Xerox DocuPrint NPS, DocuPrint 4850 NPS, DocuPrint 4890 NPS, DocuPrint 92C NPS, DocuPrint 4850 IPS System Overview Manual

...Page 1

Xerox DocuPrint

4850/4890/92C

NPS/IPS

System Overview Guide

721P90160

Version 8.0

October 2002

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©2002 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable

material and information now allowed by statutory or judicial law or hereinafter

granted, including without limitation, material generated from the software

programs which are displayed on the screen, such as icons, screen displays,

looks, etc.

Printed in the United States of America.

Publication number: 721P90160

Xerox® and all Xerox products mentioned in this publication are trademarks of

Xerox Corporation. Products and trademarks of other companies are also

acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent editions.

Page 3

System Overview Guide iii

Table of contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Radio and telecommunications equipment directive (Europe only) . . . . xii

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1. System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Functional overview of the NPS/IPS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System components overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connectivity configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

NPS/IPS concurrent printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Document Feeding and Finishing Architecture (DFA) . . . . . . . . 1-4

SNMP support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

IPP support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Sixth Sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Software license . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

How highlight color is created . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

How to convert full color to highlight color . . . . . . . . . . . . . . . . . 1-7

Color substitution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Page 4

Table of contents

iv System Overview Guide

2. Printer controller overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Printer controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Sun Blade 1000 workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Sun Ultra 60 workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Printer controller software and fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3. Printer components and options . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printer components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printer console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Additional printer features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Printer configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

High-capacity feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Dual stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Stitcher/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Bypass transport (4850 and 4890 only) . . . . . . . . . . . . . . . . . . . . . . . 3-11

Software, firmware, hardware, and paper requirements . . . . . 3-12

Operator tasks for the bypass transport . . . . . . . . . . . . . . . . . . 3-12

Profiles for third-party finishing devices . . . . . . . . . . . . . . . . . . 3-13

Mechanical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Paper paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4. Network prin ting environment . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Client workstations and system software . . . . . . . . . . . . . . . . . . . . . . . 4-1

Client software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Submitting print jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Communicating with the network . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Job status feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Ethernet LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Token Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Multiple network connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

5. IPDS printing environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Host connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Host environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Channel interface —channel-attached systems only . . . . . . . . . 5-3

Host Channel Unit (HCU)—channel-attached systems only . . . 5-4

IPDS data stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Software features for IPDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

IOCA Replicate and Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Trace facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Overstrike, underscore, subscript, and superscript . . . . . . . . . . 5-6

Color image support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Background color for OCA colors . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Bi-level IOCA colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Outline font support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Page 5

Table of conte nts

System Overview Guide v

A. Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Paper and other throughput stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Selecting paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Paper care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Other supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Dry ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Fuser lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Stitcher wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Consumable supplies tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Paper and special stocks tables . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Complete supplies list—4850/4890/92C printer . . . . . . . . . . . . A-12

Ordering supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Page 6

Table of contents

vi System Overview Guide

Page 7

System Overview Guide vii

Safety

Laser safety

WARNING

Adjustments, use of controls, or performance of procedures

other than those specified herein may result in hazardous

light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance stan dards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuPrint printers

do not emit hazardous radiation because the laser beam is

completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must

be removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XEROX SERVICE REPRESENTATIVES HAVE

ACCESS TO THESE PANELS.

Page 8

Safety

viii System Overview Guide

Ozone information: U. S. only

This product produces ozone during normal operation. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental parameters specified in the

Xerox installation instructions ensure that concentration levels

are within safe limits. If you need additional informat ion

concerning ozone, call 1-800-828-6571 to request the Xerox

publicat ion 600P83222, OZONE.

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with

environmental standards. Please observe the following

precautions to ensure your continued safety.

WARNING

Improper connection of the equipment grounding conductor

may result in risk of electrical shock.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

• Never use a ground adapter pl ug t o connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed fo r

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the printer controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. Th ere are no oper ator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

Page 9

Safety

System Overview Guide ix

• Never use supplies or cleaning materials for other than the ir

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet

and call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your loc al

Xerox representative or operating company.

Operation safety: Eur o pe

This Xerox product and supplies are manufactured, test ed and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised al teration, which may include the addition of

new functions or conn ection of external devices, may impact the

product certification.

Please contact your Xerox representative for more information.

Warning markings

All warning ins tructions ma rked on or supplied with the product

should be followed.

This WARNING alerts users to areas of the product where there

is the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surf ace s, which should not be touched.

Page 10

Safety

x System Overview Guide

Electrical supply

This product shall be operated from the type of electrical supply

indicated on the product’s data plate label. If you are not sure

that your electrical supply meet s the requirem ents, please

consult your local power co mpany for advice.

This product must b e connected t o a protectiv e earth circuit. This

product is supplied with a plug that has a protective earth pin.

This plug will fit only into an earthed electrical outlet. This is a

safety f eature . Always co nnect equipment to a properly gr ounded

electrical outlet. If in doubt, ha ve the ou tlet check ed b y a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Ventilation

Slots and ope ning in the enclosure of the product are provid ed

for ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheating.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to restrict operator access to

safe areas only. Operator access to hazardo us areas is restricted

with covers or guards, which would require a tool to remove.

Never remove these covers or guards.

WARNING

Page 11

Safety

System Overview Guide xi

Maintenance

Any operator product maintenance procedures will be described

in the user docume ntation supplied with the product. Do not

carry out any maintenance on the product, which is not

described in the customer documentation.

Before cleaning your product

Before cleaning this product, unplug the product from the

electrical outlet. Always use materials specifically designated for

this product, the use of other materials may result in poor

performance and may create a hazardous situation. Do not use

aerosol cleaners , they may be flammable under certain

circumstances.

CE mark: Europe only

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336 /EEC, approximation

of the laws of the member states related to electr omagnetic

compatibility.

March 9, 1999: Council Directive 99/5/EC, on radio equipment

and telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives

and referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment this product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this product to

maintain compliance with Council Directive 89/36/EEC.

Page 12

Safety

xii System Overview Guide

Radio and telecommunications equipment directive (Europe only)

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog public

switched telephone network (PSTN) in accordance with Directive

1999/5/EC.

The product has been design ed to w ork with the nation al PSTNs

and compatible PBXs of th e following countries:

In the event of problems, contact y our local Xe ro x r epres entative

in the first instance.

This product has bee n tested to, and is compliant with, TBR2 1, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no us er-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliable and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, invalidates

its certification.

Austria Germany Luxembourg Sweden

Belgium Greece Netherlands Switzerland

Denmark Iceland Norway United Kingdom

Finland Ireland Portugal

France Italy Spain

Page 13

Safety

System Overview Guide xiii

For further information

For more information on Enviro nment, Health and Safety in

relation to this Xerox product and supplies, please contact the

following customer help lines:

Europe:+44 1707 353434

USA:1 800 8286571

Canada:1 800 8286571

Page 14

Safety

xiv System Overview Guide

Page 15

System Overview Guide xv

Introduction

This guide prov ides a n overview of the individual component s of

the NPS/IPS printing system and how they work together. It is

designed to pro vide yo u with b ac kgro und information that can be

used to make informed decisions regarding printer use and

performance.

About this guide

This guide provides information to help you quickly determine

hardware, software, and connectivity requirements for printing

from various clients to the DocuPrint NPS/IPS.

This reference is useful for users who want to understand the

overall DocuPrint NPS/IPS. Managers can use the reference

information to assist them in making planning decisions.

Contents

This section lists the contents of this guide:

• Chapter 1, “System overview,” describes the hardware and

software f eatu res of the DocuPrint 4850/4 890/92C NPS /IPS .

It also provides information about highlight color.

• Chapter 2, “Printer controller overview,” describes the

hardware and software components of the printer controller.

• Chapter 3, “Printer components and options,” describes the

printer components and possible configurations. It also traces

the path of the paper through printer, which is helpful in

locating possible paper jams.

• Chapter 4, “Network printing,” provides information that is

specific to network printing.

• Chapter 5, “IPDS printing,” provides information that is

specific to IPDS printing.

Page 16

xvi System Overview Guide

• Appendix A, “Suppl ie s ,” provides in formation and

specifications on paper and other media used with the NPS/

IPS, as well as instructions for ordering supplies.

Conventions

This guide uses the following conventions:

• All caps and angle brackets: Withi n procedures , the names

of keys are shown in all caps within angle brackets (for

example, press <ENTER>).

• Angle brackets: Variable information, or the positi on of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold: Within procedures , te xt and number s that you e nter are

shown in bold (for example, enter privilege operator).

• The word “enter” within pr ocedures: The two-step process

of keying in data and p ressing <ENT ER> (for example,

enter y).

• Italics: Document and library names are shown in italics (for

example, the Xerox DocuPrint NPS/IPS Guide to Managing

Print Jobs).

• Quotation marks: Keywords you can enter as arguments

appear in quotes (for example, “USLetter”).

• Vertical bars: Alternatives to specifie d ar guments are

separated by vertical bars (for example, Set Time <Time |

Remote Host Name | IP Address>).

Page 17

Introduction

System Overview Guide xvii

NOTE: Notes are hints that help you perform a task or

understand the text.

CAUTION

Cautions alert you to an action that could damage hardware or

software.

WARNING

Warnings alert you to conditions that may affect the safety

of people.

Related publications

The Xerox DocuPrint NPS/IPS documentation set includes the

documents listed below.

NOTE: For a list of IBM reference manuals for IPDS printing,

refer to the Solutions Guide for IPDS Printing.

• Guide to Configuring and Managing the System

• Guide to Managing Print Jobs

• Guide to Performing Routine Maintenance

• Guide to Submitting Jobs from the Client

• Guide to Using Page Description Languages

• Installation Planning Guid e

• System Overview Guide

• Troubleshooting G uide

• Solutions Guide for IPDS Printing

• Decomposition Service and Tools Guide

• Glossary

• Master Index

• Customer Information Quick Reference Card

• Printer Contr o ller Comman d s Qu ick Reference Ca r d

• Operator Quick Reference Card

• Submitting your Jobs from Macintosh Quick Reference Card

• Submitting your Jobs from UNIX & DOS Quick Reference

Card

Page 18

xviii System Overview Guide

• Submitting your Jobs from Windows NT 4.0 (QuickPrint)

Quick Reference Card

• Submitting your Jobs Using Windows NT 4.0 Drivers Quick

Reference Card

The documentation set also includes an electronic version, the

DocuPrint NPS/IPS Interactive Custome r Documenta tion CD.

Page 19

System Overview Guide 1-1

1. System overview

This chapter introduces the DocuPrint NPS/IPS printing system

and describes its major and optional components. It also

provides information on how highl i gh t colo r is use d in printed

documents.

Functional overview of the NPS/IPS

The NPS/IPS printers support the processing and printing of

PDL and ASCII jobs fr om ne twork workstations, as well as IPDS

jobs from an IBM host. Supported PDL formats are PostScript

levels 1 and 2, HP PCL 5c, HP PCL 5e, and TIFF.

Your organization may print only IPDS job s, network PDL jo bs, or

jobs from both environments.

DocuPrint 4850, 4890, and 92C NPS/IPS printers support:

• Printing in various shades and tints of a highlight color plus

black

• Printing in highlight color (black plus one color) at a rated

speed of up to 50 ppm at 300 dpi (4850); 92 ppm at 300 dpi

(4890); and 92 ppm at 300 or 600 dpi (92C)

• Printing simplex and duplex

• Processing and printing of network PDL jobs and IPDS jobs

without soft boot to switch modes

• Multiple weights, sizes and types of paper (refer to the

“Supplies” appen dix for details)

• Optional high-capacity feeder

• Optional high-capacity stitch er/stacker

• Optional bypass transport for enhanced finishing and output

to third-party finishing devices (4850 and 92C)

• Sixth Sense, a diagnostic tool that provides system

assessment and problem analysis.

Page 20

System overview

1-2 System Overview Guide

Resolution

The 4850/4890 NPS/IPS provides high print quality at 300 dpi

resolution. It can receive data at 240, 300, or 600 dpi. The

controller converts 240 and 600 to 300 dpi data.

The 92C NPS/IPS provides exceptional print quality at 600 dpi

resolution. It can receive data at 240, 300, or 600 dpi. The

controller can convert incoming data to 600 dpi for printing, or

can conv ert the data to 240 o r 30 0 dpi an d al lo w t he print en gine

to convert the pages to 600 dpi.

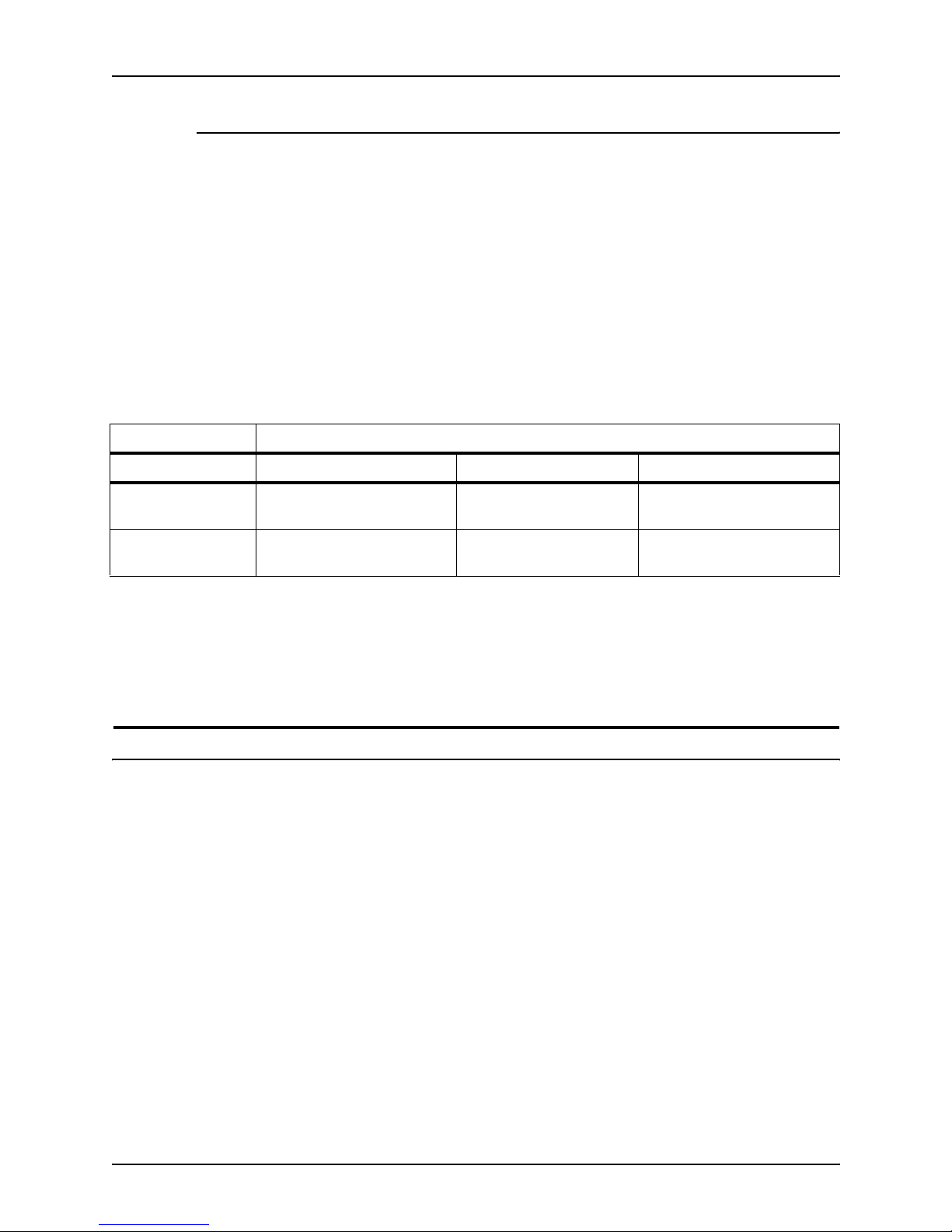

The following table shows how data streams of different

resolutions are interpolated.

NOTE: For more information on specifying appropriate

resolution settings, refer to the Guide to Managing Print Jobs

and the Guide to Configuring and Managing the System. For

IPDS printing, refer to the to Solutions Guide for IPDS printing.

System components overview

DocuPrint NPS/

IPS

The entire DocuPrint NPS/IPS system includes the printer (also

known as an IOT or print engine), printer controller, printer

interface, and all appropriate software. “DocuPrint printer” or

“printer” refers to the base printer e ng ine (IOT) only, without the

printer controller and interface.

Xerox-supplied

printer controller

The printer controller includes a processor, DVD-ROM (or CD ROM) driv e , disk ette driv e, k e ybo ard, mo use, and a m onitor. The

printer controller accepts the print job fr om the clien t wo rkstation

or host, converts the files into page images, and sends the page

images to the printer. The user interface at the printer controller

allows you to perform tasks such as monitoring job status,

prioritizing jobs, and configuring the system.

Table 1-1. Data stream conversion

Incoming input resolution of document

Printer 240 dpi data 300 dpi data 600 dpi data

4850/4890 NPS/

IPS

Converted by controller to

300 dpi

Print at 300 x 300 dpi Converted by controller to

300 dpi

92C NPS/IPS Converted by controller to

600 dpi

Converted by controller

to 300 dpi

Print at 600 x 600 dpi

Page 21

System overview

System Overview Guide 1-3

Xerox-supplied

printer interface

The printer interface cables provide high-speed data transport

and communication between the printer controller and the

printer.

Xerox-supplied

DocuPrint printer

The printer accepts data from the printer co ntroller and prints the

document according to the print options specified by the user.

The printer also provides optional paper stitching and stacking.

Connectivity configurations

The NPS/IPS ca n process network PDL and IPDS jobs

concurrently.

To support the submission of jo bs from a variety of hosts,

configuration possibilities include:

• The same T ok en Ring or Ethernet connection can be used for

both IPDS and Postscript/PCL.

• Both a Token Ring card and an Ethernet card can reside in

the Sun workstation controller, with one being used for IPDS

and the other for PostScript/PCL.

• Bus and tag attach ment thro ugh the channe l interface can be

used for IPDS jobs from a channel-attached host; T ok en Ring

or Ethernet connection can be used for jobs submitted over

the network.

NPS/IPS concurrent printing

The Xerox NPS/IPS can receive a variety of data streams

including IPDS, PostScript Levels 1 and 2, PCL 5c, PCL 5e, TIFF,

and ASCII. The system automatically senses the type of job and

processes it appropriately.

When your system is printing IPDS jobs, it can accept network

PDL data streams in the background. When network PDL jobs

are printing, only one IPDS job can be queued.

Page 22

System overview

1-4 System Overview Guide

Document Feeding and Finishing Architecture (DFA)

The Document Feeding and Finishing Architectu re (DFA) on the

NPS/IPS supports all third-party finishing devices currently

validated for the LCDS (J11) printers (DFA is not supported on

the 4850). The bypass transport option is required for in-line

finishing devices .

SNMP support

The system provides functionality to export the state of a printer

using the Simple Network Management Protocol (SNMP), thus

allowing printer management software to monitor and report on

the printer state.

SNMP is a standardized communications protocol for managing

arbitrary networked devices from different vendors, such as

workstations, servers, printers, or routers. The information to be

communicated is presented as variable name/value pairs,

defined in a set of standardized management information bases

(MIBs). The MIBs define the legal variables, their types, and

possibly a fixed set of values.

SNMP was designed to facilitate managing a heterogeneous set

of networked devices that communicate using TCP/IP.

Specifically, it addressed management of the network itself and

the network traffic betw een th ose devices. Over time, MIBs were

defined to expand the types of devices that could be managed

using SNMP. For example, MIBs were defined specific to

managing a wor kstation or a printer.

The system currently supports variables defined in the following

MIBs:

• MIB-II (RFC 1156)

This MIB defines the basic set of variables any device

running TCP/IP should make accessible . It includes, for a

particular device, variables for information such as a system

description, information about each of the network interfaces

present on the device, and information abou t all the IP

datagrams sent and received by the device.

Page 23

System overview

System Overview Guide 1-5

• Host Resources MIB (RFC 1514)

This MIB defines variables useful in managing a “host”

system. In this context, a host is a computer that is directly

used by human beings and that communicates with other

similar computers attached through a network. The Host

Resources MIB includes information such as how long the

system has been up, descriptions of the processors and

attached storage devices, and possibly information about

software running on the host.

• Printer MIB (RFC 1759)

This MIB defines information useful in managing a printer. It

includes information about the physical status of the printer,

such as the number of input trays, the media loaded in them,

and the numbe r and types of marking en gines inclu ded in the

printer.

Most variab les in these MIBs a re supported in a standard w ay, as

described in the standard documentation, except that writing to

read/write variables is not supported. All variables are treated as

read-only. In all cases, the NPS/IPS SNMP implementation

supplies textual information only in English.

IPP support

The system supports the Internet Printing Protocol (IPP), which

allows you to:

• Add the printer to your PC directly as an Internet printer with

a URL, rather than indirectly as an lpr-connected local printer.

• Use an IPP client to access the printer. A limited subset of

IPP operations is supported; query the IPP client for details.

Sixth Sense

Sixth Sense is a unique suite of diagnostic tools that allows

Xerox customer service engineers, analysts, and consultants to

serve customers more effectively.

Page 24

System overview

1-6 System Overview Guide

Sixth Sense is intended to automate and expedite the range of

service-related support functions. Sixth Sense is a tool that

enables Xerox to provide benchmark service support. Xerox

customers benefit from the ability to bring broader support to

focus more quickly.

For example, Sixth Sense can allow the Service Representative

to repeatedly "preview" the condition of the system prior to an

actual site visit. This may provide the ability to determine the

correct part or piece of information to have on hand when the site

visit is made.

Sixth Sense is a no-charge feature available to customers

through Xerox Service. The customer need only provide an

analog phone li ne for use by t he Sixth Sense modem connec tion.

For those cust omers una bl e to dedicate a ph one line to th e Sixth

Sense connection, three and five port phone share devices are

available for purchase.

To take advantage of Sixth Sense, the customer needs to:

• Request Sixth Sense enablement through Xerox Service

• Provide an analog phone line

• If necessary, purchase an optional phone share device.

More information abou t the Sixth Sen s e can be found in the

Troubleshooting Guide for your system.

Software license

In order to use the operating system software, the owner must

obtain a software license from Xerox. The license, which is a 20character text string, is entered at the printer controller.

Your Xerox service representative can obtain this license text

string for you and enter it when the printer is installed or when

the software is upgraded. Although your service representative

usually does this f or you, y ou are ab le to ente r yo ur license string

yourself from the NPS/IPS main window.

Until the license string is entered, your printer cannot print or

receive data. You can, however , perform all offline tasks, such as

setting up virtual printers.

For details on obtaining and entering the license string, refer to

the Guide to Configuring and Managing the System.

Page 25

System overview

System Overview Guide 1-7

How highlight color is created

A document with highlight color contains one color plus black.

The color ma y be printed either as a solid col or or combin ed wit h

black. The NPS/IPS prints the highlight color by printing small

dots in a single pass with near-perfect registration. The following

methods are used to create various tints, shades and tones:

• Tints of black or the highlight color are created by printing

dots of black or color with white space between them, thus

producing a percentage value of the color. An example of this

is gray or pink.

• Shades are created by printing black dots next to dots of the

highlight color. An example of this is dark red.

• Tones are created by printing a combination of black dots,

color dots, and blank space. The result is a percentage value

of black and the highlight color. Dark red is made by mixing

dots of red and black. Gray-pink is made by mixing red dots,

black dots and some blank spa ce.

• The patterns of dots are known as screens. Screens are

defined in the printer controller software as a matrix of bits,

which correspond to printed dots. The screen defines which

dots in the matrix are black, which are highlight color, and

which are not printed.

How to convert full color to highlight color

The NPS/IPS provides a selection of black dry ink and ten color

dry inks:

1. Red

2. Green

3. Blue

4. Cyan

5. Magenta

6. Cardinal (red)

7. Royal (blue)

8. Ruby

9. Violet

10.Brown.

Page 26

System overview

1-8 System Overview Guide

When the NPS/IP S receives a full-color document, the printer

software matches t he colors as closely a s possible . If y ou specify

a color in your document that the NPS/IPS cannot print, it is

printed either as a shade of gray or as an equivalent tone of

highlight color.

To control color conversion in your document, you can use the

map color option, also called “extraction color.” The map color

option is used to specify which color in the full color document

you want to print using the highlight color. Colors you do not

specify in the map color option print as shades of gray.

You can make the map color diff er fr om the highl ight color so that

red parts of a document are printed as green, or blue portions

are printed as red, and so forth.

The highlight color rendering algorithm enables you to specify

the qualities of a document that are the most important to

preserve. The highlight rendering attributes allow you to

distinguish between different colors, use preset color tables,

apply pictorial mapping for pictures, and apply presentation

mapping for other objects.

NOTE: To determine the RGB values of a specified highlight

color , vie w the system o ptions. When the Pictorial highlight colo r

rendering algorithm is used, the specified RGB value saturates

on the page. When the presentation algorithm is used, the RGB

value does not saturate on the page.

Color substitution

If the print document calls for a color that is not installed in the

printer, the printer controller acts according to the current color

substitution parameters.

The options for color substitution with the color mismatch action

are:

• Abort: Dele tes the job.

• UseLoadedColor: Uses the dry ink that is currently loaded

on the printer.

• RequestOperatorIntervention: Causes a job to be

ineligible for printing until the highlight color is changed.

You can specify these color substitution options at a client

workstation when sub mitting a job to the p rinter, or by specifying

the HightlightColorMismatchAction attribute in a virtual printer.

Page 27

System Overview Guide 2-1

2. Printer controller overview

The printer controller manages print options, provides the user

interface, and runs system management and diagnostic

operations on demand. The following is an explanation of tasks

that enable the job to be printed:

• The printer controller detects which job protocol is being sent.

• Print option parameters are stored in the Job Pool Manager

(JPM) database, which maintains a database of all jobs. This

database contains a reference to the print data on the fixed

disk, as well as the print optio ns paramete rs for the prin t data.

The JPM responds to the printer controller commands for

deleting, hol ding, and prioritizing jobs.

• Print data is stored on the printer controller disk for queuing

and while printing.

• When the printer controller begins processing a job, it sends

the print data to the decomposer. The decomposer converts

the print data into a bitmap in the resolution appropriate to

the printing device.

The decomposer utilizes font data from font files stored on

the printer c ontroller disk or font information sent to the

printer controller with the print job.

• When processed da ta come s back from the decomposer, the

printer controller Device Driver transmits the print data and

print option parameters to the printer. Printing is then

initiated.

• After the job has been printed successfully, the print data file

is deleted from the disk. If an error inhibits job completion, the

printer controller manages the recovery and completion of

the job.

The system can manage the processing of multiple jobs and the

printing of another job simultaneously. When you are printing

IPDS jobs, the printer controller is able to queue multiple

PostScript and PCL jobs at the same time. When you are printing

PostScript and PCL jobs, you can send only one IPDS job.

Page 28

Printer controller overview

2-2 System Overview Guide

Printer controller components

The printer controller consists of a specially-configured Sun

workstation and uses prop rietary Xerox h ardware, firmware, and

software.

Your system may use one of two platforms for the printer

controller:

• Sun Blade 1000

• Sun Ultra 60 workstation

Sun Blade 1000 works tat ion

The printer controller is based on the Sun Blade 1000, a

workstation with a high-performance architecture for complex

processing tasks. It contains the following hardware

components:

• Processor (system unit) containing the following:

– Two UltraSPARC III 750 Mhz central processing unit

(CPU) modules

– 4 GB memory (four 1 GB Dual In-line Memory Modules,

or DIMMs)

– 36 GB hard disk drive

– DVD-ROM drive

– 3.5 inch diskette drive

• Keyboard and mouse

• Monitor

• Optional Token Ri ng board

• Two printer controller Inter face (PCI) boards installed in the

processor to interface with the print engine.

Optional

components

For channel connection to a host for IPDS printing, the system

may use a channel in ter face board that is connected to a

channel cable connector box.

An external 4 mm ta pe drive is available and recommended for

backing up site files. A typical color calibration file is 1.5 MB.

A second internal 36 GB hard disk drive is optional, as are two

additional external disks.

Page 29

Printer controller overview

System Overview Guide 2-3

Figure 2-1. Components of the printer controller

1. Monitor

2. Mouse

3. Keyboard

4. Diskette drive

5. DVD-ROM drive

6. Processor

Processor The central processing unit contains the memory, internal disk

drive, a graphics board, a DVD-ROM drive, a diskette drive,

power receptacle and outlet, connectors and ports.

• Memory: Four 1 GB Dual In-line Memory Modules, or DIMMs

are provided as a standard feature of the processor.

• Hard disk drive: A 36 GB primary disk drive is provided as a

standard feature of the processor. The operating system, the

NPS/IPS applicat ion, and an y queued print jobs are stored on

the internal disk. This disk cannot be used to store other

applications or data except as directed by your service

representative.

• Graphics board: The Creator-3D series 3 graphics board is

provided as a standard feature of the processor.

Page 30

Printer controller overview

2-4 System Overview Guide

• Diskette drive: Diskettes inserted into a diskette drive are

used to install fonts and to load files to, and back up files

from, the internal disk drive. The diskette drive uses industry

standard 3.5 inch, 1.44 MB, double-sided, high-density

diskettes.

• DVD-ROM drive: The DVD-ROM drive is a high density,

read-only, optical laser storage device used for loading the

NPS/IPS operating system and other files. The CD-ROM

drive is located in the processor above the diskette drive.

• Back panel: The back panel of the processor has a power

receptacle an d outlet, conn ectors, connect or openings, and

ports. The following figure shows the back panel of the

controller.

Figure 2-2. Back panel of the printer controller

1. Access panel lock block

2. Serial connectors A and B, DB-25

3. Parallel connector

4. SCSI connector

5. Universal serial bus (USB) connectors

Page 31

Printer controller overview

System Overview Guide 2-5

6. Twisted-pair Ethernet (TPE) connector

7. IEEE 1394 connectors

8. Fibre Channel-Arbitrated Loop (FC-AL) connector

9. Audio module headphones, line-in, line-out, and

microphone connectors

10.Graphics card / video connector (frame buffer 0)

11.PCI card slot 4

12.Graphics card / video connector (frame buffer not used)

13.PCI card slots 3 and 2

14.Power connector

15.PCI card slot 1

Keyboard The keyboard consists of alphanumeric keys similar to a

typewriter, symbols and special character keys, an extended

character set, and function keys. You can use the keyboard to

make selections, and to enter commands that control fu nctions

such as requesting sample prints, or shutting down the system.

Mouse Use the mouse to select, move, or resize the windows.

Display monitor The 18.1-i nch LC D mo nitor allo w s y o u to in ter act w ith th e printer

and to monitor its interaction with the various components.

During a print job, printer error messages may display to notify

you of any unexpected conditions.

NOTE: For information on channel-attached systems, refer to

the chapter, “IPDS printing enviro nment”.

NOTE: Printer controller hardware configurations are subject to

upgrade.

Sun Ultra 60 workstation

A PCIM2 card for the Sun Ultra 60 is installed in the processor.

The printer cable is connected to the processor. In addition, the

processor contains the connectivity boards for Ethernet and

optional Token Ring. The disk stores the operating system, the

system software, and any buffered pages.

Page 32

Printer controller overview

2-6 System Overview Guide

Optional

components

For channel connection to a host for IPDS printing, the system

may use an HCU.

An external 4 mm ta pe drive is available and recommended for

backing up site files. A typical color calibration file is 1.5 MB.

Figure 2-3. Printer controller components (Sun Ultra 60)

1. Monitor

2. Keyboard

3. Mouse

4. Processor

5. Diskette drive

6. CD-ROM

7. Optional cartridge tape drive

8. Optional HCU

Processor The central processing unit contains the memory, internal disk

drive, a CD-ROM drive, a diskette drive, power receptacle and

outlet, connectors and ports.

• Diskette drive: The floppy disk drive is located in the

processor. It uses industry standard 3.5 inch, 1.44-MB,

double-sided, high-den sity floppy disks. This disk drive is not

an input source for print jobs or for any other data or

application. It is reserved exclusively for use by a service

representative to update software and to store files.

Page 33

Printer controller overview

System Overview Guide 2-7

• CD-ROM: The CD-ROM drive, located in the processor

above the diskette drive, is a high-density, read-only, optical

laser storage device used for loading the software, fonts and

other files.

• Cartridge tape drive: The Sun Ultra 60 offers an optional 8

GB, 4 mm external SCSI cartridge tape drive. Unlike the

diskette and CD drives, this tape drive is not an input source

for print jobs or for any other data or application. It provides

the service representative with another means of loading

system maintenance files or saving diagnostic information.

Keyboard The keyboard consists of alphanumeric keys similar to a

typewriter, symbols and special character keys, an extended

character set, and function keys. You can use the keyboard to

make selections, and to enter commands that control fu nctions

such as requesting sample prints, or shutting down the system.

Mouse Use the mouse to select, move, or resize windows.

Display monitor The display monitor has a high-resolution color screen, which

displays the user interface screen.

NOTE: For information on channel-attached systems, refer to

the chapter, “IPDS printing enviro nment”.

NOTE: Printer controller hardware configurations are subject to

upgrade.

Printer controller software and fonts

The installation of printer controller software is performed by your

service representative once all the hardware components are in

place and properly connected. The following is a summary of

major software components installed on the printer controller:

• Xerox printer controller software

– UNIX Sun operating system

NOTE: The Sun operating system used on the controller

is based on the standard Sun operating system; however ,

it has been customized for use with the Xerox pr inter

controller. Therefore, not all standard Sun operating

system features are available.

Page 34

Printer controller overview

2-8 System Overview Guide

– DocuPrint Print Service Software including software

components for the user interface, driver, decomposers,

Job Pool Manager, and other operating system utilities.

• Xerox Client Software

– Xerox client protocol so ftware (print command) can be

downloaded to client workstations or PCs as a means of

sending jobs.

• Adobe Type 1 PostScript fonts

– Courier (Courier, Bold, Oblique, Bold Oblique)

– Helvetica (Helvetica, Bold, Oblique, Bold Oblique, Light,

Light Oblique, Black, Black Oblique Condensed,

Condensed Oblique, Condensed Bold, Condensed Bold

Oblique Narrow, Narrow Bold, Narrow Oblique, Narrow

Bold Oblique)

– ITC Av antGa rde Gothic (Book, Boo k Oblique , Demi, Demi

Oblique)

– ITC Bookman (Demi, Demi Italic, Light, Light Italic)

– ITC Garamo nd (Light, L ight Italic, Bold, Bold Italic)

– ITC Korinna (Korinna, Kursiv Regular, Bold, Kursive Bold)

– ITC Zapf Chancery (Medium Italic)

– ITC Zapf Dingbats (Medium)

– New Century Schoolbook (Roman, Bold, Italic, Bold Italic)

– Palatino (Roman, Bold, Italic, Bold Italic)

– Symbol (Medium)

– Times (Roman, Bold, Italic, Bold Italic)

Using font installation commands, you can load oth er Type 1

PostScript fonts in *.PFB file format from a MS-DOSformatted, 3.5-inch diskette or CD-ROM or DVD-ROM. Refer

to the Guide to Configuring and Managing the System for

more information on the font installation commands. Type 1

and Type 3 PostScript fonts can also be downloaded with a

print job.

• PCL fonts: Intellifont (scalable)

– CG Times (Medium, Italic, Bold, Bold Italic)

– Universe (Medium, Italic, Bold, Bold Italic)

– Universe Condensed (Medium, Italic, Bold, Bold Italic)

– Courier (Medium, Italic, Bold, Bold Italic)

Page 35

Printer controller overview

System Overview Guide 2-9

– Letter Gothic (Medium, Italic, Bold)

– Albertus [Medium (semi-bold), Extra Bold

– Antique Olive (Medium, Italic, Bold)

– Clarendon Condensed (Bold)

– Coronet (Medium Italic)

– Garamond [Antique (medium), Kursiv (Italic), Halbfett

(Bold), Kursiv Halbfett (Bold Italic)]

– Marigold (Me di um )

– CG Omega (Medium, Italic, Bold, Bold Italic

• PCL fonts: Truetype (scalable)

– Arial (Medium, Italic, Bold, Bold Italic)

– Times new Roman (Medium, Italic, Bold, Bold Italic)

– Symbol (Medium)

– Wingdings (Medium)

• PCL fonts: Bitmap

– Line Printer (16.67 pitch / 8.5 point medium)

NOTE: The resident fonts are used for PostScript and PCL

printing.

Page 36

Printer controller overview

2-10 System Overv iew Guide

Page 37

System Overview Guide 3-1

3. Printer components and options

The printer processes the electronic data and images received

from the control ler and p roduces th e printed out put. This ch apter

describes the components and options available for the printer.

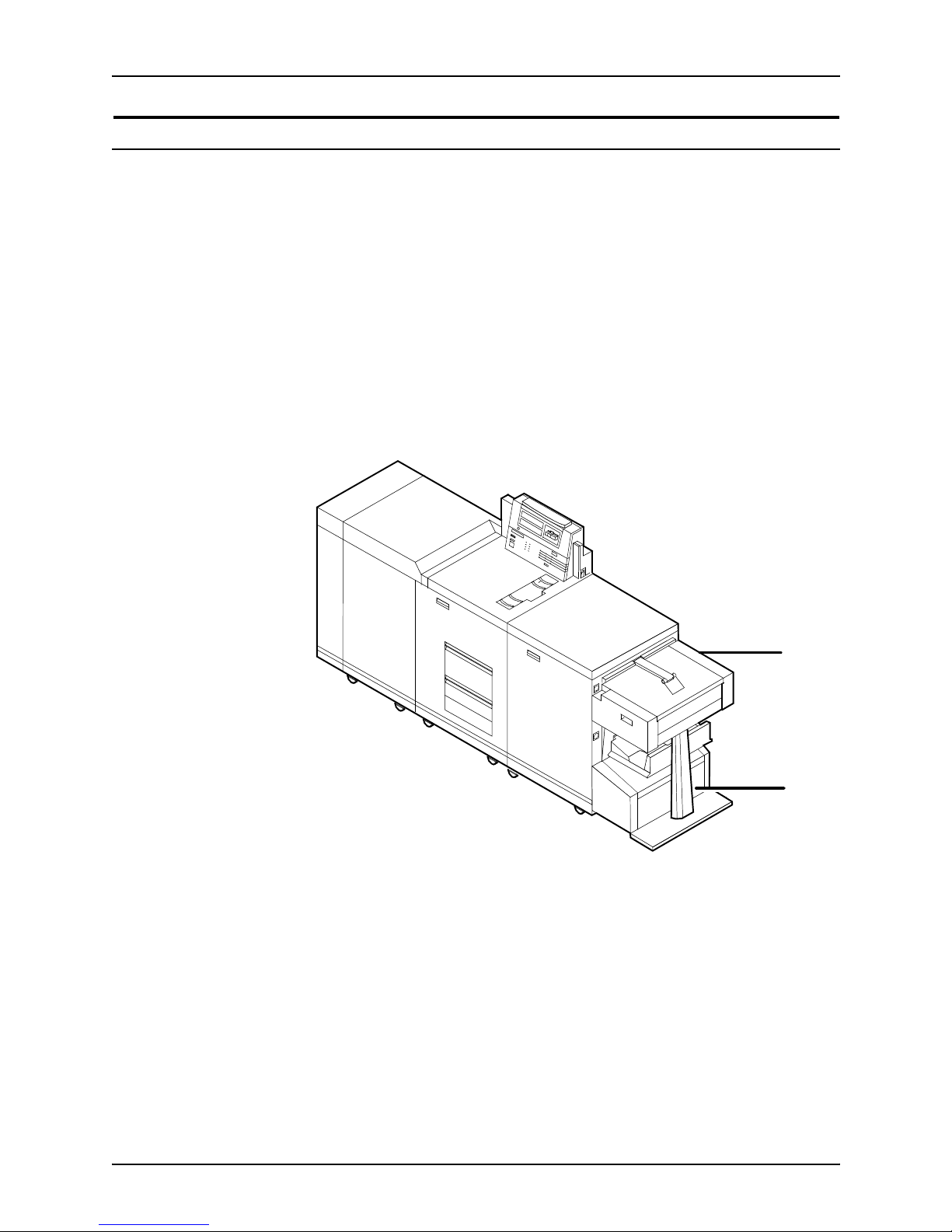

Printer components

The NPS/IPS printers contain the xerographic engine, two

standard fe eder tra ys, a sample tra y, the printer console , and one

of three possib le output co nfigur ations: the d ual stac k er, the dual

stacker with bypass transport, or the stitcher/stacker.

Figure 3-1. 4850/4890/92C NPS/IPS printer

1. Printer console

2. Sample tra y

3. Stack e r tr ay 1

4. Stack e r tr ay 2

1

3

4

5

6

2

Page 38

Printer components and options

3-2 System Overview Guide

5. Feeder tray 1

6. Feeder tray 2

Printer console The printer console contains message and graphic displays, an

attention light, and Information, Stop, and Continue buttons.

Indicator lights show which feeder tray is active and the paper

size in use.

Sample tray This output tra y is used for sample prints , rejecte d prints, and

transparencies. The capacity of the sample tray is 100 sheets of

20-pound or 80-grams per square meter (gsm) paper.

Dual stacker trays

1 and 2

Each output stacker tray has a capacity of 750 sheets of 20pound or 80-gsm paper (1,500 sheets total capacity). The

alternatives to the dual stacker configuration are the stitcher/

stacker or bypass transport option.

Feeder tray 1 The capacity of tray 1 is 1,000 sheets of 20-pound or 80-gsm

paper.

Feeder tray 2 The capacity of tray 2 is 500 sheets of 20-pound or 80-gsm

paper. Except for capacity, this tray is identical to tray 1.

Printer console

The printer console contains message and graphic displays, as

well as attention and status indicator lights that alert you to

printer conditions . The indicators and the Info rmation button help

you to solve printer problems. The Stop and Continue buttons

give you temporary cont rol of the printer without interrupting

input processing.

NOTE: The 4850/4890/92C does not provide sample prints

while a job is running, therefore, the Sample Print button has no

effect on the operation.

Page 39

Printer components and options

System Overview Guide 3-3

Figure 3-2. Printer console

1. Attention light

2. Message display

3. Graphic display

4. Wire percentage indicator

5. Feeder tray indicators

6. P ower on/off switch

7. Sample button (not used)

8. Continue button

9. Stop button

10.Fault code display

11.Information button

Attention light The yellow attention light glows whenever the system detects an

actual or potential problem. When the attention light starts

flashing, an e xplanatory message ap pears on the printer console

display. A similar error or warning message appe ars on the user

interface of the printer controller.

• When the light is flashing, you should act immediately to

remedy situations. Typical problems are a paper jam or a full

waste container that have caused the printer to stop.

1

4

7

6

8

9

10

11

3

2

5

Page 40

Printer components and options

3-4 System Overview Guide

• When the light glows steadily, act soon to avoid a cycle-down.

A steady glow typically indicates that paper or dry ink is low.

Message display Printer status and sim p le operating and maint enance

instructions are shown in a two-line me ssage. One of the

following icons indicates the printer mode:

Also in the lower panel, the dry ink color currently loaded is

shown.

Graphic display The graphic displa y sho ws a sp ecific are a of the printer requi ring

attention. The graphics help you locate the problem.

Icon display The icon display is located in a rectangle below the graphic

display. The printer mode is indicated by the words that are

lighted--Black or Highlight (color). The printer indicates the color

of ink loaded in the printer by lighting one of the icons on the

right (red, blue, green, or “other”).

Wire percentage

indicator

If your printer has a stitcher/stacker, it displays the percentage of

stitcher wire remaining on the spool.

Feeder tray

indicators

These lights indicate the select ed feeder tray or trays and the

size of paper loaded in each tray.

Printer Mod e

Black Highlight

Black

Printer Mode

Highlight

Page 41

Printer components and options

System Overview Guide 3-5

Power on/off

switch

This sw it ch co ntr o ls power to the printer and is used primarily by

service representatives.

Sample button The sample feature is not used.

Continue button The Continue button resumes printing when it is pressed.

While it is formatting a complex page, the printer controller may

cycle down the printer if the page image is not available within a

certain amount of time. If this occurs, the following message

appears:

Press <CONTINUE> to resume printing

You can ignore this message. As soon as the page image is

available, the printer controller cycles up the printer and printing

automatically resumes.

Stop button Pressing the Stop button halts printing.

Fault code display When enabled by a service representative, shows the number of

completed pr ints and printer fault codes. When a fault code

displays here, the corresponding message appears in the

message display.

Information button When “i” appears on the message display, you can press this

button for additional information on printer operation. You ca n

press the button repeatedly for more information as long as “i”

appears.

Sample tray This output tray receives sample prints of system files, rejected

prints, and transparencies. The capacity of the sample tray is

100 sheets of 20-pound or 80 gsm bond. There is no tray full

sensor, therefore, empty this tray regularly to avoid paper jams.

Dual stacker trays

1 and 2

Each output stacker tray has a capacity of 750 sheets of 20pound or 80 gsm bon d (1 500 sh eets t otal cap acity). An al ternate

to the dual stacker configuration is the stitcher/stacker.

Feeder trays The standard configuration contains two feeder trays with the

following capacities (based on 20-pound or 80 gsm bond):

• Tray 1: 1000 sheets

• Tray 2: 500 sheets. (Except for capacity, this tray is identical

to tray 1.)

Page 42

Printer components and options

3-6 System Overview Guide

Additional printer features

Additional features of the NPS/IPS include the following:

Instruction labels Located throughout the printer to assist you with a variety of

tasks.

Power savers To conserve energ y, the printer has tw o pow er sav ers: one f or the

raster output scanner (ROS) and one for the fuser.

After a predetermined period, each of these parts times out and

shuts down. The time-out period can be adjusted by a service

representative to meet your needs. The printer console

automatically brings the printer out of power saver mode when

there is a document to be printed.

• The ROS power saver times out after about an hour of

inactivity and requires about 30 seconds to warm up.

• The fuser power saver times out after about four hours and

requires four to seven minutes to warm up.

Language button Systems with the dual language option have this button to select

a message display that shows a different language, such as

French instead of English.

Figure 3-3. Language button on printer console

Page 43

Printer components and options

System Overview Guide 3-7

CCU changeout

cart

The cart is used to remove and install the customer changeable

unit (CCU). The CCU consists of the color developer housing

and the dry ink bottle. Because the CCU is heavy, the user will

need the cart to make the change.

The carts also serve as storage devices for the CCUs that are

not currently in use. For example, if you use both the red and

blue dry inks in your operation, one CCU is always out of the

machine in storage on the car t while the other CCU is installed.

Figure 3-4. CCU on cart

NOTE: You should have a cart for each CCU so that a cart is

always available to remove the CCU that is installed in the

system. You may not need a cart for each CCU if only one color

is used or if there is more than one color printer at your site.

Consult your site representative for more details.

Printer configurations

The NPS/IPS may be configured with a high-capacity feeder, a

dual stacker , a w ire stitch er/sta cker, or a by p ass tr ansport with a

dual stacker.

Page 44

Printer components and options

3-8 System Overview Guide

High-capacity feeder

The high-capacity feeder (HCF) provides two additional feeder

tra ys. The extra trays w ork interchangeab ly with feeder trays 1

and 2 to allow automatic tray switching and uninterrupted printing

time.

Figure 3-5. 4850/4890/92C NPS/IPS with high-capacity feeder

1. High-capacity feeder unit

2. Feeder tray 3

3. Feeder tray 4

Tray capacities Each high-capacity feeder tra y holds 100 0 sheets of 20- pound or

80 gsm bond.

Paper sizes Both high-capacity feeder trays handle paper sizes from 8 by 10

inches / 203 by 254 mm to 8.5 by 14 inches / 216 by 352 mm.

This range includes international paper size A4 (8.27 by 11.16

inches / 210 by 297 mm).

1

2

3

Page 45

Printer components and options

System Overview Guide 3-9

Dual stacker

The dual stacker contains two identical output trays. Output can

be sent to either of these trays or both of these trays.

NOTE: A dual stacker is required on the NPS/IPS f or in stallation

of the bypass transport.

Figure 3-6. 4850/4890/92C NPS/IPS printer with du al stacker

1. Sample tray (top tray)

2. Stacker tray 1

3. Stacker tray 2

Sample tray Used for sample prints, rejected prints, and transparencies.

Holds up to 100 sheets of 20-pound or 80 gsm bond.

Stacker tray 1 Holds up to 750 sheets of 20-pound or 80 gsm bond.

Stacker tray 2 Holds up to 750 sheets of 20-pound or 80 gsm bond.

1

2

3

Page 46

Printer components and options

3-10 System Overv iew Guide

Stitcher/stacker

The stitcher/stacker inserts wire-stitches (staples) into

documents.

Figure 3-7. 4850/4890/92C NPS/IPS printer with stitcher/

stacker

1. Sample tray

2. Stitcher/stacker tray

Sample tray Used for sample prints, rejected prints, and transparencies.

Holds up to 100 sheets of 20-pound or 80 gsm bond.

Stitcher/stacker

tray

Used for ou tpu t that is stitched (stapled) and/or offset. The tray

holds up to 2000 sheets o f unstitche d 20-pound or 80 gsm b ond,

or an equally high stack of stitched sets (200 two-sheet sets). A

stitched set consists of up to 50 sheets of 20-pound or 80 gsm

bond. The wire supply provides up to 32000 staples.

NOTE : Mixed pap er siz es ar e not supported f or st itchi ng. If y o ur

system has a stitcher/stacker, the printer cycles down when it

detects any specification for stitching different-sized papers.

1

2

Page 47

Printer components and options

3-11 System Overv iew Guide

Bypass transport (4850 and 4890 only)

The optional bypass transport enables individual printed sheets

of paper to pass through the NPS/IPS output tray to third-party

finishing devices. These devices perform a variety of finis hing

tasks, such as saddle-stitching, binding, folding, stapling,

trimming, and stacking.

The bypass transp ort fits into tra y 1 of t he NPS/IP S dual stacker.

Printed pages flow from left to right (when viewed from the front

of the printer). The printed pages travel through the NPS/IPS

output module and bypass transport, out of the paper exit slot,

and into the finishing device. For paper up to 14 i nche s l on g, th e

maximum delivery rate is 92 sheets per minute.

Figure 3-8. 4890/92C printer with bypass transport and dual

stacker

1. Bypass transport

2. Bypass transport support

1

2

Page 48

Printer components and options

3-12 System Overv iew Guide

Software, firmware, hardware, and paper requirements

The optional bypass transport requires the following:

• Dual stacker output module

• Standard white, colored, predrilled, or preprinted paper.

To minimize paper jams and misfeeds, use 20 pound or 80

gsm (grams per square meter) bond xerographic grade.

Xerox 4024 Dual Purpose Paper and Xerox 10 Series Dual

Purpose paper are optimal. Use paper with less than 6%

moisture content so that the paper will not curl and jam.

NOTE: The time between sheets e xiting th e byp ass transpo rt for

8.5 by 11-inch / 216 by 279 mm paper, A4 paper, and 8.5 by 14-

inch / 216 by 352 mm paper is 492 milliseconds in simplex mode

and 1052 milliseconds in duplex mode. All times are measured

between the trail edge of the exiting sheet and the lead edge of

the next entering sheet.

Operator tasks for the bypass transport

To use the bypass transport and third-party finishing devices, you

must perform several tasks:

• Install and remove the bypass transport .

• Set up DFA personality profiles to provide the NPS/IPS with

information about ea ch fin ishi ng device.

• Prepare the finishing de vice ha rdware ne cessary to finish the

printed output and inform the NPS/IPS of device names and

parameters.

• Enter appropriate commands at the printer controller to

initiate finisher jobs.

• Clear paper jams in the bypass transport.

You learn how to install and remove the bypass transport and

clear jams in the operator training that is provided by Xerox

following installation of the bypass transport.

In addition, you must know how to prepare the third-party

finishing device to process printed ou tput. Obtain this inf ormation

from your third-party supplier.

Page 49

Printer components and options

3-13 System Overv iew Guide

Profiles for third-party finishing devices

When a bypass transport is connected to the NPS/IPS, you can

add any number of third- pa rty finishing de vi ce s.

Figure 3-9. Third-party finishing device configuration

1. Paper path

2. Bypass transport

3. Third-party finishing devices

Each third-party device is identified by a specific personality

profile. The personality profile contains information about the

options available with the finishing device (for example, a

booklet-making device that can produce both side-stitched and

saddle-stitched booklets). It also specifies timing requirements,

constraints, flags, and other parameters.

You can create severa l pe rso na lity pr ofi les that correspond to

different configurations of the finishing device. Refer to your

Guide to Configuring and Managing the System for information

on creating personality profiles.

Mechanical interfac e

To connect a third-party finishing device to the NPS/IPS bypass

transport, you align the finishing device with the paper exit slot of

the bypass tran sport, dock the finishing device, and establish an

electrical interface between the two.

Connecting the bypass transport to third-party finishing devices

involves the following:

3

2

1

Page 50

Printer components and options

3-14 System Overv iew Guide

• Alignment: Your finishing device align at the correct height

without interference from protruding features. To accomplish

this, you must consider the feature locations and the vertical

alignment.

• Paper exit: The finishing device must align with this e xit slot.

Printed sheets travel through the printer output module and

bypass transport, out of the paper exit, and into the finishing

device . The pap er e xit sl ot is 16. 75 inches ( 425.45 mm) wide .

• Module mobility: Your finishing device must be easy to

move so that you can align it precisely.

The following figure illustrates the alignment and docking

locations for the bypass transport on the printer (the bypass

transport support is not shown).

Figure 3-10. Alignment and docking locations (in

millimeters)

1. Sheet registration edge

2. Sheet edge

3. Vertical slot to accept 13 mm

4. Floor

5. 22 mm diameter docking zone

6. Center line of docking features

Page 51

Printer components and options

3-15 System Overv iew Guide

7. Sheet path

8. Finishing device left edge

Electrical connection

The printer automatically detects the presence of the bypass

transport and third-party finishing device s when it is po w ered up.

The system also begins monitoring the interloc ks (physical links)

between the bypass transport and the finishing device. It then

starts interface communications.

After a sheet of paper passes through the bypass transport to

the external finishing device, the printer loses all record of it.

Communications between the printe r with bypass transport and

the finishing device consist of command and status signals.

Command signals NPS/IPS can send three command signals to third-party

finishing devices:

• Cycle up: The printer is powered up and signals the finishing

device to power up

• Sheet exit: A sheet of paper has entered the finishing device

• End of set: The last sheet of a print job set has been sent

Status signals The third-party finishing device can send five status signals to

the NPS/IPS:

• Sheet delivered: A sheet of paper has been successfully

delivered to the finis hing device.

• Set delivered: A print job set has been successfully

delivered to the finis hing device.

• Offline: The finishing device has no power or is not

connected to the NPS/IPS.

• Full: The finishing device is full and cann ot accept mo re

sheets.

• Faulted: The finishing device is jamm ed or f a ulted and is not

ready to accept sheets of paper

Page 52

Printer components and options

3-16 System Overv iew Guide

Paper paths

The paper path is the route that stocks (paper, transparencies,

labels, and so o n) f oll ow throug h the printer from the f e eder tr a ys

to the output trays.

The figure belo w illust ra tes the simp lex (one-sided output) paper

path of a printer with a dual stacker tray and a standard feeder

tray. The materials move from either f eeder tr ay 1 or f eeder tr ay 2

and are stacked in either stacker tray 1, stacker tray 2, or the

sample tray, depending on your selection at the beginning of the

job.

Figure 3-11. Simplex paper path (dual stacker configuration)

Page 53

Printer components and options

3-17 System Overv iew Guide

The following figure illustrates the duplex (two-sided output)

paper path of a printer wit h a dual stac k er and a standa rd f e eder.

Materials may originate in either feeder tray 1 or feeder tray 2.

The duplex paper tray receives the materials before they go

through a second time to receive the second image. As the

pages move through for the second image, they follow the

simplex path . The pages are then stac k ed i n either stac k er tr a y 1

or stack er tra y 2, dep ending on y our selectio n at the beginn ing of

the job.

Figure 3-12. Duplex paper path (dual stacker configuration)

When you add a high-capacity feeder to your system, only the

beginning of the paper path changes, which is the source of

paper supply.

Page 54

Printer components and options

3-18 System Overv iew Guide

The follo wing figure il lustrate s the sim ple x paper pa th of a printer

with the high-capacity feeder.

Figure 3-13. Simplex paper path (printer with high-capacity

feeder)

If you have the stitcher/stacker option, the paper path is the

same, except there is onl y on e tray for the output (other than the

sample tray).

Page 55

System Overview Guide 4-1

4. Network printing environment

The NPS/IPS system su pports the person al comp ut er (PC) , Sun

workstation, DEC workstation, HP/Apollo, IBM RS/6000 and

Apple Macintosh. It accepts PostScr ipt levels 1 and 2, PCL 5,

TIFF, and ASCII output.

Client workstations and system software

To send print jobs to the printer, the customer needs to provide

the proper client hardware, operating system, and network

software.

Print data originates at the client workstation, mainframe or

minicomputer. This is where a user creates and formats

documents according to specifications with the help of

application software. The printer supports the following types of

networked client workstations and operating systems:

• Sun workstation running a Sun or Linux operating system

• PC running MS-DOS 6.2 and Microsoft Windows 95, 98, NT,

4.0, 2000, and ME using Ethernet with TCP/IP or Novell

NetWare 3.11 and 3.12.

NOTE: Customers using Novell 4.1 must set the “Bindery

Emulation Mode” to be backwards compatible with Novell 3.11

and 3.12.

• IBM RS/6000 running IBM AIX, version 4.1

• HP/Apollo running HP-UX, version 10.01

• DECStation 5000/200 running DEC Ultrix, version 4.3

• Apple Macintosh, System 7, 7.5, or 8.x, using AppleTalk

through EtherTalk, phase 1 or 2

• Any system that supports RFC-1179 lpr/lpd.

The software may be compatible with workstation models and

software versions other than those listed above.

Page 56

Network printi ng environment

4-2 System Overview Guide

Client software

On your PC or workstation, you must install or set up a

supported means of submitting jobs to the printer. Depending on

your system, you can use the following:

• Xerox drivers for Windows 3.x, 95/98, or NT/2000

• Xerox Document Submission Software for DOS, Windows

3.x, 95/98, NT/2000, or Macintosh

• Third-party dr ivers

– Some PostScript drivers can be used in conjunction with

Xerox-supplied PPD files

– HP Color LaserJet for PCL 5c jobs

– HP LaserJet 4 fo r monochrome jobs

• Third-party TCP/IP lpd utility

• Apple/Macintosh Printer Access Protocol (PAP)

NOTE: The printing options vary according to the network

software that is loaded on the client workstation.

Submitting print jobs

There are basically two ways you can submit print jobs: You can

send print data directl y fro m the ap pl i cati on to the printer; or y o u

can create a PDL data file on the workstation and then send the

data file to the printer. The method you choose depends on the

workstation configuration and the job submission requirements.

Sending the print data directly from the application to the printer

is accomplished with a Xerox print driver or a third-party driver.

This method is sometimes referred to as “transparent printing.” It