Yamaha

FZR400

Service

Manual

1988-1989 Models

CONTENTS

CHAPTER 1.

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

................................

l-l

VEHICLE IDENTIFICATION NUMBER

.........................

l-l

ENGINE SERIAL NUMBER

................................... l-l

IMPORTANT INFORMATION.

..........................

.......

l-2

PREPARATION FOR REMOVAL

.....................

....... l-2

ALL REPLACEMENT PARTS

........................ ....... l-2

GASKETS, OIL SEALS, AND O-RINGS

................ .......

l-2

LOCK WASHERS/PLATES AND COTTER PINS

......... ....... l-3

BEARINGS AND OIL SEALS

........................

....... l-3

CIRCLIPS

........................................

....... l-3

SPECIAL TOOLS.

.............................................

l-4

FOR TUNE UP

.............................................

1-4

FOR ENGINE SERVICE

.....................................

l-5

FOR CHASSIS SERVICE

.....................................

1-B

FOR ELECTRICAL COMPONENTS

............................

l-9

CHAPTER 2.

SPECIFICATIONS

SPECIFICATIONS

.............................................

2-l

GENERAL SPECIFICATIONS

................................. 2-l

MAINTENANCE SPECIFICATIONS

............................

2-4

ENGINE................................................2-

4

CHASSIS...............................................2-11

ELECTRICAL

..........................................

.2-14

GENERAL TORQUE SPECIFICATIONS.

.......................

.2-16

DEFINITION OF UNITS

.....................................

2-16

LUBRICATION POINT AND GRADE OF LUBRICANT

.............

2-17

LUBRICATION DIAGRAM. . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

. . . . . . . . . . . . . . . . . . . . . . . . . .

2-20

COOLANT DIAGRAM

................

CABLE ROUTING

.................................

. . . . . . . . . . . .

2-21

CHAPTER 3.

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,

3-1

MAINTENANCE INTERVALS CHART

.............................

.3-l

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

........

.3-l

GENERAL MAINTENANCE/LUBRICATION

..................... .3-2

COWLING REMOVAL AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .

.3-4

ENGINE .....................................................

3-7

EXUP CABLE ADJUSTMENT (For California only)

................

3-7

VALVE CLEARANCE ADJUSTMENT

..........................

3-8

CARBURETOR SYNCHRONIZATION

.......................... 3-15

IDLE SPEED ADJUSTMENT

..................................

3-17

THROTTLE CABLE FREE PLAY ADJUSTMENT

.................

3-18

SPARK PLUG INSPECTION

..................................

3-19

IGNITION TIMING CHECK

...................................

3-20

COMPRESSION PRESSURE MEASUREMENT

....................

3-21

ENGINE OIL LEVEL INSPECTION

.............................

3-23

ENGINE OIL REPLACEMENT

................................ 3-23

ENGINE OIL FILTER REPLACEMENT

......................... 3-24

CLUTCH ADJUSTMENT.

.................................... 3-26

AIR FILTER CLEANING

.....................................

3-27

CARBURETOR JOINT INSPECTION

...........................

3-27

FUEL LINE INSPECTION

....................................

3-27

CRANKCASE VENTILATION HOSE INSPECTION ................

3-28

EXHAUST SYSTEM INSPECTION

.............................

3-28

COOLANT LEVEL INSPECTION

..............................

3-29

COOLANT REPLACEMENT

..................................

3-29

CHASSIS

......

.

..............................................

3-32

FRONT BRAKE ADJUSTMENT

...............................

3-32

REAR BRAKE ADJUSTMENT

................................

3-32

BRAKE FLUID INSPECTION

................................. 3-33

BRAKE PAD INSPECTION

................................... 3-33

REAR BRAKE LIGHT SWITCH ADJUSTMENT. .................. 3-33

BRAKE HOSE INSPECTION

.................................. 3-34

AIR

BLEEDlNG............................................3-3

4

DRIVE CHAIN SLACK ADJUSTMENT

.......................... 3-35

DRIVE CHAIN LUBRICATION

................................

3-37

STEERING HEAD INSPECTION

...............................

3-37

FRONT FORK INSPECTION

..................................

3-40

REAR SHOCK ABSORBER ADJUSTMENT

...................... 3-40

TIRE INSPECTION

.........................................

3-41

WHEEL INSPECTION

.......................................

3-42

CABLE INSPECTION

........................................ 3-43

LUBRICATION

............................................ 3-43

ELECTRICAL.

................................................

3-44

BATTERY INSPECTION

.....................................

3-44

FUSE INSPECTION

.........................................

3-46

HEADLIGHT BEAM ADJUSTMENT

............................

3-46

HEADLIGHT BULB REPLACEMENT

...........................

3-47

TAIL/BRAKE BULB REPLACEMENT

..........................

3-48

CHAPTER 4.

ENGINE OVERHAUL

ENGINE REMOVAL

...........................................

.4-l

LOWER COWLING, CENTER COWLING,

UPPER COWLING AND TOP COVER.

.........................

.4-l

FUEL TANK

...............................................

.4-l

ENGINEOIL..

.................................

..~.........4-

1

COOLANT.................................................4-

1

AIR FILTER CASE AND CARBURETOR.,

......................

.4-l

RADIATOR................................................4-

2

MUFFLER ASSEMBLY

......................................

.4-2

CLUTCH CABLE AND DRIVE CHAIN

..........................

.4-4

LEADS....................................................4-

4

ENGINE REMOVAL

........................................

.4-5

ENGINE DISASSEMBLY

........................................

.4-7

CYLINDER HEAD COVER, CAMSHAFT AND

CYLINDER HEAD

.........................................

.4-7

CYLINDER AND PISTON

...................................

.4-10

STARTER CLUTCH

........................................

.4-12

CLUTCH..................................................4-13

A.C. MAGNETO

...........................................

.4-14

WATER PUMP

............................................

.4-15

OIL PUMP AND SHIFT SHAFT

...............................

.4-16

OIL PAN AND OIL STRAINER.

..............................

.4-17

STARTER MOTOR

.........................................

4-18

CRANKCASE DISASSEMBLY

.................................

4-18

TRANSMISSION, SHIFTER AND SHIFT CAM.

...................

4-19

CRANKSHAFT

.............................................

4-20

VALVE PAD AND VALVE

...................................

4-21

CONNECTING ROD

.........................................

4-23

INNER ROTOR (OIL PUMP).

.................................

4-23

INSPECTION AND REPAIR

.....................................

4-24

CYLINDER HEAD

.............................

,

............

4-24

VALVE...................................................4-2

5

VALVE GUIDE

I:.

.................................

.4-26........

VALVE SEAT.

............................................

.4-27

VALVE SPRING

...........................................

.4-30

VALVE LIFTER

...........................................

.4-31

CAMSHAFT, CAM CHAIN AND CAM SPROCKET

................

.4-31

CYLINDER AND PISTON

...................................

.4-33

PISTON RING AND PISTON PIN

.............................. 4-35

CRANKSHAFT AND CONNECTING ROD

.......................

4-37

OlLPUMP.................................................4-4

1

PRlMARYDRlVE..........................................4-4

2

STARTER CLUTCH

........................................

.4-43

CLUTCH..................................................4-4

4

TRANSMISSION

.......................................... .4-46

RELIEF VALVE AND PIPE

..................................

.4-47

CRANKCASE

............................................. .4-47

BEARING AND OIL SEAL

..................................

.4-47

YAMAHA EXHAUST VARIABLE VALVE (For California only)

..... .4-48

ENGINE ASSEMBLY AND ADJUSTMENT.

........................

.4-49

INNER ROTOR (OIL PUMP).

................................ .4-49

CONNECTING ROD.

.......................................

.4-49

CRANKSHAFT

............................................

.4-50

VALVE PAD AND VALVE

.................................. .4-51

CRANKCASE

.............................................

.4-54

TRANSMISSION

..........................................

.4-55

TRANSMISSION, SHIFTER AND SHIFT CAM

................... .4-56

CRANKCASE ASSEMBLY

................................... .4-57

STARTER MOTOR

........................................ .4-59

OIL PAN AND OILSTRAINER

............................... .4-59

OIL PUMP AND SHIFT SHAFT.

.............................. .4-60

A.C. MAGNETO

........................................... .4-61

CLUTCH..................................................4-6

3

STARTER CLUTCH

........................................

.4-65

PISTON AND CYLINDER

...................................

.4-67

CYLINDER HEAD AND CAMSHAFT

.......................... .4-70

CAM CHAIN TENSIONER

................................... .4-75

REMOUNTING ENGINE

.................................... .4-76

YAMAHA EXHAUST VARIABLE VALVE (For California only)

......4-78

CHAPTER 5.

COOLING SYSTEM

RADlATOR...................................................5-

1

REMOVAL.................................................5-

2

INSPECTION...............................................5-

3

INSTALLATION

...........................................

.5-4

WATER PUMP AND THERMOSTATIC VALVE.

......................

5-6

REMOVAL.................................................5-

7

lNSPECTlON...............................................5-

9

INSTALLATION

..........................................

.5-10

CHAPTER 6.

CARBURETOR

CARBURETOR

...............................................

6-l

SECTIONVIEW

............................................

6-2

REMOVAL ................................................

6-3

DISASSEMBLY

............................................

6-5

INSPECTION ..............................................

6-6

ASSEMBLY.. .............................................

6-B

INSTALLATION

...........................................

6-9

,:

i;

ADJUSTMENT

.............................................

6-10

CHAPTER 7.

CHASSIS

FRONT WHEEL.

..............................................

7-l

REMOVAL

................................................

7-2

INSPECTION ..............................................

7-2

INSTALLATION

...........................................

7-4

REAR WHEEL

................................................

7-7

REMOVAL ................................................

7-B

INSPECTION

..............................................

7-B

INSTALLATION

...........................................

7-9

FRONT AND REAR BRAKE.

................................... .7-10

BRAKE PAD REPLACEMENT

................................

.7-12

CALIPER DISASSEMBLY

...................................

.7-16

MASTER CYLINDER DISASSEMBLY

......................... .7-18

INSPECTION AND REPAIR

.................................

.7-19

ASSEMBLY ...............................................

7-21

FRONT FORK ...............................................

.7-28

REMOVAL................................................7-2

9

DISASSEMBLY ............................................ 7-30

lNSPECTlON..............................................7-3

1

ASSEMBLY

............................................... 7-32

INSTALLATION ...........................................

7-34

STEERING HEAD AND HANDLEBAR.

.............................

7-36

REMOVAL................................................7-3

8

lNSPECTlON..............................................7-4

1

INSTALLATION ........................................... 7-42

REAR SHOCK ABSORBER AND

SWINGARM

.......................

7-47

HANDLING NOTES

.........................................

7-49

DISPOSAL NOTES.

.........................................

7-49

REMOVAL................................................7-4

9

lNSPECTlON..............................................7-5

2

INSTALLATION ........................................... 7-54

DRIVE CHAIN AND SPROCKET

.................................

7-56

REMOVAL................................................7-5

6

INSPECTION AND CLEANING

................................

7-56

INSTALL’ATION

...........................................

7-57

CHAPTER 8.

ELECTRICAL

FZR400U/SUC

CIRCUIT DIAGRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1

ELECTRICAL COMPONENTS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3

CHECKING OF SWITCHES.

..................................... .8-5

SWITCH CONNECTION AS SHOWN IN MANUAL

.................

.8-5

CHECKING SWITCH FOR TERMINAL CONNECTION

............. .8-5

CHECKING OF BULBS

.........................................

.8-8

KINDS OF BULBS

.......................................... .8-8

CHECKING BULB CONDITION

...............................

.8-8

IGNITION SYSTEM.

...........................................

8-l

1

Cl RCUIT DIAGRAM

........................................

8-11

DIGITAL IGNITION CONTROL SYSTEM DESCRIPTION

........... 8-13

OPERATION

............................................

..8-13

TROUBLESHOOTING

.......................................

8-14

ELECTRIC STARTING SYSTEM.

.................................

8-21

CIRCUIT DIAGRAM

........................................

8-21

STARTING CIRCUIT OPERATION

............................. 8-23

TROUBLESHOOTING.

...................................... 8-24

STARTER MOTOR

......................................... 8-30

CHARGING SYSTEM.

.......................................... 8-33

CIRCUITDIAGRAM..

....................................

..8-3 3

TROUBLESHOOTING

.......................................

8-35

LIGHTING SYSTEM

...........................................

8-39

CIRCUIT DIAGRAM

........................................ 8-39

TROUBLESHOOTING

.......................................

8-41

LIGHTING SYSTEM CHECK

..................................

8-44

SIGNALSYSTEM ..............................................

8-49

CIRCUIT DIAGRAM

........................................

8-49

TROUBLESHOOTING

.......................................

8-51

SIGNAL SYSTEM CHECK.

...................................

8-53

COOLING SYSTEM.

........................................... 8-69

Cl

RCUIT

DIAGRAM

........................................

8-69

TROUBLESHOOTING

.......................................

8-71

FUELSYSTEM................................................8.7

5

CIRCUIT DIAGRAM

.......................................

.8-75

FUEL PUMP CIRCUIT OPERATION

............................

8.77

TROUBLESHOOTING

.......................................

8-78

FUEL PUMP TEST.

........................................

.8-82

YAMAHA EXHAUST VARIABLE VALVE SYSTEM

(For California only).

......................................... .8-83

CIRCUIT DIAGRAM ....................................... .8-83

TROUBLESHOOTING ......................................

.8-85

METER ASSEMBLY

...........................................

.8-89

REMOVAL................................................8-9

0

INSTALLATION ...........................................

8-91

CHAPTER 9.

TROUBLESHOOTING

STARTING FAILURE/HARD STARTING. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-l

POOR IDLE SPEED PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

POOR MEDIUM AND HIGH SPEED PERFORMANCE.. . . . . . . . . . . . . . . . . 9-4

FAULTY GEAR SHIFTING.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

CLUTCH SLIPPING/DRAGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

OVERHEATING OR OVER-COOLING.. . . . . . . . . .

I..

. . . . . . . . . . . . . . . . 9-6

FAULTY BRAKE.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _ . . . . 9-7

FRONT FORK OIL LEAKAGE/MALFUNCTION.. . . . . . . . . . . . . . . . . . . . . 9-7

INSTABLE HANDLING.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

FAULTY SIGNALS AND LIGHTS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

FAULTY EXUP

(For California only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.9-l

0

CONTENTS

GENERAL INFORMATION

.......................................

1

MOTORCYCLE IDENTIFICATION

..............................

1

VEHICLE IDENTIFICATION NUMBER

........................

1

ENGINE SERIAL NUMBER

.................................

1

SPECIFICATIONS ...............................................

2

GENERAL SPECIFICATIONS

..................................

2

MAINTENANCE SPECIFICATIONS

..............................

3

CHASSIS

................................................

3

TIGHTENING TORQUE

....................................

4

GENERAL TORQUE SPECIFICATIONS ..........................

5

PERIODIC INSPECTIONS AND ADJUSTMENTS

......................

6

CHASSIS

...................................................

6

DRIVE

CHAIN SLACK ADJUSTME NT ........................

6

CHASSIS

......................................................

8

REARWHEEL ...............................................

8

REMOVAL ..............................................

9

INSPECTION ............................................

10

INSTALLATION .........................................

10

STATIC WHEEL BALANCE ADJUSTMENT ...................

11

FRONT AND REAR BRAKE

..................................

12

BRAKE PAD REPLACEMENT

..............................

14

CALIPER DISASSEMBLY

..................................

19

MASTER CYLINDER DISASSEMBLY ........................

21

INSPECTION AND REPAIR

................................

23

ASSEMBLY.. ........................................... 26

MOTORCYCLE IDENTIFICATION

GENERAL

INFORMATION

MOTORCYCLE IDENTIFICATION

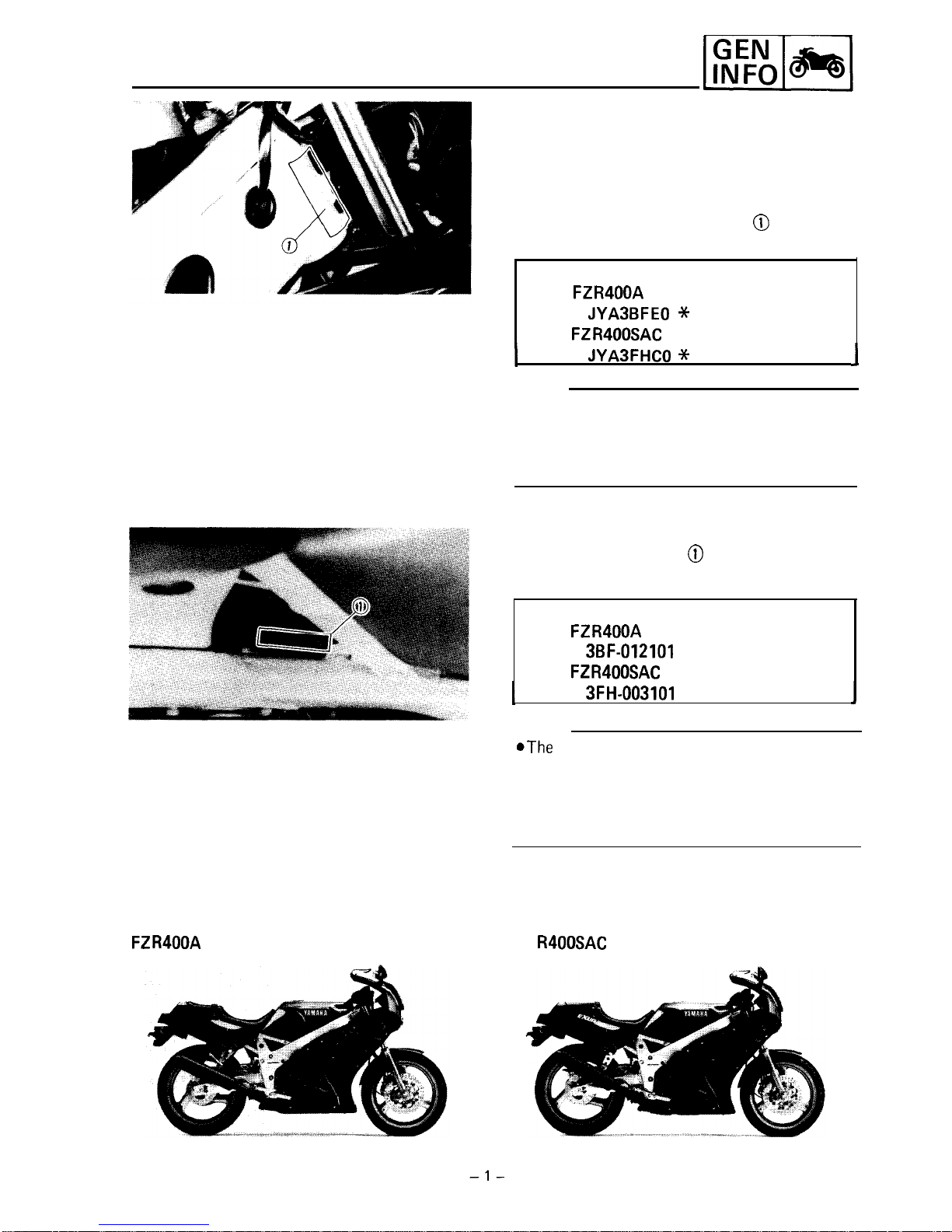

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number @ is stemped

into the right side of the steering head.

Starting serial number:

FZR400A

(Except for California):

JYA3BFEO *

LA012101

FZR400SAC

(For California):

I

JYASFHCO *

LA003101

J

NOTE:

The vehicle identification number is used to

identify your motorcycle and may be used to

register your motorcycle with the licensing

authority in your state.

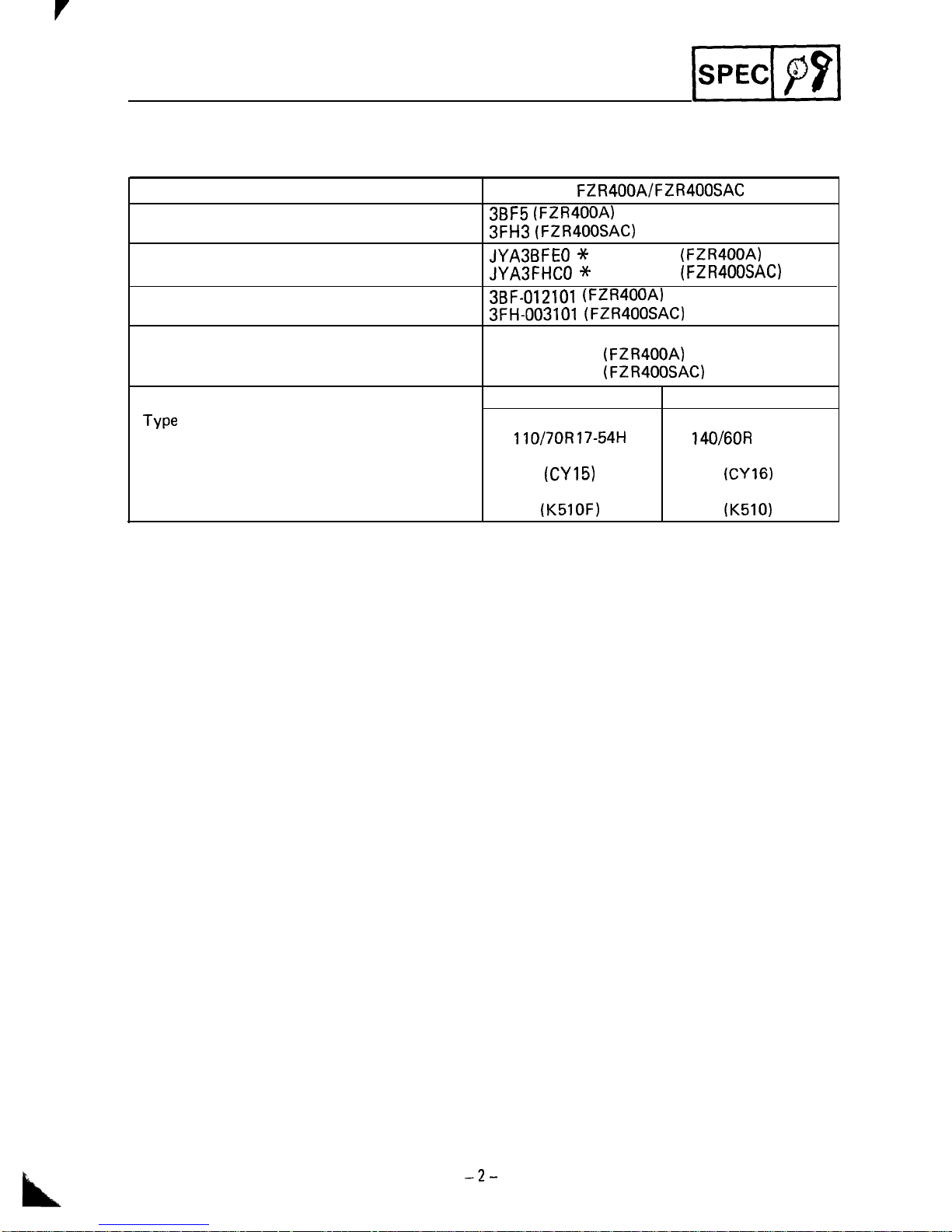

ENGINE SERIAL NUMBER

The engine serial number

@

is stamped into the

right side of the

engine.

Starting serial number:

FZR400A

(Except for California):

3BF-012101

FZR400SAC

(For California):

I

3FH-003101

1

NOTE:

@The

first three digits of these numbers are for

model identifications; the remaining digits are

the unit production number.

@Designs and specifications are subject to

change without notice.

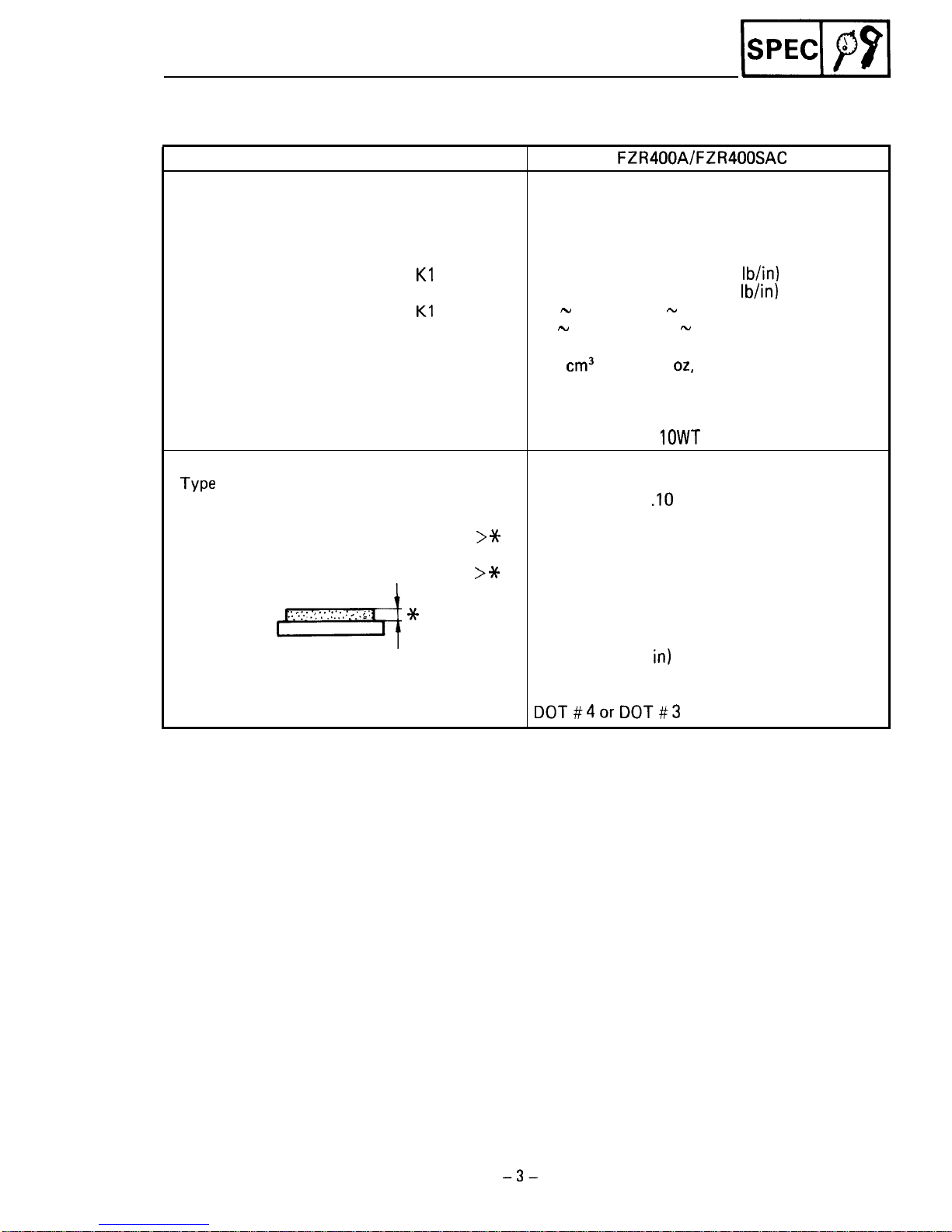

FZRIQOOA

FZ

R400SAC

GENERAL SPECIFICATIONS

JSPECII

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model

Model Code Number:

Vehicle Identification Number:

Engine Starting Number:

Basic Weight:

With Oil and Full Fuel Tank

Tire:

Type

Size

Manufacture (Type)

FZR400A/FZR400SAC

3BF5 (FZR400A)

3FH3 (FZR400SAC)

JYA3BFEO -X

LA012101

(FZR400A)

JYA3FHCO +X-

LA003101

(FZR400SAC)

3BF-012101 (FZR400A)

3FH-003101 (FZR400SAC)

188 kg (414 lb)

(FZR400A)

191 kg (421 lb)

(FZR400SAC)

Front Rear

Tubeless Tubeless

110/70R17-54H 140/60R

1 B-64H

BRIDGESTONE BRIDGESTONE

(CYl5)

(CY16)

DUNLOP DUNLOP

(K5lOF)

(K510)

-2-

MAINTENANCE SPECIFICATIONS

pqq

MAINTENANCE SPECIFICATIONS

CHASSIS

Model

FZR400A/FZR400SAC

Front Suspension:

Front Fork Travel

130 mm (5.12 in)

Front Spring Free Length

412 mm (16.2 in)

< Limit > 408 mm (16.1 in)

Collar Length

160 mm (6.3 in)

Spring Rate:

Kl

4.4 N/mm (0.5 kg/mm, 25.2

lb/in)

K2

6.6 N/mm (0.7 kg/mm, 37.5

lb/in)

Stroke

Kl

0.0 - 90 mm (0.0 - 3.54 in)

K2

90 - 130 mm (3.54 - 5.12 in)

Optional Spring No

Oil Capacity

440

cm3

(15.5 Imp

02,

14.9 US oz)

Oil Level (Fully Compression) 92 mm (3.62 in)

Bellow the top of inner fork tube without

fork spring

Oil Grade Yamaha Fork Oil

10WT

or equivalent

Front Disc Brake:

Type

Dual

Disc Outside Diameter x Thickness

282 x 4 mm (11

.lO

x 0.16 in)

Pad Thickness

Inner 5.5 mm (0.22 in)

< Limit

>*

0.5 mm (0.02 in)

Pad Thickness

Outer 5.5 mm (0.22 in)

< Limit

>*

0.5 mm (0.02 in)

4

.: ‘.I.

. .,

‘,‘;:.‘;.

. ;.

.;:

*

Master Cylinder Inside Diameter

15.87 mm (0.62

in)

Caliper Cylinder Inside Diameter

32.10 mm (1.26 in)

Brake Fluid Type

DOT#4or DOT#3

-3-

MAINTENANCE SPECIFICATIONS

-1

TIGHTENING TORQUE

Part to be tightened

Front Axle and Outer Tube

Rear Axle and Nut

Handlebar Crown and Inner Tube

Handlebar Crown and Steering Stem

Brake Caliper (Front/Rear)

Bleed Screw and Brake Caliper

Brake Hose and Union Bolt

Front Master Cylinder and Master Cylinder Holder

Front Master Cylinder and Cylinder Cap

Front Fender and Outer Tube

Handlebar and Inner Tube

Engine Mounting: Front

Rear - Upper

Rear - Lower

Down Tube and Frame: Front

Rear

Footrest Bracket and Frame

Pivot Axle and Nut

Relay Arm and Frame

Arm and

Swingarm

Arm and Relay Arm

Rear Shock Absorber and Relay Arm

Rear Shock Absorber and Frame

Footrest and Footrest Bracket

Rear Footrest Bracket and Frame

Rear Master Cylinder and Rear Arm Bracket

Cowling and Stay

Compression Bar and Brake Caliper Bracket

Front Fork Pinch Bolt

Sprocket and Clutch Hub

Brake Disc and Clutch Hub

Inner Tube and Steering Stem

Frame and Rear Frame: Upper

Lower

Thread size

-

MI4x

I.5

Ml6 x 1.5

M8 x I.25

M22 x 1.0

MIOx

1.25

M8 x 1.25

MIOx

1.25

M6 x 1.0

M5 x 0.8

M6 x 1.0

M8 x 1.25

MlOx

1.25

MlOx

1.25

M8

x 1.25

MlOx

I.25

M8 x 1.25

Ml0 x 1.25

Ml4x

1.5

MIOx

1.25

Ml0 x 1.25

MlOx

I.25

MIOx

I.25

Ml0 x 1.25

Ml0 x 1.25

M8 x 1.25

M8 x I.25

M6 x 1.0

M8 x I.25

M8 x I.25

M8 x I.25

M8 x 1.25

M8 x I.25

MlOx

1.25

Ml2 x 1.25

-r

Tightening torque

T\

Nm

ma

kg

ft.

lb

58 5.8

42

107

10.7

77

26 2.6

19

110

11.0 80

35 3.5 25

6

0.6 4.3

26 2.6

19

9

0.9 6.5

2

0.2 1.4

6

0.6 4.3

23 2.3

17

55 5.5

40

55 5.5 40

45 4.5 32

60 6.0

43

33 3.3 24

33

3.3

24

90 9.0 65

40

4.0 29

40 4.0

29

40 4.0

29

40 4.0 29

40 4.0 29

57

5.7

41

20

2.0

I4

20 2.0 I4

4

0.4 2.9

23

2.3

17

20 2.0

14

32

3.2 23

20 2.0

14

22

2.2

16

64 6.4 46

88 8.8 64

-4-

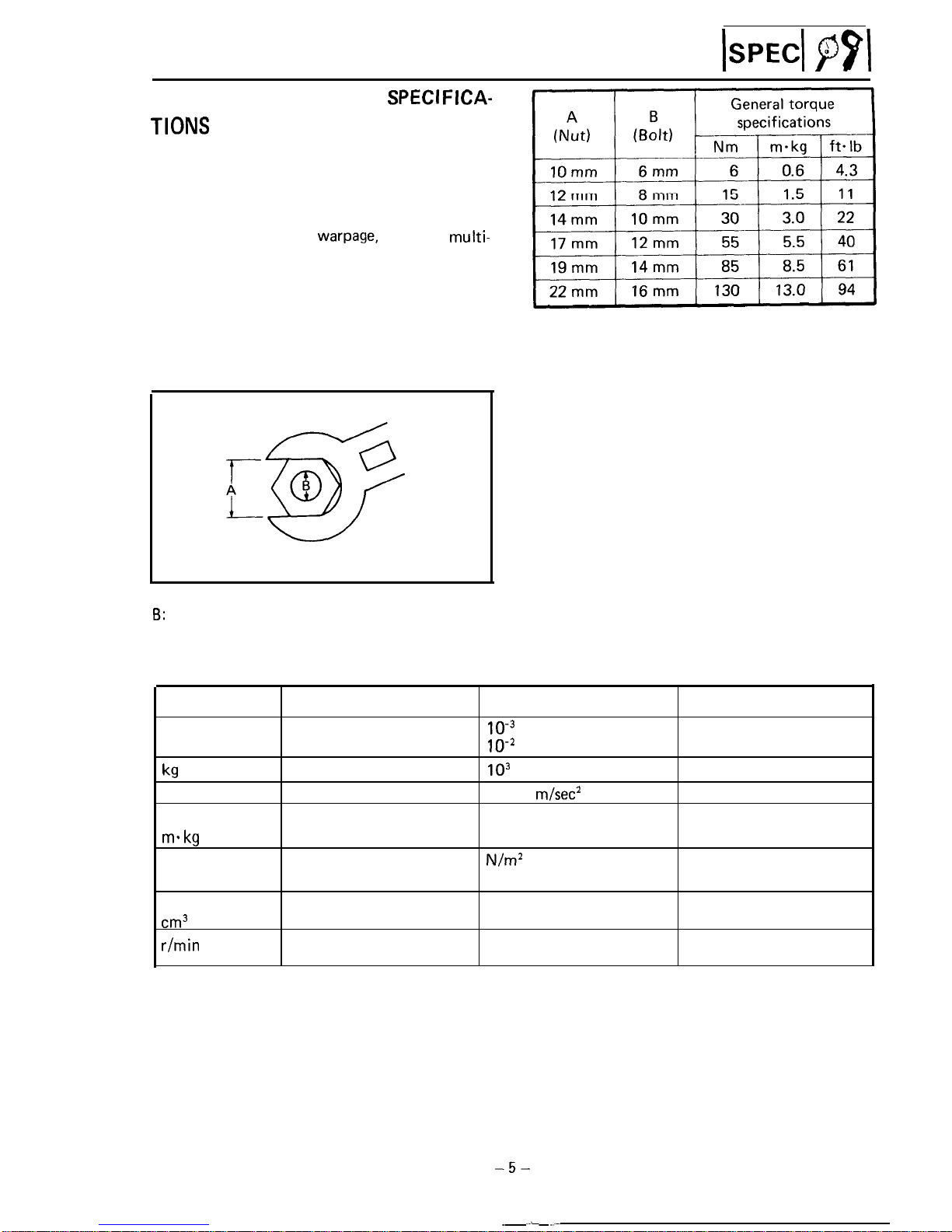

GENERAL TORQUE SPECIFICATIONS

Is4

P9l

GENERAL

TORQUE

SPECI FICA-

TIONS

This chart specifies torque for standard fasteners

with standard I.S.O. pitch threads. Torque

specifications for special components or assemblies are included in the applicable sections of

this book. To avoid

warpage,

tighten

multi-

fastener assemblies in a crisscross fashion, in

progressive stages, until full torque is reached.

Unless otherwise specified, torque specifications

call for clean, dry threads. Components should

be at room temperature.

A: Distance across flats

6:

Outside thread diameter

DEFINITION OF UNITS

Unit

Read

mm

millimeter

cm

centimeter

kg

kilogram

N

Newton

Nm

Newton meter

mskg

Meter kilogram

Pa Pascal

N/mm Newton per millimeter

L

Liter

cm3

Cubic centimeter

r/min

Revolution per minute

Definition

10e3

meter

IO-*

meter

lo3

gram

1 kg x

m/set*

Nxm

m x kg

N/m2

N/mm

Measure

Length

Length

Weight

Force

Torque

Torque

Pressure

Spring rate

Volume or Capacity

Engine Speed

-5-

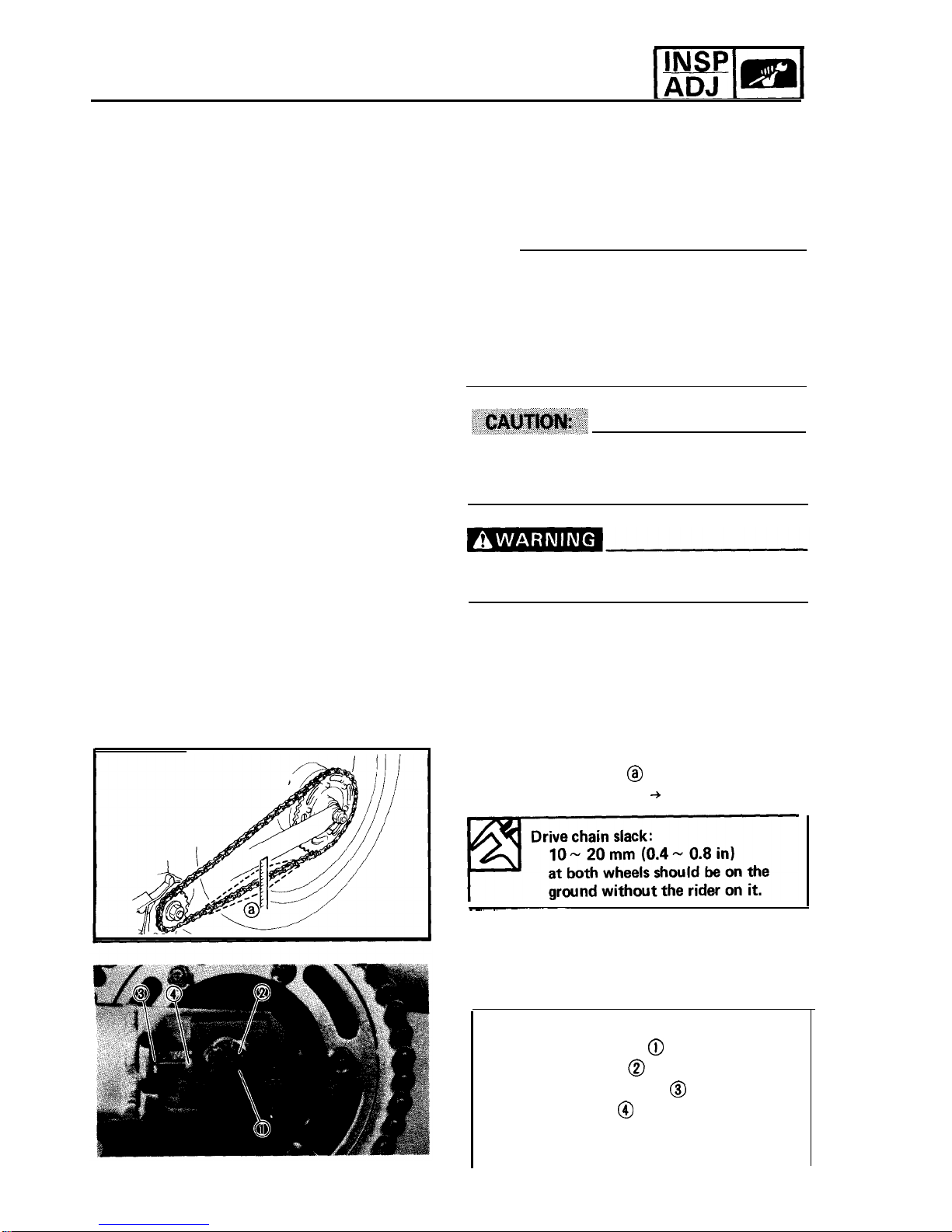

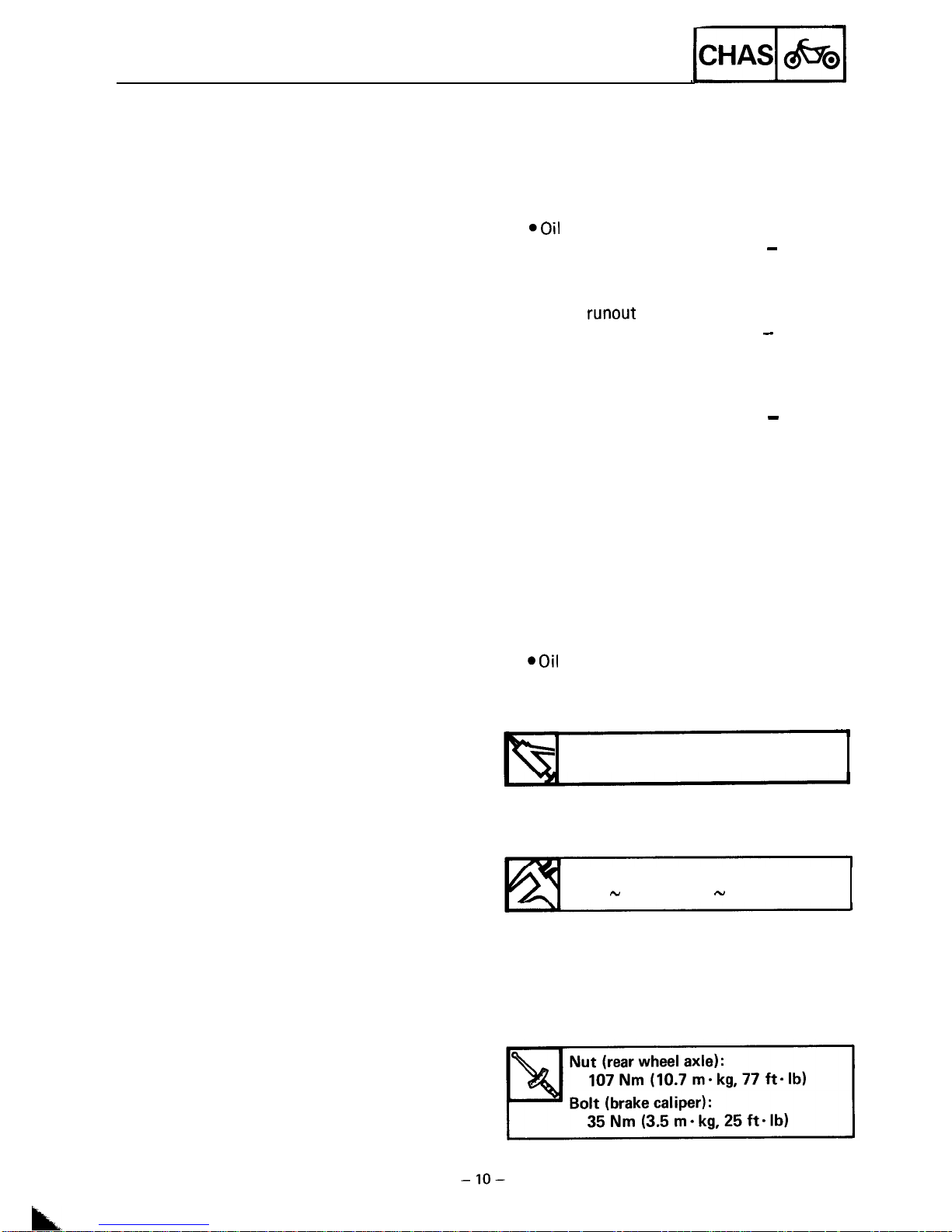

DRIVE CHAIN SLACK ADJUSTMENT

PERIODIC INSPECTIONS

AND ADJUSTMENTS

CHASSIS

DRIVE CHAIN SLACK ADJUSTMENT

NOTE:

Before checking and/or adjusting the chain slack,

rotate the rear wheel several revolutions. Check

the chain slack several times to find the point

where the chain is the tightest. Check and/or

adjust the chain slack where the rear wheel is in

this “tight chain” position.

Too little of chain slack will overload the engine

and over vital parts; keep the slack within the

specified limits.

Securely support the motorcycle so there is

no danger of it falling over.

1. Place the motorcycle on a level place, and

hold it in an upright position.

2. Check:

??

Drive chain slack

@

Out of specification + Adjust.

>

3. Adjust:

??

Drive chain slack

Adjustment steps:

??

Remove the cotter pin @ .

??

Loosen the axle nut @ .

?? Loosen both locknuts

@

(adjuster) and

turn the adjuster @ clockwise or counter-

clockwise until the specified slack is

obtained.

-6-

.

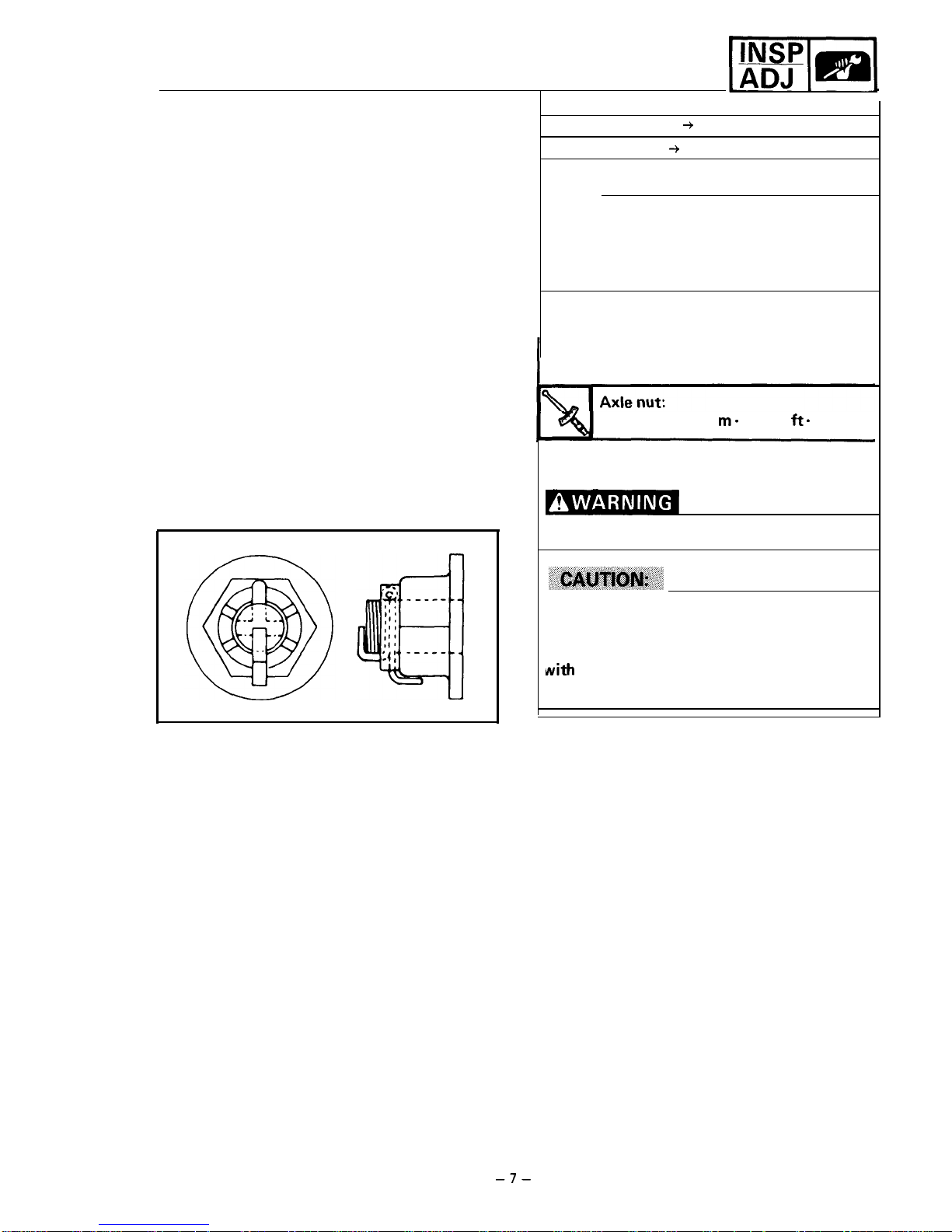

DRIVE CHAIN SLACK ADJUSTMENT

ADJ m

I1NspI(

Clockwise

+

Slack is increased.

Counterclockwise

--,

Slack is decreased.

NOTE:

Turn each adjuster exactly the same amount

to maintain correct axle alignment. (There

are

marks on each side of swingarm; use them to

check for proper alignment.)

??

Tighten the locknut.

??

Tighten the axle nut to specification, while

pushing up or down on the chain to zero

slack.

107 Nm (10.7 m- kg, 77

ft.

lb)

??

Install the cotter pin.

Always use a new cotter pin on the axle nut.

Do not loosen the axle nut after torque

tightening. If the axle nut groove is not

aligned with the cotter pin hole, align groove

rnrith

the hole by tightening up on the axle

nut.

-7-

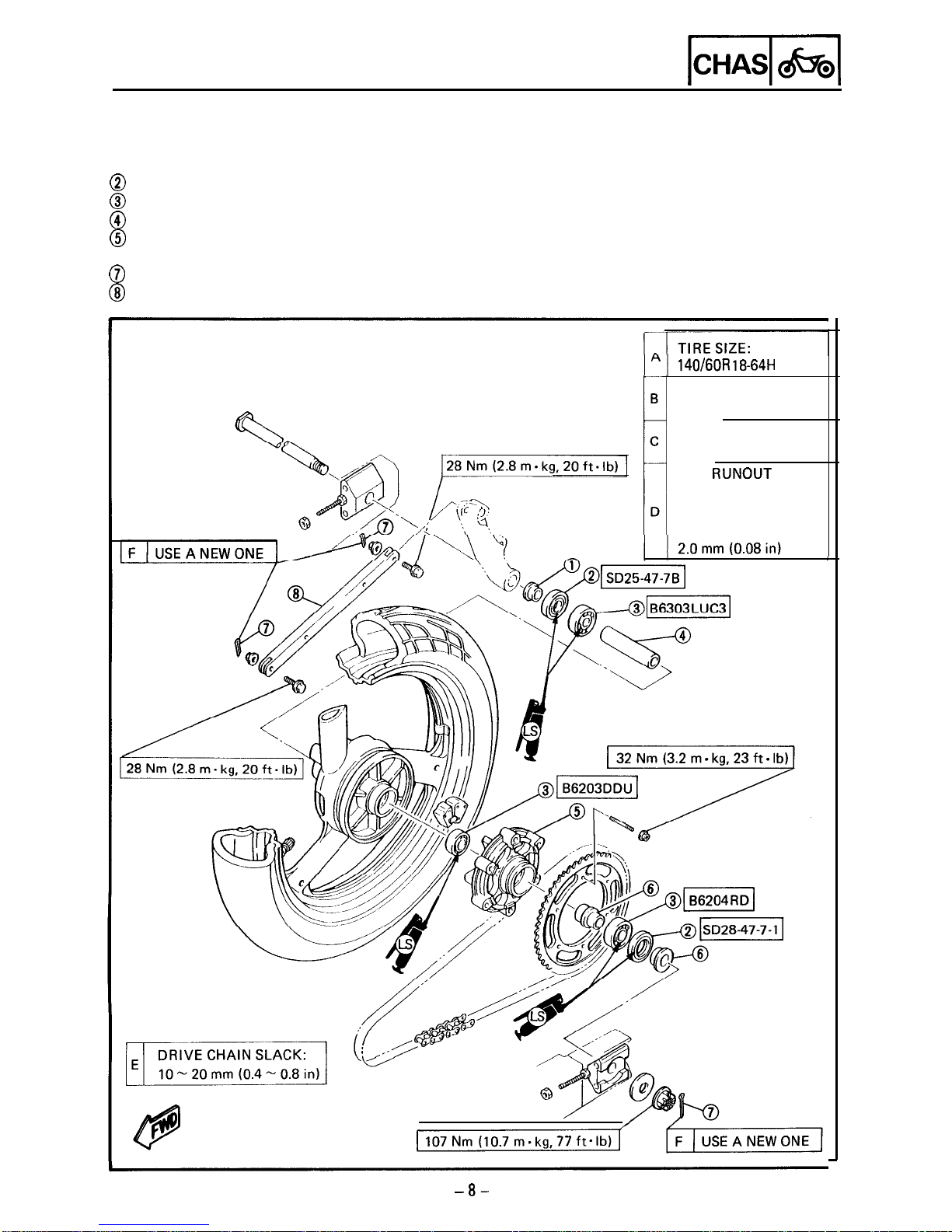

REAR WHEEL

-1

CHASSIS

REAR WHEEL

@Collar

@

Oil seal

@

Bearing

@

Spacer

@

Clutch hub

@Collar

@

Cotter pin

@

Tension bar

WEAR LIMIT:

1 .O mm (0.04 in)

140160R 18-64H

RIM SIZE:

MT4.00 x 18

RIM

RUNOUT

LIMIT:

RADIAL:

2.0 mm (0.08 in)

LATERAL:

I

-8-

REAR WHEEL

-1

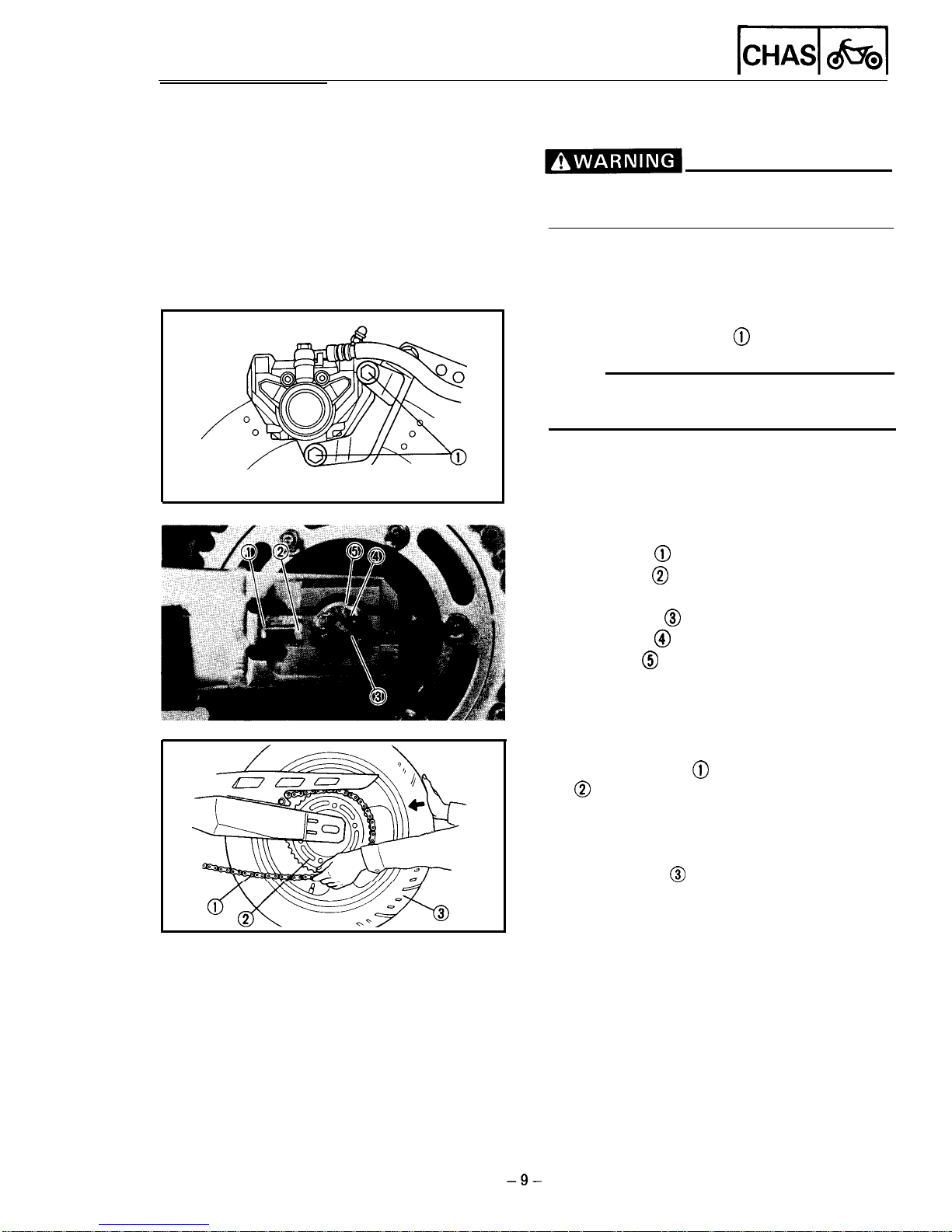

REMOVAL

1. Place the motorcycle on a level place.

Securely support the motorcycle so there is no

danger of it falling over.

2. Elevate the rear wheel by placing a suitable

stand under the swingarm.

3. Remove:

??

Bolts (brake caliper)

@

NOTE:

Do not depress the brake pedal while the caliper

is removed.

4. Loosen:

??

Locknut

@

??

Adjuster

@

5. Remove:

??

Cotter pin

@I

*Axle nut

@I

??

Washer

@

6. Push the rear wheel forward and disconnect

the drive chain @ from the driven sprocket

0

7. Remove:

??

Rear wheel axle

??

Adjuster collars (left and right)

??

Rear wheel

@

8. Remove:

??

Collar (left and right)

-9-

REAR WHEEL

INSPECTION

1. Inspect:

??

Tire

??

Rear wheel axle

??

Wheel

??

Wheel bearings

@Oil seals

Refer to the “FRONT WHEEL - INSPEC-

TION”.

2. Measure:

??

Wheel

runout

Refer to the “FRONT WHEEL - INSPEC- .

TION”.

3. Check:

??

Wheel balance

Refer to the “FRONT WHEEL - INSPEC-

TION”.

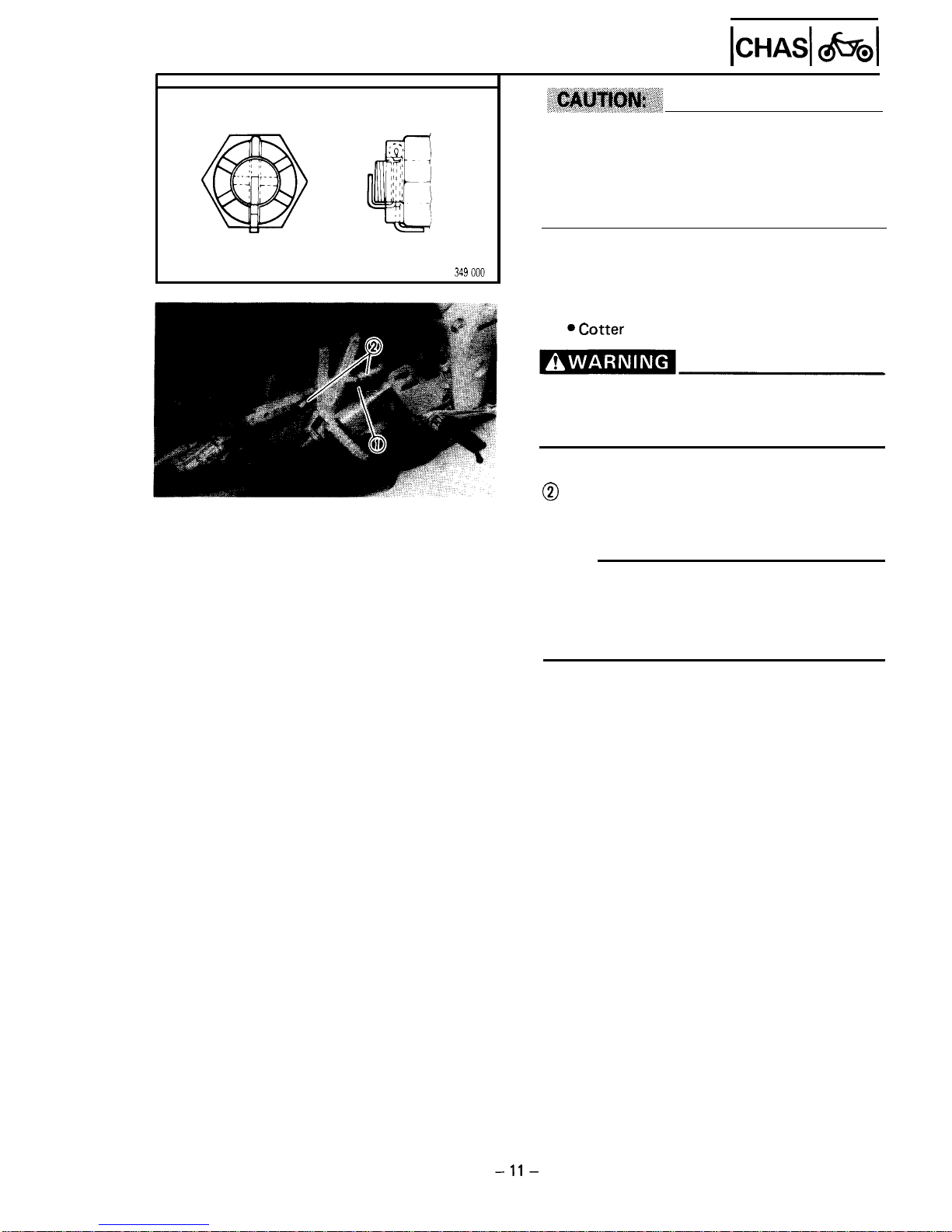

INSTALLATION

Reverse the “Removal” procedure.

Note the following points.

1. Lubricate:

??

Rear wheel axle

??

Bearings

*Oil

seals

??

Spacer

??

Collar

Lithium soap base grease

2. Adjust:

??

Drive chain slack

Drive chain slack:

10 - 20 mm (0.4 - 0.8 in)

Refer to the “DRIVE CHAIN SLACK

ADJUSTMENT”.

3. Tighten:

?? Nut (rear wheel axle)

??

Bolts (brake caliper)

REAR WHEEL

lctf=l

&x31

??

Do not loosen the axle nut after torque tighten-

ing.

??

If the axle nut groove is not aligned with the

wheel shaft cotter pin hole, align groove with

the hole by tightening up on the axle nut.

4. Install:

aCotter

pin

??

Always use a new cotter pin on the axle nut.

??

Make sure that the brake hose is routed prop-

erly.

@Brake hose

@

Brake hose guide

STATIC WHEEL BALANCE ADJUSTMENT

NOTE:

?? After replacing the tire and/or rim, wheel

balance should be adjusted.

?? Adjust the wheel balance with brake disc

and wheel hub installed.

1. Adjust:

??

Wheel balance

Refer to the “FRONT WHEEL -STATIC

WHEEL BALANCE ADJUSTMENT”

section.

-ll-

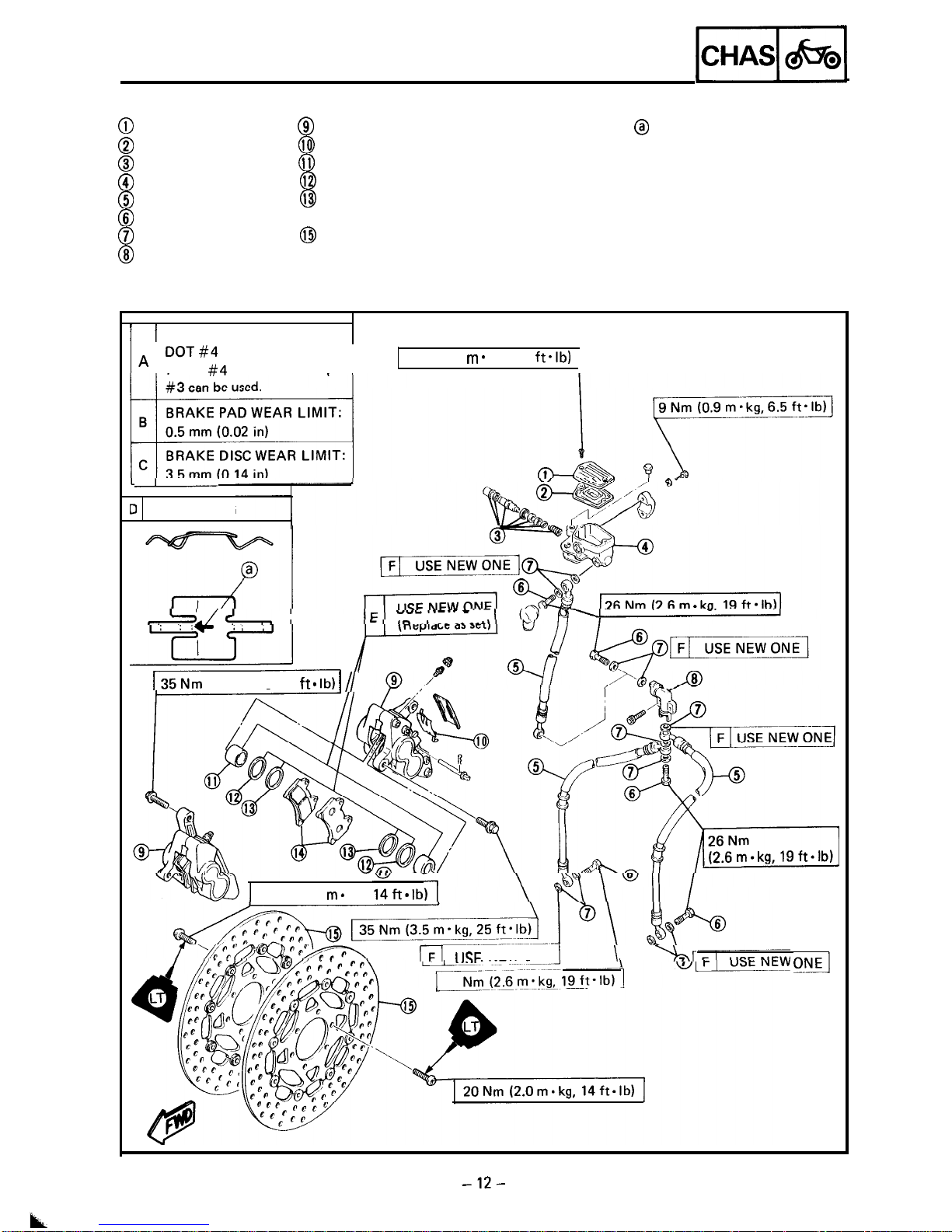

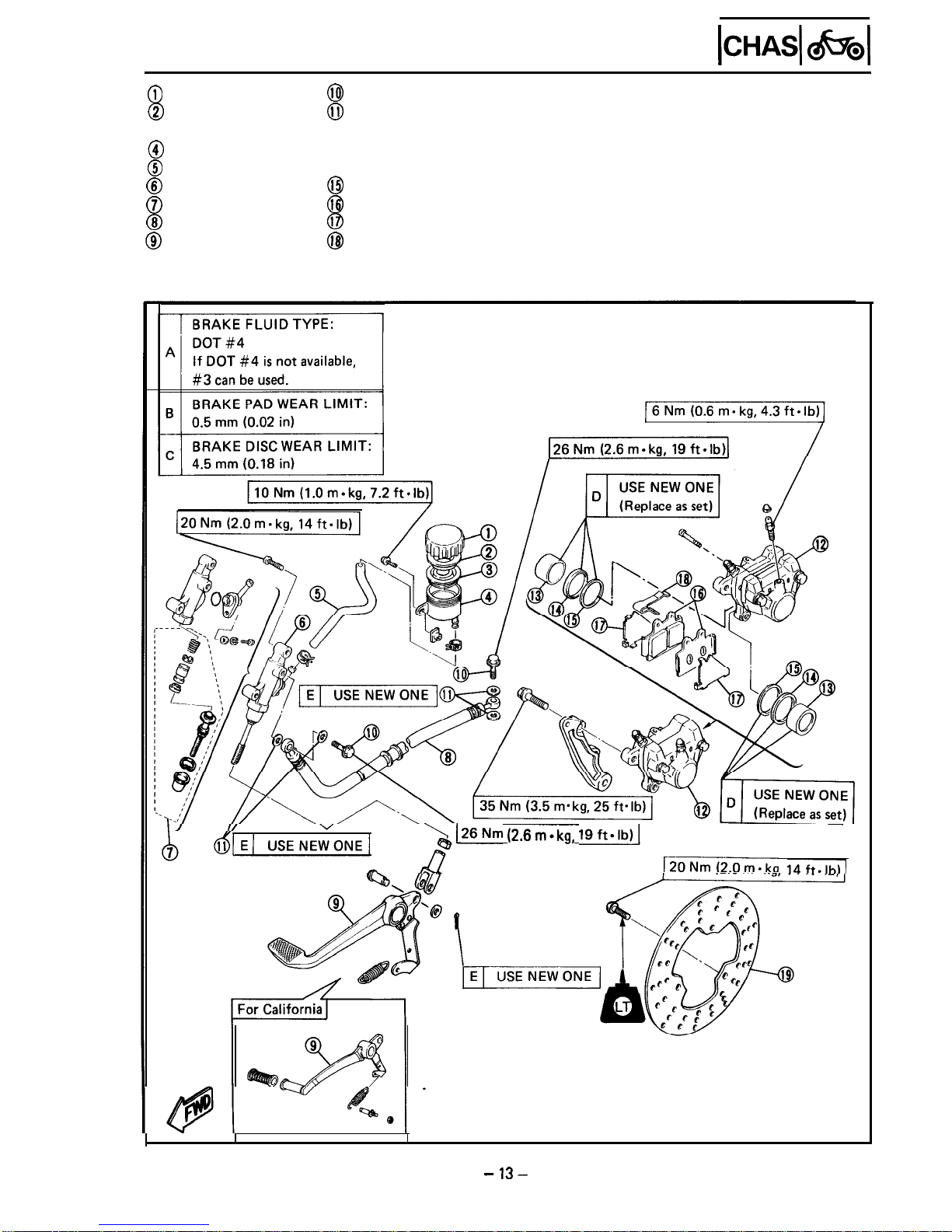

FRONT AND REAR BRAKE

pqzq

FRONT AND REAR BRAKE

@

Master cylinder cap

@

Brake caliper

@

Diaphragm

@I

Pad spring

@

Master cylinder kit

Q-j?

Piston

@

Master cylinder

@

Piston seal

@

Brake hose

@

Dust seal

@

Union bolt

@Brake pad

@

Copper washer

@

Brake disc

@

Joint

?

The arrow mark @ on the pad spring must pointing

the disc rotating direction.

1 BRAKE FLUID TYPE:

A DOT#4

If DOT #4 is not available,

2 Nm (0.2

rn.

kg, 1.4

ftslb)

I-

1 PAD SPRING

SYL

I

---‘----

-

135

(3.5 m . kg, 25

ft. lb)

1

//

,

20 Nm (2.0 ma kg,

rd

lJSF

NEW ONE 1

\

yr;\r

26

ONA

k

FRONT AND REAR BRAKE

l-s1

@bibi

@

Reservoir tank cap

@

Bush

@Diaphragm

@

Reservoir tank

@

Reservoir hose

@

Master cylinder

@

Master cylinder kit

@

Brake hose

@

Brake pedal

@

Union bolt

0

Copper washer

@Brake caliper

@Piston

@Piston seal

@

Dust seal

@I

Brake pad

@

Pad shim

@I

Pad spring

@Brake disc

>/26Nm

(2.6m=kg, 19ft*Ib)I

~20NmI2.0m.kn

14ft.lhl)

- 13-

FRONT AND REAR BRAKE

pi$q

Disc brake components rarely require disassem-

bly. DO NOT:

??

Disassembly components unless absolutely nec-

essary.

??

Use solvents on internal brake component.

??

Use contaminated brake fluid for cleaning.

Use only clean brake fluid.

??

AIIOW brake fluid to come in contact with the

eyes otherwise eye injury may occur.

??

Allow brake fluid to contact painted surfaces

or plastic parts otherwise damage may occur.

?? Disconnect any hydraulic connection other-

wise the entire system must be disassembled,

drained, cleaned, and then properly filled and

bled after reassembly.

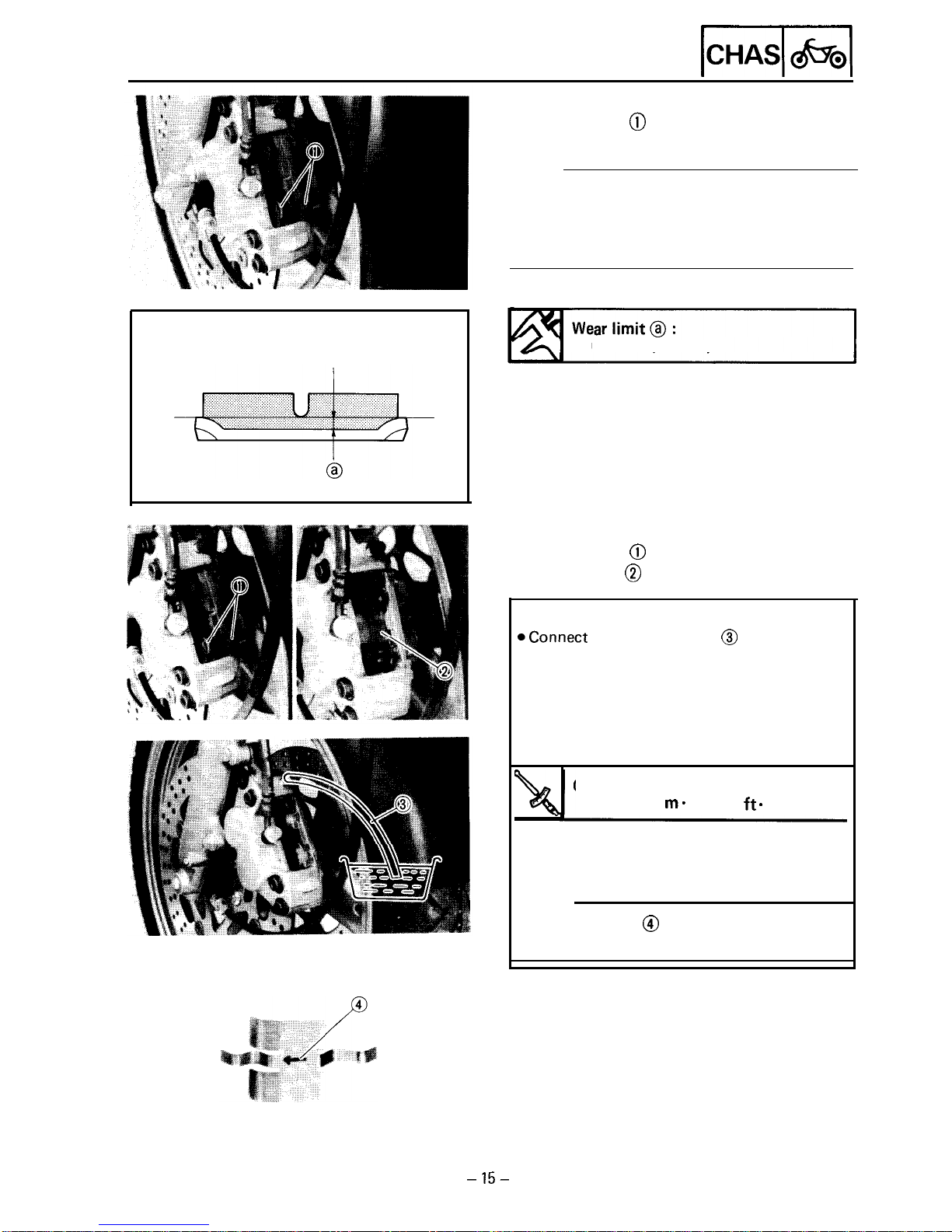

BRAKE PAD REPLACEMENT

NOTE:

It is not necessary to disassemble the brake

caliper and brake hose to replace the brake

pads.

Securely support the motorcycle so there is

no danger of it falling over.

Front brake

1.

Remove:

??

Cover

@

FRONT AND REAR BRAKE

-1

3. Remove:

??

Brake pads

@

NOTE:

?? Replace the pad spring if the pad replacement

is required.

?? Replace the pads as a set if either is found to

be worn to the wear limit.

0.5 mm

(0.02 in)

4. Install:

??

Brake pads

@

??

Pad spring

@

Installation steps:

@Connect

a suitable hose @ tightly to the

caliper bleed screw. Then, place the other

end of this hose into an open container.

?? Loosen the caliper bleed screw and push the

piston into the caliper by your finger.

*Tighten the caliper bleed screw.

Caliper bleed screw:

6 Nm (0.6 m- kg, 4.3

ft.

lb)

*Install the brake pad (new) and pad spring

(new).

NOTE:

The arrow mark @ on the pad spring must

point in the disc rotating direction.

-15-

FRONT AND REAR BRAKE

-1

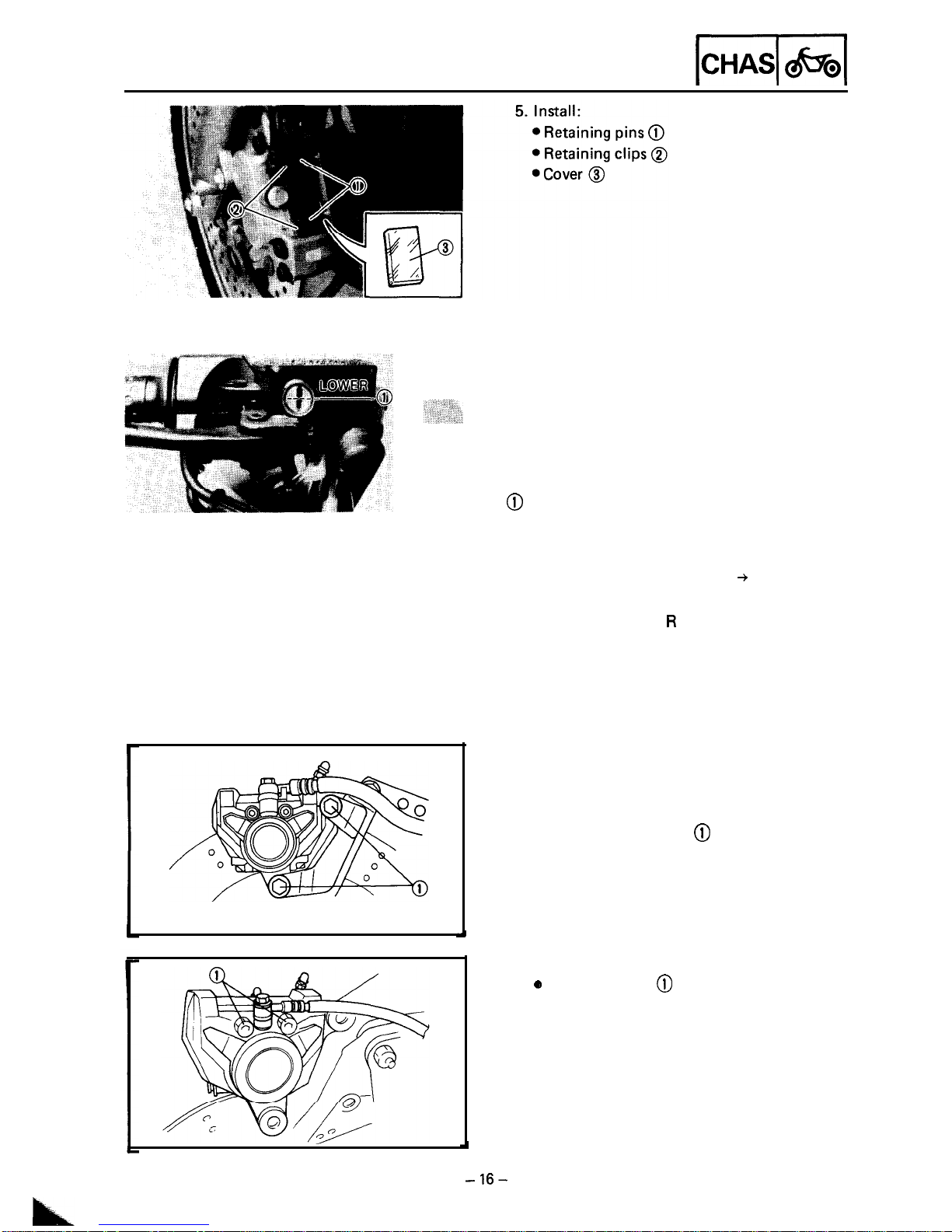

6. Inspect:

?? Brake fluid level

Refer to the “BRAKE FLUID INSPEC-

TION” section in the CHAPTER 3.

@

“LOWER” level line

7.

Check:

?? Brake lever operation

A softy or spongy filling + Bleed brake

system.

Refer to the “Al R BLEEDING” section in

the CHAPTER 3.

3. Remove:

e

Retaining bolts

@

-16-

Rear brake

1. Remove:

??

Seat

2. Remove:

?? Bolts (brake caliper)

@

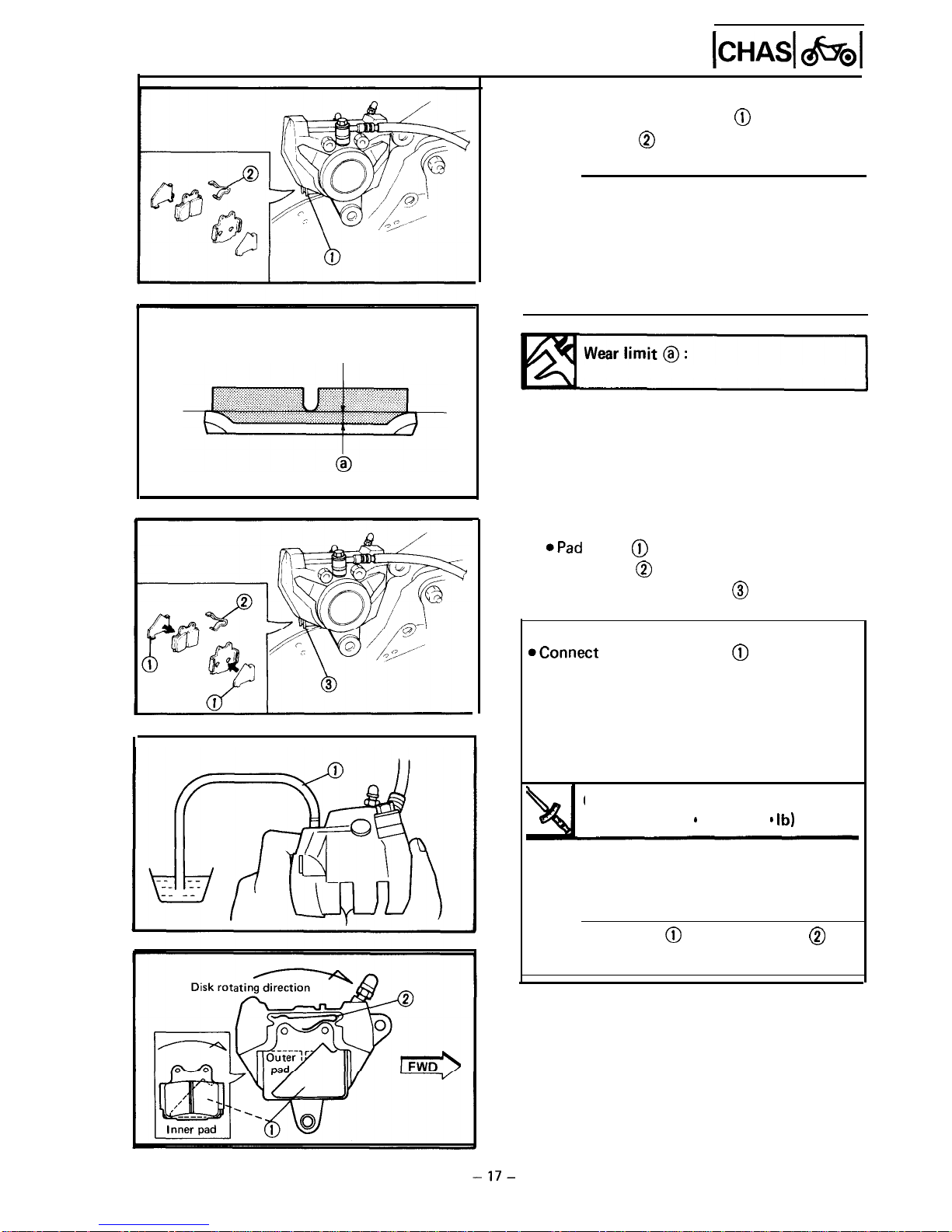

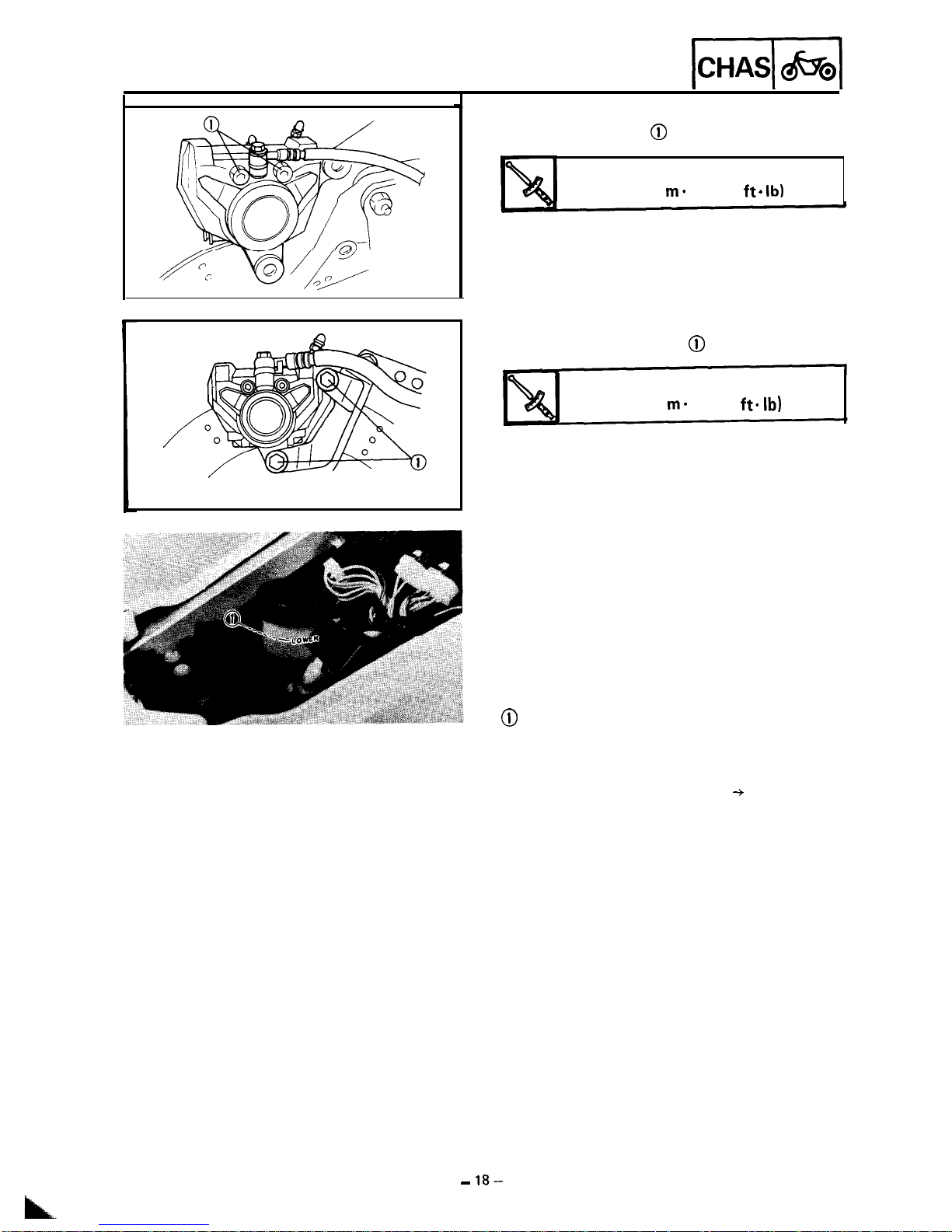

FRONT AND REAR BRAKE

b-l

&I

4. Remove:

??

Brake pads (with shims)

@

??

Pad spring

@

NOTE :

??

Replace the pad spring if the pad replacement

is required.

??

Replace the pads as a set if either is found to

be worn to the wear limit.

??

Replace the pad shim if the pad replacement is

required.

0.5 mm

(0.02 in)

5. Install:

@Pad

shims

@

??

Pad spring

@

??

Brake pads (with shims)

@

Installation steps:

@Connect

a suitable hose @ tightly to the

caliper bleed screw. Then, place the other

end of this hose into an open container.

??

Loosen the caliper bleed screw and push the

piston into the caliper by your finger.

*Tighten the caliper bleed screw.

Caliper bleed screw:

6 Nm (0.6 m - kg, 4.3 ft -

lb)

@Install the brake pads (new), pad spring

(new) and pad shims (new).

NOTE:

Install pad shims @ and pad spring @ on

caliper as shown in the disc rotating direction.

FRONT AND REAR BRAKE

-1

6. Install:

??

Retaining bolts

@

Retaining bolts:

10 Nm (1.0 ma kg, 7.2

ft. lb)

7. Install:

??

Bolts (brake caliper)

@

Bolts (brake caliper):

35 Nm (3.5

rn-

kg, 25

ft. lb)

8. Inspect:

??

Brake fluid level

Refer to the “BRAKE FLUID INSPEC-

TION” section in the CHAPTER 3.

@

“LOWER” level line

9. Check:

??

Brake pedal operation

A softy or spongy filling + Bleed brake

system.

Refer to the “AIR BLEEDING” section in

the CHAPTER 3.

10. Install:

??

Seat

-

18-

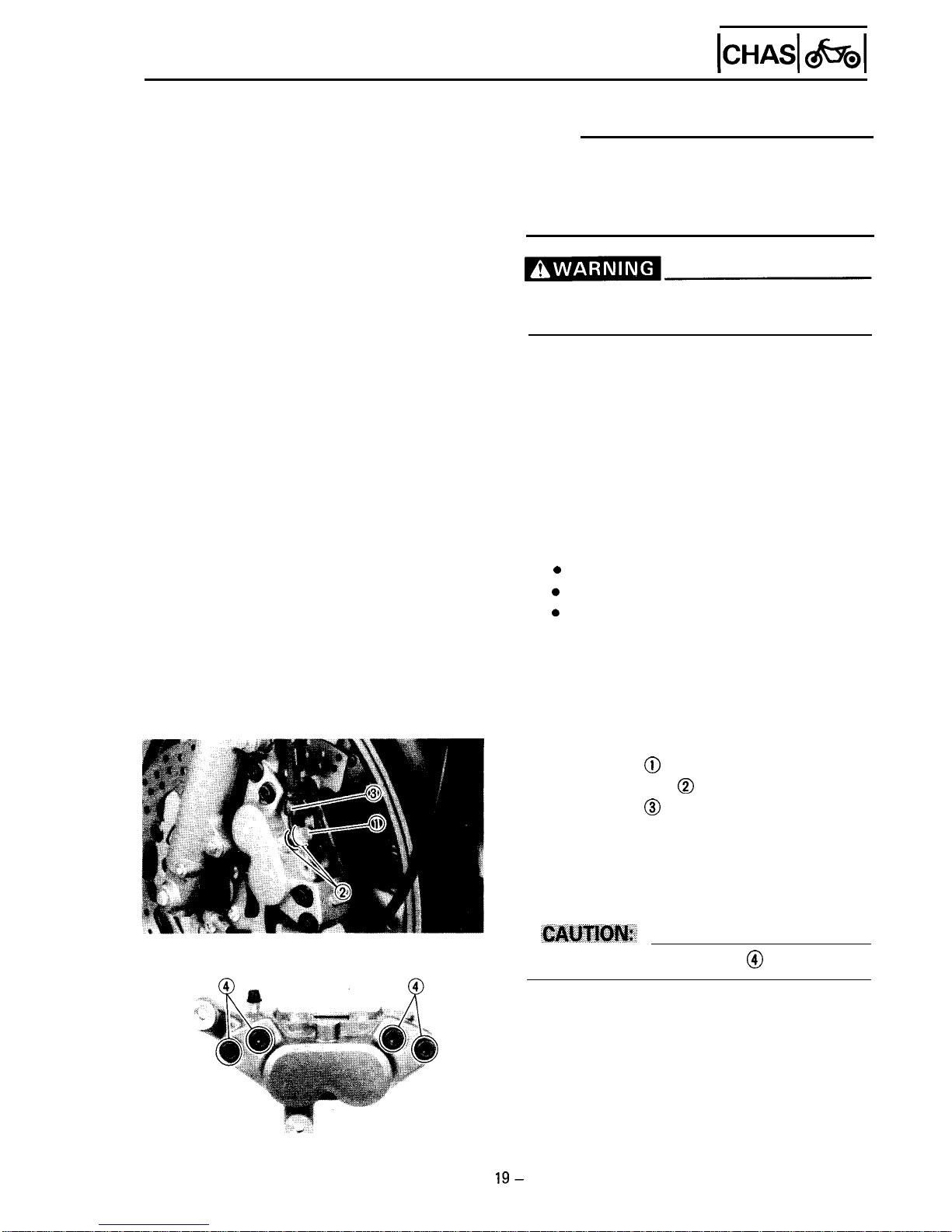

FRONTANDREARBRAKE

ICHASl c&x31

CALIPER DISASSEMBLY

NOTE:

Before disassembling the front or rear brake

master cylinders, drain the brake hose, master

cylinder, brake caliper and reservoir tank of

their brake fluid.

Securely support the motorcycle so there is

no danger of it falling over.

Front brake

1. Remove:

0 Cover

0 Reflector

0 Retaining clips

??

Retaining pins

??

Pad spring

??

Brake pads

Refer to the “BRAKE PAD REPLACE-

MENT” section.

2. Remove:

??

Union bolt

@

??

Copper washers

@

??

Brake hose

@

Place the open hose end into a container

and pump the old fluid out carefully.

3. Remove:

??

Caliper body

Do not loosen the bridge bolts @ .

- 19-

Loading...

Loading...