Page 1

February 2009

701P49575

FreeFlow® Print Server

Color Handbook

Page 2

©2009 Xerox Corporation. All rights reserved. Xerox and the sphere of connectivity design, and

FreeFlow® are trademarks of Xerox Corporation in the United States and/or other countries.

Adobe® and the Adobe logo, InDesign®, Illustrator®, PageMaker®, Photoshop®, Acrobat®,

Distiller®, and the Acrobat logo are either registered trademarks or trademarks of Adobe

Systems Incorporated in the United States and/or other countries.

PANTONE® is a registered trademark of Pantone, Inc.

Document Version: February 2009

Page 3

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Multi-media program for FreeFlow® Print Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Where: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Typographical conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Xerox FreeFlow® Print Server Overview. . . . . . . . . . . . . . . . . . 2-1

ConfidentColorTechnology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Consistent Results through Superior Color Calibration . . . . . . . . . . . . . . . . . . . 2-2

Built-in printer profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Dynamic DeviceLink profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

RGB file handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Color standards: evolving to meet changing needs . . . . . . . . . . . . . . . . . . 2-4

Every Object Type is Optimized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Smart technology tends to the details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Spot colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Fine-tune the results to your satisfaction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Color tuning down to the page level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Automatic Image Enhancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

When and How Often to Calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Three Input Methods:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1. Calibrating with a spectrophotometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2. Calibrating using a scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

4 Adjusting Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

TRC editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

The User TRCs window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

User TRC menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Opening the User TRCs Edit window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjusting Color Balance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Color Balance Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Adjusting color balance using slide bars. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Using Advanced Preview to identify color for adjustment. . . . . . . . . . . . 4-5

Saving and re-using Tone Reproduction Curves (TRCs) . . . . . . . . . . . . . . 4-7

Adjusting color with Tone Reproduction Curves (TRCs) . . . . . . . . . . . . . . 4-9

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Going Further . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Automatic Image Enhancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Color Handbook 3

Page 4

Table of Contents FreeFlow Print Server

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Spot Color Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Spot color processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

PANTONE® colors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

About the Spot Color List window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

About the Spot Color Editor window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

5 Color Management Workflows. . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

What is Color Management?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Use the Color Default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

About Xerox color gamut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Understanding the FreeFlow Color Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Device Link Emulation Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

ICC Standard Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Custom Color Workflows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

CMYK Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

About the CMYK tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Establishing your Default CMYK Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Sample CMYK Workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Printing with your default CMYK Source Profile. . . . . . . . . . . . . . . . . . . . . . 5-9

Changing your CMYK Rendering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Using Direct CMYK to maximize color from your printer . . . . . . . . . . . . 5-11

Matching another press (CMYK). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

RGB Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

About the RGB tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Source Profile and Rendering Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Using Embedded Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Sample RGB Workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Professional Photo workflows (RGB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Consumer Photo workflow (RGB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Gray Color and Monochrome Workflows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

About the Gray tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Printing Gray Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Printing Gray in RGB, when R=G=B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Printing RGB and CMYK as Black and White . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Sample Grayscale workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Using Gray Color Embedded Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Printing with Gray Color settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Printing RGB Gray (R=B=G) using Black-Only . . . . . . . . . . . . . . . . . . . . . . . 5-22

Printing Color as Black and White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Spot Color Workflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

About the Spot tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Sample Spot Color workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Printing the Spot Color Swatch Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Using Preflight to identify Spot Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

4 Color Handbook

Page 5

FreeFlow Print Server Table of Contents

Using View Report to identify missing Spot Colors. . . . . . . . . . . . . . . . . 5-30

Adding a custom color to the server’s Spot Color List . . . . . . . . . . . . . . 5-31

Adjusting a color on the server’s Spot Color List . . . . . . . . . . . . . . . . . . . 5-35

Advanced Color Matching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Laying a Foundation for Color Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Advanced Color Matching using Profiling Software . . . . . . . . . . . . . . . . . . . . 5-41

Standardizing Color to Match Prepress Color Management . . . . . . . . . . . . 5-42

Sample Color Matching Workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Using the same CMYK Source and Relative Colorimetric . . . . . . . . . . . 5-43

Using profiling software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Setting the server to use prepress color definitions . . . . . . . . . . . . . . . . 5-45

Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Color Workflow considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

When to apply RGB Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Importing a source profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Adding ICC Profiles to the DFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

6 Other Image Quality Considerations . . . . . . . . . . . . . . . . . . . . 6-1

Image Interpolation “Smart” Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Key uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Low Resolution Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Very High Resolution Images. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Smart Interpolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Trapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Anti-aliasing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

PDF/X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

About PDF/X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Accepting and using PDF/X files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Creating a PDF/X file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

About the PDF/X tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Commercial Offset workflow (PDF/X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Other considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

7 Xerox FreeFlow® Print Server Color Workflow. . . . . . . . . . . . 7-1

Rendering Intent summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Color Workflow Using Standard ICC Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How are the Color Settings defined? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Most Popular RGB Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Most Popular CMYK Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Most Popular Grayscale Processing (not illustrated) . . . . . . . . . . . . . . . . . . . . . 7-2

Most Popular Spot Color Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

PDL color management (embedded profiles) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Color Handbook 5

Page 6

Table of Contents FreeFlow Print Server

6 Color Handbook

Page 7

Introduction

About this guide

The Color Handbook is designed to inform you about the features and operation of the

FreeFlow® Print Server to help you achieve the best color from your printer as quickly as

possible.

While this document was developed using v7 software, the concepts contained within

apply to other software releases.

This guide contains information about the following topics:

• Benefits and features of the FreeFlow® Print Server

• Description of calibration including when and how often to calibrate.

• Custom and built-in color profiles

• Color Management controls for objects within a page

• Spot color editing

• Automatic Image Enhancement

• Descriptions of the different color paths in the FreeFlow® Print Server

• Customizing the color workflow.

1

Contents

• Chapter 1 Introduction

Describes the purpose and conventions of the guide.

• Chapter 2 Xerox FreeFlow® Print Server Overview

Describes the new features of the FreeFlow® Print Server with ConfidentColor technology.

•Chapter 3 Calibration

Provides information on when and how to perform calibration on the FreeFlow® Print

Server.

• Chapter 4 Adjusting Color

Describes the use of the different color editing tools on the FreeFlow® Print Server.

• Chapter 5 Color Management Workflows

Describes the different workflows and provides procedures and examples of these

workflows.

• Chapter 6 Other Image Quality Considerations

Describes additional FreeFlow® Print Server tools such as Smart Interpolation, trapping,

anti-aliasing and printing PDF/X files.

• Chapter 7 Xerox FreeFlow® Print Server Color Workflows

Displays a graphic of the FreeFlow® Print Server Workflow.

Color Handbook 1-1

Page 8

Introduction FreeFlow Print Server

Multi-media program for FreeFlow® Print Server

Summary

Xerox is now offering a new resource designed to help you learn the basic operation of the

FreeFlow® Print Server to get you printing as quickly as possible with your new Xerox printing

system. If you are a new user or have not used the FreeFlow® Print Server much, the Getting

Started resource is the perfect place for you to start!

This one hour program will kick start your learning!

Where:

Getting Started is multi-media based and available for download from www.xerox.com/

freeflowgettingstarted.

The multimedia version will also be available on the “Customer Documentation” CD-ROM.

Inside the folder named “Getting Started FreeFlow® Print Server Multi-media Program”

What:

Getting Started with the FreeFlow® Print Server covers topics including:

1-2 Color Handbook

Page 9

FreeFlow Print Server Introduction

Basic Printing

• Print Server Tour and Job Flow

•How to Submit Jobs

• How to Manage Jobs

• How to Customize your Screen

Managing Color

•Calibrating Color for your System

• Color Management Flow

• Adjusting Color Balance

What’s New with FreeFlow® Print Server 7.0:

• Changes to the User Interface

• New Features

• Enhanced Features

• Performance Improvements

How Long?

Getting Started with the FreeFlow® Print Server will take approximately one hour to complete.

At the end there are exercises that you can print and take to your system so you’ll be able to

start using the FreeFlow® Print Server to print and manage basic jobs quickly!

Color Handbook 1-3

Page 10

Introduction FreeFlow Print Server

Typographical conventions

This guide uses the following conventions:

• Select [option] - Within procedures, the term select can represent various methods of

launching a feature; the option to be selected is enclosed in square brackets.

• To open a drop-down menu, move the cursor to the menu name or to the drop-down

arrow and press the left mouse button once. For example, select [System].

• To choose a menu item, move the cursor to the item, press the left mouse button to

highlight the item, then release the left mouse button. For example, select [Logon].

• To choose an icon or row and open the associated window, move the cursor to the item

and double click. For example, double click [upper tray] on the Feeders window to open

the next level window.

• Select [option > option] - Multiple options are separated by an arrow, with the name of the

drop-down menu appearing first, followed by the menu item name. For example, select

[System > Logon].

• In a Portable Document Format (PDF) file displayed on a workstation, blue text identifies a

link to other information in the file. Select the specified text to activate the link. For

example, refer to Typographical conventions in this guide.

In a hard copy version of the PDF file, the link is printed as non-black text. Locate the

specified section title in your document.

Note

This icon identifies notes. A note is a paragraph (separate from the body text) containing

related information that merits emphasis.

1-4 Color Handbook

Page 11

Xerox FreeFlow® Print Server Overview

2

ConfidentColorTechnology

From preflight to press, the Xerox FreeFlow® Print Server with ConfidentColor Technology gives

you the power to manage color and quality—with ease, speed, and confidence.

Built-in and transparent controls optimize color for great results, right out of the box. Or refine

server settings with hands-on flexibility. The user-friendly interface puts high-level control at

your fingertips, so you can fine-tune for individual preferences or compensate for less-thanperfect files.

Whether you’re starting out in digital color or already delivering color-critical jobs, this sleek,

simple, and smart print server can help you get the job done. It makes easy work out of both

traditional CMYK and digital-age RGB workflows (including emulations), so you can move jobs

between offset and digital workflows. And programmable queues allow you to easily customize

your setup once, consistently giving you the results you need.

This is the print server to count on for the most creative—and most critical—customers. Yours.

Color Handbook 2-1

Page 12

Xerox FreeFlow® Print Server Overview FreeFlow Print Server

Consistent Results through Superior Color Calibration

To meet the specialized needs of digital production environments, ConfidentColor Technology

draws on a strong color heritage to take calibration to the next level. Thanks to a unique,

patented calibration technology, the FreeFlow® Print Server provides superior image quality—

every time.

This technology moves beyond traditional density control to provide true gray-balance

calibration. So in addition to individual color levels, the FreeFlow® Print Server analyzes CMY

combinations from highlight through shadow, refining curves to assure neutral balance. You can

count on exceptionally smooth transitions, and skin tones that are rendered with incredible

accuracy.

For long print-on-demand and variable data jobs, the FreeFlow® Print Server shines with

outstanding consistency. It allows you to calibrate in the middle of the run—without the need

to restart the job. And when it’s time to reprint, Fast Reprint Format (FRF) assures that the job

will run with the current calibration for superior and consistent results.

Calibration yields predictability over time. But to get the “right” color, you need to account for

how color is defined upstream, and how output can be matched across digital and offset

devices. That’s where ICC color management comes in and where ConfidentColor Technology

provides a powerful toolset for ease and efficiency.

2-2 Color Handbook

Page 13

FreeFlow Print Server Xerox FreeFlow® Print Server Overview

Built-in printer profiles

Under most circumstances, the FreeFlow® Print Server automatically delivers consistency and

quality using its built-in profile representing general printer characteristics. Several Gray

Component Replacement (GCR) options are included and optimized for each Xerox digital color

press. Default GCR settings provide for efficient toner usage while still yielding high-quality skin

tones and excellent highlight colors. Optional settings allow you to fine-tune toner usage for

your own desired balance between image stability and smoothness.

Dynamic DeviceLink profiles

DeviceLink profiles are a snap when you need the control to emulate output from another

digital printer or even an offset press. When you use a custom-loaded profile, the FreeFlow®

Print Server dynamically creates a look-up table in real time to link the source and destination

profiles. By building these tables only as they’re needed and used, the FreeFlow® Print Server

efficiently uses disk resources. DeviceLink technology also preserves the K (black) information

that’s lost in traditional ICC color conversion. So with the FreeFlow® Print Server, you get

output that more clearly matches the original intent.In addition, DeviceLink provides the final

component necessary for unifying offset and digital color workflows by giving you the same

option with RGB data. The FreeFlow® Print Server does this by passing RGB data through your

selected CMYK device emulations, producing the closest reproducible output for both RGB and

CMYK.

Dynamic

DeviceLink

Profile

DeviceLink technology on the FreeFlow® Print

Server connects your source and destination

profiles. So you can output to a digital or offset

press—even split a run—and get the same results.

Color Handbook 2-3

Page 14

Xerox FreeFlow® Print Server Overview FreeFlow Print Server

RGB file handling

ConfidentColor Technology also gives special attention to optimizing RGB color. Leave your files

defined as RGB and let the Print Server produce the best possible color on your printer—without

an intermediate and limiting CMYK conversion. By delaying conversion of RGB files to the last,

possible point in the workflow, the FreeFlow® Print Server gives you the richest colors.

Note

Digital photography in your workflow? RGB images are more accurate with ConfidentColor

Technology. Since files are converted at the Print Server, CMYK is defined for the output

device, using its full gamut of colors.

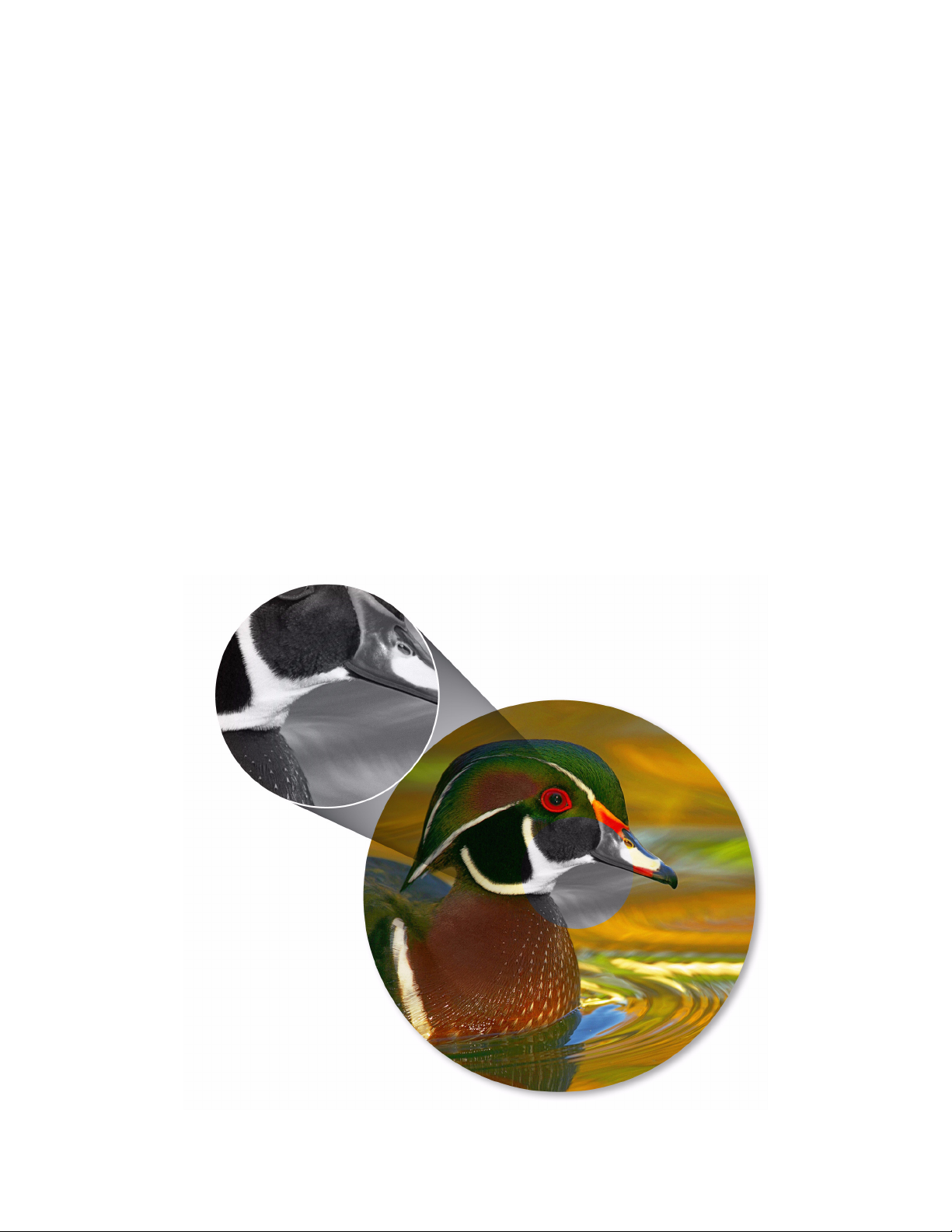

RGB converted to CMYK at the file

source

RBG converted to CMYK at the

FreeFlow® Print Server

Color standards: evolving to meet changing needs

Press-to-press variability in a traditional offset color workflow—and even with today’s digital

output devices—makes standardization an ongoing challenge.

SWOP and FOGRA standards developed for traditional offset are a start, but they can be

limiting in the digital world where a broader range of colors can be produced. To bridge the gap

between older standards and newer device gamuts—without changing workflow upstream—

Xerox first developed “SWOP Plus” and “FOGRA Plus” to help digital output devices produce

better color with standard print files.

Today’s new and emerging standards, such as Gracol and ISO Coated, are more in keeping with

actual capabilities and provide more realistic targets for both offset and digital presses.

The FreeFlow® Print Server with ConfidentColor Technology accommodates all of these

standards to give you the functionality you need.

2-4 Color Handbook

Page 15

FreeFlow Print Server Xerox FreeFlow® Print Server Overview

Every Object Type is Optimized

Within any given page, you can have a combination of contone data such as photographs,

vector graphics, and text in both RGB and CMYK. Optimizing for only one object type—or

compromising to accommodate all types—can result in less-than-optimal printing.

To get the best results, you need a way to focus attention on each object and tailor its

treatment.

The FreeFlow® Print Server automatically recognizes what object type is being processed and

treats it in the way that will maintain the highest possible quality. So when you send even a

single page that contains several different elements, it will recognize which parts of the page

are text, which parts contain graphics, and which parts contain images—and then treat each

accordingly.

• Separate color-management controls allow you to manually manipulate object types. For

example, saturate your line work while preserving the integrity of images.

• Color overprints are honored and trapping is optimized for your printer so that overlapping

text, graphics, and/or images yield desirable and expected results.

• Anti-aliasing of text and graphics uses special processing to smooth the rasterization of

curves and diagonal lines.

The beauty of all of this? You end up with beautiful results, automatically.

Smart technology tends to the details.

Page content comes in various encodings and compression types, and images can vary greatly

in resolution. The FreeFlow® Print Server makes easy work of these challenges, taking into

account both the type of printer being used and human visual perception.

Xerox Multi-Mode Compression dynamically adapts to compress objects for easier file

management without compromising image quality. It preserves sharp edges and fine detail in

text and line work, while optimizing the compression of contone images on the same page.

Xerox Smart Interpolation uses sophisticated, context-based calculations to scale content up

or down to match printer resolution.

These and other patented technologies help assure that the details you began with are the

details you output.

Color Handbook 2-5

Page 16

Xerox FreeFlow® Print Server Overview FreeFlow Print Server

Spot colors

With ConfidentColor Technology on the FreeFlow® Print Server, your spot colors will be exactly

what you expect.

When a spot color is identified in a file, the Print Server uses PANTONE®-licensed CMYK

formulas defined for each Xerox digital printer family to preserve the color and fully utilize the

rich gamut available. Because spot colors are processed independently, they’re preserved

regardless of other settings or adjustments made for RGB and CMYK.

Standard formulas can be modified through the Print Server’s Spot Color Editor to meet your

needs or preferences. For example, you can match a reference print or object using swatch

books printed for your digital press as a guide. You also have the ability to create your own

named spot colors for customized workflows.

ConfidentColor Technology preserves spot colors when they’re used in tints and sweeps, as well

as by calculating tints in an independent LAB space. When you lighten a spot using the Print

Server’s tint control, the hue will hold true, giving you more creative control while assuring

consistency.

Whether applied to simple graphics, sophisticated multi-color sweeps, or multi-tone images, the

FreeFlow® Print Server produces spot colors with predictable results.

Note

ConfidentColor Technology does

wonders for your spot colors, putting

control and creativity at your fingertips.

Tints are automatically calculated in an

independent LAB space to maintain

hue, delivering predictable screens,

sweeps, and multi-tone images.

10%

80%

70%

20%

30%

2-6 Color Handbook

PANTO NE®

7469 CS

40%

60%

50%

Page 17

FreeFlow Print Server Xerox FreeFlow® Print Server Overview

Fine-tune the results to your satisfaction

Color tuning down to the page level

While most print servers force you to apply the same color settings to a document in its entirety,

with the FreeFlow® Print Server, you have the flexibility to make adjustments to the entire

document or at page level.

• Image quality features can be customized to each individual page, including color profiles,

anti-aliasing, and trapping.

• With Tone Reproduction Curve (TRC) control, operators can manipulate CMYK separations

independently and with extreme precision.

• In a save/reprint workflow, images do not have to be re-RIPped to apply these corrections.

The FreeFlow® Print Server has several levels of color control built in, so images can be

corrected at the print server when adjusting the source files isn’t practical.The resulting output

quality is optimized because each page is treated exactly as needed.

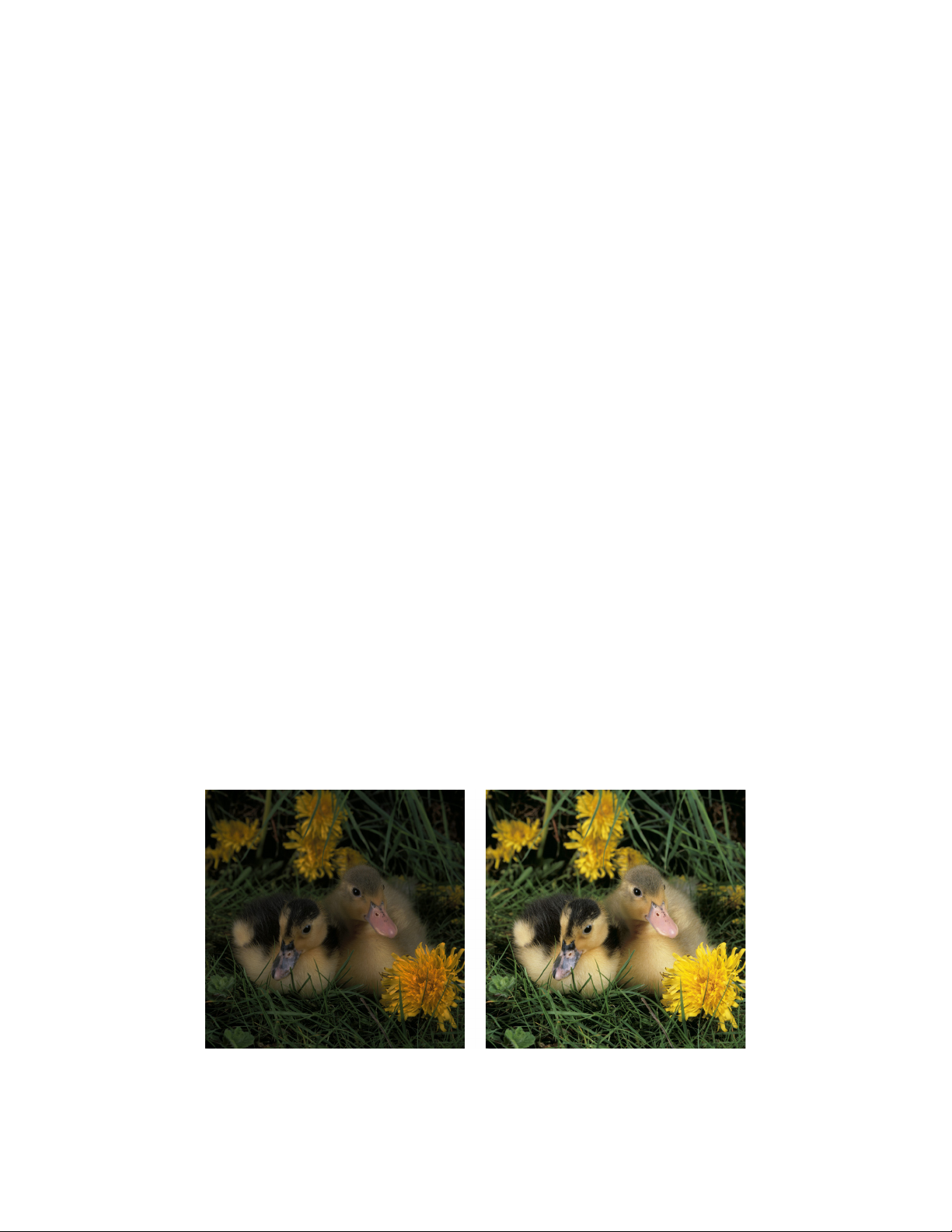

Automatic Image Enhancement

Through its Automatic Image Enhancement (AIE) feature, the FreeFlow® Print Server enables

“one click” photo enhancements for exposure, sharpening, saturation, red-eye reduction, and

more. Use it to compensate for underexposure or overexposure. Bring details out of the

shadows. Saturate colors flattened by ambient light. And more. With AIE, you can make quick

and simple modifications to photo applications while maintaining the integrity of the rest of

the document. You’ll get better results when using lower-quality images, without timeconsuming or expensive prepress processes. You can even adjust AIE to target your preferences

with custom color controls.

Note

Put more life into less-than-perfect images with Automatic Image Enhancement (AIE) on

the FreeFlow® Print Server. It’s ideal for jobs featuring amateur or candid photography, or

images clipped from Web pages or compressed in emails.

Before AIE After AIE

Color Handbook 2-7

Page 18

Xerox FreeFlow® Print Server Overview FreeFlow Print Server

2-8 Color Handbook

Page 19

Calibration

3

Background

To meet the specialized needs of digital production environments, ConfidentColor Technology

draws on a strong color heritage to take calibration to the next level. Thanks to a unique,

patented calibration technology, the FreeFlow® Print Server provides superior image quality--every time.

This technology moves beyond traditional density control to provide true gray-balance

calibration. So in addition to individual color levels, the FreeFlow® Print Server analyzes CMY

combinations from highlight through shadow, refining curves to assure neutral balance. You can

count on exceptionally smooth transitions, and skin tones that are rendered with incredible

accuracy.

When and How Often to Calibrate

Calibrating your system is the easiest way to manage your color output. It’s quick and it

effectively removes any color variations that occur over time. Color calibration ensures

consistent quality for all print jobs. If you do nothing more that calibrate frequently and print

with the default color settings on your server, you will achieve high-quality color output.

A printer may drift from its original color output due to general use, changes in temperature

and humidity, and changes in paper. When you calibrate, you bring the printer back to its

original quality output.

How often should you calibrate? You’ll need to get a feel for the best frequency for your specific

printer. Each printer is different. In general, if you are printing high volumes of color, you’ll

probably find it beneficial to calibrate once each day. At a minimum, you should calibrate at

least once a week.

It is also a good practice to calibrate after your printer has been serviced, and some customers

like to calibrate after a major change of stock. After performing a few calibrations, you’ll be able

to see how far your printer has drifted from the last calibration. This will help you determine the

best frequency for your environment.

You should calibrate on your most commonly used stock, or a centerline stock that has a midrange weight and coating for your type of printing. You may need to check with your key

operator or supervisor to see what stock is typically used.

To calibrate your system, you first print a spectrum of color on a page. This is called a target.

The target is printed using the printer’s current settings for color.

Color Handbook 3-1

Page 20

Calibration FreeFlow Print Server

Next you scan the target using either a spectrophotometer or your scanner, depending on your

system. This is called “measuring the target”. The spectrophotometer or scanner reads the color

on the target and feeds the values to the print server.

Then the print server generates calibration data. This data represent a mathematical formula

that the color data will process through. Finally, you click the Accept or OK button. This instructs

the system to accept the calibration data and adjust itself to the new formula. The actual

calibration takes only a few minutes.

Three Input Methods:

With the FreeFlow® Print Server, there are three different procedures for color calibration.

Which one you use depends on your printer model and options.

1. Hand-held spectrophotometer. You should follow the procedure first described below.

2. Off-the-glass / off-the-copier method (Xerox 700). If you do not have a spectrophotometer,

you should follow the procedure for calibrating using a scanner.

3. The final method is a an in-line automatic method. Gen4 has a standard in-line

spectrophotometer standard while iGen3 and DC8000 have optional in-line

spectrophotometers.

The in-line automatic method does not require a manual procedure to perform calibration.

Following are the calibration procedures using a spectrophotometer and a scanner.

1. Calibrating with a spectrophotometer

Use this procedure if your system has a spectrophotometer. If your system does not have a

spectrophotometer, follow the 2. Calibrating with a scanner procedure.

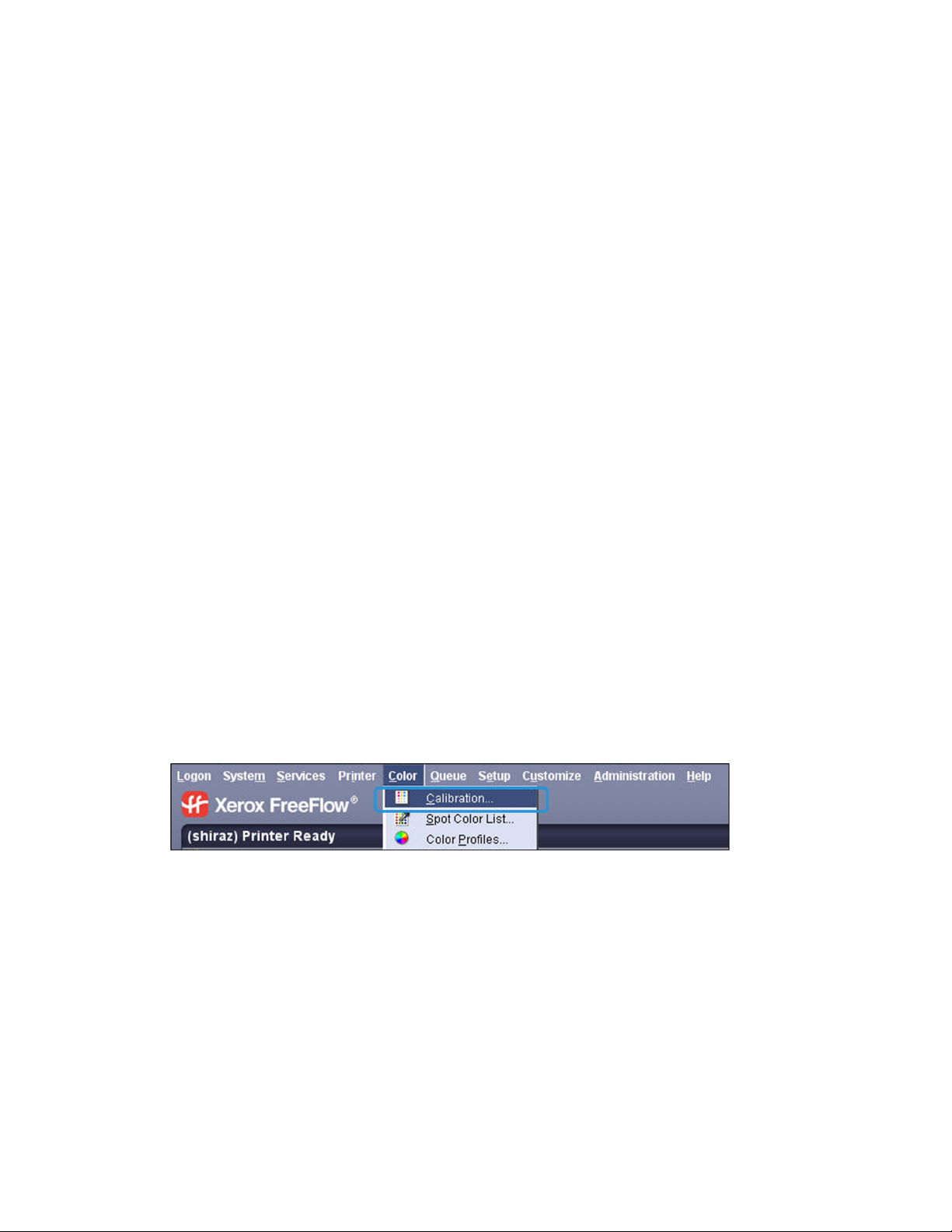

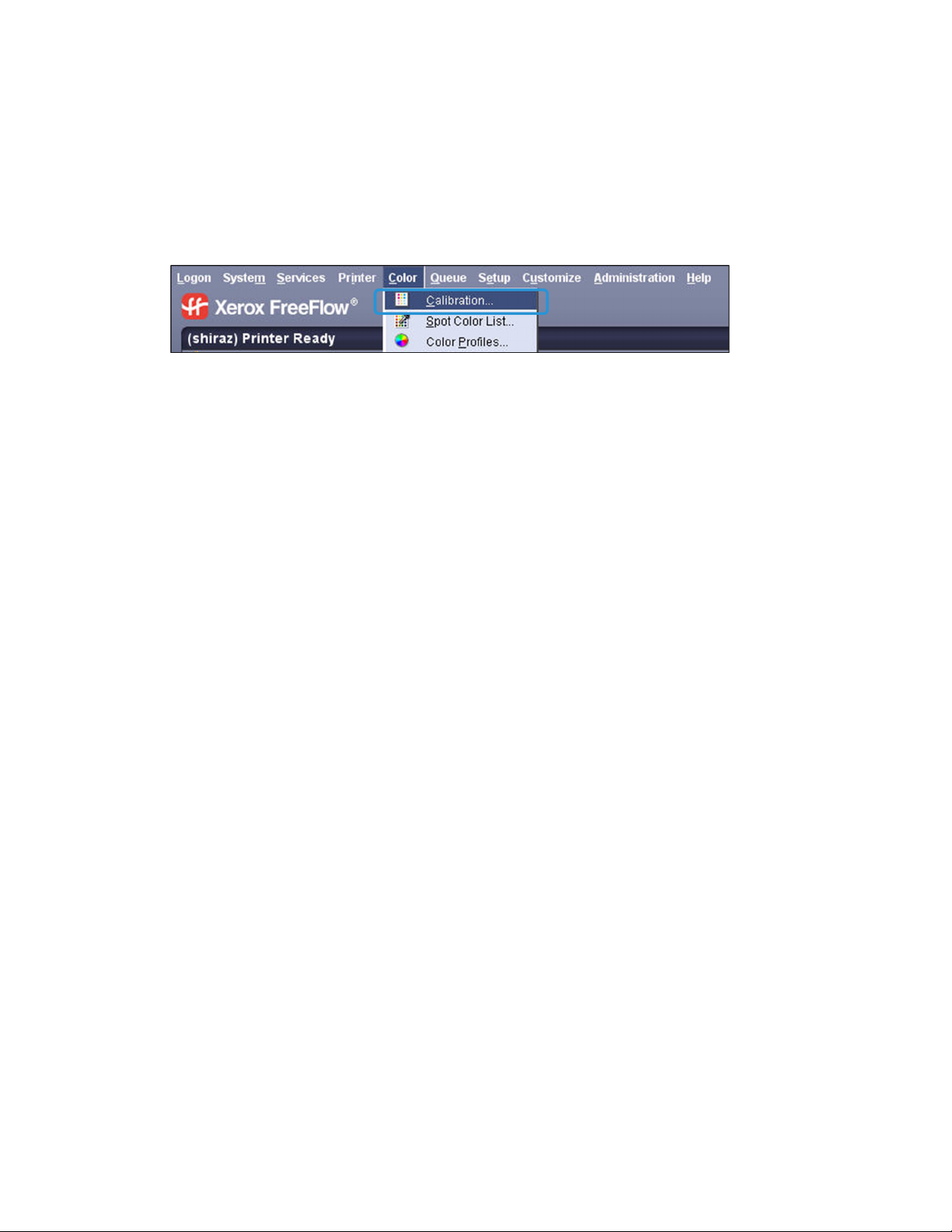

1. At FreeFlow® Print Server, select [Calibration] from the Color drop-down menu.

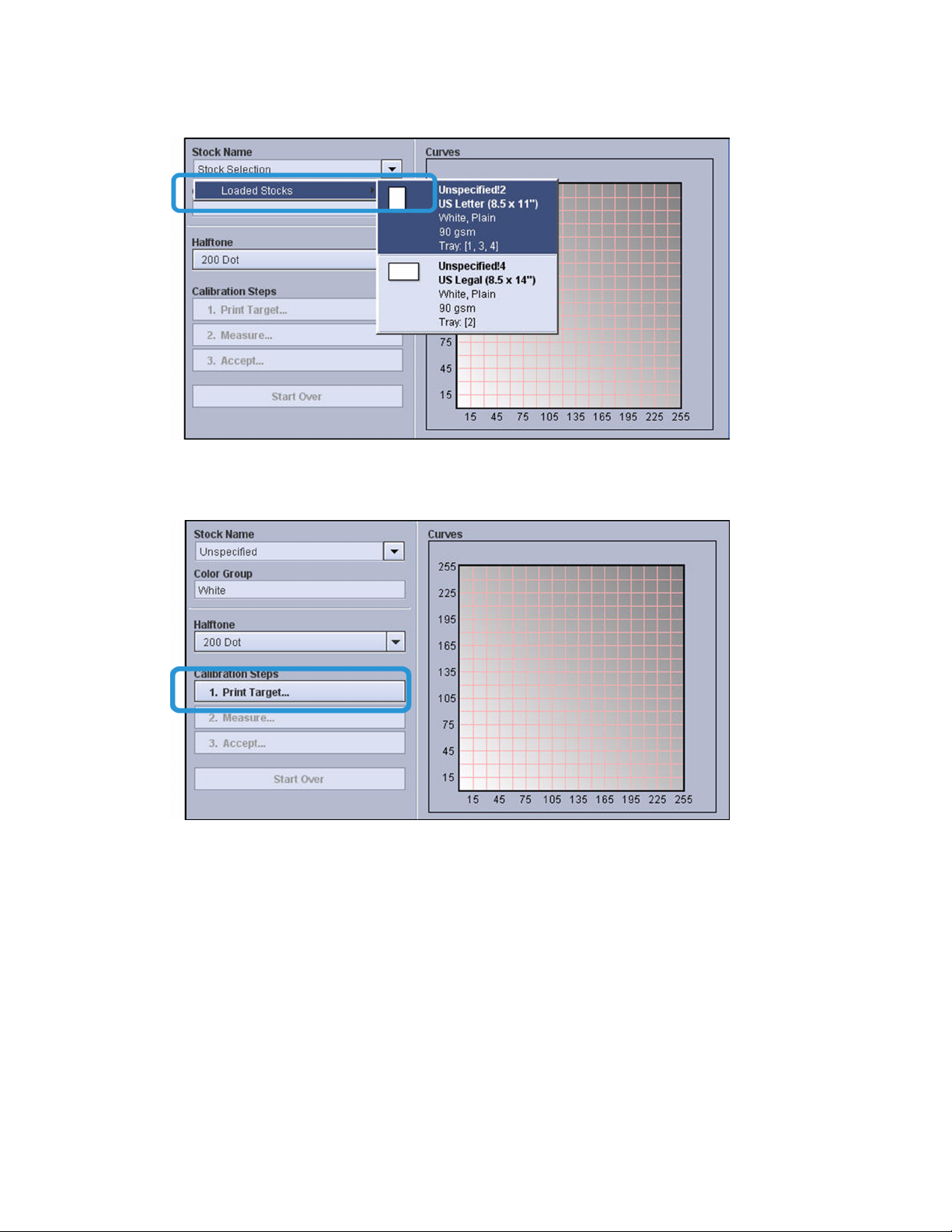

2. From the Stock Name field, select the loaded stock that you want to calibrate on.

Note

This should be the paper you use most often. If you use a variety of stocks, you can use a

“centerline stock”, which means a stock that is mid-range in terms of weight and coating.

3-2 Color Handbookk

Page 21

FreeFlow Print Server Calibration

3. After setting the paper, click [Print Target].

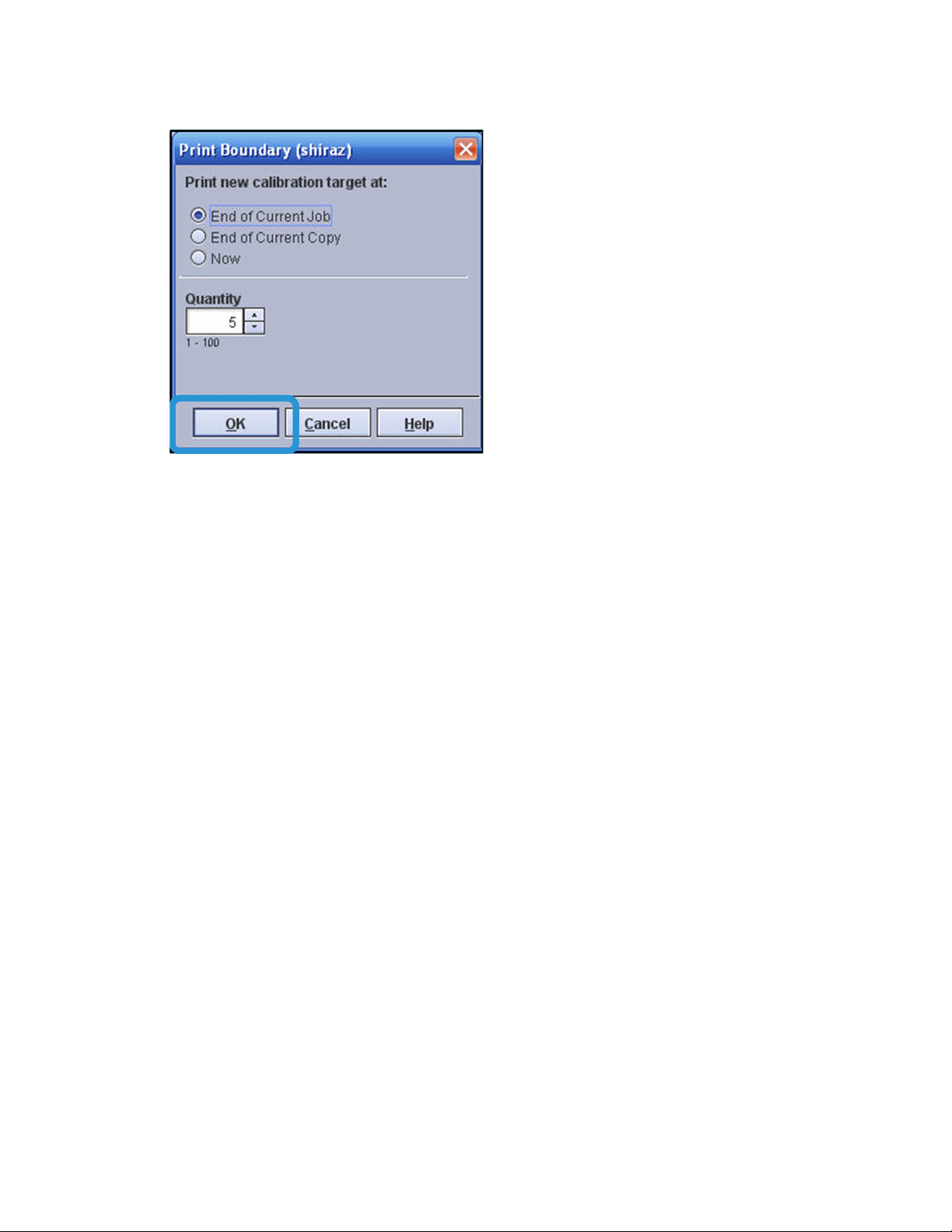

• A dialog box opens to give you the option to print at the end of the current copy, the

current job or immediately:

Color Handbook 3-3

Page 22

Calibration FreeFlow Print Server

• Generally, you won’t be printing when you calibrate, but if a long job is running and the

color appears to be drifting, you can request to print the target before the job

completion. This way the job is paused and you can correct the color quality for the rest

of the run.

• This box also lets you select more that one target to print. The default is 5, because it is

generally best to let the printer warm up on a few prints and use the last one. You

should leave it set for 5, and use the 5th print for the target to scan.

4. Click [OK] to the dialog box.

5. Collect the printed targets, and discard the first 4 that printed. Retain the 5th or last one

that printed.

6. Click [Measure] on the Calibration screen.

7. Click [Follow instructions] on the Measurement Instruction screen that opens. Then when

ready, click [Next] to follow the instructions.

Note

When you first perform a calibration, you should select Follow instructions for help. After

completing a few calibrations, you may want to select Skip detailed instructions.

Note

The steps for measuring the target vary for different spectrophotometers, but generally

you’ll have to draw the instrument over the target so it can read the color on the page.

When you are done scanning the target, the system performs calculations and then a

Calibration Complete message pops up on the server screen.

8. When the Calibration Complete message pops up on the server screen, click [OK].

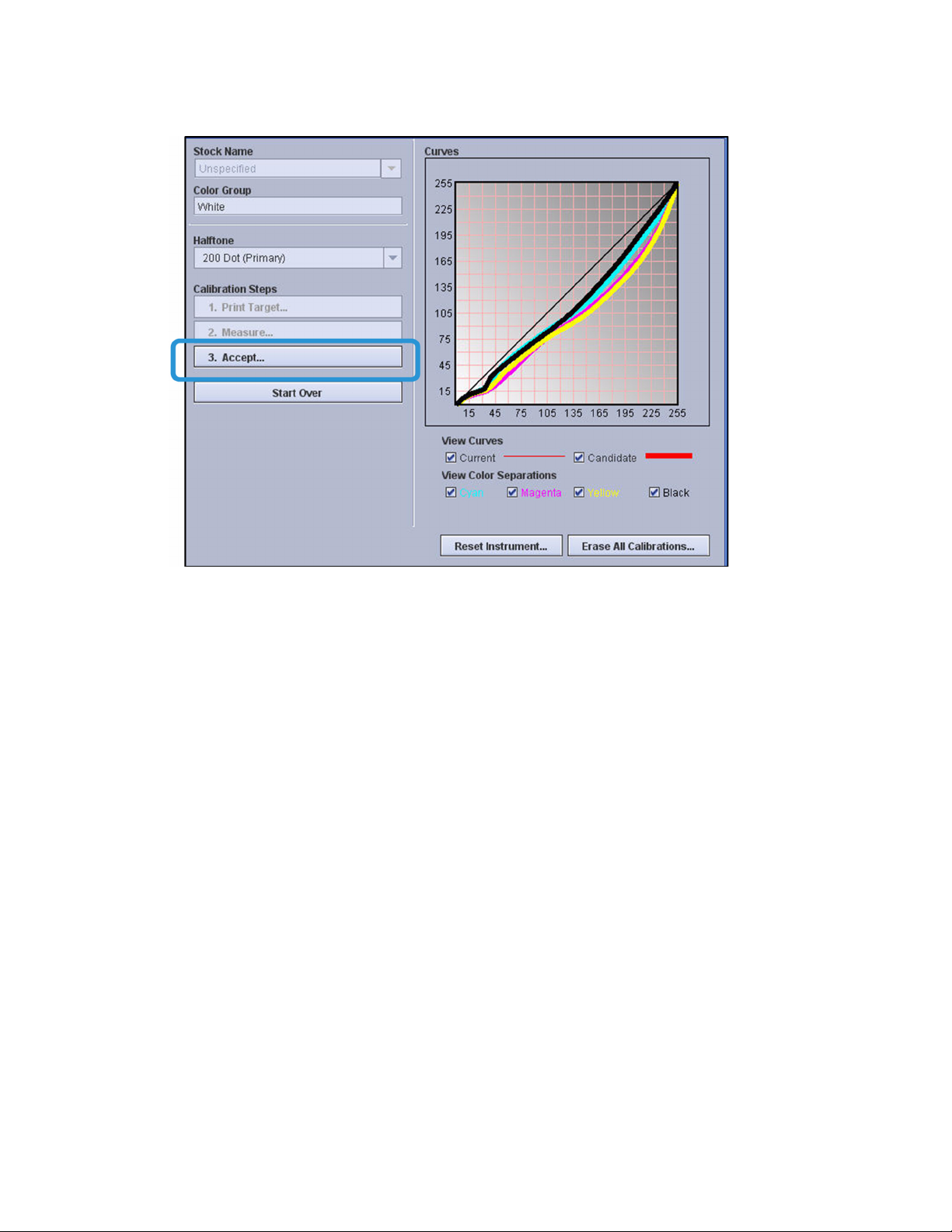

The calculation results display on a graph. This graph shows the mathematical curves that

will be used to adjust your printer’s data.

3-4 Color Handbookk

Page 23

FreeFlow Print Server Calibration

Note

You can compare the thin lines for each color with the thick lines. The new curve, taken from

a calculation on the target, is shown by the thick lines. The thin lines show the previous

calibration curve. If the new curves align perfectly with curves from the previous calibration,

then the system is holding steady with consistent output. If this happens every time you

calibrate, you do not need to calibrate as often. You will get a sense of how much the

system is changing between calibrations. Also, you will see a general shape to the curves,

and become familiar with the pattern over time. The curves should be generally smooth,

without bumps.

9. Click [Accept] to apply the new calibration data, and then [OK] to the dialog box that

opens.

This completes the calibration.

Color Handbook 3-5

Page 24

Calibration FreeFlow Print Server

2. Calibrating using a scanner

Use this procedure if your system does not have a spectrophotometer. The procedure begins at

the FreeFlow® Print Server and then moves to the User Interface on the printer.

1. At FreeFlow® Print Server, select [Calibration] from the Color drop-down menu.

2. Select the Loaded Stock that you want to calibrate on. This should be the paper you use

most often. If you use a variety of stocks, use a centerline stock, which is mid-range in terms

of weight and coating.

3. Change the Halftone Option only if you want to calibrate on a different halftone from the

default. For this practice, leave the default value as it is in the field.

4. Click [Start Calibration].

5. A measurement instruction sheet prints along with a calibration target and a test page.

6. Follow the instruction sheet to scan the target.

7. Retrieve the test page that prints out.

8. Return to FreeFlow® Print Server and click [OK] if the test page is acceptable.

Click [Cancel] if the test page is not acceptable.

Points to Remember

As you work with your printer, remember that color calibration is the foundation of good color

management. It’s the single most important thing you can do to maintain quality.

3-6 Color Handbookk

Page 25

Adjusting Color

4

TRC editing

The User TRCs window

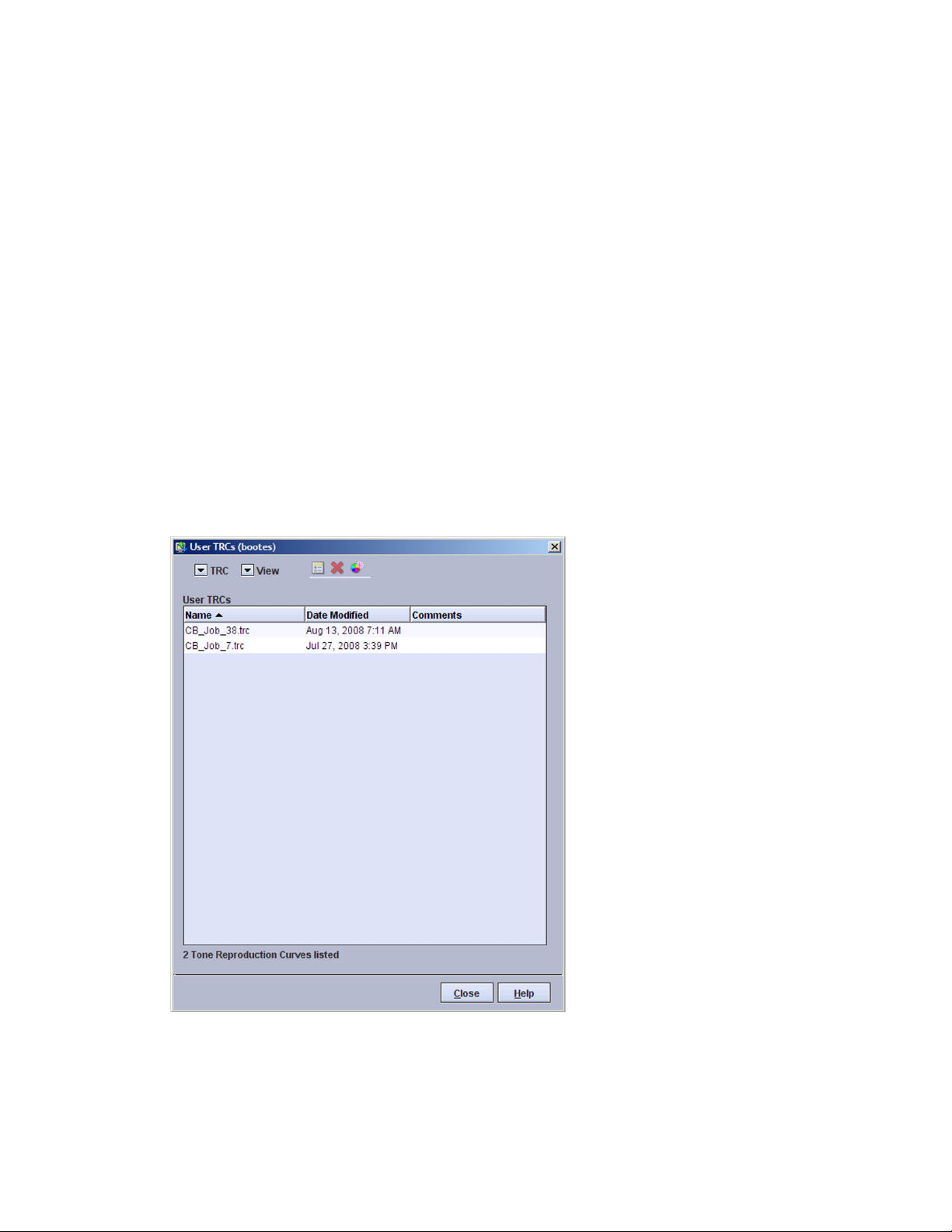

The User TRCs window enables you to manage all custom Tone Reproduction Curves (TRCs).

You can import, export, delete, copy, print, and create new and edit existing TRCs. The New and

Edit functions are best used with a specific job as the only valid test of a color adjustment is a

proof print.

The table listing of TRCs can be sorted by either name or the file modified date by clicking the

column heading.

Color Handbook 4-1

Page 26

Adjusting Color FreeFlow Print Server

User TRC menus

Selecting [Color > User TRCs] will display a list of available TRCs. Within the TRC menu, which

appears when you right-click on a TRC, or alternatively by accessing a pull down menu, are the

following selections:

• Edit...: The selected TRC can be edited using this selection.

• Copy...: The selected TRC opens in the Edit/Preview window. A copy must be saved with a

different name prior to or after editing.

• Delete: Selecting this option will delete the TRC.

• Print...: The selected TRC can be printed using this selection.

• New...: To create a new User TRC you may choose this option.

• Import...: A User TRC may be imported from another FreeFlow® Print Server using this

option.

• Export...: A User TRC can be exported to another FreeFlow® Print Server using this option.

• Redisplay: This menu option enables you to refresh the display.

Opening the User TRCs Edit window

User TRCs can be applied to a job or page to adjust the color output of a specific job. They can

also be applied to a queue to adjust the color for all jobs in the queue.

The User TRCs Edit window can be opened by using one of the following methods:

Changes made to User TRCs using any of the methods listed below appear in all the other

methods.

• From the Home Screen: Double-click a job, select the Image Quality tab and the Color

Adjustments FAB. From the Adjustment Type menu, select a User TRC and click [Edit /

Preview].

• From the Services menu: Select [Services > Print From File]. Select the Image Quality tab

and the Color Adjustments FAB. From the Adjustment Type menu, select a User TRC and

click [Edit / Preview].

• From the Queue menu: Select [Queue > Queue Manager]. Double-click a queue, select the

Image Quality tab and the Color Adjustments FAB. From the Adjustment Type menu,

select a User TRC and click [Edit / Preview].

• From the Color menu: Select [Color > User TRCs] and double-click a User TRC.

In this dialog, TRCs can be selected, edited, and previewed but cannot be applied to a job, page,

or queue.

4-2 Color Handbook

Page 27

FreeFlow Print Server Adjusting Color

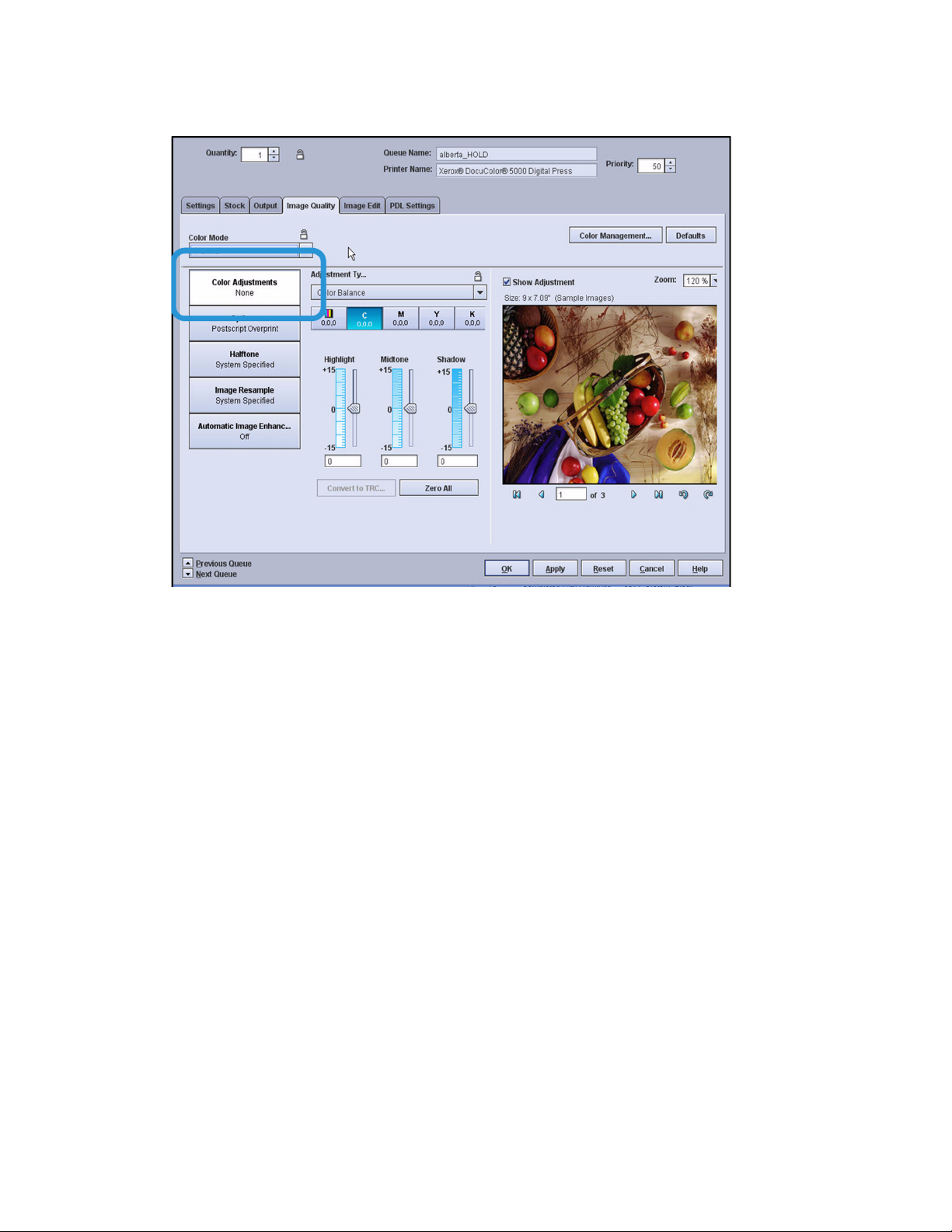

Adjusting Color Balance

Background

Colors, other than Spot Colors, can be adjusted using the Color Adjustment function on the

server. These include CMYK and RGB colors. As with Spot Color adjustment, settings can be

changed for an entire queue, a particular job, or a page within a job. The Color Adjustment

function is available from the Image Quality tab for a queue or for a job. For an individual page,

you can adjust color from the Special Pages tab, under Job Properties.

Color Handbook 4-3

Page 28

Adjusting Color FreeFlow Print Server

Generally you should set your standard color flow for a queue; that is: Source Profile, Rendering,

and Destination Profile. Once you set color flow for queues, color adjustments can then be

made on individual jobs or pages within a job.

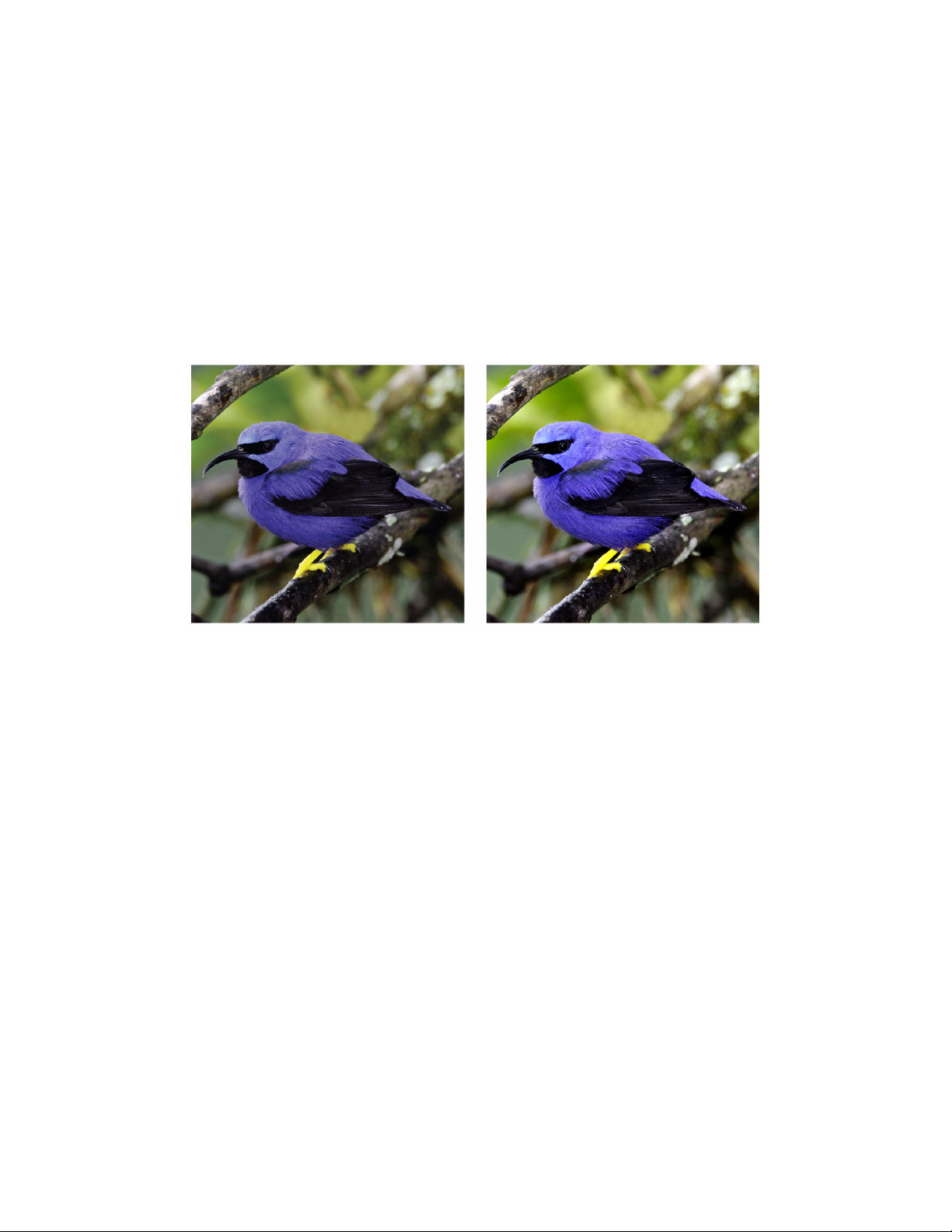

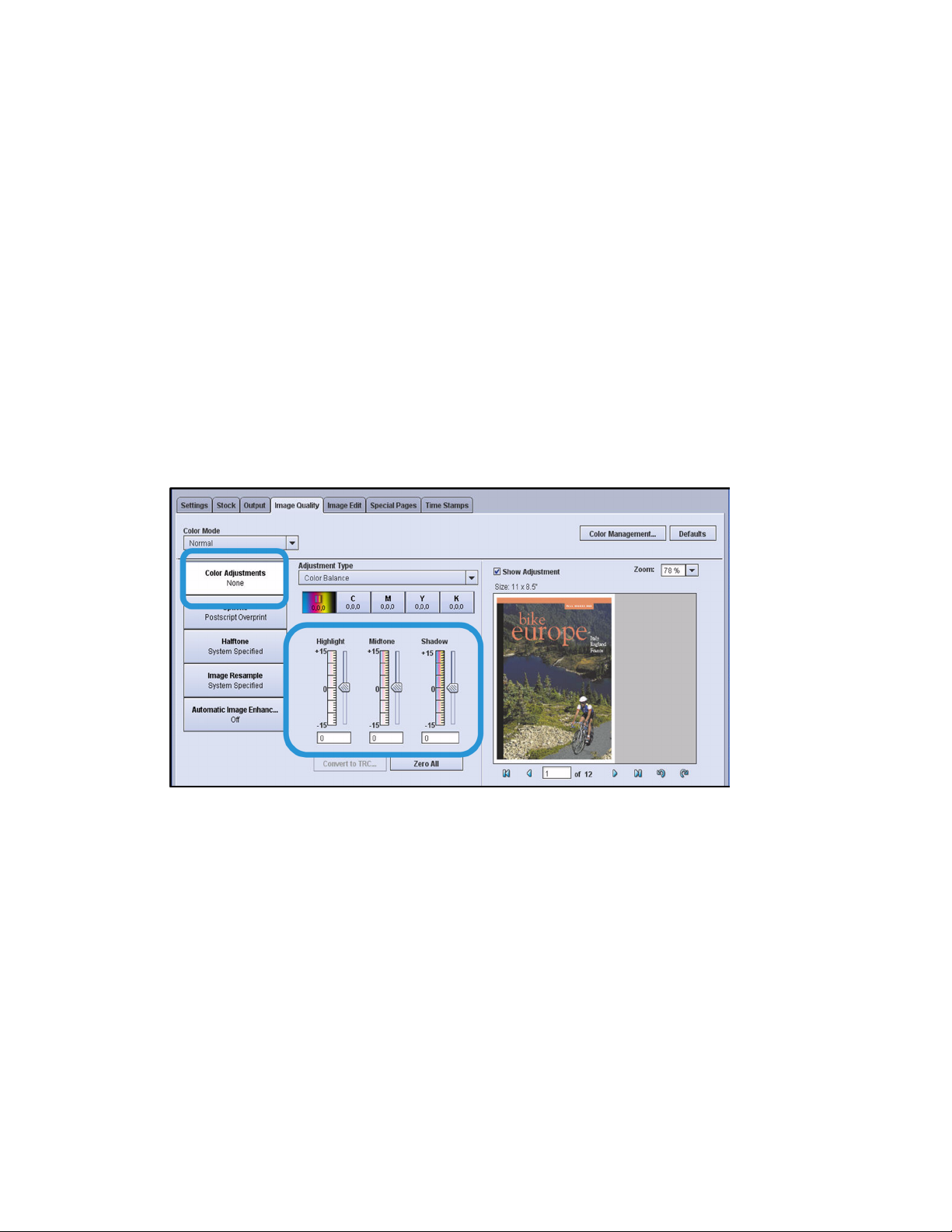

There are two ways to adjust color. The first option, Color Balance lets you change the balance

of colors using a slide bar for each CMYK color. You can modify highlights, midtones, and

shadows for cyan, magenta, yellow, black, or for all colors together. As you make changes by

increasing and decreasing color, using the slide bars, you can see the effect on one of several

stock images when the modification is made at the queue level. When you are adjusting an

individual job, you can view the changes right on a representation of your job file.

The second method for adjusting color, New TRC, lets you to create a detailed Tone

Reproduction Curve (TRC). The TRC screen provides you with a graph showing the color balance

for all colors. You can select a curve for all colors or select a curve for a particular CMYK color,

and drag it to form a new curve. When you do this, the color changes and you can see the effect

of your changes on a graphic display. With TRC you have many points of control, allowing you

to accurately modify color in small increments. This method is generally used by operators who

are experienced with adjusting color.

If you use the Color Balance slide bar method to adjust color, you can click a Convert to TRC

button to convert the values to a TRC. You can then name the TRC and reuse it for other queues

or other documents.

Remember that Spot Color is not affected by these adjustments, but can be changed using the

Spot Color Editor.

4-4 Color Handbook

Page 29

FreeFlow Print Server Adjusting Color

Color Balance Examples

Adjusting color balance using slide bars

Adjust the color for a job using slide bars on the Color Adjustment screen. While you will be

adjusting color for an individual job, the process is exactly the same to adjust color balance for

a queue.

1. Double-click on a job to open Job Properties.

2. Click the [Image Quality] tab.

3. Select [Color Adjustments] on the Image Quality tab. This is the top selection on the left.

4. To adjust color, you first select the color you want to change above the three slide bars. The

options for selecting a color to adjust are (from left to right) All Colors, C, M, Y and K. After

selecting the color, you move the slide bars up to increase the percentage of a color and

down to decrease the percentage of a color. There are three slide bars giving you the

option to adjust the color in Highlight areas, Midtone areas, and Shadow areas of the

image.

5. Notice that beneath the image are controls to rotate the image and page through the

document. If you are adjusting color for a multi-page job, you will probably want to page

through the job to see the effect of changes on all pages. You can also zoom in and out on

the image using the Zoom control above the image.

Using Advanced Preview to identify color for adjustment

Advanced Preview is useful for identifying the CMYK color components on different areas of an

image. When you run Advanced Preview, a high resolution image of the file is created and

displayed. You can then click an eye dropper icon and move it over the image using your mouse.

The CMYK color under the eyedropper is displayed at the top of the screen. Knowing the CMYK

composition of areas of an image can help you adjust color by knowing how much to increase

or decrease CMYK components to achieve a certain look.

1. Right-click on a job and select [Preview > Advanced Preview].

Color Handbook 4-5

Page 30

Adjusting Color FreeFlow Print Server

2. When the job opens in Advanced Preview, click the eye dropper icon and move your mouse

pointer over the image. The pointer becomes a small eyedropper that you can move. Notice

that as you move the eye dropper to different locations on the image, the CMYK values

change at the top of the screen. You can see the color components at any point on the

image.

4-6 Color Handbook

Page 31

FreeFlow Print Server Adjusting Color

Saving and re-using Tone Reproduction Curves (TRCs)

A TRC is simply a graphic representation of your color adjustment. You can save your color

adjustments for reuse in the future on the same queue or different queues, or to apply to

another job. The save process involves converting the adjustment to a TRC, naming the TRC and

clicking OK. After saving, the new TRC appears in the Adjustment Type drop-down menu at the

top of the Color Adjustment screen.

1. Right-click on a job and select [Preview > Advanced Preview].

2. Use the slide bars on the Color Adjustment screen to adjust the color balance on the job.

3. When the color balance is properly adjusted, click the [Convert to TRC] button, under the

slide bars.

4. In the Name field at the top of the screen, enter the name for the new TRC. In this example

it is called “NewTRC”.

Color Handbook 4-7

Page 32

Adjusting Color FreeFlow Print Server

5. Click [OK] to save this TRC.

6. On the Color Adjustment screen, view and select your new TRC in the Adjustment Type

drop-down menu.

Note

Saved TRCs can be selected and reused for all jobs and queues

4-8 Color Handbook

Page 33

FreeFlow Print Server Adjusting Color

Adjusting color with Tone Reproduction Curves (TRCs)

Another way to adjust color balance is to work directly with Tone Reproduction Curves (TRCs).

This method accomplishes the same adjustments as the sliding bars, but is a little more

technical and generally used by more experienced operators. With TRCs, lines on a graph

represent color. To make adjustments, you grab a point on each color line with your mouse

pointer, and drag it to a new location. As with the sliding bars, you can select All Colors or

individual CMYK colors.

1. Select a TRC from the Adjustment Type drop-down menu.

2. To adjust color using a TRC, you first select one ofbuttons above the graph to adjust all

colors, or one specific color.

3. Select a point on the TRC and then drag that point to a new location on the graph. You can

also click a point and then increase or decrease the X and Y values beneath the graph. Note

that the bottom left area of the graph represents highlights and the upper right area

represents shadows. Midtones are represented in-between the two. The gradual shading on

the graph from light on the bottom left to dark on the upper right is used to show this.

Color Handbook 4-9

Page 34

Adjusting Color FreeFlow Print Server

4. Click on the dot on the lower left of the curve, indicated by the lower arrow, to adjust colors

in highlight areas.

5. Click on the dot on the center of the curve to adjust the color in the highlight area of the

image.

6. Click on the dot on the upper right of the curve, indicated by the upper arrow to adjust in

shadows areas.

7. You can reset the TRC to its original form, prior to your recent adjustments. To do this, click

the [Options] drop-down menu and select [Default All Curves].

Note

Next to the Options menu, there are two small arrows that Undo and Redo the actions, one

step at a time.

4-10 Color Handbook

Page 35

FreeFlow Print Server Adjusting Color

Points to Remember

• Remember you do not need to adjust your standard color flow settings on the Color

Management screen to fix individual jobs.

• Color Adjustment does not affect Spot Color, just RGB and CMYK color. If you are

attempting to adjust a color and it is not responding, it may be a Spot Color. You can run

Preflight to verify that it is a Spot Color, and then use the Spot Color editor to make

changes to it.

• To save a color adjustment, it must be in TRC format. However, you can create your color

adjustment using slide bars and then easily convert the adjustment to a TRC for saving.

Going Further

When attempting to adjust individual colors, it is useful to use the color wheel below to

determine which CMYK value to change to affect a given color. If you want to decrease the

intensity of a color, you can increase the intensity of the color opposite it – its complementary

color. For example, to decrease the intensity of blue, you would increase yellow. Conversely, to

increase the intensity of a color, you should decrease its complementary color.

Color Handbook 4-11

Page 36

Adjusting Color FreeFlow Print Server

Note that each color is made from the two colors adjacent to it. For example, Blue is made from

a combination of Cyan and Magenta. Red is made from a combination Yellow and Magenta. So

another way to change a color is to change its component colors. To make Red darker, you can

increase the amount of Yellow and Magenta. To make Red lighter, you can decrease the amount

of Yellow and Magenta.

4-12 Color Handbook

Page 37

FreeFlow Print Server Adjusting Color

Automatic Image Enhancement

Background

Along with Color Adjustments, Automatic Image Enhancement or AIE is another useful

function on your Image Quality tab for each queue. AIE will automatically analyze and enhance

your RGB and Grayscale images. Like the other color management functions, you can set AIE to

work on a queue, a selected job or a page within a job.

AIE has three main settings: Off, Normal, and Custom. When turned Off it is set to not work. In

Normal mode, AIE works to complete all checks, except Noise Reduction, and it then adjusts

images if needed. In general, Normal Mode provides the best default settings for the best photo

images.

In Custom mode, you select specific items for AIE to check and enhance. You have individual

settings for eight adjustments. These are the adjustments and their definitions:

Contrast refers to the visual distance between light and dark areas. If you select Contrast High

AIE ensures that the final image stretches out the levels of gray as much as possible to make

subtle detail visible without loosing detail in the highlights and shadows. Contrast Low delivers

an image with levels of gray close together, bringing both dark areas and light areas closer to

the midtones. In both cases, AIE determines exactly what adjustment, if any, is needed to

achieve your preferred appearance.

Saturation refers to the vividness or dullness of colors in an image. Saturation High delivers an

image with intense, vibrant colors and Saturation Low delivers an image with subdued colors.

Sharpness refers to the crisp appearance of an image. Sharpness High ensures that an image

has a sharp appearance while Sharpness Low produces an image with a softer appearance. AIE

Color Handbook 4-13

Page 38

Adjusting Color FreeFlow Print Server

may sharpen, blur or leave the image alone, depending on the characteristics of the original

image.

Exposure impacts the lightness or darkness of an image. This is a historical term from the

photography field, where exposing a film to more light results in a lighter image. Exposure High

indicates that you would like images to be lighter than is typical while Exposure Low indicates

that you would like the images to be darker than is typical.

Color Balance adjusts hue to achieve neutral white and grays. When Color Balance is turned On,

AIE determines if it is advantageous and safe to adjust the balance of colors in the image.

When Color Balance is Off, AIE will not adjust the hue of the images.

The Noise Reduction filter reduces grain or noise in an image resulting in a smoother

appearance. The noise filter is turned off by default, except for iGen printers. When this filter is

on, AIE determines if removing noise from an image is beneficial. When turned Off, noise will

not be removed from the image.

Shadow Detail lightens and increases contrast in shadow areas to make detail in those areas of

the image more visible. When turned on, enhancement of shadow detail will occur only if an

analysis of the image determines that it is advantageous and safe. Increasing shadow detail

might not be safe when enhancing a photo taken with a high ISO setting, resulting in high noise

levels in shadow areas. Also, it might not be safe when a photo is taken using a high camera

compression setting that results in rectangular artifacts being introduced by the camera

compression. AIE automatically checks for these conditions and adjusts the image if needed.

Red Eye Reduction locates and removes red retro-reflection from the pupils of human eyes. This

filter ensures that the image is analyzed to determine if removing red from a human being is

needed. The decision is made partially on the size of the eye. When red eye reduction is Off, AIE

will not check or remove red eye.

By turning on these settings, you are not directing AIE to make changes, but requesting the sort

of appearance you would like to have. AIE automatically determines if changes are needed, and

what changes to make.

AIE is especially useful for applications with images such as catalogs, yearbooks, photo

directories, newsletters, calendars and greeting cards. Since it works automatically, AIE can add

value without incurring the extra production time that is usually associated with traditional

photo manipulation.

Points to Remember

• AIE is especially useful for applications with images and photos such as catalogs,

yearbooks, photo directories, newsletters, calendars and greeting cards.

• Many customers don’t want photos adjusted, except for Red Eye Reduction, the most useful

setting. If you also find this the most useful of the eight, you can create a special queue to

handle photos and set AIE to Custom with only Red Eye Reduction enabled.

• Since AIE performs an analysis of every RGB image, processing time is longer when this

setting is used. You can create a special purpose queue for photo applications, and direct

selected jobs to it, to avoid affecting all jobs with longer processing.

4-14 Color Handbook

Page 39

FreeFlow Print Server Adjusting Color

Spot Color Editing

Background

Spot colors are specific named colors that are processed separately by the print server to help

ensure that the printed output color matches a physical standard reference color.

Spot colors are simulated in the printed output by mixing specific amounts of cyan (C),

magenta (M), yellow (Y), and black (K) process colors. The print server displays CMYK recipes for

spot colors in the Spot Color List window.

There is a Spot Color List onthe server, located under the Color menu, showing all standard

Pantone colors. The Spot Color List also shows any custom colors that have been added to the

server. For the server to be able to optimally match a document designer’s intent, the color

name must be in this list.

However, every spot color in a file has both a name and also an alternative color space

definition. The alternative color definition is usually CMYK, but it could be RGB. If FreeFlow®

Print Server does not find a Spot Color name in this list, the server will automatically use the

alternative color definition to process the color. Also, the server will use the standard color

settings for that color space. Since the alternative color definition is generic, it does not always

achieve the best color on your printer. To ensure that the best color gets printed for Spot Colors,

you may need to occasionally add a custom color to this list. You may also want to edit a color if

you are not satisfied with it.

For both adding new Spot Colors and editing existing ones, it is helpful to print a Swatch Book of

the Spot Color List. You can then compare the swatches to sample printed pages to identify a

color. Once you identify a color, you can use its formula to add a new color or to adjust its

balance to your color preference. To print the Swatch Book, you simply click the Print Swatch

Book button on the Spot Color screen.

Color Handbook 4-15

Page 40

Adjusting Color FreeFlow Print Server

The easiest way to identify Spot Color jobs is to Preflight the incoming job. This can be done at

the queue level — for all jobs entering a queue, or performed upon each job. Configuring a

queue-level Preflight is done on the Settings tab in the Preflight pane. For a single job, you rightclick the job and select Preflight > Setup. You simply check Spot Colors and Report as Error and a

preflight check will flag any job with named colors.

Spot color processing

When spot color processing is enabled, and a color recipe has been defined on the print server

with exactly the same name as the spot color defined in the file, the color is printed using the

CMYK color recipe on the print server. No source profile, rendering intent, destination profile, or

user TRC is applied to the spot color.

If no matching color name is found in the spot color list, or when spot color processing is

disabled, the spot color is rendered using an alternate color space (CMYK or RGB) defined in the

input file. Any source profile, rendering intent, destination profile, or user TRC applied to the rest

of the color path is also applied to the spot color.

In some cases you may wish to disable spot color processing. For example:

• If a job contains spot colors for text, graphics, and images you may wish to disable spot

color processing to avoid the text and graphic spot color looking different from the image

spot color.

• If a job contains spot color data adjacent to CMYK or RGB data that should match, you

may wish to disable spot color processing so that both are processed in the CMYK or RGB

color space.

PANTONE® colors

PANTONE® is one color reference system for spot colors. Recipes for printing PANTONE® spot

colors on coated and uncoated paper stocks are included in the Spot Color List.

4-16 Color Handbook

Page 41

FreeFlow Print Server Adjusting Color

If you edit a PANTONE® color, it retains the same name, but it is re-categorized as a custom

color. The original recipe for the PANTONE® color is always retained, and you can revert to the

original recipe and PANTONE® category at any time.

Limitations

There are many variables in process reproduction of colors generated by the FreeFlow® Print

Server, any one of which may affect the quality of the spot color simulation, including:

• type of paper used•effective final resolution

•dot structures and halftones

• non-Xerox toner or colorant

The FreeFlow® Print Server supports spot color simulation for text and graphics. It does not

support spot color processing for images.

About the Spot Color List window

The Spot Color List window organizes your PANTONE® and custom spot colors, and allows you

to create, modify, delete, and print spot colors.

You can access functions to manage spot colors by right-clicking any spot color, or by selecting a

color in the list and then using the buttons in the Spot Color List window.

If the spot color list has been updated with a halftone profile, you can remove profile updates

from the PANTONE® colors by selecting Defaults. If halftone profile updates have not been

applied to the spot color list, the Defaults button does not appear.

Color Handbook 4-17

Page 42

Adjusting Color FreeFlow Print Server

The Spot Color List control changes which spot color types are displayed in the list. The choices

are:

•All

•PANTONE Coated

•PANTONE Uncoated

• Custom - only colors that you created (New Color) or PANTONE® colors that you modified

(Modified Color) are displayed.

You can find a particular color in the list by typing part of its name in the Find Color field, then

selecting Find Next. Entries in the Find Color field are not case sensitive.

The list of spot colors can be sorted by clicking any of the labeled headings. The headings are:

• Custom Color (icon) - displays icons to indicate colors that you created (New Color) or

PANTONE® colors that you modified (Modified Color).

• Color Name - the name of the spot color.

• CMYK - the numerical values corresponding to the respective values of Cyan, Magenta,

Yellow, and Black for each spot color.

• Preview (unlabeled) - an approximation of each spot color.

About the Spot Color Editor window

The Spot Color Editor window allows you to select from an array of color variations to change

the cyan, magenta, yellow and black (C, M, Y, and K) values of a spot color recipe.

The center color in the diagram in the window shows the current spot color. Color variations are

arranged around the center color along a line for each process color. Along each line, each color

4-18 Color Handbook

Page 43

FreeFlow Print Server Adjusting Color

varies from its neighbor by the percentage selected in the Color Variations list. Medium (5%

increments) is the default selection. As you get closer to the desired color, you may wish to

adjust the color variation increments for finer control.

When you place the pointer over one of the colors, the C, M, Y, and K values of the color are

displayed and the Adjusted color swatch temporarily shows that color. When you click any color

that color becomes the new center color from which new color variations are generated.

When editing an existing color you can select Reset to change the Adjusted C, M, Y, and K

values back to the Original values.

By selecting Print Sample... you can print the adjusted spot color along with its variations to help

you match the printed output to your desired color. Selecting OK applies the adjustments to the

spot color without printing. Selecting Cancel closes the Spot Color Editor window without

applying any changes.

Points to Remember

• If you need to do a lot of Spot Color matching, you can set a queue to automatically run

Preflight for all jobs submitted to it. Remember to select the Spot Colors checkbox on

Preflight setup, so that all Spot Colors are identified for jobs and listed in the Preflight

report.

• After running Preview or printing a job, you can click View Report on the Job Properties

screen to see any Spot Colors that are not listed on the server. Unless these are added to

the server list, they will be processed with their alternative CMYK or RGB definitions in the

file.

• If you are having trouble matching Spot Colors to other colors on a page or within a

document, you can Disable Spot Color on the Spot Color tab on the Color Management

screen:

Color Handbook 4-19

Page 44

Adjusting Color FreeFlow Print Server

Disabling Spot Color instructs the server to use the alternative color definitions in a job file.

This will usually standardize the colors. If you do this, you should carefully review how all

Spot Colors in the printed document have been affected.

• When you edit a standard Pantone Spot Color to match a preferred look or a standard, the

color will remain changed for all jobs that call for that color. The Spot Color List is a system

resource, not an individual queue resource. This means that the modified color will be

applied to all jobs that call for it, no matter what queue they go through. Therefore, you

may need to periodically return modified Spot Colors to their original Pantone standard to

meet the requirements of new jobs.

4-20 Color Handbook

Page 45

Color Management

5

Workflows

What is Color Management?

Color Management is the process of matching color across different input and output devices

by referencing color reproduction standards using International Color Consortium (ICC) profiles.

Color Management tools are used to assist with matching color for printing. Color Management

tools can include hardware devices such as spectrophotometers and colorimeters, and software

such as color profiles, Tone Reproduction Curves (TRCs), and color space transformations.

Devices such as the spectrophotometer measure the printed output of a printer; this data is

then used to calibrate the printer and/or create appropriate TRCs which can adjust for any color

matching problems caused by the printer itself.

Color matching software is used to convert between device dependent RGB and CMYK color

spaces to a device independent color space in order to match colors by adjusting for differences

between device color gamuts.

For most jobs, the default color settings of the Color Management window provide optimal

quality and the optimal color output required.

Color Handbook 5-1

Page 46

Color Management Workflows FreeFlow Print Server

Use the Color Default settings

The Color Management Flow feature of the print server is designed to automatically use the

default color settings and options. While the color default settings will provide optimal color

output for the majority of jobs, the Custom Color Workflows section of this chapter describes

some custom workflows you can follow to fine tune the system and produce a particular color

output.

About Xerox color gamut

The Xerox press is a digital alternative to the offset press. The specifications developed by the

Graphic Communications Association (GRACoL) are used to ensure color consistency between

color design choices in the workflow of offset printing devices.

5-2 Color Handbook

Page 47

FreeFlow Print Server Color Management Workflows

Understanding the FreeFlow Color Paths

Jobs can take one of the following color image paths through the Xerox FreeFlow® Print Server:

• Device Link Emulation Path

• ICC Standard Path

The image path is the way in which a source profile becomes mapped to the destination profile

of the printer CMYK. The path used is determined by the source space selected.

Device Link Emulation Path

The system identifies a source profile, a destination profile, and a rendering intent to create one

device link profile. Device Link profiles provide increased color quality of prints by performing

more accurate color transformations, maintaining pure colors, and preserving black.

When a preinstalled source profile, destination profile, and rendering intent are selected, the

FreeFlow® Print Server uses a proprietary enhanced path look up table to translate the color

data that provides a faster RIP and preserves the K channel for CMYK source files. This path also

enables R=G=B to print as 100%K. This feature allows you to generate a direct color mapping

from the CMYK source to destination and create a custom 4x4 conversion or a direct color

mapping from RGB source to destination to create a custom 3x4 transformation.

If your file contains an embedded profile but the profile is not included on the DFE, the

standard ICC translation path will be used.

The CMYK or RGB source color

space defines the intended

destination device of each object

(e.g., sRGB monitor or GRACoL

offset press).

When possible, program the job to follow the Device Link Emulation image path, as it offers the

highest quality color outcome for incoming color.

The objects are then converted to

Direct CMYK through a 3x4 or 4x4

transformation. This conversion is

determined by the rendering intent

and Destination Profile selected.

Any color adjustments (TRCs) are

applied to the final color.

Color Handbook 5-3

Page 48

Color Management Workflows FreeFlow Print Server

ICC Standard Path

A job that contains an embedded source profile that is being honored but the profile cannot be

located by the press (either the profile is not loaded on the DFE or the profile setting is not

selected) will follow the ICC Standard image path.

Jobs that follow this path undergo a color transformation to an independent color space before

the color transformation to the Print Server CMYK space. Jobs originated in RGB or CMYK color

spaces are transformed using a translation table (ICC profile) into the Direct CMYK color space.

For CMYK incoming data, pure black is not preserved.

Note

L*a*b* objects are converted directly to Direct CMYK using the destination profiles through

the ICC path. No source space is used with L*a*b* objects.

The process followed when an object in the file is converted through the ICC standard path is:

The CMYK or RGB source color

space defines the intended

destination device of each object

(e.g., sRGB monitor or GRACoL

offset press).

Each object is converted to a

device independent profile

connection space (XYZ color

space on FreeFlow® Print

Server)

Note

If you have a file with an embedded source space that is not loaded on the DFE and would

like to use the Device Link Emulation image path, import an ICC profile to the DFE and then

select the profile as the source. To import a source file, refer to Importing a source profile.

Note

Workflows with tagged CMYK data on an

incoming file, or that use a loaded output

profile as a source CMYK profile, provide good

color matching to custom printers that are not

covered by the included source profiles.

The objects are then converted to Direct

CMYK using the destination profile. The

details of this conversion are determined

by the rendering intent and Destination

Profile selected.

Any color adjustments (TRCs) are applied

to the final color.

5-4 Color Handbook

Page 49

FreeFlow Print Server Color Management Workflows

Custom Color Workflows

While the default color settings of the Color Management feature on the print server provide