YAMAHA PZ50X, PZ50GTX, PZ50RTX, PZ50MTX, PZ50VTX SERVICE MANUAL

...

SUPPLEMENTARY SERVICE MANUAL

2008

PZ50X

PZ50GTX

PZ50RTX

PZ50MTX

PZ50VTX

PZ50MPX

LIT-12618-02-67 8GC-28197-11

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and new data for

the PZ50X, PZ50GTX, PZ50RTX, PZ50MTX, PZ50VTX, PZ50MPX. For complete information, on

service procedures, it is necessary to use this Supplementary Service Manual together with following manual:

PZ50W, PZ50GTW, PZ50FXW, PZ50MW, PZ50VTW, PZ50MPW SERVICE MANUAL:

8GC-28197-10 (LIT-12618-02-58)

PZ50X, PZ50GTX, PZ50RTX, PZ50MTX,

PZ50VTX, PZ50MPX

SUPPLEMENTARY SERVICE MANUAL

©2007 by Yamaha Motor

Corporation, U.S.A.

1st Edition, November 2007

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation,

U.S.A. is expressly prohibited.

Printed in U.S.A.

P/N.LIT-12618-02-67

NOTICE

This manual was written by the Yamaha Motor Company primarily for use by Yamaha dealers and

their qualified mechanics. It is not possible to put an entire mechanic’s education into one manual,

so it is assumed that persons using this book to perform maintenance and repairs on Yamaha

snowmobiles have a basic understanding of the mechanical concepts and procedures inherent in

snowmobile repair. Without such knowledge, attempted repairs or service to this model may render

it unfit and/or unsafe to use.

This model has been designed and manufactured to perform within certain specifications in regard

to performance and emissions. Proper service with the correct tools is necessary to ensure that the

vehicle will operate as designed. If there is any question about a service procedure, it is imperative

that you contact a Yamaha dealer for any service information changes that apply to this model. This

policy is intended to provide the customer with the most satisfaction from his vehicle and to conform

to federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all models manufactured by

Yamaha. Modifications and significant changes in specifications or procedures will be forwarded to

all authorized Yamaha dealers and will, where applicable, appear in future editions of this manual.

HOW TO USE THIS MANUAL

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BE ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

CAUTION:

NOTE:

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The information has been compiled to provide the mechanic with an easy to read, handy reference that contains

comprehensive explanations of all inspection, repair, assembly, and disassembly operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the

course of action required to correct the problem will follow the symbol, e.g.,

•Bearings

Pitting/damage → Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section to facilitate correct disassembly and assembly procedures.

Failure to follow WARNING instructions could result in severe injury or death

the snowmobile operator, a bystander, or a person inspecting or repairing the

snowmobile.

A CAUTION indicates special precautions that must be taken to avoid damage

to the snowmobile.

A NOTE provides key information that can make procedures easier or clearer.

to

1 2

GEN

INFO

34

INSP

ADJ

POWR

CHAS

TR

56

ENG

78

COOL

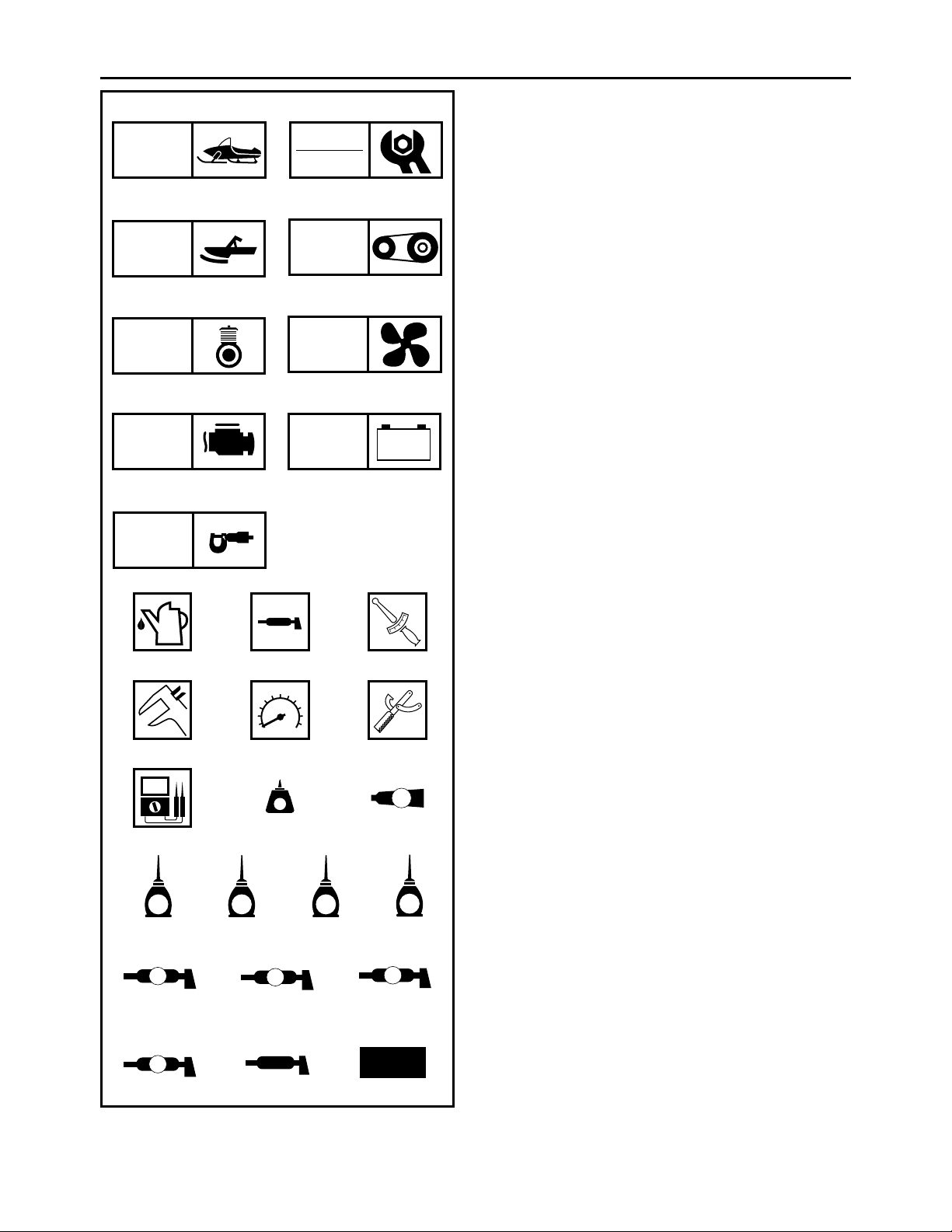

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 9 are designed as thumb

tabs to indicate the chapter’s number and content.

1 General information

2 Periodic inspection and adjustment

3 Chassis

4 Power train

5 Engine

6 Cooling system

7 Fuel injection system

8 Electrical

9 Specifications

–+

9

FI

ELEC

SPEC

0

CDE

FGH

IJKL

E

MNO

B

PQR

AB

T

.

R

.

LT

G

LS

M

5

BF

M

Illustrated symbols 0 to F are used to identify the

specifications which appear.

0

Filling fluid

A Lubricant

B Tightening torque

C Wear limit, clearance

D Engine speed

E Special tool

F Electrical data (Ω, V, A)

Illustrated symbols G to R in the exploded diagram

indicate grade of lubricant and location of lubrication point.

G Apply locking agent (LOCTITE

H Apply Yamabond No.5

I Apply engine oil

J Apply gear oil

K Apply molybdenum disulfide oil

L Apply brake fluid

M Apply wheel bearing grease

N Apply low-temperature lithium-soap-based grease

O Apply molybdenum disulfide grease

P Apply silicone grease

Q ESSO beacon 325 grease or Aeroshell grease #7A

R Use new one

®

®

)

S

New

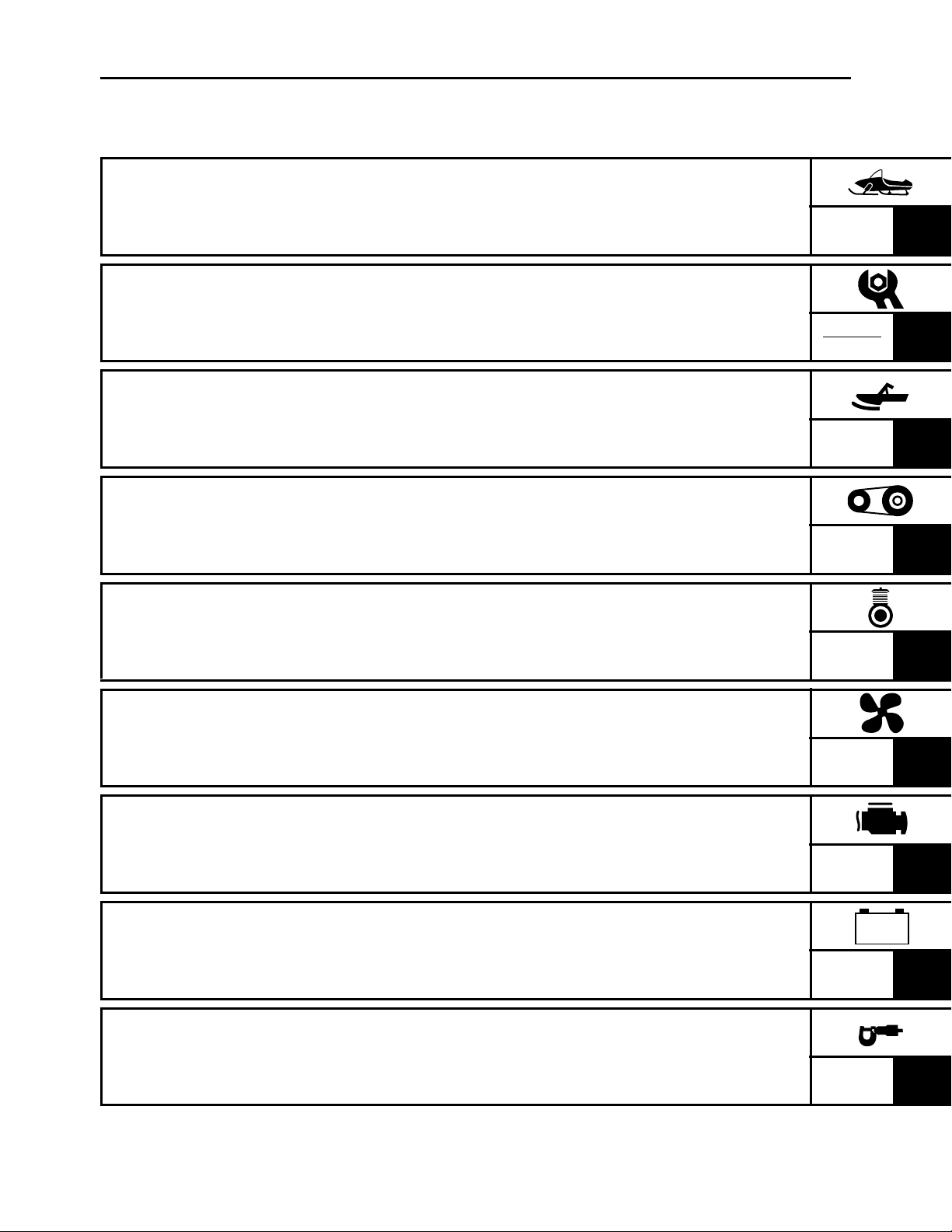

INDEX

GENERAL INFORMATION

PERIODIC INSPECTION AND

ADJUSTMENT

CHASSIS

POWER TRAIN

ENGINE

GEN

INFO

INSP

ADJ

CHAS

POWR

TR

ENG

1

2

3

4

5

COOLING SYSTEM

FUEL INJECTION SYSTEM

ELECTRICAL

SPECIFICATIONS

COOL

FI

– +

ELEC

SPEC

6

7

8

9

PERIODIC INSPECTION AND

ADJUSTMENT

CHASSIS ..................................................... 52

ELECTRICAL ............................................... 54

TUNING

................................................................1

FRONT SUSPENSION ...................................1

AIR PRESSURE ADJUSTMENT (PZ50RT) ...3

REAR SUSPENSION .....................................5

CHASSIS

COWLINGS

PZ50/PZ50GT/PZ50RT/PZ50MT..................10

STEERING

PZ50/PZ50GT/PZ50RT/PZ50MT..................12

FRONT SUSPENSION

PZ50/PZ50RT/PZ50MT ................................15

PZ50GT/PZ50VT/PZ50MP ...........................17

INSTALLATION ............................................19

........................................................10

..........................................................12

.......................................15

POWER TRAIN

TIGHTENING TORQUE

ENGINE ....................................................... 57

POWER TRAIN............................................ 59

CHASSIS ..................................................... 61

GENERAL TORQUE SPECIFICATIONS

DEFINITION OF UNITS

CABLE ROUTING

..................................... 57

..................................... 63

............................................. 64

.......... 63

SLIDE RAIL SUSPENSION

PZ50/PZ50GT/PZ50RT/PZ50MT..................20

PZ50VT/PZ50MP..........................................24

................................20

ENGINE

SEAT AND FUEL TANK

PZ50/PZ50GT/PZ50RT/PZ50MT..................29

BALANCER

REMOVAL ....................................................33

INSTALLATION ............................................33

........................................................31

....................................29

FUEL INJECTION SYSTEM

THROTTLE BODY

INJECTORS..................................................35

..............................................35

SPECIFICATIONS

GENERAL SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE ........................................................41

POWER TRAIN.............................................46

...........................37

..................41

INSP

ADJ

FRONT SUSPENSION

È

É

Ê

a

2

1

PERIODIC INSPECTION AND

ADJUSTMENT

TUNING

FRONT SUSPENSION

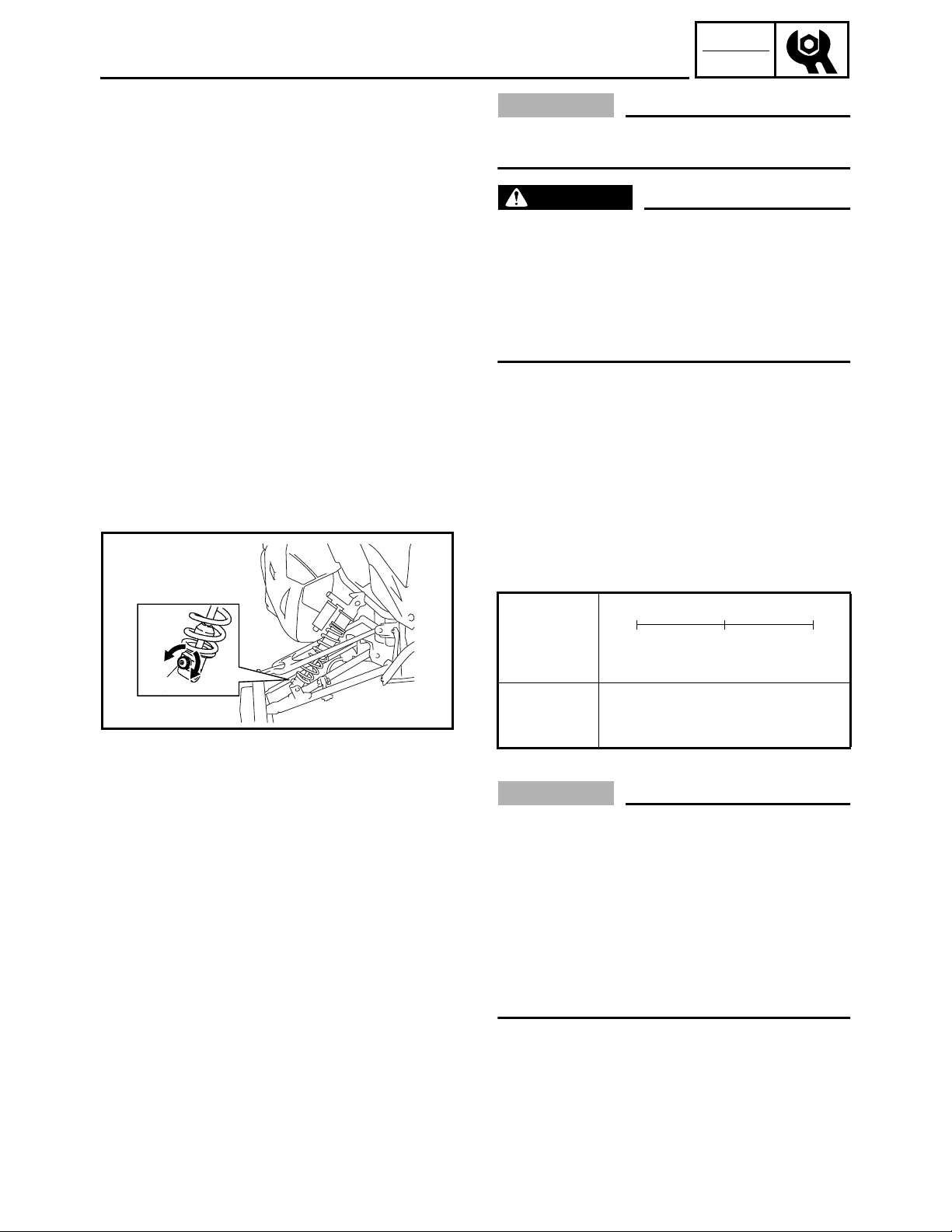

Spring preload

1. Adjust:

• Spring preload

Adjustment steps:

• Loosen the locknut 1.

• Turn the spring seat 2 in or out.

PZ50GT

Spring seat

distance

Preload Harder

Length a

PZ50MT “Europe”

Spring seat

distance

Preload Harder

Length a

Shorter

Min.

172 mm

(6.77 in)

Shorter

Min.

215 mm

(8.46 in)

Standard

←→

←→

182 mm

(7.17 in)

Standard

←→

←→

225 mm

(8.86 in)

Longer

Softer

Max.

182 mm

(7.17 in)

Longer

Softer

Max.

226 mm

(8.90 in)

PZ50VT “Europe”/PZ50MP

Spring seat

distance

Preload Harder

Length a

• Turn the adjusting ring 3 to the proper position.

PZ50/PZ50MT “USA/Canada”/PZ50VT “USA/

Canada”

Spring adjuster

position

Preload Softer

Standard 1

È PZ50MT “Europe”/PZ50VT “Europe”/PZ50MP

É PZ50GT

Ê PZ50/PZ50MT “USA/Canada”/PZ50VT “USA/Can-

ada”

Shorter

Min.

205 mm

(8.07 in)

Standard

←→

←→

215 mm

(8.46 in)

12345

←→

Longer

Softer

Max.

216 mm

(8.50 in)

Harder

1

INSP

ADJ

FRONT SUSPENSION

CAUTION:

Be sure that the left and right spring preload are

the same.

WARNING

These shock absorber contain highly pressurized nitrogen gas.

Do not tamper with or attempt to open the

shock absorber assemblies.

Do not subject the shock absorber assemblies

to flames or high heat, which could cause it to

explode.

b

1

a

Rebound damping force adjustment (PZ50GT)

The rebound damping force can be adjusted by

turning the adjuster 1.

20 clicks out 12 clicks out 3 clicks out

Adjuster

position

Rebound

damping

force

* With the adjuster fully turned lightly in direction a

Minimum Standard Maximum

Turns out b*

Soft

←→

←→

Turns in a

Hard

CAUTION:

• Do not continue to turn the adjuster in direction a after it stops. The shock absorber can

be damaged and rebound damping force

adjustments cannot be made.

• Do not turn the adjuster in direction b more

than 20 clicks. Even if the adjuster is continually turned after 20 clicks, there will be no

change in the rebound damping force.

• Be sure to stop the adjuster at a position

where there is a click.

2

INSP

ADJ

b

1

a

FRONT SUSPENSION/

AIR PRESSURE ADJUSTMENT (PZ50RT)

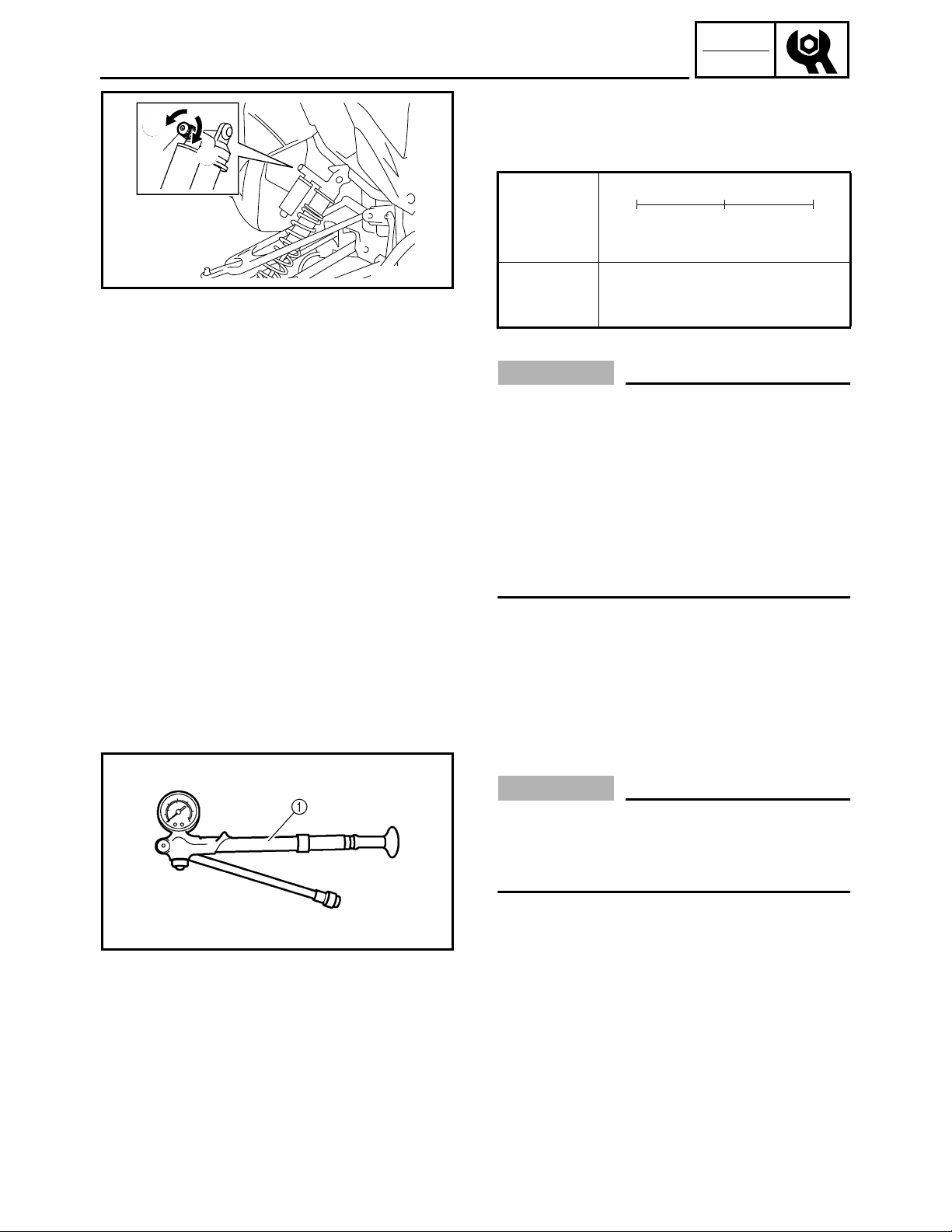

Compression damping force adjustment

(PZ50GT)

The compression damping force can be adjusted

by turning the adjuster 1.

12 clicks out 7 clicks out 2 clicks out

Adjuster

position

Compression damping force

* With the adjuster fully turned lightly in direction a

CAUTION:

• Do not continue to turn the adjuster in direction a after it stops. The shock absorber can

be damaged and compression damping force

adjustments cannot be made.

• Do not turn the adjuster in direction b more

than 12 clicks. Even if the adjuster is continually turned after 12 clicks, there will be no

change in the compression damping force.

• Be sure to stop the adjuster at a position

where there is a click.

Minimum Standard Maximum

Turns out b*

Soft

←→

←→

Turns in a

Hard

AIR PRESSURE ADJUSTMENT (PZ50RT)

CAUTION:

The left and right shock absorber air pressure

must be set to the same setting. Uneven settings can cause poor handling and loss of stability.

This snowmobile is equipped with FOX shock

absorbers as standard equipment.

The air pressure of the shock absorbers can be

adjusted using the shock absorber pump

included with your snowmobile.

3

1

INSP

ADJ

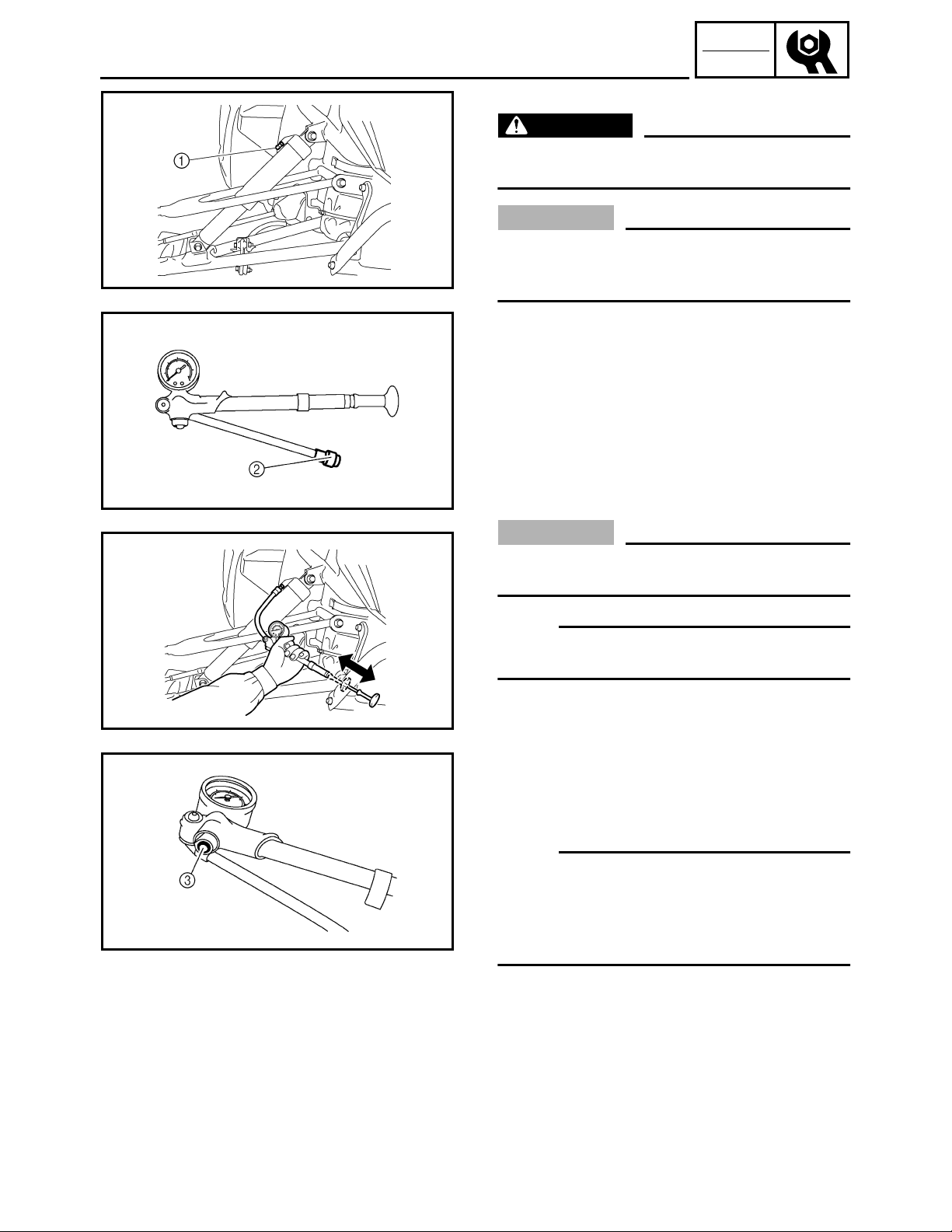

AIR PRESSURE ADJUSTMENT (PZ50RT)

Adjustment steps:

WARNING

Support the snowmobile securely on a suitable

stand before adjusting the shock absorbers.

CAUTION:

Make sure that there is no load on the shock

absorbers and that they are fully extended

before making any air pressure adjustments.

1. Place the snowmobile on a level surface and

apply the parking brake.

2. Lift the front of the snowmobile onto a suitable

stand to raise the skis off the ground.

3. Remove the air valve cap 1 from the shock

absorber.

4. Install the hose connector 2 of the shock

absorber pump onto the air valve of the shock

absorber and tighten it approximately six turns

until the pressure registers on the pump gauge.

CAUTION:

Do not overtighten the connector onto the air

valve as this will damage the connector seal.

NOTE:

If the shock absorber has no air pressure, the

gauge reading will be zero.

5. To increase the air pressure, operate the pump

a few times. The pressure should increase

slowly. If the pressure increases rapidly, check

to make sure that the pump is properly connected and tightened onto the air valve. To

decrease the air pressure, push the black bleed

valve button 3.

NOTE:

To allow pressure to escape from the pump and the

shock absorber, push the button halfway down and

hold it. To allow only a small amount of pressure to

escape, push the button all the way down and

quickly release it.

4

INSP

ADJ

AIR PRESSURE ADJUSTMENT (PZ50RT)/

REAR SUSPENSION

6. Remove the hose connector from the air valve.

NOTE:

When removing the connector, the sound of air

escaping may be heard, but this is from the pump

hose, not the shock absorber.

Air pressure range:

345 kPa (3.4 kgf/cm², 50 psi) to 1,034 kPa

(10.3 kgf/cm², 150 psi)

Recommended air pressure:

483 kPa (4.8 kgf/cm², 70 psi)

CAUTION:

Do not exceed 1,034 kPa (10.3 kgf/cm², 150 psi).

7. Install the air valve cap.

NOTE:

If the front suspension bottoms too easily or rolls

too much during cornering, increase the air pressure by 34 kPa (0.3 kgf/cm², 5 psi). If the suspension is too firm and you want a more compliant ride,

decrease the air pressure by 34 kPa (0.3 kgf/cm², 5

psi).

REAR SUSPENSION

Stopper band

1. Adjust:

• Stopper band length

CAUTION:

Make sure the left and right rear suspension

stopper bands are adjusted evenly. (PZ50VT,

PZ50MP)

NOTE:

This adjustment affects the handling characteristics

of the machine.

5

INSP

ADJ

REAR SUSPENSION

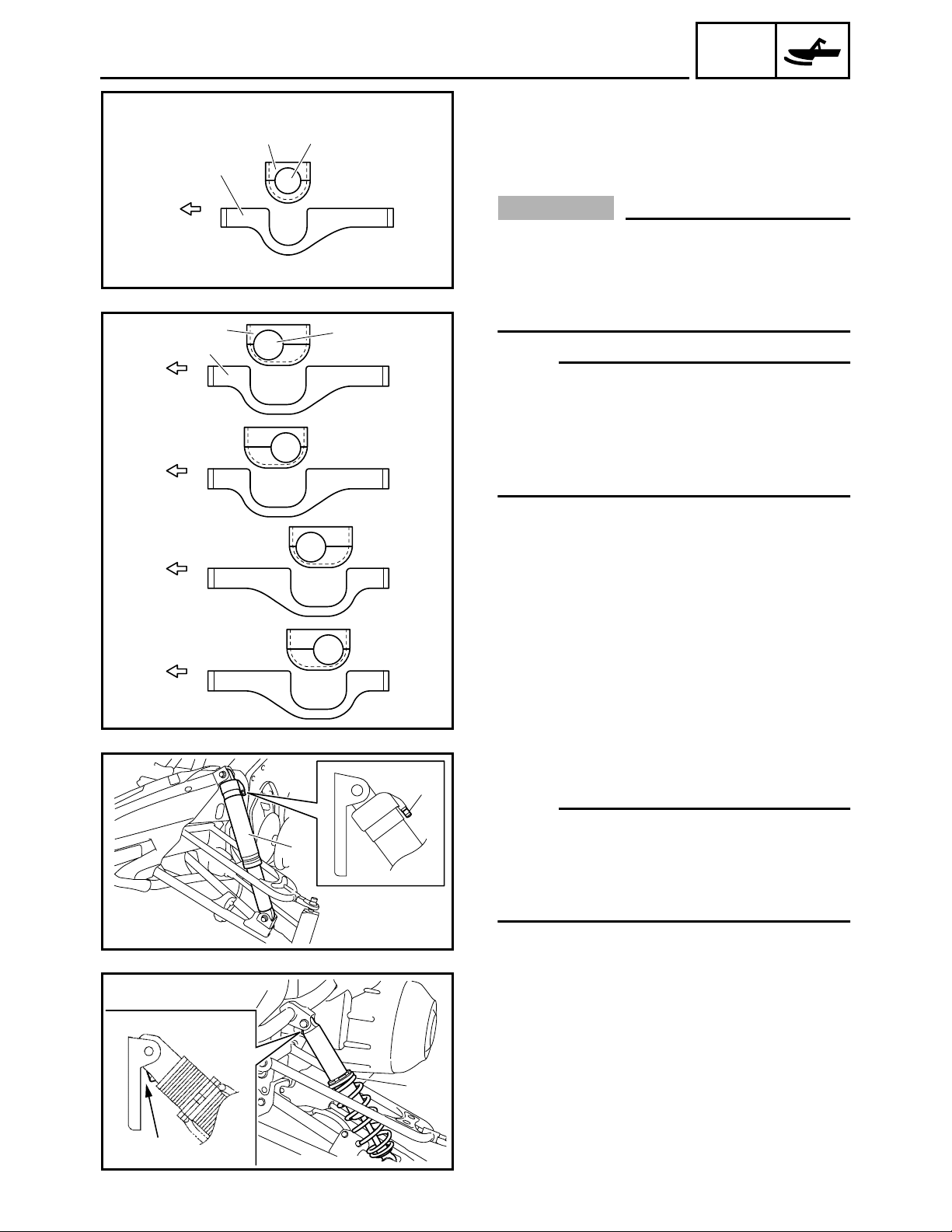

È

È

É

2

1

2

1

1

No.1

No.2

No.3

No.4

No.5

No.1

No.2

No.3

No.4

Adjustment steps:

• Remove the stopper band bolts 1, nuts and

washers.

• Adjust the length of the stopper bands 2 by

inserting the bolts in different holes.

Standard setting:

No. 1 hole (PZ50/PZ50VT “Europe”/PZ50MP)

No. 2 holes (PZ50GT/PZ50RT)

No. 3 holes (PZ50MT)

No. 4 hole (PZ50VT “USA/Canada”)

• Tighten the stopper band nuts.

Stopper band nut:

4 Nm (0.4 m · kg, 2.9 ft · lb)

T

.

R

.

È PZ50/PZ50GT/PZ50RT/PZ50MT

É PZ50VT/PZ50MP

Choosing other settings:

CAUTION:

The standard settings work well under most

general riding conditions. The suspension can

be adjusted to work better in one condition, but

only at the expense of another. Keep this in

mind when you adjust the suspension.

È

: No. 5 hole

É

: No. 4 hole

(shortest)

More weight on skis:

• Heavy steering/

oversteer

• More maneuverability

Favors: hardpack

snow, ice, smooth

trails, tight turns

È PZ50/PZ50GT/PZ50RT/PZ50MT

É PZ50VT/PZ50MP

No. 1 hole

(longest)

Less weight on skis:

• Light steering/

understeer

• Better acceleration

and speed

Favors: deep snow,

straight line acceleration, top speed

6

INSP

ADJ

REAR SUSPENSION

È

Spring preload

1. Adjust:

• Spring preload

Adjustment step:

Front side

• Loosen the locknut 1.

• Turn the spring seat 2 in or out.

PZ50GT “Europe”/PZ50RT “USA/Canada”/

PZ50MT “Europe”

Spring seat

distance

Preload Harder

Length a

PZ50RT “Europe”

Spring seat

distance

Preload Harder

Length a

Shorter

Min.

180 mm

(7.09 in)

Shorter

Min.

178 mm

(7.01 in)

Standard

←→

←→

190 mm

(7.48 in)

Standard

←→

←→

188 mm

(7.40 in)

Longer

Softer

Max.

191 mm

(7.52 in)

Longer

Softer

Max.

189 mm

(7.44 in)

PZ50VT “Europe”/PZ50MP

Spring seat

distance

Preload Harder

Length a

È PZ50GT “Europe”/PZ50RT/PZ50MT “Europe”/

PZ50VT “Europe”/PZ50MP

Shorter

Min.

194 mm

(7.64 in)

Standard

←→

←→

204 mm

(8.03 in)

205 mm

(8.07 in)

Longer

Softer

Max.

7

INSP

ADJ

REAR SUSPENSION

É

• Turn the adjusting ring 3 to the proper position.

PZ50/PZ50GT “USA/Canada”/PZ50MT “USA/

Canada”/PZ50VT “USA/Canada”

Spring adjuster

position

Preload Softer

Standard 1

12345

←→

Harder

WARNING

This shock absorber contains highly pressurized nitrogen gas.

Do not tamper with or attempt to open the

shock absorber assembly.

Do not subject the shock absorber assembly to

flames or high heat, which could cause it to

explode.

É PZ50/PZ50GT “USA/Canada”/PZ50MT “USA/Can-

ada”/PZ50VT “USA/Canada”

Rear side

• Turn the adjuster 1 to proper position.

Spring adjuster

position

Spring rate Soft Medium Hard

Standard M

SMH

WARNING

Always adjust both spring preload (left and

right) to the same setting. Uneven adjustment

can cause poor handling and loss of stability.

8

INSP

ADJ

REAR SUSPENSION

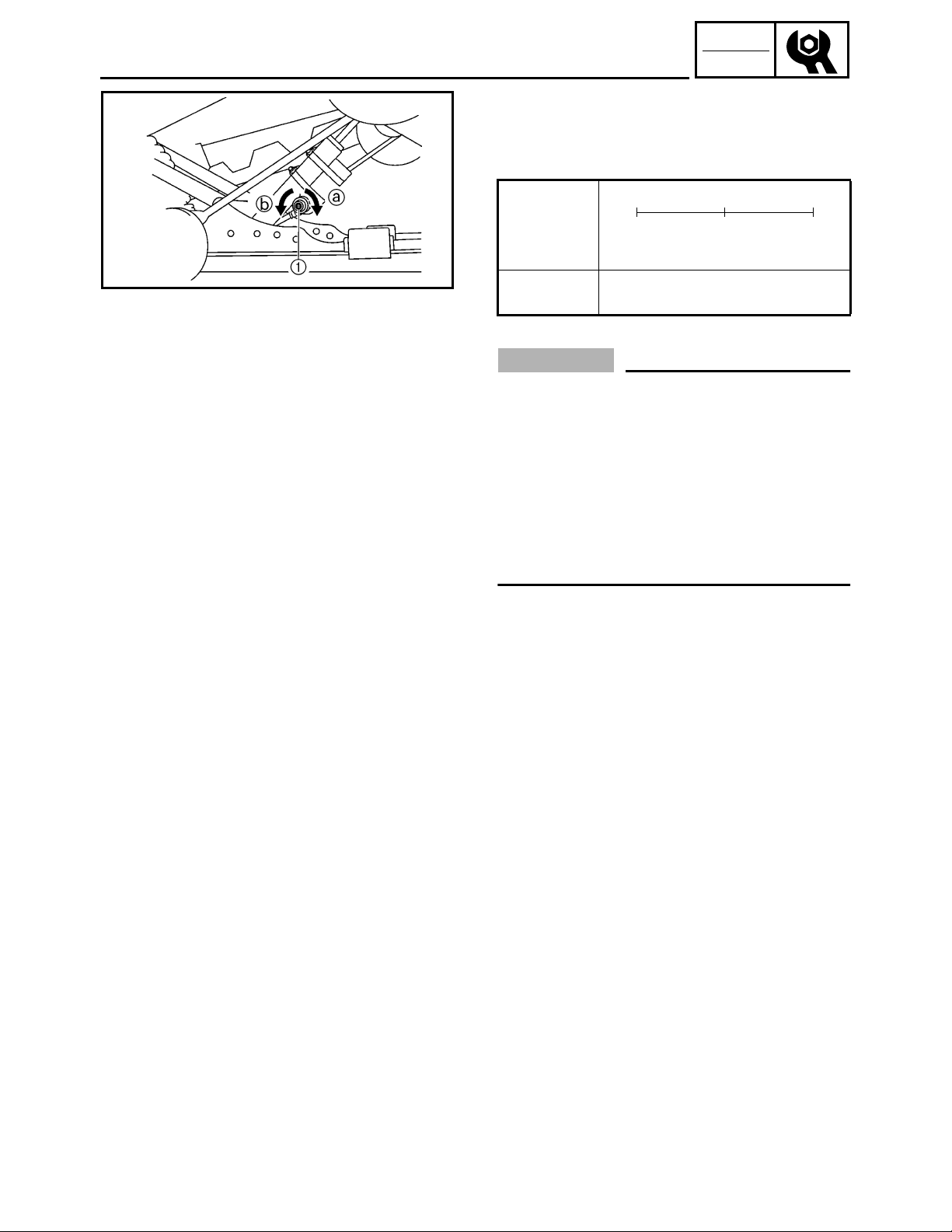

Rear suspension damping force adjustment

The damping force can be adjusted by turning the

adjuster 1.

PZ50RT

20 clicks out 11 clicks out 1 click out

Adjuster

position

Damping

force

* With the adjuster fully turned lightly in direction a

CAUTION:

• Do not continue to turn the adjuster in direction a after it stops. The shock absorber can

be damaged and damping force adjustments

cannot be made.

• Do not turn the adjuster in direction b more

than 20 clicks. Even if the adjuster is continually turned after 20 clicks, there will be no

change in the damping force.

• Be sure to stop the adjuster at a position

where there is a click.

Minimum Standard Maximum

Turns out b*

Soft

←→

←→

Turns in a

Hard

9

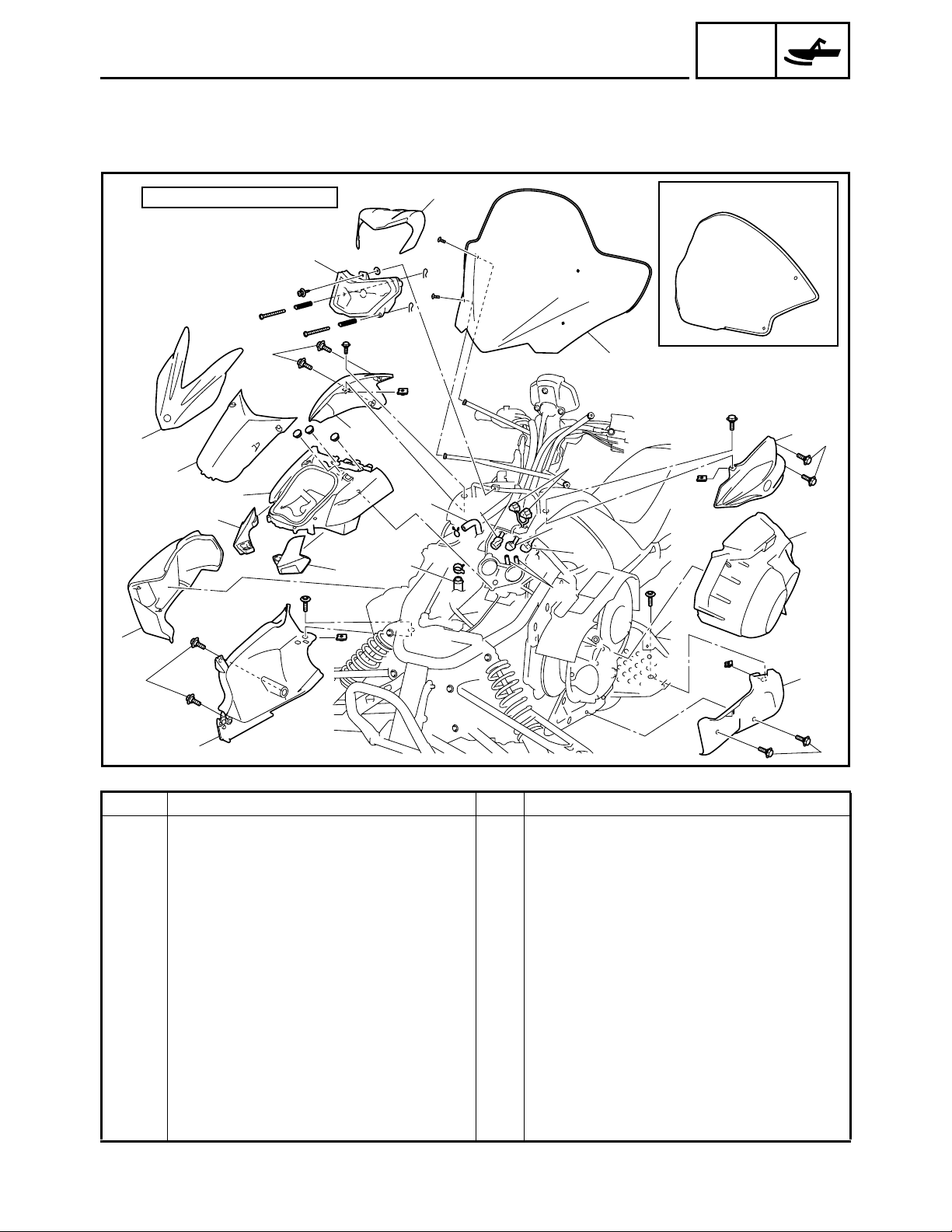

COWLINGS

PZ50/PZ50GT/PZ50RT/PZ50MT

CHASSIS

COWLINGS

CHAS

È:

2

8

8 Nm (0.8 m

3

19

• kg, 5.8 ft • lb)

È

18

12

19

4

PZ50RT

1

6

5

È

11

16

17

15

13

7

14

20

È

10

Order Job name/Part name

Cowling removal

1 Windshield 1 PZ50GT

2 Front panel 1

3 Air filter case cover 1

4 Headlight cover 1

5 Left side panel 1

6 Right side panel 1

7 Left side cover 1

8 Right side cover 1

9 Left lower cover 1

10 Right lower cover 1

11 Headlight coupler 2

12 Headlight assembly 1

13 Cylinder-#2 intake air pressure sensor cou-

pler

Q’ty Remarks

Remove the parts in the order listed below.

1 Disconnect.

9

È

10

COWLINGS

CHAS

È:

2

8

8 Nm (0.8 m

3

19

• kg, 5.8 ft • lb)

È

18

12

19

4

PZ50RT

1

6

5

È

11

16

17

15

13

7

14

20

È

10

Order Job name/Part name

14 Cylinder-#1 intake air pressure sensor cou-

pler

15 Intake air temperature sensor coupler 1 Disconnect.

16 Cylinder head breather hose 1 Disconnect.

17 Oil tank breather hose 1 Disconnect.

18 Air filter case assembly 1

19 Air filter case assembly pad (left and right) 2

20 Intake air pressure sensor hose 2

Q’ty Remarks

1 Disconnect.

For installation, reverse the removal procedure.

9

È

11

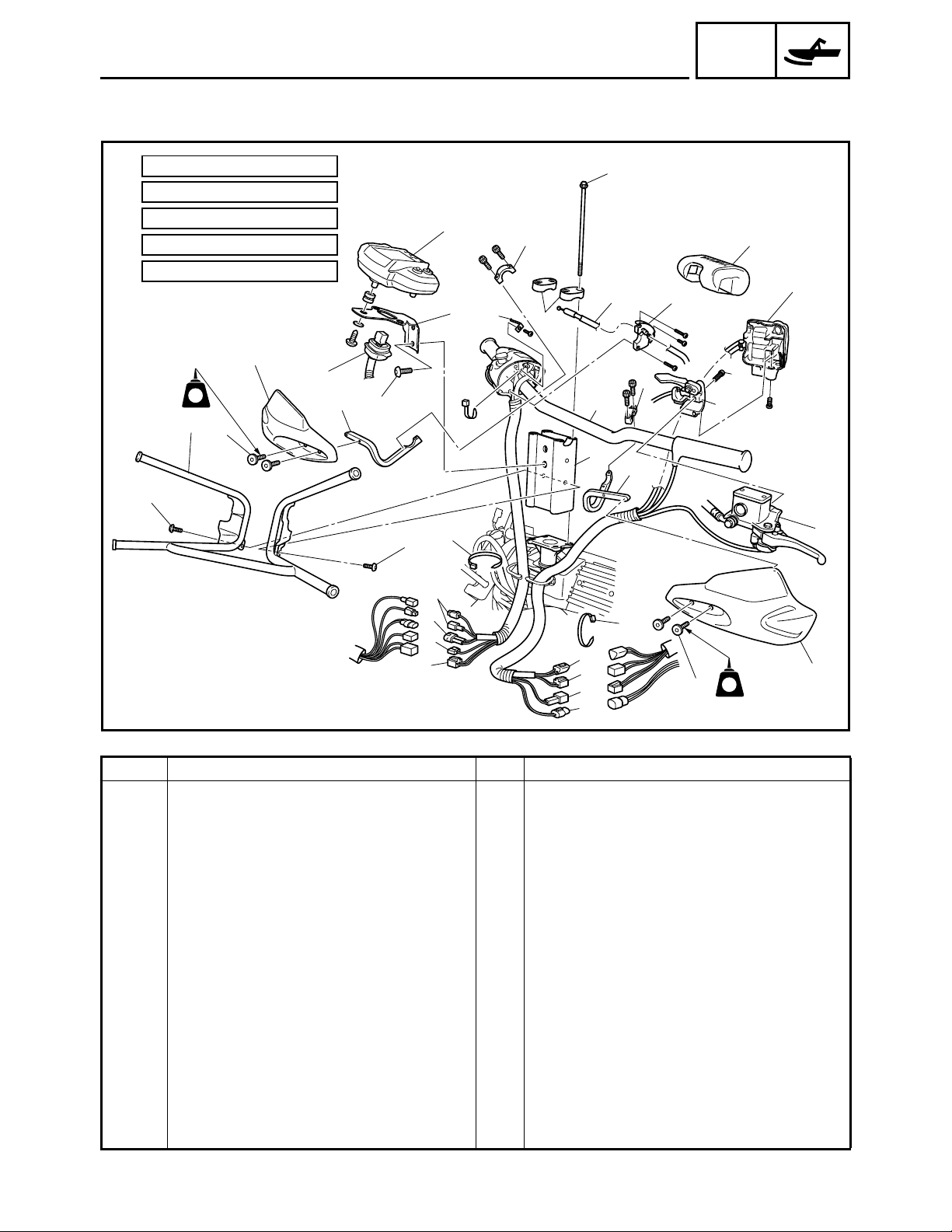

STEERING

PZ50/PZ50GT/PZ50RT/PZ50MT

STEERING

CHAS

È:

10 Nm (1.0 m

É:

15 Nm (1.5 m

Ê:

16 Nm (1.6 m

Ë:

20 Nm (2.0 m

Ì:

Ë

7 Nm (0.7 m

LT

1

È

• kg, 5.1 ft • lb)

• kg, 7.2 ft • lb)

• kg, 11 ft • lb)

• kg, 11 ft • lb)

• kg, 14 ft • lb)

2

Ê

6

7

18

5

4

Ì

3

19

17

8

20

23

3

24

É

21

25

4

Ë

9

22

12

11

10

13

14

13

15

9

È

LT

2

16

Order Job name/Part name

Handlebar removal

Windshield/left side panel/right side panel Refer to “COWLINGS”.

1 Windshield bracket 1 PZ50GT/PZ50RT/PZ50MT

2 Wind deflector (left and right) 2 PZ50RT

3 Wind deflector bracket holder 2 PZ50RT

4 Wind deflector bracket 2 PZ50RT

5 Multi-function meter coupler 1

6 Multi-function meter 1

7 Multi-function meter bracket 1

8 Steering pad 1 PZ50GT/PZ50RT/PZ50MT

9 Plastic band 2

10 Thumb warmer lead coupler 1 Disconnect.

11 Engine stop switch coupler 1 Disconnect.

12 Throttle switch coupler 2 Disconnect.

13 Grip warmer lead connector 2 Disconnect.

14 Grip thumb warmer adjustment switch lead

coupler

Q’ty Remarks

Remove the parts in the order listed below.

1 Disconnect.

12

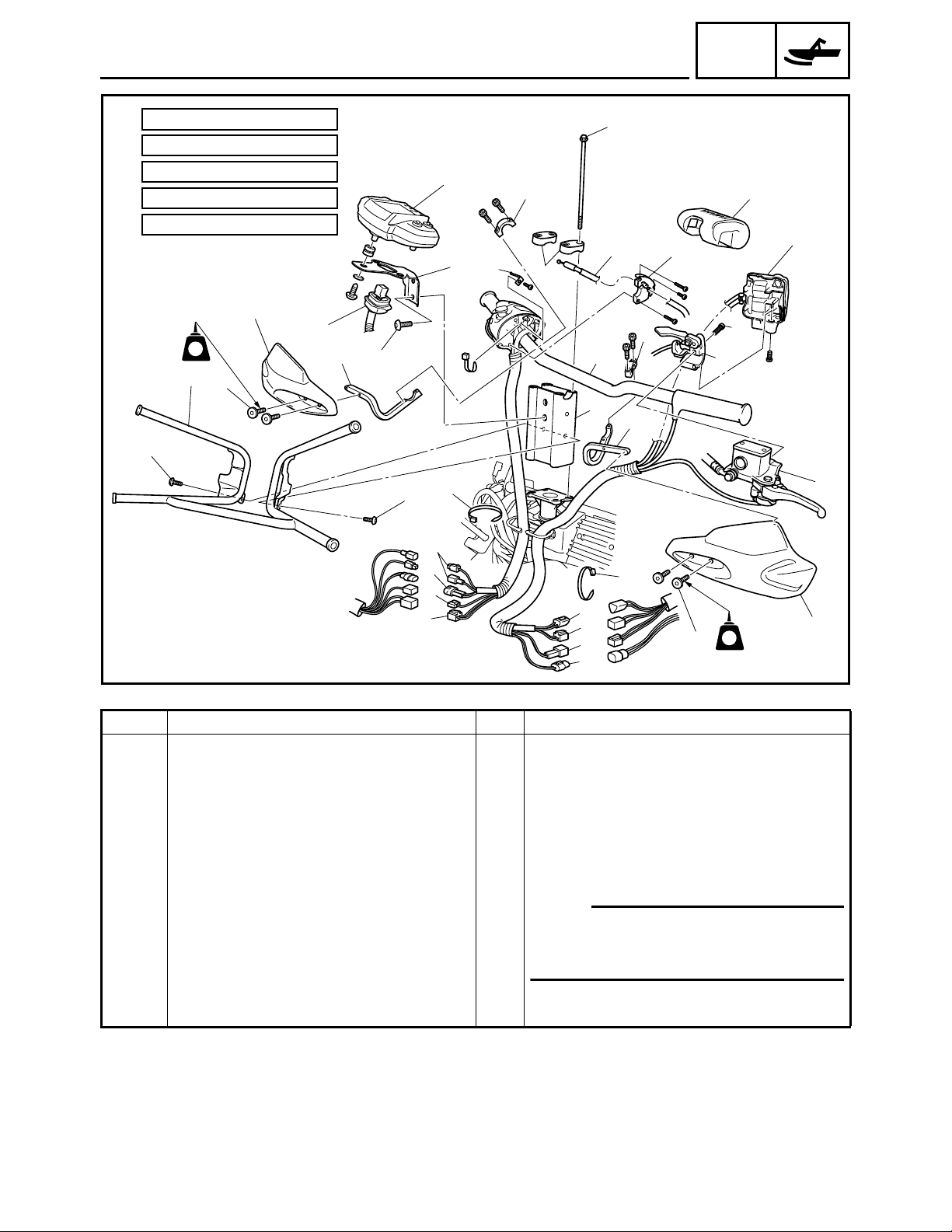

STEERING

CHAS

È:

10 Nm (1.0 m

É:

15 Nm (1.5 m

Ê:

16 Nm (1.6 m

Ë:

20 Nm (2.0 m

Ì:

Ë

7 Nm (0.7 m

LT

1

È

• kg, 5.1 ft • lb)

• kg, 7.2 ft • lb)

• kg, 11 ft • lb)

• kg, 11 ft • lb)

• kg, 14 ft • lb)

2

Ê

6

7

18

5

4

Ì

3

19

17

8

20

23

3

24

É

21

25

4

Ë

9

22

12

11

10

13

14

13

15

9

È

LT

2

16

Order Job name/Part name

15 Brake light switch coupler 1 Disconnect.

16 Headlight beam switch coupler 1 Disconnect.

17 Right handlebar switch cover 1

18 Throttle cable holder 1

19 Throttle cable 1

20 Left handlebar switch 1

21 Brake master cylinder holder 1

22 Master cylinder assembly 1

23 Handlebar holder 2

24 Handlebar 1

25 Steering joint 1

Q’ty Remarks

NOTE:

After installing all parts, refer to “CABLE

ROUTING”, to check the cable and lead routings.

For installation, reverse the removal procedure.

13

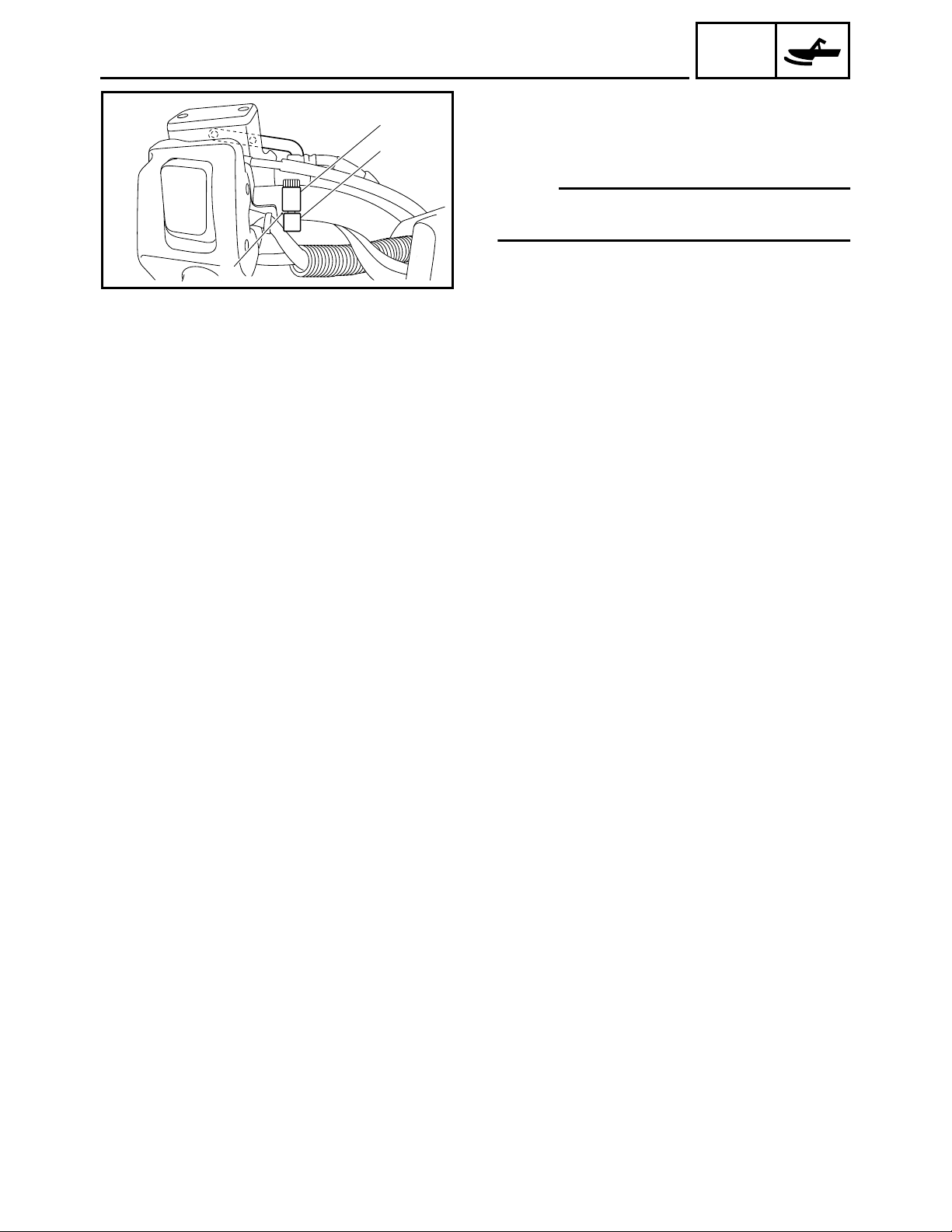

a

1

2

STEERING

1. Install:

For PZ50RT

• Wind deflector bracket holder 1

• Wind deflector bracket 2

NOTE:

Align the end of the wind deflector bracket with the

punch mark a on the handlebar.

CHAS

14

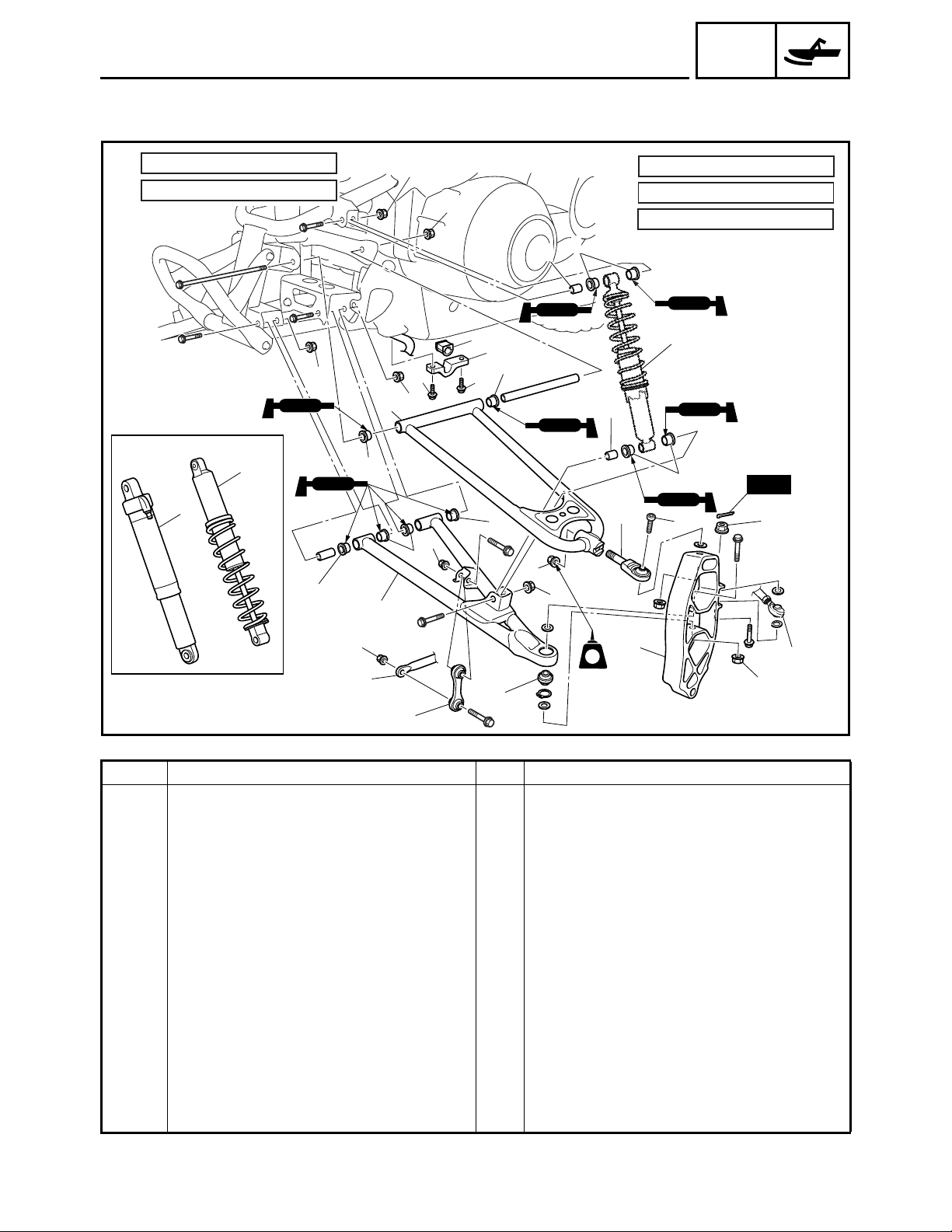

FRONT SUSPENSION

PZ50/PZ50RT/PZ50MT

FRONT SUSPENSION

CHAS

È:

É:

28 Nm (2.8 m

34 Nm (3.4 m

2

• kg, 20 ft • lb)

• kg, 24 ft • lb)

Ì

3

16

10

15

45 Nm (4.5 m

Ê

Ê

4

12

11

É

Ì

9

É

10

Ê:

90 Nm (9.0 m

Ë:

65 Nm (6.5 m

Ì:

5

1

4

5

16

8

Ê

• kg, 32 ft • lb)

• kg, 65 ft • lb)

• kg, 47 ft • lb)

New

È

É

16

Ë

Ê

Ê

LT

7

14

17

13

Order Job name/Part name

Front suspension removal

Air filter case cover Refer to “COWLINGS”.

Pivot arm cover Refer to “STEERING”.

Ski Refer to “SKI” in CHAPTER 3.

1 Shock absorber 1 PZ50/PZ50MT “USA/Canada”

2 Shock absorber 1 PZ50RT

3 Shock absorber 1 PZ50MT “Europe”

4 Collar 2 PZ50/PZ50MT

5 Bushing 4 PZ50/PZ50MT

6 Tie rod 1 Disconnect.

7 Steering knuckle 1

8 Upper arm ball joint 1

9 Upper arm 1

10 Bushing 2

11 Stabilizer holder 1

12 Bushing 1

Q’ty Remarks

Remove the parts in the order listed below.

6

Ì

15

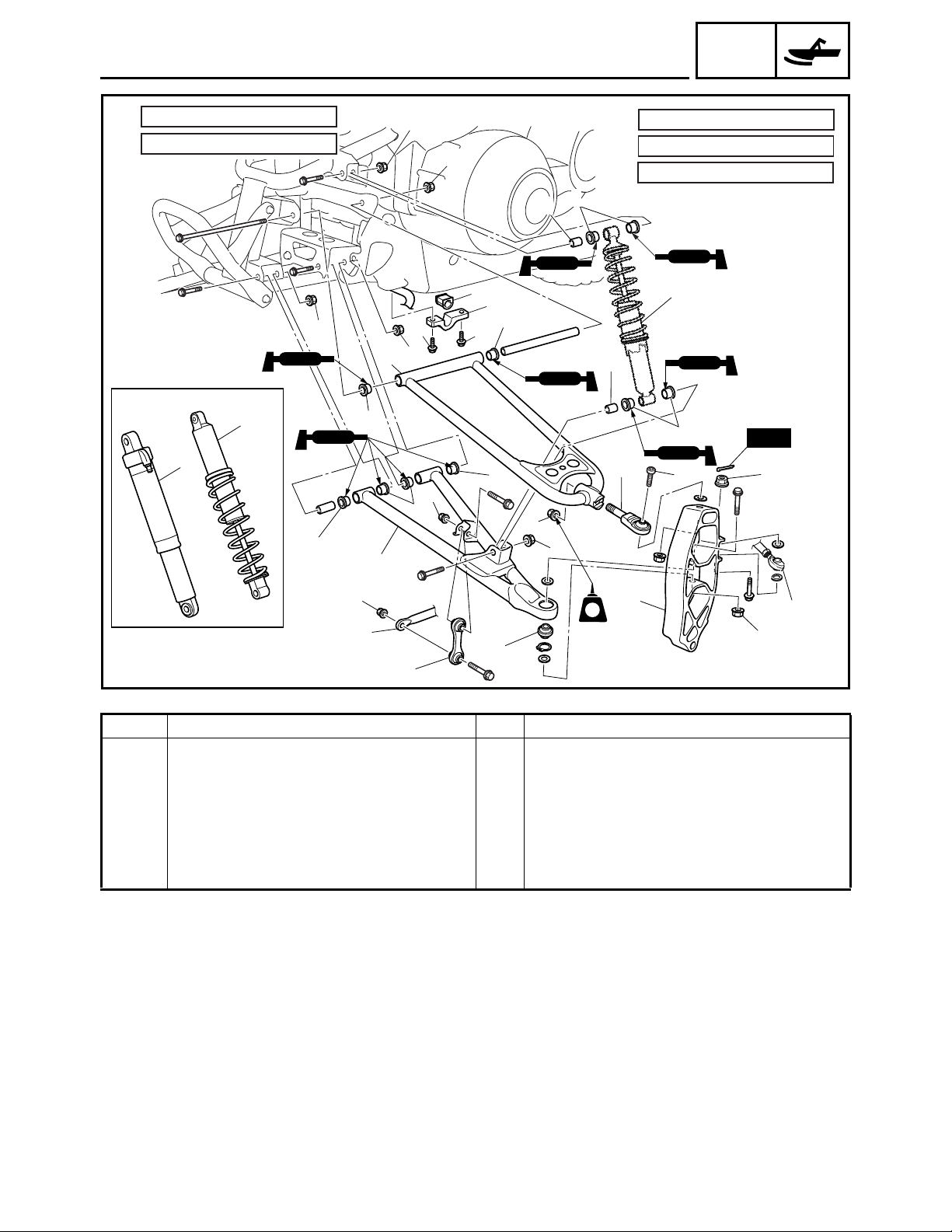

FRONT SUSPENSION

CHAS

È:

É:

28 Nm (2.8 m

34 Nm (3.4 m

2

• kg, 20 ft • lb)

• kg, 24 ft • lb)

Ì

3

16

10

15

45 Nm (4.5 m

Ê

Ê

4

12

11

É

Ì

9

É

10

Ê:

90 Nm (9.0 m

Ë:

65 Nm (6.5 m

Ì:

5

1

4

5

16

8

Ê

• kg, 32 ft • lb)

• kg, 65 ft • lb)

• kg, 47 ft • lb)

New

È

É

16

Ë

Ê

Ê

14

13

Order Job name/Part name

13 Stabilizer joint 1

14 Stabilizer 1

15 Lower arm 1

16 Bushing 4

17 Lower arm ball joint 1

7

LT

17

Q’ty Remarks

For installation, reverse the removal procedure.

6

Ì

16

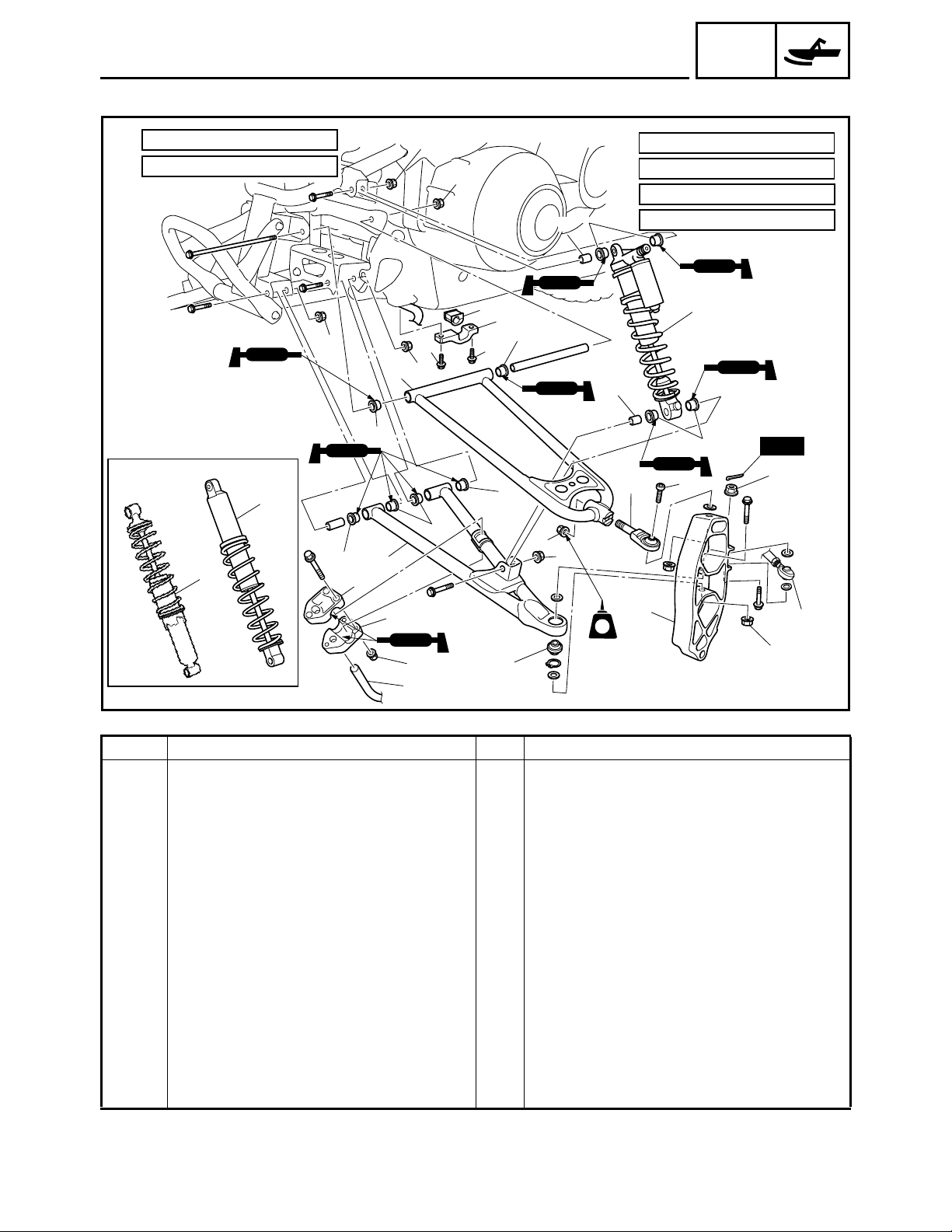

PZ50GT/PZ50VT/PZ50MP

FRONT SUSPENSION

CHAS

7 Nm (0.7 m

È:

28 Nm (2.8 m

É:

• kg, 5.1 ft • lb)

• kg, 20 ft • lb)

2

• kg, 24 ft • lb)

• kg, 32 ft • lb)

• kg, 65 ft • lb)

• kg, 47 ft • lb)

1

Í

Ë

Ë

5

4

12

11

10

Ê

Í

9

Ê

Ê:

Ë:

Ì:

Í:

34 Nm (3.4 m

45 Nm (4.5 m

90 Nm (9.0 m

65 Nm (6.5 m

4

10

3

16

16

15

16

Ì

Ë

8

Ë

5

New

É

13

13

È

17

7

LT

14

Order Job name/Part name

Front suspension removal

Air filter case cover Refer to “COWLINGS”.

Pivot arm cover Refer to “STEERING”.

Ski Refer to “SKI” in CHAPTER 3.

1 Shock absorber 1 PZ50GT

2 Shock absorber 1 PZ50VT “USA/Canada”

3 Shock absorber 1 PZ50VT “Europe”/PZ50MP

4 Collar 2

5 Bushing 4

6 Tie rod 1 Disconnect.

7 Steering knuckle 1

8 Upper arm ball joint 1

9 Upper arm 1

10 Bushing 2

11 Stabilizer holder 1

12 Bushing 1

Q’ty Remarks

Remove the parts in the order listed below.

6

Í

17

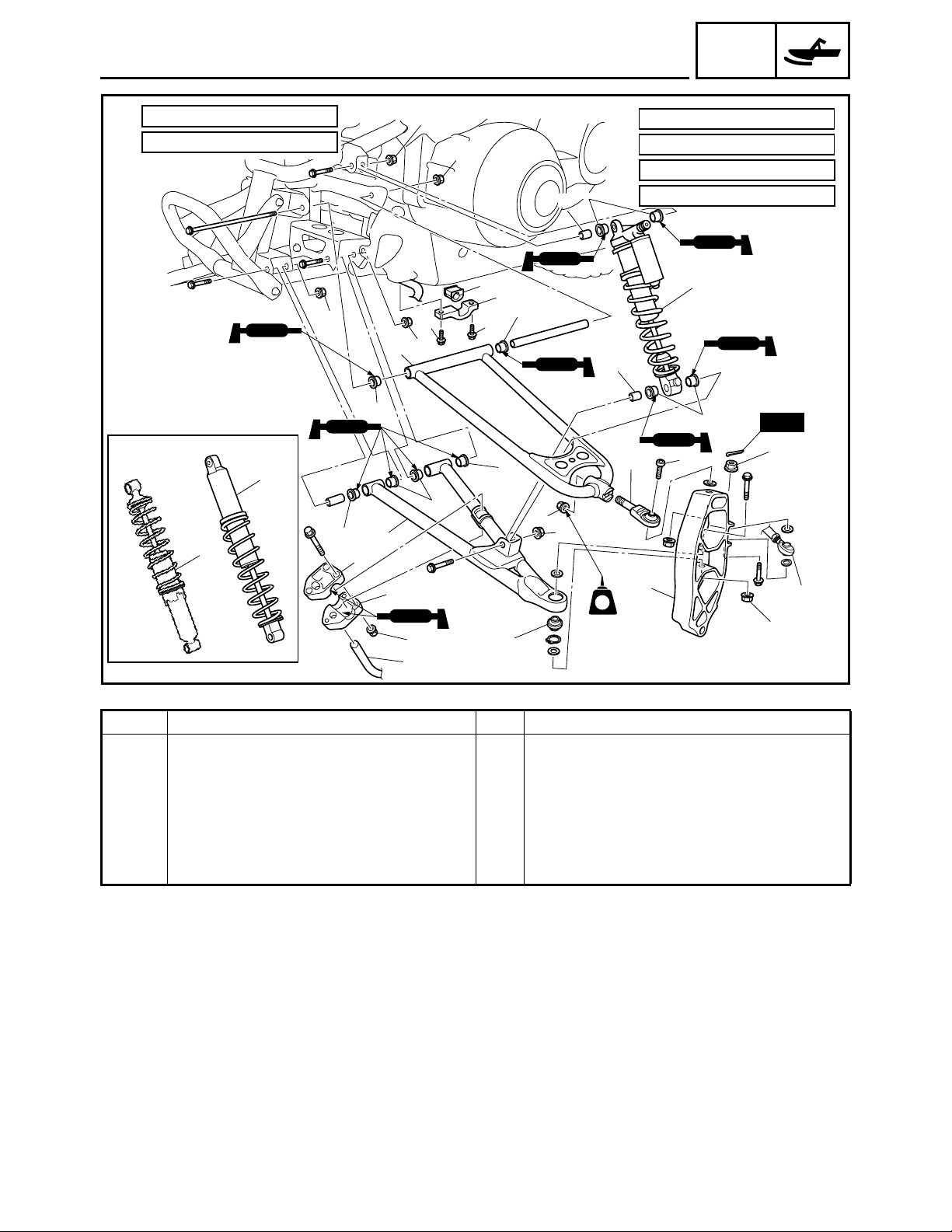

FRONT SUSPENSION

CHAS

7 Nm (0.7 m

È:

28 Nm (2.8 m

É:

• kg, 5.1 ft • lb)

• kg, 20 ft • lb)

2

• kg, 24 ft • lb)

• kg, 32 ft • lb)

• kg, 65 ft • lb)

• kg, 47 ft • lb)

1

Í

Ë

Ë

5

4

12

11

10

Ê

Í

9

Ê

Ê:

Ë:

Ì:

Í:

34 Nm (3.4 m

45 Nm (4.5 m

90 Nm (9.0 m

65 Nm (6.5 m

4

10

3

16

16

15

16

Ì

Ë

8

Ë

5

New

É

13

13

È

14

Order Job name/Part name

13 Stabilizer bracket 2

14 Stabilizer 1

15 Lower arm 1

16 Bushing 4

17 Lower arm ball joint 1

7

LT

17

Q’ty Remarks

For installation, reverse the removal procedure.

6

Í

18

FRONT SUSPENSION

CHAS

È

É

a

a

a

a

a

3

3

2

INSTALLATION

1. Install:

12

• Stabilizer 1

• Bushing 2

• Stabilizer holder 3

CAUTION:

Always install the stabilizers, bushings, and

stabilizer holders in the same positions on both

sides of the snowmobile, otherwise poor handling and loss of stability may result. (PZ50GT/

PZ50VT/PZ50MP)

1

NOTE:

b

c

d

e

• Install the stabilizer holder in the direction shown

in the illustration. (PZ50/PZ50RT/PZ50MT)

• The stabilizer force can be adjusted by changing

the installation positions of the stabilizer, bushing,

and stabilizer holder. (PZ50GT/PZ50VT/

PZ50MP)

È PZ50/PZ50RT/PZ50MT

É PZ50GT/PZ50VT/PZ50MP

a Forward

b Very hard

c Hard

d Medium

e Soft

Stabilizer, bushing, and stabilizer holder standard installation positions:

d

(PZ50GT)

b

(PZ50VT/PZ50MP)

b

1

1

a

2. Install:

• Shock absorber

1

NOTE:

• Install the shock absorber with the air valve

facing outward. (PZ50RT)

• Install the shock absorber with the charging valve

b

facing inward. (PZ50MT “Europe”/PZ50VT

“Europe”/PZ50MP)

19

a

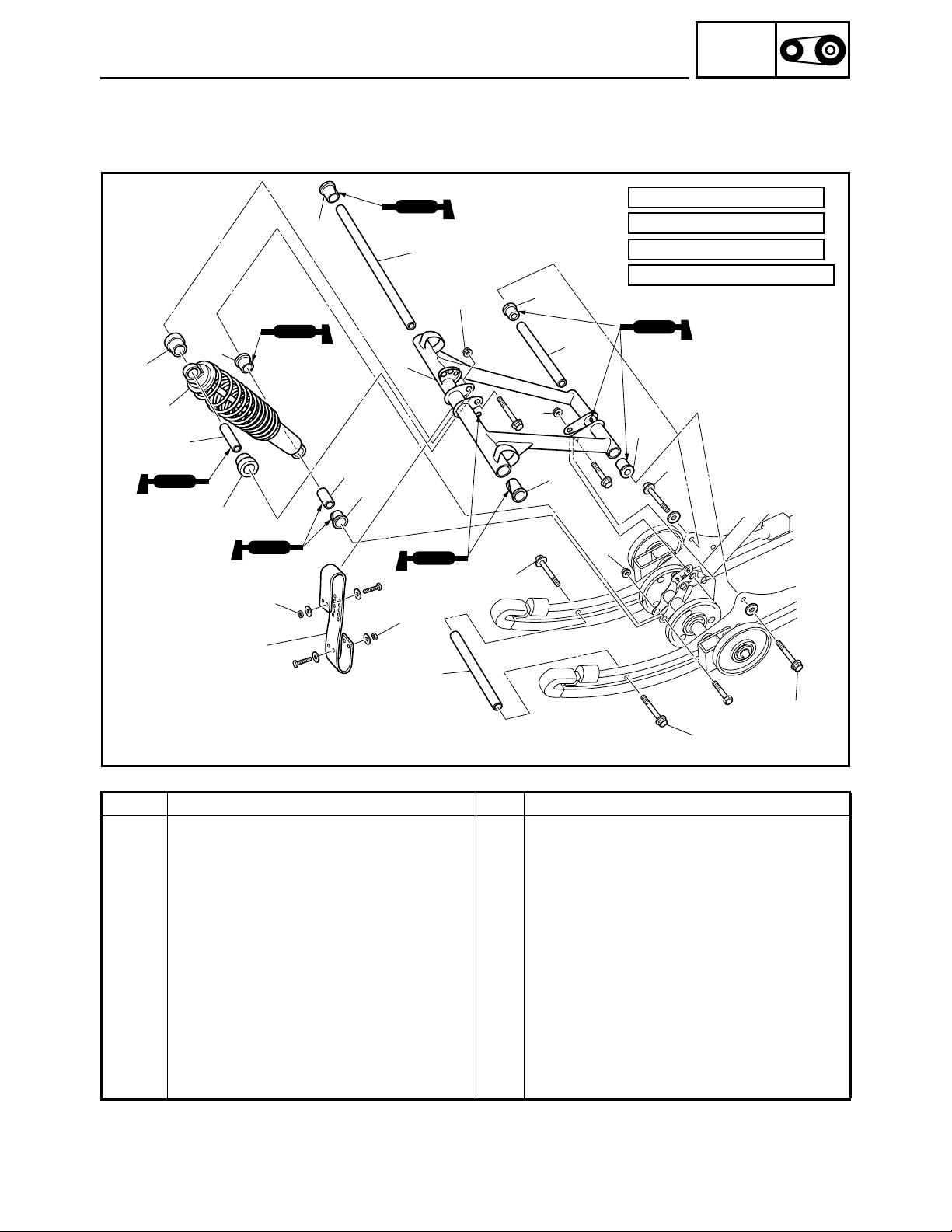

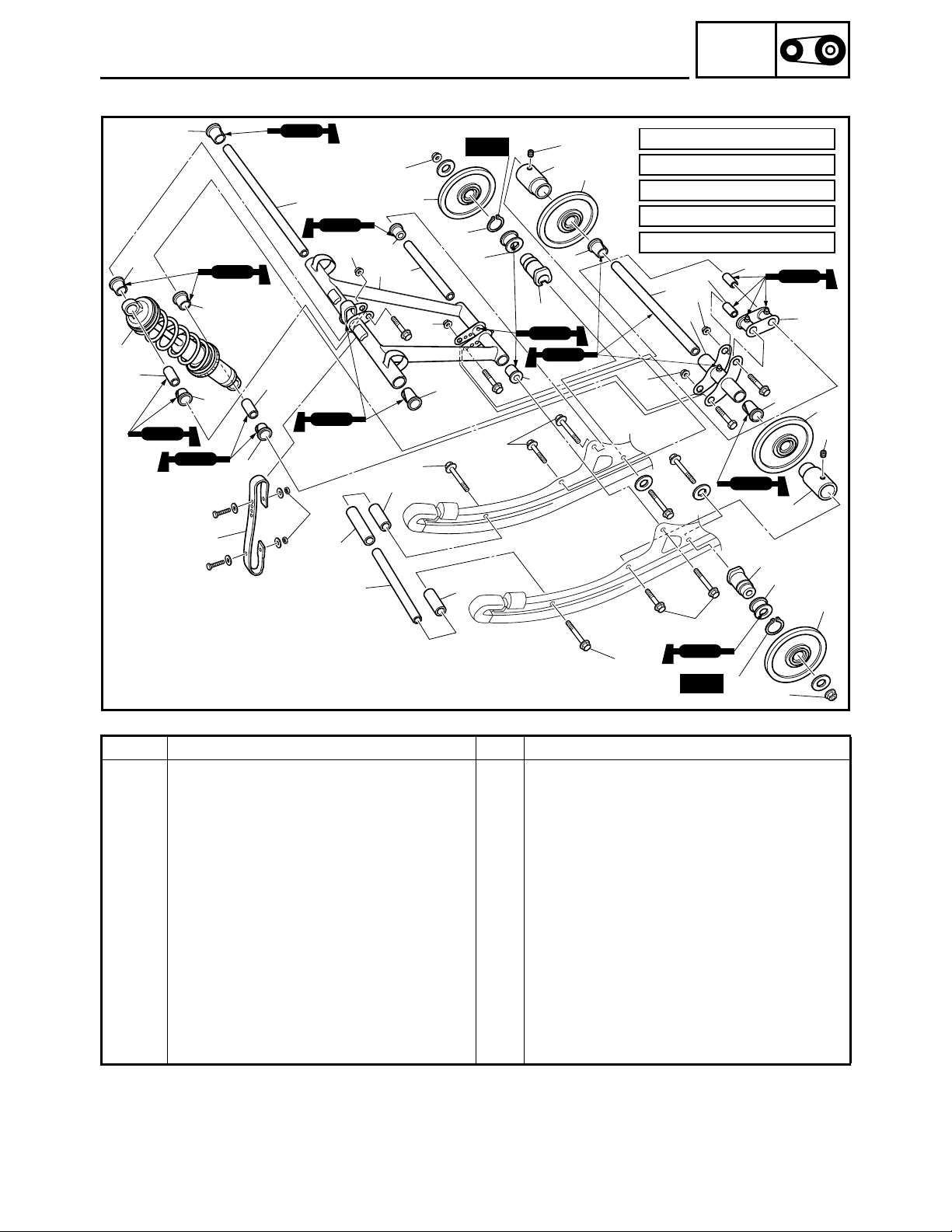

SLIDE RAIL SUSPENSION

PZ50/PZ50GT/PZ50RT/PZ50MT

SLIDE RAIL SUSPENSION

POWER TRAIN

POWR

TR

3

2

4

5

3

1

È

8

6

5

7

È

9

É

Ê

Ë

0

8

A

4 Nm (0.4 m

È:

49 Nm (4.9 m

É:

60 Nm (6.0 m

Ê:

110 Nm (11.0 m

Ë:

0

É

• kg, 2.9 ft • lb)

• kg, 35 ft • lb)

• kg, 43 ft • lb)

• kg, 80 ft • lb)

Ê

B

Order Job name/Part name

Slide rail suspension disassembly

Stopper band 1

1

Front shock absorber 1

2

Bushing 2

3

Collar 1

4

Bushing 2

5

Collar 1

6

Front pivot arm 1

7

Bushing 2

8

Shaft 1

9

Collar 2

0

Shaft 1

A

Shaft 1

B

Ê

Ê

Q’ty Remarks

Remove the parts in the order listed below.

20

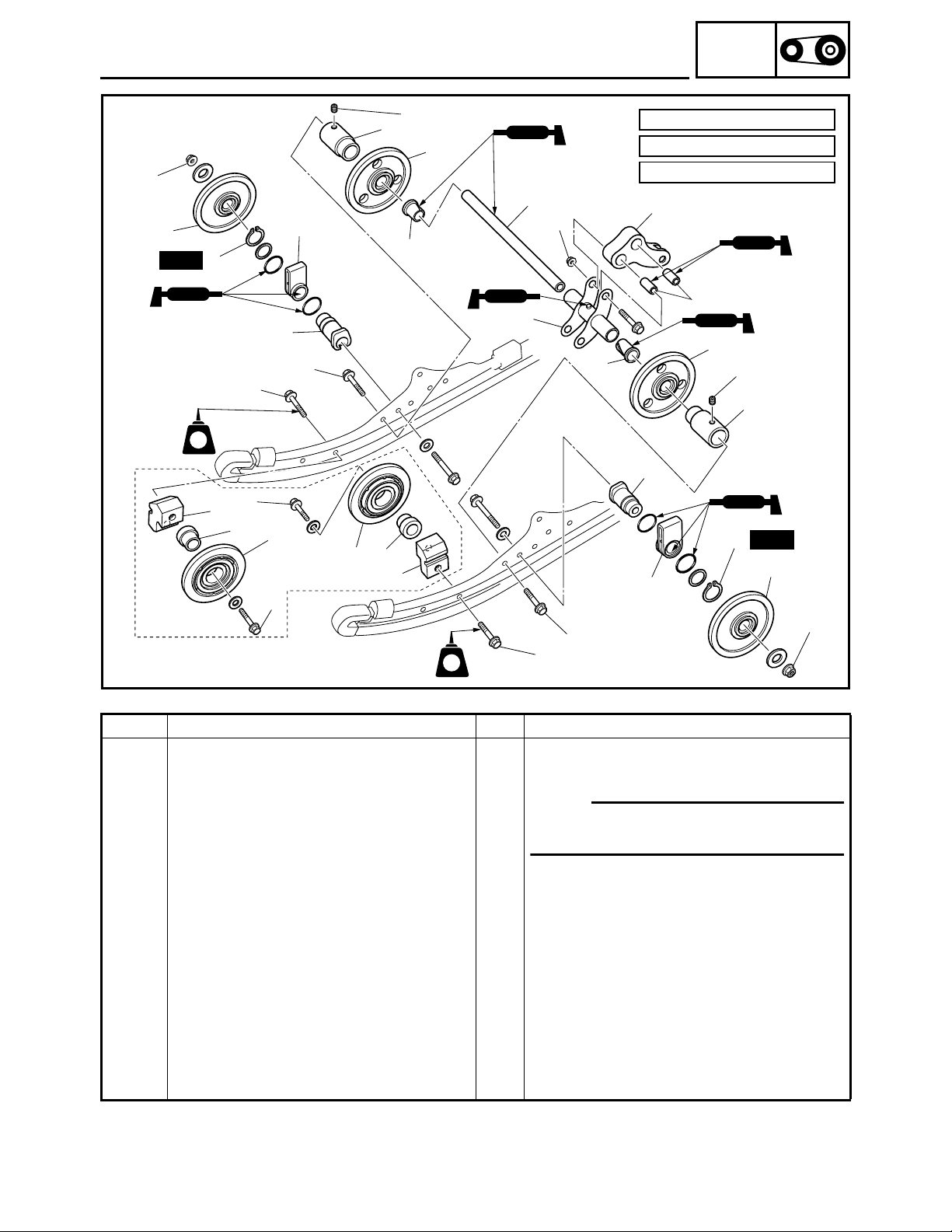

SLIDE RAIL SUSPENSION

POWR

TR

É

C

New

LT

PZ50MT

D

N

M

É

Ê

L

É

F

E

É

L

M

G

N

È

I

H

LT

K

J

Ê

Ê

É

I

6 Nm (0.6 m

È:

60 Nm (6.0 m

É:

72 Nm (7.2 m

Ê:

O

F

E

P

H

• kg, 4.3 ft • lb)

• kg, 43 ft • lb)

• kg, 52 ft • lb)

È

G

New

D

C

É

Order Job name/Part name

Suspension wheel 2

C

Circlip 2

D

Spring end guide 2

E

Spring end guide bracket 2

F

Wheel bracket 2

G

Suspension wheel 2

H

Bushing 2

I

Shaft 1

J

Front suspension bracket 1

K

Suspension wheel 2

L

Collar 2

M

Wheel bracket 2

N

Connecting arm 1

O

Collar 2

P

Q’ty Remarks

NOTE:

Apply grease to the inner surface of each

spring end guide.

21

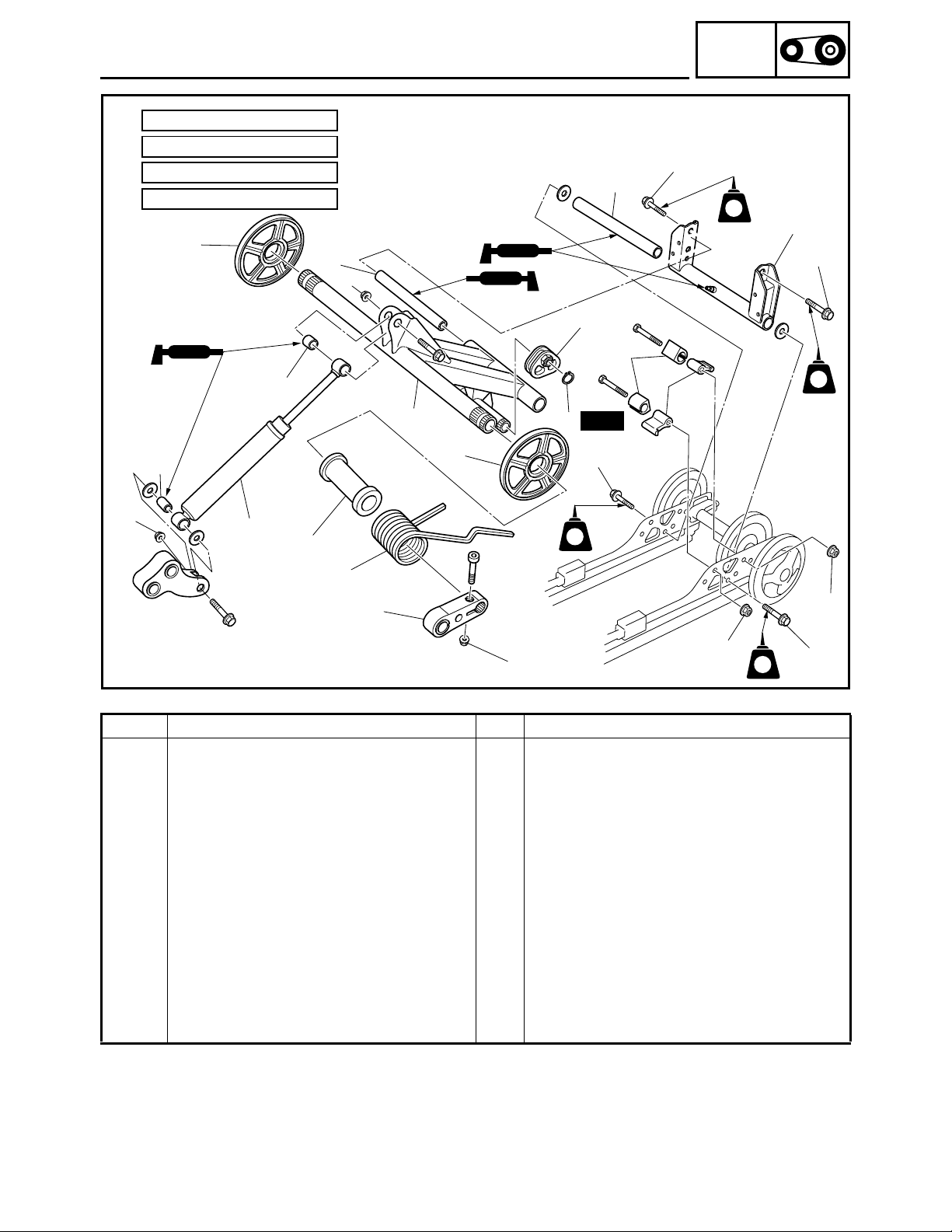

SLIDE RAIL SUSPENSION

POWR

TR

35 Nm (3.5 m

È:

49 Nm (4.9 m

É:

60 Nm (6.0 m

Ê:

72 Nm (7.2 m

Ë:

R

É

Z

• kg, 25 ft • lb)

• kg, 35 ft • lb)

• kg, 43 ft • lb)

• kg, 52 ft • lb)

R

Q

U

Y

É

X

Z

V

LT

W

New

Ë

\

]

^

Ë

LT

[

Ë

LT

T

S

Order Job name/Part name

Rear shock absorber 1

Q

Collar 2

R

Rear pivot arm joint 2

S

Torsion spring 2

T

Rear pivot arm protector 2

U

Circlip 2

V

Adjuster 2

W

Rear pivot arm 1

X

Shaft 1

Y

Guide wheel 2

Z

Rear pivot arm bracket 1

[

Shaft 1

\

Collar 4

]

Stopper 4

_

È

Q’ty Remarks

Ê

Ê

Ë

LT

22

SLIDE RAIL SUSPENSION

POWR

TR

PZ50MT

È

h

i

b

d

e

k

e

60 Nm (6.0 m

È:

75 Nm (7.5 m

É:

d

k

g

• kg, 43 ft • lb)

• kg, 54 ft • lb)

a

c

f

b

j

PZ50MT

Order Job name/Part name

Rear axle 1

a

Guide wheel 2

b

Guide wheel 1

c

Collar 2

d

Tension adjuster 2

e

Collar 1

f

Collar 1

g

Suspension wheel 2

h

Wheel bracket 2

i

Shaft 1

j

Sliding frame 2

k

i

h

Q’ty Remarks

For assembly, reverse the disassembly procedure.

PZ50MT

È

É

23

PZ50VT/PZ50MP

SLIDE RAIL SUSPENSION

POWR

TR

H

J

I

6

I

I

1

I

J

7

È

4

Ê

2

5

8

Ë

3

9

K

Ë

Ì

6

L

3

New

M

Ë

N

8

A

É

D

B

4 Nm (0.4 m

È:

6 Nm (0.6 m

É

:

49 Nm (4.9 m

Ê

:

60 Nm (6.0 m

Ë

:

72 Nm (7.2 m

Ì

:

Ê

C

G

F

Ì

Ë

• kg, 2.9 ft • lb)

• kg, 4.3 ft • lb)

• kg, 35 ft • lb)

• kg, 43 ft • lb)

• kg, 52 ft • lb)

0

E

D

A

N

M

B

É

K

Order Job name/Part name

Slide rail suspension disassembly

Stopper band 2

1

Shaft 1

2

Collar 2

3

Collar 1

4

Front pivot arm 1

5

Bushing 2

6

Shaft 1

7

Collar 2

8

Shaft 1

9

Collar 1

0

Wheel bracket 2

A

Suspension wheel 2

B

Shaft 1

C

Ë

New

Q’ty Remarks

Remove the parts in the order listed below.

L

Ë

24

Loading...

Loading...