YAMAHA F50A, FT50B, FT50C PARTS CATALOGUE

F50A

FT50B

FT50C

SERVICE MANUAL

290408

62Y-28197-3A-11

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, a bystander, or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

1

F50A, FT50B, FT50C

SERVICE MANUAL

©2000 by Yamaha Motor Co., Ltd.

1st Edition, November 2000

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in the Netherlands

Contents

General information

Specifications

Periodic checks and adjustments

Fuel system

GEN

INFO

SPEC

CHK

ADJ

FUEL

1

2

3

4

Power unit

Lower unit

Bracket unit

Electrical systems

POWR

LOWR

BRKT

–+

ELEC

5

6

7

8

Index

GEN

INFO

General information

How to use this manual.................................................................................1-1

Manual format............................................................................................1-1

Symbols.....................................................................................................1-2

Safety while working......................................................................................1-3

Fire prevention...........................................................................................1-3

Ventilation..................................................................................................1-3

Self-protection ...........................................................................................1-3

Parts, lubricants, and sealants ..................................................................1-3

Good working practices .............................................................................1-4

Disassembly and assembly .......................................................................1-4

Identification...................................................................................................1-5

Applicable models .....................................................................................1-5

Serial number ............................................................................................1-5

Features and benefits....................................................................................1-6

Newly designed four carburetors............................................................... 1-6

CDI unit with microcomputer .....................................................................1-7

Lower unit ..................................................................................................1-8

Technical tips ...............................................................................................1-10

Carburetor ...............................................................................................1-10

Acceleration pump...................................................................................1-15

Ignition system.........................................................................................1-17

Ignition timing control...............................................................................1-19

Power trim and tilt....................................................................................1-22

1

2

3

4

5

62Y3A11

Propeller selection.......................................................................................1-32

Propeller size...........................................................................................1-32

Selection..................................................................................................1-32

Predelivery checks ......................................................................................1-33

Checking the fuel system ........................................................................1-33

Checking the gear oil...............................................................................1-33

Checking the engine oil ...........................................................................1-33

Checking the battery................................................................................1-33

Checking the outboard motor mounting position.....................................1-34

Checking the remote control cables ........................................................1-34

Checking the steering wheel/tiller handle................................................1-34

Checking the gearshift and throttle operation..........................................1-34

Checking the tilt system...........................................................................1-35

Checking the engine start switch and

engine stop switch/engine shut-off switch .............................................1-35

Checking the pilot water outlet ................................................................1-35

Test run ...................................................................................................1-35

Break-in ...................................................................................................1-36

After test run ............................................................................................1-36

6

7

8

I

GEN

INFO

General information

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

1

Parts are shown and detailed in an exploded diagram and are listed in the components list.

2

Tightening torque specifications are provided in the components list at the beginning of each

section and after a numbered step with tightening instructions.

3

Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant

and lubrication point.

4

The components list consist of parts and part quantities, as well as bolt and screw dimensions.

5

Service points regarding removal, checking, and installation are shown in individual illustrations

to explain the relevant procedure.

6

This service manual has two types of special service tools. Use part numbers that start with “J-”,

“YB-”, “YM-”, “YS-”, “YU-”, “YW-”, or “YX-” for USA and Canada. Use parts numbers that start

with “90890-” for all other countries.

POWR

Cylinder head

Power unit

No. Part name Q’ty Remarks

1 Cylinder head 1

2Oil pump1

3 Cylinder head cover 1

4Bolt 7 M6 × 20 mm

5 Cylinder head cover

gasket

6 Bolt 10 M9 × 95 mm 1st

7 Spark plug 4 18 1.8 13

8Bolt 5 M6 × 25 mm 1st

9 Dowel pin 2

10 Cylinder head gasket 1

11 Grommet 4

12 Anode 4

13 Cover 4

14 Bolt 4

15 Cover 4

16 Bolt 4

17 O-ring 1

18 O-ring 1

19 O-ring 1

20 Bolt 4 M6 × 40 mm

21 Housing 1

22 Drive shaft 1

23 Pin 1

24 Inner rotor 1

25 Outer rotor 1

26 Gasket 1

27 Cover 1

28 Screw 2 M6 × 20 mm

È

Tightening sequence

POWR

Removing the timing belt and

sprockets

1. Set the cylinder #1 piston position to

1

Not reusable

Not reusable

Power unit

Not reusable

Not reusable

TDC of the compression stroke by aligning the “1” mark a on the driven sprocket

with the “” mark b on the cylinder

head.

Not reusable

Not reusable

Cylinder head

Tightening torques

Stage N·mkgf·mft·lb

2.3

2nd2347

4.71734

0.6

2nd612

3. Remove the tensioner 4 and timing belt

5

4.3

1.2

8.7

from the driven sprocket side.

5

1

1-1

5-35

62Y1A11

62Y1A11

CAUTION:

Do not turn the drive sprocket counterclockwise, otherwise the valve system

may be damaged.

2. Remove the breather hose and loosen

the drive sprocket nut 1.

NOTE:

• Use a deep socket 2 (M42) for this proce-

dure.

• Do not turn the camshaft when loosening

the drive sprocket nut.

Crankshaft holder 3: YB-06562

Crankshaft holder 18 3: 90890-06562

5-31

4. Loosen the driven sprocket bolt 6 and

remove the driven sprocket .

For USA and Canada

È

For worldwide

É

NOTE:

Do not turn the camshaft when loosening the

driven sprocket bolt.

Flywheel magnet holder: YB-06139

Flywheel holder: 90890-06522

5-36

62Y1A11

62Y3A11

How to use this manual

Symbols

The symbols below are designed to indicate the content of a chapter.

General information

GEN

INFO

Specifications

SPEC

Periodic checks and adjustments

CHK

ADJ

Fuel system

FUEL

Symbols 1 to 5 in an exploded diagram indicate the grade of lubricant and the lubrication point.

12345

Power unit

POWR

Lower unit

LOWR

Bracket unit

BRKT

Electrical systems

ELEC

– +

1

2

3

4

A M

E

Apply Yamaha 4-stroke motor oil

1

Apply water resistant grease (Yamaha grease A, Yamaha marine grease)

2

Apply molybdenum disulfide grease

3

Apply anti-corrosion grease (Yamaha grease D)

4

Apply low temperature resistant grease (Yamaha grease C)

5

Symbols 6 to A in an exploded diagram indicate the type of sealant or locking agent and the application point.

67890A

GM

Apply Gasket Maker

6

Apply Yamabond No. 4

7

Apply LOCTITE

8

Apply LOCTITE

9

Apply LOCTITE

0

Apply silicon sealant

A

4

®

®

No. 271 (Red LOCTITE)

®

No. 242 (Blue LOCTITE)

®

No. 572

LT

271

LT

242

D C

LT

572

SS

5

6

7

8

62Y3A11

1-2

I

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to

ensure quality service, follow the safety procedures provided below.

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled

in large quantities they may cause loss of

consciousness and death within a short time.

When test running an engine indoors (e.g., in

a water tank) be sure to do so where adequate ventilation can be maintained.

1

Parts, lubricants, and sealants

Use only genuine Yamaha

and sealants or those recommended by

Yamaha, when servicing or repairing the

outboard motor.

Under normal conditions, the lubricants mentioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

parts, lubricants,

Self-protection

Protect your eyes by wearing safety glasses

or safety goggles during all operations involving drilling and grinding, or when using an air

compressor.

Protect your hands and feet by wearing protective gloves and safety shoes when necessary.

1-3

1. Maintain good standards of personal and

industrial hygiene.

2. Change and wash clothing as soon as

possible if soiled with lubricants.

3. Avoid contact with skin. Do not, for

example, place a soiled rag in your

pocket.

4. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

5. To protect your skin, apply a protective

cream to your hands before working on

the outboard motor.

62Y3A11

6. Keep a supply of clean, lint-free cloths for

wiping up spills, etc.

Good working practices

Special tools

Use the recommended special tools to protect parts from damage. Use the right tool in

the right manner—do not improvise.

Tightening torques

Follow the tightening torque specifications

provided throughout the manual. When tightening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable parts

Always use new gaskets, seals, O-rings, cotter pins, circlips, etc., when installing or

assembling parts.

Safety while working

3. Install bearings with a manufacture identification mark in the direction indicated in

the installation procedure. In addition, be

sure to lubricate the bearings liberally.

4. Apply a thin coat of water-resistant

grease to the lip and out periphery of an

oil seal before installation.

5. Check that moving parts operate normally after assembly.

1

2

3

4

5

Disassembly and assembly

1. Use compressed air to remove dust and

dirt during disassembly.

2. Apply engine oil to the contact surfaces

of moving parts before assembly.

62Y3A11

1-4

6

7

8

I

GEN

INFO

General information

Identification

Applicable models

This manual covers the following models.

Applicable models

USA, Canada Worldwide

— F50AEHD

F50TH F50AEHT

— F50AED

F50TR F50AET

T50TR FT50BET

— FT50CEHD

— FT50CED

— FT50CET

Serial number

The outboard motor serial number is

stamped on a label attached to the port

clamp bracket.

1

Model name

Approved

model code

Starting

serial No.

USA, Canada

F50TH

L: 451812–

62Y

F50TR L: 421732–

T50TR 64J L: 406850–

Worldwide

F50AEHD

L: 350505–

L: 451812–

F50AEHT

X: 750469–

62Y

F50AED L: 301090–

L: 421626–

F50AET

X: 700700–

FT50BET

L: 406850–

FT50CEHD L: 650101–

64J

FT50CED L: 550101–

FT50CET L: 450101–

Model name

1

Approved model code

2

Transom height

3

Serial number

4

1-5

62Y3A11

Identification / Features and benefits

Features and benefits

Newly designed four carburetors

Newly designed four carburetors have been based on the current F50A. Prime Start has been

adopted for the starting system to further increase starting performance and serviceability. Furthermore, the acceleration pump and the dashpot have been integrated to simplify construction and to

ease serviceability. The four carburetors can be accurately and easily adjusted due to the simple

construction of the links.

1

1

2

3

4

5

6

7

Prime Start

1

Acceleration pump

2

62Y3A11

1-6

8

I

GEN

INFO

CDI unit with microcomputer

The ignition system consists of a flywheel, stator, pulser coil, thermoswitch, oil pressure switch, CDI

unit, and ignition coil. The CDI unit contains a built-in microcomputer that determines the ignition

timing separately for acceleration and for normal operation, based on signals received from the

pulser coil, thermoswitch, and oil pressure switch.

.

General information

1

2

3

4

5

6

CDI unit

1

Flywheel

2

Stator

3

Pulser coil

4

Thermoswitch

5

Ignition coil

6

Oil pressure switch

7

1-7

7

S62Y1210

62Y3A11

Features and benefits

Lower unit

Higher class pinion and gears

The lower unit of the new T50/FT50B, FT50C uses the same type of large gears that are used in the

F100. The use of the same type of gears that are used in a higher class model provides ample durability, making it possible to accommodate a wider range of applications throughout the market.

1

2

3

F50/F50A T50/FT50B, FT50C

Pinion Forward gear Reverse gear

Model

F50/F50A 13 45 24 74 24 75 1.8

T50/FT50B,

FT50C

Number

of teeth

13 46 30 95 30 95 2.3

Diameter

(mm)

Number

of teeth

Diameter

(mm)

Number

of teeth

Diameter

(mm)

S62Y1220

Gear ratio

4

5

6

7

62Y3A11

1-8

8

I

GEN

INFO

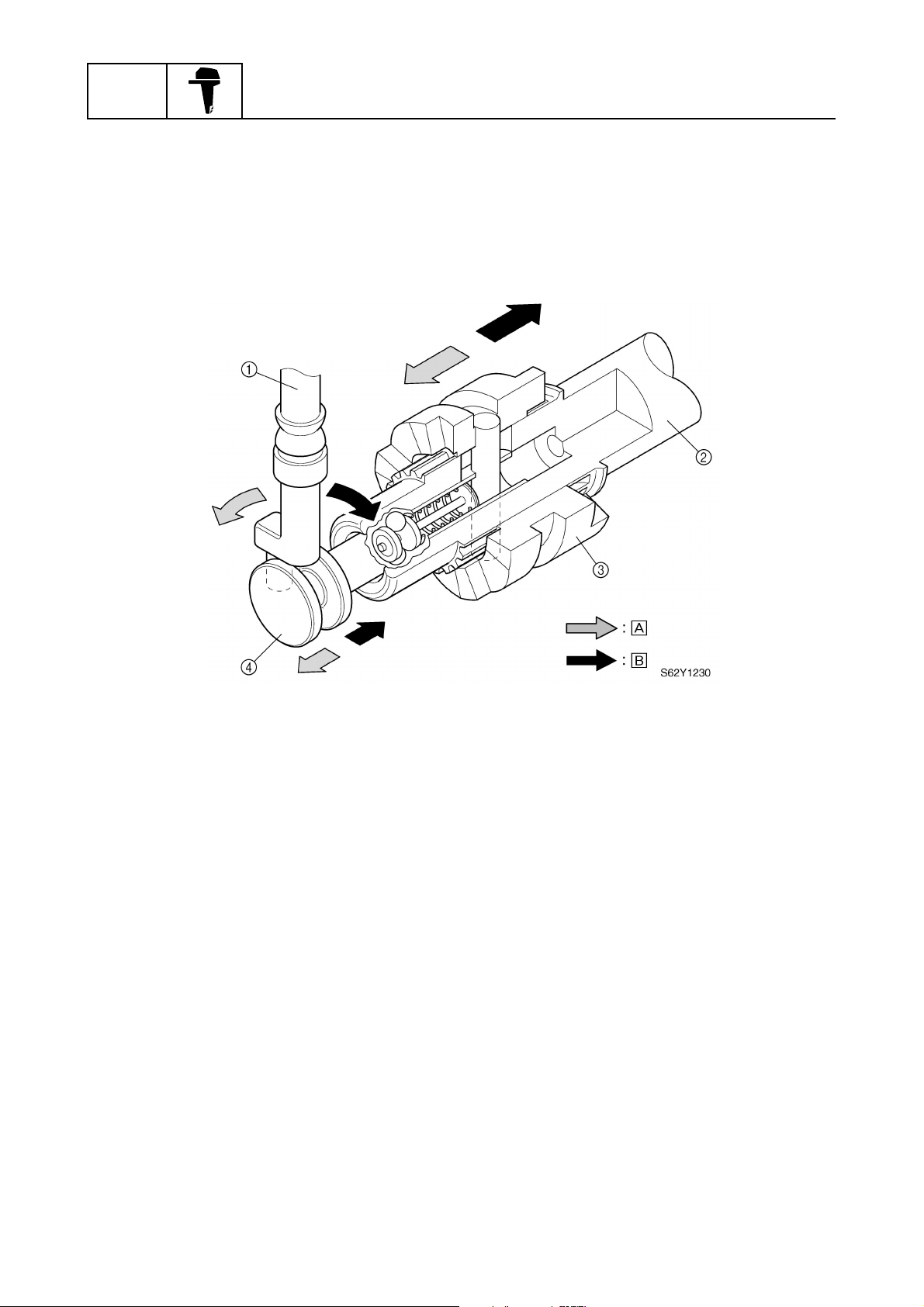

Shift slider type shift mechanism

The T50/FT50B, FT50C has adopted the shift slider type shift mechanism. This shift mechanism

enables a prompt engagement of the dog clutch regardless of the operating speed of the shift lever.

Thus, smooth and positive shift operation has been made possible.

General information

Shift rod

1

Propeller shaft

2

Dog clutch

3

Shift slider

4

Forward

È

Reverse

É

1-9

62Y3A11

Features and benefits / Technical tips

Technical tips

Carburetor

Starting system (Prime Start)

To facilitate the starting of a cold engine, an air-fuel mixture that is richer than normal is required.

For this reason, the Prime Start system has been adopted in the F50/F50A, T50/FT50B, FT50C. In

the Prime Start system, the thermo heater plunger is in a position that fully opens the fuel enrichment valve while the engine is being started. Thus, fuel enrichment is achieved during the starting of

the engine, and continues while the engine is being warmed up. Once the engine starts, current

flows from the lighting coil of the to the thermo heater, allowing the wax in the Prime Start unit to

expand. The expanded wax moves the thermo heater plunger in the direction to close the enrichment valve. As a result, the volume of fuel that passes through the fuel enrichment valve decreases.

A few minutes after the engine has started, the thermo heater plunger completely closes the fuel

enrichment valve, thus ending the fuel enrichment by the Prime Start system.

1

1

1

2

3

7

6

4

3

2

4

5

6

:

:

:

7

Prime Start

1

Intake manifold of the engine

2

Thermo heater plunger

3

Fuel enrichment valve

4

To carburetor #2 or #4

5

62Y3A11

5

Carburetor

6

Intake silencer

7

Air

È

Fuel

É

Plunger movement

Ê

S62Y1240

1-10

8

I

GEN

INFO

General information

Prime Start

1

The enriched air-fuel mixture is delivered to

È

cylinders #1 and #2 by the Prime Start system

attached to carburetor #1.

The enriched air-fuel mixture is delivered to

É

cylinders #3 and #4 by the Prime Start system

attached to carburetor #3.

1-11

62Y3A11

Technical tips

Carburetor operation

1. Idle and low-speed operation

Since the vacuum at the venturi is low when the throttle valve is opened slightly, the main nozzle

does not supply any air-fuel mixture to the engine.

When the engine is operating at idle, the fuel that passes through the pilot jet and the air that passes

through the pilot air jet mix, enabling the air-fuel mixture that has been regulated by the pilot screw

to be fed through the pilot outlet.

Because the throttle valve opens slightly when the engine is operating at low speeds, air-fuel mixture also starts to be fed from the bypass holes.

3

3

2

2

2

2

:

:

:

:

:

:

1

2

3

Pilot screw

1

Pilot outlet

2

Bypass holes

3

Venturi

4

Main nozzle

5

Pilot jet

6

Main jet

7

Pilot air jet

8

1

1

0

0

9

9

8

8

7

7

9

0

È

É

Ê

6

6

Main air jet

Throttle valve

Air

Air-fuel mixture

Fuel

5

5

3

3

S62Y1260

S62Y1260

4

4

4

5

6

7

8

62Y3A11

1-12

I

GEN

INFO

2. Medium speed operation

When the throttle valve opens further, air-fuel mixture is fed from the pilot outlet and all the bypass

holes. In addition, air-fuel mixture is also supplied from the main nozzle in accordance with the

opening angle of the throttle valve.

General information

3

2

2

:

:

:

0

3

1

4

9

8

5

7

6

S62Y1270

Pilot screw

1

Pilot outlet

2

Bypass holes

3

Venturi

4

Pilot jet

5

Main jet

6

Main nozzle

7

Pilot air jet

8

1-13

Main air jet

9

Throttle valve

0

Air

È

Air-fuel mixture

É

Fuel

Ê

62Y3A11

Technical tips

3. High-speed operation

When the throttle valve approaches its fully open position, the fuel that has been regulated by the

main jet and the air that has been regulated by the main air jet are mixed in the main nozzle. The

resultant mixture is then sprayed by the main nozzle into the venturi. The air-fuel mixture that is

sprayed through the venturi is then fed into the engine.

:

:

:

2

3

1

2

3

8

1

7

6

5

4

5

4

6

S62Y1280

7

Pilot screw

1

Pilot outlet

2

Bypass holes

3

Main nozzle

4

Pilot jet

5

Main jet

6

Main air jet

7

Throttle valve

8

62Y3A11

Air

È

Air-fuel mixture

É

Fuel

Ê

1-14

8

I

GEN

INFO

Acceleration pump

The function of the acceleration pump is to ensure a smooth acceleration by preventing the air-fuel

mixture from becoming temporarily lean in case the throttle valve is opened suddenly. When the

throttle valve is opened suddenly, a large volume of air is introduced into the engine. However,

because fuel is heavier than air, it is not possible to supply the volume of fuel that is necessary for

the large volume of air that has been introduced. Thus, because it is not possible to achieve the airfuel mixture that is required by the engine, bucking or hesitation results. For this reason, the acceleration pump temporarily increases the fuel volume in order to adjust the air-fuel mixture to a ratio that

is necessary for the engine in case the throttle valve is opened suddenly.

General information

:

:

Bypass hose

1

Acceleration pump

2

Pump chamber

3

Diaphragm 1

4

Throttle lever

5

Air flow

È

Throttle valve opening direction

É

5

1

2

3

4

S62Y1290

1-15

62Y3A11

Technical tips

Operation

When the throttle is opened suddenly, diaphragm 1 (via the link that is connected to the throttle

lever) operates to pressurize the air in the pump chamber. The pressurized air opens diaphragm 2,

and becomes distributed to the carburetors by passing through the pipes that are connected to the

carburetors. The pressurized and distributed air then utilizes the passage of the main air jet to flow

into the main nozzle. The pressure of the air helps suck fuel from the main jet, which increases the

fuel in the main nozzle, and thus achieves the fuel enrichment.

1

:

:

1

2

3

5

4

8

6

1

2

3

2

7

3

4

90

A

A

5

Main air jet

1

Main nozzle

2

Main jet

3

Throttle valve

4

Pilot screw

5

Pilot outlet

6

Pilot jet

7

From acceleration pump

8

Throttle valve closing

9

Throttle valve opening

0

62Y3A11

B

B

Diaphragm 1

A

Diaphragm 2

B

To carburetors

C

Air flow

È

Throttle valve opening direction

É

C

S62Y1300

1-16

6

7

8

I

GEN

INFO

Ignition system

In order to determine the optimal ignition timing that is necessary for the proper operation of the

engine, the built-in microcomputer in the CDI unit detects the signals from various types of sensors

and controls the ignition timing in accordance with a control map that is based on those signals. The

microcomputer also effects controls to protect the engine against overheating, over-revolution, and

oil pressure drops, as well as to control warning devices.

General information

Pulser coil

1

Flywheel

2

Charge coil

3

CDI unit

4

Microcomputer

5

1

2

3

8

9

4

5

Ignition coils #1 and #4

6

Ignition coils #2 and #3

7

Oil pressure switch

8

Thermoswitch

9

6

7

S62Y1310

Flywheel

Three protrusions for the pulser coil are provided along the periphery of the flywheel. The purpose

of these protrusions is for detecting the engine speed. Two of them are used for ignition signals, and

one is used for identifying the cylinders, and these signals are transmitted to the microcomputer.

1-17

62Y3A11

Technical tips

Pulser coil

The pulser coil transmits the pulser signals, which are generated in the pulser coil in accordance

with the rotation of the flywheel, to the CDI unit. Among the two protrusions that are provided for

generating signals, one is used for cylinders #1 and #4, and the other for cylinders #2 and #3, thus

enabling the pulser coil to simultaneously ignite two cylinders.

To provide ignition signals to the cylinders, the microcomputer determines the ignition cylinder and

ignition timing. These are based on the cylinder identification signals generated by the protrusion for

identifying cylinders, and on the pulser signals generated by the protrusions for generating ignition

signals.

1

Flywheel

1

Rotating direction

2

Protrusion for cylinders #1 and #4

3

Pulser coil

4

Cylinder identification protrusion

5

Protrusion for cylinders #2 and #3

6

1

6

2

3

5

2

4

3

4

S62Y1320

5

6

62Y3A11

1-18

7

8

I

GEN

INFO

Ignition timing control

Control circuit diagram

General information

Operation

Engine start

Acceleration

Over-revolution

Low oil pressure

Overheat

Detection Microcomputer

Engine temperature

Engine speed

Oil pressure

Ignition timing control

(optimized ignition

timing)

Engine speed control

Warning buzzer

(in remote-control

unit)

Warning lamp

(low oil pressure)

Warning lamp

(to overheat)

Positive start

Quick acceleration

Damage prevention

S62Y1330

Basic control

The ignition timing is determined by using the map based on the engine speed (r/min). Then, ignition signals are output from the microcomputer in accordance with the ignition timing map so that

ignition can take place at the optimal timing in relation to the engine speed. Then, the microcomputer corrects the ignition timing in accordance with the operating conditions of the engine as

detected by the signals that are input from the engine temperature sensor and oil pressure sensor.

The pulser signals that are output when the protrusions for cylinders #1 and #4, and for cylinders #2

and #3 pass by the pulser coil, are used to calculate the engine speed. In addition, the pulser signals are used to determine the forecast starting position of the ignition timing.

9

1

5

Cylinder identification protrusion

1

Pulser coil

2

Protrusion for cylinders #1 and #4

3

Protrusion for cylinders #2 and #3

4

Pulser coil signal

5

1-19

2

34

6

7

8

Cylinder identification signal

6

Identification signal for cylinders #1 and #4

7

Identification signal for cylinders #2 and #3

8

Rotating direction

9

S62Y1340

62Y3A11

Technical tips

Starting control

When starting the engine, the timing is set to 5° BTDC until the crankshaft speed maintains 600

r/min for two seconds or longer.

3

9

1

5

Cylinder identification protrusion

1

Protrusion for cylinders #1 and #4

2

Pulser coil

3

Protrusion for cylinders #2 and #3

4

Pulser coil signal

5

Cylinder identification signal

6

Warm-up control

After the starting control is completed, the control transfers to the ignition timing based on the warmup map for three minutes. From the time the three-minute warm-up control has been completed, the

control transfers to the normal map.

24

6

7

8

Starting signal (5° BTDC) for cylinders #1 and

7

#4

Starting signal (5° BTDC) for cylinders #2 and

8

#3

Rotating direction

9

S62Y1350

1

2

3

4

1

5

0

Ignition timing (BTDC°)

1

Engine speed (× 1,000 r/min)

2

Warm-up map

3

Acceleration map

4

Normal map

5

3

4

5

123456

2

S62Y1360

5

6

7

8

62Y3A11

1-20

I

GEN

INFO

Acceleration control

This control is activated when the throttle valve is opened suddenly. If the engine speed increases

more than the specified figures, the control of the ignition timing transfers to the acceleration map.

Thereafter, the control of the ignition timing transfers gradually to the control map before acceleration. If it was under warm-up control, the timing transfers to the warm-up control map, and if it was

under normal control, the timing transfers to the normal control map. The control described above

will be repeated if the engine is accelerated again.

Over-revolution control

This control operates by detecting the engine speed. If the engine speed increases to over 6,200

r/min, the ignition of cylinders #1 and #4 is stopped in order to regulate the speed. If the engine

speed increases further to over 6,300 r/min, the ignition of cylinders #2 and #3 is also stopped. This

control will not be deactivated until the engine speed drops below 6,200 r/min.

Overheating control

This control operates in accordance with the engine temperature, which is detected by the signal

that is input from the thermoswitch. When the microcomputer detects via the thermoswitch signal

that the engine temperature has increased to over 80 °C (176 °F), it outputs a signal to stop the ignition of cylinders #1 and #4, if the engine speed is over 2,000 r/min. At the same time, the microcomputer issues a warning by operating the warning lamp and the warning buzzer. When the

overheating control is activated, it will not be deactivated until the engine is stopped or the engine

temperature decreases to under 70 °C (158 °F).

The determination of overheating stops when the engine is stopped. However, until the engine temperature decreases to approximately 70 °C (158 °F) or below, the overheating control will be activated upon restarting the engine. Upon restarting, if the engine speed is under 2,000 r/min, the

overheating control will not be activated for 75 seconds. However, if the engine is operated at over

2,000 r/min for more than 25 seconds, the overheating control will be activated.

Oil pressure control

The oil pressure control operates in accordance with the signals from the oil pressure switch. The oil

pressure is determined to have dropped if the engine continues to operate at over 2,000 r/min with

an oil pressure of under 49 kPa (0.49 kgf/cm

pressure control is activated, the warning buzzer sounds and the warning lamp illuminates. If the

engine speed is over 2,000 r/min, the control stops the ignition of cylinders #1 and #4 so that the

engine speed will not increase to over 2,000 r/min. Once an oil pressure drop is determined, this

control will not be deactivated even if the oil pressure recuperates, until the engine is stopped.

General information

2

, 6.97 psi) for more than one second. When the oil

1-21

62Y3A11

Technical tips

Power trim and tilt

The newly designed power trim and tilt consists of an up-main valve, a down-main valve, an uprelief valve, a single cylinder, and a single ram, which control both trim and tilt functions.

The power trim and tilt cylinder has been integrated with the gear pump housing, the reservoir tank,

and the power trim and tilt motor in order to achieve a smaller and more compact unit.

Hydraulic system diagram

9

8

1

1

2

2

3

4

5

3

4

6

73

3

S62Y1370

Power trim and tilt cylinder

1

Ram

2

Reservoir

3

Manual valve

4

Down-main valve

5

Down-relief valve

6

Hydraulic pump

7

Up-relief valve

8

Up-main valve

9

5

6

7

8

62Y3A11

1-22

I

GEN

INFO

Power trim and tilt components

1

General information

2

3

6

F

5

C

4

9

B

7

A

8

9

0

E

Cylinder

1

Ram

2

Check valve

3

Down-main valve

4

Down-relief valve

5

Motor

6

Gear pump

7

Up-main valve

8

Reservoir

9

Manual valve

0

1-23

D

Up-relief valve

A

Up-shuttle piston

B

Down-shuffle piston

C

Trim cylinder base

D

Free piston

E

Tilt piston

F

S62Y1380

62Y3A11

Technical tips

Trim-up function

The gear pump pumps power trim and tilt fluid to the up-main valve. As a result, the fluid pressure

opens the up-shuttle piston causing the fluid to flow into the lower part of the power trim and tilt cylinder. At the same time, vacuum from the gear pump opens the down-main valve and down-shuttle

piston, which causes fluid from the upper part of the power trim and tilt cylinder to return to the gear

pump, and also sucks fluid in through the reservoir.

The pressurized fluid forces up the trim cylinder along with the tilt piston, free piston, and trim cylinder base. As the trim cylinder moves up, the ram extends and the outboard motor is trimmed up.

The end of the trim range is when the trim cylinder tops out in the power trim and tilt cylinder.

Trim-up function

1

2

1

C

2

3

A

4

0

5

8

6

7

9

8

:

:

3

4

5

6

Power trim and tilt cylinder

1

Ram

2

Trim cylinder

3

Down-main valve

4

Motor

5

Gear pump

6

Up-main valve

7

Reservoir

8

62Y3A11

B

Up-shuttle piston

9

Down-shuttle piston

0

Free piston

A

Trim cylinder base

B

Tilt piston

C

Return

È

Send

É

S62Y1390

1-24

7

8

I

GEN

INFO

Trim-down function

When the power trim and tilt switch is pressed to “Down”, the motor turns the gear pump counterclockwise and the power trim and tilt fluid flows in the opposite direction to that of the trim-up function.

Tilt-up function

When the trim cylinder tops out, the check valve is pushed down by the end screw wall. This causes

the ball in the check valve to move down, opening the fluid passage and allowing the power trim and

tilt fluid to flow from the upper part of the trim cylinder, through the down-shuttle piston and the

down-main valve, and back to the gear pump. In addition, fluid is also sucked in through the reservoir and the pressurized fluid continues to flow into the lower part of the trim cylinder, pushing up the

tilt piston and free piston, and further extending the ram.

As the tilt piston moves up and off of the trim cylinder base, the base moves up and pushes the balls

outward to fit into holes of the power trim and tilt cylinder. Once the balls have been fitted into the

holes the trim cylinder base cannot move.

The end of the tilt-up range is when the tilt piston tops out in the trim cylinder and the ram is fully

extended.

The tilt-up function operates when the fluid pressure is under 10 MPa (100 kgf/cm

When the fluid pressure in the lower part of the trim cylinder increases to over 10 MPa (100 kgf/cm

1,423 psi), the up-relief valve opens and allows the pressurized fluid to flow into the reservoir. Thus,

the tilt piston and free piston are not pushed up and the ram cannot be extend further.

General information

2

, 1,423 psi).

2

,

1-25

62Y3A11

Loading...

Loading...