Page 1

Page 2

Page 3

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

TDM900 (R) 2003. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

TDM900 (N) 2001 SERVICE MANUAL: 5PS1-AE1

TDM900 (R) 2003

SUPPLEMENTARY

SERVICE MANUAL

E2002 by Yamaha Motor Co., Ltd.

First Edition, September 2002

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Page 4

EAS00002

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles

should have a basic understanding of mechanics and the techniques to repair these types of vehicles.

Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and

will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE: A NOTE provides key information to make procedures easier or clearer.

Failure to follow WARNING instructions could result in severe injury or death

the motorcycle operator, a bystander or a person checking or repairing the motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage

to the motorcycle.

to

Page 5

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid

out with the individual steps in sequential order.

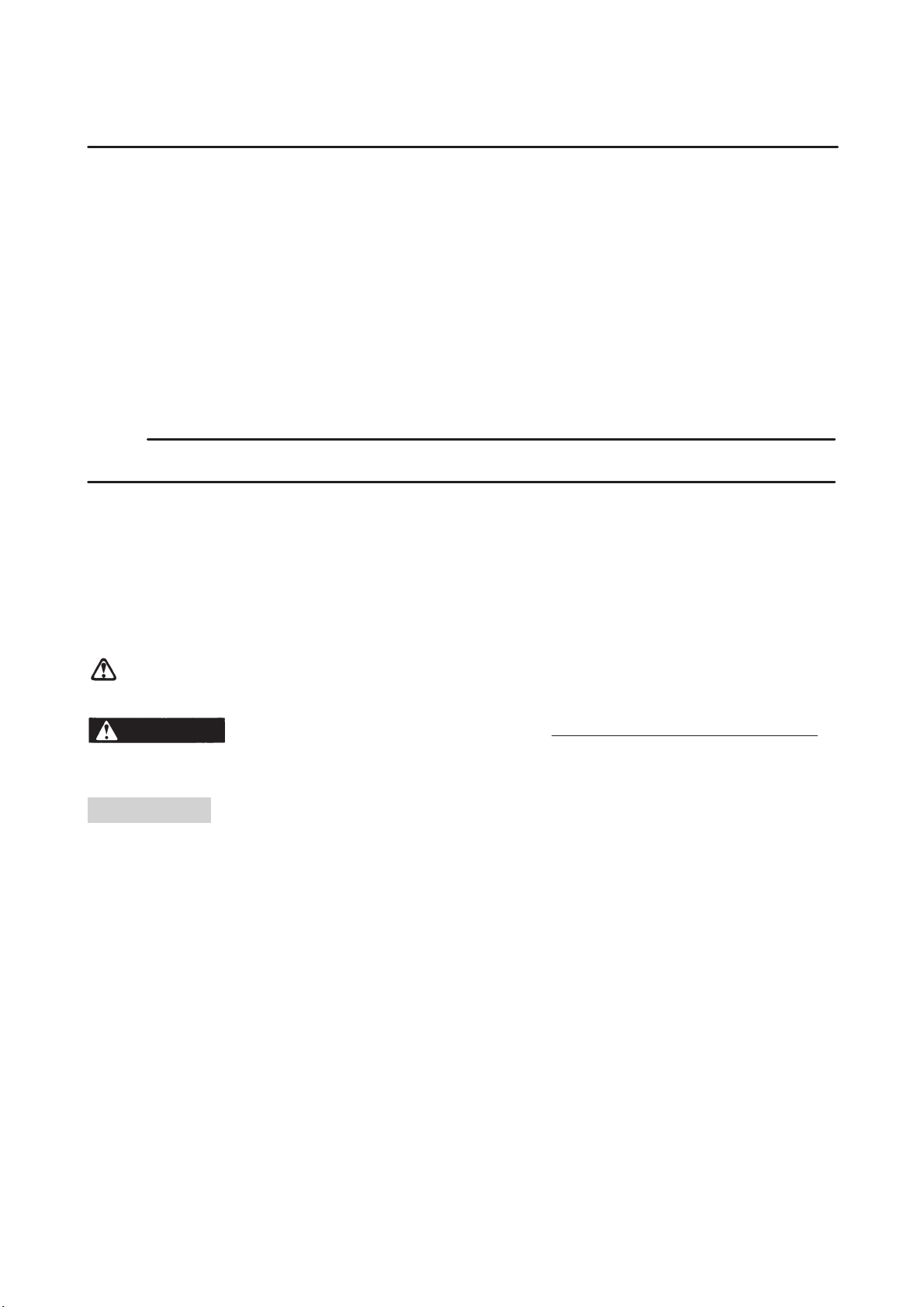

1

The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each

page indicate the current chapter.

Refer to “SYMBOLS”.

2

Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s) appears.

3

Sub-section titles appear in smaller print than the section title.

4

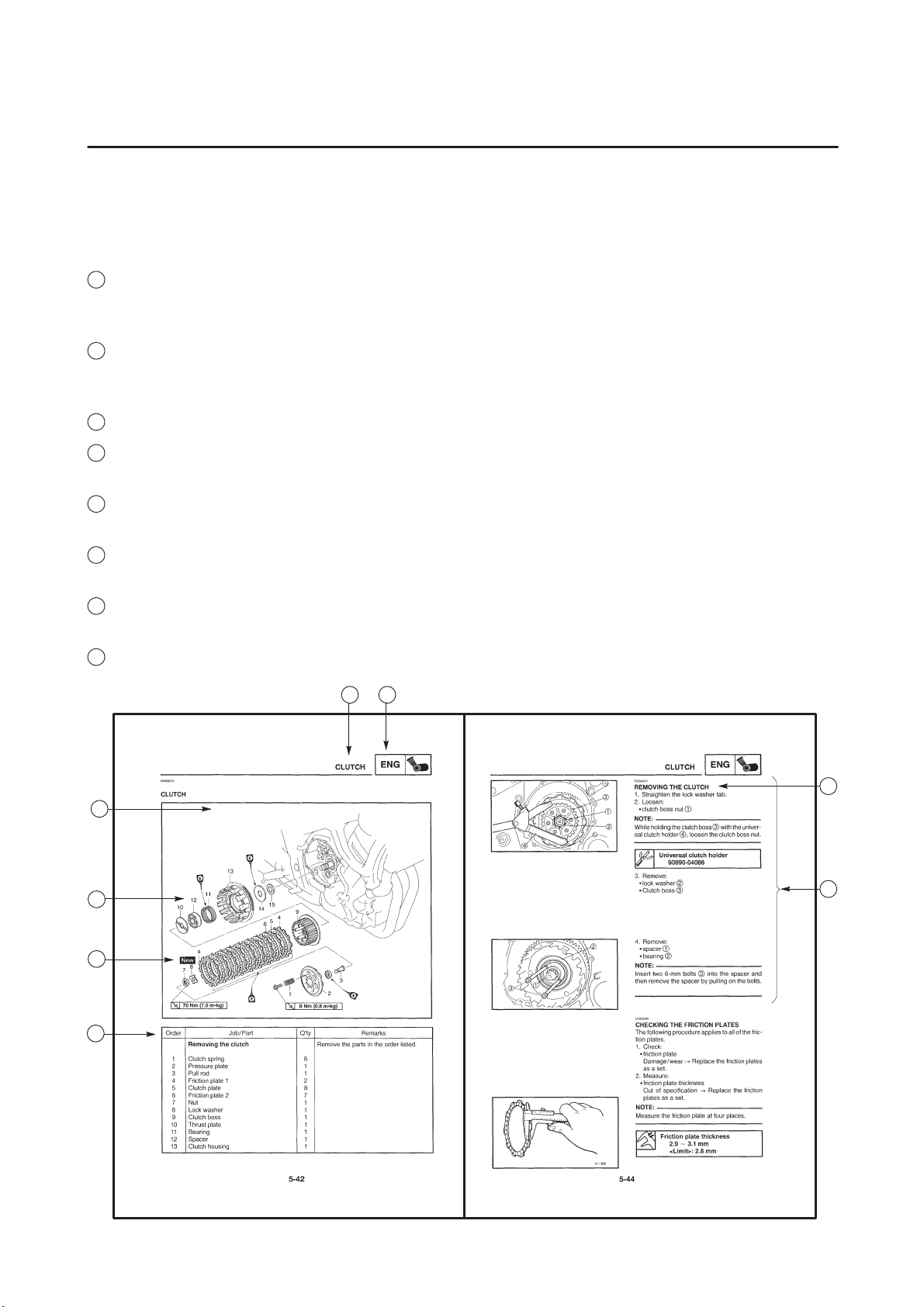

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

5

Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a

disassembly step.

6

Symbols indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

7

A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

8

Jobs requiring more information (such as special tools and technical data) are described sequentially.

12

4

5

6

7

3

8

Page 6

1

GEN

INFO

3

CHK

ADJ

5

ENG

7

2

SPEC

4

CHAS

6

COOL

8

EAS00008

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols

chapter.

1

General information

2

Specifications

3

Periodic checks and adjustments

4

Chassis

5

Engine

6

Cooling system

7

Fuel injection system

8

Electrical system

9

Troubleshooting

1

to 9 indicate the subject of each

FI ELEC

9

10

TRBL

SHTG

11 12

1413

16 1715

19 2018

Symbols 10 to 17 indicate the following.

10

Serviceable with engine mounted

11

Filling fluid

12

Lubricant

13

Special tool

14

Tightening torque

15

Wear limit, clearance

16

Engine speed

17

Electrical data

Symbols

18

to 23 in the exploded diagrams indicate the types of lubricants and lubrication

points.

18

Engine oil

19

Gear oil

20

Molybdenum-disulfide oil

21

Wheel-bearing grease

22

Lithium-soap- based grease

23

Molybdenum-disulfide grease

Symbols 24 to 25 in the exploded diagrams indicate the following.

24

Apply locking agent (LOCTITE)

25

Replace the part

22

24 25

2321

Page 7

CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL

CHECKING THE SWITCHES 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRIC STARTING SYSTEM 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING CIRCUIT CUT-OFF SYSTEM OPERATION 5. . . . . . . . . .

TROUBLESHOOTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIGHTING SYSTEM 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING

FAULTY LIGHTING SYSTEM 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEADLIGHT DOES NOT COME ON 14. . . . . . . . . . . . . . . . . . . . . . . . . .

HEADLIGHT BULB BURNT OUT 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDM900 (R) 2003 WIRING DIAGRAM (EUR)

TDM900 (R) 2003 WIRING DIAGRAM (OCE)

Page 8

Page 9

GENERAL SPECIFICATIONS/ENGINE SPECIFICATIONS/

CHASSIS SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard Limit

SPEC

Model code 5PS4 (EUR)

5PS5 (OCE)

ENGINE SPECIFICATIONS

Item Standard Limit

Throttle bodies

Model (manufacturer) quantity

Intake vacuum pressure

Throttle cable free play (at the flange

of the throttle grip)

ID mark

Throttle valve size

38EIS (MIKUNI) 2

33 X 36 kPa

3 X 5 mm

5PS1 10

#50

CHASSIS SPECIFICATIONS

Item Standard Limit

Front tire

Tire type

Size

Model (manufacturer)

Tire pressure (cold)

0 X 90 kg

90 X 203 kg

High-speed riding

Min. tire tread depth

Rear tire

Tire type

Size

Model (manufacturer)

Tire pressure (cold)

0 X 90 kg

90 X 203 kg

High-speed riding

Min. tire tread depth

Tubeless

120/ 70ZR 18 M/ C (59W)

MEZ4 FRONT (METZELER)/

D220FSTJ (DUNLOP)

225 kPa (2.25 kgf/ cm

225 kPa (2.25 kgf/ cm

225 kPa (2.25 kgf/ cm

SSS

Tubeless

160/ 60ZR 17 M/ C (69W)

MEZ4 (METZELER)/

D220STJ (DUNLOP)

250 kPa (2.5 kgf/ cm

290 kPa (2.9 kgf/ cm

250 kPa (2.5 kgf/ cm

SSS

2

, 2.25 bar)

2

, 2.25 bar)

2

, 2.25 bar)

2

, 2.5 bar)

2

, 2.9 bar)

2

, 2.5 bar)

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

1.6 mm

SSS

SSS

SSS

SSS

SSS

SSS

1.6 mm

–1–

Page 10

CHECKING THE SWITCHES

EAS00731

ELEC

ELECTRICAL

CHECKING THE SWITCHES

Check each switch for damage or wear, proper connections, and also for continuity between the terminals. Refer to “CHECKING SWITCH CONTINUITY”.

Damage/ wear ! Repair or replace.

Improperly connected ! Properly connect.

Incorrect continuity reading ! Replace the switch.

1 Main switch

2 Horn switch

3 Pass switch

4 Dimmer switch

5 Hazard switch

6 Turn signal switch

7 Clutch switch

8 Engine stop switch

9 Start switch

10 Front brake light switch

–2–

11 Neutral switch

12 Rear brake light switch

13 Fuses

14 Sidestand switch

Page 11

ELECTRIC STARTING SYSTEM

EAS00755

ELECTRIC STARTING SYSTEM

CIRCUIT DIAGRAM

ELEC

–3–

Page 12

4 Main fuse

5 Battery

7 Starter relay

8 Starter motor

9 Main switch

12 Starting circuit cut-off relay

13 Sidestand switch

14 Neutral switch

49 Clutch switch

59 Engine stop switch

60 Start switch

61 Ignition fuse

ELECTRIC STARTING SYSTEM

ELEC

–4–

Page 13

ELECTRIC STARTING SYSTEM

EAS00756

STARTING CIRCUIT CUT-OFF SYSTEM

OPERATION

If the engine stop switch is set to “

main switch is set to “ON” (both switches are

closed), the starter motor can only operate if at

least one of the following conditions is met:

S The transmission is in neutral (the neutral

switch is closed).

S The clutch lever is pulled to the handlebar

(the clutch switch is closed) and the sidestand is up (the sidestand switch is closed).

The starting circuit cut-off relay prevents the

starter motor from operating when neither of

these conditions has been met. In this instance,

the starting circuit cut-off relay is open so current cannot reach the starter motor. When at

least one of the above conditions has been met

the starting circuit cut-off relay is closed and the

engine can be started by pressing the starter

switch.

ELEC

” and the

WHEN THE TRANSMISSION IS IN

NEUTRAL

WHEN THE SIDESTAND IS UP AND

THE CLUTCH LEVER IS PULLED TO

THE HANDLEBAR

Battery

1

Main fuse

2

Main switch

3

Ignition fuse

4

Engine stop switch

5

Starting circuit cut-off relay

6

Diode (starting circuit cut-off relay)

7

Clutch switch

8

Sidestand switch

9

10

Neutral switch

11

Start switch

12

Starter relay

13

Starter motor

14

Diode (starting circuit cut-off relay)

–5–

Page 14

ELECTRIC STARTING SYSTEM

ELEC

EAS00757

TROUBLESHOOTING

The starter motor fails to turn.

Check:

1. main and ignition fuses

2. battery

3. starter motor

4. starting circuit cut-off relay

5. diode

6. starter relay

7. main switch

8. engine stop switch

9. neutral switch

10. sidestand switch

11. clutch switch

12. start switch

13. wiring connections

(of the entire starting system)

NOTE:

S Before troubleshooting, remove the following

part(s):

1. seat

2. fuel tank

3. air filter case

4. side cowlings

S Troubleshoot with the following special

tool(s).

EAS00739

2. Battery

S Check the condition of the battery.

Refer to “CHECKING AND CHARGING

THE BATTERY” in chapter 3. (Manual No.:

5PS1-AE1)

Minimum open-circuit voltage

12.8 V or more at 20_C

S Is the battery OK?

YES NO

S Clean the battery

terminals.

S Recharge or re-

place the battery.

EAS00758

3. Starter motor

S Connect the positive battery terminal and

starter motor lead with a jumper lead .

2 3

1

Pocket tester

90890-03132

EAS00738

1. Main and ignition fuses

S Check the main and ignition fuses for conti-

nuity.

Refer to “CHECKING THE FUSES” in chapter 3. (Manual No.: 5PS1-AE1)

S Are the main and ignition fuses OK?

YES

NO

Replace the fuse(s).

WARNING

S A wire that is used as a jumper lead

must have at least the same capacity or

more as that of the battery lead, otherwise the jumper lead may burn.

S This check is likely to produce sparks,

therefore make sure nothing flammable

is in the vicinity.

S Does the starter motor turn?

YES

Repair or replace the

starter motor.

NO

–6–

Page 15

ELECTRIC STARTING SYSTEM

ELEC

EAS00759

4. Starting circuit cut-off relay

S Disconnect the starting circuit cut-off relay

from the wire harness.

S Connect the pocket tester (Ω 1) and bat-

tery (12 V) to the starting circuit cut-off relay

terminals as shown.

Battery positive terminal ! red/ black

Battery negative terminal !

black/ yellow

Tester positive prove ! blue/ white

Tester negative prove ! black

3

4

Tester positive probe !

sky blue

1

Tester negative probe !

black/ yellow

2

Tester positive probe !

sky blue

Tester negative probe !

1

2

Tester positive probe !

blue/ yellow

blue/ green

1

Continuity

3

4

Tester negative probe !

blue/ yellow

3

Tester positive probe !

black/ yellow

2

Tester negative probe !

sky blue

1

Tester positive probe !

blue/ yellow

Tester negative probe !

sky blue

3

No continuity

1

S Does the starting circuit cut-off relay have

continuity between blue/ white and black?

YES NO

Replace the starting

circuit cut-off relay.

EAS00760

5. Starting circuit cut-off relay (diode)

S Disconnect the starting circuit cut-off relay

from the wire harness.

S Connect the pocket tester (Ω 1) to the

starting circuit cut-off relay terminals as

shown.

S Measure the starting circuit cut-off relay for

continuity as follows.

Tester positive probe !

blue/ yellow

3

Tester negative probe !

blue/ green

4

NOTE:

When you switch the tester’s positive and

negative probes, the readings in the above

chart will be reversed.

S Are the testing readings correct?

YES NO

–7–

Replace the starting

circuit cut-off relay.

Page 16

ELECTRIC STARTING SYSTEM

ELEC

EAS00761

6. Starter relay

S Disconnect the starter relay from the cou-

pler.

S Connect the pocket tester (Ω 1) and bat-

tery (12 V) to the starter relay terminals as

shown.

Battery positive terminal ! red/ white

Battery negative terminal !

blue/ white

Tester positive probe ! red

Tester negative probe ! black

3

4

S Does the starter relay have continuity be-

tween red and black?

YES NO

Replace the starter

relay.

EAS00750

8. Engine stop switch

S Check the engine stop switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the engine stop switch OK?

YES NO

1

Replace the right

2

EAS00751

handlebar switch.

9. Neutral switch

S Check the neutral switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the neutral switch OK?

YES NO

Replace the neutral

switch.

EAS00752

10. Sidestand switch

S Check the sidestand switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the sidestand switch OK?

EAS00749

7. Main switch

S Check the main switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the main switch OK?

YES NO

Replace the main

switch.

YES NO

Replace the sidestand switch.

EAS00763

11. Clutch switch

S Check the clutch switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the clutch switch OK?

YES NO

Replace the clutch

switch.

–8–

Page 17

ELECTRIC STARTING SYSTEM

EAS00764

12. Start switch

S Check the start switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the start switch OK?

YES NO

Replace the right

handlebar switch.

EAS00766

13. Wiring

S Check the entire starting system’s wiring.

Refer to “CIRCUIT DIAGRAM”.

S Is the starting system’s wiring properly con-

nected and without defects?

ELEC

YES NO

The starting system

circuit is OK.

Properly connect or

repair the starting

system’s wiring.

–9–

Page 18

EAS00780

LIGHTING SYSTEM

CIRCUIT DIAGRAM

LIGHTING SYSTEM

ELEC

–10–

Page 19

4 Main fuse

5 Battery

9 Main switch

23 ECU

37 High beam indicator light

40 Meter light

45 Pass switch

46 Dimmer switch

55 Headlight

56 Headlight relay

62 Headlight fuse

63 Hazard light fuse

64 Signaling system fuse

67 Tail/brake light

70 Auxiliary light

LIGHTING SYSTEM

ELEC

–11–

Page 20

LIGHTING SYSTEM

ELEC

EAS00781

TROUBLESHOOTING

Any of the following fail to light: headlight,

high beam indicator light, taillight, auxiliary light or meter light.

Check:

1. main, signaling system and headlight fuses

2. battery

3. main switch

4. headlight relay

5. dimmer switch

6. pass switch

7. wiring connections

(of the entire lighting system)

NOTE:

S Before troubleshooting, remove the following

part(s):

1. fuel tank

2. front cowling

3. rear cowling

S Troubleshoot with the following special

tool(s).

EAS00739

2. Battery

S Check the condition of the battery.

Refer to “CHECKING AND CHARGING

THE BATTERY” in chapter 3. (Manual No.:

5PS1-AE1)

Minimum open-circuit voltage

12.8 V or more at 20_C

S Is the battery OK?

YES NO

S Clean the battery

terminals.

S Recharge or re-

place the battery.

EAS00749

3. Main switch

S Check the main switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the main switch OK?

Pocket tester

90890-03132

EAS00738

1. Main, signaling system and headlight

fuses

S Check the main, signaling system and head-

light fuses for continuity.

Refer to “CHECKING THE FUSES” in chapter 3. (Manual No.: 5PS1-AE1)

S Are the main, parking lighting and headlight

fuses OK?

YES NO

Replace the fuse(s).

YES NO

Replace the main

switch.

4. Headlight relay

S Disconnect the headlight relay from the wire

harness.

S Connect the pocket tester (Ω 1) and bat-

tery (12 V) to the headlight relay terminal as

shown.

S Check the headlight relay for continuity.

Battery positive terminal ! red/ yellow

Battery negative terminal !

yellow/ black

Tester positive probe ! red/ yellow

Tester negative probe ! blue/ black

3

4

1

2

–12–

Page 21

LIGHTING SYSTEM

ELEC

S Dose the headlight relay have continuity be-

tween red/ yellow and green/blue?

YES NO

Replace the headlight relay.

EAS00784

5. Dimmer switch

S Check the dimmer switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the dimmer switch OK?

YES NO

EAS00787

7. Wiring

S Check the entire lighting system’s wiring.

Refer to “CIRCUIT DIAGRAM”.

S Is the lighting system’s wiring properly con-

nected and without defects?

YES NO

Check the condition

of each of the lighting

system’s circuits.

Properly connect or

repair the lighting

system’s wiring.

Refer to “CHECKING THE LIGHTING

SYSTEM”.

The dimmer switch is

faulty. Replace the

left handlebar

switch.

EAS00786

6. Pass switch

S Check the pass switch for continuity.

Refer to “CHECKING THE SWITCHES”.

S Is the pass switch OK?

YES NO

The pass switch is

faulty. Replace the

left handlebar

switch.

–13–

Page 22

EAS00866

TROUBLESHOOTING

FAULTY LIGHTING SYSTEM

HEADLIGHT DOES NOT COME ON

S Wrong headlight bulb

S Too many electrical accessories

S Hard charging

S Incorrect connection

S Improperly grounded circuit

S Poor contacts (main or dimmer switch)

S Headlight relay

S Burnt-out headlight bulb

HEADLIGHT BULB BURNT OUT

S Wrong headlight bulb

S Faulty battery

S Faulty rectifier/ regulator

S Improperly grounded circuit

S Faulty main switch

S Faulty dimmer switch

S Faulty headlight relay

S Headlight bulb life expired

FAULTY LIGHTING SYSTEM

TRBL

SHTG

–14–

Page 23

WIRING DIAGRAM (EUR)

1 Crankshaft position sensor

2 A.C magneto

3 Rectifier/ regulator

4 Main fuse

5 Battery

6 Fuel injection system fuse

7 Starter relay

8 Starter motor

9 Main switch

10 Alarm

11 Buck up fuse

12 Starting circuit cut-off relay

13 Sidestand switch

14 Neutral switch

15 Cylinder identification sensor

16 Throttle position sensor

17 Intake air pressure sensor

18 Atmospheric pressure sensor

19 Intake air temperature sensor

20 Coolant temperature sensor

21 Lean angle cut-off relay

22 O

sensor

2

23 ECU

24 Injector (#1)

25 Injector (#2)

26 Al system solenoid

27 Intake solenoid

28 Ignition coil

29 Spark plug

30 Fuel pump

31 Speed sensor

32 Meter assembly

33 Oil level warning light

34 Neutral indicator light

35 Multi-function meter

36 Engine trouble warning light

37 Hi beam indicator light

38 Left turn signal indicator light

39 Right turn signal indicator light

40 Meter light

41 Oil level switch

42 Turn signal relay

43 Left handlebar switch

44 Horn switch

45 Pass switch

46 Dimmer switch

47 Hazard switch

48 Turn signal switch

49 Clutch switch

50 Horn

51 Rear turn signal light (left)

52 Rear turn signal light (right)

53 Front turn signal light (left)

54 Front turn signal light (right)

55 Headlight

56 Headlight relay

57 Right handlebar switch

58 Front brake light switch

59 Engine stop switch

60 Start switch

61 Ignition fuse

62 Headlight fuse

63 Hazard fuse

64 Signaling system fuse

65 Radiator fan motor fuse

66 Rear brake light switch

67 Tail/brake light

68 Radiator fan relay

69 Radiator fan motor

70 Auxiliary light

COLOR CODE

B Black. . . . . . .

Br Brown. . . . . .

Ch Chocolate. . . . .

Dg Dark green. . . . .

G Green. . . . . .

Gy Gray. . . . .

L Blue. . . . . . .

Lg Light green. . . . . .

O Orange. . . . . .

P Pink. . . . . . .

R Red. . . . . . .

Sb Sky blue. . . . . .

W White. . . . . .

Y Yellow. . . . . . .

B/ L Black/ Blue. . . . .

B/ W Black/ White. . . .

B/ Y Black/ Yellow. . . .

Br/ B Brown/ Black. . . .

Br/ G Brown/ Green. . .

Br/ L Brown /Blue. . . .

Br/ R Brown /Red. . . .

Br/ W Brown/ White. . .

G/ B Green/ Black. . . .

G/ R Green/ Red. . . .

G/ W Green / White. . . .

G/ Y Green/ Yellow. . . .

Gy/ G Gray/ Green. . .

Gy/ R Gray / Red. . .

L/ B Blue/ Black. . . . .

L/ G Blue/ Green. . . .

L/ R Blue /Red. . . .

L/ W Blue/ White. . . .

L/ Y Blue/ Yellow. . . . .

P/ W Pink/ White. . . .

R/ B Red / Black. . . .

R/ G Red/ Green. . . .

R/ L Red /Blue. . . .

R/ W Red/ White. . . .

R/ Y Red / Yellow. . . .

W/ B White/ Black. . . .

W/ Y White/ Yellow. . . .

Y/ B Yellow/ Black. . . .

Y/ G Yellow/ Green. . . .

Y/ L Yellow/ Blue. . . . .

Page 24

WIRING DIAGRAM (OCE)

1 Crankshaft position sensor

2 A.C magneto

3 Rectifier/ regulator

4 Main fuse

5 Battery

6 Fuel injection system fuse

7 Starter relay

8 Starter motor

9 Main switch

10 Buck up fuse

11 Starting circuit cut-off relay

12 Sidestand switch

13 Neutral switch

14 Cylinder identification sensor

15 Throttle position sensor

16 Intake air pressure sensor

17 Atmospheric pressure sensor

18 Intake air temperature sensor

19 Coolant temperature sensor

20 Lean angle cut-off switch

21 O

sensor

2

22 ECU

23 Injector (#1)

24 Injector (#2)

25 Al system solenoid

26 Intake solenoid

27 Ignition coil

28 Spark plug

29 Fuel pump

30 Speed sensor

31 Meter assembly

32 Oil level warning light

33 Neutral indicator light

34 Multi function meter

35 Engine trouble warning light

36 Hi beam indicator light

37 Left turn signal indicator light

38 Right turn signal indicator light

39 Meter light

40 Oil level switch

41 Turn signal relay

42 Left handlebar switch

43 Horn switch

44 Pass switch

45 Dimmer switch

46 Turn signal switch

47 Clutch switch

48 Horn

49 Rear turn signal light (left)

50 Rear turn signal light (right)

51 Front turn signal light (left)

52 Front turn signal light (right)

53 Headlight

54 Headlight relay

55 Right handlebar switch

56 Front brake light switch

57 Engine stop switch

58 Start switch

59 Ignition fuse

60 Headlight fuse

61 Signaling system fuse

62 Radiator fan motor fuse

63 Radiator fan relay

64 Radiator fan motor

65 Auxiliary light

66 Rear brake light switch

67 Tail/brake light

COLOR CODE

B Black. . . . . . .

Br Brown. . . . . .

Ch Chocolate. . . . .

Dg Dark green. . . . .

G Green. . . . . .

Gy Gray. . . . .

L Blue. . . . . . .

Lg Light green. . . . . .

O Orange. . . . . .

P Pink. . . . . . .

R Red. . . . . . .

Sb Sky blue. . . . . .

W White. . . . . .

Y Yellow. . . . . . .

B/ L Black/ Blue. . . . .

B/ W Black/ White. . . .

B/ Y Black/ Yellow. . . .

Br/ B Brown/ Black. . . .

Br/ L Brown /Blue. . . .

Br/ R Brown /Red. . . .

Br/ W Brown/ White. . .

G/ B Green/ Black. . . .

G/ R Green/ Red. . . .

G/ W Green / White. . . .

G/ Y Green/ Yellow. . . .

Gy/ G Gray/ Green. . .

Gy/ R Gray / Red. . .

L/ B Blue/ Black. . . . .

L/ G Blue/ Green. . . .

L/ R Blue /Red. . . .

L/ W Blue/ White. . . .

L/ Y Blue/ Yellow. . . . .

P/ W Pink/ White. . . .

R/ B Red / Black. . . .

R/ G Red/ Green. . . .

R/ L Red /Blue. . . .

R/ W Red/ White. . . .

R/ Y Red / Yellow. . . .

W/ Y White/ Yellow. . . .

Y/ B Yellow/ Black. . . .

Y/ G Yellow/ Green. . . .

Y/ L Yellow/ Blue. . . . .

Page 25

Page 26

Page 27

TDM900 (R) 2003 WIRING DIAGRAM (EUR)

Gy

G/W

L/Y

G/W

1

2 3

WWW

R

ON

OFF

P

L/BBr/R

L/Y

Br/L L/Y

L/Y

B

Br/R

Br/R B

D C

Y/L

R/G

Y/L

G/R

L/W R/WL/Y L/YL/G

L

W/B

B/L

B/L

P/W

B/L P L

B/W

WIRE

HARNESS

L

B/L

Br/W

B/L

G/R

R/G

W

L Y B/L

17

18

W

HEADLIGHT

SUB-WIRE

HARNESS 1

Sb B/Y Lg

16

E

B/L B/L

B/W

L

B/L

L

P

B/L

19

20

B/L G/R

DgLgBr

L/B L/R

Gy

G/W

W

W

W

W

W

W

-

RB

R R R

B

9

R

Br/L

R

Br/L

B

61

Br/L

62

Br/L

R/W

R/Y

B

G/Y G/Y

BB

R/B R/B

R

BBB

BBB

10

BBB

BBB

B

B

B

B

B

B

B

B

BB

B

57

R/W R/W L/W

Br Br

4

R

R

R

R

B

B

B

BB

B

187

R

6

-

RR

R

7

5

8

B

BB

58

187

L/WR/W

R/W

L/W

R/W R/B B

59

OFF

RUN

L/W

R

11

R/G

60

OFF

ON

B

R/W

B/Y

BYChGL

WIRE HARNESS

12

Sb L/Y

L/G

B

Sb

14

L/G

13

BB

B

L/G

Dg Lg Br

L/BL/R

BYChGL

HEADLIGHT

SUB-WIRE HARNESS 2

RLgR/BL/W

R/L

R L/W R/LR/B B

L/Y

15

L/Y

W

B/L

W/B

L

B/L

B/RB/W

B

YY

P/W P/W R/B

B/L B/L

SUB-WIRE

WIRE

HARNESS

HARNESS 2

B

B/L B/L

B/L

B

Y Y

Y

A

L

L L

B

P/WP/W P/W

Br/W

E

Br/W

Br/W

-

--

Y/G

L

B/L

21

L

WIRE

HARNESS

Y/G

A

R/B

G/B

G/B

L

R/L

L

R/L

SUB-WIRE

HARNESS 1

R/L

L/Y

R/W

B/Y

B

L/W

G/Y

G/W

W/B

B/L Br/B

L

Y

P/W

P

Br/W

G/R

Y/G

R/W

Gy/G

22

B/L

Gy/G

Br/B

R/W

B/L Br/W

WIRE

HARNESS

B/W B/W

B/W B/W

E

23

B/L

Br/B

R/W

B/LBr/W

SUB-WIRE

HARNESS 3

O

Gy/R

R/B

G/B

Br/R

Y/B

G/Y

Y/L

W/Y

Gy/G

L

-

Y/G

W/Y

A

R/B R/B

A

G/B G/B

G/W

W/BR/L

G/R

P

- --- -

Br/W

P/W

Gy

Y/L

Y

24

25

Br/R

E

Br/B Br/B

--

B/L

R/L

A

R/L

R/L

R/L

26

27

B

B/YL/WB/W

G/YBr/B

R/W

Br/R

L/Y

R/L

R/B

R/L

G/B

R/W

Br/R

Br

R/W

Y/B

R/W

E

R/W

Gy/R

R/B

G/B

---

Br/R

R/W

R/W

Br/B

O

B/W

B/WB/WR/W

R/B

205

O

R/B

205

Gy/R

30

B/W

G

BR/L

L

W/Y

31

B/L

W

L/Y

B/L

W/YL

B/L

28

29

28

29

R/L

G

B

B/W

Br

L

R/W G/Y

B

L

G/Y

63

Br/R

64

Br/L

R

65

Br

Br

R/W

68

L

G/Y

L

B

69

L

B

Br/G

Br

L/R

D

L/R

L/R

L/R

B

70

B

Br

66

Br Y

BB

Y

L/R

YB

L/RY

YLB

YB

67

B

BBr

R/Y

56

L/B

R/Y Y/B

--

Y

55

B B

B

D

B

32

33

Br/G

-

Br/W

42

Br/G

R/YR/Y

Y/BL/B

L/B

D

L/B

B

L/B

L/B

43

44

OFF

ON

B/W

Br

Br

G/Y

50

R/YBr L/B Br/W

45 46

OFF

ON

HI

LO

YB

Y

D

Y

47 48

OFF

ON

Ch

51

-

Ch

B

B

-

Ch

B

Br/W

B/Y L/Y

R

N

L

B/Y

B/Y

L/Y

L/Y

B/Y

L/Y

B/Y

L/Y

YDg

L/Y

Ch

Br/W

R/Y L/B

B/YBr

Br/W

R/YL/B

B

B/Y Br

YDg

B

L/Y

Ch

49

Ch

Dg

D

Ch Ch

Dg

52

-

Dg

B

B

-

Dg

B

D

Dg Dg

Ch

Ch

B

B

-

B

Dg

53

-

Ch

54

-

Dg

B

B

B

-

Dg

B

G

Br

R/G

D

D

C

G

Br

R/G

R/G

W

C

W

D

L

LL

BW

W

BW

41

B

34

Br

G

W

35

36

37

Y

38

Ch

39

Dg

40

-

R/G

BrLgDg

B/W

Y/L

W

----

YChLG

Lg

Y/L

Lg

D

Lg

Y/L

C

Y/L

B/WB/W B/W

C

Page 28

TDM900 (R) 2003 WIRING DIAGRAM (OCE)

WIRE HARNESS

HEADLIGHT

SUB-WIRE HARNESS 2

R L/W R/LR/B L/W

B/RB/W

WIRE

HARNESS

G/R

L/W R/WL/Y L/YL/G

HEADLIGHT

SUB-WIRE

HARNESS 1

Sb B/Y Lg

WIRE

HARNESS

SUB-WIRE

HARNESS 2

WIRE

HARNESS

SUB-WIRE

HARNESS 1

WIRE

HARNESS

SUB-WIRE

HARNESS 3

Br

Br/W

YDg

R/YL/B

B

B/Y Br

L/Y

Br

Ch

Br/W

R/Y L/B

B/YBr

YDg

B

L/Y

Ch

Loading...

Loading...