Page 1

Chapter

1

General Information

This service manual contains information useful for troubleshooting, repairing,

adjusting, and maintaining a Tektronix Phaser

includes troubleshooting guides, adjustment procedures, a field replaceable

units (FRU) list and assembly/disassembly procedures for selected FRUs. To

ensure complete understanding of the product, we recommend participation in

Phaser 550 service training.

®

550 Color Printer. This manual

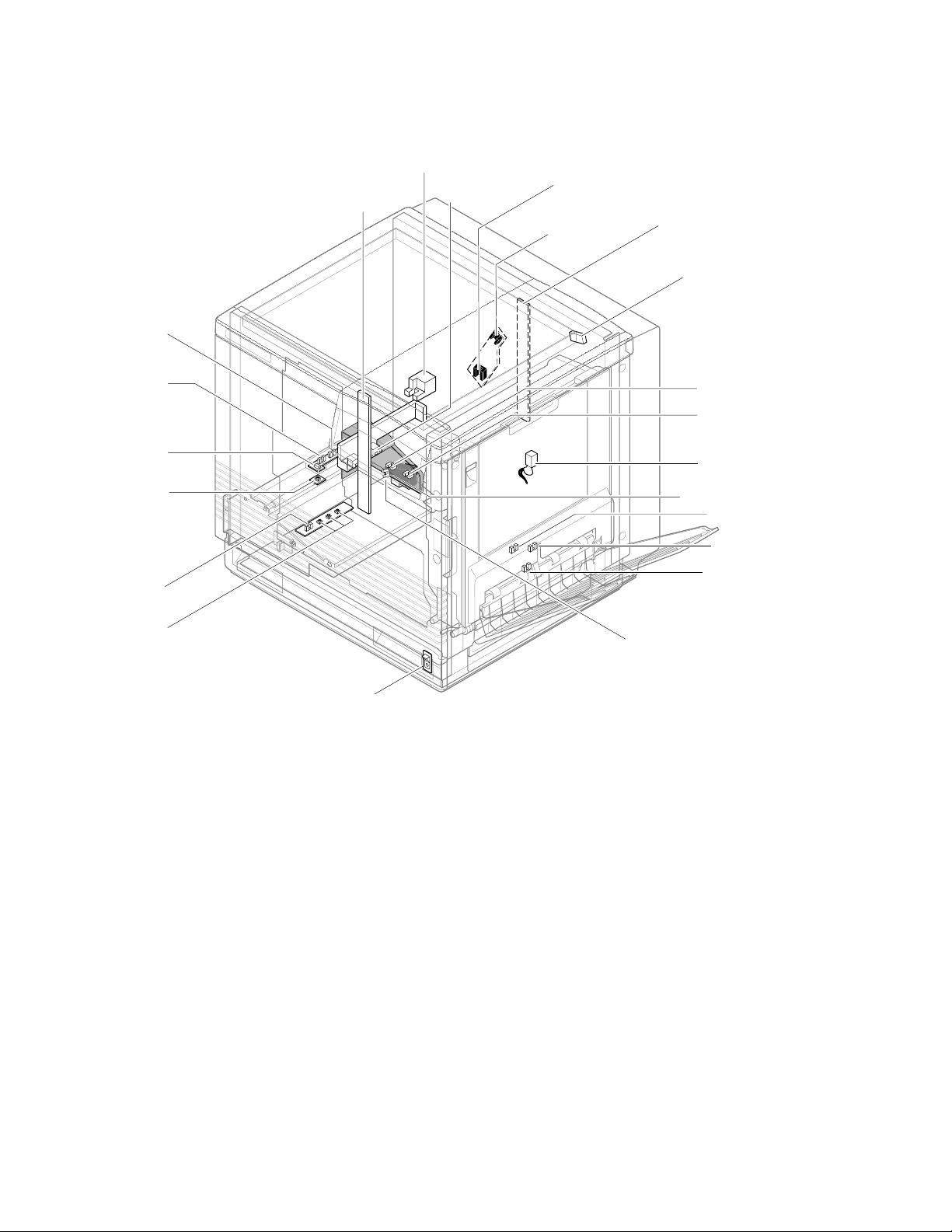

Figure 1-1 The Phaser 550 Color Printer

9013-01

Service Manual

1-1

Page 2

General Information

1

The Phaser 550 Color Printer

The Phaser 550 Color Printer combines a color laser, continuous-tone print

engine with an image processor supporting Adobe’s PostScript Level 2 page

description language. The image processor features a bi-directional parallel

interface for host communication. Optional network adapter cards to the image

processor allow the printer to communicate on networks using LocalTalk, serial,

Ethernet or Token Ring protocols. The Ethernet network card supports

EtherTalk, Novell and TCP/IP. With the Token Ring network card, the printer

supports Token Ring protocols. The network cards are sometimes referred to as

“smart cards” because each houses its own processor for executing specific

on-board protocols; only data is transferred from the installed smart card to the

printer’s image processor board. The PCL printer language is optionally

supported and is activated with a downloadable authorization code.

The Phaser 550 comes standard with 8 Mbytes of RAM which can be

supplemented with one or two additional 16- or 32-Mbyte RAM SIMMs;

maximum capacity is 72 Mbytes. The printer contains 17 standard, built-in

fonts. An additional 22 fonts can be added via an optional snap-in SIMM

(which also enables other extended features). The standard Phaser 550 prints at

a resolution of 600 x 600 dots-per-inch.

The addition of the extended feature (font) SIMM allows the printer to print at

higher resolutions of 600 x 600 (Standard mode), 1200 x 600 (Enhanced mode)

and 1200 x 1200 (Premium mode) dots per inch. The extended feature Phaser

550 also supports image pipelining for greater throughput, a print collation

mode, and a “check print before proceeding with job” mode.

The Phaser 550 support a 5 page-per-minute, composite-black printing called

Fast Color. It also feature Presentation mode printing in which a paper print is

printed with the color settings of a transparency print. Presentation mode

produces the smoothest and brightest large-area fills. This mode can only be

selected from the front panel. The printer print in monochrome at 14 prints per

minute.

The printer also feature a SCSI-compatible interface to connect to an external

hard disk drive for additional font storage. An orderable option, the Phaser

CopyStation can also be connected to the printer’s SCSI port to give the printer

the ability to optically copy color images. The printer requires a minimum of

24 Mbytes of RAM to support the CopyStation.

The printers support printing on A- and A4-sized paper and transparency film

from an A or A4-size tray. An optional two-tray second feeder (called the Lower

Tray Assembly) is available. The printer supports legal-size paper when fed

manually or from a Legal-size paper tray. The printer requires at least 12 Mbytes

of installed RAM to support Legal-size printing. The printer also supports

manual feeding.

1-2

Phaser 550 Color Printer

Page 3

After being idle for one hour the printer switches into its Energy Star mode

where it consumes less than 45 watts of power. It “awakens” upon receiving

data at any of its ports. The printer also features a closed-loop image density

sensor system that allows it to auto-calibrate its color imaging so printing output

remains consistent over the life of the print engine and its consumable supplies.

Print speeds depend on the chosen resolution and selected media. For

resolutions of 600 x 600 (standard) and 1200 x 600 (enhanced) dpi, in color, the

printer prints at 3.5 pages per minute (ppm) on paper. Monochrome printing is

at 14 ppm on paper. Transparency film printing is always 1.5 ppm. For

1200 x 1200 (premium) dpi color printing, the printer color prints at 1.75 ppm.

Monochrome printing is at 7 ppm. Transparency film printing is 1.5 ppm. The

printer prints 600 x 600 dpi, composite black (CMY) draft prints at a rate of

5 pages per minute.

RAM and printer capabilities

The printer features 8 Mbytes of base RAM and two SIMM connectors which

accept both 16- or 32-Mbytes RAM SIMMs. With more memory the printer gains

the capabilities of printing at higher resolutions, printing without having to use

image compression (which trades off less installed RAM for longer image

processing time) and dual frame buffers for printing one image while processing

a second image (which gives greater printing throughput). With additional

RAM memory the printer’s capabilities increase as detailed in the following

table:

General Information

1

Table 1-1 Installed RAM and printer capabilities

Print mode 8 Mbytes 34 Mbytes 40 MBytes 56 Mbyte 72 Mbytes

600 x 600 dpi

3.5 ppm

1200 x 600 dpi

3.5 ppm,

extended

feature option

600 x 1200 dpi

1.75 ppm,

extended

feature option

1200 x 1200 dpi

1.75 ppm,

extended

feature option

1 frame buffer

with image

compression

NA

NA

NA

1 frame buffer

with no image

compression

2 frame buffers

with image

compression

2 frame buffers

with image

compression

1 frame buffer

with image

compression

2 frame buffers

with no image

compression

1 frame buffer

with no image

compression

1 frame buffer

with no image

compression

2 frame buffers

with image

compression

2 frame buffers

with no image

compression

1 frame buffer

with no image

compression

1 frame buffer

with no image

compression

2 frame buffers

with image

compression

2 frame buffers

with no image

compression

2 frame buffers

with no image

compression

2 frame buffers

with no image

compression

1 frame buffer

with no image

compression

Installing a single 4-Mbyte RAM SIMM in the image processor’s SIMM 1

connector (total of 12 Mbytes RAM installed) gives the printer the ability to print

full color on legal-size paper.

Service Manual

1-3

Page 4

General Information

1

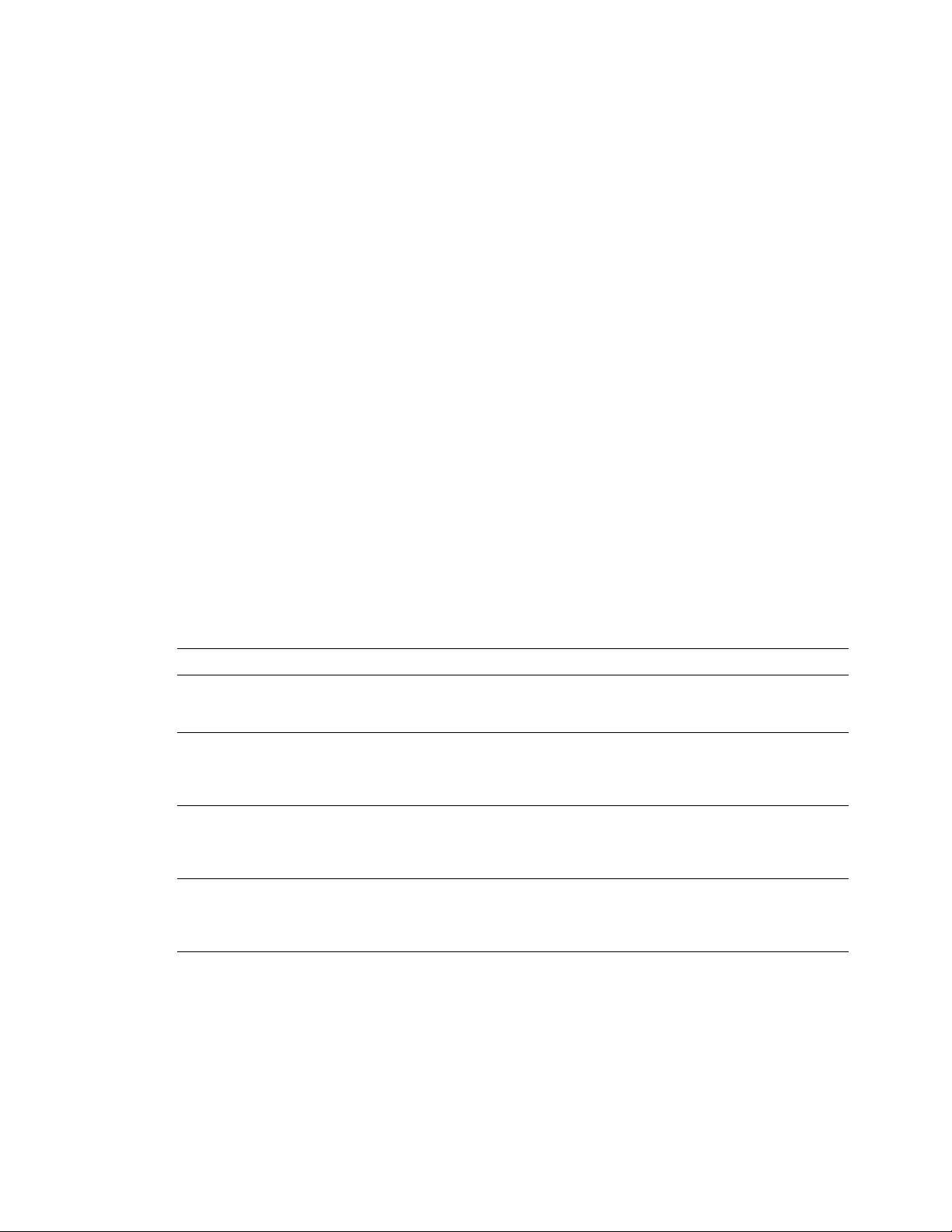

Print engine assemblies

Toner level

sensor board

Pre-exposure lamp

Imaging unit

Paper feeder

Black toner cartridge

Yelllow toner cartridge

Magentatoner cartridge

Cyan toner cartridge

Pre-transfer lamp

Ozone filter

Fuser

Laser scanner

Toner cartridge

selector/paper

exit unit

(right door)

ER

P

A

P

A4

Paper tray

9322-85

Figure 1-2 Print engine major components

The imaging unit may contain a removable pre-transfer corona unit. The

pre-transfer corona unit makes the imaging unit backwards compatible with the

Phaser 540 Color Laser Printer. Unlike the Phaser 540, the Phaser 550 does not

use a pre-transfer corona.

1-4

Phaser 550 Color Printer

Page 5

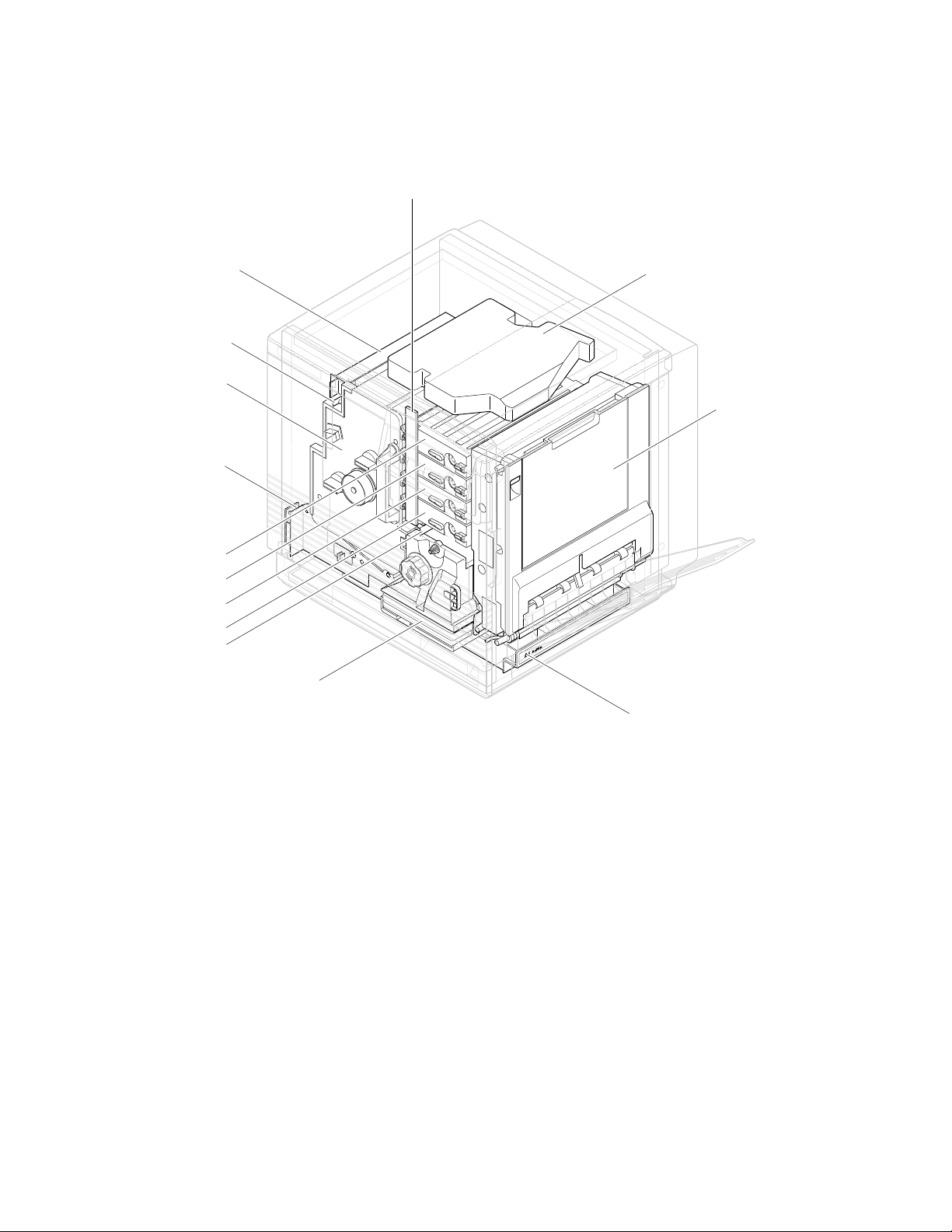

Toner cartridge

drive unit

Power

supply fan

Power

supply unit

Engine

control board

Fuser fan

Charger

sensor board

Cleaning board

Toner

cartridge

motor

Ozone fan

Laser motor drive board

General Information

Image processor

board

High voltage board

1

Main motor

Paper feed motor

Engine driver board

Figure 1-3 Print engine components (continued)

9322-86

Service Manual

1-5

Page 6

General Information

1

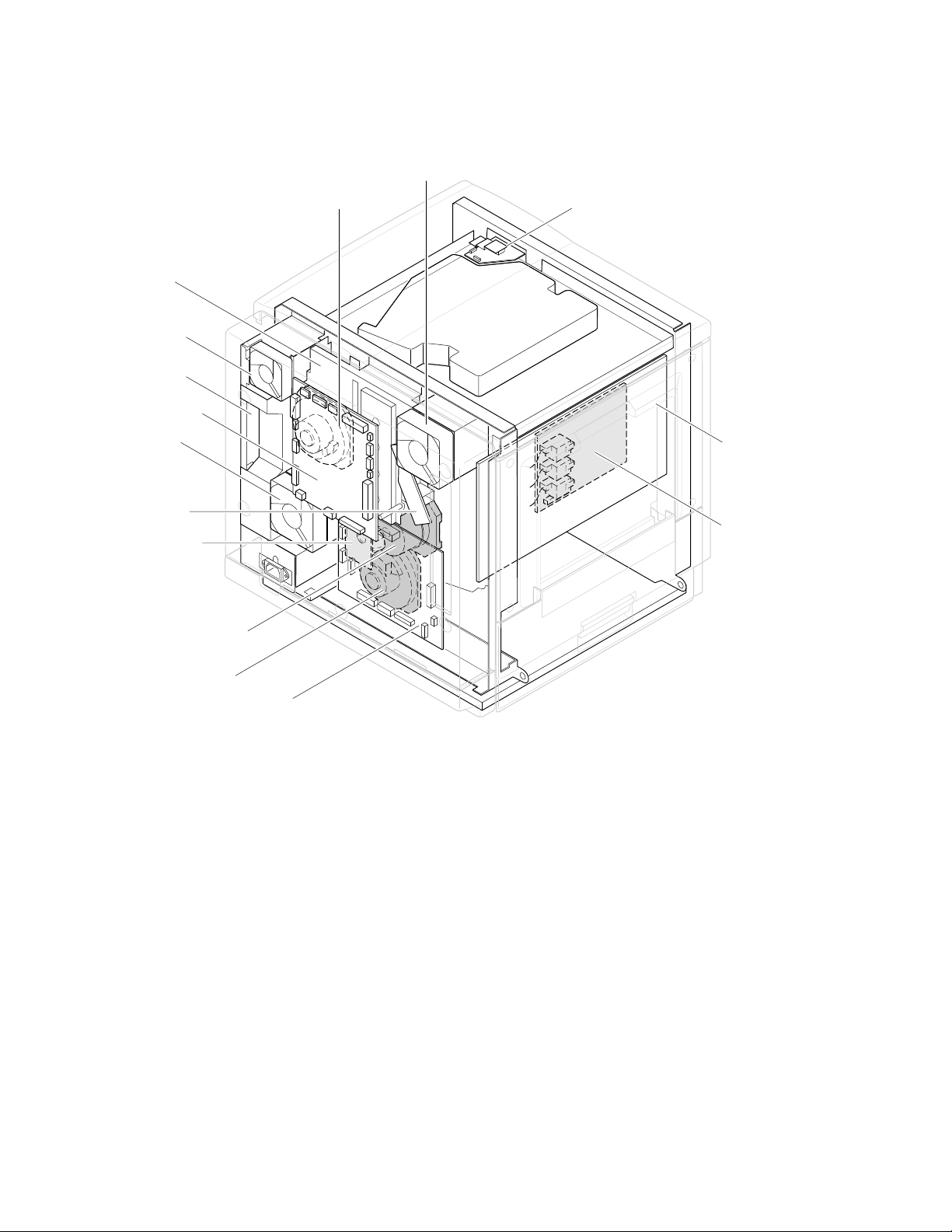

Manual feed

sensor

Accumulator belt

Toner level

sensors

(transmitters)

home position sensor

Image density

sensor

Scorotron

charger

sensor

Pre-transfer

charger

sensor

Toner level sensors

(receivers) are mounted

inside the toner cartridge

driver unit

Front right door

opened switch

Aligning

sensor

Transparency

sensor

(transmitter)

Transparency

sensor

(receiver)

Paper low

sensor*

Paper tray

type sensors

Power switch

*Unused by image processor

Figure 1-4 Print engine sensor, switch and solenoid locations

The photoconductive belt position sensor is not illustrated. This optical sensor

marks the home position of the photoconductive belt. It is mounted inside the

customer-replaceable imaging unit.

Transfer waste

bin sensor

Transfer roller

position sensor

Fuser-installed

switch

Left door opened

switch

Fuser-exit

sensor

Output tray full

sensor

Paper-exit

sensor

Paper-empty

sensor

9322-01

1-6

The logic state of the paper low sensor is not monitored nor used by the image

processor.

Phaser 550 Color Printer

Page 7

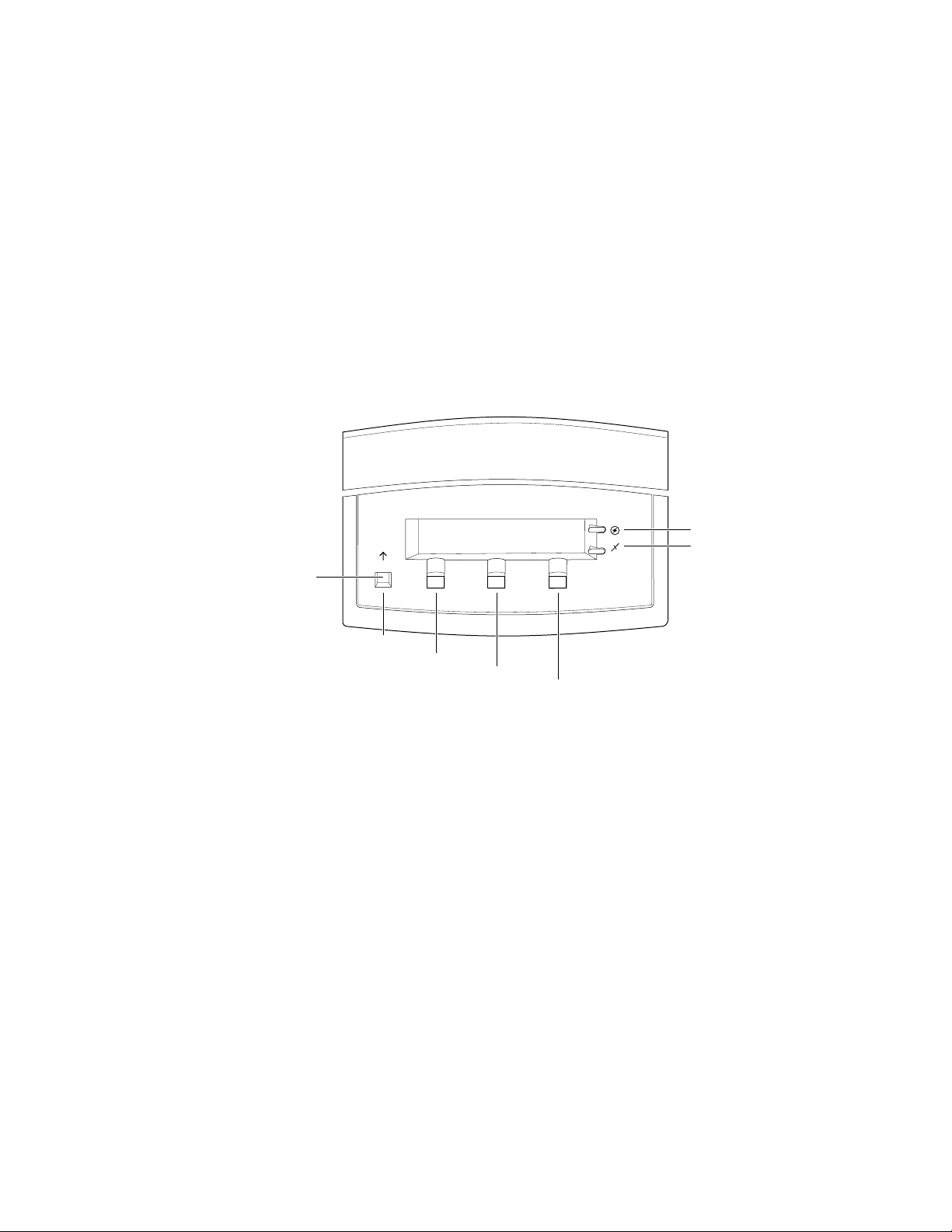

Front panel

General Information

These front panel features are found on the printer:

■

A two-line, 24-character LCD and two LEDs

Four push buttons

■

LCD

The LCD serves two purposes: displaying current controller and print

engine status information and displaying an interactive menu. Status

information includes controller status such as

Printing . Print engine status includes messages such as Out of paper ,

Paper Jam , and Out of toner . The interactive menu can only be entered

while the print engine and controller are idle. The interactive menu allows the

user to review and change certain NVRAM, I/O ports and peripheral

parameters. Using the front panel to review and change parameters is discussed

in Chapter 9, “Checks and Adjustments.”

Buttons

while in the interactive menu. The functions of Buttons 2, 3 and 4 are defined by

the particular menu or function being displayed on the LCD display. The

bottom row of the LCD labels the current function of each button.

Button 1, the left-most button labeled the Exit key, cancels an operation

Ready , Receiving data and

1

In addition, pressing the buttons as you turn on the printer enables certain

diagnostic modes:

Pressing and holding Button 1, as you turn on the printer, skips

■

power-up diagnostics (except for a brief kernel test) and proceeds to

PostScript startup.

■

Pressing and holding Button 2, as you turn on the printer, executes

extended diagnostics.

■

Pressing and holding Button 3, as you turn on the printer, executes

interactive service tests. These are described in “Printer

self-diagnostics” on page 9-6.

The Chapter 9 topic, “Resetting NVRAM” on page 9-31 explains how to use the

front panel buttons to reset the printer’s NVRAM to its factory default values.

Service Manual

1-7

Page 8

General Information

On

1

LEDs

The Power LED indicates the printer has +5 VDC available for its logic

control boards.

The

Error LED has three indications:

■

Off indicates that no errors have been detected.

■

indicates a warning to the user. An explanatory message, such as

Low Paper , is displayed on the LCD.

Blinking indicates an error has been detected. An error message, such

■

Paper Jam at Output , is displayed on the LCD. Error codes

as,

are listed and explained in the Section 6 topic, “Error messages” on

page 6-19.

Power

Error

Exit

Exit

Button 1

Button 2

Button 3

Button 4

9013-06

1-8

Figure 1-5 The front panel and its functions

Phaser 550 Color Printer

Page 9

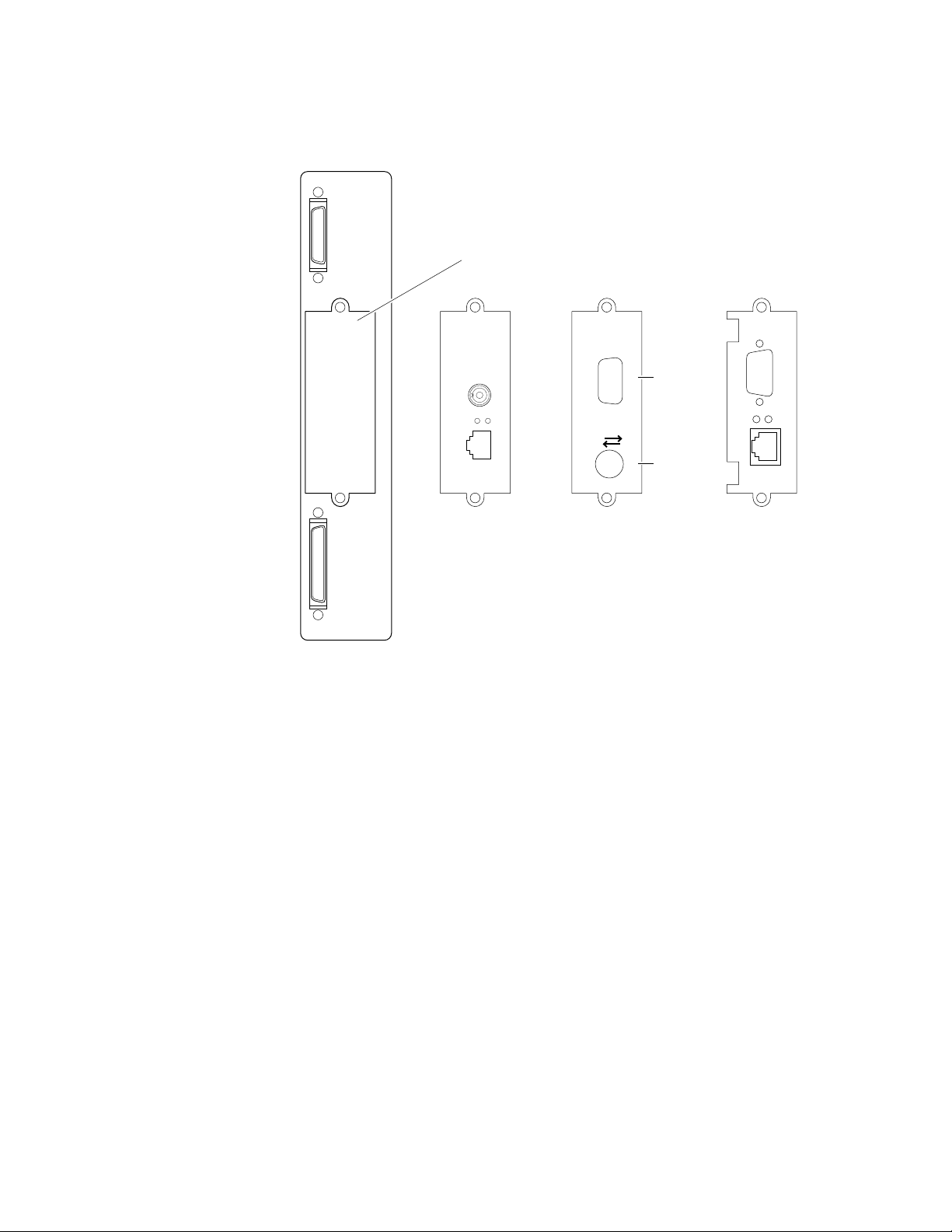

Rear panel

General Information

Connectors

The rear panel of the Phaser 550 printer features the host interface connectors to

the printer. It includes the following connectors:

Standard parallel (high-density connector).

■

■

SCSI high-density connector (font hard disk drive or

Phaser CopyStation only).

With the addition of a network card, the printer can feature either of these

groups of connectors:.

■

ThinNet (10base2) and Twisted Pair (10baseT) Ethernet connectors.

This is Option P1 and P2.

■

RS-232 serial and LocalTalk connectors. This is Option P2

1

Unshielded Twisted Pair (10baseT) and shielded Twisted Pair (DB-9)

■

Token Ring connectors. This is Option P4.

Service Manual

1-9

Page 10

General Information

1

The figure below illustrates the rear panel.

Parallel

SCSI

Smart card slot

for network card

Phaser™ Share

Ethernet Card

10Base2

Link

RX

TX

10Base-T

Option

P1

P2

Figure 1-6 The Phaser 550 rear panel

LocalTalk/Serial Card

Phaser™ Share

Serial LocalTalk®

Option

P3

RS-232

serial

LocalTalk

Token Ring Card

PhaserShare™

Option

P4

9013-05a

Network card LEDs

The Ethernet network card has two LED indicators:

■

■

Note

1-10

Phaser 550 Color Printer

TX indicator (yellow); blinks while data is transmitted to the host. The

LED is off while no data is being sent.

Twisted Pair (10baseT). RX indicator (green); blinks while the

network card is receiving data. The LED is

being received. If the LED is

off steady , then a problem (probably

on steady while no data is

hardware) has occurred at the network hub.

ThinNet (10base2). RX indicator (green); blinks while the network

card is receiving data. The LED is

received. If the LED is

on steady , then a problem (probably hardware)

off stead y while no data is being

has occurred at the network hub.

Do not use both Ethernet connectors at the same time. If both are

used the 10base2 line is ignored.

Page 11

on

on

Test print button

General Information

The Token Ring network card has two LED indicators:

■

Connection (yellow); off when the printer is not inserted into the Token

blinks while the printer is attempting to insert itself into the

Ring,

Token Ring,

Ring Speed (green); off when the card is set for 4 megabits per second

■

(MBPS),

When both LEDs blink, a network card failure has occurred.

■

In the center of the rear cabinet panel is the test print button. Pressing this

button while the printer is idle causes the print engine to print a built-in test

print. The print consists of a field of thin horizontal lines. The print is made

independently of the image processor board. Hold in the test button for at least

4 seconds before releasing, or until you hear the print process begin.

when the printer is properly inserted in the ring.

when the card is set for 16 MBPS.

1

Service Manual

1-11

Page 12

General Information

On

1

Health LED

A health LED indicates the status of the image processor board. The health LED

is mounted on the image processor board and is viewable through the grill

behind the manual feed tray. (The grill is the removable RAM SIMM options

cover.) Once the PostScript code is loaded into memory and the image processor

is initialized and running, the image processor blinks the LED at a one-second

rate.

Blinking (at a steady rate): The printer is operating normally. The LED

■

blinks irregularly during power-up self-diagnostics.

If a soft error occurs, the image processor board operates, but in a

reduced capacity. Soft failures include failure of expansion memory

SIMMs or any of the interface ports. When a soft error occurs, the

printer automatically prints a startup page listing the error.

■

or Off : A hard error condition has occurred that would keep the

image processor board from operating.

Media tray type sensing

The combinations of the three tray sensors “tell” the print engine what type of

paper tray is installed. The tray sensors are located on the left-side interior of

the paper tray slot. Sensor actuators are attached to the bottom end of the tray to

close the appropriate sensor. There are four tray types:

■

Letter (A-size) paper

Letter (A-size) transparency film

■

■ Metric Letter (A4-size) paper

■ Metric Letter (A4-size) transparency film

■ Legal-size paper

Table 1-2 Tray switch sensor combinations

Left switch Middle switch Right switch Tray type

Closed Open Open Letter (A-size) paper

1-12

Closed Closed Open Letter (A-size) transparency film

Open Open Closed Metric Letter (A4-size) paper

Closed Open Closed Metric Letter (A4-size) transparency film

Open Closed Open Legal size paper

Phaser 550 Color Printer

Page 13

General Information

1

Sensor actuators

Middle

Left

Right

Tray sensors

Figure 1-7 Tray switch sensors and actuators

9013-40

Service Manual

1-13

Page 14

1

General Information

Specifications

Table 1-3 Physical dimensions

Dimensions Specification

Height:

Width: 48.3 cm (19 in.) With output tray: 69.6 cm (27.4 in.)

Depth: 48.3 cm (19.5 in.)

45.7 cm (18 in.) With Lower Tray Assembly: 68.6 cm (27 in.)

Weight: Approximately 53.3 kgs (117 lbs.) with Lower Tray Assembly

and consumables installed.

Approximately 39.1 kgs (86.2 lbs.) without Lower Tray

Assembly.

Table 1-4 Printer clearances

Clearances Specification

Top: 7.6 cm (3 in.)

Left: 7.6 cm (3 in.)

Right: 10.2 cm (4 in.) for handling the output tray

Front: Unlimited for removal of consumable

Rear: 15.3 cm (6 in.) for connecting computer cable and pow er cord

Bottom: No obstruction under printer that could block its cooling vents.

Mounting surface

flatness:

Within 2 degrees of horizontal with all four feet in contact with

the table surface.

1-14

Phaser 550 Color Printer

Page 15

General Information

Table 1-5 Functional specifications

Characteristic Specification

Printing process Electro-photographic, four color (CMYK) transfer printing

1

Color medium Four toner cartridges each contain one of four colors: cyan,

Addressability Standard, Fast Color and Presentation

Printing speed Time from paper-load to paper-eject:

Minimum printing

margins

Usable paper A-size (letter) and A4-size (Metric letter) of a good quality

magenta, yellow or black. The toner is a nonmagnetic,

monocomponent contact medium.

mode: 600 x 600 dots-per-inch text and graphics

Enhanced mode: 1200 x 600 dots-per-inch text and graphics

Premium mode: 1200 x 1200 dpi text and graphics

Four-color 3.5 pages per minute at 600 dpi

paper: 1.75 pages per minute at 1200 dpi

Monochrome: 14 pages per minute at 600 dpi

7 pages per minute at 1200 dpi

Four-color transparency: 1.5 pages per minute

Fast color, three-color

(CMY): 5 pages per minute at 600 dpi

Print times do not include image processing time, which can

vary depending on image complexity.

All sides, 5 mm (0.2 ins.).

premium laser printer or copier paper.

Tray feed paper weight: 75 to 105 g/m

Manual feed paper weight: 60 to 120 g/m

Double-sided printing is not supported.

Envelope printing is not supported.

2

(20 to 28 lb.)

2

(16 to 32 lb)

Paper tray capacity 250 sheets using 20-lb. paper. 100 sheets of transparency

film. The optional Lower Tray Assembly also uses trays with

the same capacity.

Service Manual

1-15

Page 16

1

General Information

Table 1-6 Electrical specifications

Characteristic Specification

Primary line voltages 87 to 128 VAC (115 VAC or 100 VAC nominal); 174 to 260

VAC (220 VAC nominal)

Primary voltage

47 to 63 Hz

frequency range

Power consumption 60 watts (fuser off), 850 watts (fuser on) during Ready state,

950 watts during Warm-up, 45 watts during Energy Star state

Primary voltage fusing 110 VAC configuration – 10 amp

220 VAC configuration – 6.3 amp

Secondary DC voltages Image processor:

+ 5 VDC ± 0.25 (1A minimum, 6 A maximum)

± 12 VDC ± 0.6 (100 mA max)

Print engine:

+ 5V ± 0.25 (2.2 A max)

+ 12V ± 0.25 (0.4 A max)

- 12V ± 0.25 (0.1 A max)

+ 24V ± 0.25 (3.0 A max)

RF emissions Both 110 and 220 VAC-configured instruments pass these

standards: FCC Part 15 Class B

VDE Class B

EN55022 (CISPR 22) Class B

VCCI (CISPR 22) Class B

Table 1-7 Environmental specifications

Characteristic Specification

Temperature

Operating

Non-operating

Storage

Humidity

Operating

Non-operating

Altitude

Operating

Non-operating

Vibration/shock

Operating

Non-Operating

(vibration)

Non-operating (shock)

Acoustic Noise

(operating)

10o to 32.5o C (50oto 91oF)

o

0

to 40o C (32o to 104o F)

o

-20

to 60o C (-4

o

to 140o F)

Media should be acclimated 24 hours before using in the

printer.

10 to 80% relative humidity, non-condensing

10 to 90% relative humidity, non-condensing

Media should be acclimated 24 hours before using in the

printer.

0 to 2500 m (8,000 ft.) at 25

0 to 15000 m (50,000 ft.)

(Fuser maximum 4000 m (13,300 ft.)

May drop any side or corner 50 mm (2 in.) without impairment

of subsequent operation.

On five mutually perpendicular axes: 0.5 g, 25-minute sweep,

5 to 200 to 5 Hz, 100 to 200 sec./sweep cycle. No resonant

frequencies below 50 Hz.

30 g, trapezoidal flared pulse, 20 msec each axis.

Aver age sound le vel (LEQ) is less than 53 dbA. Peak noise in

standby mode is 47 dbA.

o

C

1-16

Phaser 550 Color Printer

Page 17

Regulatory specifications

The printer is a recognized component in conformance with the following

regulatory standards:

■ The packaged product meets ASTM D4169-86 and ASTM D4728-87

Transportation Standards.

■ Listed UL 1950 Information Processing and Business Equipment.

■ Certified CSA C22.2 No. 950 Safety of Information Technology

Equipment, Including electrical Business Equipment.

■ GS licensed IEC 950 (1991) Second Edition; EN60950 Information

Processing and Business Equipment.

■ VDE 0871/6.78 (Class B) Regulation for the Radio Frequency Interface

Suppression of High Frequency Apparatus and Installations.

■ VDE 0875, Regulation for RFI Suppression of Electrical Equipment

and Installations

General Information

1

■ EN55022 (CISPR 22) Class B

VCCI (CISPR 22) Class B

■ FCC Class B (for 115 VAC equipment) pursuant to Sub-part J

of Part 15.

Service Manual

1-17

Page 18

Page 19

Appendix

D

Test Pattern Generator

The Test Pattern Generator contains PostScript scripts to start test patterns for a

number of Tektronix color printers. It allows you to test a printer as if it were

receiving a file from a host computer. The test patterns are generated by the

printer's image processor and then printed by the print engine.

Note

The Test Pattern Generator should contain firmware version 1.2 or

higher.

Service Manual

D-1

Page 20

1.

2.

3.

4.

D

Test Pattern Generator

To use the Test Pattern Generator, do the following:

Select a test pattern to be printed using the Test Pattern Generator's

five DIP switches. The following tables lists the available test

patterns.

Plug the Test Pattern Generator onto the printer's parallel port. Use

the parallel cable adapter (013-0299-00) to convert between the Test

Pattern Generator’s Centronics-style connector and the printer’s

new-style, high-density parallel port connector. You do not have to

turn the printer off; you can plug in the Test Pattern Generator “hot.”

Press the Test Pattern Generator's START button. Its green LED

flashes as you press the button.

The printer will print the transmitted print file. The front panel

displays the message “Waiting for data,” with the READY light

flashing, for five minutes after a test print has been sent to the printer.

However, you do not have to wait five minutes before sending

another test print from the Test Pattern Generator; the printer will

accept another test print.

Besides print files, the test pattern generator also allows you to turn off and on

the printer's startup page.

Additionally, the Test Pattern Generator lets you set up a printer for printing

from a 4511A Network Interface. To do so, just select the appropriate DIP switch

setting.

Table D-1 Test Pattern Generator DIP Switch settings for Phaser 550

Pattern or function 1 2 3

Print quality test pattern On On On On On

Blank sheet Off On On On On

Engine Pattern 1

(100%)

Service print 1 Off Off On On On

Blank sheet On On Off On On

Engine pattern 2 (50%) Off On Off On On

Service print 2 On Off Off On On

Enable startup page Off Off Off On On

Disable startup page On On On Off On

On Off On On On

45

D-2

Phaser 550 Color Printer

Page 21

Appendix

C

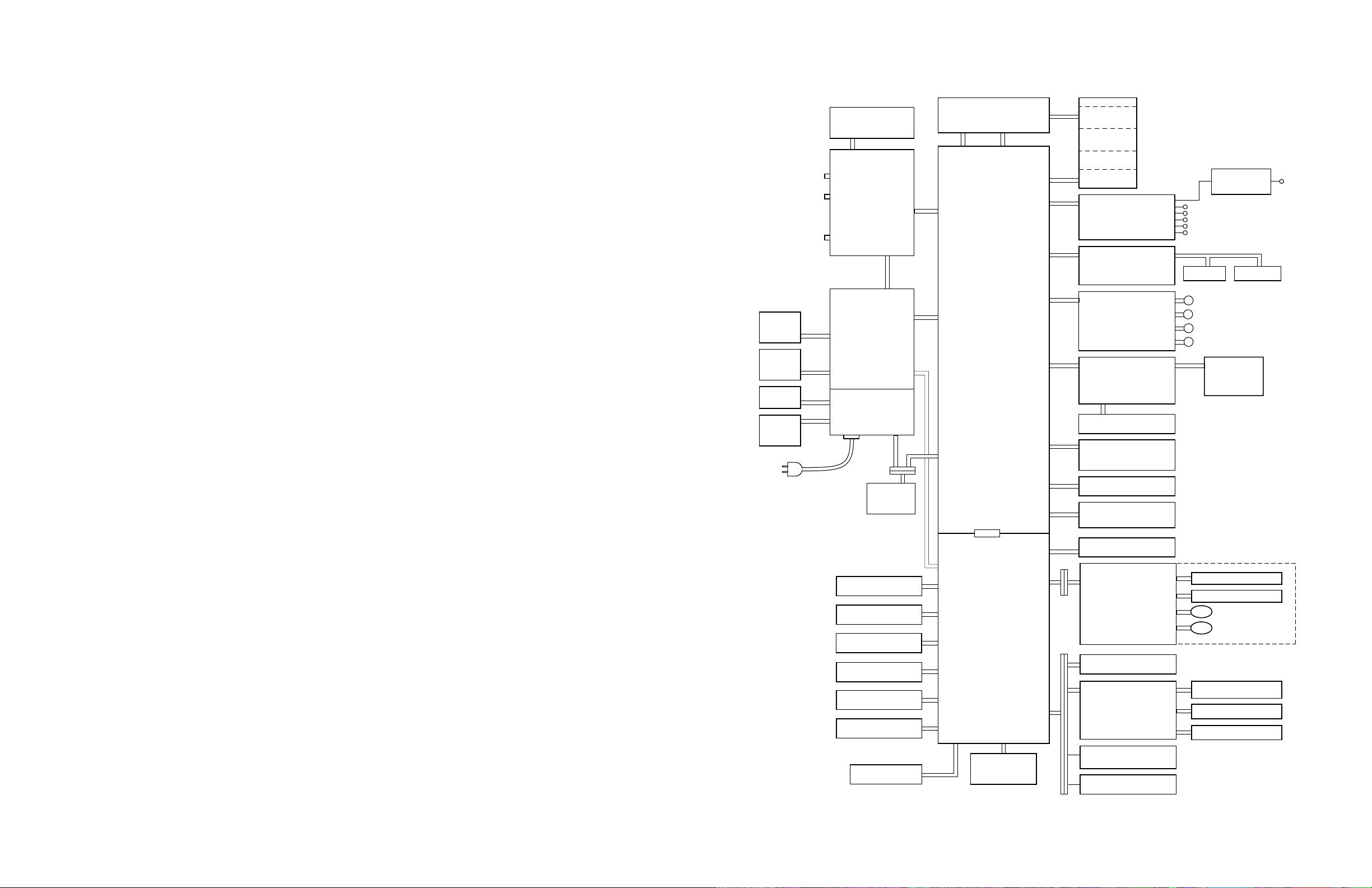

Wiring Diagram

Power

supply

fan

Door-

open

switch

Power

switch

Fuser-

installed

sensor

SCSI

Parallel

Network

card

Front panel

J219

J811

J211

J515

CN 853

CN 851

CN 802

CN 804

Image

processor

CN 854

Power

supply

J511

J921

CN 855

CN 852

CN 805

Laser driver board

CN 1

CN 11

CN 1

CN 5

CN 12

Engine

control

board

CN502

CN 16

CN 4

CN 9

CN 7

CN 6

CN 13

CN 540

Laser

scanner

CN 570

CN 701

High voltage

power supply

board

CN 627

Image density

sensor connector

CN 619

Toner cartridge

level sensor

(Receiver) and

roller clutch

board

CN 625

Charger unit

sensor board

CN 624

Imaging unit

CN 632

Accumulator belt

position sensor

Toner cartridge

sub bias board

FTR Orange

DEV Yellow

STR Black

CHG Red

GRID Blue

CN 628

BK sensor

CN 620

CN 621

CN622

CN623

CN 626 CN 630

B

Y

M

C

Pre-exposure

lamp

CMY sensor

Fuser

Left door closed

sensor

Fuser fan

Paper-feed motor

Developer cartridge

drive motor

Main motor

Cleaning board

Paper tray switches

CN 618

CN 307

CN 312

CN 304

CN 306

CN 305

CN 313

CN 302

CN 311

CN 2

CN 301

Engine

driver

board

CN 310

Optional

lower tray

assembly

CN 14

CN 17

CN 303

CN 309

CN 308

Ozone fan

Toner cartridge level

(transmitter) sensor

Pre-transfer lamp

CN 601

Paper

feeder

Exit tray full

CN 617

sensor

CN 611

Exit roller

sensor board

Toner cartridge

CN 615

movement sensor

CN 616

Cam motor

board

CN 603

CN 602

CN 606

CN 605

CN 614

CN 612

CN 613

Paper-pick sensor

Aligning sensor

Transfer roller solonoid

Aligning roller clutch

Fuser exit

CN 610

sensor

Switchback solenoid

Face switching solenoid

9322-65

Figure C-1 Wiring diagram

Service Manual

C-1

Page 22

Page 23

Contents

1 General Information

The Phaser 550 Color Printer 1-2

RAM and printer capabilities 1-3

Print engine assemblies 1-4

Front panel 1-7

Rear panel 1-9

Network card LEDs 1-10

Test print button 1-11

Health LED 1-12

Media tray type sensing 1-12

Specifications 1-14

Regulatory specifications 1-17

2 Installing the Printer and Drivers

Pre-install questions for customers 2-2

Unpacking 2-5

Printer inventory 2-5

Accessory box 2-5

Setting up the printer 2-7

Installing SIMM memory 2-7

Installing a font SIMM 2-7

Installing a network card 2-7

Cabling the printer 2-8

Connecting the printer to a Macintosh 2-8

LocalTalk connection to a Macintosh 2-8

Ethernet connection to a Macintosh 2-8

Connecting the printer to a PC 2-9

Direct connection to a PC 2-9

Networked connection using the Ethernet port 2-9

Networked connection using the Token ring port 2-9

Connecting the printer to a workstation 2-10

Direct connection to the workstation 2-10

Networked connection to a workstation 2-10

Networked connection using the Token Ring port 2-10

Connecting an optional SCSI hard disk drive to the printer 2-11

Connecting the optional CopyStation to the printer 2-12

Turning on the printer 2-13

The startup page 2-13

The configuration page 2-14

Service Manual

v

Page 24

vi

Driver and communication set up 2-21

Loading the LaserWriter PPD file 2-21

Installing a printer driver for Microsoft Windows 95 2-22

Installing the Tektronix driver for Windows 3.1 2-24

If you have other Tektronix printer drivers already installed 2-24

Configuring the Tektronix Windows printer driver 2-25

Updating the standard Microsoft Windows PostScript driver 2-27

Installing the printer driver for OS/2 Version 2 2-28

Setting the printer’s IP address using the front panel 2-30

Configuring the printer's serial port for a PC 2-31

Using printcap to configure a workstation for the printer's serial port 2-33

Configuring a Novell NetWare server for the printer 2-34

Configuring TCP/IP on a UNIX host 2-35

3 Verifying the Printer and Host Connections

Macintosh verification 3-1

Selecting the printer via the Chooser 3-1

Printing the directory from a Macintosh 3-3

Verifying that an application communicates to the printer 3-4

Using the Error Handler utility 3-4

PC verification 3-5

DOS connection verification 3-5

Windows 95 driver verification 3-5

Windows 3.1 driver verification 3-6

OS/2 connection verification 3-6

Novell NetWare verification 3-7

Send a print file to the printer 3-7

Using the Error Handler utility 3-8

Workstation verification 3-9

Verifying connection and printing using TCP/IP protocols 3-9

Using the Error Handler utility 3-10

Phaser 550 Color Printer

Page 25

4 Key Operator Training

Overview 4-1

Printer controls and indicators 4-2

Loading media 4-3

Customer-replaceable consumables 4-4

Imaging unit 4-4

Toner cartridges 4-4

Transfer roller 4-4

Fuser 4-4

Clearing paper jams 4-5

Cleaning 4-5

Warranty information 4-6

Service support 4-6

Supplies ordering 4-7

If you need help 4-7

Using the automated fax systems 4-7

Tektronix Color Printer Information Server 4-10

Customer Support Hotline 4-10

Service support 4-11

Electronic bulletin board service 4-11

5 Theory of Operation

Overview 5-1

Functional block diagram 5-2

Laser imaging 5-4

Overview 5-4

Pre-exposure 5-6

Electrostatic charging 5-7

Laser exposure 5-8

The laser scanner 5-9

Toner pickup (development) 5-10

Toner transfer to the accumulator belt 5-11

Paper picking 5-12

Toner transfer to paper 5-13

Fusing and exiting 5-14

Print modes 5-15

Printer color correction 5-16

Power supply 5-17

Image processor 5-18

Image rendering technology 5-18

Service Manual

vii

Page 26

6 Troubleshooting

System power-up sequence 6-1

Print engine troubleshooting 6-2

Testing the print engine 6-2

Verifying printer operation by using its self-test print 6-3

Verifying power supply operation 6-3

Measuring power supply voltages 6-3

Inspecting the power supply fuses 6-5

Safety interlocks 6-5

Testing for a shorted motor 6-6

Testing motor resistances 6-7

Media jams and the paper path 6-8

Media-based problems 6-8

Media problems 6-8

Multiple-sheet pick 6-8

The printer is not distinguishing between paper and transparency film 6-9

The media skews passing through the paper path 6-9

Paper tray indicates empty when it is not 6-10

No paper feeder installed 6-10

No imaging unit installed 6-10

Jams 6-11

Paper mis-picks at the paper tray 6-11

Paper jams midway in the paper feeder 6-11

Paper jams at the second bias transfer roller 6-12

Fuser jams 6-13

Eject jams 6-13

Manual feed jams 6-14

Other problems 6-15

The printer continuously displays “Initializing” 6-15

Transfer roller waste tray indicates not full when it is 6-15

No toner cartridge installed when it is 6-16

No fuser installed when it is 6-16

Front door open when it is closed 6-16

Left-side door open when it is not 6-16

High temperature error 6-17

Low temperature error 6-17

High voltage error 6-17

Thermistor open error 6-18

Power supply fan does not run 6-18

Front Panel Cycling between READY and WARMING UP 6-18

viii

Phaser 550 Color Printer

Page 27

ix

Error messages 6-19

Print engine error codes 6-19

Printing and print quality problems 6-24

Blank print 6-24

All-black print 6-24

Missing primary color 6-25

Light print 6-25

Repeated spots or lines on print in-line with each other 6-26

Dark vertical line in print 6-26

Missing primary color on one side of print 6-26

White horizontal line or band in all the colors of a print 6-27

White vertical lines in the print 6-27

Dirty background 6-27

Mis-transfer, missing portions of toner 6-27

Partial black dots 6-27

Dark, irregular steaks in all colors 6-28

Ghosting 6-28

Unfused or partially fused printing 6-28

Image is skewed on the paper 6-28

Stains on the back of the print 6-29

No printing on edge of print 6-29

Image is not centered on the print when it should be 6-29

The print is wrinkled 6-30

Macintosh printing problems 6-31

Image never prints 6-31

Image prints in black-and-white 6-31

Image is rotated 90 degrees 6-31

Printer isn’t in the Chooser 6-32

PC DOS printing problems 6-32

Image never prints 6-32

Windows printing problems 6-34

Image never prints 6-34

Blue color on the screen is printing too purple 6-34

Windows message “Problem writing device LPT1: Cancel or Retry” 6-34

Workstation printing problems 6-35

Image never prints 6-35

Service Manual

Page 28

x

7 Cleaning and Maintenance

Service preventive maintenance procedure 7-1

Recommended tools 7-1

Cleaning 7-2

Lubrication 7-2

8 FRU Disassembly/Assembly

Required tools 8-1

The printer cabinet 8-2

Upper rear cover 8-2

Lower rear cover 8-2

Top cover 8-2

Left door (for paper feeder access) 8-2

Left side cover 8-2

Manual feed tray 8-2

Front door 8-4

Upper and lower front covers 8-4

Bottom front cover 8-4

Front panel board 8-4

Toner level sensor board 8-4

Right side covers (front, rear and lower) 8-5

Paper feeder 8-6

Paper tray sensor board 8-6

Cartridge selector/eject unit (right door) 8-8

Laser scanner 8-9

Laser motor drive board 8-10

Power supply 8-11

Fuser installed switch 8-11

Power supply fuse 8-13

Printer rear assemblies 8-14

Engine control board 8-14

Engine driver board 8-14

Charger sensor board 8-15

Main motor 8-16

Paper feed motor 8-16

Cleaning board 8-16

Toner cartridge drive unit 8-18

Home position sensor assembly and the left door opened switch 8-18

Phaser 550 Color Printer

Page 29

xi

High-voltage board 8-20

Pre-exposure lamp 8-21

Pre-transfer lamp 8-21

Toner auto-density sensor 8-21

Image processor board 8-23

Installing RAM SIMMs 8-24

Installing an Extended Features SIMM 8-26

Installing a network card 8-28

Enabling TCP/IP with the authorization code 8-29

Replacing the code ROM SIMM 8-30

9 Checks and Adjustments

Required tools 9-1

Front panel menu 9-2

Printing test prints 9-4

Print service test prints 9-4

Printing the configuration page 9-4

Printing the demonstration pages 9-4

Printing the print engine’s test print 9-4

Image processor normal indicators 9-5

Image processor hard and soft error indicators 9-5

Printer self-diagnostics 9-6

Service mode status code meanings 9-11

Resetting NVRAM 9-31

Print engine calibration 9-32

Printer color correction 9-32

Starting printer semi-automatic color correction 9-32

Manually setting color corrections 9-32

Checking print registration 9-34

A Field Replaceable Units List

B Test Prints

C Wiring Diagram

D Test Pattern Generator

Index

Service Manual

Page 30

Figures

Figure 1-1

Figure 1-2

Figure 1-3

Figure 1-4

Figure 1-5

Figure 1-6

Figure 1-7

Figure 2-1

Figure 2-2

Figure 2-3

Figure 5-1

Figure 5-2

Figure 5-3

Figure 5-4

Figure 5-5

Figure 5-6

Figure 5-7

Figure 5-8

Figure 5-9

Figure 5-10

Figure 5-11

Figure 5-12

Figure 5-13

Figure 5-14

The Phaser 550 Color Printer 1-1

Print engine major components 1-4

Print engine components (continued) 1-5

Print engine sensor, switch and solenoid locations 1-6

The front panel and its functions 1-8

The Phaser 550 rear panel 1-10

Tray switch sensors and actuators 1-13

The Phaser 550 and its packaging 2-6

Connecting a SCSI hard disk drive to the Phaser 550 2-11

Connecting a CopyStation to the Phaser 550 2-12

Block diagram of the printer 5-2

Laser printing process overview 5-5

Pre-exposing the photoconductive belt 5-6

Electrostatic charging of the photoconductive belt 5-7

Laser exposure of the photoconductive belt 5-8

The laser scanner 5-9

Toner pickup 5-10

Toner transfer to the accumulator belt 5-11

Paper picking 5-12

Transferring toner to the paper 5-13

Fusing the toner to the paper 5-14

Print modes and printing dots 5-15

The power supply 5-17

The image processor graphics pipeline 5-19

Figure 6-1

Figure 6-2

xii

Measuring the DC voltages (test points) 6-4

Door safety interlock switches 6-6

Phaser 550 Color Printer

Page 31

Figure 8-1

Figure 8-2

Figure 8-3

Figure 8-4

Figure 8-5

Figure 8-6

Figure 8-7

Figure 8-8

Figure 8-9

Figure 8-10

Figure 8-11

Figure 8-12

Figure 8-13

Figure 8-14

Figure 8-15

Figure 8-16

Figure 8-17

Figure 8-18

Removing cabinet covers 8-3

Removing cabinet covers 8-5

Removing the paper feeder and the paper tray sensor board 8-7

Removing the cartridge selector/eject unit 8-8

Removing the laser scanner 8-9

Removing the laser modulation board 8-10

Removing the power supply and the fuser installed switch 8-12

Replacing the power supply fuse 8-13

Removing the engine control, engine driver and charger sensor boards 8-15

Removing the main motor, paper-feed motor and cleaning board 8-17

Removing the toner cartridge drive unit, home position sensor and

the left door interlock switch 8-19

Removing the high-voltage board 8-20

Removing the pre-exposure lamp, pre-transfer lamp and toner auto-density sensor 8-22

Removing the image processor board 8-23

Installing RAM SIMMs 8-25

Installing an extended feature SIMM 8-27

Installing a network card in the printer 8-28

Installing the code ROM SIMM 8-30

Figure 9-1

Figure 9-2

Figure 9-3

Figure 9-4

Figure 9-5

Figure A-1

Figure A-2

Figure A-3

Figure C-1

Menu map 9-2

Menu map 9-3

Status codes diagnostic tree 9-11

Manual color correction reference print 9-33

Checking the registration of the toner layers 9-34

Cabinet FRUs A-2

Cabinet FRUs A-3

The internal printer A-5

Wiring diagram C-1

Service Manual

xiii

Page 32

Tables

Table 1-1

Table 1-2

Table 1-3

Table 1-4

Table 1-5

Table 1-6

Table 1-7

Table 2-1

Table 2-2

Table 6-1

Table 6-2

Table 9-1

Table 9-2

Table A-1

Table A-2

Table A-3

Table A-4

Installed RAM and printer capabilities 1-3

Tray switch sensor combinations 1-12

Physical dimensions 1-14

Printer clearances 1-14

Functional specifications 1-15

Electrical specifications 1-16

Environmental specifications 1-16

Configuration page settings for the Phaser 550 2-14

Values for modifying the DEVPARAMS.PS file 2-32

Motor and solenoid resistances 6-7

Print engine service error codes 6-19

Print engine service test descriptions 9-8

Status code meanings 9-12

FRU parts list of the printer cabinet A-2

FRU part list of the printer cabinet A-3

FRU parts list of the exploded printer A-4

Supplies and accessories A-6

Table D-1

xiv

Test Pattern Generator DIP Switch settings for Phaser 550 D-2

Phaser 550 Color Printer

Page 33

Appendix

B

Test Prints

This appendix illustrates the test prints produced by the print engine. It also

illustrates a number of defective prints and the reason for the defects. The

Chapter 6

page 6-24 discusses solutions to the problems shown in this appendix.

Test Print consists of four 25% tint primary color bands. Service Print 1 prints out

four 25% tint full page fills, each page one primary color. Service Print 2 shows

1200 dpi printing.

From the Help Pages menu in the front panel, select Test Print

From the Help Pages menu in the front panel, select Service Print 1

Troubleshooting topic “Printing and print quality problems” on

Black

Test Print

<--- ---> Print

Service Print 1

<--- ---> Print

Power

Error

Power

Error

Cyan

Magenta

=

Yellow

Imaging Unit XXXX

Corona Wire XXXX

Test Print

Transfer Kit XXXX

Fuser XXXX

=

Black Cyan Magenta Yellow

Single color mottled or with non-uniform density streaks.

If a single color displays a mottled appearance or if a single color

shows many vertical streaks of varying densities, then that color’ s

toner cartridge is running of toner. Replace the cartridge.

Service Manual

B-1

Page 34

Test Prints

Vertical line or scratch in print, single color

If the scratch is of one missing primary color, then the trouble can

usually be traced to a scratch in the developer roller of the

missing toner’s toner cartridge. No toner is transferred from the

developer roller to the photoconductive belt at the defect point.

Vertical line or scratch in print, all colors

The problem may be caused by contamination on the laser

window where the laser beam exits the laser scanner and enters

the imaging unit. Since the b loc k ed laser beam cannot discharge

the portion of the photoconductive belt it cannot reach, toner will

not transfer to those portions of the belt. Consequently a blank,

vertical line will appear on the prints in all colors. Remove the

imaging unit and, with a squeeze bulb, blow any dust or toner off

of the window (located in the “ceiling” of the cavity left in the

printer once the imaging unit is removed).

If it is in all colors then the problem may be in the imaging unit,

such as a scratched photoconductive belt. Replace the imaging

unit.

A very thin, white line could be caused by a scratched roller in the

fuser which replacing will solve. The scratch in the print may not

be continuous but rather a set of in-line vertical scratches. If the

scratches are about 5 inches (12.5 cm) apart, then the problem is

a scratch on the fuser roller. Replace the fuser.

Lastly a protrusion of some kind in the paper path could be

scratching the print.

B

Dark vertical line in print, single color

If the line is of one primary color, then the trouble can usually be

traced to a defect in the color’ s toner cartridge. Too much toner is

transferred from the developer roller to the photoconductive belt

at the defect point.

Vertical line in print, all colors

The problem may be caused by contamination on the laser

window where the laser beam exits the laser scanner and enters

the imaging unit. A b locked laser beam problem can appear as a

fuzzy, vertical line running through the entire print.

Service Manual

B-2

Page 35

Test Prints

Small, repeating light dot in one color

This can usually be traced to a dent-like defect in the developer

roller of the toner cartridge in question. The dents should be

1.5 inches (3.4 cm) apart or 1 inch (2.5 cm) for 1200 dpi printing.

No toner is transferred from the developer roller to the

photoconductive belt at the defect point.

If the sports are about 5 inches (12.5 cm) apart, then the problem

is a defect on the fuser roller. Replace the fuser.

In some instances, the spots may be dark instead of white. They

may also be shaped something other than round.

B

Single light, horizontal line in all the prints

This is probably caused by a defective photoconductive belt onto

which toner will not transfer. Replace the imaging unit.

Service Manual

B-3

Page 36

Test Prints

Large, random light smudges

Spots such as those illustrated are caused by fingerprints on the

photoconductive or accumulator belt. Often, the smudges will

gradually fade with additional printing. Alternately, the imaging

unit will have to be replaced.

Finger prints can be removed by applying some toner (any color)

to the fingerprints and rubbing lightly with a cotton-tipped swab.

Don’t remove the toner. The printer will remove the toner with its

the cleaning blade.

ambient light for more then a minute.

Remember not to expose the imaging unit to

B

One or more dark vertical line in all colors

This can often be traced to a dirty scorotron charger (main

charger) corona wire. Contamination (dust or toner) interferes

with the flow of electrons from the wire to the photoconductive

drum. Toner is then transferred to the area of low electron charge

and consequently to the accumulator belt and finally the print.

Remove the scorotron charger from the imaging unit and clean

the charger’s corona wire. Replace the scorotron charger, if

necessary. If this fails to correct the problem, replace the imaging

unit.

Service Manual

B-4

Page 37

Test Prints

Faded, pale prints

The imaging unit is old or has been exposed to too much room

light. Replace the imaging unit.

The image density sensors are not properly measuring the

amount of toner transferred to the accumulator belt. Clean or

replace the sensors.

The high-voltage board is not outputting sufficient voltage to the

second bias transfer roller, causing poor transfer of toner to

paper. Likewise, low voltage to the toner cartridge will cause

insufficient transfer of toner to the photoconductive belt.

The beam from the laser scanner is weak and is not properly

exposing the photoconductive belt. Poor laser exposure results

in the negative charges remaining on the drum instead of being

“erased” by the laser beam, thereby retarding toner transfer from

the toner cartridges. Replace the laser scanner.

B

Dark, vertical streaks and smears on the entire page

This is usually due to the accumulator belt toner waste bin being

filled and spilling out on the belt. The spilled toner is then being

transferred to the print. Most prominent in the middle of the print

and in the yellow band. A defective cleaning blade could also

cause this. In either case, replacing the imaging unit should fix

the problem.

Service Manual

B-5

Page 38

Test Prints

One primary color faded or pale OR a single color has a dark

vertical streak

This indicates a problem with a single toner cartridge. Replacing

the toner cartridge should fix the problem.

If it does not, there may be a problem with the toner cartridge

selector/eject unit. It may not be pushing the cartridge quite far

enough to make proper contact with the photoconductive belt,

resulting in poor toner transfer. Replace the toner cartridge

selector/eject unit.

Lastly, poor electro-mechanical contact my be the problem,

although this usually shows itself as light, horizontal streaks and

lines. Replace the toner cartridge biasing assembly.

B

Single white spot appear in the same place on the print

This indicates a bad spot has developed on the imaging unit’s

photoconductive belt which will not transfer toner. The imaging

unit must be replaced. If the spot appears to migrate vertically

from print to print then the defect is on the imaging unit’s

accumulator belt. In either case the imaging unit must be

replaced.

Service Manual

B-6

Page 39

Test Prints

Contamination of one color by another

This is most noticeable on solid primary fills. This is caused by a

defective photoconductive cleaning blade. The blade is not

scraping off all of the untransferred toner from the previous pass

of the photoconductive belt to the accumulator belt prior to the

next toner’s transfer to the photoconductive belt. Replacing the

imaging unit corrects this problem.

Rarely, a sheet of paper can become folded and jam in the

imaging unit, smudging the image.

B

A single color is cut off, with a jagged edge, on either the left

or right side.

The toner cartridge above the missing color is keeping that

color’s toner cartridge from fully opening its door.

If the symptom appears in yellow, fix or replace the black toner

cartridge.

If the symptom appears in magenta, fix or replace the yellow

toner cartridge.

If the symptom appears in cyan, fix or replace the black magenta

cartridge.

Service Manual

B-7

Page 40

Test Prints

Interpreting Service Print 2

1

2

5

Service Print 2 is useful for evaluating the condition of the

3

imaging unit. With a properly functioning imaging unit and printer ,

you should see the following:

1. Diagonal lines. These two lines should be smooth and

unbroken.

2. Crosshairs. A thin white crosshair should be visible in each

block square. As the photoconductive belt ages and fatigues,

the crosshair in the top box will disappear followed in time by

4

6

the lower crosshairs. The belt may “rejuvenate” after a few

hours of non-use, but this will only last for a few prints before

fatigue sets in again.

3. Fine parallel lines. Distinct parallel lines, both horizontal and

vertical, should be viewable. No mottling or b lending should be

seen. All vertical lines should be identical in appearance and

thickness to their horizontal counterparts.

4. 2 pt. text. The 2point te xt, the smallest printed on the test print,

should be easily readable.

5. Registration. Thin horizontal composite black lines will show

misconvergence if each pass of the accumulator belt does not

properly register with each pass of the photoconductive belt.

6. Blended fills. The fills should be smooth and e v en in both the

primary and secondary color fills.

B

9013-74

Service Manual

B-8

Page 41

Index

A

Adobe PostScript Level 2

all-black print

antistatic mat

authorization code, TCP/IP

6-24

8-1

1-2

8-29

B

black print

blank print

block diagram of printer

6-24

6-24

5-2

C

checking print registration

5-16

2-14

2-3

cleaning the printer

clearances, printer

color correction

communication parameters

serial and parallel ports

communication setup

configuration page

description

printing

configuring

a Novell server for the printer

TCP/IP

connecting

the printer to an Ethernet network

the printer to the Macintosh

the printer to the PC

to a Token Ring network

connectors, rear panel

Customer Support Hotline

9-4

2-35

7-1

,

2-21

1-9

9-32

2-9

9-34

2-8

4-10

2-9

2-8

2-34

2-9

F

Fast Color

field replaceable units list

Font Downloader Utility

front panel

FRUs

1-2

A-1

2-11

9-2

6-19

A-1

1-7

description

menu

messages

parts list

removal and replacement

8-1

G

Graphics Supplies Order Desk

grease

7-2

2-3

H

HAL, automated fax system

hard error

health LED

Highly Automated Library (HAL)

1-12

1-12

4-7

I

image processor board

theory

troubleshooting

imaging unit, do not expose to light

interface cables

IP address, setting

5-18

2-3

9-5

2-30

J

jams

6-11

,

2-4

4-7

4-4

D

driver and communication setup

E

electrically-conductive grease

engine failure codes

EuroHAL, automated fax system

6-19

7-2

2-21

4-8

K

key operator, training

4-1

L

laser electrophotography

2-11

1-2

5-4

laser printing, theory

6-25

7-2

5-9

laser scanner

Laserwriter Utility

legal-size printing

light print

lubrication

5-4

Service Manual

Index-1

Page 42

M

Macintosh

connecting the printer

printing

using the Error Handler Utility

measuring power supply voltages

media problems

Microsoft Windows

standard PostScript printer driver

missing color

molybdenum-based grease

3-1

6-25

6-8

2-8

7-2

3-4

6-3

2-27

N

network card

1-10

1-2

8-28

2-33

2-34

3-7

description

installing

LEDs

normal power-up self-test, image processor

Novell configuration

Novell Netware verification

null modem cable

O

OS/2

connection verification

loading drivers

2-28

3-6

P

paper path jams

paper picking, theory

PC

connecting the printer

using the Error Handler Utility

PC verification

PCL printer language, optional

Phaser 550 PPD file, installing

Phaser 550,description

photoconductive belt

PostScript Level 2

power supply

theory

verifying

5-17

6-3

3-5

6-8

1-2

5-12

1-2

5-4

2-9

1-2

2-21

3-8

9-7

power-up sequence

pre-exposure during laser printing

pre-installation interview

Presentation mode

pre-transfer corona

preventive maintenance

print modes, description

print quality problems

print registration, checking

printcap file

printer color correction

printer page description file

printer, troubleshooting

printing

from a

from a PC

from a workstation

test prints

the configuration page

the startup page

2-33

3-1

6-1

2-1

1-2

1-4

7-1

5-15

6-24

9-34

9-32

3-4

6-1

3-5

3-9

9-4

9-4

9-4

R

RAM and printer capabilities 1-3

RAM SIMMs, installing

rear panel

connectors

description

registration, checking

regulatory standards

removal procedures

repeated spots or lines on print

required tools, disassembly

resetting NVRAM, image processor

1-10

1-9

8-24, 8-26

9-34

1-17

8-1

6-26

8-1

5-6

9-31

Index-2

Phaser 550 Color Printer

Page 43

S

safety interlock 6-5

SCSI address

SCSI hard disk drive, installing on the

self-test modes, image processor

self-test print

sensing media

Service Option S0

service support, calling

skewed copy

smart cards

soft error

Standard Windows PostScript driver,

startup page

description

printing

supplies, ordering

2-11

printer

2-11

6-3

1-12

6-9

1-2

1-12

updating

2-13

9-4

9-6

2-1

4-11

2-28

4-7

T

TCP/IP

configuring

enabling

verification of printing

terminator, SCSI

Test Pattern Generator, using

test print button

test prints

descriptions and interpreting

printing

testing the print engine

theory of laser printing

time-outs, Windows

Token Ring, connecting a printer to

toner cartridges during printing

transmission retry, Windows

tray sensors

troubleshooting

the image processor

the printer

2-35

8-29

3-9

2-11

D-1

1-11

B-1

9-4

6-2

5-4

2-26

2-9

5-10

2-26

1-12

9-5

6-1

U

using the Error Handler utility

for Macintosh

3-8

for PC

for workstation

3-4

3-10

V

verifying

a PC can print

a workstation can print

using the TCP/IP protocols

3-5

3-9

W

white print 6-24

Windows 3.1

driver verification

Tektronix driver

Windows 95 printer driver

Windows printer driver

configuring

installing

workstation

connecting the printer

using the Error Handler Utility

workstation verification

wrinkled print

2-25

2-24

6-30

3-6

2-24

2-22

2-9

3-9

3-9

3-10

Service Manual

Index-3

Page 44

Page 45

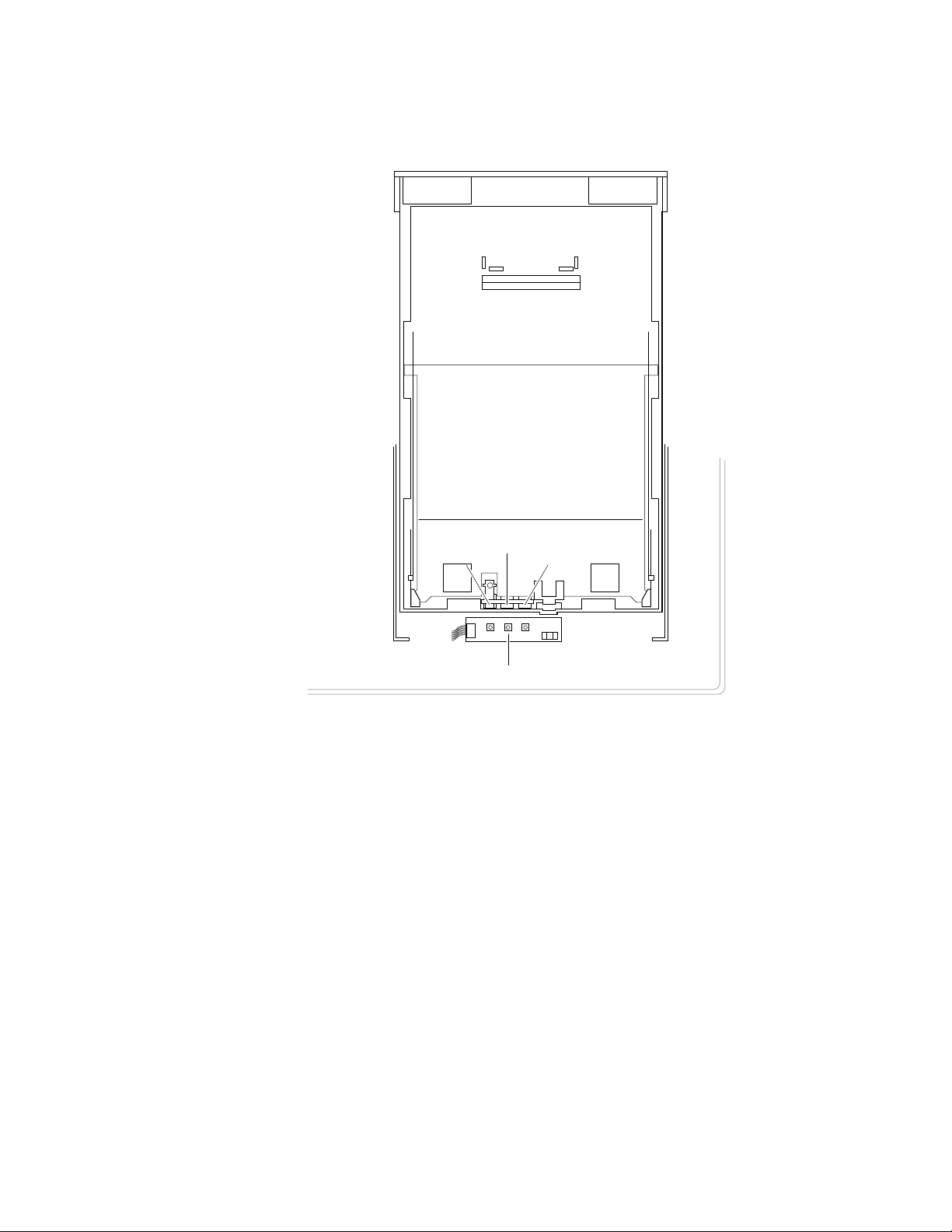

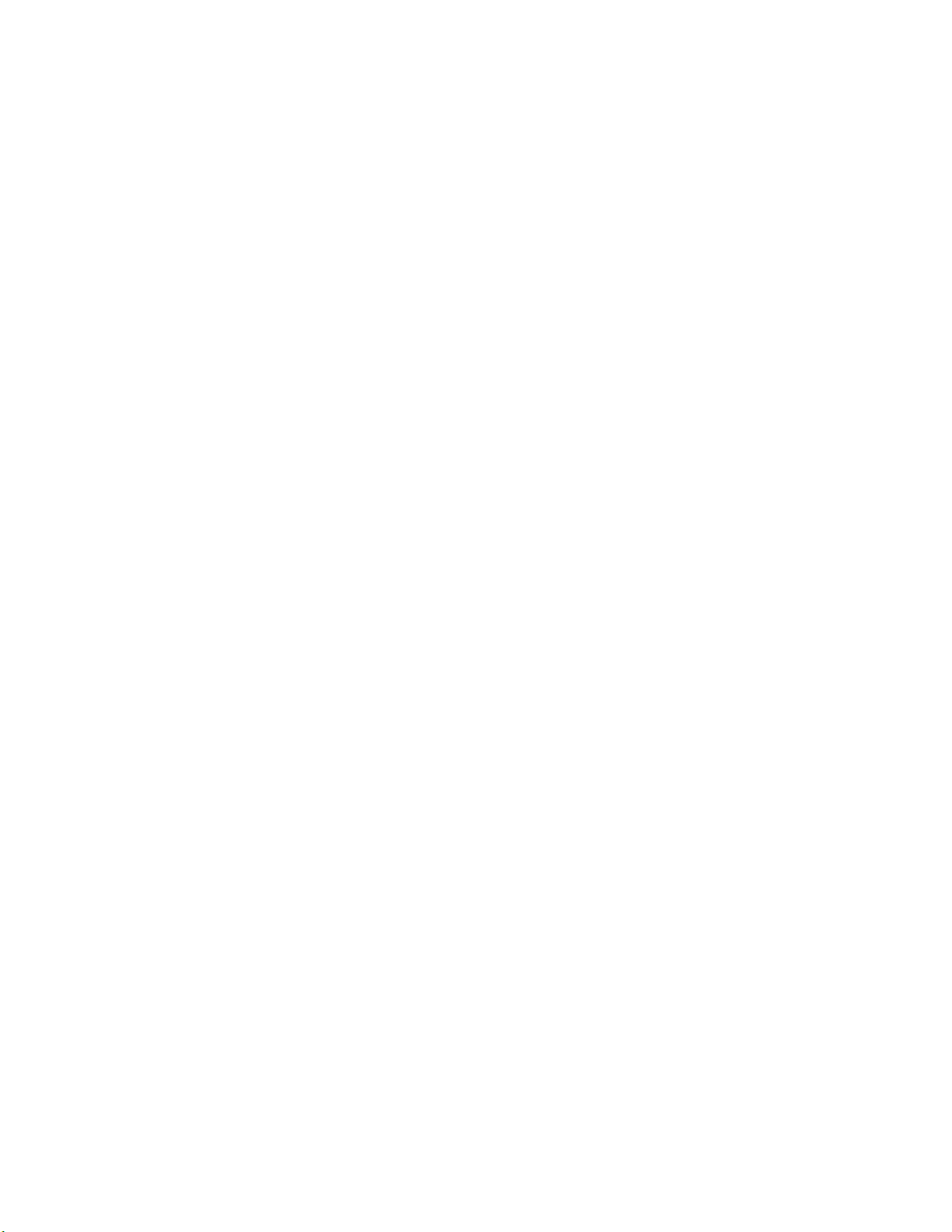

A

Figure A-3 The internal printer

7

6

4

5

28

8

9

10

11

13

14

12

25

26

3

2

1

20

27

24

23

22

21

30

19

18

17

15

31

16

Service Manual

9322-72

A-5

Page 46

A

Table A-4 Supplies and accessories

Part number Serial number

Effective Discontinued

Supply 016-1457-00 Imaging unit

Supply 016-1323-00 Fuser (110 VAC)

Supply 016-1354-00 Fuser (220 VAC)

Supply 436-0282-00 Paper tray, Letter-size

Supply 436-0283-00 Paper tray, A4-size

Supply 436-0314-00 Paper tray, Legal-size

Supply 436-0284-00 Transparency tray, Letter-size

Supply 436-0285-00 Transparency tray, A4-size

436-0297-01 Output tray (standard)

119-4799-01 Lower Tray Assembly (no trays supplied)

070-9317-00 Phaser 550 User Manual (English)

070-9317-10 Phaser 550 User Manual (French)

070-9317-20 Phaser 550 User Manual (Italian)

070-9317-30 Phaser 550 User Manual (German)

070-9317-40 Phaser 550 User Manual (Spanish)

070-9117-00 Phaser 550 Drivers and Utilities Printing

070-9508-00 Phaser Share Network Manual

070-9539-00 Phaser Share Status Monitor Manual

070-9322-00 Phaser 550 Service Manual

063-2179-03 Ethernet Network Software Kit

063-2181-02 LocalTalk Network Software Kit

063-2486-00 Drivers and Utilities Software Kit

063-2183-02 TokenRing Network Software Kit

012-1379-00 Cable Serial, 9-pin to 9-pin

012-1299-00 Cable, interconnect., 2.5 m 50-pins. to

012-1468-00 Cable, Parallel w/IEEE 1284C (mini)

012-1465-00 Cable, SCSI II to 50-pin SCSI

012-1379-00 Cable, Serial, 9-pin to 9-pin

012-1380-00 Cable, Serial, 9-pin to 25-pin

013-0299-00 Parallel cable adapter (standard to mini)

003-1496-00 Toner Vacuum (115 VA C)

Quantity Name and description

Reference Manual

25-pins

Table A-4 Supplies and accessories (cont'd.)

Part number Serial number

Effective Discontinued

Supply 016-1414-00 1 Transparency, Letter-size, 50 sheets

Supply 016-1415-00 1 Transparency, Metric-size, 50 sheets

Supply 016-1368-00 1 Paper, A-size, 500 sheets

Supply 016-1369-00 1 Paper, A4-size, 500 sheets

013-0297-00 1 SCSI cable adapter, 50-pin to SCSI II

103-0030-00 1 Adapter, Connector, BNC

011-0123-00 1 Coaxial Term. 50 ohms, BNC

016-1417-00 1 Black toner cartridge

016-1418-00 1 Cyan toner cartridge

016-1419-00 1 Magenta toner cartridge

016-1420-00 1 Yellow toner cartridge

161-0066-00 1 Power cord, domestic

161-0066-09 1 Power cord, 220V Euro

161-0066-10 1 Power cord, U.K.

161-0066-11 1 Power cord, Australian

161-0154-00 1 Power cord, Swiss

016-1318-00 1 Transfer Kit (Transfer roll and Waste box)

118-9070-00 1 Scorotron charger corona unit

006-7998-00 1 Conductive grease, silicon

006-7971-00 1 Imaging unit light shield/drape

065-0553-00 1 Shipping box, replacement

4685F16 1 16 Mbyte RAM upgrade

4685F32 1 32 Mbyte RAM upgrade

Z550FX 1 Extended features SIMM (requires either

4676FTA 1 Auxiliary feeder

4676FTA01 1 Auxiliary feeder, metric

4676FP1 1 Ethernet card upgrade

4676FP2 1 TCP/IP upgrade (required 4676FP1)

4676FP3 1 LocalTalk/Serial card upgrade

4676FP4 1 TokenRing card upgrade

4540 1 Phaser Copystation

Quantity Name and description

4685F16 or 4685F32)

A-6

003-1497-00 Toner Vacuum (220 VA C)

003-1498-00 Filter for 3M Toner Vacuums

Phaser 550 Color Printer

Page 47

Appendix

A

Field Replaceable

Units List

This appendix provides a list of field replaceable units for the printer.

Changes to Tektronix instruments are made to accommodate improved

components as they become available. It is important when ordering parts to

include the following information:

■

Component's part number.

Instrument type or number.

■

■

Instrument serial number.

■

Modification number, if any.

Service Manual

A-1

Page 48

Field Replaceable Units List

A

Table A-1 FRU parts list of the printer cabinet

Figure

A-1

1 118-9205-00 1 Front door

2 118-9204-00 1 Lower front cover

3 118-9203-00 1 Upper front cover (operation panel)

4 118-9206-00 1 Right side cover rear

5 118-9208-00 1 Right side cover front

6 118-9207-00 1 Right side cover lower

7 118-9182-00 1 Bottom front cover

8 436-0297-01 1 Output tray (standard)

Part number Serial number

Effective Discontinued

Quantity Name and description

w/display board

Figure A-1 Cabinet FRUs

8

4

3

5

2

7

6

1

9013-44

A-2

Phaser 550 Color Printer

Page 49

Field Replaceable Units List

Table A-2 FRU part list of the printer cabinet

Figure

A-2

1 118-9202-00 1 Lower rear cover

2 118-9330-00

3 118-9198-00 1 Top cover

4 118-9200-00 1 Left side cover

5 118-9199-00 1 SIMM access door

6 118-9184-00 1 Manual feed tray

7 118-9183-00 1 Left door

8 334-8366-30 1 Logo, Phaser 550

Part number Serial number

Effective Discontinued

118-9331-00

Quantity Name and description

1 Upper rear cover (110 VAC)

Upper rear cover (220 VAC)

8

3

A

2

1

Figure A-2 Cabinet FRUs

4

5

6

7

9013-45

Service Manual

A-3

Page 50

Field Replaceable Units List

A

Table A-3 FRU parts list of the exploded printer

Figure

A-3

1 118-9192-00 1 Ozone fan

2 118-9269-00 1 Engine control board

3 118-9191-00 1 Fuser/toner cartridge fan

4 118-9154-00

5 118-9181-00 1 Toner cartridge drive motor

6 118-9186-00 1 Toner cartridge selector/paper-eject unit

7 118-9268-00 1 Laser scanner

8 118-9333-00 1 Laser motor drive board

9 118-9166-00 1 Pre-transfer lamp

10 118-9169-00 1 Toner cartridge biasing assembly

11 118-9170-00 1 Toner level sensor board

12 118-9164-00 1 Pre-exposure erase lamp

13 118-9165-00 1 Image density sensor assembly

14 118-9167-00 1 Tray sensor board

15 118-9185-00 1 Paper feeder

16 118-9329-00 1 High-voltage board

17 671-3133-00 1 16-Mbyte RAM SIMM

17 671-3138-00 1 32-Mbyte RAM SIMM

18 671-3686-00 1 Image processing board w/rear panel

19a

19b

19c

19d

20 118-9196-00 1 Engine driver board

21 118-9173-00 1 Left door-open switch

22 118-9193-00 1 Main motor

23 118-9172-00 1 Home-position sensor assembly

24 118-9171-00 1 Charger sensor board

25 118-9194-00 1 Paper feed motor

26 118-9190-00 1 Fuser installed switch

27 118-9195-00 1 Cleaning board

28 118-9168-00 1 Toner cartridge drive unit

30a

30b

31 671-3847-00 1 PostScript Code ROM SIMM (masked)

Part number Serial number

Effective Discontinued

118-9154-01

118-9332-00

671-3468-02

671-3469-00

671-3470-02

386-6815-00

213-1090-00

671-3805-00

671-3688-00

671-3847-00 1 Masked ROM, engine control board Z550

118-9174-00 1 Hardware kit

118-9176-00 1 Gear kit

650-3170-00 1 Spring kit

Quantity Name and description

1

1

1

1

1

1

1

2

1 Extended Features SIMM, Roman Font

Power Supply (110 - 120 VAC)

Power Supply (100 - 120 VAC)-Japan

Power Supply (220 VAC)

Ethernet network card

LocalTalk/serial network card

Token Ring network card

Blank cover plate (no card installed)

Blank cover plate thumbscrews

Extended Features SIMM, Kanji Font

A-4

Phaser 550 Color Printer

Page 51

Chapter

9

Checks and Adjustments

This chapter discusses using the front panel’s interactive mode to review and

change the printer’s operation. It also contains the procedures to calibrate the

printer after you replace key Field Replaceable Units and to evaluate the

printer's functionality.

Required tools

■

■

Magnifying lens (preferably illuminating)

Phillips screwdriver

Service Manual

9-1

Page 52

9

Checks and Adjustments

Front panel menu

The print engine features an interactive front panel menu that allows you to

review or change the printer’s stored parameters as well as initiate test prints

and printer service routines. When the front panel displays

to enter the printer’s interactive menu.

Figure 9-1 Menu map

Idle

Menu

Ready , p ress Menu

Help Pages

Menu Map

Test Print

Demonstration Page

Startup Page

Configuration Page

Service Print 1

Service Print 2

Calibrate Colors

Adjust light/dark

Auto Calibrate

Adjust each color

reference page

Adjust cyan

Adjust magenta

Adjust yellow

Adjust black

Reset Adjustments

System counts

Page count

Imaging Unit

Transfer Kit

Fuser

TekColor Correction

TekColor: None

TekColor: None

TekColor: Vivid Color

TekColor:Display

TekColor: SWOP

TekColor: Euroscale

TekColor: Commercial

Monochrome

Print Quality

Standard

Enhanced

Premium

Fast Color

Presentation

9-2

Phaser 550 Color Printer

Page 53

Figure 9-2 Menu map

Printer defaults menu

Default tray

Upper

Middle

Lower

Media Tray

Manual Feed

Paper

Transparency

Auto Select

Startup Page

Startup Page: enabled

Startup Page: disabled

Startup Mode

Startup Mode: enabled

Startup Mode: disabled

Output order

Serial settings*

Baud Rate

Baud Rate: 300

Baude Rate: 600

Baud Rate: 1200

Baud Rate: 2400

Baud Rate: 4800

Baud Rate: 9600

Baud Rate: 19200

Baud Rate: 38400

Data Bits

Data Bits: 7

Data Bits: 8

Stop Bits

Stop Bits:1

Stop Bits: 2

Parity

Checks and Adjustments

Network settings**

TCP/IP***

TCP/IP: enabled

TCP/IP: disabled

EtherTalk

EtherTalk: enabled

EtherTalk: disabled

Netware

Novell: enabled

Novell: disabled

HTTP***

HTTP: enabled

HTTP: disabled

Token Talk****

Token Talk: enabled

Token Talk: disabled

Language menu

Language: English

Language: Español

Language: Français

Language: Deutsch

Language: Italiano

Language: Japanese

Set IP Address

Selected

Press buttons 2 & 3

XXX.XXX.XXX.XXX

Increment Shift Set

9

Output order: face up

Output order: face down

Energy Star

Energy Star: enabled

Energy Star: disabled

Energy Star timeout

Energy Star timeout: xxx hrs

Timeout: xxx hrs

Print Check

Enabled

Disabled

Print Check timeout

Flow Control

Xon/Xoff

Even

Odd

Mark

Space

None

dtr

if P3 option installed

*

if P2 option installed

**

if P2 option installed

***

if P4 option installed

****

9322-67

Service Manual

9-3

Page 54

1.

2.

1.

2.

1.

2.

1.

Checks and Adjustments

9

Printing test prints

The prints printed via the front panel the are generated by the image processor.

While the printer is idle you can use the front panel to print an image stored in

the image processor such as the configuration page.

Print service test prints

The service prints allow you to evaluate the printer’s print quality. Service

Print 1 is four pages of 25% tint primary color fills. Service Print 2 prints in

600 dpi.

Press the Menu button.

With the Help pages menu displayed, scroll to the Service

Print 1

or Service Print 2 menu item. Press Print .

Printing the configuration page

The configuration page shows a great deal of information regarding the data

and set-up values stored in NVRAM. Refer to the topic, “The configuration

page” on page 2-14 for an explanation of the configuration page. In the same

Help pages menu you can also print the startup page.

Press the Menu button.

With the Help pages menu displayed, scroll to the Configuration

menu item. Press Print .

Page

Printing the demonstration pages

Demo pages demonstrate the capabilities of the printer.

Press the Menu button.

With the Help pages menu displayed, scroll to the Demonstration

item. Press Print .

Page

Printing the print engine’s test print

The print engine can print a test print independent of the image processor. The

print is a composite gray fill composed of cyan, magenta and yellow toner. No

black toner is used in the print.

9-4

Press and hold for 2 seconds the Test Print button in the center of the

upper rear cover.

This verifies the print engine’s ability to print independent of the image

processor. Do not use this print to verify print quality.

Phaser 550 Color Printer

Page 55

on

Image processor normal indicators

There are three indications that the print engine and its image processor are

powered-up and operating normally: the front panel POWER LED is on

(steady),

processor health light is blinking (the flashing health light is viewable through

the grill behind the manual feed tray).

When the printer is receiving or processing data, the front panel displays the

messages

for Data

Ready is displayed on the front panel LCD display and the image

Receiving Data and Processing Data . The message Waiting

may also be displayed periodically.

Image processor hard and soft error indicators

Image processor hard errors are self-test failures that would prevent the printer

from printing a page. Hard errors cause the health light to stop blinking and

remain

Soft errors are errors that occur during the normal power-up self-test that, while

limiting the printer, would not stop the printer from printing. A message

regarding the soft error would then be printed on the startup page (even if the

startup page had been turned off). Soft errors include failures of the expansion

SIMMs, as well as the SCSI, serial, LocalTalk, parallel, and Ethernet ports.

or off . Hard errors are also any error that occurs during service mode.

Checks and Adjustments

9

Service Manual

9-5

Page 56

Checks and Adjustments

9

Printer self-diagnostics

The printer’s image processor features four types of self-test modes. The type of

self-tests run depend upon which front panel buttons are pressed while the

printer is turned on. The button combinations are listed here.

■

Turning on the printer or restarting the printer remotely executes

normal image processor power-up self-tests and then, if the tests pass,

proceed to launch its PostScript interpreter.

Pressing and holding Button 1 (the left-most button, marked Exit), as

■

you turn on the printer, skips the image processor’s self tests and

proceed directly to launching its PostScript interpreter.

■

Pressing and holding Button 2 (the second from the left button), as