Page 1

OWNER’S MANUAL

Read this manual carefully before operating this

outboard motor.

F350A

FL350A

F350A2

FL350A2

6AW-28199-78-E0

Page 2

EMU25052

Read this manual carefully before operating this outboard motor. Keep this

manual onboard in a waterproof bag when boating. This manual should stay

with the outboard motor if it is sold.

Page 3

Important manual information

WARNING

NOTICE

TIP:

TIP:

EMU25107

To the owner

Thank you for selecting a Yamaha outboard

motor. This Owner’s Manual contains information needed for proper operation, maintenance and care. A thorough understanding

of these simple instructions will help you obtain maximum enjoyment from your new

Yamaha. If you have any question about the

operation or maintenance of your outboard

motor, please consult a Yamaha dealer.

In this Owner’s Manual particularly important

information is distinguished in the following

ways.

: This is the safety alert symbol. It is

used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

EWM00781

A WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

ECM00701

A NOTICE indicates special precautions

that must be taken to avoid damage to the

outboard motor or other property.

there is any question concerning this manual, please consult your Yamaha dealer.

To ensure long product life, Yamaha recommends that you use the product and perform

the specified periodic inspections and maintenance by correctly following the instructions in the owner’s manual. Any damage

resulting from neglect of these instructions is

not covered by warranty.

Some countries have laws or regulations restricting users from taking the product out of

the country where it was purchased, and it

may be impossible to register the product in

the destination country. Additionally, the warranty may not apply in certain regions. When

planning to take the product to another country, consult the dealer where the product was

purchased for further information.

If the product was purchased used, please

consult your closest dealer for customer reregistration, and to be eligible for the specified services.

The F350AET, FL350AET, F350AET2,

FL350AET2 and the standard accessories

are used as a base for the explanations and

illustrations in this manual. Therefore some

items may not apply to every model.

EMU25121

A TIP provides key information to make procedures easier or clearer.

Yamaha continually seeks advancements in

product design and quality. Therefore, while

this manual contains the most current product information available at the time of printing, there may be minor discrepancies

between your machine and this manual. If

F350A, FL350A, F350A2, FL350A2

OWNER’S MANUAL

©2011 by Yamaha Motor Co., Ltd.

1st Edition, December 2011

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

Page 4

Table of contents

Safety information............................. 1

Outboard motor safety .....................1

Propeller............................................ 1

Rotating parts.................................... 1

Hot parts ........................................... 1

Electric shock.................................... 1

Power trim and tilt ............................. 1

Engine shut-off cord (lanyard)........... 1

Gasoline............................................ 1

Gasoline exposure and spills ............ 2

Carbon monoxide.............................. 2

Modifications ..................................... 2

Boating safety ..................................2

Alcohol and drugs ............................. 2

Personal flotation devices ................. 2

People in the water ........................... 2

Passengers ....................................... 2

Overloading....................................... 2

Avoid collisions ................................. 3

Weather ............................................ 3

Passenger training ............................ 3

Boating safety publications ............... 3

Laws and regulations ........................ 3

General information .......................... 4

Identification numbers record...........4

Outboard motor serial number .......... 4

Digital electronic control serial

number............................................ 4

Key number....................................... 5

EC Declaration of Conformity

(DoC) ............................................. 5

CE Marking .....................................5

Read manuals and labels................. 7

Warning labels ................................. 7

Specifications and

requirements.................................... 10

Specifications ................................. 10

Installation requirements ................ 11

Boat horsepower rating................... 11

Mounting motor ............................... 11

Yamaha Security System ............... 11

Digital electronic control

requirements ................................ 12

Battery requirements......................12

Battery specifications ...................... 12

Mounting battery ............................. 12

Multiple batteries ............................. 12

Propeller selection ......................... 13

Counter rotation models..................13

Start-in-gear protection .................. 13

Engine oil requirements ................. 14

Fuel requirements.......................... 14

Gasoline .......................................... 14

Anti-fouling paint ............................ 15

Motor disposal requirements.......... 15

Emergency equipment................... 15

Emission control information.......... 15

North American models................... 15

Star labels ....................................... 16

Components .................................... 18

Components diagram..................... 18

Remote control transmitter ............. 23

Receiver ......................................... 24

Yamaha Security System lock

and unlock mode........................... 24

Digital electronic control .................. 25

Digital electronic control-active

indicator ........................................26

Digital electronic control-alert

indicator ........................................26

Control lever....................................27

Neutral interlock trigger ................... 28

Free throttle switch..........................28

Throttle friction adjuster................... 29

Station selector switch .................... 30

Engine selector switch .................... 30

Engine shut-off cord (lanyard)

and clip.......................................... 31

Main switch ..................................... 32

Start/Stop switch panel ................... 33

All Start/Stop switch panel .............. 34

Power trim and tilt switch on

digital electronic control ................34

Power trim and tilt switch on

bottom cowling .............................. 35

Power trim and tilt switches............. 35

Tilt limiter.........................................36

Tilt support lever for power trim

and tilt model................................. 36

Cowling lock lever (turn type)..........36

Page 5

Table of contents

Flushing device ............................... 37

Fuel filter ......................................... 37

Instruments and indicators ............ 38

6Y9 Multifunction Color

Gauge ..........................................38

YAMAHA SECURITY SYSTEM

indicator ........................................ 38

Engine warm-up indicator ............... 38

Engine synchronization

indicator ........................................ 38

Overheat alert ................................. 39

Low oil pressure-alert...................... 39

Water separator alert ...................... 40

Low battery voltage-alert................. 40

Engine trouble alert......................... 40

6Y8 Multifunction meters................ 41

6Y8 Multifunction tachometers.......41

Yamaha Security System

information ................................... 42

Low oil pressure-alert...................... 42

Overheat alert ................................. 43

Water separator alert ...................... 43

Engine trouble alert......................... 43

Low battery voltage-alert................. 43

6Y8 Multifunction speed & fuel

meters .......................................... 44

6Y8 Multifunction

speedometers ..............................44

6Y8 Multifunction fuel

management meters .................... 45

Optional meters..............................46

Engine control system.................... 47

Alert system ...................................47

Digital Electronic Control alert......... 47

Overheat alert ................................. 47

Low oil pressure alert...................... 49

Water separator alert ...................... 50

Installation .......................................51

Installation ...................................... 51

Mounting the outboard motor.......... 51

Operation .........................................53

First-time operation ........................ 53

Fill engine oil ................................... 53

Breaking in engine .......................... 53

Getting to know your boat ............... 53

Checks before starting engine ....... 53

Fuel level.........................................53

Remove cowling..............................54

Fuel system.....................................54

Controls...........................................54

Engine shut-off cord (lanyard).........55

Engine oil ........................................ 55

Engine ............................................. 55

Flushing device ............................... 55

Install cowling..................................56

Checking power trim and tilt

system........................................... 56

Battery.............................................57

Filling fuel ...................................... 58

Operating engine ........................... 58

Sending fuel .................................... 58

Change of station ............................ 59

Starting engine ................................ 59

Checks after starting engine .......... 65

Cooling water .................................. 65

Warming up engine........................ 65

Electric start models........................65

Checks after engine warm up ........ 66

Shifting ............................................ 66

Stop switches .................................. 66

Selecting outboard motor (triple

engine)......................................... 66

Shifting........................................... 68

Stopping boat................................. 69

Operating the port / center /

starboard engine.......................... 69

Boat direction................................. 73

Trolling ........................................... 76

Adjusting trolling speed ................... 76

Stopping engine............................. 76

Procedure for single station and

dual station (main station)

models ..........................................76

Procedure for dual station models

(sub station) .................................. 78

Trimming outboard motor............... 79

Adjusting trim angle (Power trim

and tilt) .......................................... 79

Adjusting boat trim .......................... 80

Tilting up and down........................ 81

Page 6

Table of contents

Procedure for tilting up (power

trim and tilt models) ...................... 81

Procedure for tilting down (power

trim and tilt models) ...................... 83

Shallow water ................................84

Power trim and tilt models............... 84

Operating in other conditions ......... 87

Maintenance..................................... 88

Transporting and storing

outboard motor.............................88

Storing outboard motor ................... 88

Procedure ....................................... 88

Lubrication ...................................... 89

Flushing power unit......................... 89

Cleaning the outboard motor ......... 90

Checking painted surface of

outboard motor ............................. 90

Periodic maintenance..................... 90

Replacement parts.......................... 90

Severe operating conditions ........... 91

Maintenance chart 1 ....................... 92

Maintenance chart 2 ....................... 94

Greasing ......................................... 95

Inspecting spark plug ...................... 96

Inspecting engine idle speed .......... 97

Changing engine oil ........................ 98

Inspecting wiring and

connectors .................................... 98

Checking propeller .......................... 98

Removing propeller......................... 99

Installing propeller........................... 99

Changing gear oil.......................... 101

Inspecting and replacing

anode(s)...................................... 102

Checking battery (for electric

start models) ............................... 103

Connecting the battery.................. 103

Disconnecting the battery ............. 105

Storing the battery......................... 106

Trouble Recovery.......................... 107

Troubleshooting ...........................107

Temporary action in

emergency .................................110

Impact damage ............................. 110

Running in an emergency (twin

engines or triple engines)............ 110

Replacing fuse .............................. 111

Power trim and tilt will not

operate........................................ 112

Water separator-alert indicator

blinks while cruising .................... 112

Treatment of submerged

motor.......................................... 114

Page 7

Safety information

EMU33622

Outboard motor safety

Observe these precautions at all times.

EMU36501

Propeller

People can be injured or killed if they come

in contact with the propeller. The propeller

can keep moving even when the motor is in

neutral, and sharp edges of the propeller can

cut even when stationary.

Stop the engine when a person is in the

water near you.

Keep people out of reach of the propeller,

even when the engine is off.

EMU33630

Rotating parts

Hands, feet, hair, jewelry, clothing, PFD

straps, etc. can become entangled with internal rotating parts of the engine, resulting in

serious injury or death.

Keep the top cowling in place whenever possible. Do not remove or replace the cowling

with the engine running.

Only operate the engine with the cowling removed according to the specific instructions

in the manual. Keep hands, feet, hair, jewelry, clothing, PFD straps, etc. away from any

exposed moving parts.

EMU33640

Hot parts

During and after operation, engine parts are

hot enough to cause burns. Avoid touching

any parts under the top cowling until the engine has cooled.

EMU33650

Electric shock

Do not touch any electrical parts while starting or operating the engine. They can cause

shock or electrocution.

EMU33660

Power trim and tilt

Body parts can be crushed between the mo-

tor and the clamp bracket when the motor is

trimmed or tilted. Keep body parts out of this

area at all times. Be sure no one is in this

area before operating the power trim and tilt

mechanism.

The power trim and tilt switches operate

even when the main switch is off. Keep people be away from the switches whenever

working around the motor.

Never get under the lower unit while it is tilted, even when the tilt support lever is locked.

Severe injury could occur if the outboard motor accidentally falls.

EMU33671

Engine shut-off cord (lanyard)

Attach the engine shut-off cord so that the

engine stops if the operator falls overboard

or leaves the helm. This prevents the boat

from running away under power and leaving

people stranded, or running over people or

objects.

Always attach the engine shut-off cord to a

secure place on your clothing or your arm or

leg while operating. Do not remove it to leave

the helm while the boat is moving. Do not attach the cord to clothing that could tear

loose, or route the cord where it could become entangled, preventing it from functioning.

Do not route the cord where it is likely to be

accidentally pulled out. If the cord is pulled

during operation, the engine will shut off and

you will lose most steering control. The boat

could slow rapidly, throwing people and objects forward.

EMU33810

Gasoline

Gasoline and its vapors are highly flammable and explosive. Always, refuel ac-

cording to the procedure on page 58 to

reduce the risk of fire and explosion.

1

Page 8

Safety information

EMU33820

Gasoline exposure and spills

Take care not to spill gasoline. If gasoline

spills, wipe it up immediately with dry rags.

Dispose of rags properly.

If any gasoline spills onto your skin, immediately wash with soap and water. Change

clothing if gasoline spills on it.

If you swallow gasoline, inhale a lot of gasoline vapor, or get gasoline in your eyes, get

immediate medical attention. Never siphon

fuel by mouth.

EMU33900

Carbon monoxide

This product emits exhaust gases which contain carbon monoxide, a colorless, odorless

gas which may cause brain damage or death

when inhaled. Symptoms include nausea,

dizziness, and drowsiness. Keep cockpit and

cabin areas well ventilated. Avoid blocking

exhaust outlets.

EMU33780

Modifications

Do not attempt to modify this outboard motor. Modifications to your outboard motor

may reduce safety and reliability, and render

the outboard unsafe or illegal to use.

EMU33740

Boating safety

This section includes a few of the many important safety precautions that you should

follow when boating.

EMU33710

Alcohol and drugs

Never operate after drinking alcohol or taking

drugs. Intoxication is one of the most common factors contributing to boating fatalities.

EMU33720

Personal flotation devices

Have an approved personal flotation device

(PFD) on board for every occupant. Yamaha

recommends that you must wear a PFD

whenever boating. At a minimum, children

and non-swimmers should always wear

PFDs, and everyone should wear PFDs

when there are potentially hazardous boating conditions.

EMU33731

People in the water

Always watch carefully for people in the water, such as swimmers, skiers, or divers,

whenever the engine is running. When

someone is in the water near the boat, shift

into neutral and stop the engine.

Stay away from swimming areas. Swimmers

can be hard to see.

The propeller can keep moving even when

the motor is in neutral. Stop the engine when

a person is in the water near you.

EMU33751

Passengers

Consult your boat manufacturer’s instructions for details about appropriate passenger

locations in your boat and be sure all passengers are positioned properly before accelerating and when operating above an idle

speed. Standing or sitting in non-designated

locations may result in being thrown either

overboard or within the boat due to waves,

wakes, or sudden changes in speed or direction. Even when people are positioned properly, alert your passengers if you must make

any unusual maneuver. Always avoid jumping waves or wakes.

EMU33760

Overloading

Do not overload the boat. Consult the boat

capacity plate or boat manufacturer for maximum weight and number of passengers. Be

sure that weight is properly distributed according to the boat manufacturers instructions. Overloading or incorrect weight

distribution can compromise the boats handling and lead to an accident, capsizing or

2

Page 9

Safety information

ZMU06025

swamping.

EMU33772

Avoid collisions

Scan constantly for people, objects, and other boats. Be alert for conditions that limit your

visibility or block your vision of others.

Operate defensively at safe speeds and

keep a safe distance away from people, objects, and other boats.

Do not follow directly behind other boats or

waterskiers.

Avoid sharp turns or other maneuvers that

make it hard for others to avoid you or understand where you are going.

Avoid areas with submerged objects or

shallow water.

Ride within your limits and avoid aggres-

sive maneuvers to reduce the risk of loss

of control, ejection, and collision.

Take early action to avoid collisions. Re-

member, boats do not have brakes, and

stopping the engine or reducing throttle

can reduce the ability to steer. If you are

not sure that you can stop in time before

hitting an obstacle, apply throttle and turn

in another direction.

EMU33790

Weather

Stay informed about the weather. Check

weather forecasts before boating. Avoid

boating in hazardous weather.

EMU33880

Passenger training

Make sure at least one other passenger is

trained to operate the boat in the event of an

emergency.

EMU33890

Boating safety publications

Be informed about boating safety. Additional

publications and information can be obtained

from many boating organizations.

EMU33600

Laws and regulations

Know the marine laws and regulations where

you will be boating- and obey them. Several

sets of rules prevail according to geographic

location, but all are basically the same as the

International Rules of the Road.

3

Page 10

General information

TIP:

1

ZMU05814

ZMU06224

1

ZMU05885

1

ZMU05887

1

EMU25171

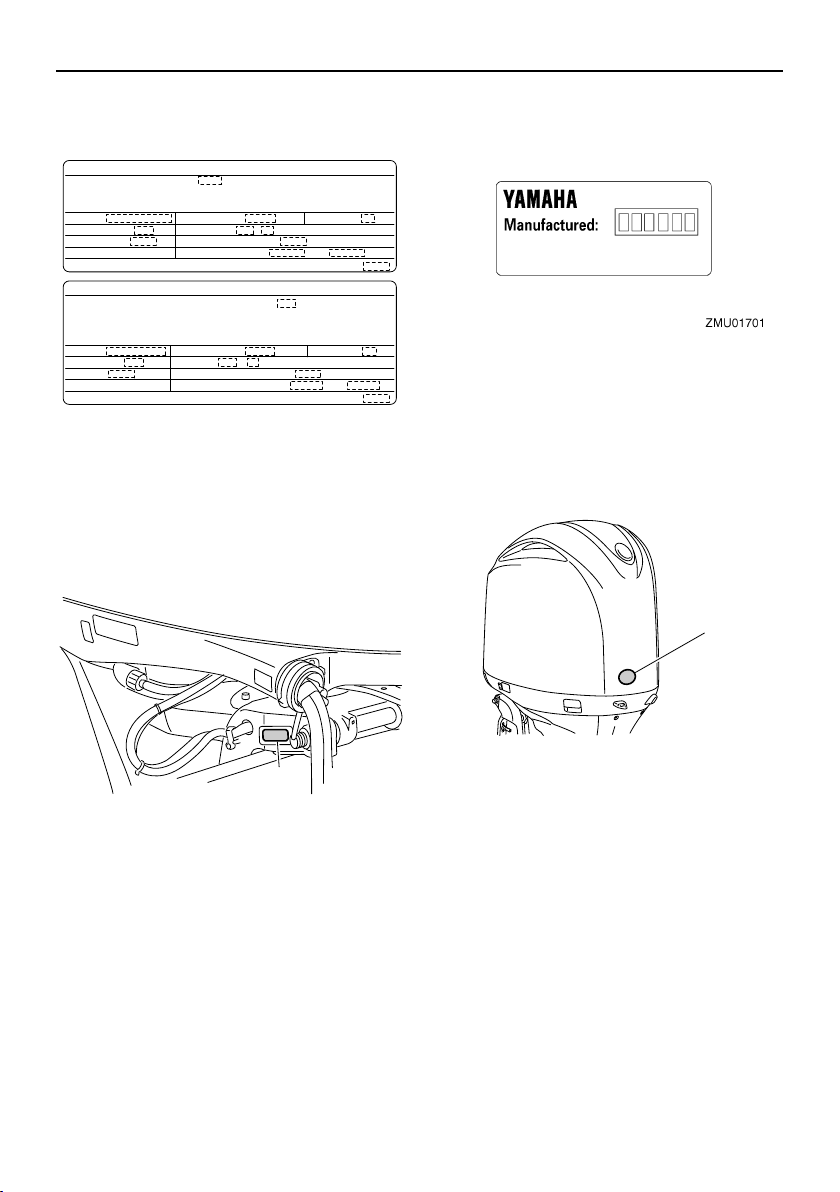

Identification numbers record

EMU25184

Outboard motor serial number

The outboard motor serial number is

stamped on the label attached to the port

side of the clamp bracket.

Record your outboard motor serial number in

the spaces provided to assist you in ordering

spare parts from your Yamaha dealer or for

reference in case your outboard motor is stolen.

1. Outboard motor serial number location

Record your digital electronic control serial

number in the spaces provided to assist you

in newly connecting the digital electronic

control to the outboard motor.

Consult your Yamaha dealer if you have any

questions concerning the digital electronic

control serial number.

EMU34943

Digital electronic control serial

number

The digital electronic control serial number is

stamped on the label attached to the digital

electronic control box.

4

Page 11

1. Digital electronic control serial number loca-

ZMU05958

1

1

ZMU07133

tion

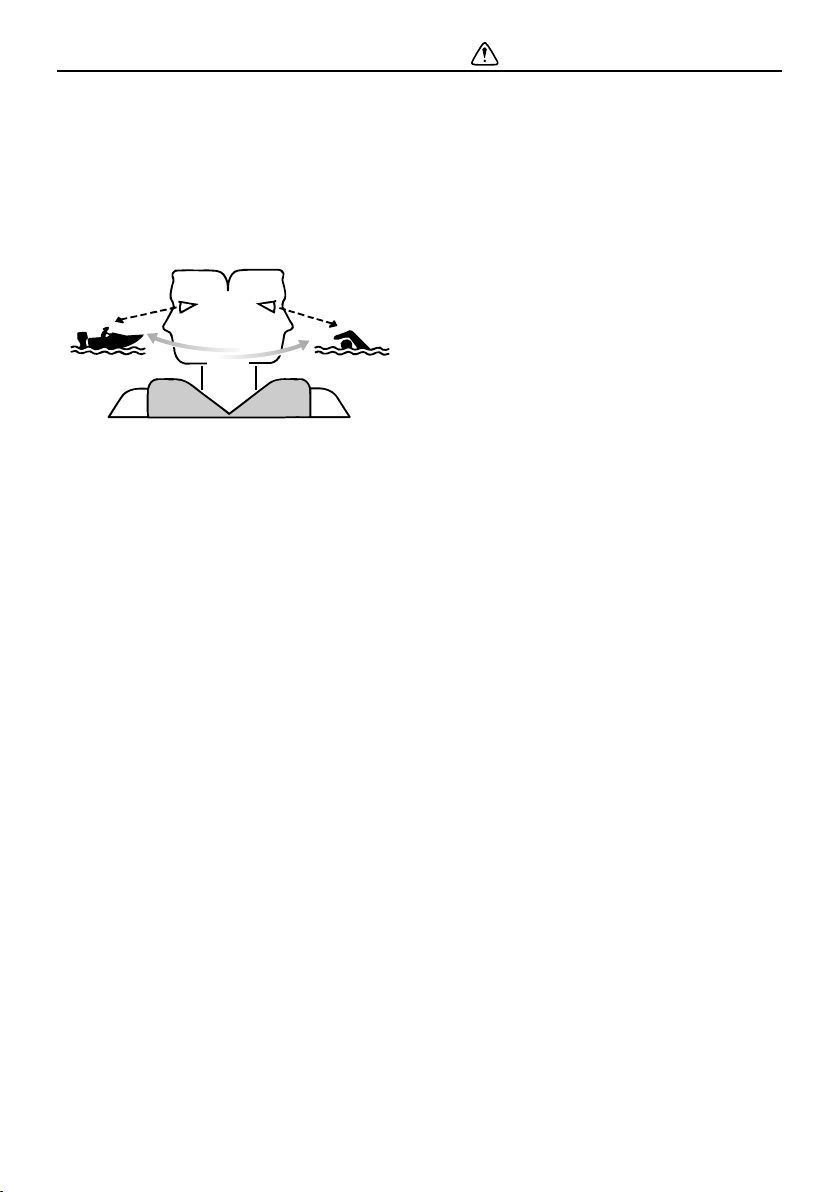

EMU25191

Key number

If a main key switch is equipped with the motor, the key identification number is stamped

on your key as shown in the illustration.

Record this number in the space provided for

reference in case you need a new key.

General information

1. Key number

EMU37291

EC Declaration of Conformity

(DoC)

This outboard motor conforms to certain portions of the European Parliament directive

relating to machinery.

Each conformed outboard motor accompanied with EC DoC.EC DoC contains the following information;

Name of Engine Manufacture

Model name

Product code of model (Approved model

code)

Code of conformed directives

EMU25205

CE Marking

Outboard motors affixed with this “CE”marking conform with the directives of; 98/37/EC,

94/25/EC - 2003/44/EC and 2004/108/EC.

5

Page 12

General information

ZMU05943

1

ZMU06040

1. CE marking location

6

Page 13

General information

3

2

1

ZMU05950

EMU33523

Read manuals and labels

Before operating or working on this outboard motor:

Read this manual.

Read any manuals supplied with the boat.

Read all labels on the outboard motor and the boat.

If you need any additional information, contact your Yamaha dealer.

EMU33832

Warning labels

If these labels are damaged or missing, contact your Yamaha dealer for replacements.

F350A, FL350A, F350A2, FL350A2

7

Page 14

General information

WARNING

WARNING

1

2

ZMU06191

3

ZMU05710

EMU34651

Contents of labels

The above warning labels mean as follows.

1

EWM01681

Keep hands, hair, and clothing away

from rotating parts while the engine is

running.

Do not touch or remove electrical parts

when starting or during operation.

2

EWM01671

Read Owner’s Manuals and labels.

Wear an approved personal flotation

device (PFD).

Attach engine shut-off cord (lanyard) to

your PFD, arm, or leg so the engine

stops if you accidentally leave the

8

helm, which could prevent a runaway

boat.

EMU33850

Other labels

Page 15

General information

ZMU05696

ZMU05664

ZMU05665

ZMU05666

EMU35132

Symbols

The following symbols mean as follows.

Notice/Warning

Read Owner’s Manual

Electrical hazard

Hazard caused by continuous rotation

9

Page 16

Specifications and requirements

TIP:

EMU34521

Specifications

“(AL)” stated in the specification data below

represents the numerical value for the aluminum propeller installed.

Likewise, “(SUS)” represents the value for

stainless steel propeller installed and “(PL)”

for plastic propeller installed.

EMU2821P

Dimension:

Overall length:

1029 mm (40.5 in)

Overall width:

633 mm (24.9 in)

Overall height X:

2006 mm (79.0 in)

Overall height U:

2133 mm (84.0 in)

Motor transom height X:

637 mm (25.1 in)

Motor transom height U:

764 mm (30.1 in)

Dry weight (SUS) X:

358 kg (789 lb)

Dry weight (SUS) U:

366 kg (807 lb)

Performance:

Full throttle operating range:

5000–6000 r/min

Rated power:

257.4 kW (350 HP)

Idle speed (in neutral):

600-700 r/min

Engine:

Type:

4-stroke DOHC V8 32valves

Displacement:

5330 cm

(180.2 US oz, 188.0 Imp.oz)

3

Bore stroke:

94.0 96.0 mm (3.70 3.78 in)

Ignition system:

TCI

Spark plug (NGK):

LFR6A-11

Spark plug gap:

1.0–1.1 mm (0.039–0.043 in)

Control system:

Remote control

Starting system:

Electric starter

Starting carburetion system:

Electronic fuel injection

Valve clearance IN (cold engine):

0.17–0.24 mm (0.0067–0.0094 in)

Valve clearance EX (cold engine):

0.31–0.38 mm (0.0122–0.0150 in)

Min. cold cranking amps (CCA/EN):

670 A

Min. rated capacity (20HR/IEC):

110 Ah

Maximum generator output:

49 A

Drive unit:

Gear shift positions:

Forward-neutral-reverse

Gear ratio:

1.73(26/15)

Trim and tilt system:

Power trim and tilt

Propeller mark:

F350AET X

F350AET2 X

FL350AET XL

FL350AET2 XL

Fuel and oil:

Recommended fuel:

Premium unleaded gasoline

Min. research octane number:

94

10

Page 17

Specifications and requirements

WARNING

WARNING

NOTICE

Recommended engine oil:

4-stroke outboard motor oil

Recommended engine oil grade 1:

SAE 10W-30/10W-40/5W-30

API SE/SF/SG/SH/SJ/SL

Engine oil quantity (without oil filter replacement):

6.3 L (6.66 US qt, 5.54 Imp.qt)

Engine oil quantity (with oil filter replacement):

6.5 L (6.87 US qt, 5.72 Imp.qt)

Lubrication system:

Wet sump

Recommended gear oil:

Hypoid gear oil

Recommended gear oil grade:

SAE 80W API GL-5/SAE 90 API GL-5

Gear oil quantity:

F350AET 1.520 L (1.607 US qt,

1.338 Imp.qt)

F350AET2 1.520 L (1.607 US qt,

1.338 Imp.qt)

FL350AET 1.310 L (1.385 US qt,

1.153 Imp.qt)

FL350AET2 1.310 L (1.385 US qt,

1.153 Imp.qt)

Tightening torque for engine:

Spark plug:

28 Nm (2.86 kgf-m, 20.7 ft-lb)

Propeller nut:

54 Nm (5.51 kgf-m, 39.8 ft-lb)

Engine oil drain bolt:

27 Nm (2.75 kgf-m, 19.9 ft-lb)

Engine oil filter:

18 Nm (1.84 kgf-m, 13.3 ft-lb)

Noise and vibration level:

Operator sound pressure level:

79.1 dB(A)

EMU33554

Installation requirements

EMU33564

Boat horsepower rating

EWM01560

Overpowering a boat can cause severe

instability.

Before installing the outboard motor(s), confirm that the total horsepower of your outboard motor(s) does not exceed the boats

maximum horsepower rating. See the boat’s

capacity plate or contact the manufacturer.

EMU33571

Mounting motor

EWM01570

Improper mounting of the outboard mo-

tor could result in hazardous conditions such as poor handling, loss of

control, or fire hazards.

Because the motor is very heavy, spe-

cial equipment and training is required

to mount it safely.

Your dealer or other person experienced in

proper rigging should mount the motor using

correct equipment and complete rigging instructions. For further information, see page

51.

EMU41592

Yamaha Security System

ECM02460

The Yamaha Security System is sold in

conformity with the relevant laws and

regulations regarding radio wave transmission. Therefore, if this product is used

outside the country where it was sold, it

may violate the laws or regulations regarding radio wave transmission in the

country it is used in. For details, consult

11

Page 18

Specifications and requirements

WARNING

ZMU07305

your Yamaha dealer.

The outboard motor with this label is

equipped with the Yamaha Security System

to protect against theft, which consists of the

receiver and remote control transmitter. The

engine can not be started if the security system is in the lock mode, and only be started

in the unlock mode. Consult your Yamaha

dealer for installation of the receiver.

EMU34952

Digital electronic control

requirements

The digital electronic control be equipped

with a start-in-gear protection device(s). This

device prevents the engine from starting unless it is in neutral.

EWM01580

If the engine starts in gear, the boat can

move suddenly and unexpectedly, possibly causing a collision or throwing

passengers overboard.

If the engine ever starts in gear, the

start-in-gear protection device is not

working correctly and you should discontinue using the outboard. Contact

your Yamaha dealer.

This digital electronic control unit is only

available for the outboard motor which you

have purchased.

Prior to use of the digital electronic control

unit, set it in order to operate your outboard

motor only. Otherwise, it will not be possible

to operate the outboard motor.

Perform setting of the outboard motor and

the digital electronic control unit in the following cases.

If a used outboard motor is installed

If the digital electronic control unit is re-

placed

If the ECM (Electronic control module) of

the used outboard motor is replaced

If the ECM (Electronic control module) of

the digital electronic control unit is replaced

Consult your Yamaha dealer for setting.

EMU25694

Battery requirements

EMU25721

Battery specifications

Minimum cold cranking amps (CCA/EN):

670 A

Minimum rated capacity (20HR/IEC):

110 Ah

The engine cannot be started if battery voltage is too low.

EMU36290

Mounting battery

Mount the battery holder securely in a dry,

well-ventilated, vibration-free location in the

boat. WARNING! Do not put flammable

items, or loose heavy or metal objects in

the same compartment as the battery.

Fire, explosion or sparks could result.

[EWM01820]

EMU36300

Multiple batteries

To connect multiple batteries, such as for

multiple engine configurations or for an accessory battery, consult your Yamaha dealer

12

Page 19

Specifications and requirements

ZMU05937

-

3

12

about battery selection and correct wiring.

EMU41600

Propeller selection

Next to selecting an outboard motor, selecting the right propeller is one of the most important purchasing decisions a boater can

make. The type, size, and design of your propeller have a direct impact on acceleration,

top speed, fuel economy, and even engine

life. Yamaha designs and manufactures propellers for every Yamaha outboard motor

and every application.

Your Yamaha dealer can help you select the

right propeller for your boating needs. Select

a propeller that will allow the engine to reach

the middle or upper half of the operating

range at full throttle with the maximum boatload. Generally, select a larger pitch propeller for a smaller operating load and a smaller

pitch propeller for a heavier load. If you carry

loads that vary widely, select the propeller

that lets the engine run in the proper range

for your maximum load but remember that

you may need to reduce your throttle setting

to stay within the recommended engine

speed range when carrying lighter loads.

Yamaha recommends to use a propeller suitable for the “Shift Dampener System (SDS)”.

For further information, consult your Yamaha

dealer.

To check the propeller, see page 98.

1. Propeller pitch in inches

2. Type of propeller (propeller mark)

3. Propeller diameter in inches

EMU36310

Counter rotation models

Standard outboard motors rotate clockwise.

Counter rotation models rotate counterclockwise. Counter rotation models are typically

used in multiple motor setups and are

marked with an “L” on the gear case above

the anti-ventilation plate.

On counter rotation models, be sure to use a

propeller intended for counterclockwise rotation. These propellers are identified with the

letter “L” after the size indication on the propeller. WARNING! Never use a standard

propeller with a counter rotation motor,

or a counter rotation propeller with a

standard motor. Otherwise the boat could

go in the direction opposite of that expected (for example, reverse instead of

forward), which could lead to an accident.

[EWM01810]

For instructions on propeller removal and installation, see page 99 and 99.

EMU35140

Start-in-gear protection

Yamaha outboard motors or Yamaha-approved digital electronic control units are

equipped with start-in-gear protection device(s). This feature permits the engine to be

13

Page 20

Specifications and requirements

NOTICE

ZMU06854

122˚F

50˚C

104

40

86

30

68

SAE API

SE

SF

SG

SH

SJ

SL

20

50

10

32

0

14

-10

-4

-20

10W–30

10W–40

5W–30

ZMU06855

122˚F

50˚C

104

40

86

30

68

SAE API

SH

SJ

SL

20

50

10

32

0

14

-10

-4

-20

15W–40

20W–40

20W–50

started only when it is in neutral. Always select neutral before starting the engine.

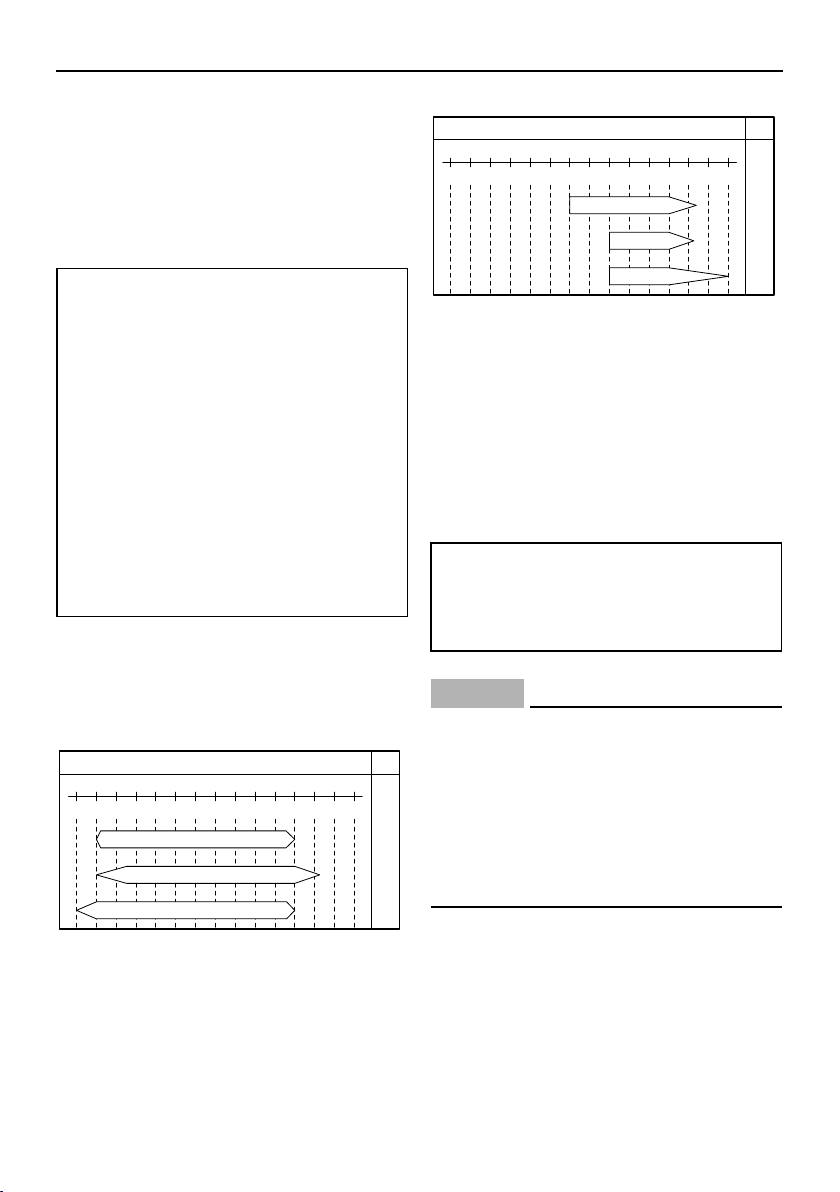

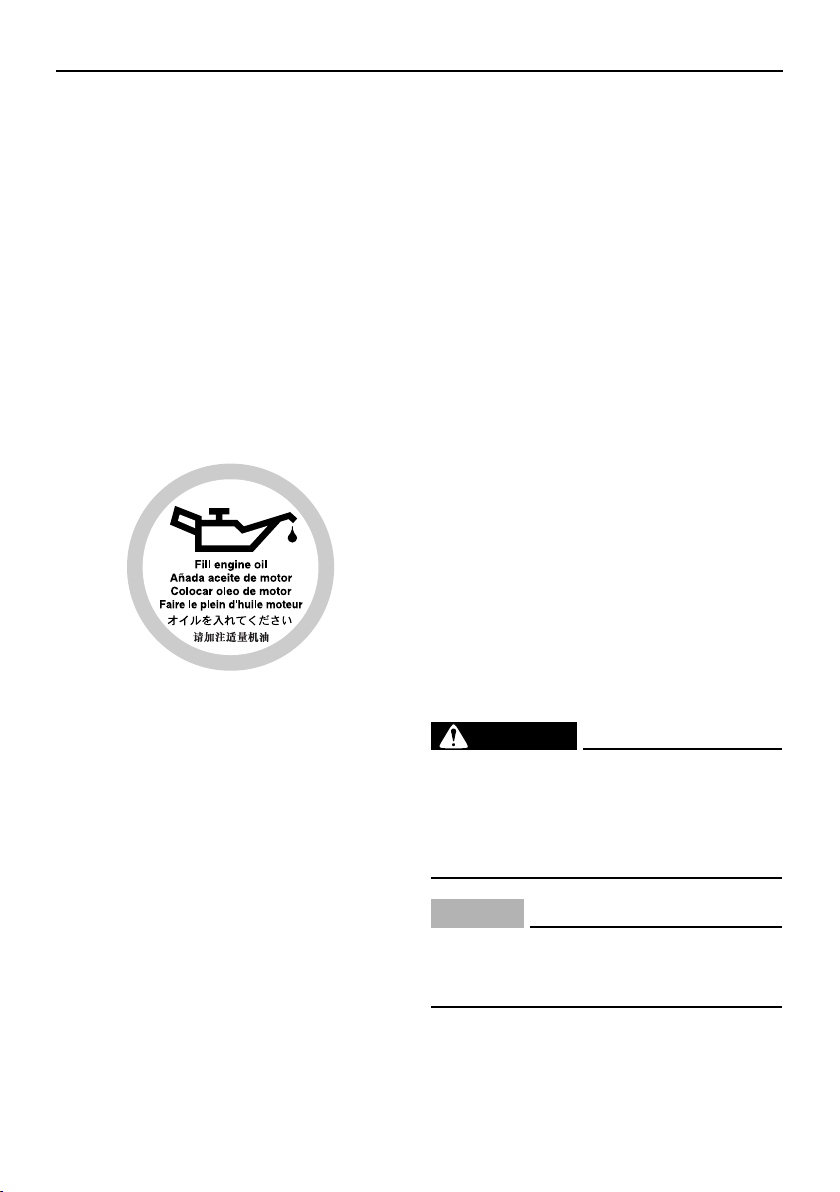

EMU41952

Engine oil requirements

Select an oil grade according to the average

temperatures in the area where the outboard

motor will be used.

Recommended engine oil:

4-stroke outboard motor oil

Recommended engine oil grade 1:

SAE 10W-30/10W-40/5W-30

API SE/SF/SG/SH/SJ/SL

Recommended engine oil grade 2:

SAE 15W-40/20W-40/20W-50

API SH/SJ/SL

Engine oil quantity (without oil filter replacement):

6.3 L (6.66 US qt, 5.54 Imp.qt)

Engine oil quantity (with oil filter replacement):

6.5 L (6.87 US qt, 5.72 Imp.qt)

If oil grades listed under Recommended engine oil grade 1 are not available, select an

alternative oil grade listed under Recommended engine oil grade 2.

Recommended engine oil grade 1

Recommended engine oil grade 2

EMU36360

Fuel requirements

EMU40201

Gasoline

Use a good quality gasoline that meets the

minimum octane rating. If knocking or pinging occurs, use a different brand of gasoline

or premium unleaded fuel.

Recommended fuel:

Premium unleaded gasoline

Min. research octane number:

94

ECM01981

Do not use leaded gasoline. Leaded

gasoline can seriously damage the engine.

Avoid getting water and contaminants

in the fuel tank. Contaminated fuel can

cause poor performance or engine

damage. Use only fresh gasoline that

has been stored in clean containers.

14

Gasohol

There are two types of gasohol: gasohol containing ethanol (E10) and that containing

methanol. Ethanol can be used if the ethanol

content does not exceed 10% and the fuel

meets the minimum octane ratings. E85 is a

fuel containing 85% ethanol and must not be

Page 21

Specifications and requirements

1

ZMU06024

used in your outboard motor. All ethanol

blends containing more than 10% ethanol

can cause fuel system damage or cause engine starting and running problems. Yamaha

does not recommend gasohol containing

methanol because it can cause fuel system

damage or engine performance problems.

It is recommended that you install a waterseparating marine fuel filter assembly (10 micron minimum) between your boat’s fuel tank

and outboard motor when using ethanol.

Ethanol is known to allow moisture to be absorbed into boat fuel tanks and systems.

Moisture in the fuel can cause corrosion of

metallic fuel system components, starting

and running complaints and require additional fuel system maintenance.

EMU36330

Anti-fouling paint

A clean hull improves boat performance. The

boat bottom should be kept as clean of marine growth as possible. If necessary, the

boat bottom can be coated with an anti-fouling paint approved for your area to inhibit

marine growth.

Do not use anti-fouling paint which includes

copper or graphite. These paints can cause

more rapid engine corrosion.

Yamaha recommends consulting the dealer

about discarding the motor.

EMU36352

Emergency equipment

Keep the following items onboard in case

there is trouble with the outboard motor.

A tool kit with assorted screwdrivers, pli-

ers, wrenches (including metric sizes), and

electrical tape.

Waterproof flashlight with extra batteries.

An extra engine shut-off cord (lanyard)

with clip.

Spare parts, such as an extra set of spark

plugs.

Consult your Yamaha dealer for details.

EMU39000

Emission control information

The following labels are affixed to outboard

motors that conform to US regulations.

EMU25230

North American models

This engine conforms to U.S. Environmental

Protection Agency (EPA) regulations for marine SI engines. See the label affixed to your

engine for details.

EMU31561

Approval label of emission control certificate

This label is attached to the bottom cowling.

New Technology; (4-stroke) MFI

EMU36341

Motor disposal requirements

Never illegally discard (dump) the motor.

1. Approval label location

15

Page 22

Specifications and requirements

ZMU06895

EMISSION CONTROL INFORMATION MFI

THIS ENGINE CONFORMS TO CALIFORNIA AND U.S. EPA EXHAUST

REGULATIONS FOR SI MARINE ENGINES. REFER TO THE OWNER'S

MANUAL FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

MEETS U.S. EPA EVAP STANDARDS USING CERTIFIED COMPONENTS.

FAMILY:

DISPLACEMENT: liters

SPARK PLUG:

FUEL: GASOLINE

FELs(HC+NOx / CO)

: / g/kW-hr MAX POWER: kW

IDLE SPEED: ± rpm IN NEUTRAL

SPARK PLUG GAP (mm):

VALVE LASH (mm) IN: EX:

YAMAHA MOTOR CO.,LTD.

INFORMATION ANTIPOLLUTION MFI

CE MOTEUR EST CONFORME AUX NORMES D’ÉMISSIONS EPA DES É.-U. ET DE LA

CALIFORNIE POUR MOTEURS MARINS À ÉTINCELLE. POUR LES SPÉCIFICATIONS ET LES

RÉGLAGES À EFFECTUER, CONSULTEZ LE MANUEL DU PROPRIÉTAIRE. INSTALLÉ AVEC

LES COMPOSANTS HOMOLOGUÉS, IL SATISFAIT AUX NORMES EVAP EPA DES É.-U.

YAMAHA MOTOR CO.,LTD.

FAMILLE :

CYLINDRÉE : litre

BOUGIE :

CARBURANT : ESSENCE

FELs(HC+NOx / CO)

: / g/kW-h PUISS. MAX. : kW

RALENTI : ± tr/mm AU POINT MORT

BOUGIE-ÉCARTEMENT (mm) :

JEU DE SOUPAPES (mm) ADM: ÉCH:

1

ZMU05816

1

ZMU05817

EMU25263

Manufactured date label

This label is attached to the clamp bracket or

the swivel bracket.

EMU25274

Star labels

Your outboard motor is labeled with a California Air Resources Board (CARB) star label. See below for a description of your

particular label.

1. Manufactured date label location

16

1. Star labels location

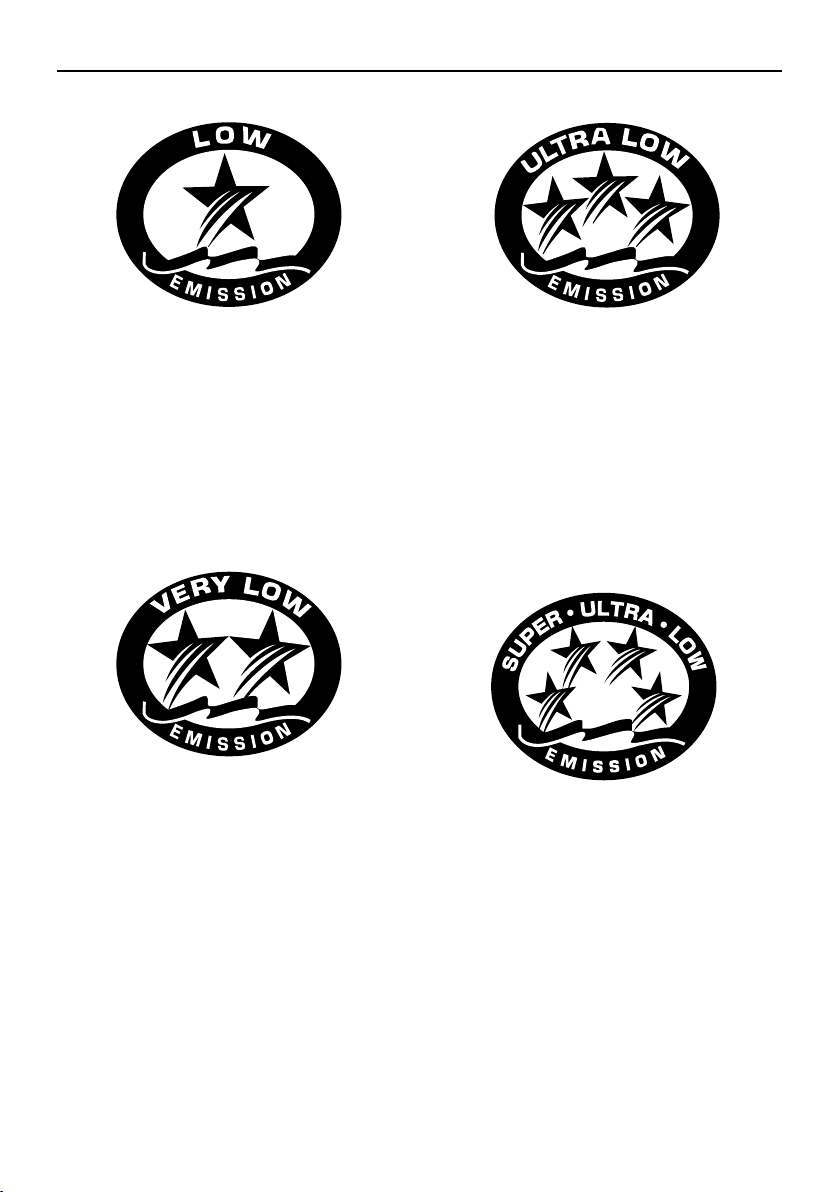

EMU40330

One Star—Low Emission

The one-star label identifies engines that

meet the Air Resources Board’s Personal

Watercraft and Outboard marine engine

2001 exhaust emission standards. Engines

meeting these standards have 75% lower

emissions than conventional carbureted twostroke engines. These engines are equivalent to the U.S. EPA’s 2006 standards for

marine engines.

Page 23

Specifications and requirements

ZMU01702

ZMU01703

ZMU01704

ZMU05663

EMU40340

Two Stars—Very Low Emission

The two-star label identifies engines that

meet the Air Resources Board’s Personal

Watercraft and Outboard marine engine

2004 exhaust emission standards. Engines

meeting these standards have 20% lower

emissions than One Star-Low-Emission engines.

EMU40350

Three Stars—Ultra Low Emission

The three-star label identifies engines that

meet the Air Resources Board’s Personal

Watercraft and Outboard marine engine

2008 exhaust emission standards or the

Sterndrive and Inboard marine engine 20032008 exhaust emission standards. Engines

meeting these standards have 65% lower

emissions than One Star-Low-Emission engines.

EMU33861

Four Stars—Super Ultra Low Emission

The four-star label identifies engines that

meet the Air Resources Board’s Sterndrive

and Inboard marine engine 2009 exhaust

emission standards. Personal Watercraft

and Outboard marine engines may also

comply with these standards. Engines meeting these standards have 90% lower emissions than One Star-Low-Emission engines.

17

Page 24

Components

TIP:

1

2

3

4

5

6

7

7

8

9

7

10

10

6

ZMU05813

EMU2579Y

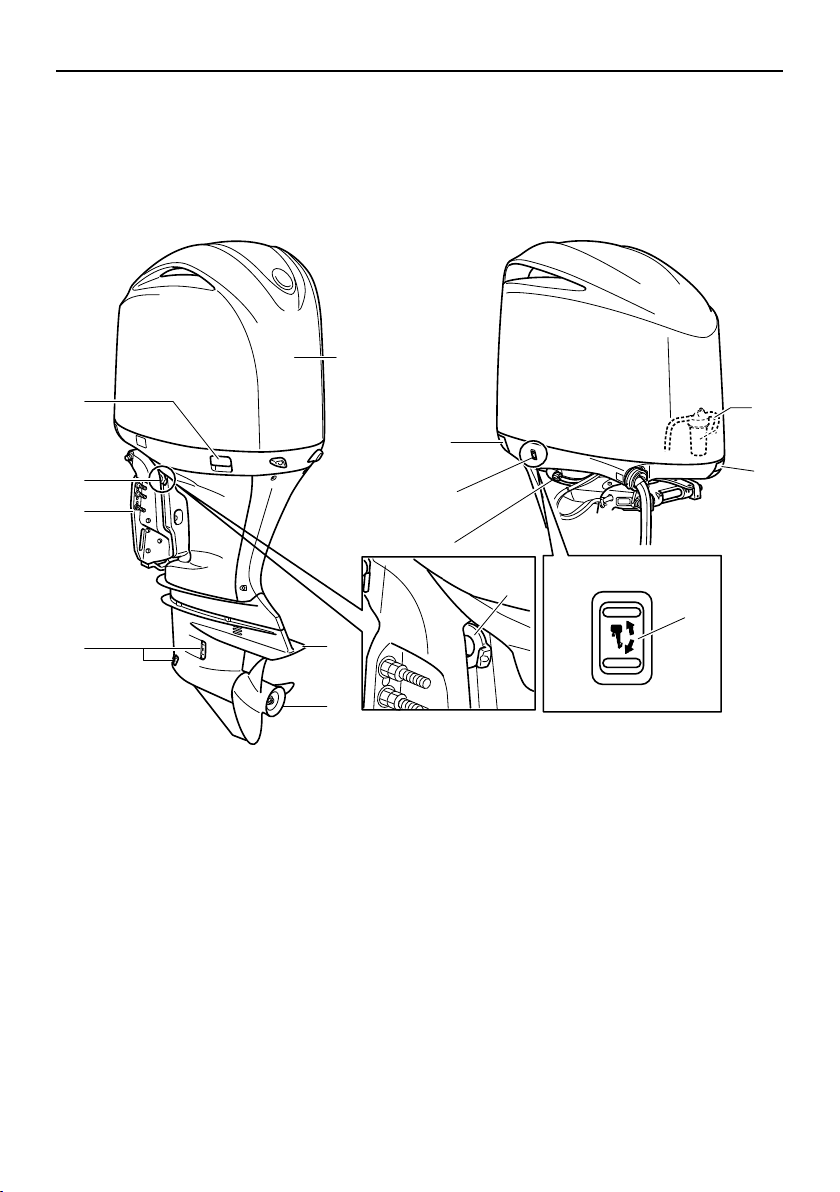

Components diagram

* May not be exactly as shown; also may not be included as standard equipment on all models (order from dealer).

F350A, FL350A, F350A2, FL350A2

1. Top cowling

2. Anti-cavitation plate

3. Propeller*

4. Cooling water inlet

5. Clamp bracket

6. Tilt support lever

7. Cowling lock lever(s)

8. Fuel filter/water separator

9. Flushing device

10. Power trim and tilt switch

18

Page 25

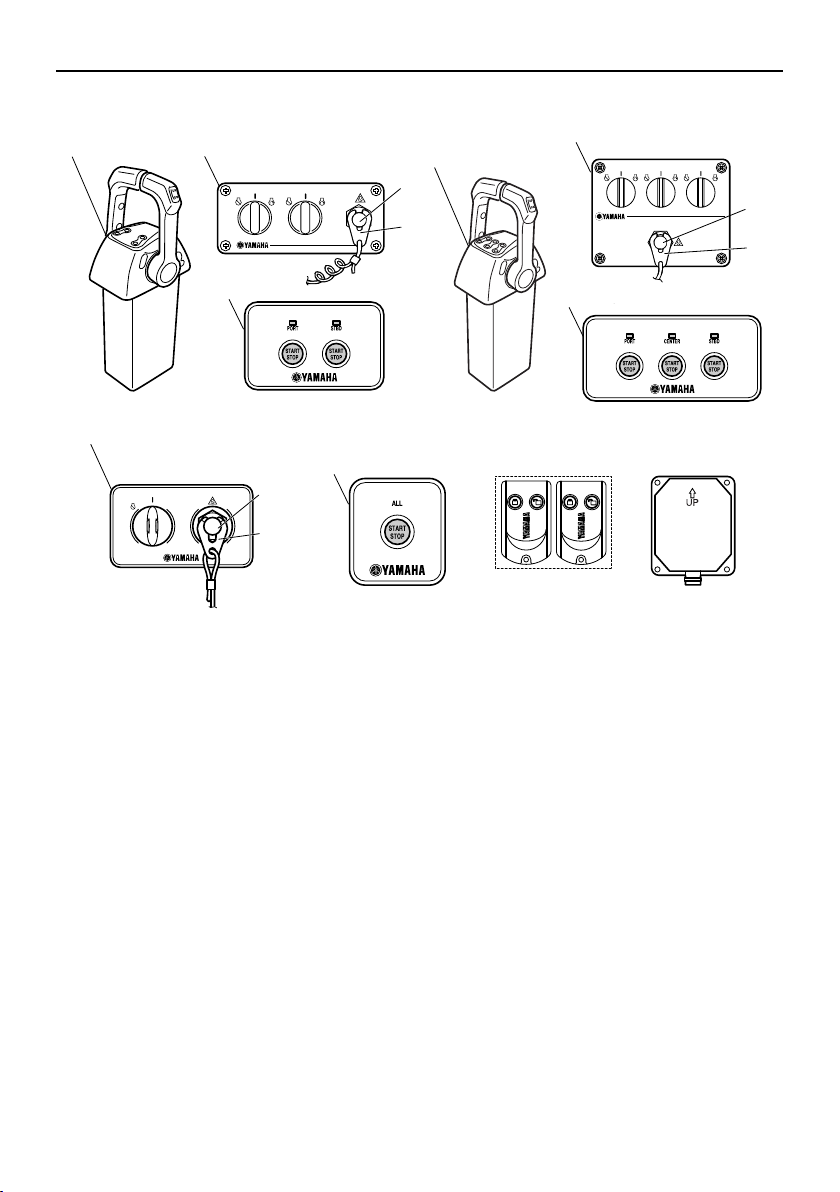

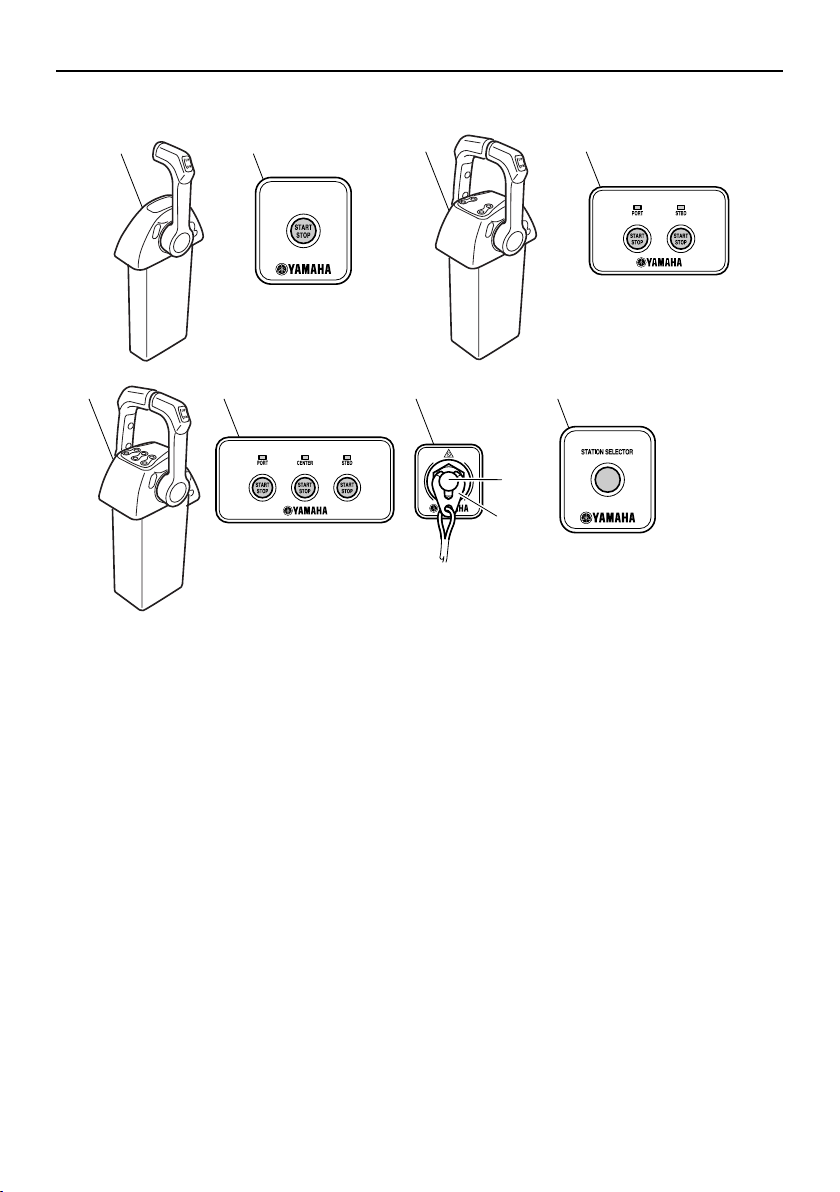

Single station models (single type)

ZMU07273

5

1

4

2

3

6

2

6

2

3

3

8

7

1. Digital electronic control (side-mount type)*

2. Engine shut-off switch*

3. Clip*

4. Switch panel (for use with side-mount type)*

5. Digital electronic control (single type)*

6. Switch panel (for use with single type)*

7. Remote control transmitter*

8. Receiver*

Components

19

Page 26

Components

ZMU07280

3

2

1

6

9

4

7

5

8

10

11

12

3

2

3

2

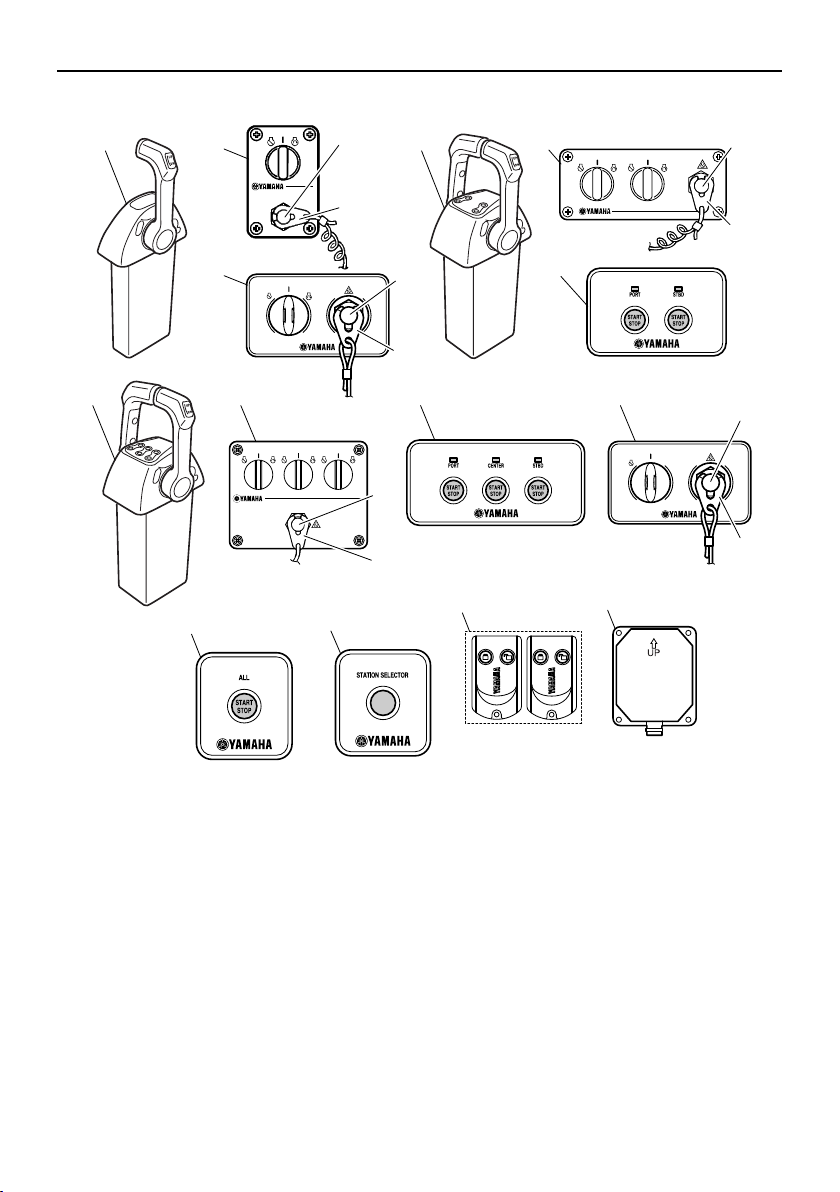

Single station models (twin/triple type)

1. Digital electronic control (twin type)*

2. Engine shut-off switch*

3. Clip*

4. Switch panel (for use with twin type)*

5. Start/Stop switch panel (for use with twin

type)*

6. Digital electronic control (triple type)*

7. Switch panel (for use with triple type)*

8. Start/Stop switch panel (for use with triple

type)*

9. Switch panel (for use with twin/triple type)*

10. All Start/Stop switch panel (for use with

twin/triple type)*

11. Remote control transmitter*

12. Receiver*

20

Page 27

Dual station models / main station

ZMU07274

1

8

5

13

11

3

4

9

12

15

14

10

4

3

2

3

4

2 3

4

6

7

3

4

Components

1. Digital electronic control (single type)*

2. Switch panel (for use with single type)*

3. Engine shut-off switch*

4. Clip*

5. Digital electronic control (twin type)*

6. Switch panel (for use with twin type)*

7. Start/Stop switch panel (for use with twin

type)*

8. Digital electronic control (triple type)*

9. Switch panel (for use with triple type)*

10. Start/Stop switch panel (for use with triple

type)*

11. Switch panel (for use with twin/triple type)*

12. All Start/Stop switch panel (for use with

twin/triple type)*

13. Station selector switch panel

14. Remote control transmitter*

15. Receiver*

21

Page 28

Components

ZMU07275

1

5

3

68

2 4

9

10

7

Dual station models / sub station

1. Digital electronic control (single type)*

2. Start/Stop switch panel (for use with single

type)*

3. Digital electronic control (twin type)*

4. Start/Stop switch panel (for use with twin

type)*

5. Digital electronic control (triple type)*

6. Start/Stop switch panel (for use with triple

type)*

7. Engine shut-off switch panel*

8. Station selector switch panel

9. Engine shut-off switch*

10. Clip*

22

Page 29

NOTICE

SET

MENU

CANCEL

1

3

4

2

5

ZMU07266

1. Tachometer unit (Square type)*

ZMU06455

2. Speedometer unit (Square type)*

3. Speed & fuel meter unit (Square type)*

4. Fuel management meter (Square type)*

5. 6Y9 Multifunction Color Gauge*

Components

EMU38591

Remote control transmitter

The lock and unlock modes of the Yamaha

Security System are selected using the remote control transmitter. While the engine is

running, input from the remote control transmitter is not received.

Store the remote control transmitter carefully

so it will not be lost.

ECM02100

The remote control transmitter is not

completely waterproof. Do not submerge the transmitter or operate it underwater. If the transmitter is

submerged, dry it with a soft, dry cloth,

23

Page 30

Components

TIP:

12

ZMU06456

and then check that it is operating properly. If the transmitter is not operating

properly, contact a Yamaha dealer.

Keep the remote control transmitter

away from high temperatures and do

not place it in direct sunlight.

Do not drop the remote control trans-

mitter, subject it to strong shocks, or

place any heavy items on it.

Use a soft, dry cloth to clean the remote

control transmitter. Do not use detergent, alcohol, or other chemicals.

Do not attempt to disassemble the re-

mote control transmitter yourself. Otherwise, the transmitter may not operate

properly. If the transmitter needs a new

battery, contact a Yamaha dealer.

If you have lost the remote control

transmitter, consult your Yamaha dealer. Keep the least 2 transmitters at all

the time. If you have lost both transmitters, consult your Yamaha dealer.

Since the receiver is programmed to rec-

ognize the internal code from this transmitter only, the security system setting can

only be changed with this transmitter. If the

remote control transmitter does not operate properly, contact a Yamaha dealer.

Replace the battery cell after 1 year, and

every two years thereafter as a standard

measure.

Refer to local hazardous waste regulations

when disposing of transmitter batteries.

The Yamaha Security System permits to

register up to 5 remote control transmitters. Consult your yamaha dealer for details.

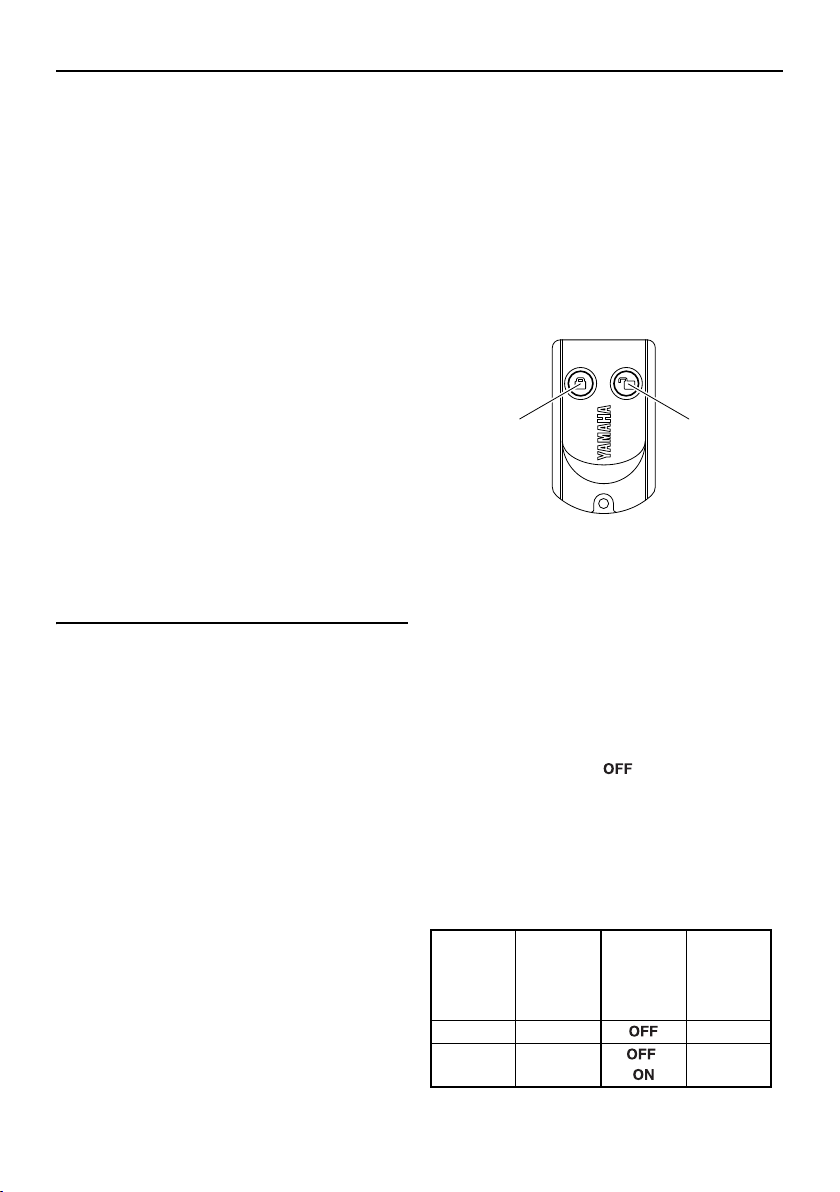

EMU38601

Receiver

The receiver control the ECM (Electronic

control module) to prevent the engine from

starting. Consult your Yamaha dealer for installation of the receiver.

EMU41610

Yamaha Security System lock and

unlock mode

The Yamaha Security System settings are

selected by pressing the lock or unlock button on the remote control transmitter briefly.

1. Lock button

2. Unlock button

LOCK

When the lock button on the remote control

transmitter is pressed briefly, the beeper

sounds once. This indicates the lock mode is

selected and the engine cannot be started.

The lock mode is selected only when the

main switch is in the “ ” (off) position.

UNLOCK

When the unlock button on the remote control transmitter is pressed briefly, the beeper

sounds twice. This indicates the unlock

mode is selected and the engine can be

started.

Yama ha

Security

System

mode

Lock 1 beep

Unlock 2 beeps

Number

of beeps

Main

switch

“”

“”/

“”

Engine

can be

started

NO

YES

24

Page 31

Yama ha

ZMU06225

9

1

2

6

7

8

5

4

3

ZMU05850

1

6

5

4

2

3

ZMU05851

1

6

5

4

3

2

ZMU05959

1

6

5

4

7

3

2

Security

System

mode

Lock Off

Unlock Light

EMU35943

Digital electronic control-active

indicator

Digital electronic control

The digital electronic control actuates the

shifter, the throttle and remote electrical operations. Make sure that the active indicator

lights and that the digital electronic control

unit is correctly connected to the outboard

motor.

The digital electronic controls of the main

station and sub station have the same functions.

Components

1. Control lever

2. Neutral interlock trigger

3. Digital electronic control-alert indicator

4. Digital electronic control-active indicator

5. Free throttle switch

6. Clip

7. Engine shut-off switch

8. Throttle friction adjuster

9. Power trim and tilt switch

1. Control lever

2. Digital electronic control-active indicator

3. Digital electronic control-alert indicator

4. Free throttle switch

5. Throttle friction adjuster

6. Power trim and tilt switch

7. Engine selector switch

25

Page 32

Components

ZMU06276

1

ZMU05888

ZMU05890

1

ZMU05966

ZMU06227

1

EMU34973

Digital electronic control-active

indicator

The digital electronic control-active indicator

indicates that the digital electronic control

system is in the operating state.

Lights: Operation of both shift and throttle

possible.

Blinks (when the gear shift is in neutral

only): Shift not operable. Only throttle operation available.

Off: Shift and throttle not operable.

1

1

1. Digital electronic control-active indicator

EMU34984

Digital electronic control-alert

indicator

The digital electronic control-alert indicator

lights when trouble occurs in the connection

between the digital electronic control and

outboard motor. Consult your Yamaha dealer for details.

26

Page 33

Components

ZMU05889

ZMU05891

ZMU05960

ZMU06228

1

N

2

F

3

44

55

6

6

7

7

R

ZMU05878

N

1

F

7

6

2

R

3

4

4

6

5

7

5

Digital electronic control for twin type has the

function to automatically synchronize both

engine speeds.

Also digital electronic control for triple type

has the function to automatically synchronize

the engine speeds of the center engine and

starboard side engine, adapting the port side

1

engine speed.

The functions of the control lever for tripletype digital electronic control are as follows.

Operate the port side engine using the port

side control lever.

The center engine runs at the average

speed of port side and starboard side engines’ speeds.

Operate the starboard side engine using

the starboard side control lever.

1

1. Digital electronic control-alert indicator

EMU35822

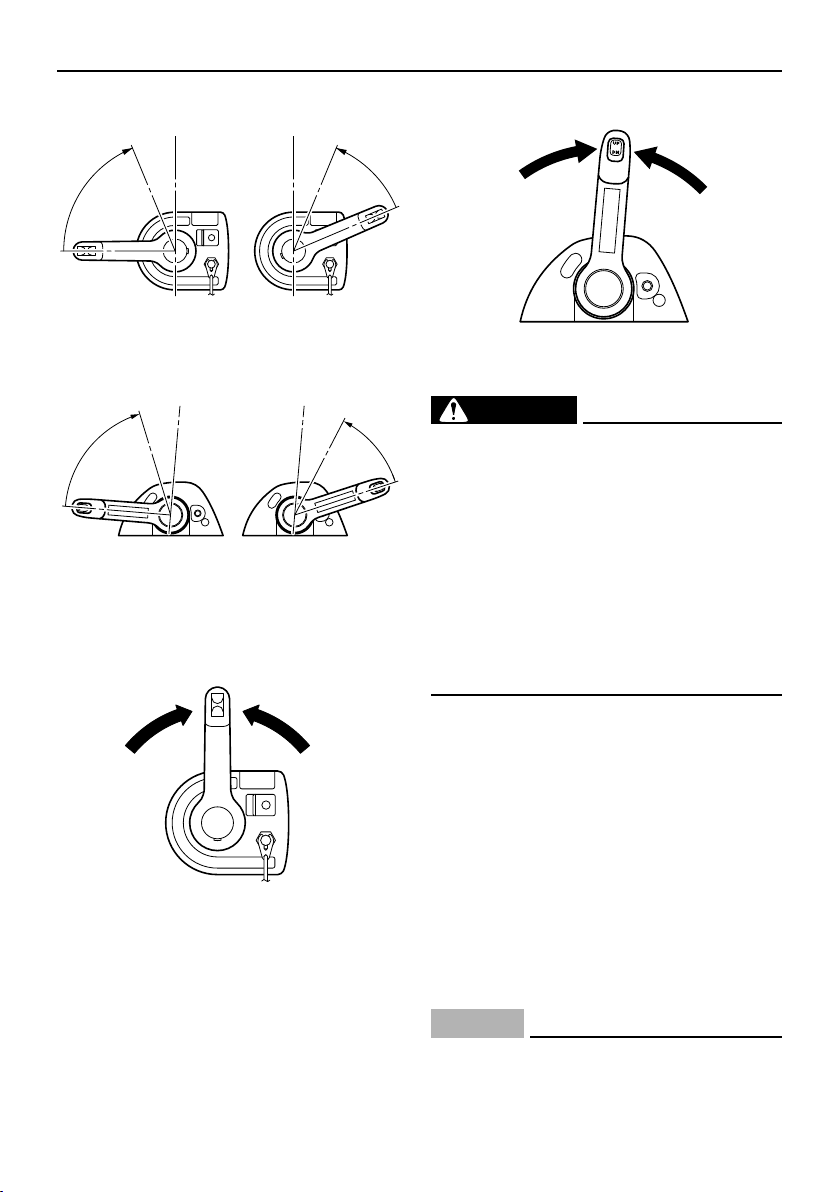

Control lever

Moving the lever forward from the neutral position engages forward gear. Pulling the lever back from neutral engages reverse. The

engine will continue to run at idle until the lever is moved 22.5 (a detent can be felt).

Moving the lever farther opens the throttle,

and the engine will begin to accelerate.

1

1. Neutral “ ”

2. Forward “ ”

3. Reverse “ ”

4. Shift

27

Page 34

Components

ZMU06285

1

ZMU06231

N

F

ZMU06232

N

2

22.5˚

3

1

ZMU05880

FN

ZMU05881

N

1

2

3

22.5

5. Fully closed

6. Throttle

7. Fully open

EMU26201

Neutral interlock trigger

To shift out of neutral, first pull the neutral interlock trigger up.

1. Neutral interlock trigger

EMU35832

Free throttle switch

In neutral, keep this switch pressed, move

the control lever forward, and release the

switch after the digital electronic control-active indicator starts blinking. While the indicator blinks, you can open or close the throttle.

This can also be done when the control lever

is set in reverse.

Single type

1. Fully open

2. Fully closed

3. Free accelerator

Single type

1. Fully open

2. Fully closed

3. Free accelerator

28

Page 35

Twin type

WARNING

ZMU05882

NF

ZMU05883

N

1

2

3

22.5

ZMU05961

NF

ZMU05962

N

1

2

3

22.5

1. Fully open

2. Fully closed

3. Free accelerator

Triple type

Components

1. Fully open

2. Fully closed

3. Free accelerator

The free throttle switch can only be used

when the control lever is in the neutral position.

During operation the digital electronic control-active indicator changes from continuously lit to blinking. When the indicator starts

blinking, the throttle begins to open after the

control lever is moved at least 22.5.

After using the free throttle switch, return the

control lever to the neutral position. The free

throttle switch will return automatically to its

set position. The digital electronic control-active indicator will change from blinking to

continuously lit and the digital electronic control will then engage forward and reverse

normally.

EMU35872

Throttle friction adjuster

A friction device provides adjustable resistance to movement of the control lever, and

can be set according to operator preference.

To increase resistance, turn the adjuster

clockwise. To decrease resistance, turn the

adjuster counterclockwise.

EWM01770

If the friction is too small, the control le-

29

Page 36

Components

ZMU06233

ZMU05820

ZMU05819

ZMU05963

ZMU07141

ver could move freely and cause an accident.

Do not overtighten the friction adjuster.

If there is too much resistance, it could

be difficult to move the control lever,

which could result in an accident.

Single type

Single type

Triple type

When constant speed is desired, tighten the

adjuster to maintain the desired throttle setting.

EMU35711

Station selector switch

The station selector switch can select either

the main station or sub station for the digital

electronic control which operates the boat.

The digital electronic controls of the main

station and sub station have the same functions. You can change the station when the

main switch is turned to “ ” (on) and all control levers are in Neutral.

The switch panel can be operated at both the

main station and sub station when the main

switch is set to “ ” (on).

Twin type

30

EMU35720

Engine selector switch

When all engines have started, you can select the desired engine for operation by

pushing the engine selector switch. The en-

Page 37

gine selector switch works only when all the

WARNING

TIP:

ZMU05977

ZMU06235

1

3

2

ZMU04565

1

2

3

1

2

3

ZMU07143

control levers are in neutral.

1

1. Engine selector switch

EMU35774

Engine shut-off cord (lanyard) and

clip

The clip must be attached to the engine shutoff switch for the engine to run. The cord

should be attached to a secure place on the

operator’s clothing, or arm or leg. Should the

operator fall overboard or leave the helm, the

cord will pull out the clip, stopping ignition to

the engine. This will prevent the boat from

running away under power.

EWM01790

Components

The engine cannot be started with the clip removed.

Attach the engine shut-off cord to a se-

cure place on your clothing, or your

arm or leg while operating.

Do not attach the cord to clothing that

could tear loose. Do not route the cord

where it could become entangled, preventing it from functioning.

Avoid accidentally pulling the cord dur-

ing normal operation. Loss of engine

power means the loss of most steering

control. Also, without engine power,

the boat could slow rapidly. This could

cause people and objects in the boat to

be thrown forward.

31

Page 38

Components

ON

STARTOFF

ON

STARTOFF

1

2

3

ZMU05818

1

2

3

ZMU05978

1

2

3

ZMU07144

1

2

3

ZMU07142

1. Cord

2. Clip

3. Engine shut-off switch

EMU35782

Main switch

The main switch controls the ignition system;

its operation is described below. Only

equipped with the main station.

“” (off)

With the main switch in the “ ” (off) position, the electrical circuits are off, and the key

can be removed.

“” (on)

With the main switch in the “ ” (on) position, the electrical circuits are on, and the key

cannot be removed. The engine can be started by pressing the Start/Stop button.

“” (start)

With the main switch in the “ ” (start) position, the starter motor turns to start the engine. When the key is released, it returns

automatically to the “ ” (on) position.

32

Page 39

Single type

ZMU06245

ON

OFF

START

ON

OFF

START

ZMU04567

ON

OFF

ZMU07145

START

ON

OFF

START

ON

OFF

START

ZMU05821

ON

OFF

ZMU07146

ZMU05982

ON

OFF

ZMU07146

Components

Triple type

Twin type

EMU42080

OFF

ON

START

OFF

ON

START

OFF

ON

START

Start/Stop switch panel

The engine can be started or turned off by

pressing the Start/Stop button. For twin and

triple type, it is possible to start or turn off individual engine. The indicator for the corresponding engine will come on.

PORT:Port side engine

CENTER:Center engine

STBD:Starboard side engine

33

Page 40

Components

1

ZMU07173

1

2

ZMU07174

1

2

ZMU07175

1

ZMU07176

ZMU06234

UP

DN

1. Start/Stop button

1. Indicator

2. Start/Stop button

1. All Start/Stop button

EMU35153

Power trim and tilt switch on digital

electronic control

The power trim and tilt system adjusts the

outboard motor angle in relation to the transom. Pressing the switch “ ” (up) trims the

outboard motor up, and then tilts it up. Pressing the switch “ ” (down) tilts the outboard

motor down and trims it down. When the

switch is released, the outboard motor will

stop in its current position. For instructions

on using the power trim and tilt switch, see

pages 79 and 81.

EMU41631

All Start/Stop switch panel

The Start/Stop button allows all engines to

start or turn off.

34

Page 41

Components

WARNING

ZMU05822

UP

DN

UP

DN

ZMU05823

UP

DN

11

1

UP

DN

ZMU05835

UP

DN

1

1

UP

DN

ZMU05964

EMU26155

Power trim and tilt switch on bottom

cowling

The power trim and tilt switch is located on

the side of the bottom cowling. Pushing the

switch “ ” (up) trims the outboard motor up,

and then tilts it up. Pushing the switch “ ”

(down) tilts the outboard motor down and

trims it down. When the switch is released,

the outboard motor will stop in its current position.

For instructions on using the power trim and

tilt switch, see page 81.

EWM01031

Use the power trim and tilt switch located

on the bottom cowling only when the boat

is at a complete stop with the engine off.

Attempting to use this switch while the

boat is moving could increase the risk of

falling overboard and could distract the

operator, increasing the risk of collision

with another boat or an obstacle.

EMU35851

Power trim and tilt switches

The power trim and tilt system adjusts the

outboard motor angle in relation to the transom. Pushing the switch “ ” (up) trims the

outboard motor up, and then tilts it up. Pressing the switch “ ” (down) tilts the outboard

motor down and trims it down. When the

switch is released, the outboard motor will

stop in its current position.

1. Power trim and tilt switch

35

Page 42

Components

TIP:

NOTICE

ZMU05824

ZMU05852

ZMU05853

On the twin engine control, the switch on the

control grip controls both outboard motors at

the same time.

On the triple engine control, the switch on the

control grip controls all outboard motors at

the same time.

For instructions on using the power trim and

tilt switches, see pages 79 and 81.

EMU35040

Tilt limiter

This outboard motor is equipped with a tilt

limiter that controls the tilt range.

Consult your Yamaha dealer about changing

the setting.

EMU35030

Tilt support lever for power trim and

tilt model

To keep the outboard motor in the tilted up

position, lock the tilt support lever to the

clamp bracket. Make sure that the lever is

securely retained by the bolts.

ECM00660

Do not use the tilt support lever or knob

when trailering the boat. The outboard

motor could shake loose from the tilt support and fall. If the motor cannot be trailered in the normal running position, use

an additional support device to secure it

in the tilt position.

EMU35053

Cowling lock lever (turn type)

To remove the top cowling, turn the cowling

lock levers at the front and side to release

them and lift off the cowling. Reverse this

procedure when reinstalling the top cowling.

36

When installing the cowling, align the 3 positions of the grommets to fit the cowling in the

rubber seal.

Page 43

When installing the cowling, check to be sure

TIP:

ZMU05934

1

ZMU05825

ZMU05854

it fits properly in the rubber seal.

Be sure to check that the gap between the

top cowling and the bottom cowling is even

all around the cowling. If the top cowling is

loose or the gap is not even, reinstall the

cowling.

EMU26463

Flushing device

This device is used to clean the cooling water passages of the motor using a garden

hose and tap water.

Components

1. Flushing device

For details on usage, see page 89.

EMU41310

Fuel filter

The fuel filter functions to remove foreign

material and separate water from the fuel. If

water separated from the fuel exceeds a

specific volume, the alert system will activate. For further information, see page 50.

37

Page 44

Instruments and indicators

SET

MENU

CANCEL

1

2

3

4

5

ZMU07233

54321 6

7

8

9

10

12

11

ZMU07234

ZMU07235

ZMU07236

EMU41781

6Y9 Multifunction Color Gauge

The 6Y9 Multifunction Color Gauge (hereinafter called the Multi-Display) shows engine

status and alert information. The display of

optional items can be changed. This manual

mainly covers the alert display. For information on other settings or changing the display, see the 6Y9 Multifunction Color Gauge

owner’s manual.

1. Arrow keys

2. Set button

3. Cancel button

4. Menu button

5. Display

6. Optional items

7. Engine trouble-alert indicator

8. Low battery voltage-alert indicator

9. Water separator-alert indicator

10. Low oil pressure-alert indicator

11. Overheat-alert indicator

12. Tachometer

EMU41640

YAMAHA SECURITY SYSTEM

indicator

This indicator appears when the YAMAHA

SECURITY SYSTEM is in lock mode. Make

sure it is off before starting the engine.

EMU41650

Engine warm-up indicator

This indicator appears while the engine is

being warmed up and goes off when warming-up is finished.

1. Shift position display

2. YAMAHA SECURITY SYSTEM indicator

3. Engine warm-up indicator

4. Engine synchronization indicator

5. Trim meter

38

EMU42090

Engine synchronization indicator

In multiple engine types, this display appears

Page 45

Instruments and indicators

NOTICE

ZMU07237

ZMU07238

ZMU07239

ZMU07240

ZMU07241

while the engines are under engine synchronization control. It goes off when engine synchronization control is released.

EMU41680

Overheat alert

If the engine temperature rises too high while

cruising, the pop-up window will appear.

Press the “ ” (set) button to change to normal display, and the overheat-alert indicator

will start to blink. The engine speed will automatically decrease to about 2000 r/min.

Stop the engine immediately if the buzzer

sounds and the overheat alert device has activated. Check the cooling water inlet for

clogging.

ECM01592

Do not continue to run the engine if the

overheat-alert indicator blinks. Serious

engine damage will occur.

Do not continue to operate the engine if

a alert device has activated. Consult

your Yamaha dealer if the problem cannot be located and corrected.

EMU41690

Low oil pressure-alert

If the engine oil pressure drops too low, the

pop-up window will appear. Press the “ ”

(set) button to change to normal display, and

the low oil pressure-alert indicator will start to

blink. The engine speed will automatically

decrease to about 2000 r/min.

39

Page 46

Instruments and indicators

NOTICE

NOTICE

ZMU07242

ZMU07250

ZMU07251

ZMU07252

Stop the engine immediately if the buzzer

sounds and the low oil pressure-alert device

has activated. Check the engine oil quantity

and replenish oil if necessary. If the alert device has activated while the appropriate engine oil quantity is maintained, consult your

Yamaha dealer.

ECM01601

Do not continue to run the engine if the

low oil pressure alert device has activated. Serious engine damage will occur.

EMU41700

Water separator alert

The pop-up window will appear if water has

accumulated in the water separator (fuel filter) while cruising. Press the “ ” (set) button to change to normal display, and the

water separator-alert indicator will start to

blink.

110 of this manual to drain the water from the

fuel filter. Get back to the port soon and consult a Yamaha dealer immediately.

ECM00910

Gasoline mixed with water could cause

damage to the engine.

EMU41720

Low battery voltage-alert

The pop-up window will be displayed if the

battery voltage drops. Press the “ ” (set)

button will change to the normal display and

the battery voltage-alert indicator will start to

blink.

Stop the engine immediately and see page

40

Get back to the port soon if the low battery

voltage-alert device has activated. For

charging the battery, consult your Yamaha

dealer.

EMU41710

Engine trouble alert

The pop-up window will appear if the engine

Page 47

Instruments and indicators

ZMU07253

ZMU07254

2

1

ZMU05415

malfunctions while cruising. Press the “ ”

(set) button to change to normal display, and

the engine trouble-alert indicator will start to

blink.

EMU36184

6Y8 Multifunction tachometers

The tachometer shows the engine revolutions per minute. It has functions of trim

meter, adjusting trolling speed, cooling water/engine temperature display, battery voltage display, total hour/trip hour display, oil

pressure display, water detection alert, engine trouble alert, and periodic maintenance

notification. If the cooling water pressure

sensor is installed, the unit can also show the

cooling water pressure display. However,

even if the cooling water pressure sensor is

not installed, the cooling water pressure display can be shown by connecting an optional

sensor to the unit. For the optional sensor,

consult your Yamaha dealer. The tachometer unit is available in round or square types.

Check your tachometer unit type.

Return to port and consult a Yamaha dealer

immediately.

EMU31653

6Y8 Multifunction meters

Multifunction meters have 6 kinds of meter

units; tachometer unit (square or round

types), speedometer unit (square type),

speed & fuel meter unit (square or round

types), and fuel management meter (square

type). The indicator system is slightly different between the round and square types.

Check the model and type of your unit carefully. This manual describes mainly the alert

indicators. For more details on setting

meters or changing indicator systems, see

the attached operation manual.

1. Set button

2. Mode button

41

Page 48

Instruments and indicators

NOTICE

2

3

1

4

5

6

7

8

ZMU05416

ZMU06457

ZMU06459

ZMU05430

Lock mode

1. Tachometer

2. Trim meter

3. Multifunction display

4. Cooling water pressure

5. Cooling water/engine temperature

6. Water detection-alert indicator

7. Battery voltage

8. Oil pressure (4-stroke models)

EMU38621

Yamaha Security System information

Turn the main switch to the “ ” (on) position, the currently selected Yamaha Security

System mode (Lock / Unlock) will show on

the display.

Unlock mode

EMU36130

Low oil pressure-alert

If the engine oil pressure drops too low, the

low oil pressure-alert indicator will start to

blink, and the engine speed will automatically decrease to about 2000 r/min.

Stop the engine immediately if the buzzer

sounds and the low oil pressure-alert indicator blinks. Check the engine oil quantity and

replenish oil if necessary. If the alert device

has activated while the appropriate engine

oil quantity is maintained, consult your

Yamaha dealer.

ECM01601

42

Do not continue to run the engine if the

low oil pressure alert device has activated. Serious engine damage will occur.

Page 49

Instruments and indicators

NOTICE

NOTICE

NOTICE

ZMU05421

ZMU05423

ZMU05425

EMU36221

Overheat alert

If the engine temperature rises too high while

cruising, the overheat-alert indicator will start

to blink. The engine speed will automatically

decrease to about 2000 r/min.

Stop the engine immediately if the buzzer

sounds and the overheat alert device has activated. Check the cooling water inlet for

clogging.

ECM01592

Do not continue to run the engine if the

overheat-alert indicator blinks. Serious

engine damage will occur.

Do not continue to operate the engine if

a alert device has activated. Consult

your Yamaha dealer if the problem cannot be located and corrected.

EMU36150

Water separator alert

This indicator will blink if water has accumulated in the water separator (fuel filter) while