Page 1

ColorQube® 8570/8870

Printer

ColorQube® 8570/8870

Service Manual

Page 2

Page 3

ColorQube 8570/8870 Service Manual

Service Documentation

Adobe® Reader®, Adobe Type Manager®, ATM™, Flash®, Macromedia®, Photoshop®, and

PostScript® are trademarks of Adobe Systems Incorporated in the United States and/or other

countries.

ColorQube 8570/8870 Service Manual

705P01286

Initial Issue

October 2010

Xerox Corporation

Office Product Training and Information

26600 Parkway - Bldg. 60

P.O. Box 1000, M/S 7060-776

Wilsonville, OR 97070-1000

NOTICE: All service documentation is supplied to Xerox external customers for informational

purposes only. Xerox service documentation is intended for use by certified, product trained

service personnel only. Xerox does not warrant or represent that such documentation is com

plete, nor does Xerox represent or warrant that it will notify or provide to such customer any

future changes to this documentation. Customer performed service of equipment, or modules,

components or parts of such equipment may affect the warranty offered by Xerox with respect

to such equipment. You should consult the applicable warranty for its terms regarding customer

or third party provided service. If the customer services such equipment, modules, compo

nents or parts thereof, the customer releases Xerox from any and all liability for the customer

actions, and the customer agrees to indemnify, defend and hold Xerox harmless from any third

party claims which arise directly or indirectly from such service.

© 2010 Xerox Corporation. All Rights Reserved. Unpublished rights reserved under the copyright laws of the United States. Contents of this publication may not be reproduced in any form

without permission of Xerox Corporation.

Apple®, AppleTalk®, Bonjour®, EtherTalk®, Macintosh®, Mac OS®, and TrueType® are trademarks of Apple Computer, Inc. in the United States and/or other countries.

HP-GL®, HP-UX®, and PCL® are trademarks of Hewlett-Packard Corporation in the United

States and/or other countries.

IBM® and AIX® are trademarks of International Business Machines Corporation in the United

States and/or other countries.

Microsoft® Windows Vista®, Windows®, and Windows Server™ are trademarks of Microsoft

Corporation in the United States and/or other countries.

Novell®, NetWare®, NDPS®, NDS®, Novell Directory Services®, IPX™, and Novell Distributed Print Services™ are trademarks of Novell, Incorporated in the United States and/or other

countries.

SGI® IRIX® is a trademark of Silicon Graphics, Inc..

SunSM, Sun Microsystems™, and Solaris™ are trademarks of Sun Microsystems, Incorporated in the United States and/or other countries.

UNIX® is a trademark in the United States and other countries, licensed exclusively through X/

Open Company Limited.

PANTONE® and other Pantone, Inc. trademarks are the property of Pantone, Inc. © Pantone,

-

Inc.

As an ENERGY STAR® partner, Xerox Corporation has determined that this product (excluding ColorQube 8570N) meets the ENERGY STAR guidelines for energy efficiency. The

ENERGY STAR name and logo are registered U.S. marks.

Copyright protection claimed includes all forms of matters of copyrightable materials and information now allowed by statutory or judicial law or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen such

as styles, templates, icons, screen displays, looks, etc.

Xerox technical training materials and service manuals are intended for use by authorized

Xerox service technicians and service partners only and are not for resale. These materials

may not be distributed, copied or otherwise reproduced without prior written consent from

Xerox Corporation.

Xerox®, the sphere of connectivity design, ColorQube®, Phaser®, CentreWare®, Printing

Scout®, Walk-Up®, Global Print Driver, and Mobile Express Driver are trademarks of Xerox

Corporation in the United States and/or other countries.

Initial Issue

October 2010

ColorQube 8570/8870 Service Manual

Introduction

Page 4

Introduction

October 2010

Initial Issue

ColorQube 8570/8870 Service Manual

Page 5

About This Manual .......................................................................................................... iii

Organization....................................................................................................................iii

How to Use this Manual .................................................................................................. iv

Power Safety................................................................................................................... iv

Service Safety Summary................................................................................................. iv

Moving the Printer........................................................................................................... vi

Symbols Used on the Printer .......................................................................................... vi

Electrostatic Discharge Precautions ............................................................................... viii

Regulatory Requirements ............................................................................................... viii

Translation of Warnings .................................................................................................. x

ColorQube 8570/8870 Overview ..................................................................................... xi

Printer Configurations ..................................................................................................... xii

Parts of the Printer .......................................................................................................... xii

Printer Options ................................................................................................................ xiv

Control Panel Layout....................................................................................................... xv

Menu Map ....................................................................................................................... xvi

Routine Maintenance Items ............................................................................................ xvii

Consumables .................................................................................................................. xvii

Printer Specifications ...................................................................................................... xix

Power Saver.................................................................................................................... xxii

Physical Dimensions and Clearances............................................................................. xxiii

Information Pages, Troubleshooting Pages, and Test Prints.......................................... xxv

Acronyms and Abbreviations .......................................................................................... xxvii

Introduction

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

i

Introduction

Page 6

Introduction

October 2010

ii

Initial Issue

ColorQube 8570/8870 Service Manual

Page 7

About This Manual

The ColorQube 8570/8870 Service Manual is the primary document used for diagnosing,

repairing, maintaining, and troubleshooting the printer. The Service Manual is the controlling

publication for a service call. Information on using this document is found in the Introduction

section. To ensure understanding of this product, complete the Xerox Service Training Program

for this particular printer.

For manual updates, Service Bulletins, knowledge base, and technical support, go to:

• Xerox Global Service Net - https://www.xrxgsn.com/secure/main.pl

• Service Partners: http://www.office.xerox.com/partners

For further technical support, contact your assigned Xerox Technical Support for this product.

Service Manual Revision

Updates are issued as the printer changes or as corrections are identified.

Organization

The titles of the sections and a description of the information contained in each chapter are

contained in the following paragraphs:

Introduction and General Information

This chapter contains documentation organization, symbology and nomenclature, translated

warnings, safety symbols, regulatory requirements, and general information about the printer.

Chapter 1 Service Call Procedures

This chapter contains procedures to be taken during a service call and in what sequence they

are to be completed. This is the entry level for all service calls.

Chapter 2 Status Indicator RAPs

This chapter contains descriptions of the diagnostic aids for troubleshooting that include Power

On Self Test (POST), Fault Codes and Messages procedures.

Chapter 3 Image Quality

This chapter contains the diagnostic aids for troubleshooting image quality problems, as well

as image quality specifications and image defect samples.

Chapter 4 Repairs/Adjustments

This chapter contains the removal, replacement, and adjustments procedures.

Repairs

Repairs include procedures for removal and replacement of spare parts listed in the Parts List.

Use the repair procedures for the correct order of removal and replacement, for warnings, cau

tions, and notes.

-

Initial Issue

ColorQube 8570/8870 Service Manual

Adjustments

Adjustments include procedures for adjusting the parts that must be within specification for the

correct operation of the printer. Use the adjustment procedures for the correct sequence of

operation for specifications, warnings, cautions and notes.

Chapter 5 Parts List

This chapter contains exploded views of the print engine and optional Field Replaceable Units

(FRUs), as well as part numbers for orderable parts and illustrated Parts List.

Chapter 6 General Troubleshooting

This chapter contains details of the embedded Service Diagnostics test suite, as well as troubleshooting procedures for printer problems not related to a specific fault code.

Chapter 7 Wiring Data

This chapter contains drawings, lists of plug/jack locations, and diagrams of the power distribution wire networks in the printer.

Chapter 8 Theory of Operation

This chapter contains detailed functional information on the print engine components.

October 2010

iii

Introduction

About This Manual, Organization

Page 8

How to Use this Manual

Always start with the Service Call Procedures in Chapter 1. Perform Initial Actions and verify

the problem, then follow the directions provided.

Power Safety

Power Source

For 115 VAC printers, do not apply more than 135 volts RMS between the supply conductors or

between either supply conductor and ground. For 230 VAC printers, do not apply more than

254 volts RMS between the supply conductors or between either supply conductor and ground.

Use only the specified power cord and connector. This manual assumes that the reader is a

qualified service technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC outlet only. If necessary, contact a licensed electrician to install a properly grounded outlet. If the product loses its

ground connection, contact with conductive parts may cause an electrical shock. A protective

ground connection by way of the grounding conductor in the power cord is essential for safe

operation.

Disconnecting Power

WARNING

Turning the power off using the power switch does not completely de-energize the

printer. You must also disconnect the power cord from the printer’s AC inlet. Disconnect

the power cord by pulling the plug, not the cord.

Disconnect the power cord in the following cases:

• if the power cord or plug is frayed or otherwise damaged,

• if any liquid or foreign material is spilled into the product,

• if the printer is exposed to any excess moisture,

• if the printer is dropped or damaged,

• if you suspect that the product needs servicing or repair,

• whenever you clean the product.

Service Safety Summary

General Safety

The printer and recommended supplies have been designed and tested to meet strict safety

requirements. Attention to the following information will ensure the continued safe operation of

the printer.

Electrical Safety

• Use the power cord supplied with the printer.

• Plug the power cord directly into a properly grounded electrical outlet.

• Do not use a ground adapter plug to connect the printer to an electrical outlet that does

not have a ground connection terminal.

• Do not use an extension cord or power strip.

• Do not place the printer in an area where people might step on the power cord.

• Do not place objects on the power cord.

• Do not block the ventilation openings. These openings are provided to prevent overheat-

ing of the printer.

• Do not drop paper clips or staples into the printer.

WARNING

Avoid the potential of electrical shock by ensuring that the printer is properly grounded.

Electrical products may be hazardous if misused.

The power cord is attached to the printer as a plug-in device on the side of the printer. If it is

necessary to disconnect all electrical power from the printer, disconnect the power cord from

the electrical outlet.

WARNING

Do not remove the covers or guards that are fastened with screws unless you are

installing optional equipment and are specifically instructed to do so. Power should be

off when performing these installations. Disconnect the power cord when removing the

covers and guards for installing optional equipment. Except for user-installed options,

there are no parts that you can maintain or service behind these covers.

WARNING

The following are hazards to your safety:

• Damaged or frayed power cord

• Liquid spilled into the printer

• Exposure to water or excessive moisture

If any of these conditions occur, do the following:

1. Turn off the power switch.

2. Disconnect the power cord from the electrical outlet.

3. Call an authorized service representative.

Introduction

How to Use this Manual, Service Safety Summary

October 2010

iv

Initial Issue

ColorQube 8570/8870 Service Manual

Page 9

Maintenance Safety

• Do not attempt any maintenance procedure that is not specifically described in the documentation supplied with the printer.

• Do not use aerosol cleaners. The use of supplies that are not approved may cause poor

performance and could create a hazardous condition.

• Do not burn any consumables or routine maintenance items. For information on Xerox

supplies recycling programs, go to www.xerox.com/gwa.

Operational Safety

The printer and supplies were designed and tested to meet strict safety requirements. These

include safety agency examination, approval, and compliance with established environmental

standards.

Pay attention to these safety guidelines to ensure the continued, safe operation of the printer.

• Use the supplies specifically designed for your printer. The use of unsuitable materials

may cause poor performance and a possible safety hazard.

• Follow all warnings and instructions marked on, or supplied with, the printer, options and

supplies.

CAUTION

Use of other than Genuine Xerox solid ink may affect print and copy quality and printer reliability. It is the only ink designed and manufactured under strict quality controls by Xerox for specific use with this printer. The Xerox Warranty, Service Agreements, and Total Satisfaction

Guarantee do not cover damage, malfunction, or degradation of performance caused by use of

non-Xerox supplies or consumables, or the use of Xerox supplies not specified for this printer.

NOTE: The Total Satisfaction Guarantee is available in the United States and Canada. Coverage may vary outside these areas; please contact your local representative for details.

General Guidelines

For qualified service personnel only - Refer also to the preceding Power Safety Precautions.

Avoid servicing alone - Do not perform internal service or adjustment of this printer unless

another person capable of rendering first aid or resuscitation is present.

Safety Interlocks

Make sure all covers are in place and all interlock switches are functioning correctly after you

have completed a printer service call. If you bypass an interlock switch during a service call,

use extreme caution when working on or around the printer.

Servicing Electrical Components

Before starting any service procedure, switch off the printer power and unplug the power cord

from the wall outlet. If you must service the printer with power applied, be aware of the potential

for electrical shock.

WARNING

Do not touch any electrical component unless you are instructed to do so by a service

procedure.

Figure 1 Electrical Components Warning

Servicing Mechanical Components

WARNING

Do not try to manually rotate or manually stop the drive assemblies while any printer

motor is running.

Use care when servicing with power - Dangerous voltages may exist at several points in this

printer. To avoid personal injury, do not touch exposed connections and components while

power is on. Disconnect power before removing the power supply shield or replacing compo

nents.

Do not wear jewelry - Remove jewelry prior to servicing. Rings, necklaces and other metallic

objects could come into contact with dangerous voltages and currents.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are displayed

on potentially dangerous components. As you service the printer, check to make certain that all

warning labels remain in place.

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

-

Figure 2 Mechanical Components Warning

Servicing Printhead Components

WARNING

The Printhead is VERY HOT. Turn the printer power off and wait at least 30 minutes for

the Printhead to cool before attempting to service the Printhead or adjacent compo

nents.

v

Service Safety Summary

-

Introduction

Page 10

Moving the Printer

WARNING

Parts of the printer are hot. To avoid personal injury or damage to the printer, allow the

ink to solidify. Run the shutdown procedure to park the Printhead and begin cooling the

printer. Wait at least 30 minutes for the printer to cool before moving or packing the

printer.

• Allow the printer to cool to avoid ink spills which can damage the printer.

• Use the shutdown procedure from the Control Panel before moving the printer.

• Never move the printer if a Power Down Error-Head not Parked message is displayed.

Damage to the printer can occur if the Printhead is not locked before shipment.

• The printer is heavy and must be lifted by two people.

Figure 1 Printer Lifting Technique

• Always move the printer separately from the Optional Trays 3, 4, and 5.

When shipping the printer, repack the printer using the original packing material and boxes or a

Xerox Repackaging Kit. Instructions for repacking the printer are included in the Kit. If you do

not have all the original packaging, or are unable to repackage the printer, contact your local

Xerox service representative.

Symbols Used on the Printer

Warnings, Cautions, and Notes

Be aware of all symbols and terms when they are used, and always read Note, Caution, and

Warning statements.

A translated version of all warnings is in Translation of Warnings section.

Warnings, Cautions, and Notes can be found throughout the service manual. The words

WARNING or CAUTION may be listed on an illustration when the specific component associ

ated with the potential hazard is pointed out; however, the message of the WARNING or CAU-

TION is always located in the text. Their definitions are as follows:

WARNING

A Warning is used whenever an operating or maintenance procedure, a practice, condition, or statement, if not strictly observed, could result in personal injury.

CAUTION

A Caution is used whenever an operating or maintenance procedure, a practice, condition, or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A Note is used whenever it is necessary to highlight an operating or maintenance procedure, practice, condition, or statement.

Common Warnings and Safety Icons

The following common warnings are used throughout the documentation and the safety icons

are displayed on the printer. Additional specific warnings are included for the listed chapters.

Common Warnings

WARNING

To avoid personal injury or shock, do not perform repair or adjustment activities with

the power switch on or electrical power applied to the machine.

DANGER: Afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des

activités de maintenance ou de réglage avec l'équipement sur Marche ou avec le cordon

d'alimentation branché.

WARNING

A Warning is used whenever an operating or maintenance procedure, a practice, conditioning, or statement, if not strictly observed, could result in personal injury.

DANGER: Une note DANGER est utilisée à chaque fois qu’une procédure de maintenance ou qu’une manipulation présente un risque de blessure si elle n’a pas été strictement observée.

-

CAUTION

Failure to repackage the printer properly for shipment can result in damage to the printer. Damage to the printer caused by improper packaging is not covered by the Xerox warranty, service

agreement, or Total Satisfaction Guarantee.

Introduction

October 2010

Moving the Printer, Symbols Used on the Printer

Initial Issue

vi

ColorQube 8570/8870 Service Manual

Page 11

The following chapters have additional specific warning information.

Table 1 Additional Warnings

Chapter 1 - Empty the Waste Tray

Chapter 2 - 99,002, 99,003 PEST - Jetstack Disconnect

Chapter 4 - REP 2.1 Funnel Cap

Chapter 4 - REP 2.2 Jetstack Cap

Chapter 4 - REP 2.3 Printhead Assembly

Chapter 4 - REP 2.9 Left and Right Printhead Restraints

Chapter 4 - REP 3.12 525-Sheet Feeder

Chapter 4 - REP 5.1 Electronics Module

Chapter 4 - REP 5.6 Boards (Power Supply, Main Controller, Power Control)

Chapter 4 - REP 5.9 Wave Amplifier

Chapter 8 - Power Supply

Avoid pinching fingers in the printer. Use caution to avoid personal injury.

Figure 2 Pinch Injury Symbol

Use caution (or draws attention to a particular component).

WARNING

HIGH VOLTAGE!

DANGER: HAUTE TENSION!

Exercise care when making the voltage check in the following steps.

DANGER: Soyez extrêmement vigilant lorsque vous effectuez les tests de tension au

cours des étapes qui suivent.

WARNING

Personal injury may result from grasping hot areas of Printhead. If a hot Printhead must

be removed, grasp the Printhead by black plastic frame component.

DANGER: Des blessures peuvent résulter si les zones chaudes du module de four sont

touchées. Si un module de four chaud doit être enlevé, le saisir par l'élément en plas

tique noir du bâti.

Machine Safety Icons

The following precautionary symbols may appear on the printer.

This symbol indicates hot surface on or in the printer. Use caution to avoid personal injury.

Figure 1 Hot Surface Symbol

Figure 3 Use Caution Symbol

Line Voltage present on the Fuse and Fuse Holder Contacts.

Figure 4 Electrical Shock Symbol

The surface is hot while the printer is running. After turning off the power, wait 30 minutes.

-

Figure 5 Wait 30 Minutes Symbol

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

vii

Introduction

Symbols Used on the Printer

Page 12

Electrostatic Discharge Precautions

Some semiconductor components, and the respective sub-assemblies that contain them, are

vulnerable to damage by Electrostatic Discharge (ESD). These components include Integrated

Circuits (ICs), Large-Scale Integrated circuits (LSIs), field-effect transistors, and other semi

conductor chip components. The following techniques will reduce the occurrence of component damage caused by static electricity.

Be sure the power is off to the chassis or the circuit board, and observe all other safety precautions.

• Immediately before handling any semiconductor components assemblies, drain the electrostatic charge from your body. This can be accomplished by touching an earth ground

source or by wearing a wrist strap device connected to an earth ground source. Wearing a

wrist strap will also prevent accumulation of additional bodily static charges. Be sure to

remove the wrist strap before applying power to the unit under test to avoid potential

shock.

• After removing a static sensitive assembly from its anti-static bag, place it on a grounded

conductive surface. If the anti-static bag is conductive, you may ground the bag and use it

as a conductive surface.

• Do not use freon-propelled chemicals. These can generate electrical charges sufficient to

damage some devices.

• Do not remove a replacement component or electrical sub-assembly from its protective

package until you are ready to install it.

• Immediately before removing the protective material from the leads of a replacement

device, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

• Minimize body motions when handling unpacked replacement devices. Motion such as

your clothes brushing together, or lifting a foot from a carpeted floor can generate enough

static electricity to damage an electro-statically sensitive device.

• Handle IC’s and Erasable Programmable Read-Only Memories (EPROM’s) carefully to

avoid bending the pins.

• Pay attention to the direction of parts when mounting or inserting them on the Printed Circuit Boards (PCB’s).

Regulatory Requirements

Xerox has tested this printer to electromagnetic emission and immunity standards. These standards are designed to mitigate interference caused or received by this printer in a typical office

-

environment.

United States (FCC Regulations)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protec

tion against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy. If it is not

installed and used in accordance with these instructions, it may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harm

ful interference in which case the user will be required to correct the interference at his/her own

expense.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiver.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/television technician for help.

Any changes or modifications not expressly approved by Xerox could void the user's authority

to operate the equipment. To ensure compliance with Part 15 of the FCC rules, use shielded

interface cables.

Canada (Regulations)

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme

à la norme NMB-003 du Canada.

-

-

Introduction

Electrostatic Discharge Precautions, Regulatory Re-

October 2010

viii

Initial Issue

ColorQube 8570/8870 Service Manual

Page 13

European Union

WARNING

This is a Class A product. In a domestic environment, this product may cause radio

interference in which case the user may be required to take adequate measures.

Table 1 CE Symbol and Description

The CE mark applied to this product symbolizes Xerox’s declaration of conformity with the following applicable Directives of

the European Union as of the dates indicated:

• December 12, 2006: Low Voltage Directive 2006/95/EC

• December 15, 2004: Electromagnetic Compatibility Directive 2004/108/EC

This product, if used properly in accordance with the user's instructions, is neither dangerous

for the consumer nor for the environment.

To ensure compliance with European Union regulations, use shielded interface cables.

A signed copy of the Declaration of Conformity for this product can be obtained from Xerox.

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

ix

Introduction

Regulatory Requirements

Page 14

Translation of Warnings

General Usage

WARNING

Use only Xerox materials and components. This product is safety certified using Xerox

materials and components. The use of non Xerox materials and components may invali-

date the safety certificate.

DANGER: N'utilisez que des matières premières et des composants Xerox. La sécurité

du produit est assurée dans le cadre de son utilisation avec des matières premières et

des composants Xerox. L'utilisation de matières premières et de composants autres

que ceux de Xerox risque d'invalider le certificat de sécurité.

AVVERTENZA: Utilizzare solo materiali e componenti Xerox per avvalersi della certifi-

cazione di protezione. L'utilizzo di materiali e componenti non Xerox può rendere nulla

la certificazione di protezione.

VORSICHT: Verwenden Sie nur Materialien und Komponenten von Xerox. Dieses

Produkt besitzt die Sicherheitszertifizierung bei Verwendung von Xerox-Materialien und

-Komponenten. Die Verwendung von Materialien und Komponenten anderer Hersteller

setzt möglicherweise das Sicherheitszertifikat außer Kraft.

AVISO: Utilice solo los materiales y componentes Xerox. Este producto dispone de un

certificado de seguridad si se utilizan los materiales y componentes Xerox. Este certifi-

cado de seguridad no será válido si se utilizan materiales y componentes que no sean

de Xerox.

WARNING

Follow the service procedure exactly as written. Use of controls or adjustments other

than those specified in this manual, may result in an exposure to invisible laser radia-

tion. During servicing, the invisible laser radiation can cause eye damage if looked at

directly.

DANGER: Les procédures de dépannage doivent être suivies à la lettre. Si les réglages

ou vérifications ne sont pas effectués suivant les instructions de ce manuel, il peut y

avoir un risque d'exposition dangereuse au faisceau laser. Celui-ci peut provoquer des

lésions oculaires s'il est observé directement.

AVVERTENZA: Eseguire le procedure di servizio esattamente come descritto. L'utilizzo

di dispositivi di controllo o di registrazione diversi da quelli riportati in questo manuale

potrebbe comportare un'esposizione a radiazioni laser invisibili. Tali radiazioni possono

danneggiare gli occhi se si guarda direttamente il fascio laser durante gli interventi di

servizio.

VORSICHT: Die Wartungsarbeiten genau den Anweisungen entsprechend durchführen.

Der Umgang mit Steuer- oder Bedienelementen, deren Verwendung nicht ausdrücklich

in diesem Handbuch angewiesen wurde, kann dazu führen, dass unsichtbare Laser-

strahlung frei gesetzt wird. Direkter Blickkontakt mit dem Laserstrahl kann bleibende

Augenschäden verursachen.

AVISO: Siga los procedimientos de mantenimiento tal como están descritos. El uso de

controles o ajustes no especificados en este manual puede tener como resultado la

exposición a radiación láser invisible. Durante las operaciones de mantenimiento, la

radiación de láser invisible puede causar daños en los ojos si se mira directamente a

ella.

Electrical

WARNING

Switch off the electricity to the machine. Disconnect the power cord from the customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury. Moving parts can cause injury.

DANGER: Mettez la machine hors tension. Déconnectez le cordon d'alimentation de l'alimentation du client lorsque vous réalisez des tâches qui ne nécessitent pas d'électricité. L'électricité peut être à l'origine de blessures, voire d'un accident mortel. Les pièces

amovibles peuvent être à l'origine de blessures.

AVVERTENZA: Spegnere la macchina. Scollegare il cavo di alimentazione dall'alimentatore quando si eseguono attività che non richiedono elettricità. L'elettricità può causare

morte o lesioni personali. Le parti in movimento possono causare lesioni personali.

VORSICHT: Schalten Sie die Stromversorgung der Maschine ab. Ziehen Sie das Stromkabel ab, wenn Sie Aufgaben ausführen, für die keine Stromversorgung benötigt wird.

Stromschläge können Todesfällen oder Verletzungen verursachen. Bewegliche Teile

können zu Verletzungen führen.

AVISO: Apague la electricidad de la máquina. Desconecte el cable de alimentación eléctrica de la toma de pared mientras esté realizando tareas que no necesiten corriente. La

electricidad puede causar daños o la muerte. Las partes móviles pueden causar daños.

WARNING

Use extreme care when working near this power supply. High voltage is present on the

power supply when the machine is in standby mode. Contact with electrical compo-

nents or high voltage cables represents a shock potential that could result in serious

personal injury.

DANGER: Faire très attention en intervenant près de ce module d’alimentation. Une

haute tension y est présente lorsque la machine est en mode d’attente. Tout contact

avec les éléments électriques ou les câbles haute tension représente un risque de choc

et de graves blessures.

AVVERTENZA: Fare estrema attenzione quando si lavora vicino a questo gruppo stat-

ico. Il gruppo statico è caricato ad alta tensione quando la macchina è in modalità

standby. Il contatto con componenti sotto tensione o cavi elettrici comportano un serio-

pericolo di scossa elettrica e gravi ferite.

VORSICHT: Bei der Verwendung unterbrechungsfreier Stromversorgung benutzt äußer-

ste Vorsichtkeit. Während die Machine sich im Energiespar-Modus befindet, steht es

unter Hochspannung. Beim Umgang mit elektrischen Bauteilen und Hochspannungslei

tungen erhöht sich das Unfallrisiko. Äußerste Vorsicht ist geboten.

AVISO: Tenga mucho cuidado al trabajar en las proximidades de la fuente de alimentación. Hay voltaje muy alto en la fuente de alimentación cuando la máquina se encuentra en el modo de espera. El contacto con componentes eléctricos o cables de alto

voltaje representa peligro de descarga eléctrica que puede ocasionar daños personales

graves.

-

Introduction

Translation of Warnings

October 2010

x

Initial Issue

ColorQube 8570/8870 Service Manual

Page 15

WARNING

Do not perform repair activities with the power on or electrical power supplied to the

machine. Some machine components contain dangerous electrical voltages that can

result in electrical shock and possible serious injury.

DANGER: Ne pas effectuer de dépannnage avec le contact principal activé ou avec l'ali-

mentation électrique appliquée à la machine. Certains éléments de la machine comportent des tensions électriques dangereuses qui peuvent causer un choc électrique et de

graves blessures.

AVVERTENZA: Non effettuare alcuna riparazione con l'alimentazione elettrica inserita.

Alcuni componenti contengono corrente ad alta tensione che può provocare forti

scosse e gravi ferite.

VORSICHT: Es dürfen erst Reparaturarbeiten durchgeführt werden, wenn das Gerät aus-

geschaltet ist oder der Netzstecker nicht mehr mit der Stromquelle verbunden ist. Einige

Komponenten des Gerätes sind stromführend und können daher zu ernsthaften Verlet-

zungen oder Stromschlägen führen.

AVISO: No realice reparaciones con la máquina encendida o conectada a la corriente.

Algunos componentes de la máquina contienen voltajes eléctricos peligrosos que

pueden producir una descarga eléctrica y causar daños graves.

ColorQube 8570/8870 Overview

The ColorQube 8570/8870 are solid ink technology printers utilizing a new formulation of solid

ink and ink stick sensing technology. It also features new power saving features that make the

printer ENERGY STAR TEC Tier II compliant.

The printers include an image processor supporting PostScript 3 and PCL5c page description

languages. The printer supports up to 40 page per minute (PPM) and resolutions up to 525 x

2400 dots-per-inch (dpi). The product features USB and 10/100/1000 Base Tx Ethernet ports.

The ColorQube 8570/8870 provides two standard paper trays. The 100-sheet Tray 1 supports

manual feed of specialty media, card stock, and envelopes. Tray 2 provides 525 sheets of

capacity. The Output Tray holds 400 sheets facedown.

The ColorQube 8570/8870 options add memory, media capacity, Hard Disk Drive, Duplex,

Wireless, and functionality. RAM memory upgrades are available to increase the standard

installed memory from standard 512 MB to 2 GB maximum. A 525-Sheet Feeder is also avail

able. Three 525-Sheet Feeders may be installed to raise the maximum media input storage

capacity to 2200 sheets. The Printer Stand is available for mobility and increased media stor

age.

-

-

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

xi

Introduction

Translation of Warnings, ColorQube 8570/8870

Page 16

Printer Configurations

The ColorQube 8570/8870 is available in five configurations.

Table 1 Printer Configurations

Features 8570N 8570DN 8570DT 8870EE

Processor and Clock

Speed

Memory Configuration* 512 MB 512 MB 512 MB 512 MB

Adobe Postscript 3 Fonts Standard Standard Standard Standard

PCL5 Fonts Standard Standard Standard Standard

USB 2.0 Standard Standard Standard Standard

Ethernet Interface 10/100/1000

Tray 1 (100 sheet) Standard Standard Standard Standard

Tray 2 (250 sheet) Standard Standard Standard Standard

Tray 3 (250 sheet) Optional Optional Standard Optional

Tray 4 (250 sheet) Optional Optional Standard Optional

Tray 5 (250 sheet) Optional Optional Standard Optional

Duplex Optional Standard Standard Standard

Hard Disk Drive Optional Optional Optional Optional

Printer Stand Optional Optional Optional Optional

Wireless LAN Optional Optional Optional Optional

Print Speed (ppm)

• Fast Color

• Standard

• Enhanced

• Photo

• PCL 600x400 Mode • 20/ 18 • 20/18 • 20/18 • 20/18

• PCL 600x600 Mode • 12/10 • 12/10 • 12/10 • 12/10

Printer Resolution - PostScript

• Fast Color

• Standard

• Enhanced

• Photo

* All configurations have two memory slots supporting 512 MB / 1 GB DDR2 SODIMMs, to a

maximum of 2.0 GB total.

1 GHz 1 GHz 1 GHz 1 GHz

Base-TX

• 40/30

• 30/ 25

• 19/18

•6/4

• 225x400

• 300x450

• 525x450

• 525x2400

10/100/1000

Base-TX

• 40/30

• 30/ 25

• 19/18

•6/4

• 225x400

• 300x450

• 525x450

• 525x2400

10/100/1000

Base-TX

• 40/30

• 30/ 25

• 19/18

•6/4

• 225x400

• 300x450

• 525x450

• 525x2400

10/100/1000

Base-TX

• 40/30

• 30/25

• 19/18

•6/4

• 225x400

• 300x450

• 525x450

• 525x2400

Parts of the Printer

Front View

Figure 1 Front View

Table 1 Front View

1 Tray 5 (Optional 525-Sheet Feeder)

2 Tray 4 (Optional 525-Sheet Feeder)

3 Tray 3 (Optional 525-Sheet Feeder)

4 Tray 2 (Standard 525 Sheet)

5 Tray 1 (MPT) (100 Sheet)

6 Control Panel

7 Exit Door Release

8 Front Door Release

9 Exit Door B

10 Ink Loader Door C

11 Legal/ A4 Output Tray Extension

12 Interface (I/O) Door E

13 Side Door D

14 Front Door A

Introduction

Printer Configurations, Parts of the Printer

October 2010

xii

Initial Issue

ColorQube 8570/8870 Service Manual

Page 17

Top View

1 Ink Loader Door

2 Ink Stick

Right Side View

Rear View

The rear view consists of the printer’s main electronics and power supply, which are enclosed

in a metal case called the Electronics Module. The rear panel allows access to the Electronics

Module, RAM, and NVRAM. The optional Hard Disk Drive, if installed, is mounted on the rear

panel.

When replacing an Electronics Module, transfer the following components to the new Electronics Module.

•RAM

• Configuration Card

• NVRAM

• Hard Disk Drive (if installed)

Figure 2 Top View

Table 2 Top View

Figure 3 Right Side View

Table 3 Right Side View

1 Drum Maintenance Unit

2 Waste Tray

3 Power Cord Connection

4 Power Switch

5 USB Connection

6 Configuration Card

7 Ethernet 10/100/1000 Base-Tx Connection

Initial Issue

ColorQube 8570/8870 Service Manual

1 Hard Disk Drive (Optional)

2 Memory (RAM) Connectors - (Primary - Left Side, Secondary - Right Side)

3 NVRAM

October 2010

xiii

Figure 4 Rear View

Table 4 Rear View

Introduction

Parts of the Printer

Page 18

Printer Options

ColorQube 8570/8870 printer options include:

• Additional Memory (512 MB or 1 GB)

• Wireless LAN

• Hard Disk Drive

• Optional 525-Sheet Feeder (Tray 3, 4, or 5)

• Printer Stand

Additional Memory

The ColorQube 8570/8870 features 2 slots that accept a 512 MB or 1 GB of DDR2 SODIMMs.

Memory modules must meet the following characteristics:

• 200 Pin SODIMMS

• Unbuffered, Non-parity

The printer’s Configuration page lists the amount of RAM installed in the printer.

Figure 1 RAM

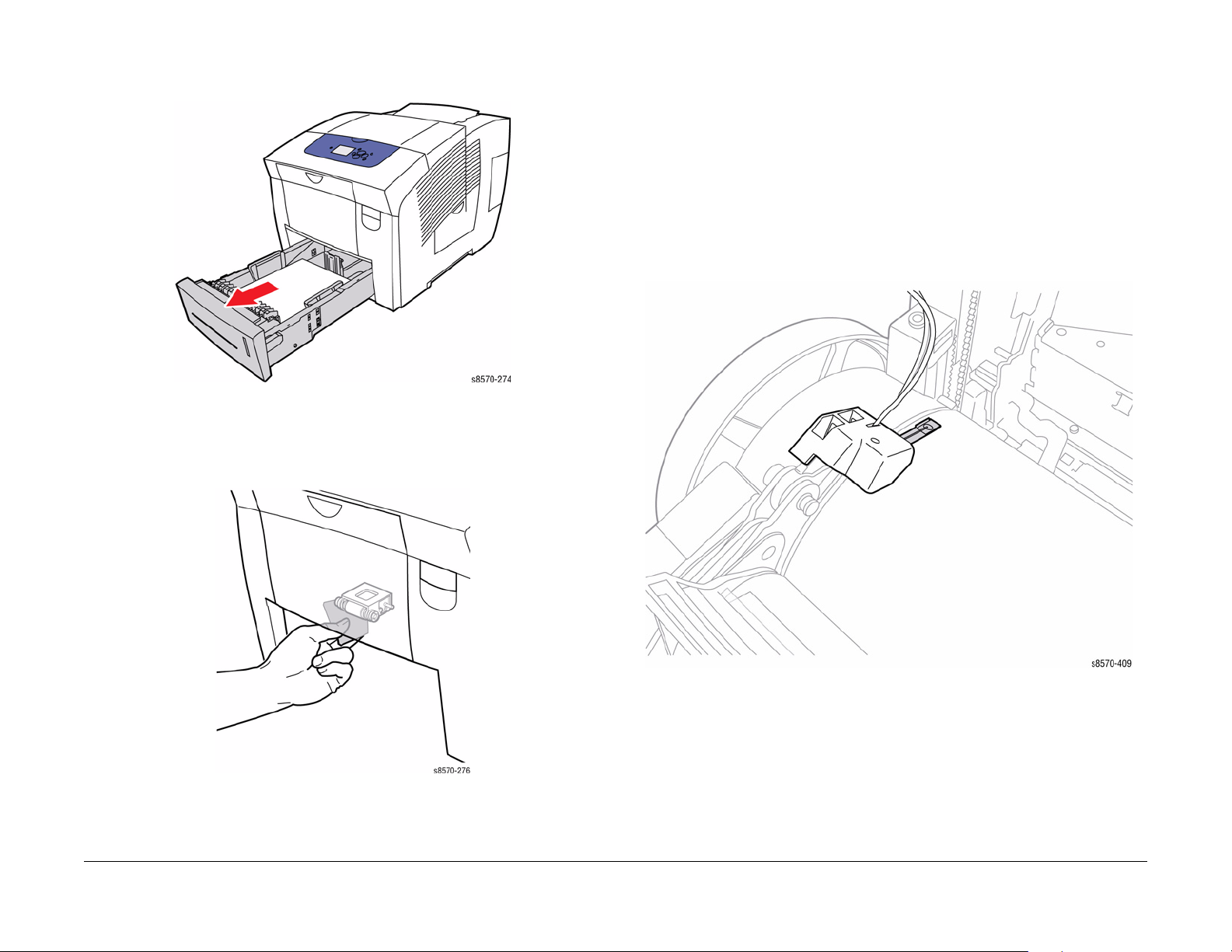

Optional 525-Sheet Feeder (Tray 3, 4, or 5)

The Optional 525-Sheet Feeder increases the input capacity of the printer and can be attached

to the printer underneath Tray 2. The Optional 525-Sheet Feeder is customer installable.

Printer Stand

The Printer Stand supports a fully-optioned printer and provides space for media storage.

Figure 3 Printer Stand

Hard Disk Drive

The ColorQube 8570/8870 supports an optional internal Hard Disk Drive. The Hard Disk Drive

has a minimum 160 GB capacity. Features include:

• Secure Print

• Proof Print

•Save Print

• Disk Collation

Figure 2 Optional 525-Sheet Feeder (Tray 3, 4, or 5)

Introduction

Printer Options

Wireless Network Adapter

The Wireless Network Adapter enables the printer to connect to a wireless network.

October 2010

xiv

Figure 4 Hard Disk Drive

Initial Issue

ColorQube 8570/8870 Service Manual

Page 19

Control Panel Layout

The Control Panel consists of one LED, a display window, and seven buttons. These buttons

are used to navigate the menu system, perform functions, and select modes of operation for

the printer.

Figure 1 Control Panel

Table 1 Control Panel Description

Button/Feature Description

1 Status Indicator LED • Green: Printer is ready to print.

• Yellow: Warming condition, printer continues to print.

• Red: Startup sequence or error condition.

• Blinking:

– Red: Error Condition

– Green: Warming up

2 Graphic Control Panel

Display

3 Cancel Button Cancels the current print job.

4 Back Button Returns to the previous menu item.

5 Up Arrow Button Scrolls upward through the menus.

6 Down Arrow Button Scrolls downward through the menus.

7 OK Button Accepts the selected settings.

8 Help (?) Button Displays a help message with information about the printer,

9 Power Saver Button/

Indicator Light

Displays printer settings, status, and messages and menus.

such as Printer Status, Error Messages, and Maintenance

Information. Also describes Control Panel menu items.

Brings the printer out of, or puts the printer into, Power Saver

mode.

• On Steady: Printer can be put in Power Saver mode at

this time.

• Off: Printer cannot be put in Power Saver mode at this

time.

• Blinking: Printer is in Power Saver mode.

Control Panel Shortcuts

Table 2 Control Panel Shortcuts

Mode or Menu Press These Buttons

Service Tools Menu From any menu, press and hold the Up Arrow, then press OK.

Hidden Service Menu From the Service Tools menu, press and hold the Up Arrow,

Service Diagnostics When the Display turns black, press and hold Back and Help

Control Panel Language Press and hold the Cancel button, then press the Help button.

Bypass Protected Menus Press and hold the Cancel button, then press the Back button.

FTTR (Fast Time To

Ready)

and then press the Down Arrow.

until Beginning Service Mode appears.

Printer goes to the Ready state without waiting for temperatures

to reach operating values. On power-up, when the Xerox splash

screen displays, press and release the Up Arrow button, then

press the Down Arrow button. If the printer detects ink on the

Drum, the display indicates a warming-up status. The printer will

not actually print until it reaches its operating temperatures.

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

xv

Introduction

Control Panel Layout

Page 20

Menu Map

Figure 1 and Figure 2 illustrate the Menu Map for the ColorQube 8570/8870. The Menu Map

can be accessed through the Control Panel: Control Panel Menu -> Information -> Menu

Map.

Introduction

Menu Map

Figure 1 Menu Map (page 1)

October 2010

xvi

Figure 2 Menu Map (page 2)

Initial Issue

ColorQube 8570/8870 Service Manual

Page 21

Routine Maintenance Items

Drum Maintenance Unit life expectancy depends on the unit capacity. For example, the standard-capacity Drum Maintenance Unit produces 10,000 prints regardless of the colors used.

Extended-capacity Drum Maintenance Unit for the ColorQube 8570/8870 produces 30,000

pages up to 20% coverage and 20,000 pages when coverage exceeds 20%. The ColorQube

8570/8870 uses a unique Drum Maintenance Unit. See Parts List in Chapter 5 for the correct

replacement part.

Consumables

CAUTION

The ColorQube 8570/8870 printer uses a new formulation of Ink having unique properties. The

Ink Loader on these products is keyed to accept this Ink shape only. The use of Ink not specifi

cally designed for this product can result in printer failures.

NOTE: Print life is based on “typical” office printing and 5% coverage per color.

-

Table 1 Routine Maintenance Life Expectancy

Item Description Print Life

1 Drum Maintenance Unit (Extended-

Capacity)

Drum Maintenance Unit (StandardCapacity)

2 Waste Tray Empty every 7 purges (70g)

30,000 cycles (0-20%) coverage

20,000 cycles (20-100%) coverage

10,000 cycles

Table 1 Consumables

Item Description Print Life (per stick)

1 Black Ink Stick - 8570N/ DN/ DT 2,200 pages

2 Cyan, Magenta, Yellow Ink Sticks - 8570N/ DN/ DT 2,200 pages

3 Black Ink Stick - 8870EE 2,800 pages

4 Cyan, Magenta, Yellow Ink Sticks - 8870EE 2,800 pages

Figure 1 Routine Maintenance Items

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

xvii

Figure 1 ColorQube 8570/ 8870 Ink Sticks

Introduction

Routine Maintenance Items, Consumables

Page 22

CAUTION

Only use ink designed exclusively for the printer.

Use of ink other than Genuine Xerox solid ink may affect print quality and printer reliability. It is

the only ink designed and manufactured under strict quality controls by Xerox for specific use

with these printers.

NOTE: Verify that the molded Xerox label is shown on top of the ink stick.

1. ColorQube 8570 N/ DN/ DT

2. ColorQube 8870 EE

NOTE: The ColorQube 8570 North America ink sticks are not compatible with the ColorQube

8870 North America printers, and the ColorQube 8570 Xerox Europe ink sticks are not compat

ible with the ColorQube 8870 Xerox Europe printers.

NOTE: The ColorQube 8570 Factory ink sticks A_D are compatible with both the ColorQube

8570 and 8870 printers. Customers are limited to using a maximum of three Factory ink sticks

for each color.

ColorQube 8570 Ink SKU

Table 2 Ink SKU Definitions - 8570N/ DN/ DT

Location A B C D 8570

North America (NA) A C x

Xerox Europe (XE) A B C x

Developing Markets Organization

(DMO)

Metered A B D x

Factory A D x

NOTE: ColorQube 8570 Metered ink stick shown in Figure 3.

A B x

-

Figure 2 ColorQube Ink Sticks

Learning Mode - The printer is programmed to lock the sensor to use a particular ink stick

when the 1st non-Factory ink stick is used.

Factory Ink Sticks - Factory ink sticks of each color are provided with new printers and

replacement Printheads.

Different ink stick types or SKU’s meant for particular geographic regions can be determined by

looking at size of the ink stick and the bottom of the ink stick. Compare the letter pattern in

Ta b l e 2 and Ta b l e 3 for the different regions on the ColorQube 8570 and 8870 ink sticks.

Introduction

October 2010

Consumables

xviii

Figure 3 Ink Stick Keys and SKU Flags Example - 8570

Initial Issue

ColorQube 8570/8870 Service Manual

Page 23

ColorQube 8870 Ink SKU

Table 3 Ink SKU Definitions - 8870

Location E F G H K 8870

North America (NA) E F G H x

Xerox Europe (XE) E F H x

Developing Markets Organization

(DMO)

Metered E F G K x

NOTE: ColorQube 8870 Metered ink stick shown in Figure 4.

Figure 4 Ink Stick Keys and SKU Flags Example - 8870

E F G x

Printer Specifications

Print Engine Specifications

Table 1 Functional Specifications

Characteristic Specifications

Printing Process Four-color (CMYK) solid ink Printhead architecture.

Image System Transfix transfer from oil coated Drum.

Color Medium Cyan, Magenta, Yellow, and Black Ink Sticks, each shape-coded. the

printer uses the subtractive color system to produce the colors Red,

Green, and Blue.

Color Management • Automatic, Black & White

• Office: sRGB, sRGB Scientific, LCD Display, Vivid Color, None

• Press: Commercial, Euroscale, SWOP

Resolution • Fast Color: 225 x 400 dpi

• Standard: 300 x 450 dpi

• Enhanced: 525 x 450 dpi

• Photo: 525 x 2400 dpi

Warm-Up Time • From Cold Start: Less than 10 minutes

• From ENERGY STAR Mode: 2.5 minutes

Printer Life 5 year/ 225,000 pages

Recommended AMPV 4,000 prints/month

Operating System • Windows 2000/ 2003 Server/ XP/ Vista

• Macintosh: OS 10.3 or higher

• Linux

* Assumes a 30 day month of printing.

Memory Specifications

Initial Issue

ColorQube 8570/8870 Service Manual

Characteristic Specifications

Minimum RAM 512 MB

Maximum RAM 2 GB

Supported RAM Supports up to 2 GB of 512 MB or 1 GB DDR2 SDRAM using 2 slots.

October 2010

xix

Table 2 Memory Specifications

Introduction

Consumables, Printer Specifications

Page 24

Electrical Specifications

Print Speed

Table 3 Electrical Specifications

Characteristic Specifications

Primary Line Voltages • 90 - 140 VAC

• 180 - 264 VAC

Primary Line Voltages Frequency Range 47 - 63 Hz

Power Consumption at Rated Voltage Input • Warm-Up Peak: 1500 W

• Printing: 600 W

• Idle: 300 W

• Power Saver: 70 W

In-rush Current Less than 60 A

Leakage Current Less than 3.5 mA

Environmental Specifications

Table 4 Environmental Specifications

Characteristic Specifications

Operating Storage

Temperature

Humidity 10% to 80% RH Non-Condensing 10% to 95% RH, non-condensing

Altitude 0 to 2,438 meters (8,000 ft.) 0 to 15,000 meters (49,212 ft.)

Acoustic Noise Operation Standby or Ready

Sound Power Level

(Bels)

Sound Pressure (Decibels)

NOTE: Check that the printer is on a stable, non-vibrating surface. Advise the customer to use

care not to shake the printer excessively when loading media or closing the Front Door. During

operation, the ink is in liquid form and can spill from the Printhead reservoir resulting in output

defects.

10º to 32º C (50º to 90º F) -30º to 60º C (-22º to 140º F)

7.0 B(A) 4.4 B(A)

57.0 dB(A) 31.0 dB(A)

Table 5 Print Speed Specifications

Resolution/ Tray Simplex, A4 Paper Auto Duplex, A4 Paper

Tray 1

Fast Color (225x400) 13 ppm 13 ppm

Standard (300x450) 11 ppm 11 ppm

Enhanced (525x450) 10 ppm 9 ppm

Photo (525x2400) 6 ppm 6 ppm

PCL 600x400 Mode 10 ppm 9 ppm

PCL 600x600 Mode 6 ppm 6 ppm

Tray 2

Fast Color (225x400) 40 ppm 30 ppm

Standard (300x450) 30 ppm 25 ppm

Enhanced (525x450) 19 ppm 18 ppm

Photo (525x2400) 6 ppm 4 ppm

PCL 600x400 Mode 20 ppm 18 ppm

PCL 600x600 Mode 12 ppm 10 ppm

First Print Output Time

First Print Output Time (FPOT) is defined as the time from when the engine receives a Start

signal in Ready state, until a single page is printed and delivered to the output tray.

From Ready State

Table 6 Ready State

Resolution FPOT

Fast Color (225x400) 4 seconds or less

Standard (300x450) 7 seconds or less

Enhanced (525x450) 9 seconds or less

Photo (525x2400) 15 seconds or less

From Non-Ready State

First Print Out Time includes the time required to print any maintenance pages (such as the

mud page) and a single customer page on A size media from Tray 2.

Introduction

Printer Specifications

Starting State FPOT

Off (cold) 12 minutes

Powe r S aver 2.5 minutes

Low Power (Standby) 30 seconds

Quiet Warm-Up 10 seconds

October 2010

xx

Table 7 Non-Ready State

Initial Issue

ColorQube 8570/8870 Service Manual

Page 25

Cool Down Transition Time

At nominal ambient conditions, the printer will cool to a movable condition within specified

times listed in Tabl e 8.

Media and Tray Specifications

The media trays accommodate most sizes and types of paper, transparencies, or other specialty media. Print the Paper Tips page for a list of supported media.

Table 8 Cool Down Transition Time

Tra nsi tion Maximum Transition Time

From Ready 35 minutes

From ENERGY STAR 20 minutes

Cold Print Process Settings

The printer uses lower temperature settings to allow the printer to have a lower FPOT from

power saver and low power modes. This allows printing to occur sooner, but at slower print

speed. Certain print types (duplex, transparencies, etc.) may be excluded from cold print pro

cess and will therefore have a longer FPOT.

Table 9 Cold Print Process Settings

Characteristic Setting

Drum Temperature

Preheat Temperature Normal Range

Transfix Speed

Reservoir Temperature Normal Range

Jetstack Temperature Normal Range

47º C

5 ips up to Drum temperature of 50º C

10 ips up to Drum temperature of 57º C

To access the Paper Tips page:

1. On the Control Panel menu, select Information, and then press the OK button.

2. Select Information Pages, and then press the OK button.

3. Select Paper Tips Page, and then press the OK button to print.

Media that may Damage to the Printer

The printer can use a variety of media for print jobs. However, some media can cause poor output quality, increased jams, or damage. Unacceptable media includes:

-

• Rough, plastic, or porous media

• Paper that has been stapled, folded, photocopied, or wrinkled

• Envelopes with windows, metal clasps, padding, or adhesives with release strips

• Media that is less than 60 g/m2 or more than 220 g/m

Media Storage Guidelines

If media handling problems are a common occurrence, review the following storage guidelines

with the customer.

• Store paper in dark, cool, relatively dry locations. Most paper items are susceptible to

damage from ultraviolet (UV) and visible light. UV radiation, which is emitted by the sun

and fluorescent bulbs, is particularly damaging to paper items. The intensity and length of

exposure to visible light on paper items should be reduced as much as possible.

• Maintain constant temperatures and relative humidity

• Avoid light, heat, and dampness.

• Avoid attics, kitchens, garages, and basements for storing paper. Inside walls are drier

than outside walls where moisture can collect.

• Store paper flat. Paper should be stored on pallets, cartons, shelves, or in cabinets.

• Avoid having food or drinks in the area where paper is stored or handled.

• Do not open sealed packages of paper until needed. Leave paper in the original packaging. For most commercial grades, the wrapper’s inner lining protects the paper.

• Some specialty media is packaged inside sealed plastic bags. Leave the media inside the

bag until needed; return unused media to the bag.

Supported Media

Information about paper sizes and weights that can be used in the printer trays is available on

the Paper Tips page (Control Panel Menu -> Information -> Information Pages -> Paper

Tips Page).

See also: Recommended Media List at www.xerox.com/paper

2

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

xxi

Introduction

Printer Specifications

Page 26

Media Tray Capacity

Table 10 Tray Capacity

Media and Weight Tray 1 Tray 2 Trays 3, 4, and 5

Standard Paper 100 Sheets 525 Sheets 525 Sheets

Transparency 50 Sheets 400 Sheets 400 Sheets

Envelope 10 40 40

Weight

60-220 g/m

2

60-220 g/m

2

60-220 g/m

Power Saver

The ColorQube 8570 & 8870 printers have Power Saver settings to reduce energy consumption without turning off the printer. The Power Saver settings can be set at the Control Panel or

in CentreWare IS. The Power Saver button on the Control Panel can be used to put the printer

in or bring it out of Power Saver mode.

When the printer is in Power Saver or Standby mode, any of the listed actions cause the printer

2

to exit Power Saver or Standby mode and start warming up.

• The printer receives a print job.

• The Power Saver button is pressed.

NOTE: Any other action, such as opening a door or inserting a tray, may or may not exit Power

Saver or Standby mode.

If the Power Saver button is lit solid, pressing the button causes a menu with no items to be displayed for 5 seconds. Pressing the button again returns the printer to Ready state.

Power Saver Mode

When the printer enters Power Saver mode, the Control Panel is displayed and printer status

show Power Saver mode. The printer does not enter Power Saver mode at the following condi

tions:

• The printer is in Standby mode displaying a Non-Xerox ink or maintenance kit query.

• The printer is out of any ink, due to that it might not be able to purge the Printhead if necessary on exit from Power Saver mode.

• A static Tray is missing.

Standby Mode

The printer can be set up to go into Standby mode periodically to save energy. Standby mode

uses the least power and the printer can take several minutes to warm up and come to Ready

to print. When the printer enters Standby mode, the Control Panel is displayed and printer sta

tus shows Standby mode.

-

-

Introduction

Printer Specifications, Power Saver

Warm-up Settings

Warm-up Setting can be used to warm up the printer automatically.

Mode Description Note

Intelligent

Ready

Scheduled The printer warms up at scheduled times. The

Job Activated The printer warms up when it receives a print job.

October 2010

xxii

Table 1 Warm-up Settings

The printer automatically monitors the printer

usage patterns and follows a warm-up schedule

based on the printer usage.

Warm-up Settings can be used to set one warm-up

time for each day. The printer can also be set to

enter Standby mode at a specific time.

ColorQube 8570/8870 Service Manual

Causes the printer to exit

Standby and Power

Saver modes.

Causes the printer to exit

Standby and Power

Saver modes.

Initial Issue

Page 27

Fast Resume

Fast Resume brings the printer out of Power Saver and Standby modes more quickly. This

changes the default Sleep/ Low Power timeouts and increases energy usage. Fast Resume

can be set to On/Off.

Physical Dimensions and Clearances

Printer Dimensions

Table 1 Print Engine

Dimensions 8570N/ DN/ DT 8870DN

Width 16.0 in. (40.6 cm) 16.0 in. (40.6 cm)

Depth 20.5 in. (52.1 cm) 20.5 in. (52.1 cm)

Height 14.6 in. (37.0 cm) 14.6 in. (37.0 cm)

Weight 60.5 lbs. (27.4 kg) 60.5 lbs. (27.4 kg)

Table 2 525-Sheet Feeder (Trays 3, 4, and 5)

Dimensions 8570N/ DN/ DT 8870DN

Width 15.5 in. (40.0 cm) 15.5 in. (40.0 cm)

Depth 20.0 in. (50.8 cm) 20.5 in. (52.1 cm)

Height 5.0 in. (12.7 cm) 5.0 in. (12.7 cm)

Weight 12.0 lbs. (5.4 kg) 12.0 lbs. (5.4 kg)

Table 3 Printer Stand

Dimensions 8570N/ DN/ DT, 8870DN

Width 19.75 in. (50.2 cm)

Depth 27.0 in. (68.6 cm)

Height 14.0 in. (35.6 cm)

Weight 63.5 lbs. (28.8 kg)

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

xxiii

Introduction

Power Saver, Physical Dimensions and

Page 28

Clearance and Mounting Surface Specifications

These specifications apply to any printer used as a table-top printer, without a Lower Tray

Assembly or Printer Stand.

1. In order to function properly, the printer must be placed on a flat surface with the following

minimum clearances.

2. Mounting surface flatness must be within the specified range.

3. The printer must not be tipped or tilted more than 10 degrees angle.

Figure 2 Tilting Specifications

Figure 1 Clearance Specifications

Introduction

Physical Dimensions and

October 2010

xxiv

Initial Issue

ColorQube 8570/8870 Service Manual

Page 29

Information Pages, Troubleshooting Pages, and Test Prints

The following Information, Troubleshooting, and Test Prints Pages are available in the ColorQube 8570/8870 printer. These pages can be accessed through the Control Panel at various

locations.

Table 1 Page Description

Page Control Panel Menu Access and Description

Information Pages

Menu Map Control Panel Menu -> Information -> Menu Map

Menu Map Lists all main and second level Control Panel menu headings.

Information Pages Control Panel Menu -> Information -> Information Pages

Configuration Page Lists all information about the current configuration of the

Paper Tips Page Lists supported paper and provides tips on setting up and load-

Supplies Usage Page Provides coverage information and part numbers for reordering

Connection Setup Page Contains information about setting up the printer on a network,

Startup Page Contains basic printer configuration and network information.

Usage Profile Provides summary page of printer usage information.

PostScript Font List Contains list of PostScript fonts available within the printer or

PCL Font List Contains list of PCL fonts available internally within the printer

Disk Directory Prints pages listing all downloaded files on the Hard Drive,

Sample Pages Control Panel Menu -> Information -> Sample Pages

Graphics Demonstration Prints a page containing a graphic image.

Office Demonstration Prints a page containing text.

2-Sided Demonstration This feature requires automatic 2-sided printing option. Prints

Print Mode Demonstration Prints three copies of the Office Demonstration Page in each

CMYK Sampler Pages Prints spectrum of color rectangles with the values of each

printer.

ing paper trays.

supplies.

or connecting directly to a computer on a Windows or Macin

tosh.

The Startup Page prints during the startup sequence when

enabled, or if the printer detects an error during the Power-On

Self Test (POST).

installed on the printer’s Hard Drive, if the optional Hard Drive is

installed.

or installed on the printer’s Hard Drive, if the optional Hard

Drive is installed.

such as fonts and macros. This feature requires optional Hard

Drive.

two pages on one sheet containing a graphic image on one

side, and text on the other side.

print-quality mode (Fast Color, Standard, Enhanced, Photo) to

demonstrate printer speed and resolution.

component color (Cyan, Magenta, Yellow, Black).

-

Table 1 Page Description

Page Control Panel Menu Access and Description

RGB Sampler Pages Prints spectrum of color rectangles with the values of each

PANTONE Color Sampler

Pages

Supplies Info Control Panel Menu -> Information -> Supplies Info

Supplies Usage Page Prints a page describing the status of the supplies used by the

Printer Setup Control Panel Menu -> Information -> Printer Setup

Configuration Page Lists all information about the current configuration of the

Connection Setup Page Contains information about setting up the printer on a network,

Troubleshooting Pages

Paper Jams Control Panel Menu -> Troubleshooting -> Paper Jams

Paper Tips Page Prints a page with information on recommended paper types

Paper Path Test

• Single Print

• Continuous Print

Print Quality Problems Control Panel Menu -> Troubleshooting -> Print Quality

Troubleshooting Print Quality

Page

Eliminate Light Stripes Provides cleaning procedures to clean light stripes in prints and

Remove Print Smears Performs a cleaning procedure to eliminate ink smears on

Network Problems Control Panel Menu -> Troubleshooting -> Network Prob-

TCP/IP Start Log Prints a report containing TCP/IP conditions at startup.

TCP/IP Runtime Log Prints pages with a recent sequence of TCP/IP network events,

AppleTalk Start Log Prints a repor t containing AppleTalk conditions at startup.

AppleTalk Runtime Log Prints a report containing AppleTalk recent runtime conditions.

Troubleshooting Control Panel Menu -> Troubleshooting -> Service Tools

Printer Status Page Provides information about the printer including Jam History

component color (Red, Green, Blue).

Prints the PANTONE/256 Color Sampler chart to help you

choose the best PANTONE/256 colors to use in applications.

printer.

printer.

or connecting directly to a computer on a Windows or Macin

tosh.

and weights.

Picks paper from a selected tray. A rectangle is printed on the

page to indicate minimum margins. Text is printed on the page’s

upper-left corner to indicate orientation. Custom-size paper will

be picked, but no graphics or text will be printed.

Problems

Prints four pages with information on correcting print quality

problems.

prints a Light Stripe Test page; these processes take about five

minutes.

prints; this process takes about 5 minutes, heats some rollers,

and runs up to 15 or more sheets of paper through the printer.

The printer prints 6 blank pages after the cleaning procedure is

complete.

lems -> Network Log Pages

the network routing table, the ARP table and the DNS cache.

and Fault History. A Light Stripe Test page is included with the

Printer Status Page.

-

Initial Issue

ColorQube 8570/8870 Service Manual

October 2010

xxv

Introduction

Information Pages, Troubleshooting Pages, and

Page 30

Table 1 Page Description

Page Control Panel Menu Access and Description

Service Usage Profile Contains a detailed log of printer use, tallying numbers of jams,

Solid Fill Prints

• Cyan Print

• Magenta Print

• Yellow Print

• Black Print

Ink Flush Prints

• Cyan Refresh

• Magenta Refresh

• Yellow Refresh

• Black Refresh

The following Test Prints can be accessed through the Hidden Service Menu.

1. From the Control Panel menu, select Troubleshooting -> Service Tools.

2. Press the OK button to access Service Tools.

3. With the cursor highlighted Printer Status Page, press both the Up and Down Arrow

buttons to display the Hidden Service Menu.

Manufacturing (for Manufacturing use only)

Jet Check Checks the jets and prints a blank page and a Cleaning Page.

Yellow Jet Check Checks the yellow jet and prints a red Solid Page and a green

Eliminate Light Stripes Performs clean process and prints 1 Cleaning Page and 1 Light

Solid Fills

• Manufacturing

•1x

•10x

• Continuous

Manufacturing Skew Margin Prints 1 Skew Margin page.

Check Ink Levels for Shipping

Test Prints

Weak/ Missing Jets Contains diagnostic image for evaluating jetting performance of

Cleaning & Light Stripes Prints a Cleaning Page and a Light Stripes Test page.

Color Bands RGBK Dithers Prints 5 pages of dithered and solid fill regions of all colors for

how often features are used, usage by tray, job and page

counts, and so on.

Prints 2 double-sided pages of solid fill print for each color.

Performs cleaning procedure to correct color mixing and prints

20 pages of solid fill prints.

Solid Page.

Stripes Test page.

• Prints 6 Solid Fill Pages of the selected color.

• Prints 1 Solid Fill Page of the selected color.

• Prints 10 Solid Pages of the selected color.

• Prints Solid Fill Pages up to 999 pages.

Prints 1 Ink Stick Shipping Status page.

the Print head and prints a Weak and Missing Jets Print page.

• Cleaning Page (Mud Page): Removes discolored ink from

print head.

• Light Stripes Test: Prints lines from each jet to see if any

jet is clogged. This page is formatted for Letter, Legal or

A4 sizes, and output may vary on other sizes.

evaluating image uniformity.

Table 1 Page Description

Page Control Panel Menu Access and Description

Paper Path Performs a general test of paper path, print process, and

Solid Fills Prints solid fill print for each color.

• YMCKRGB Solid Fills • Prints 7 solid fill pages for YMCKRGB.

Cyan Solid Fills

•1x

• 10x

• Continuous

• Adhere Ink Stick

• Cyan Refresh

Magenta Solid Fills

•1x

• 10x

• Continuous

• Adhere Ink Stick

• Magenta Refresh

Yellow Solid Fills

•1x

• 10x

• Continuous

• Adhere Ink Stick

• Yellow Refresh

Black Solid Fills

•1x

• 10x

• Continuous

• Adhere Ink Stick

• Black Refresh

Red Solid Fills

•1x

• 10x

Green Solid Fills

•1x

• 10x

Blue Solid Fills

•1x

• 10x

Manufacturing Skew Margin Evaluates image alignment to the page. This print includes a

Chase Pages Prints a blank sheet of paper.

quickly assesses the Printhead performance and prints 2 blank

pages and 1 Skew Margin page.

• Prints 1 page of Cyan solid fill.

• Prints 10 pages of Cyan solid fill.

• Prints Cyan solid fill pages up to 999 pages.

• Prints 26 double-sided pages of Cyan solid fill.

• Prints 20 double-sided pages of Cyan solid fill.

• Prints 1 page of Magenta solid fill.

• Prints 10 pages of Magenta solid fill.

• Prints Magenta solid fill pages up to 999 pages.

• Prints 26 double-sided pages of Magenta solid fill.

• Prints 20 double-sided pages of Magenta solid fill.

• Prints 1 page of Yellow solid fill.

• Prints 10 pages of Yellow solid fill.

• Prints Yellow solid fill pages up to 999 pages.

• Prints 26 double-sided pages of Yellow solid fill.

• Prints 20 double-sided pages of Yellow solid fill.

• Prints 1 page of Black solid fill.

• Prints 10 pages of Black solid fill.

• Prints Black solid fill pages up to 999 pages.

• Prints 26 double-sided pages of Black solid fill.

• Prints 20 double-sided pages of Black solid fill.

• Prints 1 page of Red solid fill.

• Prints 10 pages of Red solid fill.

• Prints 1 page of Green solid fill.

• Prints 10 pages of Green solid fill.

• Prints 1 page of Blue solid fill.

• Prints 10 pages of Blue solid fill.

blank page and Skew/Margin Test print.

Introduction

Information Pages, Troubleshooting Pages, and Test

October 2010

xxvi

Initial Issue

ColorQube 8570/8870 Service Manual

Page 31

Table 1 Page Description

Page Control Panel Menu Access and Description

Oil Bar Chase Provides information on the Drum Maintenance system diag-

Purge Efficiency Provides diagnostic image for evaluating jetting performance of

X-Axis Motion For manufacturing use only. Prints 1 X-Axis Motion page.

Drop Mass Calibration Provides diagnostic image for setting print head voltage and

Head Roll For manufacturing use only. Prints 1 Head Roll page.

Intensity CMYK For manufacturing use only. Prints 1 Intensity CMYK page.

Solid Fill Red Scan For manufacturing use only. Prints 1 red solid fill regions page.

Solid Fill Green Scan For manufacturing use only. Prints 1 green solid fill regions

Solid Fill Blue Scan For manufacturing use only. Prints 1 blue solid fill regions page.

Startup Page Provides information about the printer. The Startup Page is

Eliminate Light Stripes Includes three procedures to remove the effects of missing jets

Adjust X-Axis Scale Calibrates the X-Axis to position the Printhead in the proper

Service Usage Profile Provides a detailed log of printer use, tallying numbers of jams,

OCR Usage Profile Provides a detailed log of printer use, tallying numbers of jams,

nostic image for location of the oil bar and the printer prints 3

Oil Bar Chase pages.

the Printhead after "eliminate light stripes" and the printer prints

1 Purge Efficiency page.

the printer prints a Drop Mass Calibration page.

page.

printed each time the printer is turned on. The page can be

turned off through the Control Panel menu.

and prints 1 Cleaning Page.

• Light Stripe Test: Prints a page to determine if any jets

are printing incorrectly. A4, letter or legal paper must be

available.

• Start Basic Clean Cycle: Performs a cleaning procedure

to remove light stripes in prints; this process will take

about 5 minutes. The printer prints 1 Cleaning Page and 1

Light Stripes Test page after the cleaning process is com

plete.

• Advanced: Fixes missing light stripes that were not corrected by Basic Eliminate Light Stripes. The printer prints

5 double-sided pages prior to start the cleaning proce

dure.