Yamaha DVS-5350 Service manual

DVD-S510/DV-S5350

DVD PLAYER

DVD-S510/DV-S5350

SERVICE MANUAL

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

injury, destruction of expensive components, and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that any service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please

contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■ CONTENTS

TO SERVICE PERSONNEL .......................................... 1

WARNINGS ................................................................ 1~2

PREVENTION OF ELECTROSTATIC DISCHARGE .... 3

LOCALE MANAGEMENT INFORMATION ................... 3

FRONT PANELS............................................................ 4

REMOTE CONTROL TRANSMITTER .......................... 4

REAR PANELS .............................................................. 5

SPECIFICATIONS.......................................................... 6

DISASSEMBLY PROCEDURES ............................... 7~8

SERVICE HINTS ............................................................ 8

DIAGNOSTIC SOFTWARE ..................................... 9~10

IMPORTANT NOTICE

INTERACTIVE TESTS ........................................... 11~17

TEST INSTRUCTIONS DISPLAY BOARD ........... 18~19

TROUBLESHOOTING ........................................... 20~25

TECHNICAL SPECIFICATIONS DVD MODULE...........

LIST OF ABBREVIATIONS ......................................... 28

IC DESCRIPTIONS ................................................ 29~39

WIRING DIAGRAM ................................................ 40~41

BLOCK DIAGRAM................................................. 42~45

PRINTED CIRCUIT BOARD .................................. 46~66

SCHEMATIC DIAGRAM ........................................ 67~95

PARTS LIST......................................................... 96~107

26~27

100750

DVD-S510/DV-S5350

P.O.Box 1, Hamamatsu, Japan

DVD-S510/DV-S5350

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked s

and must be replaced with parts having specifications equal

to those originally installed.

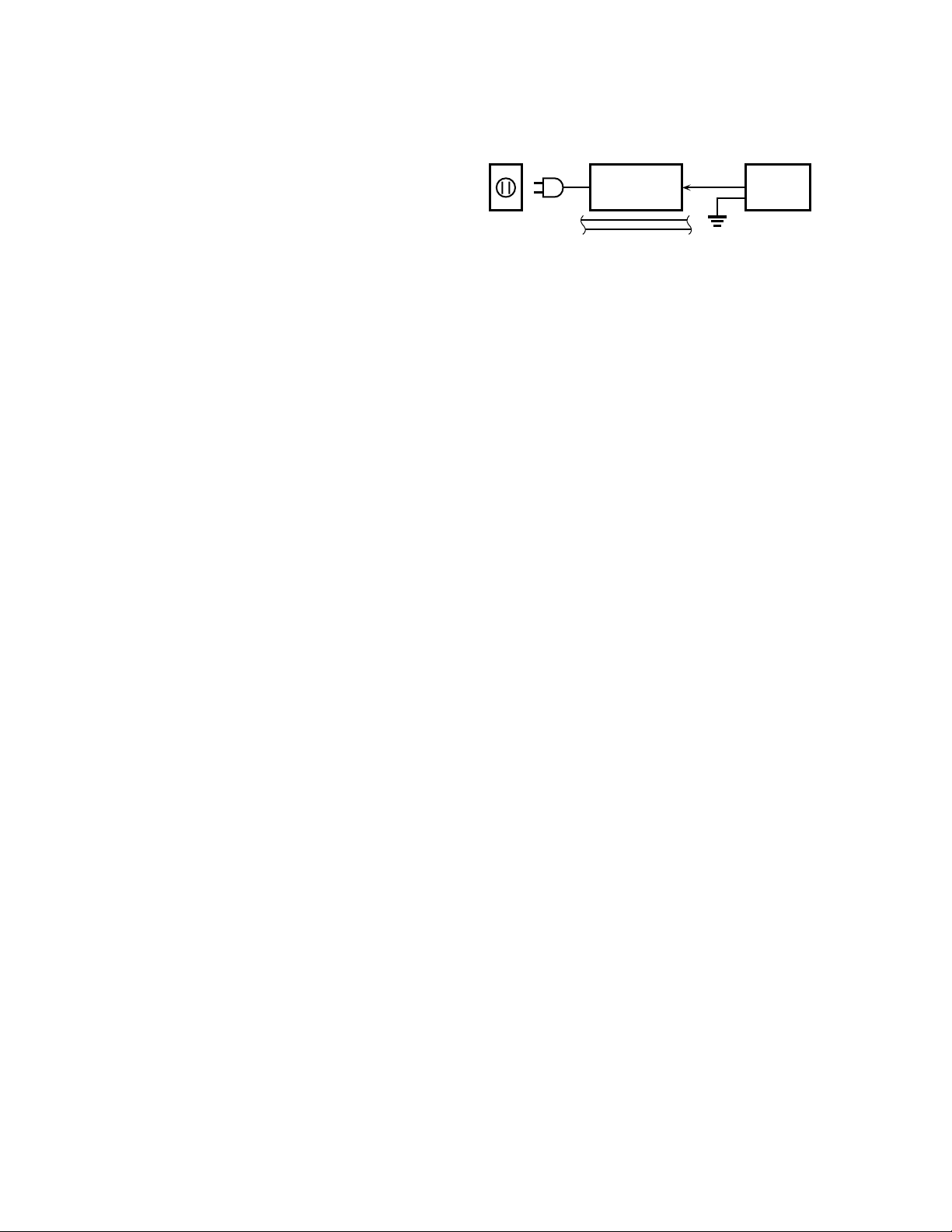

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both polarities.

WALL

OUTLET

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

CAUTION: USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED

THE DVD-VIDEO PLAYER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE EXCEPT PROPERLY QUALIFIED SERVICE

PERSONNEL.

HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

■ WARNINGS

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and /or plastic

(where applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency

(and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation, which may

cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must be used during

servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare the laser beam at any time.

2) Do not attempt readjustment, disassemble or repair of the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION: Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Laser Emitting conditions:

1) When the Top Cover is removed, and the POWER SW is turned to the "ON" position, the laser component will emit a

beam for several seconds to detect if a disc is present. During this time (5 - 10 sec.) the laser may radiate through the lens

of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. when a disc is set, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on pick-up PWB, however, this level has been set by the factory prior

to shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this manual.

Adjustment of this control can increase the laser emission level from the device.

1

DVD-S510/DV-S5350

Laser Diode Properties

Type: Semiconductor laser GaAlAs

Wave length: 650 nm (DVD)

780 nm (VCD/CD)

Output Power: 7 mW (DVD)

10 mW (VCD/CD)

Beam divergence: 60 degree

Output value is determined by CFR CHAPTER1, SUBCHAPTER J

VARO! : AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄkymÄTTÖMÄLLE LASER-

SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING! : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

U, C models B, G modelsR, A, T models

CAUTION

DANGER

- Visible and invisible laser radiation

when open. Avoid direct exposure to beam.

CAUTION

- Visible and invisible laser

radiation when open. Avoid exposure to beam.

- Visible and invisible laser

radiation when open. Avoid exposure to beam.

WARNING LOCATION: REAR PANEL

CAUTION VISIBLE AND INVISIBLE LASER RADIATI ON WHEN OPEN. AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATI ON WHEN OPEN. AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Warning for power supply

The primary side of the power supply including the heatsink carries live mains voltage when the player is

connected to the mains even when the player is switched off !

This primary area is not shielded so it is possible to touch copper tracks and/or components when servicing the player.

Service personnel have to take precautions to prevent touching this area or components in this area .

The primary side of the power supply has been indicated with a lightening stroke and a stripe-marked print on the printed

wiring board

Note:

The screws on the DVD mechanism (position 18-1 in on the exploded view drawing) may never be touched,

removed or re-adjusted.

Handle the DVD mechanism with care when the unit has to be exchanged!

The DVD mechanism is very sensitive for dropping or giving shocks.

2

DVD-S510/DV-S5350

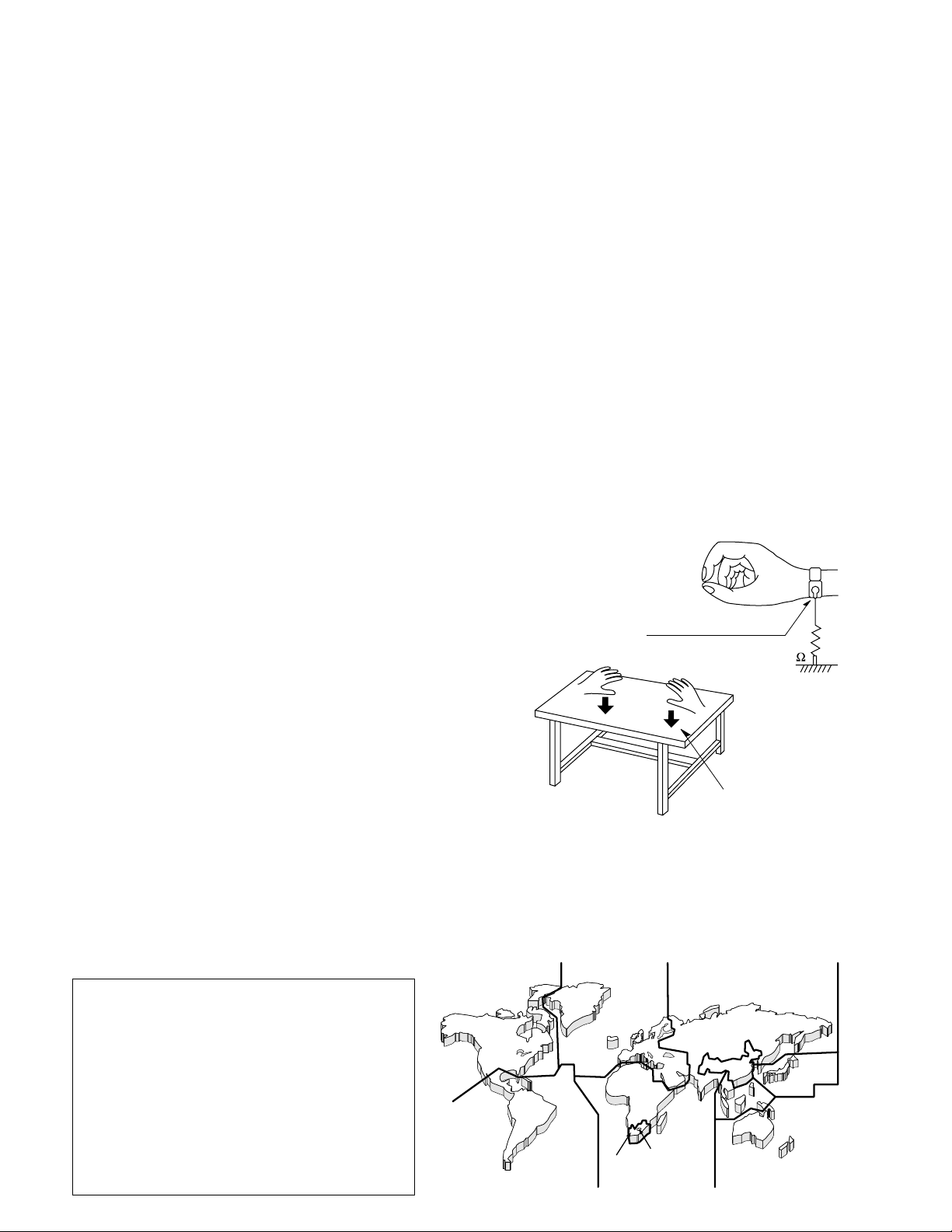

■ PREVENTION OF ELECTROSTATIC DISCHARGE

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor “chip” components. The following techniques should be used to help reduce the incidence of

component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD

wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)”

can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

HANDLING PRECAUTIONS

The laser diode in the optical pickup may break down due to potential difference caused by

static electricity of clothes or human body. So be careful of electrostatic breakdown during

repair of the DVD mechanism.

Grounding for electrostatic breakdown prevention

1. Human body grounding.

Use the antistatic wrist strap to discharge the static electricity from

Anti-static wrist strip

1M

your body.

2. Work table grounding.

Put a conductive material (sheet) or steel sheet on the area where

the optical pickup is placed and ground the sheet.

Caution:

The static electricity of your clothes will not be grounded through the

wrist strap. So take care not to let your clothes touch the optical

pickup.

Conductive material

(sheet) or steel sheet

■ LOCALE MANAGEMENT INFORMATION

Locale Management Information : This DVD player is designed and manufactured to respond to the Locale Management

Information that is recorded on a DVD disc. If the Locale number described on the DVD disc does not correspond to the

Locale number of this DVD player, this DVD player cannot play this disc.

This product incorporates copyright protection

technology that is protected by method claims of

2

5

certain U.S. patents and other intellectual

property rights owned by Macrovision

Corporation and other rights owners. Use of this

copyright protection technology must be

authorized by Macrovision Corporation, and is

intended for home and other limited viewing uses

only unless otherwise authorized by Macrovision

Corporation. Reverse engineering or

1

4

2

5

5

6

3

2

4

disassembly is prohibited.

3

■ SPECIFICATIONS

DVD-S510/DV-S5350

PLAYBACK SYSTEM

DVD-Video

Video CD

CD (CD-R and CD-RW)

OPTICAL READOUT SYSTEM

Laser type Semiconductor AlGaAs

Numerical Aperture 0.60 (DVD)

0.45 (VCD/CD)

Wavelength 650 nm (DVD)

780 nm (VCD/CD)

DVD DISC FORMAT

Medium Optical Disc

Diameter 12cm (8cm)

Playing time One layer 2.15 h*

(12cm) Dual layer 4 h*

Two side 4.30 h*

Single layer

Two side 8 h*

Dual layer

TV STANDARD EUROPE USA

(PAL/50Hz) (NTSC/60Hz)

Number of lines 625 525

Playback Multistandard (PAL/NTSC)

VIDEO FORMAT

DA Converter 10 bits

Signal handling Components

Digital Compression MPEG2 for DVD,

MPEG1 for VCD

DVD

Horiz. Resolution 720 pixels** 720 pixels**

Vertical Resolution 576 lines 480 lines

VCD

Horiz. Resolution 352 pixels 352 pixels

Vertical Resolution 288 lines 240 lines

VIDEO PERFORMANCE

Video output 1 Vpp into 75 ohm

S-Video output Y: 1 Vpp into 75 ohm

C: 0.3 Vpp into 75 ohm

Y 1 Vpp into 75 ohm (U, C, A, R, T)

CR 0.7 Vpp into 75 ohm (U, C, A, R, T)

CB 0.7 Vpp into 75 ohm (U, C, A, R, T)

RGB output 1 Vpp into 75 ohm (B, G)

Black Level Shift On/Off

Video Shift Left/Right

AUDIO FORMAT

Digital MPEG Compressed Digital

DTS Compressed Digital

AC-3 Compressed Digital

PCM

Analog Analog Sound Stereo

Dolby Pro Logic downmix from AC-3

multi-channel sound

3D Sound for virtual 5.1 channel sound

on 2 speakers

AUDIO PERFORMANCE

DA Converter 24 bits

DVD fs 48 kHz 2 Hz - 22 kHz

Video CD fs 44.1 kHz 2 Hz - 20 kHz

CD fs 44.1 kHz 2 Hz - 20 kHz

Signal-Noise (1kHz) 95 dB

Dynamic Range (1kHz) 95 dB

Harmonic Distortion + Noise (1kHz) 0.0035 %

CONNECTIONS

SCART SCART2x (B, G)

S-Video Output Mini DIN, 4 pins

Component Video Y Cinch (green)

(U, C, A, R, T) PB Cinch (blue)

PR Cinch (red)

Video Output Cinch (yellow) (B, G)

Video Output Cinch (yellow) x2 (U, C, A, R, T)

Audio L+R output Cinch (white/red) (B, G)

Audio L+R output Cinch (white/red) x2 (U, C, A, R, T)

Digital Output 1 coaxial, 1 optical

GENERAL

Dimensions(w x h x d) 435 x 91 x 314 mm

Weight Approx. 3.3 Kg

Finish Black color (U, C, A, B, G)

Power supply 120 V, 60 Hz (U)

Power consumption 20 W

Standby mode 5 W (B, G)

PACKAGE CONTENTS

DVD-Video Player, Remote Control & Batteries,

AC Power cord, Owner's Manual, Audio/Video cable (

Audio cable (B, G), Video cable (B, G)

GENERAL FUNCTIONALITY

Stop / Play / Pause

Fast Forward / Backward

Time search

Step Forward / Backward

Slow

Title / Chapter / Track Select

Skip Next / Skip Previous

Repeat (Chapter / Title / All) or (Track / All)

A-B Repeat

Shuffle

Enhanced ease of use graphical interface

Zoom (x1.33, x2, x4) with picture enhancement

3D Sound

Audio and video bit rate indicator

DVD FUNCTIONALITY

Multi-angle Selection

Audio Selection (1 out of max. 8 languages)

Subtitles Selection (1 out of max. 32 languages)

Aspect Ratio conversion (16:9, 4:3 Letterbox, 4:3 Pan Scan)

Parental Control and DISC Lock

Disc Menu support (Title Menu and Root Menu)

Resume (5 discs) after stop / standby

Screen Saver (Dim 75% after 15 min.)

Programming Titles/chapters with Favorite Selection

VIDEO CD FUNCTIONALITY

Playback Control for VCD 2.0 discs

Parental Control and DISC lock

Resume (5 discs) after stop / standby

Screen Saver (Dim 75% after 15 min.)

Programming Tracks with Favorite Selection

AUDIO CD FUNCTIONALITY

Time Display (Total / Track / Remaining Track Time)

Full audio functionality with remote control

Programming with Favorite Track Selection

* typical playing time for movie with 2 spoken languages and 3 subtitle languages.

** equivalent to 500 lines on your TV

IEC958 for CDDA / LPCM

IEC1937 for MPEG1/2, AC-3 and DTS

Gold color (R, G, T)

Titan color (G)

230 V, 50 Hz (B, G)

240 V, 50 Hz (A)

110/120/220/240 V, 50/60 Hz (R)

220 V, 50 Hz (T)

3 W (When low power Standby is on)

U, C, A, R, T

Specifications subject to change without prior notice.

U ........ U.S.A. model C .... Canada model

G........ Europe model B .... British model

A ........ Australia model R .... General model

T ........ China model

),

6

DVD-S510/DV-S5350

TruSurround and the SRS symbol are trademarks of

SRS Labs., Inc. TruSurround technology is

manufactured under license from SRS Labs., Inc.

Manufactured under license from Dolby Laboratories.

“Dolby” and the double-D symbol are trademarks of

Dolby Laboratories. Confidential Unpublished Works.

©1992 – 1997 Dolby Laboratories, Inc. All rights

reserved.

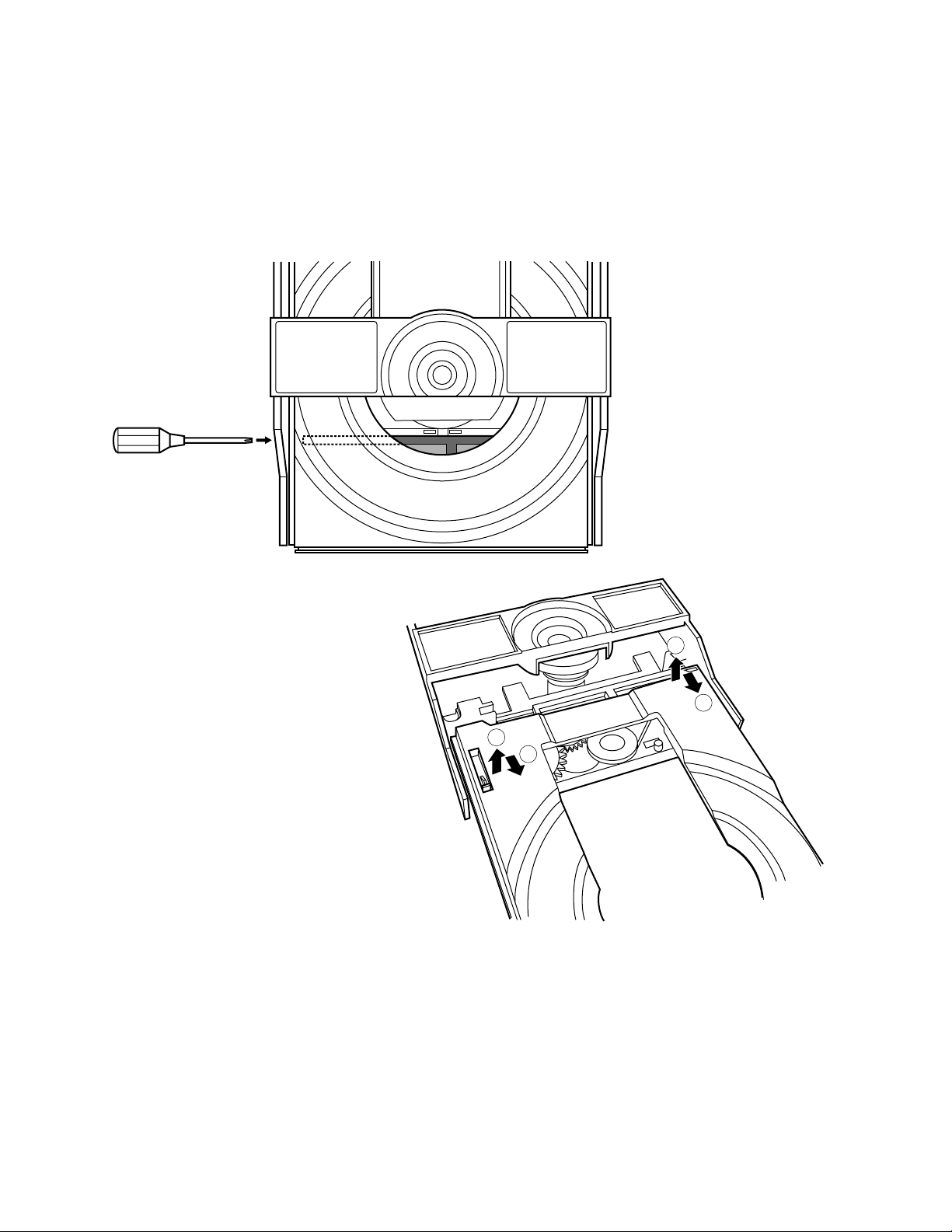

■ DISASSEMBLY PROCEDURES

See exploded view for item numbers.

When disassembling, use the special screw driver with tip

shape in figure.

This product incorporates copyright protection

technology that is protected by method claims of

certain U. S. patents and other intellectual property

rights owned by Macrovision Corporation and other

rights owners. Use of this copyright protection

technology must be authorized by Macrovision

Corporation, and is intended for home and other

limited viewing uses only, unless otherwise

authorized by Macrovision Corporation. Reverse

engineering or disassembly is prohibited.

* Manufactured under license from Digital Theater Systems,

Inc. US Pat. No. 5,451,942 and other world-wide patents

issued and pending. "DTS", "DTS Digital Surround", are

trademarks of Digital Theater Systems, Inc. copyright 1996

Digital Theater Systems, inc. All rights reserved.

Front panel ass'y

⇒ open tray

⇒ remove cover tray 19

⇒ remove 2 screws 35

(front panel 1 → frame)

⇒ unlock front panel from

frame by releasing

successively 4 snaps ( on

the left, on the bottom and

on the right) with taking care

to avoid breaking snaps.

⇒ remove 2 connectors (on

mono board and on P.S.U.)

⇒ put front panel ass'y

Top Cover 32

⇒ Remove 7 screws 33

⇒ Lift cover at rear side to

remove

DVD MODULE

⇒ Remove tray 11 of

DVD Mechanism

⇒ Remove connections to

Mono board

⇒ remove 4 screws 35

⇒ demount module

DVD MONO Board 18-2

⇒Remove flex connections to

turntable motor and sledge

motor.

⇒remove 4 screws (mono

board 18-2 → DVD

mechanism 18-1)

⇒remove carefully flex

connection to OPU and wire

connection to tray motor.

⇒demount board.

mounting

↑

↓

demounting

A/ V board 52

⇒ remove flex connections to

Mono board

⇒ remove 7* screws 35, 36

* 5 screws (B, G model)

⇒ release snaps of 2 spacers

⇒ demount board

Power supply unit 55

⇒remove connections

⇒remove 2 screws 35

(board → frame)

⇒remove screw 36 (mains

inlet → rear panel)

⇒release snaps of 2 spacers

(board → frame)

⇒demount board

Display board 53

⇒ Remove 7 screws 36

(board → front), pay

attention to earth spring.

⇒ demount board

7

Standby board and

switch ass'y

⇒Remove 2 screws 36

( board → front)

⇒demount board

⇒Remove 1 screw 36

⇒Take out switch ass'y

2.7 mm for screws with 33, 35 and 36

1.7 mm for removing MONO board (18-2) from

DVD Mechanism (18-1)

● The way to remove tray

1. Push left end of the lever under the tray toward the right

by using screwdriver, move the tray by pulling it

forward. (Fig. 1)

2. While lifting up the lever (1), move the left side of the

tray by pulling it forward (2). (Fig. 2)

3. While lifting up the tray (3), remove the tray by pulling it

forward (4). (Fig. 2)

DVD-S510/DV-S5350

Fig. 1

3

4

1

2

Fig. 2

■ SERVICE HINTS

Diagnostic software

In chapter “Diagnostic software”, some tests are refering

to the SCART functionality.

These tests are for sets with RGB-output.

For sets without RGB-output, no SCART connector is

mounted.

In these sets, the SCART tests will automatically be

skipped.

8

DVD-S510/DV-S5350

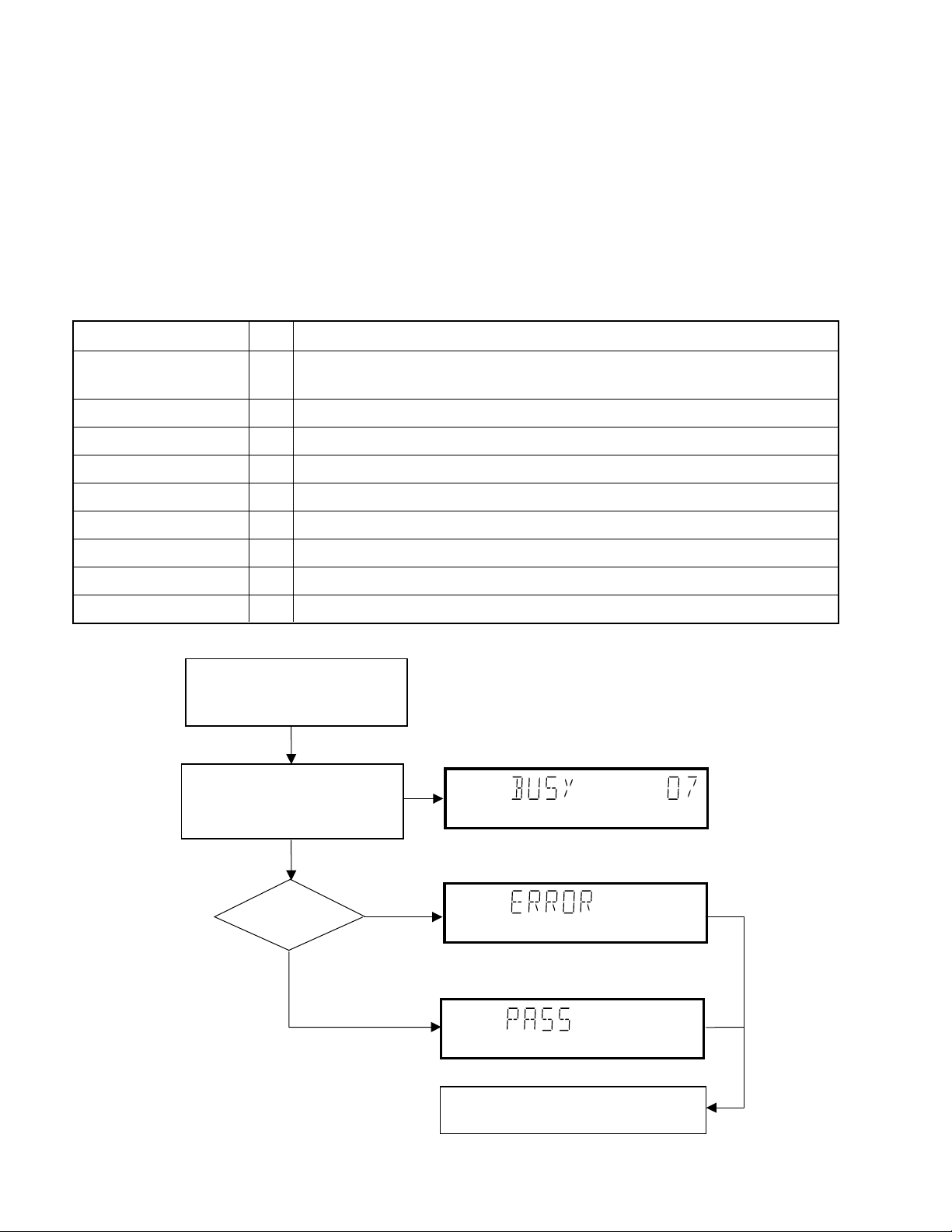

■ DIAGNOSTIC SOFTWARE : SCRIPT INTERFACES

1. DEALER SCRIPT

1.1 Purpose of Dealer Script

The dealer script can give a diagnosis on a standalone

DVD player; no other equipment is needed to perform a

number of hardware tests to check if the DVD player is

faulty. The diagnosis is simply a "error" or "pass"

message; no indication is given of faulty hardware

modules. Only tests within the scope of the diagnostic

software will be executed hence only faults within this

scope can be detected.

Nucleus Description

VideoColSetupComm 9 Checks the I2C interface with the RGB video processor on the Audio/Video board

(only for DVD players with RGB video processor).

VideoScartSwComm 8 Checks the I2C interface with the scart switch on the Audio/Video board

PapChksFl 7 Calculate and verify checksum of FLASH memory.

PapDramWrR 6 Pattern test of all locations in the DRAM(s).

1.2 Contents of Dealer Script

The dealer script executes all diagnostic nuclei that do not

need any user interaction and are meaningful on a

standalone DVD player.

The nuclei called in the dealer script are the following (the

number after each nucleus name corresponds with the

number being on the local display when the nucleus is

executed during the dealer script):

PapI2cDisp 5 Checks the I2C interface with the slave processor on the display PCB.

PapS2bEcho 4 Checks the I2C interface to the basic engine.

PapI2cNvram 3 Checks the I2C interface with the NVRAM.

PapNvramWrR 2 Pattern test of all locations in the NVRAM

CompSdramWrR 1 Pattern test of all locations in the SDRAM(s).

Press 2 keys simultaneously

<OPEN/CLOSE> + <PAUSE>

Connect to mains.

During the test, the following display

is shown: the counter counts down

from the number of nuclei to be run

before the test finishes. Example:

SET O.K.?

NO

YES

To exit DEALER SCRIPT ,disconnect from mains.

9

s

2. PLAYER SCRIPT

2.1 Purpose of Player Script

The Player script will give the opportunity to perform a test

that will determine which of the DVD player's modules are

faulty, to read the error log and error bits and to perform an

endurance loop test. To successfully perform the tests, the

DVD player must be connected to a TV set to check the

output of a number of nuclei. For DVDv2b a multi-channel

amplifier, a set of 6 boxes and an external video source

are necessary to test. To be able to check results of

certain nuclei, the player script expects some interaction

of the user (i.e. to approve a test picture or a test sound).

Some nuclei (e.g. nuclei that test functionality of the Basic

Engine module) require that the DVD player itself is

opened, to enable the user to observe moving parts and

approve their movement visually. Only tests within the

scope of the diagnostic software will be executed hence

only faults within this scope can be detected.

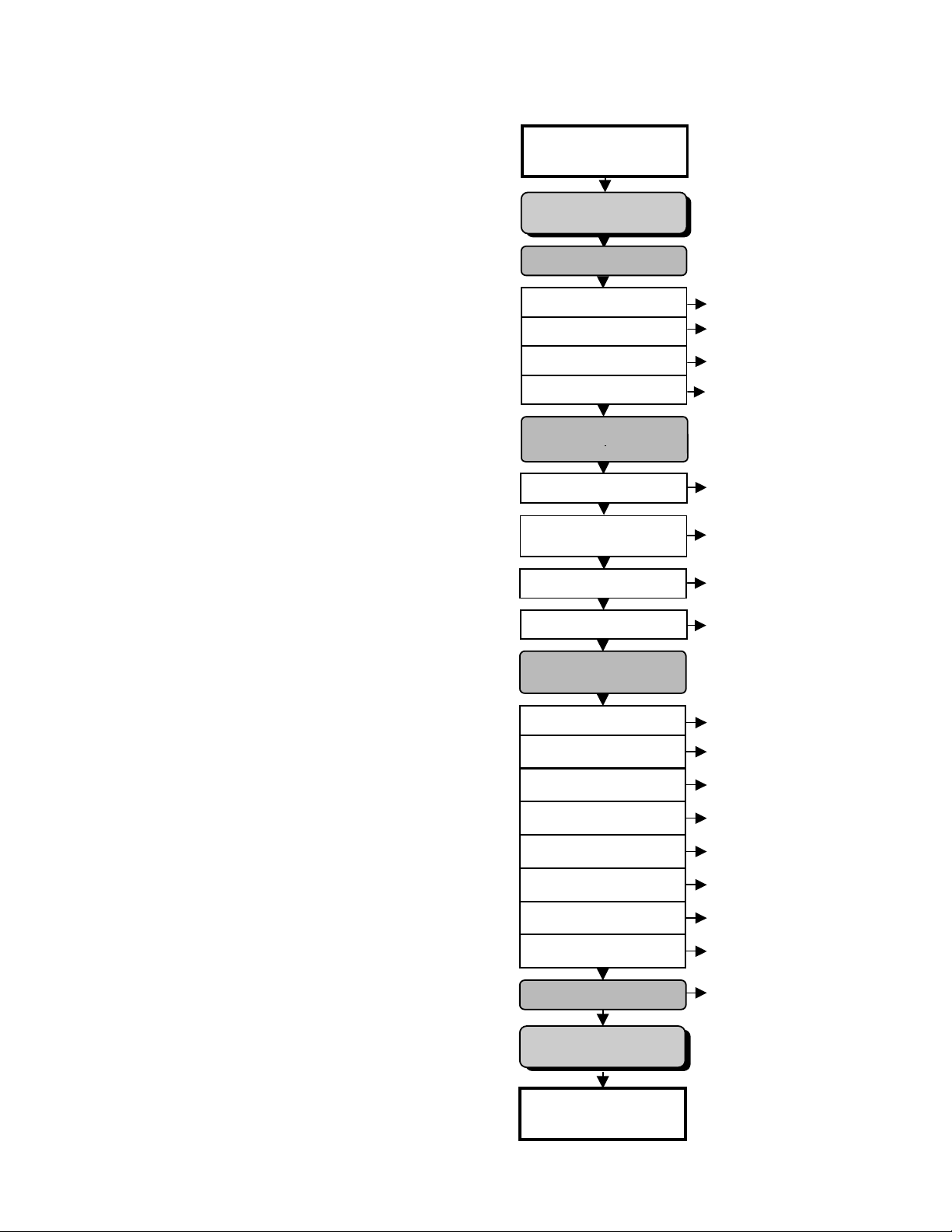

2.4 Survey

Press 2 keys simultaneously

<OPEN/CLOSE> + <STOP>

Connect to main

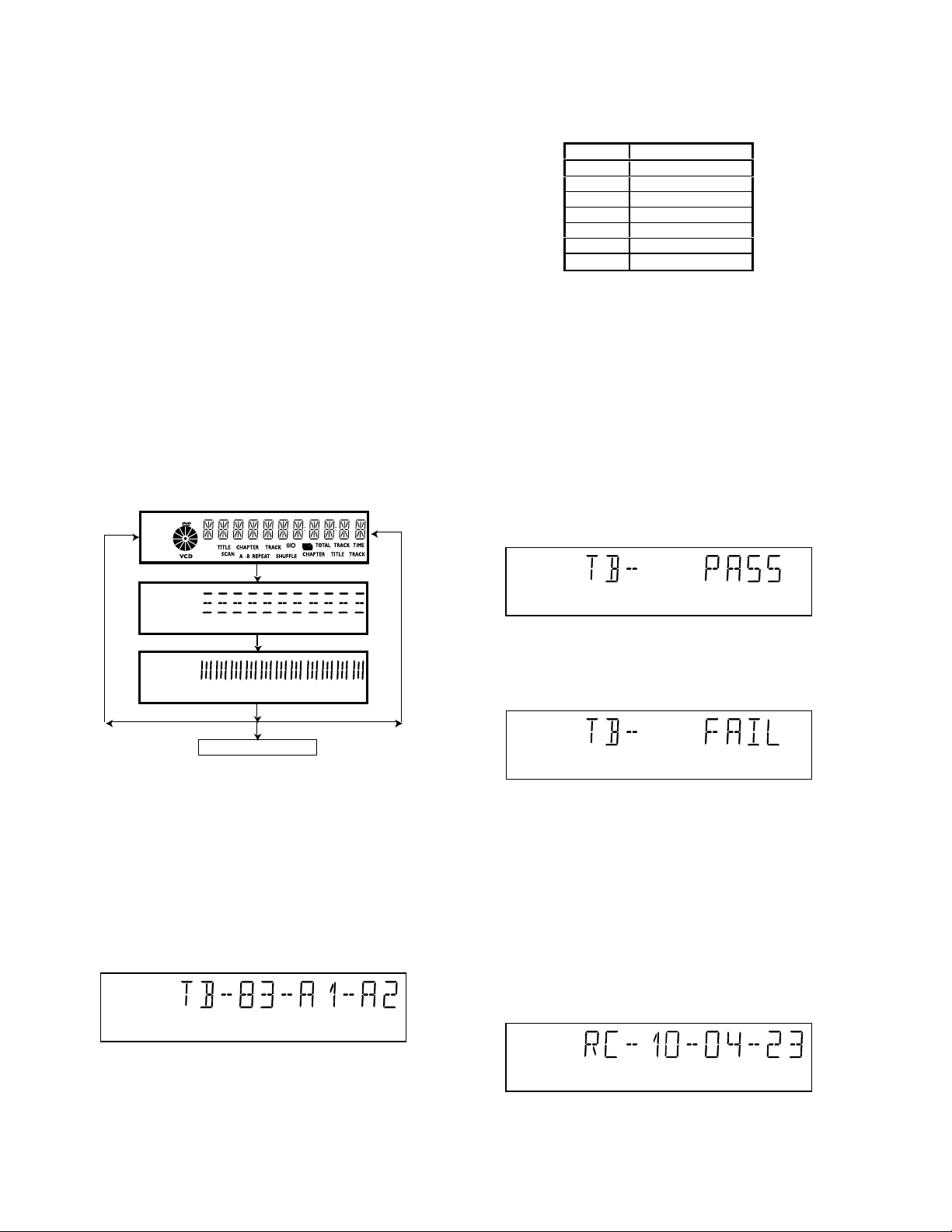

INTERACTIVE TESTS

DISPLAY PCB

DISPLAY TEST

LED TEST

KEYBOARD TEST

REMOTE CONTROL

DVD-S510/DV-S5350

DispDisplay(30)

DispLed(29)

DispKeyb(27)

DispRc(28)

2.2 Contents of Player Script

The player script contains all nuclei that are useful on a

DVD player that is connected to a TV-set and help to

determine which module of the DVD player is faulty, as

well as to read out the contents of the error logs.

2.3 Structure of Player Script

The player script consists of a set of nuclei testing the

three hardware modules in the DVD player: the Display

PWB, the Digital PWB and the Basic Engine.

Nuclei run by the player test need some user interaction;

in the next paragraph this interaction is described. The

player test is done in two phases:

1. Interactive tests: this part of the player test depends

strongly on user interaction and input to determine

nucleus results and to progress through the full test.

Reading the error log and error bits information can be

useful to determine any errors that occurred recently

during normal operation of the DVD player.

2. The loop test will perform the same nuclei as the dealer

test, but it will loop through the list of nuclei indefinitely.

MONO PCB

DIGITAL PART

PICTURE TEST

SOUND 1 TEST

SCART DVD TEST

SCART LOOP TEST

SOUND 2 TEST

MONO PCB(SERVO)

& BASIC ENGINE

VERSION NUMBER

TRAY TEST

SLEDGE TEST

DISC MOTOR TEST

FOCUS TEST

VideoColDencOn(23a)

AudioPinkNoiseOn(20a)

VideoScartSwDvd(54a)

VideoScartSwPass(54b)

AudioSineOn(21a)

BeVer(37)

BeTrayOut/In(43ab)

BeSledgeOut/In(41ab)

BeDiscMotorOn(39a)

BeFocusOn(38a)

RADIAL TEST

JUMP TEST

TRAY TEST

ERROR LOG & BITS

LOOP TEST

To exit player test,

disconnect from mains

BeRadialOn(40a)

BeGroovesIn/Mid/Out(42abc)

BeTrayOut/In(43ab)

LogReadErr(31)

LogReadbits(32)

= Dealer script exclusive of test2

10

DVD-S510/DV-S5350

■ INTERACTIVE TESTS

1. DISPLAY PCB

1.1 DISPLAY TEST

The display test is performed by nucleus DispDisplay. By

putting a series of test patterns on the local display, the

local display is tested. To step through all different

patterns, the user must either press PLAY (pattern is ok)

or PAUSE (pattern was incorrect) to proceed to the next

pattern. The display of patterns is continued in a cyclic

manner until the user presses NEXT. If the user presses

NEXT before all display patterns are tested, the

DispDisplay nucleus will return TRUE (display test

successful).

1.2 LED TEST

The LED(s) on the DVD player is (are) tested by nucleus

DispLed. The user must check if the LED(s) is (are)

lighted; if it is, press PLAY, if it is not, press PAUSE. By

pressing NEXT the script will proceed to the next test. If

the user presses NEXT before PLAY or PAUSE, the

DispLed nucleus will return TRUE (LED test successful).

key id. key

0PLAY

1NEXT

2 PREVIOUS

3 PAUSE

4STOP

5 OPEN / CLOSE

A POWER

(B, G models)

Figure 3

If any keys are detected more than once (due to hardware

error), the key-code is displayed twice (or more), with the

second digit increased by 1.

If the user does not press all keys minimally once (in any

order), the DispKeys nucleus will return FALSE and cause

an error in the overall result of the player script.

The user can leave the keyboard test by pressing the

NEXT key on the local display of the DVD player for at

least one full second.

The result of the keyboard test is shown on local display

as follows:

If OK, press PLAY If NOK, press PAUSE

If OK, press PLAY If NOK, press PAUSE

If OK, press PLAY If NOK, press PAUSE

press NEXT to continue

Figure 1

1.3 KEYBOARD TEST

The keyboard of the DVD player is tested by nucleus

DispKeyb. The user is expected to press all keys on the

local keyboard once. The code of the key pressed is

shown on the local display (1 hexadecimal digit)

immediately followed by a (hexadecimal) number

indicating how many times that key has been pressed.

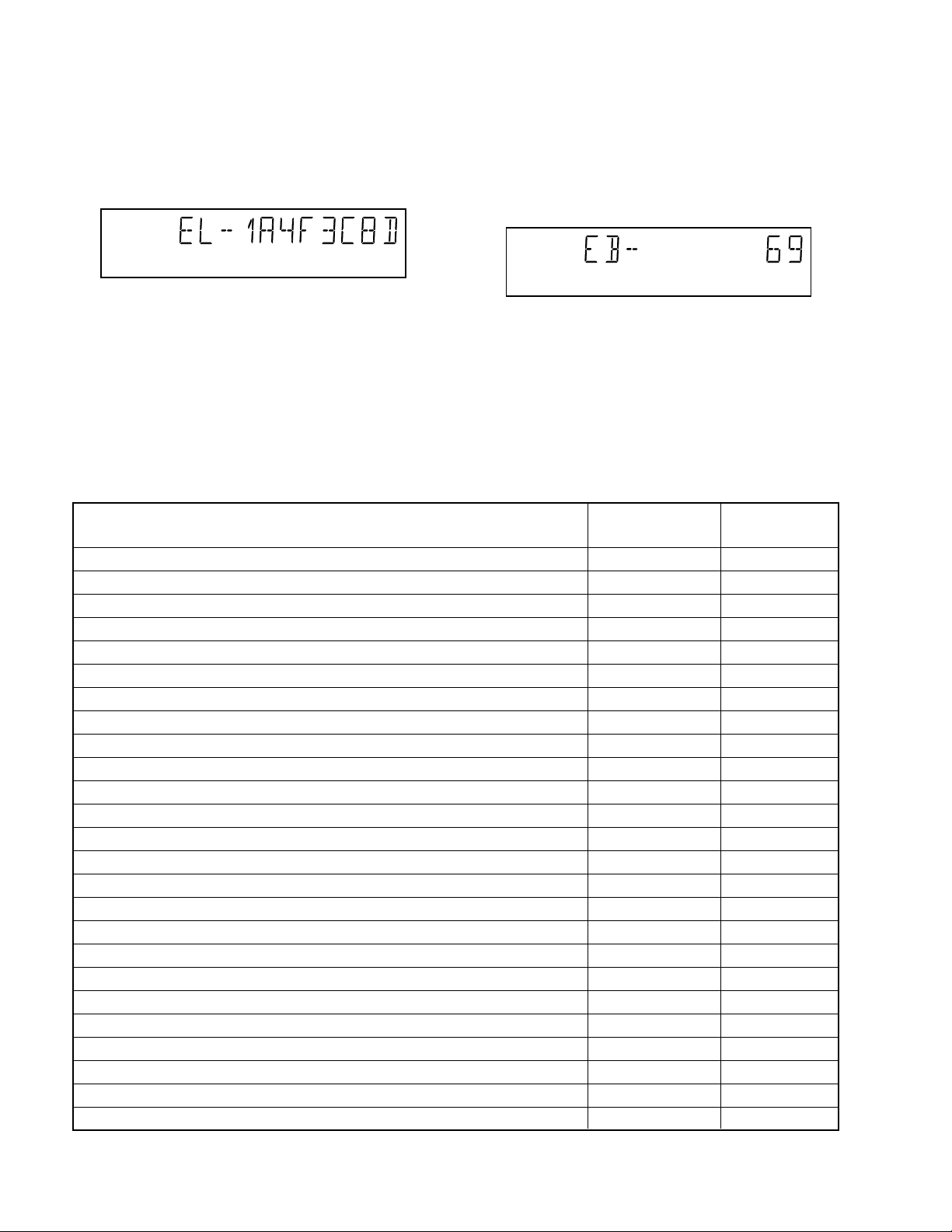

Example of the local display during this test:

Figure 4

Or

Figure 5

Pressing NEXT on the local keyboard again will proceed

to the next text.

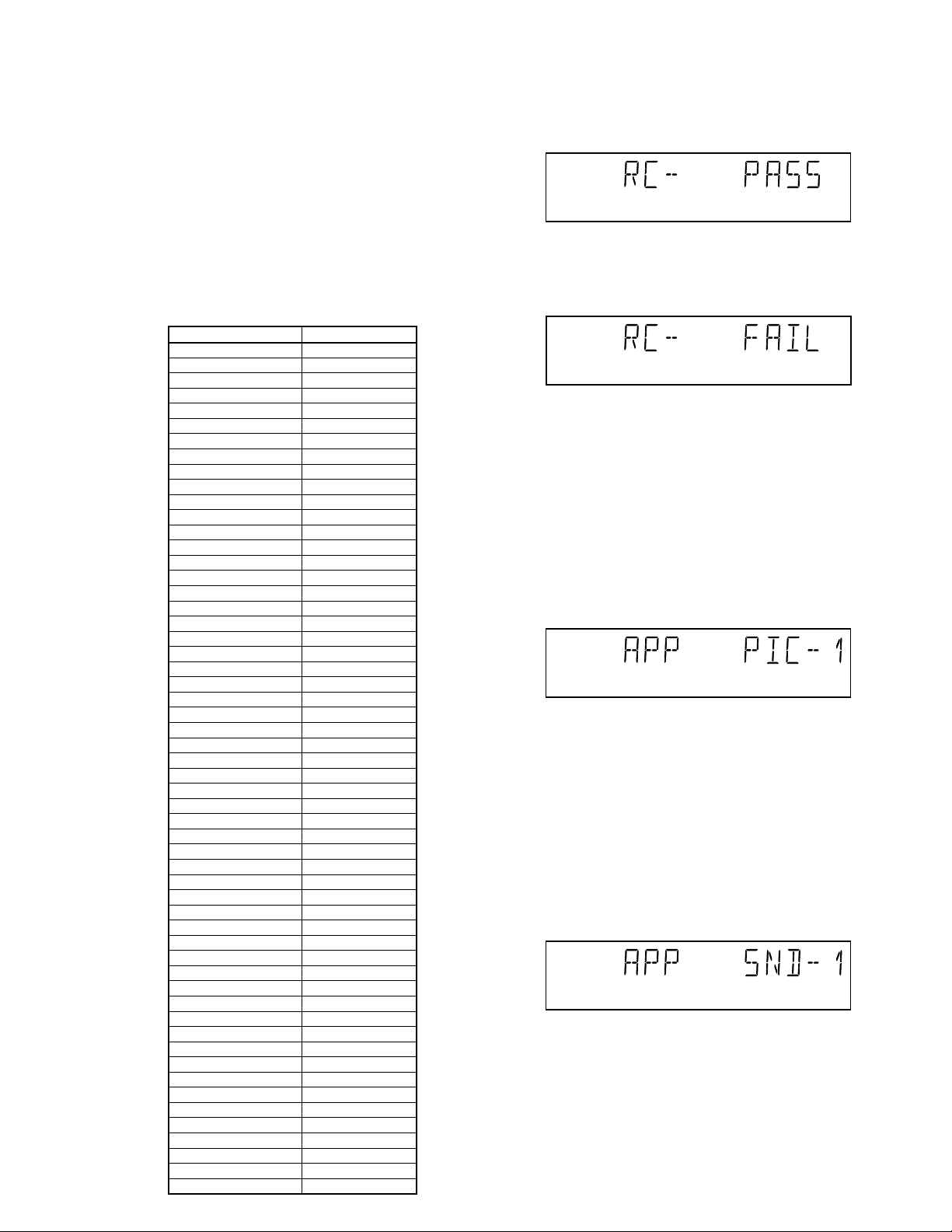

1.4 REMOTE CONTROL TEST

The remote control of the DVD player is tested by nucleus

DispRc. The user must press any key on the remote

control just once. The codes of the key pressed will be

shown on the local display in hexadecimal format.

Example:

Figure 2

The key-codes displayed on the local display will scroll

from right to left when the display gets full, the text "tb-" will

remain on display.

11

Figure 6

DVD-S510/DV-S5350

In this example 23 is the hexidecimal code of the pressed RC

key. The user can leave the remote-control test by pressing

NEXT on the local keyboard of the DVD player. The remote

control test is successful if a code was received before the

user pressed the NEXT key; pressing the NEXT key before

pressing a key on the remote control gives an error in the

remote control test (note that the remote control test will also

fail if a key on the remote control was pressed but no code

was received). The remote control test does not check upon

the contents of the received code, that is it will not be checked

if the received code matches the key pressed. If desired, the

user can manually check this code by using a code-table for

the remote control key-codes.

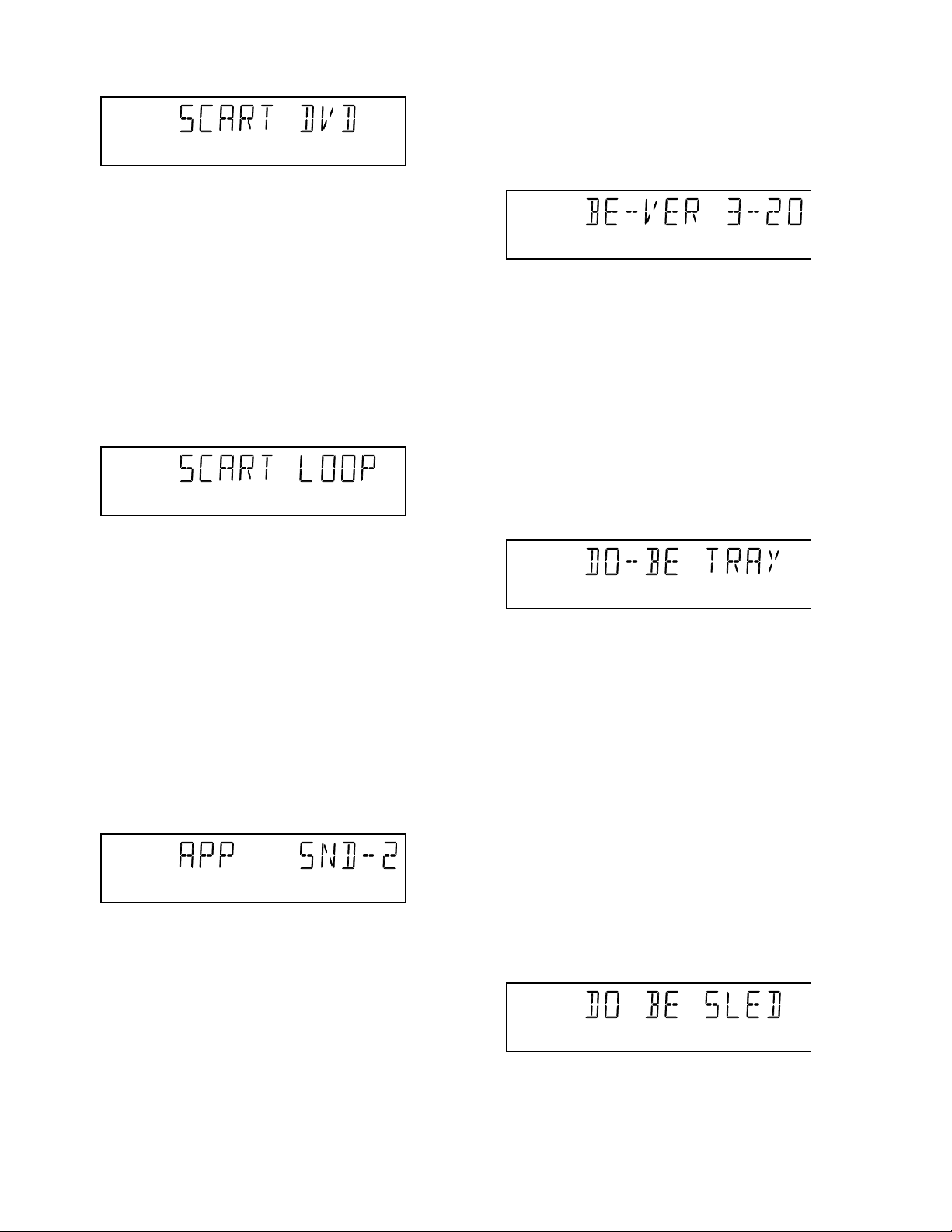

RC Key id Hexadecimal code

STANDBY

STOP

PLAY

PLAY BACKWARD

PAUSE

STEP FORWARD

STEP BACKWARD

FORWARD

FORWARD 4X

FORWARD 8X

BACKWARD

BACKWARD 4X

BACKWARD 8X

SLOW

SLOW 2

SLOW BACKWARD

SLOW BACKWARD 2

NEXT

PREVIOUS

CURSOR UP

CURSOR DOWN

CURSOR LEFT

CURSOR RIGHT

OK

0

1

2

3

4

5

6

7

8

9

TITLE/CHP

ANGLE

AUDIO

SUBTITLES

SUBTITLE ON/OFF

ROOT MENU

TITLE MENU

MENU

SETUP MENU

ON SCREEN

RETURN

RESUME

SCAN

SHUFFLE

REPEAT

A/B REPEAT

TOGGLE SCART

OPEN/CLOSE

FTS

KARAOKE

OPTION

ZOOM

C

31

2C

2D

30

F6

F5

28

DF

E0

29

DE

DD

22

D8

23

DB

20

21

58

59

5A

5B

5C

0

1

2

3

4

5

6

7

8

9

C8

85

4E

4B

E3

54

71

D1

82

F

83

D7

2A

1C

1D

3B

43

42

FB

E4

FA

F7

Figure 7

After pressing NEXT, the result of the remote control test

is displayed on the local display of the DVD player as

follows:

Figure 8

Or

Figure 9

Pressing NEXT on the local keyboard again will proceed

to the next test.

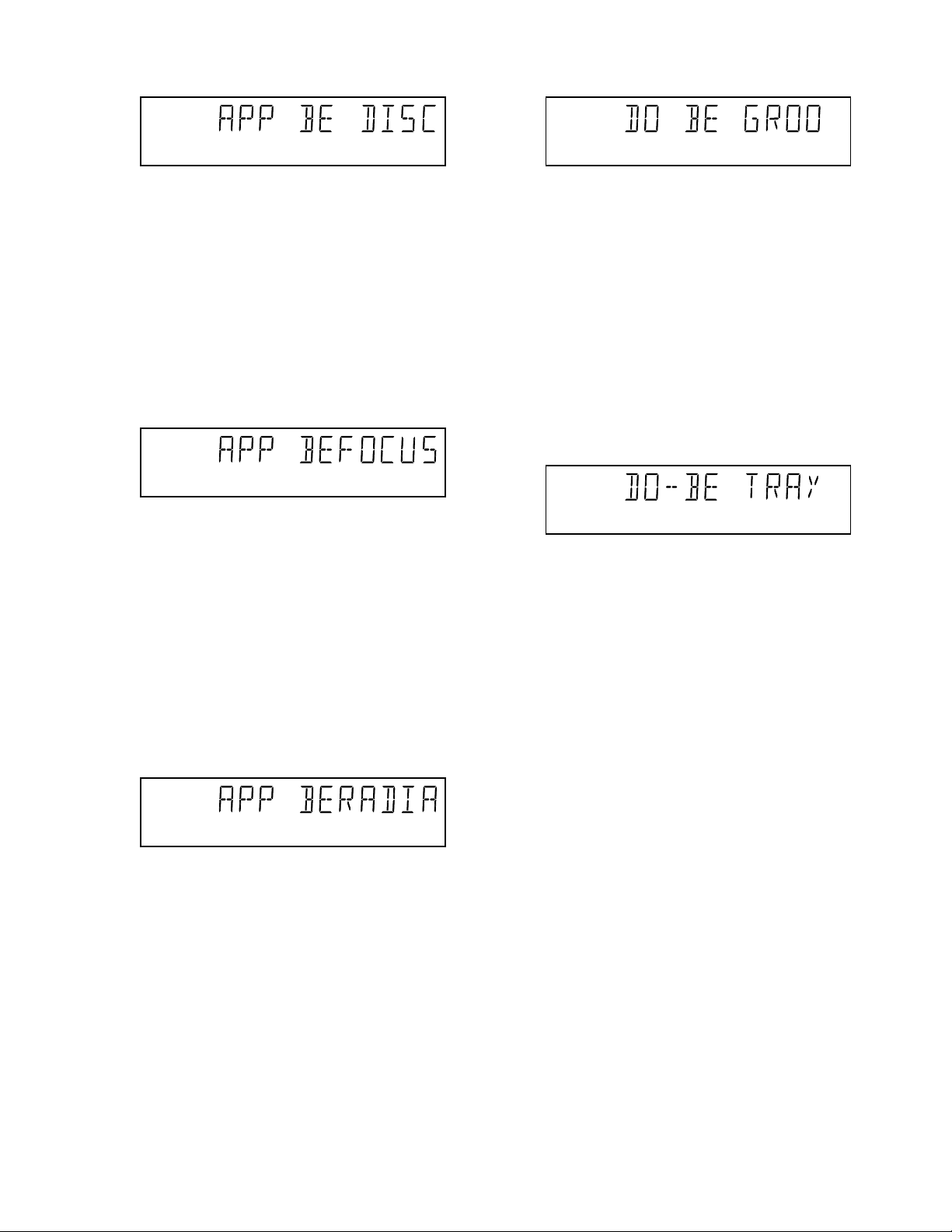

2 MONO PCB DIGITAL PART

2.1 PICTURE TEST

The picture test is performed by putting a predefined

picture (colour bar) on the display (nucleus

VideoColDencOn) and asking the user for confirmation.

The display shows the following message:

Figure 10

By pressing PLAY, the user confirms the test; pressing

PAUSE will indicate the picture was invisible or incorrect.

Pressing NEXT will proceed to the next test

2.2 SOUND 1 & SCART DVD TEST

The first soundtest is performed by starting a pink noise

sound that needs confirmation from the user (nucleus

AudioPinkNoiseOn); the display shows the following

message very shortly:

Figure 11

This sound will only be audible from version cut3.1 of

Sti5505(item7503 on mono board) onwards. After starting

up sound 1, SCART loop-trough will be simultaneously

active during this test. SCART loop-trough will be

measured with the aid of an external video source.

When entering the SCART loop-trough, the local display

indicates:

12

DVD-S510/DV-S5350

Figure 12

On the TV screen, a colour bar (generated by nucleus

VideoColDencOn) is visual and the internally generated

pinknoise is audible. By pressing PLAY, the user confirms

the test; pressing PAUSE will indicate the sound was

inaudible or incorrect. Pressing NEXT will proceed to the

next test; if the user presses NEXT without pressing PLAY

or PAUSE first, the result of this test will be TRUE (sound

ok). By pressing the NEXT button, there will be switched

over to the external source, this must become now visible

on the TV screen (using the SCART). The local display

indicates:

3 BASIC ENGINE

note) Basic engine means DVD mechanism.

3.1 VERSION NUMBER

In the basic engine tests, the version number of the Basic

Engine will be shown first, as the following example:

Figure 15

By pressing the NEXT key, the Basic Engine tests are

started.

3.2 TRAY TEST

First, the tray is tested. The purpose of this test is also to

give the user the opportunity to put a disc in the tray of the

DVD player. Some tests on the Basic Engine require that a

disc (e.g. DVD MPTD test disc) is present in the player. At

the end of the Basic Engine tests, this tray test will be

repeated solely to enable the user to remove the disc in

the tray. The local display looks as follows:

Figure 13

The internally generated colour bar is still available on the

CVBS and Y/C outputs. And the pinknoise-signal is still

available on the cinch audio outputs. By pressing the

PREV button, the internal generated colour bar becomes

visual again.

The test can be left by pressing the NEXT key for more

than one second.

2.3 SOUND 2 TEST

The second soundtest is performed by producing a sine

sound (nucleus AudioSineOn). The signal can be stopped

by pressing the STOP-key. The display shows the

following message:

Figure 14

By pressing PLAY, the user confirms the test; pressing

PAUSE will indicate that something went wrong. Pressing

NEXT will proceed to the next; if the user presses NEXT

without pressing PLAY or PAUSE first, the result of this

test will be TRUE (sound ok).

Figure 16

By pressing PLAY or PAUSE, the user can toggle the

position of the tray. Note that this test will not contribute to

the test result of the Basic Engine. Pressing NEXT will

proceed to the next test, after the tray has been closed (by

the software) if it was open.

3.3 SLEDGE TEST(visual test)

The second Basic Engine test tests the sledge; the user

can move the sledge as many times as desired by using

PLAY (nucleus BeSledgeOut) and PAUSE (nucleus

BeSledgeIn).

Pressing NEXT on the local keyboard proceeds to the next

test.

Note that this test will not contribute to the test result of the

Basic Engine. The local display looks as follows during the

sledge test:

13

Figure 17

3.4 DISC MOTOR TEST(visual test)

The third Basic Engine test tests the disc motor (nucleus

BeDiscMotorOn); the local display looks as follows:

DVD-S510/DV-S5350

Figure 18

By pressing PLAY, the user confirms that the disc motor is

running; pressing PAUSE indicates the disc motor does

not work. Pressing NEXT proceeds to the next test, after a

reset of the disc motor (nucleus BeDiscMotorOff). If the

user presses NEXT before pressing PLAY or PAUSE, the

result of this test will be TRUE (disc motor is running).

3.5 FOCUS TEST(visual test)

The fourth Basic Engine test tests the focussing; first

focussing is turned on by calling nucleus BeFocusOn. The

display looks as follows:

Figure 19

By pressing PLAY, the user confirms that the focussing

was succesful; pressing PAUSE indicates a focussing

failure.

Pressing NEXT proceeds to the next test after a reset of

the focussing (nucleus BeFocusOff); if NEXT is pressed

before PLAY or PAUSE, the result of this test will be TRUE

(focus successful).

Figure 21

The user can switch between the three different types of

groove settings by pressing PLAY (forward to next

nucleus in the list In-Mid-Out) or PAUSE (backward in the

list In-Mid-Out).

This is done in a cyclic manner; note that this test will not

contribute to the test result of the Basic Engine. Pressing

NEXT proceeds to the next test, after the disc motor has

been shut off with a call to nucleus BeDiscMotorOff.

3.8 TRAY TEST

As a last action for the Basic Engine tests, the tray test is

repeated. The local display looks as follows:

Figure 22

This test is meant to give the user the opportunity to

remove the disc in the tray. The tray position can be

toggled using the PLAY and PAUSE key. The tray will be

closed (by the software, if it is open) before proceeding to

the next test when the user presses the NEXT key.

3.6 RADIAL TEST(visual & listening test)

The fifth Basic Engine test tests the radial functionality

(nucleus BeRadialOn); the local display looks as follows:

Figure 20

By pressing PLAY, the user confirms that the radial

function worked; pressing PAUSE indicates the function

does not work.

Pressing NEXT proceeds to the next test, after a reset of

the radial (nucleus BeRadialOff). If the user presses NEXT

before pressing PLAY or PAUSE, the result of this test will

be TRUE (radial successful).

3.7 JUMP TEST(listening test)

The sixth and last Basic Engine test tests the jumping by

calling nuclei BeGroovesIn, BeGroovesMid and

BeGroovesOut.

During this test, the local display looks as follows:

14

DVD-S510/DV-S5350

3.9 ERROR LOG

Reading the error log and error bits information can be

useful to determine any errors that occurred recently

during normal operation of the DVD player. Reading the

error log is done by nucleus LogReadErr. The display

during the errorlog readout looks as follows :

Figure 23

By pressing PLAY or PAUSE, the user can move forward

or backward (respectively) through the logged error

codes. The highlighted number indicates which errorcode

is currently on display (in the example above, errorcode

number 4 is displayed). If "0000" is displayed at all

positions, the error log is empty. Display of the logged

errors is done in a cyclic manner.

Error log / bits table

Basic engine errors Value: Value:

Command to the Basic Engine not allowed in this state or unknown command 150101 8

Parameter(s) from the command to the Basic Engine is not valid 150102 7

Sledge could not be moved to the inner home position 150103 6

Focus failure 150104 5

Turntable motor speed could not be reached within timeout 150105 4

Radial servo could not get on track on the disc 150106 3

PLL could not lock in the accessing or tracking state 150107 2

Subcode or sector information could not be read 150108 1

requested subcode could not be found 150109 16

Tray could not be closed or opened completely 15010A 15

TOC could not be read within timeout 15010B 14

The requested seek on the disc could not be executed 15010C 13

A requested lead-in is not on the disc 15010D 12

A non existing burst cutting area is requested 15010E 11

S2b communication error 1501F0 10

S2b communication error 1501F1 9

S2b communication error 1501F3 24

S2b communication error 1501F4 23

S2b communication error 1501F5 22

Digital PWB errors

Communication error with the Sti 5505 90000 32

Communication error with the Sti 5505 90001 31

Disply processor errors

Communication error with the display processor 190000 40

The errorcode with the lowest highlighted number is the

most recent. By pressing NEXT on the local keyboard, the

user can proceed to the next test.

3.10 ERROR BITS

Reading the error bits is done by nucleus LogReadBits.

The display during the errorbits readout looks as follows:

Figure 24

Only the set errorbits will be shown by their (decimal)

number.

Refer to the appropriate documentation for the

explanation of each bit number. If the display only shows

"EB-0", no error bits were set. By pressing NEXT, the user

can continue to the next test.

See table below:

Read ERROR LOG Read ERROR BITS

in player script in player script

15

DVD-S510/DV-S5350

4. LOOP TEST

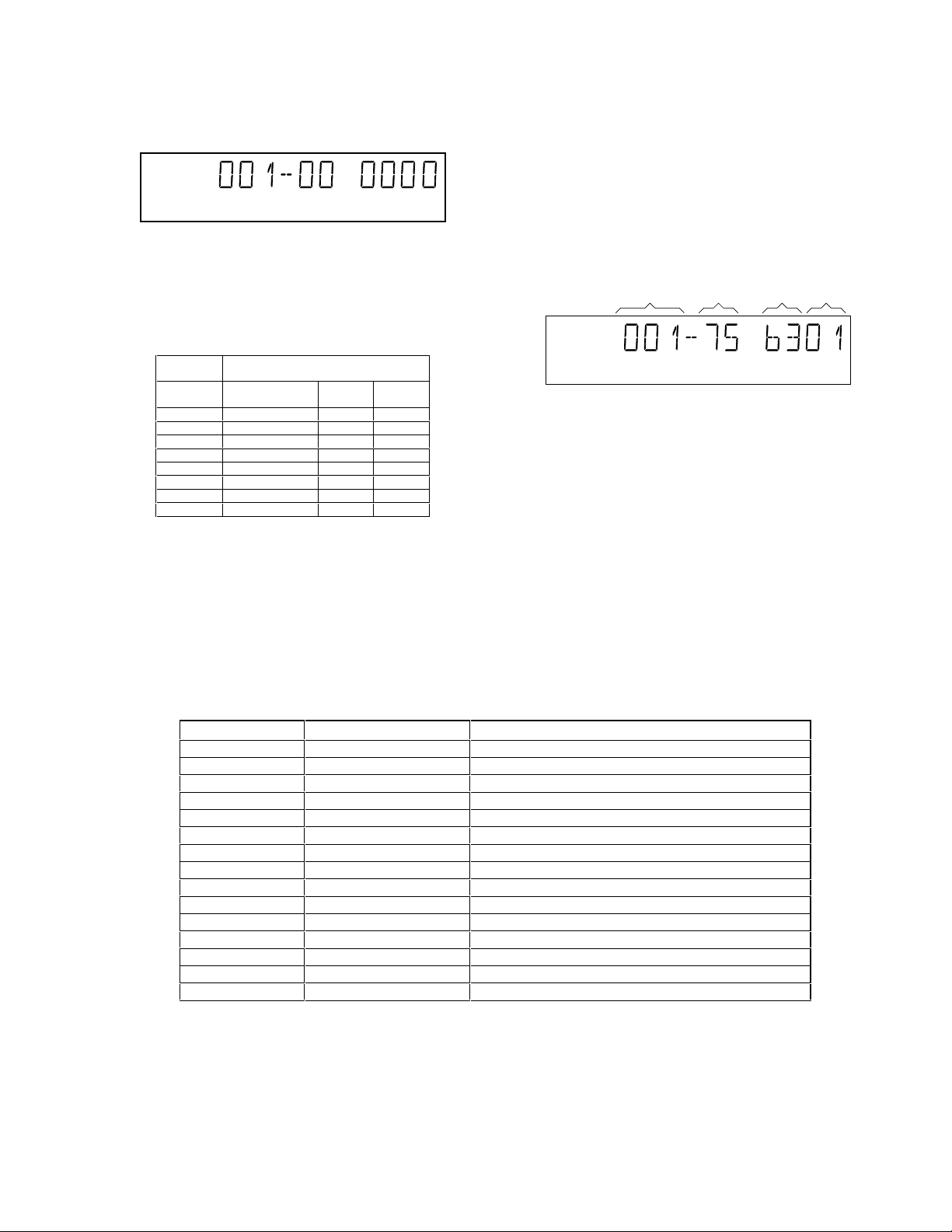

At the start of the loop test, the display will show the result

of the interactive player test:

Figure 25

The left side of the display contains a 3-digit code, which

can have a value between 000 and 111. These values are

to be interpreted as follows:

Displayed

Value

000 ok ok ok

001 ok ok faulty

010 ok faulty ok

011 ok faulty faulty

100 faulty ok ok

101 faulty ok faulty

110 faulty faulty ok

111 faulty faulty faulty

Indication for each module

Basic Engine Mono

PCB

Figure 26

Display

PCB

The loop test will perform the same nuclei as the dealer

test, but it will loop through the list of nuclei indefinitely.

The display of the DVD player will display not only the

three digits indicating correct/faulty modules and the last

found error code (as mentioned, faults are detected as far

as they can be within the scope of the diagnostic

software), but also a loop counter indicating how many

times the loop has been gone through.

Example:

FAULTY

MODULE(S)

LOOP

COUNTER NUCLEUS ERROR

Figure 27

The number after the hyphen indicates the number of

times the loop test has been performed; the 4 digits at the

right side of the display show the last error that was found

when running the loop test: the leftmost two digits of this

code indicate which nucleus resulted in a fault; the

rightmost two digits refer to the faultcode within that

nucleus. For further explanation of this error code, see list

of error codes below.

ERROR CODES LOOP TEST

ERROR CODE NUCLEUS NUMBER ERROR DESCRIPTION

0601

0901

1104

1102

1103

1104

1201

1202

1203

1204

1301

1302

1303

1304

1601

6 Calculated checksum of FLASH is not correct

9 The DVD DRAM is faulty

11 I2C bus busy before start

NVRAM access time-out

No NVRAM Acknowledge

NVRAM reply time-out

12 I2C bus busy

I2C bus not working

Slave controller not responding

Slave response is not correct

13 Parity error from basic engine to serial

Parity error from serial to basic engine

No communication between serial and basic engine

Communication time-out error

16 The SDRAM is faulty

Figure 28

16

DVD-S510/DV-S5350

5. Servicing DVD module and MONO board

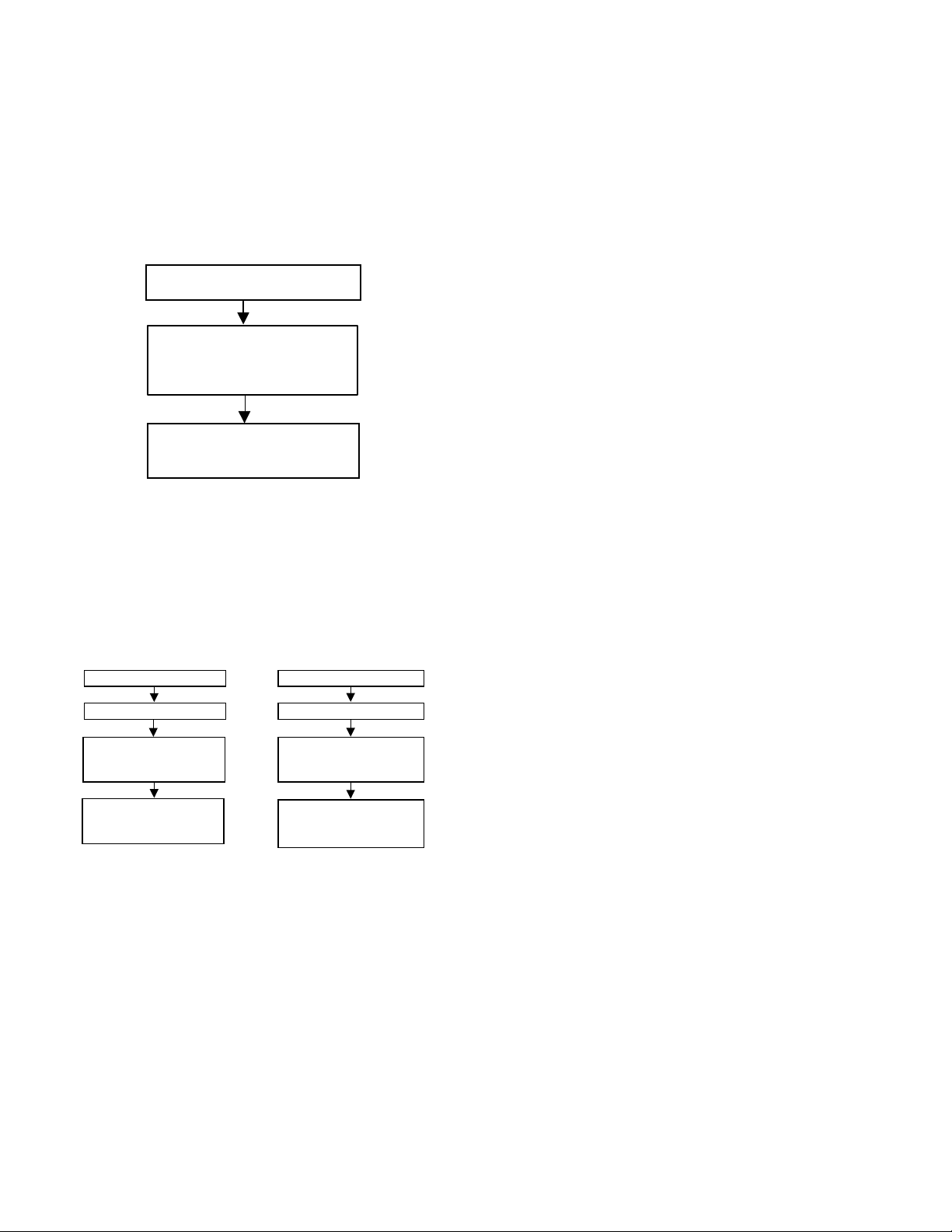

5.1 Reset of Virgin Mode

After the player has been powered up for test by the

dealer, it would have gone through the Virgin Mode. It is

possible to reset the settings made during that mode

before the delivery of player to the customer. This can be

done as shown in the following diagram:

DISCONNECT FROM MAINS

PRESS 2 KEYS

SIMULTANEOUSLY

<PLAY> + <OPEN/CLOSE>

CONNECT TO MAINS

VIRGIN MODE IS RESET

TV SCREEN SHOWS

VIRGIN MODE MENU

Figure 29

5.2 Trade Mode

When the player is in Trade Mode, the player cannot be

controlled by means of the front key buttons, but only by

means of the remote control.

IF TRADE MODE OFF

DISCONNECT FROM MAINS

PRESS 2 KEYS

SIMULTANEOUSLY

<PREVIOUS> + <OPEN/CLOSE> <PREVIOUS> + <OPEN/CLOSE>

CONNECT TO MAINS

PLAYER IS IN TRADE MODE

WHEN PRESSING FRONT

KEYS, THE PLAYER

DOESN'T RESPOND

IF TRADE MODE ON

DISCONNECT FROM MAINS

PRESS 2 KEYS

SIMULTANEOUSLY

CONNECT TO MAINS

PLAYER IS IN NORMAL MODE

WHEN PRESSING FRONT

KEYS, THE PLAYER WILL

RESPOND

Figure 30

17

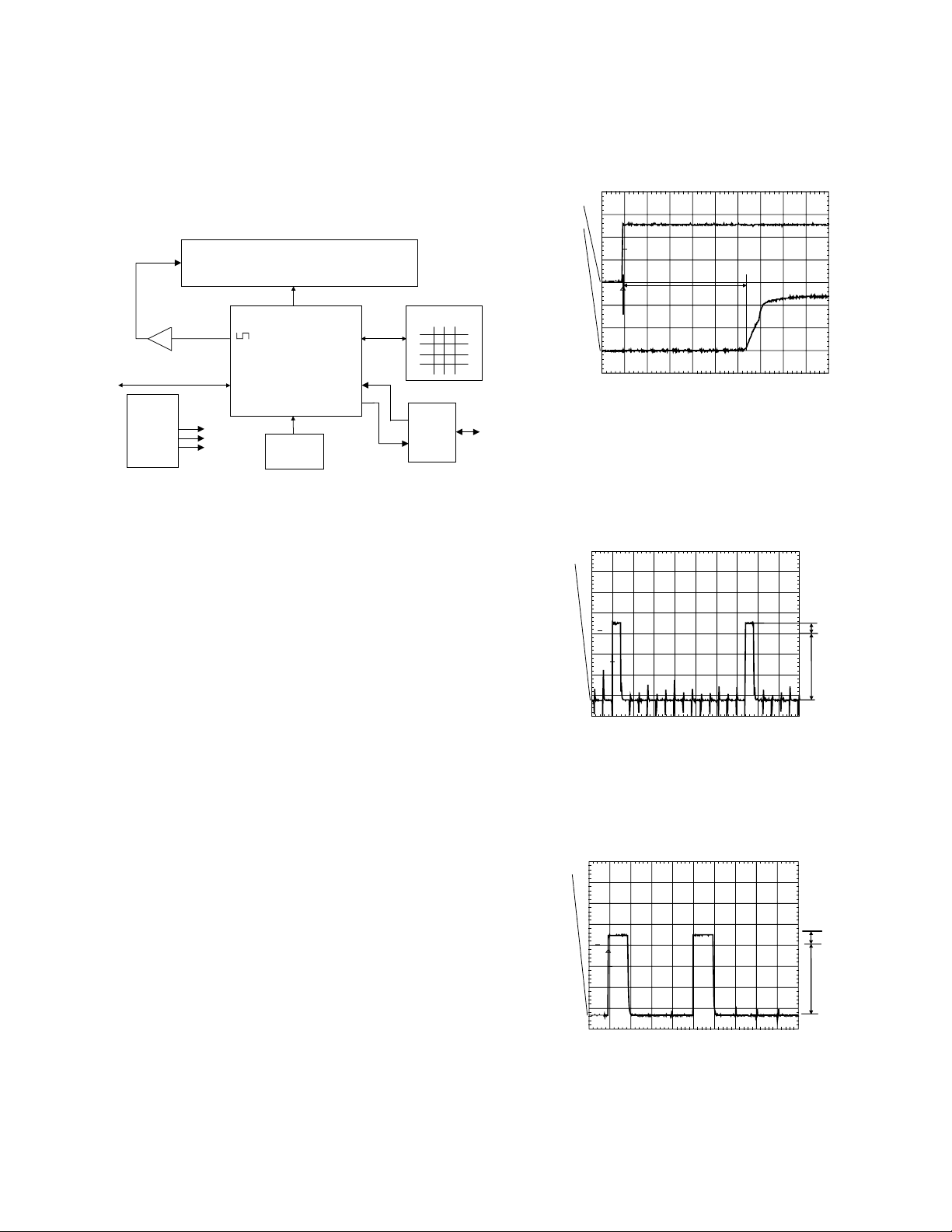

■ TEST INSTRUCTIONS DISPLAY BOARD

1. Display board

1.1 Introduction

These test instructions are written for all versions of the

display PCB.

The contents of the PCB can be split up into next blocks:

V filament

Display

1.3 Reset

Check next reset timing with an oscilloscope at pin 10 of

the microprocessor.

ch2

ch1

PM3392A

T

2

DVD-S510/DV-S5350

T1

V filament

Buffer

I2C

Supply:

+5Vstby

+12V

-40V

Processor

slave up

RC-Eye

Key-matrix

P50

I/O

Figure 1

1.2 Functionality description:

The essential component of the display PCB is the µP

(slave).

This slave works on an 8MHz resonator and has a reset

circuit that is triggered by the +5Vstby. After the reset

pulse, the standby control line will release the reset of the

host µP. This host µP will then initialize the slave. In

addition, when going to stand-by, the slave will put the

host µP in reset. When the slave receives the right IR or

key code to leave the standby mode, the reset of the host

µP will be released.

Other slave functions are:

• Square signal generator to generate the filament

voltage, which is required for an AC FTD.

• Generating the grid and segment scanning for the FTD.

• Generating a scanning grid for the keys (separated

from display scanning).

• Having inputs for RC (RC5 and RC6) and P50 (P50

controller is built in).

1

CH1 2.00 V=

CH2 2 V= BWL MTB 100ms- 1.04dv ch2+

Figure 2

Timing: 400msec < T1 > 700msec.

CH1: +5Vstby voltage at power on.

CH2: Voltage at pin 10.

1.4 Display steering

Check next timing and level for all grid-lines (G1 r G14).

PM3392A

ch1: low =-34.2 V

ch1

ch1: high= 3.98 V

1

T

STOP

CH1 10.0 V= MTB 200us 2324us ch1+

A

B

Figure 3

1. Check level A: +4V5 +/-10% for grid lines 1 => 11

2. Check level A: +4V0 +/-10% for grid lines 12 => 14

3. Check level B: -33V +/-10%

4. Check timing and levels of segment-lines P1 => P10:

PM3392A

ch1

1

T

CH1 10.0 V= BWL MTB 500us- 1.04dv ch1+

A

B

Figure 4

Level A:+4V5 +/-10%

Level B:-33V +/-10%

The data on these segment lines depend on the

characters that are displayed.

The characters can be set by sending I2C commands to

the display.

See the Slave URS how to send a display command.

18

Loading...

Loading...