Yamaha F50F, FT50G, F60C, FT60D, F70A User Manual

OWNER’S MANUAL

Read this manual carefully before operating this

outboard motor.

F40D

F40G

F50F

FT50G

F60C

FT60D

F70A

6C1-28199-79-E0

EMU25052

Read this manual carefully before operating this outboard motor. Keep this

manual onboard in a waterproof bag when boating. This manual should stay

with the outboard motor if it is sold.

Important manual information

WARNING

NOTICE

TIP:

TIP:

EMU25107

To the owner

Thank you for selecting a Yamaha outboard

motor. This Owner’s Manual contains information needed for proper operation, maintenance and care. A thorough understanding

of these simple instructions will help you obtain maximum enjoyment from your new

Yamaha. If you have any question about the

operation or maintenance of your outboard

motor, please consult a Yamaha dealer.

In this Owner’s Manual particularly important

information is distinguished in the following

ways.

: This is the safety alert symbol. It is

used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

EWM00781

A WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

ECM00701

A NOTICE indicates special precautions

that must be taken to avoid damage to the

outboard motor or other property.

there is any question concerning this manual, please consult your Yamaha dealer.

To ensure long product life, Yamaha recommends that you use the product and perform

the specified periodic inspections and maintenance by correctly following the instructions in the owner’s manual. Any damage

resulting from neglect of these instructions is

not covered by warranty.

Some countries have laws or regulations restricting users from taking the product out of

the country where it was purchased, and it

may be impossible to register the product in

the destination country. Additionally, the warranty may not apply in certain regions. When

planning to take the product to another country, consult the dealer where the product was

purchased for further information.

If the product was purchased used, please

consult your closest dealer for customer reregistration, and to be eligible for the specified services.

The F40DET, F40GET, F50FED, F50FET,

FT50GET, F60CET, FT60DET, F70AET and

the standard accessories are used as a base

for the explanations and illustrations in this

manual. Therefore some items may not apply to every model.

EMU25121

A TIP provides key information to make procedures easier or clearer.

Yamaha continually seeks advancements in

product design and quality. Therefore, while

this manual contains the most current product information available at the time of printing, there may be minor discrepancies

between your machine and this manual. If

F40D, F40G, F50F, FT50G, F60C, FT60D, F70A

OWNER’S MANUAL

©2011 by Yamaha Motor Co., Ltd.

1st Edition, April 2011

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

Table of contents

Safety information............................. 1

Outboard motor safety ..................... 1

Propeller............................................ 1

Rotating parts.................................... 1

Hot parts ........................................... 1

Electric shock.................................... 1

Power trim and tilt ............................. 1

Engine shut-off cord (lanyard)........... 1

Gasoline............................................1

Gasoline exposure and spills ............ 2

Carbon monoxide.............................. 2

Modifications ..................................... 2

Boating safety .................................. 2

Alcohol and drugs ............................. 2

Personal flotation devices ................. 2

People in the water ........................... 2

Passengers ....................................... 2

Overloading....................................... 2

Avoid collisions ................................. 3

Weather ............................................ 3

Passenger training ............................ 3

Boating safety publications ............... 3

Laws and regulations ........................ 3

General information .......................... 4

Identification numbers record ...........4

Outboard motor serial number .......... 4

Key number....................................... 4

EC Declaration of Conformity

(DoC) ............................................. 4

CE Marking ..................................... 4

Read manuals and labels................. 6

Warning labels ................................. 6

Specifications and

requirements.................................... 10

Specifications ................................. 10

Installation requirements ................ 13

Boat horsepower rating................... 13

Mounting motor ............................... 13

Yamaha Security System................ 13

Remote control requirements .........13

Battery requirements ......................14

Battery specifications ...................... 14

Mounting battery ............................. 14

Multiple batteries............................. 14

Propeller selection ......................... 14

Start-in-gear protection .................. 15

Engine oil requirements ................. 15

Fuel requirements .......................... 15

Gasoline .......................................... 15

Anti-fouling paint ............................ 16

Motor disposal requirements.......... 16

Emergency equipment ................... 16

Components .................................... 17

Components diagram..................... 17

Fuel tank ......................................... 19

Fuel joint..........................................19

Fuel gauge ...................................... 20

Fuel tank cap...................................20

Air vent screw..................................20

Remote control transmitter ............. 20

Receiver ......................................... 20

Yamaha Security System lock and

unlock mode .................................21

Remote control box ......................... 21

Remote control lever ....................... 21

Neutral interlock trigger ................... 22

Neutral throttle lever........................ 22

Tiller handle .................................... 22

Gear shift lever ............................... 22

Throttle grip .................................... 23

Throttle indicator ............................ 23

Throttle friction adjuster................... 23

Engine shut-off cord (lanyard) and

clip................................................. 24

Engine stop button ......................... 24

Main switch ..................................... 25

Steering friction adjuster ................. 25

Power trim and tilt switch on remote

control or tiller handle.................... 26

Power trim and tilt switch on bottom

cowling ..........................................26

Variable trolling RPM switches........ 27

Trim tab with anode......................... 27

Trim rod (tilt pin).............................. 28

Tilt lock mechanism......................... 28

Tilt support lever for power trim and

tilt or hydro tilt model..................... 28

Cowling lock lever(s) (turn type)...... 29

Flushing device ............................... 29

Table of contents

Fuel filter/Water separator .............. 29

Alert indicator ................................. 30

Instruments and indicators ............ 31

Indicators ....................................... 31

Low oil pressure-alert indicator ....... 31

Overheat-alert indicator .................. 31

Digital tachometer .......................... 31

Tachometer..................................... 32

Trim meter....................................... 32

Hour meter ...................................... 32

Low oil pressure-alert indicator ....... 32

Overheat-alert indicator .................. 33

Digital speedometer ....................... 33

Speedometer .................................. 33

Fuel gauge ...................................... 33

Trip meter / Clock / Voltmeter ......... 34

Fuel level-alert indicator.................. 35

Low battery voltage-alert

indicator ........................................ 35

Analog tachometer ......................... 35

Low oil pressure-alert indicator ....... 35

Overheat-alert indicator .................. 36

Analog trim meter ........................... 36

6Y8 Multifunction meters................ 36

6Y8 Multifunction tachometers....... 36

Start-up checks ............................... 37

Yamaha Security System

information ...................................38

Adjusting trolling speed ................... 38

Low oil pressure-alert...................... 39

Overheat alert ................................. 39

Water separator alert ...................... 40

Engine trouble alert......................... 40

Low battery voltage-alert................. 41

6Y8 Multifunction speed & fuel

meters .......................................... 41

6Y8 Multifunction speedometers.... 42

6Y8 Multifunction fuel

management meters .................... 43

Engine control system.................... 44

Alert system ................................... 44

Overheat alert ................................. 44

Low oil pressure alert...................... 45

Installation ....................................... 46

Installation ...................................... 46

Mounting the outboard motor ..........46

Operation ......................................... 48

First-time operation ........................ 48

Fill engine oil ................................... 48

Breaking in engine .......................... 48

Getting to know your boat ...............48

Checks before starting engine ....... 48

Fuel level......................................... 48

Remove the top cowling.................. 49

Fuel system..................................... 49

Controls........................................... 49

Engine shut-off cord (lanyard) ......... 50

Engine oil ........................................ 50

Engine .............................................51

Flushing device ............................... 51

Install top cowling............................51

Power trim and tilt system ............... 52

Battery............................................. 52

Filling fuel ...................................... 53

Operating engine ........................... 54

Sending fuel (portable tank) ............54

Starting engine ................................ 55

Checks after starting engine .......... 58

Cooling water .................................. 58

Warming up engine........................ 58

Manual start and electric start

models .......................................... 58

Checks after engine warm up ........ 59

Shifting ............................................ 59

Stop switches .................................. 59

Shifting ........................................... 59

Stopping boat................................. 60

Trolling ........................................... 61

Adjusting trolling speed ................... 61

Stopping engine ............................. 61

Procedure........................................61

Trimming outboard motor............... 62

Adjusting trim angle (Power trim

and tilt) .......................................... 63

Adjusting trim angle for hydro tilt

models .......................................... 64

Adjusting boat trim ..........................64

Tilting up and down........................ 65

Procedure for tilting up (hydro tilt

models) ......................................... 65

Table of contents

Procedure for tilting up (power trim

and tilt models) ............................. 66

Procedure for tilting down (hydro

tilt models) .................................... 67

Procedure for tilting down (power

trim and tilt models) ...................... 68

Shallow water ................................ 69

Hydro tilt models ............................. 69

Power trim and tilt models............... 70

Cruising in other conditions ............71

Maintenance..................................... 72

Transporting and storing outboard

motor ............................................ 72

Storing outboard motor ................... 72

Procedure ....................................... 73

Lubrication ...................................... 74

Flushing power unit......................... 75

Cleaning the outboard motor ......... 76

Checking painted surface of

outboard motor ............................. 76

Periodic maintenance..................... 76

Replacement parts.......................... 77

Severe operating conditions ........... 77

Maintenance chart 1 ....................... 78

Maintenance chart 2 ....................... 80

Greasing ......................................... 81

Cleaning and adjusting spark

plug ............................................... 82

Inspecting idle speed ...................... 83

Changing engine oil ........................ 84

Inspecting wiring and connectors.... 85

Checking propeller .......................... 86

Removing propeller......................... 86

Installing propeller........................... 87

Changing gear oil ............................ 88

Cleaning fuel tank ........................... 89

Inspecting and replacing

anode(s)........................................ 89

Checking battery (for electric start

models) ......................................... 90

Connecting the battery .................... 91

Disconnecting the battery ............... 91

Storing the battery........................... 91

Trouble Recovery ............................93

Troubleshooting ............................. 93

Temporary action in emergency .... 96

Impact damage ............................... 96

Replacing fuse ................................ 97

Power trim and tilt will not

operate.......................................... 97

Water separator-alert indicator

blinks while cruising ...................... 98

Starter will not operate ..................101

Emergency starting engine ........... 101

Treatment of submerged motor ... 102

Safety information

EMU33622

Outboard motor safety

Observe these precautions at all times.

EMU36501

Propeller

People can be injured or killed if they come

in contact with the propeller. The propeller

can keep moving even when the motor is in

neutral, and sharp edges of the propeller can

cut even when stationary.

Stop the engine when a person is in the

water near you.

Keep people out of reach of the propeller,

even when the engine is off.

EMU33630

Rotating parts

Hands, feet, hair, jewelry, clothing, PFD

straps, etc. can become entangled with internal rotating parts of the engine, resulting in

serious injury or death.

Keep the top cowling in place whenever possible. Do not remove or replace the cowling

with the engine running.

Only operate the engine with the cowling removed according to the specific instructions

in the manual. Keep hands, feet, hair, jewelry, clothing, PFD straps, etc. away from any

exposed moving parts.

EMU33640

Hot parts

During and after operation, engine parts are

hot enough to cause burns. Avoid touching

any parts under the top cowling until the engine has cooled.

EMU33650

Electric shock

Do not touch any electrical parts while starting or operating the engine. They can cause

shock or electrocution.

EMU33660

Power trim and tilt

Body parts can be crushed between the mo-

tor and the clamp bracket when the motor is

trimmed or tilted. Keep body parts out of this

area at all times. Be sure no one is in this

area before operating the power trim and tilt

mechanism.

The power trim and tilt switches operate

even when the main switch is off. Keep people be away from the switches whenever

working around the motor.

Never get under the lower unit while it is tilted, even when the tilt support lever is locked.

Severe injury could occur if the outboard motor accidentally falls.

EMU33671

Engine shut-off cord (lanyard)

Attach the engine shut-off cord so that the

engine stops if the operator falls overboard

or leaves the helm. This prevents the boat

from running away under power and leaving

people stranded, or running over people or

objects.

Always attach the engine shut-off cord to a

secure place on your clothing or your arm or

leg while operating. Do not remove it to leave

the helm while the boat is moving. Do not attach the cord to clothing that could tear

loose, or route the cord where it could become entangled, preventing it from functioning.

Do not route the cord where it is likely to be

accidentally pulled out. If the cord is pulled

during operation, the engine will shut off and

you will lose most steering control. The boat

could slow rapidly, throwing people and objects forward.

EMU33810

Gasoline

Gasoline and its vapors are highly flammable and explosive. Always, refuel ac-

cording to the procedure on page 54 to

reduce the risk of fire and explosion.

1

Safety information

EMU33820

Gasoline exposure and spills

Take care not to spill gasoline. If gasoline

spills, wipe it up immediately with dry rags.

Dispose of rags properly.

If any gasoline spills onto your skin, immediately wash with soap and water. Change

clothing if gasoline spills on it.

If you swallow gasoline, inhale a lot of gasoline vapor, or get gasoline in your eyes, get

immediate medical attention. Never siphon

fuel by mouth.

EMU33900

Carbon monoxide

This product emits exhaust gases which contain carbon monoxide, a colorless, odorless

gas which may cause brain damage or death

when inhaled. Symptoms include nausea,

dizziness, and drowsiness. Keep cockpit and

cabin areas well ventilated. Avoid blocking

exhaust outlets.

EMU33780

Modifications

Do not attempt to modify this outboard motor. Modifications to your outboard motor

may reduce safety and reliability, and render

the outboard unsafe or illegal to use.

EMU33740

Boating safety

This section includes a few of the many important safety precautions that you should

follow when boating.

EMU33710

Alcohol and drugs

Never operate after drinking alcohol or taking

drugs. Intoxication is one of the most common factors contributing to boating fatalities.

EMU33720

Personal flotation devices

Have an approved personal flotation device

(PFD) on board for every occupant. Yamaha

recommends that you must wear a PFD

whenever boating. At a minimum, children

and non-swimmers should always wear

PFDs, and everyone should wear PFDs

when there are potentially hazardous boating conditions.

EMU33731

People in the water

Always watch carefully for people in the water, such as swimmers, skiers, or divers,

whenever the engine is running. When

someone is in the water near the boat, shift

into neutral and stop the engine.

Stay away from swimming areas. Swimmers

can be hard to see.

The propeller can keep moving even when

the motor is in neutral. Stop the engine when

a person is in the water near you.

EMU33751

Passengers

Consult your boat manufacturer’s instructions for details about appropriate passenger

locations in your boat and be sure all passengers are positioned properly before accelerating and when operating above an idle

speed. Standing or sitting in non-designated

locations may result in being thrown either

overboard or within the boat due to waves,

wakes, or sudden changes in speed or direction. Even when people are positioned properly, alert your passengers if you must make

any unusual maneuver. Always avoid jumping waves or wakes.

EMU33760

Overloading

Do not overload the boat. Consult the boat

capacity plate or boat manufacturer for maximum weight and number of passengers. Be

sure that weight is properly distributed according to the boat manufacturers instructions. Overloading or incorrect weight

distribution can compromise the boats handling and lead to an accident, capsizing or

2

Safety information

ZMU06025

swamping.

EMU33772

Avoid collisions

Scan constantly for people, objects, and other boats. Be alert for conditions that limit your

visibility or block your vision of others.

Operate defensively at safe speeds and

keep a safe distance away from people, objects, and other boats.

Do not follow directly behind other boats or

waterskiers.

Avoid sharp turns or other maneuvers that

make it hard for others to avoid you or understand where you are going.

Avoid areas with submerged objects or

shallow water.

Ride within your limits and avoid aggres-

sive maneuvers to reduce the risk of loss

of control, ejection, and collision.

Take early action to avoid collisions. Re-

member, boats do not have brakes, and

stopping the engine or reducing throttle

can reduce the ability to steer. If you are

not sure that you can stop in time before

hitting an obstacle, apply throttle and turn

in another direction.

EMU33790

Weather

Stay informed about the weather. Check

weather forecasts before boating. Avoid

boating in hazardous weather.

EMU33880

Passenger training

Make sure at least one other passenger is

trained to operate the boat in the event of an

emergency.

EMU33890

Boating safety publications

Be informed about boating safety. Additional

publications and information can be obtained

from many boating organizations.

EMU33600

Laws and regulations

Know the marine laws and regulations where

you will be boating- and obey them. Several

sets of rules prevail according to geographic

location, but all are basically the same as the

International Rules of the Road.

3

General information

EMU25171

Identification numbers record

EMU25184

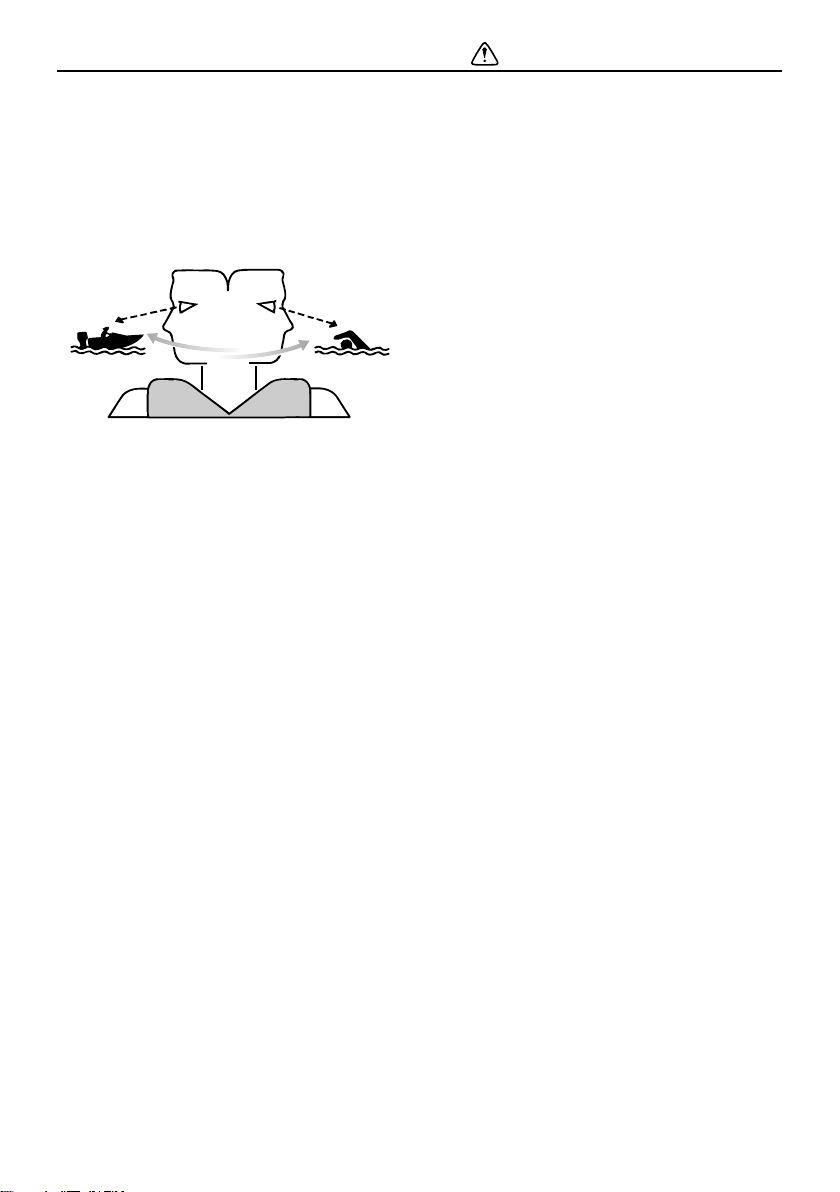

Outboard motor serial number

The outboard motor serial number is

stamped on the label attached to the port

side of the clamp bracket.

Record your outboard motor serial number in

the spaces provided to assist you in ordering

spare parts from your Yamaha dealer or for

reference in case your outboard motor is stolen.

1. Outboard motor serial number location

EMU25191

Key number

If a main key switch is equipped with the motor, the key identification number is stamped

on your key as shown in the illustration.

Record this number in the space provided for

reference in case you need a new key.

1. Key number

EMU37291

EC Declaration of Conformity

(DoC)

This outboard motor conforms to certain portions of the European Parliament directive

relating to machinery.

Each conformed outboard motor accompanied with EC DoC.EC DoC contains the following information;

Name of Engine Manufacture

Model name

Product code of model (Approved model

code)

Code of conformed directives

EMU25205

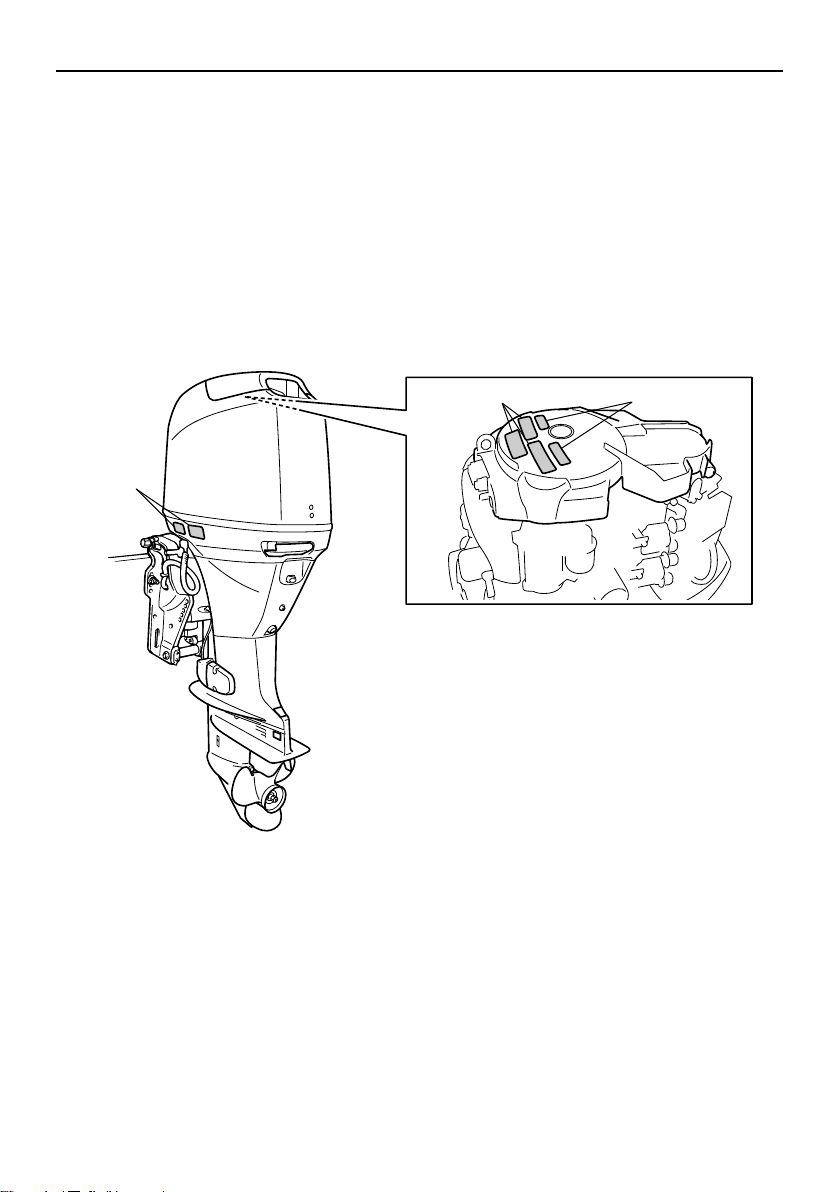

CE Marking

Outboard motors affixed with this “CE”marking conform with the directives of; 98/37/EC,

94/25/EC - 2003/44/EC and 2004/108/EC.

4

ZMU04704

1

ZMU06040

1. CE marking location

General information

5

General information

3

1

2

ZMU05712

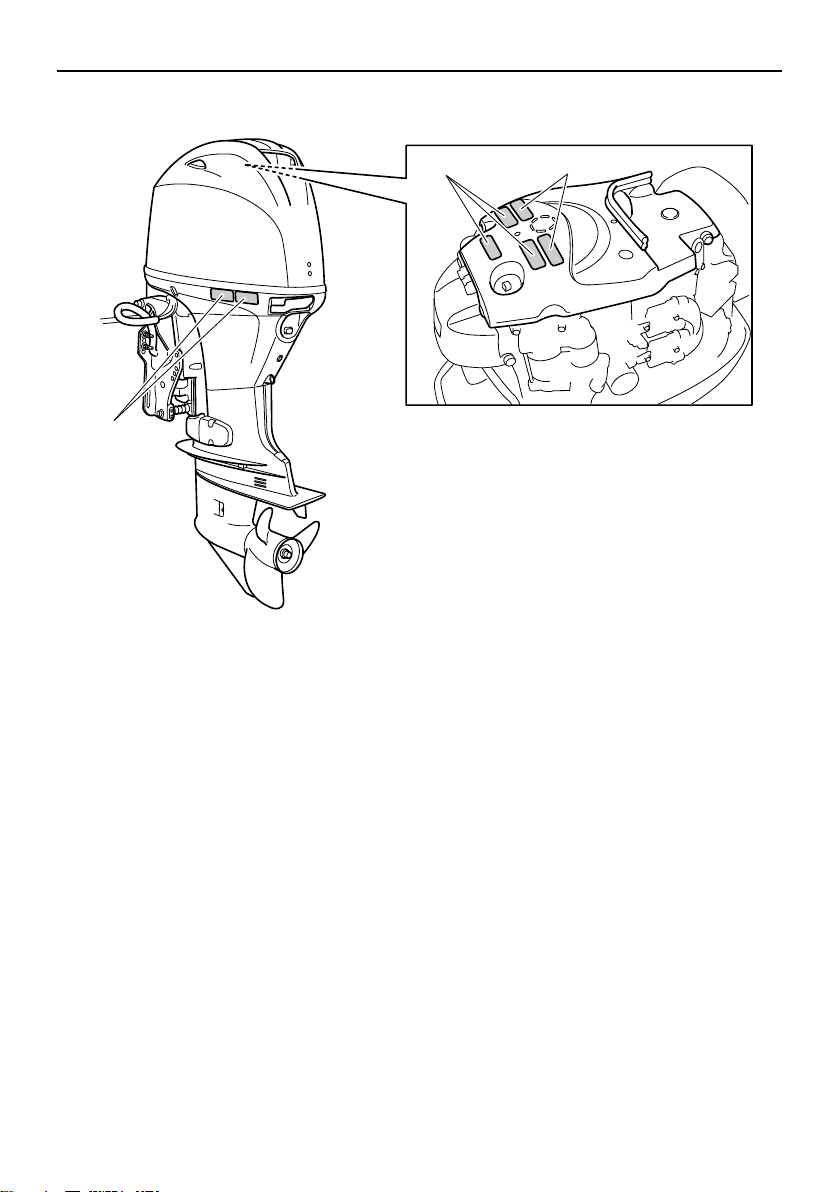

EMU33523

Read manuals and labels

Before operating or working on this outboard motor:

Read this manual.

Read any manuals supplied with the boat.

Read all labels on the outboard motor and the boat.

If you need any additional information, contact your Yamaha dealer.

EMU33832

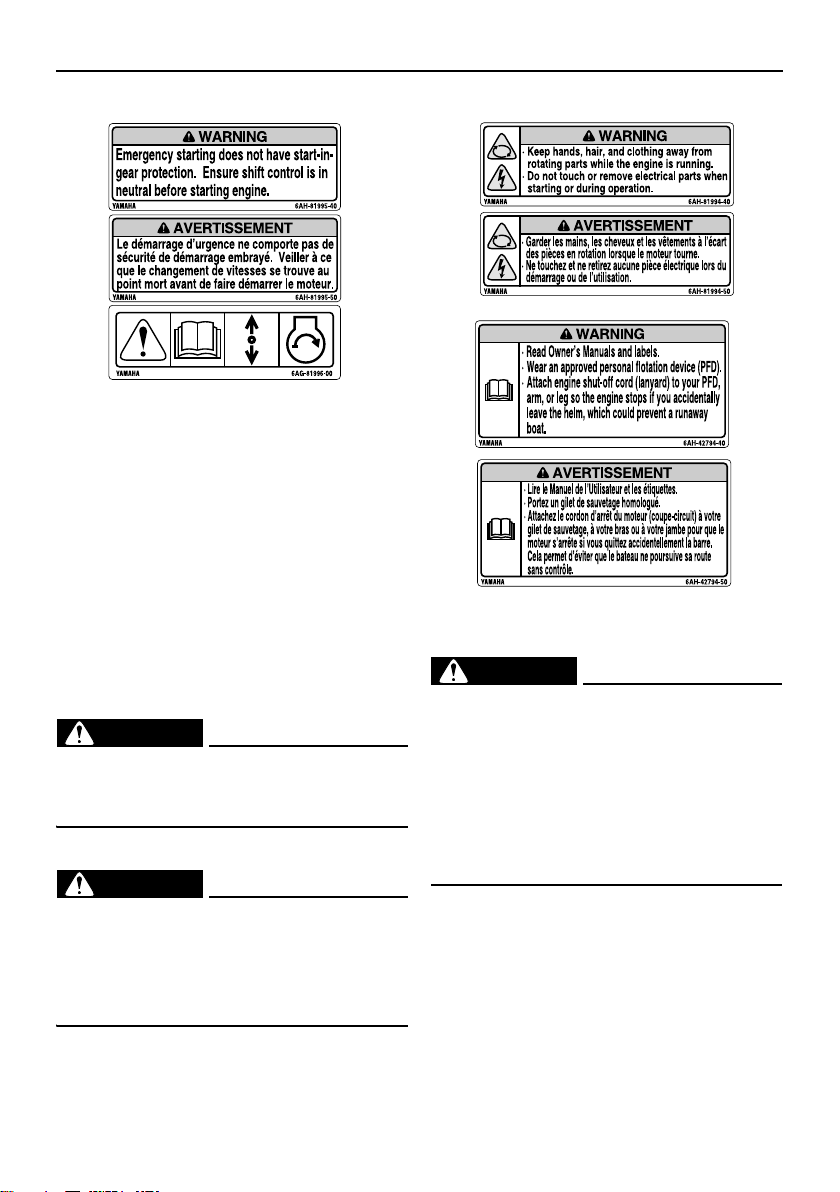

Warning labels

If these labels are damaged or missing, contact your Yamaha dealer for replacements.

F40D, F50F, F60C, FT50G, FT60D

6

F40G, F70A

3

1

2

ZMU07077

General information

7

General information

WARNING

WARNING

WARNING

ZMU05706

1

2

3

EMU33912

Contents of labels

The above warning labels mean as follows.

1

EWM01691

Emergency starting does not have startin-gear protection. Ensure shift control is

in neutral before starting engine.

2

EWM01681

Keep hands, hair, and clothing away

from rotating parts while the engine is

running.

Do not touch or remove electrical parts

when starting or during operation.

8

3

EWM01671

Read Owner’s Manuals and labels.

Wear an approved personal flotation

device (PFD).

Attach engine shut-off cord (lanyard) to

your PFD, arm, or leg so the engine

stops if you accidentally leave the

helm, which could prevent a runaway

boat.

General information

ZMU05696

ZMU05664

ZMU05665

ZMU05666

ZMU05667

ZMU05668

EMU33843

Symbols

The following symbols mean as follows.

Notice/Warning

Read Owner’s Manual

Electrical hazard

Remote control lever/gear shift lever operating direction, dual direction

Engine start/ Engine cranking

Hazard caused by continuous rotation

9

Specifications and requirements

TIP:

EMU34521

Specifications

“(AL)” stated in the specification data below

represents the numerical value for the aluminum propeller installed.

Likewise, “(SUS)” represents the value for

stainless steel propeller installed and “(PL)”

for plastic propeller installed.

EMU2821K

Dimension:

Overall length:

F40DET 706 mm (27.8 in)

F40GET 698 mm (27.5 in)

F50FED 706 mm (27.8 in)

F50FET 706 mm (27.8 in)

F60CET 706 mm (27.8 in)

F70AET 713 mm (28.1 in)

FT50GET 706 mm (27.8 in)

FT60DET 706 mm (27.8 in)

Overall width:

F40DET 385 mm (15.2 in)

F40GET 386 mm (15.2 in)

F50FED 385 mm (15.2 in)

F50FET 385 mm (15.2 in)

F60CET 385 mm (15.2 in)

F70AET 386 mm (15.2 in)

FT50GET 385 mm (15.2 in)

FT60DET 385 mm (15.2 in)

Overall height L:

F40DET 1414 mm (55.7 in)

F40GET 1476 mm (58.1 in)

F50FED 1414 mm (55.7 in)

F50FET 1414 mm (55.7 in)

F60CET 1414 mm (55.7 in)

F70AET 1476 mm (58.1 in)

FT50GET 1455 mm (57.3 in)

FT60DET 1455 mm (57.3 in)

Overall height X:

F70AET 1590 mm (62.6 in)

FT60DET 1569 mm (61.8 in)

Transom height L:

F40DET 527 mm (20.7 in)

F40GET 534 mm (21.0 in)

F50FED 527 mm (20.7 in)

F50FET 527 mm (20.7 in)

F60CET 527 mm (20.7 in)

F70AET 534 mm (21.0 in)

FT50GET 530 mm (20.9 in)

FT60DET 530 mm (20.9 in)

Transom height X:

F70AET 648 mm (25.5 in)

FT60DET 644 mm (25.4 in)

Weight (AL) L:

F40DET 113.0 kg (249 lb)

F40GET 117.0 kg (258 lb)

F50FED 107.0 kg (236 lb)

F50FET 113.0 kg (249 lb)

F60CET 113.0 kg (249 lb)

F70AET 119.0 kg (262 lb)

FT50GET 118.0 kg (260 lb)

FT60DET 123.0 kg (271 lb)

Weight (AL) X:

F70AET 121.0 kg (267 lb)

FT60DET 127.0 kg (280 lb)

Performance:

Full throttle operating range:

F40DET 5000–6000 r/min

F40GET 5300–6300 r/min

F50FED 5000–6000 r/min

F50FET 5000–6000 r/min

F60CET 5000–6000 r/min

F70AET 5300–6300 r/min

FT50GET 5000–6000 r/min

FT60DET 5000–6000 r/min

Maximum output:

F40DET 29.4 kW@5500 r/min

(40 HP@5500 r/min)

F40GET 29.4 kW@5800 r/min

(40 HP@5800 r/min)

F50FED 36.8 kW@5500 r/min

10

Specifications and requirements

(50 HP@5500 r/min)

F50FET 36.8 kW@5500 r/min

(50 HP@5500 r/min)

F60CET 44.1 kW@5500 r/min

(60 HP@5500 r/min)

F70AET 51.5 kW@5800 r/min

(70 HP@5800 r/min)

FT50GET 36.8 kW@5500 r/min

(50 HP@5500 r/min)

FT60DET 44.1 kW@5500 r/min

(60 HP@5500 r/min)

Idle speed (in neutral):

750 50 r/min

Engine:

Type:

4-stroke L

Displacement:

996.0 cm

Bore stroke:

65.0 75.0 mm (2.56 2.95 in)

Ignition system:

TCI

Spark plug (NGK):

F40DET DPR6EB-9

F40GET LKR7E

F50FED DPR6EB-9

F50FET DPR6EB-9

F60CET DPR6EB-9

F70AET LKR7E

FT50GET DPR6EB-9

FT60DET DPR6EB-9

Spark plug gap:

0.8–0.9 mm (0.031–0.035 in)

Control system:

Remote control

Starting system:

Electric starter

Starting carburetion system:

Electronic fuel injection

Valve clearance (cold engine) IN:

0.15–0.25 mm (0.0059–0.0098 in)

3

Valve clearance (cold engine) EX:

0.25–0.35 mm (0.0098–0.0138 in)

Min. cold cranking amps (CCA/EN):

430.0 A

Min. rated capacity (20HR/IEC):

70 Ah

Maximum generator output:

F40DET 16 A

F40GET 15 A

F50FED 16 A

F50FET 16 A

F60CET 16 A

F70AET 15 A

FT50GET 16 A

FT60DET 16 A

Drive unit:

Gear positions:

Forward-neutral-reverse

Gear ratio:

F40DET 1.85(24/13)

F40GET 2.33(28/12)

F50FED 1.85(24/13)

F50FET 1.85(24/13)

F60CET 1.85(24/13)

F70AET 2.33(28/12)

FT50GET 2.33(28/12)

FT60DET 2.33(28/12)

Trim and tilt system:

F40DET Power trim and tilt

F40GET Power trim and tilt

F50FED Hydro tilt

F50FET Power trim and tilt

F60CET Power trim and tilt

F70AET Power trim and tilt

FT50GET Power trim and tilt

FT60DET Power trim and tilt

Propeller mark:

F40DET G

F50FED G

F50FET G

F60CET G

11

Specifications and requirements

F70AET K

FT50GET K

FT60DET K

Fuel and oil:

Recommended fuel:

Regular unleaded gasoline

Min. research octane:

90

Fuel tank capacity:

25 L (6.60 US gal, 5.50 Imp.gal)

Recommended engine oil:

4-stroke outboard motor oil

Recommended engine oil grade 1:

SAE 10W-30/10W-40/5W-30

API SE/SF/SG/SH/SJ/SL

Total engine oil quantity (oil pan capacity):

2.5 L (2.64 US qt, 2.20 Imp.qt)

Lubrication:

Wet sump

Recommended gear oil:

Hypoid gear oil SAE#90

Gear oil quantity:

F40DET 0.430 L

(0.455 US qt, 0.378 Imp.qt)

F40GET 0.670 L

(0.708 US qt, 0.590 Imp.qt)

F50FED 0.430 L

(0.455 US qt, 0.378 Imp.qt)

F50FET 0.430 L

(0.455 US qt, 0.378 Imp.qt)

F60CET 0.430 L

(0.455 US qt, 0.378 Imp.qt)

F70AET 0.670 L

(0.708 US qt, 0.590 Imp.qt)

FT50GET 0.670 L

(0.708 US qt, 0.590 Imp.qt)

FT60DET 0.670 L

(0.708 US qt, 0.590 Imp.qt)

Tightening torque for engine:

Spark plug:

F40DET 18.0 Nm

(1.84 kgf-m, 13.3 ft-lb)

F40GET 17.0 Nm

(1.73 kgf-m, 12.5 ft-lb)

F50FED 18.0 Nm

(1.84 kgf-m, 13.3 ft-lb)

F50FET 18.0 Nm

(1.84 kgf-m, 13.3 ft-lb)

F60CET 18.0 Nm

(1.84 kgf-m, 13.3 ft-lb)

F70AET 17.0 Nm

(1.73 kgf-m, 12.5 ft-lb)

FT50GET 18.0 Nm

(1.84 kgf-m, 13.3 ft-lb)

FT60DET 18.0 Nm

(1.84 kgf-m, 13.3 ft-lb)

Propeller nut:

F40DET 35.0 Nm

(3.57 kgf-m, 25.8 ft-lb)

F40GET 34.0 Nm

(3.47 kgf-m, 25.1 ft-lb)

F50FED 35.0 Nm

(3.57 kgf-m, 25.8 ft-lb)

F50FET 35.0 Nm

(3.57 kgf-m, 25.8 ft-lb)

F60CET 35.0 Nm

(3.57 kgf-m, 25.8 ft-lb)

F70AET 34.0 Nm

(3.47 kgf-m, 25.1 ft-lb)

FT50GET 35.0 Nm

(3.57 kgf-m, 25.8 ft-lb)

FT60DET 35.0 Nm

(3.57 kgf-m, 25.8 ft-lb)

Engine oil drain bolt:

F40DET 28.0 Nm

(2.86 kgf-m, 20.7 ft-lb)

F40GET 27.0 Nm

(2.75 kgf-m, 19.9 ft-lb)

F50FED 28.0 Nm

(2.86 kgf-m, 20.7 ft-lb)

F50FET 28.0 Nm

(2.86 kgf-m, 20.7 ft-lb)

12

Specifications and requirements

WARNING

WARNING

WARNING

F60CET 28.0 Nm

(2.86 kgf-m, 20.7 ft-lb)

F70AET 27.0 Nm

(2.75 kgf-m, 19.9 ft-lb)

FT50GET 28.0 Nm

(2.86 kgf-m, 20.7 ft-lb)

FT60DET 28.0 Nm

(2.86 kgf-m, 20.7 ft-lb)

Engine oil filter:

18.0 Nm (1.84 kgf-m, 13.3 ft-lb)

Noise and vibration level:

Operator sound pressure level (ICOMIA

39/94 and 40/94):

F40DET 78.1 dB(A)

F40GET 83.9 dB(A)

F50FED 78.1 dB(A)

F50FET 78.1 dB(A)

F60CET 78.1 dB(A)

F70AET 83.9 dB(A)

FT50GET 78.1 dB(A)

FT60DET 78.1 dB(A)

EMU33554

Installation requirements

EMU33564

Boat horsepower rating

EWM01560

Overpowering a boat can cause severe

instability.

Before installing the outboard motor(s), confirm that the total horsepower of your outboard motor(s) does not exceed the boats

maximum horsepower rating. See the boat’s

capacity plate or contact the manufacturer.

EMU33571

Mounting motor

EWM01570

control, or fire hazards.

Because the motor is very heavy, spe-

cial equipment and training is required

to mount it safely.

Your dealer or other person experienced in

proper rigging should mount the motor using

correct equipment and complete rigging instructions. For further information, see page

46.

EMU38580

Yamaha Security System

This outboard motor is equipped with the

Yamaha Security System to protect against

theft, which consists of the receiver and remote control transmitter. The engine can not

be started if the security system is in the lock

mode, and only be started in the unlock

mode. Consult your Yamaha dealer for installation of the receiver.

EMU33581

Remote control requirements

EWM01580

If the engine starts in gear, the boat can

move suddenly and unexpectedly, possibly causing a collision or throwing

passengers overboard.

If the engine ever starts in gear, the

start-in-gear protection device is not

working correctly and you should discontinue using the outboard. Contact

your Yamaha dealer.

The remote control unit must be equipped

with a start-in-gear protection device(s). This

device prevents the engine from starting unless it is in neutral.

Improper mounting of the outboard mo-

tor could result in hazardous conditions such as poor handling, loss of

13

Specifications and requirements

ZMU04606

-

x

123

ZMU04607

-

x

123

EMU25694

Battery requirements

EMU25721

Battery specifications

Minimum cold cranking amps (CCA/EN):

430.0 A

Minimum rated capacity (20HR/IEC):

70 Ah

The engine cannot be started if battery voltage is too low.

EMU36290

Mounting battery

Mount the battery holder securely in a dry,

well-ventilated, vibration-free location in the

boat. WARNING! Do not put flammable

items, or loose heavy or metal objects in

the same compartment as the battery.

Fire, explosion or sparks could result.

[EWM01820]

EMU36300

Multiple batteries

To connect multiple batteries, such as for

multiple engine configurations or for an accessory battery, consult your Yamaha dealer

about battery selection and correct wiring.

EMU34195

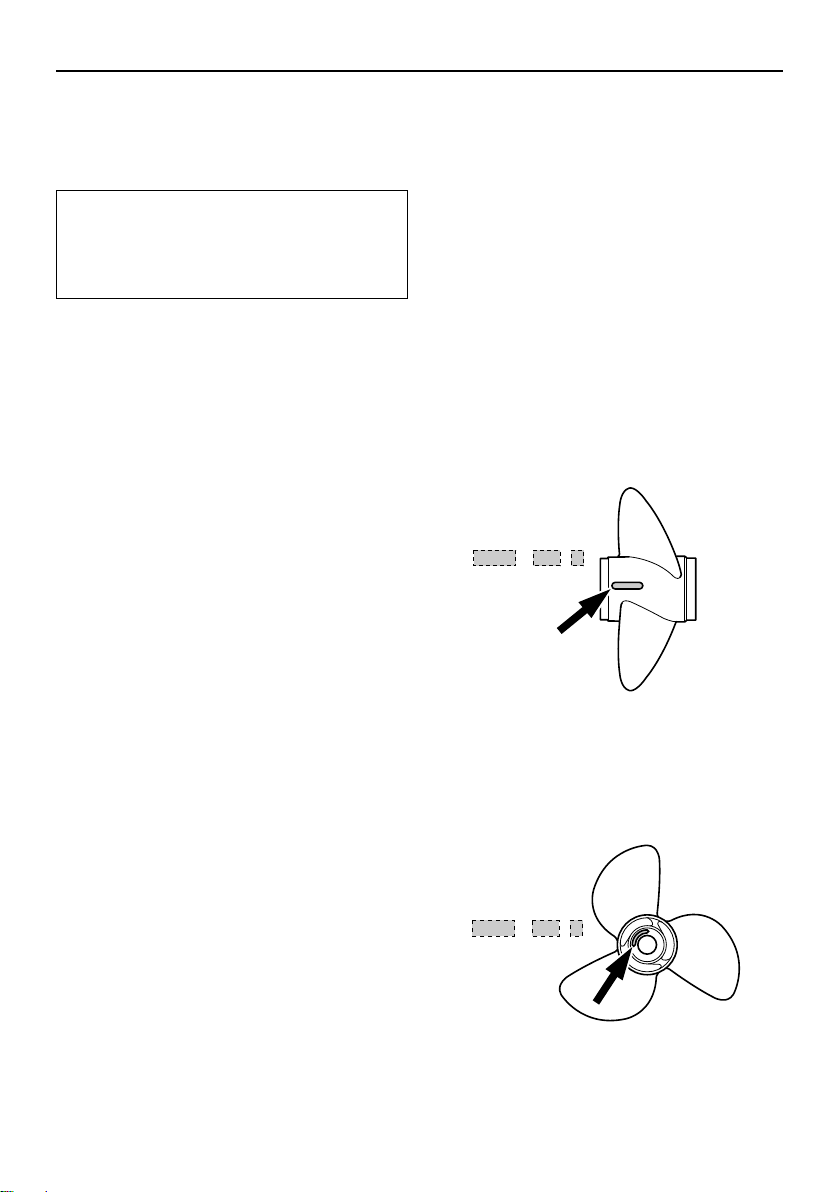

Propeller selection

Next to selecting an outboard motor, selecting the right propeller is one of the most important purchasing decisions a boater can

make. The type, size, and design of your propeller have a direct impact on acceleration,

top speed, fuel economy, and even engine

life. Yamaha designs and manufactures propellers for every Yamaha outboard motor

and every application.

Your outboard motor came with a Yamaha

propeller selected to perform well over a

range of applications, but there may be uses

where a different propeller would be more

appropriate.

Your Yamaha dealer can help you select the

right propeller for your boating needs. Select

a propeller that will allow the engine to reach

the middle or upper half of the operating

range at full throttle with the maximum boatload. Generally, select a larger pitch propeller for a smaller operating load and a smaller

pitch propeller for a heavier load. If you carry

loads that vary widely, select the propeller

that lets the engine run in the proper range

for your maximum load but remember that

you may need to reduce your throttle setting

to stay within the recommended engine

speed range when carrying lighter loads.

To check the propeller, see page 86.

1. Propeller diameter in inches

2. Propeller pitch in inches

3. Type of propeller (propeller mark)

1. Propeller diameter in inches

14

Specifications and requirements

NOTICE

ZMU06854

122˚F

50˚C

104

40

86

30

68

SAE API

SE

SF

SG

SH

SJ

SL

20

50

10

32

0

14

-10

-4

-20

10W–30

10W–40

5W–30

ZMU06855

122˚F

50˚C

104

40

86

30

68

SAE API

SH

SJ

SL

20

50

10

32

0

14

-10

-4

-20

15W–40

20W–40

20W–50

2. Propeller pitch in inches

3. Type of propeller (propeller mark)

EMU25770

Start-in-gear protection

Yamaha outboard motors or Yamaha-approved remote control units are equipped

with start-in-gear protection device(s). This

feature permits the engine to be started only

when it is in neutral. Always select neutral

before starting the engine.

EMU41951

Engine oil requirements

Select an oil grade according to the average

temperatures in the area where the outboard

motor will be used.

Recommended engine oil:

4-stroke outboard motor oil

Recommended engine oil grade 1:

SAE 10W-30/10W-40/5W-30

API SE/SF/SG/SH/SJ/SL

Recommended engine oil grade 2:

SAE 15W-40/20W-40/20W-50

API SH/SJ/SL

Total engine oil quantity (oil pan capacity):

2.5 L (2.64 US qt, 2.20 Imp.qt)

Replacement engine oil quantity (at periodic maintenance):

Without oil filter replacement:

1.9 L (2.01 US qt, 1.67 Imp.qt)

With oil filter replacement:

2.1 L (2.22 US qt, 1.85 Imp.qt)

Recommended engine oil grade 1

Recommended engine oil grade 2

EMU36360

Fuel requirements

EMU36803

Gasoline

Use a good quality gasoline that meets the

minimum octane rating. If knocking or pinging occurs, use a different brand of gasoline

or premium unleaded fuel.

Recommended gasoline:

Regular unleaded gasoline with a minimum octane rating of 90 (Research

Octane Number).

If oil grades listed under Recommended engine oil grade 1 are not available, select an

alternative oil grade listed under Recommended engine oil grade 2.

ECM01981

Do not use leaded gasoline. Leaded

gasoline can seriously damage the engine.

Avoid getting water and contaminants

in the fuel tank. Contaminated fuel can

15

Specifications and requirements

cause poor performance or engine

damage. Use only fresh gasoline that

has been stored in clean containers.

Gasohol

There are two types of gasohol: gasohol containing ethanol (E10) and that containing

methanol. Ethanol can be used if the ethanol

content does not exceed 10% and the fuel

meets the minimum octane ratings. E85 is a

fuel containing 85% ethanol and must not be

used in your outboard motor. All ethanol

blends containing more than 10% ethanol

can cause fuel system damage or cause engine starting and running problems. Yamaha

does not recommend gasohol containing

methanol because it can cause fuel system

damage or engine performance problems.

It is recommended that you install a waterseparating marine fuel filter assembly (10 micron minimum) between your boat’s fuel tank

and outboard motor when using ethanol.

Ethanol is known to allow moisture to be absorbed into boat fuel tanks and systems.

Moisture in the fuel can cause corrosion of

metallic fuel system components, starting

and running complaints and require additional fuel system maintenance.

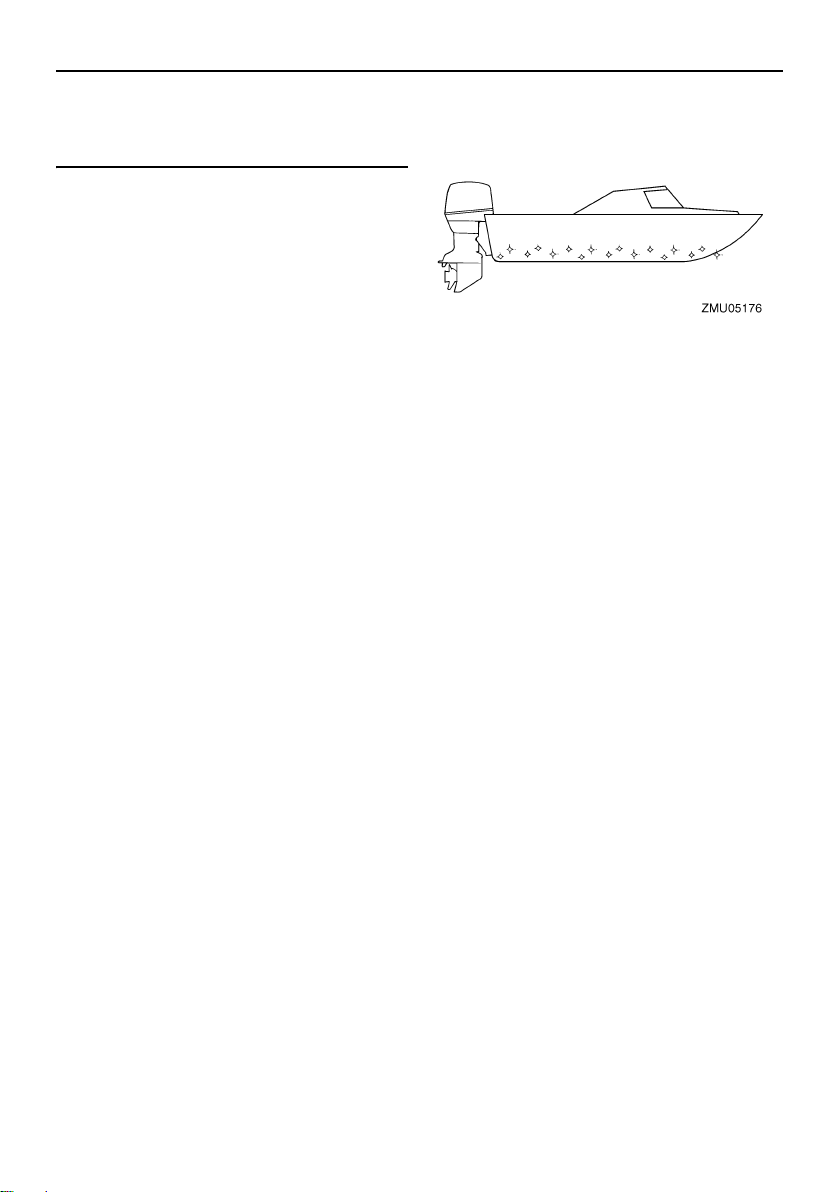

EMU36330

Anti-fouling paint

A clean hull improves boat performance. The

boat bottom should be kept as clean of marine growth as possible. If necessary, the

boat bottom can be coated with an anti-fouling paint approved for your area to inhibit

marine growth.

Do not use anti-fouling paint which includes

copper or graphite. These paints can cause

more rapid engine corrosion.

EMU36341

Motor disposal requirements

Never illegally discard (dump) the motor.

Yamaha recommends consulting the dealer

about discarding the motor.

EMU36352

Emergency equipment

Keep the following items onboard in case

there is trouble with the outboard motor.

A tool kit with assorted screwdrivers, pli-

ers, wrenches (including metric sizes), and

electrical tape.

Waterproof flashlight with extra batteries.

An extra engine shut-off cord (lanyard)

with clip.

Spare parts, such as an extra set of spark

plugs.

Consult your Yamaha dealer for details.

16

Components

TIP:

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

1

3

4

9

11

12

13

14

10

2

6

7

5

8

15

23

22

16

19

17 18

20 21

ZMU07563

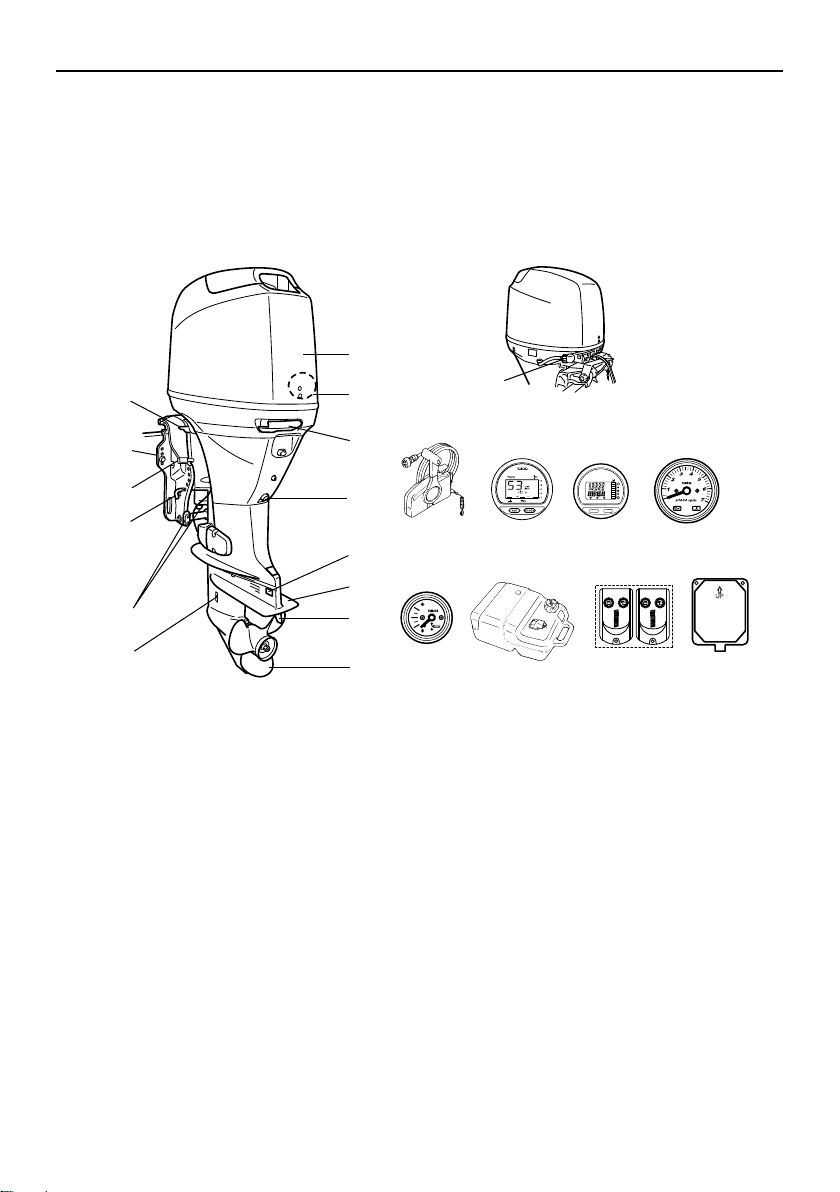

EMU2579Y

Components diagram

* May not be exactly as shown; also may not be included as standard equipment on all models (order from dealer).

F40D, F50F, F60C, FT50G, FT60D

1. Top cowling

2. Water separator

3. Cowling lock lever

4. Drain screw

5. Anode*

6. Anti-cavitation plate

7. Trim tab (anode)

8. Propeller*

9. Cooling water inlet

10. Anode(s)*

11. Trim rod*

12. Tilt lock lever*

13. Clamp bracket

14. Tilt support lever

15. Flushing device

16. Remote control box (side mount type)*

17. Digital tachometer*

18. Digital speedometer*

19. Tachometer*

20. Trim meter*

21. Fuel tank

22. Remote control transmitter

23. Receiver

17

Components

1

3

2

4

11

9

5

6

7

8

13

11

12

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

21

20

14

17

15 16

18

19

10

ZMU07075

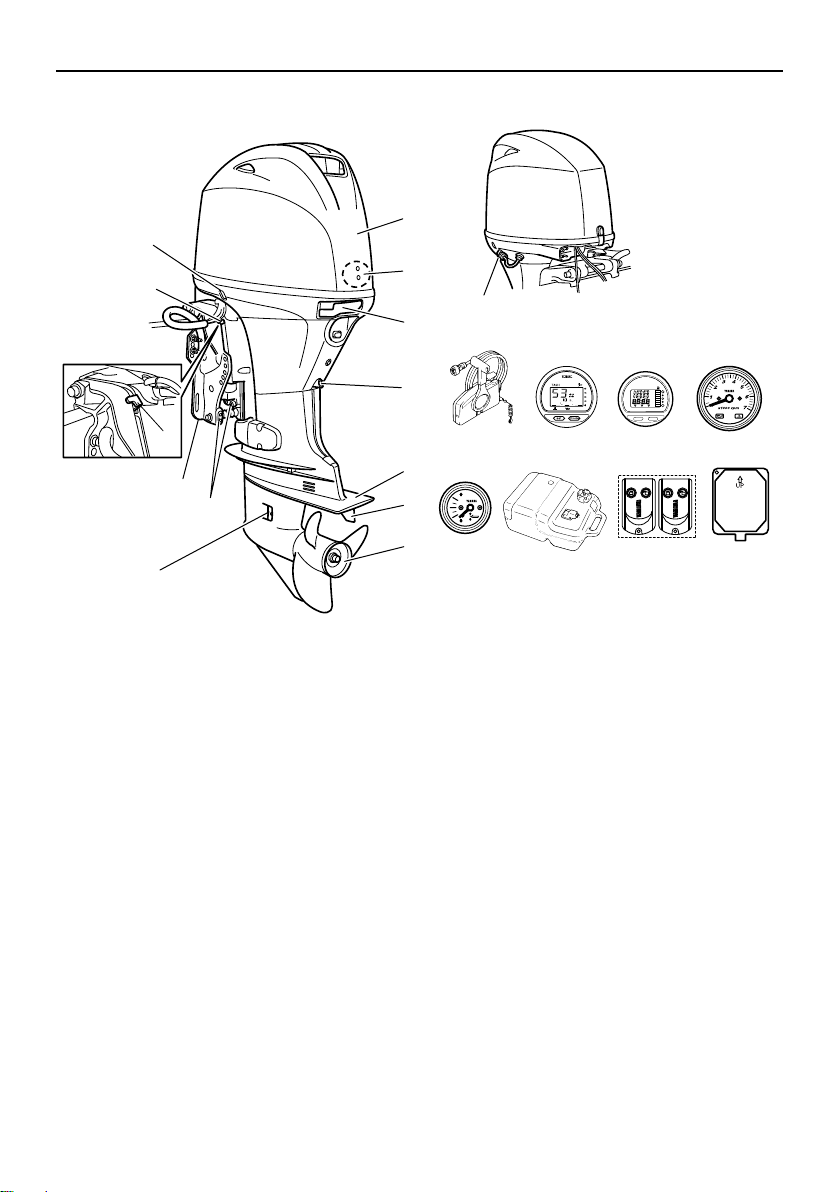

F40G, F70A

1. Top cowling

2. Water separator

3. Cowling lock lever

4. Drain screw

5. Anti-cavitation plate

6. Trim tab (anode)

7. Propeller*

8. Cooling water inlet

9. Anode(s)

10. Clamp bracket

11. Tilt support lever

12. Power trim and tilt switch

13. Flushing device

14. Remote control box (side mount type)*

15. Digital tachometer*

16. Digital speedometer*

17. Tachometer*

18. Trim meter*

19. Fuel tank

20. Remote control transmitter

18

21. Receiver

WARNING

1

4

6

3

2

5

ZMU05429

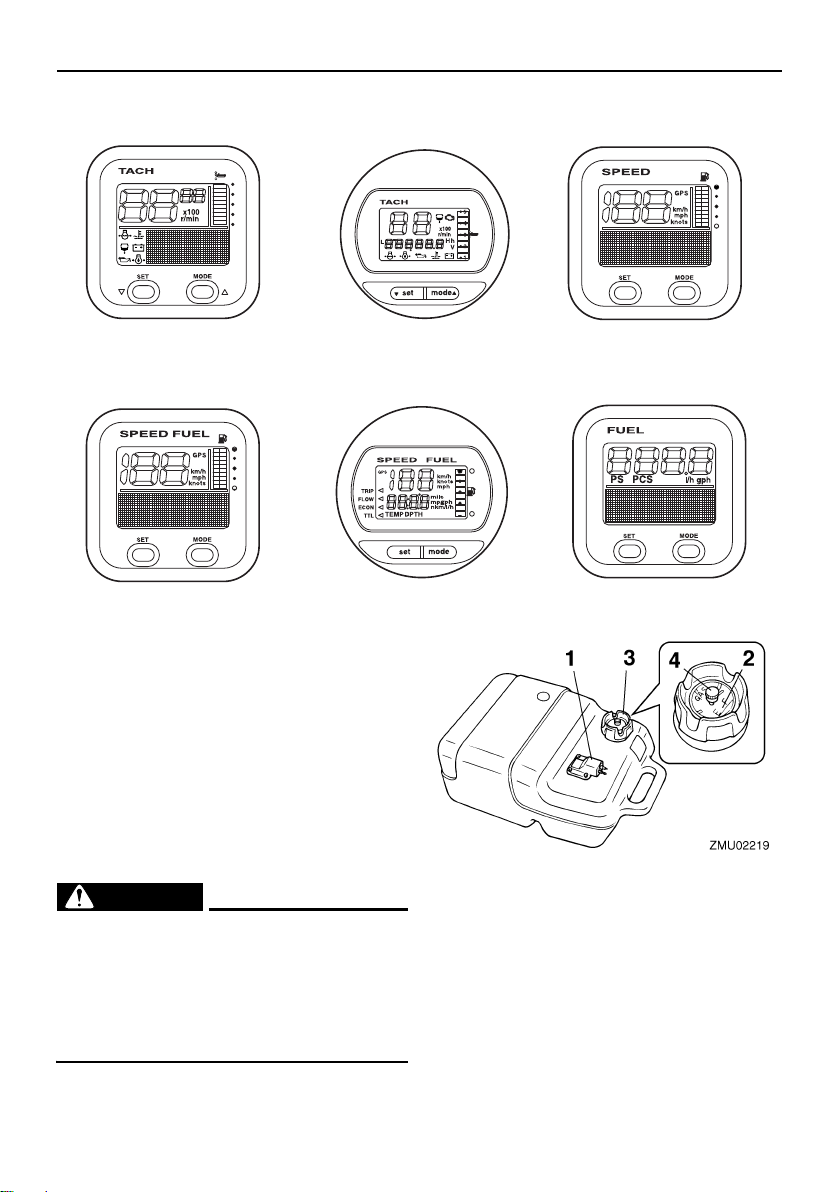

1. Tachometer unit (Square type)*

2. Tachometer unit (Round type)*

3. Speedometer unit (Square type)*

4. Speed & fuel meter unit (Square type)*

5. Speed & fuel meter unit (Round type)*

6. Fuel management meter (Square type)*

Components

EMU25802

Fuel tank

If your model was equipped with a portable

fuel tank, its function is as follows.

EWM00020

The fuel tank supplied with this engine is

its dedicated fuel reservoir and must not

be used as a fuel storage container. Commercial users should conform to relevant

licensing or approval authority regulations.

1. Fuel joint

2. Fuel gauge

3. Fuel tank cap

4. Air vent screw

EMU25830

Fuel joint

This joint is used to connect the fuel line.

19

Components

NOTICE

TIP:

ZMU06455

EMU25841

Fuel gauge

This gauge is located on either the fuel tank

cap or on the fuel joint base. It shows the approximate amount of fuel remaining in the

tank.

EMU25850

Fuel tank cap

This cap seals the fuel tank. When removed,

the tank can be filled with fuel. To remove the

cap, turn it counterclockwise.

EMU25860

Air vent screw

This screw is on the fuel tank cap. To loosen

the screw, turn it counterclockwise.

EMU38591

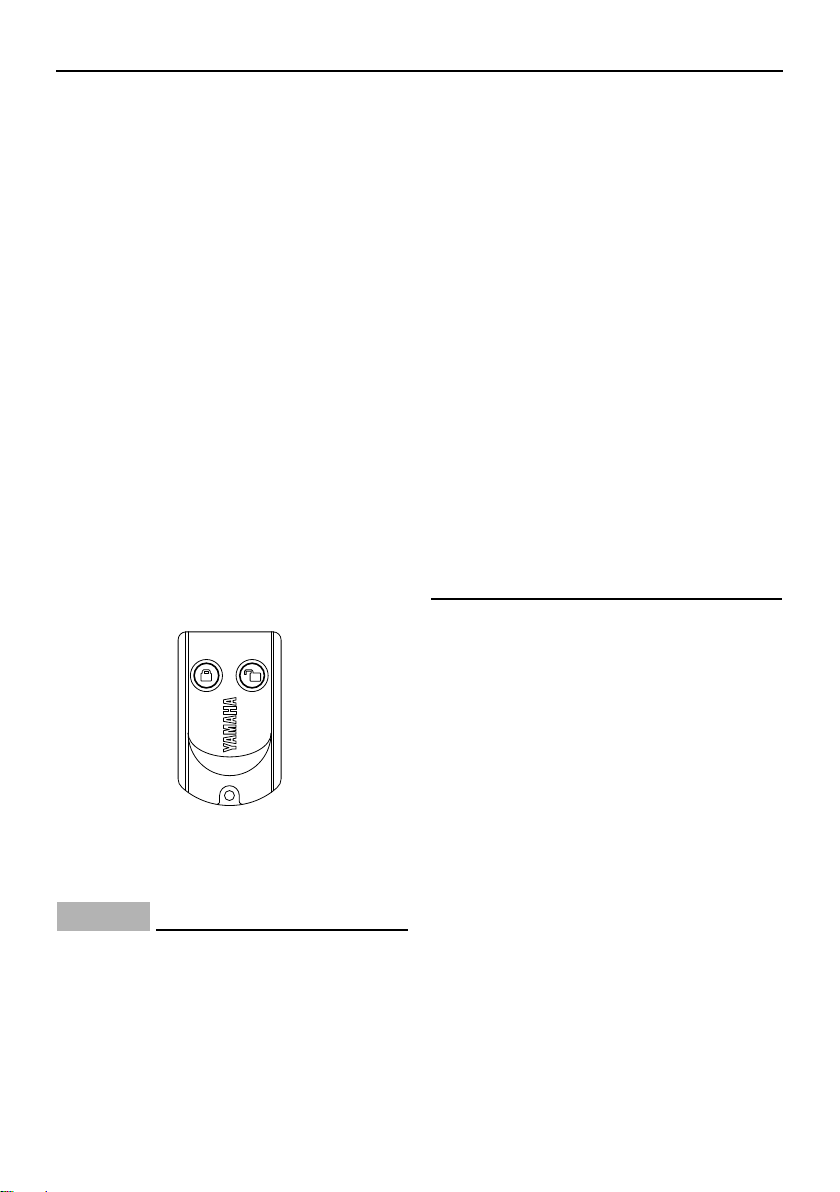

Remote control transmitter

The lock and unlock modes of the Yamaha

Security System are selected using the remote control transmitter. While the engine is

running, input from the remote control transmitter is not received.

Store the remote control transmitter carefully

so it will not be lost.

ECM02100

The remote control transmitter is not

completely waterproof. Do not submerge the transmitter or operate it underwater. If the transmitter is

submerged, dry it with a soft, dry cloth,

and then check that it is operating prop-

erly. If the transmitter is not operating

properly, contact a Yamaha dealer.

Keep the remote control transmitter

away from high temperatures and do

not place it in direct sunlight.

Do not drop the remote control trans-

mitter, subject it to strong shocks, or

place any heavy items on it.

Use a soft, dry cloth to clean the remote

control transmitter. Do not use detergent, alcohol, or other chemicals.

Do not attempt to disassemble the re-

mote control transmitter yourself. Otherwise, the transmitter may not operate

properly. If the transmitter needs a new

battery, contact a Yamaha dealer.

If you have lost the remote control

transmitter, consult your Yamaha dealer. Keep the least 2 transmitters at all

the time. If you have lost both transmitters, consult your Yamaha dealer.

Since the receiver is programmed to rec-

ognize the internal code from this transmitter only, the security system setting can

only be changed with this transmitter. If the

remote control transmitter does not operate properly, contact a Yamaha dealer.

Replace the battery cell after 1 year, and

every two years thereafter as a standard

measure.

Refer to local hazardous waste regulations

when disposing of transmitter batteries.

The Yamaha Security System permits to

register up to 5 remote control transmitters. Consult your yamaha dealer for details.

EMU38601

Receiver

The receiver control the ECM (Electronic

control module) to prevent the engine from

20

Components

12

ZMU06456

starting. Consult your Yamaha dealer for installation of the receiver.

EMU38611

Yamaha Security System lock and

unlock mode

The Yamaha Security System settings are

selected by pressing the lock or unlock button on the remote control transmitter briefly.

1. Lock button

2. Unlock button

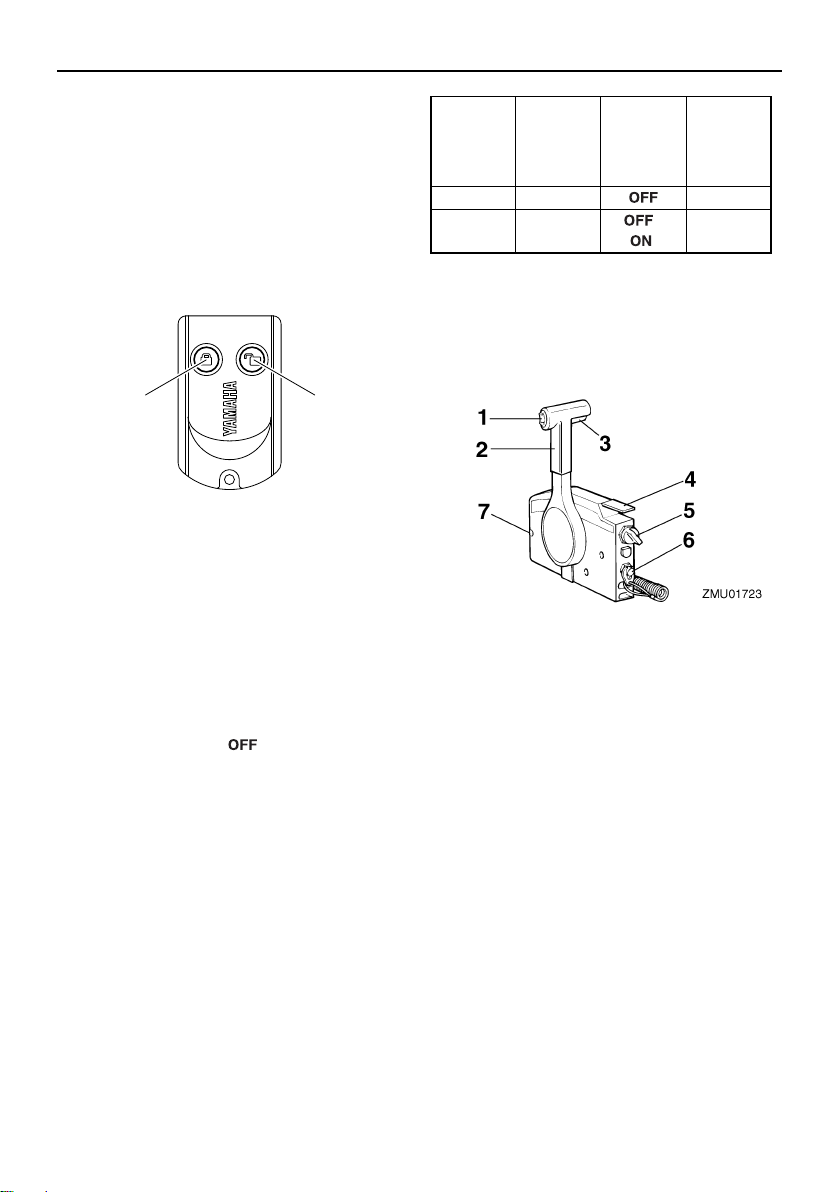

LOCK

When the lock button on the remote control

transmitter is pressed briefly, the beeper

sounds once. This indicates the lock mode is

selected and the engine cannot be started.

The lock mode is selected only when the

main switch is in the “ ” (off) position. The

engine cranks but can not be started while

the Yamaha Security System is on lock

mode.

UNLOCK

When the unlock button on the remote control transmitter is pressed briefly, the beeper

sounds twice. This indicates the unlock

mode is selected and the engine can be

started.

Yamaha

Security

System

mode

Lock 1 beep

Unlock 2 beeps

EMU26181

Number

of beeps

Main

switch

“”

“”/“

Engine

can be

started

NO

”

YES

Remote control box

The remote control lever actuates both the

shifter and the throttle. The electrical switches are mounted on the remote control box.

1. Power trim and tilt switch

2. Remote control lever

3. Neutral interlock trigger

4. Neutral throttle lever

5. Main switch

6. Engine shut-off switch

7. Throttle friction adjuster

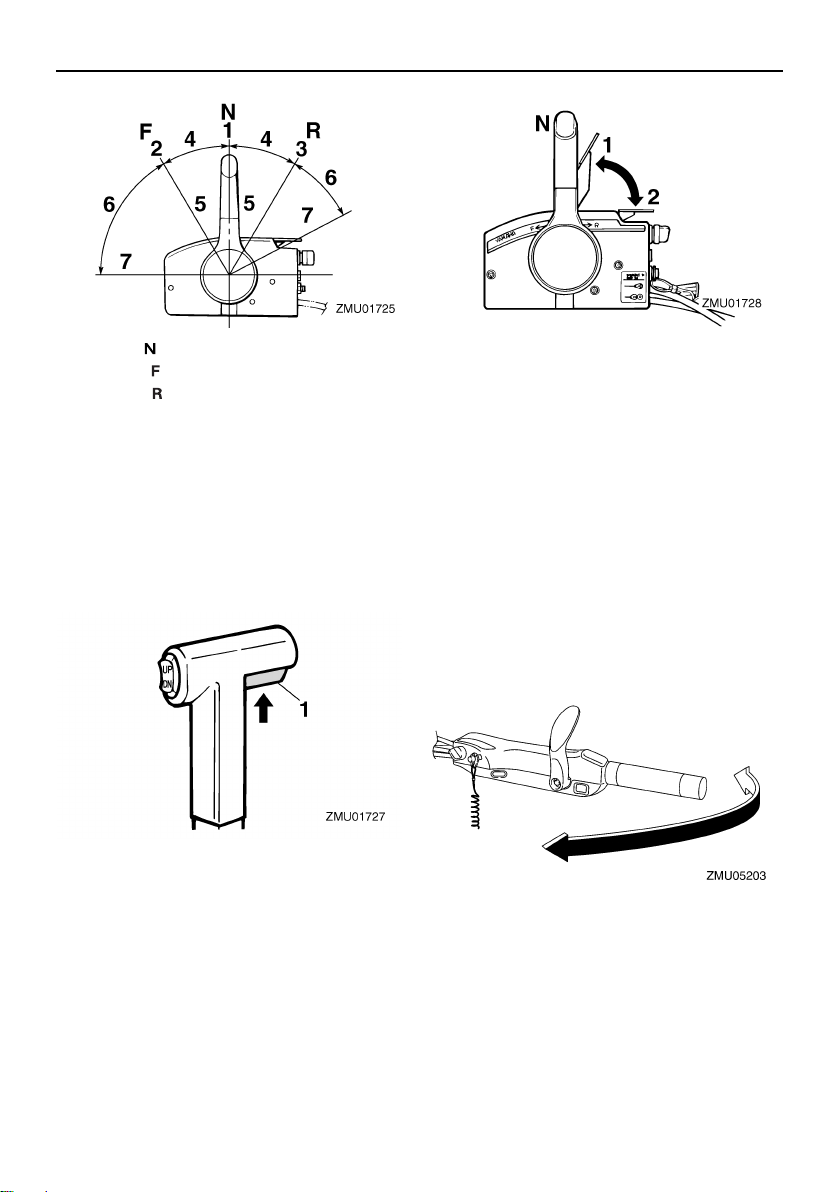

EMU26190

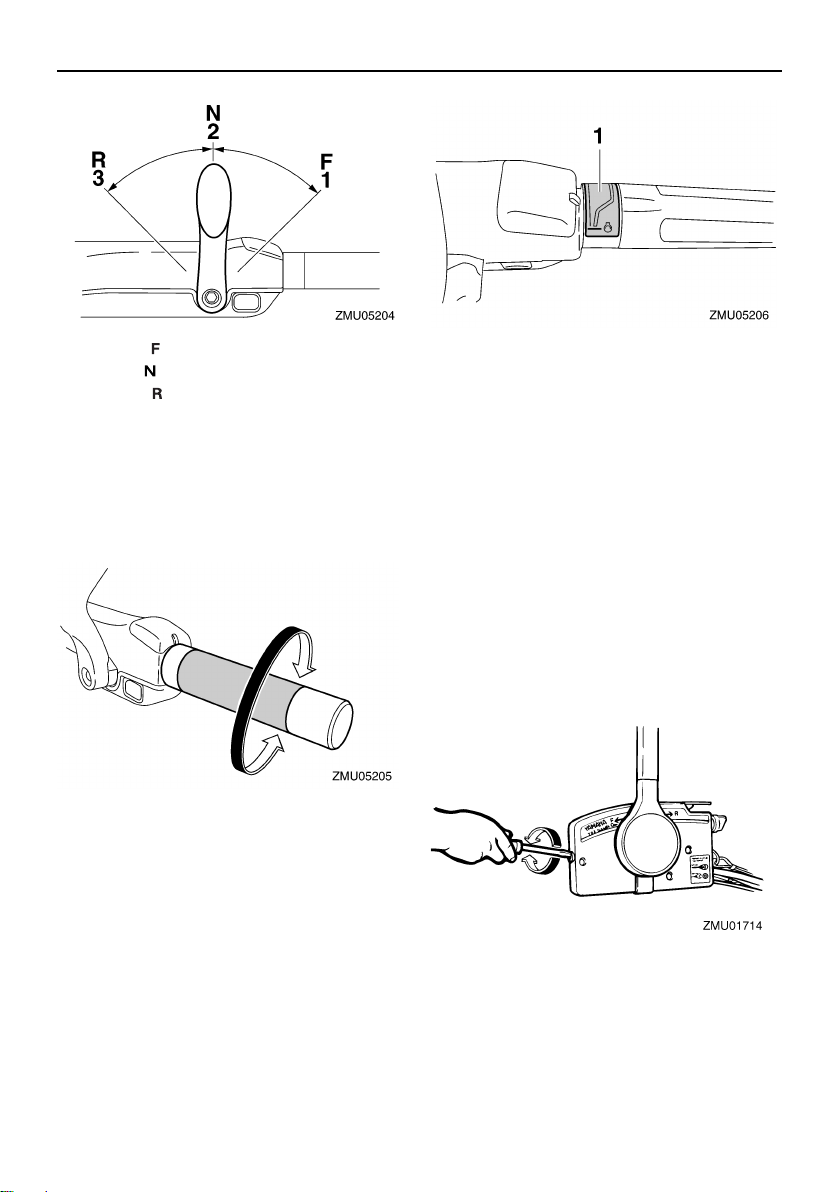

Remote control lever

Moving the lever forward from the neutral position engages forward gear. Pulling the lever back from neutral engages reverse. The

engine will continue to run at idle until the lever is moved about 35 (a detent can be felt).

Moving the lever farther opens the throttle,

and the engine will begin to accelerate.

21

Components

TIP:

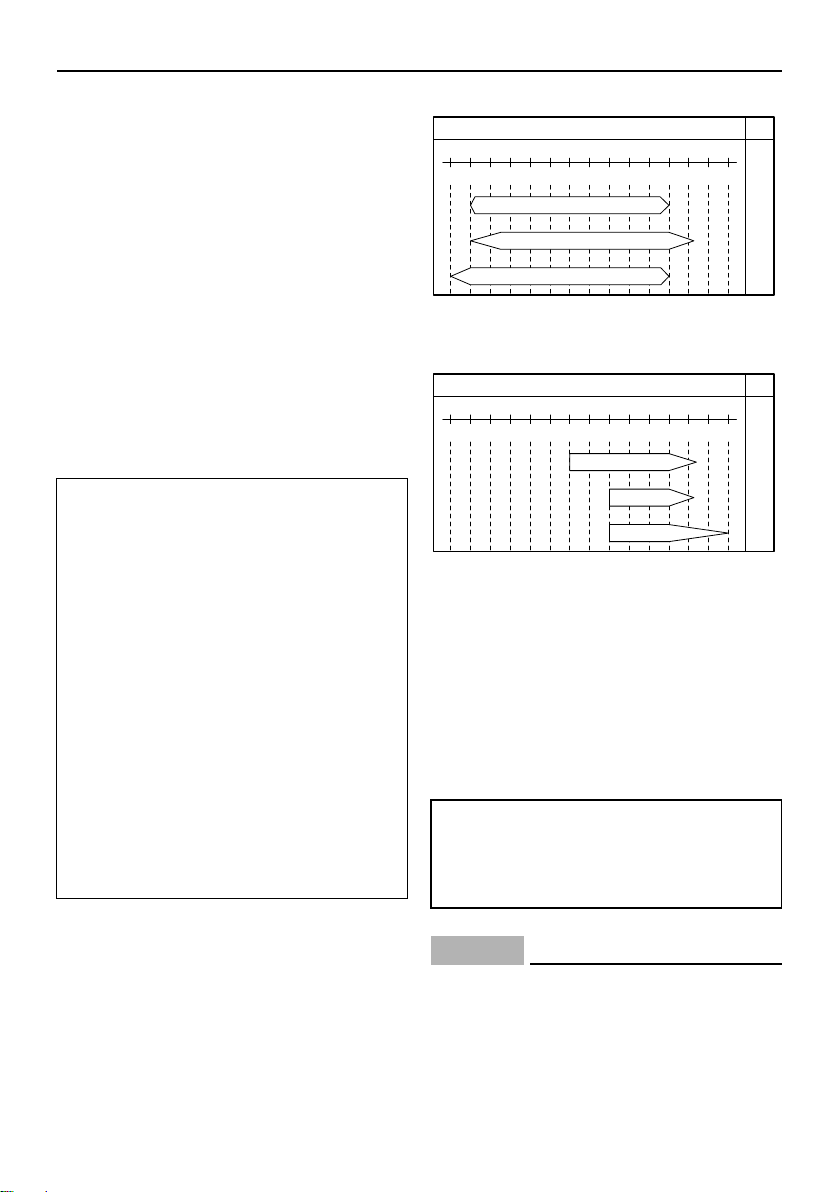

1. Neutral “ ”

2. Forward “ ”

3. Reverse “ ”

4. Shift

5. Fully closed

6. Throttle

7. Fully open

EMU26201

Neutral interlock trigger

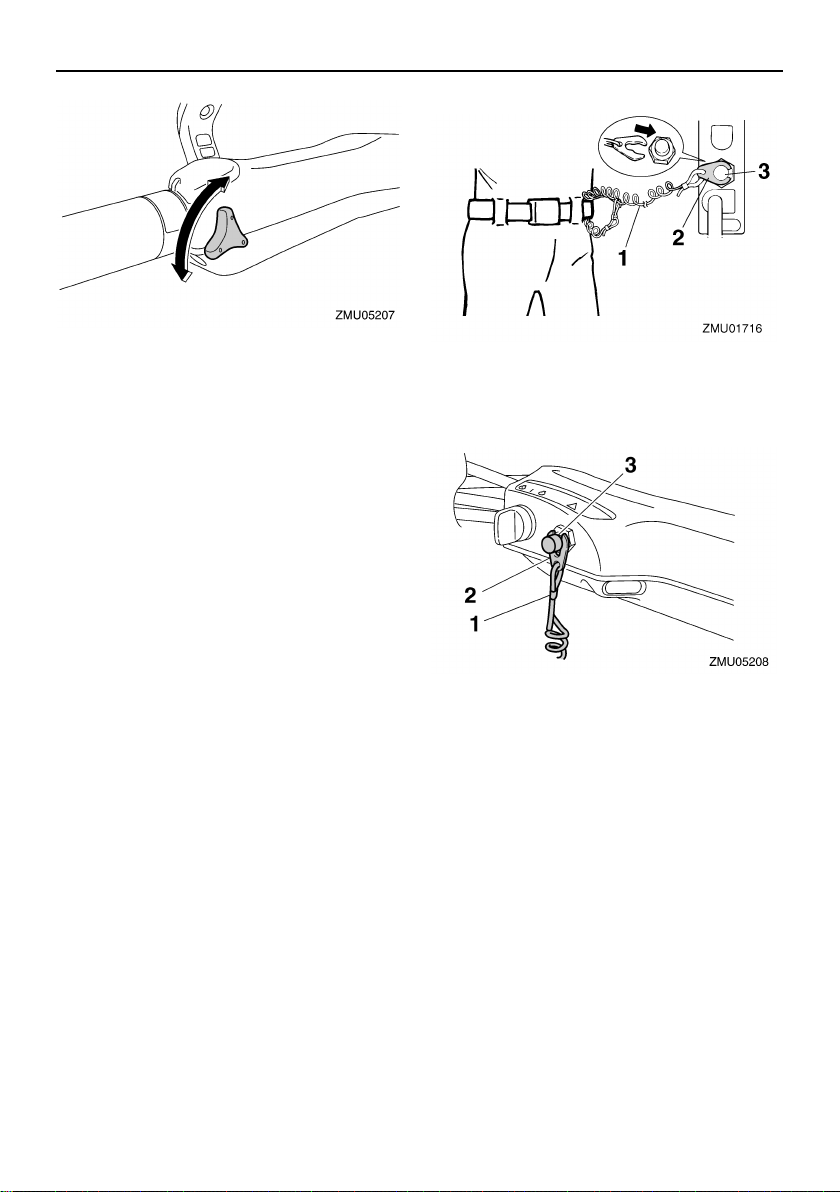

To shift out of neutral, first pull the neutral interlock trigger up.

1. Neutral interlock trigger

EMU26212

Neutral throttle lever

To open the throttle without shifting into either forward or reverse, put the remote control lever in the neutral position and lift the

neutral throttle lever.

1. Fully open

2. Fully closed

The neutral throttle lever will operate only

when the remote control lever is in neutral.

The remote control lever will operate only

when the neutral throttle lever is in the closed

position.

EMU25913

Tiller handle

To change direction, move the tiller handle to

the left or right as necessary.

EMU25924

Gear shift lever

Move the gear shift lever forward to engage

the forward gear or rearward to engage the

reverse gear.

22

Components

1. Forward “ ”

2. Neutral “ ”

3. Reverse “ ”

EMU25942

Throttle grip

The throttle grip is on the tiller handle. Turn

the grip counterclockwise to increase speed

and clockwise to decrease speed.

EMU25962

Throttle indicator

The fuel consumption curve on the throttle

indicator shows the relative amount of fuel

consumed for each throttle position. Choose

the setting that offers the best performance

and fuel economy for the desired operation.

1. Throttle indicator

EMU25976

Throttle friction adjuster

A friction device provides adjustable resistance to movement of the throttle grip or the

remote control lever, and can be set according to operator preference.

To increase resistance, turn the adjuster

clockwise. To decrease resistance, turn the

adjuster counterclockwise. WARNING! Do

not overtighten the friction adjuster. If

there is too much resistance, it could be

difficult to move the remote control lever

or throttle grip, which could result in an

accident.

[EWM00032]

23

Components

When constant speed is desired, tighten the

adjuster to maintain the desired throttle setting.

EMU25995

Engine shut-off cord (lanyard) and

clip

The clip must be attached to the engine shutoff switch for the engine to run. The cord

should be attached to a secure place on the

operator’s clothing, or arm or leg. Should the

operator fall overboard or leave the helm, the

cord will pull out the clip, stopping ignition to

the engine. This will prevent the boat from

running away under power. WARNING! At-

tach the engine shut-off cord to a secure

place on your clothing, or your arm or leg

while operating. Do not attach the cord to

clothing that could tear loose. Do not

route the cord where it could become entangled, preventing it from functioning.

Avoid accidentally pulling the cord during normal operation. Loss of engine

power means the loss of most steering

control. Also, without engine power, the

boat could slow rapidly. This could cause

people and objects in the boat to be

thrown forward.

[EWM00122]

1. Cord

2. Clip

3. Engine shut-off switch

1. Cord

2. Clip

3. Engine shut-off switch

EMU26003

Engine stop button

The engine stop button stops the engine

when the button is pushed.

24

Loading...

Loading...