Page 1

Smart choice for power

Fuse Block

Installation Guide

TFB110/TFB110C

TFB200/TFB200C

TFB300/TFB300C

TFB350/TFB350C

TFB400/TFB400C

www.xantrex.com

Page 2

About Xantrex

Trademarks

Notice of Copyright

Disclaimer

Xantrex Technology Inc., is a world-leading supplier of

advanced power electronics and controls with products

from 50 watt mobile units to 1 MW utility-scale systems

for wind, solar, batteries, fuel cells, microturbines, and

backup power applications in both grid-connected and

stand-alone systems. Xantrex products include

inverters, battery chargers, programmable power

supplies, and variable speed drives that convert, supply,

control, clean, and distribute electrical power.

Trace and Xantrex are registered trademarks of Xantrex

International.

Fuse Block Installation Guide ©June 2002 Xantrex

Technology Inc. All rights reserved.

Since the use of this guide and the conditions or

methods of installation, operation, use and

maintenance of the unit are beyond the control of

Xantrex Technology Inc., the company does not assume

responsibility and expressly disclaims liability for loss,

damage, or expense arising out of or any way connected

with such installation, operation, use, or maintenance.

See pages 12 through 18 in this guide for specific

warranty information.

Installation Guide

Date and Revision

Document Number

Contact Information

2

June 2002, Revision A

973-0019-01-02

Web: www.xantrex.com

Phone: 1.888.608.0721

Fax: 360.435.2229

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 3

Table of Contents

About Xantrex .............................................................................................. 2

Trademarks ....................................................................................................... 2

Notice of Copyright ..........................................................................................2

Disclaimer......................................................................................................... 2

Date and Revision ............................................................................................ 2

Document Number ........................................................................................... 2

Contact Information ........................................................................................ 2

Introduction .................................................................................................5

Tools/Materials Required .................................................................................. 5

Installation .................................................................................................... 6

Mounting.......................................................................................................... 6

Cable Installation into Fuse Block ................................................................... 7

For Fuse Blocks designed for Series-C Battery Cables .................................. 7

For Fuse Blocks designed for Ring-lugged Battery Cables ........................... 8

Wiring TFBs to the Battery, DC Disconnect, and Inverter ................................9

Care and Maintenance ............................................................................... 10

Fuse Replacement ........................................................................................... 10

Replacement Fuses ..................................................................................... 11

Limited Warranty ....................................................................................... 12

What does this warranty cover and how long does it last? .........................12

What will Xantrex do? ................................................................................... 12

How do you get service? ................................................................................ 13

What does this warranty not cover? ............................................................. 14

DISCLAIMER ....................................................................................................15

Product....................................................................................................... 15

Exclusions ................................................................................................... 16

Information ................................................................................................ 16

WARNING: LIMITATIONS ON USE ................................................................ 17

Return Material Authorization Policy ...........................................................17

Shipping Instructions ................................................................................. 18

If you are returning a product from outside of the USA or Canada..... 18

If you are returning a product to a Xantrex Authorized Service Center

(ASC) ................................................................................................... 18

Service Information.................................................................................... 19

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

3

Page 4

List of Figures

Figure 1 Fuse Block for Type-C Battery Cables (TFBxxxC)............................... 5

Figure 1a Fuse Block for Ring-lugged Battery Cables(TFBxxx) ........................ 5

Figure 2 Fuse Block Dimensional Drawing .................................................... 6

Figure 3 Installation for Type-C Battery Cables............................................. 7

Figure 4 Installation for Ring-lugged Battery Cables ................................... 8

Figure 5 Wiring TFB’s to the Battery, DC Disconnect, and Inverter .............. 9

Figure 6 Remove the Two Nuts and Washers and Replace Fuse .................. 10

List of Tables

Table 1 Bolt and Nut Sizes ........................................................................... 6

Table 2 Replacement Fuses and Cable Sizes .............................................. 11

Installation Guide

4

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 5

Introduction

NOTE: These fuse

blocks meet the

National

Electrical Code

requirements for

overcurrent

protection.

Xantrex offers

the DC175 and

DC250 in an

enclosure for

applications

requiring NEC

compliance for

both overcurrent

protection and a

DC disconnect.

Tools/Materials Required

The Trace™ brand fuse block (TFB) protects the power

system’s DC wiring should an overcurrent condition

occur. The fuse block is placed between the battery’s

ungrounded conductor (usually the positive cable) and

the DC input terminal of the inverter.

The TFBs include a fast acting, current limiting class-T

fuse providing extremely fast protection when a short

circuit occurs. When the fuse is properly matched to the

system current, its time delay allows the inverter to

surge to full power without blowing the fuse. A plastic

cover prevents accidental short circuits to the fuse

terminals. Fuse sizes include 110, 200, 300, 350 and

400 amps.

There are two types of fuse blocks available. The

TFBxxxC fuse block has “set” screw lugs for cables with

no terminal connector’s on the ends (hereto referred to

as C-type battery cables). The TFBxxx fuse block has

stainless steel bolt connections for cables with ring

terminals (hereto referred to as ring-lugged battery

cables). Both fuse blocks include a black polycarbonate,

fiberglass reinforced base and a clear polycarbonate

snap-on cover.

• 4 screws (type depending on mounting material)

• 5/16 inch allen wrench (for C-type fuse blocks only)

• 9/16 inch socket for 3/8" hex nuts

• 1/2 inch socket for 5/16" hex nuts

• assorted screwdrivers

• knife

Figure 1

Fuse Block for C-type

Battery Cables (TFBxxxC)

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Figure 1a

Fuse Block for Ring-lugged

Battery Cables (TFBxxx)

5

Page 6

Installation

Mounting

NOTE: It is not

recommended to

locate the fuse

block inside the

enclosure with

the batteries

where explosive

gases may exist.

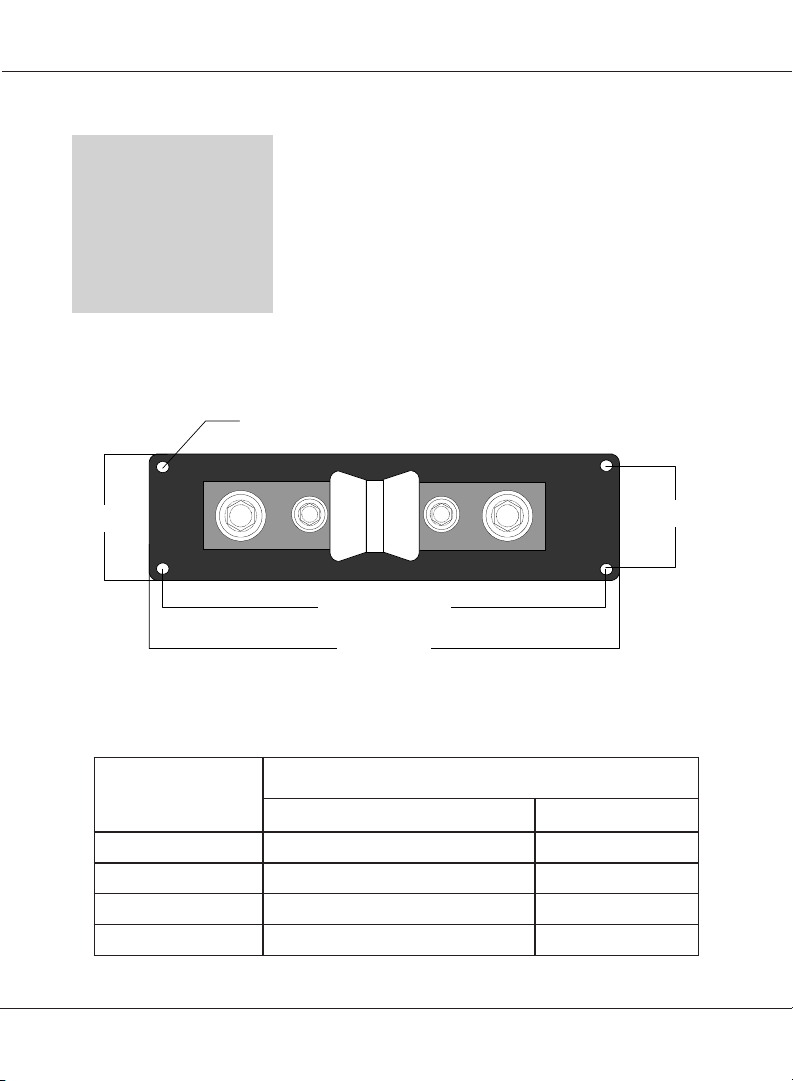

2.00"

(50.6 cm)

Locate the fuse block within 18 inches (45 cm) of the

battery. It should be placed in a location where it is

easily accessible should the fuse need replacing.

1. Squeeze the clear plastic protective cover and

remove it from the fuse block base.

2. Use the fuse block base as a template for location of

the four mounting holes. The fuse block should be

mounted to a secure surface. Allow at least 6 inches

(15 cm) from the fuse contacts to allow for removal

without shorting to a grounded object.

3. Use appropriate hardware (not supplied) to mount

the fuse block.

X4 holes for #10 screws

A

6.250" (158.75 cm)

7.0" (177.8 cm)

BB

A

Installation Guide

Figure 2

Fuse Block Dimensional Drawing

(Not to scale)

1.32"

(33.53 cm)

epyTkcolBesuF

eziSguL/tloB

)tun/tlob(xxxBFT

)wercstes(CxxxBFT

002,011BFTtunxehhtiwtlob81-8/3tunxehhtiwtlob01-61/5

004,053,003BFTtunxehhtiwtlob81-8/3tunxehhtiwtlob81-8/3

C002,C011BFTselbactuc0/2-4#rofsgul0/2#tunxehhtiwtlob01-61/5

C004,C053,C003BFTselbactucMCM052-4#rofsgulMCM052tunxehhtiwtlob81-8/3

AB

Table 1

Bolt and Nut Sizes

6

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 7

Installation (continued)

Cable Installation into Fuse Block

For Fuse Blocks designed for C-Type Battery Cables (TFBxxxC)

1. Strip back 1 inch (2.5 cm) of the insulation on the

battery cable.

2. Insert the cable into the terminal block (ensure all

conductor strands are in the block)

See Figure 3.

3. Tighten the hex screws to 10-15 ft/lbs.

4. Repeat Steps 2 and 3 for the connection to the other

end of the fuse block.

Stripped

back 1 inch

Installation for C-Type Battery Cables

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Figure 3

7

Page 8

Installation (continued)

Cable Installation into Fuse Block (continued)

For Fuse Blocks designed for Ring-lugged Battery Cables (TFBxxx)

NOTE: Do not place

anything

between the

ring-lug on the

battery cable

and the terminal

surface.

A. If necessary, install the ring-lugs (not supplied) onto

the battery cables. Ensure the terminal connector’s

have a 3/8" diameter opening for placement over the

stud connector on the fuse block.

1. Remove the 3/8" hex nut and split washers from the

fuse block.

2. Place the cable ring lugs over the 3/8-18 bolt on the

fuse block assembly and reinstall the split washer

and hex nut.

See Figure 4.

3. Tighten the hex nuts to 10-15 ft/lbs.

4. Repeat Steps 2, 3, and 4 for connection to the other

end of the fuse block.

Ring-lug on

Battery Cables

8

hex nut

Terminal surface

3/8-18

bolt

split-

washers

split-

washers

3/8-18

bolt

Installation Guide

Terminal surface

Figure 4

Installation for Ring-lugged Battery Cables

©2002 Xantrex Technology Inc. All Rights Reserved

hex nut

Ring-lug on

Battery Cables

P/N 973-0019-01-02 Rev A 06/2002

Page 9

Installation (continued)

Wiring TFBs to the Battery, DC Disconnect, and Inverter

300 AMP

FUSE CLASS T

TFB FUSE BLOCK FOR

C-TYPE

BATTERY CABLES

300 AMP

FUSE CLASS T

+

BATTERY

+

BATTERY

-

*DC

DISCONNECT

-

INVERTER

*DC DISCONNECT MAY NOT

BE REQUIRED IN ALL

APPLICATIONS

INVERTER

TFB FUSE BLOCK

FOR RING-LUGGED

BATTERY CABLES

Wiring TFBs to the Battery, DC Disconnect, and Inverter

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

*DC

DISCONNECT

Figure 5

*DC DISCONNECT MA Y NOT

BE REQUIRED IN ALL

APPLICATIONS

9

Page 10

Care and Maintenance

Fuse Replacement

WARNING:

BEFORE

REPLACING

THE FUSE,

DISCONNECT ALL

POWER SOURCES

AND TURN OFF

ALL LOADS.

NOTE: If the system

also contains a

DC disconnect,

switch it to OFF

before replacing

the fuse.

NOTE: Fuses are NOT

covered under the

limited warranty.

split-washer

Before replacing the fuse, determine and correct the

cause of the overcurrent condition.

1. Use a hex socket and remove the two nuts (and split

washers) securing the fuse. Note the hardware

installed and the order of how it is stacked. This is

important to prevent excess heat which can cause

the fuse to open again.

2. Remove the open fuse and replace it with a known

good one.

3. Reinstall the hardware as it was originally stacked on

the fuse.

4. Tighten the hex nuts securing the fuse to

10-15 ft/lbs.

5. Double-check the battery cable connections and

verify all connections are properly tightened .

hex nut

bolt

fuse

300 AMP

FUSE CLASS T

hex nut

split-washer

bolt

Installation Guide

10

hex nut

split-washer

bolt

fuse

300 AMP

FUSE CLASS T

hex nut

split-washer

bolt

Figure 6

Remove the Two Nuts and Washers and Replace Fuse

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 11

Care and Maintenance (continued)

Replacement Fuses

WARNING:

REPLACE FUSE

WITH ONLY THE

SAME TYPE

(CLASS T) AND

RATING

(AMPERAGE/

VOLTAGE).

NOTE: The temperature

rating of the

cable sizes

specified in

Table 2 are 75 °C

in free-air based

on an ambient air

temperature of

30 °C (86 °F).

Replacement fuses are available from Xantrex

Technology Inc. These fuses fit either the TFBxxx or

TFBxxxC models (of the same rating only).

See Table 2 for part numbers for replacement fuses.

#BFTegarepmA

C011FBT/011BFTspma011011FTmm2.12/GWA4#

C002FBT/002BFTspma002002FTmm4.76/GWA0/2#

C003FBT/003BFTspma003003FTmm701/GWA0/4#

C053FBT/053BFTspma053053FTmm701/GWA0/4#

C004FBT/004BFTspma004004FTmm701/GWA0/4#

Replacement Fuses and Cable Sizes

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Table 2

tnemecalpeR

esuF

eziSelbaC

2

2

2

2

2

11

Page 12

Limited Warranty

What does this warranty cover and how long does it last?

NOTE: Fuses are NOT

covered under the

limited warranty.

What will Xantrex do?

This Limited Warranty is provided by Xantrex

Technology, Inc. (“Xantrex”) and covers defects in

workmanship and materials in your Fuse Block. This

warranty lasts for a Warranty Period of two years from

the date of purchase at point of sale to you, the original

end user customer.

Xantrex will, at its option, repair or replace the defective

product free of charge, provided that you notify Xantrex

of the product defect within the Warranty Period, and

provided that Xantrex through inspection establishes

the existence of such a defect and that it is covered by

this Limited Warranty.

Xantrex will, at its option, use new and/or reconditioned

parts in performing warranty repair and building

replacement products. Xantrex reserves the right to use

parts or products of original or improved design in the

repair or replacement. If Xantrex repairs or replaces a

product, its warranty continues for the remaining

portion of the original Warranty Period or 90 days from

the date of the return shipment to the customer,

whichever is greater. All replaced products and all parts

removed from repaired products become the property

of Xantrex.

Xantrex covers both parts and labor necessary to repair

the product, and return shipment to the customer via a

Xantrex-selected non-expedited surface freight within

the contiguous United States and Canada. Alaska and

Hawaii are excluded. Contact Xantrex Customer Service

for details on freight policy for return shipments outside

of the contiguous United States and Canada.

Installation Guide

12

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 13

Limited Warranty (continued)

How do you get service?

If your product requires troubleshooting or warranty

service, contact your merchant. If you are unable to

contact your merchant, or the merchant is unable to

provide service, contact Xantrex directly at:

Phone: 360.435.8826

Fax: 360.474.0616

Email: Tracewarranty@xantrex.com

Direct returns may be performed according to the

Xantrex Return Material Authorization Policy described

in your product manual. For some products, Xantrex

maintains a network of regional Authorized Service

Centers. Call Xantrex or check our website to see if your

product can be repaired at one of these facilities.

In any warranty claim, dated proof of purchase must

accompany the product and the product must not have

been disassembled or modified without prior written

authorization by Xantrex.

Proof of purchase may be in any one of the following

forms:

• the dated purchase receipt from the original purchase

of the product at point of sale to the end user, or

• the dated dealer invoice or purchase receipt showing

• the dated invoice or purchase receipt showing the

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

original equipment manufacturer (OEM) status, or

product exchanged under warranty.

13

Page 14

Limited Warranty (continued)

What does this warranty not cover?

NOTE: Fuses are NOT

covered under the

limited warranty.

This Limited Warranty does not cover normal wear and

tear of the product or costs related to the removal,

installation, or troubleshooting of the customer’s

electrical systems. This warranty does not apply to and

Xantrex will not be responsible for any defect in or

damage to:

a) the product if it has been misused, neglected,

improperly installed, physically damaged or altered,

either internally or externally, or damaged from

improper use or use in an unsuitable environment;

b) the product if it has been subjected to fire, water,

generalized corrosion, biological infestations, or

input voltage that creates operating conditions

beyond the maximum or minimum limits listed in

the Xantrex product specifications including high

input voltage from generators and lightning strikes;

c) the product if repairs have been done to it other than

by Xantrex or its authorized service centers

(hereafter “ASCs”);

d) the product if it is used as a component part of a

product expressly warranted by another

manufacturer;

e) the product if its original identification (trademark,

serial number) markings have been defaced,

altered, or removed.

Installation Guide

14

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 15

Limited Warranty (continued)

DISCLAIMER

Product

THIS LIMITED WARRANTY IS THE SOLE AND

EXCLUSIVE WARRANTY PROVIDED BY XANTREX IN

CONNECTION WITH YOUR XANTREX PRODUCT AND

IS, WHERE PERMITTED BY LAW, IN LIEU OF ALL OTHER

WARRANTIES, CONDITIONS, GUARANTEES,

REPRESENTATIONS, OBLIGATIONS AND LIABILITIES,

EXPRESS OR IMPLIED, STATUTORY OR OTHERWISE IN

CONNECTION WITH THE PRODUCT, HOWEVER

ARISING (WHETHER BY CONTRACT, TORT,

NEGLIGENCE, PRINCIPLES OF MANUFACTURER’S

LIABILITY, OPERATION OF LAW, CONDUCT,

STATEMENT OR OTHERWISE), INCLUDING WITHOUT

RESTRICTION ANY IMPLIED WARRANTY OR

CONDITION OF QUALITY, MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE TO THE EXTENT REQUIRED

UNDER APPLICABLE LAW TO APPLY TO THE

PRODUCT SHALL BE LIMITED IN DURATION TO THE

PERIOD STIPULATED UNDER THIS LIMITED

WARRANTY.

IN NO EVENT WILL XANTREX BE LIABLE FOR ANY

SPECIAL, DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, COSTS OR

EXPENSES HOWEVER ARISING WHETHER IN

CONTRACT OR TORT INCLUDING WITHOUT

RESTRICTION ANY ECONOMIC LOSSES OF ANY KIND,

ANY LOSS OR DAMAGE TO PROPERTY, ANY PERSONAL

INJURY, ANY DAMAGE OR INJURY ARISING FROM OR

AS A RESULT OF MISUSE OR ABUSE, OR THE

INCORRECT INSTALLATION, INTEGRATION OR

OPERATION OF THE PRODUCT.

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

15

Page 16

Limited Warranty (continued)

Exclusions

If this product is a consumer product, federal law does

not allow an exclusion of implied warranties. To the

extent you are entitled to implied warranties under

federal law, to the extent permitted by applicable law

they are limited to the duration of this Limited Warranty.

Some states and provinces do not allow limitations or

exclusions on implied warranties or on the duration of an

implied warranty or on the limitation or exclusion of

incidental or consequential damages, so the above

limitation(s) or exclusion(s) may not apply to you. This

Limited Warranty gives you specific legal rights. You may

have other rights which may vary from state to state or

province to province.

Information

WITHOUT LIMITING THE GENERALITY OF THE

FOREGOING, UNLESS SPECIFICALLY AGREED TO BY IT

IN WRITING, XANTREX

(a) MAKES NO WARRANTY AS TO THE ACCURACY,

SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN MANUALS OR

OTHER DOCUMENTATION PROVIDED BY IT IN

CONNECTION WITH THE PRODUCT; AND

16

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR

LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER

SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE

OF SUCH INFORMATION.

THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

Installation Guide

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 17

Limited Warranty (continued)

WARNING: LIMITATIONS ON USE

NOTE: DO NOT RETURN

PRODUCTS TO

THIS ADDRESS.

Please call your

Xantrex Customer

Service Representative for

return mailing

instructions.

The Fuse Block is not intended for use in connection

with life support systems and Xantrex makes no

warranty or representation in connection with any use of

the product for such purposes.

Xantrex Technology, Inc.

8999 Nelson Way

Burnaby, British Columbia

Canada

V5A 4B5

Return Material Authorization Policy

Before returning a product directly to Xantrex you must

obtain a Return Material Authorization (RMA) number

and the correct factory “Ship To” address. Products

must also be shipped prepaid. Product shipments will

be refused and returned at your expense if they are

unauthorized, returned without an RMA number clearly

marked on the outside of the shipping box, if they are

shipped collect, or if they are shipped to the wrong

location.

When you contact Xantrex to obtain service, please have

your instruction manual ready for reference and be

prepared to supply:

• The part number of your product

• Information about the installation and use of the unit

• Information about the failure and/or reason for the

• A copy of your dated proof of purchase

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

return

17

Page 18

Limited Warranty (continued)

Shipping Instructions

1. Package the unit safely, preferably using the original

2. Include the following:

3. Ship the unit prepaid to the address provided by

box and packing materials. Please ensure that your

product is shipped fully insured in the original

packaging or equivalent. This warranty will not apply

where the product is damaged due to improper

packaging.

• the RMA number supplied by Xantrex

Technology Inc clearly marked on the outside

of the box,

• a return address where the unit can be shipped

(post office boxes are not acceptable),

• a contact telephone number where you can be

reached during work hours, and

• a brief description of the problem.

your Xantrex customer service representative.

If you are returning a product from outside of the USA or Canada

In addition to the above, you MUST include return

freight funds and are fully responsible for all

documents, duties, tariffs, and deposits.

Installation Guide

If you are returning a product to a Xantrex Authorized Service Center (ASC)

A Xantrex return material authorization (RMA) number

is not required. However, you must contact the ASC prior

to returning the product or presenting the unit to verify

any return procedures that may apply to that particular

facility.

18

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

Page 19

Service Information

Part Number:

Purchase Date:

Problem:

Include a telephone number where you can be reached

during business hours and a complete return shipping

address (P.O. Box numbers are not acceptable).

Name:

Address:

City:

State / Province:

Zip / Postal Code:

Country:

Phone:

FAX :

Email Address:

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 973-0019-01-02 Rev A 06/2002

19

Page 20

Xantrex Technology Inc.

1 888 608 0721 Phone

1 360 435 2229 Fax

www.xantrex.com

Installation Guide

973-0019-01-02 Rev A 06/2002

Printed in the USA

Loading...

Loading...