Xerox DOCUPRINT 92C User Manual

Xerox DocuPri n t 92C IPS

Guide to Performing Routine Maintenance

Version 7.1

August 2000

721P89140

Xerox Corporation

Printing Systems Documentation and Education

701 South Aviation Boulevard, ESM1-058

El Segundo, CA 90245

©1997, 1998, 1999, 2000 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 721P89140

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of other

companies are also acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent

editions.

Laser safe ty

Warning: Adjustments, use of controls, or performance of

!

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance standards of the U.S. Department of Health, Education,

and Welfare for Class 1 laser products. Class 1 laser products do not

emit hazardous radiation. The DocuPrint printers do not emit

hazardous radiation because the laser beam is completely enclosed

during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must be

remo ved with a to ol. DO NOT REMOVE LABELED PANELS OR

PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

Ozone information

This product produces ozone during normal operation. The amount

of ozone produced depends on copy volume. Ozone is heavier than

air. The environmental parameters specified in the Xerox installation

instructions ensure that concentration levels are within safe limits. If

you need additional information concerning ozone, call 1-800-8286571 to request the Xerox publication 600P83222, OZONE.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE iii

Operation safety

Your Xerox equipment and supplies have been designed and tested

to meet strict safety requirements. They have been approved by

safety agencies, and they comply with environmental standards.

Please observe the following precautions to ensure your continued

safety.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

Warning: Improper connection of the equipment grounding

!

conductor may result in risk of electrical shock.

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the Printer Controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety at

the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your local Xerox

representative or operating company.

iv XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

Table of contents

Laser safety iii

Ozone information iii

Ope rati on safety iv

Introduction vii

About this guide vii

Contents viii

Conventions ix

Related publications x

1. Feeder trays 1-1

Checking feeder trays 1-1

Loading feeder trays 1-2

Guidelines for loading paper 1-2

Loading the trays 1-3

2. Output trays 2-1

Checking and unloading dual stacker trays 2-1

Checking and unloading the stitcher/stacker tray 2-3

Checking and unloading the sample tray 2-4

3. Stitcher wire 3-1

4. F user lubricant and pressure roll wiper 4-1

Adding fuser lubricant 4-1

Replacing the pressure roll wiper 4-4

5. Inks 5-1

Adding dry ink 5-1

Exchanging Customer Changeable Units (CCUs) 5-5

Removing the CCU 5-6

Inserting a CC U 5-11

Storing the cart and CCU 5-13

6. Waste cont ain er s 6-1

Checking and replacing the developer waste container 6-1

Checking and replacing the dry ink waste container 6-3

7. Bypass transport 7-1

Removing the bypass transport 7-2

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE v

TABLE OF CONTENTS

Installing the bypass transport 7-4

8. Cleaning 8-1

Cleaning the keyboard, monitor, and the exterior of the Printer Controller 8-1

Cleaning the 4mm cartridge tape drive 8-2

9. Maintenance and support service s 9-1

Xerox Customer Services Support Center 9-1

Xerox Documentation and Software Services 9-2

Xerox Font Center 9-2

Operator Training 9-2

Xerox Customer Education 9-3

Reporting billing meters 9-3

Index INDEX-1

vi XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

About this guide

Introduction

The Xerox DocuPrint 92C IPS Guide to Performing Routine

Maintenance describes how to perform basic maintenance on the

Xerox DocuPrint 92C IPS.

This guide is designed for operators whose job consists of operating

each of the system components, running print jobs, solving simple

system problems, and performing basic maintenance tasks, such as

replenishing printer supplies.

Refer to the entire Xerox DocuPrint IPS Series documentation for

information on other tasks required for printing with your DocuPrint

printer.

Users should have an understanding of Printer Controller operations.

Before using this guide, bec om e familiar with its contents and

conventions.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE vii

INTRODUCTION

Contents

This section lists the contents of this guide.

• Chapter 1, “Feeder tra ys ,” provides information on how to load

feeder trays.

• Chapter 2, “Output trays,” describes how to unload output trays

for the DocuPrint printer.

• Chapter 3, “Stitcher wire,” provides information on how to

continue printing when the spool is out of wire.

• Chapter 4, “Fuser lubricant and pressure roll wiper,” describes

how to refill the fuser agent reservoir, and how to replace the

pressure roll wiper.

• Chapter 5, “Inks,” describes how to add both black and color

dry ink, and how to replace the Customer Changeable Unit

(CCU) for the color dry ink.

• Chapter 6, “Waste containers,” provides information on how to

replace the developer and the dry ink waste containers.

• Chapter 7, “Bypass transport,” describes how to install and

remove the optional bypass transport.

• Chapter 8, “Cleaning,” provides instructions on how to clean the

various printing system components.

• Chapter 9, “Maintenance and support ser vices ,” provides

information on how to call for service, order supplies, and report

meter readings.

An index is provided at the back of the guide.

viii XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

Conventions

INTRODUCTION

This guide uses the following conventions:

• Italics — Document and library names are shown in italics (for

example, the Xerox DocuPrint 92C IPS Guide to Performing

Routine Maintenance).

• Capitalization of graphical user interface (GUI) window titles

matches the titles as they appear on the screen. In cases where

a window does not have a title, it is referenced using all lower

case. For example:

— At the graphical user interface, use the Output

Configuration window to group the trays.

— The main window displays the current system status.

Note: Notes are hints that help you perform a task or understand

the text.

Caution: Cautions alert you to an action that could damage

hardware or software.

Warning: Warnings alert you to conditions that could affect the

!

safety of people.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE ix

INTRODUCTION

Related publicat ion s

Xerox documen ts Following is a list of all Xerox DocuPrint IPS documents. For a

This document is part of the Xerox DocuPrint IPS publication set.

complete list and description of available Xerox documentation, refer

to the Xerox Customer Documentation Catalog (publication number

610P17517), or call your service representative.

Application Programmer/System Administrator Quick Reference

Card

Customer Information Quick Reference Card

Generic MICR Fundamentals Guide

Glossary

Guide to Configuring and Managing the System

Guide to Performing Routine Maintenance

Helpful Facts About Paper

Installation Planning Guide

Master Index

Messages Guide

Solutions Gu ide

System Overview Gui d e

Troubleshooting Guide

Xerox Standard Font Library Font User Guide

The documentation set also includes an electronic version, the

DocuPrint IPS Interactive Customer Documentation CD.

IBM documents Following are related IBM documents. Contact your local IBM

representative for ordering instructions for IBM AFP/PSF manuals

that might be useful for your specific installation.

IBM 3825 Page Printer Product Description

IBM Intelligent Printer Data Stream Reference

IBM Advanced Function Presentation Printer Summary

IBM ITSC Distributing AFP Printing from a Host System

IBM Advanced Function Printing Data Stream Reference

IBM Data Stream and Object Architectures: Mixed Object Document

Content Architecture Reference

Guide to Advanced Function Presentation

x XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

Checking feeder trays

1. 1Feeder trays

This chapter describes the processes for loading paper in the

92C IPS feeder trays, and explains what actions are necessary if a

paper stock is changed.

Check the amount of paper in each feeder tray by examining the

green lights on the door of the tray. Each light represents 25 percent

of a ream, or about 125 sheets of 20-pound or 80 gsm (grams per

square meter) paper.

• You do not have to interrupt a print job to load paper because

you can refill one tray while the printer is feeding from another

tray.

• If you try to load a tray that is currently in use, the feeding

switches to a backup tray if one is availab le. If a backup tray is

not available, the printer stops.

• The printer does not feed all the paper out of a tray. A stack of

approximately 1/4 inch / 6 mm remains in the tray.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE 1-1

FEEDER TRAYS

Loading feeder trays

Guidelines for loading paper

It is important to load paper properly in the feeder trays to prevent

jams and loss of production time. The following guidelines will help

ensure maximum efficiency of your IPS printer’s operation.

When you are loading the paper, follow these guidelines to prevent

paper jams:

• Remove damaged sheets.

• Load the paper with the package wrapper seam side up.

• Make sure that the direction of the curl is consistent.

• Avoid fanning the paper unless the stock is predrilled.

• Do not load the paper above the MAX line on the length guide.

• Place any paper left in the bottom of the tray on top of the new

paper stack.

• When loading predrilled paper, fan the paper and remove

loose paper plugs.

1-2 XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

Loading the trays

FEEDER TRAYS

Follow these steps to load a feeder tray:

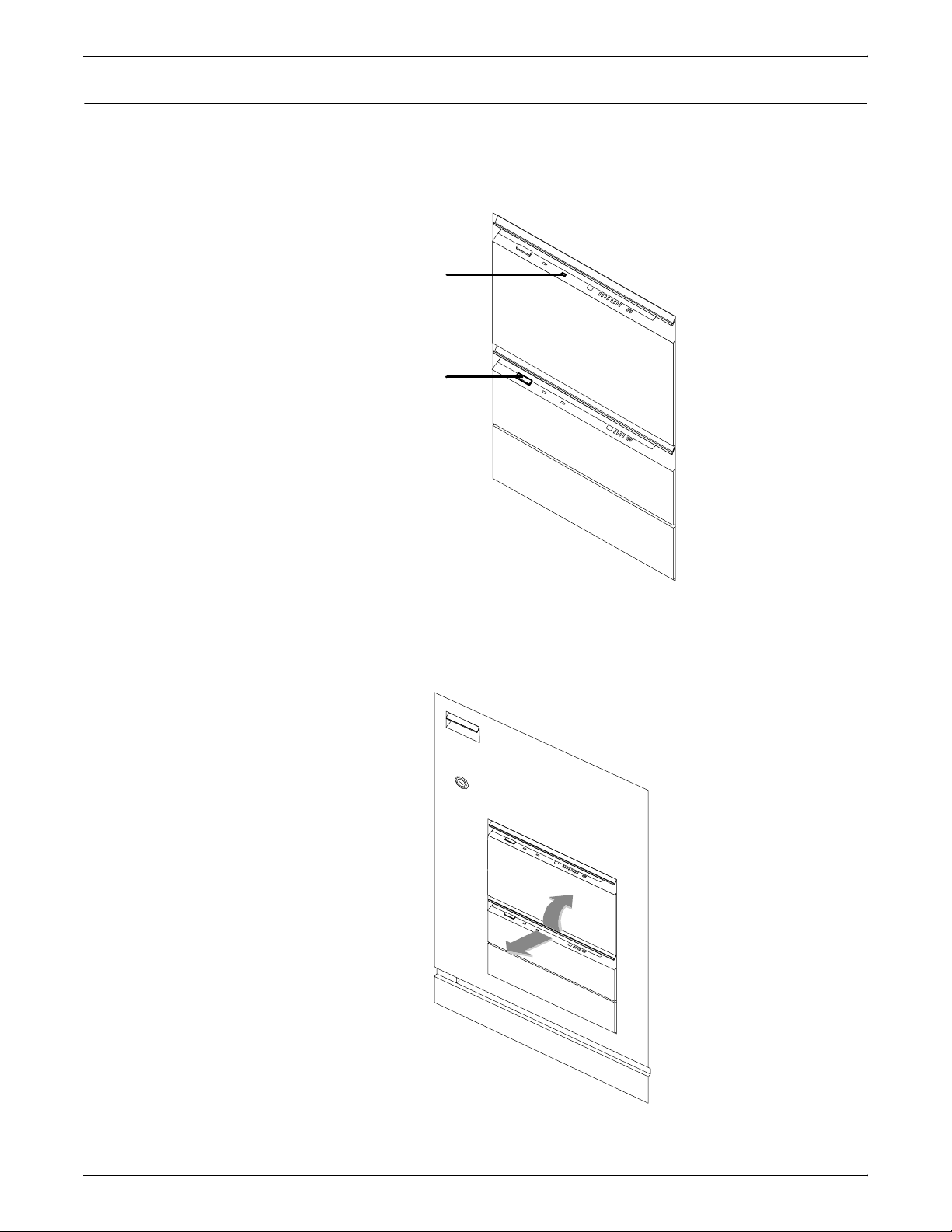

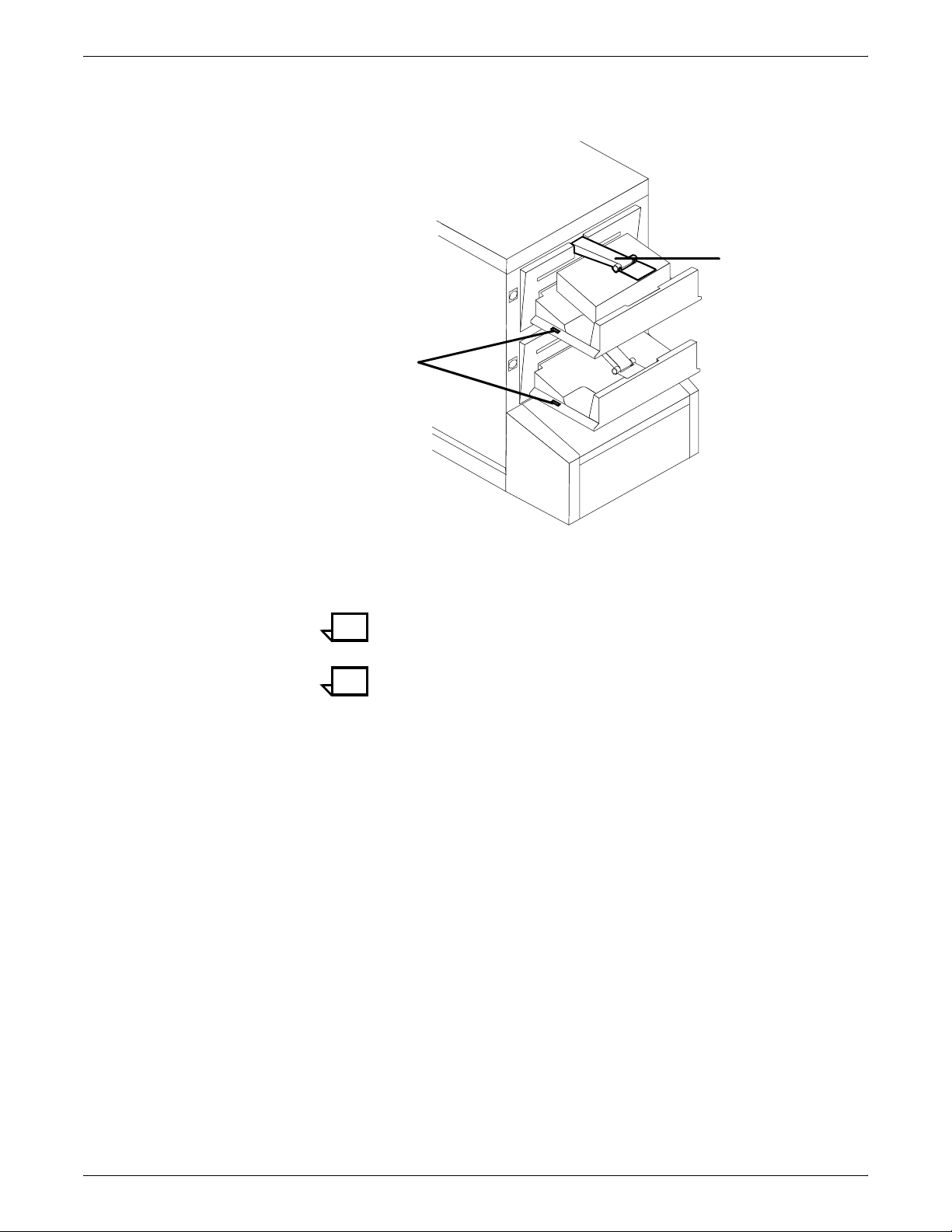

1. If the Ready T o Open indicator on the feeder tray door is not lit,

press the Tray Unlock button and wait for the tray to descend

and the Ready To Open indicator light before opening the tray.

1

2

1 Ready to Open Indicator

2 Tray Unlock button

2. Lift and pull on the bar along the top of the feeder tray. Slide the

tray all the way out for best access and ease of loading.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE 1-3

FEEDER TRAYS

3. Press the green lever down to unlatch the paper feeder

assembly.

Caution: Attempting to move the lever in any other direction

can break it.

4. Pull out any partially fed paper from the feeder assembly and

discard it. There will be some resistance.

5. Squeeze the lever against the back of the length guide and slide

the guide toward the back of the printer.

6. Remove any paper remaining in the tray and set it aside to be

placed on top of the new paper.

1-4 XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

FEEDER TRAYS

7. Load paper, following the instructions at the front of the feeder

tray and carefully positioning the paper in the right-front corner

of the tray.

8. Pull the length guide forward to touch the back of the paper

stack.

9. Latch the paper feeder assembly by pressing the green dot next

to the green release lever until the assembly clicks into position.

10. Slide the tray into the printer until it latches. The tray rises

automatically into position.

11. Press the Continue button to resume printing.

Note: If you change to larger paper after an extended run of smaller

paper, run 20 copies of a sample document to clean the fusing

system. Otherwise, the first pages of the new job may be of poor print

quality.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE 1-5

FEEDER TRAYS

Note: When you change the paper size in one of the feeder trays,

a message displays asking you to make sure the printer is warmed

up, ready, and loaded with the proper media. The message displays

the media defined for the tray, as well as the paper currently loaded

in the tray.

Currently, there is no method of restoring the Input Configuration to

its original state. Once you select Modify, the Input Configuration

window appears. Make changes on the window as appropriate, then

save your changes. For detailed information on the Input

Configuration window, refer to the Xerox DocuPrint 92C IPS Guide t o

Configuring and Managing the System.

1-6 XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

2. 2Output trays

Your print jobs are sent to printer output trays, which you must

unload. You can unload each of the output trays while the system is

printing. How you do so, however, depends on the type of tray. This

chapter discusses how to check and unload the types of trays

available.

In all cases, if the printer has stopped due to a full output tray and

does not resume automatically when the tray is emptied, press the

Continue button on the printer control console.

Checking and unloading dual stacker trays

When a stacker tray is full, the following occurs:

• The Tray Full indicator lights on the appropriate stacker tray.

• The attention light shines steadily.

• The printer control console displays a message indicating which

output tray is full.

• The picture on the graphic display shows the location of the full

tray.

• If you select only one tray, the printer stops when that tray is full.

• If you select both trays and the first tray is not emptied by the

time the second output tray is full, the printer stops and displays

the message that both output trays are full.

Each stacker tray holds 750 sheets of 20-pound or 80 gsm (grams

per square meter) paper.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE 2-1

OUTPUT TRAYS

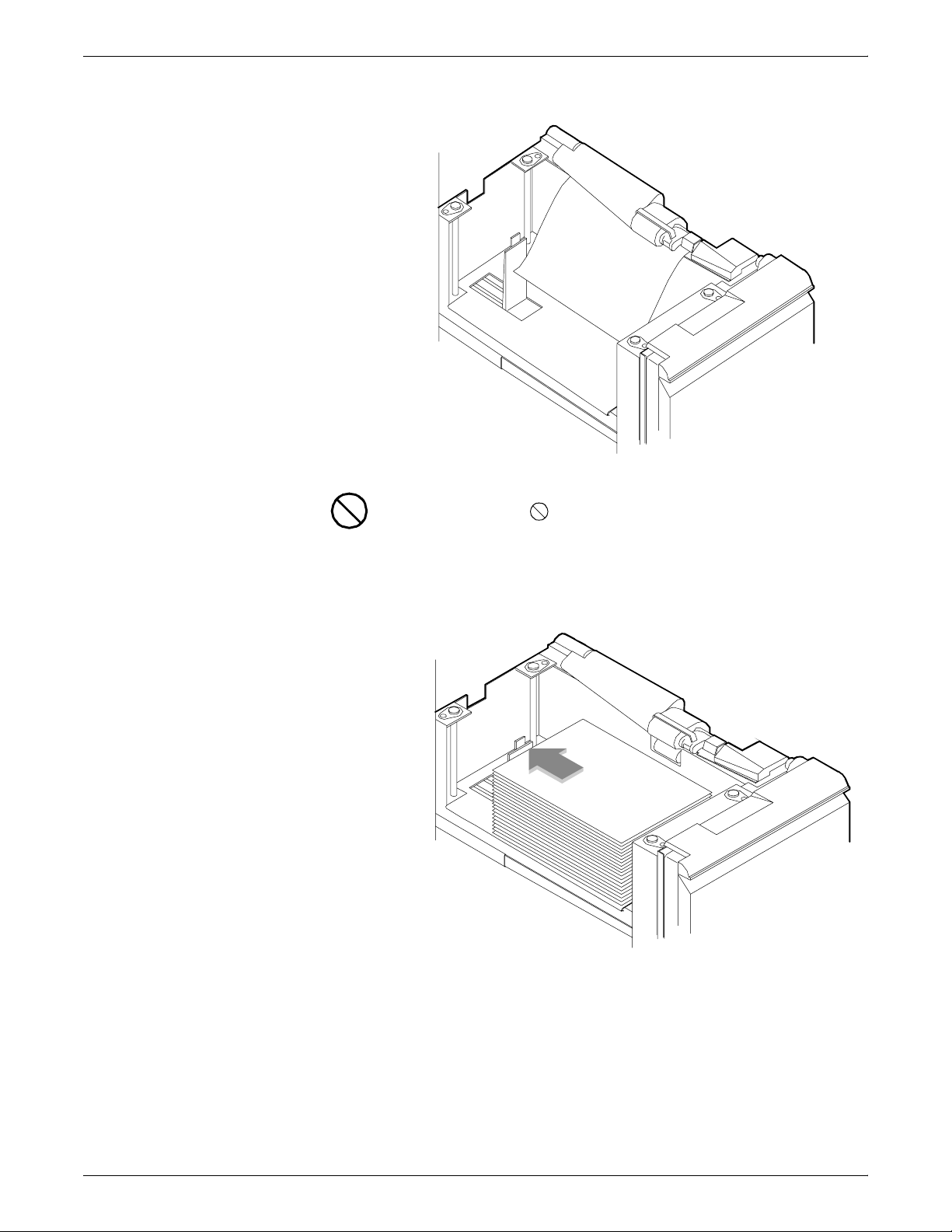

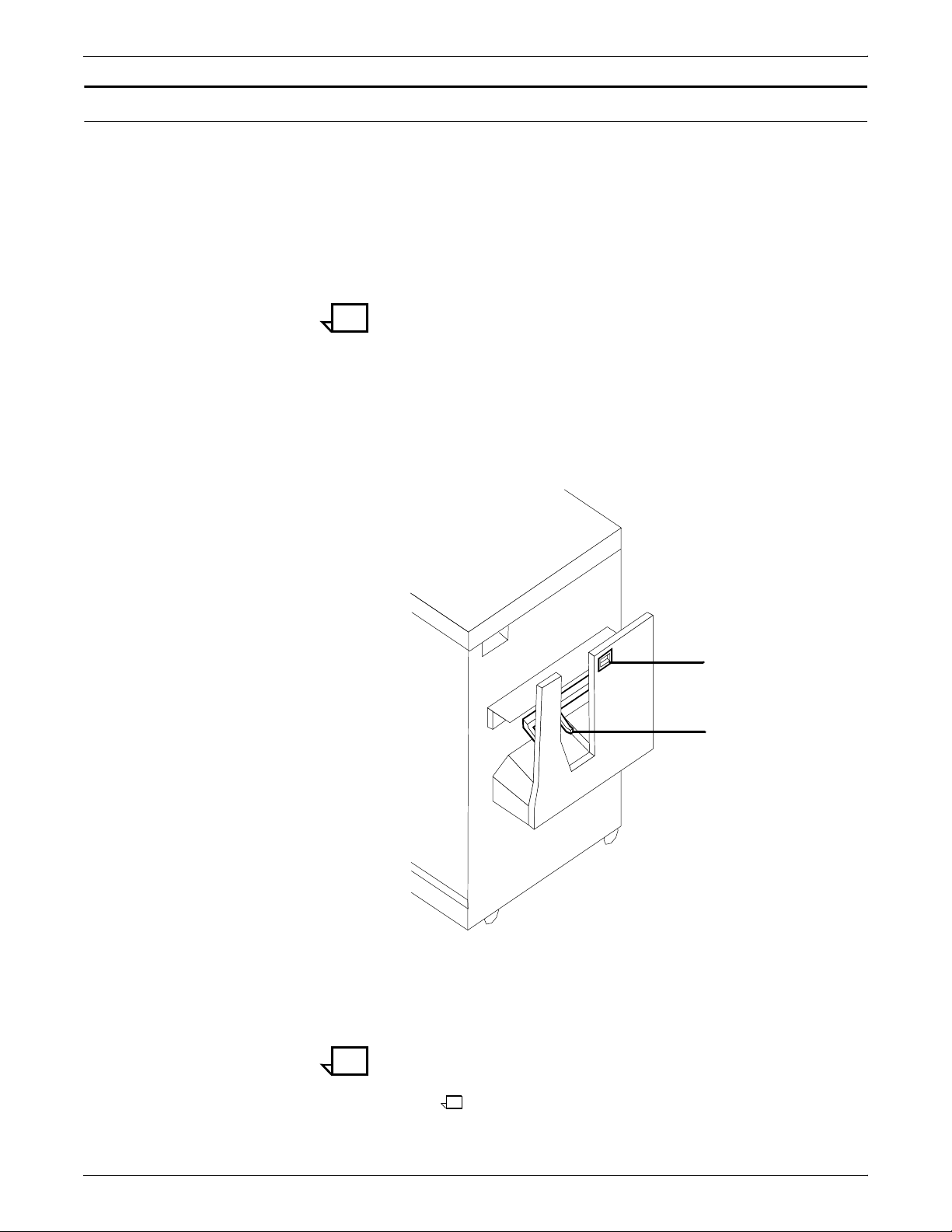

Unloading the dual stacker trays To unload each dual stacker tray, raise the scuffer arm and remove

the printed pages.

1

2

1 Scuffer arm

2 Tray Full indicators

Note: When both trays are full, you must empty at least one tray

before you can resume printing.

Note: Your service representative can set up your printer so that

printing continues automatically after a dual stacker tray is unloaded

and replaced.

2-2 XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

Checking and unloading the stitcher/stacke r tra y

An electronic counter in the stitcher/stacker keeps track of the

number of sheets printed and the number of stapled sets produced.

When a stacker tray is full, the following occurs:

• Printing stops and a message appears on the printer control

console that the output tray is full.

• The attention light shines steadily.

Note: A false tray full condition may occur when you remove small

stapled sets without pulling the tray out. The counter is not reset,

causing the printer to stop before the tray is actually full.

Each stitcher/stacker tray holds 2000 sheets of 20lb (80 gsm) paper.

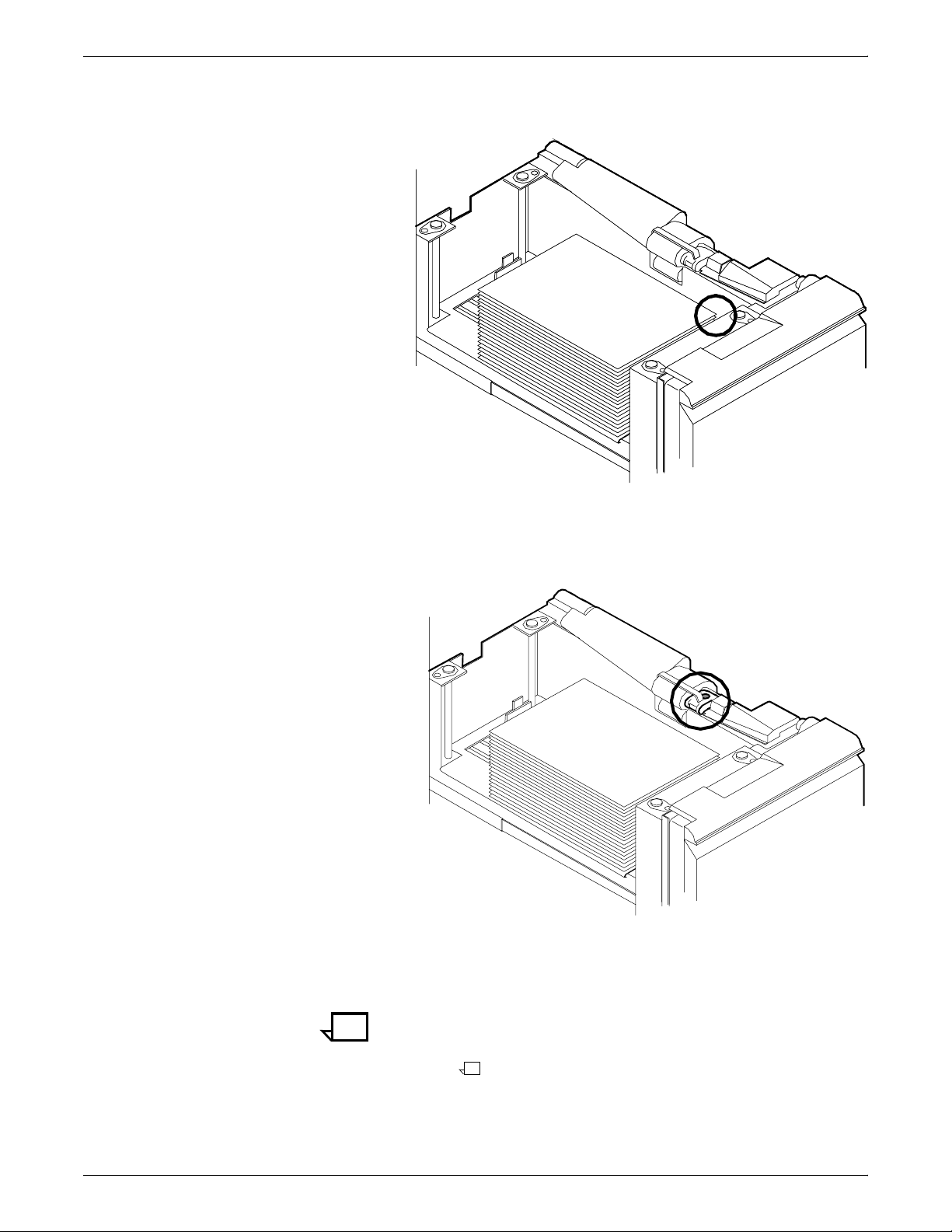

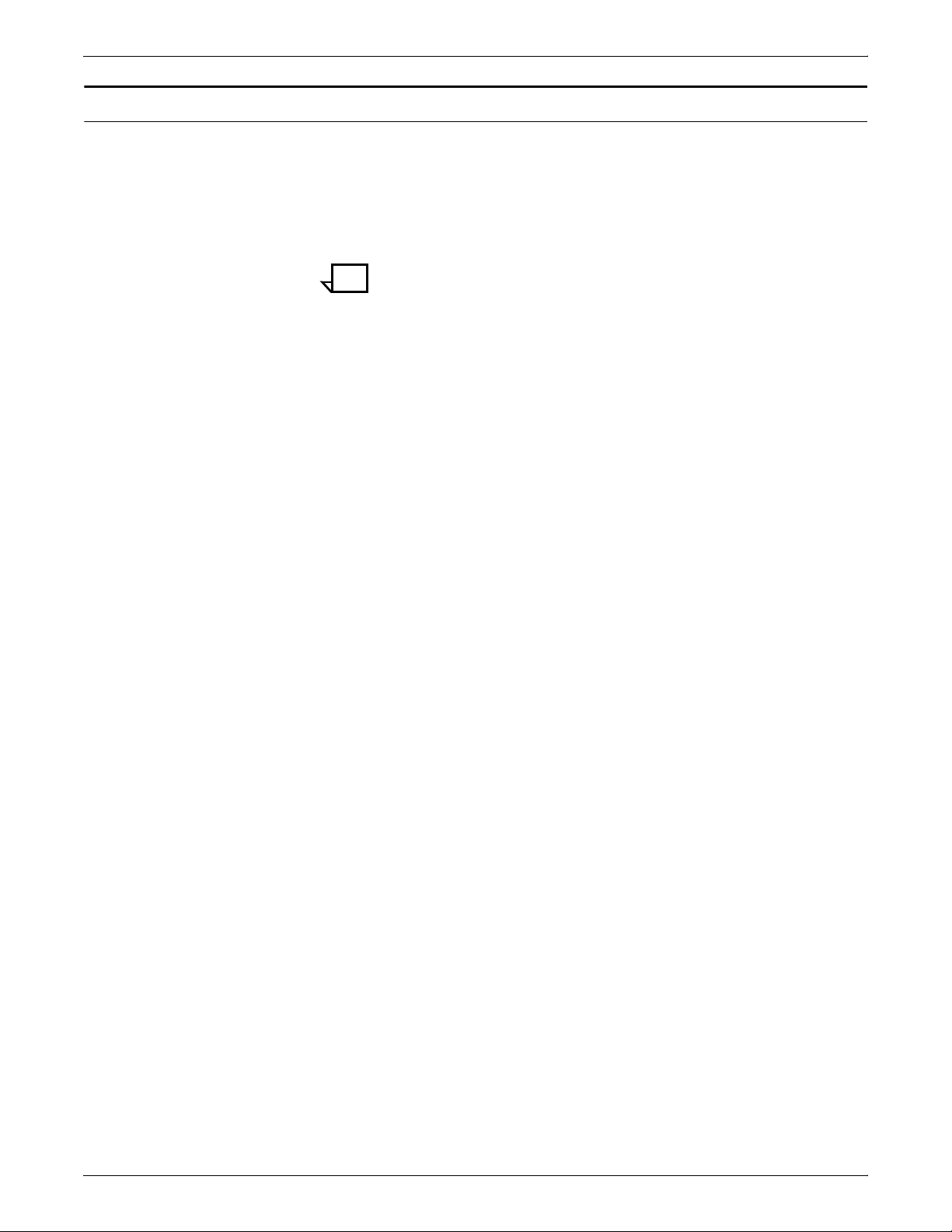

Unloading the stitcher/stacker tray To unload the stitcher/stacker tray:

1. Lift the black handle on the outside of the tray.

OUTPUT TRAYS

1

2

1 Tray handle

2 Stacker arms

2. Carefully slide the tray up and out and remove the printed

pages.

Note: A false Tray Full condition may occur when you remove

small stapled sets without pulling the tray out. The counter is not

reset, causing the printer to stop before the tray is actually full.

3. Close the tray by sliding it back under the stacker arms.

XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE 2-3

OUTPUT TRAYS

Checking and unloading the sa mple tray

The sample tray holds up to 100 sheets of paper from 8.5 by 11

inches / 216 by 279 mm to 8.5 by 14 inches / 216 by 356 mm. A

message appears when the sample tray is about to fill, as well as

when it is full. Because a paper jam can occur if the tray is overfilled,

empty the sample tray regularly if it is in use.

To empty the sample tray, remove the printed pages.

Note: The sample tray can receive purged sheets after a paper

jam. Always clear the sample tray after clearing a jam to prevent

purged sheets from being confused with good sheets.

2-4 XEROX DOCUPRINT 92C IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

Loading...

Loading...