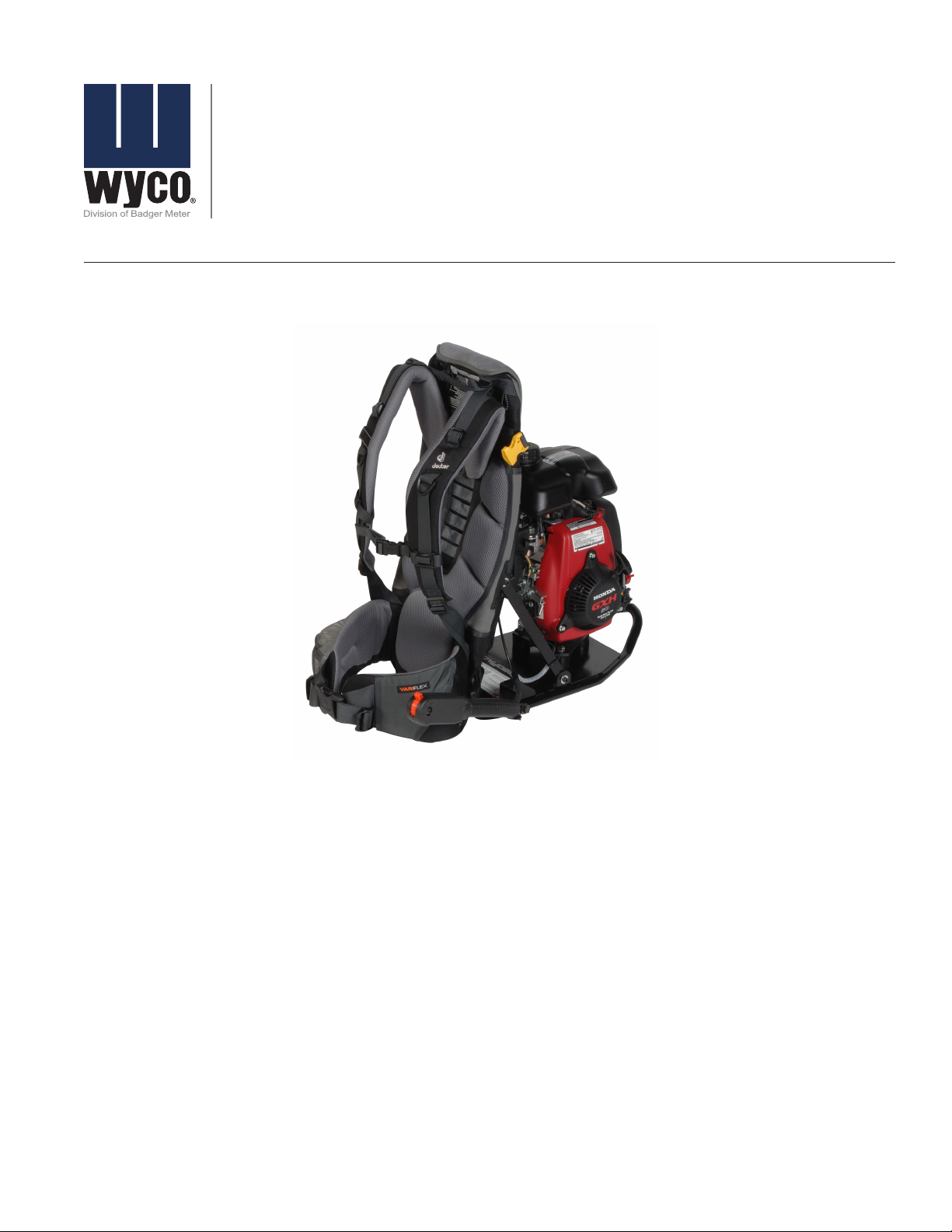

WycoTool WBP50 User Manual

Concrete Vibrator

Backpack Model WBP50

VBR-UM-00173-EN-02 (March 2014)

User Manual

Concrete Vibrator, Backpack Model WBP50

Page 2 March 2014

User Manual

CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Benets of Vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Head and Shaft Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjusting the Backpack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hip Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Shoulder Straps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Load Lifters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sternum Strap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Final Tweaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pre-Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Is Your Engine Ready to Go? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safe Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setting the Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Stopping the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Flex Shaft Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Vibrator Head Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Speed Increaser Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Honda Engine GXH50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Servicing the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

The Importance of Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refueling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Spark Arrester (Optional Equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Storing Your Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 3 March 2014

Concrete Vibrator, Backpack Model WBP50

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Honda Engine Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Honda Engine Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wyco Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wyco Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

W402535 Backpack Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

W402530 Frame Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

W402600 Speed Increaser Assembly, 1 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

W402600 Speed Increaser Assembly, 2 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

W402600 Speed Increaser Assembly, 3 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

W402600 Speed Increaser Assembly, 4 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

W402316 Replacement Clutch Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

W402630 Quick Disconnect Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page 4 March 2014

User Manual

SAFETY

Read and follow all safety precautions given in the Honda

engine instruction manual for their GXH50 engine. Read and

follow the safety instructions given below.

• WHEN THE BACKPACK IS WORN, THE FLEX SHAFT

MUST ALWAYS BE ON THE RIGHT HAND SIDE OF THE

OPERATOR AS ASSEMBLED BY THE FACTORY. IF USED

ON THE LEFT SIDE, THE MUFFLER EXHAUST WOULD BE

DIRECTED TOWARD THE OPERATOR’S BACK, CREATING

A DANGEROUS SITUATION.

• NEVER FILL THE ENGINE WITH GAS WHILE THE

BACKPACK IS ON OPERATOR’S BACK OR WHILE IT IS

RUNNING! IF FUEL IS SPILLED, WIPE IT AWAY CAREFULLY,

AND WAIT UNTIL THE FUEL HAS DRIED BEFORE

STARTING THE ENGINE.

• FLAMMABLE, NO SMOKING.

• NEVER RUN THE ENGINE WITHOUT THE FLEX SHAFT

ATTACHED. WITH THE FLEX SHAFT REMOVED, THE

ROTATING SHAFT IS EXPOSED, WHICH COULD GET

ENTANGLED WITH LOOSE CLOTHING, HANDS AND

OTHER ITEMS, CAUSING A DANGEROUS SITUATION.

• ALWAYS WEAR HEARING AND EYE PROTECTION.

• KEEP HANDS AWAY FROM HOT METAL PARTS OF THE

ENGINE AND SPEED INCREASER.

DO NOT OPERATE THE UNIT ABOVE SPEEDS LISTED IN

“OPERATION” ON PAGE7. EXCESSIVE SPEEDS WILL

DAMAGE THE ENGINE AND VIBRATOR HEAD AND IT WILL

VOID ANY WARRANTY.

HEAD AND SHAFT SELECTION

The WBP50 uses a quick disconnect (Q.D.). The Q.D. connect

lets you push the flex shaft assembly into the motor

connector, rotate it 1/4 turn, then use a lever mechanism to

lock it in place.

If using a Wyco shaft with a threaded end, threaded male

connector part number W423500 is required.

Shaft Head

CK-8900

CK-9500

LI is the largest sized head and is recommended with

this unit.

Although a standard 14-foot shaft length is available for all

head sizes, the length may be cumbersome to handle. The

recommended shaft lengths are 7 and 10 feet. Heavy duty

flex shafts—available for the 1-3/8" and larger head sizes

only—are available in the two most common lengths, 7 ft

(part number W989509) and 10 ft (part number W989512).

These shafts have reinforcing springs that increase life in

this application.

Use the head size that best matches the application. Consider

the vibrator’s radius of action when selecting a vibrator

head, ensuring that the entire area of concrete is vibrated.

A vibrator’s radius of action is approximately 4 times the

head size (head sizes are listed in the table above). This is a

general guide, and it can vary significantly with variations in

concrete mix design and type of application. The radius of

action is the distance from the vibrator head within which

consolidation occurs.

750-D (13/16" square)

750-EH (1" square)

750-FI (1-3/8" square)

750-GI (1-3/4" square)

750-LI (2" square) recommended

750-SBI (2" round short)

BENEFITS OF VIBRATION

Why use Wyco products to vibrate?

• Increased concrete strength by removing air voids.

• Improved appearance by removing air voids.

• Increased bond between concrete and reinforcing bars.

• Fluidized concrete allows a stiffener mix with a lower

water to cement ratio to be placed. This increases

concrete strength.

• Reduced cold joints and honey combing.

Page 5 March 2014

Concrete Vibrator, Backpack Model WBP50

ADJUSTING THE BACKPACK

The backpack has a number of straps that let you adjust your

load for maximum comfort.

Frame

The adjustable frame allows you to position the straps to fit

your body.

1. Loosen and pull out the Velcro closure.

2. Put the harness strap into the right position, then lace the

straps through the 4 attachment loops. Tighten the strap

and secure the Velcro closure.

Hip Belt

Sternum Strap

Adjust the sternum strap as needed to a comfortable height

across your chest.

Buckle the sternum strap and tighten until the shoulder

straps are pulled inwards comfortably from your shoulders,

allowing your arms to move freely.

Pull the stabilizer straps located on either side of the hip

belt to snug the pack body toward the hip belt and stabilize

the load.

Final Tweaks

Pull the stabilizer straps, located on either side of the hip

belt, to snug the pack body toward the hip belt and stabilize

the load.

Go back to the shoulder straps and carefully take a bit of

tension off of them. This ensures the majority of the weight is

carried by your hips.

1. Loosen all of the straps on the harness system and

position the hip belt so the top of the iliac crest is about

1” down from the top of the hip belt. Correct positioning

will direct the weight onto your hips.

2. Put the pack on your back so that the hip belt is resting

over your hip bones.

3. Close the hip belt buckle and tighten it.

4. Check the padded sections of the hip belt to make sure

they wrap around your hips comfortably. Keep at least 1"

of clearance on either side of the center buckle.

Shoulder Straps

Pull down and back on the ends of the shoulder straps to

tighten them.

Shoulder straps should fit closely to hold the pack body

against your back, keeping the load forward. They should

NOT carry the weight.

Load Lifters

Load-lifter straps are located just below the tops of your

shoulders (near your collarbones) and should angle back

toward the pack body at a 45° angle.

Gently snug the load-lifter straps to pull weight off your

shoulders. (Overtightening the load lifters will cause a gap to

form between your shoulders and the shoulder straps.)

Page 6 March 2014

User Manual

PREOPERATION CHECKS

Is Your Engine Ready to Go?

For your safety, and to maximize the service life of your

equipment, take a few minutes before you operate the

engine to check its condition. Take care of any problems you

fine, or have your servicing dealer correct them, before you

operate the engine.

IMPROPERLY MAINTAINING THE ENGINE, OR FAILURE

TO CORRECT A PROBLEM BEFORE OPERATION,CAN

CAUSE A MALFUNCTION IN WHICH YOU COULD BE

SERIOUSLY INJURED OR KILLED. ALWAYS PERFORM A PREOPERATION INSPECTION BEFORE EACH OPERATION AND

CORRECT ANY PROBLEM.

Before beginning your pre-operation checks, be sure the

engine is level and the engine switch is in the OFF position.

Always check the following items before you start the engine:

Check the General Condition of the Engine

1. Look around and underneath the engine for signs of oil or

gasoline leaks.

2. Remove any excessive dirt or debris, especially around

the muer and recoil starter.

3. Look for signs of damage.

4. Check that all shields and covers are in place, and all nuts,

bolts and screws are tightened.

Check the Engine

1. Check the fuel level (see “Refueling” on page11).

Starting with a full tank will help to eliminate or reduce

operating interruptions for refueling.

2. Check the engine oil level (see “Engine Oil” on page12).

Running the engine with a low oil level can cause engine

damage.

The Oil Alert system (applicable types) will automatically

stop the engine before the oil level falls below safe limits.

However, to avoid the inconvenience of an unexpected

shutdown, always check the engine oil level before

startup.

3. Check the air filter element (see “Air Cleaner” on

page13). A dirty air filter element will restrict air flow to

the carburetor, reducing engine performance.

4. Check the equipment powered by this engine.

Review the instructions provided with the equipment

powered by this engine for any precautions and procedures

that should be followed before engine startup.

Check the Throttle Lever

The throttle lever controls the speed of the engine. Push it

forward to increase the engine speed. Pull it back to decrease

the engine speed. The lever is an orange hand control

located on the left side of the backpack.

MPORTANTI

The engine will not start if the throttle lever is all the way back

in the OFF position. Push the lever forward about 1/2" into the

SLOW position to engage it.

OPERATION

Safe Operating Precautions

Before operating the engine for the first time, please review

the “Safety” on page5 and “Pre-Operation Checks” on

page7.

CARBON MONOXIDE GAS IS TOXIC. BREATHING IT CAN

CAUSE UNCONSCIOUSNESS AND EVEN DEATH. AVOID

ANY AREAS OR ACTIONS THAT EXPOSE YOU TO CARBON

MONOXIDE.

Vibrator Heads rotate at twice the speed of the engine and

are designed for nominal speeds of 12,000…13,000 RPM

(Engine speed of 6,000…6,500 RPM). Operating at excessive

speeds may reduce the performance or life of the product.

Starting the Engine

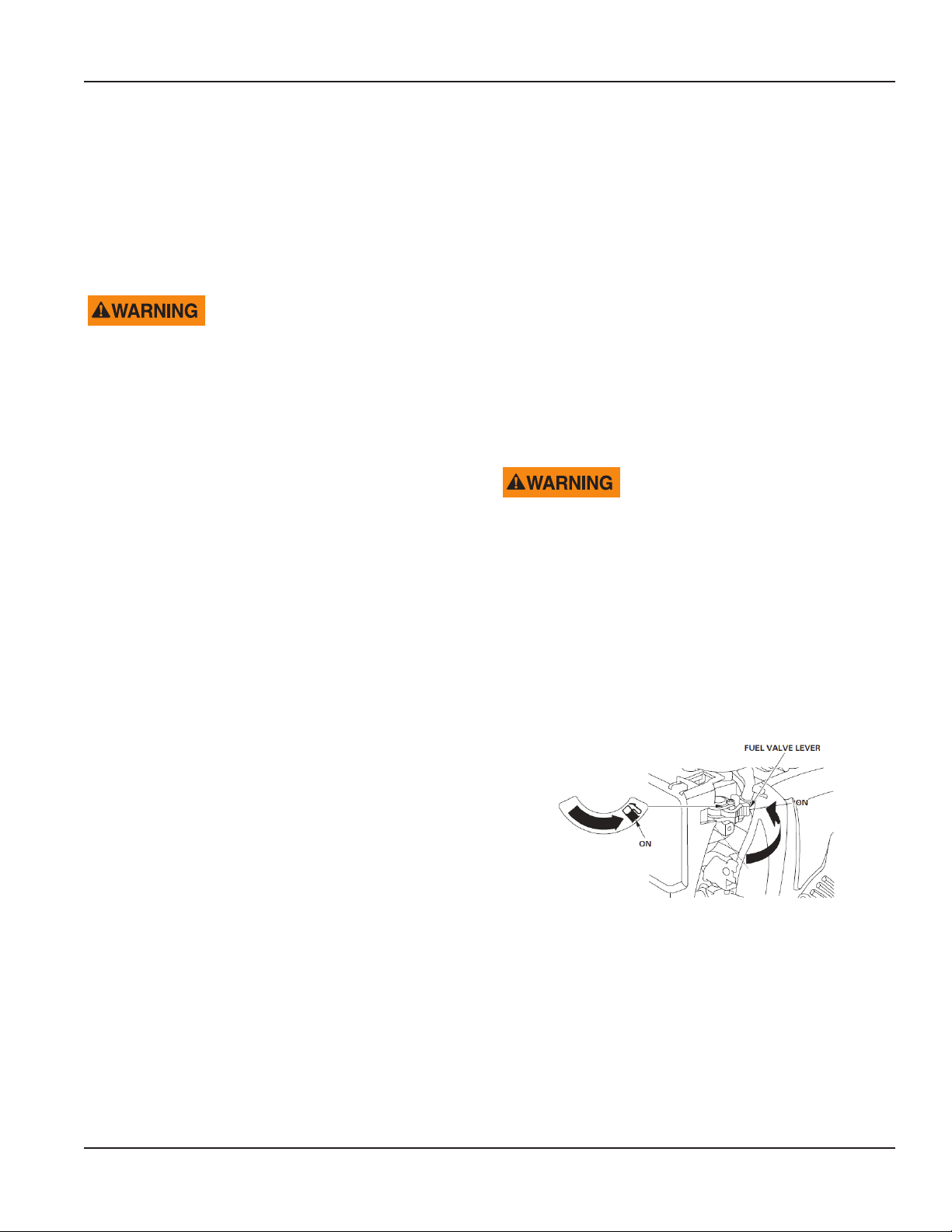

Move the fuel valve to the ON position.

Page 7 March 2014

Concrete Vibrator, Backpack Model WBP50

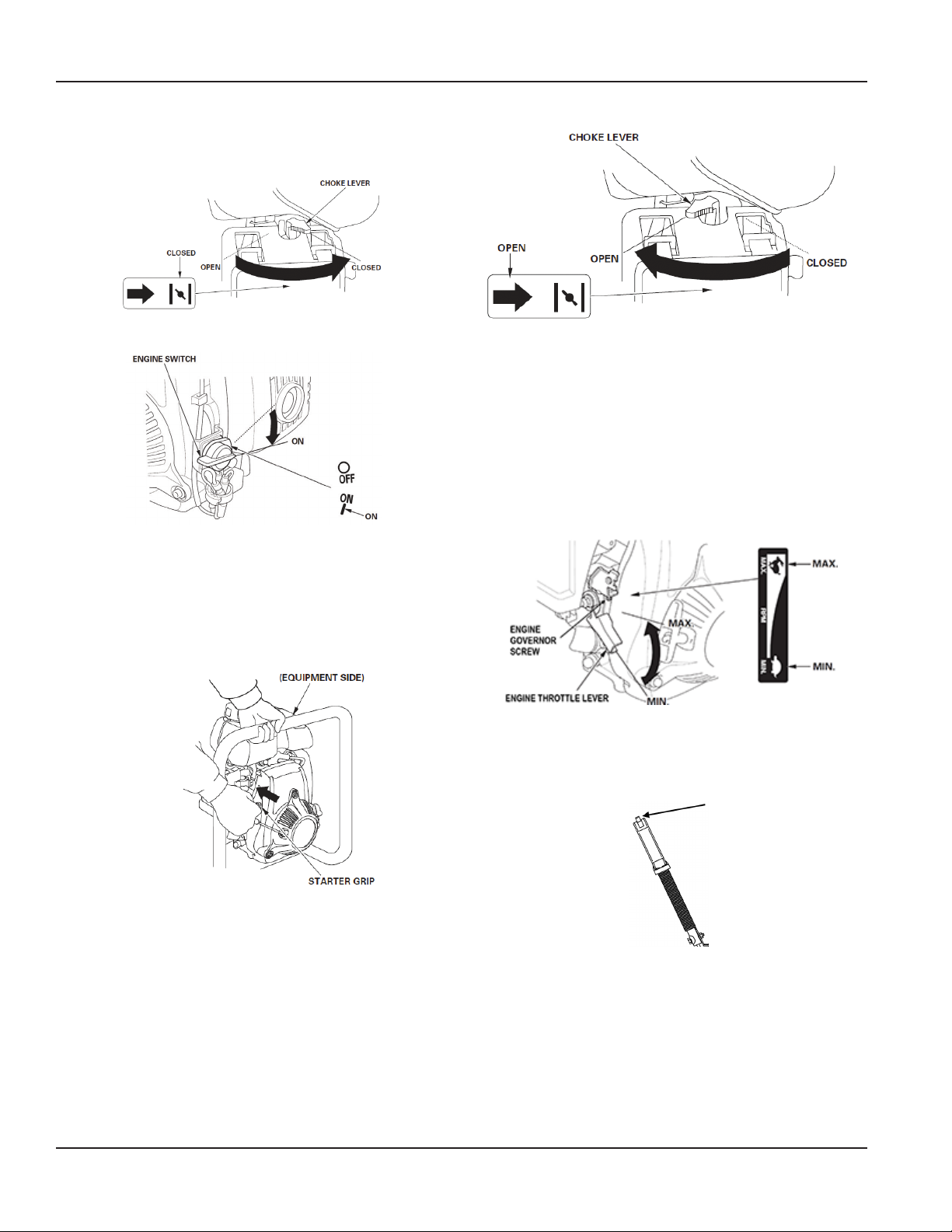

To start a cold engine, move the choke lever to the CLOSED

position. To restart a warm engine, leave the choke lever in

the OPEN position.

Turn the engine switch to the ON position.

Setting the Engine Speed

Position the throttle lever for the desired engine speed.

Vibrator heads rotate at twice the speed of the engine and

are designed for nominal speeds of 12,000…13,000 RPM

(Engine speed of 6,000…6,500 RPM). Operating at excessive

speeds may reduce the performance or life of the product.

Maximum engine speed will change with the size of the

vibrator head and shaft. Use the engine governor screw to

adjust the throttle range within safe operational limits.

Set the throttle lever to the SLOW position. Pull the starter

grip lightly until you feel resistance, then pull briskly. Return

the starter grip gently.

OTE:N Do not allow the starter grip to snap back against

the engine. Return it gently to prevent damage to

the starter.

If the choke lever has been moved to the CLOSED position to

start the engine, gradually move it to the OPEN position as

the engine warms up.

MPORTANTI

The engine will not start if the throttle lever is all the way back

in the OFF position. Push the lever forward about 1/2” into the

SLOW position to engage it.

The engine throttle lever is controlled by the orange throttle

lever on the left side of the backpack. The throttle lever

should be set to SLOW for startup, FAST for operation, and

STOP for shutdown.

Page 8 March 2014

Loading...

Loading...