YAMAHA EK25BMH PARTS CATALOGUE

EK25BMH

SSSSEEEERRRRVVVVIIIICCCCE

290404

E M

E E

MAAAAN

MM

NUUUUAAAALLLL

NN

69T-28197-ZA-11

E

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their

trained mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the

mechanical and electrical concepts and procedures inherent in the work, for without such

knowledge attempted repairs or service to the equipment could render it unsafe or unfit for

use.

Because Yamaha has a policy of continuously improving its products, models may differ in

detail from the descriptions and illustrations given in this publication. Use only the latest edition of this manual. Authorized Yamaha dealers are notified periodically of modifications and

significant changes in specifications and procedures, and these are incorporated in successive editions of this manual.

EK25BMH

SERVICE MANUAL

©2000 Yamaha Motor Co., Ltd.

1st Edition, October 2000

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

E

HOW TO USE THIS MANUAL

MANUAL FORMAT

All of the procedures in this manual are organised in a sequential, step-by-step format. The

information has been compiled to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assembly, and

inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and

the course of action required will follow the symbol, e.g.,

• Bearings

Pitting/scratches → Replace.

To assist you in finding your way through this manual, the section title and major heading is

given at the top of every page.

MODEL INDICATION

Multiple models are referred to in this manual and their model indications are noted as follows.

Model name EK25BMH

Indication EK25BMH

ILLUSTRATIONS

The illustrations within this service manual represent all of the designated models.

CROSS REFERENCES

The cross references have been kept to a minimum. Cross references will direct you to the

appropriate section or chapter.

E

IMPORTANT INFORMATION

In this Service Manual particularly important information is distinguished in the following

ways.

The safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death

operator, a bystander or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

to the machine

HOW TO USE THIS MANUAL

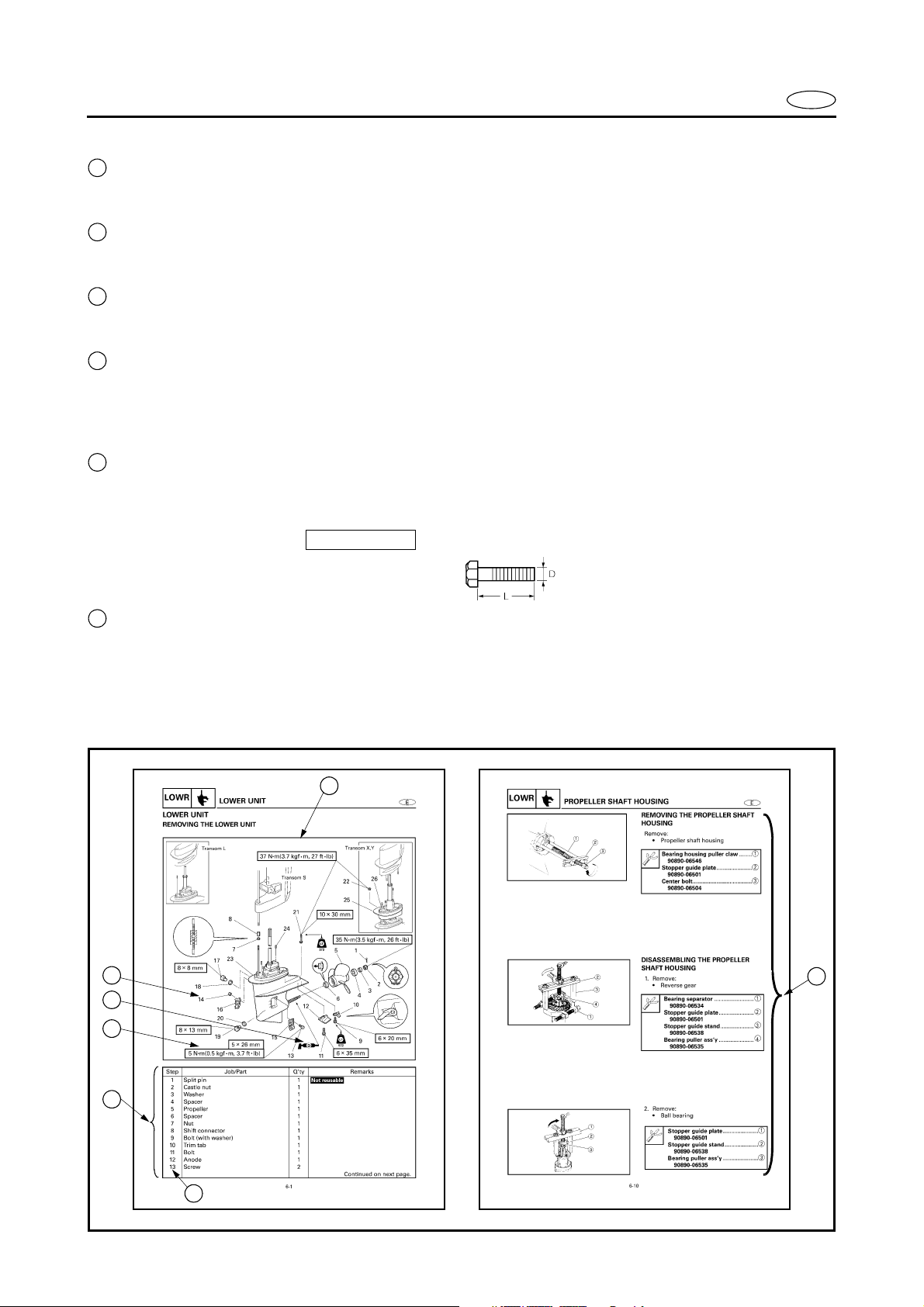

The main points regarding removing/installing and disassembling/assembling proce-

1

dures are shown in the exploded views.

The numbers in the exploded views indicate the required sequence of the procedure and

2

should be observed accordingly.

Symbols are used in the exploded views to indicate important aspects of the procedure.

3

A list of meanings for these symbols is provided on the following page.

E

It is important to refer to the job instruction charts at the same time as the exploded views

4

These charts list the sequence that the procedures should be carried out in, as well as

providing explanations on part names, quantities, dimensions and important points relating to each relevant task.

In addition to tightening torques, the dimensions of the bolts and screws are also men-

5

tioned.

Example:

Bolt and screw size 10 × 25 mm : bolt and screw diameter (D) × lenght (L)

In addition to the exploded views and job instruction charts, this manual provides indi-

6

vidual illustrations when further explanations are required to explain the relevant procedure.

1

.

2

3

5

4

2

6

E

1 2

GEN

SPEC

INFO

3 4

CHK

FUEL

ADJ

5 6

POWR LOWR

7 8

BRKT

ELEC

9 10

TRBL

ANLS

11 12

–+

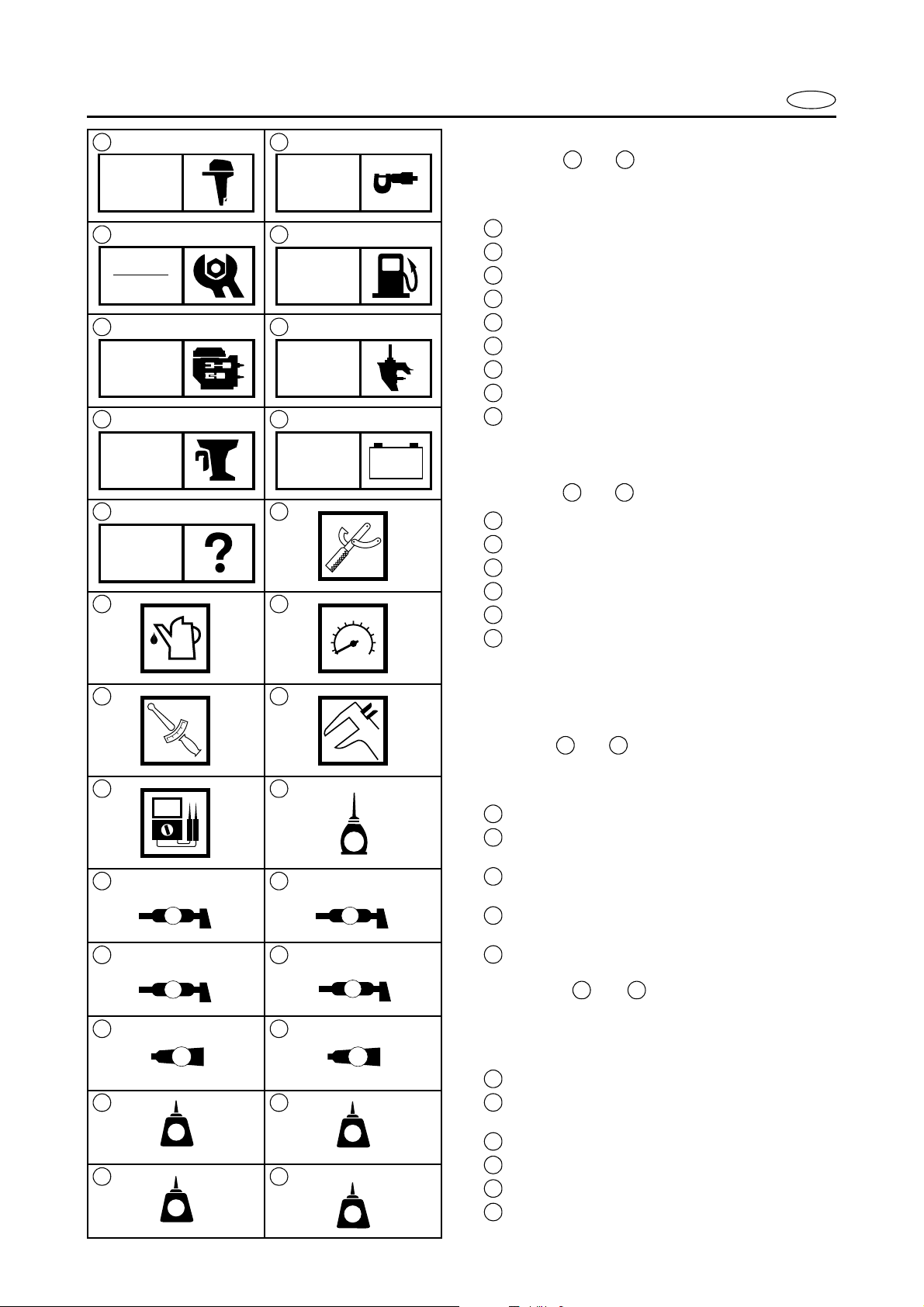

SYMBOLS

Symbols to are designed as thumbtabs to indicate the content of a chapter.

1

General information

2

Specifications

3

Periodic check and adjustments

4

Fuel system

5

Power unit

6

Lower unit

7

Bracket unit

8

Electrical systems

9

Trouble analysis

Symbols to indicate specific data.

10

Special tool

11

Specified liquid

12

Specified engine speed

13

Specified torque

14

Specified measurement

15

Specified electrical value

[Resistance (Ω), Voltage (V), Electric current

(A)]

1 9

10 15

13 14

T

.

R

.

15 16

17 18

A C

19 20

D

21 22

GM

23 24

LT

271

25 26

LT

572

E

M

LT

242

SS

LT

Symbol to in an exploded diagram

16 20

indicate the grade of lubricant and the location of the lubrication point.

16

Apply Yamaha 2-stroke motor oil

17

Apply water resistant grease

(Yamaha grease A, Yamaha marine grease)

18

Apply water resistant grease

(Yamaha grease C, Yamaha marine grease)

19

Apply water resistant grease

(Yamaha grease D, Yamaha marine grease)

20

Apply molybdenum disulfide grease

Symbols to in an exploded dia-

21 26

gram indicate the grade of the sealing or

locking agent and the location of the appli-

4

cation point.

21

Apply Gasket Maker

22

Apply Yamabond #4

(Yamaha bond number 4)

23

Apply LOCTITE® No.271 (Red LOCTITE)

24

Apply LOCTITE® No.242 (Blue LOCTITE)

25

Apply LOCTITE® No.572

26

Apply silicon sealant

®

CONTENTS

E

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECK AND

ADJUSTMENT

FUEL SYSTEM

GEN

INFO

SPEC

CHK

ADJ

FUEL

1

2

3

4

RECOIL STARTER

LOWER UNIT

BRACKET UNIT

ELECTRICAL SYSTEM

POWR

LOWR

BRKT

–+

ELEC

5

6

7

8

TROUBLE ANALYSIS

TRBL

ANLS

9

GEN

INFO

E

CHAPTER 1

GENERAL INFORMATION

IDENTIFICATION

SERIAL NUMBER ....................................................................................1-1

STARTING SERIAL NUMBERS ............................................................... 1-1

SAFETY WHILE WORKING

FIRE PREVENTION ..................................................................................1-2

VENTILATION .......................................................................................... 1-2

SELF-PROTECTION ................................................................................. 1-2

OILS, GREASES AND SEALING FLUIDS ............................................... 1-2

GOOD WORKING PRACTICES ............................................................... 1-3

DISASSEMBLY AND ASSEMBLY ........................................................... 1-4

SPECIAL TOOLS

MEASURING ........................................................................................... 1-5

REMOVING AND INSTALLING ............................................................... 1-7

FEATURES AND BENEFITS

POWER UNIT ........................................................................................... 1-9

IGNITION SYSTEM ............................................................................... 1-10

COOLING SYSTEM ................................................................................1-11

TILLER HANDLE .................................................................................... 1-13

BRACKET AND BOTTOM COWLING ................................................... 1-14

............................................................................................1-1

...........................................................................1-2

............................................................................................1-5

...........................................................................1-9

1

2

3

4

5

6

7

8

9

GEN

INFO

IDENTIFICATION

E

1

IDENTIFICATION

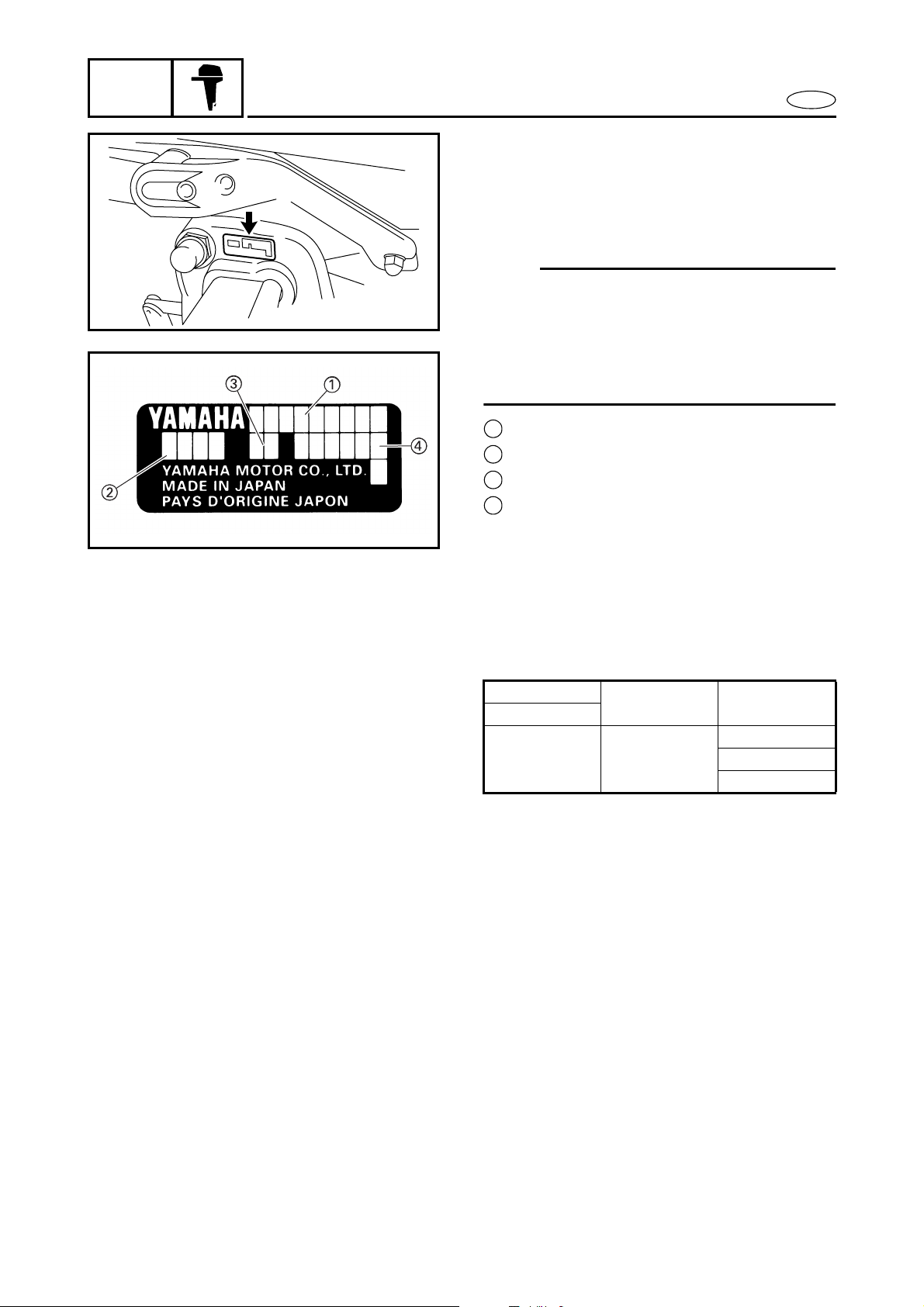

SERIAL NUMBER

The outboard motor’s serial number is

stamped on a label which is attached to the

port clamp bracket.

NOTE:

As an antitheft measure, a special label on

which the outboard motor’s serial number

is stamped is bonded to the port clamp

bracket. The label is specially treated so

that peeling it off causes cracks across the

serial number.

Model name

1

Approval model code

2

Transom height

3

Serial number

4

STARTING SERIAL NUMBERS

The starting serial number blocks are as follows:

Model name

Wor ldw ide

EK25BMH 62C

Approval

model code

Starting serial

number

S: 10 0101

L:400101

Y:750101

1-1

GEN

INFO

SAFETY WHILE WORKING

SAFETY WHILE WORKING

The procedures given in this manual are

those recommended by Yamaha to be followed by Yamaha dealers and their

mechanics.

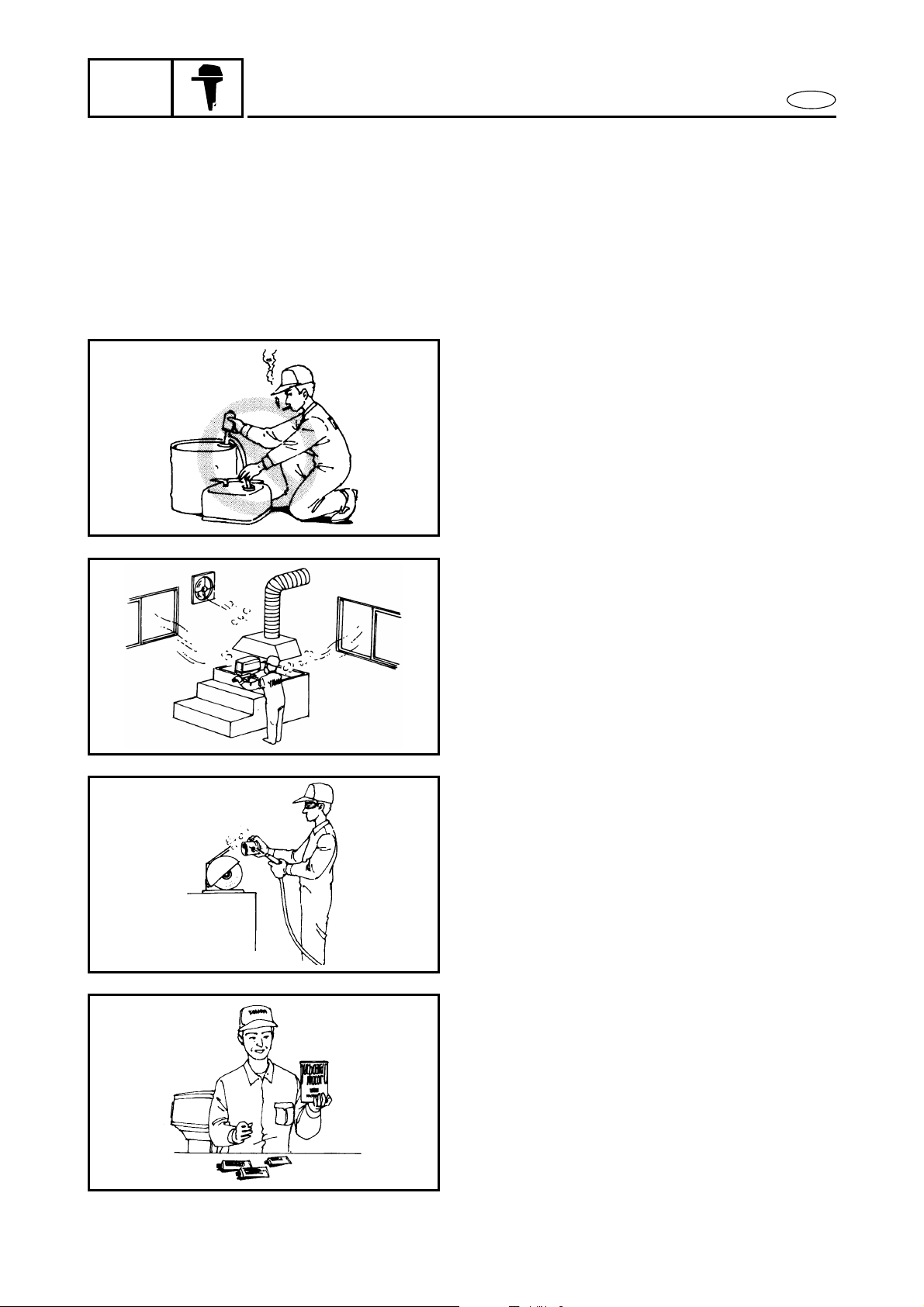

FIRE PREVENTION

Gasoline (petrol) is highly flammable.

Petroleum vapor is explosive if ignited.

Do not smoke while handling gasoline and

keep it away from heat, sparks and open

flames.

E

VENTILATION

Petroleum vapor is heavier than air and is

deadly if inhaled in large quantities. Engine

exhaust gases are harmful to breathe.

When test-running an engine indoors,

maintain good ventilation.

SELF-PROTECTION

Protect your eyes with suitable safety

glasses or safety goggles, when grinding or

when doing any operation which may cause

particles to fly off. Protect hands and feet by

wearing safety gloves or protective shoes if

appropriate to the work you are doing.

OILS, GREASES AND SEALING

FLUIDS

Use only genuine Yamaha oils, greases and

sealing fluids or those recommended by

Ya ma h a.

1-2

GEN

INFO

SAFETY WHILE WORKING

Under normal conditions or use, there

should be no hazards from the use of the

lubricants mentioned in this manual, but

safety is all-important, and by adopting

good safety practices, any risk is minimized.

A summary of the most important precautions is as follows:

1. While working, maintain good stan-

2. Clothing which has become contami-

3. Avoid skin contact with lubricants; do

4. Hands and any other part of the body

E

dards of personal and industrial

hygiene.

nated with lubricants should be

changed as soon as practicable, and

laundered before further use.

not, for example, place a soiled wipingrag in your pocket.

which have been in contact with lubricants or lubricant-contaminated clothing, should be thoroughly washed with

hot water and soap as soon as practicable.

5. To protect the skin, the application of a

suitable barrier cream to the hands

before working, is recommended.

6. A supply of clean lint-free cloths should

be available for wiping purposes.

GOOD WORKING PRACTICES

1. The right tools

Use the recommended special tools to

protect parts from damage. Use the

right tool in the right manner - do not

improvise.

2. Tightening torque

Follow the tightening torque instructions. When tightening bolts, nuts and

screws, tighten the large sizes first, and

tighten inner-positioned fixings before

outer-positioned ones.

1-3

GEN

INFO

SAFETY WHILE WORKING

3. Non-reusable items

DISASSEMBLY AND ASSEMBLY

1. Clean parts with compressed air when

2. Oil the contact surfaces of moving parts

E

Always use new gaskets, packings, Orings, split-pins, circlips, etc., on reassembly.

disassembling.

before assembly.

3. After assembly, check that moving parts

operate normally.

4. Install bearings with the manufacturer’s

markings on the side exposed to view,

and liberally oil the bearings.

5. When installing oil seals, apply a light

coating of water-resistant grease to the

outside diameter.

1-4

GEN

INFO

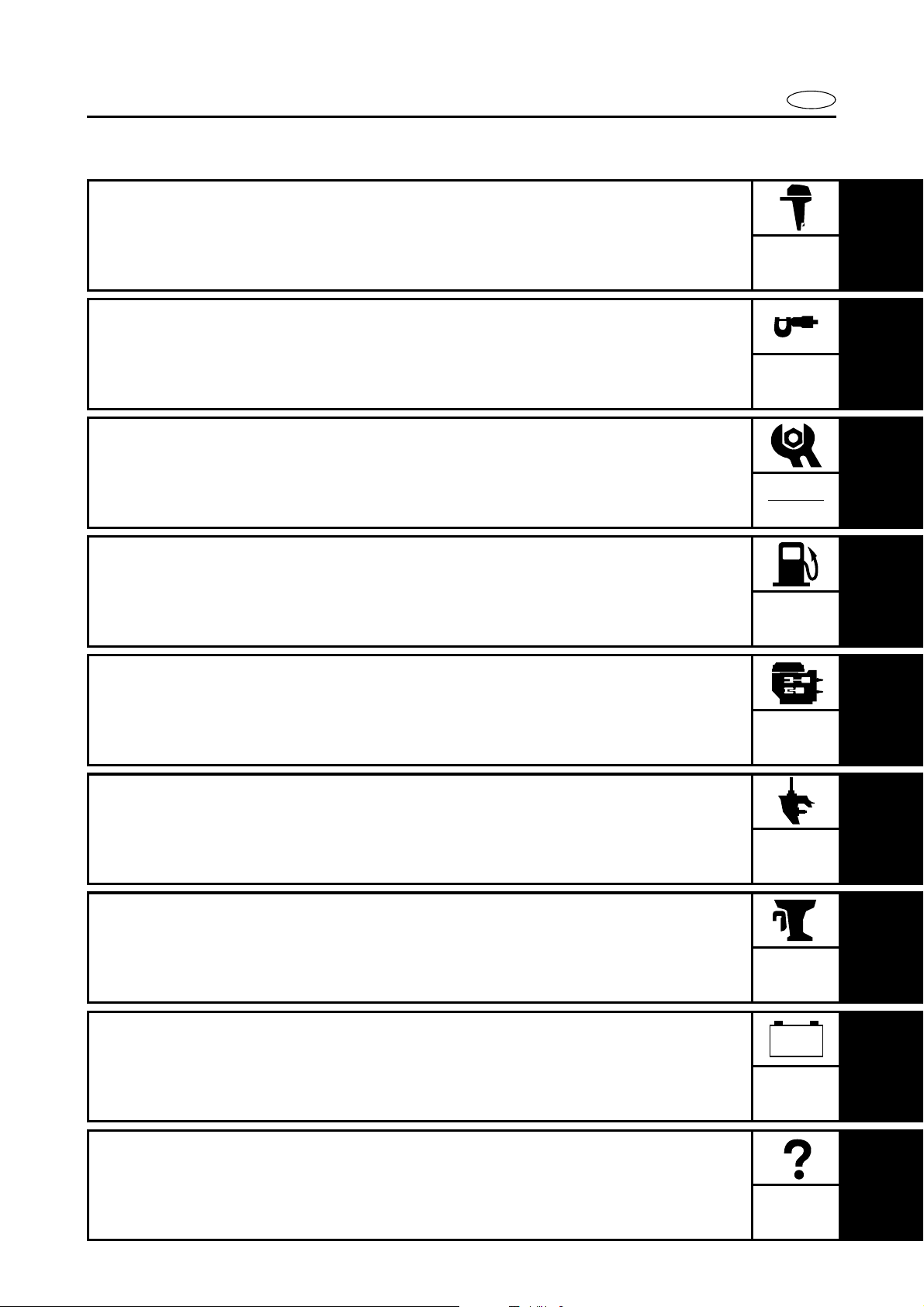

SPECIAL TOOLS

E

SPECIAL TOOLS

Using the correct special tools recommended by Yamaha, will aid the work and

enable accurate assembly and tune-up.

Improvising and using improper tools can

damage the equipment.

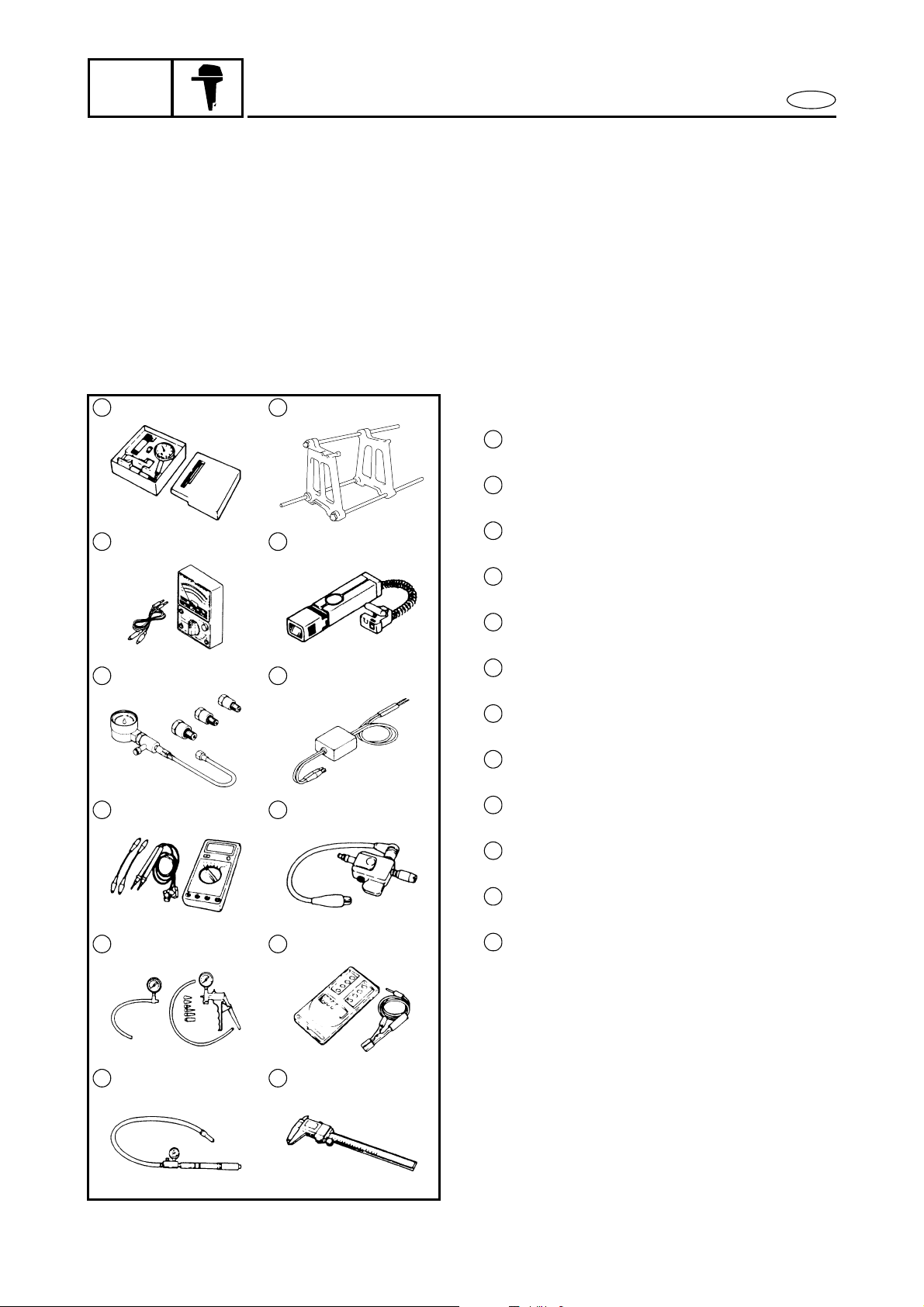

1 2

3 4

5 6

7 8

MEASURING

Dial gauge set

1

P/N. 90890-01252

Crank stand alignment

2

P/N. 90890-03107

Pocket tester

3

P/N. 90890-03112

Timing light

4

P/N. 90890-03141

Compression Gauge

5

P/N. 90890-03160

Peak voltage adaptor

6

P/N. 90890-03172

Digital circuit tester

7

P/N. 90890-03174

Ignition tester

8

P/N. 90890-06754

Vacuum/pressure pump gauge set

9

P/N. 90890-06756

Digital tachometer

10

P/N. 90890-06760

9 10

11 12

1-5

Leakage tester

11

P/N. 90890-06762

Digital caliper

12

P/N. 90890-06704

GEN

INFO

13 14

15 16

17 18

SPECIAL TOOLS

Cylinder gauge

13

P/N. 90890-06759

Outside micrometer

14

P/N. 90890-03006

P/N. 90890-03008

Inside micrometer

15

P/N. 90890-03010

Thickness gauge

16

P/N. 90890-03079

Shimming plate

17

P/N. 90890-06701

Pinion height gauge

18

P/N. 90890-06702

Magnet base

19

P/N. 90890-06705

Backlash indicator

20

P/N. 90890-06706

E

19 20

21

Magnet base plate

21

P/N. 90890-07003

1-6

GEN

INFO

SPECIAL TOOLS

E

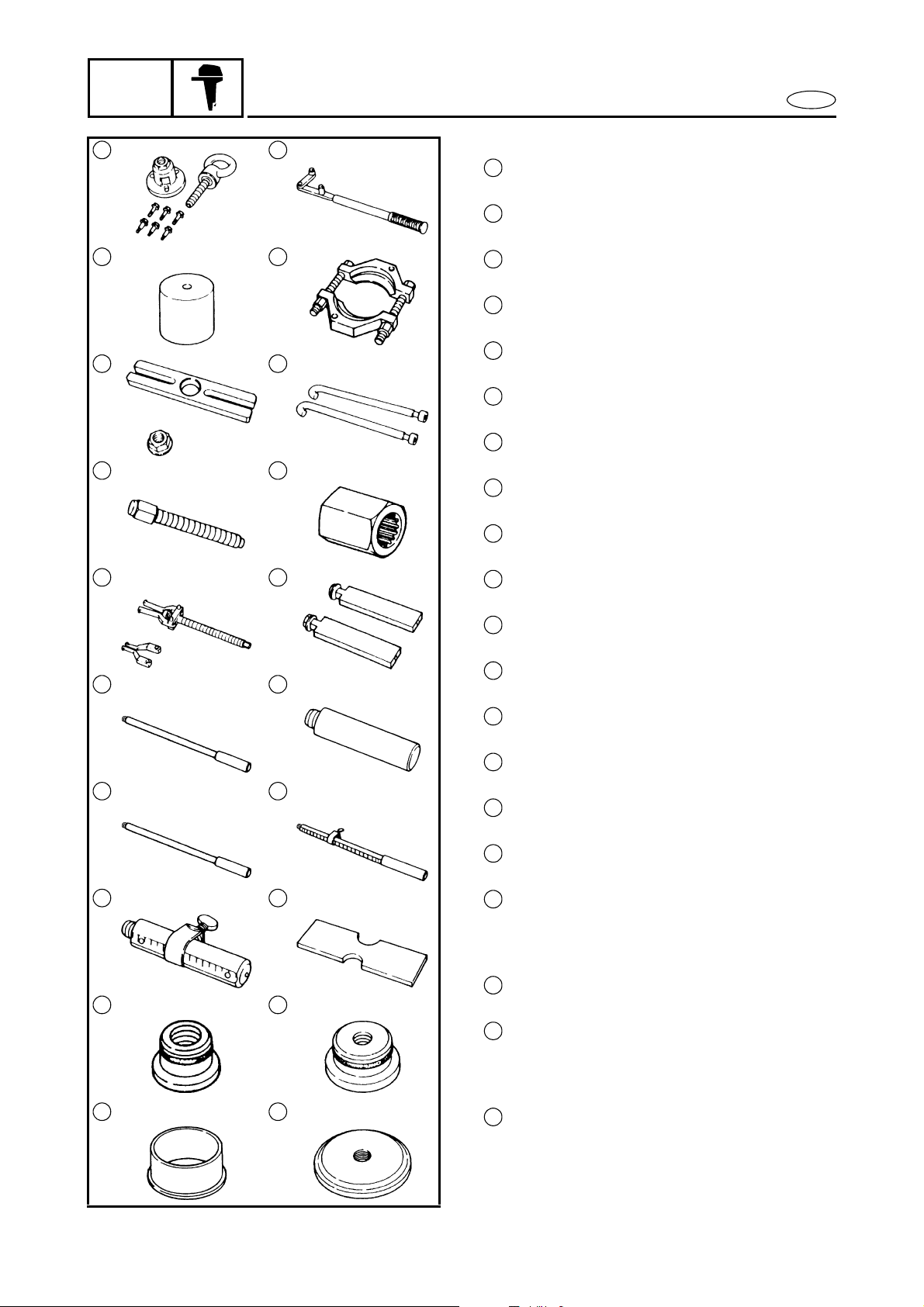

1 2

3 4

5 6

7 8

9 10

REMOVING AND INSTALLING

Flywheel puller

1

P/N. 90890-06521

Flywheel holder

2

P/N. 90890-06522

Small end bearing installer

3

P/N. 90890-06527

Bearing separator

4

P/N. 90890-06534

Stopper guide plate

5

P/N. 90890-06501

Bearing housing puller claw

6

P/N. 90890-06564

Center bolt

7

P/N. 90890-06504

Drive shaft holder 3

8

P/N. 90890-06517

Bearing puller ass’y

9

P/N. 90890-06535

Stopper guide stand

10

P/N. 90890-06538

11 12

13 14

15 16

17 18

19 20

Driver rod LL

11

P/N. 90890-06605

Driver rod LS

12

P/N. 90890-06606

Driver rod L3

13

P/N. 90890-06652

Driver rod SL

14

P/N. 90890-06602

Driver rod SS

15

P/N. 90890-06604

Bearing depth plate

16

P/N. 90890-06603

Needle bearing attachment

17

P/N. 90890-06608

P/N. 90890-06611

P/N. 90890-06615

Ball bearing attachment

18

P/N. 90890-06633

Bearing inner race attachment

19

P/N. 90890-06643

P/N. 90890-06644

P/N. 90890-06645

Bearing outer race attachment

20

P/N. 90890-06622

P/N. 90890-06628

1-7

GEN

INFO

SPECIAL TOOLS

E

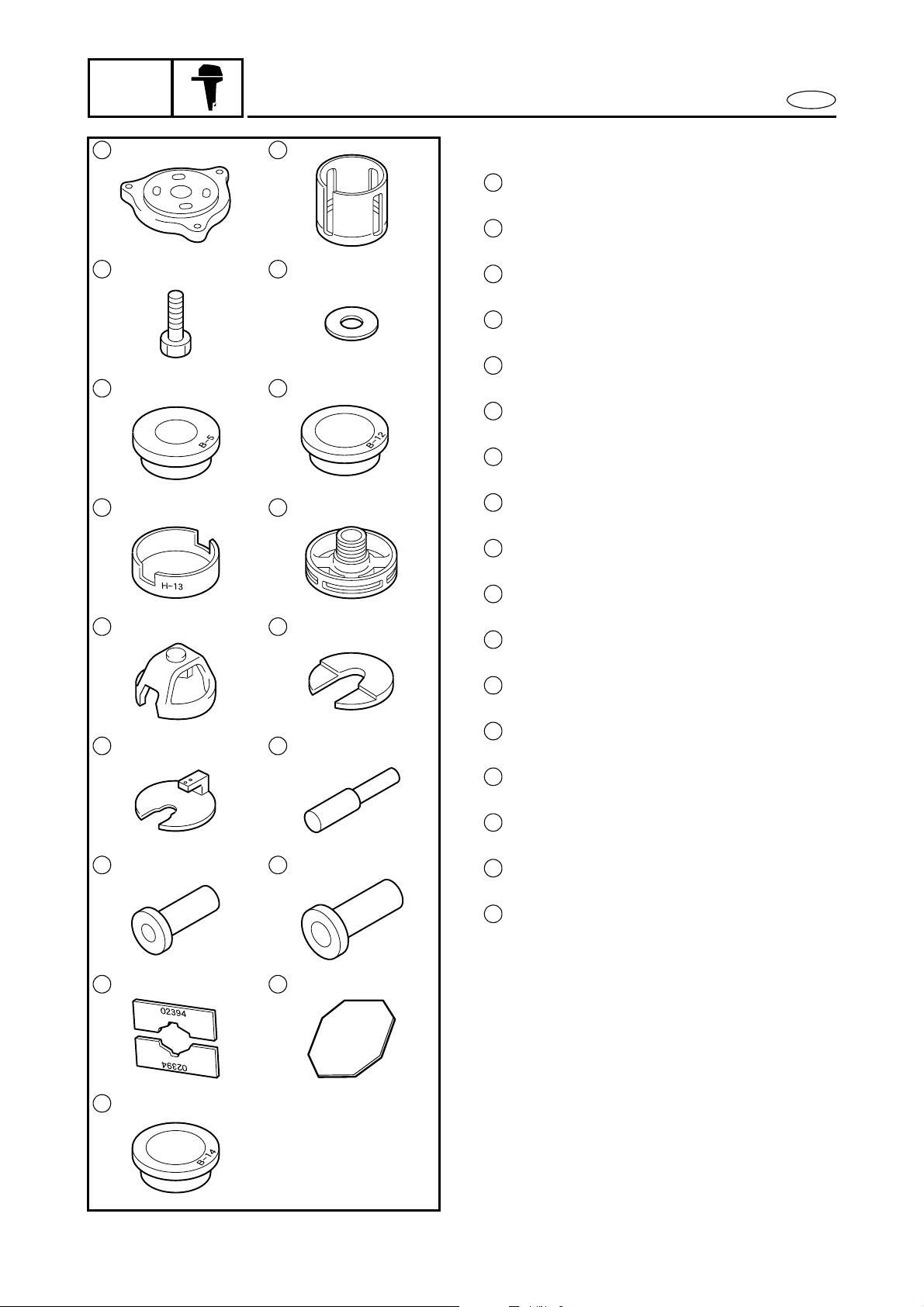

21 22

23 24

25 26

27 28

Crank jig ass’y

P/N. 90890-02421

Frange

21

P/N. 90890-02351

Body

22

P/N. 90890-02352

Bolt

23

P/N. 90890-02353

Washe r

24

P/N. 90890-02354

Bushing-5 (D25)

25

P/N. 90890-02359

Bushing-12 (D35)

26

P/N. 90890-02366

Height ring-13 (H57)

27

P/N. 90890-02379

Pressure Plate

28

P/N. 90890-02384

Press body

29

P/N. 90890-02385

29 30

31 32

33 34

35 36

Plate A

30

P/N. 90890-02386

Plate B

31

P/N. 90890-02387

Pressure pin B

32

P/N. 90890-02390

Bearing pressure B

33

P/N. 90890-02392

Bearing pressure C

34

P/N. 90890-02393

Support

35

P/N. 90890-02394

Spacer B

36

P/N. 90890-02396

Bushing-14

37

P/N. 90890-02419

37

1-8

GEN

INFO

FEATURES AND BENEFITS

FEATURES AND BENEFITS

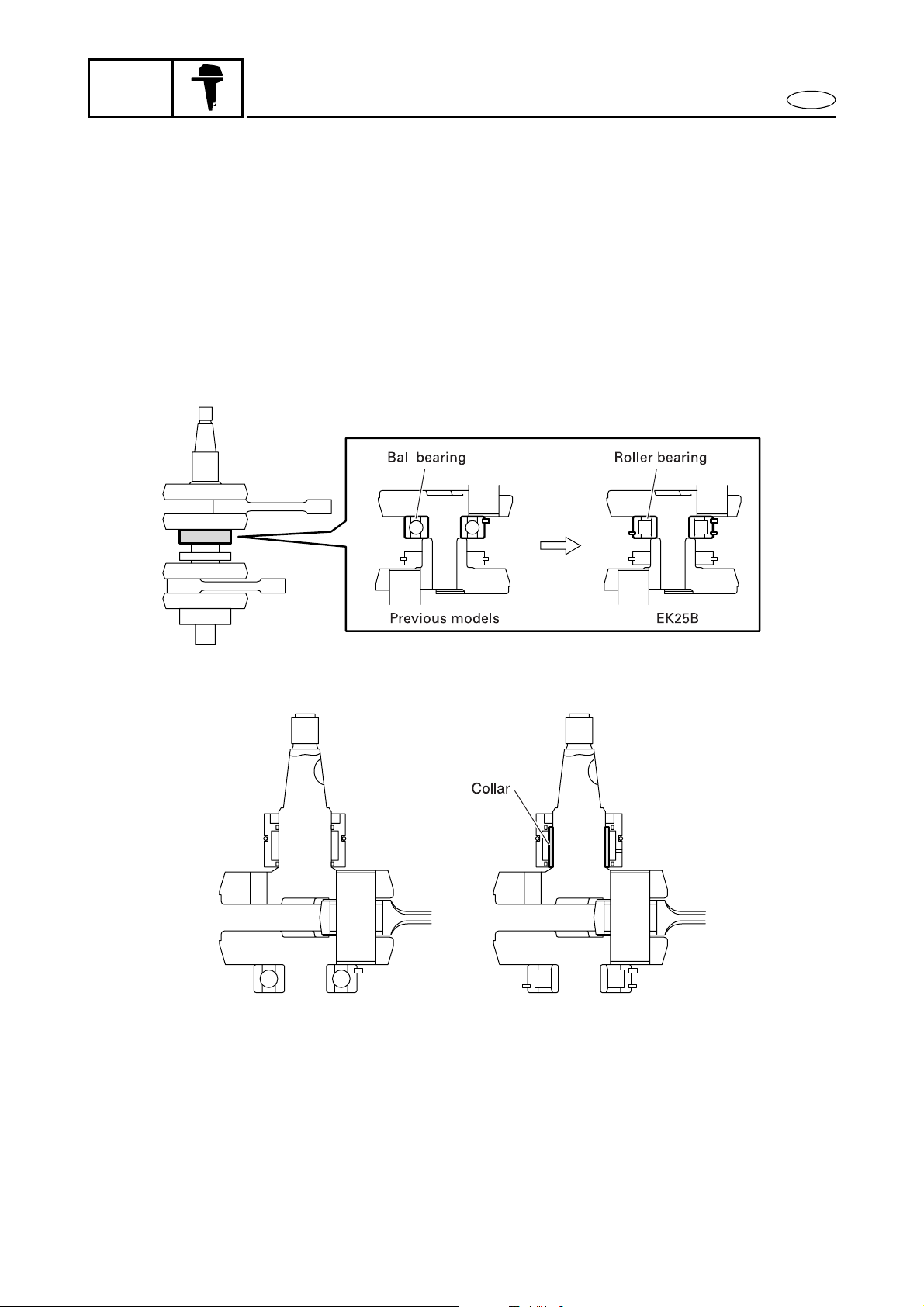

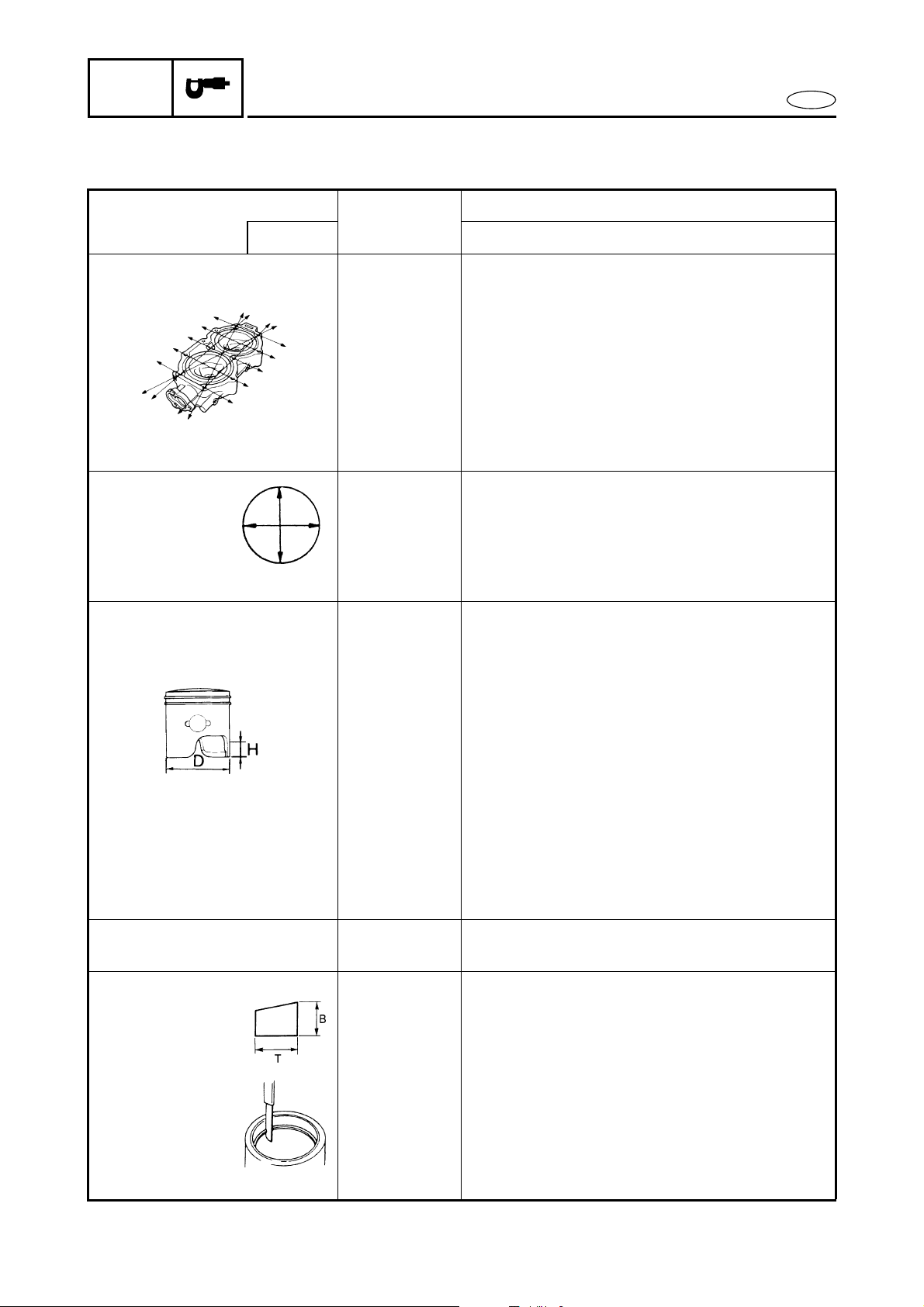

POWER UNIT

The EK25B is designed to provide superior fuel economy, serviceability, and durability.

They are based on the previous EK25A with newly designed linkage to control both throttle

opening and ignition timing mechanically and simultaneously.

Special attention was paid on the crankshaft bearings. Collar is now added to the upper main

journal of the crankshaft. Roller bearing is applied for the center bearing.

The collar added on the upper main journal contributes to get and better serviceability.

E

Fig. 1

Fig. 2

1-9

GEN

INFO

FEATURES AND BENEFITS

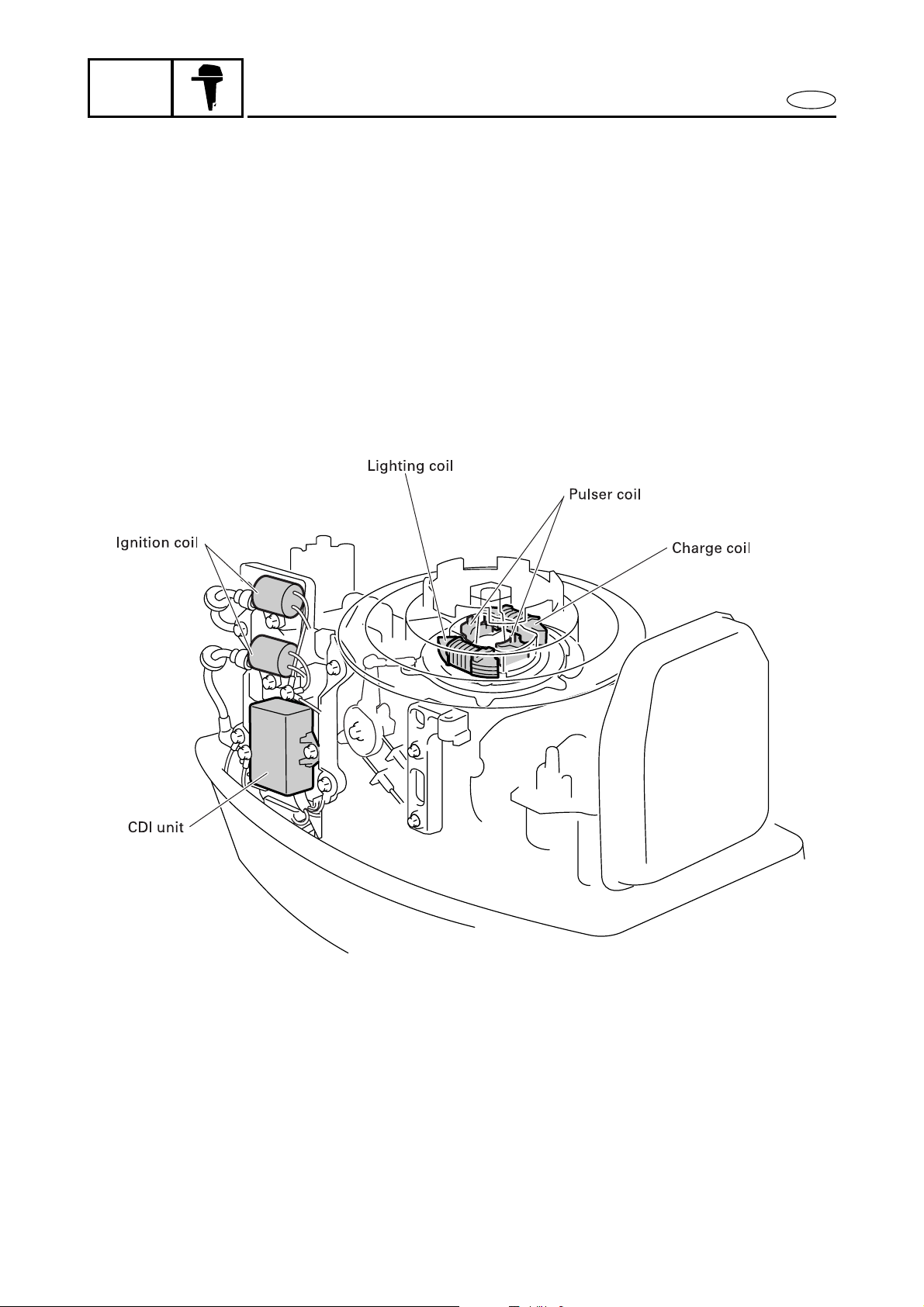

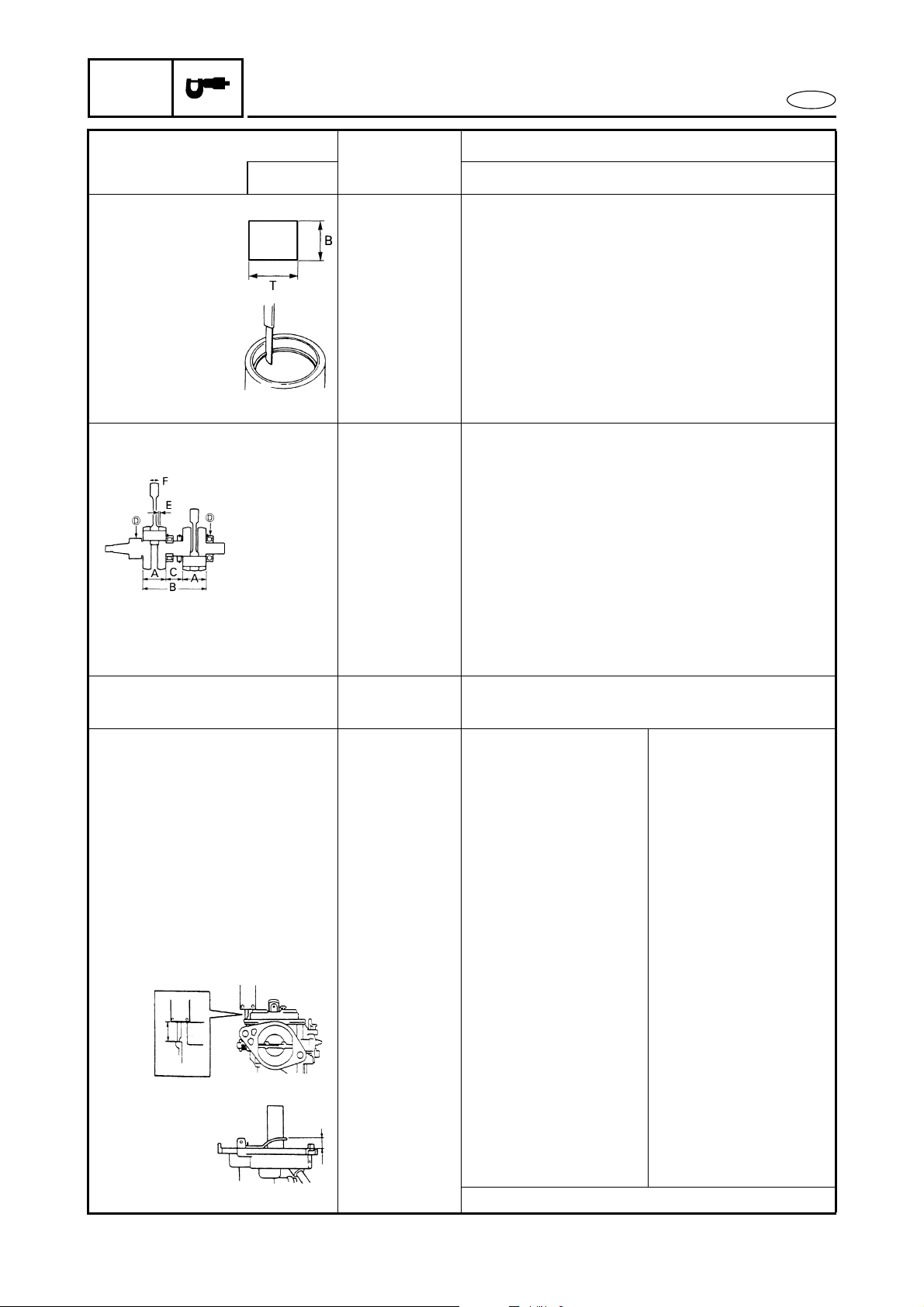

IGNITION SYSTEM

Ignition system on the EK25B consists of flywheel magnet, charge coil, pulser coil, CDI unit,

and ignition coil.

Similar to the previous EK25A, the engine has the mechanical ignition timing advance system

that works by way of the linkage.

Superior fuel economy is attained by the modified ignition timing control arrangement.

Also the system restricts the ignition timing advance to prevent engine kickback when the

shift is in neutral.

E

Fig. 3

1-10

GEN

INFO

FEATURES AND BENEFITS

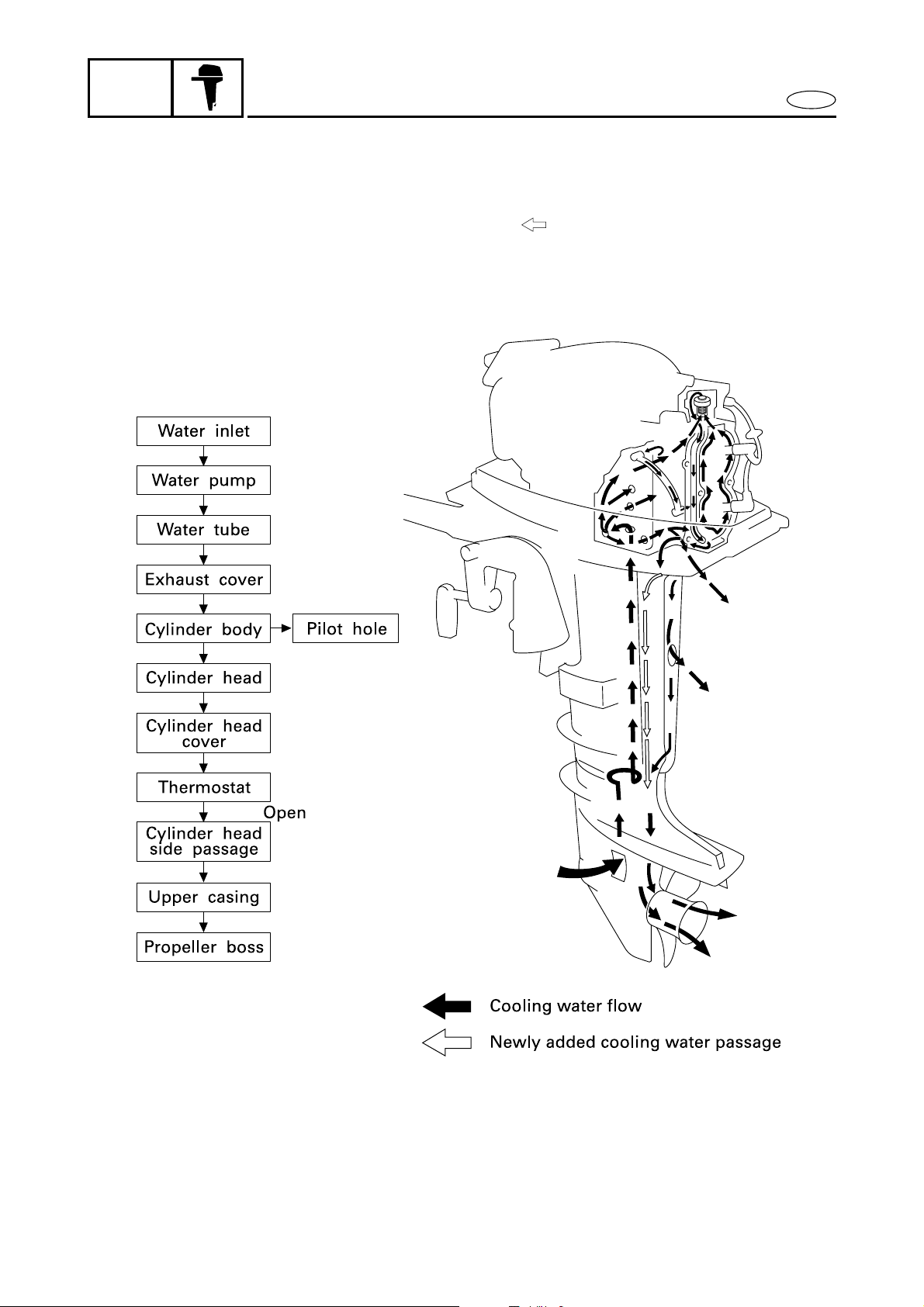

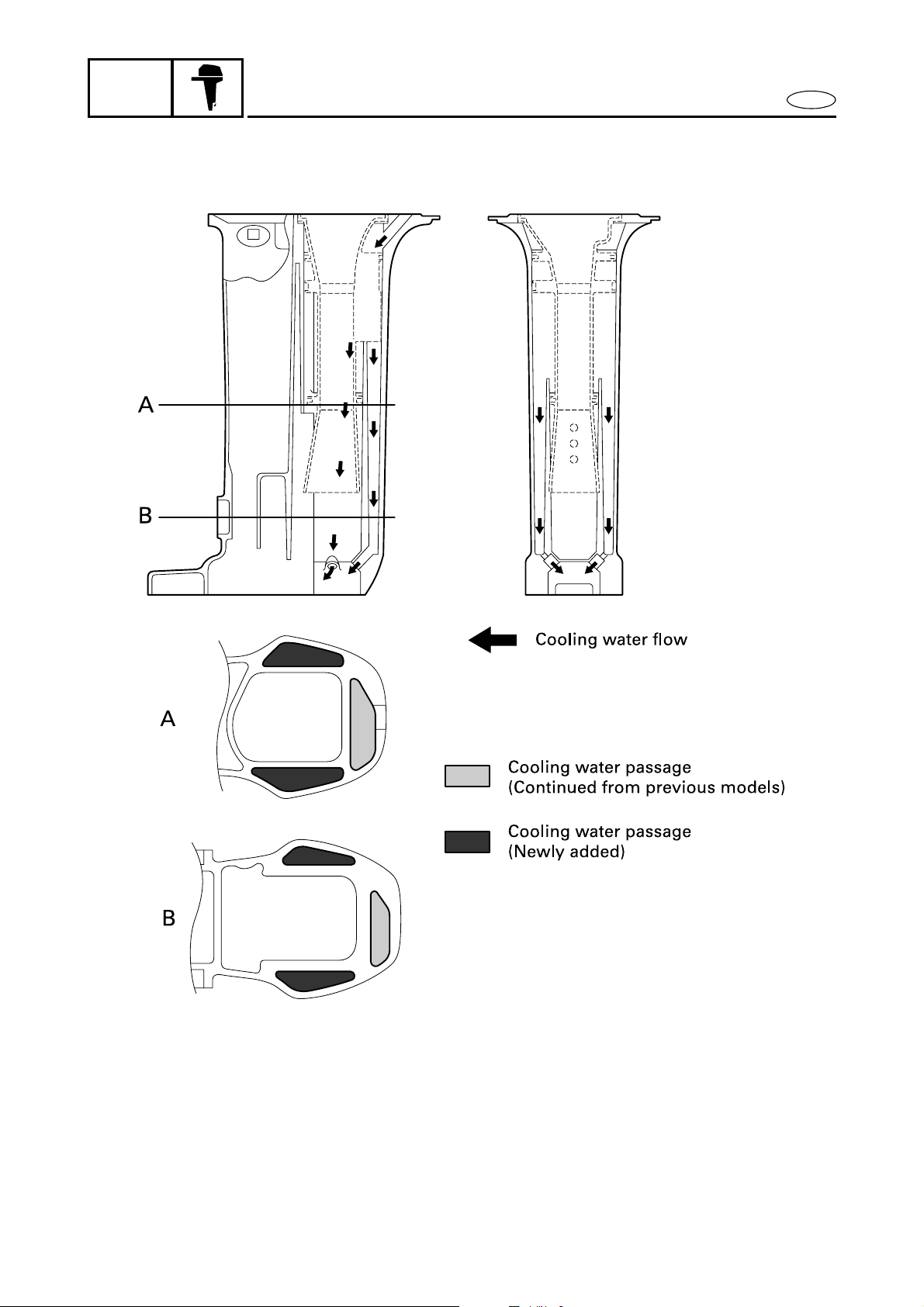

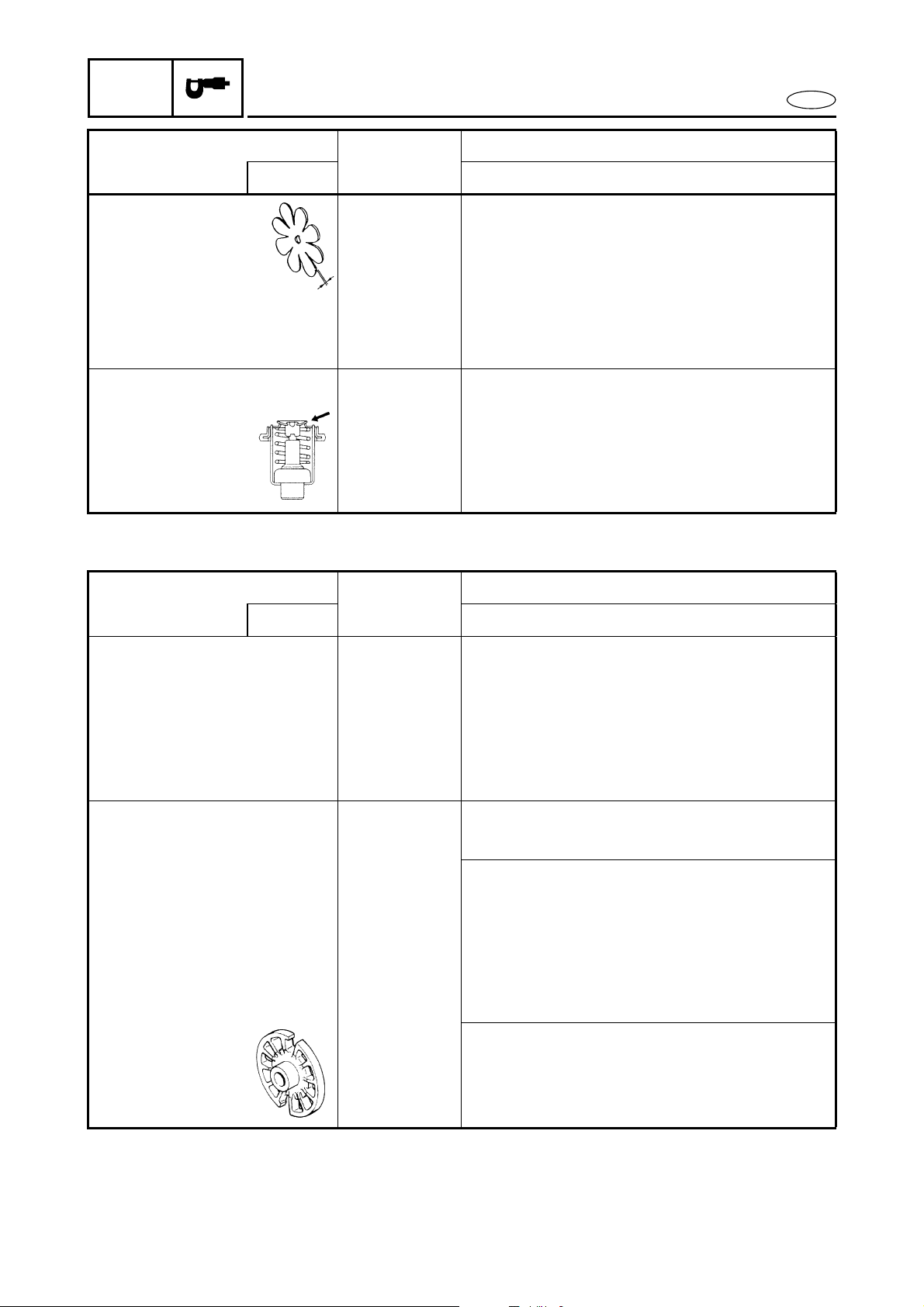

COOLING SYSTEM

New structure applied to the cooling system provides additional cooling capacity in the upper

casing.

With additional cooling water passage (indicated by ), water walls contained in the new

upper casing contribute to the reduction of outer surface temperature.

E

Fig. 4

1-11

GEN

INFO

COOLING SYSTEM

FEATURES AND BENEFITS

E

Fig. 5

1-12

GEN

INFO

FEATURES AND BENEFITS

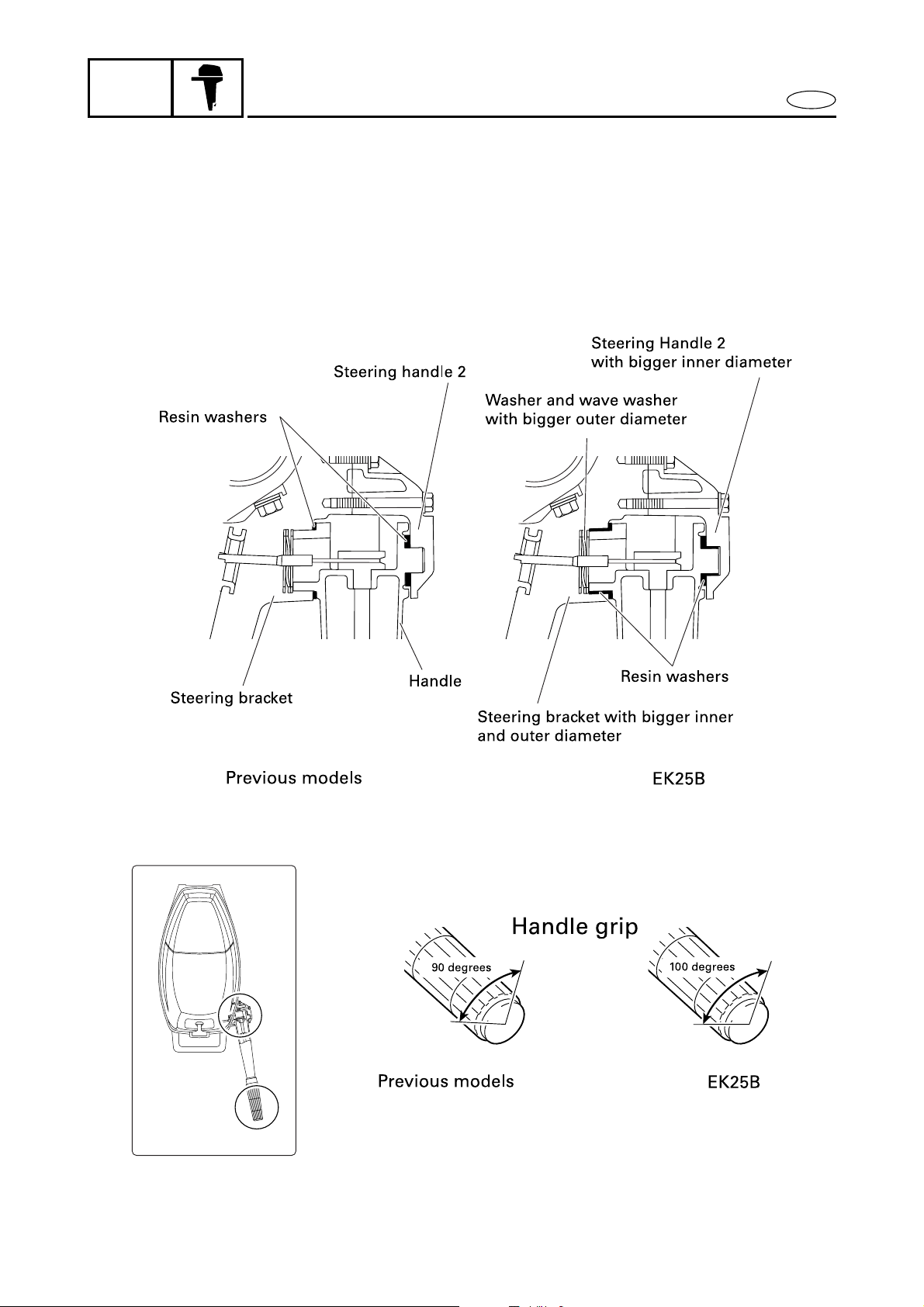

TILLER HANDLE

For the throttle grip on the steering handle of the EK25B, 100 degrees of opening angle

covers all ranges from full-closed to wide-open positions.

Also, new steering handle parts were developed to assume the long use. Inner diameter of

the steering handle engagement area, and both inner and outer diameters of steering bracket

are increased.

Please note that if the new steering handle is installed on the previous models, Steering

handle 2, Steering bracket, Collar, and Washer must be replaced.

E

Fig. 6

Fig. 7

1-13

GEN

INFO

FEATURES AND BENEFITS

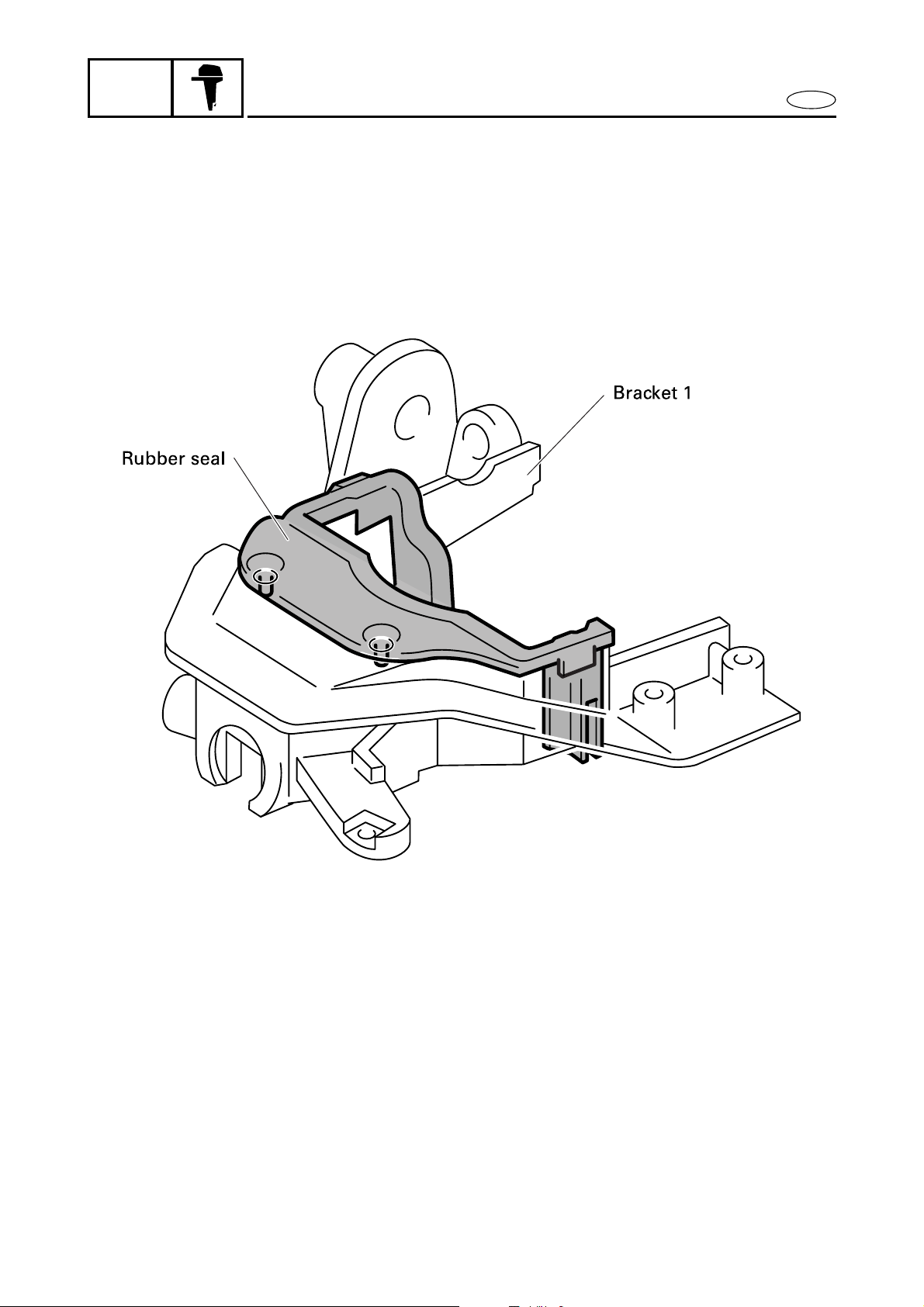

BRACKET AND BOTTOM COWLING

The Bracket 1 is modified on the EK25B, and newly designed rubber seal is added to provide

better sealing ability for the bottom cowling.

E

Fig. 8

1-14

SPEC

E

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

POWER UNIT ...........................................................................................2-3

LOWER UNIT ...........................................................................................2-5

ELECTRICAL ............................................................................................2-6

DIMENSIONS ..........................................................................................2-8

DIMENSIONS ..........................................................................................2-9

TIGHTENING TORQUES

SPECIFIED TORQUES ........................................................................... 2-11

GENERAL TORQUES ............................................................................ 2-12

.........................................................................2-1

...............................................................2-3

............................................................................. 2-11

1

2

3

4

5

6

7

8

9

SPEC

2

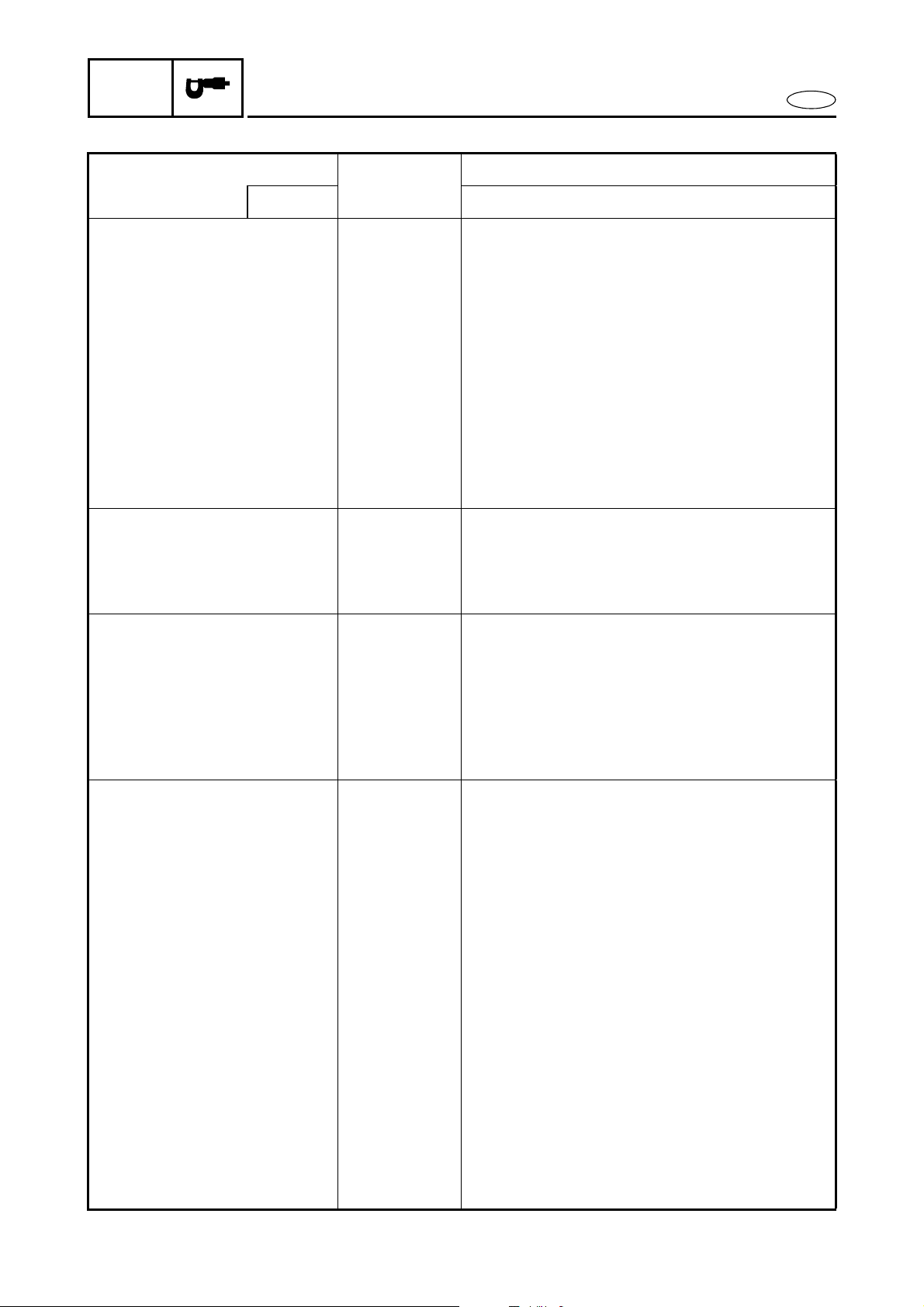

GENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

Model

Item Unit

Worldwide

DIMENSIONS

Overall length mm (in) 843 (33.2)

Overall width mm (in) 399 (15.7)

Overall height

(S) mm (in) 1,146 (45.1)

(L) mm (in) 1,273 (50.1)

(Y) mm (in) 1,320 (52.0)

Boat transom height

(S) mm (in) 381 (15.0)

(L) mm (in) 508 (20.0)

(Y) mm (in) 559 (22.0)

WEIGHT

(S) kg (lb) 53.0 (116.9)

EK25BMH

E

(L) kg (lb) 54.5 (120.2)

(Y) kg (lb) 55.0 (121.3)

PERFORMANCE

Maximum output (ISO) kW (hp)

18.4 (25.0)

@5,000 r/min

Full throttle operating range r/min 4,500 - 5,500

Maximum fuel consumption L (US gal,

Imp gal)

13.8 (3.6, 3.0)

Gasoline / Kerosene

@5,500 r/min

POWER UNIT

Type 2 stroke

Number of cylinders 2

3

Displacement cm

(cu. in) 496 (30.3)

Bore and stroke mm (in) 72.0 × 61.0 (2.83 × 2.40)

Compression ratio kPa

(kgf/cm

2

Compression pressure kPa

(kgf/cm

2

<Minimum> kPa

(kgf/cm

2

, psi)

, psi)

, psi)

#1: 5.3 (0.05, 0.8), #2: 5.7 (0.06, 0.8)

#1: 680 (6.8, 98.6), #2: 730 (7.3, 105.9)

#1: 540 (5.4, 78.3), #2: 580 (5.8, 84.1)

Spark plug(NGK) B7HS-10

Number of carburetor 1

Enrichment system Chock valve

Intake system Reed valve

Induction system Loop charge

Exhaust system Through propeller boss

2-1

SPEC

Item Unit

Lubrication system Mixed (Gasoline and oil, Kerosene and oil)

Cooling system Water

Ignition control system CDI

Alternator output V - W 12 - 80

POWER UNIT

Starting system Manual

Control system Mechanical

Advanced system Mechanical

CARBURETOR

ID mark 69T00

FUEL AND OIL

Fuel type

(Main) Kerosene

GENERAL SPECIFICATIONS

Worldwide

Model

EK25BMH

E

Mixing ratio 30 : 1

(Sub) Unleaded regular gasoline

Mixing ratio 50 : 1

Engine oil type 2 stroke outboard engine oil

Engine oil grade TC - W3

Gear oil Hypoid gear oil

Gear oil grade SAE #90 (API GL - 4)

3

Gear oil capacity cm

BRACKET

Tilt angle Degree 4, 8, 12, 16, 20

Tilt-up angle Degree 76

Shallow water angle from

transom

Steering angle Degree 40 + 40

DRIVE UNIT

Gear shift positions F - N - R

Gear ratio 2.08 (27/13)

(US oz,

Imp oz)

Degree Tilt angle + 20

320 (10.8, 11.3)

Gear type Spiral bevel

Propeller direction

(rear view)

Propeller drive system Spline

Propeller mark F

2-2

Clockwise

SPEC

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

POWER UNIT

Model

Item Unit

Worldwide

CYLINDER HEAD

Warpage limit

(lines indicate straightedge

position)

CYLINDERS

Bore size mm (in) 72.00 - 72.02 (2.8346 - 2.8354)

Wear limit mm (in) 72.10 (2.8386)

Taper limit mm (in) 0.08 (0.0031)

Out-of-round limit mm (in) 0.05 (0.0020)

PISTON

Piston side "D" mm (in) 71.94 - 71.96 (2.8323 - 2.8331)

Measuring point "H" mm (in) 10.0 (0.3937)

mm (in) 0.1 (0.004)

EK25BMH

E

Piston-cylinder clearance mm (in) 0.060 - 0.065 (0.0024 - 0.0026)

<Limit> mm (in) 0.1 (0.0039)

Oversize piston

diameter

Pin boss inside diameter mm (in) 19.904 - 19.915 (0.7836 - 0.7841)

PISTON PINS

Outside diameter mm (in) 19.895 - 19.900 (0.7833 - 0.7835)

PISTON RING (1st)

Ty pe K ey s to n e

(B) mm (in) 2.0 (0.079)

(T) mm (in) 3.0 (0.118)

End gap

(installed)

<Limit> mm (in) 0.35 (0.014)

Side clearance mm (in) 0.03 - 0.05 (0.0012 - 0.0020)

<Limit> mm (in) 0.05 (0.0020)

1st mm (in) 72.25 (2.8445)

2nd mm (in) 72.50 (2.8543)

mm (in) 0.20 - 0.35 (0.008 - 0.014)

2-3

SPEC

Item Unit

PISTON RING (2nd)

Type Plain

(B) mm (in) 2.0 (0.079)

(T) mm (in) 3.0 (0.118)

End gap

(installed)

<Limit> mm (in) 0.35 (0.014)

Side clearance mm (in) 0.03 - 0.07 (0.0012 - 0.0028)

<Limit> mm (in) 0.07 (0.0028)

CRANKSHAFT

Crank width (A) mm (in) 56.90 - 56.95 (2.2401 - 2.2421)

MAINTENANCE SPECIFICATIONS

Model

Worldwide

mm (in) 0.20 - 0.35 (0.0079 - 0.0137)

(B) mm (in) 153.7 - 154.0 (6.0512 - 6.0630)

(C) mm (in) 39.9 - 40.1 (1.5709 - 1.5787)

EK25BMH

E

Runout limit (D) mm (in) 0.03 (0.0012)

Side clearance (E) mm (in) 0.2 - 0.7 (0.0079 - 0.0276)

Maximum axial play (F) mm (in) 2.0 (0.079)

CONNECTING ROD

Small end diameter mm (in) 23.904 - 23.917 (0.941 - 0.942)

CARBURETOR

Main jet (M.J.) # 155 —

Main air jet (M.A.J.)

Main nozzle (M.N.)

Pilot jet (P.J.) # 50 48

Pilot air jet (P.A.J.) mm (in) 0.92 (0.036) 0.90 (0.035)

Pilot screw (P.S.) turns out 1/2 + 2

Valve seat size (V.S.) mm (in) 1.4 (0.055) 1.2 (0.047)

Float height mm (in) 18 (0.079) —

mm (in) 1.3 (0.051) —

φ

mm (in) 2.8 (0.110) —

φ

Kerosene carburetor Gasoline carburetor

1 - 1/2 ± 1/2

1/2 - 1/2

Float arm height mm (in) — 3 (0.118)

Idle speed r/min 1,300 ± 50

2-4

SPEC

Item Unit

REED VALVES

Thickness 0.2 (0.008)

Valve stopper height

(Standard) mm (in) 3.46 - 3.50 (0.136 - 0.138)

(for Sri Lanka) mm (in) 4.20 - 4.60 (0.165 - 0.181)

Valve bending limit mm (in) 0.2 (0.008)

THERMOSTAT

Valve opening

temperature

Full-open

temperature

Minimum valve lift mm (in) 3 (0.12)

MAINTENANCE SPECIFICATIONS

Worldwide

°C (°F) 48 - 52 (118 - 126)

°C (°F) 60 (140)

Model

EK25BMH

E

LOWER UNIT

Model

Item Unit

Worldwide

GEAR BACKLASH

Pinion - forward gear mm (in) 0.31 - 0.72 (0.012 - 0.028)

Pinion - reverse gear mm (in) 0.93 - 1.65 (0.037 - 0.065)

Pinion gear shims mm 0.7 / 1.0 / 1.1 / 1.2 / 1.3 / 1.4 / 1.5 / 1.6

Forward gear shims mm 1.0 / 1.1 / 1.2 / 1.3 / 1.4

Reverse gear shims mm 1.0 / 1.1 / 1.2 / 1.3

PROPELLER

Material Aluminium

No. of blades × diameter ×

pitch

in 3 × 9 - 7/8 × 11 - 1/4

EK25BMH

3 × 9 - 7/8 × 8

3 × 9 - 7/8 × 9

3 × 9 - 7/8 × 10 - 1/2

3 × 9 - 7/8 × 12

3 × 9 - 7/8 × 13

3 × 9 - 7/8 × 14

Test propeller P/N. 90890-01629

r/min 5,250 - 5,450

2-5

Loading...

Loading...