Xerox Color 8250, iGen4 Diamond Edition Brochure

Xerox® Color 8250

Production Printer

®

Xerox

Xerox

Finishing Guide

iGen4® Press

®

iGen® 150 Press

Xerox® Finishing Solutions:

Freedom to Finish Whatever You Start

Keep pace with your production, no matter

how you slice, staple, punch or bind it.

With the range of finishing options available for Xerox® Color 8250 Production

Printer and Xerox

your job mix and improve your workflow, keeping more jobs in progress all with optimal

return on your investments.

This guide will help you match your finishing

choices to the type of work you produce on

your Xerox

or Xerox

your shop. Whether you need high-capacity

stacking, converting, stapling, inserting or

booklet making, all our finishing options can

keep pace with your equipment’s production

level speeds. And we’re expanding our

automation options to help you save even

more time and cost in prepress and in

postpress finishing processes. Deliver the

quality and polish your customers want

with your Xerox

Finishing Solutions.

®

Color 8250 Production Printer

®

iGen Presses and how you run

®

iGen Press and Xerox®

®

iGen® Digital Presses, you can add the capabilities that best suit

2

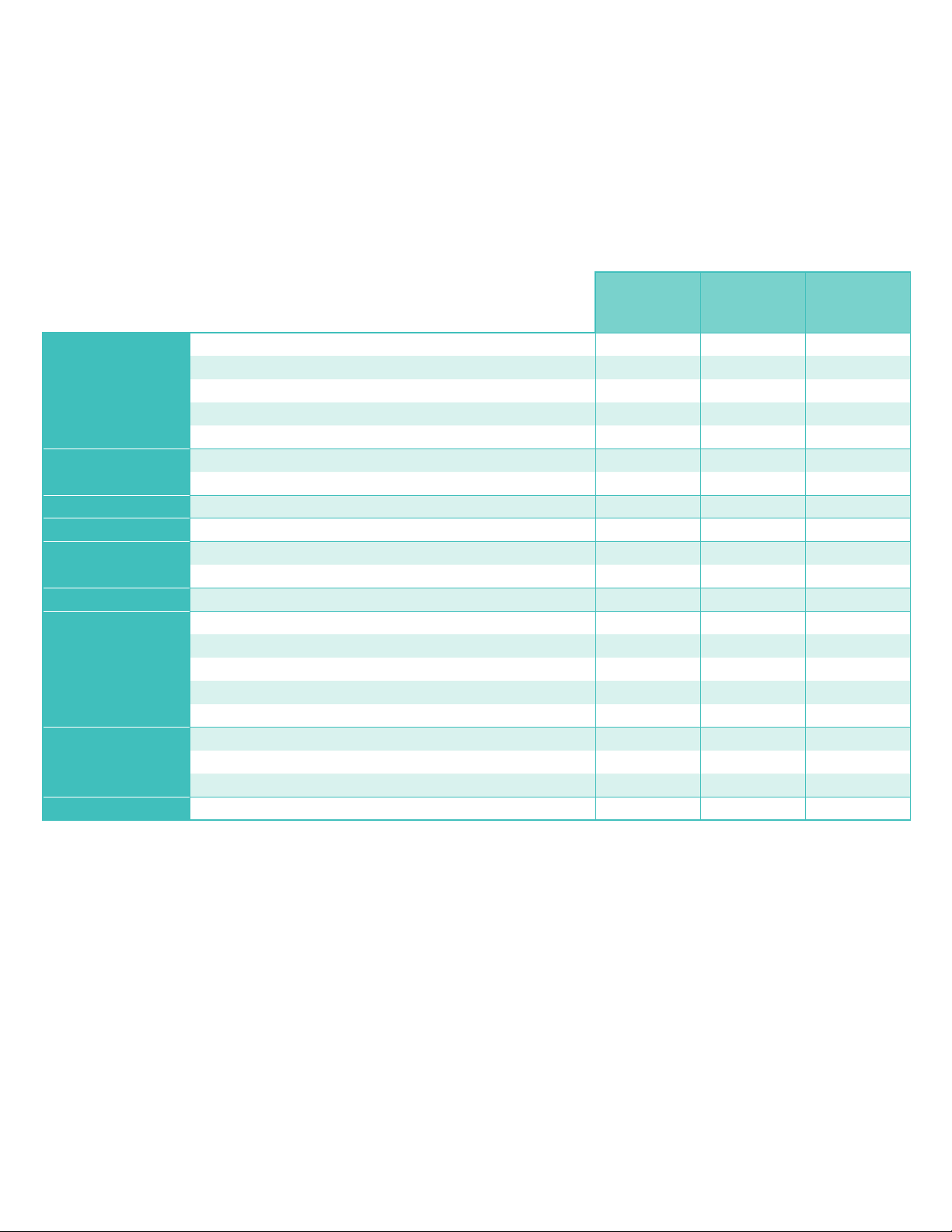

Booklets

(Saddle-Stitched)

Coating

Feeding/Bypass

Packaging

Perfect Bound

Punch/Lay Flats

Slit/Cut/Crease

Stack/Bypass

Stitched Sets

Xerox® Color

8250 Production

Xerox

iGen4

®

®

Press

®

iGen®

Xerox

150 Press

Printer

• C.P. Bourg® BDFEx Booklet Maker x x x

• C.P. Bourg® BMEx Booklet Maker x x x

• Duplo DBM-5001 Inline Booklet Maker x x x

• Duplo Slitter/Cutter/Creaser (SCC) Nearline Booklet Maker x x x

• Watkiss PowerSquare™ 224 x x x

• Duplo Ultra 145A/205A UV Offline Coater x x x

• Epic CTi-635 Inline Coating Sysetm x x x

• Xerox® Dual-Mode Sheet Feeder (BSFEx) x x x

• Automated Packaging System x x

• C.P. Bourg® 3202 Book Factory x x x

• Xerox® Manual + Book Factory x x x

• GBC® FusionPunch® II x x x

• CEM Docu Cutt™ x x x

• CEM Docu Converter™ x x x

• Duplo DC-645 Slitter/Cutter/Creaser x x x

• Duplo DC-745 Slitter/Cutter/Creaser x x x

• Rollem JetSlit x x x

• 22.5" (572mm) Stacker x x

• 26" (660mm) Stacker x x

• Multigraf PST-52 Stacker x x x

• C.P. Bourg® BDFEx Booklet Maker x x x

3

Efficient Finishing

Xerox® Dual-Mode

Sheet Feeder (BSFEx)

As a standalone device or as part of the

®

Xerox

IntegratedPLUS Solution for Booklets,

the Xerox

provides an efficient means of preparing jobs

for finishers, providing automated finisher

set up and for sharing a finishing device with

multiple printers. A printer that is equipped

with the BSFEx inline can bypass the BSFEx

Sheet Feeder and send sheets directly to

the inline finisher. In addition, stacks from

other printers can be fed into the BSFEx to

use that inline finisher when the attached

printer is not using it. The BSFEx can also be

used as input to offline auto-finishers if inline

finishing doesn’t fit into your business plan.

®

Dual-Mode Sheet Feeder (BSFEx)

The BSFEx includes two separate feeding

compartments: a lower high-capacity tray

that can accommodate pile heights up to

20" (508 mm) and an upper feed drawer

that accommodates pile heights up to 6.3"

(160 mm) of cover or insert sheets. When

in bypass mode, the upper feed tray can

be used as a covers feeder. A hand scanner

is used to read JDF data from job-specific

printed banner sheets that travel with the

stacks. The BSFEx is equipped with OMR

mark recognition, double and missed sheets

detection from both compartments and

detects when either tray is empty.

Benefits

• Combines the benefits of an inline finishing

device with the convenience and cost

effectiveness of sharing one finisher with

multiple printers.

• Saves time and enables you to produce

more jobs through automated setup of files

and automated setup of inline or offline

finishers with the Xerox

Finishing Solution for Booklets.

®

IntegratedPLUS

• Adds integrity by allowing printed stacks to

easily be moved to the finisher without splitting

the stack.

• In offline mode, the attached finisher can run

at up to 15,000 sheets/hour.

• Maximizes load balancing between printers.

Xerox® Dual-Mode Sheet Feeder

4

Stacking Up Your Output

Multigraf PST-52 Pile Stacker

The Multigraf PST-52 Pile Stacker is an

ideal solution for Xerox

who need precision stacking of large papers

and want to simultaneously increase output

and productivity.

This inline unit provides high quality stacking

of extra large papers on an easily removable

paper trolley. The PST-52 stacker is equipped

with two standard paper trolleys. Once the

stacker is full, users simply wheel out the full

trolley, wheel in the second empty one and

continue production. Additional trolleys are

available to improve production further.

There are two models of the Multigraf

Stacker. The Short Version can be attached

to the iGen to enable stacking of sheets

up to 26" (660 mm). The Long Version is

compatible with the Epic CTi-635 Coating

System for enhanced stack quality and

stacking capacity of coated sheets up to

22.5" (572 mm). The Long Version also

includes a cooling device as an inline output

solution with Epic coating units. The cooling

device dries varnished sheets to improve

stacking quality.

®

iGen® press users

Benefits

Multigraf Stacker Short Version

• Oversized sheets up to 26" (660 mm) can easily

and efficiently be stacked at the end of any

iGen Press.

• Maximum productivity with the iGen Press.

• Extra Large Paper Kit 22.5” (572 mm) or

26” (660 mm).

• Increased output and productivity on the

iGen Press.

• Uses Xerox® Device Feeding and Finishing

Architecture (DFA) Protocol.

Multigraf Stacker Long Version

• Increased stacking capacity and productivity

on the Epic CTi-635 Coating System.

• Cooling system dries coated sheets to prevent

sheets from sticking together in the stacker.

• Stacks oversize sheets up to 22.5" (572 mm).

Production Media Cart and Power

Eject for the Xerox® iGen Presses

Experience a powerful combination of

efficiency and convenience in a solution built

for professional, safe transportation of printed

media from the iGen’s stacker to work tables,

pallets or nearline/offline finishing.

The Power Eject unit uses an automatically

triggered drive system to safely eject large

stacks of printed media from the printer’s

stacker to the Production Media Cart. The

Production Media Cart uses a battery powered

vertical elevation system to set the media

table height and a hand crank to transfer the

paper stack from the Cart.

Benefits:

• Handle massive print runs of the largest sheet

sizes and weights with ease.

• Create longer print runs with reduced

interruption.

• Improve operator ergonomics and efficiency.

• Minimize handling and stack integrity errors

with printed sheets.

Multigraf PST-52 Stacker

Xerox® Power Eject

• Enhance compatibility with Xerox® print

finishing solutions.

• Streamline the process from print to bindery.

• Field Upgradable—can be installed as

an upgrade to existing iGen4

iGen 150 stackers.

Production Media Cart

®

and

5

A Professional Bind

GBC® FusionPunch® II

The GBC FusionPunch II prepares documents

for coil binding by punching and stacking a

wide range of stocks with the speed, quality

and reliability you need for high-volume

production. This inline punch solution

features an outstanding paper handling

system that maximizes uptime and reduces

skewing with remarkably consistent

registration. It even handles challenging

jobs with intermixed stocks, index tabs and

lighter stocks that have traditionally been

difficult to finish.

Benefits

• Heavy-duty design ensures a reliable high

quality punch each and every time.

• Over a dozen dies available—which can be

changed in seconds without tools— ensures

support of all commonly-used coil bindings.

• Offset stacking dramatically reduces finishing

time by fully preparing each printed set for

immediate binding.

Xerox® Book Factory

Produce finished books with ease, speed

and flexibility on the Xerox

Press equipped with the Xerox

Together they provide the perfect inline

solution for producing trade and reference

books, catalogs, out-of-print, vanity books

and more. With its document finishing

architecture, cut sheets are moved directly

onto an output transport conveyor, inline

to the Xerox

perforated, rotated, folded and nested into

signature book blocks. They are automatically

sent to the binder where the spine is scored

and synthetic hot glue is applied before a cover

is added for a final perfect bind. The book

then automatically travels through a threeside trimmer where the finishing touches are

added. (The CMT 330 three-side trimmer is an

optional module.) Produced at the rated speed

of the Xerox

for immediate delivery.

®

Book Factory where they are

®

iGen4, your books will be ready

®

iGen4® Digital

®

Book Factory.

Benefits

• Produce high-end, professional quality

books quickly and easily.

• Immediate setup streamlines the book

production process.

• Automated inline finishing requires less manual

intervention.

• Ability to print 2-up speeds productivity

and improves turnaround times.

• Full job recovery lets jobs keep running

and preserves full job integrity.

GBC® FusionPunch® II Xerox® Book Factory

6

Loading...

Loading...