WycoTool BD User Manual

Wyco Pneumatic

Operator’s and Service Manual

wwyyccoo

RRRR

“BD” Pneumatic Concrete Vibrators

READ ALL SAFETY INSTRUCTIONS

1. WORKING AREA: Do not operate a machine that is

powered by a gas or diesel engine in a poorly ventilated

space. These types of engines produce toxic gasses

which cause serious health problems.

2. POWER EQUIPMENT:

- Pneumatic Machine: Check that the compressed air

hose and the hose coupling are not damaged.

WARNING: Never attempt to loosen any

!

compressed air hose that is pressurized. First

switch off the air at the compressor and then allow the

machine to run to a stop to discharge any existing

compressed air.

- Machine Powered By Gas or Diesel Engine: Gas has

an extremely low flash point and can be explosive in

certain situations. WARNING: Keep away from all

hot or spark generating objects, do not smoke

when handling fuel. Wait until the machine has

cooled before filling the tank. Avoid spilling gas or

diesel fuel on the ground.

3. GENERAL SAFETY INFORMATION & EQUIPMENT:

The admissible sound of 85 dB (A), can be exceeded

because of the machine and/or the application. Long

time exposure to loud noise without ear protection can

cause permanent damage to hearing. Long time

exposure to vibration can cause damage to the hands

fingers and wrists. Do not use these vibrators if you are

experiencing discomfort, cramping or pain. Consult a

doctor before working again with the vibrator.

!

3. SAFETY INFORMATION & EQUIPMENT (cont’d):

Always use approved safety equipment. The following

safety equipment applies to operators and other

personnel in the immediate vicinity of the working zone.

- Safety Helmet - Protective Gloves

- Ear Protection - Protective Shoes

- Dust mask (dusty environments) - Eye Protection

`

4. MACHINE KNOWLEDGE: Before starting the equip ment make yourself familiar with the machine and

make sure that the machine does not show any

obvious faults or wear. Then start the machine

according to the instructions.

5. OPERATION: Use the machine only for the purpose

for which it is intended. Make sure you know how to

stop the machine quickly in the event of an emergency

situation. Do not touch rotating parts during operation.

6. MAINTENANCE: Maintenance work must only be

carried out by a skilled operator. Keep unauthorized

people away from the machine. Do not carry out

maintenance work while the machine is moving or

while the engine is running. Never use a machine that

is damaged.

7. BE ALERT: Always concentrate on what you are doing.

Use common sense and never operate the machine if

you are tired or under the influence of drugs, alcohol or

other substances which can affect your vision, reaction

time, ability or judgement.

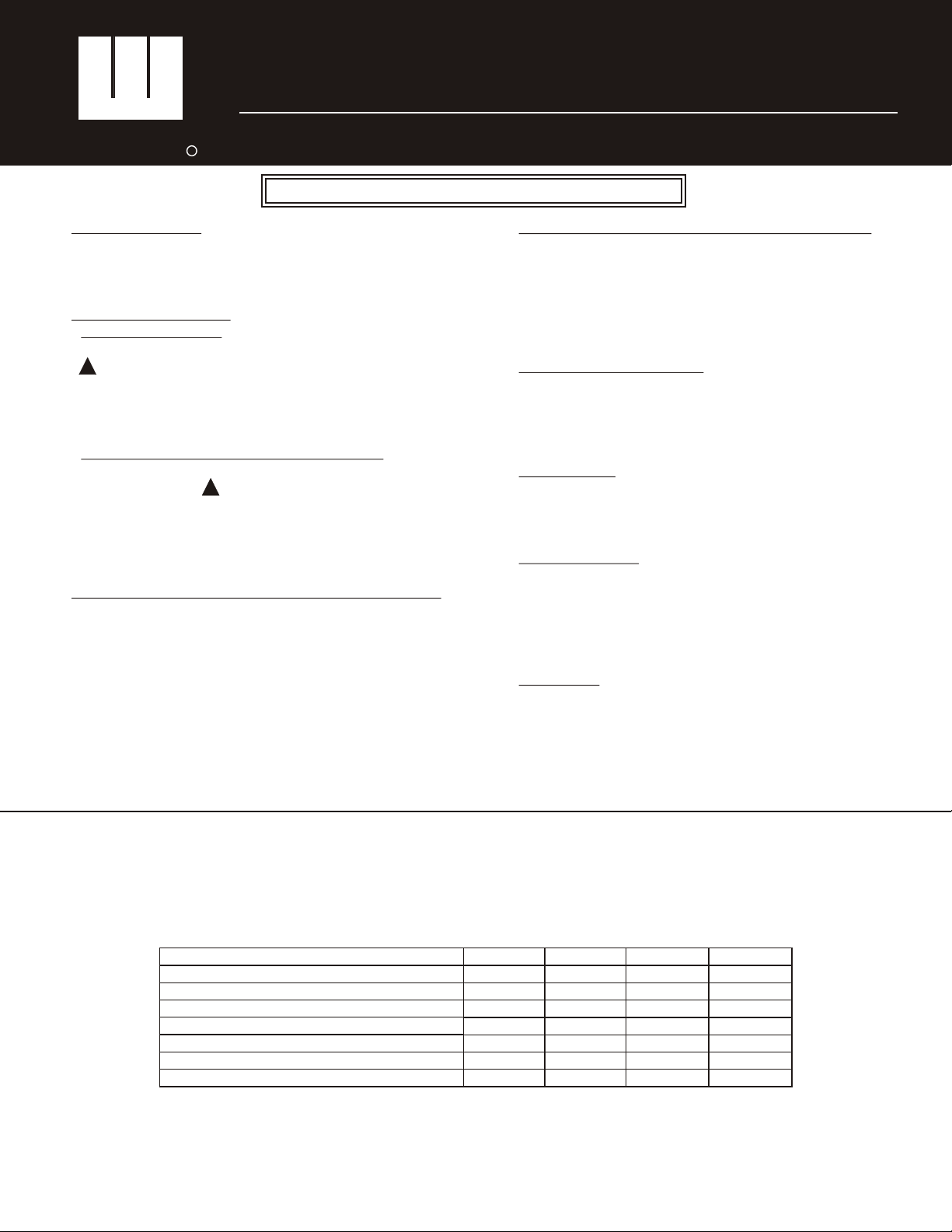

TECHNICAL DATA

Type BD 35 BD 55 BD 65 BD 75

Head Diameter in(mm) 1.42(36) 2.20(56) 2.64(67) 3.03(77)

Head Length in(mm) 10.51(267) 13.54(344) 14.37(365) 15.67(398)

Head Weight lbs(kg) 3.3(1.5) 9.9(4.5) 17.38(7.9) 19.6(8.9)

Amplitude (Total at tip) in(mm) .027(.69) .037(.94) .054(1.37) .070(1.78)

Frequency (Max at 85 psi) (v.p.m.) 17,600 17,700 17,700 17,000

Centrifugal Force (Max at 85 psi) lbs(kg) 441(200) 1484(675) 2548(1158) 3278(1490)

Air Consumption (Max at 85 psi) (cfpm) 27 54 54 85

Operation & Service Information

OPERATION AND MAINTENANCE

- CLEAR AIR SUPPLY LINE: Before connecting vibrator, clear the compressed air supply line of possible impurities,

contaminants and water.

- LUBRICATE: Every day or every four hours of continuous service, pour a ½ teaspoon of non-detergent (Viscosity 20

to 30 SAE) oil into the quick release coupling. NOTE: An optional oiler/strainer is available (See Page 3)

WARNING: So as to facilitate shipment, new or repaired units are not lubricated before delivery to customers.

!

WARNING: Do not use hydrocarbons and especially do not use fuel oil for lubricating purposes.

!

- CONNECT: Connect the vibrator to the quick release coupling securely. Insure that locking pin is in place.

- START: To start vibration, rotate the variable control assembly near the quick release coupling. It is sometimes

necessary to tap the head to begin vibration. If the vibration intensity drops, check that the filters are not clogged or that

hoses are not kinked.

- STORAGE: To properly store unit after use, hang the vibrator with the head up and set the handle (variable control

assembly) in the open position to permit the discharge of possible impurities, contaminants and water.

ASSEMBLY INSTRUCTIONSDISASSEMBLY INSTRUCTIONS

VIBRATOR HEAD:

- Hold vibrator head housing (6) in a vice and unscrew

the tip (1). (Right Hand Thread)

- Remove vibrator head from vice and tap vertically on a

wooden block. This will aid in the removal of the front

flange (3) and the rotor. (4)

- Again clamp vibrator head housing (6) in vice and

unscrew hose holder (11). (Left Hand Thread)

- Remove rear flange (7) (tap on wooden block again if

necessary), cut hose clamp (9) & remove inlet hose (13)

from flange nipple. (8)

- Unscrew the hose retain sleeve (10) & remove exhaust

hose (12). Also remove spring (See Optional Parts List)

from this hose only when it is provided.

- Cut hose clamp (14) on the outer end cap (17) and

remove exhaust hose. (12)

VARIABLE CONTROL ASSEMBLY:

- Unscrew the outer end cap (17) (Right Hand Thread).

Cut hose clamp (9) & remove inlet hose. (13)

- Remove screw from bushing. Remove body from bushing.

(Tap on a wooden block if necessary).

Note: Make use of the maintenance kits (See Page 3)

VIBRATOR HEAD:

- Reverse previous procedures.

- Replace the following parts each time the vibrator head

has been disassembled:

- Vane (5) - O-Rings (2 & 16)

- Filter (on quick disconnect) - Hose Clamps (9 & 14)

- Slightly lubricate all parts before reassembly.

- Adjust the new vane (5) so that it slides snug in the

groove in the rotor (4). Note: Be sure that vane (5) slots

are facing away from cutout in rotor (4).

- Check the condition of front (3) & rear (7) flange &

replace them if there is a hollow area where the rotor

turns.

- Reassemble tip (1) & outer hose holder (11) making

sure that the O-rings (2) are in place.

VARIABLE CONTROL ASSEMBLY:

- Reverse previous procedure.

- Replace O-rings on body making sure you do not cut

O-rings when sliding body back into bushing.

- Reassemble all hoses onto the vibrator head assembly

and reattach the on/off control valve.

* When screwing tip and hose holder into housing torque

as follows:

- BD 35 37ft/lbs - BD 65 434 ft/lbs

- BD 55 246 ft/lbs - BD 75 636 ft/lbs

2

Loading...

Loading...