WycoTool Single and Double Powerhead User Manual

Single and Double Powerhead

Operator’s and Service Manual

®

CONTENTS

INTRODUCTION• ..........................................................................................................3

SPECIFICATIONS• .........................................................................................................3

SAFETY•.........................................................................................................................4

GENERAL SAFETY• .......................................................................................................4

OPERATING SAFETY•..........................................................................................................................4

STORAGE SAFETY• ............................................................................................................................. 5

REFUELING SAFETY• .......................................................................................................................... 5

OIL LEVEL CHECK• .............................................................................................................................. 5

POWER UNIT ASSEMBLY• ............................................................................................6

PRE-ASSEMBLY• ................................................................................................................................. 6

FINAL ASSEMBLY• ........................................................................................................6

HANDLE ASSEMBLY• .......................................................................................................................... 6

THROTTLE ASSEMBLY• .......................................................................................................................7

WEIGHT ADJUSTMENT• ..................................................................................................................... 8

OTHER SETTINGS• .............................................................................................................................. 8

THROTTLE CABLE ADJUSTMENT• ...................................................................................................... 9

ATTACHING THE SCREED BAR• .......................................................................................................... 9

SERIAL NUMBER LOCATION• ............................................................................................................10

NOTES• ........................................................................................................................10

LIMITED WARRANTY• ................................................................................................11

Power Head #1 Model

Power Head # 1 Serial Number

Power Head #2 Model

Power Head # 2 Serial Number

Screed Bar Model

Screed Bar Serial Number

Date Purchased

Page 2Form: 01-SCR-UM-00442 Rev 6/12

INTRODUCTION

Congratulations on your choice of a Wyco Screed King power screed to complement your construction

operation. This equipment has been designed and manufactured to meet the needs of a discriminating

buyer for the ecient nishing of concrete.

Safe, ecient and trouble free operation of your Wyco Screed King power screed requires that you and

anyone else who will be operating or maintaining the screed, read and understand the Safety, Operation,

Maintenance and Trouble Shooting information contained in the Operator’s Manual.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call Wyco

Tool or your dealer if you need assistance or information.

Operator Orientation - The directions left, right, front and rear as mentioned throughout this manual, are

as seen from behind the machine, standing between the handles.

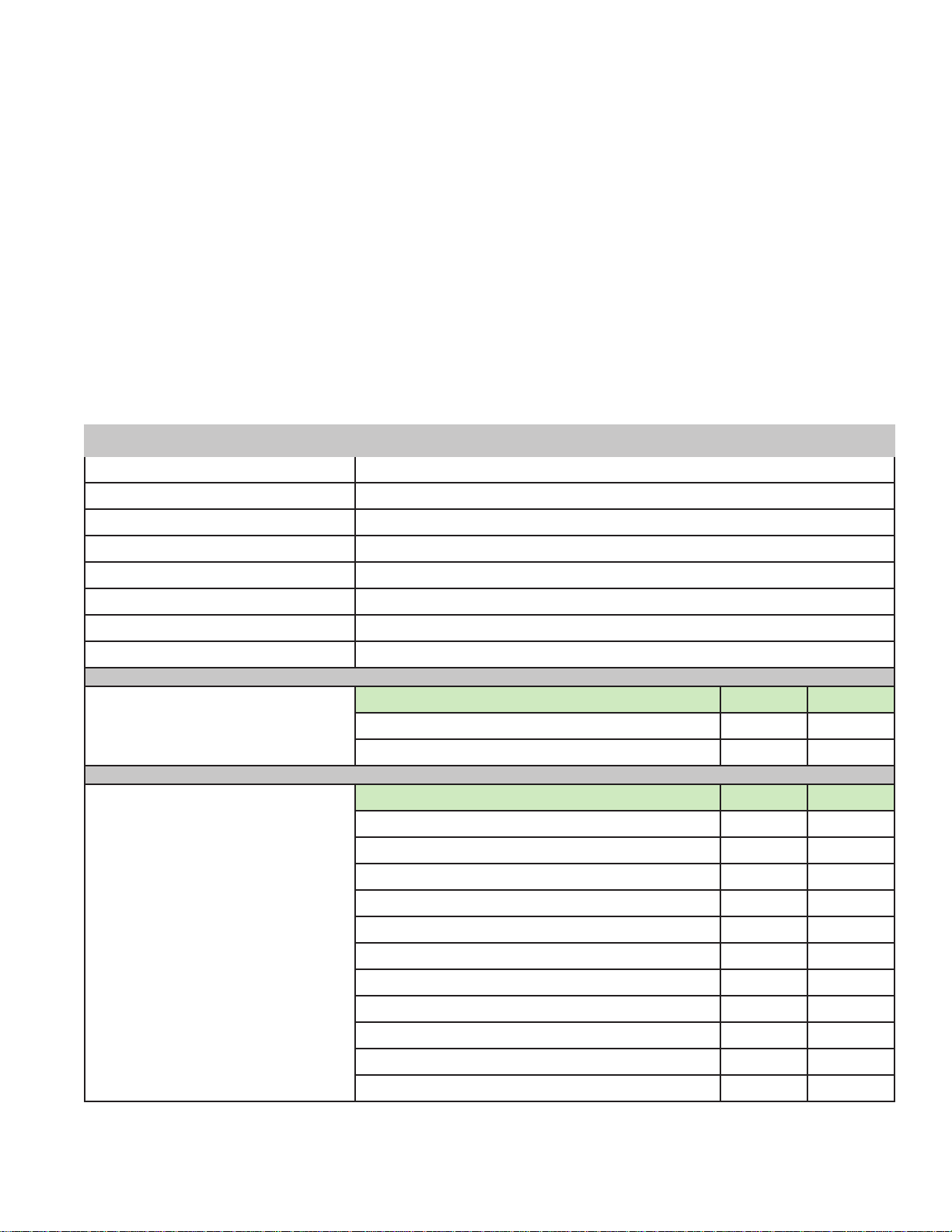

SPECIFICATIONS

Engine GX35 Mini 4-Stroke

Starting Mechanism Recoil

Maximum Power Output 1.5 HP @ 7000 RPM

Handle Design Vibration reducing, quick adjusting

Fuel Capacity 0.17 U.S. Gallon (0.644 Liter)

Oil Capacity 3.4 ounce U.S. Liquid (0.1 Liter)

Sound Pressure 87-90 dB(A) @ 5500 RPM

Vibration (m/sec2) 7.4 m/sec @ 5500 RPM in 4" slump concrete

Power Head Weight

Screed Bar Weight

Single Powerhead alone 27 12.25

Dual Powerhead alone 54 24.25

4 foot screed bar 8 3.63

5 foot screed bar 10 4.54

6 foot screed bar 12 5.44

8 foot screed bar 15 6.80

10 foot screed bar 19 8.62

12 foot screed bar 22 9.98

Lbs. Kg

Lbs. Kg

14 foot screed bar 26 11.79

16 foot screed bar 29 13.15

16 foot screed bar (double power unit) 31 14.10

18 foot screed bar (double power unit) 33 14.97

20 foot screed bar (double power unit) 37 16.78

Page 3Form: 01-SCR-UM-00442 Rev 6/12

SAFETY

GENERAL SAFETY

YOU are responsible for the SAFE

operation and maintenance of your

Wyco Screed King power screed. YOU

must ensure that you and anyone

else who is going to operate, maintain or work

around the screed be familiar with related SAFETY

information contained in this manual. This manual

will take you step-by-step through your working

day and alerts you to all good safety practices that

should be adhered to while operating the screed.

Remember YOU are the key to safety. Good safety

practices not only protect you but also the people

around you. Make these practices a working part of

your safety program. Be certain that EVERYONE operating this equipment is familiar with the recommended operating and maintenance procedures

and follows all of the safety precautions. Most

accidents can be prevented. Do not risk injury or

death by ignoring safety practices.

* Screed owners must give operating instructions

to operators or employees before allowing them to

operate the machine, and at least annually thereafter.

1. Read and understand the Operators

Manual and all safety signs before

operating, maintaining, adjusting,

servicing or cleaning the screed.

2. Only trained competent persons shall operate

the screed. An untrained operator is not qualied to operate the machine.

3. Have a rst aid kit available for use

should the need arise and know how

to use it.

4. Have a re extinguisher available for

use should the need arise and know

how to use it.

5. Wear appropriate protective gear. This

list includes but is not limited to:

-A hard hat

-Protective boots with slip

resistant soles

-Protective goggles

-Heavy gloves

-Hearing protection

* The most important safety device on this equipment is a SAFE operator. It is the operator’s responsibility to read and understand ALL Safety and

Operating instructions in the manual and to follow

these. All accidents can be avoided.

* A person who has not read and understood all

operating and safety instructions is not qualied

to operate the machine. An untrained operator

exposes himself and bystanders to possible serious

injury or death.

* Do not modify the equipment in any way. Unauthorized modication may impair the function

and/or safety and could aect the life of the equipment.

6. Stop engine, disconnect spark plug wire and

wait for all moving parts to stop before servicing, adjusting, repairing or cleaning.

7. Wear appropriate hearing protection

when operating for long periods of

time

8. Review safety related items with all personnel

annually.

OPERATING SAFETY

1. Read and understand the operators manual and all

safety signs before operating, servicing, adjusting or

cleaning the screed.

2. Clear the area of all bystanders before starting.

Page 4Form: 01-SCR-UM-00442 Rev 6/12

Loading...

Loading...