Yamaha FZR400 Service Manual Ch567

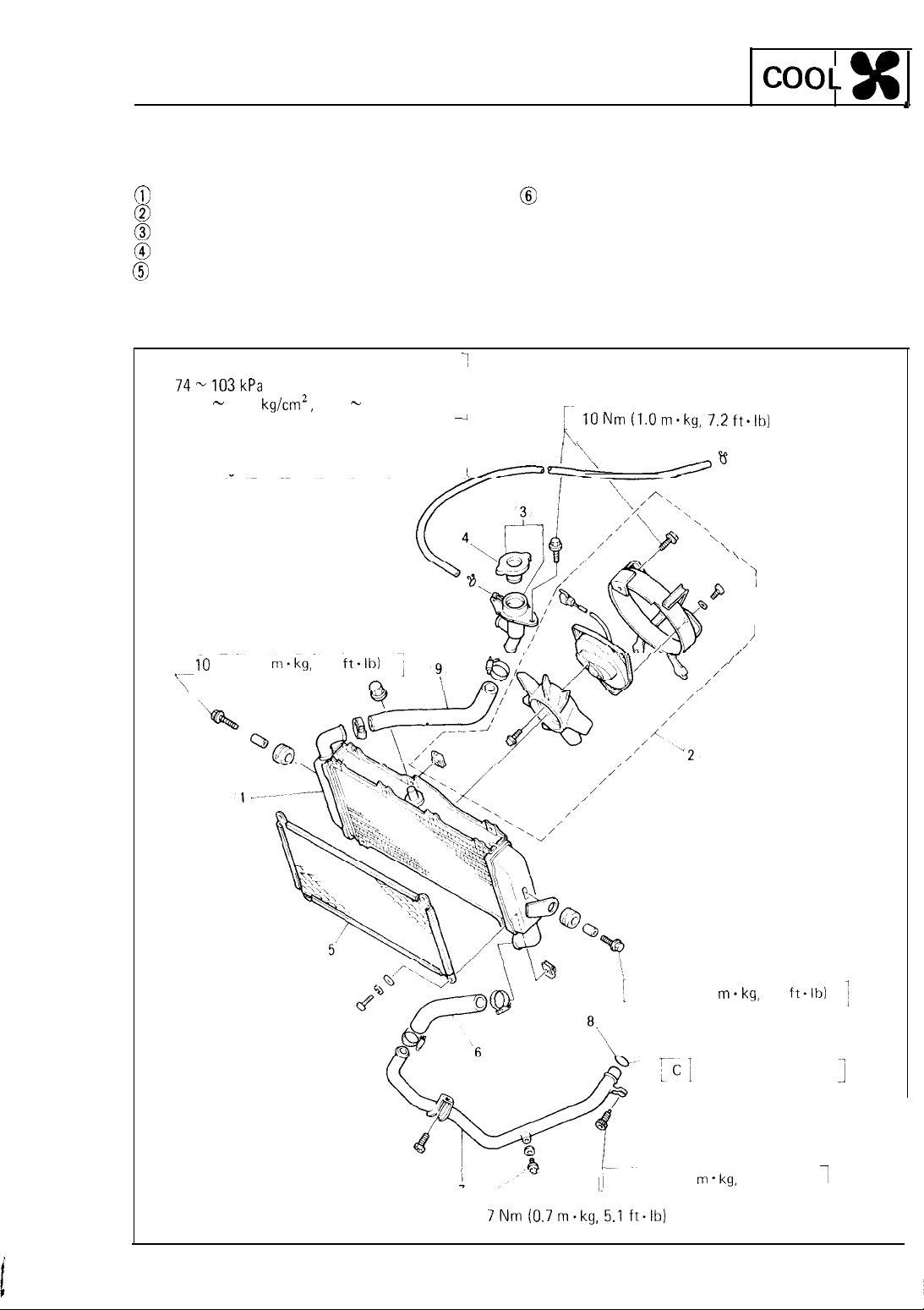

RADIATOR

@

Radiator assembly

@

Fan motor assembly

@

Radiator cap assembly

@

Radiator cap

0

Radiator cover

RADIATOR

COOLING SYSTEM

@

Hose (Radiator - Outlet)

@Outlet pipe

@O-ring

@Hose (Radiator - Inlet)

COOL #

\

) RADIATOR CAP OPENING PRESSURE:

A

74-103kPa

(0.75 - 1.05

COOLANT CAPACITY:

B

19 L (1.7 Imp qt, 2.0 US qt)

lncludinq all routes

10

Nrn (1.0

‘i

\

kg/cm’,

m-kg,

10.7 - 14.9 psi)

7.2

ftelh)

-1

4

I-Q

1~ 10Nm (l.Om.kg, 7.2ft.Ib)

h

\

‘\

\

P

I

‘?

I

I

1)

/

;

/

~_

7Nm(0.7m~kg,5.1ft~Ib)

5-l

7 Nm (0.7

1-C i

10 Nm (1.0

m.kg,

5.1

USE NEW ONE

7.2

ft-lb)

m-kg,

ftelh)

1

]

1

RADIATOR

COOL %

REMOVAL

1. Remove:

?? Lower cowlings (Left and Right)

?? Side cowlings (Left and Right)

Refer to the “COWLING REMOVAL ANC

INSTALLATION - REMOVAL”

in the CHAPTER 3.

2. Drain:

0

Cooling system

Refer to the”COOLANT REPLACEMENT

section in the CHAPTER 3.

3. Remove:

?? Muffler assembly

NOTE:

Thoroughly flush the cooling system with

tap water.

ACAUTION:

Take care so that coolant does not splash 1

painted surfaces. If splashes, wash it

with water.

sectiol

cles

awi

Do not remove the radiator cap, drain bol

and hoses especially when the engine ar

radiator are hot. Scalding hot fluid and stea

may be blown out under pressure, which cou

cause serious injury. When the engine has

coole

place a thick rag like a towel over the radiat

cap, slowly rotate the cap counterclockwi

to the detent. This procedure allows any

pressure to escape. When the hissing sound

stopped, press down on the cap while

reside

r

turni

counterclockwise and remove it.

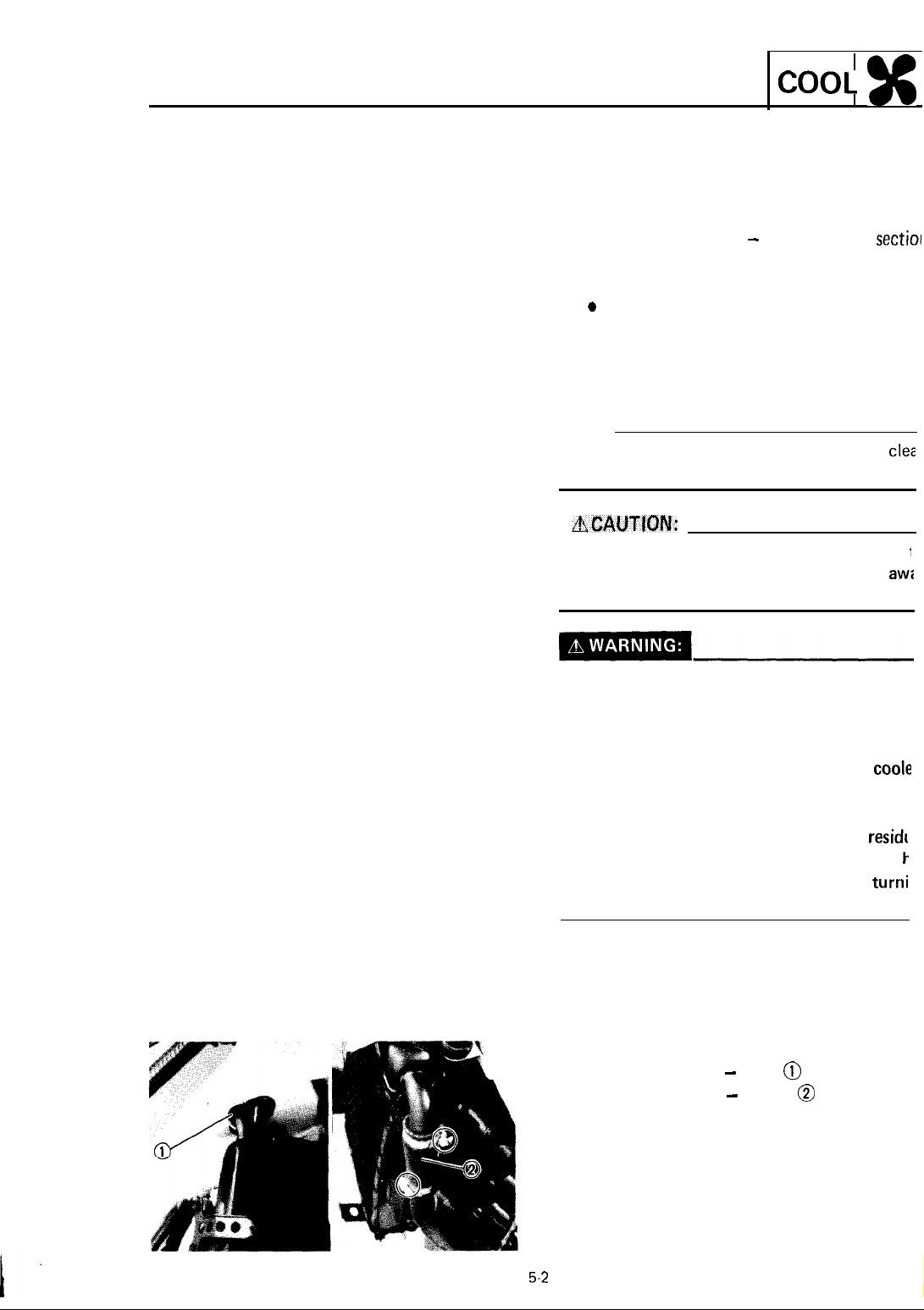

4. Disconnect:

?? Hose (Radiator

?? Hose (Radiator

-

Inlet)

-

Outlet)

@

@

5-2

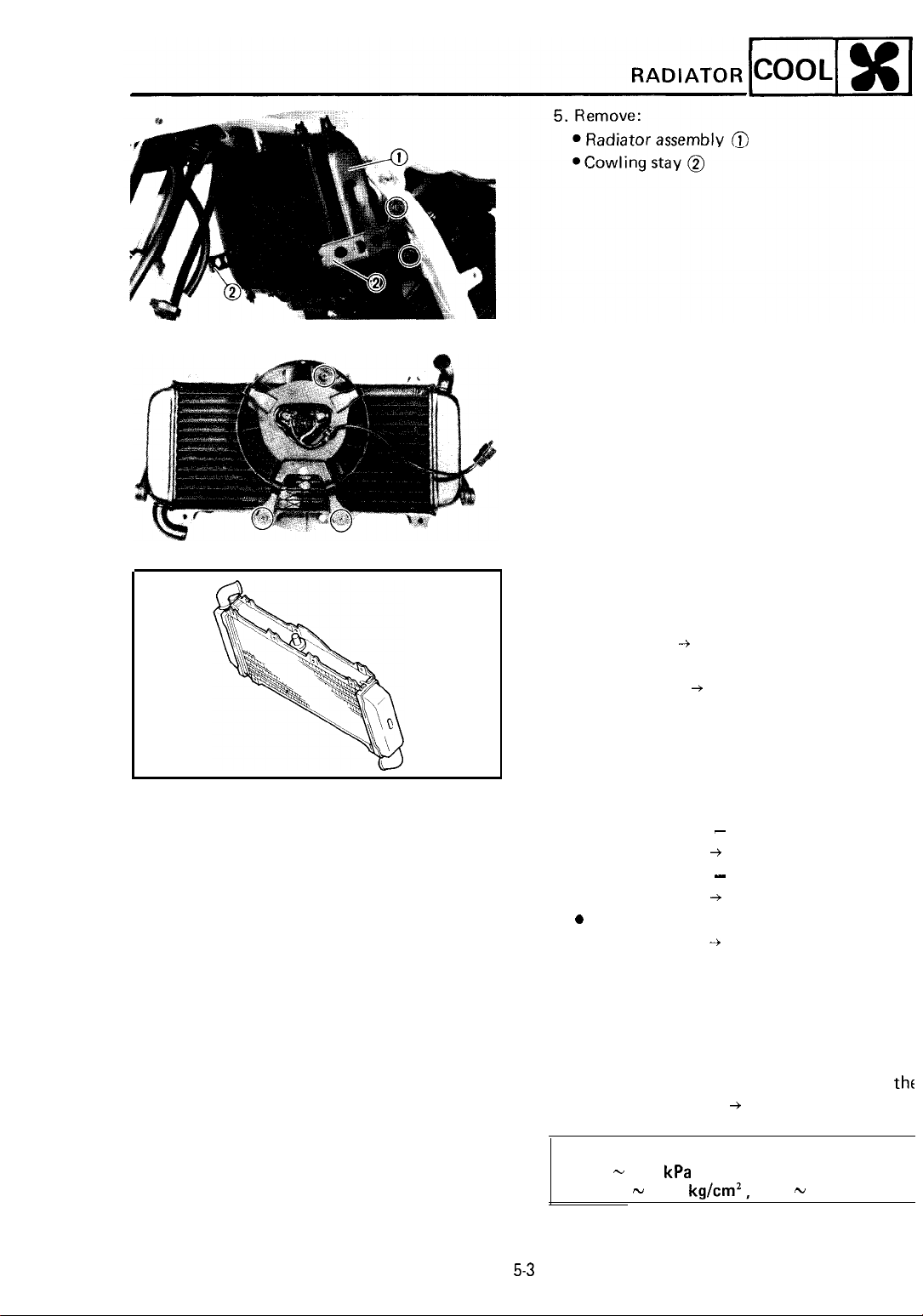

6. Remove:

?? Fan motor assembly

INSPECTION

1. Inspect:

?? Radiator core

Obstruction + Blow out with compressed

air through rear of the radiator.

Flattened fin + Repair/replace.

2. Inspect:

?? Hose (Radiator

-

Inlet)

Cracks/Damage + Replace.

?? Hose (Radiator

-

Outlet)

Cracks/Damage + Replace.

0

Outlet pipe

Cracks/Damage

--f

Replace.

5-3

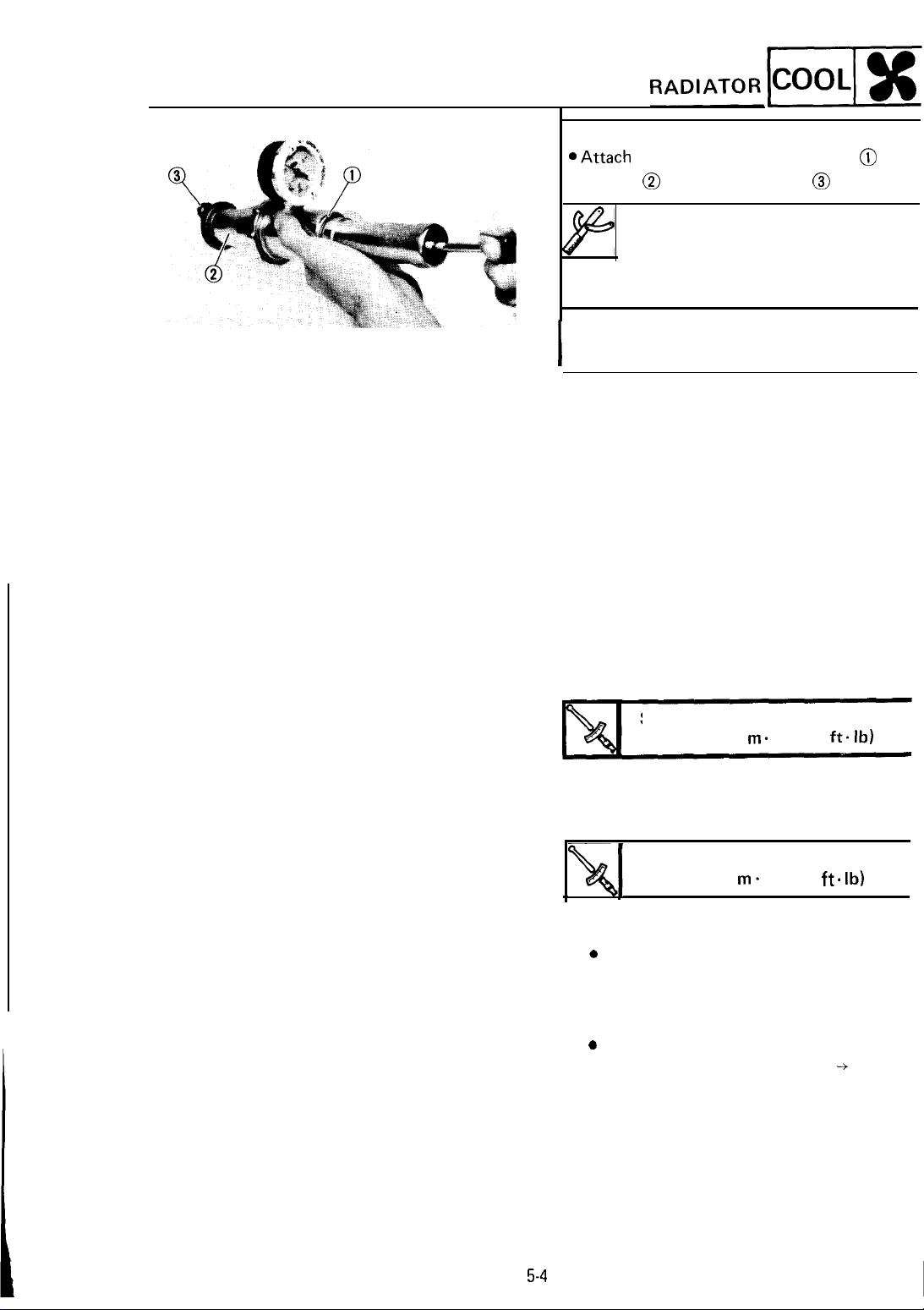

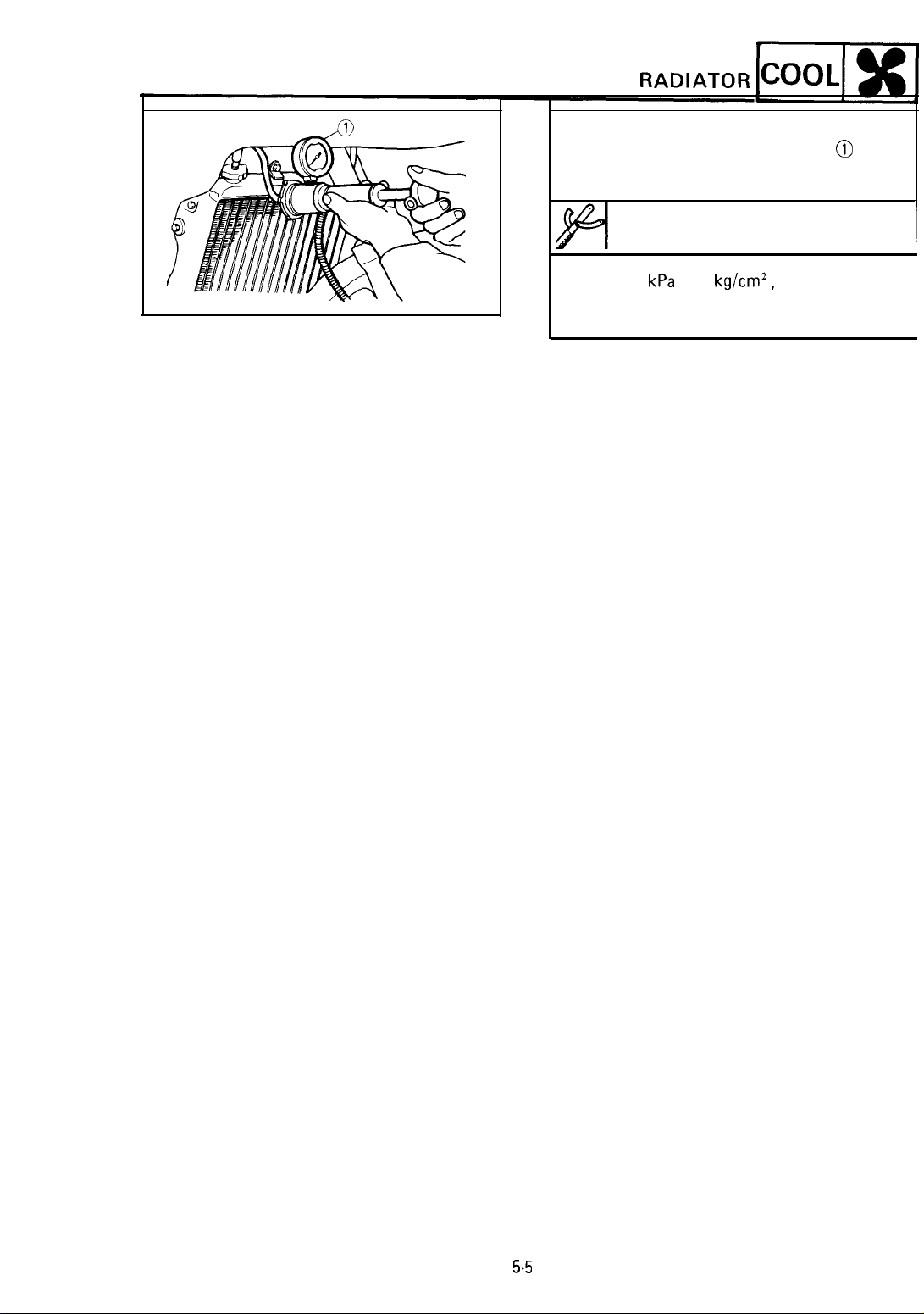

3. Measure:

?? Radiator cap opening pressure

Radiator cap opens at pressure below

specified pressure + Replace.

Radiator Cap Opening Pressure:

74 - 103

(0.75 - 1.05

kPa

kg/cm’,

10.7 - 14.9 psi)

the

Measurement steps:

@Attach

1

?? Apply the specified pressure for 10 seconds,

I

INSTALLATION

Reverse the “REMOVAL” procedure.

Note the following points.

1. Install:

the Cooling System Tester @ and

Adapter @ to the radiator cap @ .

Cooling System Tester:

Y U-24460-0 1

Adapter:

Y U-33984

and make sure there is no pressure drop.

?? Fan motor assembly

Screws (Fan Motor Assembly):

10 Nm (1.0 mm kg, 7.2

2. Install:

??

Radiator

Bolts (Radiator):

%’

3. Fill:

0

Cooling system

Refer to the “COOLANT REPLAC

MENT” section in the CHAPTER 3.

4. Inspect:

0

Cooling system

Decrease of pressure (leaks) + Repair

required.

7 Nm (0.7 me kg, 5.1

ft. lb)

ft. lb)

5-4

Inspection steps:

@Attach the Cooling System Tester @ to the

radiator.

Cooling System Tester:

Y U-24460-0 1

?? Apply 100

kPa

(1 .O

kg/cm*,

14 psi) pressure .

@Measure the indicated pressure with the

gauge.

5-5

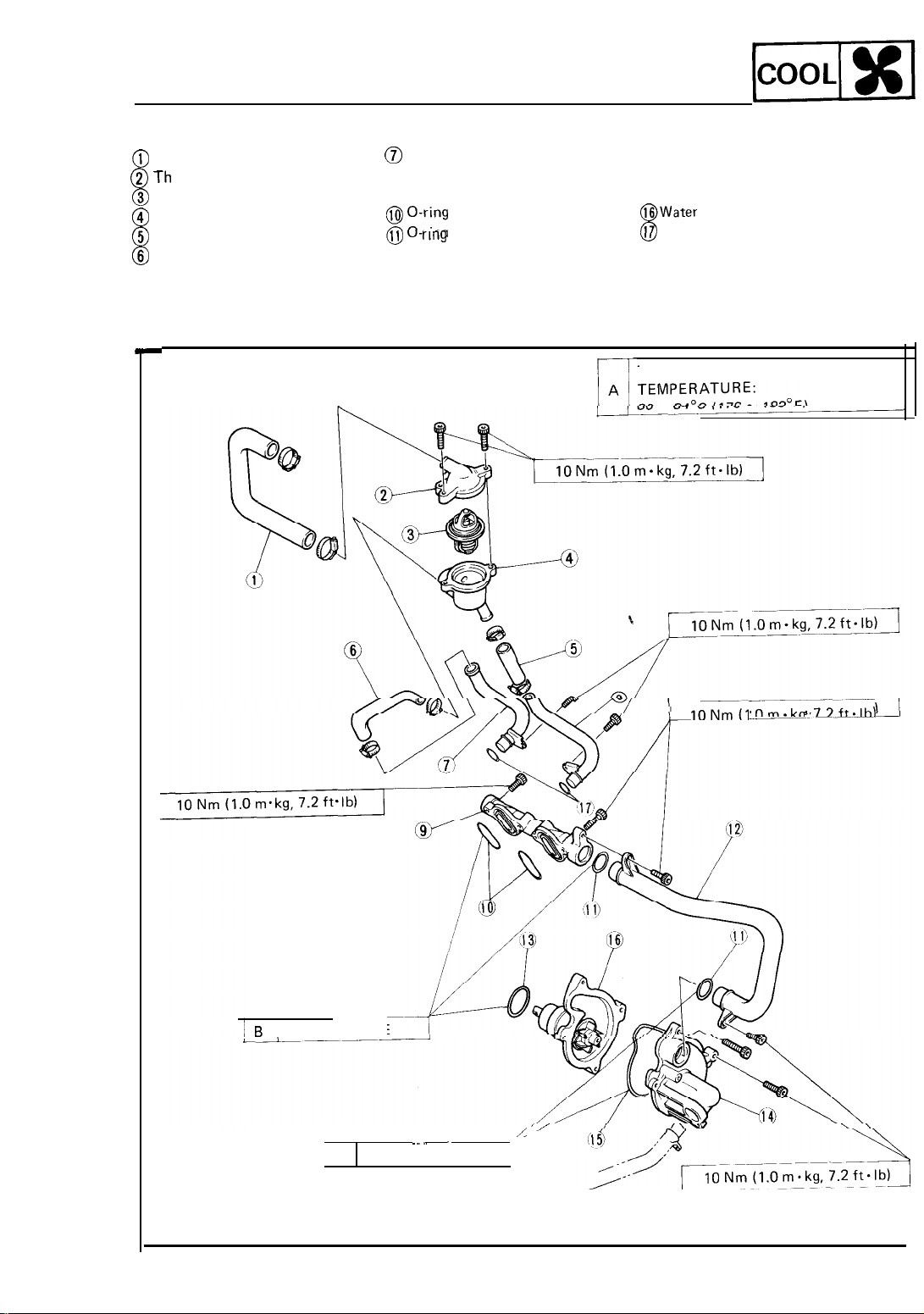

WATER PUMP AND THERMOSTATIC VALVE

I

WATER PUMP AND THERMOSTATIC VALVE

0

@

Hose 3

ermostatic cover

@ Th

@

Thermostatic

@

Thermostatic housing

@

Hose 1

@

Hose 2

Pipe 2

@Pipe 1

@Water jacket joint

8 ($Jng

ring

@Water pipe

COOL

@O-ring

@Water pump cover

@O-ring

@Water

C@

THERMOSTATIC VALVE OPENING

pump housing

O-ring

/6 /

USE NEW ONE

B USE NEW ONE

~_

lnhlmfi nm.kn

I

73ft.lhl

/

5-6

WATER PUMP AND THERMOSTATIC VALVE

REMOVAL

1. Remove:

?? Lower cowlings (Left and right)

?? Center cowlings (Left and right)

0

Seat

?? Top cover

Refer to the “COWLING REMOVAL AND

INSTALLATION - REMOVAL” section

in the CHAPTER 3.

2. Drain:

0

Cooling system

Refer to

section in the CHAPTER 3.

the”COOLANT

COOL

r-ml

REPLACEMENT”

3. Remove:

?? Fuel tank

Refer to the

“CARBURETOR - RE-

MOVAL” section in the CHAPTER 6.

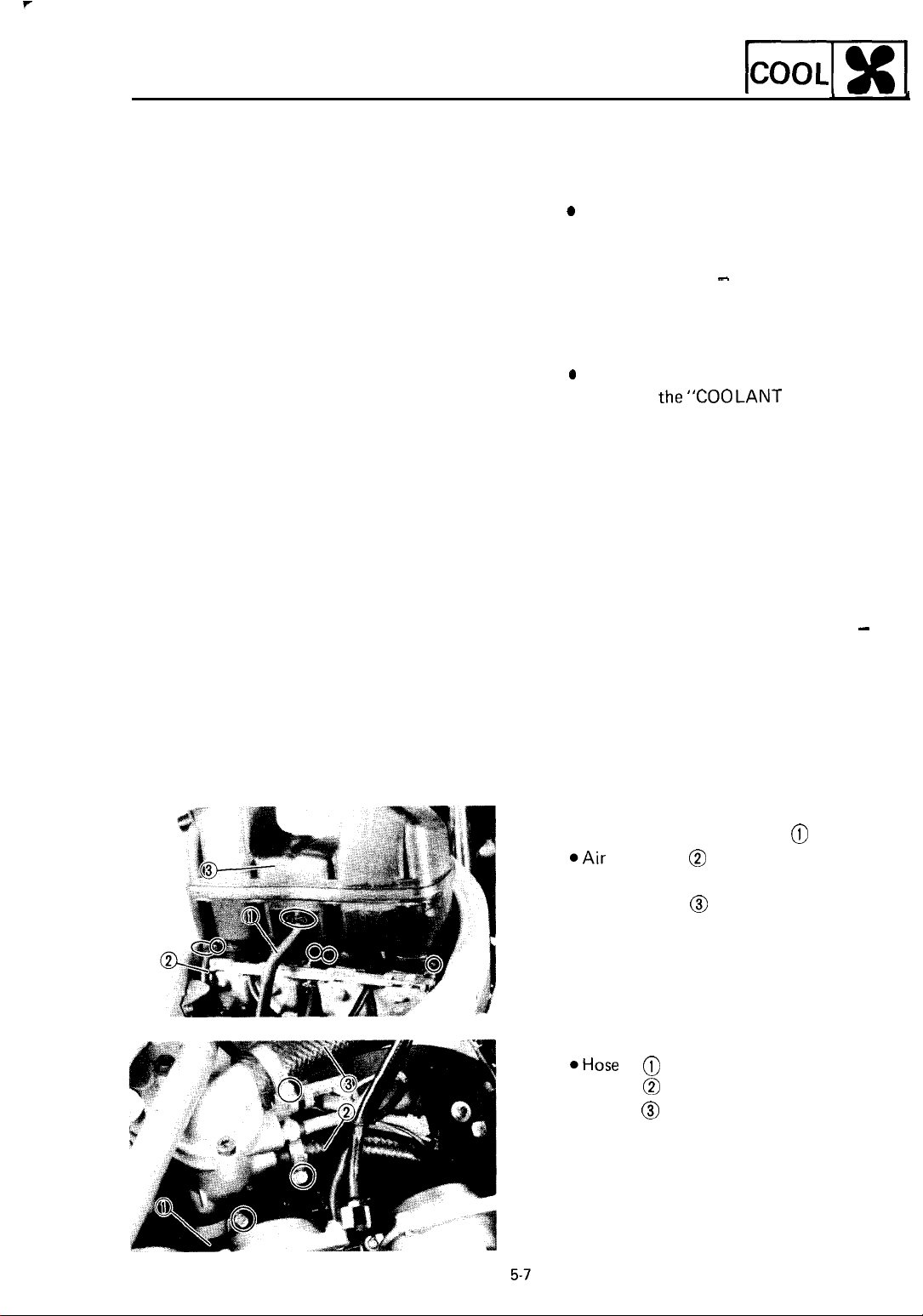

4. Disconnect:

?? Crankcase ventilation hose

lair

vent hose

@

@

5. Remove:

?? Air filter case

@

6. Disconnect:

whose

1

@

??

Hose2

@

??

Hose 3

@

WATER PUMP AND THERMOSTATIC VALVE

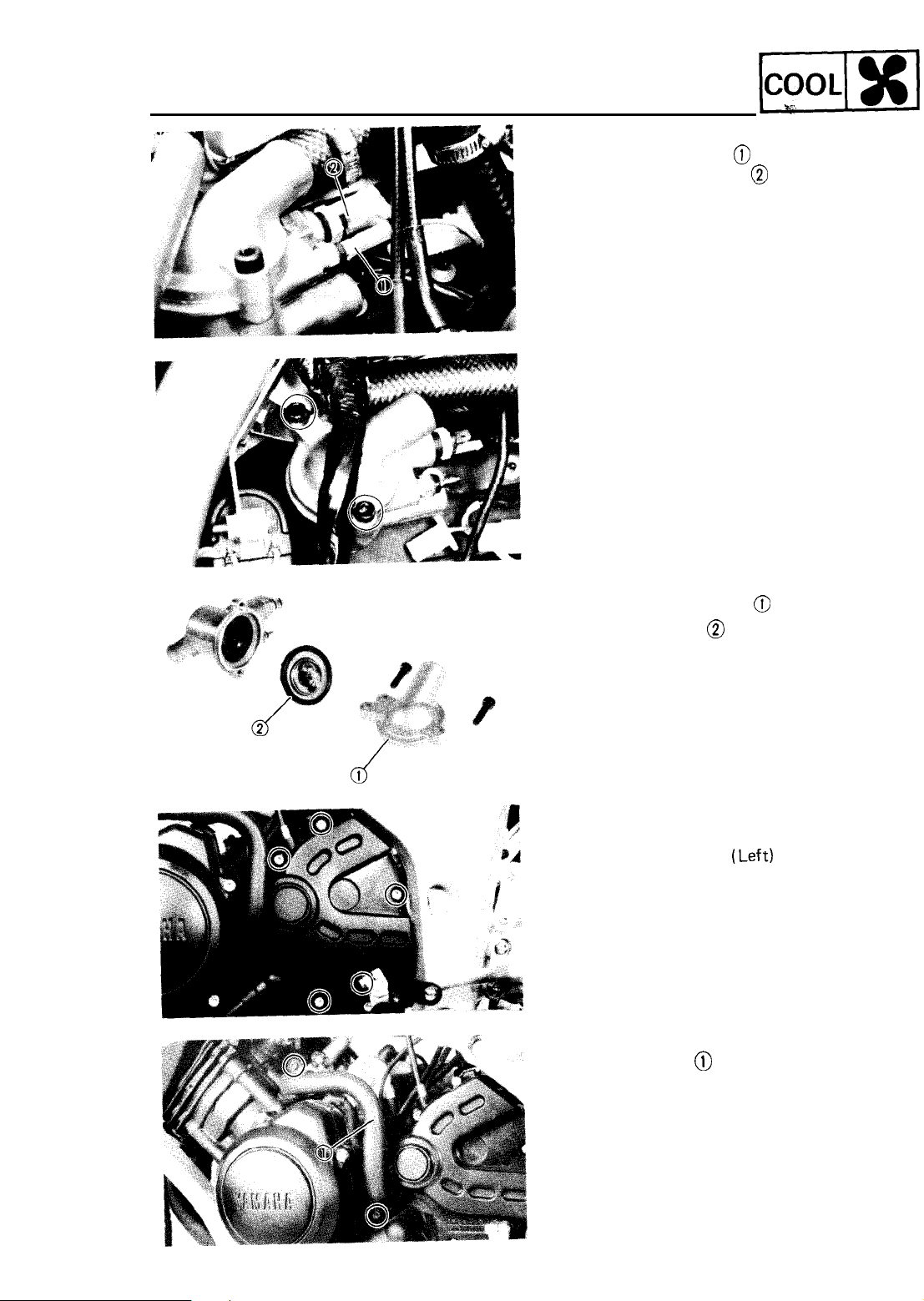

7. Disconnect:

??

Thermo unit lead

??

Thermo switch lead

8. Remove:

??

Thermostatic housing

@

COOL

rJ%l

@

9. Remove:

?? Thermostatic cover

?? Thermostatic

10. Remove:

??

Shift arm

??

Crankcase cover

11. Remove:

??

Water pipe

@

@

(Left)

0

5-8

WATER

PUMP

AND THERMOSTATIC

12. Remove:

@Water

0

13. Remove:

?? Water pump housing

@O-ring

pipe

Water pump cover

VALVE I-f

(Q

@

@

w

323 003

INSPECTION

1. Inspect:

?? Thermostatic valve

Valve does not open at 80 - 84°C (176

183” F)

+

Replace.

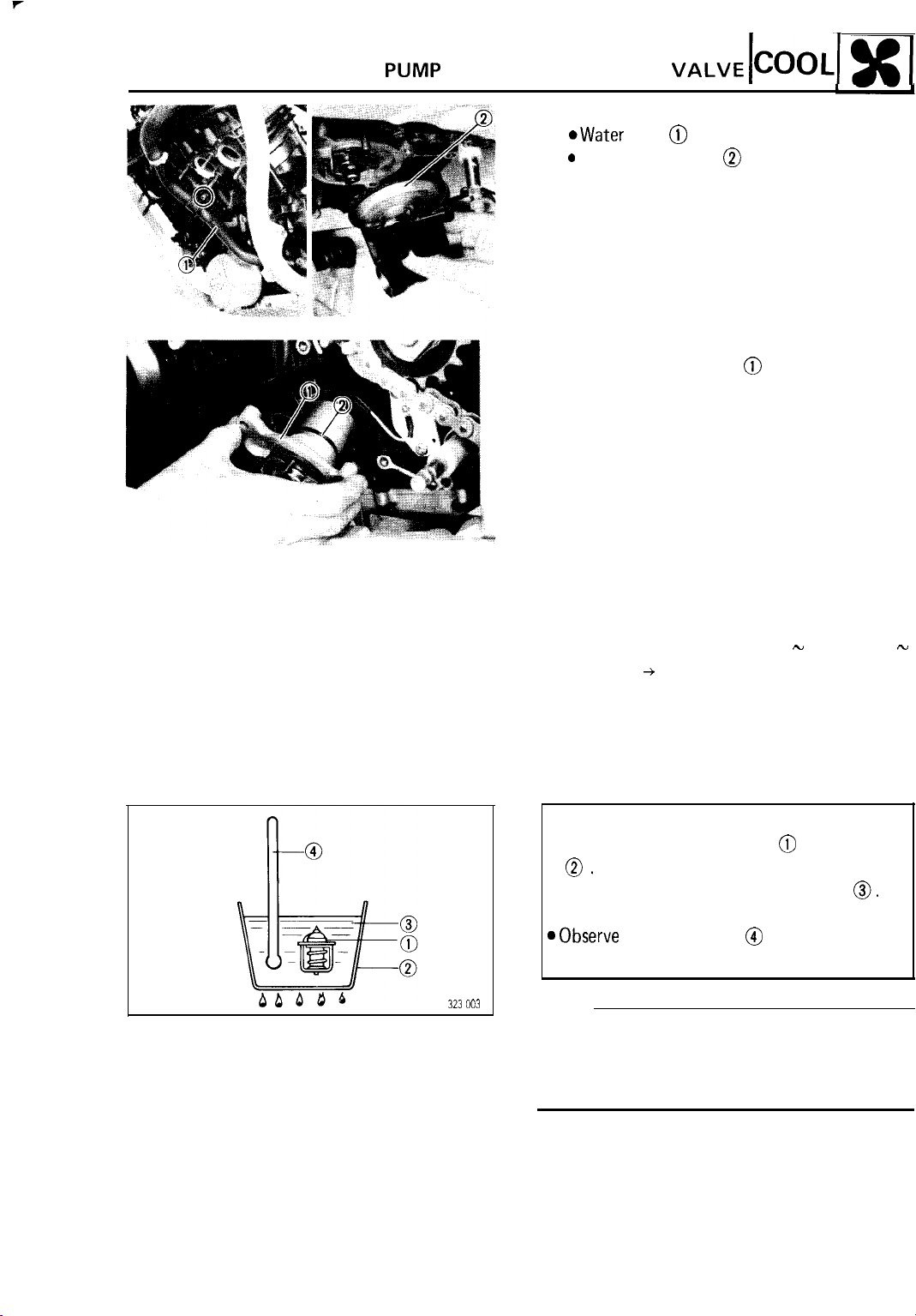

Inspection steps:

*Suspend thermostatic valve @ in a vessel

0.

?? Place reliable thermometer in a water

?? Head water slowly.

aObserve

water continually.

thermometer @ , while stirring

0.

NOTE:

Thermostatic valve is sealed and its setting is

specialized work. If its accuracy is in doubt,

always replace it. A faulty unit could cause

serious overheating or overcooling.

-

5-9

WATER PUMP AND THERMOSTATIC VALVE

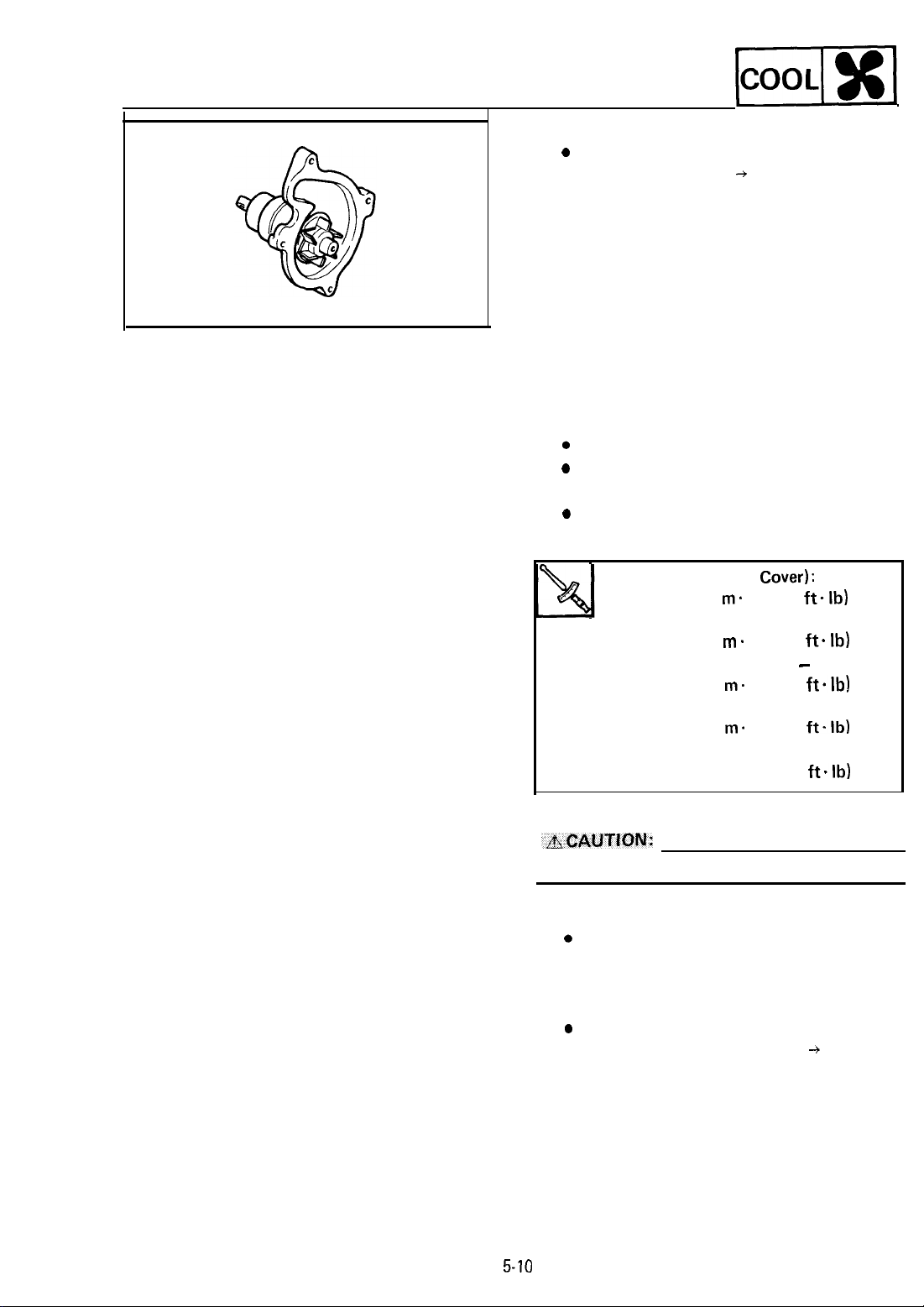

2. Inspect:

0

Impeller

Cracks/Wear/Damage + Replace.

INSTALLATION

Reverse the “REMOVAL” procedure.

Note the following points.

1. Install:

0

Water pump cover

0 Pipe

?? Crankcase cover (Left)

o

Shift arm

??

Thermostatic cover

pqjiq

Bolts (Water Pump

Cover):

10 Nm (1.0 ma kg, 7.2

Bolts (Pipe) :

10 Nm (1.0 ma kg, 7.2

Bolts (Crankcase Cover - Left):

10 Nm (1.0 me kg, 7.2

Bolt (Shift Arm):

10 Nm (1.0 ma kg, 7.2

Bolts (Thermostatic Cover) :

10 Nm (1.0 m-kg, 7.2

~BCAWWN:

Always use new O-ring.

2. Fill:

0

Cooling system

Refer to the “COOLANT REPLACEMENT’

section in the CHAPTER 3.

3. Inspect:

0

Cooling system

Decrease of pressure (Leaks) + Repair as

required.

ftalb)

ft*lb)

ft*lb)

ft*Ib)

ftslb)

5-10

CARBURETOR

@

Upper bracket

@

Throttle stop screw

@

Fuel overflow hose

@

Lower bracket

ncronizing screw

0 SY

@

Float

0

Float pin

@

Float chamber

@

Needle jet

@

Fuel drain screw

CARBURETOR

0

Valve seat assembly

@

Pilot jet

@

Main jet

@

Starter plunger assembly

@

Pilot screw

@

Piston valve assembly

0

Jet needle set

@

Starter lever shaft

@

O-ring

CARBURETOR

r

ID Mark

MAIN JET

MAIN AIR JET

PI LOT JET

PILOT AIR JET

JET NEEDLE

PILOT SCREW

THROTTLE VALVE

ENGINE IDLE SPEED

FUEL LEVEL

SPEClf

piqq

CATIONS

3BF-00

(Except for California),

3FH-00

(For California)

#87.5

#60

#15

#I30

5CFZ2

3%

#I30

1,250 - 1,350

4.5 - 6.5 mm (0.18 - 0.26 ir

r/min

1 3 Nm (0.3 me kg, 2.2

ft.

lb)

6-1

CARBURETOR

I-

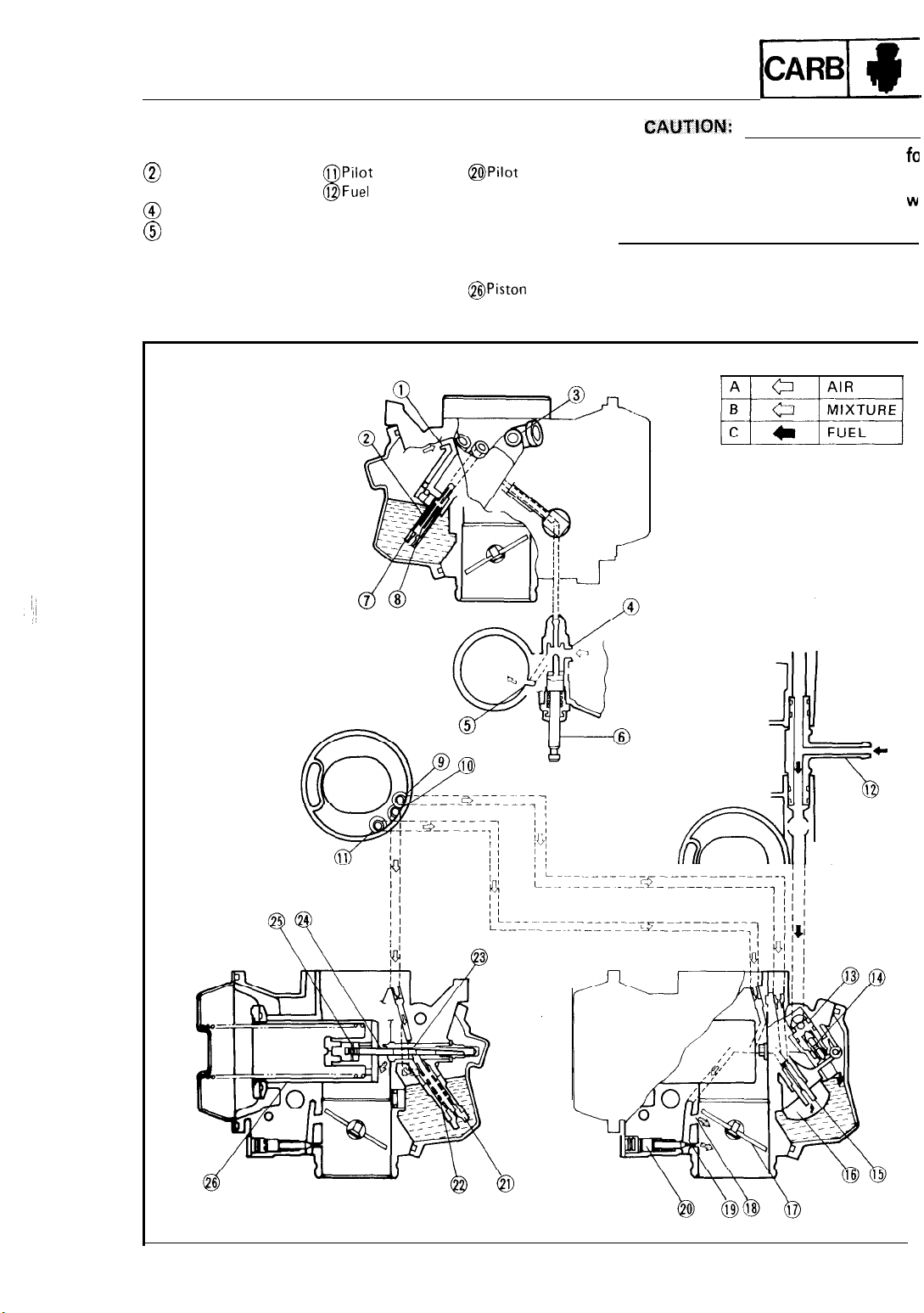

SECTION VIEW

@Starter air bleed

@

Starter air bleed pipe

@Air vent

@

Air inlet

@

Mixture outlet @Valve seat @Needle jet

@Starter plunger

@Starter jet No 1

@Starter jet No. 2 @Throttle valve

@Pilot air jet 2 @Bypass hole

@Main air jet @Pilot outlet

@)Pilot

air jet 1

@Fuel

inlet @Main jet

@Float needle valve @Main bleed pipe

@Pilot jet @Jet needle

@Float @Spring clip

@Pilot

@Piston

screw

valve

A

CAUtlON;

The pilot screw settings are adjusted fa

maximum performance at the factory.

Any attempt to change these settings

w

II decrease engine performance.

6-2

CARBURETOR

-1

REMOVAL

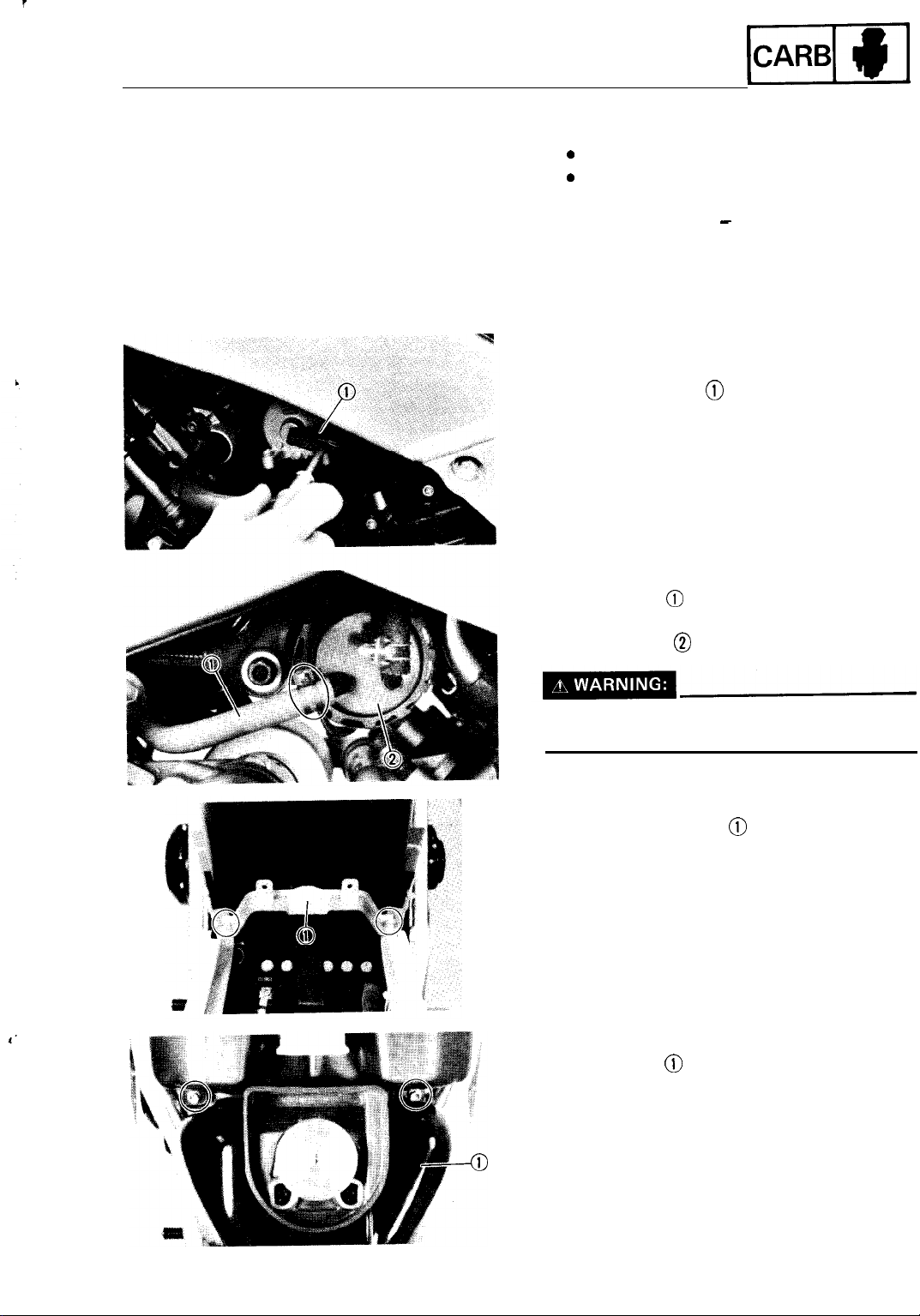

1. Remove:

0

Seat

a

Top cover

Refer to the “COWLING REMOVAL AND

INSTALLATION - REMOVAL” section

in the CHAPTER 3.

2. Turn the fuel cock to “OFF” position.

3. Remove:

?? Fuel cock lever

@

4. Disconnect:

?? Fuel hose

@

5. Remove:

?? Fuel pump

@

Gasoline is highly flammable.

Avoid spilling fuel on the hot engine.

6. Remove:

?? Fuel tank bracket

@

7. Remove:

?? Fuel tank

@

6-3

CARBURETOR

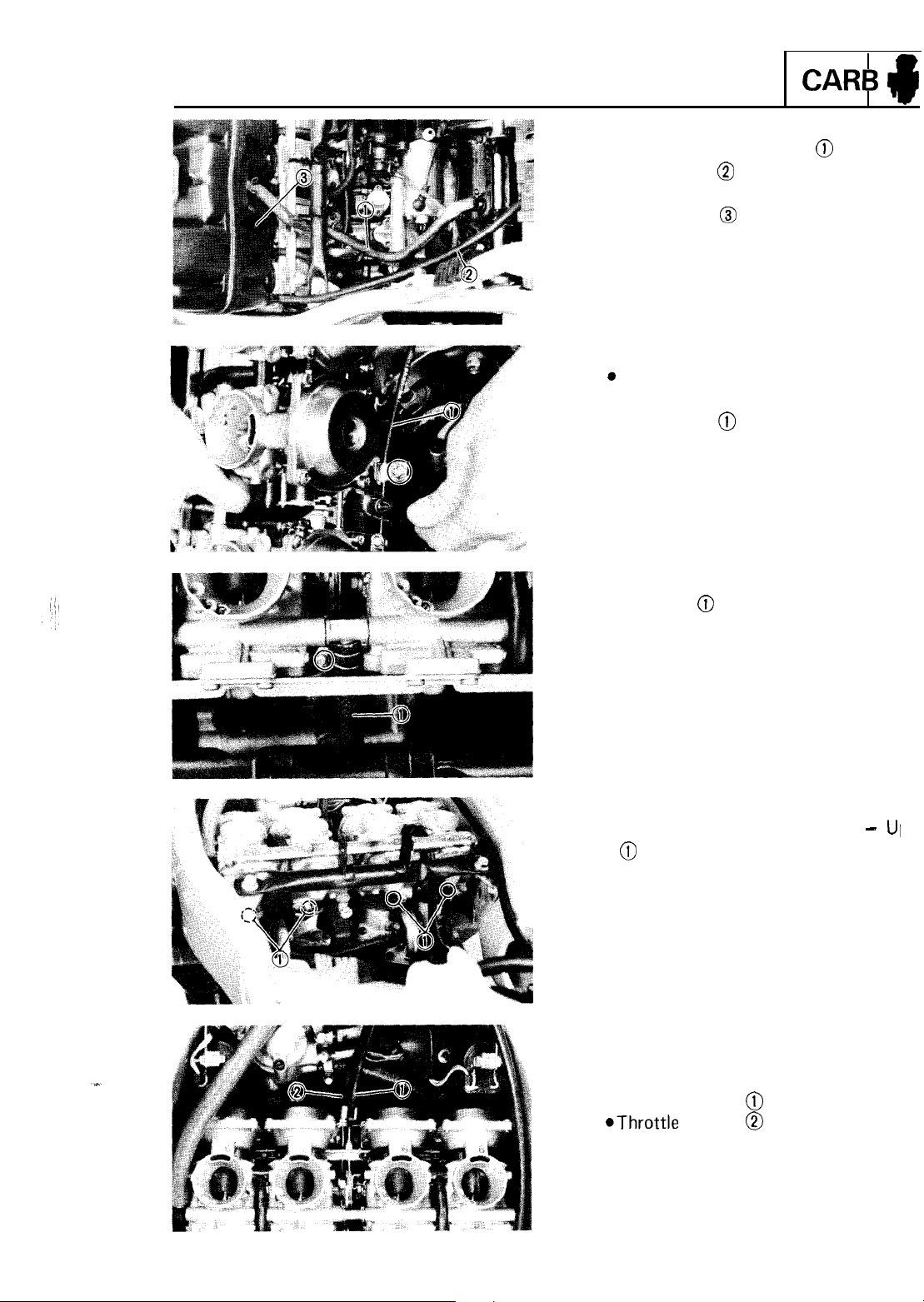

8. Disconnect:

?? Crankcase ventilation hose

?? Air vent hose

9. Remove:

?? Air filter case

10. Loosen :

0

Screw (Starter cable clamp)

11. Disconnect:

??

Starter cable

@

@

@

CARB #

@

12. Disconnect:

?? Fuel hose

@

13. Loosen :

*Screws (Carburetor joint clamp -

0

14. Remove:

??

Carburetor assembly

15. Disconnect:

*Throttle cable 1

aThrottle

cable 2

@

@

UI

6-4

CARBURETOR

(CARBII

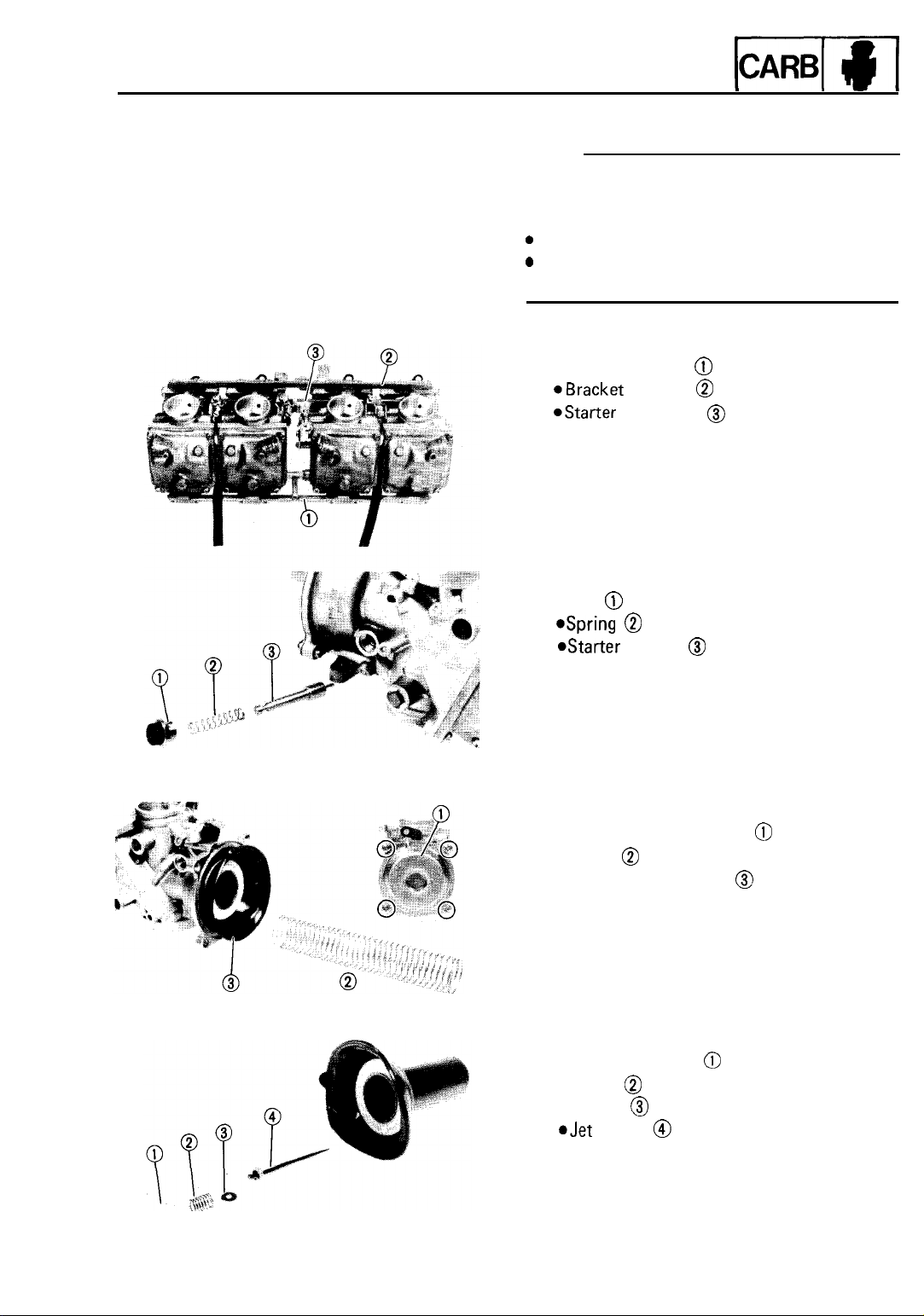

DISASSEMBLY

NOTE:

The following parts can be cleaned and inspected without carburetor separation.

?? Throttle valve

0

Piston valve

0

Starter plunger

?? Float chamber components

1. Remove:

*Bracket (Upper)

~Bracket

@Starter

(Lower)

lever shaft

@

@

@

2. Remove:

??????

?

*Spring 0

@Starter

plunger

@

3. Remove:

?? Vacuum chamber cover

??

Spring

@

?? Piston valve assembly

4. Remove:

?? Plug (Jet needle)

*Spring

??

aJet

@

Washer

needle

@

@I

@

@

0

6-5

CARBURETOR

[CARB(

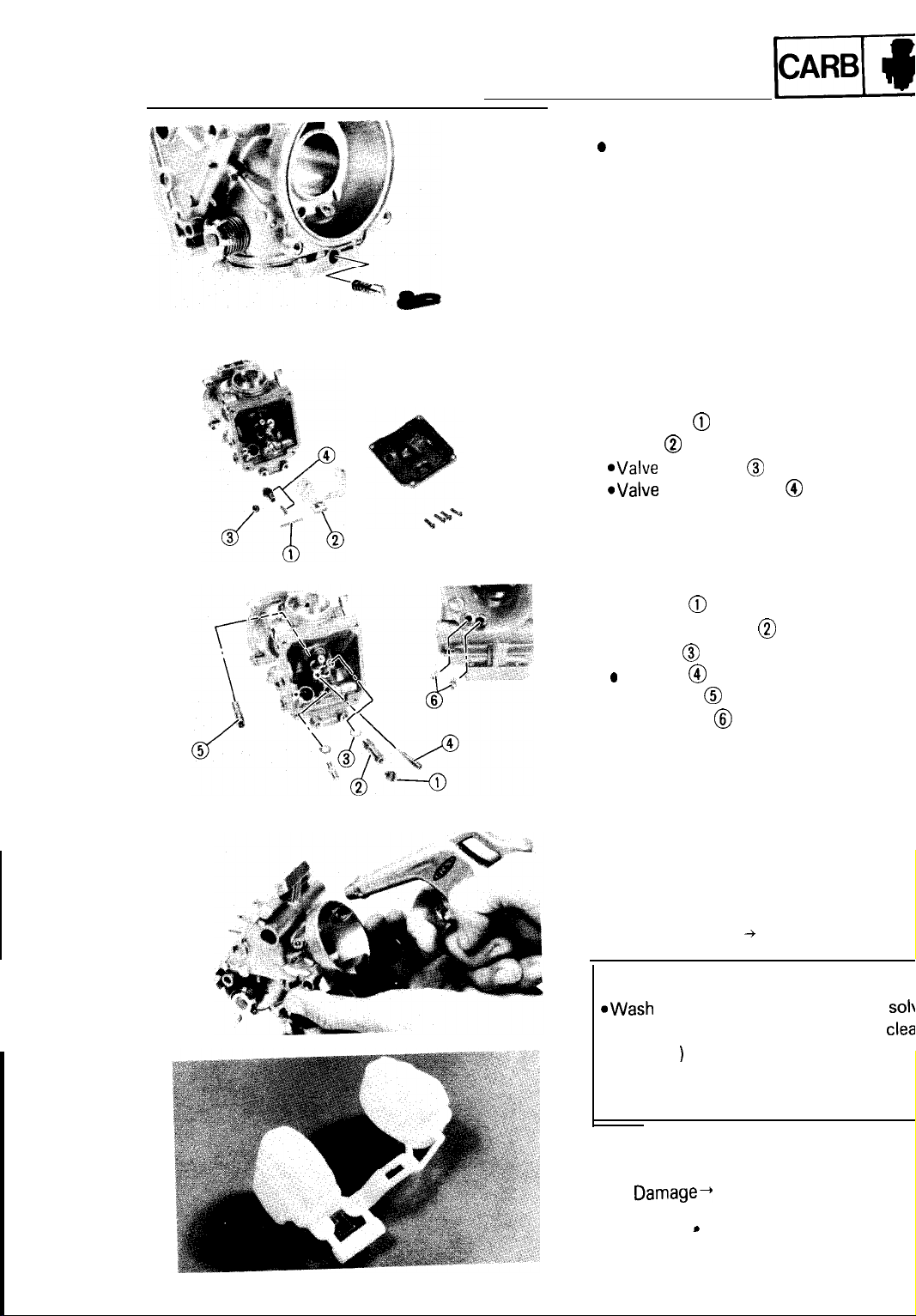

5. Remove:

0

Pilot screw

6. Remove:

?? Float chamber cover

*Gasket

*Float pin

*Float

@Valve

*Valve

@

@

seat screw

seat assembly

@

@

7. Remove:

??

Main jet

@

?? Holder (Main jet)

??

Washer

@

0

Pilot jet

?? Needle jet

??

0

@

Pilot air jet

@

8

INSPECTION

1. Inspect:

?? Carburetor body

?? Float chamber

??

Fuel passage

Contamination + Clean as indicated.

Carburetor cleaning steps:

*Wash

carburetor in petroleum based

(Do not use any caustic carburetor

solution.

*Blow out all passages and jets with a

pressed air.

1

sol\

clea

6-6

2. Inspect:

??

Floats

Damage4

Replace.

CARBURETOR

~CARB~ j@ 1

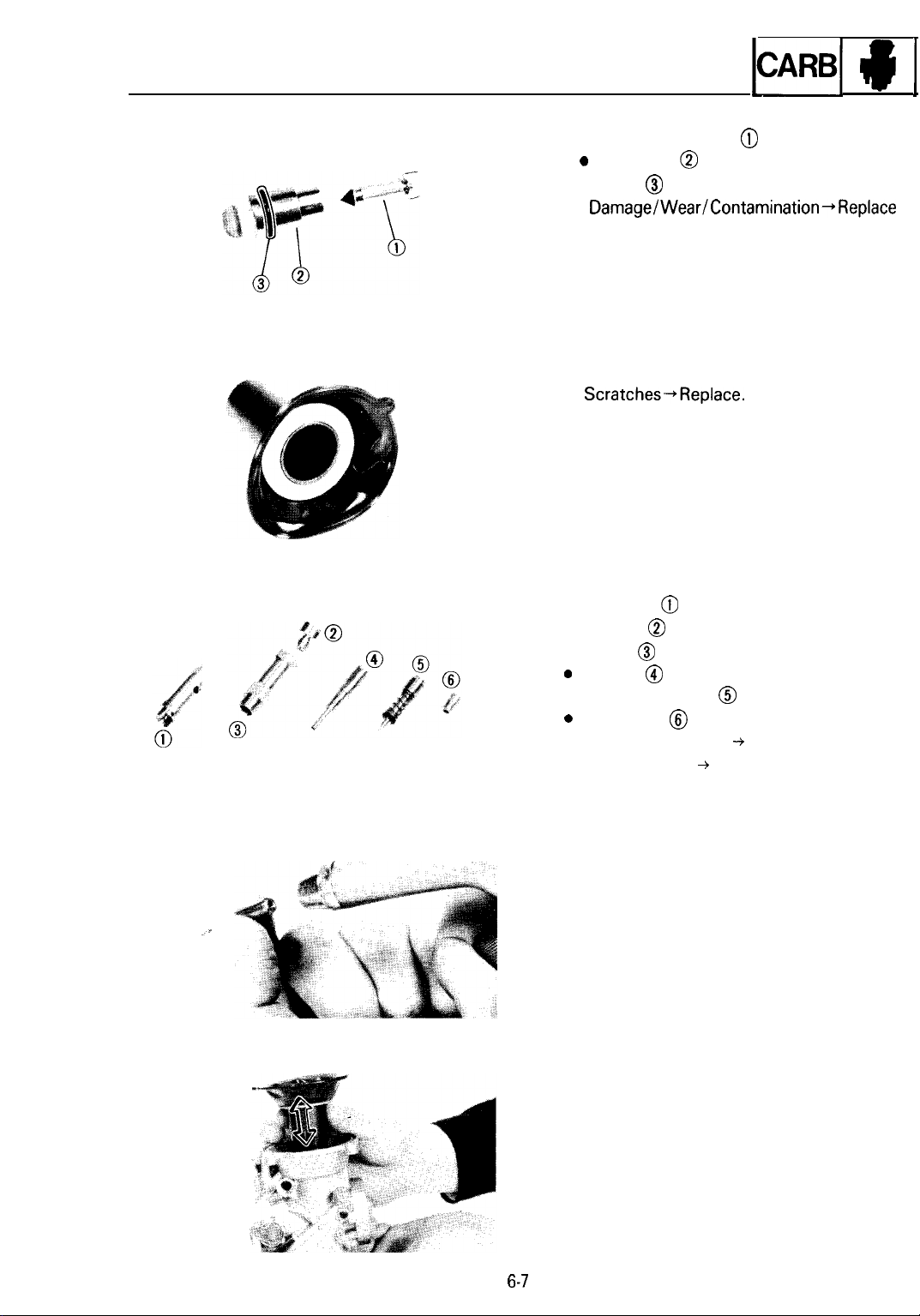

3. Inspect:

*Float needle valve

0

Valve seat

??

O-ring

@

@

@

Damage/Wear/Contamination+Replace

a set.

4. Inspect:

*Throttle valve

Scratches-+Replace.

*Rubber diaphragm

Tears+ Replace.

as

5. Inspect:

??

Needle jet

?? Main jet

?? Holder

0

Pilot jet

??

Pilot adjust screw

0

Pilot air jet

@

@

@

@

@

@

Bends/Wear/Damage -+ Replace.

Contamination + Blow out jets with a

compressed air.

6. Check:

*Free movement

Insert the throttle valve into the carburetor

body, and check for free movement.

Stick- Replace.

6-7

CARBURETOR

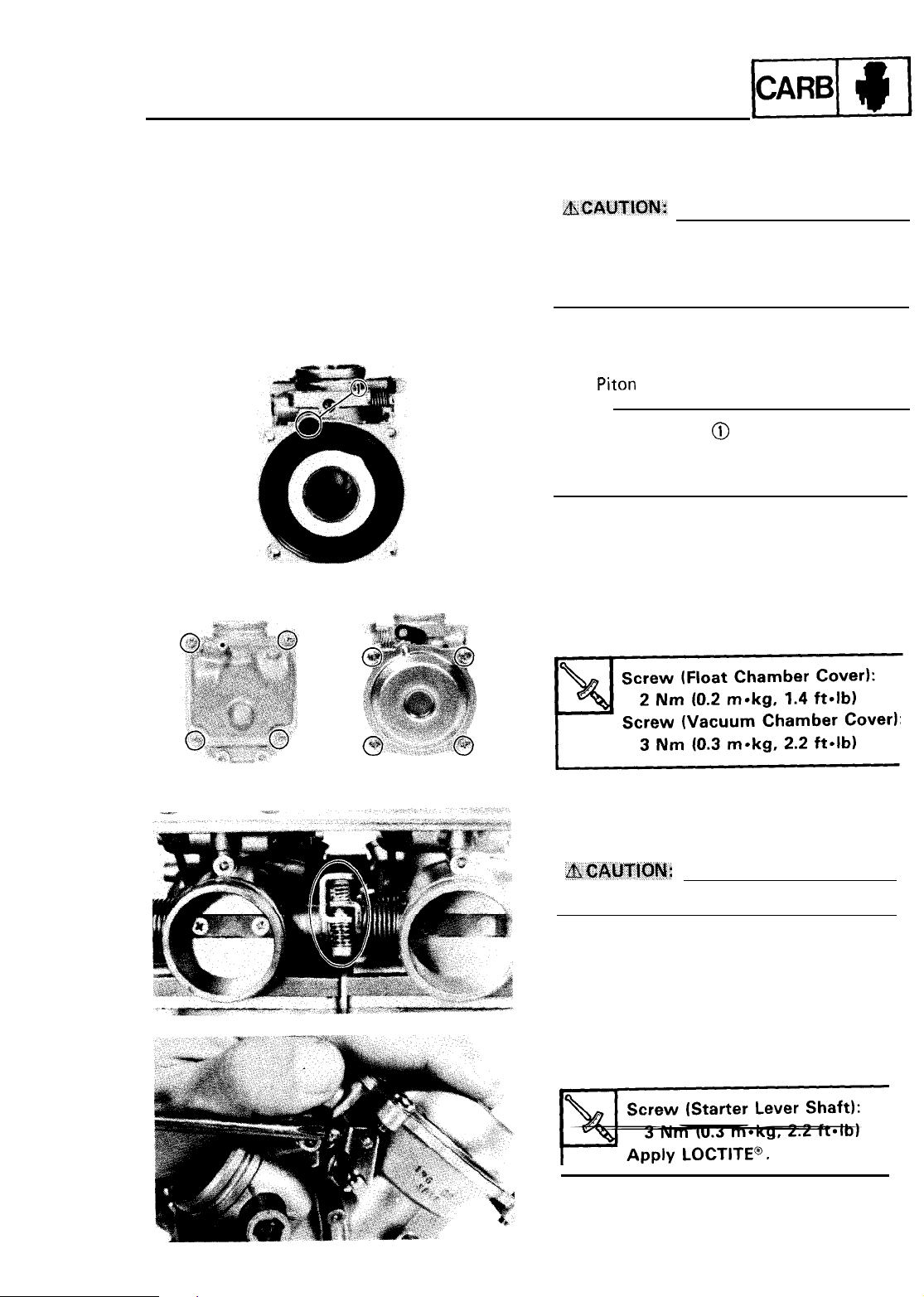

ASSEMBLY

To assemble the carburetor, reverse the disassembly procedures. Note the following points.

??

Before reassembling, wash all parts in clean

gasoline.

??

Always use a new gasket.

1. Install:

??

Piton valve assembly

NOTE:

Note position of tab @ on diaphragm. This tab

must be placed in the cavity of the carburetor

body during reassembly.

2. Install:

??

Float chamber cover

*Vacuum chamber cover

3. Connect:

??

Throttle shaft

Throttle valves must be fully closed.

4. Install:

??

Starter lever shaft

CARBURETOR

pg-j

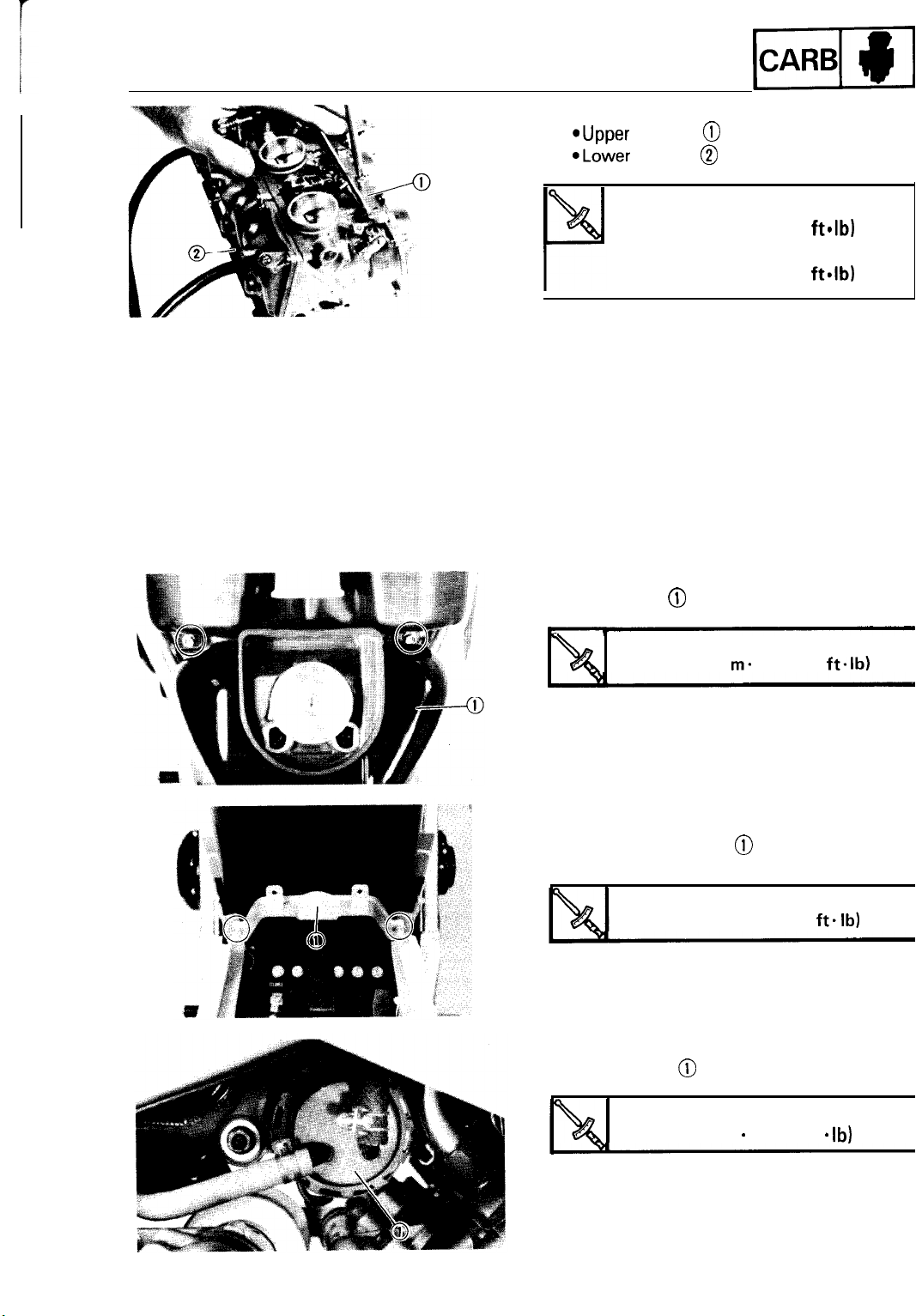

5. Installer:

*Upper

glower

INSTALLATION

Reverse the “REMOVAL” procedure.

Note the following points.

bracket

bracket

@

@

Screw (Upper Bracket):

3 Nm (0.3 m-kg, 2.2

Screw (Lower Bracket):

5 Nm (0.5 m-kg, 3.6

ftelb)

ft.lb)

1. Install:

?? Fuel tank

@

Bolts (Fuel Tank):

14 Nm (1.4 ma kg, 10.2

2. Install:

?? Fuel tank bracket

Bolts (Fuel Tank Bracket):

10 Nm (1.0 m-kg, 7.2

3. Install:

?? Fuel pump

@

ft- lb)

@

ft.lb)

6-9

Bolt (Fuel Pump):

8 Nm (0.8 m -kg,

5.6 ft -

lb)

m

I &

n.5-6.5mm

CARBURETOR

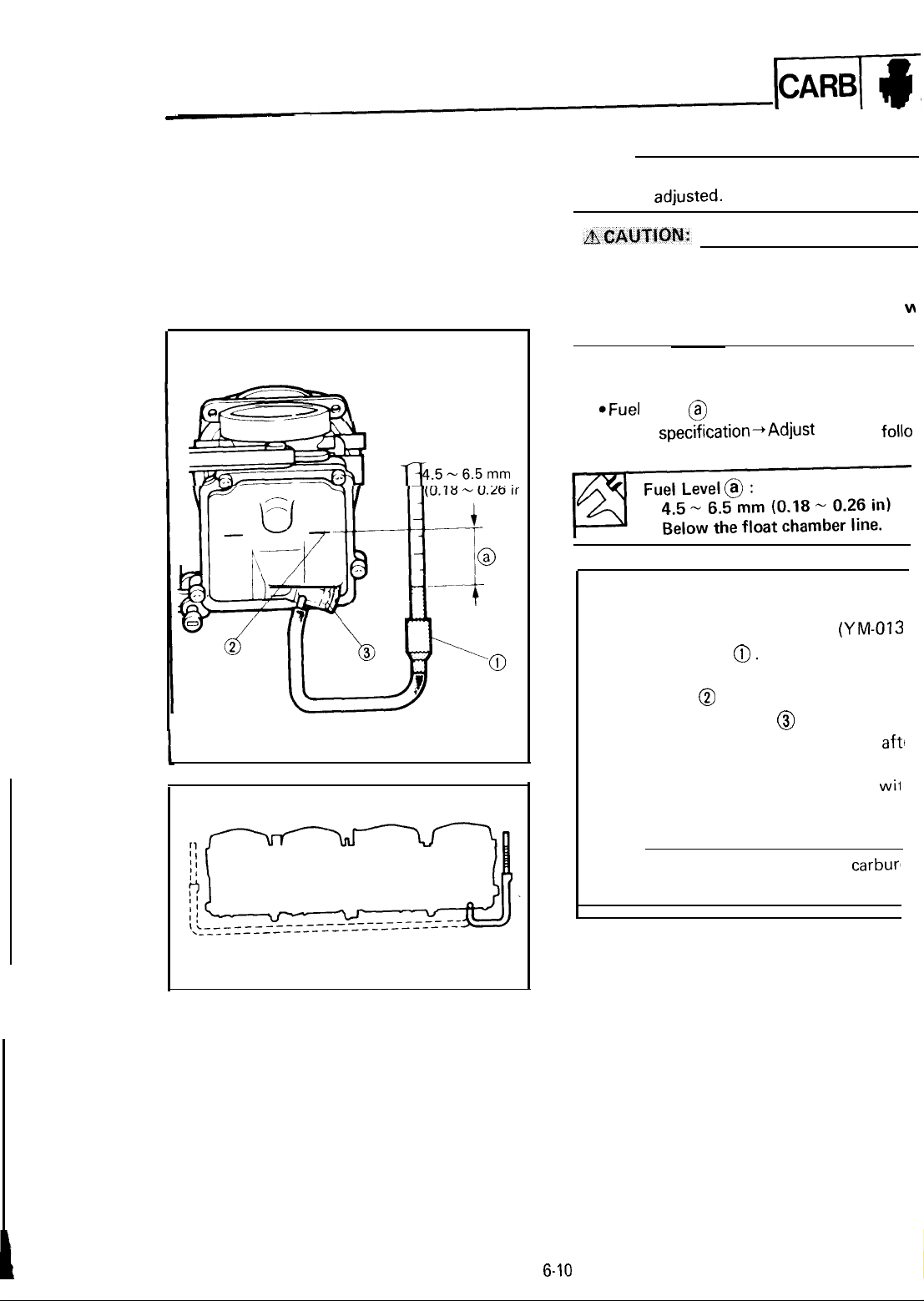

ADJUSTMENT

NOTE:

Before adjusting the fuel level, the float heigl

should be

The pilot screw settings are adjusted f

maximum performance at the factory. A

attempt to change these settings

decrease enaine performance.

Fuel Level Adjustment

1. Measure:

.Fuel

adlusted.

level

@

Out of

specification+Adjust

ing adjustment steps.

it by the

folio

\II

Fuel level measurement steps:

?? Place the motorcycle on the level place.

?? Connect the Fuel Level Gauge

to the carburetor

?? Place the Gauge vertically next to the fl

chamber line @ .

?? Loosen the drain screw

?? Warm up the engine, then shut it off

few minutes.

?? fvleasure the fuel level. It should be

the specified range.

NOTE:

Fuel level readings of both side of

line should be equal.

0.

@

(YM-013

.

aft!

wii

carburN

6-10

CARBURETOR

(CARBI

2. Adjust:

??

Fuel level

Fuel level adjustment steps:

*Remove the carburetor assembly.

Refer to “REMOVAL” section.

*Remove the float, valve seat and the needle

valve.

??

inspect the valve seat and the needle valve.

If either is worn, replace as a set.

*If both are fine, adjust the float height by

bending the float tang

@Recheck the fuel level.

0.

6-11

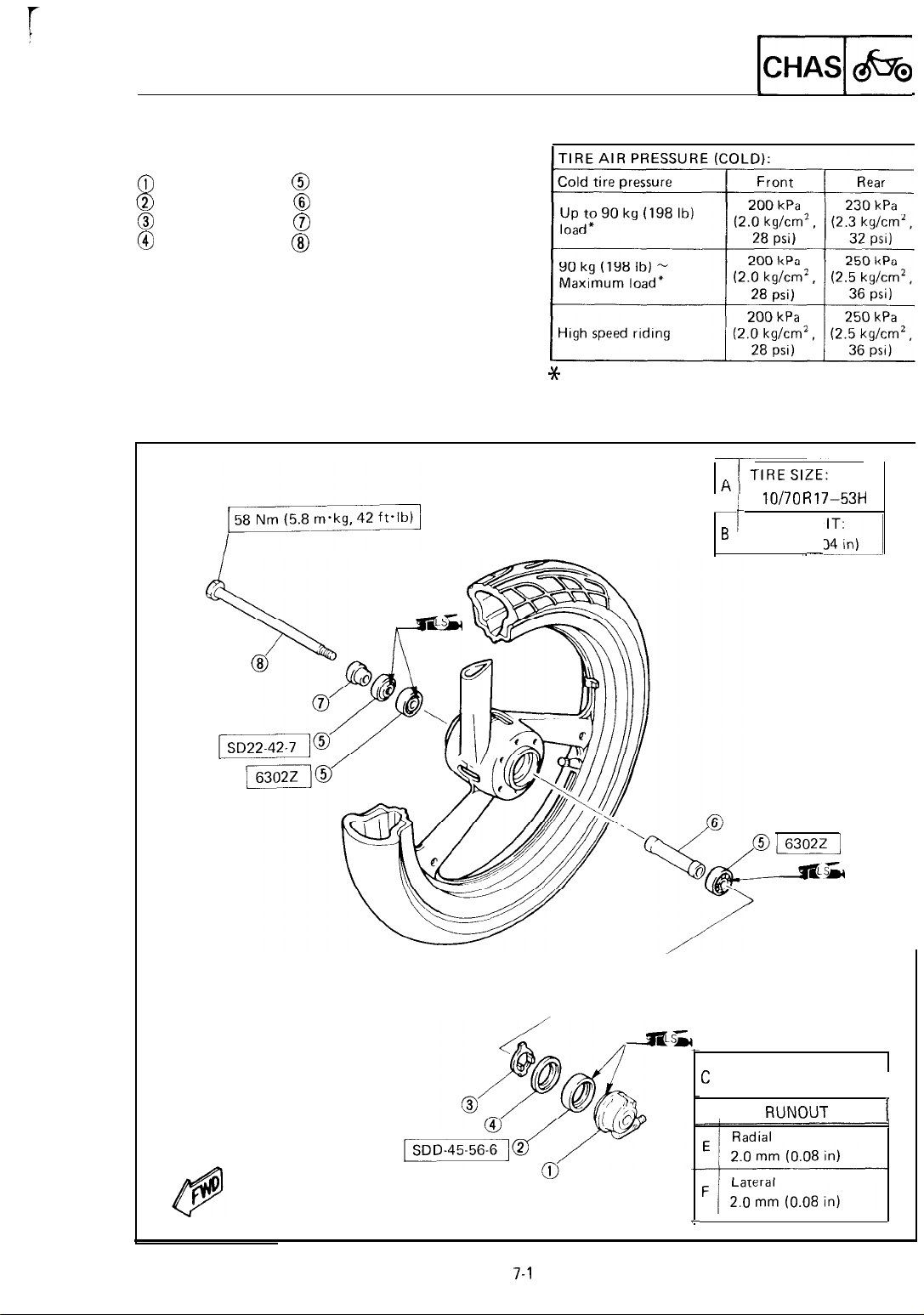

FRONT WHEEL

@

Gear unit assembly @ Bearing

@

Oil seal

@

Meter clutch

@

Clutch retainer

@

Spacer

@

Collar

@

Wheel axle

CHASSIS

*

Load is the total weight of cargo, rider, passenger,anc

accessories.

FRONT WHEEL

-1

r

B

i 1.0 mm (0.04 in)

pii&G

1

lo/70 R17-53H

WEAR LIMIT:

-

i

1

7-l

1 RIM SIZE:

’

i MT3.00 X 17

D / RIM

I

-

RUNOUT

LIMIT:

I

/

FRONT WHEEL

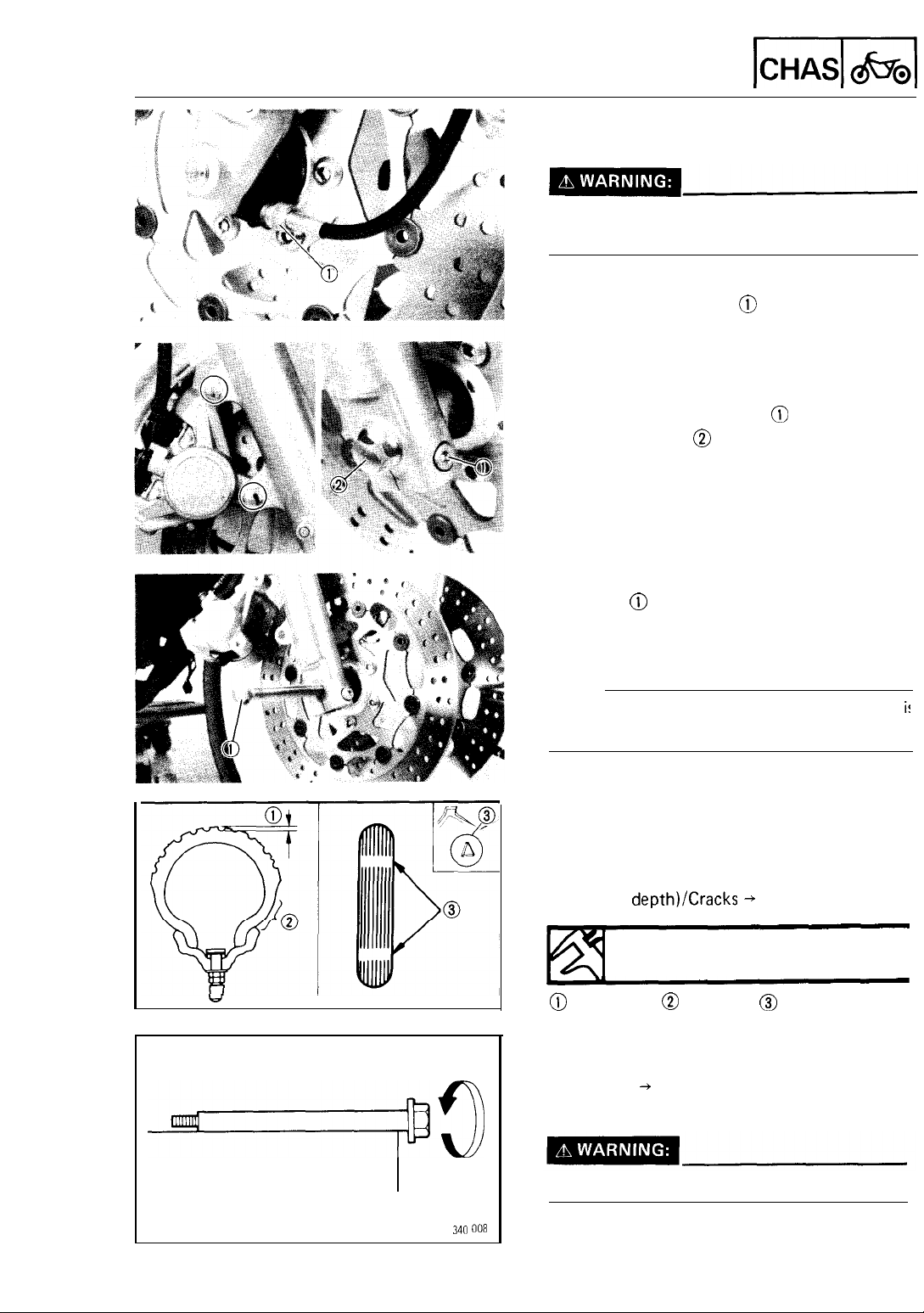

Ml

REMOVAL

1. Place the motorcycle on a level place.

Securely support the motorcycle so there is no

danger of it falling over.

2, Remove:

?? Speedometer cable

3. Remove:

?? Brake calipers (Right/Left)

4. Loosen:

?? Pinch bolt (Front axle)

?? Axle (Front)

5. Elevate the front wheel by placing a suitablt

stand under the engine.

@

@

@

6. Remove:

??

Axle

@

?? Wheel (Front)

??

speedometer gear unit

NOTE:

Do not squeeze the brake lever while the wheel

off the motorcycle.

INSPECTION

1. Inspect:

??

Tire

Tire tread shows crosswise lines (minimun

tread

depth)/Cracks +

Minimum Tire Tread Depth:

1.0 mm (0.04 in)

w

I I

@

Tread depth @ Side wall @ Wear indicator

2. Inspect:

?? Front axle

Bends + Replace.

Roll the axle on a flat surface.

Repalce.

i!

dcl

34”

“08

Do not attempt to straighten a dent axle.

7-2

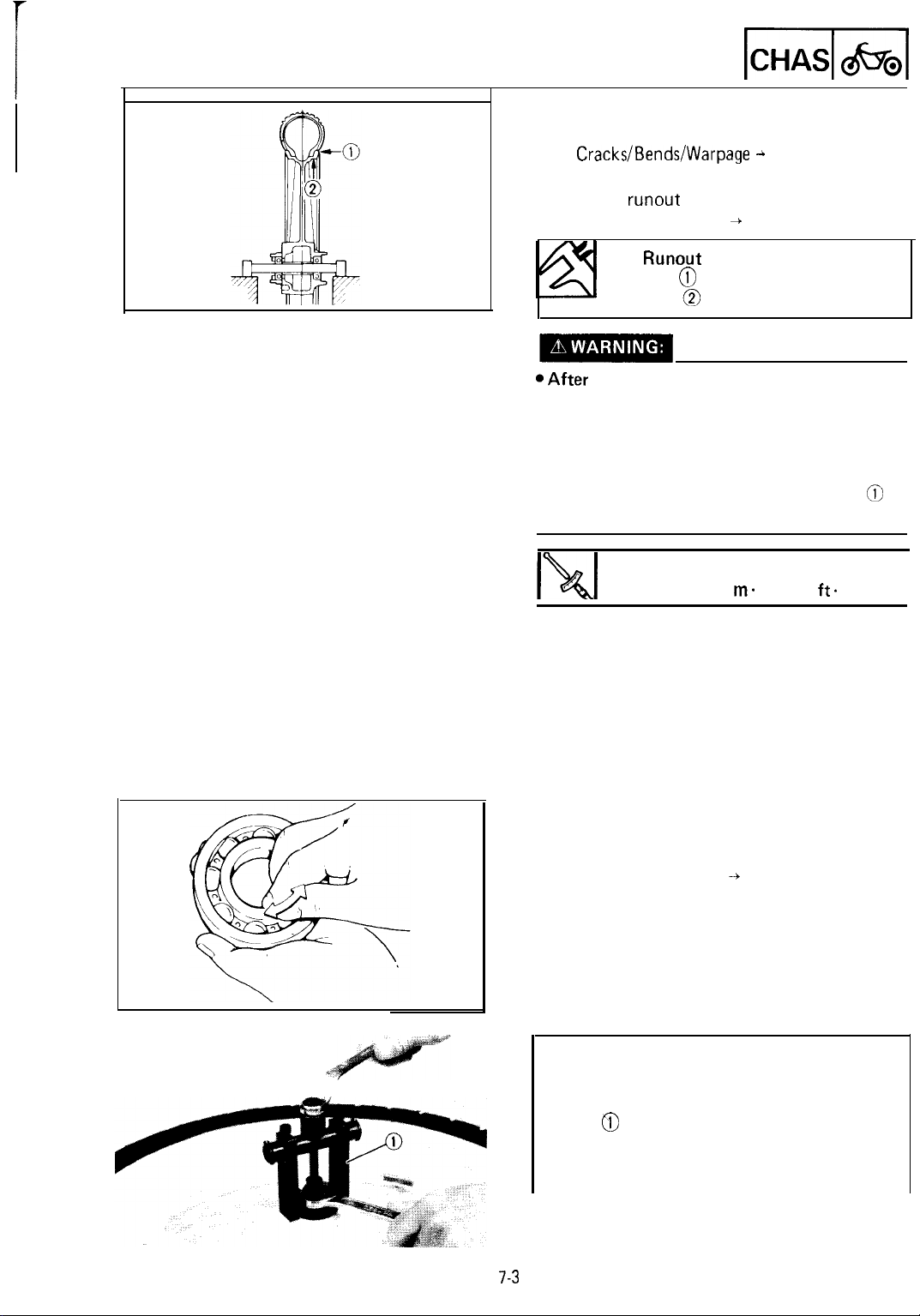

r

FRONT WHEEL

3. Inspect:

??

Wheel

Cracks/Bends/Warpage A

4. Measure:

??

Wheel

runout

Over specified limit + Repalce.

Rim

Runout

Radial @ : 2.0 mm (0.08 in)

Lateral @ : 2.0 mm (0.08 in)

@After

mounting a tire, ride conservatively to

allow proper tire to rim seating. Failure to do

so may cause an accident resulting in motor-

cycle damage and possible operator injury.

?? After a tire repair or replacement, be sure to

torque tighten the valve stem locknut @ to

specification.

-1

Replace.

Limits:

Valve-stem Locknut:

1.5 Nm (0.15

5. Inspect:

??

Wheel bearings

Bearings allow play in the wheel hub or

wheel turns roughly + Repalce.

Wheel bearing replacement steps:

?? Clean the outside of the wheel hub.

?? Remove the bearing using a general bearing

puller @I .

?? Install the new bearing by reversing the

previous steps.

rn.

kg, 1.1

ft.

lb)

I

7-3

Loading...

Loading...