Page 1

Job Management Guide

DOCUCOLOR 40 CP

Page 2

Page 3

Copyright © 1998 Electronics for Imaging, Inc. All rights reserved.

This publication is protected by copyright, and all rights are reserved. No part of it may be reproduced or transmitted in any form or by any means for any purpose

without express prior written consent from Electronics for Imaging, Inc., except as expressly permitted herein. I nformation in this document is subject to change

without notice and does not represent a commitment on the part of Electronics for Imaging, Inc.

The software described in this publication is furnished under license and may only be used or copied in accordance with the terms of such license.

Patents: 5,666,436; 5,553,200; 5,543,940; 5,537,516; 5,517,334; 5,506,946; 5,424,754; 5,343,311; 5,212,546; 4,941,038; 4,837,722; 4,500,919

Trademarks

EFI, the EFI logo, Fiery , the Fiery logo, EFICOLOR, and Rip-While-P rint are trademarks registered in the U.S. P atent and Trademark Office. F iery ZX, Fiery X2,

Command Wor kStation, AutoCal, Starr Compression, Memory M ultiplier, ColorWise, NetWise, and V isualCal ar e trademarks of E lectronics for I maging, I nc.

DocuColor and all Xerox product names mentioned in this publication are trademarks of the XEROX CORPORATION.

Adobe, the Adobe logo, Adobe Illustrator , P ostScript, Adobe P hotoshop, Adobe S eparator , and A dobe P ageMaker are trademarks of A dobe Systems Incorporated,

registered in certain jurisdictions. EPS (Encapsulated PostScript) is a trademark of Altsys Corporation. Apple, the A pple logo, AppleS hare, A ppleTalk, E therTalk,

LaserWriter, and Macintosh are registered trademarks, and MultiFinder is a trademark of Apple Computer, Inc. Microsoft, MS, MS-DOS, and Windows are

registered trademarks of Microsoft in the US and other countries. QuarkXPress is a registered trademark of Quark, Inc. Times, Helvetica, and Palatino are

trademarks of Linotype AG and/or its subsidiaries. ITC Avant Garde, ITC Bookman, ITC Zapf Chancery, and ITC Zapf Dingbats are registered trademarks of

International Typeface Corporation. Ethernet is a registered trademark of Xerox Corporation. Farallon, PhoneNET PC, and PhoneNET Talk are trademarks of

Farallon Computing, Inc. COPS and COPSTalk are trademarks of CoOperative Printing Solutions, Inc. NetWare and Novell are registered trademarks and

Internetwork Packet Exchange (IPX) is a trademark of N o vell, Inc. SyQ uest is a registered trademark, in the U nited S tates and certain other countries, of SyQuest

Technology , Inc. UNIX is a registered trademark of UNIX System Laboratories, a wholly owned subsidiary of Novell, Inc. PANTONE is a registered trademark

of Pantone, Inc.

All other terms and product names may be trademarks or registered trademarks of their respective owners, and are hereby acknowledged.

Legal Notices

APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, REGARDING THE APPLE SOFTWARE.

APPLE DOES NOT WARRANT, GUARANTEE, OR MAKE ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE

OF THE APPLE SOFTWARE IN TERMS OF ITS C ORRECTNESS, ACCURA CY, RELIABILITY , CURRENTNESS, OR OTHERWISE. THE ENTIRE

RISK AS TO THE RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU. THE EXCLUSION OF IMPLIED

WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE TO YOU FOR ANY CONSEQUENTIAL,

INCIDENTAL OR INDIRECT DAMA GES (INCLUDING DAMA GES FOR LOSS OF BUSINESS PR OFITS, BUSINESS INTERRUPTION, L OSS OF

BUSINESS INFORMATION, AND THE LIKE) ARISING OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF APPLE

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Apple’s liability to you for actual damages from any cause whatsoever, and regardless of the form of the action (whether in contract, tort [including negligence],

product liability or otherwise), will be limited to $50.

Restricted Rights Legends

For defense agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer Software clause at 252.227.7013.

For civilian agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (a) through (d) of the

commercial Computer Software Restricted Rights clause at 52.227-19 and the limitations set forth in Electronics for Imaging, Inc.’s standard commercial

agreement for this software. Unpublished rights reserved under the copyright laws of the United States.

Printed in the United States of America on recycled paper.

Part Number:

n/a

Page 4

CE Mark

The CE marking applied to this product symbolises Rank Xerox’s declaration of conformity with the following applicable directives of the European Union as of

the dates indicated.

January 1, 1996—Council Directive 70/80/CCO amended by Council Directive 93/68/EEO. Approximation of the laws of the member states related to low

voltage equipment.

January 1, 1996—Council Directive 59/336/EEC. Approximation of the laws of the member states related to electromagnetic compatibility.

A full declaration defining the relevant directives and referenced standards can be obtained from your Rank Xerox representative.

W ARNING: In or der to allow this equipment to operate in proximity to industrial, scientific, and M edical (ISM) equipment, the external radiation fr om

ISM equipment may have to be limited or special migration measures taken.

FCC Information

WARNING: FCC Regulations state that any unauthorized changes or modifications to this equipment not expressly approved by the manufacturer could void

the user’s authority to operate this equipment.

Class B Declaration of Conformity

This equipment has been tested and found to comply with the limits for a class B digital device, pursuant to Part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio fr equency energy

and if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment. Operation with non-approved equipment or unshielded

cables is likely to result in interference to radio and TV reception. The user is cautioned that changes and modifications made to the equipment without the

approval of manufacturer could void the user’s authority to operate this equipment.

Industry Canada Class B Notice

This Class B digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment Regulations.

Avis de Conformation Classe B de l’Industrie Canada

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Certificate by Manufacturer/Importer

This is to certify that the FC07 is shielded against radio interference in accordance with the provisions of VFG 243/1991. The G erman Postal Services have been

advised that this device is being put on the market and that they have been given the right to inspect the series for compliance with the regulations.

Electronics for Imaging, Inc.

Bescheinigung des Herstellers/Importeurs

Heirmit wird bescheinigt, dass der FC07 im Uebereinstimmung mit den Bestimmungen der VFG 243/1991 Funk-Entstort ist. Der D eutschen Bundespost wurde

das Inverkehrbringen dieses Geraetes angezeigt und die Berechtigung zur Ueberpruefung der Serie auf Einhaltung der Bestimmungen eingeraumt.

Electronics for Imaging, Inc.

RFI Compliance Notice

This equipment has been tested concerning compliance with the relevant RFI protection requirements both individually and on system level (to simulate normal

operation conditions). However, it is possible that these RFI Requirements are not met under certain unfavorable conditions in other installations. It is the user

who is responsible for compliance of his particular installation.

Page 5

Dieses Geraet wurde einzeln sowohl als auch in einer Anlage, die einen normalen Anwendungsfall nachbildet, auf die Einhaltung der Funk-entstoerbestimmungen

geprueft. Es ist jedoch moeglich, dass die Funk-enstoerbestimmungen unter unguenstigen Umstaenden bei anderen Geraetekombinationen nicht eingehalten

werden. Fuer die Einhaltung der Funk-entstoerbestimmungen seigner gesamten Anlage, in der dieses Geraet betrieben wird, ist der Betreiber verantwortlich.

Compliance with applicable regulations depends on the use of shielded cables. It is the user who is responsible for procuring the appropriate cables.

Einhaltung mit betreffenden Bestimmungen kommt darauf an, dass geschirmte Ausfuhrungen gebraucht werden. Fuer die beschaffung richtiger Ausfuhrungen

ist der Betreiber verantwortlich.

Software License Agreement

Before using the Software, please carefully read the following terms and conditions. BY USING THIS SOFTWARE, YOU SIGNIFY THAT YOU HAVE

ACCEPTED THE TERMS OF THIS AGREEMENT. If you cannot or do not accept these terms, you may return the entire package within ten (10) days to

the Distributor or Dealer from which you obtained them for a full refund.

Electronics for Imaging, Inc. grants to you a non-exclusive, non-transferable license to use the software and accompanying documentation (“Softwar e”) included

with the DocuColor 40 CP you have purchased, including without limitation the PostScript

®

software provided by Adobe Systems Incorporated.

You may:

a. use the Software solely for your own customary business purposes and solely with DocuColor 40 CP;

b. use the digitally-encoded machine-readable outline and bitmap programs (“Font Programs”) provided with DocuColor 40 CP in a special encrypted format

(“Coded Font Programs ”) to r eproduce and display designs, styles, weights, and versions of letters, numerals, characters and symbols (“Typefaces ”) solely for y our

own customary business purposes on the display window of the DocuColor 40 CP or monitor used with DocuColor 40 CP;

c. use the trademarks used by Electronics for Imaging to identify the Coded Font Programs and Typefaces reproduced therefrom (“Trademarks”); and

d. assign your rights under this Agreement to a transferee of all of your right, title and interest in and to DocuColor 40 CP provided the transferee agrees to be

bound by all of the terms and conditions of this Agreement.

You may not:

a. make use of the Software, directly or indirectly , to print bitmap images with print resolutions of 600720 dots per inch or gr eater , or to generate fonts or typefaces

for use other than with DocuColor 40 CP;

b. make or have made, or permit to be made, any copies of the Software, Coded Font Programs, accompanying documentation or portions thereof, except as

necessary for use with the DocuColor 40 CP unit purchased by you; provided, however, that under no circumstances may you make or have made, or permit to

be made, any copies of that certain portion of the Software which has been included on the DocuColor 40 CP hard disk drive. You may not copy the

documentation;

c. attempt to alter, disassemble, decrypt or reverse engineer the Software, Coded Font Programs or accompanying documentation.

d. rent or lease the Software.

Proprietary Rights

You acknowledge that the Software, Coded Font Programs, Typefaces, Trademarks and accompanying documentation are proprietary to Electronics for Imaging

and its suppliers and that title and other intellectual property rights therein remain with Electronics for Imaging and its suppliers. Except as stated above, this

Agreement does not grant you any right to patents, copyrights, trade secrets, trademarks (whether registered or unregistered), or any other rights, franchises or

licenses in respect of the Software, Coded Font Programs, Typefaces, Trademarks or accompanying documentation. You may not adapt or use any trademark or

trade name which is likely to be similar to or confusing with that of Electronics for Imaging or any of its suppliers or take any other action which impairs or reduces

the trademark rights of Electronics for Imaging or its suppliers. The trademarks may only be used to identify printed output produced by the Coded Font

Programs. At the reasonable request of Electronics for Imaging, you must supply samples of any Typeface identified with a trademark.

Confidentiality

You agr ee to hold the Software and Coded F ont P rograms in confidence, disclosing the Softwar e and Coded Font P rograms only to authoriz ed users having a need

to use the Software and Coded Font Programs as permitted by this Agreement and to take all reasonable precautions to prevent disclosure to other parties.

Remedies

Unauthorized use, copying or disclosure of the Software, Coded F ont Programs, Typefaces, Trademarks or accompanying documentation will result in automatic

termination of this license and will make available to Electronics for Imaging other legal remedies.

Page 6

Limited Warranty And Disclaimer

Electronics for Imaging warrants that, for a period of ninety (90) days from the date of delivery to you, the Software under normal use will perform without

significant errors that make it unusable. Electronics for Imaging’s entire liability and your exclusive remedy under this warranty (which is subject to you returning

DocuColor 40 CP to Electronics for Imaging or an authorized dealer) will be, at Electronics for Imaging’ s option, to use reasonable commercial efforts to attempt

to correct or work around errors, to replace the Software with functionally equivalent software, or to refund the purchase price and terminate this Agreement.

Some states do not allow limitations on duration of implied warranty, so the above limitation may not apply to you.

Except for the above express limited warranty, Electronics for Imaging makes and you receive no warranties or conditions on the Products, express, implied, or

statutory, and Electronics for Imaging specifically disclaims any implied warranty or condition of merchantability or fitness for a particular purpose.

For warranty service, please contact your authorized service/support center.

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, ELECTRONICS FOR IMAGING MAKES AND YOU RECEIVE NO WARRANTIES

OR CONDITIONS ON THE SOFTW ARE OR CODED FONT PROGRAMS, EXPRESS, IMPLIED, STATUTORY, OR IN ANY OTHER PROVISION

OF THIS AGREEMENT OR COMMUNICATION WITH YOU, AND ELECTRONICS FOR IMAGING SPECIFICALL Y DISCLAIMS ANY IMPLIED

WARRANTY OR CONDITION OF MER CHANT ABILITY OR FITNESS FOR A PAR TICULAR PURPOSE. Electr onics for Imaging does not warrant that

the operation of the software will be uninterrupted or error free or that the Software will meet your specific requirements.

Limitation Of Liability

IN NO EVENT WILL ELECTRONICS FOR IMAGING OR ITS SUPPLIERS BE LIABLE FOR ANY DAMA GES, INCLUDING LOSS OF DATA, LOST

PROFITS, COST OF COVER OR O THER SPECIAL, INCIDENT AL, CONSEQ UENTIAL OR INDIRECT DAMAGES ARISING FR OM THE USE OF

THE SOFTWARE, CODED FONT PROGRAMS OR ACCOMPANYING DOCUMENTATION, HOWEVER CAUSED AND ON ANY THEORY OF

LIABILITY. THIS LIMITATION WILL APPLY EVEN IF ELECTRONICS FOR IMAGING OR ANY AUTHORIZED DEALER HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGE. YOU ACKNO WLEDGE THAT THE PRICE OF THE UNIT REFLECTS THIS ALLOCA TION OF RISK.

BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

Export Controls

You agr ee that you will not export or re-export the S oftware or Coded Font Programs in any form without the appropriate United States and foreign government

licenses. Your failure to comply with this provision is a material breach of this Agreement.

Government Use

Use, duplication or disclosure of the Software by the United States Government is subject to restrictions as set forth in subdivision (c) (1) (ii) of the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013 or in subparagraphs (c) (1) and (2) of the Commercial Computer Software—Restricted

Right Clause at 48 CFR 52.227-19, as applicable.

Third Party Beneficiary

You are hereby notified that Adobe Systems Incorporated, a California corporation located at 345 Park Avenue, San Jose, CA 95110-2704 (“Adobe”) is a thirdparty beneficiary to this Agreement to the extent that this Agreement contains provisions which relate to your use of the Fonts, the Coded Font Programs, the

T ypefaces and the Trademarks licensed hereby. S uch provisions are made expressly for the benefit of A dobe and are enforceable by Adobe in addition to Electronics

for Imaging.

General

This Agreement will be governed by the laws of the State of California.

This Agreement is the entire agreement held between us and supersedes any other communications or advertising with respect to the Software, Coded Font

Programs and accompanying documentation.

If any provision of this Agreement is held invalid, the remainder of this Agreement shall continue in full force and effect.

If you have any questions concerning this Agreement, please write to Electronics for Imaging, Inc., Attn: Licensing Dept. or see Electronics for I maging’s web site

at www.efi.com.

Electronics for Imaging, Inc.

2855 Campus Drive

San Mateo, CA 94403

Page 7

Contents

Preface

About this manual

Terminology xii

About the documentation

DocuColor 40 CP job environments

Permissions xiv

Safety warnings

Cleaning the DocuColor 40 CP

Chapter 1: Using the Control Panel

Introduction to the DocuColor 40 CP Control Panel

Activity light 1-1

Buttons 1-2

Display window 1-3

Functions menu 1-5

Starting and shutting down the DocuColor 40 CP

Starting the DocuColor 40 CP 1-6

Restarting the DocuColor 40 CP 1-7

Shutting down the DocuColor 40 CP 1-8

xi

xii

xiii

xv

xv

1-1

1-6

Chapter 2: Overview of DocuColor 40 CP WebTools

About WebTools

Access privileges 2-2

Checking DocuColor 40 CP status with the Status WebTool 2-4

Accessing information with the WebLink WebTool 2-5

2-1

Page 8

viii Contents

Chapter 3: Tracking and Managing Print Jobs

WebTools for job tracking and management

WebSpooler

Job management features 3-2

Job List window 3-3

Job icons 3-9

Spool area 3-9

RIP area 3-10

Print area 3-11

Job commands 3-12

Overriding print settings 3-14

Thumbnails and full-screen previews (DocBuilder) 3-16

Using the Job Log 3-25

Chapter 4: Color Calibration

Introduction to color calibration

Understanding calibration

How calibration works 4-3

Scheduling calibration 4-4

Checking calibration status 4-5

Calibrating with AutoCal from the Control Panel

Connecting the scanner to the DocuColor 40 CP 4-6

Using AutoCal 4-7

Removing calibration 4-9

3-1

3-1

4-1

4-2

4-6

Calibrating with Print Calibrator

Using a scanner 4-10

Using a densitometer 4-10

The Calibration Mode window 4-14

Measurements 4-15

Measuring values with a DTP32 densitometer 4-16

Testing and applying calibration 4-20

Calibration checklist 4-22

Calibrating the densitometer 4-23

4-9

Page 9

ix Contents

Chapter 5: Advanced Print Calibrator Topics

Using advanced calibration features

Choosing a measurements file 5-1

Working with targets 5-2

Customizing calibration targets 5-5

Backing up DocuColor 40 CP targets 5-9

Deleting custom targets 5-10

Removing calibration 5-10

Using advanced simulation features

Working with simulations 5-11

Using the Simulation Mode window 5-13

Checking the current simulation 5-14

Editing simulations 5-15

Managing simulations 5-18

Testing and setting a new default simulation 5-19

Appendix A: Troubleshooting

Error messages

Maintaining optimal system performance

Troubleshooting

Unexpected printing results A-6

Clearing the server A-7

Users are unable to connect to the printer A-7

Setup error messages A-8

AutoCal error messages A-8

5-1

5-11

A-1

A-5

A-6

Index

Page 10

Page 11

xi About this manual

Preface

This manual is intended for DocuColor 40 CP Color Server™ operators or

administrators, or users with the necessary access privileges, who monitor and manage

job flow, perform color calibration, and troubleshoot problems that may arise. It

describes the functions and features of DocuColor 40 CP utilities and

DocuColor 40 CP WebTools for the purposes of print job management and color

quality control.

About this manual

This manual is organized as follows:

• Chapter 1 describes the DocuColor 40 CP Control Panel. It explains the various

messages and icons that you might see on the Control Panel and describes how to

print system information pages from the Control Panel. It also explains how to

properly start up and shut down the DocuColor 40 CP.

• Chapters 2 introduces DocuColor 40 CP WebTools, explains how to access them,

and directs you to sources of more information (in this manual or in other manuals

in the documentation set).

• Chapter 3 describes WebSpooler, which can be used to view and manage

DocuColor 40 CP job activity. In addition to providing a graphic display of the job

flow, WebSpooler allows you to reprint or hold jobs, view and override print option

settings, preview print jobs, and merge rasterized jobs.

• Chapter 4 tells you how to monitor and maintain color quality of your print output

by calibrating the DocuColor 40 CP with Print Calibrator or AutoCal (with a

desktop scanner).

• Chapter 5 describes advanced applications of Print Calibrator, such as creating

custom calibration and simulation targets to customize the color responses of the

DocuColor 40 CP.

• Appendix A lists error messages that you might see at the DocuColor 40 CP Control

Panel, WebSpooler, or the DocuColor 40, and contains some troubleshooting

information.

Page 12

xii Preface

Terminology

Specific terms are explained as they are introduced. However, the following general

terms are used throughout:

•

PostScript (PS)

DocuColor 40 CP uses this language for imaging the page and for communication

with applications and with the print engine.

•

—A file consisting of PostScript commands and comments that describe the

Job

graphics, sampled images, and text that should appear on each page of a document,

and the printer options that should be used in printing, such as media or color

rendering style.

Spool

•

•

•

—Write to a disk. Usually used here to refer to a PostScript print job being

saved to the DocuColor 40 CP hard disk in preparation for processing and printing.

RIP

—Acronym for raster image processing, which changes text and graphics

commands into descriptions of each mark on a page. In common use as a noun, a

“raster image processor ” (RIP) is the computer processor that performs this function.

Print

—The process of rendering, or imaging, a page or a job on a printer.

These concepts can explain how the DocuColor 40 CP Color Server and the

DocuColor 40 work together as a powerful printing system. The D ocuColor 40 CP

PostScript RIP changes text and graphics commands in PostScript into color

specifications for each dot of toner deposited on a page by the DocuColor 40.

—A computer language designed as a page description language. The

About the documentation

This manual is part of the set of DocuColor 40 CP documentation, which includes

the following manuals for users and system administrators:

• The

Configuration Guide

DocuColor 40 CP for the supported platforms and network environments. It also

includes guidelines for setting up UNIX, Windows NT, and NetWare servers to

provide PostScript printing services to clients.

•

Getting Started

DocuColor 40 CP. Specifically, it describes installation of PostScript printer drivers,

printer description files, and other user software provided on the User S oftware CD.

It also explains how to connect each user to the network.

describes how to install software to enable users to print to the

explains basic configuration and administration of the

Page 13

xiii DocuColor 40 CP job environments

• The

Printing Guide

who send jobs via remote workstations on the network or via a direct parallel port

connection.

• The

Color Guide

to a DocuColor 40 CP Color Server. It also includes practical color printing tips and

application notes that explain how to print to the DocuColor 40 CP from popular

Windows and Mac OS applications.

• The

Job Management Guide

utilities and WebTools, and how they can be used to manage jobs and maintain

color quality. This book is intended for an operator or administrator, or a user with

the necessary access privileges, who needs to monitor and manage job flow , perform

color calibration, and troubleshoot problems that may arise.

•

Release Notes

the problems you may encounter.

describes the printing features of the DocuColor 40 CP for users

provides an introduction to the basics of color theory and printing

explains the functions of the DocuColor 40 CP client

provide last-minute product information and workarounds for some of

DocuColor 40 CP job environments

The DocuColor 40 CP supports several levels of control of printing, job management,

and setup, and offers you the flexibility to choose the configuration that corresponds to

the requirements of your site. Your situation may correspond to one of the descriptions

outlined below, or you may prefer an intermediate level of control.

At one extreme, an administrator or operator in a high-volume printing environment

controls the entire job flow and all printing using WebSpooler. Print jobs arriving from

remote users are spooled to the server disk and stored until the operator decides it is

time to print them. Additional functions (calibration, job overrides, prioritizing, font

management) are reserved for the administrator or operator.

At the other extreme, anyone on the local network can control all printing and server

functions; operator intervention is not necessary. Users can print from their

workstations to any of the published print connections. Anyone can use WebSpooler

to control any print job.

The spectrum of control that an administrator can implement is described fully in the

Configuration Guide

.

Page 14

xiv Preface

Permissions

Support for these job environments is achieved by a combination of DocuColor 40 CP

Setup options. By default, anyone can access Setup (both from the Control Panel and

WebSetup), but the administrator can limit access to Setup by specifying an

Administrator password for the DocuColor 40 CP (see the

Also by default, anyone can log in to WebSpooler and control job flow, but an

administrator can restrict access to these functions by specifying an Operator

password.

The three security levels from greatest to least control are:

Configuration Guide

).

•

Administrator

—confers control of Setup and is the highest level of control. The

person who has access to Setup can control the printing and job management

environment by choosing which queues are enabled, and by electing to set

passwords. The Administrator can also set a common web link for all users who log

in to the DocuColor 40 CP using their web browser.

Operator

•

—includes control of print jobs that arrive at the server and the ability to

perform calibration.

Guest

•

—allows users to view the status of active jobs and the list of stored jobs. They

cannot make changes to jobs or change their printing instructions. A password is not

needed to log in as Guest and view jobs from WebSpooler.

This manual describes the features of the DocuColor 40 CP client utilities and

WebTools, and all operator privileges, whether those privileges are available to

everyone or are exclusive to only certain people. It also includes descriptions of

administrator functions, sometimes referring you to other manuals for more

information.

Page 15

xv Safety warnings

Safety warnings

The DocuColor 40 CP display window is a liquid crystal display (LCD) that is made

of glass and can break. Do not subject it to strong shocks.

If the display window breaks and the liquid crystal material leaks out, do not inhale,

ingest, or touch it. If the material gets on your skin or clothing, wash it off with soap

and water immediately.

Do not touch or put pressure on the panel. This will change the color of the panel.

Cleaning the DocuColor 40 CP

Clean the DocuColor 40 CP with a soft cloth moistened with isopropyl alcohol or

ethyl alcohol.

Never

use water or ketone as these may permanently alter the display.

Page 16

Page 17

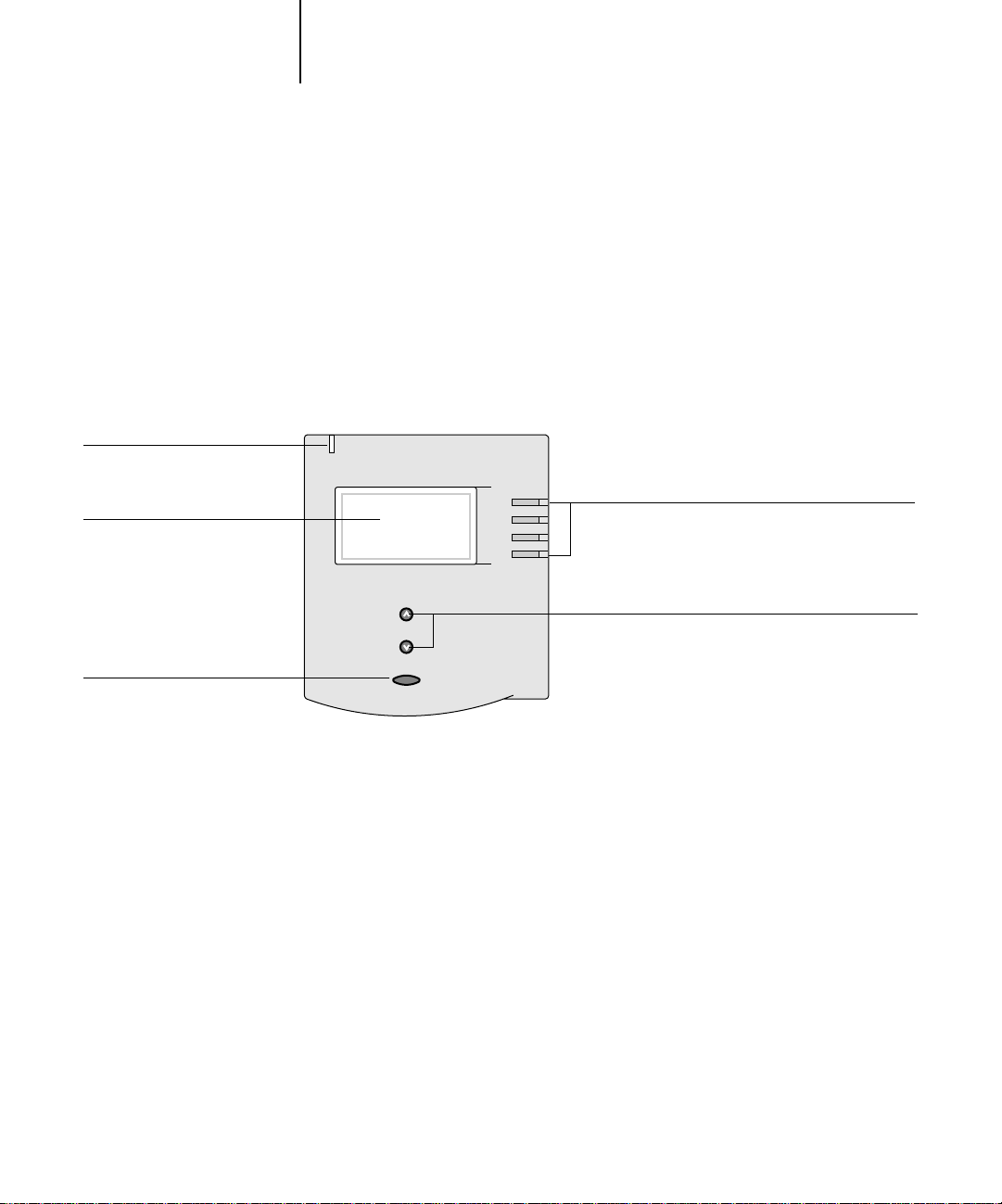

1-1 Introduction to the DocuColor 40 CP Control Panel

1

Chapter 1: Using the Control P anel

Activity light

Display window

Menu button

You can use the DocuColor 40 CP Control Panel to view status information, print

special pages, and set up printing.

Introduction to the DocuColor 40 CP Control Panel

The Control Panel, shown belo w on the front of the D ocuColor 40 CP, comprises the

following parts:

Line selection buttons

Up and down buttons

Activity light

The activity light indicates the current DocuColor 40 CP activity. If the light is:

Solid red An error has occurred causing the DocuColor 40 CP to be

disabled.

Flashing red There is an error causing printing to be disabled, but the

DocuColor 40 CP is capable of processing.

Solid green The DocuColor 40 CP is idle.

Flashing green The DocuColor 40 CP is processing or printing a job, or

communicating with a remote computer.

No light The DocuColor 40 CP is off or starting up.

Page 18

1-2 Using the Control Panel

1

Buttons

Line selection

buttons

Up and down

buttons

Menu button Press this button to view other screens. Under normal

There are four line selection buttons on the right side of the

Control Panel. Use these buttons to select the command

displayed on the corresponding line of the display window.

When a button is active, a special character (>) appears in the

display window next to the button.

Use these buttons to scroll to different screens in multi-

screen lists, to select Setup options from a list of available

options, and to scroll alphanumeric characters.

operation, the Control Panel displays the Info, RIP, or Print

Status screen with information about the status of the

DocuColor 40 CP. If you press the Menu button, the

Functions menu is displayed and you can perform additional

operations (see page 1-5). If a job is processing or printing,

press the Menu button to cycle among the active screens.

Page 19

1-3 Introduction to the DocuColor 40 CP Control Panel

1

Display window

The display window provides information about the status of the DocuColor 40 CP,

displays menu information, and enables you to view and edit information in the Setup

menus.

The last line of the display window displays text that tells you what screen you are

looking at and highlights one of the icons to indicate what the DocuColor 40 CP is

doing. Only the icons for the screens that are currently available appear. The menu

button cycles among the active screens.

The screens are:

Alert Status If there is a problem with processing a job or printing functions, an error message

appears on the Control Panel. F or information on error messages, see Appendix A,

“Troubleshooting.”

Print Status When the DocuColor 40 CP is printing a job, the Print Status screen appears.

This screen displays the following:

Cancel Job

printing.

User name

Pages/Total

number of copies of the job requested.

RIP Status When the DocuColor 40 CP is processing a job, the RIP Status screen appears.

This screen displays the following:

Cancel Job

processing. The DocuColor 40 CP cancels the job before printing begins.

Document name

User name

Kilobytes

OTE

N

1000KB; for example, 10MB is displayed as 10000KB.

—Press the top line selection button to cancel the job currently

—The name of the user who sent the job currently processing.

—The number of copies of the current job printed and the total

—Press the top line selection button to cancel the job currently

—The name of the document currently processing.

—The name of the user who sent the job currently processing.

—The size (in kilobytes) of the job processed so far.

:

This number is always displayed in kilobytes, even if the amount goes over

Page 20

1-4 Using the Control Panel

1

Info Status When the DocuColor 40 CP is not processing or printing a job, it displays

information about the current server and software. It displays the following

information:

Server Name

Status

status can be: Idle, Initializing, Busy, Processing, or Printing.

Megabytes

disk, for example, 756MB.

Version

Functions You can press the Menu button to display the Functions menu. Use the up and

down buttons to scroll through the list. Press the line selection button to the right

of a command to select that command. See page 1-5 for more information.

Network The network icon appears at the bottom left of any of the other screens when a

job is being sent to the DocuColor 40 CP, either over the network or through the

parallel port. The network icon also appears, together with a flashing green

activity light, when a remote utility is running.

—The DocuColor 40 CP name.

—The current status of the DocuColor 40 CP. The DocuColor 40 CP

—The space (in megabytes) available on the DocuColor 40 CP hard

—The system software version running on the DocuColor 40 CP.

Page 21

Print Pages

1-5 Introduction to the DocuColor 40 CP Control Panel

1

Functions menu

You can choose the following commands from this menu:

Print special pages from the DocuColor 40 CP. You can print the following pages

from the submenu that appears:

Suspend Printing

Resume Printing

Reboot Server

Test Page

properly connected to the copier, and provides color and grayscale samples to

troubleshoot problems with the copier or the DocuColor 40 CP. The following

settings are among those listed on the Test Page: Server Name, Printer Model,

color settings, calibration information, date and time the Test Page was printed.

Configuration

device configuration. This page lists general information about the hardware and

software configuration of the DocuColor 40 CP, the current options for all Setup

settings, information about the current calibration, and the Ethernet and Token

Ring addresses of the DocuColor 40 CP.

Job Log

Log and on printing it in other forms, see “Using the Job Log” on page 3-25.

Control Panel Map—

screens you can access from the Control P anel. For information about using these

screens to set up the DocuColor 40 CP, see the

Color Charts

from the DocuColor 40 CP.

Font List

Suspend communication between the DocuColor 40 CP and the copier. You

suspend printing if you want to interrupt the current DocuColor 40 CP job so

that you can use the copier to make copies. Jobs continue to process on the

DocuColor 40 CP. After you make the copies, select

printing jobs from the DocuColor 40 CP.

Resume communication between the copier and the DocuColor 40 CP after you

have finished making copies.

Shut down all DocuColor 40 CP activity in the correct manner and then restart.

You should use this option instead of the power switch on the back of the

DocuColor 40 CP.

—A Test Page enables you to confirm that the DocuColor 40 CP is

—Prints the Configuration page, which gives the current server and

—Prints a log of the last 55 jobs. For information on the fields in the Job

Prints the Control Panel Map, which is an overview of the

Configuration Guide

—Prints samples of the RGB, CMY, and PANT ONE colors av ailable

—Prints a list of all fonts currently on the DocuColor 40 CP hard disk.

Resume Printing

.

must

to continue

Page 22

1-6 Using the Control Panel

1

Starting and shutting down the DocuColor 40 CP

Generally, you can leave the DocuColor 40 CP running all the time. This section

describes how to shut down and restart the DocuColor 40 CP when necessary.

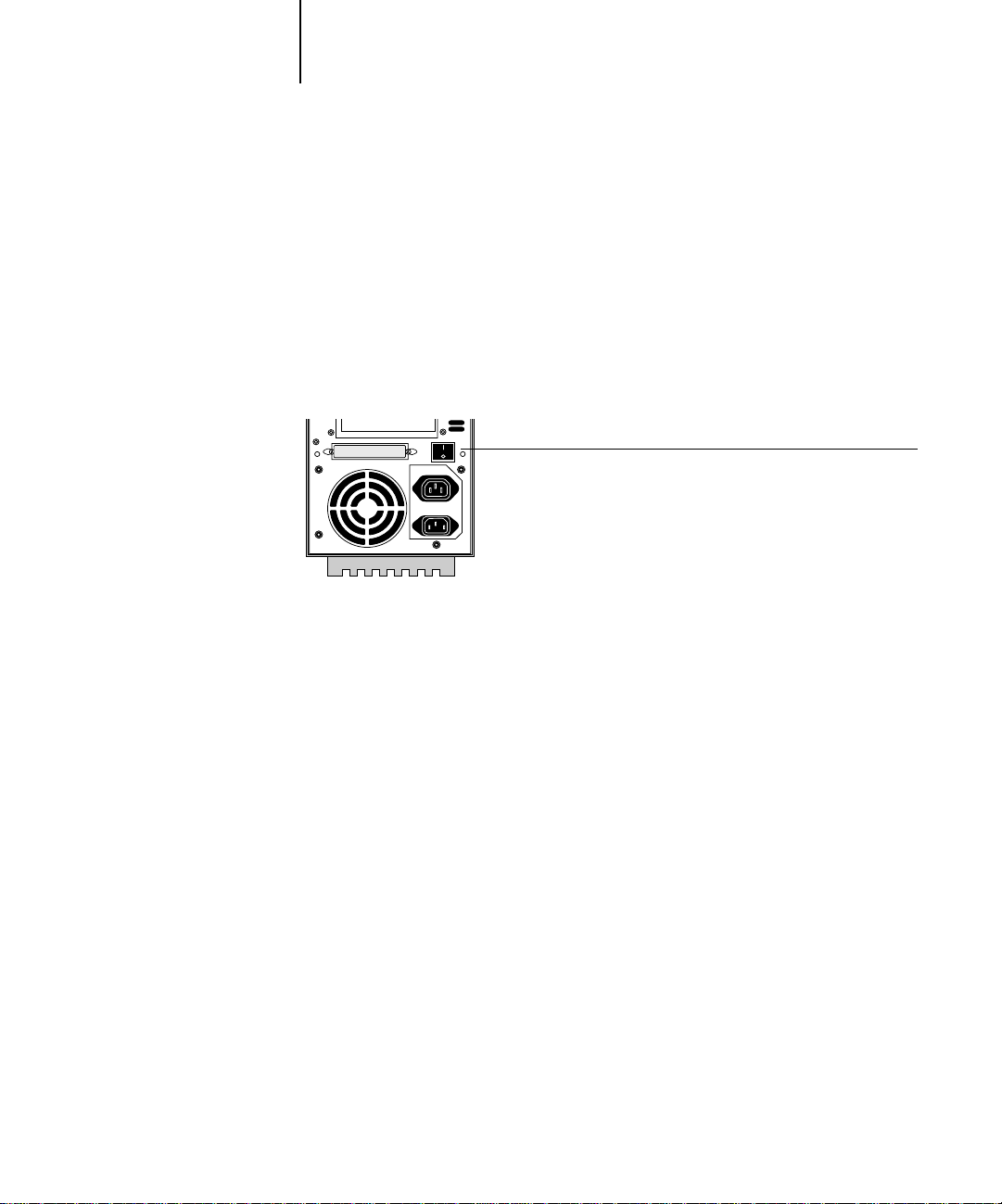

Starting the DocuColor 40 CP

To start the DocuColor 40 CP, move the power switch on the back of the

DocuColor 40 CP to the On position. If the copier is also powered off, power it on

before powering on the DocuColor 40 CP.

Power switch

Diagnostic messages appear on the DocuColor 40 CP Control Panel. If any

diagnostics fail, more information and instructions appear. Contact your service

representative if the DocuColor 40 CP encounters problems while running the

diagnostics.

When the diagnostics are finished, the following message is displayed:

For software update or setup, press any key.

If you want to change Setup option settings, press any button; if you do not press a

button, the DocuColor 40 CP continues starting up and displays the message

when it is ready to receive data.

N

:

If an Administrator password has been set, you are required to enter it to access

OTE

Setup.

If you press a button, the following options appear.

Idle

Page 23

1-7 Starting and shutting down the DocuColor 40 CP

1

For information about the Setup menus and options, see the Configuration Guide.

Choose: To do this:

Exit Setup

Server Setup

Network Setup

Printer Setup

PS Setup

Color Setup

Job Log Setup

Calibration

Change Password

Clear Server

Exit the Setup menus; the DocuColor 40 CP reboots.

Enter the Server Setup menus.

Enter the Network Setup menus.

Enter the Printer Setup menus.

Enter the PostScript Setup menu.

Enter the Color Setup menu.

Enter the Job Log Setup menu.

Calibrate the DocuColor 40 CP using AutoCal. For more

information, see “Calibrating with AutoCal from the Control

Panel” on page 4-6 and the Configuration Guide.

Change the Administrator password.

Clear all jobs in all server queues and the Job Log. Check

with your administrator or operator before choosing

Clear Server.

Restarting the DocuColor 40 CP

You should use the procedure described below to restart the DocuColor 40 CP rather

than using the power switch on the back of the DocuColor 40 CP.

TO RESTART THE DOCUCOLOR 40 CP:

1. Make sure that the DocuColor 40 CP is not receiving, processing, or printing a job.

Make sure that the status message on the Control Panel is Idle.

NOTE: If a job from the Print queue is processing, it will continue processing and print

after the DocuColor 40 CP is restarted; if a job sent to the Direct connection is

processing, it will not finish processing or printing.

2. Press the Menu button to display the Functions menu.

3. Use the down button to scroll to the last screen and choose Reboot Server.

Page 24

1-8 Using the Control Panel

1

Shutting down the DocuColor 40 CP

You may need to shut down the DocuColor 40 CP for service. When you do so, fonts

that have been downloaded to the hard disk drive are not deleted. Print jobs in the

Hold and Printed queues and jobs that have been processed but not printed are not

deleted and are available for printing when you restart the DocuColor 40 CP.

TO SHUT DOWN THE DOCUCOLOR 40 CP:

1. Make sure that the DocuColor 40 CP is not receiving, processing, or printing a job.

Make sure that the status message on the Control P anel is Idle. If a job has just finished

processing or printing, wait at least five seconds after the Control Panel status message

switches to Idle before proceeding to step 2.

NOTE: If a job from the Print queue is processing, it will continue processing and print

after the DocuColor 40 CP is restarted; if a job to the Direct connection is processing,

it will not finish processing or printing.

2. Power off the DocuColor 40 CP by moving the power switch on the back to the Off

position.

N

OTE: After powering off the DocuColor 40 CP, make sure to also power off the

copier. Leaving the copier po w ered on while the DocuColor 40 CP is powered off can

lead to excessive drain on the DocuColor 40 CP motherboard battery.

Page 25

2-1 About WebTools

2

Chapter 2:

Overview o f

DocuColor 40 CP

W ebTools

This chapter introduces the DocuColor 40 CP WebTools: Status, WebSpooler,

WebLink, Installer, and WebSetup. It explains how to access these tools and describes

their functions. For more information on WebSetup and Installer WebTools, you are

referred to other manuals in the documentation set.

About WebTools

WebTools reside on the DocuColor 40 CP but can be accessed over the network from

Windows 95, Windows NT 4.0, and Mac OS client computers. The

DocuColor 40 CP has a home page that lets remote users view server functions and

manipulate jobs. For specific information on the browsers supported with WebTools,

see Getting Started.

The following DocuColor 40 CP WebTools can be accessed from the

DocuColor 40 CP WebTools home page.

WebTool: Summary: For more information:

Status Shows you the jobs currently processing

and printing.

W ebSpooler Allows you to view , manipulate, reorder ,

reprint, and delete jobs currently

spooling, processing, or printing on the

DocuColor 40 CP. Also allows you to

view, print, export, and delete the Job

Log. Most of these functions require an

Administrator or Operator password, if

one has been set.

See page 2-4

See “WebSpooler” on page 3-1

WebLink Provides a link to another web page,

provided you have a valid Internet

connection. The WebLink destination

can be changed; this function requires

the Administrator password, if one has

been set.

See page 2-5 and the

Configuration Guide

Page 26

2-2 Overview of DocuColor 40 CP WebTools

2

WebTool: Summary: For more information:

Installer Allows you to download

DocuColor 40 CP printer file installers

directly from the server.

WebSetup Allows you to modify the

DocuColor 40 CP configuration

(Setup) remotely . This function r equires

the Administrator password, if one has

been set.

Access privileges

The DocuColor 40 CP system allows the site administrator to choose and implement

a level of access and control appropriate for your particular site. The levels of access

allowed to remote users depend on whether the administrator has enabled use of the

W ebTools, and whether a password is required to use certain features of the W ebTools.

The three possible levels of access to WebTools are Administrator, Operator, and

Guest. To enable maximum password protection, Administrator and Operator

passwords must be specified in Setup (see the Configuration Guide).

NOTE: An Operator password can be set only by using WebSetup.

When both an Administrator password and an Operator password have been specified,

the access levels are as follows:

See Getting Started

See the Configuration Guide

Access level: Privileges and password requirements:

Administrator Has full access to all WebTools and DocuColor 40 CP Control

Panel functions; Administrator password required.

Operator Has access to all functions of WebTools except WebSetup and

clearing the Job Log from WebSpooler; Operator password

required.

Guest Can view job status, but cannot make changes to jobs or Setup,

and cannot view the Job Log; no password required.

Page 27

2-3 About WebTools

2

If you have been given the Operator password, you can manage job flow and override

print settings of your jobs with WebSpooler. If not, you can still log in as Guest and

use these tools, and the Status WebTool, to track the status of your jobs. Check with

your site administrator for information on your access privileges.

TO ACCESS WEBTOOLS:

1. Start up your Internet browser application.

See Getting Started for information about supported platforms and browsers.

2. Enter the IP address or the DNS name of the DocuColor 40 CP.

Check with the operator or administrator for this information.

3. If the Log In dialog box appears, select a login lev el, enter the passw or d, and click OK.

The Log In dialog box appears only if the administrator has set an Administrator or

Operator password (or both).

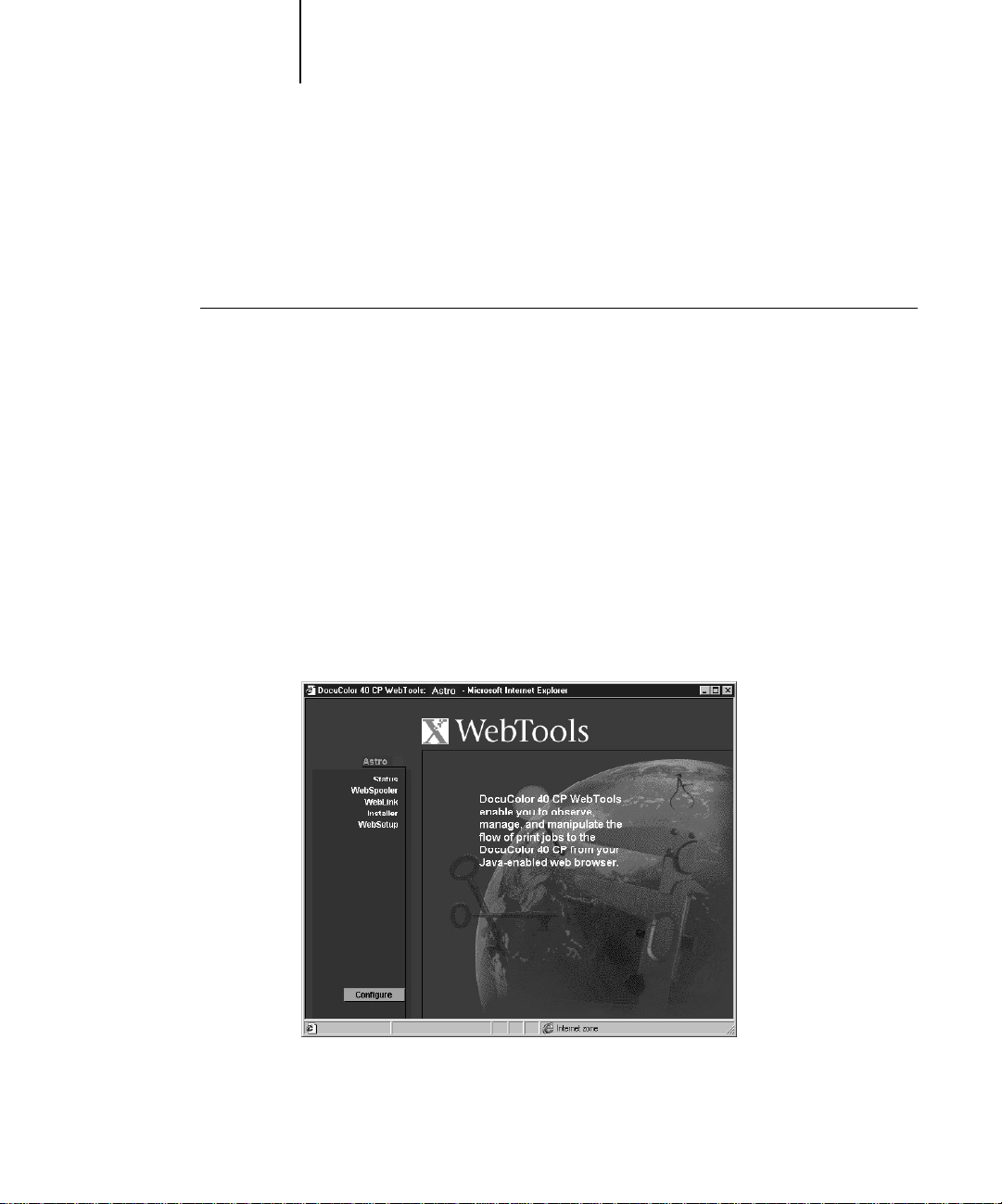

4. When the DocuColor 40 CP WebTools home page appears, click to select one of the

WebTools.

Move the cursor over the buttons to display information about the selections.

Page 28

NOTE: The Configure button appears only if you logged in as Administrator. With

Administrator privileges, you can click this button and specify which of the WebTools

are available to other users.

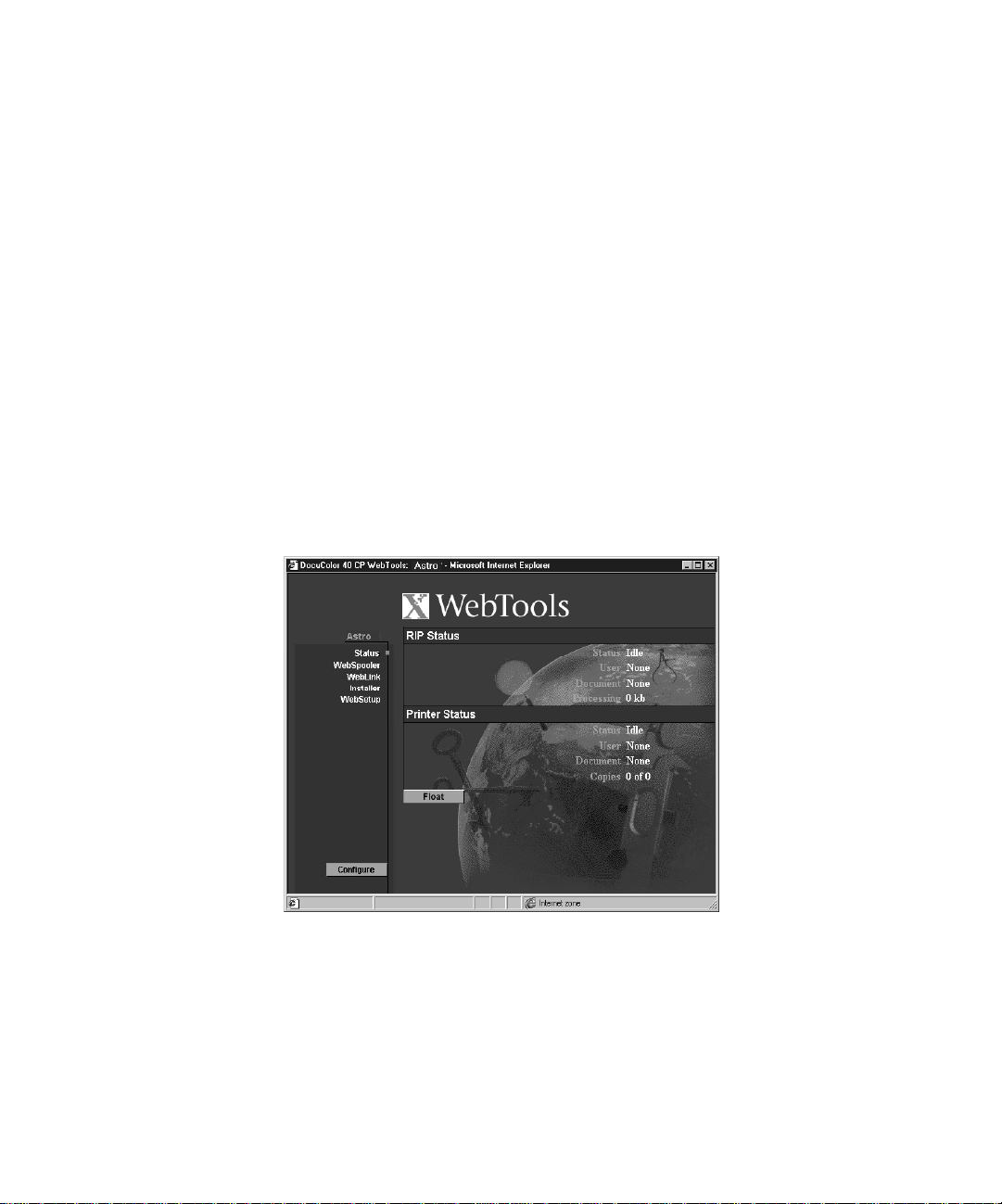

Checking DocuColor 40 CP status with the Status WebTool

You can use the Status WebTool to see what jobs are currently processing and printing.

The Status WebTool does not require any special access privileges. If the administrator

has enabled Web Services in Setup and has provided you with the IP address of the

DocuColor 40 CP, you can use the Status W ebTool to monitor the status of print jobs

as they are rasterized and printed.

To access the Status WebTool, point y our bro wser to the D ocuColor 40 CP WebTools

home page and click Status. The current RIP Status and Printer Status appear in the

window.

To open a new browser window for the Status display, click Float. You can then close

other browser windows and leave the Status window open to continue checking the

status of the DocuColor 40 CP. As long as you keep the Status window open, it is

dynamically updated.

To obtain more information about the status of jobs, use WebSpooler.

Page 29

2-5 About WebTools

2

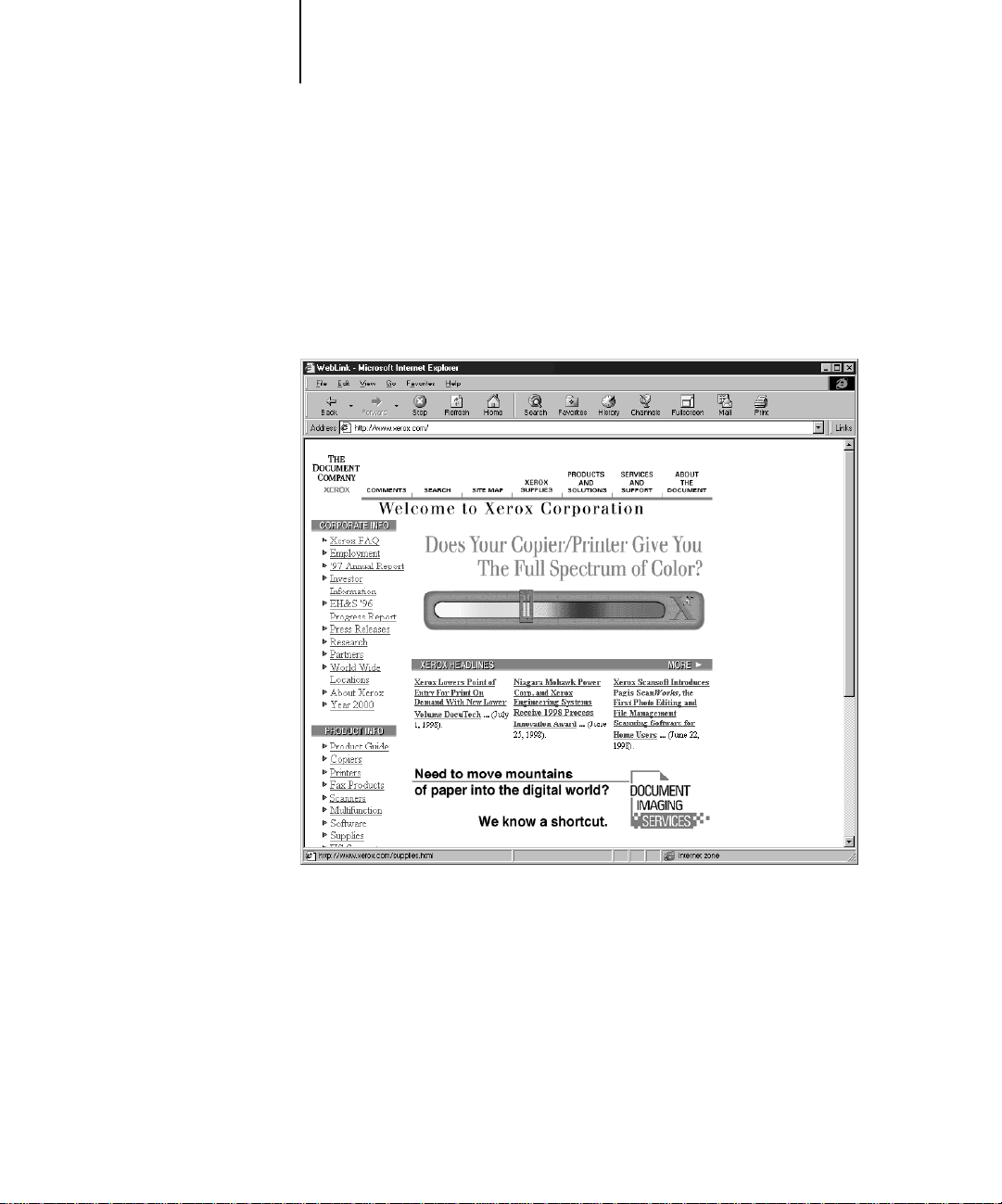

Accessing information with the WebLink WebTool

The WebLink button on the DocuColor 40 CP WebTools home page provides a link

to another web page or to multiple web pages, provided you have a valid Internet

connection. The WebLink destination is initially set to www.xerox.com. The

administrator at your site can set the WebLink destination. Check the WebLink sites

for any information available there.

Page 30

Page 31

3-1 WebTools for job tracking and management

3

Chapter 3: Tracking and Managing Print Jobs

TO LAUNCH WEBSPOOLER:

This chapter describes the functions of the DocuColor 40 CP WebTools that let you

track and manage jobs sent to the DocuColor 40 CP.

WebTools for job tracking and management

If your site administrator has enabled Web Services on the DocuColor 40 CP, you can

access WebTools from Windows 95, Windows NT 4.0, and Mac OS computers with

an Internet browser. The WebTools that provide job tracking capabilities are

WebSpooler and the Status WebTool. WebSpooler also provides job management

capabilities, provided you have the necessary access privileges (see page 2-2). For

specific information on the browsers supported with WebTools, see Getting Started.

WebSpooler

WebSpooler provides a window on DocuColor 40 CP and copier functions, and an

interface from which you can control those functions.

1. Launch your internet browser and enter the IP address or DNS name of the server you

want to connect to.

2. If a password has been set, the Log In window appears.

To log in as Administrator, enter the Administrator password and click OK.

To log in as Operator, enter the Operator password and click OK.

To log in as Guest, click OK, without entering any password.

3. From the DocuColor 40 CP WebTools home page window, click WebSpooler.

For instructions on how to access the DocuColor 40 CP WebTools home page

window, see page 2-3.

Page 32

3-2 Tracking and Managing Print Jobs

3

The WebSpooler window appears in a new browser window.

Job management features

Unless passwords have been defined in D ocuColor 40 CP Setup, you can log in to the

WebTools home page without entering a password, and you are given full privileges to

WebSpooler which include:

• A view of current printing jobs and jobs stored on the DocuColor 40 CP

• Control of printing jobs and a view of the Job Log

• Ability to clear the Job Log

Page 33

3-3 Tracking and Managing Print Jobs

3

After the Administrator has performed Setup and specified passwords, user options

depend on your login level. If you log in to the WebTools home page as Guest, you

have the first option only. If you log in as Operator, you have the first two options. If

you log in as Administrator, you have all three options. For information about Setup

and specifying passwords, see the Configuration Guide.

You can use WebSpooler to perform the following functions from your workstation:

• Override current job option settings

• Delete jobs

• Duplicate or rename jobs

• RIP a job and hold the raster data

• Hold jobs in the spooled area or the RIPped area

• Remove raster data from RIPped files

• Change the priority of jobs

• Edit and merge raster data jobs (DocBuilder)

• Display, print, export, or delete the Job Log

Most of these functions require Administrator or Operator privileges. However, even

without a password, you can log in to the WebTools home page as Guest with viewonly privileges in WebSpooler.

Job List window

Your first view of WebSpooler is the Job List window, which is divided into three areas

by Spool, RIP, and Print status bars. The Job List window is surrounded by a frame

that includes slider buttons and menus. System information indicators at the bottom

of the window show the current availability of hard disk space and RAM on the

currently selected DocuColor 40 CP server.

When the DocuColor 40 CP is receiving and processing print jobs, the Job List

window is a dynamic display, filled with the names of jobs and their characteristics.

Status bars animate in real time as new jobs are processed and printed, and jobs move

to different display areas.

Page 34

3

S

Menu bar

pool status bar

Spooled jobs

RIP status bar

Rasterized (RIPped) jobs

Print status bar

Printed jobs

3-4 Tracking and Managing Print Jobs

System information indicators

The Spool, RIP, and Print areas of the Job List window represent the stages of printing

a job. Jobs come in at the top level (Spool) and drop down to the Print level, unless

they are held along the way.

• Spooled jobs—Jobs listed in the area below the Spool status bar area are PostScript

files stored on the DocuColor 40 CP disk. These jobs were sent to either the Print

queue (white icons) or the Hold queue (yellow icons). These PostScript files are

saved on the server’s hard disk. PostScript files can come in packets from the

network, or from another place on the server hard disk. Jobs are added to a queue in

the order in which they arrive, and they generally move to another queue in the same

order unless an operator has intervened to change the order.

• RIPped jobs—Jobs listed in the area below the RIP status bar are ready to print.

They have already been rasterized (RIPped, or processed for printing) and are

waiting, in order , for access to the printer. Rasterized jobs can also be held; held jobs

are shown with a yellow icon. During RIPping, PostScript commands are

Page 35

3-5 Tracking and Managing Print Jobs

3

interpreted in the DocuColor 40 CP to allow the DocuColor 40 to print the file the

way its originator intended. The result of this interpretation is a raster file associated

with the original PostScript file. In this raster file (raster image), color data is

associated with each dot that can be rendered by the print engine. The color data

tells the print engine whether or not to apply cyan, magenta, yellow, or black toner

to each position on the page.

• Printed jobs—Jobs listed in the area below the Print status bar have already been

printed. Printed jobs can be stored on the DocuColor 40 CP disk. The number of

jobs that can be stored (from 1 to 99) is defined in Setup. While the PostScript file is

usually saved to disk, raster images are held in RAM during and after each print job.

However, you can request that the DocuColor 40 CP save the raster image to disk

along with the PostScript file. Saving the raster image to disk offers some

advantages—raster files are already processed so they print quickly, and each part of

the raster file is still identified with a page in the original document, which means

that individual pages of a saved raster file can be accessed.

Errors—Jobs with an error are shown in red. To display the error, double-click the

•

job line.

If you are logged in with Administrator or Operator privileges, you can interact with a

job in the window by selecting it and choosing a command from the Job menu, or by

double clicking it and setting print option overrides. (However, if passwords have been

set and you are logged in with Guest privileges, you can only view jobs; you cannot

interact with them.)

The job icons displayed in the WebSpooler window are explained on page 3-9.

NOTE: If your job does not appear anywhere in the WebSpooler window, it may have

already been printed; if so, it will appear in the Job Log. To view the Job Log, choose

Show Job Log from the Window menu. (For more information on the Job Log, see

page 3-25.)

Menu bar

The menu bar has five menus. When an action is not available in the current context,

the command is dimmed.

Page 36

3-6 Tracking and Managing Print Jobs

3

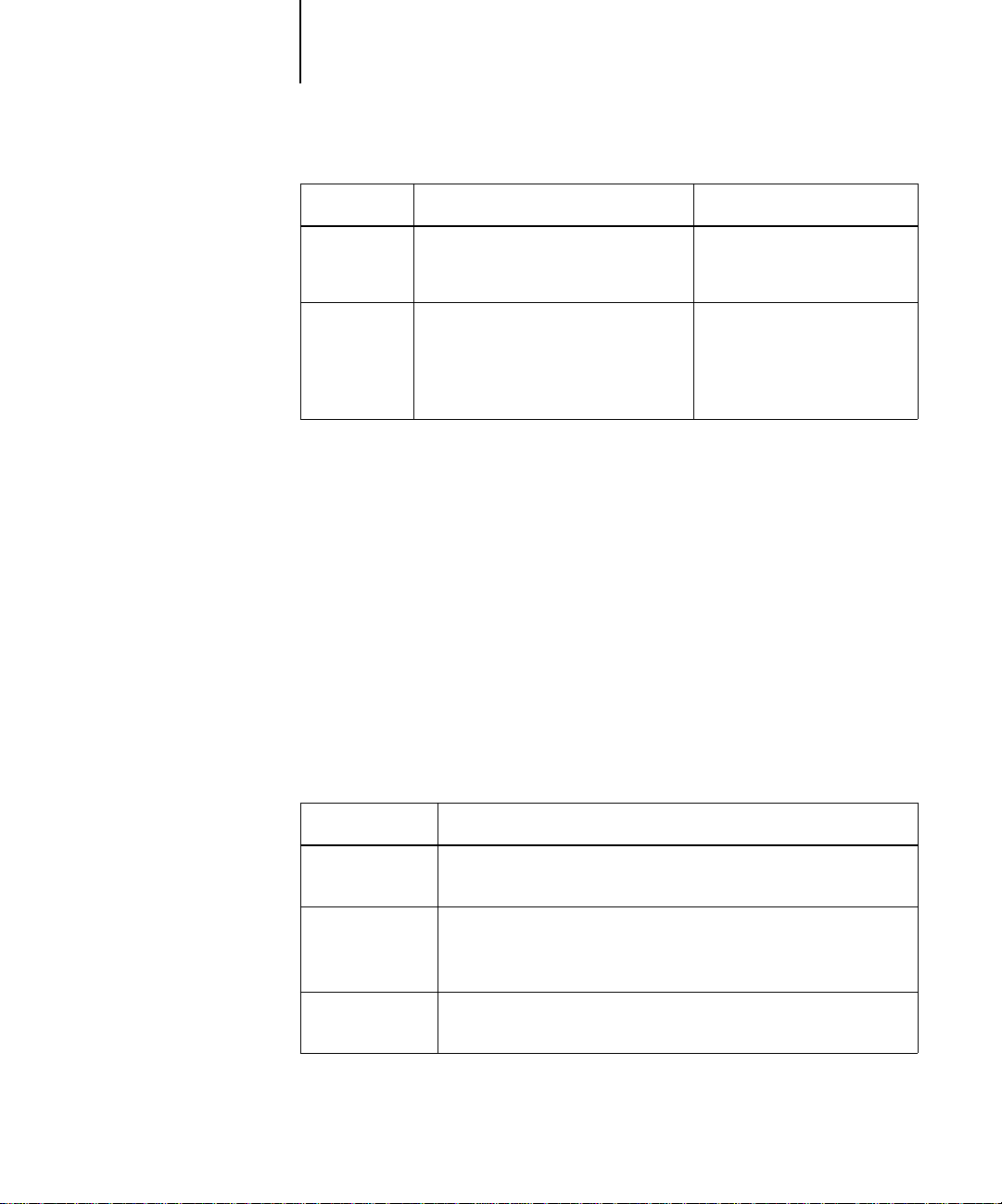

Menu: Choose this: To do this:

File Print Job Log Print the Job Log

Delete Job Log Delete the Job Log

Export Job Log Export the Job Log

Exit Exit W ebSpooler

Job

(For more

information on

these commands,

see page 3-12)

Page

(DocBuilder

commands for

Thumbnail A)

Delete Job(s) Delete one or more selected jobs

Duplicate Job(s) Duplicate one or more selected PostScript data jobs in the Spool or Print areas

Rename Rename a selected job

Hold Hold the selected job(s); see page 3-7

RIP and Hold RIP and then hold the selected job(s); see page 3-7

Print Print the selected job(s); see page 3-11

Print and Hold Print the selected job(s) and then hold it in the RIP area; see page 3-7

Process Next Give top priority to this job

Remove Raster Remove the raster information from the selected job(s); see page 3-14

Override Print

Settings

Thumbnail A Open a selected held raster data job in the Thumbnail A window where you

Thumbnail B Open a selected raster data job (not necessarily a held job) in the Thumbnail B

Delete Delete the selected page(s)

Duplicate Duplicate the selected page(s)

Preview View a full-screen preview of the selected page; see page 3-24

View and edit print settings for the selected job(s); see page 3-14

can view a full-screen preview of the job, edit the job, or merge it with raster

data from other jobs; see page 3-16

window for viewing or for copying pages into a job in the Thumbnail A

window; see page 3-18

Undo Undo previous Page menu commands (multiple undos available)

Page 37

3-7 Tracking and Managing Print Jobs

3

Menu: Choose this: To do this:

Window Show Job List Show the Job List window

Show Job Log Show the Job Log window

Help About View the WebSpooler information screen

Status bars

Jobs actively involved in the three processes (spooling, rasterizing, and printing) are

listed in the status bars that span the Job List window.

Status bars show the filename and user name for the active process, and an indication

of its progress. Each status bar heads the list of jobs that have completed the process.

Thus, beneath the Spool status bar, you see a list of spooled files; beneath the RIP

status bar, you see a list of rasterized (RIPped) files. Beneath the Print status bar, you

see a list of jobs that have already been printed.

NOTE: In the Spool status bar, the filename and user information always appear as

“Unknown” (as shown below). This information is not available until the job has

finished spooling to the DocuColor 40 CP disk.

Active jobs and Held jobs

You can hold a job at any stage of the process we have described, as illustrated below. I n

the figure, boxes indicate types of job icons you would see in the Job List window.

Page 38

3-8 Tracking and Managing Print Jobs

3

Spool

Spooled and held

Spooled for printing

RIP

RIPped and held

Print*

RIPped for printing

Print

Print and hold

Printed

*A copy of the held job is printed; the held job remains in the RIP area.

Jobs that are held are shown with a yellow icon, just beneath the Spool or RIP status

bar. Jobs that are held must be activated with a command in order to print.

Active jobs are shown with white icons; new jobs are added above older jobs.

PostScript and

raster data

Deleted

Page 39

3-9 Tracking and Managing Print Jobs

3

Job icons

There are three types of icons that are used for both active jobs and jobs on hold.

Icon:

Printer icons

Raster icon

Active jobs:

(white icons and rows)

PostScript or raster data

headed for printing (top) or

after printing (bottom)

PostScript and raster data

after printing, ready for fast

reprint

PostScript data headed for

and Hold

printing (

PostScript data already rasterized

and held

Jobs on Hold:

(yellow icons and rows)

or job on Hold after

Hold)

Spool area

The job icons in the Spool area are described below:

Spool area icon: What it indicates: How long you see the job:

1

Yellow printer icon

Yellow job row

2

White printer icon

White job row

PostScript data from a user on

the network; no destination is

defined

PostScript data headed for

Print

Until a destination is chosen

Until the RIP is free

Print

3

Yellow raster icon

White job row

4

Yellow printer icon

White job row

PostScript data headed for

RIP and Hold

PostScript data headed for

Print and Hold

Page 40

3-10 Tracking and Managing Print Jobs

3

The Spool area is both the receiving area for jobs from users on the network (Hold

queue) and the waiting area for jobs that will be RIPped (jobs in the Spool queue).

Hold queue jobs When printing requires an operator (because the Print queue and

Direct connection are disabled), the operator must assign a destination to all jobs

received from users on the network (icon 1 in the table above). Once assigned, jobs

(icons 2, 3, and 4) move down the Spool queue for processing. All jobs printed to the

Hold queue require routing by an operator.

Print queue jobs When printing does not require an operator, network jobs sent to

the Print queue appear in the Spool area where they are shown with a white printer

icon (icon 2). When they reach the head of the queue, they are RIPped and printed

without operator intervention.

Direct connection jobs Jobs printed to the D irect connection are not displayed in the

job lists. They are displayed briefly in the status bars (where they cannot be selected)

and are included in the Job Log.

RIP area

The job icons in the RIP area are described below:

RIP area icon: What it indicates: How long you see the job:

1

Yellow raster icon

Yellow job row

2

White printer icon

White job row

After a job is rasterized, it goes into the RIP area. The RIP area holds only raster data

(i.e., jobs that have been rasterized). Jobs in the RIP area are either waiting for the

copier to be free (Print queue jobs, icon 2 in the above table), or they are being held.

Raster data, no destination

defined; may have been

printed before and held

Raster data headed for

in its turn; no hold defined

Print

Until it is deleted or stripped

of its raster data and sent to

the Spool area

Until copier is free to print

the job

Page 41

3-11 Tracking and Managing Print Jobs

3

Held jobs in the RIP area have already been rasterized (RIP and Hold) or they have

been printed and their raster data has been routed back to the RIP area (Print and

Hold), where they are shown in yellow rows (icon 1).

NOTE: Raster jobs in the RIP area that are waiting to print (icon 2 in the table above)

cannot be manipulated by job commands.

Jobs held in the RIP area remain there until the operator deletes them. Printing these

jobs does not remove them from the RIP area. Instead, a copy of the job is cr eated and

printed.

NOTE: For all rasterized jobs, the print option settings, in addition to the current

calibration state of the DocuColor 40 CP, remain with the saved raster data each time

the job is reprinted. To print the job with new print option settings and with new

calibration data, you must remove the raster data and reRIP the job.

Print area

The job icons in the Print area are described below:

Print area icon: What it indicates: How long you see the job:

1

White printer icon

White job row

2

White raster icon

White job row

The Print area, also referred to as the Printed queue, contains jobs that have already

been printed. These jobs were assigned the Print destination (white printer icon in the

Spool or RIP areas) without any Hold instructions; therefore, they all hav e white icons

and rows.

NOTE: A job row that appears in light red indicates that a PostScript error occurred

while printing the job. To see the error, double-click anywhere in the row.

PostScript data only—raster

data has been deleted

Raster and PostScript data

If RAM is needed to RIP an

active job, the raster data is

deleted and the job gets the

PS icon (icon 1, above)

Until the job limit is reached

Until the job is reprinted or

the job limit is reached

Page 42

3-12 Tracking and Managing Print Jobs

3

Newly printed jobs are added to the Printed queue, and ar e shown at the top of the list.

Jobs are saved in the Printed queue until the job limit is reached. When the first job

over the limit is printed, the oldest job is deleted from the disk. The default job limit is

10 jobs. The value for Jobs Saved in Printed Queue can be changed in Setup by the

administrator.

NOTE: If you reprint a job in the Printed queue, the job returns to its original position

in the Printed queue after it is printed.

While it is printing, a job consists of PostScript and raster data. The raster data in

RAM is not cleared until memory is needed to rasterize the next job. As long as the

raster data is intact, the job can be reprinted from the Printed queue. Printed jobs that

still have their raster data are represented by a white raster icon in the Printed queue

(icon 2 in the previous table); jobs with only PostScript data r emaining are r epresented

by a white PS icon (icon 1). If the job was printed from a held raster job (in the RIP

area), the raster data in the RIP area remains and can be used to reprint the job after

the raster data has been cleared from the Printed queue.

Job commands

Using the commands in the Job menu, you can alter the destinations, priorities and

other characteristics of jobs that appear in the WebSpooler window.

Job commands are used to assign a selected job to a new destination or process. These

commands are available from the Job menu (see page 3-5). The job commands

available at a given time depend on the context; unavailable commands are dimmed.

Page 43

3-13 Tracking and Managing Print Jobs

3

The job commands available for selected jobs in the Job List window are listed in the

following table. The table also describes the effect of each command on raster data

associated with the affected job(s).

Choose this: To do this: Raster data is:

Delete Job(s) Delete the job(s) Deleted

Duplicate Job(s) Duplicate one or more selected PostScript data

jobs in the Spool or Print areas. You can use the

duplicate job(s) for different print options or a

different destination. (The Duplicate command

actually creates a reference to the original job,

with the same name)

Rename Rename the job (PostScript file with or without

raster)

Hold Hold the job in the current place (except for a job

in the Print area, which is moved to the Spool or

RIP area, depending on whether it still has raster

data associated with it)

RIP and Hold RIP the job and hold it in the RIP area Held in RIP area indefinitely

Print Print the job in its turn (RIP it first if it does not

have raster data)

After printing, keep the printed job in the Print

area until the job limit is reached.

Print and Hold

(Like the user print

option Save Fast

Reprint)

Print the job in its turn (RIP it first if it does not

have raster data)

After printing, hold the PostScript data and the

raster in the RIP area

N

OTE: The Duplicate command is not

available for raster jobs

Unaffected, but associated with the new name

OTE: If the renamed job is printed, the J ob Log

N

reflects the job’s original name.

Held in RIP area, if included with job

Temporarily held in RAM after printing until

memory is needed for another job

(If the job was printed from a held job in the RIP

area, the raster data in the RIP area is kept

indefinitely)

Held in RIP area indefinitely (saved to disk)

Process Next Give top priority to this job

RIP (and then print) it as soon as the processor is

free, before other waiting jobs

Option is dimmed if there are no other waiting

jobs

N

OTE: This command is available only for jobs in

the Spool area that are not currently held.

Page 44

3-14 Tracking and Managing Print Jobs

3

Choose this: To do this: Raster data is:

Remove Raster Remove the raster data from a job that has raster

data (indicated by a raster icon); leave the

PostScript data unaffected

Override Print

Settings

Thumbnail A Open the selected held raster data job in the

Thumbnail B Open the selected raster data job (not necessarily

View and override print settings for a selected job

or a group of selected jobs

Thumbnail A window where you can view a full-

screen preview of the job, edit the job, or merge it

with raster data from other jobs

a held job) in the Thumbnail B window for

viewing or for merging into a job in the

Thumbnail A window

Overriding print settings

When logged in with Operator or Administrator privileges, you can use the Override

Print Settings command to check and override the print option settings (pr operties) of

all jobs.

You can use this command for several purposes:

• To override a setting based on printed output or other print device conditions

Deleted

N

OTE: If you remove raster from a job in the RIP

area, the job is sent to the Spool area.

Possibly deleted and regenerated, depending on

whether you change any settings that require reRIPping

May be changed if job is edited

Unchanged

• To change settings for a duplicate of the original job

• To print a single copy of a job before printing the number of copies required by the

user

To change the job options of a job, double-click the job line or select the job and

choose Override Print Settings from the Job menu. If necessary, scroll down to see all

the various job options.

Page 45

3

Indicates reRIPping is required

3-15 Tracking and Managing Print Jobs

PDF Settings dialog box for PDF files

Override Print Settings dialog box for

PostScript files

The options you set here are the same ones you set from the P rint dialog box when you

print from an application. For information about print options, see the P rinting G uide.

For some options, changing the setting requires that the job be reRIPped; these

options show an icon to the left of the option name.

For PDF files, you can override only the number of copies and page range from the

Properties dialog box.

If you want to retain a copy of the job with its original settings, duplicate the job and

rename the duplicate before you change any settings (see “Job commands” on

page 3-12).

The Override Print Settings dialog box displays all the job settings encoded by the

PostScript printer driver that can be decoded by the DocuColor 40 CP. If you (as

operator) have not changed anything, these are the settings a user entered before

sending the job.

Page 46

3-16 Tracking and Managing Print Jobs

3

NOTE: Some print options that are available in the printer driver are not displayed in

the Override Print Settings dialog box.

For information on print option settings, see the Printing Guide.

Thumbnails and full-screen previews (DocBuilder)

The WebSpooler includes a powerful DocBuilder tool that allows you to preview and

edit raster data. (For information on how to identify a raster data job, see page 3-9.)

DocBuilder consists of two thumbnail windows and several page-manipulation

commands (listed in the Page menu).

The DocBuilder tool can be used in the following ways:

• In the Thumbnail A window, you can see thumbnails of the currently RIPping job,

as it is processed, or of any raster data job.

• From the Thumbnail A window you can open a full-screen preview of a raster file.

• Using the Thumbnail A and Thumbnail B windows together, you can merge raster

data from more than one file, even if the files were printed from different

applications on different computer platforms.

DocBuilder’s merge features eliminate the limitations of particular software

applications. You can merge raster pages of documents of different types, and even

different computer operating systems. You can merge color pages from graphics

programs with text pages from a word processor.

Previewing print jobs

You can use the Thumbnail A window to preview pages of the currently RIPping job.

You can also use Thumbnail A, as well as Thumbnail B, to preview any raster data job

in the RIP or Print areas.

The thumbnail windows also allow you to open an editable thumbnail view of a held

raster job in the RIP area and perform electronic collation or document merging. This

feature, called DocBuilder, is described on page 3-18.

To see the progress of jobs as they are RIPped, you can leave the Thumbnail A window

open in RIP preview mode.

Page 47

3-17 Tracking and Managing Print Jobs

3

TO VIEW THUMBNAILS OF THE CURRENTLY RIPPING FILE:

1. Click the Thumbnail A tab at the right of the Job List window to open the slider.

2. Click the RIP preview icon at the left side of the window.

In this mode, Thumbnail A displays each page of the currently processing job after it

has been RIPped.

Click to display the currently

rasterizing job

TO VIEW THUMBNAILS OF ANY RASTER DATA FILE:

Click to close the

thumbnail window

3. Choose a PS file in the Spool or Print area and select RIP and Hold, Print, or

Print and Hold.

As pages are RIPped, they are displayed in the Thumbnail A window.

4. When you have finished viewing, click the Thumbnail A tab to close the thumbnail

window.

1. Select any raster data job in the RIP or Print area.

2. Choose Thumbnail A or Thumbnail B from the Job menu.

If you choose Thumbnail A, make sure the raster data preview icon (at the left side of

the window) is selected.

NOTE: Wait until all pages have been displayed before opening another raster file with

Thumbnail A. If the job contains many pages, it may take some time for the entire job

to be displayed.

Page 48

3-18 Tracking and Managing Print Jobs

3

Raster data preview icon

Click to close the

thumbnail window

3. When you have finished viewing, click the Thumbnail A or Thumbnail B tab to close

the thumbnail window.

Editing and merging files with DocBuilder

When you select a raster data job and choose the Thumbnail A or Thumbnail B

command from the Job menu, the corresponding Thumbnail slider opens

automatically , displaying thumbnails of the editable file. To close the Thumbnail slider,

click anywhere in the tab along the right edge of the Thumbnail window. When the

Thumbnail window is open, the arrows in the tab point to the right, indicating that

clicking the tab retracts the slider.

With the Thumbnail A window you can see thumbnail views of any raster data job—

that is, any file that is currently RIPping, or any file that has been RIPped and held to

disk. You can also use the Thumbnail A window to edit a raster file—you can change

the sequence of pages, delete pages, duplicate pages, and copy pages from other raster

files into the Thumbnail A window. You can save the edited raster file as a new

printable document.

The Thumbnail B window can also display thumbnails of a raster job, and the

document displayed in Thumbnail B can be used as a source for editing the document