Xerox DocuTech 155, DocuTech 6100, DocuTech 180, DocuTech 135, DocuTech 6115 Planning Manual

...Page 1

r

Finishing

C.P. Bourg Document Finisher (BDFx)

with optional Cover Feeder,

Square Edge Module and Sheet Rotato

Solutions

Planning

Guide

Supported Printers:

• Xerox DocuTech 61xx

• Xerox DocuTech 1xx HighLight Color (HLC)

• Xerox DocuPrint 1xx

• Xerox iGen3 Digital Production Press

• Xerox Nuvera 100 / 120 Digital Production System

July 13, 2005

Rev. E

Page 2

Xerox Corporation

Global Knowledge & Language Services

800 Philips Road Bldg. 845 – 17S

Webster, NY 14580

Copyright 2004 Xerox Corporation. All rights reserved.

Printed in the United States of America.

Please contact Xerox Feeding and Finishing with any comments or suggestions regarding the content

within this document:

xeroxfinishing@usa.xerox.com

Copyright protection claimed includes all forms and matters of copyrighted material and information now

allowed by statutory or judicial law of hereinafter granted, including without limitation, material generated

from the software programs that are displayed on the screen such as styles, icons, screen displays,

looks, etc.

Xerox, The Document Company, the digital X, the Xerox DocuTech, the Xerox DocuPrint,

Xerox iGen3 Digital Production Press and Xerox Nuvera Digital Production System are trademarks

of, or licensed to, Xerox Corporation.

Other product names used herein are trademarks of their respective owners.

Page 3

Table Of Contents

INTRODUCTION .......................................................................................................................................... I

About this guide .................................................................................................................................... I

Contents................................................................................................................................................. I

1. PRODUCT OVERVIEW ...................................................................................................................... 1-1

Install Planning.................................................................................................................................. 1-2

Device Configurations .................................................................................................................. 1-2

Space Requirements.................................................................................................................... 1-2

Electrical Requirements............................................................................................................... 1-5

Environmental Requirements...................................................................................................... 1-6

Estimated Installation Time ......................................................................................................... 1-6

Operating Supplies ....................................................................................................................... 1-6

Floor Load...................................................................................................................................... 1-7

Floor Level ..................................................................................................................................... 1-7

Unique Features Set ........................................................................................................................ 1-8

Saddle Stitch.................................................................................................................................. 1-8

Edge / Top / Corner Stitch ........................................................................................................... 1-8

2. XEROX DOCUTECH 61XX ............................................................................................................. 2-1

Performance Specifications (DT61xx) ........................................................................................... 2-1

Performance Specifications (DT61xx with XSIS kit).................................................................... 2-1

Limitations.......................................................................................................................................... 2-2

System Dependencies and Prerequisites ..................................................................................... 2-2

Configuration Guide.......................................................................................................................... 2-2

Productivity Guide............................................................................................................................. 2-3

3. XEROX DOCUTECH 1XX HIGHLIGHT COLOR (HLC) ................................................................... 3-1

Performance Specifications (DT1xx HLC) .................................................................................... 3-1

Limitations.......................................................................................................................................... 3-2

System Dependencies and Prerequisites ..................................................................................... 3-2

Configuration Guide.......................................................................................................................... 3-3

Productivity Guide............................................................................................................................. 3-3

4. XEROX DOCUPRINT 1XX .............................................................................................................. 4-1

Performance Specifications (DP180)............................................................................................. 4-1

Performance Specifications (DP180 with XSIS kit) ..................................................................... 4-2

Limitations.......................................................................................................................................... 4-2

System Dependencies and Prerequisites ..................................................................................... 4-3

Configuration Guide.......................................................................................................................... 4-3

Productivity Guide............................................................................................................................. 4-4

5. XEROX IGEN3 DIGITAL PRODUCTION PRESS.............................................................................. 5-1

Performance Specifications............................................................................................................. 5-1

Limitations.......................................................................................................................................... 5-2

System Dependencies and Prerequisites ..................................................................................... 5-2

Configuration Guide.......................................................................................................................... 5-2

Productivity Guide............................................................................................................................. 5-3

6. XEROX NUVERA 100 / 120 DIGITAL PRODUCTION SYSTEM....................................................... 6-1

Performance Specifications............................................................................................................. 6-1

Limitations.......................................................................................................................................... 6-2

System Dependencies and Prerequisites ..................................................................................... 6-2

Configuration Guide.......................................................................................................................... 6-3

Productivity Guide............................................................................................................................. 6-3

7. CUSTOMER AGREEMENT................................................................................................................. 7-5

Devices............................................................................................................................................... 7-5

Primary Customer Applications ...................................................................................................... 7-5

Special Considerations / Limitations.............................................................................................. 7-5

Page 4

Table Of Contents

Page 5

C.P. Bourg Document Finisher (BDFx)

Introduction

About this guide

This Solutions Planning Guide contains information on how to

prepare for the installation of the C.P. Bourg Document Finisher

(BDFx) together with:

• Xerox DocuTech 61xx

• Xerox DocuTech 1xx HighLight Color (HLC)

• Xerox DocuPrint 1xx

• Xerox iGen3 Digital Production Press

• Xerox Nuvera 100 / 120 Digital Production System

This guide also contains information on the optional C.P. Bourg

Cover Feeder (BCFx), SquareEdge Module (SQEDG) and C.P.

Bourg Sheet Rotator (BSR).

This guide will provide the Analyst and the coordinating

Customer with common BDFx specifications and specific preinstallation tasks for the Xerox printer (DocuTech 61xx,

DocuTech 1xx HighLight Color (HLC), DocuPrint 1xx, Xerox

iGen3 Digital Production Press and Nuvera 100 / 120 Digital

Production System) to which the BDFx is to be installed with.

Contents

This section lists the contents of this guide:

• Introduction - provides information about the use of this

Guide.

• Product Overview– provides Installation Planning, including

Space requirements, Floor Load and Level, Electrical and

Environmental requirements, Installation Time and Operating

Supplies.

• Xerox DocuTech (DT 61xx) – provides information about

Limitations, System Dependencies, Configuration Guide and

Unique Features Set.

• Xerox DocuTech (DT 1xx HighLight Color (HLC)) – provides

information about Limitations, System Dependencies,

Configuration Guide and Unique Features Set.

• Xerox DocuPrint (DP1xx) – provides information about

Limitations, System Dependencies, Configuration Guide and

Unique Features Set.

• Xerox iGen3 Digital Production Press – provides information

about Limitations, System Dependencies, Configuration

Guide and Unique Features Set

• Xerox Nuvera 100 / 120 Digital Production System –

provides information about Limitations, System

Dependencies, Configuration Guide and Unique Features

Set.

I

Page 6

C.P. Bourg Document Finisher (BDFx)

• Customer Agreement – contains the Customer Agreement

form.

II

Page 7

Introduction

About this guide

This Solutions Planning Guide contains information on how to

prepare for the installation of the C.P. Bourg Document Finisher

(BDFx) together with:

• Xerox DocuTech 61xx

• Xerox DocuTech 1xx HighLight Color (HLC)

• Xerox DocuPrint 1xx

• Xerox iGen3 Digital Production Press

• Xerox Nuvera 100 / 120 Digital Production System

This guide also contains information on the optional C.P. Bourg

Cover Feeder (BCFx), SquareEdge Module (SQEDG) and C.P.

Bourg Sheet Rotator (BSR).

This guide will provide the Analyst and the coordinating

Customer with common BDFx specifications and specific preinstallation tasks for the Xerox printer (DocuTech 61xx,

DocuTech 1xx HighLight Color (HLC), DocuPrint 1xx, Xerox

iGen3 Digital Production Press and Nuvera 100 / 120 Digital

Production System) to which the BDFx is to be installed with.

Contents

This section lists the contents of this guide:

• Introduction - provides information about the use of this

Guide.

III

Page 8

Page 9

C.P. Bourg Document Finisher (BDFx)

1. Product Overview

Cover Feeder

(BCFx)

Booklet Maker

(BDFx)

Square Edge

(SQEDG)

The C.P. Bourg BDFx is a fully automated signature booklet maker,

which produces high quality saddle stitched booklets in-line. The

optional cover insertion module (BCFx) can feed preprinted cover

stock up to 300 gsm excluding window cutouts (the BCFx is not

available for iGen3).

The new Square Edge (SQEDG) Module option further expands its

capability by offering an optional square edge spine.

The BDFx can top or corner stitch from 2 to 50 sheets and it can

also be used in the fold only mode.

The Bourg Sheet Rotator (BSR) enables maximimum small Booklet

productivity on Xerox printers that are not equipped with an internal

rotator. (Not shown.) The BSR is mandatory when the BDFx is

installed with the iGen3 Digital Production Press.

1-1

Page 10

C.P. Bourg Document Finisher (BDFx)

Install Planning

Device Configurations

This Install Planning guide will help you prepare for the installation

of the C.P Bourg Document Finisher (BDFx) together with:

• Xerox DocuTech 61xx

• Xerox DocuTech 1xx HighLight Color (HLC)

• Xerox DocuPrint 1xx

• Xerox iGen3 Digital Production Press

• Xerox Nuvera 100 / 120 Digital Production System

The Bourg Document Finisher components are:

• BDFx with Conveyor and 2 Cassette Stitch Heads

• Bourg Cover Feeder X (BCFx), optional (not available with

iGen3)

• Square Edge Module (SQEDG), optional

• Bourg Sheet Rotator (BSR), optional (mandatory with iGen3)

• Hohner or Cassette Stitch Heads (2 –4 heads total), optional

Note: The BDFx is delivered with 2 stitch heads. A third and / or

forth stitch head must be ordered and installed with the machine.

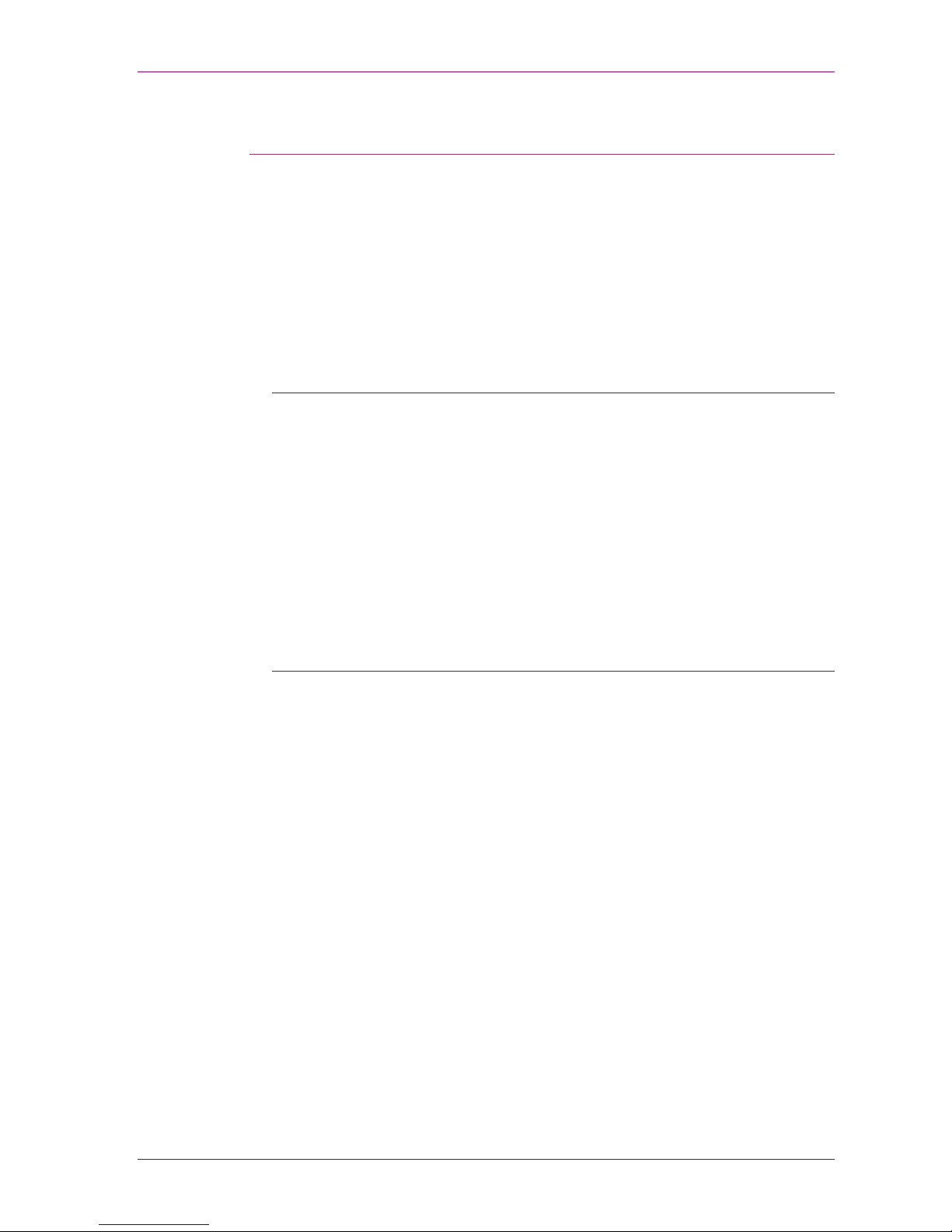

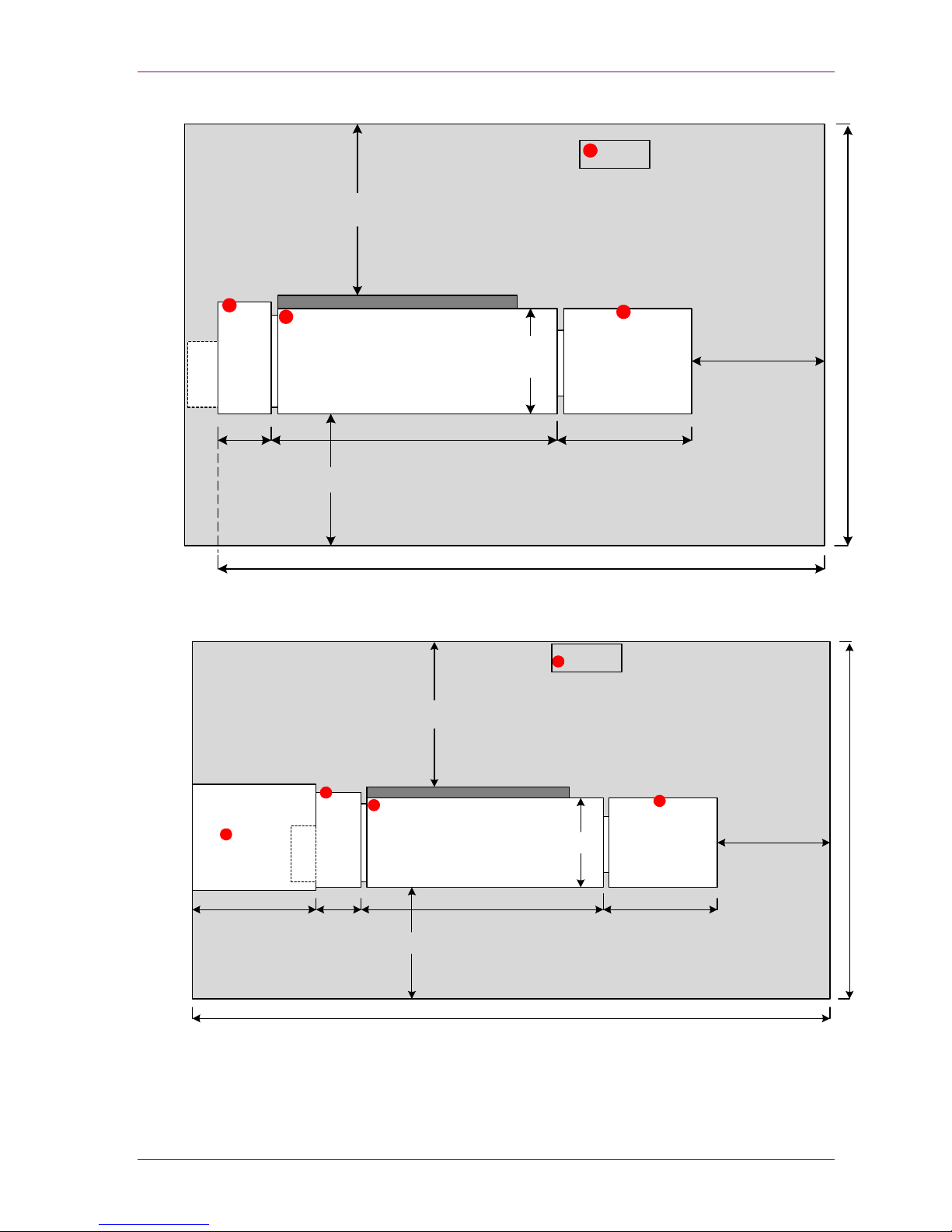

Space Requirements

The space requirements illustration provides machine footprint as

well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of 82

inches (2.083 mm) clearance from the floor to the nearest overhead

obstruction.

1-2

Page 11

C.P. Bourg Document Finisher (BDFx)

r

r

Powe

35 inches

889 mm

Bourg Document

Finisher X

(BDFx)

35 inches

889 mm

68 inches

1736 mm

24 inches

613 mm

139 inches

3539 mm

Conveyor

36 inches

914 mm

35 inches

889 mm

94 inches

2391 mm

Powe

35 inches

889 mm

BSR

31.5 inches

805 mm

35 inches

889 mm

Bourg Document

Finisher X

(BDFx)

68 inches

1736 mm

170.5 inches

4344 mm

1-3

Conveyor

36 inches

914 mm

35 inches

889 mm

94 inches

2391 mm

Page 12

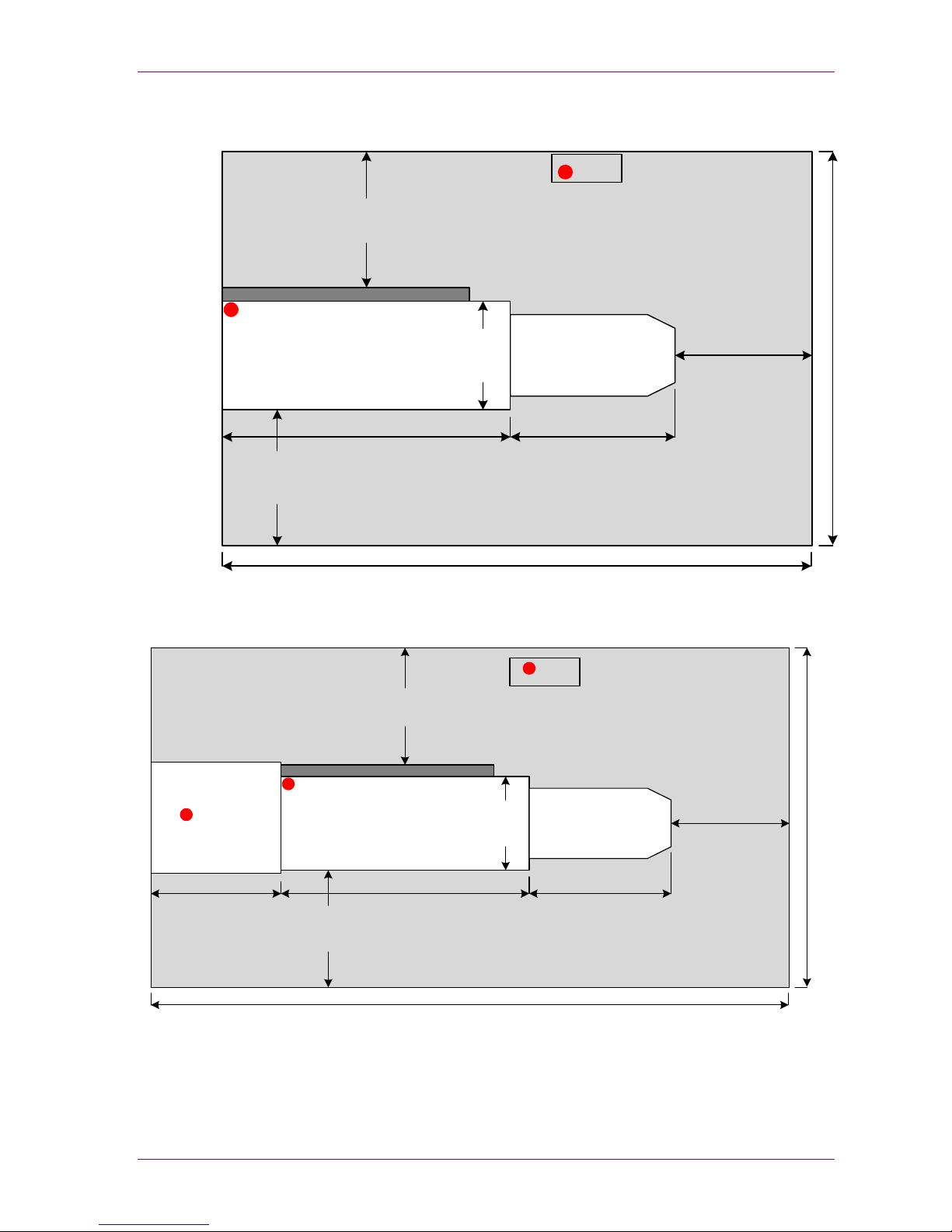

C.P. Bourg Document Finisher (BDFx)

r

r

Powe

35 inches

889 mm

BCFx SQEDG

Bourg Document

Finisher X

24 inches

613 mm

(BDFx)

19.7 inches

500 mm

35 inches

889 mm

68 inches

1736 mm

162.8 inches

4145 mm

40.1 inches

1020 mm

Powe

35 inches

889 mm

35 inches

889 mm

94 inches

2391 mm

31.5 inches

805 mm

19.7 inches

BCFx BSR

Finisher X

Bourg Document

24 inches

613 mm

SQEDG

(BDFx)

500 mm

35 inches

889 mm

68 inches

1736 mm

194.3inches

4950 mm

40.1 inches

1020 mm

Note: The space requirements diagram for the BDFx and the

optional devices are representations only and not drawn to scale.

1-4

35 inches

889 mm

94 inches

2391 mm

Page 13

C.P. Bourg Document Finisher (BDFx)

Dimensions Bourg Document Finisher Square Edge Module

Width x Depth x Height 104.3” * x 24” x 71”

2650 x 739 x 1803 mm

* - Including Conveyor

Shipping Dimensions

Width x Depth x Height

Weight 992 lbs (450 kg) 198 lbs (90 kg) 291 lbs (132 kg)

Shipping Weight 1235 lbs (560 kg) 507 lbs (230 kg) 264 lbs (120 kg)

Operator Clearance Minimum 24” (609.6mm) in

Service Clearance Minimum 35” on all sides of

77” x 30” x 73”

1950 x 750 x 1850 mm

front of the device

the device

40.1” x 24.25” x 49”

1020 x 616 x 1242 mm

47.2” x 35.8” x 63”

1200 x 910 x 1600 mm

Minimum 24” (609.6mm) in

front of the device

Minimum 35” on all sides of

the device

(optional)

Bourg Cover Feeder

(optional,)

26.75” * x 27” x 52”

680 x 687 x 1242 mm

* - 19.7” (500 mm) actual

floor space.

51” x 31.5” x 59”

1300 x 800 x 1500 mm

Minimum 24” (609.6mm) in

front of the device

Minimum 35” on all sides of

the device

Dimensions Bourg Sheet Rotator (optional,

Width x Depth x Height 31.5” x 28.5” x 38.5”

805 mm x 720 mm x 980 mm

Shipping Dimensions

Width x Depth x Height

Weight 298 lbs (135 kg)

Shipping Weight 353 lbs (160 kg)

Operator Clearance Minimum 24” (609.6mm) in front of the

Service Clearance Minimum 30” (763 mm) on all sides of

34.6” x 32.7” x 49.2”

880 mm x 830 mm x 1250 mm

device

the device

mandatory with iGen3)

Electrical Requirements

Nema # for all the devices listed below: 5R-15

Device North America Europe

BDF-X Power 120 VAC (+/- 10%), 60 Hz, 10A 230 VAC (+/- 10%), 50 Hz, 7A

BCF-X Power 120 VAC (+/- 10%), 60 Hz, 5A 230 VAC (+/- 10%), 50 Hz, 3A

SQEDG Power 120 VAC (+/- 10%), 60 Hz, 5A 230 VAC (+/- 10%), 50 Hz, 3A

Device North America Europe

BSR 110VAC (+/- 10%), 60 Hz, 4A 220VAC, (+/- 10%), 50 Hz, 2A

Note: For power cord locations on each device please refer to the

space diagrams in the Space Requirements

1-5

section.

Page 14

C.P. Bourg Document Finisher (BDFx)

Environmental Requirements

Environment BDFx / BCFx / SQEDG

Temperature

Humidity 50 - 85%

Heat Emission BDFx: 2560 btu / hr

Sound Emission 72 db

Altitude

41 - 85° F (5 - 29°C)

BCFx: 1590 btu / hr

SQEDG: 2400 btu / hr

-100 ft. (-31m) to 4,000 ft. (1,219 m)

Environment BSR

Temperature

Humidity 50 – 85%

Heat Emission 1,535 btu / hr

Sound Emission 55 db

Altitude -100 – 4,000 ft (-31 – 1,219 m)

41 - 85° F (5 - 29°C)

Estimated Installation Time

C.P. Bourg installs the BDFx (including BCFx and SQEDG) and the

estimated installation time is 4 – 8 hours.

Installation and customer training will require approximately 2 days

total.

Operating Supplies

Each Bourg Document Finisher is delivered with 2 stitch heads. The

machine can be equipped with 1 or 2 additional stitch heads (any

additional stitch heads must be ordered when the machine is

ordered as this is not an upgrade that can be done in the field).

There are no operating supplies for the BSR.

Supply No. Description. Quantity / Unit

9158017 Wire Cassette (Acme Stitch Heads) 50, 0000 stitches / cassette

9158018 Wire Spool (Hohner Stitch Heads) 50, 0000 stitches / spool

You can reach C.P. Bourg Customer Service using the following

phone number:

• United States and Canada: 1-508-998-2171

(2 cassettes / box)

For Europe, please visit the C.P. Bourg web site and select your

region:

http://www.cpbourg.com

1-6

Page 15

C.P. Bourg Document Finisher (BDFx)

Floor Load

Device Uniform load Point load

BDFx 68 lbs / sq.ft. (326 kg / sq. m) Casters A: 4,840 lbs / sq.in. (340 kg / sq.cm)

BCFx 30 lbs / sq.ft. (148 kg / sq. m) Casters: 1,053 lbs / sq.in. (75 kg / sq.cm)

SQEDG Module 44 lbs / sq.ft. (212 kg / sq. m) Casters: 2,680 lbs / sq.in. (190 kg / sq.cm)

BSR 48 lbs / sq.ft. (233 kg / sq. m) Casters: 1,585 lbs / sq.in. (112 kg / sq.cm)

Caster

Casters B: 3,957 lbs / sq.in. (279 kg / sq.cm)

BSR BCFx BDFx

A

B

Floor Level

X4

X3

X2

X1

BSR

BDFx

SQEDG

SQEDG

Configuration Measurement Specification

X1 5 ft (1.52 m) 3/16 in./ ft (4.77 mm / m)

X2 7.75 ft (2.36 m) 1/8 in./ ft (3.175 mm / m)

X3 7.5 ft (2.28 m) 1/8 in./ ft (3.175 mm / m)

X4 10 ft (3.05 m) 3/32 in./ ft (2.4 mm / m)

Note:The floor level is based on a printer paper exit height above

the floor of 34” (860 mm) for DP1xx, DT1xx, iGen3 and 40.2” (1021

mm) for DT61xx and Nuvera.

1-7

Page 16

C.P. Bourg Document Finisher (BDFx)

Unique Features Set

Saddle Stitch

Listed below are diagrams of the various stitch positions that the

BDF-X can produce.

Note: The BDFx is delivered with 2 stitch heads. A third and forth

stitch head must be ordered and installed with the machine to

enable the 3 and 4 stitch options shown in the diagrams below.

For high volume machines, it is recommended to use the Hohner

(Spool) Stitch Heads.

Edge / Top / Corner Stitch

1-8

Page 17

C.P. Bourg Document Finisher (BDFx)

2. Xerox DocuTech 61xx

Performance Specifications (DT61xx)

Listed below are the Performance Specifications for the C.P.

Bourg Document Finisher, Cover Feeder and SquareEdge

Module.

Stapling / Folding Specifications

Paper Type /

Weight

Paper Size BDFx: 8 x 10” – 14 x 17” (203 x 254 mm – 364 x 432 mm)

Booklet Sizes BDFx: 8 x 5” – 14 x 8.5” (203 x 127 mm – 364 x 216 mm)

Edge Stapling BDFx: 8 x 10 – 11.7 x 14 (203 x 254 mm – 298 x 356 mm)

Face Trim 0 – ¾” (0 – 19 mm)

Stitch Head Two to four stitch heads (Hohner or Acme)

Sheet Capacity

(Stitching)

Input Height 34” (860 mm) and 40.2” (1021 mm)

BDFx / SQEDG: Uncoated Stock, 16 lbs Bond – 110 lbs Index (60 - 200 gsm)

BCFx: Uncoated Cover Stock, 20 lbs Bond – 10 pt cover stock (80 – 300 gsm∗)

∗ - for all cover stocks, excluding window cutouts

BDFx w / BCFx in bypass mode: 8 x 10” – 12.25 x 17” (203 x 254 mm – 310 x 432 mm)

BDFx w / BCFx feeding covers: 8 x 10” – 11.75 x 17” (203 x 254 mm – 298 x 432 mm)

BDFx w / BCFx in bypass mode: 8 x 5” – 12.25 x 8.5” (203 x 127 mm – 310 x 216 mm)

BDFx w / BCFx feeding covers: 8 x 5” – 11.75 x 8.5” (203 x 127 mm – 298 x 216 mm)

BDFx w / BCFx: 8 x 10 - 11.7 x 12.25 (203 x 254 mm – 298 x 310 mm)

Edge / Top / Corner Stitching: 2 – 50 sheets

Saddle Stitching: 2 – 22 sheets (20 lb Bond / 80 gsm)

Performance Specifications (DT61xx with XSIS kit)

Stapling / Folding Specifications

Paper Size BDFx: 7 x 10” – 14 x 19.2” (178 x 254 mm – 364 x 488 mm)

BDFx w / BCFx in bypass mode: 8 x 10” – 12.25 x 17” (203 x 254 mm – 364 x 432 mm)

BDFx w / BCFx feeding covers: 8 x 10” – 11.75 x 17” (203 x 254 mm – 298 x 432 mm)

Booklet Sizes BDFx: 8 x 5” – 14 x 8.5” (203 x 127 mm – 364 x 216 mm)

BDFx w / BCFx in bypass mode: 8 x 5” – 12.25 x 8.5” (203 x 127 mm – 364 x 216 mm)

BDFx w / BCFx feeding covers: 8 x 5” – 11.75 x 8.5” (203 x 127 mm – 298 x 216 mm)

Edge Stapling BDFx: 8 x 10 – 11.7 x 14 (203 x 254 mm – 298 x 356 mm)

BDFx w / BCFx: 8 x 10 - 11.7 x 12.25 (203 x 254 mm – 298 x 310 mm)

Face Trim 0 – ¾” (0 – 19 mm)

2-1

Page 18

C.P. Bourg Document Finisher (BDFx)

Limitations

System Dependencies and Prerequisites

Configuration Guide

• The BDFx can only be guaranteed to work to its maximum

book thickness when feeding (8.5 x 11 / A4) paper if the

paperweight is 90 gsm or less. (Long grain paper with a

weight above 90 gsm should be tested with the customer

paper and application before selling the BDFx.)

• Use of short grain paper is highly recommended for 11 x 17”

/ A3 sized paper.

Listed below are the dependencies and prerequisites for

installing the BDFx, BCFx and SQEDG module.

• The DT61xx must be equipped with a Bypass Transport to

enable In-line Finishing.

The Configuration Guide contains diagrams over the various

Finishing Solutions that are currently supported.

Printer Configurations Finisher Configurations

IOT

INTERPOSER

BYPASS

TRANSPORT

BDFx

DS5000

DS5000

DS5000

DS5000

BCFx

BDFx

BCFx

DS5000

DS5000

BDFx

DS5000

BDFx

BDFx

BCFx

SQEDG

DS5000

BDFx

BCFx

BCFx

BDFx

DS5000

SQEDG

BDFx

SQEDG

BCFx

BDFx

2-2

Page 19

C.P. Bourg Document Finisher (BDFx)

Productivity Guide

The calculated productivity for the BDFx is based on host

machine running duplex job.

Set Size /

8.5 x 11” (A4)

Booklets / Hour 2700 2195 1538 1385 1037 523 338 239

Set Size /

11 x 17” (A3)

Booklets / Hour 1540 1179 675 588 451 237 153 108

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

2-3

Page 20

C.P. Bourg Document Finisher (BDFx)

2-4

Page 21

C.P. Bourg Document Finisher (BDFx)

3. Xerox DocuTech 1xx HighLight Color (HLC)

Performance Specifications (DT1xx HLC)

Listed below are the Performance Specifications for the C.P.

Bourg Document Finisher, Cover Feeder, SquareEdge Module

and Sheet Rotator.

Stapling / Folding Specifications

Paper Type /

Weight

Paper Size BDFx: 8 x 10” – 14 x 17” (203 x 254 mm – 364 x 432 mm)

Booklet Sizes BDFx: 8 x 5” – 14 x 8.5” (203 x 127 mm – 364 x 216 mm)

Edge Stapling BDFx: 8 x 10 – 11.7 x 14 (203 x 254 mm – 298 x 356 mm)

Face Trim 0 – ¾” (0 – 19 mm)

Stitch Head Two to four stitch heads (Hohner or Acme)

Sheet Capacity

(Stitching)

Input Height 34” (860 mm) and 40.2” (1021 mm)

BDFx / SQEDG: Uncoated Stock, 16 lbs Bond – 110 lbs Index (60 - 200 gsm)

BCFx: Uncoated Cover Stock, 20 lbs Bond – 10 pt cover stock (80 – 300 gsm∗)

∗ - for all cover stocks, excluding window cutouts

BDFx w / BCFx in bypass mode: 8 x 10” – 12.25 x 17” (203 x 254 mm – 310 x 432 mm)

BDFx w / BCFx feeding covers: 8 x 10” – 11.75 x 17” (203 x 254 mm – 298 x 432 mm)

BDFx w / BSR in bypass mode: 8.5 x 11” - 14 x 17” (216 x 279 mm - 356 x 431 mm)

BDFx w / BSR in rotate mode: 8.5 x 11” - 9 x 14” (216 x 279 mm - 229 x 356 mm)

BDFx w / BCFx in bypass mode: 8 x 5” – 12.25 x 8.5” (203 x 127 mm – 310 x 216 mm)

BDFx w / BCFx feeding covers: 8 x 5” – 11.75 x 8.5” (203 x 127 mm – 298 x 216 mm)

BDFx w / BSR in bypass mode: 8.5 x 5.5” - 14 x 8.5” (216 x 140 mm - 356 x 216 mm)

BDFx w / BSR in rotate mode: 8.5 x 5.5” - 9 x 7” (216 x 140 mm - 229 x 178 mm)

BDFx w / BCFx: 8 x 10 - 11.7 x 12.25 (203 x 254 mm – 298 x 310 mm)

Edge / Top / Corner Stitching: 2 – 50 sheets

Saddle Stitching: 2 – 22 sheets (20 lb Bond / 80 gsm)

Rotating / Bypass Specifications / Limitations

Paper Size (Rotating) Maximum: 9” x 14” LEF (228 x 356 mm)

Paper Size

(Pass through)

Paper Weight 16 lbs – 110 lbs (60 - 200 gsm)

Input Height 34” (860 mm)

Output Height 34” (860 mm)

Minimum: 8” x 10” LEF (203 x254 mm)

Maximum: 14” x 18.5” SEF (356 x 470 mm)

Minimum: 8” x 10” SEF (203 x 254 mm)

3-1

Page 22

C.P. Bourg Document Finisher (BDFx)

Limitations

System Dependencies and Prerequisites

• Due to the height of the bypass transport on DocuTech 1xx

HLC it is not possible to attach the BCFx without the BSR.

• Requires a minimum of 2 skipped pitches (3 skipped pitches

with BCF), which results in low productivity with small

booklets. (A3/ 11 x 17 requires only one skipped pitch with or

without the BCF.)

• The BDFx can only be guaranteed to work to its maximum

book thickness when feeding (8.5 x 11 / A4) paper if the

paperweight is 90 gsm or less. (Long grain paper with a

weight above 90 gsm should be tested with the customer

paper and application before selling the BDFx.)

• Use of short grain paper is highly recommended for 11 x 17”

/ A3 sized paper.

Listed below are the dependencies and prerequisites for

installing the BDFx, BCFx and SQEDG module.

• The printer must be equipped with a Bypass Transport to

enable In-line Finishing.

• It is highly recommended that the printer is equipped with a

Bourg Sheet Rotator (BSR) to maximize output.

• Due to the height of the bypass transport on DocuTech 1xx

HLC it is not possible to attach the BCFx without the BSR.

• Requires a minimum of 2 skipped pitches (3 skipped pitches

with BCF), which results in low productivity with small

booklets. (A3/ 11 x 17 requires only one skipped pitch with or

without the BCF.)

3-2

Page 23

C.P. Bourg Document Finisher (BDFx)

Configuration Guide

Printer Configurations Finisher Configurations

The Configuration Guide contains diagrams over the various

Finishing Solutions that are currently supported.

IOT

STACKER

STACKER

BYPASS

TRANSPORT

BDFx

BCFx

BSR

BSR

BSR

BDFx

BDFx

BDFx

BCFx

BCFx

BDFx

SQEDG

BSR

SQEDG

BDFx

BCFx

SQEDG

BDFx

SQEDG

BDFx

Productivity Guide

The calculated productivity for the BDFx is based on host

machine running duplex job.

Set Size /

8.5 x 11” (A4)

without BCFx

Booklets / Hour 1800 1384 1090 900 782 450 320 231

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

Set Size /

8.5 x 11” (A4)

with BCFx

Booklets / Hour 1384 1090 900 782 681 420 303 218

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

3-3

Page 24

C.P. Bourg Document Finisher (BDFx)

3-4

Page 25

C.P. Bourg Document Finisher (BDFx)

4. Xerox DocuPrint 1xx

Performance Specifications (DP180)

Listed below are the Performance Specifications for the C.P.

Bourg Document Finisher, Cover Feeder, SquareEdge Module

and Sheet Rotator.

Stapling / Folding Specifications

Paper Type /

Weight

Paper Size BDFx: 8.5 x 11” – 14 x 17” (216 x 279 mm – 356 x 432 mm)

Booklet Sizes BDFx: 8.5 x 5.5” – 14 x 8.5” (216 x 140 mm – 356 x 216 mm)

Edge Stapling BDFx: 8 x 10 – 11.7 x 14” (203 x 254 mm – 297 x 356 mm)

Face Trim 0 – ¾” (0 – 19 mm)

Stitch Head Two to four stitch heads (Hohner or Acme)

Sheet Capacity

(Stitching)

Input Height 34” (860 mm) and 40.2” (1021 mm)

BDFx / SQEDG: Uncoated Stock, 16 lbs Bond – 110 lbs Index (60 - 200 gsm)

BCFx: Uncoated Cover Stock, 20 lbs Bond – 10 pt cover stock (80 – 300 gsm∗)

∗ - for all cover stocks, excluding window cutouts

BDFx w / BCFx in bypass mode: 8.5 x 11” – 12.25 x 17” (216 x 279 mm – 310 x 432 mm)

BDFx w / BCFx feeding covers: 8.5 x 11” – 11.75 x 17” (216 x 279 mm – 298 x 432 mm)

BDFx w / BSR in bypass mode: 8.5 x 11” - 14 x 17” (216 x 279 mm - 356 x 431 mm)

BDFx w / BSR in rotate mode: 8.5 x 11” - 9 x 14” (216 x 279 mm - 229 x 356 mm)

BDFx w / BCFx in bypass mode: 8.5 x 5.5” – 12.25 x 8.5” (216 x 140 mm – 310 x 216 mm)

BDFx w / BCFx feeding covers: 8.5 x 5.5” – 11.75 x 8.5” (216 x 140 mm – 298 x 216 mm)

BDFx w / BSR in bypass mode: 8.5 x 5.5” - 14 x 8.5” (216 x 140 mm - 356 x 216 mm)

BDFx w / BSR in rotate mode: 8.5 x 5.5” - 9 x 7” (216 x 140 mm - 229 x 178 mm)

BDFx w / BCFx: 8 x 10 - 11.7 x 12.25 (203 x 254 mm – 298 x 310 mm)

Edge / Top / Corner Stitching: 2 – 50 sheets

Saddle Stitching: 2 – 22 sheets (20 lb Bond / 80 gsm)

4-1

Page 26

C.P. Bourg Document Finisher (BDFx)

Performance Specifications (DP180 with XSIS kit)

Stapling / Folding Specifications

Paper Size BDFx: 7 x 10” – 14 x 18.5” (178 x 254 mm – 356 x 470 mm)

BDFx w / BCFx in bypass mode: 8 x 10” – 12.25 x 18.5” (203 x 254 mm – 310 x 470 mm)

BDFx w / BCFx feeding covers: 8 x 10” – 11.75 x 17” (203 x 254 mm – 298 x 432 mm)

BDFx w / BSR in bypass mode: 8 x 10” - 14 x 18.5” (203 x 254 mm - 356 x 470 mm)

BDFx w / BSR in rotate mode: 8 x 10” - 9 x 14” (203 x 254 mm - 229 x 356 mm)

Booklet Sizes BDFx: 7 x 5” – 14 x 9.25” (178 x 127 mm – 356 x 235 mm)

BDFx w / BCFx in bypass mode: 8 x 5” – 12.25 x 9.25” (203 x 127 mm – 310 x 235 mm)

BDFx w / BCFx feeding covers: 8 x 5”” – 11.75 x 8.5” (203 x 127 mm – 298 x 216 mm)

BDFx w / BSR in bypass mode: 8 x 5”” - 14 x 9.25” (203 x 127 mm - 356 x 235 mm)

BDFx w / BSR in rotate mode: 8 x 5”” - 9 x 7” (203 x 127 mm - 229 x 178 mm)

Edge Stapling BDFx: 8 x 10 – 11.7 x 14 (203 x 254 mm – 298 x 356 mm)

BDFx w / BCFx: 8 x 10 - 11.7 x 12.25 (203 x 254 mm – 298 x 310 mm)

Face Trim 0 – ¾” (0 – 19 mm)

Rotating / Bypass Specifications / Limitations

Paper Size (Rotating) Maximum: 9” x 14” LEF (228 x 356 mm)

Minimum: 8” x 10” LEF (203 x254 mm)

Paper Size

(Pass through)

Paper Weight 16 lbs – 110 lbs (60 - 200 gsm)

Input Height 34” (860 mm)

Output Height 34” (860 mm)

Maximum: 14” x 18.5” SEF (356 x 470 mm)

Minimum: 8” x 10” SEF (203 x 254 mm)

Limitations

• Due to the height of the bypass transport on DocuPrint it is

not possible to attach the BCFx without the BSR.

• Requires a minimum of 2 skipped pitches (3 skipped pitches

with BCF), which results in low productivity with small

booklets. (A3/ 11 x 17 requires only one skipped pitch with or

without the BCF.)

• The BDFx can only be guaranteed to work to its maximum

book thickness when feeding (8.5 x 11 / A4) paper if the

paperweight is 90 gsm or less. (Long grain paper with a

weight above 90 gsm should be tested with the customer

paper and application before selling the BDFx.)

• Use of short grain paper is highly recommended for 11 x 17”

/ A3 sized paper.

4-2

Page 27

C.P. Bourg Document Finisher (BDFx)

System Dependencies and Prerequisites

Configuration Guide

Listed below are the dependencies and prerequisites for

installing the BDFx, BCFx and SQEDG module.

• The printer must be equipped with a Bypass Transport to

enable In-line Finishing.

• It is highly recommended that the printer is equipped with a

Bourg Sheet Rotator (BSR) to maximize output.

• Due to the height of the bypass transport on DocuPrint it is

not possible to attach the BCFx without the BSR.

• Requires a minimum of 2 skipped pitches (3 skipped pitches

with BCF), which results in low productivity with small

booklets. (A3/ 11 x 17 requires only one skipped pitch with or

without the BCF.)

The Configuration Guide contains diagrams over the various

Finishing Solutions that are currently supported.

Printer Configurations Finisher Configurations

IOT

STACKER

STACKER

BYPASS

TRANSPORT

BDFx

BCFx

BSR

BSR

BSR

BDFx

BDFx

BDFx

BCFx

BCFx

BDFx

SQEDG

BSR

SQEDG

BDFx

BCFx

SQEDG

BDFx

SQEDG

BDFx

4-3

Page 28

C.P. Bourg Document Finisher (BDFx)

Productivity Guide

The calculated productivity for the BDFx is based on host

machine running duplex job.

Set Size /

8.5 x 11” (A4)

without BCFx

Booklets / Hour 1800 1384 1090 900 782 450 320 231

Set Size /

8.5 x 11” (A4)

with BCFx

Booklets / Hour 1384 1090 900 782 681 420 303 218

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

4-4

Page 29

C.P. Bourg Document Finisher (BDFx)

5. Xerox iGen3 Digital Production Press

Performance Specifications

Listed below are the Performance Specifications for the C.P.

Bourg Document Finisher, Cover Feeder, SquareEdge Module

and Sheet Rotator.

Note: For specific information on the BDFx together with the

Xerox Book Factory, please refer to the Xerox Book Factory

SPG.

Stapling / Folding Specifications

Paper Type /

Weight

Paper Size BDFx w / BSR in bypass mode: 8 x 10” - 14” x 18.5” SEF” (203 x 254 mm - 356 x 470 mm)

Booklet Sizes BDFx w / BSR in bypass mode: 8 x 5” - 14 x 9.25” (203 x 127 mm - 356 x 235 mm)

Edge Stapling BDFx w / BSR: 8 x 10” – 11.7 x 14” (203 x 254 mm – 297 x 356 mm)

Face Trim 0 – ¾” (0 – 19 mm)

Stitch Head Two to four stitch heads (Hohner or Acme)

Sheet Capacity

(Stitching)

Input Height 34” (860 mm) and 40.2” (1021 mm)

BDFx / SQEDG: Uncoated Stock, 16 lbs Bond – 110 lbs Index (60 - 200 gsm)

BDFx w / BSR in rotate mode: 8” x 10” LEF - 9” x 14” LEF (203 x 254 mm - 228 x 356 mm)

BDFx w / BSR in rotate mode: 8 x 5” - 9 x 7” (203 x 127 mm - 228 x 178 mm)

Edge / Top / Corner Stitching: 2 – 50 sheets

Saddle Stitching: 2 – 22 sheets (20 lb Bond / 80 gsm)

Note: For more information on the BSR, please refer to the C.P.

Bourg Sheet Rotator Solutions Planning Guide.

Rotating / Bypass Specifications / Limitations

Paper Size (Rotating) Maximum: 9” x 14” LEF (228 x 356 mm)

Minimum: 8” x 10” LEF (203 x254 mm)

Paper Size

(Pass through)

Paper Weight 16 lbs – 110 lbs (60 - 200 gsm)

Input Height 34” (860 mm)

Output Height 34” (860 mm)

Maximum: 14” x 18.5” SEF (356 x 470 mm)

Minimum: 8” x 10” SEF (203 x 254 mm)

5-1

Page 30

C.P. Bourg Document Finisher (BDFx)

Limitations

System Dependencies and Prerequisites

• The BDFx can only be guaranteed to work to its maximum

book thickness when feeding (8.5 x 11 / A4) paper if the

paperweight is 90 gsm or less. (Long grain paper with a

weight above 90 gsm should be tested with the customer

paper and application before selling the BDFx.)

• Use of short grain paper is highly recommended for 11 x 17”

/ A3 sized paper.

• The BCFx is not an available option together with the iGen3.

• The Cover Page of the booklet must be sent as the last page

in the set.

• If installing a new Book Factory on an existing iGen3

installation, a Xerox iGen3 Finishing Interface kit (product

code UYR) must be ordered.

• The BSR is mandatory when a BDFx is installed inline with

iGen3. (The BSR is equipped with an enhanced static

elimination transport (Tag 21) that greatly reduces static on

papers delivered from the iGen3).

• Transition of an existing BSR to an iGen3 is not possible

unless Tag 21 is already installed.

Configuration Guide

The Configuration Guide contains diagrams over the various

Finishing Solutions that are currently supported.

Printer Configurations Finisher Configurations

FEEDER FEEDER PRINT

The diagram above is only an example. The

Xerox iGen3 Digital Production Press can have

the following configurations:

• Up to 6 Feeders

• 1 inserter

• Up to 4 Stackers

ENGINE

OUTPUT

MODULE

INSERTER STACKER STACKER BSR BDFx

BSR BDFx SQEDG

5-2

Page 31

C.P. Bourg Document Finisher (BDFx)

Productivity Guide

The calculated productivity for the BDFx is based on host

machine running duplex job.

Set Size /

8.5 x 11” (A4)

Booklets / Hour 1500 1000 750 600 500 272 188 130

Set Size /

11 x 17” (A3, SRA3)

Booklets / Hour 750 500 375 300 250 136 94 65

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

5-3

Page 32

C.P. Bourg Document Finisher (BDFx)

5-4

Page 33

C.P. Bourg Document Finisher (BDFx)

6. Xerox Nuvera 100 / 120 Digital Production System

Performance Specifications

Listed below are the Performance Specifications for the C.P.

Bourg Document Finisher, Cover Feeder, SquareEdge Module

and Sheet Rotator.

Stapling / Folding Specifications

Paper Type /

Weight

Paper Size BDFx / SQEDG: 5.5 x 8.5” – 12.6 x 18.5” (140 x 216 mm – 320 x 470 mm)

Booklet Sizes BDFx: 5.5 x 4.25” – 12.6 x 9.25” (140 x 108 mm – 320 x 235 mm)

Edge Stapling BDFx / SQEDG: 5.5 x 8.25” – 11.7 x 14” (140 x 210 mm – 297 x 356 mm)

Face Trim 0 – ¾” (0 – 19 mm)

Stitch Head Two to four stitch heads (Hohner or Acme)

Sheet Capacity

(Stitching)

Input Height 34” (860 mm) and 40.2” (1021 mm)

BDFx / SQEDG: Uncoated Stock, 16 lbs Bond – 110 lbs Index (60 - 200 gsm)

Uncoated Cover Sheet: Uncoated 20lb - 10 pt cover (80 - 300gsm)

BCFx: Uncoated Cover Stock, 20 lbs Bond – 10 pt cover stock (80 – 300 gsm∗)

∗ - for all cover stocks, excluding window cutouts

BDFx w / BCFx in bypass mode: 8 x 8” – 12.25 x 17” (203 x 203 mm – 310 x 432 mm)

BDFx w / BCFx feeding covers: 8 x 8” – 11.75 x 17” (203 x 203 mm – 298 x 432 mm)

BDFx w / BCFx in bypass mode: 8 x 4” – 12.25 x 8.5” (203 x 101 mm – 310 x 216 mm)

BDFx w / BCFx feeding covers: 8 x 4” – 11.75 x 8.5” (203 x 101 mm – 298 x 216 mm)

With BCFx: 8 x 10” (SEF) – 11.7 x 12.25” (LEF) (203 x 254 mm – 297 x 310 mm)

8 x 10” – 11.7 x 14” (203 x 254 mm – 297 x 356 mm)

Edge / Top / Corner Stitching: 2 – 50 sheets

Saddle Stitching: 2 – 22 sheets (20 lb Bond / 80 gsm)

6-1

Page 34

C.P. Bourg Document Finisher (BDFx)

Limitations

• A Finisher Transport Module is required for in-line

connectivity to the printer.

• A slight Cover Feeder feed mechanism adjustment may be

necessary when changing cover weights (lightweight stocks

may require a more precise adjustment).

• For 11” x 17” / A3 simplex single fold only documents, paper

weight greater than 20 lb (80 gsm) are recommended.

• For 8.5” x 11” / A4 simplex single fold only documents, the

N-1 face up orientation is required.

• Currently coated stock is not recommended.

• The BDFx can only be guaranteed to work to its maximum

book thickness when feeding (8.5 x 11 / A4) paper if the

paperweight is 90 gsm or less. (Long grain paper with a

weight above 90 gsm should be tested with the customer

paper and application before selling the BDFx.)

• Use of short grain paper is highly recommended for 11 x 17”

/ A3 sized paper.

System Dependencies and Prerequisites

• The Finisher Transport Module is required for in-line

connectivity to the printer.

• Currently, a Xerox Document Stacker 5000 must be installed

in-line with the printer and the BDFx.

• If there is a transition of an existing BCFx to a Nuvera Digital

Production System, an upgrade is needed.

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

6-2

Page 35

C.P. Bourg Document Finisher (BDFx)

A

Configuration Guide

The Configuration Guide contains diagrams over the various

Finishing Solutions that are currently supported.

Printer Configurations Finisher Configurations

Note: These options are

currently not supported.

DS5000 is required.

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

BDFX

DS5000

BDFX DS5000

BDFX

DS5000

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

BDFX

BCFX BDFXBCFX SQEDG

DS5000

SQEDG

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

BDFX SQEDG

DS5000

BDFXBCFX SQEDGBDFXBCFX

BDFX SQEDG

Productivity Guide

The calculated productivity for the BDFx is based on host

machine running duplex job.

Set Size /

8.5 x 11” (A4)

Booklets / Hour 1000 781 727 724 656 329 220 148

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

Set Size /

11 x 17” (A3)

Booklets / Hour 867 727 610 409 333 176 123 82

1 sheet 2 sheets 3 sheets 4 sheets 5 sheets 10 sheets 15 sheets 22 sheets

6-3

Page 36

C.P. Bourg Document Finisher (BDFx)

6-4

Page 37

C.P. Bourg Document Finisher (BDFx)

7. Customer Agreement

Devices

As a final step in the install planning you must complete the

Customer Agreement form.

Check off the modules that will be part of this install:

• C.P. Bourg Document Finisher

• C.P. Bourg Cover Feeder (optional, not with iGen3)

• C.P. Bourg Square Edge Module (optional)

• Xerox DocuTech Bypass Transport

• Xerox DocuPrint Bypass Transport

• C.P. Bourg Sheet Rotator

• Xerox iGen3 Finishing Interface kit

Primary Customer Applications

Record the primary customer applications:

Special Considerations / Limitations

Record any special considerations and / or limitations identified

by Xerox and agreed to by the customer:

I have reviewed the solution expectations and understand the specifications and

limitations for each of the modules that will be installed: (Signature and Date)

Customer

Xerox Sales Representative

Xerox Analyst Representative

Xerox Service Representative

C.P Bourg Representative

For installations made in the US and Canada, a copy of the signed Customer Agreement must

be:

A) Attached to the XOA / Customer purchase order and faxed to SPA: 1-800 –407-8430.

B) Scanned and emailed to Phil.Schmelzlen@xerox.com

, or faxed to Phil Schmelzlen (585)

427-3140 (8*227-3140).

7-5

Page 38

A)

Loading...

Loading...