brake hose 1

3

at the same

2

.

2

onto

b

a

to-

as

NOTE:

Turn the handlebar to the left and to the right to

make sure that the brake hose does not touch

other parts (e.g., wire harness, cables, leads).

Correct if necessary.

28

Page 36

FRONT AND REAR BRAKES

3. Fill:

S brake master cylinder reservoir

(with the specified amount of the recommended brake fluid)

Recommended brake fluid

DOT 4

WARNING

S Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

S Refill with the same type of brake fluid that

is already in the system. Mixing brake

fluids may result in a harmful chemical

reaction, leading to poor brake performance.

S When refilling, be careful that water does

not enter the reservoir. Water will significantly lower the boiling point of the brake

fluid and could cause vapor lock.

CHAS

CAUTION:

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

4. Bleed:

S brake system

Refer to “BLEEDING THE HYDRAULIC

BRAKE SYSTEM” in chapter 3. (Manual No.:

5EA3-AE1)

5. Check:

S brake fluid level

Below the minimum level mark

recommended brake fluid to the proper level.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” in chapter 3. (Manual No.:

5EA3-AE1)

6. Check:

S brake lever operation

Soft or spongy feeling ! Bleed the brake

system.

Refer to “BLEEDING THE HYDRAULIC

BRAKE SYSTEM” in chapter 3. (Manual No.:

5EA3-AE1)

a

! Add the

29

Page 37

EAS00616

REAR BRAKE CALIPER

FRONT AND REAR BRAKES

CHAS

30 Nm (3.0 mSkg)

40 Nm (4.0 mSkg)

Order Job/ Part Q’ty Remarks

Removing the rear brake caliper

Brake fluid

Union bolt

1

Copper washer

2

Brake hose

3

Brake caliper

4

Remove the parts in the order listed.

Drain.

1

2

1

1

For installation, reverse the removal

procedure.

30

Page 38

EAS00617

6 Nm (0.6 mSkg)

FRONT AND REAR BRAKES

CHAS

Order Job/ Part Q’ty Remarks

Disassembling the rear brake caliper

1

Brake pad clip

Brake pad pin

2

Brake pad spring

3

Brake pad

4

Brake caliper piston

5

Brake caliper piston seal

6

Bleed screw

7

Disassemble the parts in the order listed.

4

2

1

2

2

4

2

For assembly, reverse the disassembly

procedure.

31

Page 39

CARBURETOR HEATING SYSTEM

ELECTRICAL

CARBURETOR HEATING SYSTEM

ELEC

32

2 Fuse (main)

3 Battery

5 Main switch

6 Fuse (ignition)

14 Neutral switch

51 Carburetor heater relay

52 Thermo switch

53 Carburetor heater

Page 40

CARBURETOR HEATING SYSTEM

ELEC

EAS00821

TROUBLESHOOTING

The carburetor heating system fails to operate.

Check:

1. Main and ignition fuses

2. Battery

3. Main switch

4. Neutral switch

5. Carburetor heater relay

6. Thermo switch

7. Carburetor heater

8. Wiring connections

(of the entire carburetor heating system)

NOTE:

Before troubleshooting, remove the following

part(-s):

1) Rider and passenger seats

Troubleshoot with the following special tool(-s).

Pocket tester

90890-03112

EAS00738

1. Main, and ignition fuses

EAS00749

3. Main switch

S Check the main switch for continuity.

Refer to “CHECKING THE SWITCHES” in

chapter 8. (Manual No.: 5EA3-AE1)

S Is the main switch OK?

YES NO

Replace the main

switch.

EAS00751

4. Neutral switch

S Check the neutral switch for continuity.

Refer to “CHECKING THE SWITCHES” in

chapter 8. (Manual No.: 5EA3-AE1)

S Is the neutral switch OK?

YES NO

Replace the neutral

switch.

S Check the main and ignition fuses for conti-

nuity.

Refer to “CHECKING THE FUSES” in chap-

ter 3. (Manual No.: 5EA3-AE1)

S Are the main and ignition fuses OK?

YES

NO

Replace the fuse(-s).

EAS00739

2. Battery

S Check the condition of the battery.

Refer to “CHECKING THE BATTERY” in

chapter 3. (Manual No.: 5EA3-AE1)

Open-circuit voltage

12.8 V or more at 20_C

S Is the battery OK?

YES

NO

EAS00822

5. Carburetor heater relay

S Disconnect the carburetor heater relay cou-

pler from the wire harness.

S Connect the pocket tester (Ω 1) to the car-

buretor heater relay coupler as shown.

Tester positive probe ! red/ white

Tester negative probe ! black

1

2

S Check the carburetor heater relay for no

continuity.

S Is the carburetor heater relay OK?

YES

NO

S Clean the battery

terminals.

S Recharge or re-

place the battery.

Replace the carburetor heater relay.

33

Page 41

CARBURETOR HEATING SYSTEM

6. Thermo switch

S Remove the thermo switch from the thermo

switch plate.

S Connect the pocket tester to the (Ω 1) to

the thermo switch as shown.

Tester positive probe ! black

Tester negative probe ! black/ red

S Check the thermo switch for continuity at the

temperatures indicated below.

1

2

ELEC

EAS00825

The following procedure applies to all of the

carburetor heating elements.

7. Carburetor heater

S Remove the carburetor heating element

from the carburetor.

S Connect the pocket tester to the carburetor

heating element as shown.

Tester positive probe !

heating element

Tester negative probe !

heating element body

1

2

ON

11_C

COOL DOWN

A

HEAT UP

B

16_C

OFF

S Does the thermo switch operated properly?

YES

NO

Replace the thermo

switch.

S Measure the carburetor heater resistance.

Carburetor heating element

resistance

12 V 15 W: 4 X 11 Ω at 20_C

12 V 20 W: 4 X 11 Ω at 20_C

S Is the carburetor heating element OK?

YES

NO

Replace the carburetor heating element.

EAS00826

8. Wiring

S Check the entire carburetor heating sys-

tem’s wiring.

Refer to “CIRCUIT DIAGRAM”.

S Is the carburetor heating system’s wiring

properly connected and without defects?

34

NO

Properly connect or

repair the carburetor

heating system’s wir-

ing.

Page 42

Page 43

XJR1300 2002 WIRING DIAGRAM (for EUR)

COLOR CODE

B Black. . . . .

Br Brown. . . .

Ch Chocolate. . .

Dg Dark green. . .

G Green. . . .

Gy Gray. . .

L Blue. . . . .

Lg Light green. . . .

O Orange. . . .

Sb Sky blue. . . .

P Pink. . . . .

R Red. . . . .

Y Yellow. . . . .

B/ L Black/ Blue. . .

B/ R Black/ Red. .

B/ Y Black /Yellow. .

Br/ L Brown / Blue. .

Br/ W Brown/ White.

G/ Y Green / Yellow. .

L/ B Blue/ Black. . .

L/ R Blue/ Red. .

L/ W Blue/White. .

L/ Y Blue/ Yellow. . .

R/ B Red/ Black. .

R/ L Red/ Blue. .

R/ W Red/ White. .

R/ Y Red/ Yellow. .

W/ G White/ Green. .

W/ R White/ Red. .

Y/ B Yellow/ Black. .

1 AC generator

2 Fuse (main)

3 Battery

4 Starter relay

5 Main switch

6 Fuse (ignition)

7 Starter motor

8 Starting circuit cut-off relay

9 Ignitor unit

10 Ignition coil

11 Spark plug

12 Pickup coil

13 TPS (throttle position sensor)

14 Neutral switch

15 Sidestand switch

16 Start switch

17 Engine stop switch

18 Lights switch

19 Front brake switch

20 Handlebar switches (right)

21 Alarm

22 Fuse (turn)

23 Fuse (signal)

24 Fuse (headlight)

25 Horn

26 Flasher relay

27 Rear brake switch

28 Oil level relay

29 Oil level switch

30 Meter assembly

31 Speedometer

32 Neutral indicator light

33 Tachometer

34 Fuel gauge

35 Meter lights

36 Turn signal indicator light (left)

37 Turn signal indicator light (right)

38 Oil warning light

39 High beam indicator light

40 Fuel sender

41 Auxiliary light

42 Tail/brake light

43 Clutch switch

44 Hazard switch

45 Turn signal switch

46 Horn switch

47 Dimmer switch

48 Pass switch

49 Handlebar switch (left)

50 Headlight

51 Carburetor heater relay

52 Thermo switch

53 Carburetor heater

54 Rear turn signal lights

55 Front turn signal lights

Page 44

XJR1300P 2002 WIRING DIAGRAM (for AUS)

COLOR CODE

B Black. . . . .

Br Brown. . . .

Ch Chocolate. . .

Dg Dark green. . .

G Green. . . .

Gy Gray. . .

L Blue. . . . .

Lg Light green. . . .

O Orange. . . .

Sb Sky blue. . . .

P Pink. . . . .

R Red. . . . .

Y Yellow. . . . .

B/ L Black/ Blue. . .

B/ R Black/ Red. .

B/ Y Black /Yellow. .

Br/ L Brown / Blue. .

Br/ W Brown/ White.

G/ Y Green / Yellow. .

L/ B Blue/ Black. . .

L/ R Blue/ Red. .

L/ W Blue/White. .

L/ Y Blue/ Yellow. . .

R/ B Red/ Black. .

1 AC generator

2 Fuse (main)

3 Battery

4 Starter relay

5 Main switch

6 Fuse (ignition)

7 Starter motor

8 Starting circuit cut-off relay

9 Ignitor unit

10 Ignition coil

11 Spark plug

12 Pickup coil

13 TPS (throttle position sensor)

14 Neutral switch

15 Sidestand switch

16 Start switch

17 Engine stop switch

18 Front brake switch

19 Handlebar switches (right)

20 Carburetor heater relay

21 Thermo switch

22 Carburetor heater

23 Fuse (signal)

24 Fuse (headlight)

25 Meter assembly

26 Speedometer

27 Neutral indicator light

28 Tachometer

29 Fuel gauge

30 Meter lights

31 Turn signal indicator light (left)

32 Turn signal indicator light (right)

33 Oil warning light

34 High beam indicator light

35 Fuel sender

36 Oil level relay

37 Oil level switch

38 Rear brake switch

39 Tail/brake light

40 Flasher relay

41 Horn

42 Handlebar switch (left)

43 Pass switch

44 Dimmer switch

45 Horn switch

46 Turn signal switch

47 Clutch switch

48 Headlight

49 Rear turn signal lights

50 Front turn signal lights

R/ L Red/ Blue. .

R/ W Red/ White. .

R/ Y Red/ Yellow. .

W/ G White/ Green. .

W/ R White/ Red. .

Y/ B Yellow/ Black. .

Loading...

Loading...