Yamaha FZR400 Service Manual Ch4

ENGINE REMOVAL

ENGINE OVERHAUL

ENGINE REMOVAL

NOTE:

It is not necessary to remove the engine in order

to remove the following components:

??

Cylinder head

?? Cylinder

0

Piston

. Clutch

0

Water pump

?? A.C. magneto

LOWER COWLING, CENTER COWLING,

UPPER COWLING AND TOP COVER

1. Remove:

?? Lower cowlings (Left and right)

?? Center cowlings (Left and right)

0

Upper cowling

0 Seat

??

Top cover

Refer to the “COWLING REMOVAL

AND INSTALLATION - REMOVAL”

section in the CHAPTER 3.

FUEL TANK

1. Remove:

?? Fuel tank

Refer to the “CARBURETOR - REMOVAL” section in the CHAPTER 6.

ENGINE OIL

1. Drain:

??

Engine oil

Refer to the “ENGINE OIL REPLACE-

MENT” section in the CHAPTER 3.

COOLANT

1. Drain:

0

Coolant

Refer to the “COOLANT REPLACE-

MENT” section in the CHAPTER 3.

AIR FILTER CASE AND CARBURETOR

1. Remove:

??

Air filter case

??

Carburetor

Refer to the “CARBURETOR - RE-

MOVAL” section in the CHAPTER 6.

4-1

ENGINE REMOVAL

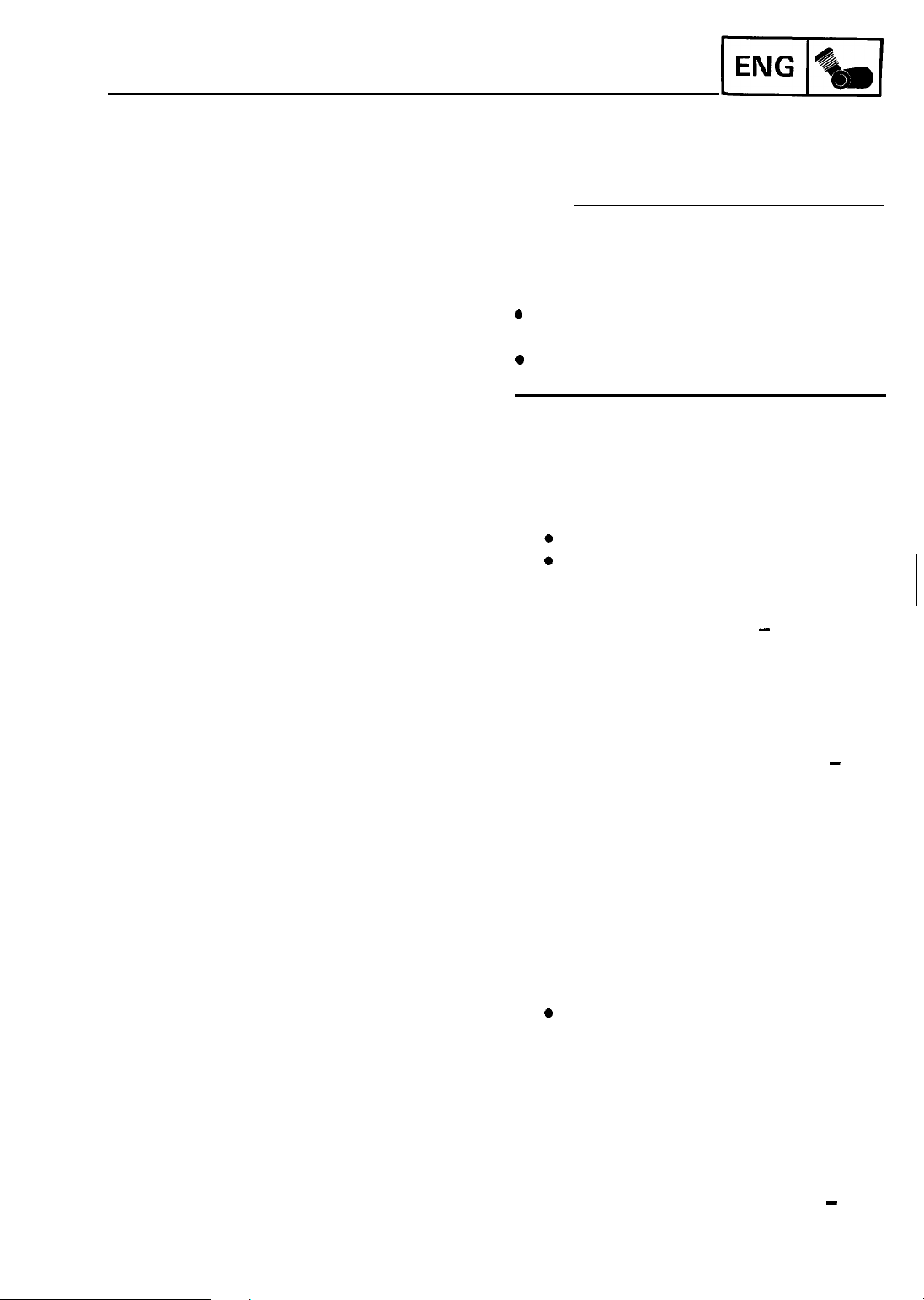

RADIATOR

1. Disconnect:

?? Hose (Radiator

?? Hose (Radiator

2. Disconnect:

?? Fan motor coupler

3. Remove:

??

Radiator assembly

Cover the cylinder head cover and the fender

with rugs to prevent a scratching.

-

Inlet)

-

Outlet)

@

@

4. Disconnect:

?? Pipes (Left and right)

5. Remove:

?? Pipes (Radiator

-

MUFFLER ASSEMBLY

1. Remove:

?? Nuts (Exhaust pipe)

?? Cowling stays

?? Bolt (Muffler bracket)

@

Outlet)

@

@

@

4-2

ENGINE DISASSEMBLY

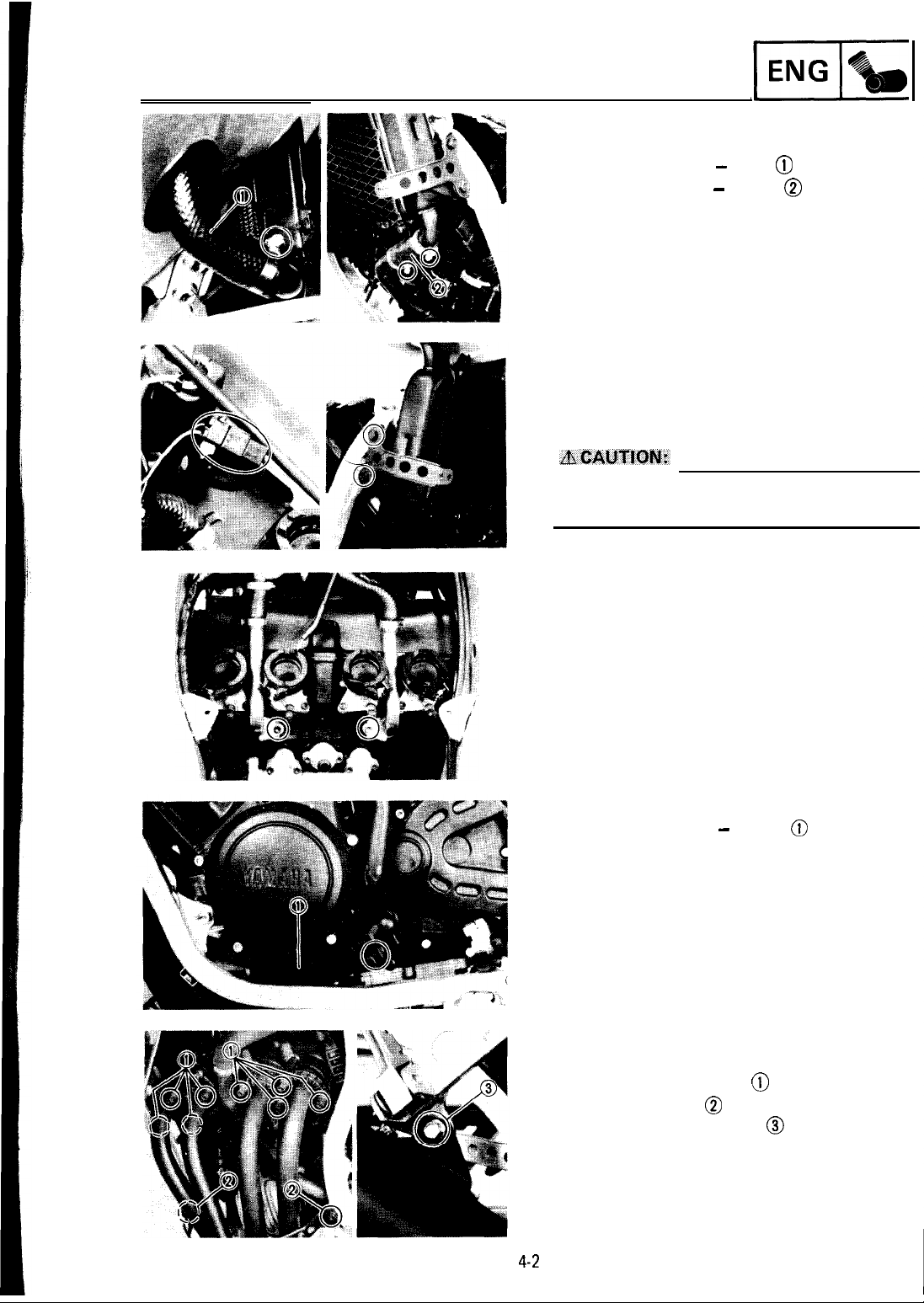

MUFFLER ASSEMBLY (For California only)

1. Remove:

?? Nuts (Exhaust pipe)

??

Cowling stays

?? Bolt (Muffler bracket)

2. Remove:

??

Bolt (Muffler stay)

@

@

@

3. Loosen:

?? Lock nut

?? Adjuster

4. Remove:

0

Cover

??

Clips

aPulley @

*Cables @

5. Remove:

*Washer @

??

Bracket

?? Housing

??

Gasket

(Left side)

??

Shaft arm

@

@

0

@

@

4-3

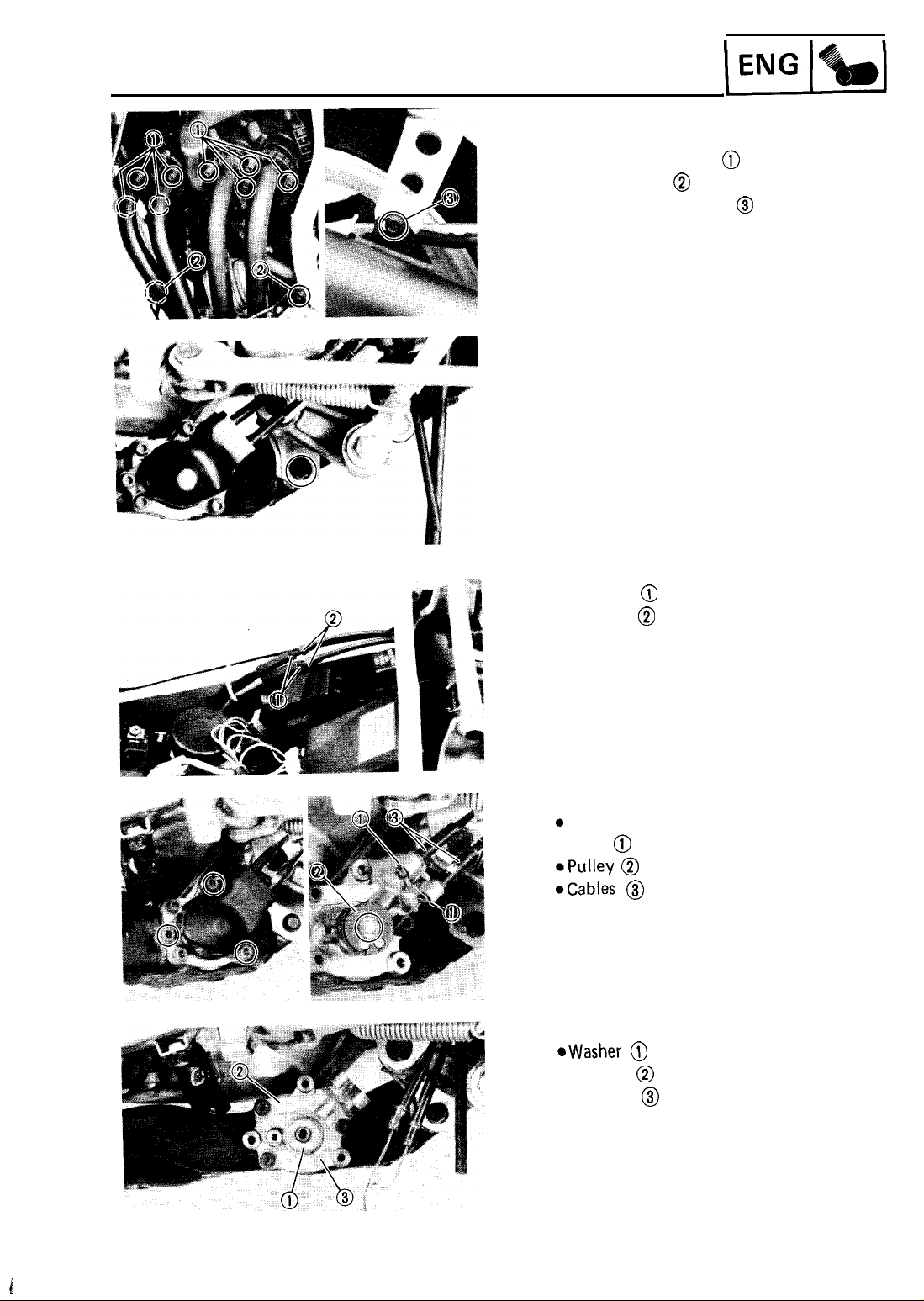

ENGINE REMOVAL

CLUTCH CABLE AND DRIVE CHAIN

1. Remove:

?? Shift arm

?? Crankcase cover (Left)

2. Remove:

?? Clutch cable

3. Straighten:

?? Lock washer tab

4. Remove:

?? Drive sprocket

LEADS

1. Straighten:

0

Clamp

2. Disconnect:

?? Battery leads

NOTE:

Disconnect the negative lead @ first.

ENGINE REMOVAL

3. Disconnect:

?? Lead (Starter motor)

4. Remove:

0

Cover

5. Disconnect:

?? Coupler (Oil level Neutral switch)

?? Coupler (A.C. generator)

?? Coupler (Sidestand switch)

6. Remove:

??

Spark plug leads

ENGINE REMOVAL

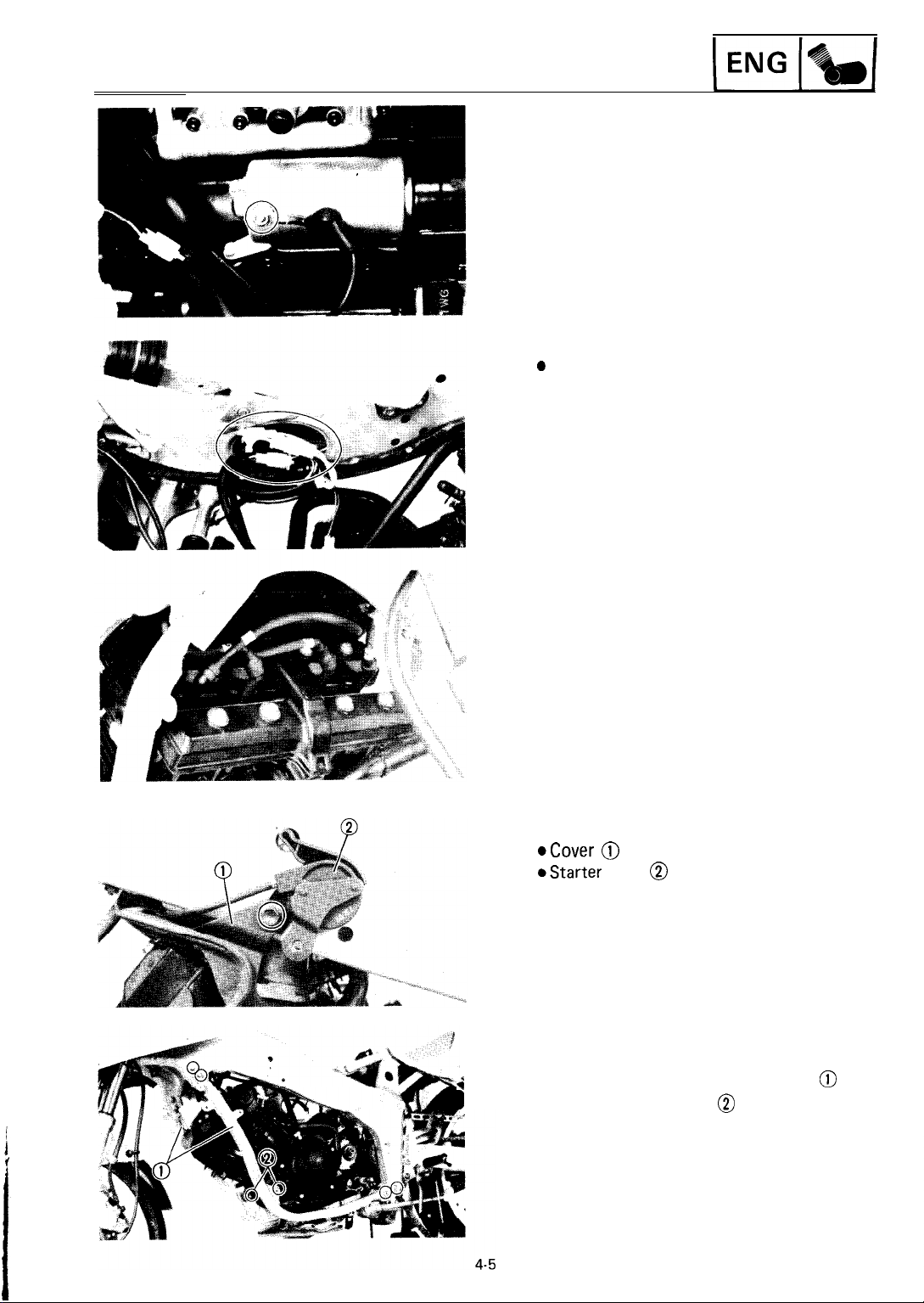

1. Remove:

@Cover @

aStarter

lever

0

2. Place a suitable stand under the engine.

3. Remove:

i

I

?? Down tube frames (Left and right)

?? Bolt (Engine-mount)

@

@

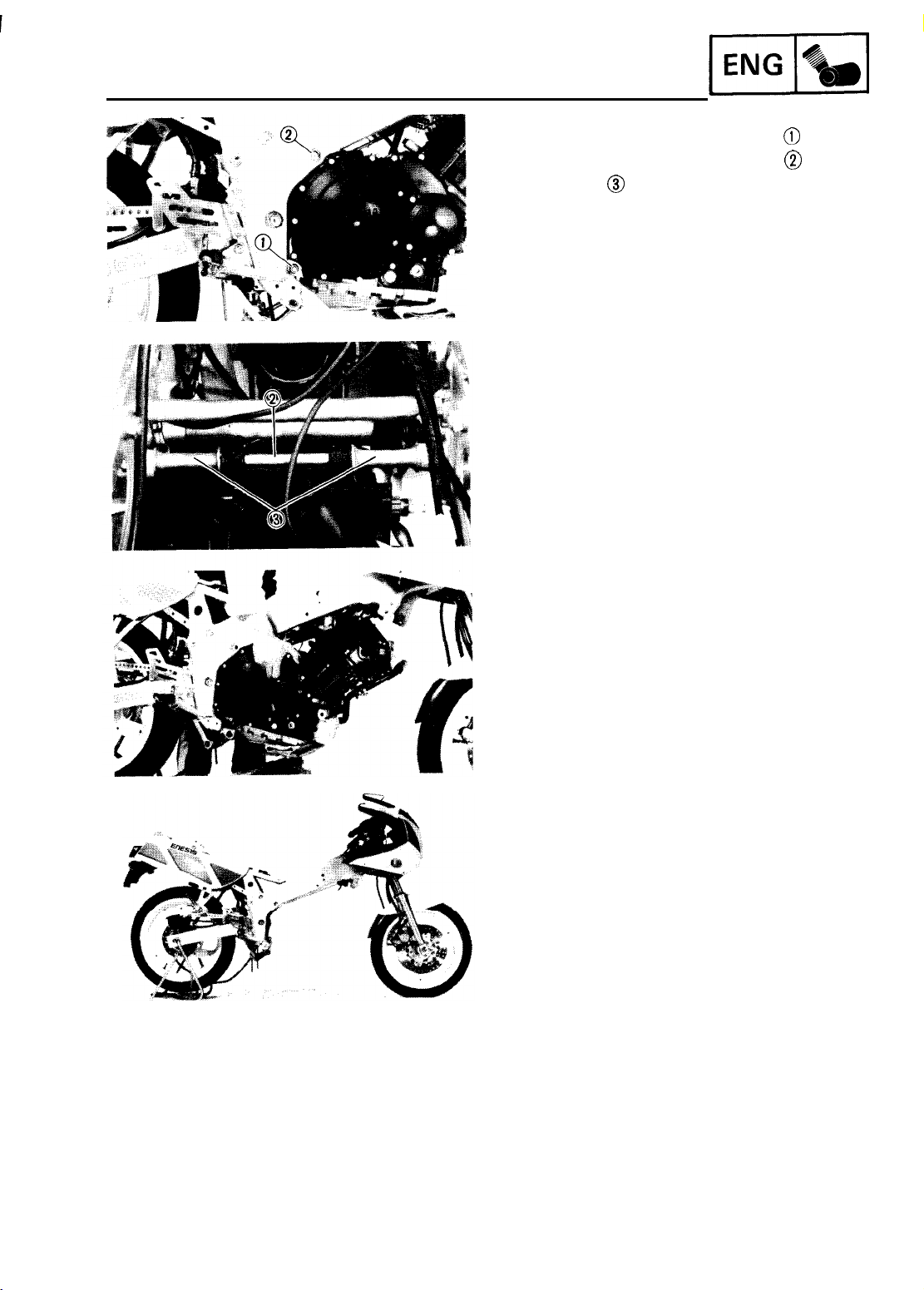

ENGINE REMOVAL

4. Remove:

?? Bolt (Engine-mounting Lower)

?? Bolt (Engine-mounting Upper)

??

Collars

@

@

@

5. Remove:

??

Engine assembly.

From right side.

4-6

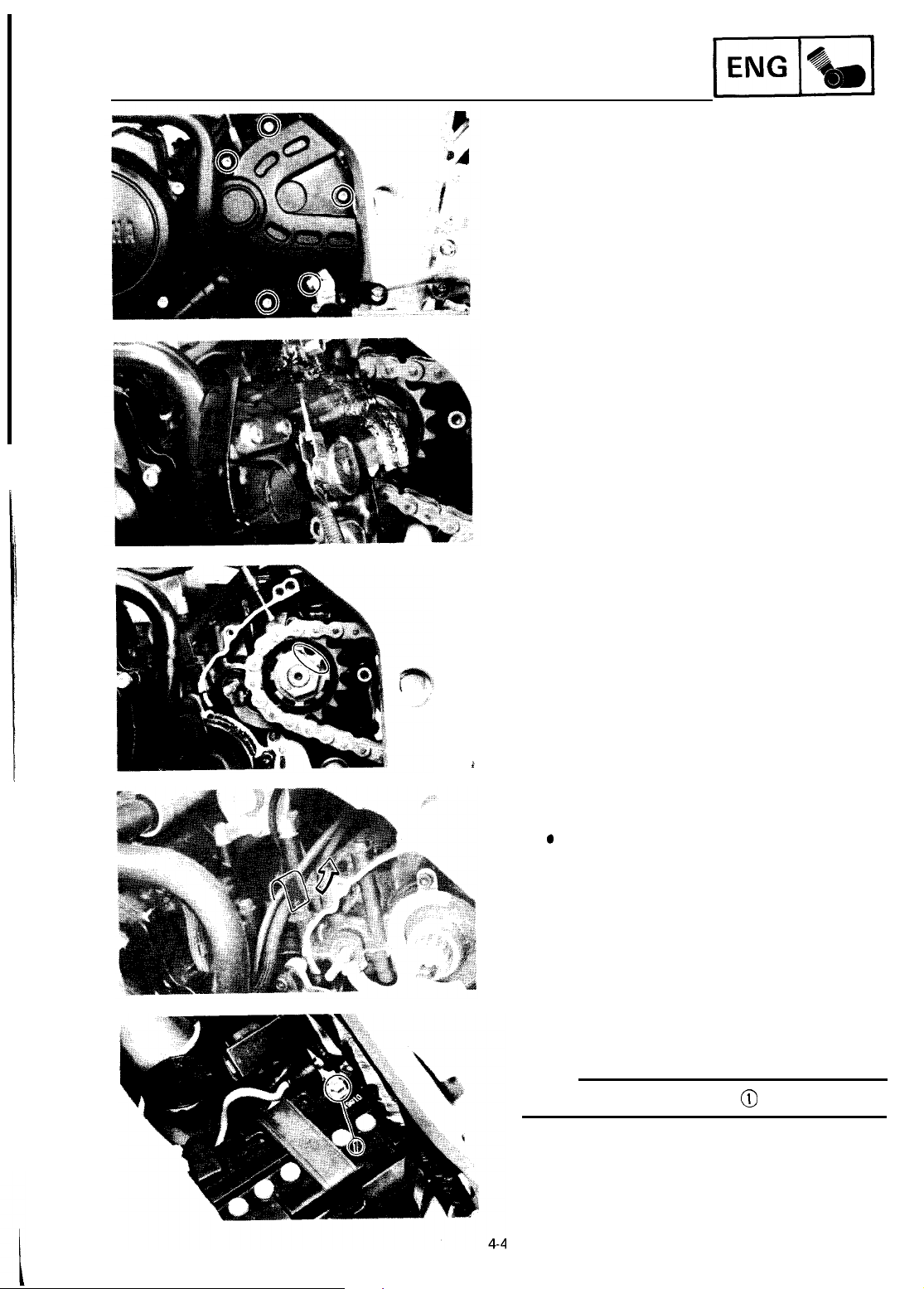

ENGINE DISASSEMBLY

ENGINE DISASSEMBLY

CYLINDER HEAD COVER, CAMSHAFT AND

CYLINDER HEAD

NOTE:

With the engine mounted, the cylinder head

cover,

maintained by removing the following parts.

?? Lower cowlings (Left and right)

?? Center cowlings (Left and right)

??

??

??

@Air

??

??

?? Down tube frame (Right)

camshaft and cylinder head can be

Seat

Top cover

Radiator

filter case

Carburetor

Muffler assembly

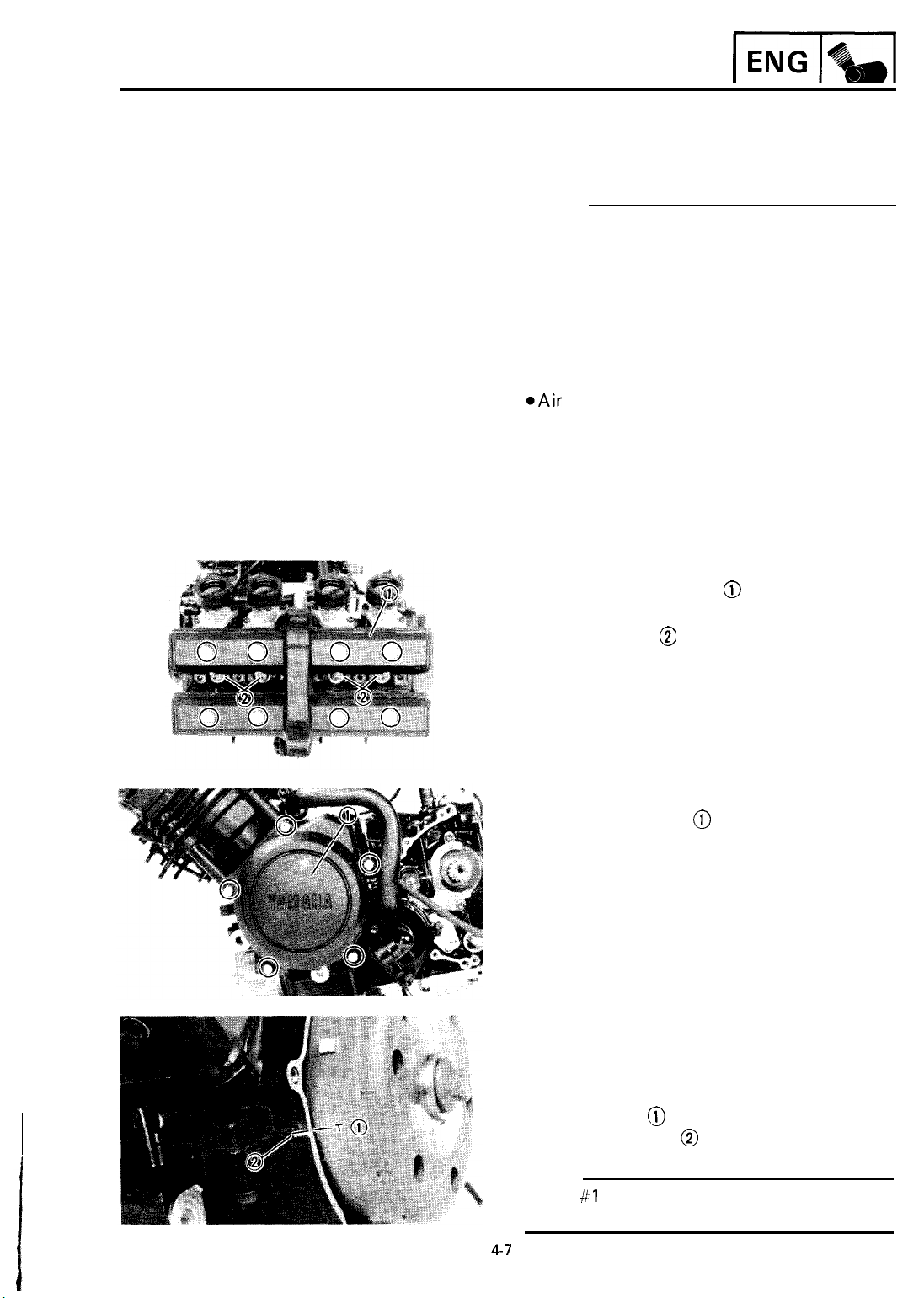

1. Remove:

@Cylinder head cover

??

Gasket (Cylinder head cover)

*Spark plugs

@

2. Remove:

@Generator cover

??

Dowel pins

3. Turn:

??

Crankshaft

Counterclockwise

4. Align:

?? “T” mark

??

Crankcase end

@

@

@

@

NOTE:

When #1 piston is at TDC on compression

stroke.

ENGINE DISASSEMBLY

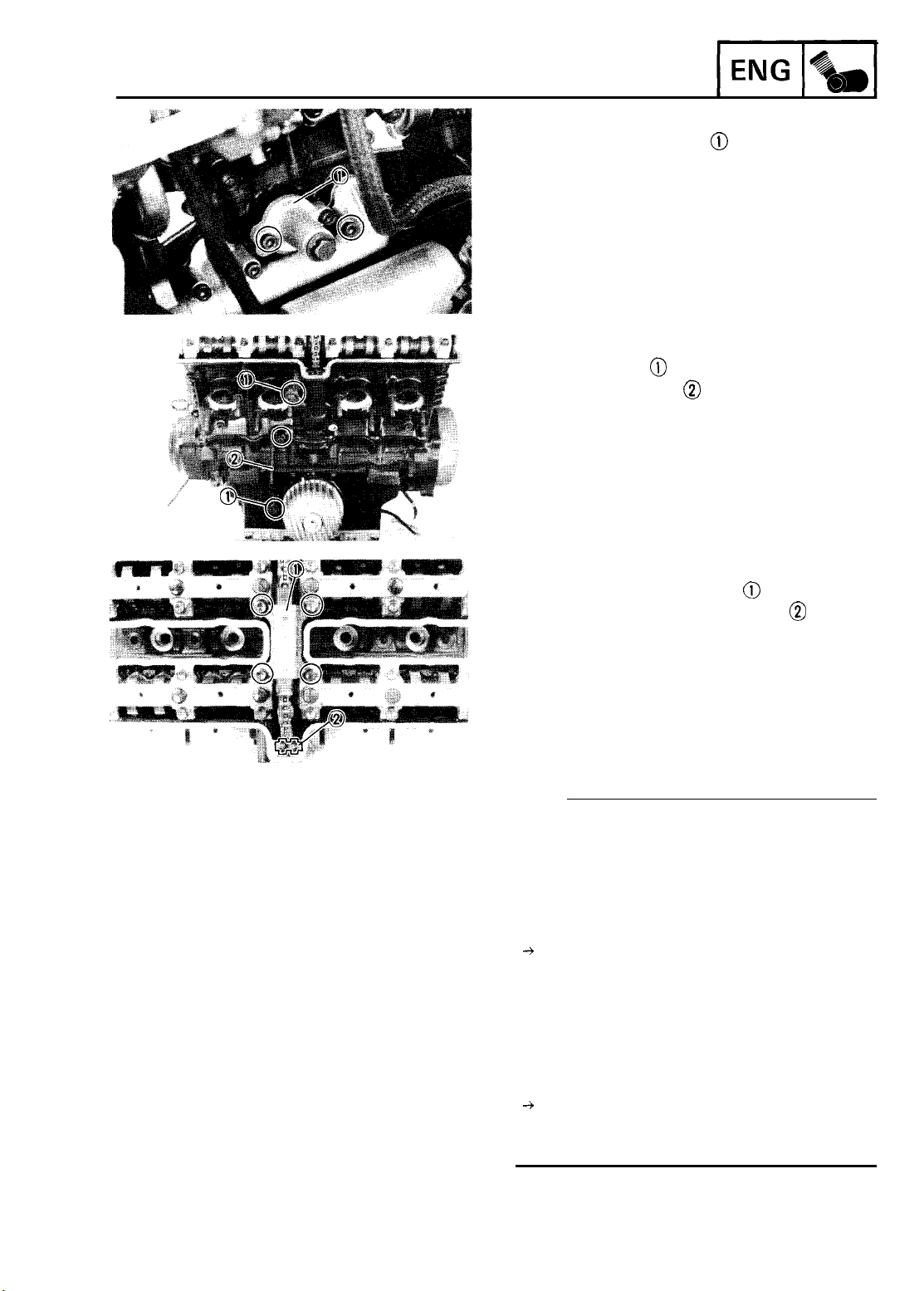

5. Remove:

??

Cam chain tensioner

?? Gasket (Cam chain tensioner)

6. Remove:

?? Union bolts

?? Oil delivery pipe

@

@

@

7. Remove:

??

Cam chain guide (Upper)

??

Cam chain guide (Exhaust side)

@

@

NOTE:

?? Select either of the two procedures explained

in this manual, as follows:

??

Procedure 1.

For engine service except cylinder head dis-

assembly.

-+

Disconnect the cam chain.

The pistons and cylinder can be removed

without removing the camshafts.

??

Procedure 2.

For engine service including cylinder head

disassembly.

--f

Remove the cam caps and camshafts.

The camshafts can be removed without disconnecting the cam chain.

4-8

ENGINE DISASSEMBLY

)

ENG

lq-1

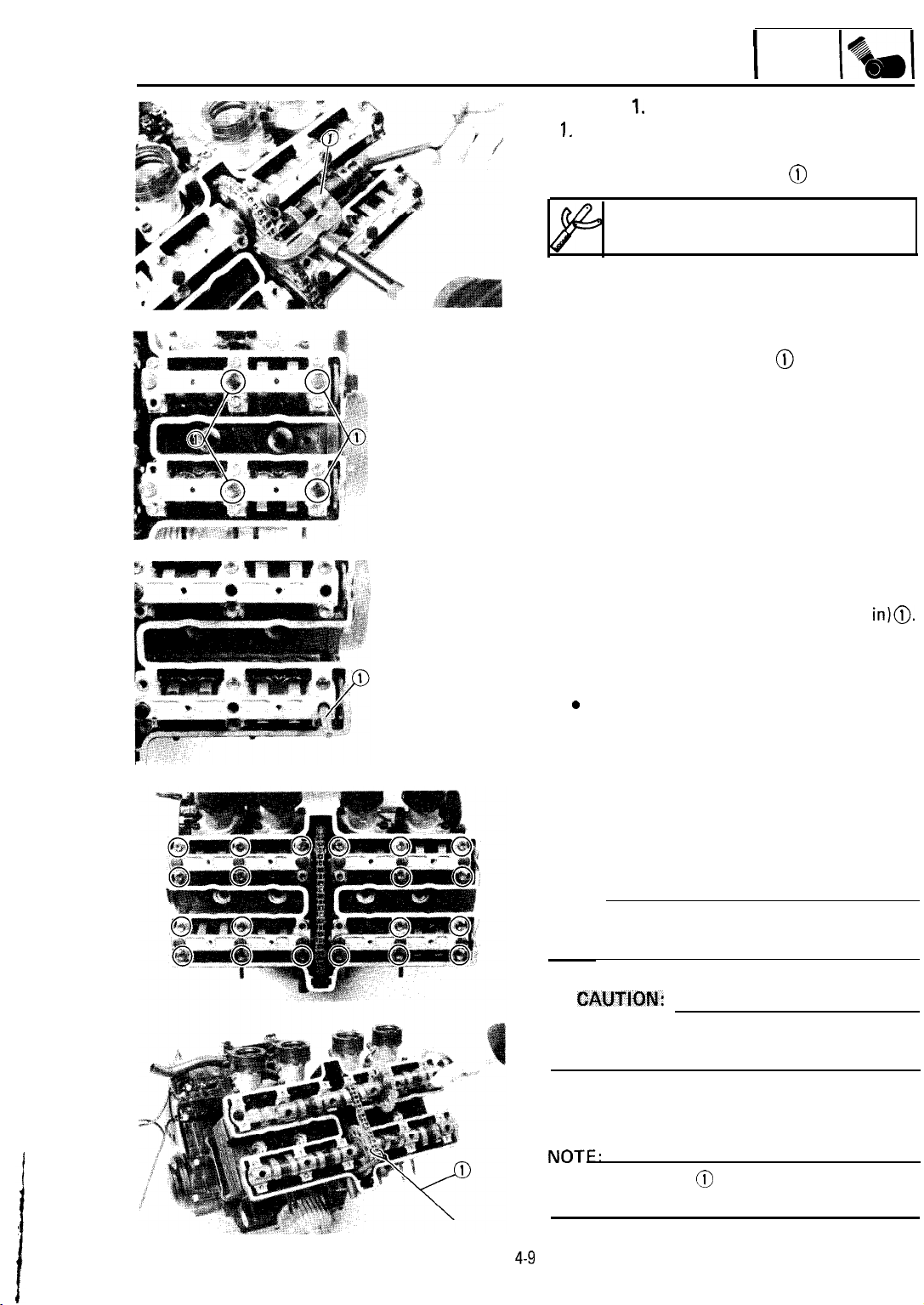

Procedure

1.

Disconnect:

??

2. Remove:

?? Rubbers (Camshaft cap)

3. Remove:

?? Nuts (Cylinder head)

4. Remove:

?? Cylinder head

?? Gasket (Cylinder head)

o

Dowel pins

5. Go to “CYLINDER AND PISTON”.

1.

Cam chain

Use the Cam Chain Cutter @ .

Cam Chain Cutter:

P/N YM-01112

@

Use the Hexagon Wrench 6 mm (0.24

in)@.

Procedure 2.

1. Remove:

??

Camshaft caps

??

Dowel pins

NOTE:

Remove the camshaft caps in a crisscross pattern

from outermost to inner caps.

A

CAUTIOM:

Do not rotate the camshaft or valve damage may

occur.

2. Remove:

??

Camshafts

Fasten safety wire @ to the cam chain to pre-

vent it from falling into the crankcase.

4-9

ENGINE DISASSEMBLY

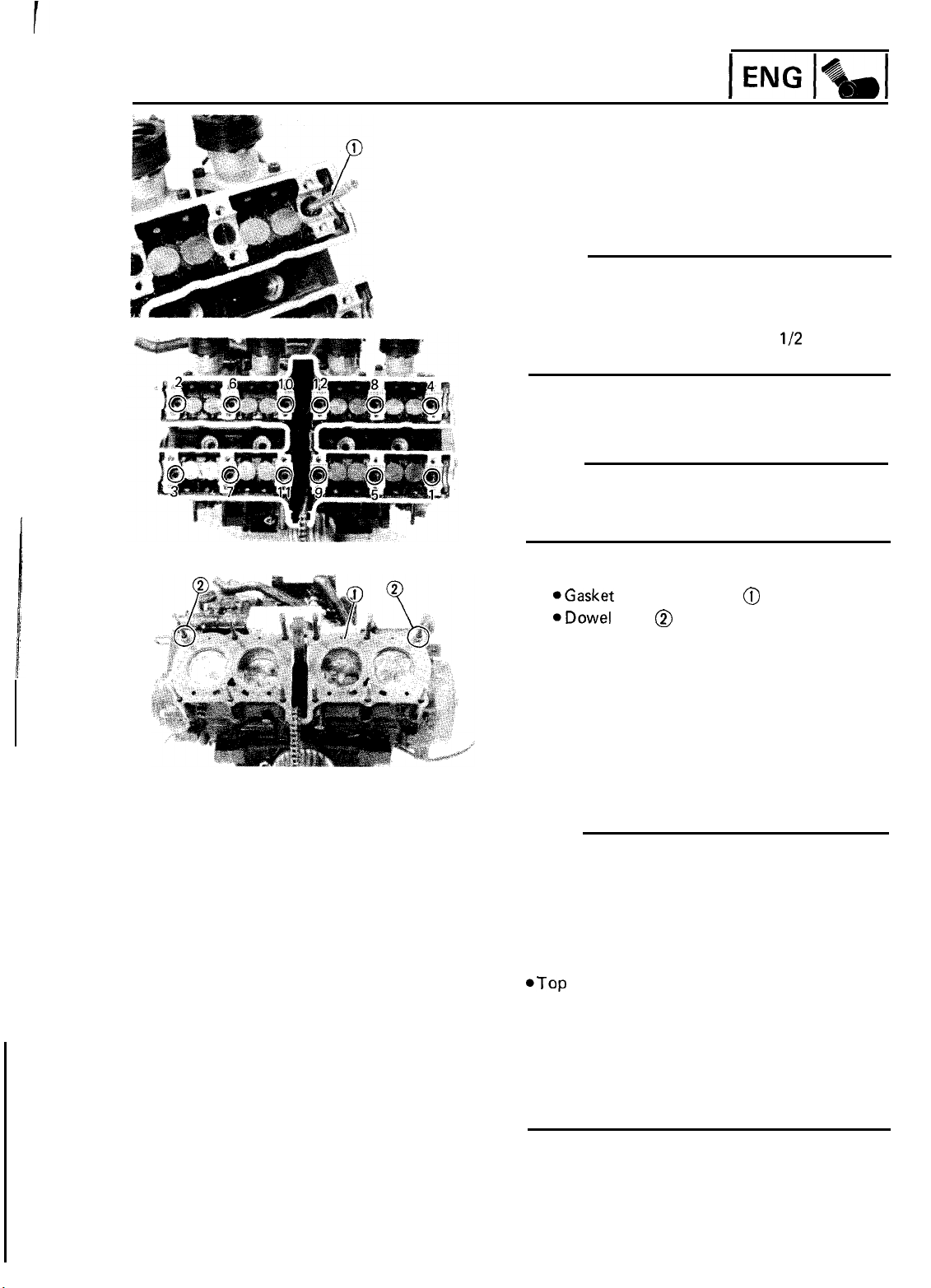

3. Remove:

?? Nuts (Cylinder head)

Use the Hexagon Wrench 6 mm (0.24 in)@.

NOTE:

?? Loosen the nuts in their proper loosening

sequence.

?? Follow numerical order shown in photo.

Start by loosening each nut

all are loose.

4. Remove:

??

Cylinder head

NOTE:

Remove the cylinder head as a whole to prevent

the valve lifters and adjusting pads from falling

into the crankcase.

l/2

turn until

5. Remove:

aGasket

@Dowel

(Cylinder head)

pins

@

@

CYLINDER AND PISTON

NOTE:

With the engine mounted, the cylinder and piston

can be maintained by removing the following

parts.

?? Lower cowlings (Left and right)

??

Center cowlings (Left and right)

??

Seat

*Top

cover

??

Radiator

??

Air filter case

??

Carburetor

??

Muffler assembly

?? Down tube frame (Right)

??

Cylinder head

4-10

ENGINE DISASSEMBLY

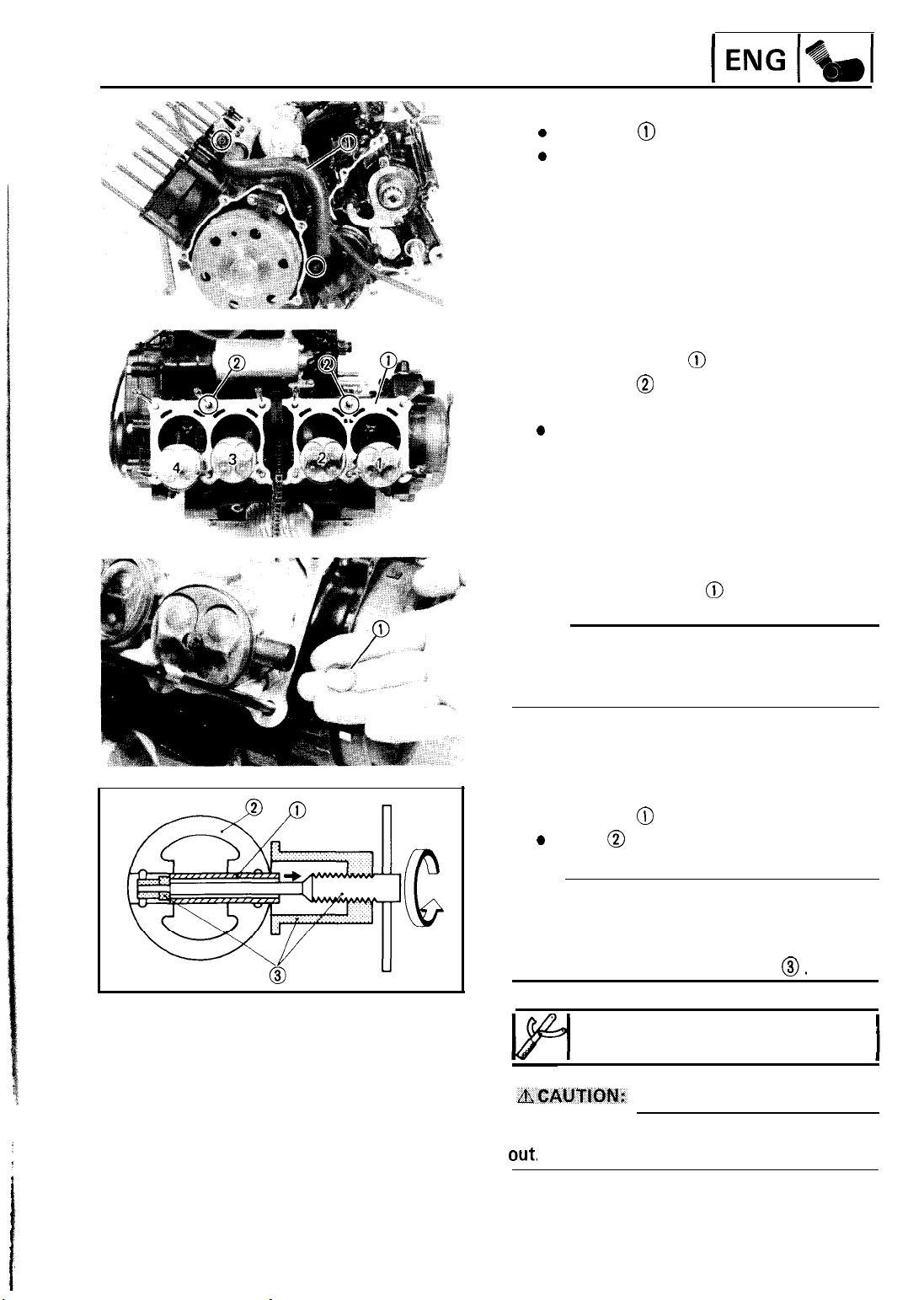

1. Remove:

0

Water pipe

0

O-rings

?? Cylinder

2. Remove:

?? Gasket (Cylinder)

?? Dowel pins

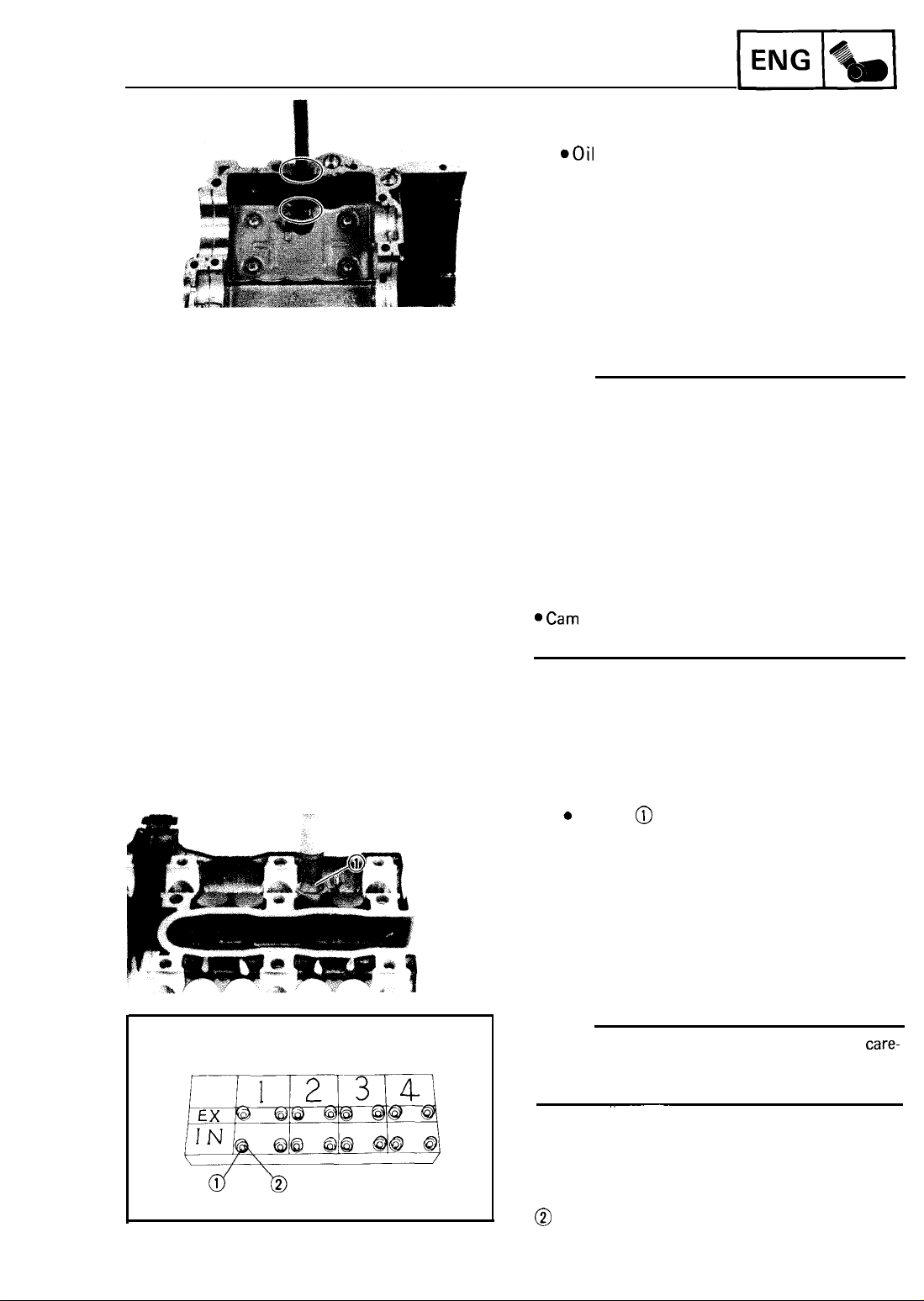

3. Mark:

0 Pistons

With the piston number designations as

shown.

@

@

@

4. Remove:

??

Circlips (Piston pin)

@

NOTE:

Before removing the piston pin circlip, cover the

crankcase with a clean rag to prevent the circlip

from falling into the crankcase cavity.

5. Remove:

??

Piston pins

0

Pistons

0

@

NOTE:

Before removing the piston pin, deburr the clip

grooved and pin hole area. If the piston pin

groove is deburred and piston pin is still difficult

to remove, use the Piston Pin Puller

0.

Piston Pin Puller:

P/N YU-01304

Do not use a hammer to drive the piston pin

out.

4-11

ENGINE DISASSEMBLY

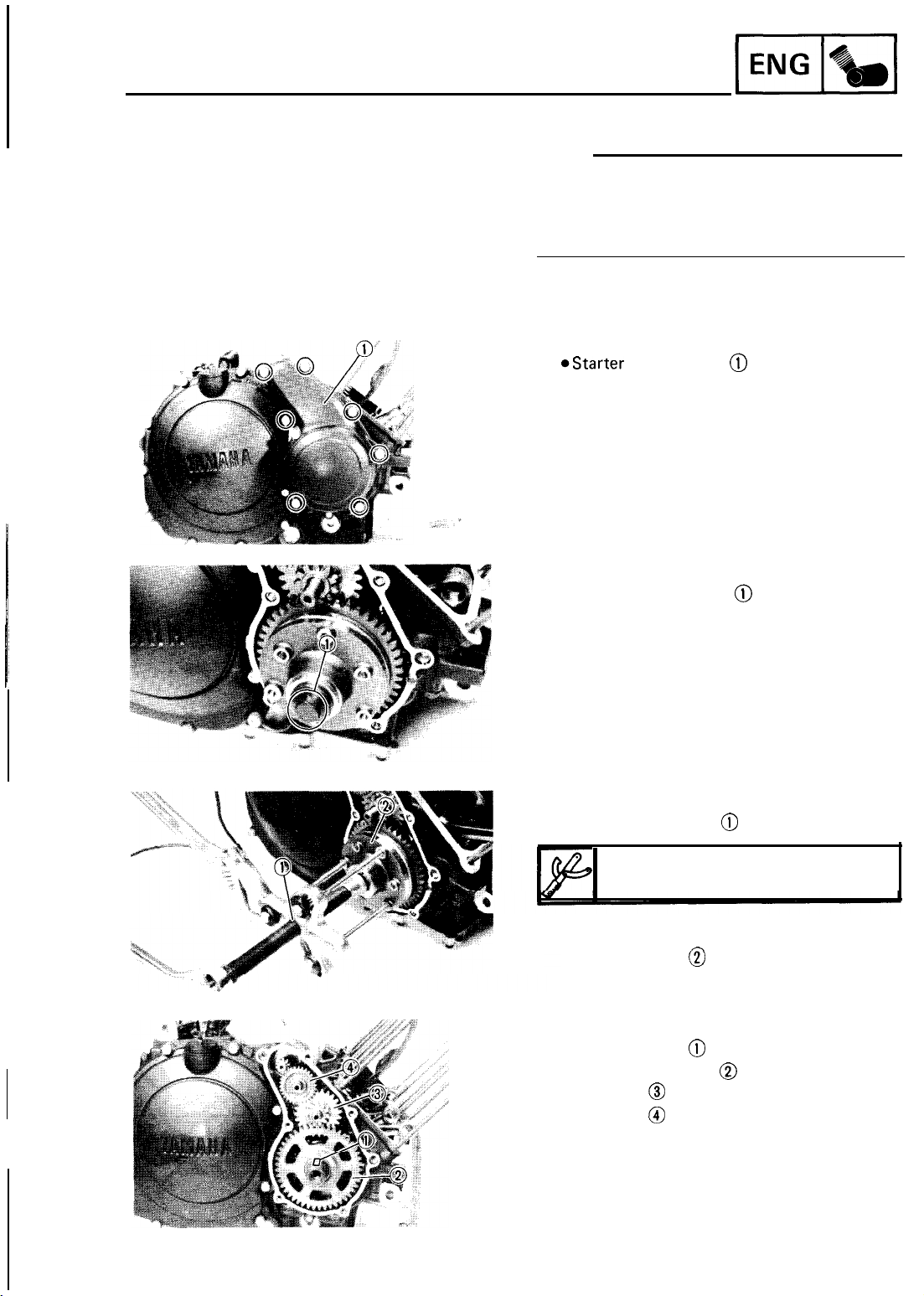

STARTER CLUTCH

NOTE:

With the engine mounted, the starter clutch can

be maintained by removing the following parts.

?? Lower cowling (Right)

?? Starter clutch cover

1. Remove:

*Starter

?? Gasket (Starter clutch cover)

??

clutch cover

Dowel pens.

@

2. Remove:

?? Bolt (Starter clutch)

??

Washer

3. Attach:

?? Heavy Duty Puller

Heavy Duty Puller:

Y U-33270

4. Remove:

?? Starter clutch

5. Remove:

?? woodruff key

??

Starter clutch gear

?? Idle gear

?? Idle gear

@I

@

@

@

@

@

@

4-12

ENGINE DISASSEMBLY

CLUTCH

NOTE:

With the engine mounted, the starter clutch can

be maintained by removing the following parts.

?? Lower cowling (Right)

??

Crankcase cover (Right)

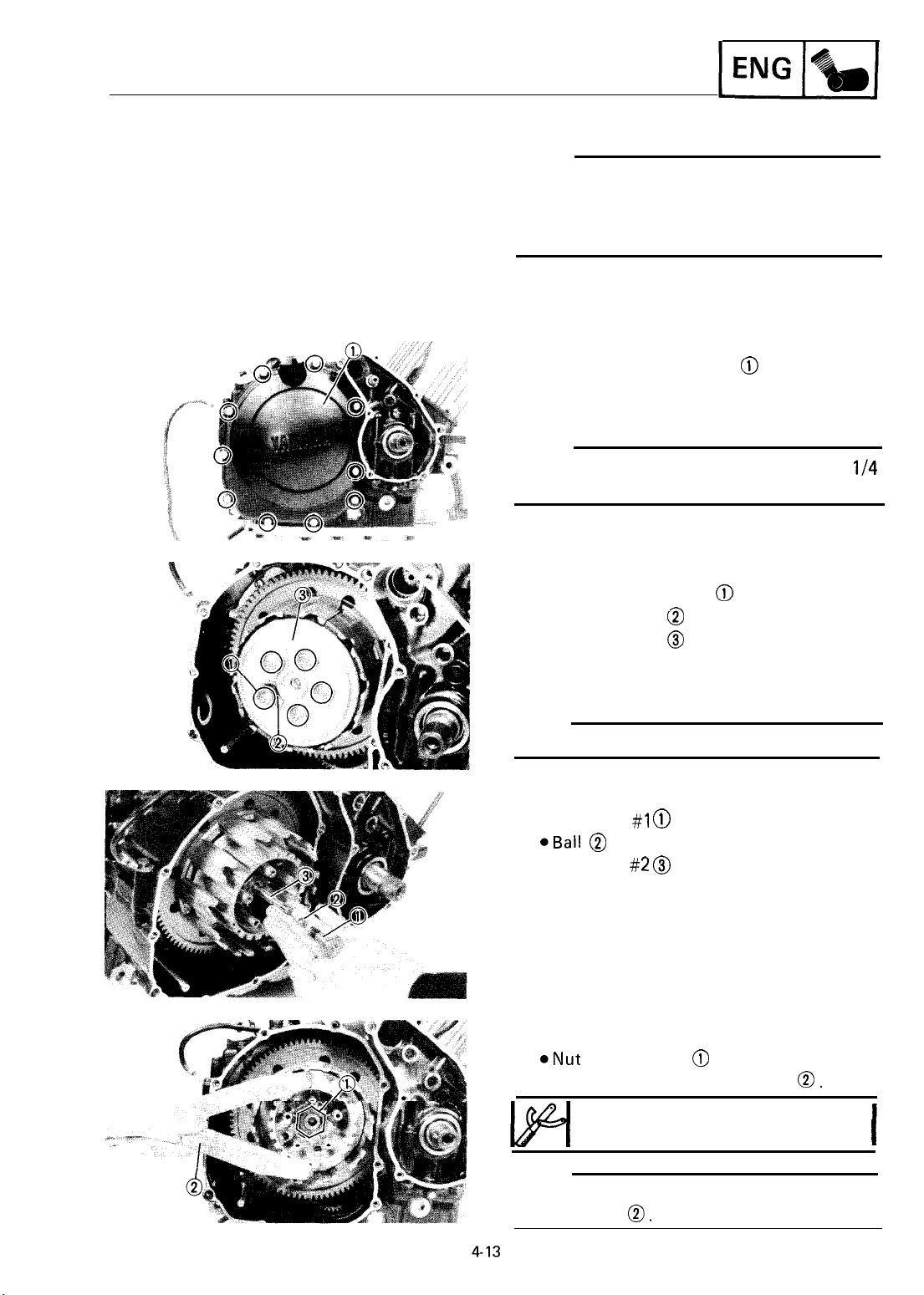

1. Remove:

?? Crankcase cover (Right)

??

Gasket (Crankcase cover)

??

Dowel pins

NOTE:

Working in a crisscross pattern, loosen bolts

turn each. Remove them after all are loosened.

@

l/4

2.

Remove:

?? Bolts (Clutch spring)

*Clutch springs

??

Pressure plate

??

Friction plates

??

Clutch plates

@

@

@

NOTE:

Loosen the bolts in a crisscross pattern.

3. Remove:

?? Push rod

#l @

aBall @

?? Push rod

#2 @

4. Straighten the lock washer tabs.

5. Loosen:

@Nut

(Clutch boss)

Use the Universal Clutch Holder

@

0.

Universal Clutch Holder:

P/N Y M-91 042

NOTE:

Hold the clutch boss loosen the nut by Universal

Clutch Holder

0.

ENGINE DISASSEMBLY

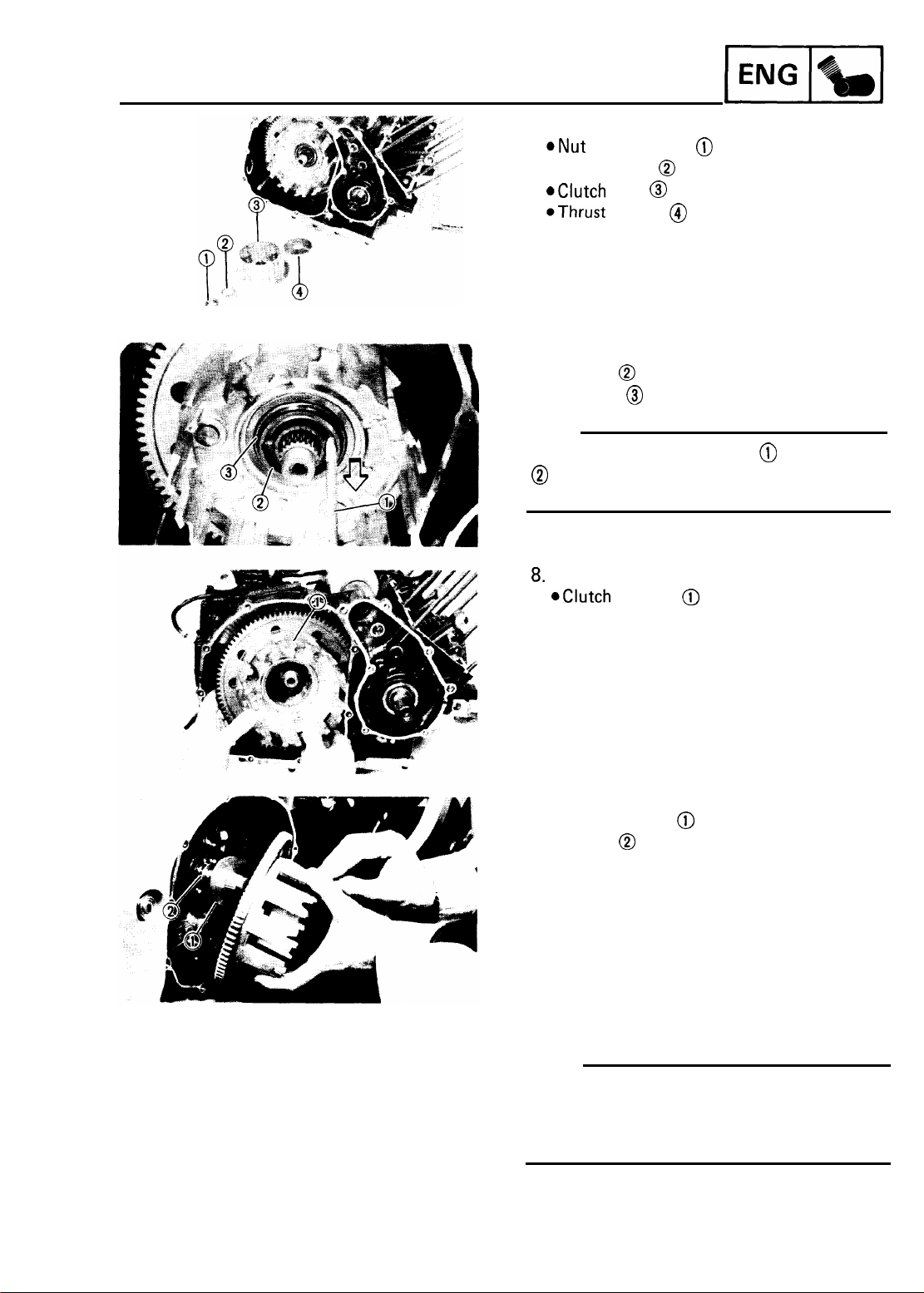

6. Remove:

.Nut

(Clutch boss)

??

Lock washer

@Clutch

thrust

boss

washer

7. Remove:

??

Spacer

@

??

Bearing

@

NOTE:

Install the 5 mm (0.2 in) screw @ on the spacer

@

then remove the spacer with pulling out

screw.

@

@

@

@

8.

Remove:

aClutch

housing

9. Remove:

??

Thrust washer

*Collar

@

A.C. MAGNETO

@

@

NOTE:

With the engine mounted, the A.C. Magneto can

be maintained by removing the following parts.

?? Lower cowling ( Left)

??

Generator cover

4-14

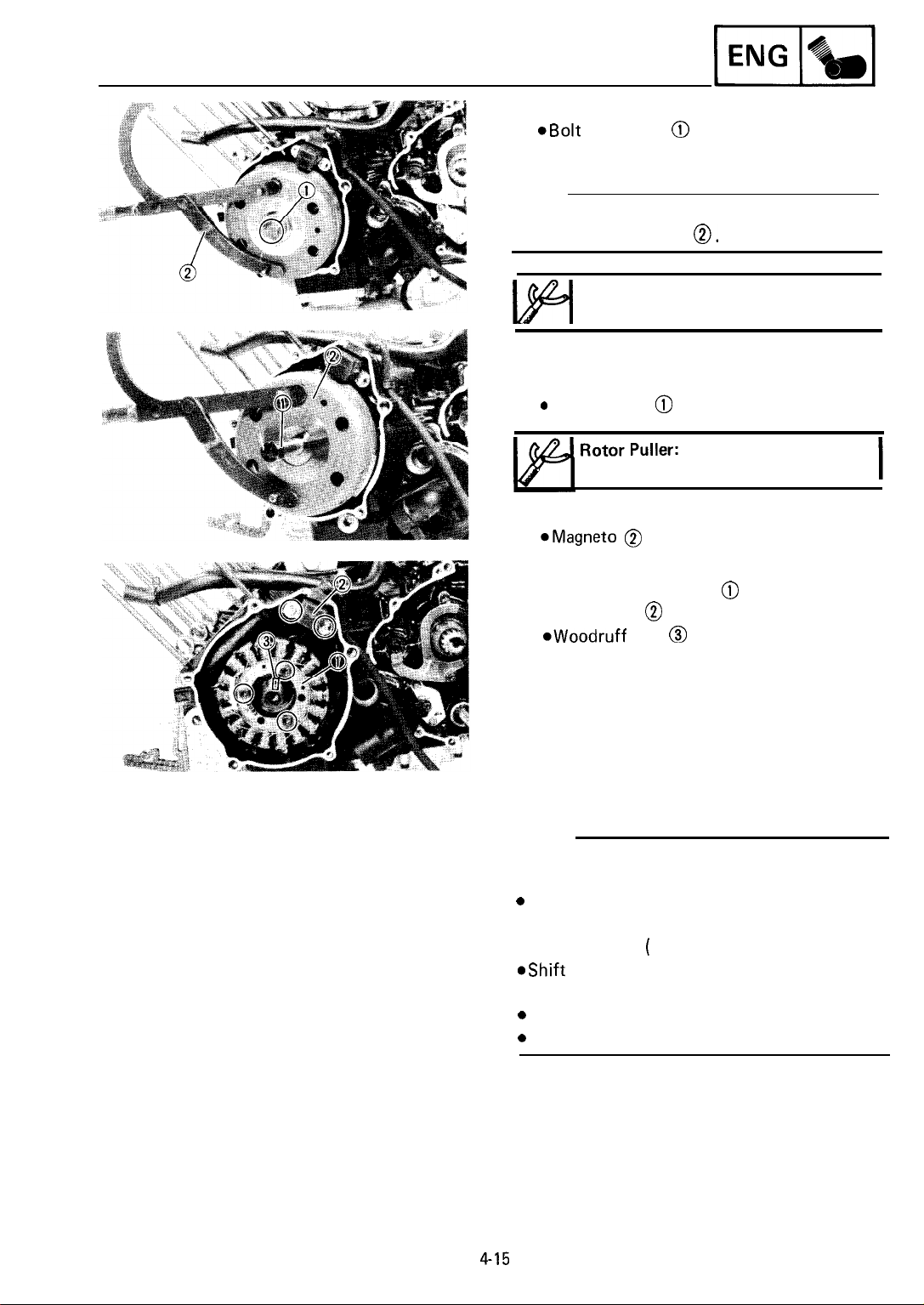

ENGINE DISASSEMBLY

1. Remove:

@Bolt

(Magneto)

??

Washer

NOTE:

Hold the magneto to loosen the nut by the

Universal Rotor Holder

Universal Rotor Holder:

LFI

2. Attach:

0

3.

*Magneto @

P/N YU-01235

Rotor puller

P/N YM-01080

Remove:

@

0.

@

I

4. Remove:

??

Starter coil assembly

??

Pickup coil

@Woodruff

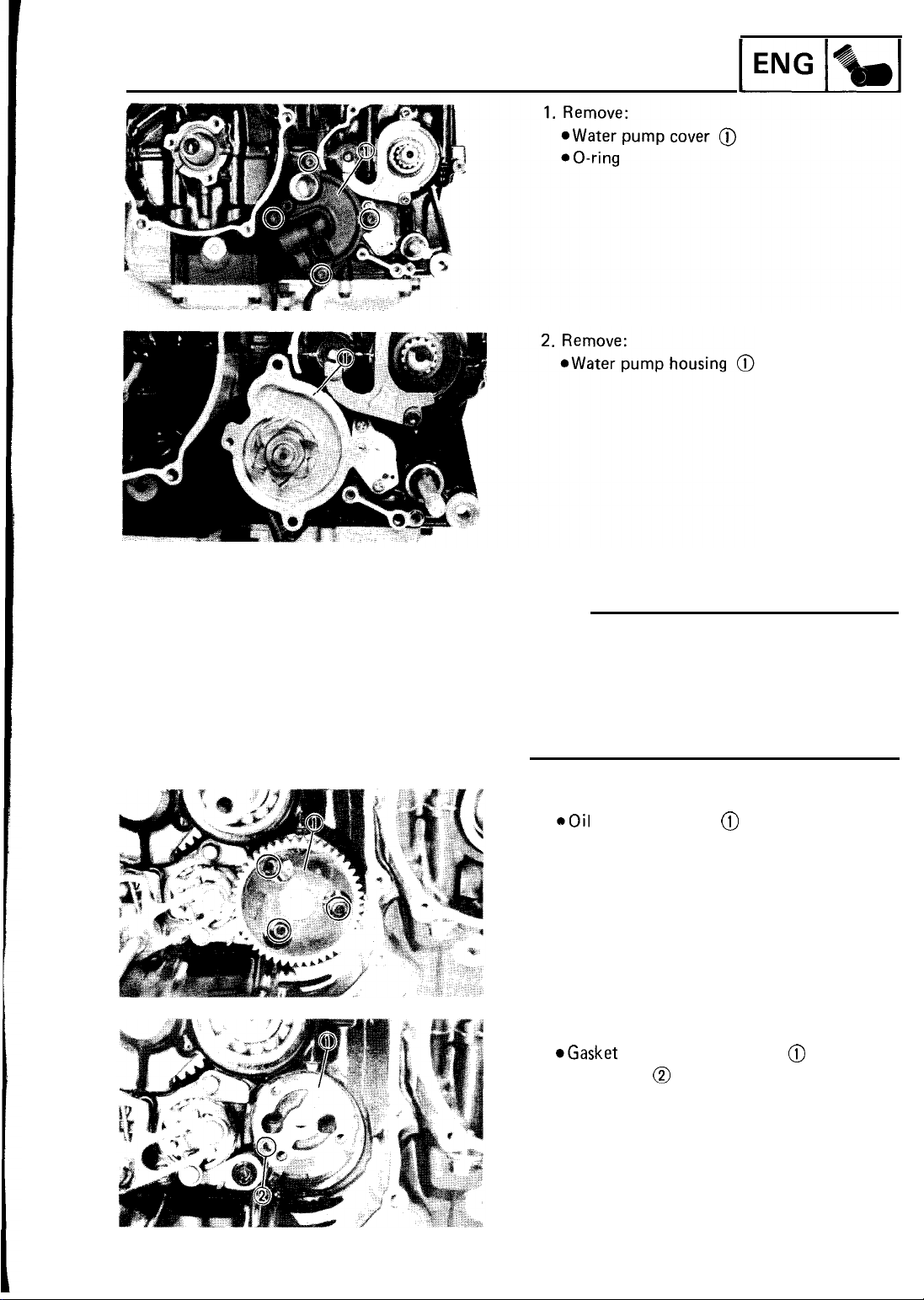

WATER PUMP

NOTE:

With the engine mounted, the water pump can

be maintained by removing the following parts.

0 Seat

??

Top cover

?? Lower cowling

aShift

arm

??

Crankcase cover (Right)

0 Water pipe

0

Water pump cover

@

key

(

Right)

@

@

4-15

ENGINE DISASSEMBLY

OIL PUMP AND SHIFT SHAFT

NOTE:

With the engine mounted, the oil pump and

shift shaft can be maintained by removing the

following parts.

?? Lower cowling (Right)

??

Crankcase cover (Right)

??

Clutch housing

1. Remove:

*Oil

pump assembly

2. Remove:

*Gasket

??

Dowel pin

(Oil pump assembly)

@

@

@

4-16

ENGINE DISASSEMBLY

(ENG lb1

3. Remove:

??

Shift shaft assembly

@

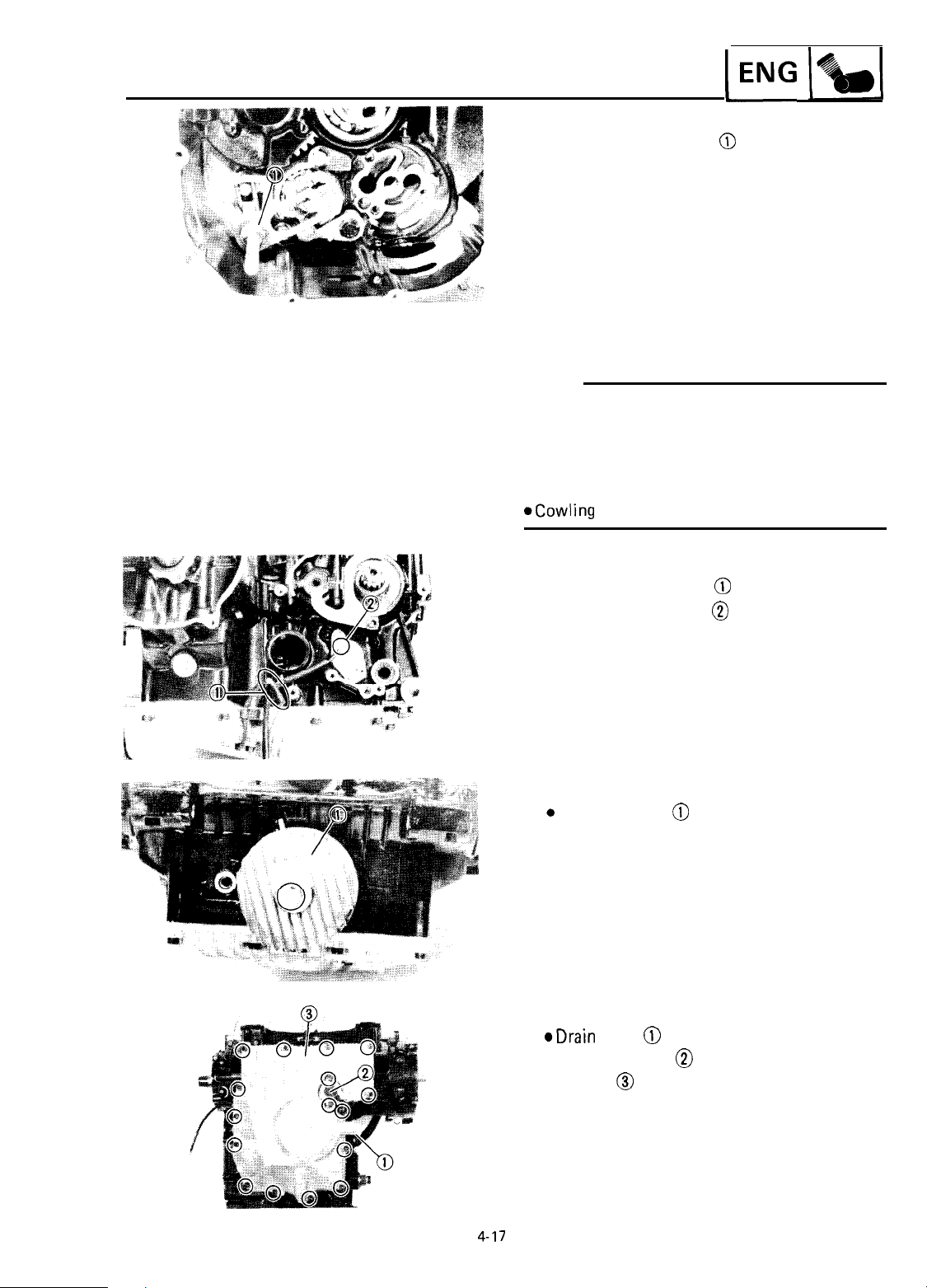

OIL PAN AND OIL STRAINER

NOTE:

With the engine mounted, the oil pan and oil

strainer can be maintained by removing the

following parts.

?? Lower cowlings (Left and right)

?? Muffler assembly

scowling

stay

1. Disconnect:

?? 0il level switch lead

?? Neutral switch lead

2. Remove:

0

Oil filter cover

??

Oil filter

3. Remove:

@Drain

plug

@

?? 0il level switch

??

Oil pan

@

??

Gasket (Oil pan)

??

Dowel pins

@

@

@

@

4-17

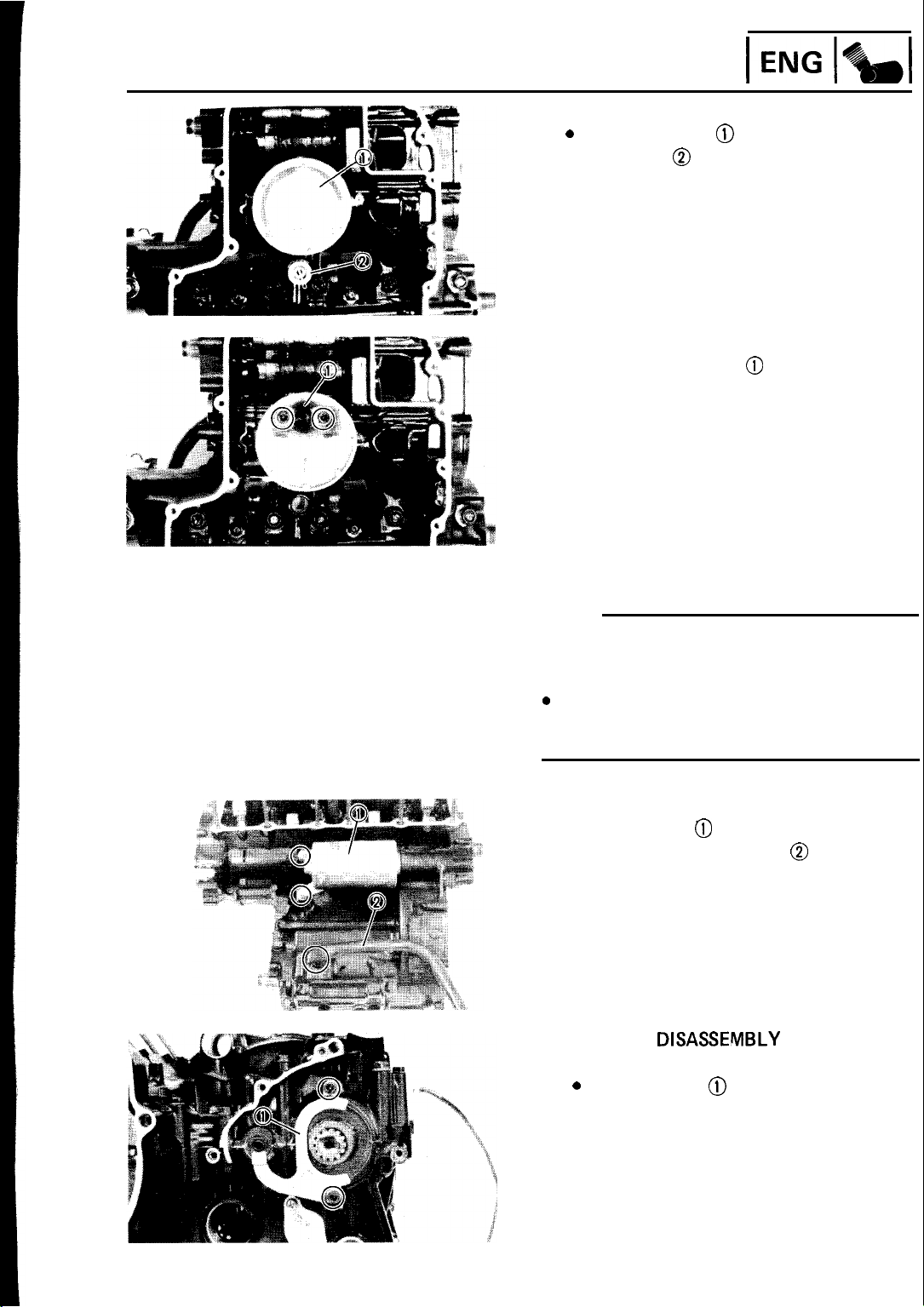

ENGINE DISASSEMBLY

4. Remove:

0

Oil strainer cover

?? Relief valve

5. Remove:

??

Oil strainer assembly

0

@

@

STARTER MOTOR

NOTE:

With the engine mounted, the starter motor,

can be maintained by removing the following

parts.

0

Seat

??

Top cover

??

Fuel tank

1. Remove:

??

Starter motor

??

crankcase ventilation hose

CRANKCASE

0

@

DlSASSErVlBLY

1. Remove:

0

Oil seal stopper

@

4-18

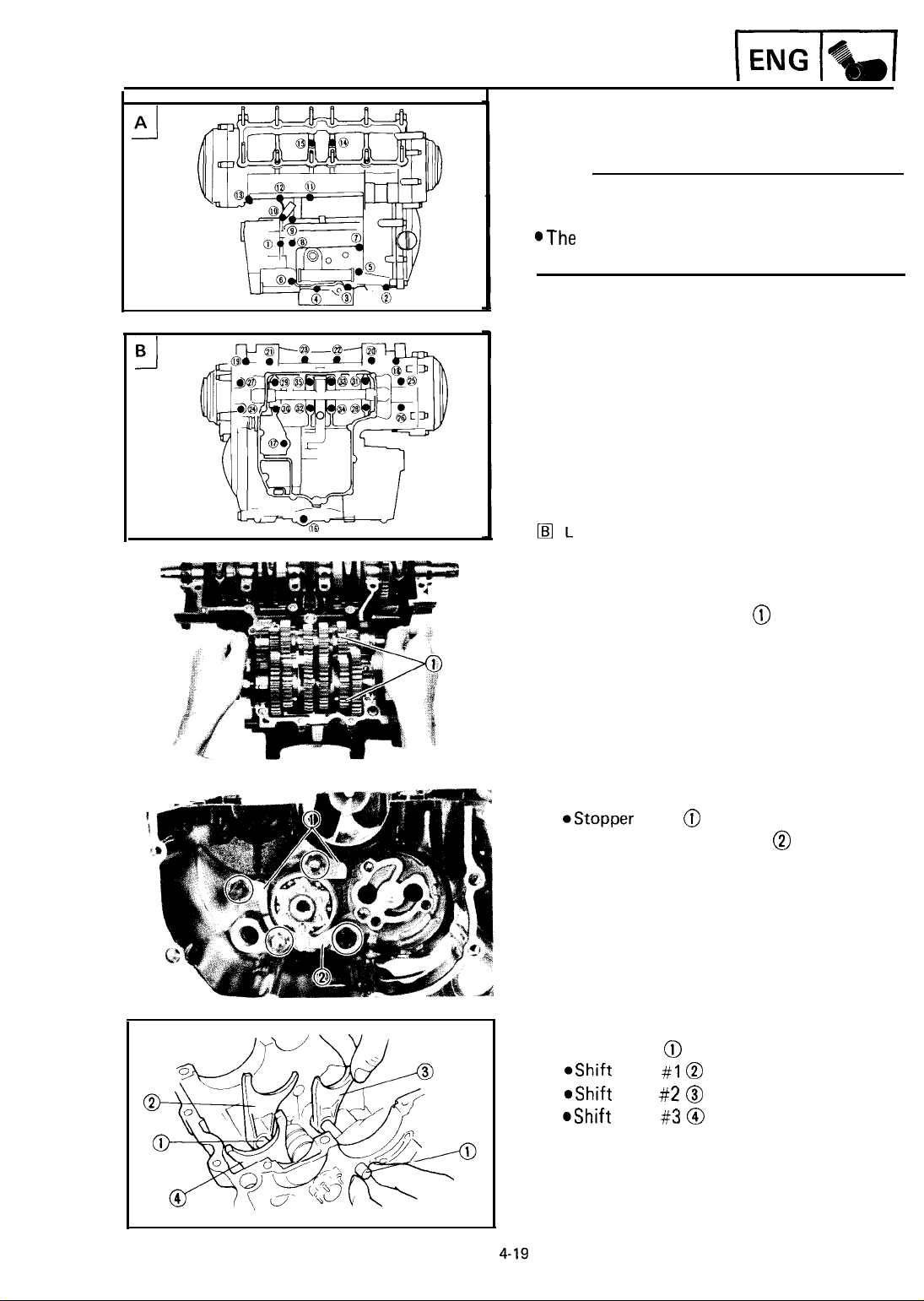

ENGINE DISASSEMBLY

A

J

3. Remove:

??

Bolts (Crankcase)

NOTE:

G

?? Remove the bolts starting with the highest

numbered one.

*The

embossed numbers in the crankcase

designate the crankcase tightening sequence.

4. Place the engine upside down.

5. Remove:

?? Crankcase (Lower)

Use a soft hammer.

??

Upper case

ower case

[BIL

TRANSMISSION, SHIFTER AND SHIFT CAM

1. Remove:

??

Transmission assembly

??

Dowel pins

@

2. Remove:

@Stopper

lever

0

?? Stopper plate (Shift cam)

3. Remove:

?? Guide bars

@Shift

fork #l

*Shift

fork #2

aShift

fork #3

@

@

@

@

@

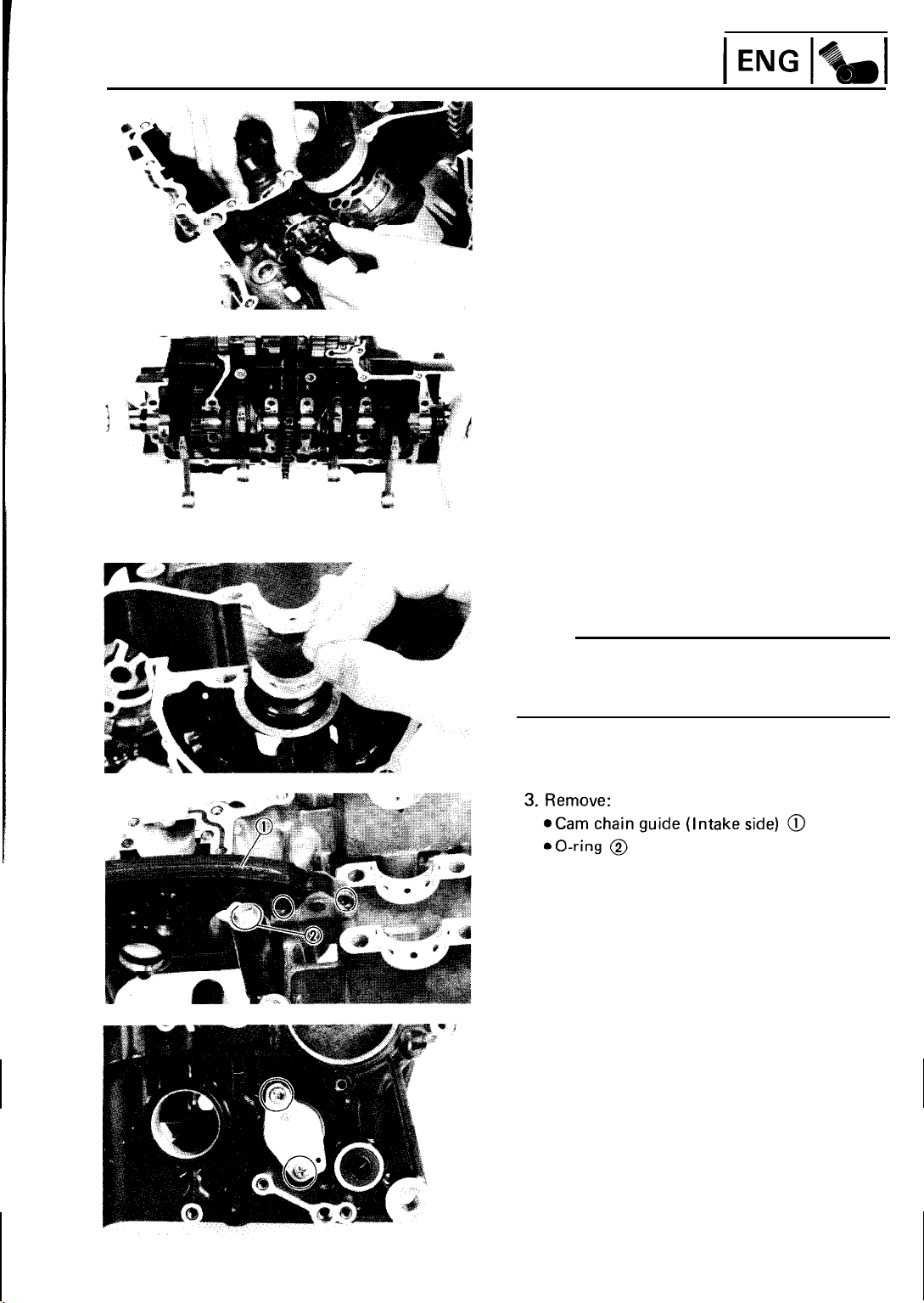

ENGINE DISASSEMBLY

4. Remove:

??

Shift cam

CRANKSHAFT

1. Remove:

??

Crankshaft assembly

2. Remove:

??

Main journal bearing

NOTE:

Identify each main journal bearing position

very carefully so that it can be reinstalled in

its original place.

4. Remove:

??

Neutral switch

4-20

ENGINE DISASSEMBLY

5. Remove:

??

Breather hose

@Oil

baffle plate

VALVE PAD AND VALVE

NOTE:

With the engine mounted, the valve pad and

valve can be maintained by removing the

following parts.

?? Lower cowlings (Left and right)

@Center cowlings (Left and right)

??

Fuel tank

??

Carburetor

??

Radiator

@Generator cover

?? Cylinder head cover

eCam

chain tensioner

@Cylinder head

1. Remove:

0

Lifters

??

Valve pads

0

NOTE:

Identify each lifter and pad position very

fuly so that it can be reinstalled in its original

4-21

place.

@ Lifters

@

Valve pads

--

care-

ENGINE DISASSEMBLY

2. Check:

0

Valve sealing

Leakage at valve seat + inspect the valve

face, valve seat and valve seat width.

Refer to the “INSPECTION AND REPAIR

-

VALVE SEAT” section.

NOTE:

Before removing the internal parts (valve, valve

spring, spring seat, etc.) of the cylinder head, the

valve sealing should be checked.

Valve seal checking steps:

?? Supply a clean solvent

and exhaust ports.

?? Check the valve sealing. There should be no

leakage at the valve seats

@

into the intake

0.

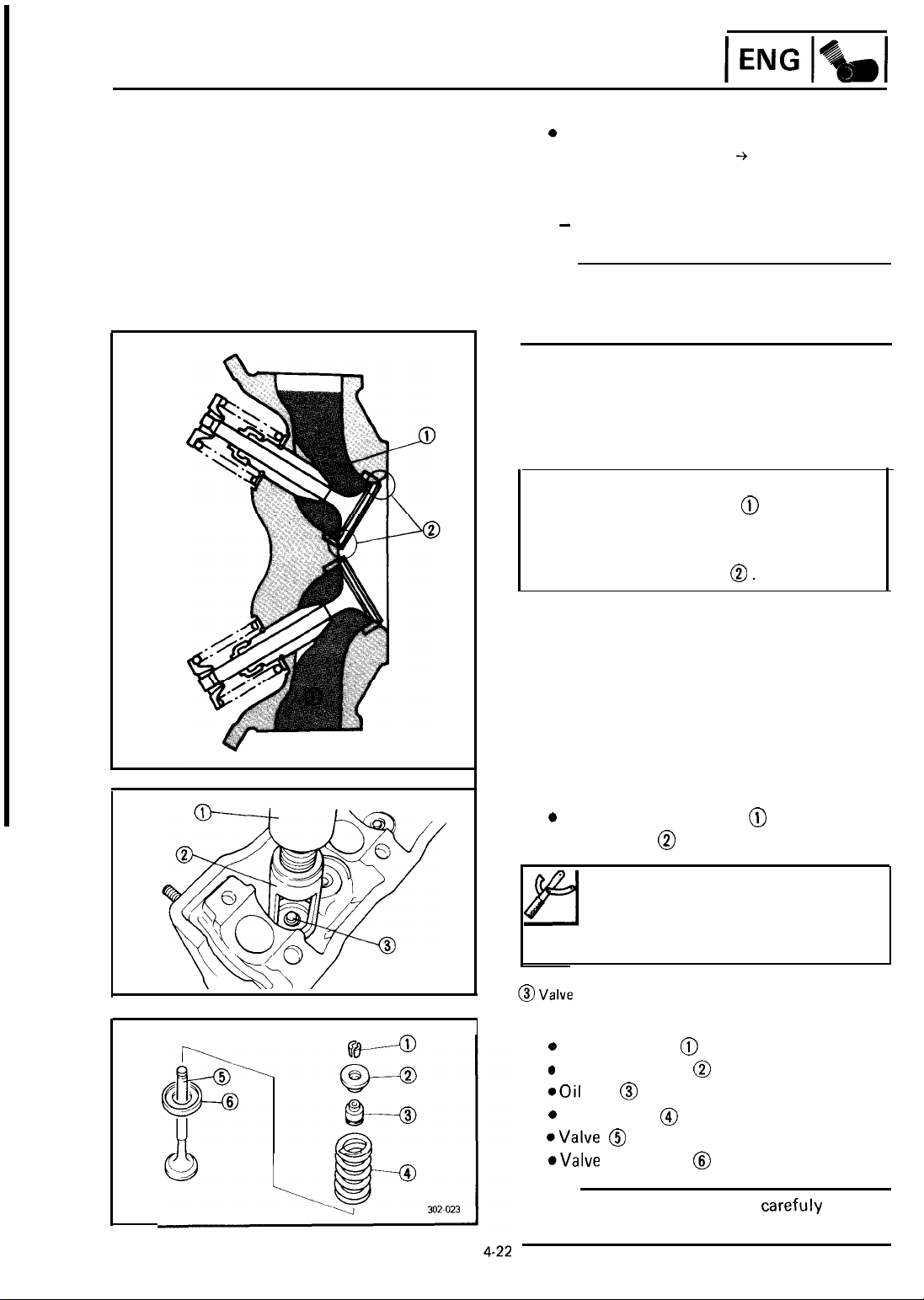

3. Attach:

0

Valve spring compressor

?? Attachment

@

@

Valve Spring Compressor:

P/N YM-04019

Attachment:

P/N Y M-04108

@Valve

retainers

4. Remove:

0

Valve retainers

0

Valve spring seat

*Oil

seal

@I

0

Valve spring

@

@

@

*Valve @

*Valve

spring seat

@

NOTE:

Identify each part position very

carefuly

it can be reinstalled in its original place.

so that

ENGINE DISASSEMBLY

CONNECTING ROD

1. Remove:

??

connecting rod

?? Connecting rod bearing

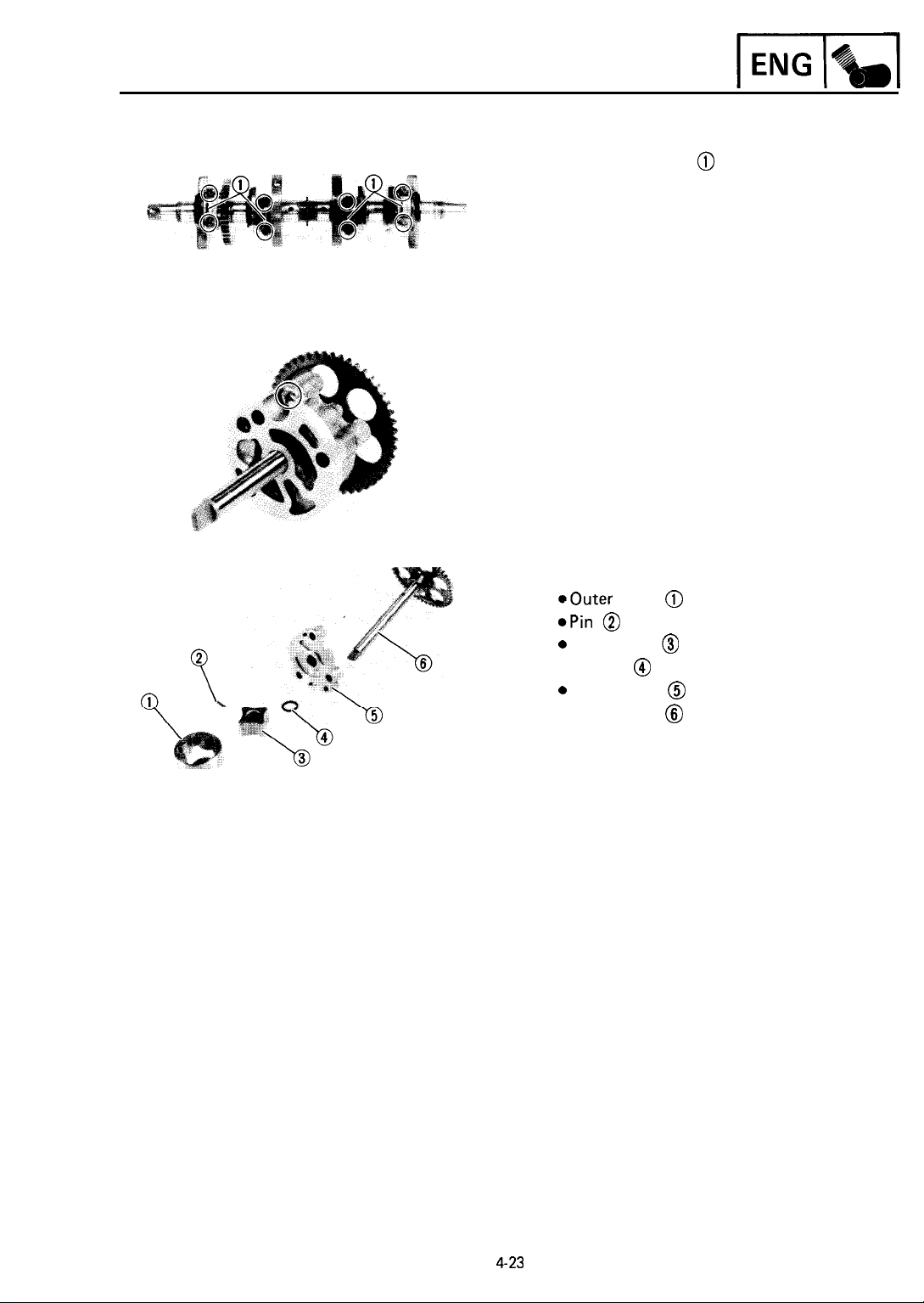

INNER ROTOR (OIL PUMP)

1. Remove:

??

Pump housing

@

2. Remove:

*Outer

rotor

@Pin @

0

Inner rotor

??

Washer

0

Pump cover

?? Pump shaft

@

0

@

@

@

4-23

INSPECTION AND REPAIR

INSPECTION AND REPAIR

CYLINDER HEAD

1. Eliminate:

??

NOTE:

Do not use a sharp instrument and avoid

--

ing or scratching:

??

??

Va Ive seat

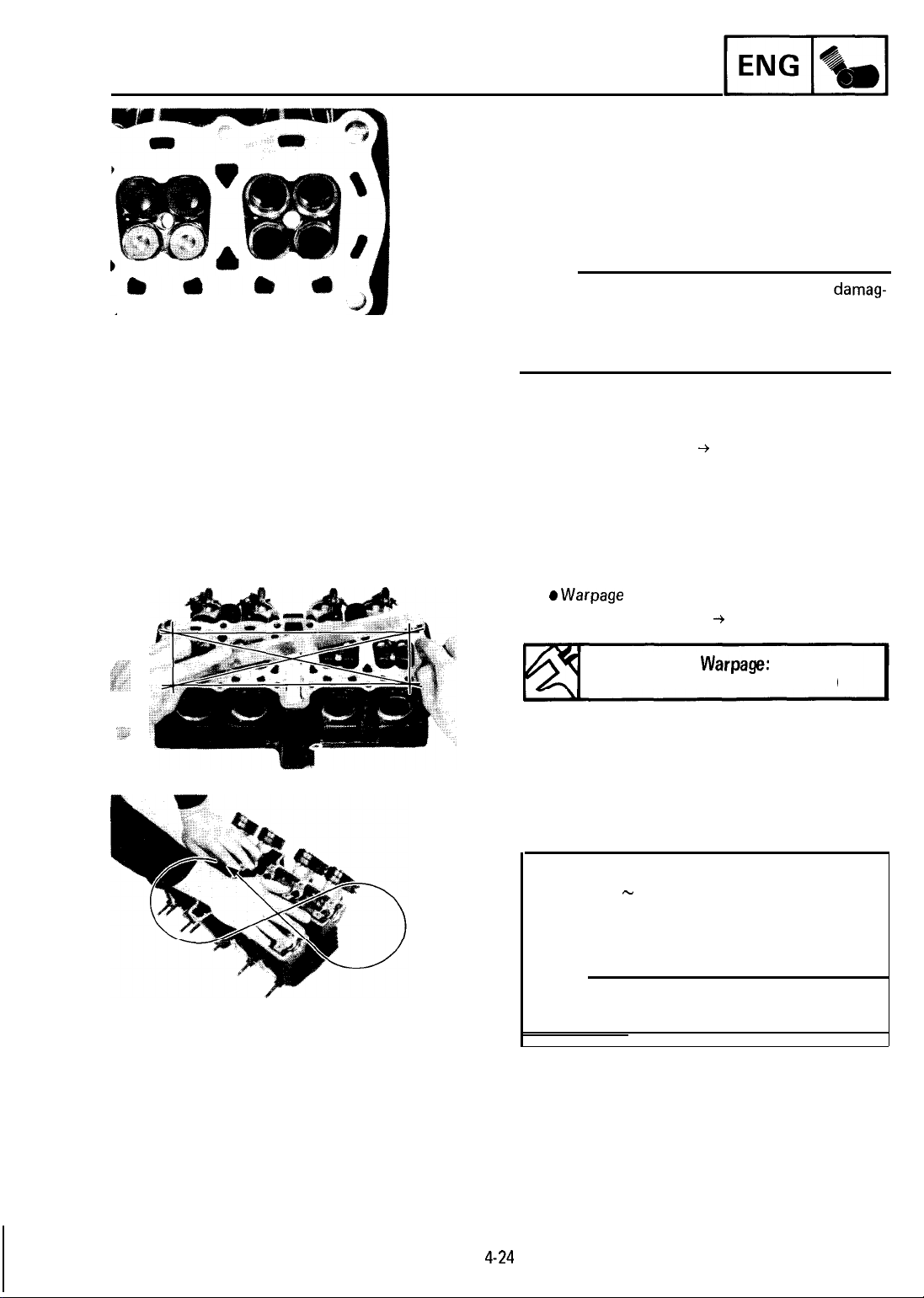

2. Inspect:

??

Carbon deposit

(from combustion chamber)

Use rounded scraper.

damag-

Spark plug threads

Cylinder head

Scratches/Damage + Replace.

3. Measure:

0 Warpage

Out of specification -+ Resurface.

Cylinder Head Warpage:

Less than 0.03 mm (0.0012 in)

4. Resurface:

??

Cylinder head

Resurfacement steps:

Place a 400

600 grit wet sandpaper on the

-

surface plate, and resurface the head using a

figure-eight sanding pattern.

NOTE:

Rotate the head several times to avoid remov-

ing too much material from one side.

I

I

4-24

Loading...

Loading...