Page 1

975-0289-01-01(PowerHub_1800).book Page 1 Friday, January 5, 2007 12:47 PM

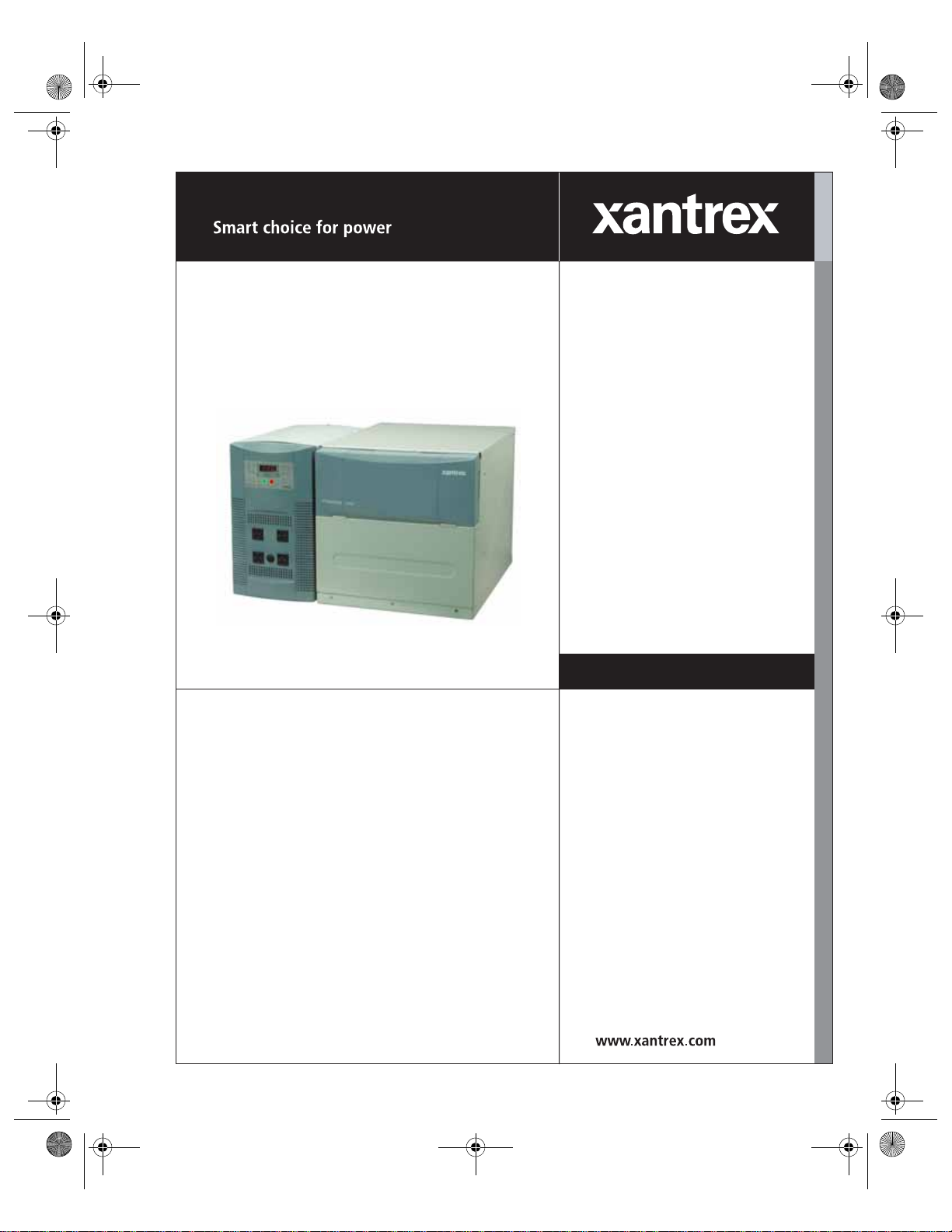

PowerHub 1800

PH1800

Installation Guide

Page 2

975-0289-01-01(PowerHub_1800).book Page 2 Friday, January 5, 2007 12:47 PM

Page 3

975-0289-01-01(PowerHub_1800).book Page i Friday, January 5, 2007 12:47 PM

PowerHub 1800

Installation Guide

Page 4

975-0289-01-01(PowerHub_1800).book Page ii Friday, January 5, 2007 12:47 PM

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with

products from 50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells,

microturbines, and backup power applications in both grid-connected and stand-alone systems. Xantrex

products include inverters, battery chargers, programmable power supplies, and variable speed drives

that convert, supply, control, clean, and distribute electrical power.

Trademarks

PowerHub 1800 is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex

International.

Other trademarks, registered trademarks, and product names are the property of their respective owners

and are used herein for identification purposes only.

Notice of Copyright

PowerHub 1800 Installation Guide © January 2007 Xantrex Internation a l. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER

SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF

SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH

STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT

BE GUARANTEED. APPROVED XANTREX CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE

VERSION WHICH IS POSTED AT WWW.XANTREX.COM.

Date and Revision

January 2007 Revision C

Part Number

975-0289-01-01

Product Number

PH1800-GFP

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free North America)

1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

975-0289-01-01(PowerHub_1800).book Page iii Friday, January 5, 2007 12:47 PM

About This Guide

Purpose

The purpose of this Installation Guide is to provide procedures for

installing the PowerHub 1800.

Scope

The Guide provides safety guidelines, detailed planning and setup

information, and procedures for installing the inverter. It does not provide

operational or troubleshooting information. It does not provide details

about particular brands of batteries. Consult individual battery

manufacturers for this information.

Audience

Organization

The PowerHub 1800 is an entry-level inverter system. This Guide is

intended for anyone who needs to plan for and install the PowerHub

1800. Permanent installations should be done by certified technicians or

electricians. Installers should have adequate knowledge of national and

local electric code to ensure code-compliance by inspection from the local

electric authority.

This Guide is organized into three chapters and one app e ndix.

Chapter 1 describes the features and functions of the PowerHub 1800.

Chapter 2 contains information on planning the installation of this

equipment.

Chapter 3 contains information on assembling and installing this

equipment.

Appendix A provides electrical and physical specifications for the

PowerHub 1800.

iii

Page 6

975-0289-01-01(PowerHub_1800).book Page iv Friday, January 5, 2007 12:47 PM

About This Guide

Conventions Used

The following conventions are used in this guide.

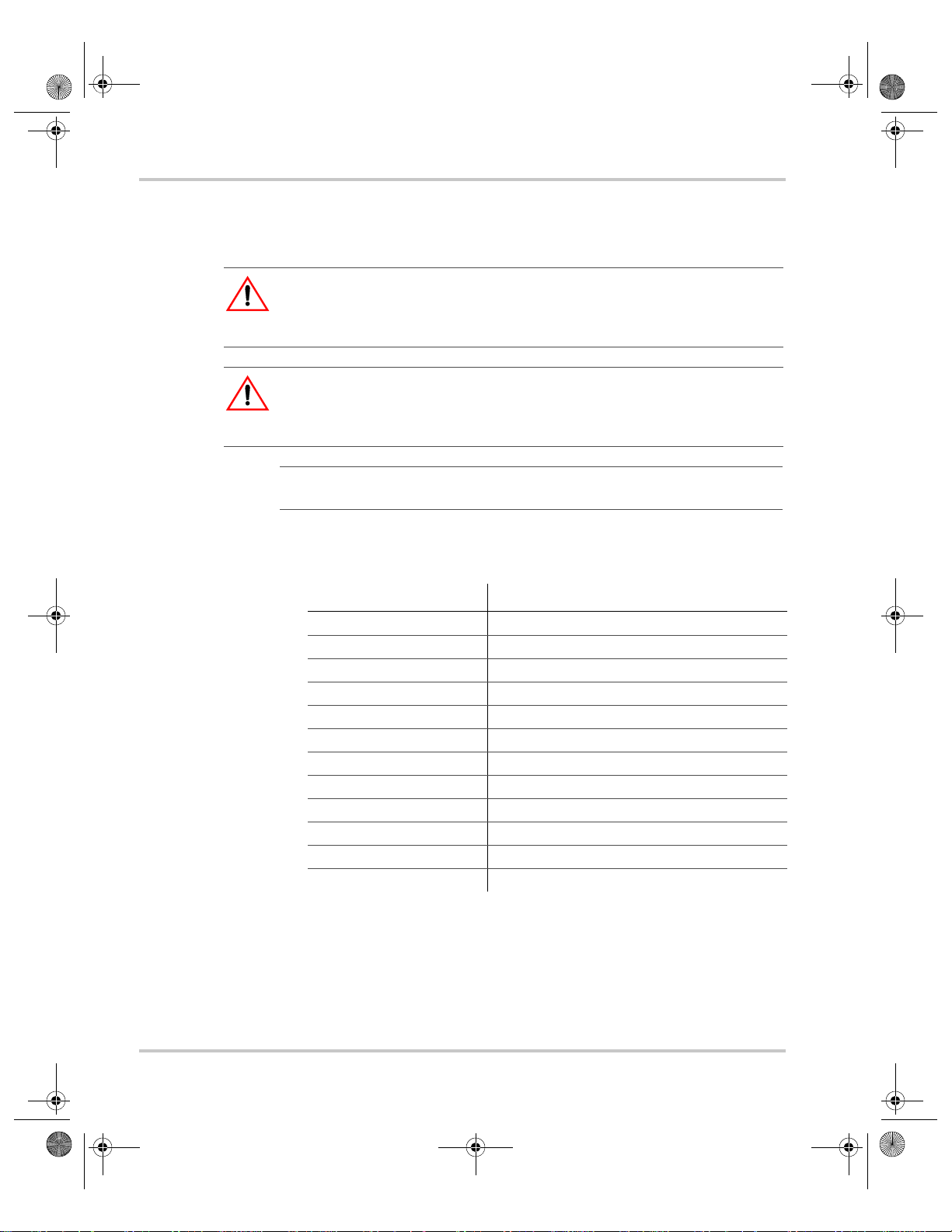

WARNING

Warnings identify conditions or practices that could result in personal injury or

loss of life

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or

other equipment.

Important:

but not as serious as a caution or warning.

These notes describe things which are important for you to know,

Abbreviations and Acronyms

Abbreviation or Acronym Definition

AAmps

AC Alternating Current

DC Direct Current

ft-lbs Foot-pounds (a measure of torque)

kW Kilowatts (1000 watts)

LED Light Emitting Diode

Nm Newton-meters (a measurement of torque)

PV Photovoltaic

RE Renewable Energy

Vac Volts AC

Vdc Volts DC

WWatts

Related Information

You can find more information about this product by seeing the

PowerHub 1800 Operator’s Guide (part nu mber 9 75-02 88-01- 01 Rev A).

You can find more information about Xantrex Technology Inc. as well as

its products and services at www.xantrex.com.

A French version of this document is available at www.xantrex.com.

iv 975-0289-01-01

Page 7

975-0289-01-01(PowerHub_1800).book Page v Friday, January 5, 2007 12:47 PM

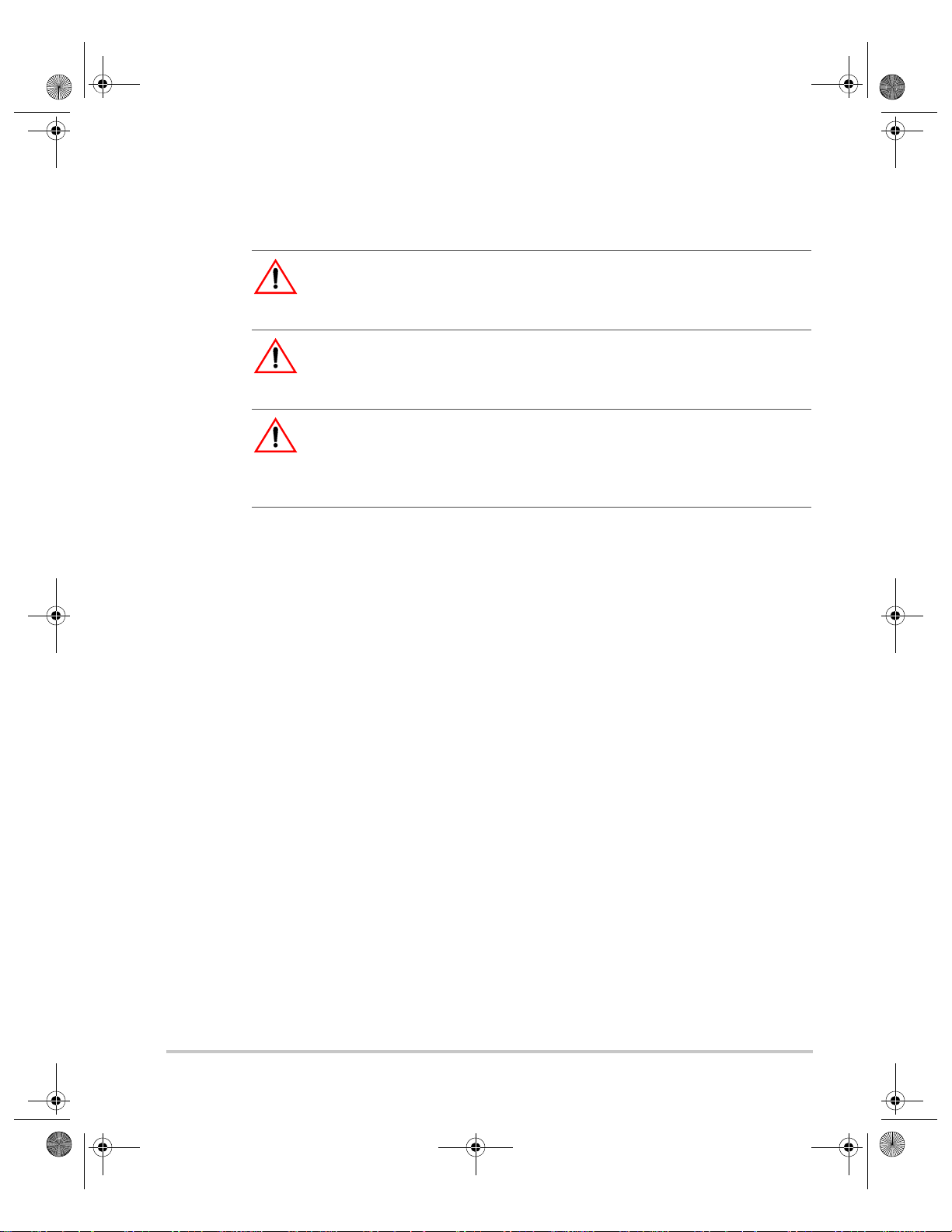

Important Safety Instructions

WARNING

This chapter contains important safety and operating instructions. Read and keep

this Installation Guide for future reference.

WARNING: Limitations on use

The PowerHub 1800 is not intended for use in connection with life support

systems or other medical equipment or devices.

WARNING

To avoid the risk of carbon mo noxide poisoning, generators are not to be used

indoors. When generators are used outdoors there must be sufficient circulation

to vent the carbon monoxide.

1. Before installing and using the PowerHub, read all instructions and

cautionary markings on the PowerHub, the batteries, and in both this

Installation Guide and the Operator’s Guide.

2. The PowerHub is intended for indoor use only. Do not expose the

PowerHub to rain, snow, or spray. To reduce risk of fire hazard, do

not cover or obstruct the ventilation openings. Do not install the

PowerHub in a zero-clearance compartment. Overheating may result.

3. The PowerHub may connect to as many as three source s of DC Power

and one source of AC Power. To reduce the risk of electrical shock,

disconnect all sources of AC and DC power from the PowerHub

before attempting any maintenance or cleaning or working on any

circuits connected to the PowerHub. Turning off controls will not

eliminate this risk.

4. Use only attachments that are intended for use with this product.

Doing otherwise may result in a risk of fire, electric shock, or injury

to persons.

5. To avoid a risk of fire and electric shock, make sure that all of the

installation wiring is in good condition and that wire is not

undersized. Do not operate the PowerHub with damaged or

substandard wiring.

6. Do not operate the PowerHub if it has received a sharp blow, been

dropped, or otherwise damaged in any way. If the PowerHub is

damaged, see the Warranty section.

v

Page 8

975-0289-01-01(PowerHub_1800).book Page vi Friday, January 5, 2007 12:47 PM

Safety

7. Do not disassemble the PowerHub, except where noted to wire it for a

permanent installation. The PowerHub 1800 contains no userserviceable parts. See Warranty for instructions on obtaining service.

Attempting to service the PowerHub yourself may result in a risk of

electrical shock or fire and will void your warranty. Internal

capacitors remain charged after all power is disconnected.

8. The PowerHub must be provided with an equipment-grounding

conductor. Grounding and all other wiring must comply with National

and local codes and regulations.

No!

No!

No!

No!

Figure i

vi 975-0289-01-01

Basic Safety

Page 9

975-0289-01-01(PowerHub_1800).book Page vii Friday, January 5, 2007 12:47 PM

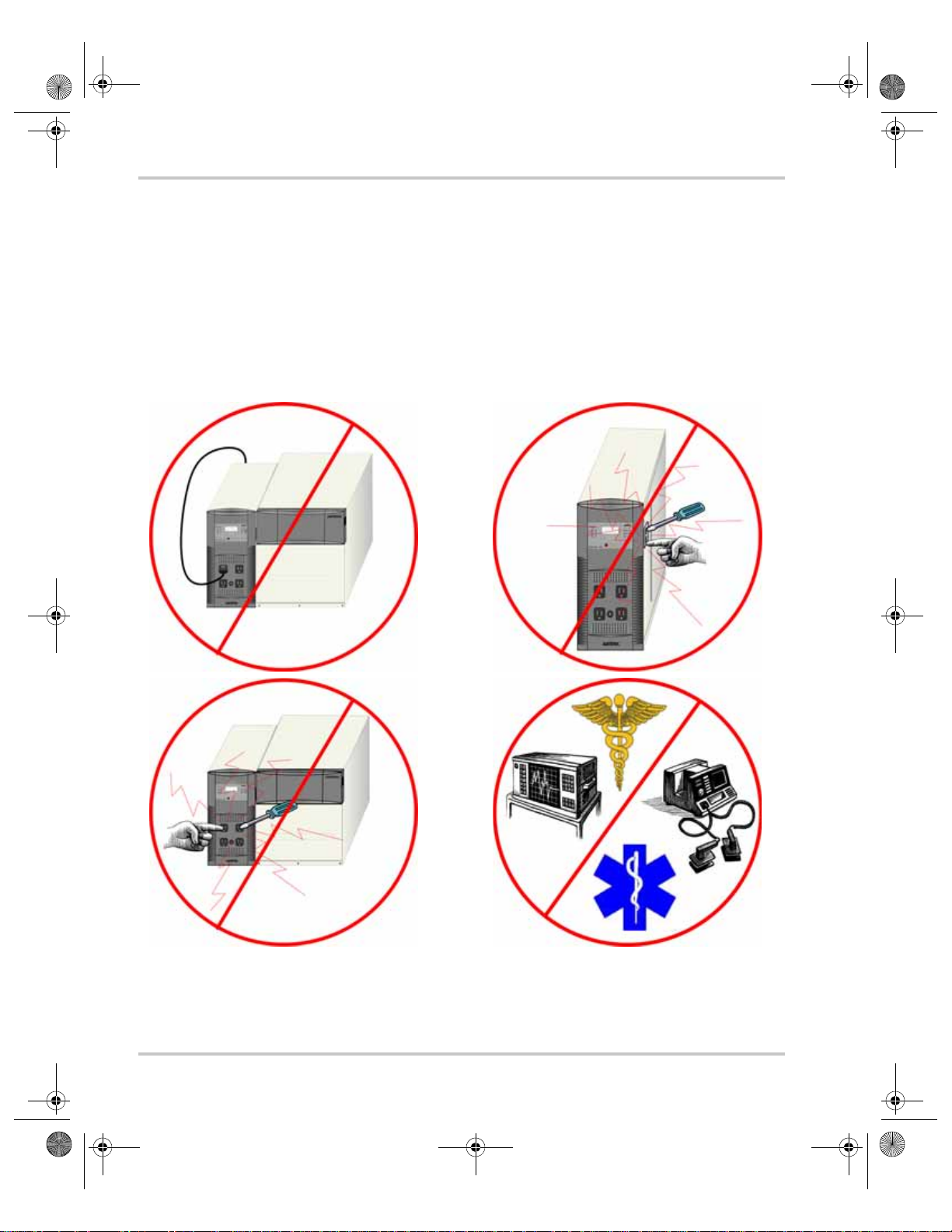

Precautions When Working With Batteries

WARNING: Fire or Explosion Hazard

1. Use only SEALED batteries with the PowerHub 1800.

2. Follow all instructions published by the battery manufacturer.

3. Working in the vicinity of batteries may be dangerous. Unsealed

batteries can generate explosive gases during normal operation.

Therefore, you must read this guide and follow the instructions

exactly before installing or using the PowerHub.

4. This equipment contains components which tend to produce arcs or

sparks. To prevent fire or explosion, do not install the PowerHub in

locations that require ignition-protected equipment. This includes any

space containing gasoline-powered machinery, fuel tanks, as well as

joints, fittings, or other connections between components of the fuel

system.

5. To reduce the risk of battery explosion, follow these instructions and

those published by the battery manufacturer.

6. Make sure that nothing is blocking the air vents on the back of the

enclosure.

7. Never smoke or allow a spark or flame near the batteries.

Safety

8. Use caution to reduce the risk of dropping a metal tool on the

batteries. It could spark or short circuit the battery or other electrical

parts and could cause an explosion.

9. Remove all personal metal items, like rings, bracelets, and watches

when working with batteries. Batteries can produce a short circuit

current high enough to weld metal, causing a severe burn.

10. Have someone within range of your voice or close enough to come to

your aid when you work near a battery.

11. Wear complete eye protection and clothing protection. Avoid

touching your eyes while working near batteries.

12. Have plenty of fresh water and soap nearby in case battery acid

contacts skin, clothing, or eyes.

975-0289-01-01 vii

Page 10

975-0289-01-01(PowerHub_1800).book Page viii Friday, January 5, 2007 12:47 PM

Safety

13. If battery acid contacts skin or clothing, wash immediately with soap

and water. If acid enters your eye, immediately flood it with running

cold water for at least twenty minutes and get medical attention

immediately.

Precautions for Using Rechargeable Appliances

CAUTION: Equipment Damage

This equipment produces a modified sine wave output. Equipment damage may

occur if the rechargeable appliance is not designed to use modified sine wave

output. If you are unsure about using your rechargeable appliance with the

modified sine wave, contact the equipment manufacturer.

Most rechargeable battery-operated equipment uses a separate charger or

transformer that is plugged into an AC receptacle and produces a low

voltage charging output.

Some chargers for small rechargeable batteries can be damaged if

connected to the PowerHub. Do not use the following with the PowerHub:

• Small battery-operated appliances like flashlights, razors, and night

lights that can be plugged directly into an AC receptacle to recharge.

• Some chargers for battery packs used in power hand tools. These

affected chargers display a warning label stating that dangerous

voltages are present at the battery terminals.

FCC/ICES 003 Information to the User

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

viii 975-0289-01-01

Page 11

975-0289-01-01(PowerHub_1800).book Page ix Friday, January 5, 2007 12:47 PM

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Power Down Procedure

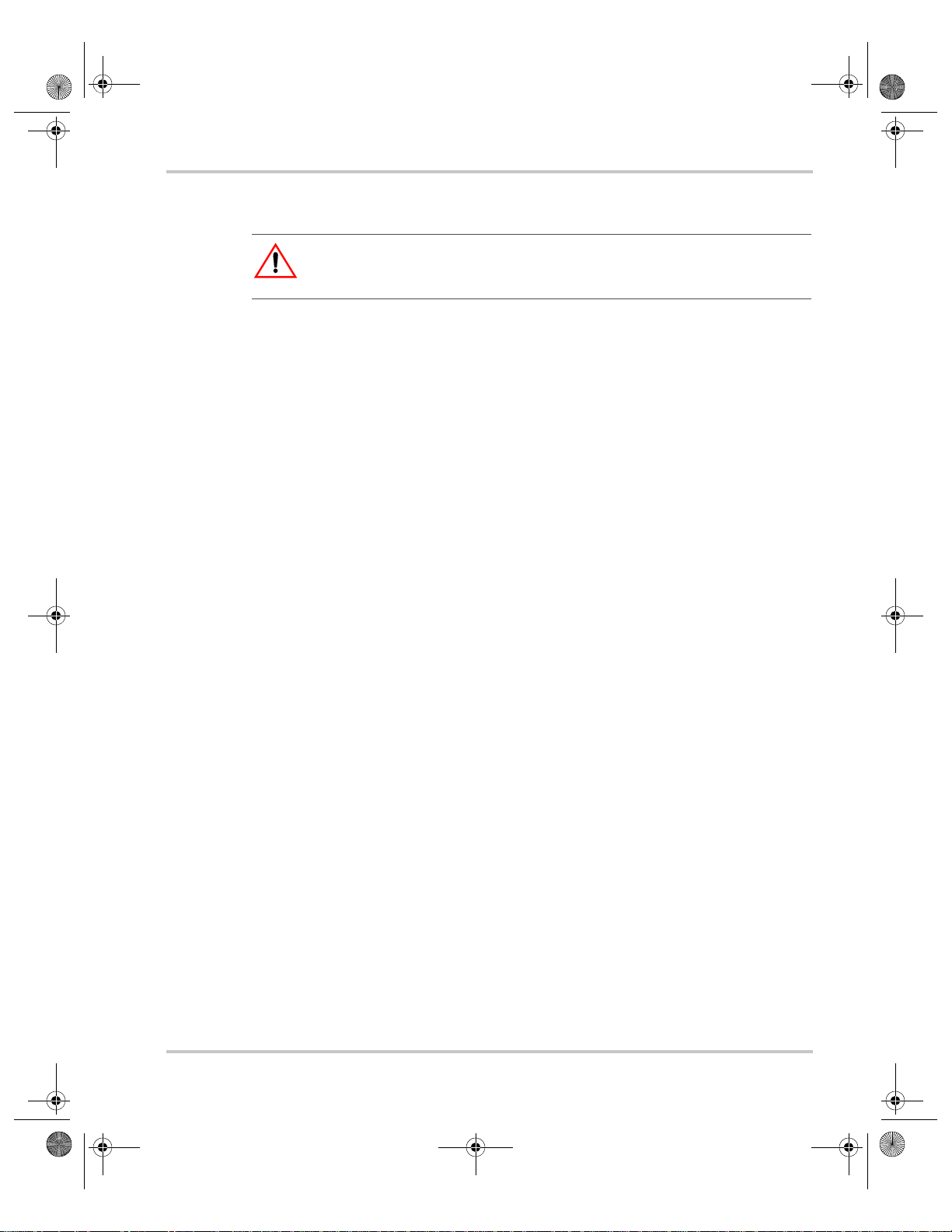

If softwired...... To Power Down the PowerHub 1800:

Press ON/OFF Switch to turn

2

OFF Inverter/Charger

Safety

1

Disconnect the PowerHub

3

from the generator and

turn the generator OFF.

OFF

Figure ii

975-0289-01-01 ix

Power Down Procedure for Softwired Installations

Disconnect Loads

Disconnect the Battery Box(es)

4

from the Inverter

Page 12

975-0289-01-01(PowerHub_1800).book Page x Friday, January 5, 2007 12:47 PM

Safety

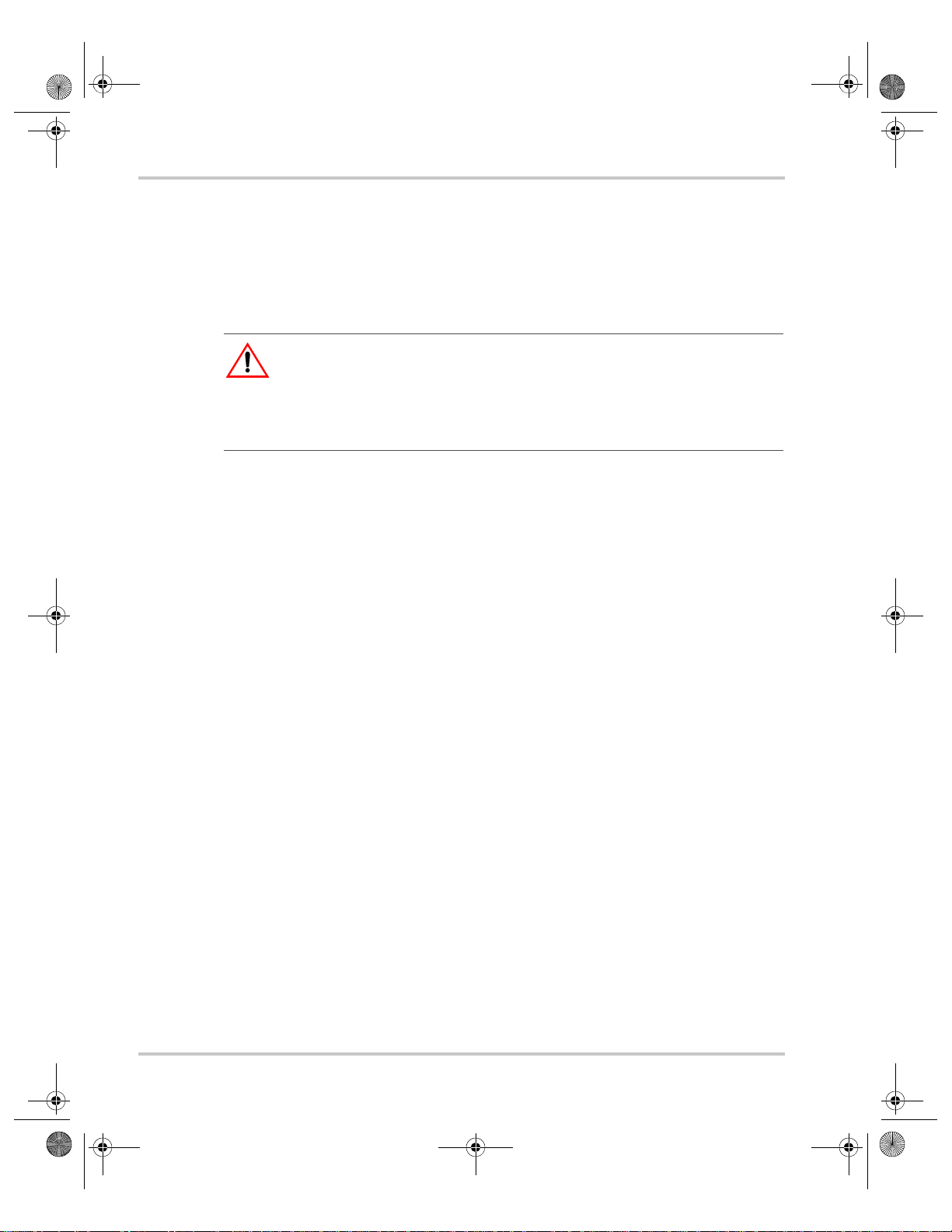

If hardwired...... To Power Down the PowerHub 1800:

WARNING: Shock Hazard

If no DC disconnect is used, then the DC input sources (solar or wind) will have

to be physically disconnected to ensure power is OFF.

2

1

Disconnect any loads directly

connected to the front panel of

the PowerHub

Press ON/OFF

3

Switch to turn OFF

Inverter/Charger

Disconnect the Utility

5

power by opening the AC

input circuit breaker in the

main panel.

Disconnect Loads connected to

the PowerHub through AC

Distribution Panel (Sub-panel)

by opening the Inverter Output

Circuit Breaker.

Disconnect the

DC Input.(s)

Disconnect the Battery Box(es)

6

from the Inverter

4

Figure iii

Power Down Procedure for Hardwired Installations

x 975-0289-01-01

Page 13

975-0289-01-01(PowerHub_1800).book Page xi Friday, January 5, 2007 12:47 PM

Contents

Important Safety Instructions

Precautions When Working With Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

Precautions for Using Rechargeable Appliances - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC/ICES 003 Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Power Down Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ix

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -v

1 Introduction

Features and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Softwired Generator Applications (Plug-and-go) - - - - - - - - - - - - - - - - - - - - - - 1–5

Hardwired Permanent Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Utility Backup Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Solar Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Wind Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Combination Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

2 Planning

Planning Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Tools Required- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Hardware / Materials Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Environmental Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Renewable Energy (RE) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Solar Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Wind - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

3 Installation

Installation Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–1

Assembling the Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Preparing the Battery Bank - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Connecting the Battery Bank to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Connecting Two Battery Boxes to the Inverter - - - - - - - - - - - - - - - - - - - - - - -3–7

Replacing the Top to the Battery Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

975-0289-01-01 xi

Page 14

975-0289-01-01(PowerHub_1800).book Page xii Friday, January 5, 2007 12:47 PM

Contents

Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Plug-and-go (Softwiring) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Permanent Wiring (Hardwiring) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Terminal Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Removing the Factory-installed AC Cord and Knockouts - - - - - - - - - - - - 3–11

AC Input and Output Wiring from a Generator - - - - - - - - - - - - - - - - - - - 3–13

AC Input and Output Wiring from the Utility Grid - - - - - - - - - - - - - - - - 3–14

DC Wiring with Ground Fault Protection

(Renewable Energy Solar Panel; Maximum 400 W) - - - - - - - - - - - - - - - 3–15

DC Wiring with Ground Fault Protection

(Renewable Energy Solar Array; Maximum 1000 W) - - - - - - - - - - - - - - 3–16

DC Wiring (Renewable Energy Wind, Maximum 1000 W) - - - - - - - - - - - 3–17

Replacing the Top Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–18

Double-check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–18

Power Up Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–19

Power Down Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Ground Fault Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

Replacing the Ground Fault Protection Fuse - - - - - - - - - - - - - - - - - - - - - - - - 3–23

A Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Physical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Battery Charger Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Charging Profiles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

40-amp Charging Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

10-amp Charging Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–6

0-amp Charging Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–6

xii 975-0289-01-01

Page 15

975-0289-01-01(PowerHub_1800).book Page xiii Friday, January 5, 2007 12:47 PM

Figures

Figure i Basic Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Figure ii Power Down Procedure for Softwired Installations- - - - - - - - - - - - - - - - - - ix

Figure iii Power Down Procedure for Hardwired Installations - - - - - - - - - - - - - - - - - -x

Figure 1-1 The PowerHub 1800 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–1

Figure 1-2 PowerHub 1800 Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Figure 1-3 PowerHub 1800 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-4 Softwired Utility or Generator Applications- - - - - - - - - - - - - - - - - - - - - 1–5

Figure 1-5 Hardwired Utility Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Figure 1-6 Hardwired Solar Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Figure 1-7 Hardwired Wind Applications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Figure 1-8 Hardwired Combination Applications- - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 2-1 Dimensions (not to scale) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Figure 2-2 Battery Box and Battery Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Figure 3-1 Preparing the Components for Assembly- - - - - - - - - - - - - - - - - - - - - - - 3–2

Figure 3-2 Connecting the Battery Box to the Inverter - - - - - - - - - - - - - - - - - - - - - 3–3

Figure 3-3 Preparing the Battery Bank- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-4 Battery Cabling for Two Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Figure 3-5 Connecting the Battery Bank to the Inverter - - - - - - - - - - - - - - - - - - - - 3–6

Figure 3-6 Connecting Two Battery Boxes to the Inverter- - - - - - - - - - - - - - - - - - - 3–7

Figure 3-7 Replacing the Top to the Battery Box- - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-8 Plug-n-Go Wiring (Softwired)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-9 Terminal Access for Hardwiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Figure 3-10 Removing the AC Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Figure 3-11 Preparing the Knockouts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Figure 3-12 Connecting the AC Input and Output from a Generator - - - - - - - - - - - - - 3–13

Figure 3-13 Connecting the AC Input and Output from the Utility - - - - - - - - - - - - - - 3–14

Figure 3-14 Connecting the DC Input (Renewable Energy Solar Panel) - - - - - - - - - - 3–15

Figure 3-15 Connecting the DC Input (Renewable Energy Solar Array) - - - - - - - - - - 3–16

Figure 3-16 Connecting the DC Input (Renewable Energy Wind) - - - - - - - - - - - - - - 3–17

Figure 3-17 Replacing the Top Cover on the Inverter- - - - - - - - - - - - - - - - - - - - - - - 3–18

Figure 3-18 Power Up Procedure for Softwired Installations- - - - - - - - - - - - - - - - - - 3–19

Figure 3-19 Power Up Procedure for Hardwired Installations - - - - - - - - - - - - - - - - - 3–20

975-0289-01-01 xiii

Page 16

975-0289-01-01(PowerHub_1800).book Page xiv Friday, January 5, 2007 12:47 PM

Figures

Figure 3-20 Power Down Procedure for Softwired Installations- - - - - - - - - - - - - - - - 3–21

Figure 3-21 Power Down Procedure for Hardwired Installations - - - - - - - - - - - - - - - 3–22

Figure 3-22 Replacing Ground Fault Protection Fuse- - - - - - - - - - - - - - - - - - - - - - - 3–24

Figure A-1 Three-Stage Charging Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

xiv 975-0289-01-01

Page 17

975-0289-01-01(PowerHub_1800).book Page i Friday, January 5, 2007 12:47 PM

Tables

Table 2-1 Typical AC Appliances and Run Times - - - - - - - - - - - - - - - - - - - - - - - 2–7

Table 3-1 Recommended Wire Gauges for Input and Output Terminals- - - - - - - - - 3–11

Table A-1 Electrical Specifications for the Inverter - - - - - - - - - - - - - - - - - - - - - - - A–2

Table A-2 Electrical Specifications for the Battery Box - - - - - - - - - - - - - - - - - - - - A–2

Table A-3 Physical Specifications of the Inverter - - - - - - - - - - - - - - - - - - - - - - - - A–3

Table A-4 Physical Specifications of the Battery Box - - - - - - - - - - - - - - - - - - - - - A–3

Table A-5 40-amp Charging Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Table A-6 10-amp Charging Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

975-0289-01-01 i

Page 18

975-0289-01-01(PowerHub_1800).book Page ii Friday, January 5, 2007 12:47 PM

ii

Page 19

975-0289-01-01(PowerHub_1800).book Page 1 Friday, January 5, 2007 12:47 PM

1 Introduction

Chapter 1 describes the features and functions of the PowerHub

1800.

Figure 1-1

The PowerHub 1800

Page 20

975-0289-01-01(PowerHub_1800).book Page 2 Friday, January 5, 2007 12:47 PM

Introduction

Features and Functions

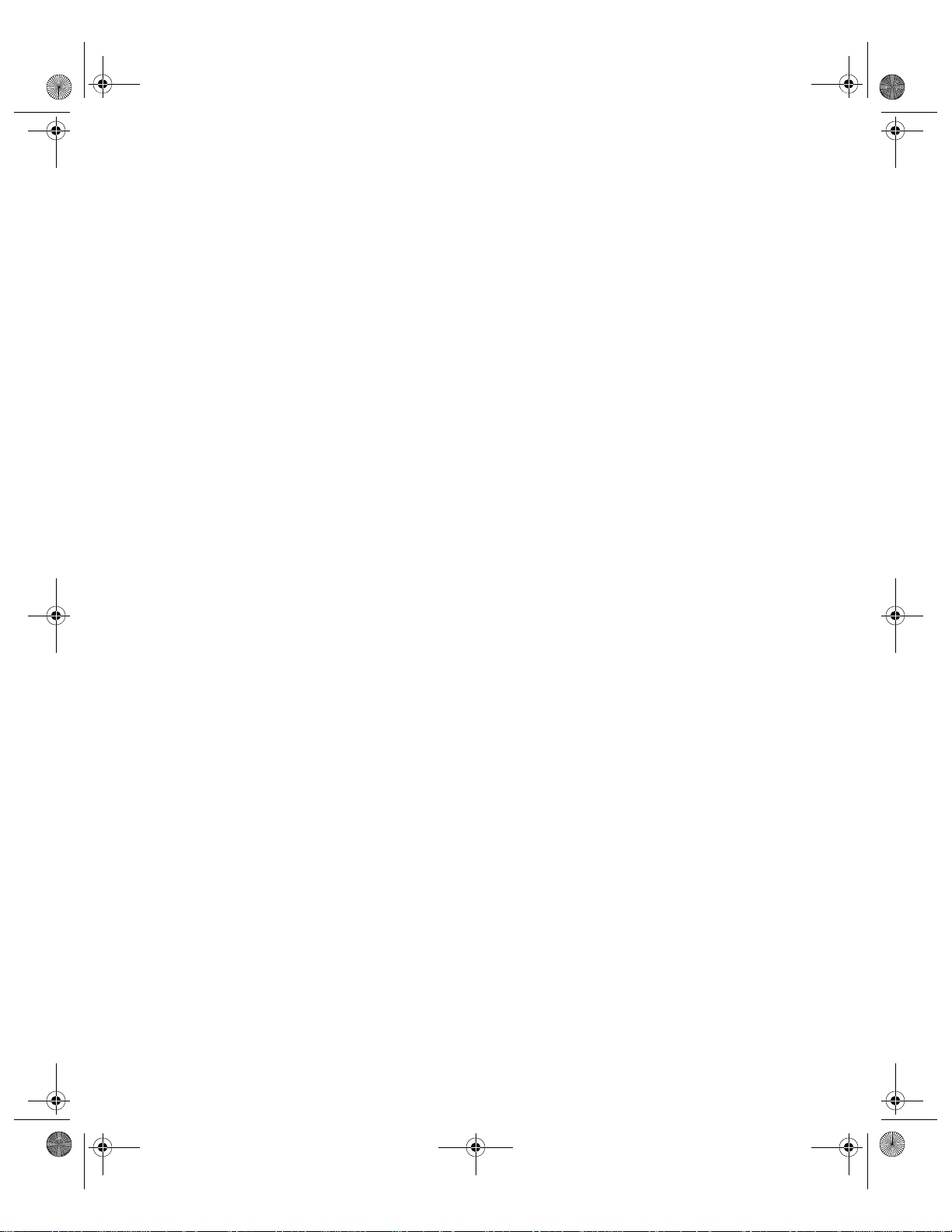

Components The PowerHub 1800 consists of the following components.

Batteries not

included.

PowerHub 1800

Installation Guide

and User’s Guide

Accessory Plate

for Hardwired

Installations

1 set #1/0 AWG

Battery Cables

Figure 1-2

1800 W Inverter/Charger

Includes:

• 1800 W modified sine wave

inverter

• 40 A charger

• Seven 20-amp/32 Vdc

Regulatory approved

automotive-type fuses for

circuitry protection

• One supplementary protector

PowerHub 1800 Components

Includes:

• Battery Cables(positive-red,

• CSA/UL Approved Anderson

• 10 Regulatory approved

Battery Box

negative-black)

( #1/0 AWG 11" long)

connector inside the front panel

for connecting enclosure to

inverter.

20 A/32 Vdc automotive-type

fuses for circuitry protection.

Purpose The PowerHub 1800 is intended to be an entry-level inverter system for

use in support of AC loads up to1440 W continuous, (1800 W on a

5-minute surge). It can be used as a stand-alone power source (softwired)

or be permanently installed on site (hardwired). It is not intended to be

used as an uninterruptible power source (UPS).

Function The PowerHub 1800 is specifically designed to use power stored in two

battery boxes that hold up to four 12 Vdc sealed, lead-acid batteries (not

provided) to power AC loads and to recharge those batteries when an A C

source (generator or utility grid) is available. Run-time on batteries will

vary depending on the size of the loads using the po wer.

1–2 975-0289-01-01

Page 21

975-0289-01-01(PowerHub_1800).book Page 3 Friday, January 5, 2007 12:47 PM

Features and Functions

Renewable

Energy Input

Inverter

Features

It can also use renewable energy, such as 12 V solar panels and small

12 V wind turbines, to recharge the batteries. Using renewable energy

sources require a permanent “hardwired” installation and will require

additional equipment and structural enhancement to be code-compliant.

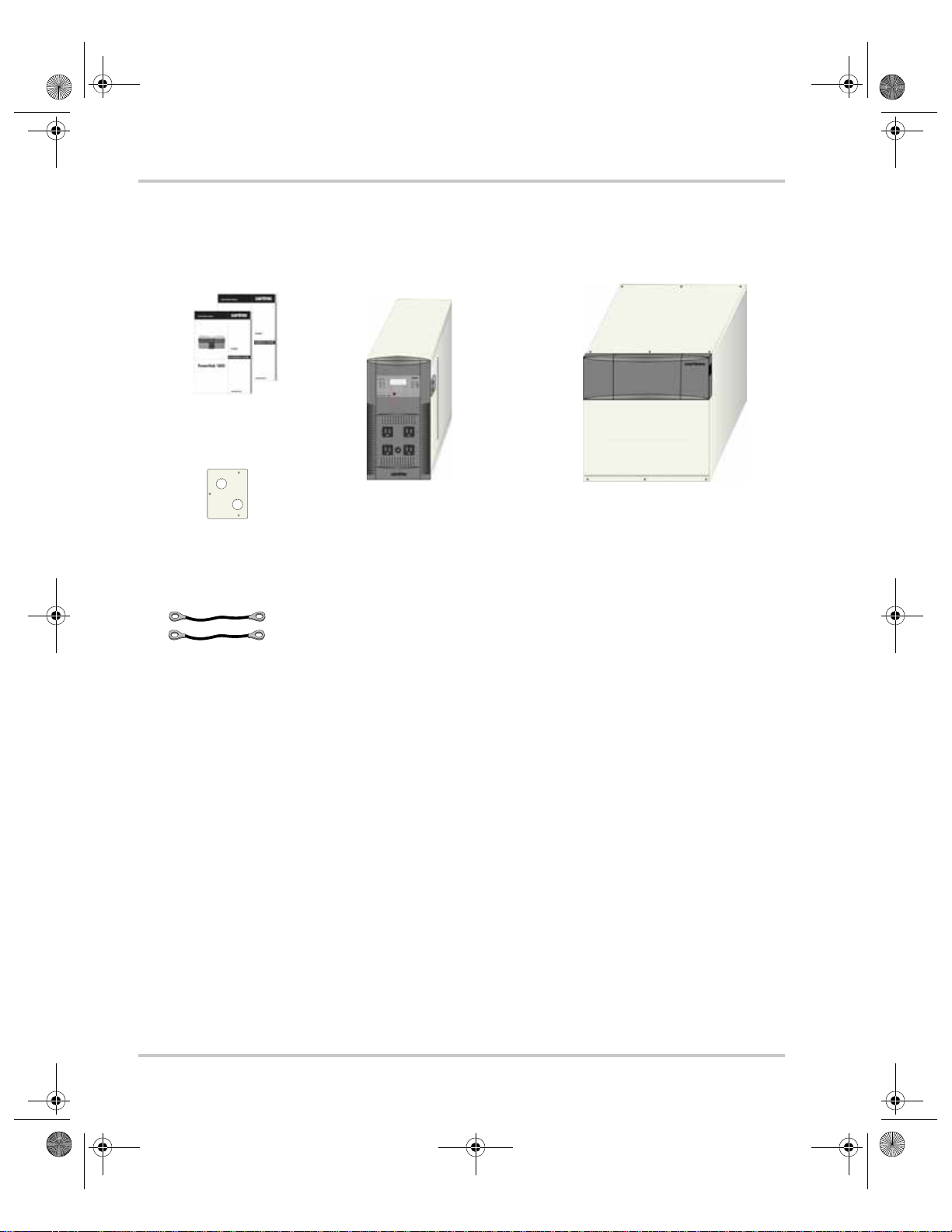

The inverter consists of the following user features:

• Inverter Control Panel

• Four 120 Vac outlets on the front panel.

• One supplementary protector to protect the 120 Vac outlets from

overload.

• Two Battery Box Connection Ports (one on each side)

Inverter

Control

Panel

AC Outlets (x4)

Input/Output terminals are located

under top panel. See Figure 3-9

on page 3–10 for a detailed

illustration of these terminals.

Battery Box Connection Ports

for Anderson-type Connector

Plus (x2-one on each side)

AC Indicator LED

Supplementary

Protector

Figure 1-3

Input/Output

Terminals

PowerHub 1800 Features

The inverter has the following input/output terminals:

• Two DC Anderson ports for 12 V battery connections from the

Battery Box; one on each side.

• Two pairs of DC input terminals for renewable energy connections:

one 32 A input terminal and one 80 A input terminal. External inputs

to these terminals must be externally regulated. Solar panels must

use charge controllers and wind turbines must be self-regulated.

• The 32 A terminals can be used for 12 Vdc input up to

400 W maximum.

• The 80 A terminals can be used for 12 Vdc input up to

1000 W maximum.

• AC input terminal (for grid or generator input)

• AC output terminal (for AC output in hardwired installations)

975-0289-01-01 1–3

Page 22

975-0289-01-01(PowerHub_1800).book Page 4 Friday, January 5, 2007 12:47 PM

Introduction

Grounding The inverter has two AC Ground terminals and one equipment ground

terminal. In addition, there are ground fault protection terminals for solar

and wind renewable energy inputs (a 32 A and an 80 A). See Figure 3-9

on page 3–10 for a detailed illustration of the Input/Output and ground

terminals.

Regulatory This system complies with CSA 107.1-01 and UL1741and is certified for

a permanent installation that is compliant with national electrical codes.

1–4 975-0289-01-01

Page 23

975-0289-01-01(PowerHub_1800).book Page 5 Friday, January 5, 2007 12:47 PM

Applications

The PowerHub 1800 can be used for the following entry-level

applications.

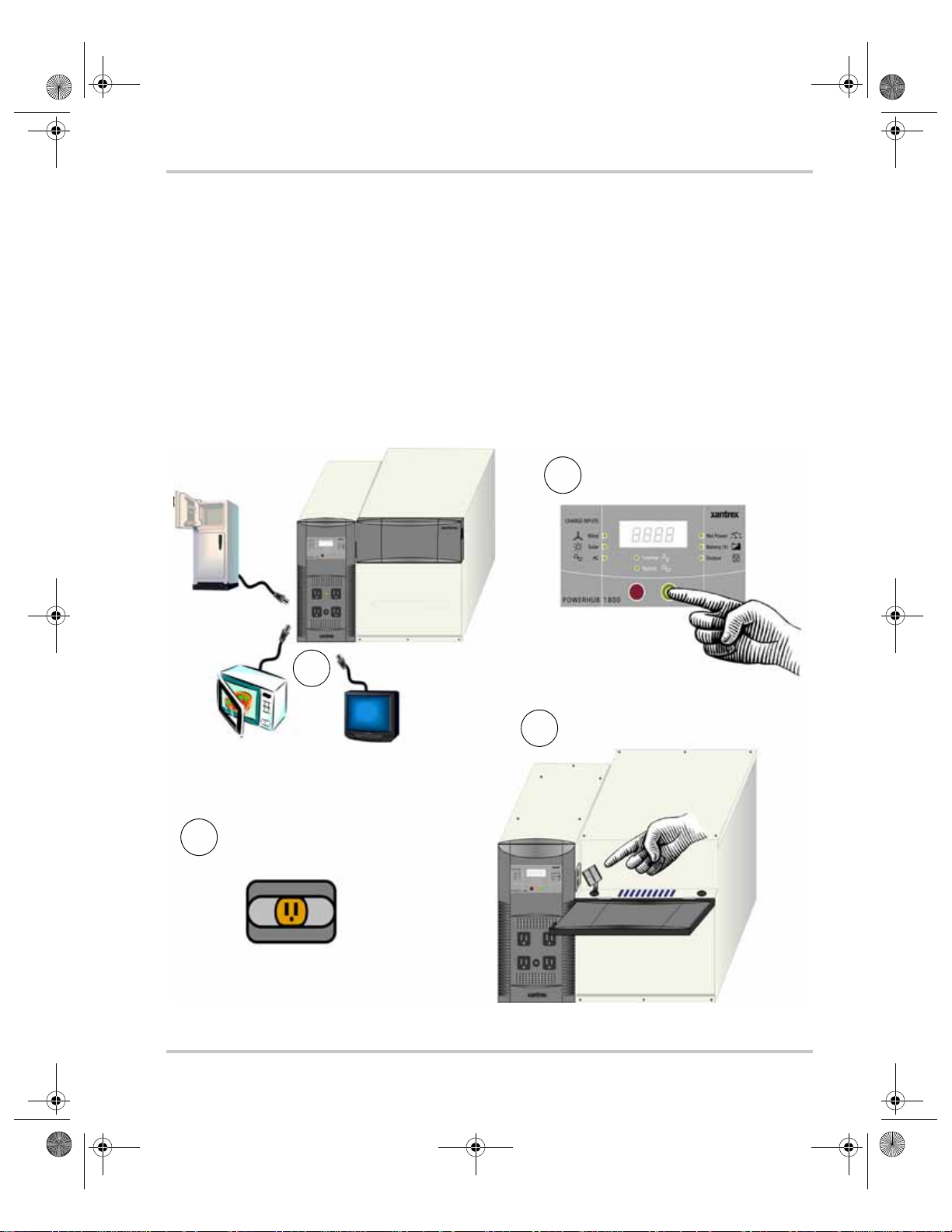

Softwired Generator Applications (Plug-and-go)

The PowerHub 1800 comes assembled with an AC input cord. This AC

cord can be plugged into a 120 Vac outlet on a generator to charge the

batteries.

Applications

Important:

generators in non-permanent installations. For fixed permanent installations,

Xantrex recommends using electrical code-compliant wiring methods.

Important:

1440 watts, due to the 15 A supplementary protector whi ch p rot ects the circuitry.

AC Generator

The input cord is intended to allow connection to portable

The total amount of output power available to power the loads is

120 Vac Outlet

AC OUT

Important:

loads cannot exceed 1440 W.

Run-times will depend on the

amp-hour rating of the batteries.

Figure 1-4

975-0289-01-01 1–5

Softwired Utility or Generator Applications

The combination of

Page 24

975-0289-01-01(PowerHub_1800).book Page 6 Friday, January 5, 2007 12:47 PM

Introduction

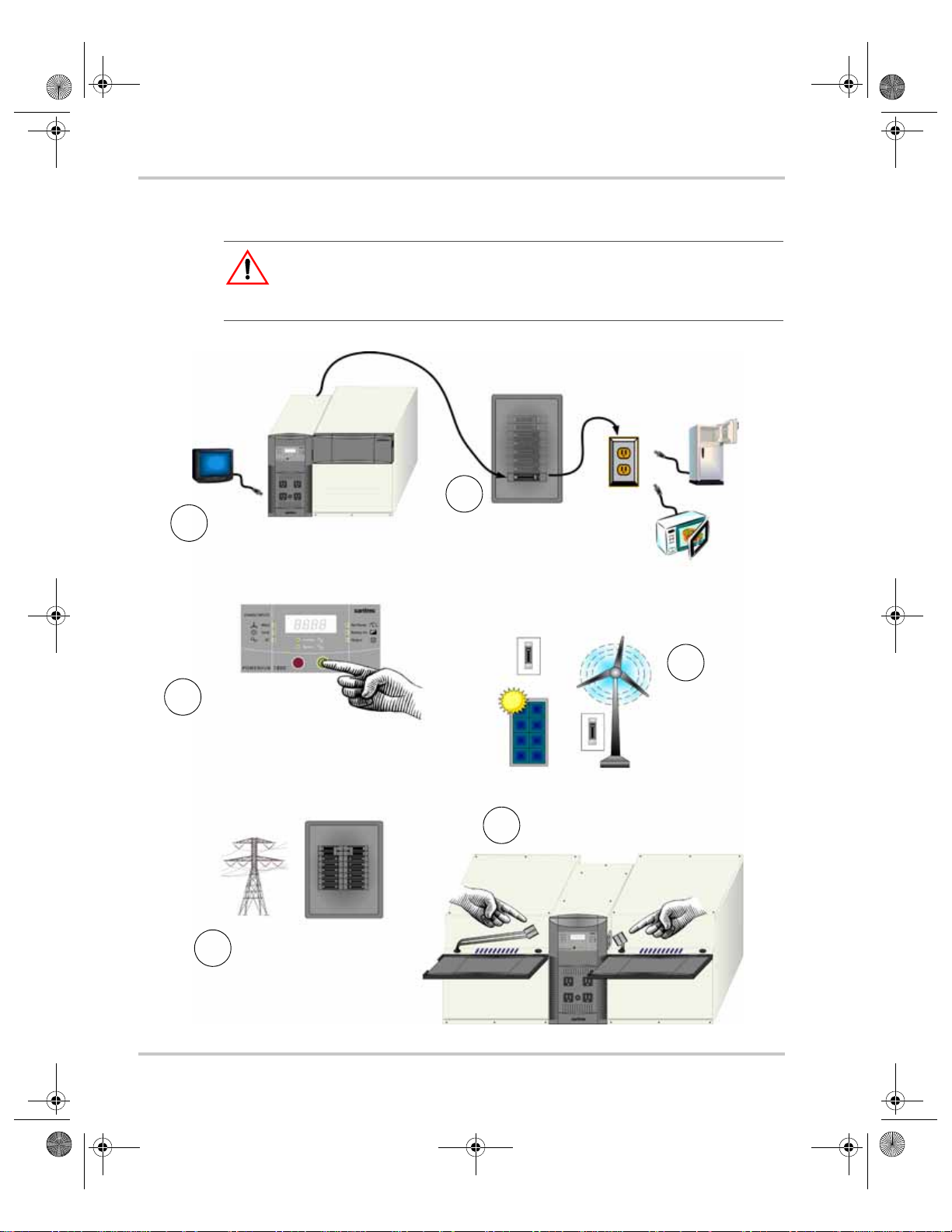

Hardwired Per mane nt Applications

Utility Backup Applications

Important:

“code-compliant” to the national and local building and electrical codes.

Installers should have adequate knowledge of national and local code to ensure

the installation passes inspection by the local electric authority.

Example only.

Actual installation may vary.

Installations of this kind must be certified/approved as

AC Distribution Panel

(Sub-Panel)

120 Vac

Outlets

AC OUT

Main AC

Panel

AC IN

Important:

The combination of loads

cannot exceed 1440 W. Run-times will depend

on the amp-hour rating of the batteries.

Figure 1-5

Hardwired Utility Applications

1–6 975-0289-01-01

Page 25

975-0289-01-01(PowerHub_1800).book Page 7 Friday, January 5, 2007 12:47 PM

Solar Applications

Applications

Important:

“code-compliant” to the national and local building and electrical codes.

Installers should have adequate knowledge of national and local code to ensure

the installation passes inspection by the local electric authority.

Maximum size of PV array depends on the DC input terminals used:

• 400 W Maximum on 32 A DC terminal

• 1000 W Maximum on 80 A DC terminal

• Additional charge controllers and other hardware may be required.

Example only.

Actual installation may vary.

Installations of this kind must be certified/approved as

Solar Panel(s)

AC Distribution Panel

(Sub-Panel)

Charge Controller

(required)

(C60 shown as

example only)

DC Disconnect

(recommended)

DC IN

Important:

AC OUT

The combination

of loads cannot exceed 1440 W.

Run-times will depend on the

amp-hour rating of the batteries.

Figure 1-6

Hardwired Solar Applications

975-0289-01-01 1–7

Page 26

975-0289-01-01(PowerHub_1800).book Page 8 Friday, January 5, 2007 12:47 PM

Introduction

Wind Applications

Important:

“code-compliant” to the national and local building and electrical codes.

Installers should have adequate knowledge of national and local code to ensure

the installation passes inspection by the local electric authority.

Maximum size of wind turbine:

• 1000 W maximum on 80 A DC terminal only

• Self-regulation required.

• Disconnect recommended

Example only.

Actual installation may vary.

Installations of this kind must be certified/approved as

Wind Turbine

AC Distribution Panel

(Sub-Panel)

DC Disconnect

(recommended)

DC IN

Important:

AC OUT

The combination

of loads cannot exceed 1440 W.

Run-times will depend on the

amp-hour rating of the batteries.

Figure 1-7

Hardwired Wind Applications

1–8 975-0289-01-01

Page 27

975-0289-01-01(PowerHub_1800).book Page 9 Friday, January 5, 2007 12:47 PM

Combination Applications

Applications

Important:

“code-compliant” to the national and local building and electrical codes.

Installers should have adequate knowledge of national and local code to ensure

the installation passes inspection by the local electric authority.

Example only.

Actual installation may vary.

Installations of this kind must be certified/approved as

Charge Controller(s)

AC Distribution

Panel

(Sub-Panel)

Solar Panel(s) and

Main AC

Distribution

Panel

AC IN

Wind Turbine

(Must be self-regulated)

DC Disconnects

(recommended)

DC IN

DC IN

AC OUT

Important:

The

combination of loads

cannot exceed 1440 W.

Run-times will depend on

the amp-hour rating of

the batteries.

Figure 1-8

Hardwired Combination Applications

975-0289-01-01 1–9

Page 28

975-0289-01-01(PowerHub_1800).book Page 10 Friday, January 5, 2007 12:47 PM

1–10

Page 29

975-0289-01-01(PowerHub_1800).book Page 1 Friday, January 5, 2007 12:47 PM

2 Planning

Chapter 2 contains information on planning the installation of this

equipment.

Page 30

975-0289-01-01(PowerHub_1800).book Page 2 Friday, January 5, 2007 12:47 PM

Planning

Planning Overview

Important:

system. To use it as a stand-alone power source, it is not required to do any

special installation procedures.

However, if your installation involves renewable energy (solar or wind

generators) or requires hardwiring for any reason, if you do not have adequate

knowledge of national and local building and electrical codes, do not attempt to

install this unit in a permanent installation. Consult your local renewable energy

dealer or qualified electrician for assistance.

This unit is intended as an entry-level inverter/charger backup

1. Plan your installation carefully!

2. Determine if the installation will be softwired (plug-and-go) or

hardwired.

• If hardwired, are there any special permits required.

3. Know your limits.

• Know the limits of the loads to be attached to the system.

• Know the limits of the input and output to the inverter and the

batteries.

• Know the electrical and building code requirements for the

desired location.

• Analyze the location for the PowerHub for access and adequate

structural support.

• Measure the distances for the cabling and wiring.

4. Extract the PowerHub from its packaging material and inventory all

parts to ensure there is nothing missing.

5. Review all instructions and materials provided with all the

equipment.

6. Review all material provided with the batteries.

7. Review any material related to the installation of the renewable

energy components.

8. Collect all necessary tools and materials for the installation.

9. Prepare the location for the installation and position the components.

2–2 975-0289-01-01

Page 31

975-0289-01-01(PowerHub_1800).book Page 3 Friday, January 5, 2007 12:47 PM

Tools Required

The following tools may be required for installing this equipment:

❐ #2 Phillips screwdriver(s)

❐ Slotted screwdriver(s)

❐ Wire strippers

❐ Torque wrench

❐ Socket wrench and sockets (½ in. for the wind DC input terminal, and

10 mm for the solar DC input terminal)

❐ Electrical tape

Hardware / Materials Required

The following customer supplied items are required to use the PowerHub

1800.

❐ One or two 12 Vdc SEALED (100 amp-hour), lead-acid batteries.

Tools Required

❐ 1 ground cable #3 AWG copper (length to be determined by the

location of the installation)

The following items may be required for completing this installation.

❐ Electrical wire of appropriate gauge and length for AC input, AC

output, and AC ground (length to be determined by the location of the

installation). See Table 3-1 on page 3–11.

❐ Conduits and appropriate fittings for wire runs (e.g., wire nuts)

❐ Breaker panels, 15 A circuit breakers and appropriately sized DC

disconnects

❐ Wire connectors and crimp tool for the wind and solar DC cables

Environmental Requirements

Ventilation Ensure the environment where the PowerHub is to be installed is properly

ventilated, free of dust, dirt, etc. and where the temperature will not fall

below 0°C (32°F) or rise above 40°C (104°F).

Clearance Ensure there is a minimum of 8 inches (preferably 12 inches) of clearance

around all ventilation holes and vents. Ensure nothing flammable is stored

anywhere near this unit. Be sure to leave adequate room to access the

terminals if the unit is to be hardwired. Twelve inches may not be

adequate for access purposes to hardwire the unit.

975-0289-01-01 2–3

Page 32

975-0289-01-01(PowerHub_1800).book Page 4 Friday, January 5, 2007 12:47 PM

Planning

Dimensions

16”

(40.64 cm)

14.25”

(35.56 cm)

8”

(20.32 cm)

Recommended Minimum Required Floor Space =

22" (55.88 cm) x 33" (84 cm)

33” (84 cm)

29”

(73.7 cm)

20.5”

(52.7 cm)

12" Clearance

8" Clearance

Equipment

Footprint

22”

(55.88 cm)

13.875”

(35.24 cm)

Back

Front

20.5”

(52.7 cm)

14”

(35.56 cm)

IMPORTANT:

The Powerhub should be

mounted on concrete floors or

on floors designed to support

a minimum load of

100 pounds per square foot.

IMPORTANT:

Allow 8" minimum clearance

around the back of this unit for

ventilation. (12" preferable).

Be sure to leave adequate

space for access if the unit is to

be hardwired. 12" may not be

adequate.

Figure 2-1

Dimensions (not to scale)

2–4 975-0289-01-01

Page 33

975-0289-01-01(PowerHub_1800).book Page 5 Friday, January 5, 2007 12:47 PM

Batteries

Batteries

Important:

small 12-volt battery bank. Do not operate this equipment without connecting a

battery or battery bank.

The PowerHub 1800 is designed to be permanently connected to a

The PowerHub will use the power stored in the batteries to run AC loads

up to 1440 W (continuously). Run times for the AC loads will depend on

the amp-hour capacity of the batteries and the total of the loads drawing

power through the unit.

Types to use The following battery types are recommen ded for use with the PowerHub

1800:

Voltage 12 Vdc (required) (100 Ah minimum)

Chemistry SEALED, lead-acid batteries (required), Gel-type

(recommended), AGM (acceptable)

Size Standard Group 27. Maximum dimension of battery to be 12" W ×

6.75" D × 9" H (including terminal posts)

Terminal Location Top (required)

Terminal Type L-type or screw-in terminal

WARNING: Shock hazard

T erminal adaptors are not acceptable as they may short circuit to the battery box,

and cause an energy hazard.

Battery Box

Internal

dimensions

12.75" W x 16"D

Figure 2-2

975-0289-01-01 2–5

Battery Box and Battery Size

12.75"

16"

Battery Box holds 2 Standard Sealed

Lead-acid 12 Vdc Batteries*

sized 12" W × 6.75" D × 9" H

12"

6.75"

9"

Page 34

975-0289-01-01(PowerHub_1800).book Page 6 Friday, January 5, 2007 12:47 PM

Planning

Important:

battery types or sizes. Do not mix old batteries with new batteries. Performance

and charging anomalies can occur if types, sizes, or age of batteries are not

identical.

All batteries used for this system should be identical. Do not mix

CAUTION

Keep the weight of the batteries in mind when installing dual battery boxes.

Ensure the structure floor where the battery boxes are to be installed is strong

enough to support the additional weight. Do not try to move the system once

batteries have been installed as damage could occur to the enclosure.

See “Preparing the Battery Bank” on page 3–4 for instructions on how to

cable two batteries together.

2–6 975-0289-01-01

Page 35

975-0289-01-01(PowerHub_1800).book Page 7 Friday, January 5, 2007 12:47 PM

Batteries

Average runtimes

Table 2-1 provides typical AC appliance run times. These values are

examples only. Run times will vary depending on the amp-hour rating of

the batteries.

Table 2-1

AC Appliance Watts

Cordless telephone (stand by) 5 396.0 792.0

Home security system 5 396.0 792.0

Clock Radio 8 217.8 435.6

Inkjet Printer 8 217.8 435.6

Stereo 14 145.0 290.4

Fireplace fan 20 64.35 128.7

Laptop computer 20 64.35 128.7

Table lamp (25W) 25 54.45 108.90

17" LCD Monitor 35 49.5 99.0

Table Light (40W) 40 43.0 86.0

Color TV – 13" 50 20.80 50.4

Table lamp (60 W) 60 26.4 53.0

8.8 cu. ft. freezer 80 19.8 39.6

18 cu ft. fridge 120 14.8 29.7

Sump Pump 300 W 300 4.29 8.58

20" LCD TV 370 2.8 5.5

Microwave 1000 1.43 2.86

Coffee Maker 1200 1.00 2.86

a. Represents actual power consumption as measured on sample appliances.

b. Operating times assume a fully charged 200 Ah battery bank and may vary based on model/brand of appliance.

c. Operating times assume a fully charged 400 Ah battery bank and may vary based on model/brand of appliance.

Typical AC Appliances and Run Times

Run Time PowerHub

a

1 battery box

b

(hours)

Run Time PowerHub

2 battery boxes

c

(hours)

For more detailed information about batteries and battery banks, see the

Battery Banks for Inverter Systems Application Note, available at

www.xantrex.com.

975-0289-01-01 2–7

Page 36

975-0289-01-01(PowerHub_1800).book Page 8 Friday, January 5, 2007 12:47 PM

Planning

Renewable Energy (RE)

The PowerHub 1800 supports the following renewable energy sources.

• Photovoltaic (Solar)

•Wind

Renewable energy generators are required by code to be hardwired into a

permanent installation. Permanent installations required inspection and

approval by the local electric authority.

Some additional components may be required for code-compliance, such

as charge controllers, a DC combiner box, and/or DC disconnect

switches.

In some cases, additional structural support may be required.

Be sure to consult with a qualified RE installer BEFORE THE

INSTALLATION if renewable energy generators are to be used.

Solar Panels

Wind

The PowerHub 1800 can be connected to photovoltaic (solar) panels that

meet the following requirements.

• 12 V solar panels (up to 400 W maximum on 32 A DC input terminal

or 1000 W maximum on 80 A DC input terminal).

• Solar panels require additional equipment such as charge controllers

or possibly a DC combiner box.

• A DC disconnect switch is recommended.

• Solar panels may require additional structural support for code

compliance. Be sure to consult local code for any additional

requirements.

• PVGFP (Ground Fault Protection)

The PowerHub 1800 can be connected to wind turbines that meet the

following requirements.

• Supports 12 V wind turbines (up to 1000 W maximum.)

• Wind turbines must be self-regulated.

• A DC disconnect switch is recommended.

• Wind turbines may require additional structural support for code

compliance. Be sure to consult local code for any additional

requirements.

2–8 975-0289-01-01

Page 37

975-0289-01-01(PowerHub_1800).book Page 9 Friday, January 5, 2007 12:47 PM

Notes __________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

Renewable Energy (RE)

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

975-0289-01-01 2–9

Page 38

975-0289-01-01(PowerHub_1800).book Page 10 Friday, January 5, 2007 12:47 PM

2–10

Page 39

975-0289-01-01(PowerHub_1800).book Page 1 Friday, January 5, 2007 12:47 PM

3 Installation

Chapter 3 contains information on assembling and installing this

equipment.

Installation Overview

1. Assemble the battery box(es) to the inverter.

2. Prepare the battery bank.

3. Assemble and prepare the renewable energy components (if used).

4. Connect the battery bank to the inverter.

5. Connect the DC sources (if used).

6. Connect the AC sources:

a) if hardwired: close utility input breaker, or

b) if softwired: plug AC cord into generator

7. If hardwired, close the disconnect in the AC Distribution Panel to

feed hardwired outlets.

8. Turn on power to the PowerHub.

9. Plug in the desired AC appliances.

Page 40

975-0289-01-01(PowerHub_1800).book Page 2 Friday, January 5, 2007 12:47 PM

Installation

Assembling the Components

Important:

Ensure that the location chosen for the inverter allows 8 to

12 inches (15.2 to 30.5 cm) clearance behind both the inverter and the Battery

Box(es). Additional room may be needed for access.

1. Decide on which side of the inverter box

the Battery Box will be placed and locate the

four #6-32 mounting screws on that side(s) of

the inverter. These screws can be identified

by the small ring of bare metal around them.

Mounting Screw

Bare Metal

Inverter Side View

2. Loosen these screws just

enough to allow the keyhole slots

on the side of the battery Box to

slip over the top of them. Do NOT

remove these screws completely.

Continued in Figure 3-2.

Figure 3-1

Preparing the Components for Assembly

3–2 975-0289-01-01

Page 41

975-0289-01-01(PowerHub_1800).book Page 3 Friday, January 5, 2007 12:47 PM

Continued from Figure 3-1.

3. Locate the four keyhole

shaped slots on the side of

the battery box that is to be

attached to the inverter.

Assembling the Components

Battery Box Side View

4. Align the Battery Box keyhole

slots with the mounting screws on

the inverter box. Place the keyhole

slots over the screws and lower into

place, so that the head of the screw

interlocks with the top of the keyhole

slot inside the Battery Box.

Also ensure that the washers on the

mounting screws end up on the

inside of the battery box and not

between the battery box and the

inverter.

5. Secure the Battery Box to

the Inverter box by tightening

the mounting screws.

Torque to 1.3 nm (11.5 in-lb).

Important:

Attaching the battery box(es)

to the inverter grounds the chassis’ of the two

components and is required, not optional.

Figure 3-2

Connecting the Battery Box to the Inverter

975-0289-01-01 3–3

Page 42

975-0289-01-01(PowerHub_1800).book Page 4 Friday, January 5, 2007 12:47 PM

Installation

Preparing the Battery Bank

1. Insert the batteries into the

compartment.

2. Connect the batteries as

shown below depending on the

battery configuration used.

3. Tighten the Hex nut on the

battery terminal to the battery

manufacturer’s torque

requirement.

If using two batteries, see

Figure 3-6 for additional

cabling instructions.

If using one battery......

*These cables are connected

to the Anderson Plugs in the

front panel of the battery box.

CONNECT SECOND:

Positive (+) (red) Cable from

the Battery Box to the Inverter*

DISCONNECT FIRST:

Positive (+) (red) Cable from

the Battery Box to the Inverter*

Important:

When disconnecting

batteries, ensure all incoming power

has been disconnected.

Then remove the Positive (+) (red)

cable FIRST , and the negative (–)

(black) cable LAST.

Figure 3-3

Preparing the Battery Bank

CONNECT FIRST:

Negative (–) (black) Cable from

the Battery Box to the Inverter*

DISCONNECT LAST:

Negative (–) (black) Cable from

the Battery Box to the Inverter*

Cable Connection Order:

Hex Nut

Split Washer

Cable from Battery Box

Battery Terminal

3–4 975-0289-01-01

Page 43

975-0289-01-01(PowerHub_1800).book Page 5 Friday, January 5, 2007 12:47 PM

If using two 12 Vdc batteries, connect the cables in "parallel".

Positive (+) to Positive (+)

Negative (–) to Negative (–)

Battery

Cable

Assembling the Components

Battery

Cable

CONNECT SECOND:

Positive (+) (red) Cable from

the Battery Box to the Inverter*

DISCONNECT FIRST:

Positive (+) (red) Cable from

the Battery Box to the Inverter*

Cable Connection Order:

Battery Cable*

Cable from Battery Box

Figure 3-4

Battery Cabling for Two Batteries

Hex Nut

Split Washer

Battery Terminal

Important:

batteries, ensure all incoming power

has been disconnected.

Then remove the Positive (+) (red)

cable FIRST , and the negative (–)

(black) cable LAST.

CONNECT FIRST:

Negative (–) (black) Cable from

the Battery Box to the Inverter*

DISCONNECT LAST:

Negative (–) (black) Cable from

the Battery Box to the Inverter*

When disconnecting

975-0289-01-01 3–5

Page 44

975-0289-01-01(PowerHub_1800).book Page 6 Friday, January 5, 2007 12:47 PM

Installation

Connecting the Battery Bank to the Inverter

WARNING: Shock Hazard

Once the battery bank is connected to the inverter, if the batteries are char ged, the

inverter outlets may become "live". If the PowerHub is to be hardwired, wait

until all wiring is complete BEFORE connecting the battery bank.

CAUTION: Equipment Damage

Double-check the cabling of the batteries to ensure proper polarity BEFORE

connecting the battery box to the inverter. Damage caused to the inverter due to

improper battery cabling is not covered by the limited warranty.

Battery Connection

Port (x2)

Figure 3-5

Insert the Anderson connectors into

the Battery Connection Port on the

Inverter.

Ensure the connector is inserted

completely. This may require some

force as the connectors are tight.

Connecting the Battery Bank to the Inverter

3–6 975-0289-01-01

Page 45

975-0289-01-01(PowerHub_1800).book Page 7 Friday, January 5, 2007 12:47 PM

Connecting Two Battery Boxes to the Inverter

Up to two Battery Boxes can be used with the PowerHub 1800 at one time

for a maximum of four 12-volt batteries only.

Connect dual Battery Boxes as follows:

1. Prepare the opposite side of the inverter as described in Figure 3-1 on

page 3–2.

2. Connect the second Battery Box to the inverter as described in Figure

3-2 on page 3–3

3. Prepare the battery bank for the second battery box as described in

“Preparing the Battery Bank” on page 3–4

4. Route the cables with the Anderson connectors from the second

Battery box over the top of the fuses in the front of the second battery

box.

5. If the unit is going to be softwired, connect the Anderson cables to the

inverter as shown in Figure 3-5 on page 3–6.

6. If the unit is going to be hardwired, make the AC IN and AC OUT

connections prior to connecting the Anderson Connectors to the

inverter.

Assembling the Components

Figure 3-6

Connecting Two Battery Boxes to the Inverter

WARNING: Shock Hazard

Once the battery banks are connected to the inverter, if the batteries are charged,

the inverter outlets may become “live”. If the PowerHub is to be hardwired,

wait until all wiring is complete BEFORE connecting the battery banks.

975-0289-01-01 3–7

Page 46

975-0289-01-01(PowerHub_1800).book Page 8 Friday, January 5, 2007 12:47 PM

Installation

Replacing the Top to the Battery Box

Back

Front

Sides with

folded down

edges

1. Place the top to the battery box on

the enclosure, back edge first so

that the back edge of the enclosure

is inserted into the folded down

edges of the sides of the top.

There is a label on the underside of

the top to indicate front from back.

2. Align the screw holes from the

top to the enclosure.

3. Use the 6 6x32 Phillips

screws in the plastic bag

provided to secure the top in

place.

Torque to 1.3 nm (11.5 in-lb).

4. Remove the knockout panel on

the side of the front panel on the

battery box to accommodate the

battery connections to the inverter.

Repeat this procedure for the

second battery box if used.

To close the front panel on the battery box:

Lift the front panel

into place.

Knockout Panel

(one on each side)

Figure 3-7

Replacing the Top to the Battery Box

Gently push the lip on

the front panel under

the lip on the top of the

battery box enclosure.

3–8 975-0289-01-01

Page 47

975-0289-01-01(PowerHub_1800).book Page 9 Friday, January 5, 2007 12:47 PM

Wiring

Plug-and-go (Softwiring)

The PowerHub 1800 comes assembled with an AC input cord. This AC

cord can be plugged into a 120 Vac outlet on a 120 Vac generator to

charge the batteries.

Wiring

120 Vac

Outlet only

Important:

generators in non-permanent installations. For fixed permanent installations,

Xantrex recommends using electrical code-compliant wiring methods. See

“Permanent Wiring (Hardwiring)” on page 3–10 for instructio ns.

AC Generator

The input cord is intended to allow connection to portable

Important:

of loads cannot exceed 1440 W.

Figure 3-8

975-0289-01-01 3–9

Plug-n-Go Wiring (Softwired)

The combination

Page 48

975-0289-01-01(PowerHub_1800).book Page 10 Friday, January 5, 2007 12:47 PM

Installation

Permanent Wiring (Hardwiring)

WARNING: Shock Hazard

Hardwiring this equipment should be done by a person with adequate knowledge

of electrical and building code requirements. Failure to follow safe installation

practices could result in a significant, and possibly lethal, shock hazard.

Terminal Access

BEFORE REMOVING INVERTER COVER:

Check to ensure the AC Indicator LED is NOT

illuminated and that there are absolutely no

sources of power connected to the PowerHub.

Remove the 5 #6-32

Phillips screws on

the top of the

inverter. Lift off the

panel to expose the

terminals.

Wiring Terminals Enlargement

AC Indicator LED

Once hardwiring is complete 120 Vac power will be

available at the outlets on the front panel as well as the

outlets directly connected to the PowerHub through the

AC Distribution Panel.

Figure 3-9

Terminal Access for Hardwiring

3–10 975-0289-01-01

Page 49

975-0289-01-01(PowerHub_1800).book Page 11 Friday, January 5, 2007 12:47 PM

Wiring

Table 3-1

Recommended Wire Gauges for Input and Output Terminals

Terminal Acceptable Wire Gauge Torque to.....

AC Input (Neutral and Line) #14 AWG 1.3 Nm (11.5 in-lbs)

AC Output (Neutral and Line) #14 AWG 1.3 Nm (11.5 in-lbs)

AC Ground #14 AWG 1.8 Nm (16.0 in-lbs)

DC Input (32 A DC Input/40 A fused) Manufacturer’s recommendation. 20.3 Nm (180 in-lbs)

DC Input (80 A DC Input/100 A fused) Manufacturer’s recommendation. 20.3 Nm (180 in-lbs)

DC Ground Manufacturer’s recommendation. 20.3 Nm (180 in-lbs)

System Ground #3 AWG

Removing the Factory-installed AC Cord and Knockouts

1. Locate the AC wiring from the

cord and loosen the screws on

the Ground, Line 1 (L1), and

Neutral terminals.

2. Remove the 3 #6-32

Phillips screws on the AC

cord access plate and

remove the plate along

with the cord.

Proceed to Figure 3-11.

Figure 3-10

Removing the AC Cord

975-0289-01-01 3–11

Page 50

975-0289-01-01(PowerHub_1800).book Page 12 Friday, January 5, 2007 12:47 PM

Installation

Continued from Figure 3-10.

3. Locate the AC Accessory

Plate and remove one or the two

of the knockouts depending on

whether both input and output

wiring will be needed.

If only input is needed, then only

remove one knockout.

4. Secure the AC Accessory Plate to the

opening where you removed the AC

cord and with the 3 Phillips screws

removed with the other plate.

5. Remove any DC knockouts required

for installing DC input from Renewable

Energy Sources.

6. Proceed to wiring instructions:

If installing AC from a generator,

see Figure 3-12, “Connecting the

AC Input and Output from a

Generator” on page 3–13.

If installing AC from a utility grid,

see Figure 3-13, “Connecting the

AC Input and Output from the

Utility” on page 3–14.

If installing DC from renewable energy

sources, see Figure 3-14, “Connecting

the DC Input (Renewable Energy

Solar Panel)” on page 3–15.

Figure 3-11

Preparing the Knockouts

IMPORTANT:

Be sure to install approved conduit and strain relief in the

knockout holes to protect the wiring from being

damaged by any sharp edges along the hole openings.

3–12 975-0289-01-01

Page 51

975-0289-01-01(PowerHub_1800).book Page 13 Friday, January 5, 2007 12:47 PM

AC Input and Output Wiring from a Generator

Wiring

This 15 A circuit breaker is only

required if the generator being

used doesn’t already have one.

Connect the PowerHub to a

15 A circuit breaker in the AC

Distribution Panel. This AC

Distribution Panel may not be

fed with any other AC sources.

Torque Neutral and Line

terminals to 1.3 nm (11.5 in-lbs)

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

Figure 3-12

Connecting the AC Input and Output from a Generator

Torque Neutral and Line

terminals to 1.3 nm (11.5 in-lbs)

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

975-0289-01-01 3–13

Page 52

975-0289-01-01(PowerHub_1800).book Page 14 Friday, January 5, 2007 12:47 PM

Installation

AC Input and Output Wiring from the Utility Grid

Connect the PowerHub to

a 15 A circuit breaker in the

Main AC Distribution

Panel.

Connect the PowerHub to

a 15 A circuit breaker in the

AC Distribution Panel. This

AC Distribution Panel may

not be fed with any other

AC sources.

Torque Neutral and Line

terminals to 1.3 nm (11.5 in-lbs)

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

terminals to 1.3 nm (11.5 in-lbs)

Figure 3-13

Torque Neutral and Line

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

Connecting the AC Input and Output from the Utility

3–14 975-0289-01-01

Page 53

975-0289-01-01(PowerHub_1800).book Page 15 Friday, January 5, 2007 12:47 PM

DC Wiring with Ground Fault Protection

(Renewable Energy Solar Panel; Maximum 400 W)

Wiring

Important:

Renewable energy input may require additional hardware to be

code-compliant. There may also be additional grounding requirements. Be sure

to consult your local electric authority for additional requirements.

Example only. Actual installation may vary.

Figure 3-14

Torque Positive, Negative, and

Ground terminals to

20.3 nm (180 in-lbs)

Connecting the DC Input (Renewable Energy Solar Panel)

Torque Neutral and Line terminals

to 1.3 nm (11.5 in-lbs)

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

975-0289-01-01 3–15

Page 54

975-0289-01-01(PowerHub_1800).book Page 16 Friday, January 5, 2007 12:47 PM

Installation

DC Wiring with Ground Fault Protection

(Renewable Energy Solar Array; Maximum 1000 W)

Important:

Renewable energy input may require additional hardware to be

code-compliant. There may also be additional grounding requirements. Be sure

to consult your local electric authority for additional requirements.

.

Example only. Consult the PV

Manufacturer for specific wiring

requirements of Solar Arrays.

Example only. Actual installation may vary.

Torque Neutral and Line terminals

to 1.3 nm (11.5 in-lbs)

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

Figure 3-15

Torque Positive, Negative,

and Ground terminals to

20.3 nm (180 in-lbs)

Connecting the DC Input (Renewable Energy Solar Array)

3–16 975-0289-01-01

Page 55

975-0289-01-01(PowerHub_1800).book Page 17 Friday, January 5, 2007 12:47 PM

DC Wiring (Renewable Energy Wind, Maximum 1000 W)

Wiring

Important:

Renewable energy input may require additional hardware to be

code-compliant. There may also be additional grounding requirements. Be sure

to consult your local electric authority for additional requirements.

Example only. Actual installation may vary.

IMPORTANT:

Wind turbines must be selfregulated.

Consult wind turbine

manufacturer for specific

wiring instructions.

Torque Neutral and Line terminals

to 1.3 nm (11.5 in-lbs)

Torque Ground terminal

to 1.8 nm (16.0 in-lbs)

Figure 3-16

Torque Positive, Negative, and

Ground terminals to

20.3 nm (180 in-lbs)

Connecting the DC Input (Renewable Energy Wind)

975-0289-01-01 3–17

Page 56

975-0289-01-01(PowerHub_1800).book Page 18 Friday, January 5, 2007 12:47 PM

Installation

Replacing the Top Cover

1. Place the top cover back on

the inverter and align the holes.

2. Replace the 5 #6-32 Phillips

screws on the top of the

inverter.

3. Torque to 1.3 nm (11.5 in-lbs)

Figure 3-17

Replacing the T o p Cover on the Inverter

Double-check

Before applying power, double-check the following connections.

❐ Are the batteries cabled properly? No reverse polarity!

❐ Battery Box to Inverter Connections - Are the Anderson connectors

securely in place?

❐ Are the solar panels wired properly?

❐ Are the wind generators cabled properly?

❐ Are the appropriate disconnects, circuit breakers, etc. in place?

❐ Is all the wiring and cabling in undamaged condition?

3–18 975-0289-01-01

Page 57

975-0289-01-01(PowerHub_1800).book Page 19 Friday, January 5, 2007 12:47 PM

Power Up Procedure

If softwired...... To Power Up the PowerHub 1800:

Power Up Procedure

AC Generator

2

120 Vac Outlet

Connect the PowerHub to

the generator and turn the

generator ON (if required).

Connect the Battery

1

Box(es) to the Inverter.

3

Press ON/OFF Switch to

turn ON Inverter/Charger.

Connect the Loads.

4

Figure 3-18

975-0289-01-01 3–19

Power Up Procedure for Softwired Installations

Page 58

975-0289-01-01(PowerHub_1800).book Page 20 Friday, January 5, 2007 12:47 PM

Installation

If hardwired...... To Power Up the PowerHub 1800:

Connect the DC Input

2

Connect the AC Input

3

Connect the Battery

1

Box(es) to the Inverter

4

Apply DC Input power by closing

the DC Disconnect Input Breaker

or disconnect from the

Renewable Energy inputs.

Connect the Loads

6

Figure 3-19

Power Up Procedure for Hardwired Installations

Main Panel

Apply Utility power (if available)

from the Main AC Distribution

Panel by closing the Main AC

Input Circuit Breaker.

Open Inverter

5

Output breaker.

Sub-Panel

Apply power to the AC outlets

by close the AC output breaker

in the AC Distribution Panel to

the connected outlets.

Press ON/OFF

Switch to turn ON

Inverter/Charger

Connect the Loads

6

3–20 975-0289-01-01

Page 59

975-0289-01-01(PowerHub_1800).book Page 21 Friday, January 5, 2007 12:47 PM

Power Down Procedure

If softwired...... To Power Down the PowerHub 1800:

Disconnect Loads.

1

Power Down Procedure

Press ON/OFF Switch to turn

2

OFF Inverter/Charger.

3

Figure 3-20

4

Disconnect the PowerHub

from the generator and

turn the generator OFF.

OFF

Power Down Procedure for Softwired Installations

Disconnect the Battery Box(es)

from the Inverter.

975-0289-01-01 3–21

Page 60

975-0289-01-01(PowerHub_1800).book Page 22 Friday, January 5, 2007 12:47 PM

Installation

If hardwired...... To Power Down the PowerHub 1800:

WARNING: Shock Hazard

If no DC Disconnect is used, then the DC input generators (solar or wind) will

have to be physically disconnected to ensure power is OFF.

2

1

Disconnect any loads directly

connected to the front panel of

the PowerHub

Press ON/OFF

3

Switch to turn OFF

Inverter/Charger

Disconnect the Utility

5

power by opening the AC

input circuit breaker in the

main panel.

Disconnect Loads connected to

the PowerHub through AC

Distribution Panel (Sub-panel)

by opening the Inverter Output

Circuit Breaker.

Disconnect the

DC Input.(s)

Disconnect the Battery Box(es)

6

from the Inverter

4

Figure 3-21

Power Down Procedure for Hardwired Installations

3–22 975-0289-01-01

Page 61

975-0289-01-01(PowerHub_1800).book Page 23 Friday, January 5, 2007 12:47 PM

Ground Fault Protection

WARNING: Shock hazard

Troubleshooting a grounding fault should be performed by qualified personnel,

such as a certified electrician or technician.

Ground fault protection is required when using either solar or wind

renewable energy input. Figure 3-22 shows the location of the ground fault

protection terminals and replaceable fuse.

When a grounding fault is detected, the ground fault protection fuse will

blow. The system must be shut down completely, the fault corrected, the

fuse replaced (see “Replacing the Ground Fault Protection Fuse”) and then

the system restarted.

If an error is made on the installation or if the installer is called in to help

repair the installation after damage that caused the ground fault protection

fuse to open, the main symptom is that the unit will be shut down and will

not invert or charge. The error that is shown on the front panel is E09.

Ground Fault Protection

Replacing the Ground Fault Protection Fuse

WARNING: Energy and fire hazard

For continued protection against risk of fire, replace the ground fault protection

fuse only with the same type and ratings of fuse.

WARNING: Shock hazard

After disconnection both AC and DC power for the the system, wait five minutes

before attempting any maintenance or cleaning or working on any circuits

connected to the inverter. Internal capacitors remain charged for five minutes

after disconnecting all sources of power.

The ground fault protection fuse will blow when severe leakage occurs

between the PV array and earth ground, or when the system has been

installed with faulty DC wiring. Before replacing the fuse, it is important to

have qualified service personnel, such as a certified electrician or

technician, to determine the cause of the ground fault.

975-0289-01-01 3–23

Page 62

975-0289-01-01(PowerHub_1800).book Page 24 Friday, January 5, 2007 12:47 PM

Installation

To replace the ground fault protection fuse:

1. Remove the five Phillips screws on the top of the inverter and lift off

the panel to expose the terminals, as shown in Figure 3-22.

2. Locate the PV ground fault protection fuse.

3. Using a slot blade screwdriver, remove the blown fuse and replace it

with a new Littelfuse 5mm×20mm fuse rated 1A 250 Vac slow blow

(or equivalent).

4. Replace the panel on the top of the inverter and tighten all five screws

securely.

BEFORE REMOVING INVERTER COVER:

Check to ensure the AC Indicator LED is NOT

illuminated and that there are absolutely no

sources of power connected to the PowerHub.

Remove the 5 #6-32

Phillips screws on

the top of the

inverter. Lift off the

panel to expose the

terminals.

PV Ground Fault

Protection Fuse

AC Indicator LED

Figure 3-22

Replacing Ground Fault Protection Fuse

3–24 975-0289-01-01

Page 63

975-0289-01-01(PowerHub_1800).book Page 1 Friday, January 5, 2007 12:47 PM

A Specifications

Appendix A provides electrical and physical specifications for the

PowerHub 1800.

Page 64

975-0289-01-01(PowerHub_1800).book Page 2 Friday, January 5, 2007 12:47 PM

Specifications

Electrical Specifications

Table A-1

Parameter P owerHub 1800 Inverter

Maximum Output Power 1800 W (15A) (5 minutes maximum)

Continuous Output Power 1440 W (12 A)

Surge Rating 2880 W (24 A)

Input Voltage Range 10.5 to 15.0 Vdc

Input Frequency Range 60 Hz

Peak Efficiency 88%

System Shutdown Mode

(Display On)

Idle Mode <1.5 W

Output Frequency 60 Hz / ±1 Hz

Output Waveform (resistive load) Modified sine wave (>30% THD)

Output Voltage (at no load) 110 to 125 Vac

Low Battery Cutout 10.5 Vdc with < 240 W load and 11.0 V with > 240 W load

High Battery Cutout 15.0 Vdc

Transfer Relay Rating 20 A

Electrical Specifications for the Inverter

< 12 W

Transfer Time AC to Inverter < 40 ms

AC Qualification Time ~ 20 seconds

Protection • Five 20 A/32 Vdc fuses protecting the 80A/1000 W DC input

terminal.

• Two 20 A/32 Vdc fuses protecting 32A/ 400 W DC input

terminal.

• One 15 Aac supplemental protector.

• One 1 A/250 Vac fuse for system ground fault protection.

Table A-2

Parameter Battery Box

Protection Ten 20 A/32 Vdc Fuses for short circuit and reverse polarity

1.Stand-alone battery box Xantrex Part Number: PH1800-BBX

A–2 975-0289-01-01

Electrical Specifications for the Battery Box

1

conditions.

Page 65

975-0289-01-01(PowerHub_1800).book Page 3 Friday, January 5, 2007 12:47 PM

Physical Specifications

Physical Specifications

Table A-3

Parameter PowerHub 1800

Dimensions (H x W x L) 14.75" × 8.0" × 16.0"

Weight 28.6 lb (13.0 kg)

Operating Temperature 0 °C (32 °F) to 40 °C (104 °F)

Storage Temperature -30 °C (-22 °F) to 70 °C (158 °F)

Table A-4

Parameter Battery Box

Dimensions (H x W x L) 14.0" × 13.875" × 20.5"

Weight 29 lb (13.2 kg)

Operating Temperature 0 °C (32 °F) to 40 °C (104 °F)

Storage Temperature -30 °C (-22 °F) to 70 °C (158 °F)

1.Stand-alone battery box Xantrex Part Number: PH1800-BBX

Physical Specifications of the Inverter

(37.5 cm × 20 cm × 41 cm)

Physical Specifications of the Battery Box

1

(35.6 cm × 35.2 cm × 52.7 cm)

Battery Charger Specifications

Charging

Process

Bulk Stage The bulk stage will start upon connection of AC and the unit turned on.

Absorption

Stage

975-0289-01-01 A–3

The Battery Charger uses a three-stage charging process to maintain the

battery (or batteries) in operational condition. This process is illustrated in

Figure A-1, “Three-Stage Charging Process” on page A–4.

The constant current mode is limited to 40 A or 10 A depending on

setting. The voltage setpoint for this stage is 14.2 Vdc. The Charger will

transition to the Absorption Stage upon reaching the bulk voltage

setpoint.

In the Absorption Stage, the constant voltage mode is limited to 14.2 Vdc.

The current will drop as batteries voltage rises. Upon dropping to 4 A, the

unit will transition to the Float charge. This stage will not exceed 4 hours

maximum.

Page 66

975-0289-01-01(PowerHub_1800).book Page 4 Friday, January 5, 2007 12:47 PM

Specifications

Float Stage In the Float stage, the constant voltage mode limited to 13.7 Vdc. An 8-

hour timer is started at this point.

If, during the 8-hour timer, the current rises to 6 A, the unit transitions

back to the Bulk Stage and starts over.

If the unit stays at 4A or less for the 8 hour timer, it will transition to

Standby Mode.

Standby Mode In the Standby Mode, the Charger is OFF but monitors the battery

voltage. If battery voltage drops below

12.5 Vdc, the unit will start a new