Yamaha FZR400 Service Manual Ch89

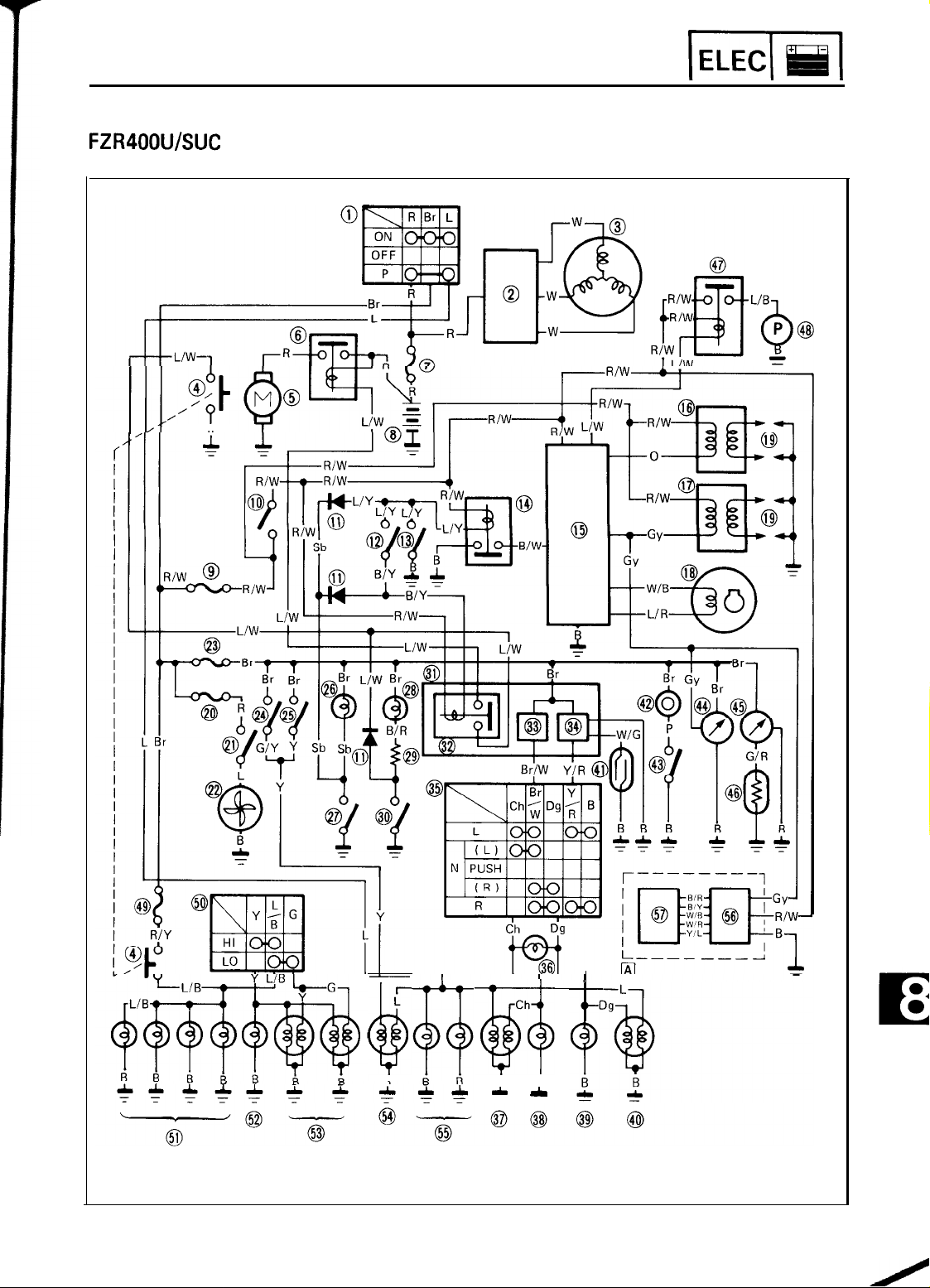

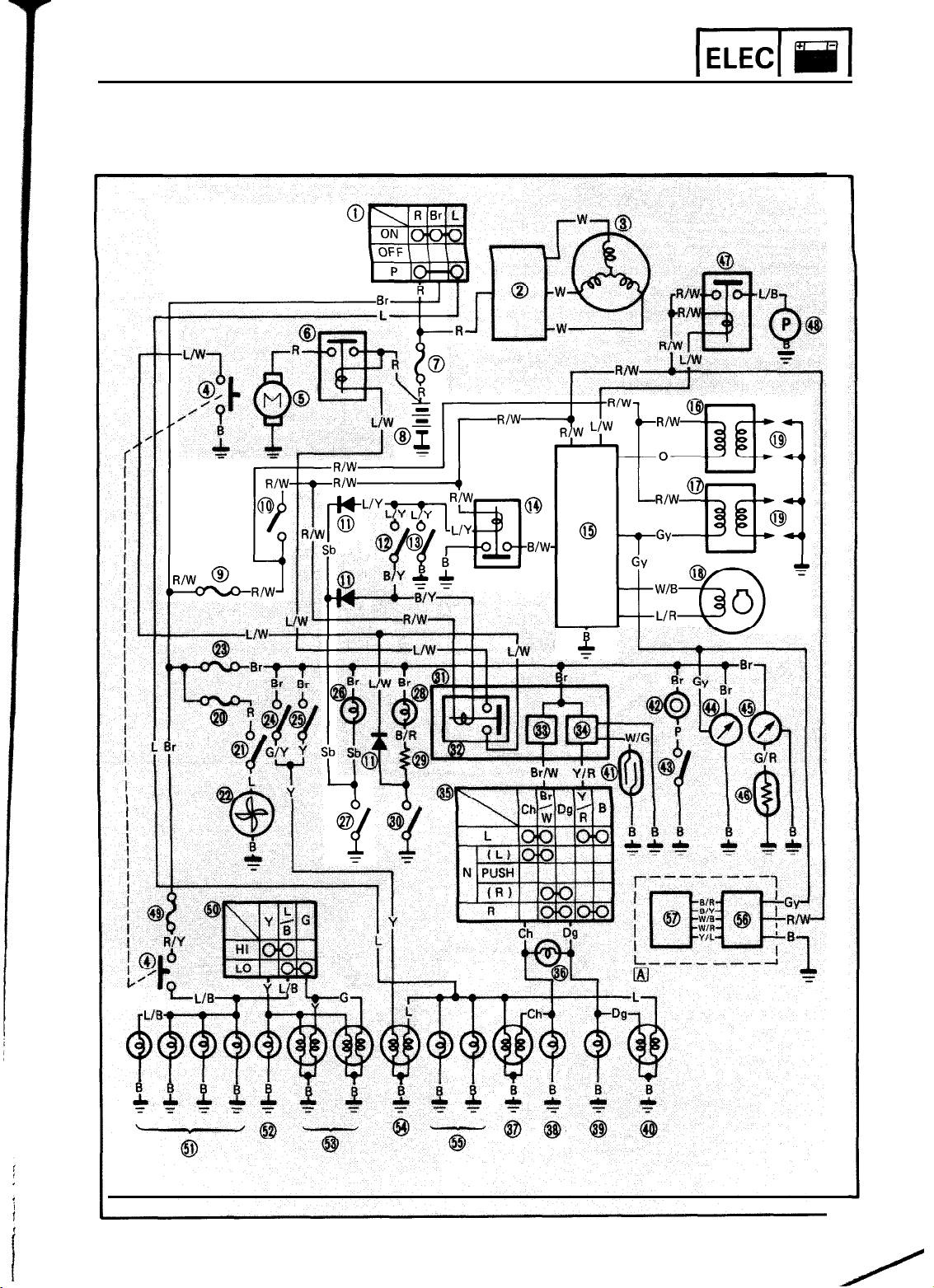

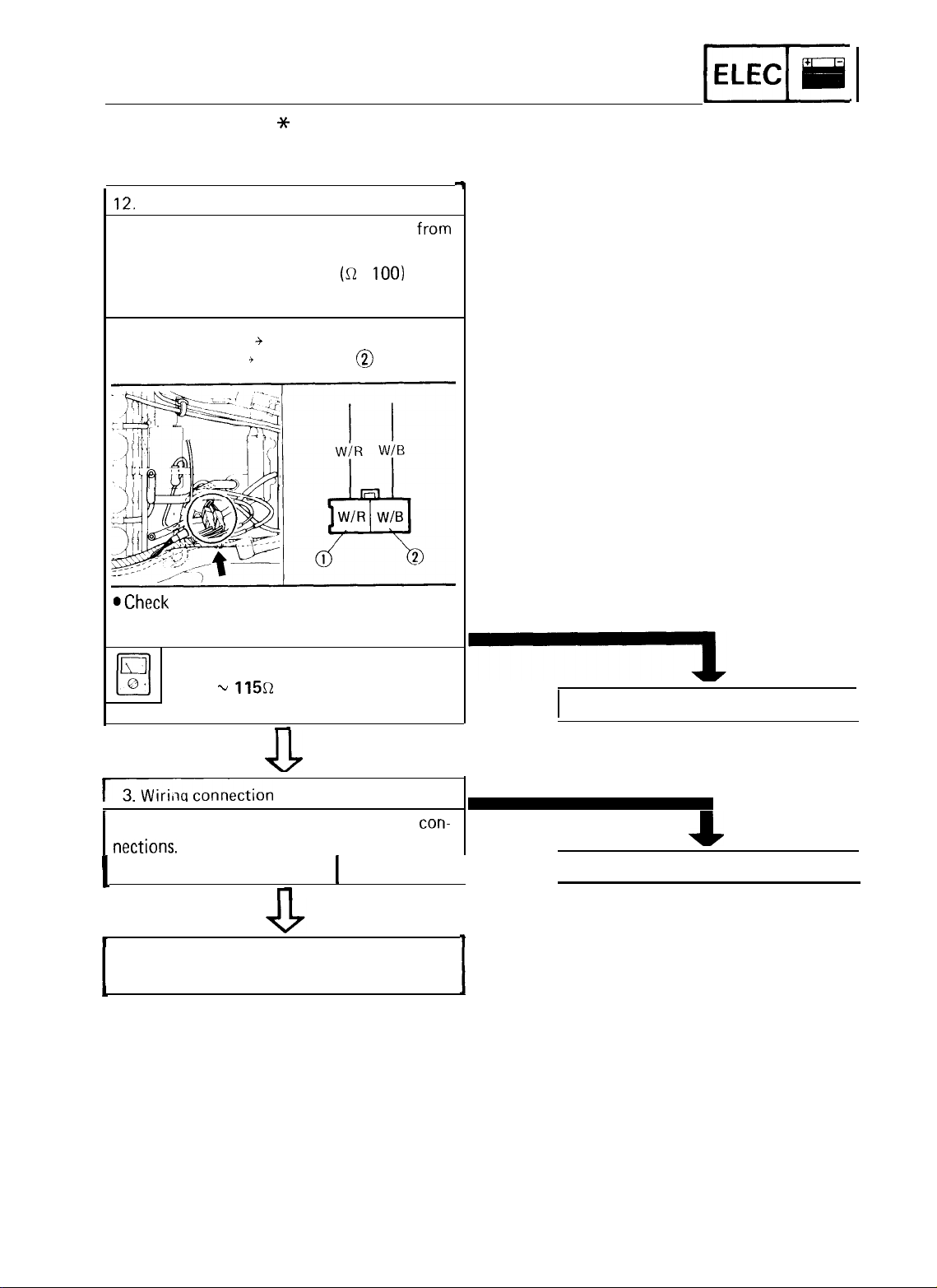

CIRCUIT DIAGRAM

ELECTRICAL

wELEC(

FZR400WSUC

,,q

B

CIRCUIT DIAGRAM

I

L

6

B

8-l

@

B B

IL A

Ch

@

Main switch

@

Rectifier/Regulator

@

A.C. generator

@

“START” switch

@

Starter motor

@

Starter relay

@

Fuse “MAIN”

@

Battery

@

Fuse “IGNITION”

@

“ENGINE STOP” switch

@

Diode block

@I

Clutch switch

@

Sidestand switch

@

Ignition circuit cut-off relay

@

Digital ignitor unit

@

Ignition coil

@

Ignition coil

@

Pickup coil

@ Spark plug

@

Fuse “FAN”

@ Therm0

@

Fan motor

@

Fuse “SIGNAL”

@

Front brake switch

@

Rear brake switch

@

“NEUTRAL” indicator light

@,)

Neutral switch

@ “01

L” indicator light

@

Resistor

@!

Oil level switch

@

Relay assembly

switch

(#l

and #4 cylinder)

(#2

and #3 cylinder)

\ELECl

CIRCUIT DIAGRAM

@?

Starting circuit cut-off relay

@

Flasher relay

@

Cancelling unit

@

“TURN” switch

@

“TURN” indicator light

@

Front position light/Flasher light (Left)

@

Rear flasher light (Left)

@

Rear flasher light (Right)

@

Front position light/Flasher light (Right)

@

Reed switch

@

Horn

@?

“HORN” switch

@

Tachometer

@

Temp meter

@ Therm0

@

Fuel pump relay

@I

Fuel pump

@

Fuse “HEAD”

@?

“LIGHTS” (Dimmer) switch

@

Meter light

@

“HIGH BEAM” indicator light

@

Headlight

@

Tail/Brake light

@

License light

@I

EXUP control unit

@

EXUP servomotor

unit

m]

?? For California only

COLOR CODE

0

R Red

L Blue

Br

B

Y Yellow

W

G Green

P

DC3

Ch

GY

Sb

Orange

Brown

-

Black

White

Pink

Dark green

Chocolate

Gray

Sky blue

Y/R

Br/W

R/W

R/Y

-

B/R

B/W

B/Y

L/W

L/B

L/Y

G/Y

W/R

WIG

B-2

Yellow/Red

Brown/White

Red/White

Red/Yellow

Black/Red

Black/White

Black/Yellow

Blue/White

Blue/Black

Blue/Yellow

Green/Yellow

White/Red

White/Green

-.

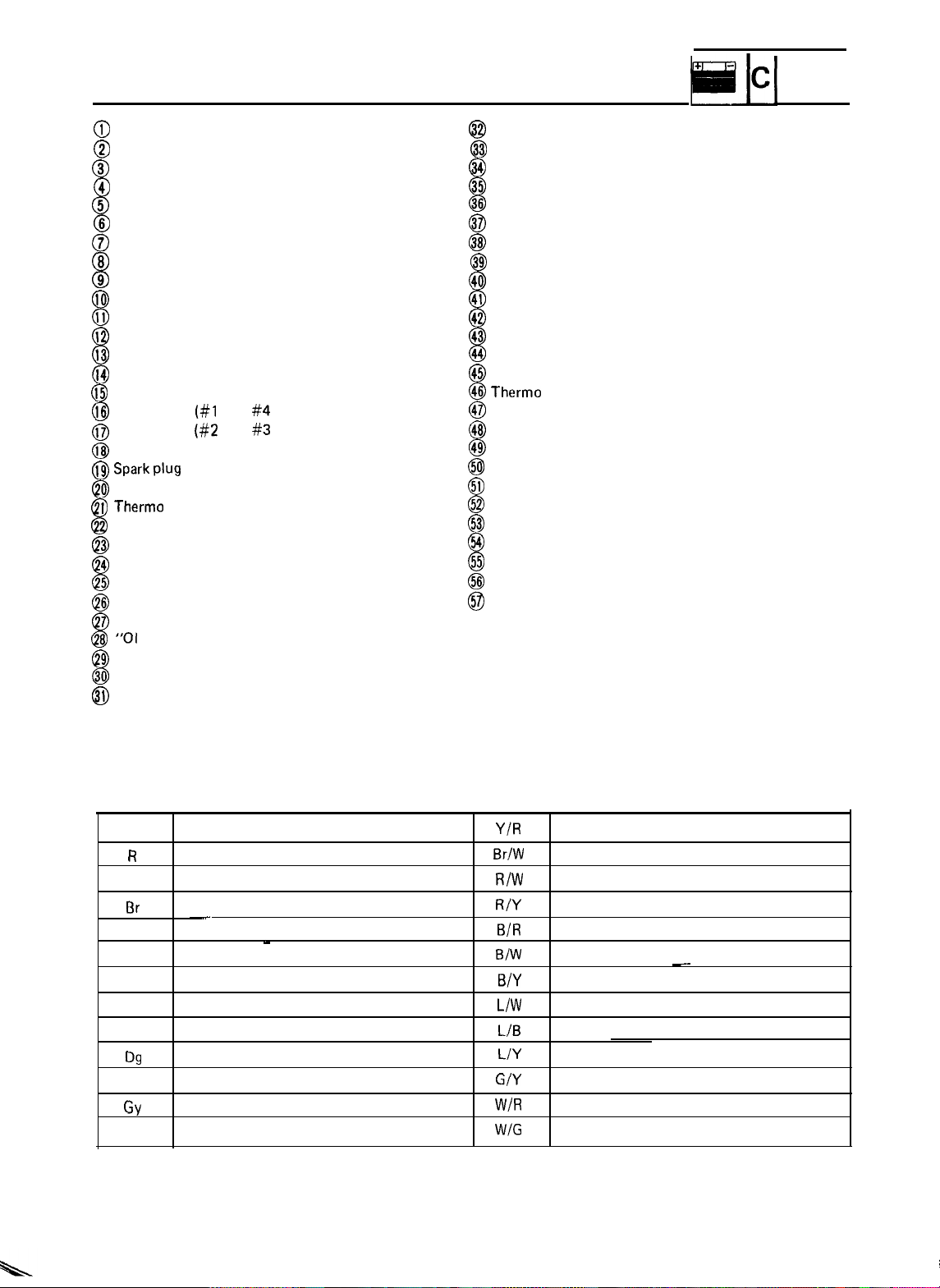

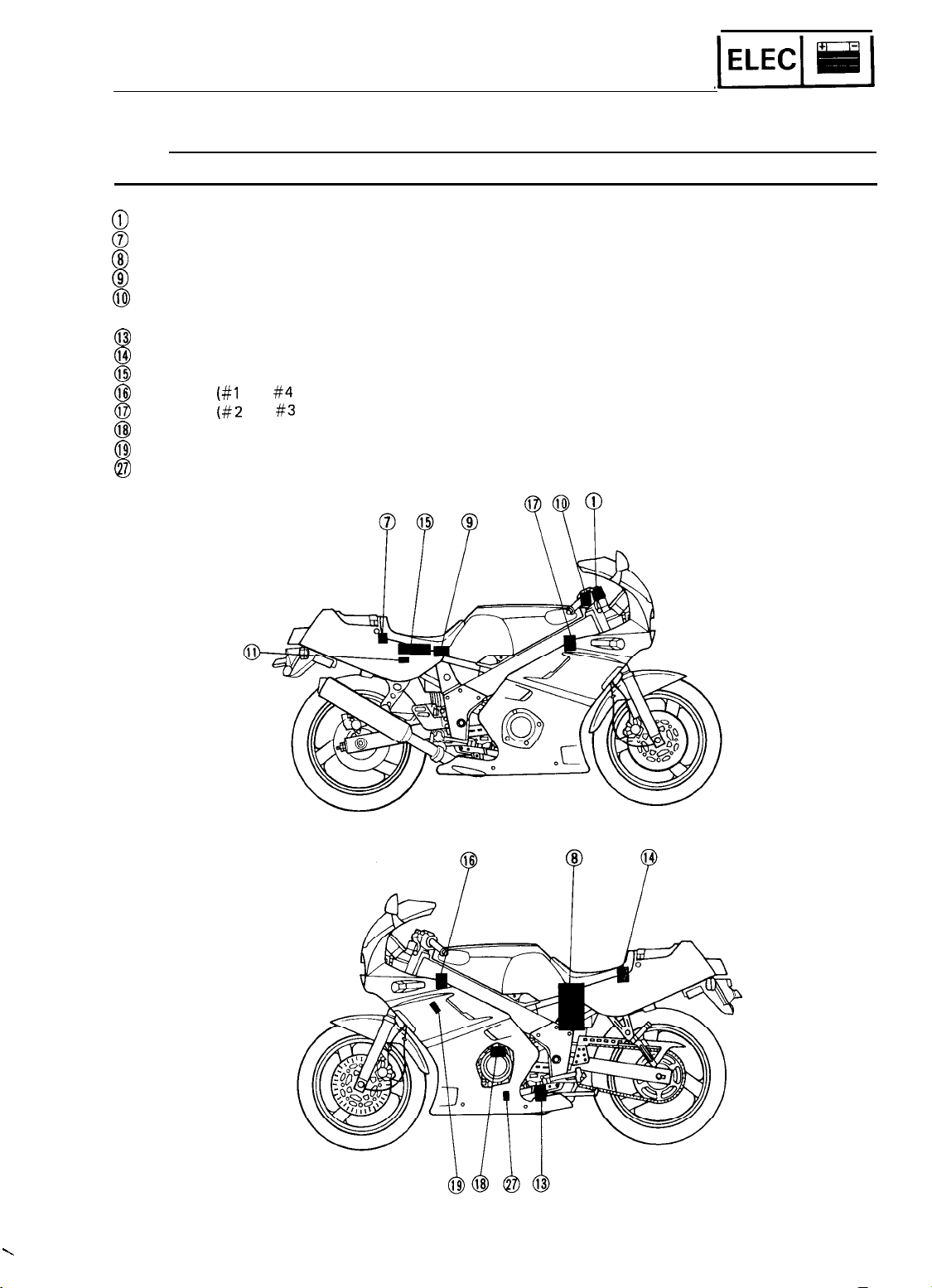

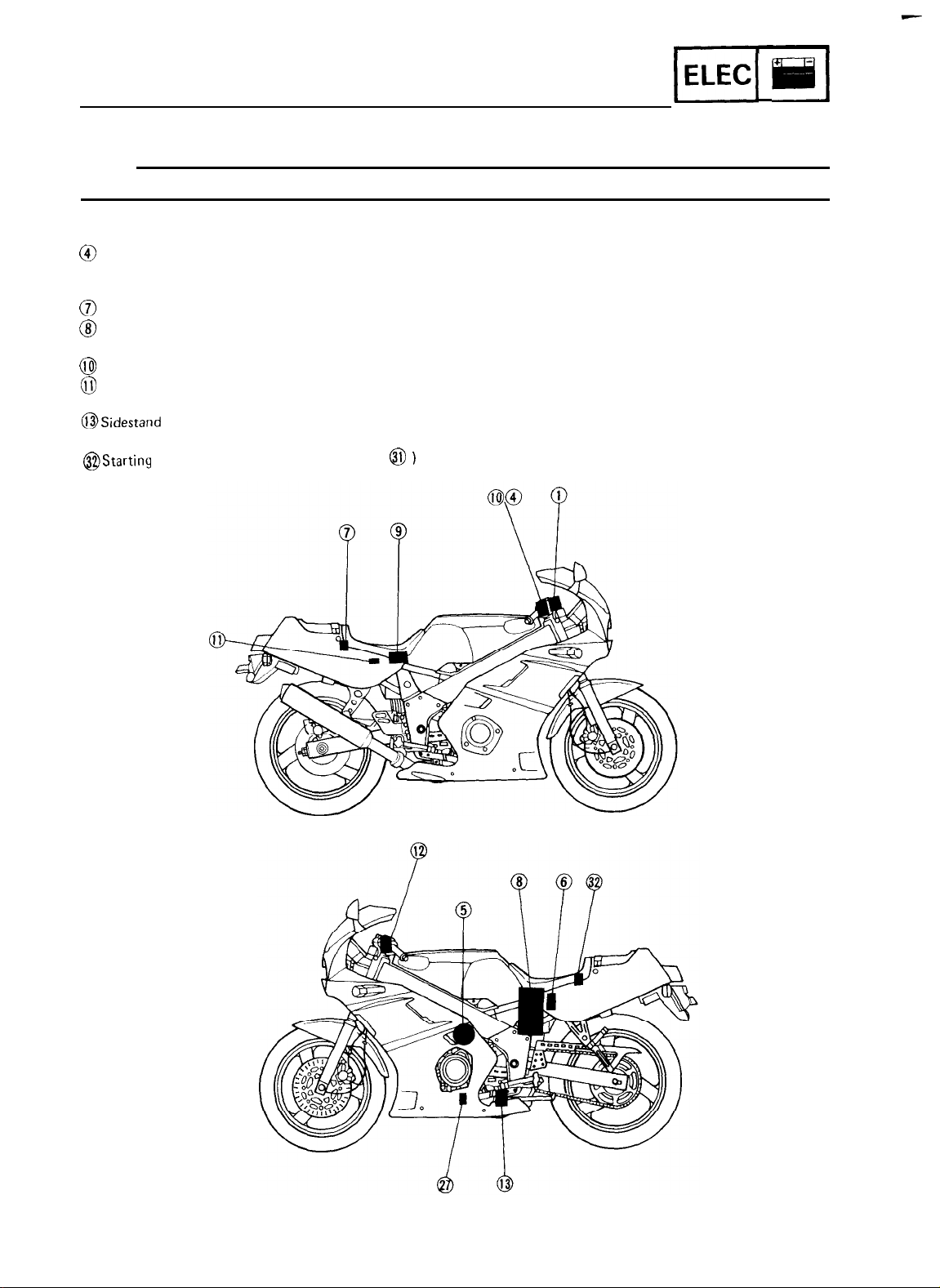

ELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS (1)

@Therm0

@Th

@

Relay assembly

@

Fuel pump relay

@Horn

@Oil

@

Neutral switch

@

Sidestand switch

switch

ermo unit

level switch

@

Sidestand relay

@

EXUP control unit

(For California only)

$j)

ServOmOtOr

EXUP

(For California only)

8-3

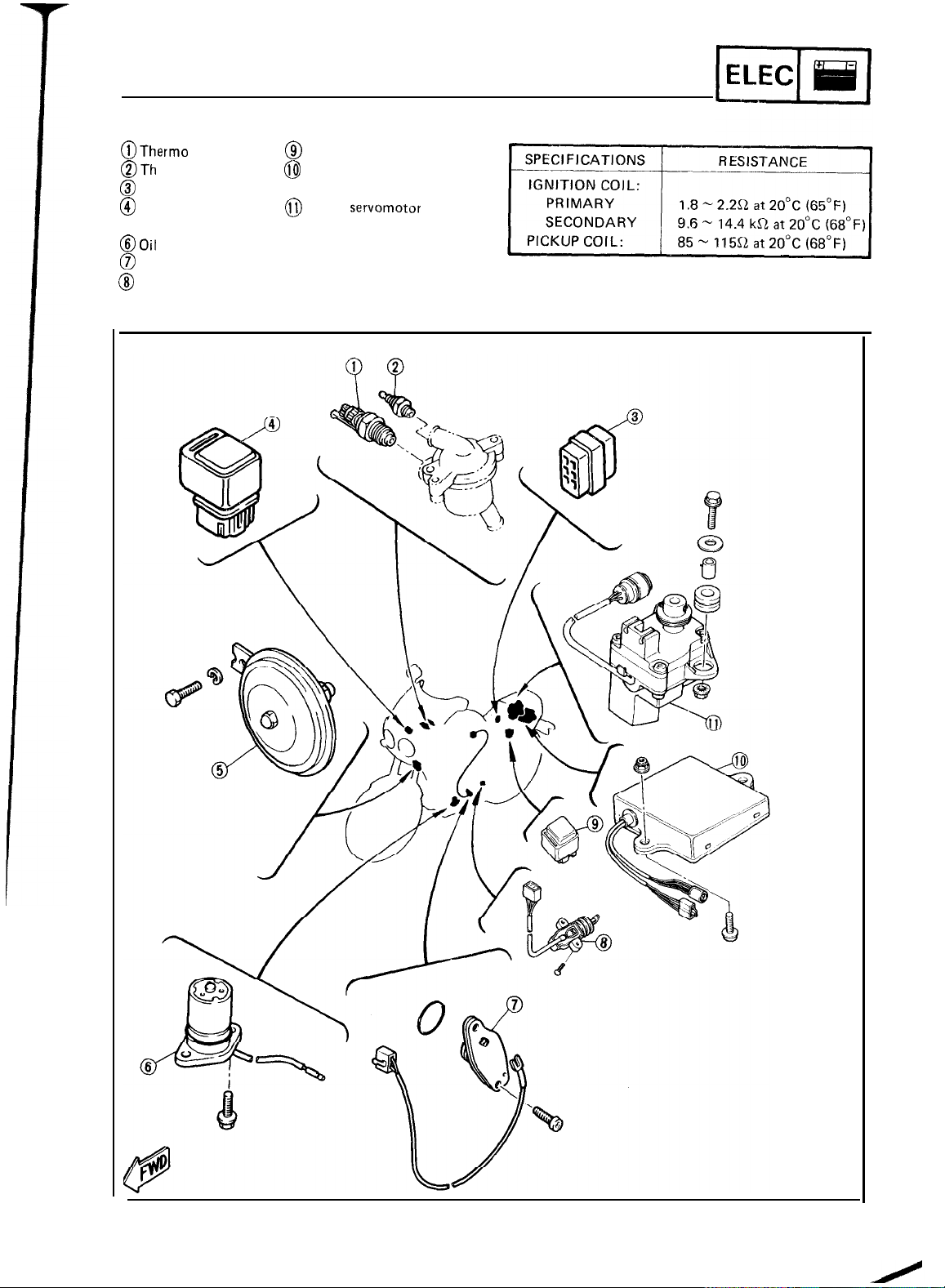

ELECTRICAL COMPONENTS

\ELEC( m]

ELECTRICAL COMPONENTS

@

Wireharness

@

Rear brake switch

@

Diode block

@Fuse “MAIN”

@Main switch

@Ignition coil

@Plug

cap

@Battery

@Starter relay

@Rectifier/Regulator

@Digital

(2)

ignitor unit

B-4

\I I” 112V,RAH

CHECKING OF SWITCHES

CHECKING OF SWITCHES

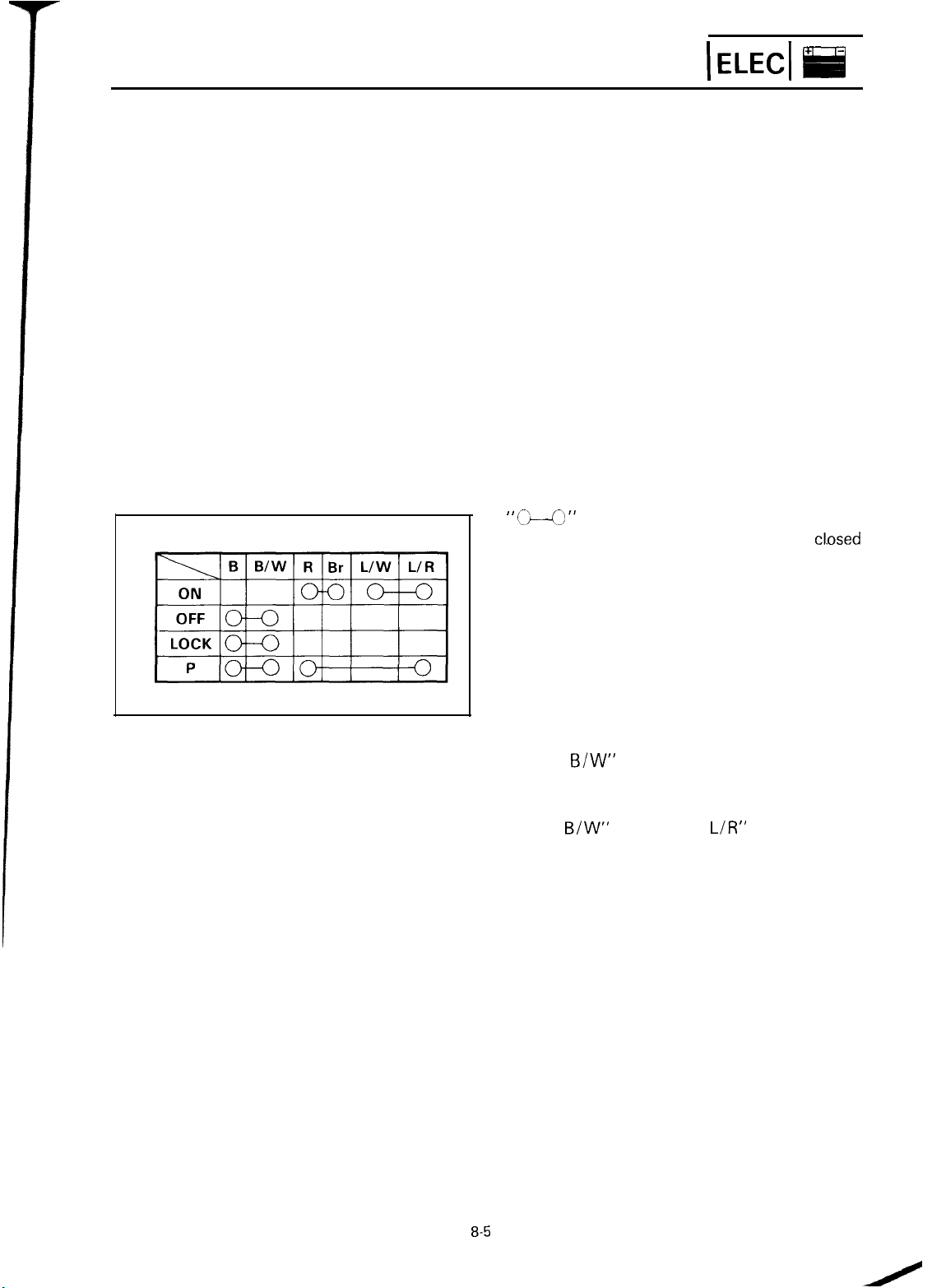

Check the switches for the continuity between

the terminals to determine correct connection.

Read the following for switch inspection.

SWITCH CONNECTION AS SHOWN IN

MANUAL

The manual contains a connection chart as shown

left showing the terminal connections of the

switches (e.g.,

brake switch, lighting switch, etc.)

The extreme left column indicates the switch po-

sitions and the top line indicates the colors of

leads connected with the terminals in the switch

component.

main switch, handlebar switch,

IELECI Eii

I

“C’&-0”

there is a continuity of electricity; i.e., a

circuit at the respective switch positions.

In this chart:

“R and Br” and “L/W and L/R” are continuous

with the “ON” switch position.

“B and B/W” is continuous with the “OFF”

switch position.

“B and

switch position.

“B and

with the “P” switch position.

indicates the terminals between which

cl.osed

B/W”

is continuous with the “LOCK”

B/W”

and “R and

L/R”

are continuous

CHECKING SWITCH FOR TERMINAL

CONNECTION

Before checking the switch, refer to the connec-

tion chart as shown above and check for the cor-

rect terminal connection (closed circuit) by the

color combination.

To explain how to check the switch, the main

switch is taken for example in the following.

8-5

_I-

CHECKING OF SWITCHES

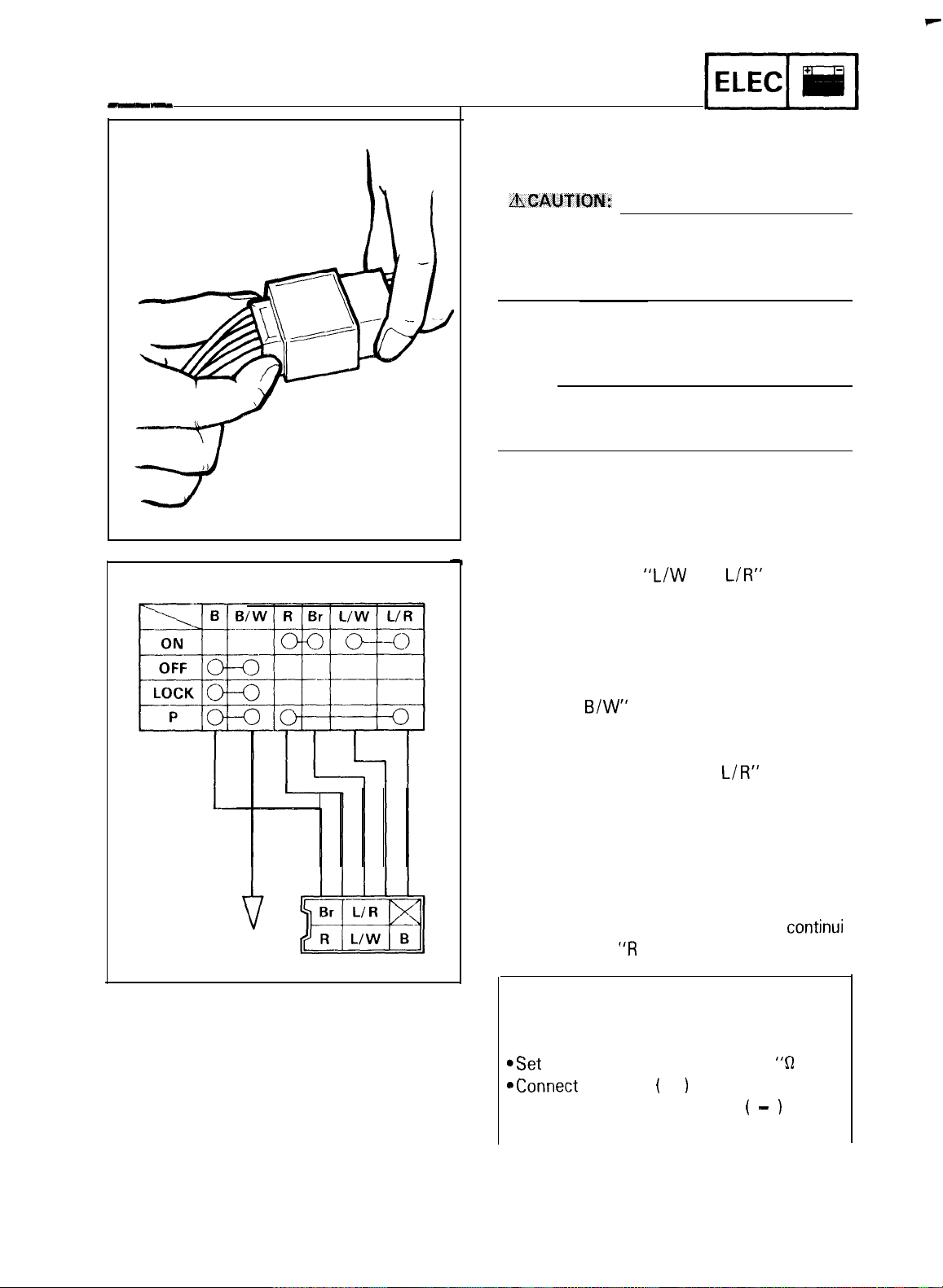

1. Disconnect the main switch coupler from the

wireharness.

Never disconnect the main switch coupler

by pulling the leads. Otherwise, leads may

be pulled off the terminals inside the coupler.

2. Inspect whether any lead is off the terminal

inside the coupler. If it is, repair it.

NOTE:

If the coupler is clogged with mud or dust, blow

it off by compressed air.

3. Use the connection chart to check the color

combination for continuity (a closed circuit).

In this example, the continuity is as follows.

“R and Br” and

ous with the “ON” switch position.

“B and B/W” is continuous with the “OFF”

switch position.

“B and

switch position.

“B and B/W” and “R and

ous with the “P” switch position.

Please note that there is no continuity (an

open circuit) at all for the color combinations

other than the above.

4. Check the switch component for the continui

ty between “R and Br”.

Checking steps:

??

“LOCK”, and “P” several times.

*Set

aConnect the tester ( + ) lead to the “R” lead

terminal in the coupler and the ( - 1 lead to

the “Br” lead terminal.

B/W”

Turn the switch key to the “ON”, “OFF”,

the pocket tester selector to the ‘9 x 1”.

“L/W

and

L/R”

are continu-

is continuous with the “LOCK”

L/R”

are continu-

8-6

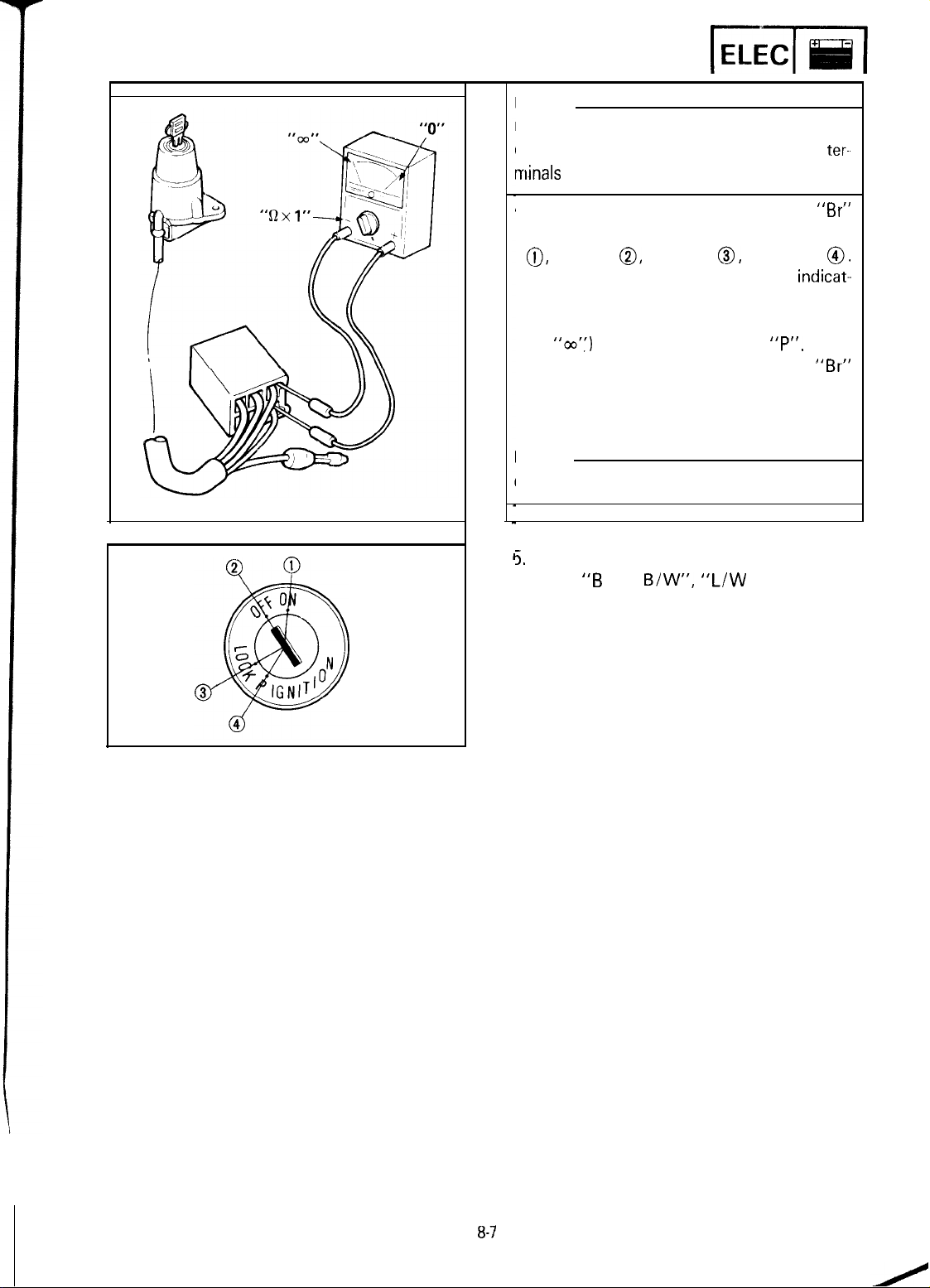

CHECKING OF SWITCHES

NOTE:

Use thin probes for checking the continuity.

Otherwise, the probes may contact other

minals

inside the coupler.

IiL-iii~

ter--

*Check the continuity between “R” and

at the respective switch positions of “ON”

0,

“OFF”

There must be continuity (the tester

ing “0”) at the “ON” switch position, and

there must be no continuity (the tester indicat-

ing

“oo’l)

at “OFF”, “LOCK”, or

is something wrong between “R” and

if there is no continuity at the “‘ON” position

or if there is some continuity either at the

“OFF” or “LOCK” or “P”.

NOTE:

Check the switch for continuity several times.

5.

Next go on to checking of the continuity be-

tween “B and

“R and L/R” at the respective switch positions, as in the same manner mentioned

above.

“LOCK” 0, and “P”

0,

B/W”, “L/W

and L/R”, and

“PI’.

“Br”

0.

indicat--

There

“Br”

6. If there is something wrong with any one of

the combinations, replace the switch component.

8-7

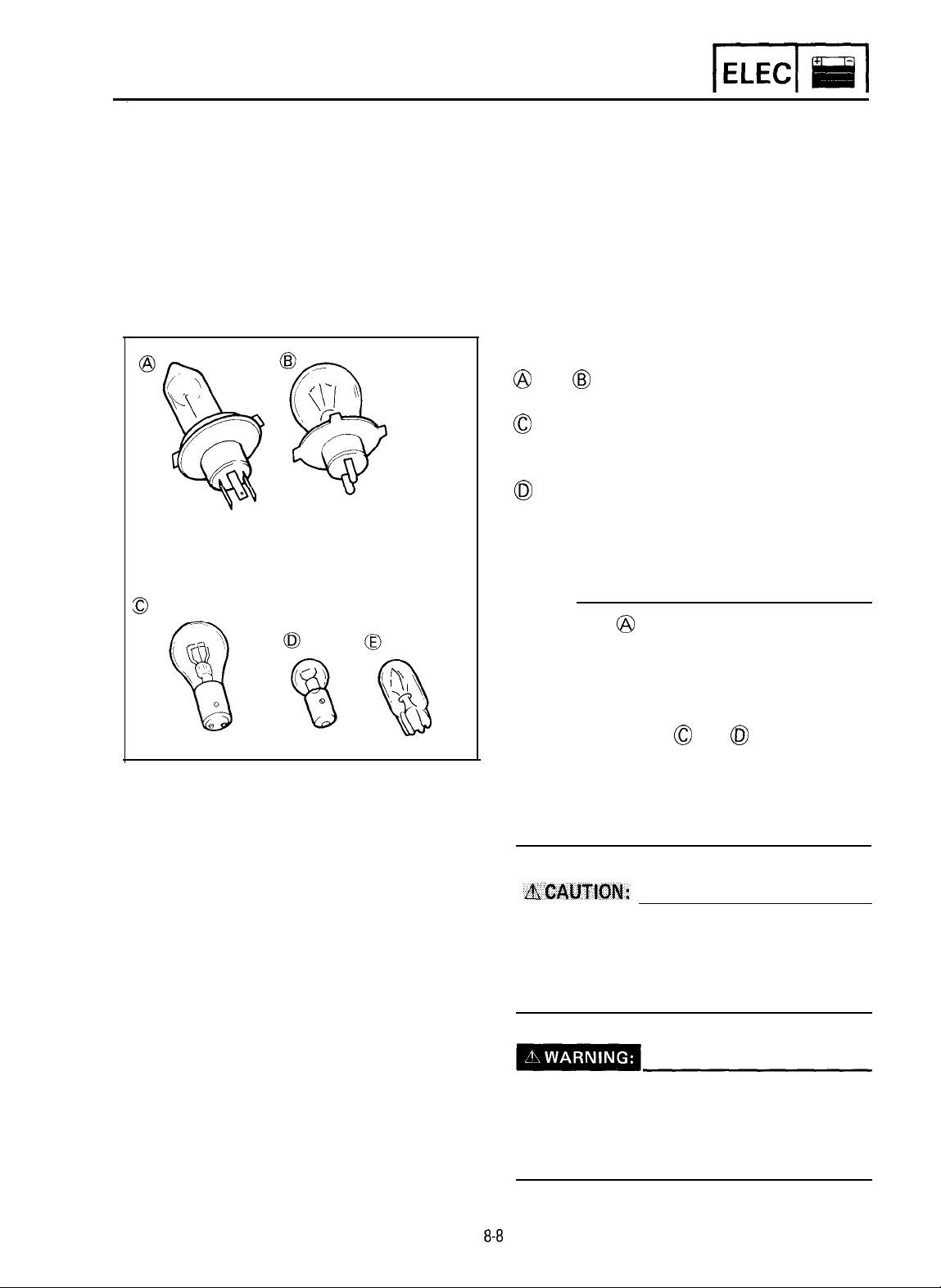

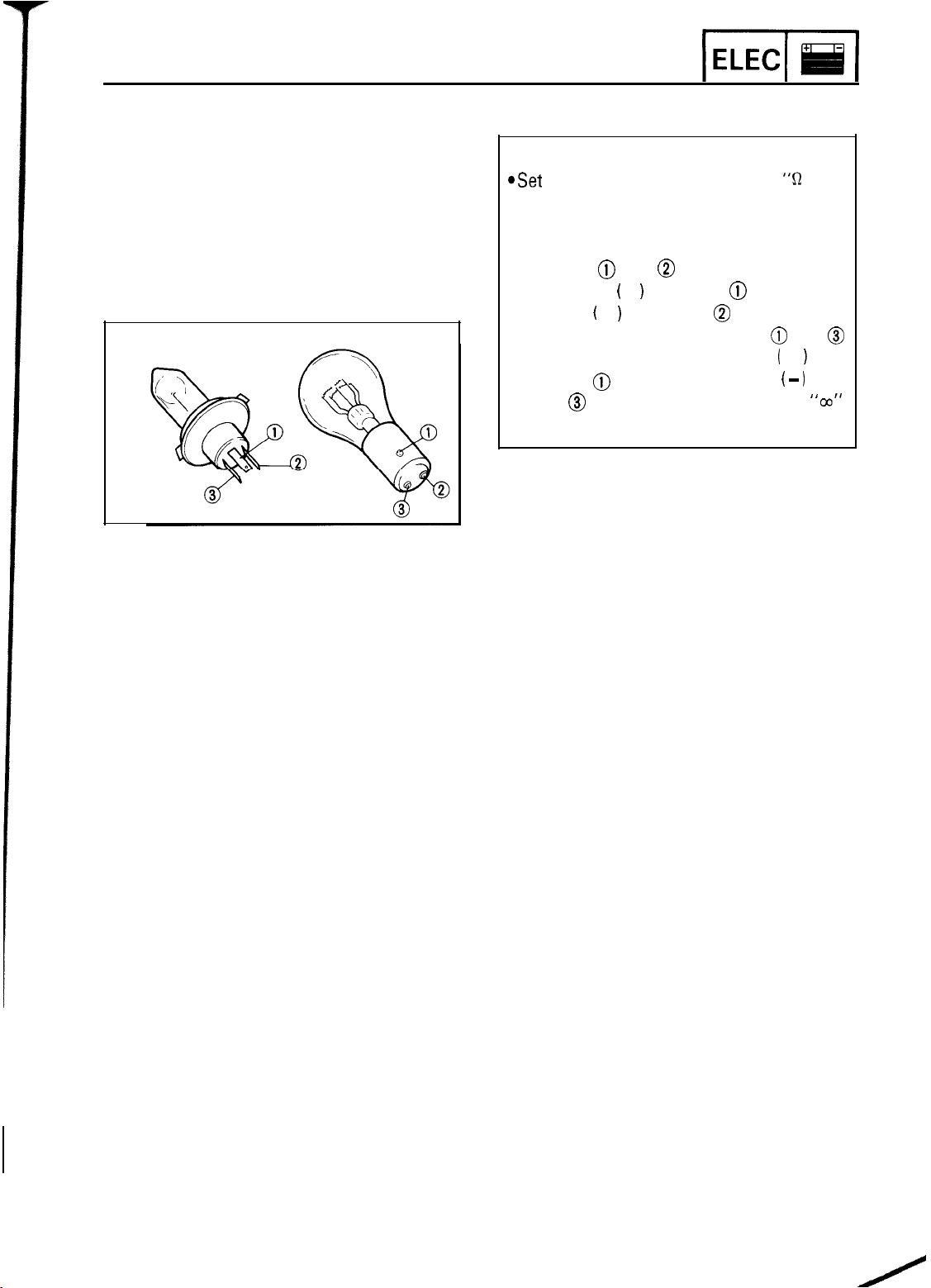

CHECKING OF BULBS

-1

CHECKING OF BULBS (FOR

HEADLIGHT, TAIL/BRAKE

LIGHT, FLASHER LIGHT, METER

LIGHT, ETC.)

Check the bulb terminal continuity for the condi-

tion of the bulb.

KINDS OF BULBS

The bulbs used in the motorcycle are classified

as shown left by the shape of the bulb socket.

@

and @ are mainly used for the headlight.

0

is mainly used for the flasher light and

tail/brake light.

0

and @are mainly used for the meter light and

other indicator lights.

CHECKING BULB CONDITION

1. Remove the bulb.

NOTE:

*Bulbs of the @ and @type uses a bulb holder.

Remove the bulb holder before removing the

bulb itself. Most of the bulb holders for this type

can be removed by turning them counterclockwise.

*Most of the bulbs of 0 and 0 type can be re-

moved from the bulb sockets by pushing and

turning them counterclockwise.

*Bulbs of the @type can be removed from the

bulb sockets by simply pulling them out.

Be sure to hold the socket firmly when

removing the bulb. Never pull the lead.

Otherwise, the lead may be pulled off the ter-

minal in the coupler.

Keep flammable products or your hands

away from the headlight bulb while it is on.

It will be hot. Do not touch the bulb until it

cools down.

8-8

CHECKING OF BULBS

2. Check the bulb terminals for continuity.

Checking steps:

*Set

the pocket tester selector to the “Q x 1”.

*Connect the tester leads to the respective bulb

terminals. Take for example a 3-terminal bulb

as shown left. First check the continuity between the @ and @ terminals by connecting the tester ( + 1 lead to the @ terminal and

the tester ( - ) lead to the @ terminal. Then

check the continuity between the @ and

terminals by connecting the tester ( + ) lead

still to the @ terminal and the tester ( - 1 lead

to the @ terminal. If the tester shows

in either case, replace the bulb.

3. Check the bulb socket by installing a proven

bulb to it. As in the checking of bulbs, connect the pocket tester leads to the respective

leads of the socket and check for continuity

in the same manner as mentioned above.

ITiETiil

@

“a”

I

8-9

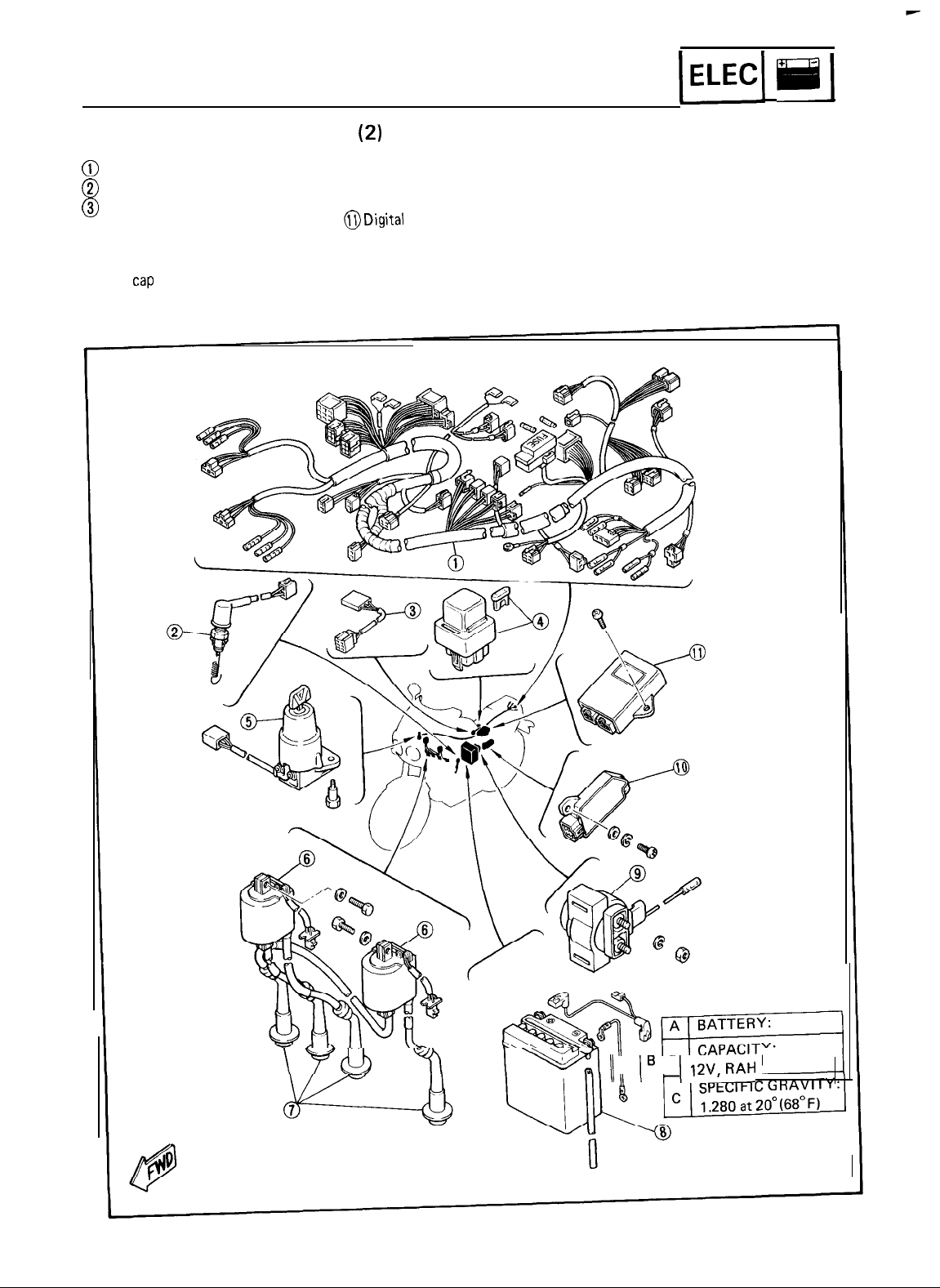

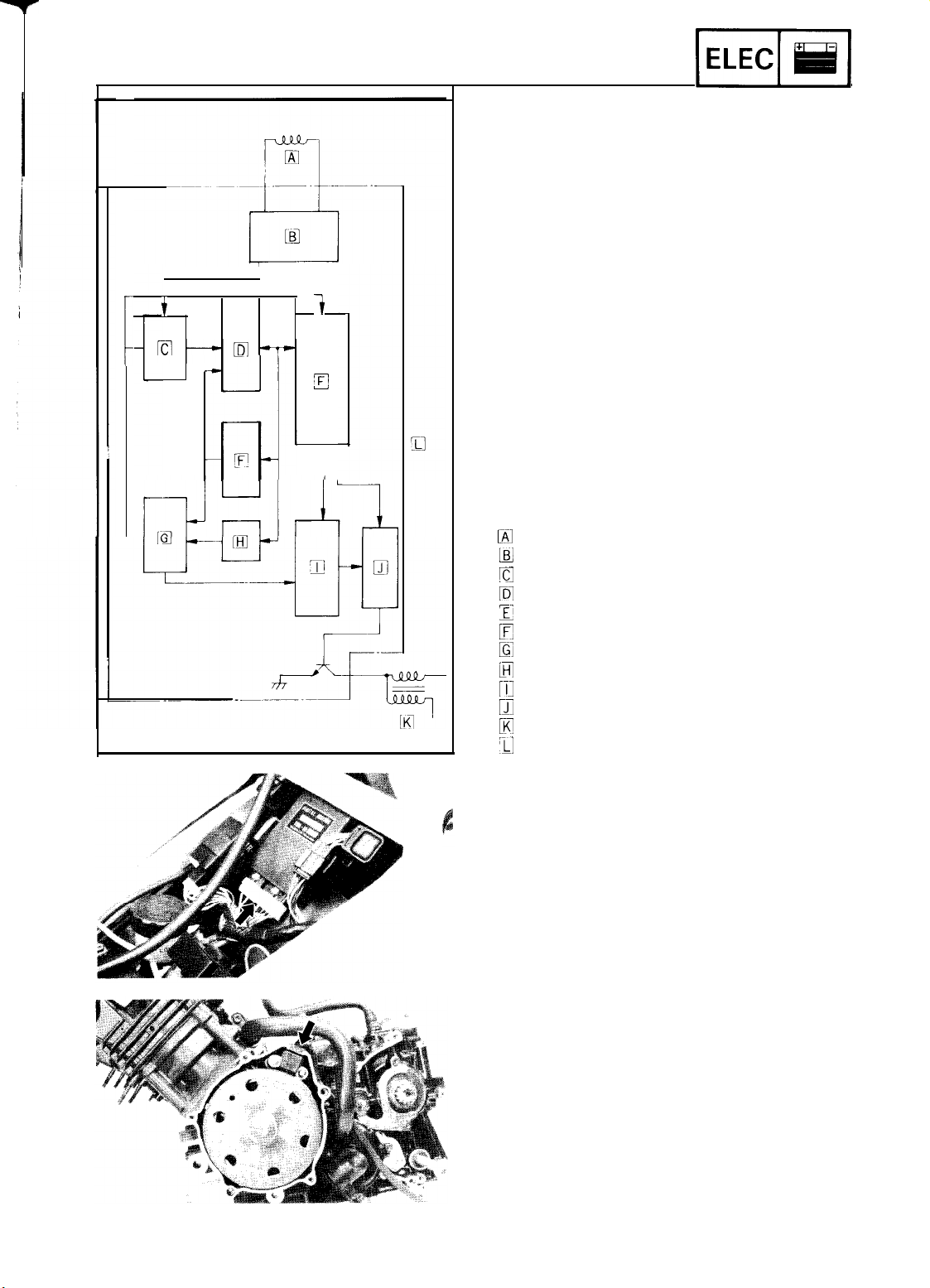

IGNITION SYSTEM

CIRCUIT DIAGRAM

IGNITION SYSTEM

(ELECII

8-11

IGNITION SYSTEM

Aforementioned circuit diagram shows the ignition circuit in the wiring diagram.

NOTE:

For the color codes, see page 8-2.

@

Main switch

@

Fuse “MAIN”

@

Battery

@

Fuse “IGNITION”

@

“ENGINE STOP” switch

@Diode block

@

Sidestand switch

@

Sidestand relay

@

Digital ignitor unit

@

Ignition coil

@

Ignition coil

@

Pickup coil

@

Spark plug

@

Neutral switch

(#I

and #4 cylinder)

(#2

and #3 cylinder)

.

8-12

I

IGNITION SYSTEM

DIGITAL IGNITION CONTROL SYSTEM

DESCRIPTION

The electronic ignition that sparks the engine is

computer controlled and operated by the digital

microprocessor.

advance curve.

This programed advance curve closely matches

the spark timing to the engine’s ignition require-

I

t

i

F-

-

ments. Only one pickup coil is needed to meet

the requirements of the digital ignitor unit.

The digital ignitor also includes the control

unit for the electric fuel pump.

It has a pre-programed ignition

(ELECII

I I

[a

Pickup coil

m

Wave-shape shaping circuit

a

Edge detection circuit

DJ

Latch circuit

z

Microprocessor

Lj

Free-running counter

[G]

Comparison circuit

La

Register

[Tl

Flip-flop circuit

[JJ

Driving circuit

[KJ

Ignition coil

71

Digital ignitor unit

OPERATION

The following operations are digitally-performed

by signal from the pickup coil signal:

1. Determing proper ignition timing.

2. Sensing the engine revolution speed.

3. Determing timing for switching on ignition

coil (duty control).

4. Increasing ignition coil primary current for

starting the engine.

5. Sensing engine stall.

6. Preventing over-revolution of the engine.

8-13

IGNITION SYSTEM

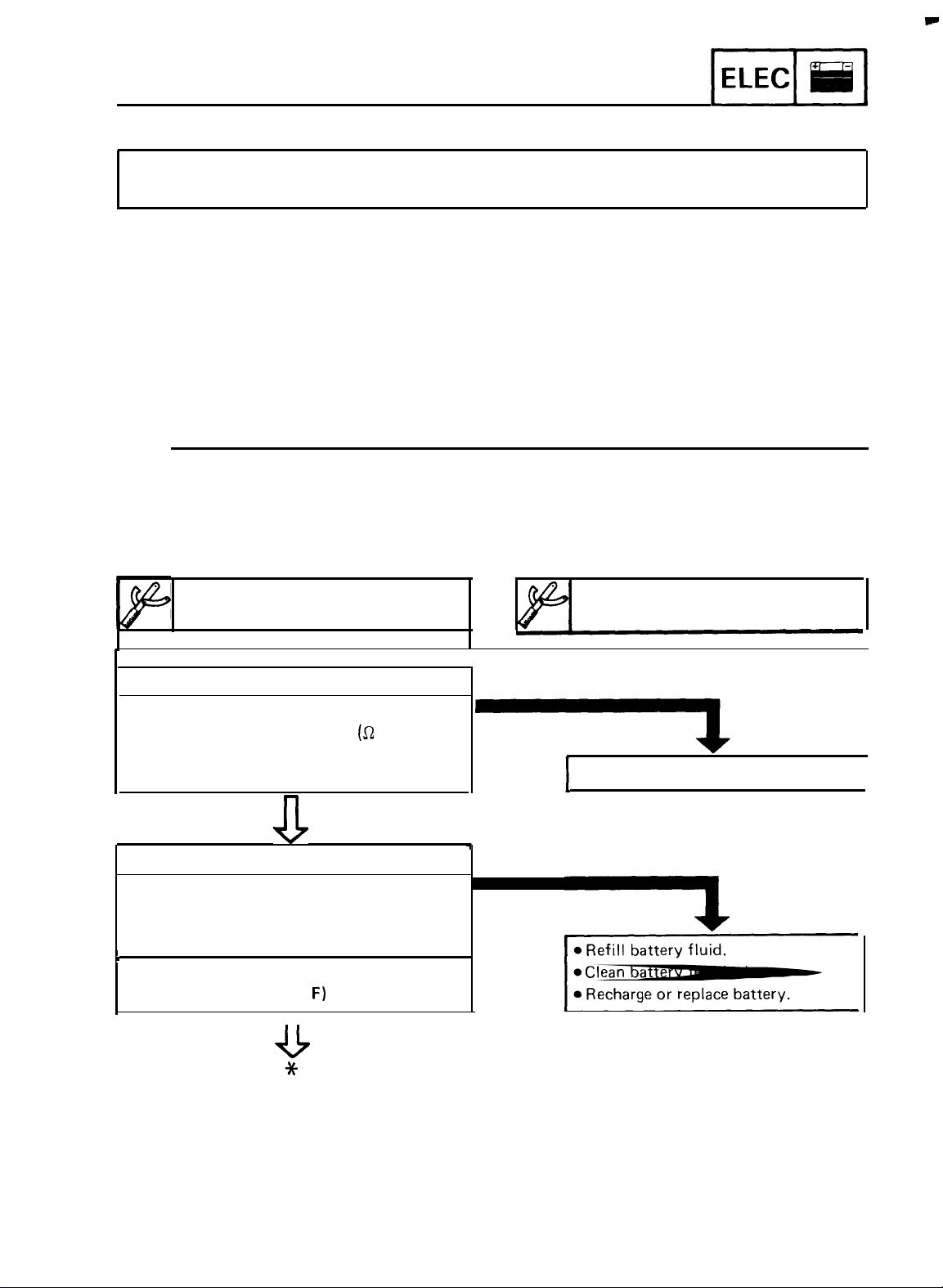

TROUBLESHOOTING

IF IGNITION SYSTEM SHOULD BECOME INOPERATIVE

(NO SPARK OR INTERMITTENT SPARK)

Procedure

Check;

1. Fuse “MAIN”

2. Battery

3. Spark plug

4. Ignition spark gap 11. Sidestand relay

5. Spark plug cap resistance

6. Ignition coil resistance

7. Main switch (Entire ignition system)

NOTE:

?? Remove the following before troubleshooting.

1) Seat

2) Lower cowling 5) Air filter case

3) Center cowling 6) Crankcase cover (Left)

?? Use the following special tools in this troubleshooting.

8. “ENGINE STOP” switch

9. Neutral switch

10. Sidestand switch

12. Pickup coil resistance

13. Wiring connection

4) Top cover

r

Dynamic Spark Tester:

P/N. Y M-34487

1. Fuse “MAIN”

?? Remove the fuse “MAIN”.

?? Connect the Pocket Tester

fuse “MAIN”.

(fi

x 1) to the

?? Check the fuse “MAIN” for continuity.

CONTINUITY

8

2. Battery

?? Check the battery condition.

Refer to the “BATTERY INSPECTION”

section in the CHAPTER 3.

r

Specific Gravity:

1.280 at 20°C (68”

F)

n

CORRECT

&

*

Pocket Tester:

P/N. YU-03112

NON CONTINUITY

Replace fuse “MAIN”.

+

INCORRECT

I

8-14

*

a

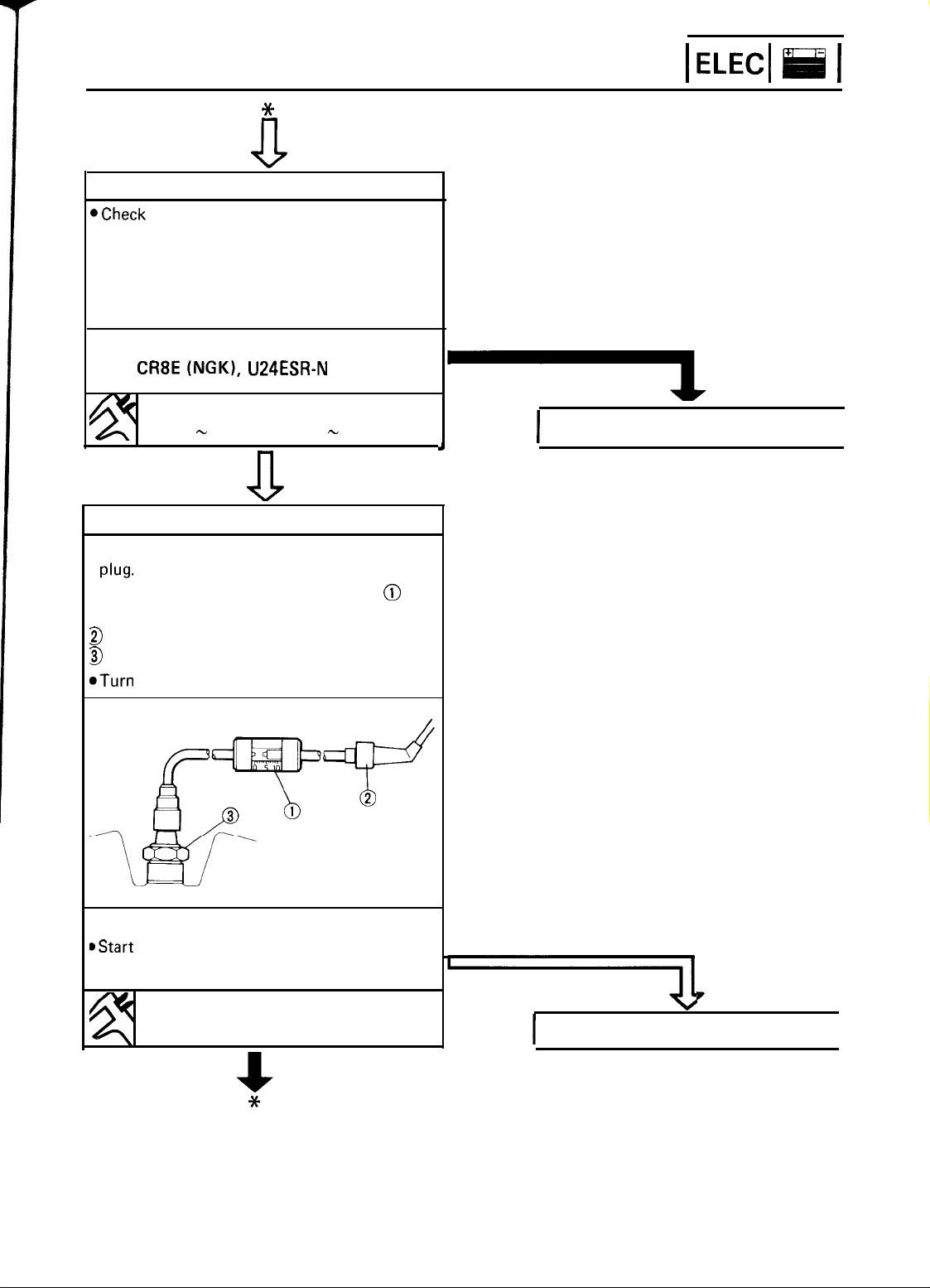

3. Spark plug

*Check

?? Check the spark type.

@Check the spark plug gap.

the spark plug condition.

Refer to the “SPARK PLUG INSPECTION”

section in the CHAPTER 3.

IGNITION SYSTEM

IELECl liiiiil 1

Standard Spark Plug:

CR8E (NGK), U24ESR-N

Spark Plug Gap:

0.7 - 0.8 mm (0.028 - 0.032 in)

(N.D.)

CORRECT

a

4. Ignition spark gap

*Disconnect the spark plug cap from spark

plug.

@Connect the Dynamic Spark Tester @ as

shown.

3

Spark plug cap

3

Spark plug

@Turn

the main switch to “ON”.

INCORRECT

I

Repair or replace spark plug.

A

I

I

?? Check the ignition spark gap.

BStart

engine, and increase spark gap until

misfire occurs.

Minimum Spark Gap:

6.0 mm (0.24 in)

OUT OF SPECIFICATION

OR NO SPARK

*

MEETS SPECIFICATION

Ignition system is good.

I

8-15

7

I

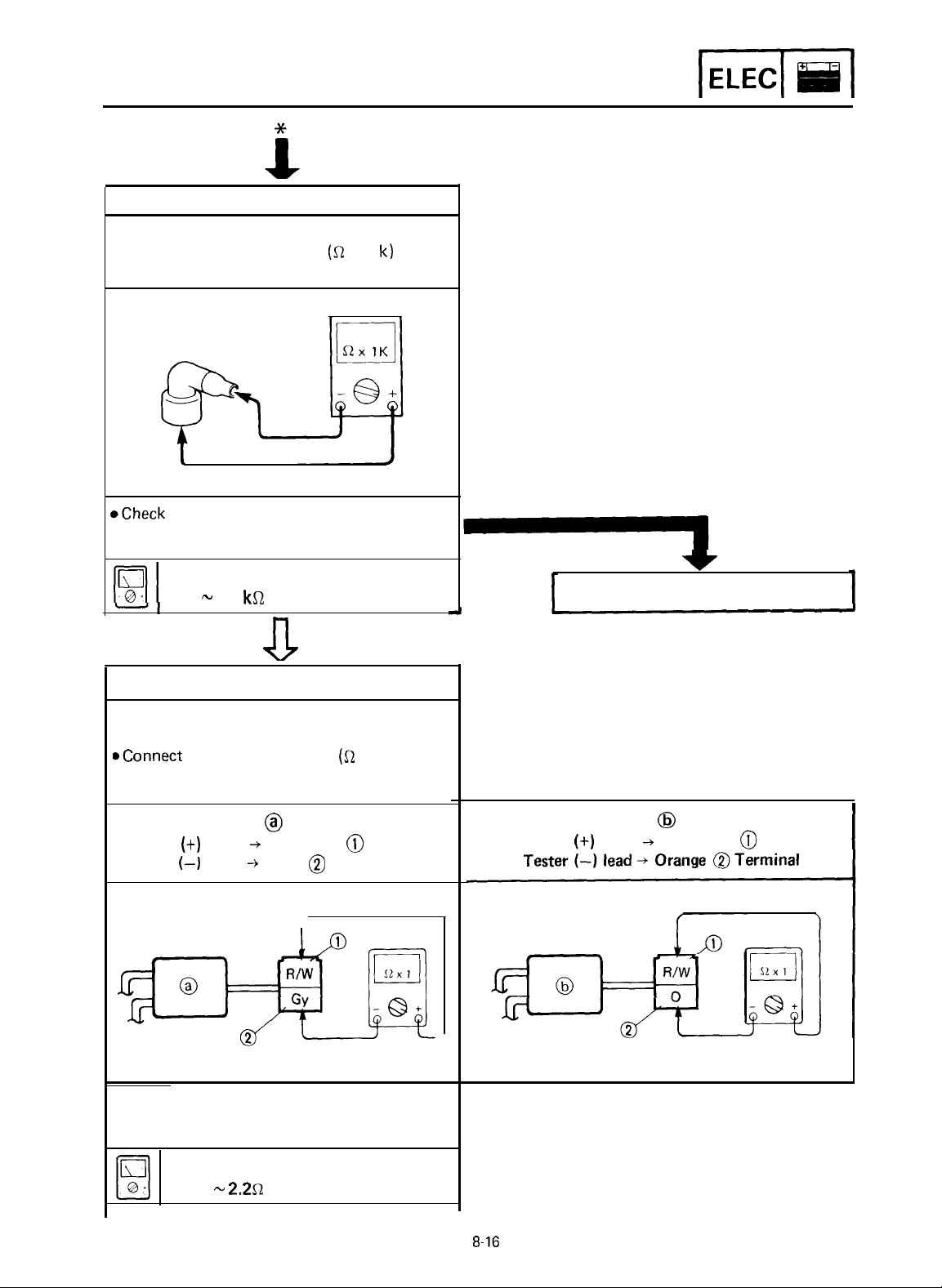

5. Spark plug cap resistance

?? Remove the spark plug cap.

?? Connect the Pocket Tester

spark plug cap.

(n

x 1 k) to the

IGNITION SYSTEM

-1

@Check

r-II

@Disconnect the ignition coil coupler from

@Connect

the spark plug cap for specificated

resistance.

a

Spark Plug Cap Resistance:

63.

6. Ignition coil resistance

the wireharness.

ignition coil.

Ignition coil (Right) @ :

Tester (+) lead + Red/White @ Terminal

Tester

9 - 11 kR at 20°C (68°F)

MEETS

SPECIFICATION

a

the Pocket Tester

(-)

lead + Gray @ Terminal

(SL

x 1) to the

OUT OF SPECIFICATION

Replace spark plug cap.

Ignition coil (Left) @ :

Tester (+) lead

--f

Red/White @ Terminal

*

?? Check the primary coil for specificated

resistance.

Primary Coil Resistance:

1.8 -

2.2n

at 20°C (68” F)

8-16

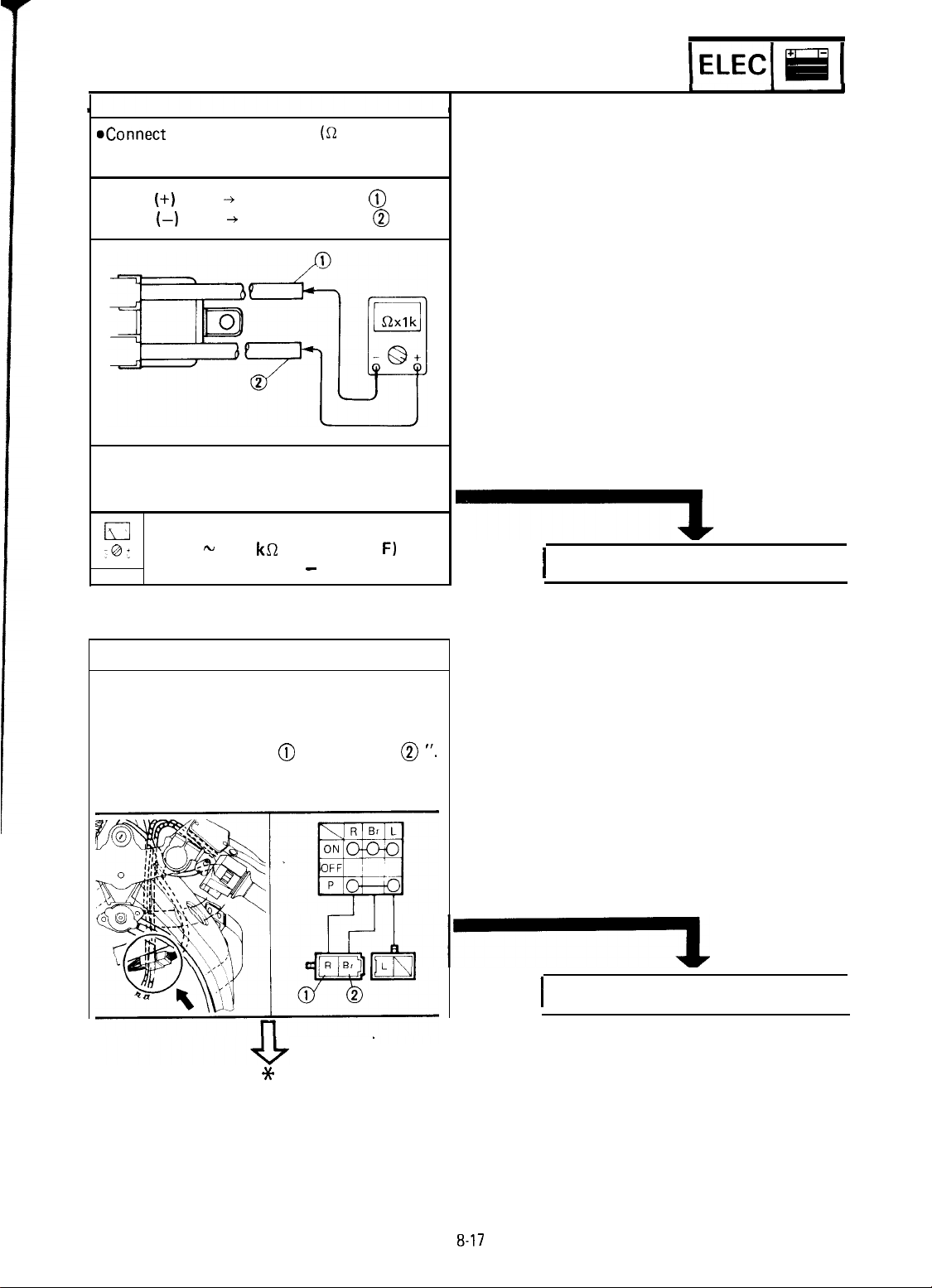

IGNITION SYSTEM

I=(

Ed [

@Connect

ignition coil.

Tester (+I Lead + Spark Plug Lead

Tester

the Pocket Tester (0 x lk) to the

@

(-)

Lead + Spark Plug Lead

@

?? Check the Secondary coil for specificated

resistance.

m

Secondary Coil Resistance:

-8:

cl

7. Main switch

9.6 - 14.4 kR at 20°C (68”

(Spark Plug Lead - Spark plug)

BOTH MEET

SPECIFICATIONS

a

F)

OUT OF SPECIFICATION

Replace ignition coil.

I

I

*Disconnect the main switch coupler from

the wire harness.

?? Check the switch component for the conti-

nuity between “Red @ and Brown @

Refer to the “CHEKING OF SWITCHES”

section.

CORRECT

*

‘I.

INCORRECT

Replace main switch.

I

I

8-17

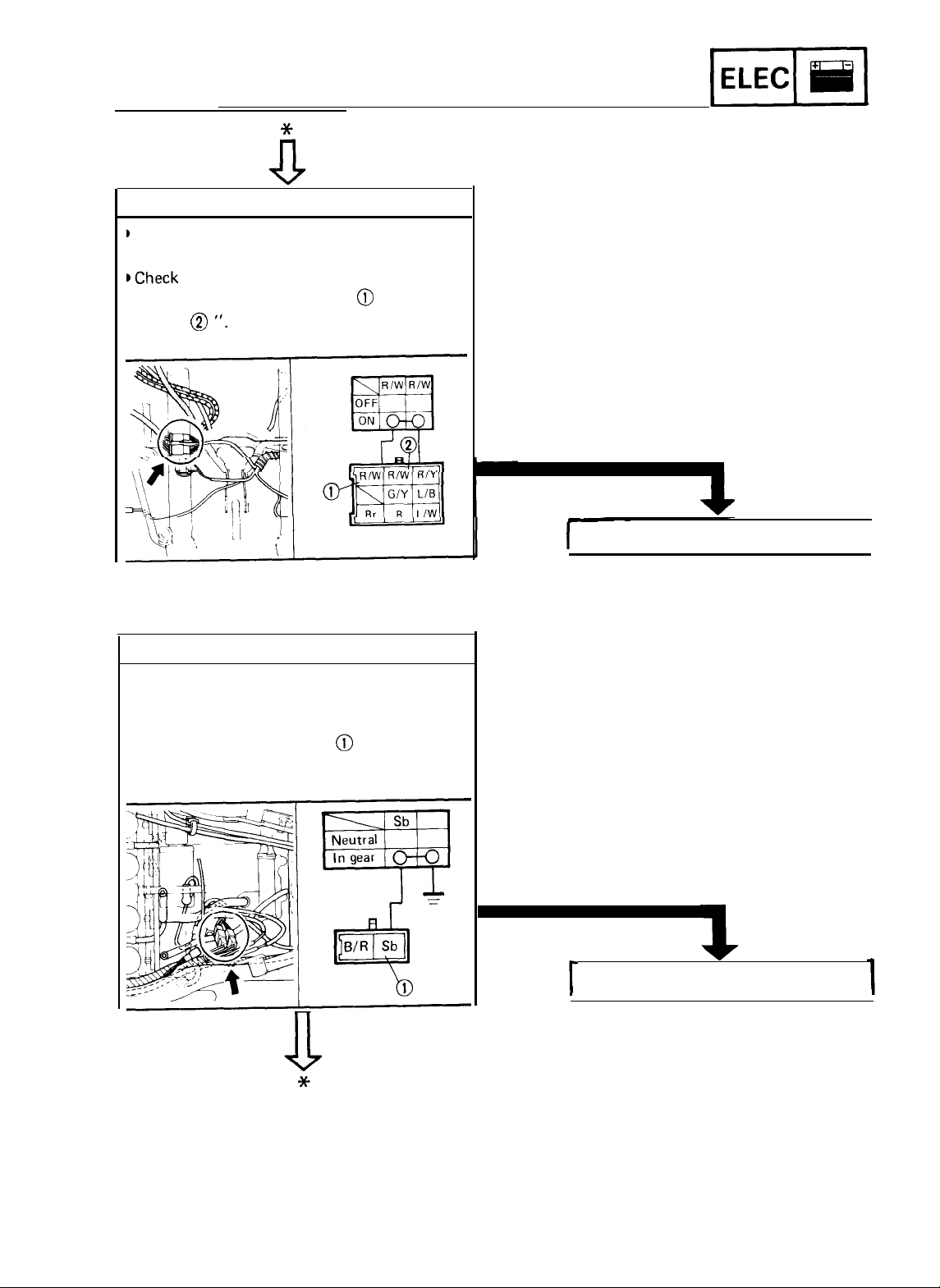

8. “ENGINE STOP” switch

)

Disconnect the

coupler from the wire harness.

~Check

the switch component for the continuity between “Red/White @ and Red/White @

SWITCHES” section.

“ENGINE STOP” switch

Refer to the “CHECKING OF

“.

IGNITION SYSTEM

INCORRECT

pqiq

CORRECT

a

9. Neutral switch

?? Disconnect the neutral switch coupler from

the wire harness.

?? Check the switch component for the conti-

nuity between ‘Sky blue @ and Ground”.

Refer to the “CHECKING OF SWITCHES”

section.

Replace handlebar switch (Right).

I

INCORRECT

Replace neutral switch.

I

CORRECT

8-18

*

n

10. Sidestand switch

B

Disconnect the sidestand switch coupler

from the wire harness.

?? Check the switch component for the conti-

nuity between “Blue/Yellow

@ “.

Refer to the “CHECKING OF

SWITCHES” section.

@,?

and Black

IGNITION SYSTEM

INCORRECT

CORRECT

&

Il. Sidestand relay

B

Disconnect the sidestand relay coupler from

the wire harness.

BConnect

battery

coupler terminals.

Tester (+) Lead + Red/White @ Terminal

Tester

Battery (+) Lead

Battery (-) Lead

the Pocket Tester (a x 1) and

(12V)

voltage to the sidestand relay

(-)

Lead

--f

Black @ Terminal

--f

Red/White @ Terminal

--f

Blue/Yellow

Terminal

@

Replace sidestand switch.

I

)Check

the relay for continuity.

CONTINUITY

a

*

NOCONTINUITY

8-19

1

Replace sidestand relay.

IGNITION SYSTEM

(ELECI

*

a

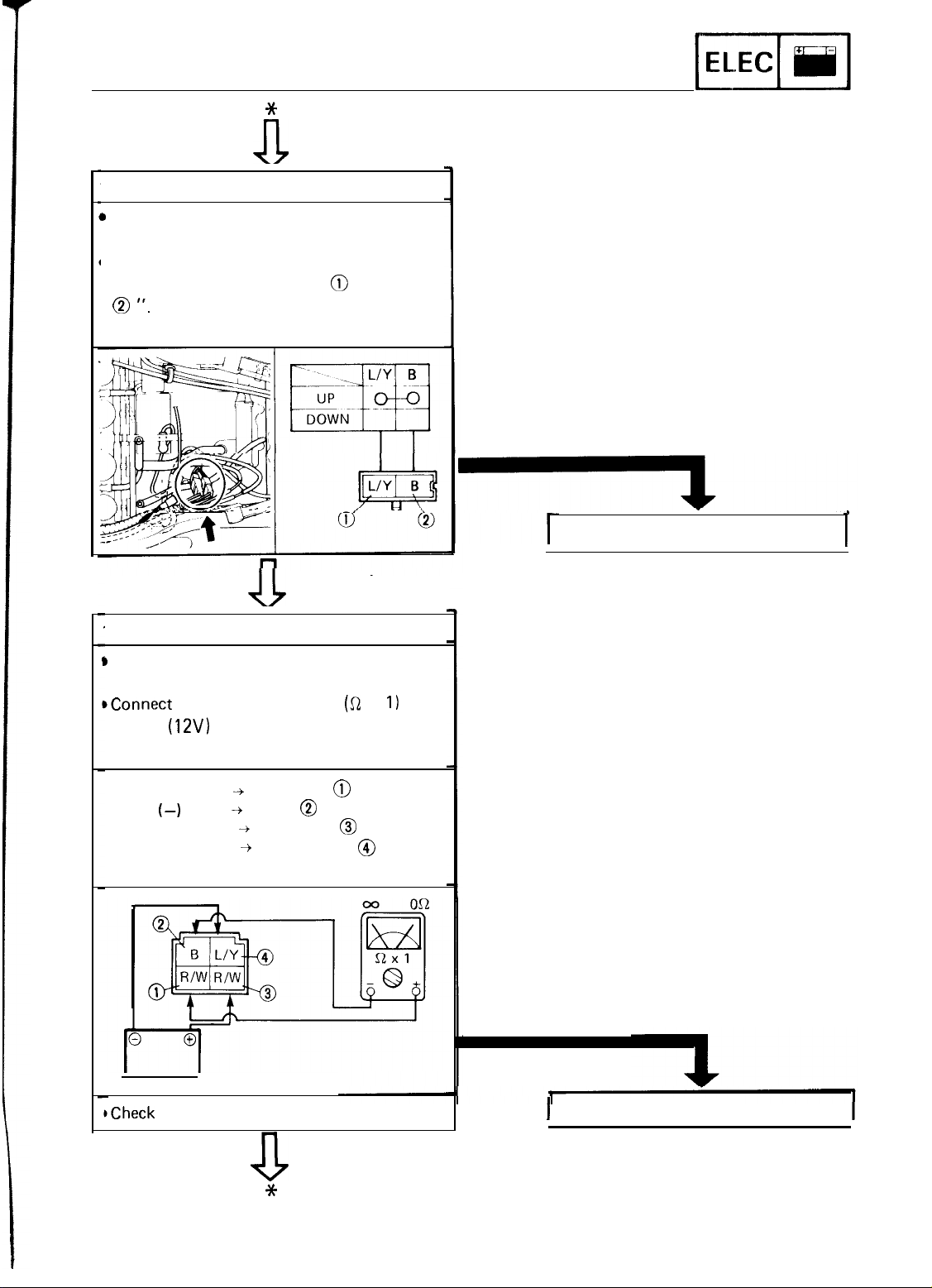

12.

Pickup coil resistance

?? Disconnect the A.C. magneto Coupler

the wire harness.

?? Connect the Pocket Tester

pickup coil terminal.

Tester (+) Lead + White/Red @Terminal

Tester (-) Lead + White/Black @ Terminal

@Check

the pickup coil for specificated

resistance.

(!2

x

100)

to the

q

from

OUT OF SPECIFICATION

Pickup Coil Resistance:

85 -

11551

at 20°C (68°F)

(White/Red -White/Black)

-

MEET SPECIFICATION

v

lYKi7Yconnection

Check the entire ignition system for

[ nections.

1

l-l

Digital ignitor unit is faulty.

Replace the digital ignitor unit.

1

Correct.Refer to the “WI RING DIAGRAM” section.

CORRECT

con-

Replace pickup coil.

I

POOR CONNECTION

I

4

I

I

8-20

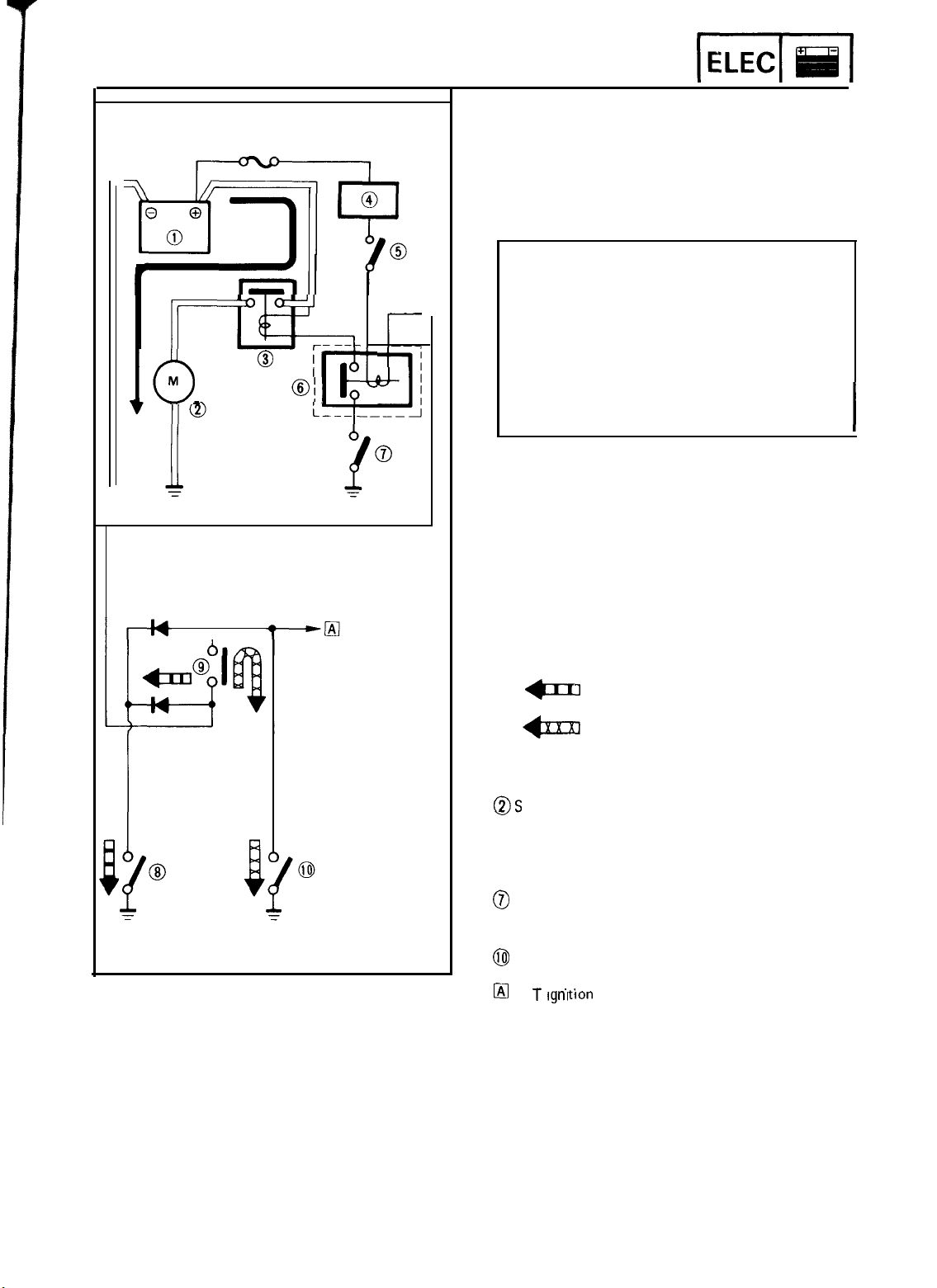

ELECTRIC STARTING SYSTEM

CIRCUIT DIAGRAM

ELECTRIC STARTING SYSTEM

8-21

ELECTRIC STARTING SYSTEM

IELEC~ @i/ii

A forementioned circuit diagram shows the electric starting circuit in the wiring diagram.

NOTE:

For the color codes, see page 8-2.

@Main switch

@

“START” switch

@Starter motor

@Starter relay

@

Fuse “MAIN”

@

Battery

@Fuse “IGNITION”

@

“ENGINE STOP” switch

(@

Diode block

@Clutch switch

@Sidestand

@Neutral switch

@Starting

switch

circuit cut-off relay (Relay assembly @

)

8-22

ELECTRIC STARTING SYSTEM

STARTING CIRCUIT OPERATION

The starting circuit on this model consist of the

starter motor, starter relay, and the relay unit

(starting circuit cut-off relay). If the engine stop

switch and the main switch are both closed, the

starter motor can operate only if:

The transmission is in neutral (the neutral

switch is closed).

-1

0

II

M

-

or if

0 j.

r

1

The clutch lever is pulled to the handlebar

(the clutch switch is closed) and the sidestand

is up (the sidestand switch is closed.)

The starting circuit cut-off relay prevents the

starter from operating when neither of these

conditions has been met. In this instance, the

starting circuit cut-off relay is open so current

cannot reach the starter motor.

When one of both of the above conditions have

been met, however, the starting circuit cut-off

relay is closed, and the engine can be started by

pressing the starter switch.

w

@Battery

tarter motor

OS

@Starter relay

@Main switch

@“ENGINE STOP”switch

@Starting circuit cut-off relay

@

‘START” switch

@Neutral switch

@Clutch switch

@

Sidestand switch

WHEN THE TRANSMISSION IS IN

NEUTRAL

WHEN THE SIDESTAND IS UP AND

THE CLUTCH LEVER IS PULLED IN

I

@ T ‘t’

8-23

0

1gnl Ion

circuit cut-off relay

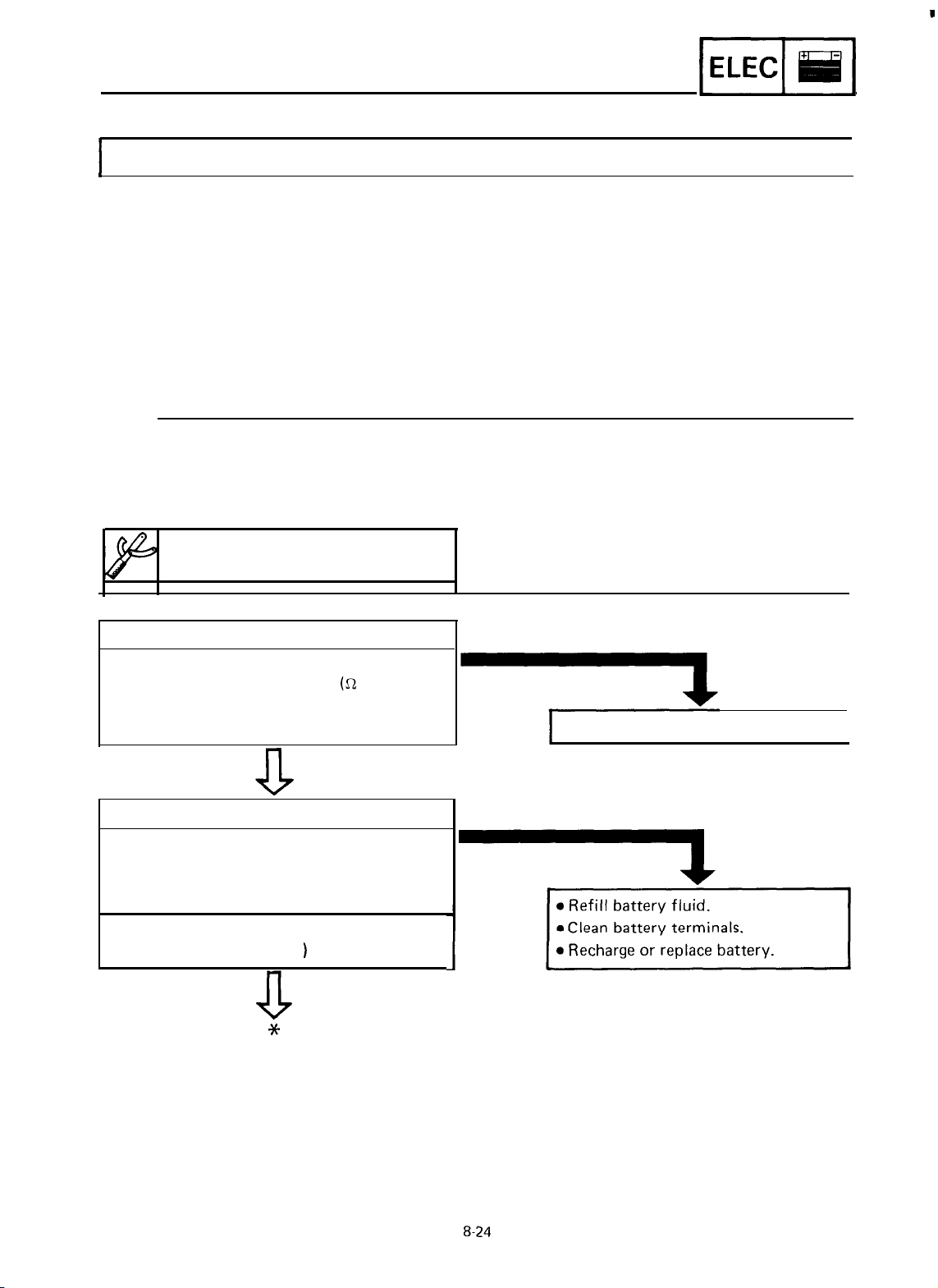

TROUBLESHOOTING

ELECTRIC STARTING SYSTEM

pEpq

I

Procedure

Check;

1.

Fuse “MAIN”

2.

Battery

3.

Starter motor

4.

Starter relay

5. Starting circuit cut-off relay

6. Main switch

7. “ENGINE STOP” switch

NOTE:

Remove the following before troubleshooting.

1) Seat

2) Seat cowling 4) Fuel tank

?? Use the following special tool in this troubleshooting.

Pocket Tester:

P/N. YU-03112

1. Fuse “MAIN”

?? Remove the fuse “MAIN”.

?? Connect the Pocket Tester

fuse “MAIN”.

*Check the fuse “MAIN” for continuity.

STARTER MOTOR DOES NOT OPERATE.

8.

Neutral switch

9.

Sidestand switch

10.

Clutch switch

11.

“START” switch

12. Wiring connection

(Entire electric starting system)

3) Lower cowling

NON CONTINUITY

(s2

x 1) to the

l-l

CONTINUITY

1

Replace fuse “MAIN”.

1

2. Battery

Check the battery condition.

Refer to the “BATTERY INSPECTION”

section in the CHAPTER 3.

Specific Gravity:

1.280 at 20” C (68” F

1

CORRECT

-(1

*

INCORRECT

8-24

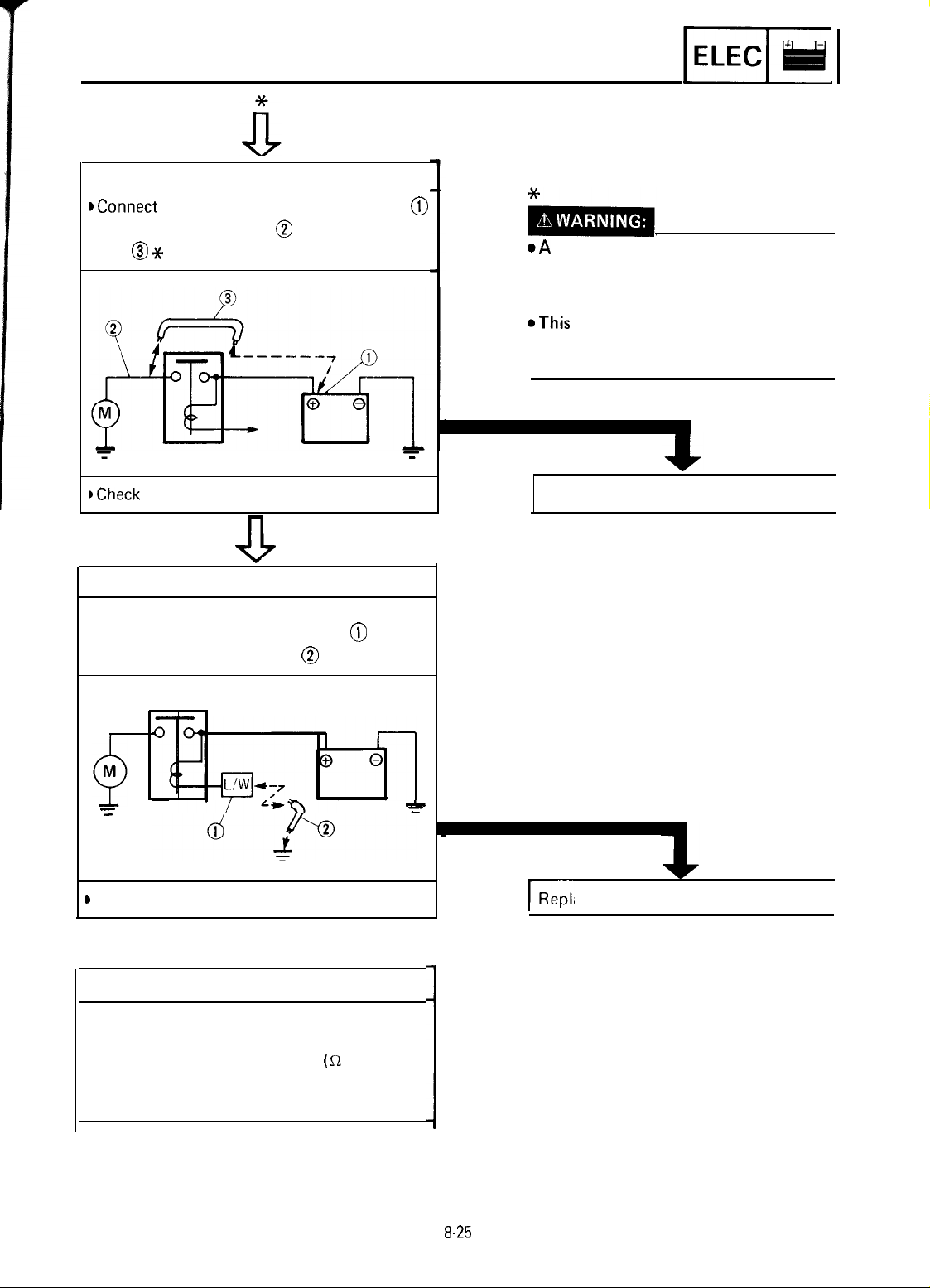

3. Starter motor

ELECTRIC STARTING SYSTEM

p-p@

BConnect

and starter motor cable @ using the jumper

lead @ * as shown.

Y

)Check

4. Starter relay

?? Disconnect the starter relay lead.

?? Ground the starter relay lead

frame using the jumper lead @ as shown.

the battery positive terminal

the starter motor operation.

OPERATIVE

@

to the

@

@A

wire for the jumper lead must have

the equivalent capacity as that of the

battery lead or more, otherwise it may

cause the jumper lead to be burned.

aThis

check is likely to produce sparks,

so be sure that no flammable gas or

fluid is in the vicinity.

NO OPERATIVE

7

Repair or replace starter motor.

I

=

D

Check the starter motor operation.

OPERATIVE

a

5. Starting circuit cut-off relay

?? Disconnect the relay assembly coupler from

the wire harness.

?? Connect the pocket tester

battery (12V) voltage to the relay assembly

coupler terminals.

(a

x 1) and

-

z

NO OPERATIVE

I

Replace starter relay.

r--~

I

I

8-25

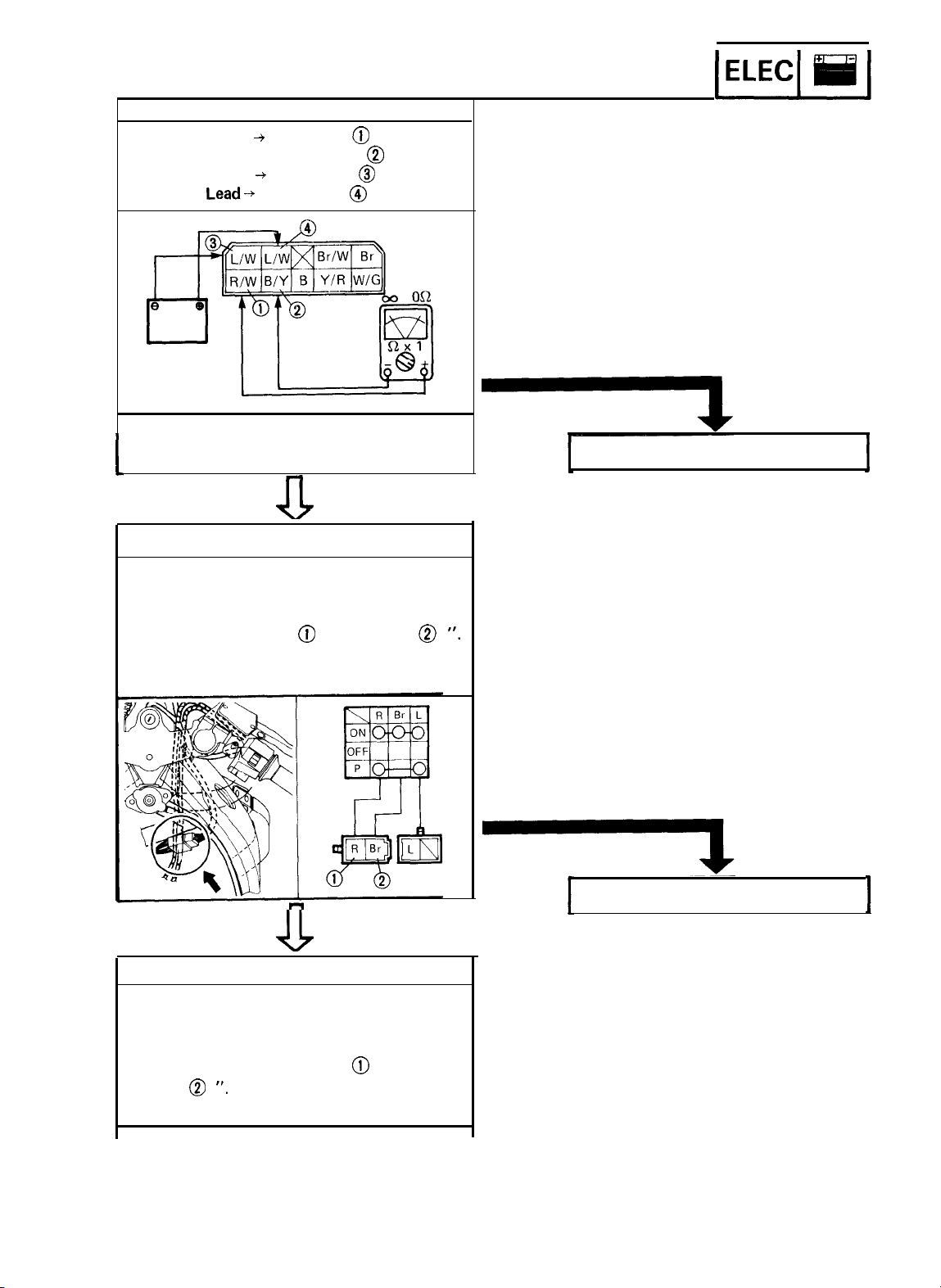

ELECTRIC STARTING SYSTEM

Tester (+) Lead + Red/White @ Terminal

Tester (-) Lead+ Black/Yellow @ Terminal

Tester (+) Lead + Blue/White @ Terminal

Tester (-)

?? Check the starting circuit cut-off relay for

continuity.

1

Lead-+

Blue/White @ Terminal

m

CONTINUITY

a

6. Main switch

?? Disconnect the main switch coupler and

lead from the wire harness.

?? Check the switch component for the conti-

nuity between “Red @ and Brown @

Refer to the “CHECKING OF SWITCHES”

section.

NO CONTINUITY

I

Replace relay assembly.

“.

CORRECT

v

7. “ENGINE STOP” switch

?? Disconnect the

coupler from the wire harness.

?? Check the switch component for the conti-

nuity between “Red/White @ and Red/White @ “.Refer to the “CHECKING OF

SWITCHES” section.

“ENG I NE STOP” switch

INCORRECT

Replace main switch.

8-26

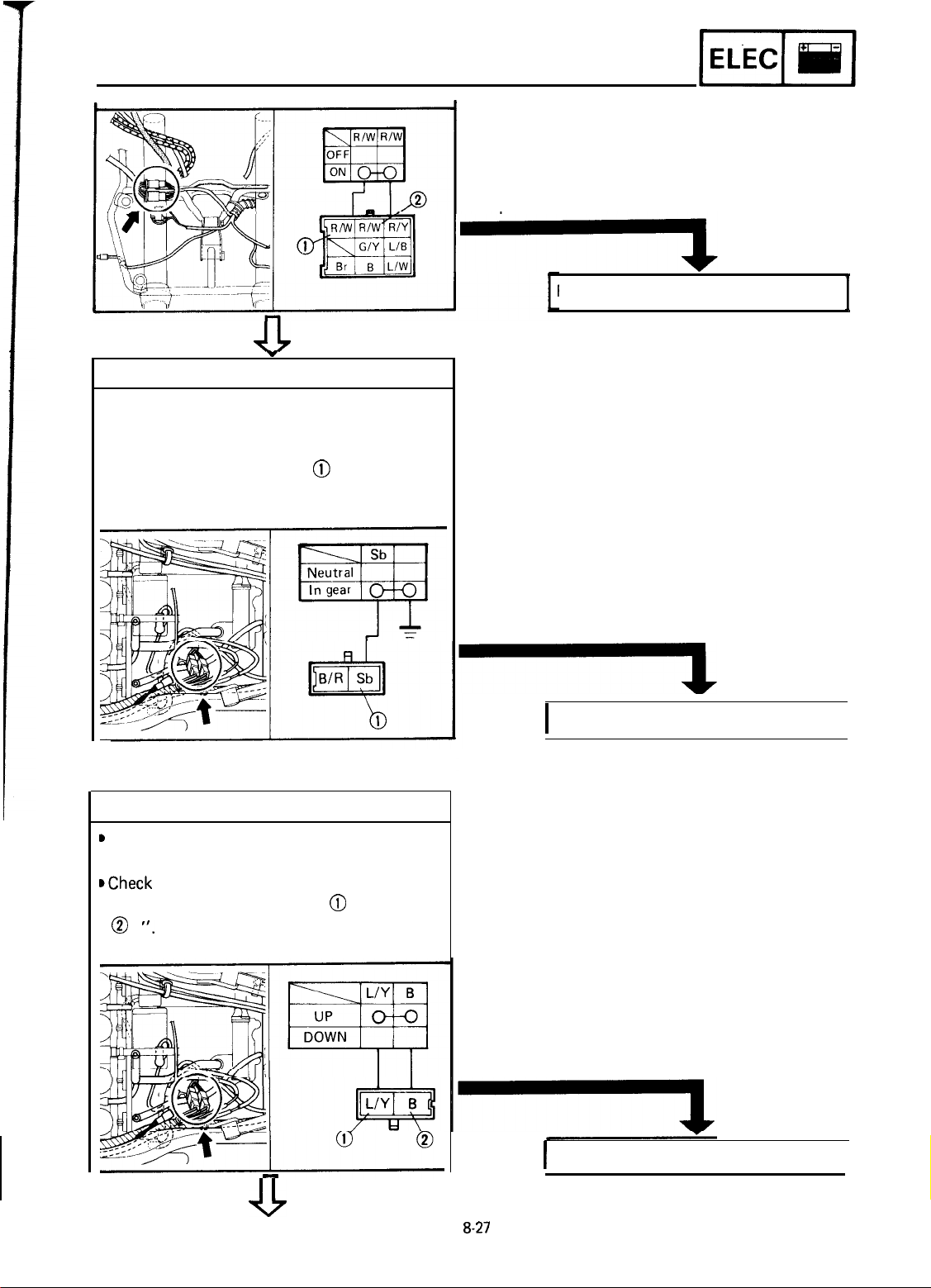

ELECTRIC STARTING SYSTEM

INCORRECT

CORRECT

4L

\-

8. Neutral switch

?? Disconnect the neutral switch coupler from

the wire harness.

?? Check the switch component for the conti-

nuity between “Sky blue @ and Ground”.

Refer to the “CHECKING OF SWITCHES”

section.

CORRECT

a

Replace handlebar switch (Right).

INCORRECT

Replace neutral switch.

I

1

1

9. Sidestand switch

B

Disconnect the sidestand switch coupler

from the wire harness.

~Check

the switch component for the conti-

nuity between “Blue/Yellow @ and Black

0 “.

SWITCHES” section.

Refer to the “CHECKING OF

CORRECT

v

INCORRECT

8-27

Replace sidestand switch.

I

1

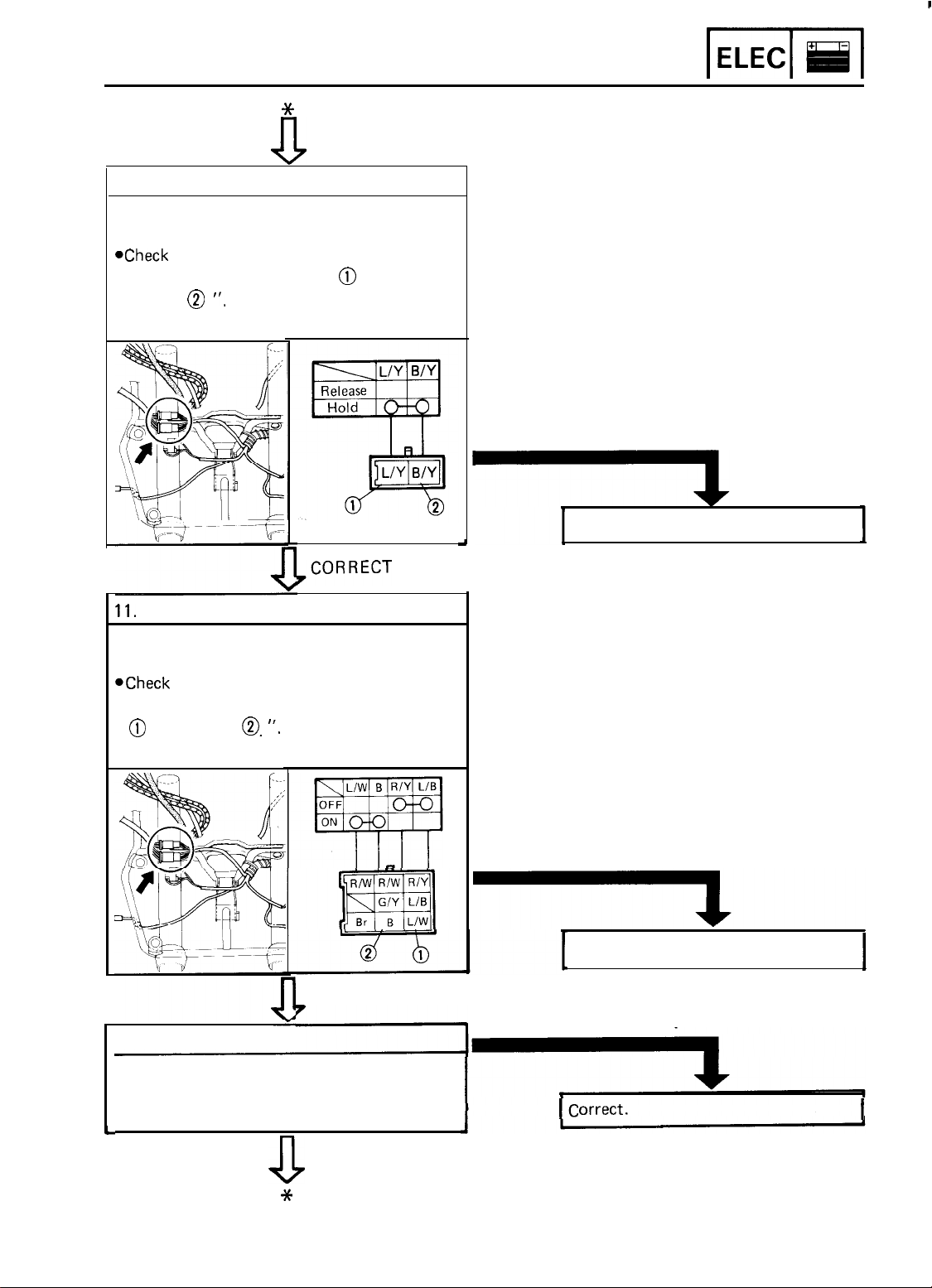

ELECTRIC STARTING SYSTEM

*

a

10. Clutch switch

?? Disconnect the clutch switch coupler from

wire harness.

@Check

the switch component for the continuity between “Blue/Yellow @ and Black/Yellow @ “.Refer to the “CHECKING OF

SWITCHES” section.

-1

INCORRECT

I

,CORRECT

11.

“START” switch

@Disconnect the “START” switch coupler

from wire harness.

@Check

the

for the continuity between “Blue/White

@

and Black 0.

ING OF SWITCHES” section.

“START” switch component

Refer to the “CHECK-

I’.

CORRECT

d

Replace clutch switch.

INCORRECT

Replace handlebar switch (Right).

I

12. Wiring connection

Check the entire ignition system for connections.

Refer to the “WIRING DIAGRAM” section.

L

I

OK

a

*

POOR CONNECTION

orrect.

IC

8-28

I

Diode block is faulty.

Replace the diode block.

I

ELECTRIC STARTING SYSTEM

*

a

I

8-29

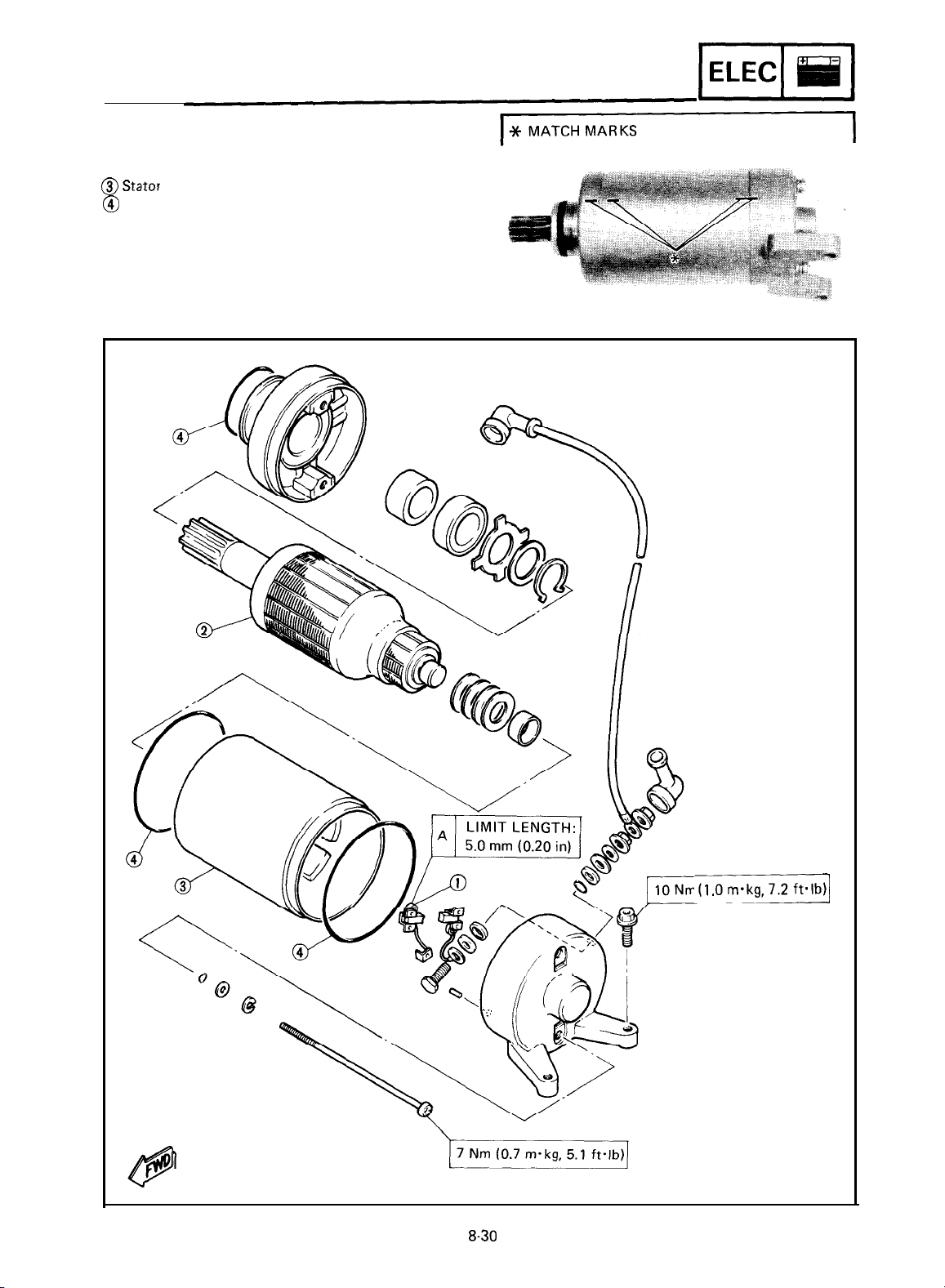

STARTER MOTOR

@Brush

@Armature

@ Stator

@

O-ring

ELECTRIC STARTING SYSTEM

8-30

11.01

ELECTRIC STARTING SYSTEM

Removal

1. Remove:

??

Starter motor

Refer to the “ENGINE OVERHAUL

ENGINE REMOVAL” section in the

CHAPTER 4.

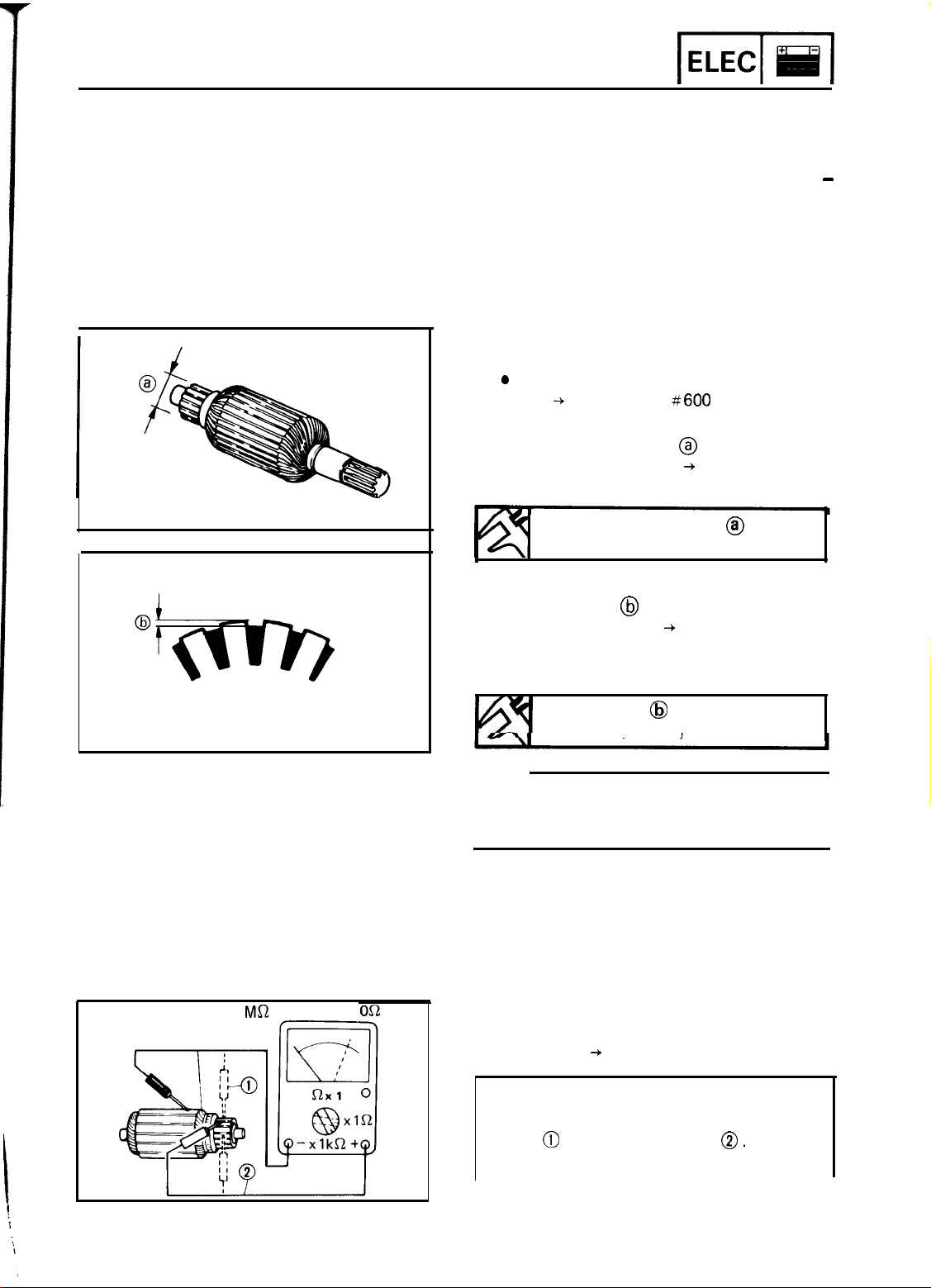

Inspection and Repair

1. Inspect:

0

Commutator

Dirty + Clean it with

2. Measure:

?? Commutator diameter

Out of specification -+ Replace starter

motor.

Commutator Wear Limit @ :

22 mm (0.87 in)

-1

#600

grit sandpaper.

@

-

1 MR

or more

052

3. Measure:

??

Mica undercut

Out of specification + Scrape the mica to

proper value use a hacksaw blade can be

ground to fit.

@

Mica Undercut @ :

1.8 mm

(0.07

in)

NOTE:

The mica insulation of the commutator must

be undercut to ensure proper operation of

commutator.

4. Inspect:

*Armature coil (insulation/continuity)

Defects(s)

--f

Replace starter motor.

Armature coil inspecting steps:

?? Connect the Pocket Tester for continuity

check @ and insulation check

??

Measure the armautre resistances.

8-31

0.

Loading...

Loading...