Page 1

Save this manual

for future reference.

Gardez ce manuel pour

référence ultérieure.

Conserve este manual

para referencia futura.

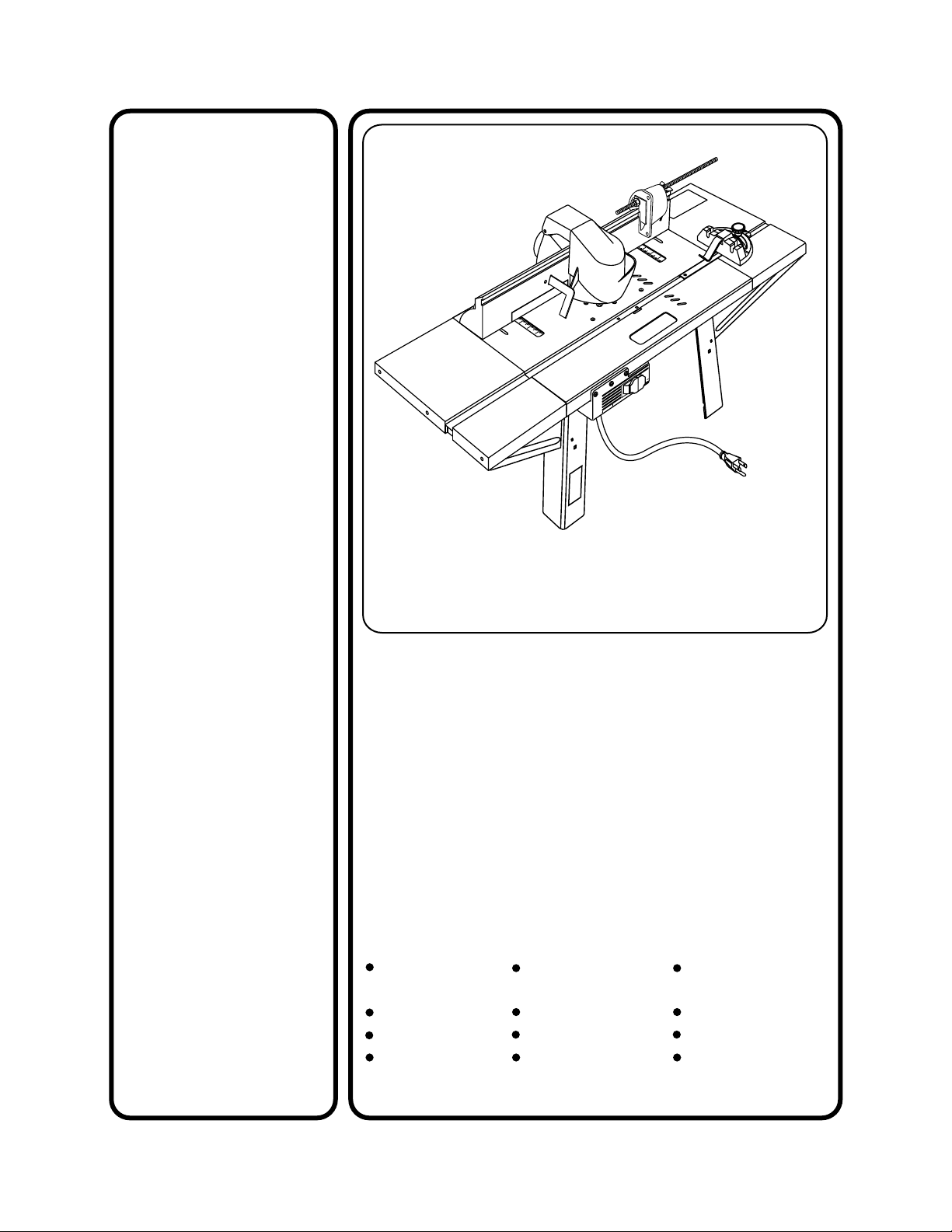

wolfcraft

630-773-4777

www.wolfcraft.com

OWNER'S

MANUAL

MANUEL

D'UTILISATION

MANUAL DEL

PROPIETARIO

MODEL NO. 6155 / 6156

MODÈLE No 6155 / 6156

MODELO NO. 6155 / 6156

WARNING

4

5

60

0

3

15

0

15

0

3

5

4

0

6

®

N

O

L

UL

F

P

F

O

H

US

P

T

E

S

RE

S

T

LE

T

OU

NG

RNI

A

W

6155 / 6156

Power tools and some accessories NOT included.

Les outils motorisés et certains accessoires NE sont PAS inclus.

NO se incluyen las herramientas eléctricas y ciertos accesorios.

Pages 47-89

Français/Español

CAUTION:

Before using this product,

read this manual entirely

and follow all safety rules

and operating instructions.

MISE EN GARDE:

Avant d'utiliser ce produit,

lire ce manuel entièrement

et respecter toutes les

consignes de sécurité et le

mode d'emploi.

PRECAUCIÓN:

Antes de utilizar este producto,

lea este manual en su totalidad

y siga todas las reglas de

seguridad e instrucciones de

operación.

wolfcraft

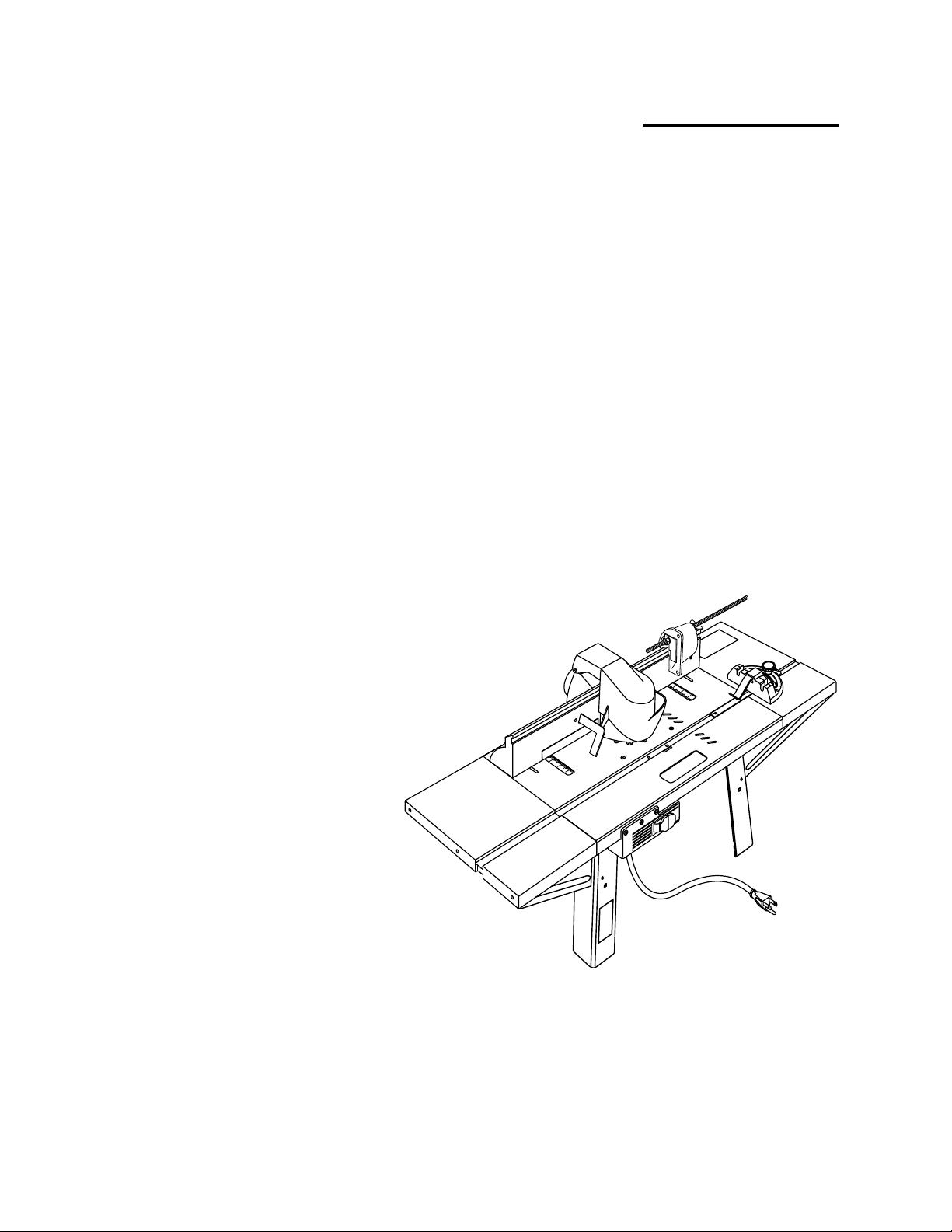

ROUTER TABLE

TABLE À TOUPIE

MESA PARA FRESADORA

Safety

instructions

Assembly

Operation

Repair parts

Consignes de

sécurité

Assemblage

Utilisation

Pièces de

rechange

®

Instrucciones

de seguridad

Armado

Operación

Piezas para

reparación

Page 2

TABLE OF CONTENTS

WARRANTY..................................................................

SAFETY INSTRUCTIONS ............................................

UNPACKING AND CHECKING CONTENTS ...............

INTRODUCTION ..........................................................

FEATURES AND SPECIFICATIONS............................

PACKAGE CONTENTS & HARDWARE LEGEND.......

ASSEMBLY .................................................................

MOUNTING THE ROUTER........................................

WARRANTY

LIMITED LIFETIME WARRANTY

WARRANTY

This wolfcraft® Router Table is warranted

against defects in material and workmanship

for the life of the product. The obligation of the

manufacturer under this warranty is limited to

replacement or repair, at its option, of the

product or of any defective portions thereof.

This warranty extends to the first purchaser

only and does not apply to conditions resulting

from abuse, misuse, alteration, negligence,

improper maintenance, or normal wear and

tear. Unauthorized repairs or tampering with

the product will void this warranty in its

entirety.

If you find a defect in material or

workmanship, contact the wolfcraft®

Customer Service Department by e-mail at

customer.service@woa.wolfcraft.com, by

telephone at 630.773.4777, by fax at

630.773.4805, or through the mail at 333 Swift

Road, Addison, Illinois 60101. You will be

given instructions on how to resolve the

problem or, if the problem cannot be resolved,

on how to return the product to the

manufacturer for repair or replacement.

LIMITATION ON LIABILITY

Manufacturer shall not be liable for loss or

damage of any kind including incidental or

consequential damages, resulting either

directly or indirectly from the use of this

product.

12

21

2

3

4

4

5

6

SECURING THE ROUTER TABLE..........................

SWITCH BOX...........................................................

ASSEMBLING FENCE TO THE ROUTER TABLE....

OPERATION.............................................................

REPAIR PARTS........................................................

FRANÇAIS/ESPAÑOL.............................................

PRODUCT REGISTRATION CARD.........................

26

27

30

32

43

47

91

Some states do not allow the exclusion or

limitation of incidental or consequential

damages so the above limitation or exclusion

may not apply to you. User assumes all risk or

liability in connection with installation or use of

this product.

This warranty gives you specific legal rights and

you may also have other rights which vary from

state to state.

THE EXPRESS WARRANTY HEREIN IS IN

LIEU OF ANY AND ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED.

NO IMPLIED WARRANTY OF

MERCHANTABILITY IS MADE AND THERE

ARE NO WARRANTIES WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE

HEREOF.

WARRANTY CARD

Please complete the information on the

attached warranty card and mail it to

wolfcraft® within 30 days of purchase,

or complete the card on-line at

www.wolfcraft.com. Failure to submit this card

will not adversely affect your warranty rights if

you can otherwise show in a reasonable way

that you were the original purchaser of the

product. Nevertheless, sending this card is a

convenient way to establish in our files the date

of your purchase and help us better meet your

needs in the future.

2

Page 3

SAFETY INSTRUCTIONS

Safety items throughout this manual are labeled with WARNING and CAUTION.

WARNING

Means that failure to follow this safety statement may result in extensive

product damage, serious personal injury, or death.

CAUTION

WARNING

READ ALL SAFETY INSTRUCTIONS

BEFORE USING

Read the owner's manual carefully. Learn its

applications and limitations as well as the

specific potential hazards.

GROUND ALL TOOLS (UNLESS DOUBLE

INSULATED)

If tool is equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit

the proper grounding type receptacle. The

green conductor in the cord is the grounding

wire. NEVER connect the green wire to a live

terminal.

KEEP AWAY FROM HAZARDOUS

MATERIALS

Normal sparking of the motor could ignite

fumes, flammable liquids, or combustibles.

Means that failure to follow this safety statement may result in minor or

moderate personal injury, or property or equipment damage.

NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped

or if the cutting tool is accidentally contacted.

DO NOT store materials above or near the tool

making it necessary to stand on the tool to

reach them.

PROTECT AND USE SUITABLE CORDS

NEVER carry tool by cord or yank it to

disconnect from receptacle. Protect cord from

heat, oil, and sharp edges. For temporary

outdoor operation, use extension cords

intended for outdoor use.

AVOID A DANGEROUS ENVIRONMENT

DO NOT use power tools in damp or wet

locations or expose them to rain. Keep work

area well lit and provide an adequate

surrounding work space.

PROTECT YOURSELF AGAINST PERSONAL

INJURY

DO NOT operate any tool while under the

influence of drugs, alcohol, or any medication.

DRESS FOR SAFETY

Do not wear loose clothing, gloves, neckties, or

jewelry, as these items can get caught and

draw you into moving parts. ALWAYS wear

non-slip footwear. Tie back long hair. Roll long

sleeves above the elbow.

WEAR SAFETY GOGGLES

Wear safety goggles (must comply with ANSI

Z87.1) at ALL times. Also, use face or dust

mask if cutting operation is dusty, and use ear

protectors (plugs or muffs) during extended

periods of operation.

AVOID ACCIDENTAL STARTING

Make sure all switches are in "OFF" position

before plugging in.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other

part that is damaged should be carefully

checked to ensure that it will operate properly

and perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

CHECK DIRECTION OF FEED

Feed work into a blade or cutter against the

direction of rotation of the blade or cutter only.

NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Do not leave tool until it

comes to a complete stop.

3

Page 4

WARNING

CONTINUED

SECURE ROUTER TABLE

DO NOT attempt to use your router table unless

it is fastened firmly to your workbench or rests

stably on the floor.

KEEP HANDS AWAY FROM CUTTING AREA

CAUTION

STORE PROPERLY

Do not store router table outdoors or in a

damp location.

KEEP WORK AREA CLEAN

ALWAYS keep your work area clean,

uncluttered, and well lit. DO NOT work on or

place router table legs on floor surfaces that

are slippery from sawdust, oil, water, or wax.

DO NOT FORCE THE TOOL

Do not force tool or attachment to do a job for

which it was not designed. It will do the job

better and more safely at the rate for which it

was designed.

USE CLAMPS TO HOLD WORK WHEN

PRACTICAL

Using clamps to hold work is safer than using

your hand. It also frees both hands to

operate the tool.

DO NOT OVERREACH

Keep proper footing and balance at all times.

DISCONNECT TOOLS BEFORE SERVICING

When changing bits, make sure router is

unplugged.

KEEP GUARDS IN PLACE

Be sure guards are in working order, properly

adjusted, and aligned.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

USE RECOMMENDED ACCESSORIES

Consult this manual for recommended

accessories. Follow the instructions that

accompany the accessories. The use of

improper accessories may cause hazards.

REMOVE ADJUSTING KEYS AND

WRENCHES

Form the habit of checking to see that keys

and adjusting wrenches are removed from

the tool before turning it on.

ENSURE SAFETY OF OTHERS

Keep visitors and children a safe distance

away from the work area, especially when

operating a power tool. Visitors should wear

the same safety equipment as the operator.

SAVE THESE INSTRUCTIONS

UNPACKING AND CHECKING CONTENTS

IMPORTANT: Separate all parts from

packaging materials and check each item

against the package contents listed in this

manual, found on page 6.

Your wolfcraft® Router Table is shipped

complete in one carton. Make sure all items

are accounted for before discarding any of the

packaging materials.

INTRODUCTION

The wolfcraft® Router Table is designed to

provide an economical means to extend the

capabilities of your router.

We are certain you will find the wolfcraft®

Router Table a valuable addition to your shop.

NOTE: This manual covers assembly

instructions, setup, operation, and parts lists

for both the Model 6155 Router Table and the

Model 6156 Router Table.

4

Page 5

FEATURES AND SPECIFICATIONS

6155 & 6156 Table work space.......................................................................................

6155 Table weight...............................................................................................................................

6156 Table weight...............................................................................................................................

6155 Working heights.....................................................................................................................

570 square inches

50 lbs.

30 lbs.

32" to 38"

6156 Working height.................................................................................................................................

6155 Dimensions...........................................................................................

6156 Dimensions................................................................................................

14-1/4"W x 40-1/2"L x 32-38"H

14-1/4"W x 40-1/2"L x 14"H

6155 and 6156 Router Table features include:

• Unitized fence that allows mounting of boards up to 8"

• Front-mounted, keyed power switch with two 120-volt receptacles and circuit breaker protection

• Bottom-accessible outlets accept router and shop vacuum plugs to turn both on at the same time

• Die-cast aluminum top that provides a smooth, clean routing surface

• Reinforced steel extensions for 570 square inches of work surface

• Vertical push shoe that allows vertical cutting of boards up to 4-1/2" wide

• Tabletop measuring guides include scales and large miter guide for

quick and accurate straight or 0 to 60° angle cuts

• Universal router adapting plate, fits most routers

• Fence-mounted feather boards

G

IN

N

R

A

W

4

5

6

0

0

3

5

1

0

15

0

3

5

4

0

6

14"

• Combination dust collector/safety shield

Additional 6155 Router Table features include:

• Exclusive dovetail and box joint jig

• Height-adjustable legs that provide floor mounting from 32" to 38"

• Steel storage tray

5

N

O

L

UL

F

P

F

O

H

US

P

T

E

S

RE

S

T

E

L

T

U

O

NG

RNI

A

W

Page 6

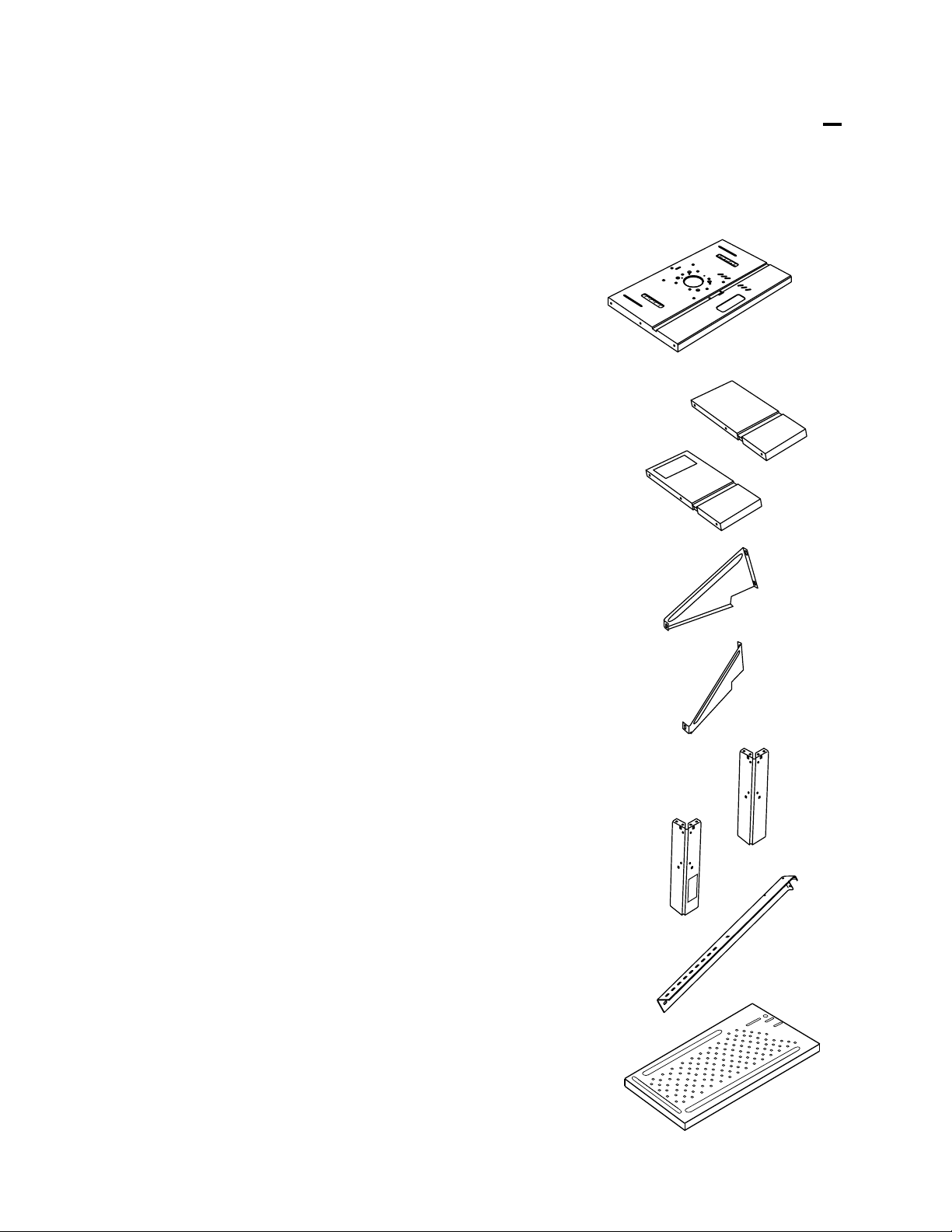

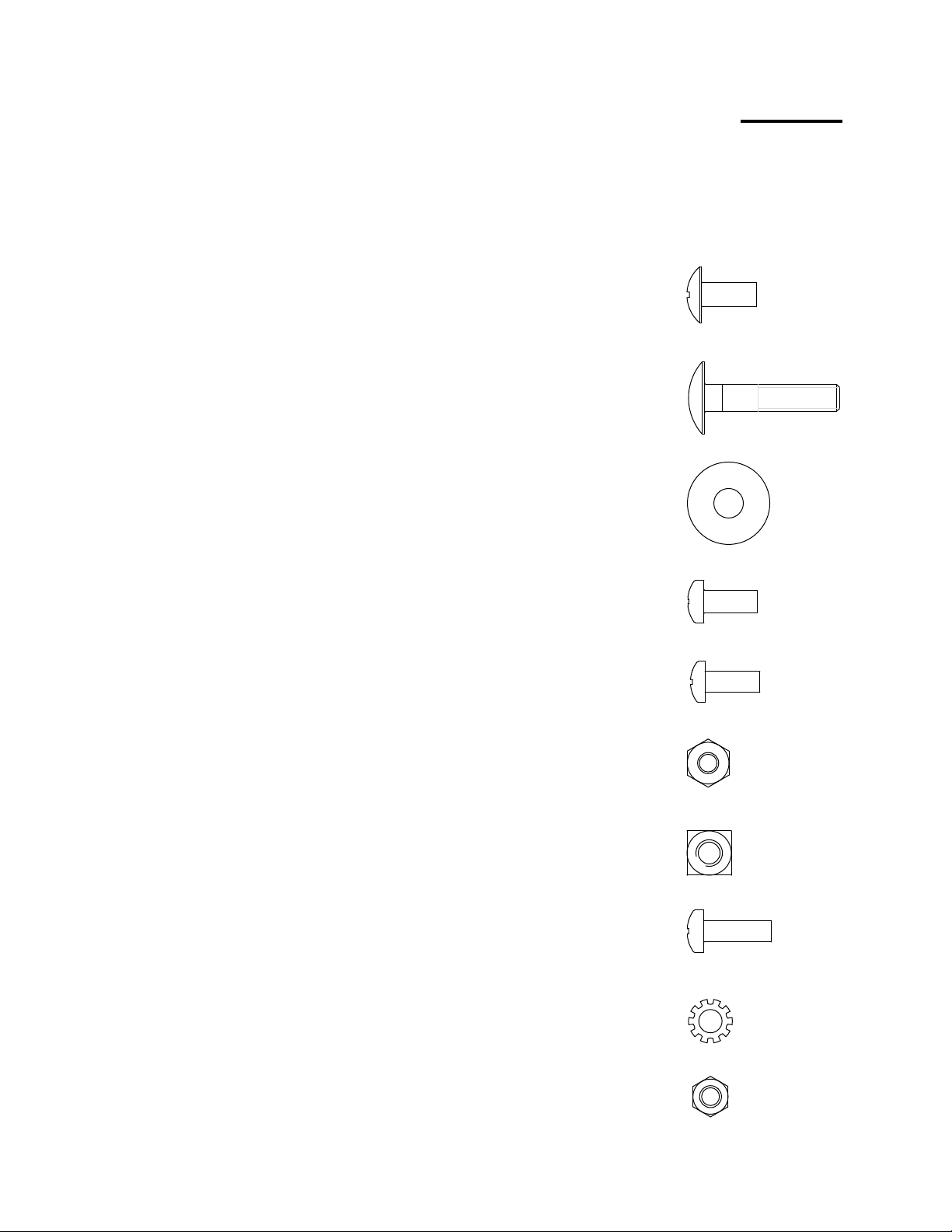

PACKAGE CONTENTS & HARDWARE LEGEND

NOTE: Unless otherwise marked, all parts are common to Models 6155 and 6156.

DESCRIPTION QTY.ITEM

B-1

B-2

C

Tabletop 1A

Extension

6155: 2

6156: 1

Extension, right

1

(Model 6156 only)

Leg support, left 2

Leg support, right 2D

A

B-1

B-2

C

D

RNING

A

W

Leg, shortE-1

Leg, short front left

(Model 6156 only)

Leg, long

(Model 6155 only)

Tool tray

(Model 6155 only)

6155: 4

6156: 3

1E-2

4F

1G

6

E-1

E-2

F

G

G

IN

N

AR

W

Page 7

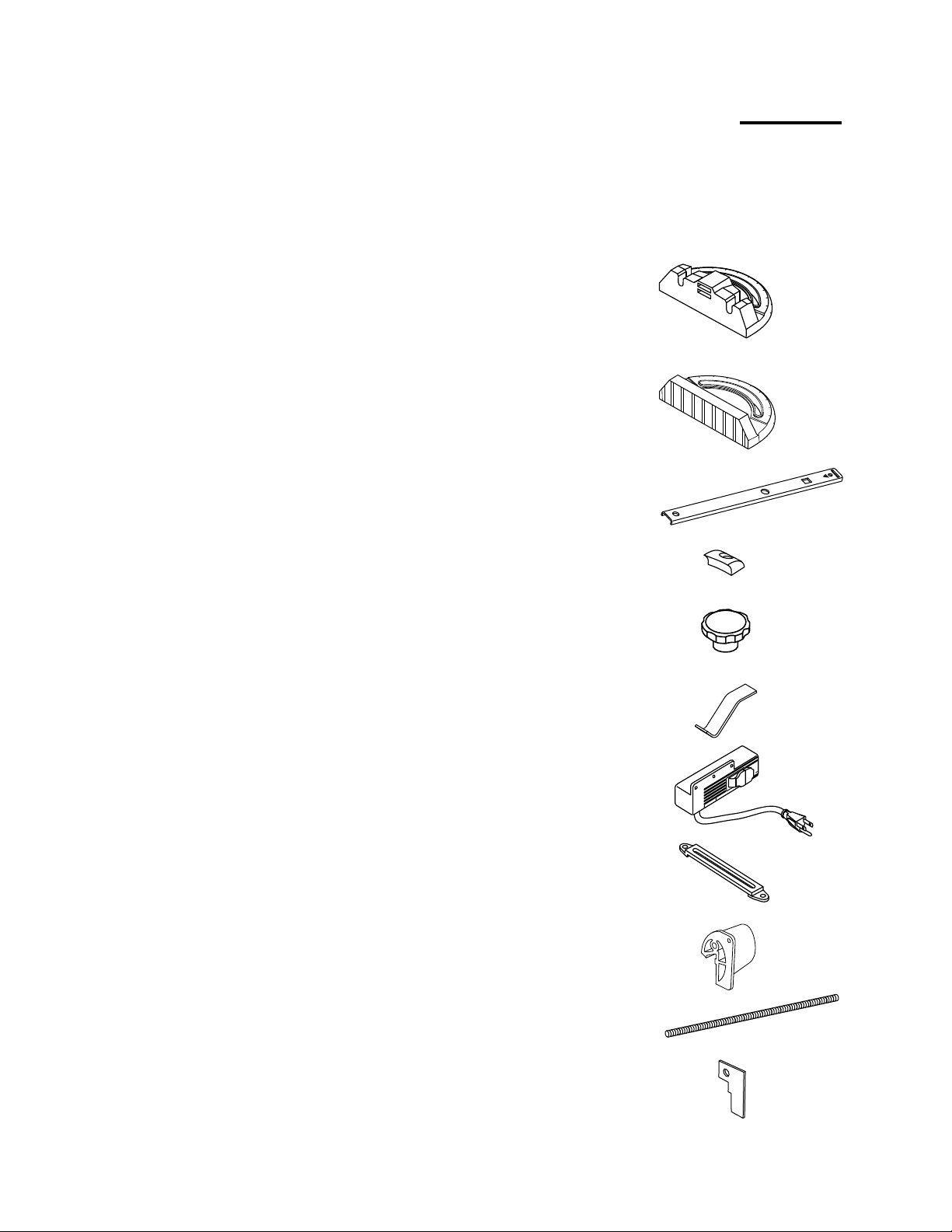

PACKAGE CONTENTS & HARDWARE LEGEND (Continued)

NOTE: Unless otherwise marked, all parts are common to Models 6155 and 6156.

ITEM

H

DESCRIPTION

Miter guide head,

aluminum

(Model 6155 only)

Miter guide head, plastic

(Model 6156 only)

Miter bar 1K

Miter pointer 1L

Miter guide knob 1M

QTY.

1

1J

H

J

K

L

M

45

6

0

30

5

1

0

15

0

3

5

4

60

45

6

0

0

3

15

0

5

1

0

3

45

0

6

N

P

Q

R

S

T

Miter guide clamp

(Model 6155 only)

Switch box 1

Retainer 2

Push shoe 1

Clamp rod 1

Clamp plate 1

1

N

P

N

O

L

L

U

F

P

F

O

H

S

U

P

T

E

S

E

R

TS

E

UTL

O

Q

R

S

T

7

Page 8

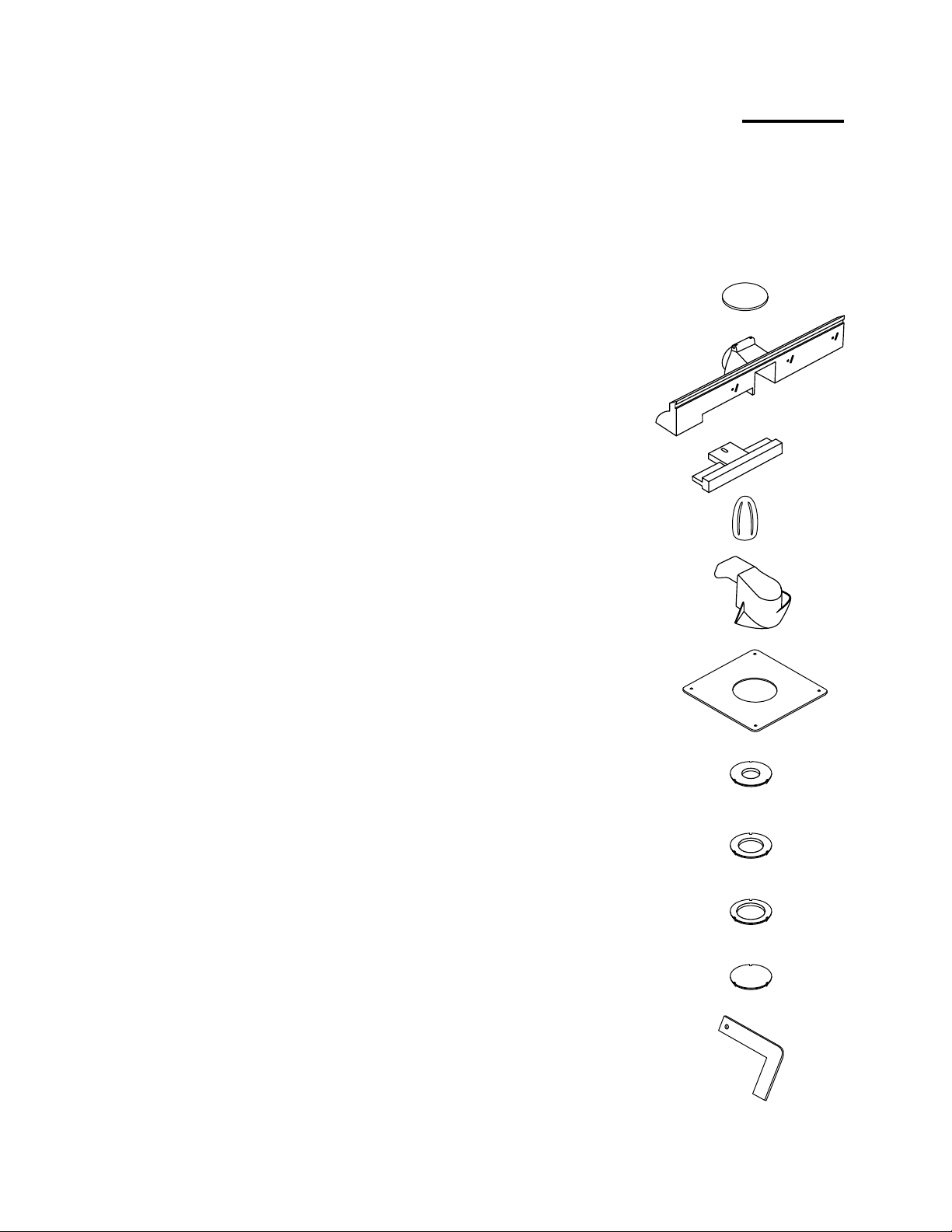

PACKAGE CONTENTS & HARDWARE LEGEND (Continued)

NOTE: Unless otherwise marked, all parts are common to Models 6155 and 6156.

ITEM

U

X

DESCRIPTION

QTY.

Rubber shoe

(Model 6155 only)

Fence 1V

Jointing fence

(attached to fence)

Jointing fence knob 1

Safety shield 1Y

Square adaptor

base plate

4

U

V

1W

W

X

Y

1Z

Z

AA

AB

AC

AD

Tabletop insert,

small hole

Tabletop insert,

medium hole

Tabletop insert,

large hole

Tabletop insert,

solid

Feather flap 3AE

1

1

1

1

AA

AB

AC

AD

AE

8

Page 9

PACKAGE CONTENTS & HARDWARE LEGEND (Continued)

NOTE: Hardware parts shown (screws, nuts, washers) are actual size.

Unless otherwise marked, all parts are common to Models 6155 and 6156.

ITEM

AF

DESCRIPTION

Pan head screw, zinc

(M5x12)

(Model 6155 only)

Carriage bolt, black

(M6x30)

Washer, black (M6) 2AH

Phillips head screw, selftapping, zinc (M5x12)

Pan head screw,

black (10-32x1/2)

QTY.

1

1AG

21AJ

3AK

AF

AG

AH

AJ

AK

AM

AP

AQ

Hex nut, black

3AL

(10-32)

Square nut, zinc

(M6)

Pan head screw,

18AN

black (M5x16)

Toothed washer,

34

black (M5)

Hex nut, black (M5) 18

AL

2

AM

AN

AP

AQ

9

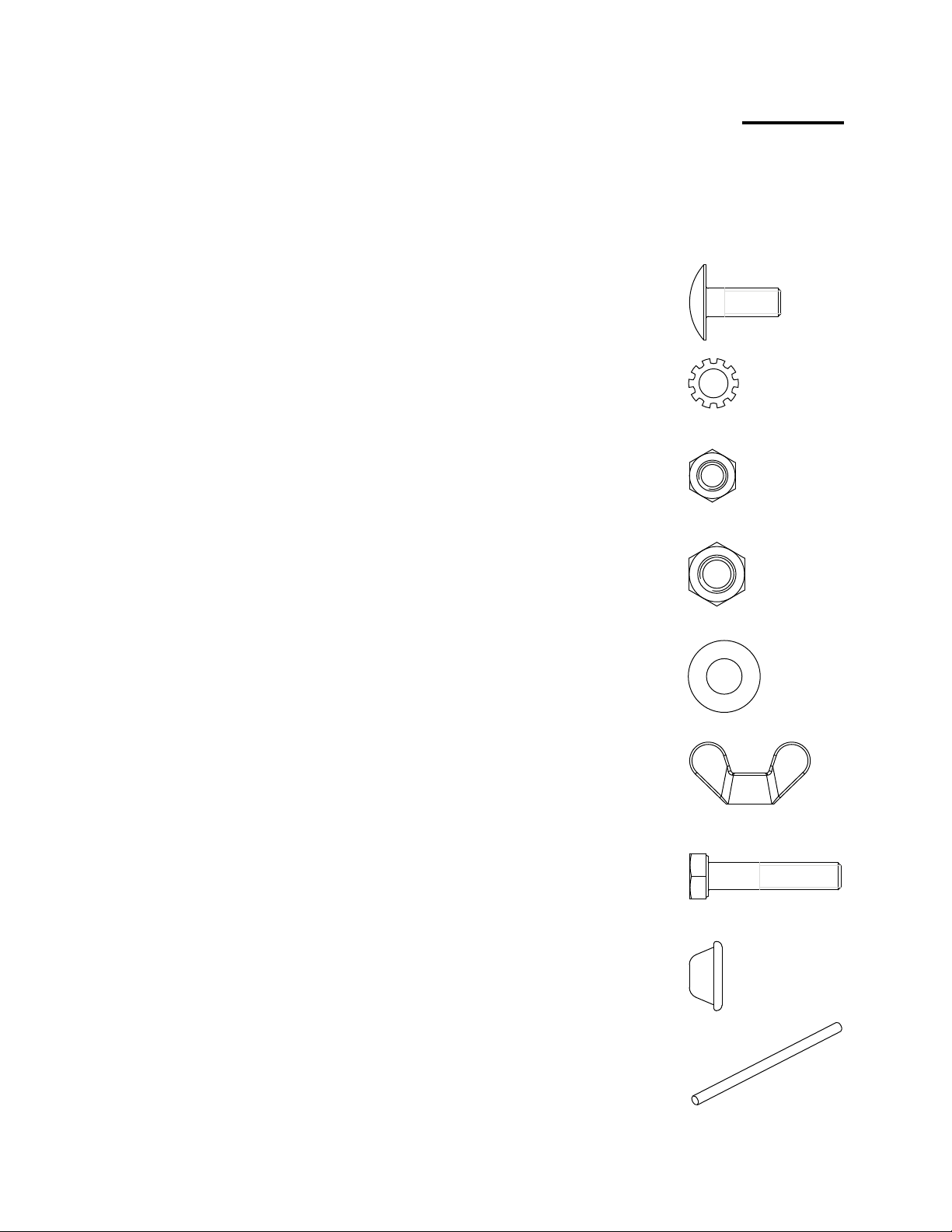

Page 10

PACKAGE CONTENTS & HARDWARE LEGEND (Continued)

NOTE: Hardware parts (screws, nuts, washers) shown are actual size.

Unless otherwise marked, all parts are common to Models 6155 and 6156.

ITEM

AR

AS

AT

AU

AV

DESCRIPTION

Carriage bolt, black (M6x16)

QTY.

24

(Model 6155 only)

Toothed washer, black (M6)

24

(Model 6155 only)

Hex nut, black (M6)

24

(Model 6155 only)

Hex nut, black (M8) 1

Washer, black (M8) 2

AR

AS

AT

AU

AV

AW

Wing nut, black (M8)

AX Hex head bolt, zinc

(M6x30)

Cap nut, zinc (M6)

AZ Pivot pin 1

10

1

1

2AY

AW

AX

AY

AZ

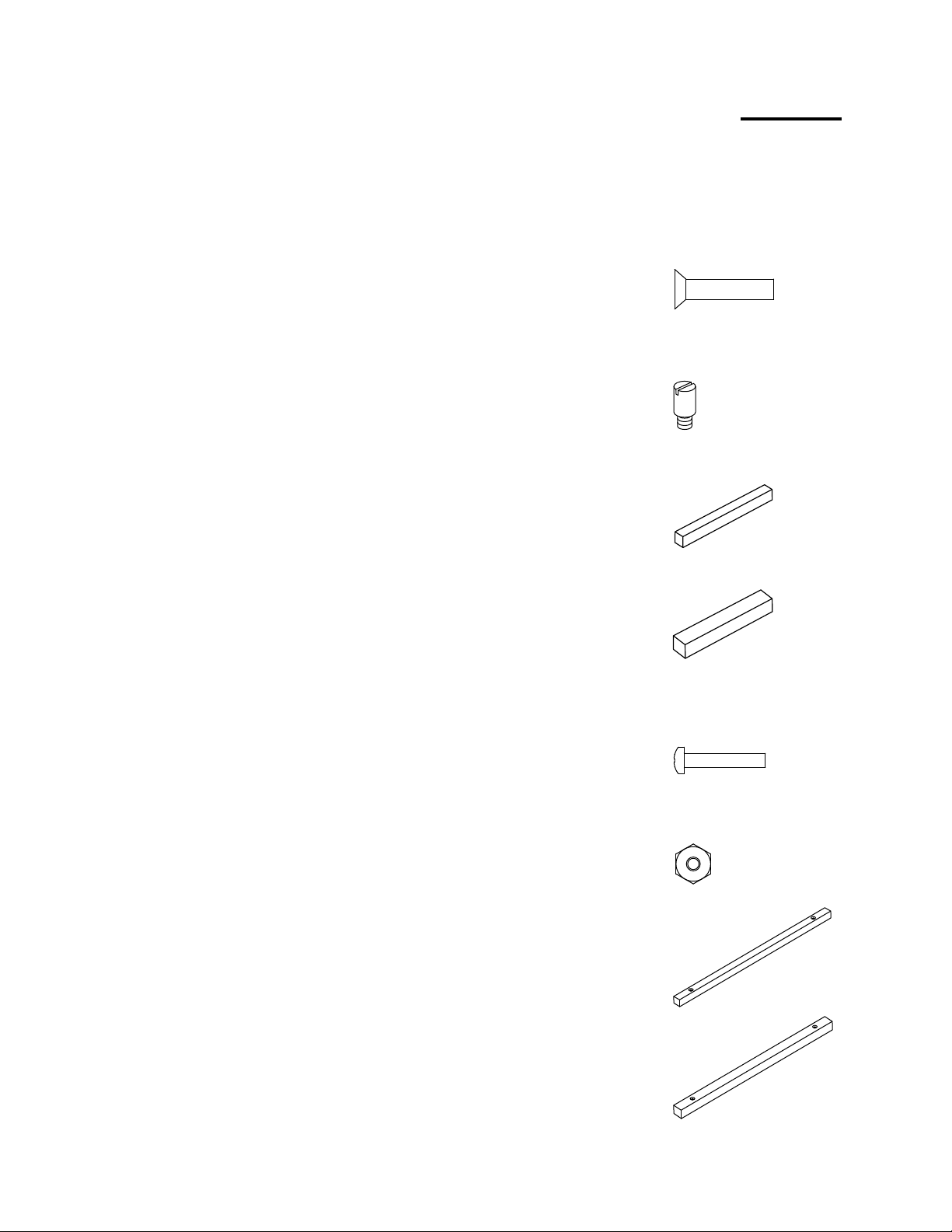

Page 11

PACKAGE CONTENTS & HARDWARE LEGEND (Continued)

NOTE: Hardware parts (screws, nuts, washers) shown are actual size.

Unless otherwise marked, all parts are common to Models 6155 and 6156.

ITEM

BA

BB

BC

DESCRIPTION

QTY.

Flat head countersink screw,

black (10-32x7/8)

Starter pin, black 1

Spacer bar, 1/4"

(Model 6155 only)

Spacer bar, 3/8"

(Model 6155 only)

4

BA

BB

1

1BD

BC

BD

BE

BF

BG

BH

Pan head screw, zinc (5-40x3/4)

(Model 6155 only)

Hex nut, zinc (5-40)

(Model 6155 only)

Dovetail/box joint bar, 1/4"

(Model 6155 only)

Dovetail/box joint bar, 3/8"

(Model 6155 only)

11

2

2

1

1

BE

BF

BG

BH

Page 12

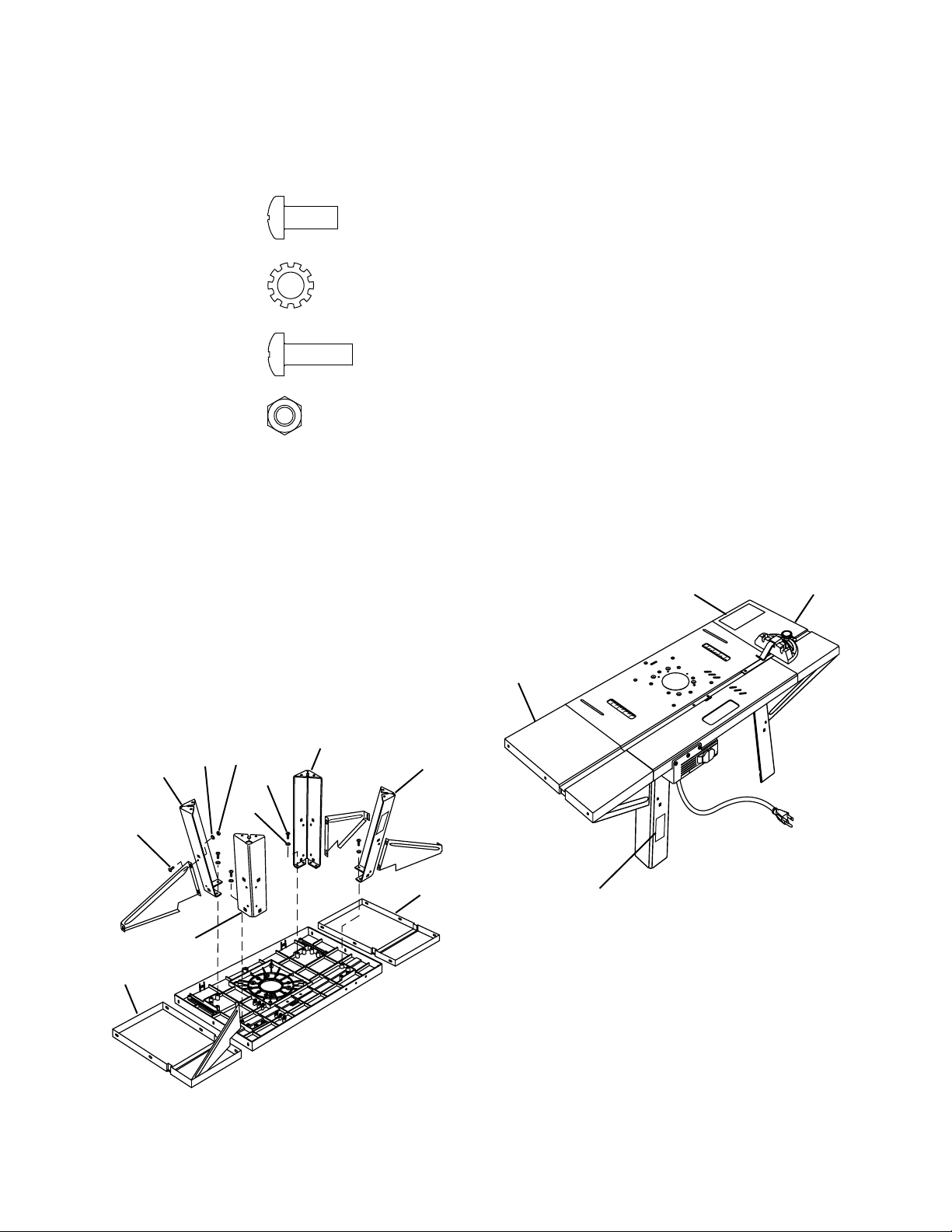

ASSEMBLY

NOTE: While most instructions are

common to both units, some instructions

apply to either Model 6155 (floorstanding) OR Model 6156 (benchtop).

Tools Required

#2 and #3 Phillips Screwdrivers

Hammer

Adjustable Wrench

Assemble Metal Miter Guide

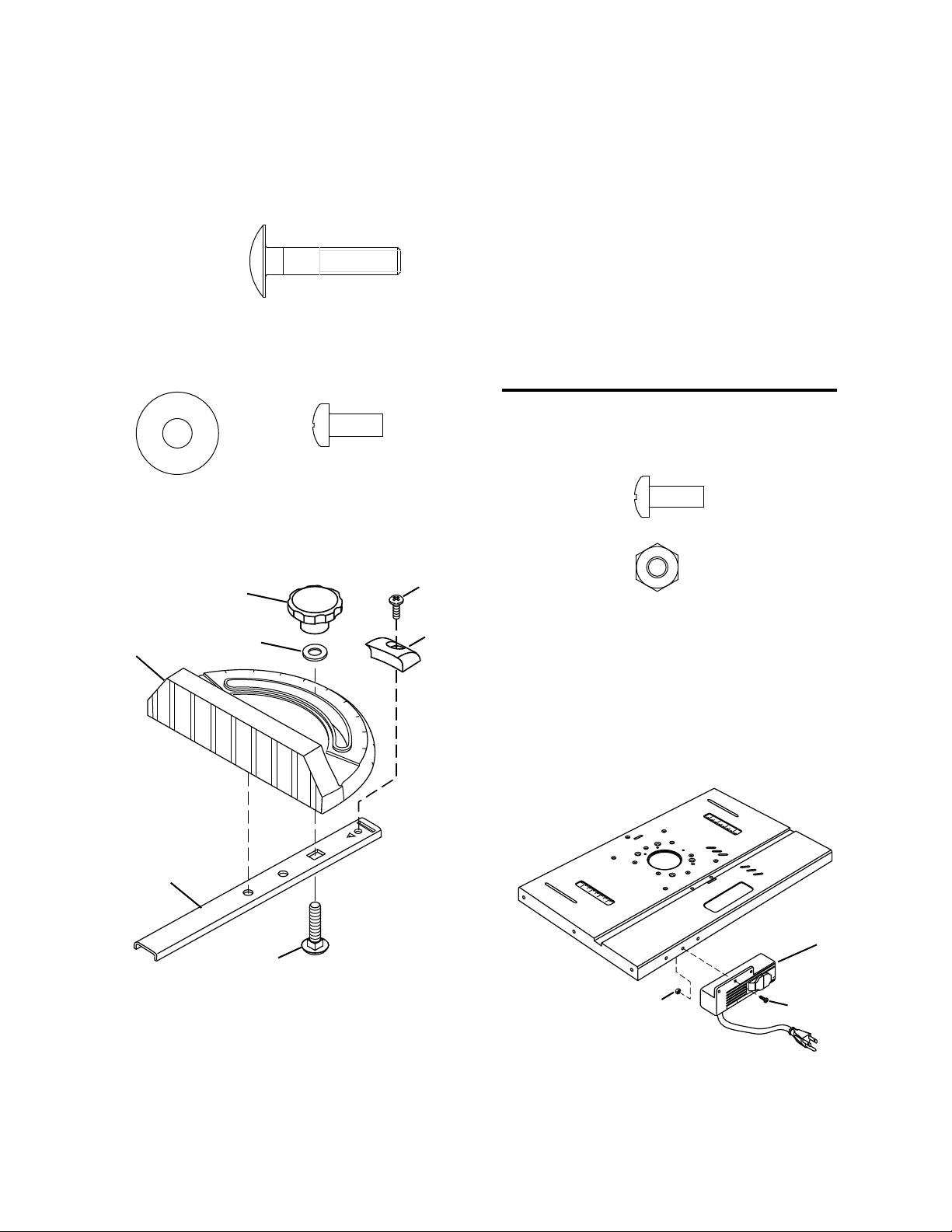

(5° Increments, Model 6155 Only)

AF, zinc (1) AG, black (1)

M

H

N

K

AH

45

60

30

5

1

0

15

30

5

4

0

6

AG

AF

Figure 1

3. Attach miter pointer (L) to miter bar

(K) with Phillips head screw (AJ).

AJ

L

AH, black (1) AJ, zinc (1)

1. Assemble miter guide by threading

pan head screw (AF) into miter guide

head (H) through miter bar (K) and by

threading carriage bolt (AG) through

miter bar (K). See Figure 1.

2. Place washer (AH) and knob (M) on

end of carriage bolt (AG). Tighten

knob.

4. Slide clamp (N) into one of two slots

on front of miter gauge.

12

Page 13

Assemble Plastic Miter Guide

(1° Increments, Model 6156 Only)

AG, zinc (1)

AH, black (1) AJ, zinc (1)

1. Assemble miter guide by threading

carriage bolt (AG) through miter bar

(K). See Figure 2.

2. Place washer (AH) and knob (M) on

end of carriage bolt (AG). Tighten

knob.

3. Attach miter pointer (L) to rear of

miter bar with Phillips head screw

(AJ).

Attach Switch Box to Tabletop

AK, black (3)

M

0

6

AH

45

30

15

0

15

0

3

45

60

J

K

AG

Figure 2

AJ

L

Use a #2 Phillips screwdriver to attach

switch box (P) to front of router table

(A) with 3 pan head screws (AK) and

3 hex nuts (AL). See Figure 3.

P

AL

AK

AL, black (3)

13

Figure 3

Page 14

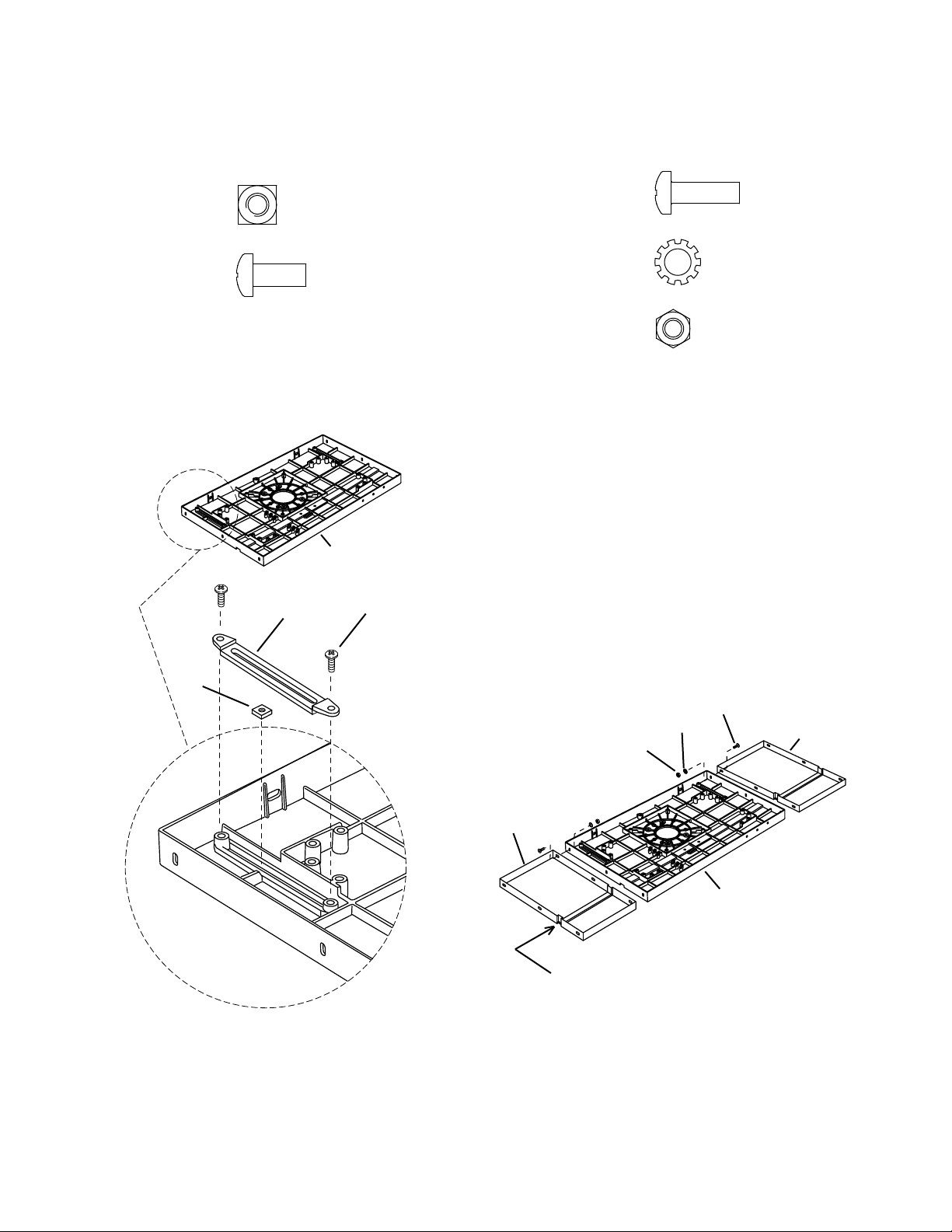

Attach Square Nuts and

Retainers

Attach Extensions

AM, zinc (2)

AJ, zinc (4)

1. Place one square nut (AM) in each of

the two slots on the underside of the

aluminum tabletop (A). See Figure 4.

A

Q

AJ

AN, black (6)

AP, black (6)

AQ, black (6)

1. Position extensions (B-1) and (B-2) on

ends of the router tabletop (A) with flat

sides down (upside down). Note

position of miter guide slots in all three

parts. Ensure alignment as shown in

Figure 5.

2. Attach each extension to the ends of

the table using 3 pan head screws

(AN), 3 toothed washers (AP), and 3

hex nuts (AQ).

AM

Figure 4

2. Place one yellow retainer (Q) in each

slot and fasten each with two pan

head screws (AJ). Note orientation

of retainer.

B-2

AP

AQ

MITER GUIDE SLOT

AN

B-1

A

Figure 5

14

Page 15

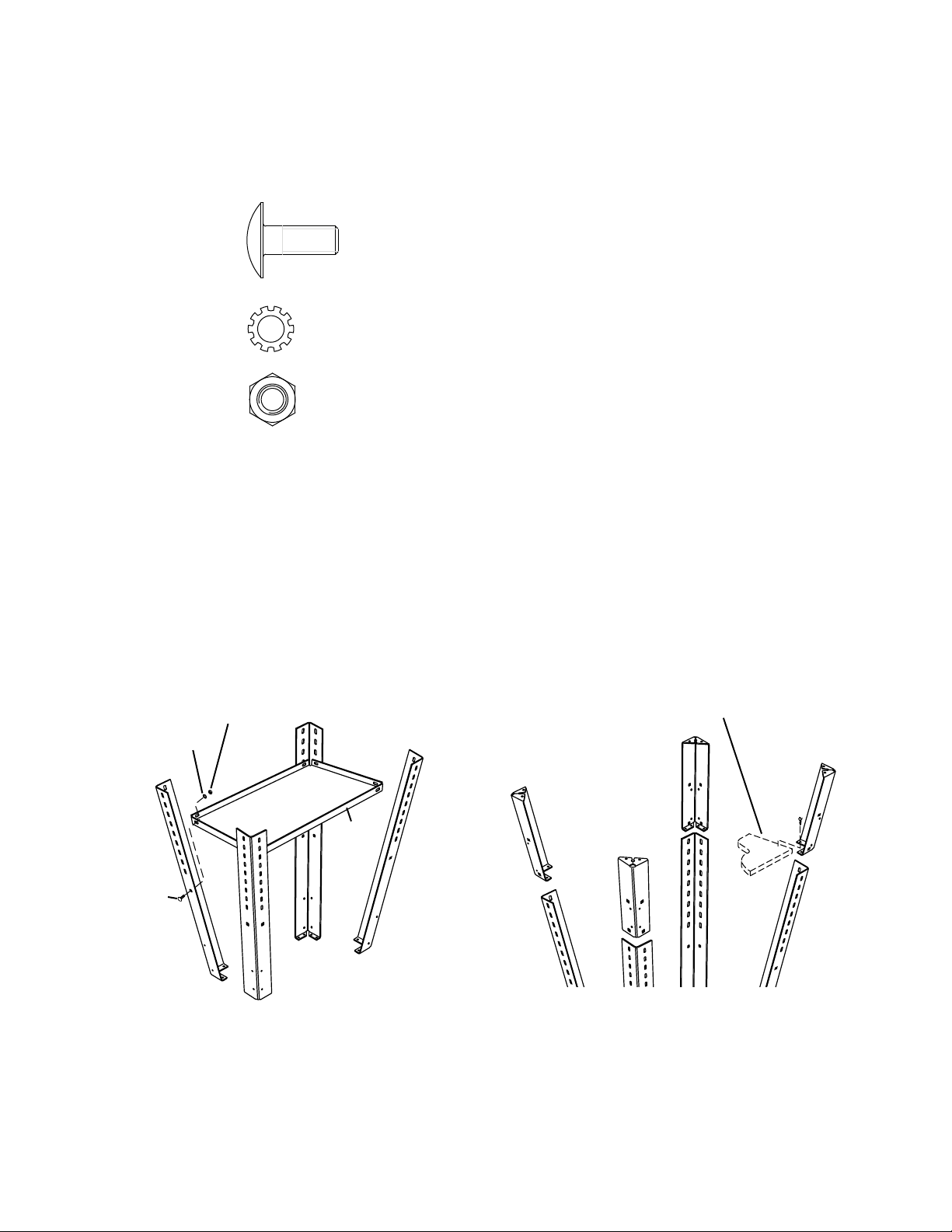

Attach Supports to Tabletop

AN, black (4)

AP, black (4)

AQ, black (4)

Attach Height-Adjustable Legs

(Model 6155 Only)

AJ, zinc (16)

AP, black (24)

AN, black (8)

Use 2 pan head screws (AN), 2

toothed washers (AP), and 2 hex nuts

(AQ) to attach a pair of supports (C

and D) to each extension (F). See

Figure 6.

D

C

D

AQ

AP

AN

Figure 6

AQ, black (8)

AR, black (24)

AS, black (24)

C

AT, black (24)

AQ

AP

AJ

AN

F

15

AP

Figure 7

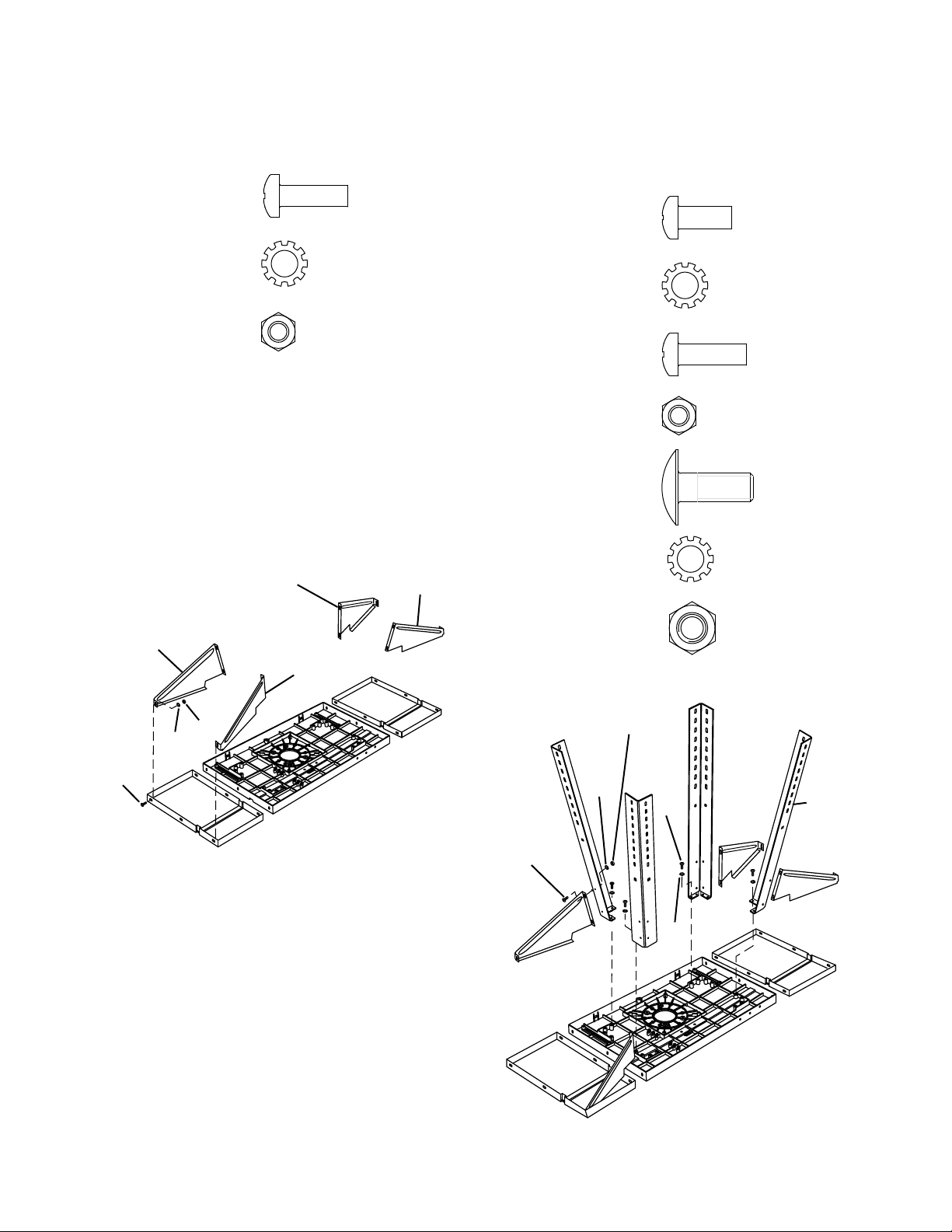

Page 16

Attach Height-Adjustable Legs

AS

AT

E-1

AR

F

(Model 6155 Only) (continued)

1. Mount four long legs (F) to table using

four pan head screws (AJ) and four

toothed washers (AP) per leg. Use a

#3 Phillips screwdriver to keep from

stripping the screw heads. See

Figure 7.

2. Use 2 pan head screws (AN), 2

toothed washers (AP), and 2 hex nuts

(AQ) to attach a support (C or D) to

each long leg (F).

3. Decide what height you want your

Router Center table to be from the

floor.

4. With the "foot" of short legs (E-1)

pointing upward, align 2 holes in short

leg with 2 holes in long leg at

appropriate height. See Figure 8.

5. Thread 4 carriage bolts (AR) through

the holes in both leg members.

Assemble 1 toothed washer (AS) and

1 hex nut (AT) to each bolt.

Tighten nuts.

6. Attach the three remaining legs in the

same manner. In order to obtain the

same height above the floor, use the

same hole positions as the first leg

you attached.

7. Attach 4 molded "shoes" (U) to feet.

See Figure 9.

8. The table can be leveled by adjusting

short legs (E-1) within the slotted

mounting holes on the long legs (F).

NOTE: Short legs (E-1) mount to the

inside of long legs (F).

Figure 8

U

Figure 9

16

Page 17

Attach Short Legs

(Model 6156 Only)

AJ, zinc (16)

AP, black (24)

2. Use 2 pan head screws (AN), 2

toothed washers (AP), and 2 hex nuts

(AQ) to attach a support (C or D) to

each leg (E).

Alignment of Tabletop and

Extensions

AN, black (8)

AQ, black (8)

1. Mount four legs (E-1 and E-2) to table

using four pan head screws (AJ) and

four toothed washers (AP) per leg.

Use a #3 Phillips screwdriver to keep

from stripping the screw heads.

NOTE: Leg (E-2) is mounted on the

front left position of the table top with the

safety sticker toward the front of the

table. See Figure 10.

E-1

AQ

E-1

AP

AJ

E-2

Turn tabletop/extension assembly over

and check alignment of extensions and

tabletop by sliding miter guide assembly

through slot. Loosen screws and adjust

alignment of tabletop and extensions if

necessary. Retighten screws.

NOTE: Extension (B-2) to be mounted

on the right side of the table top. See

Figure 11.

B-1

SAFETY

STICKER

G

IN

N

R

A

W

0

N

O

L

L

U

F

P

F

O

H

S

U

P

T

E

S

E

R

S

T

E

L

T

U

O

B-2

4

5

6

0

3

5

1

0

5

1

0

3

5

4

0

6

B-2

AN

E-1

AP

W

A

R

N

I

N

G

Figure 10

B-1

17

SAFETY

STICKER

G

IN

N

AR

W

Figure 11

Page 18

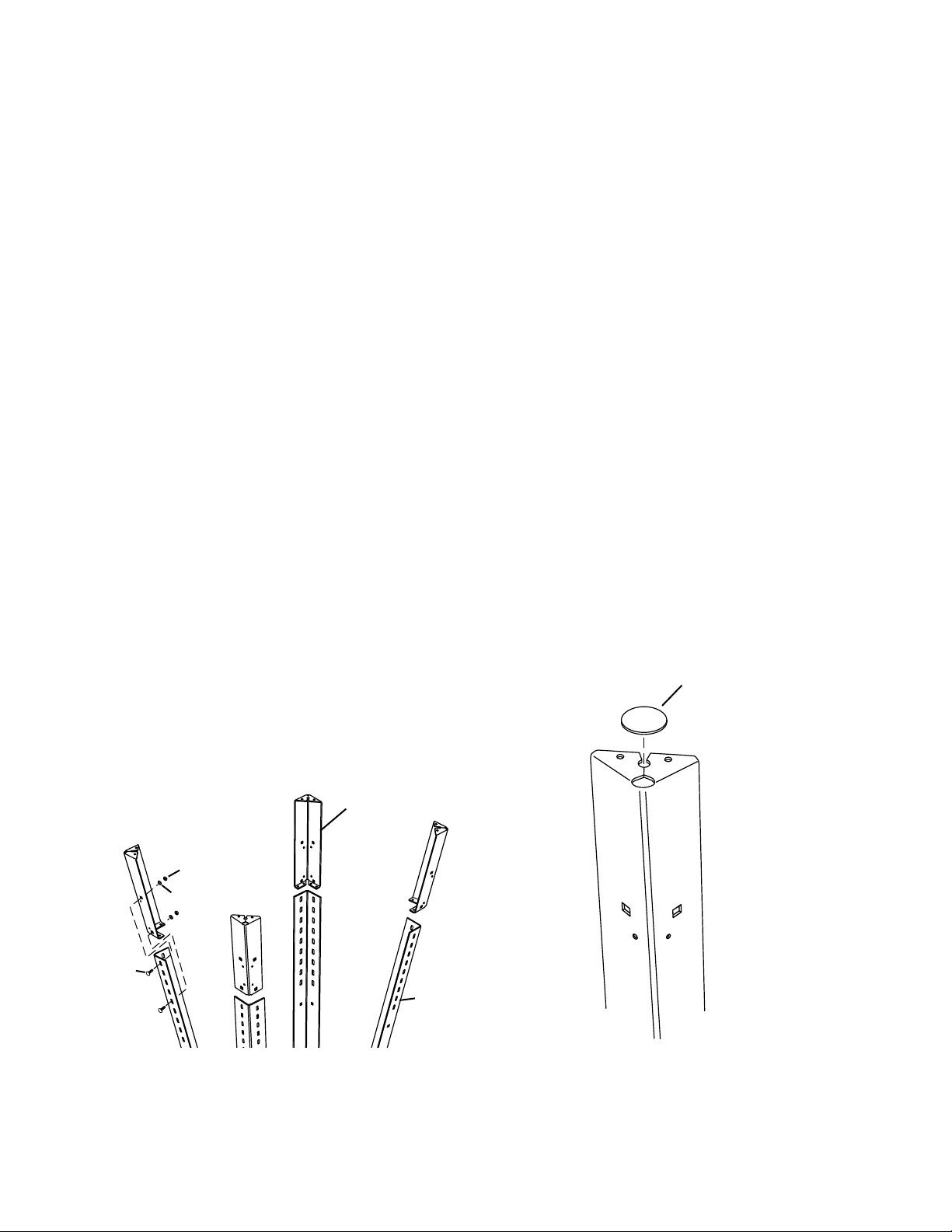

Attach Tool Tray

(Router Table Model 6155 Only)

AR, black (8)

AS, black (8)

Attach Optional, Second Shelf

(Router Table Model 6155

Only)

1. Size of optional, second shelf (not

provided) will depend on position of

the height-adjustable legs (J). Once

adjusted to operating height,

measure and cut plywood or

medium density fiberboard to fit your

stand.

AT, black (8)

1. Align holes in legs to holes in corners

of tool tray (G). See Figure 12.

2. Use 8 carriage bolts (AR), 8 toothed

washers (AS), and 8 hex nuts (AT) to

attach the tray to the legs. Tighten

securely.

AT

AS

G

2. With the router table in an upright

orientation, place corners of shelf

board on each one of the "brackets"

that protrudes from the heightadjustable legs. See Figure 13,

stand inverted for clarity.

3. Use screws (not provided) to secure

the shelf.

Location of optional shelf

on corners of heightadjustable legs

AR

Figure 13

Figure 12

(Height-adjustable legs

removed for clarity)

18

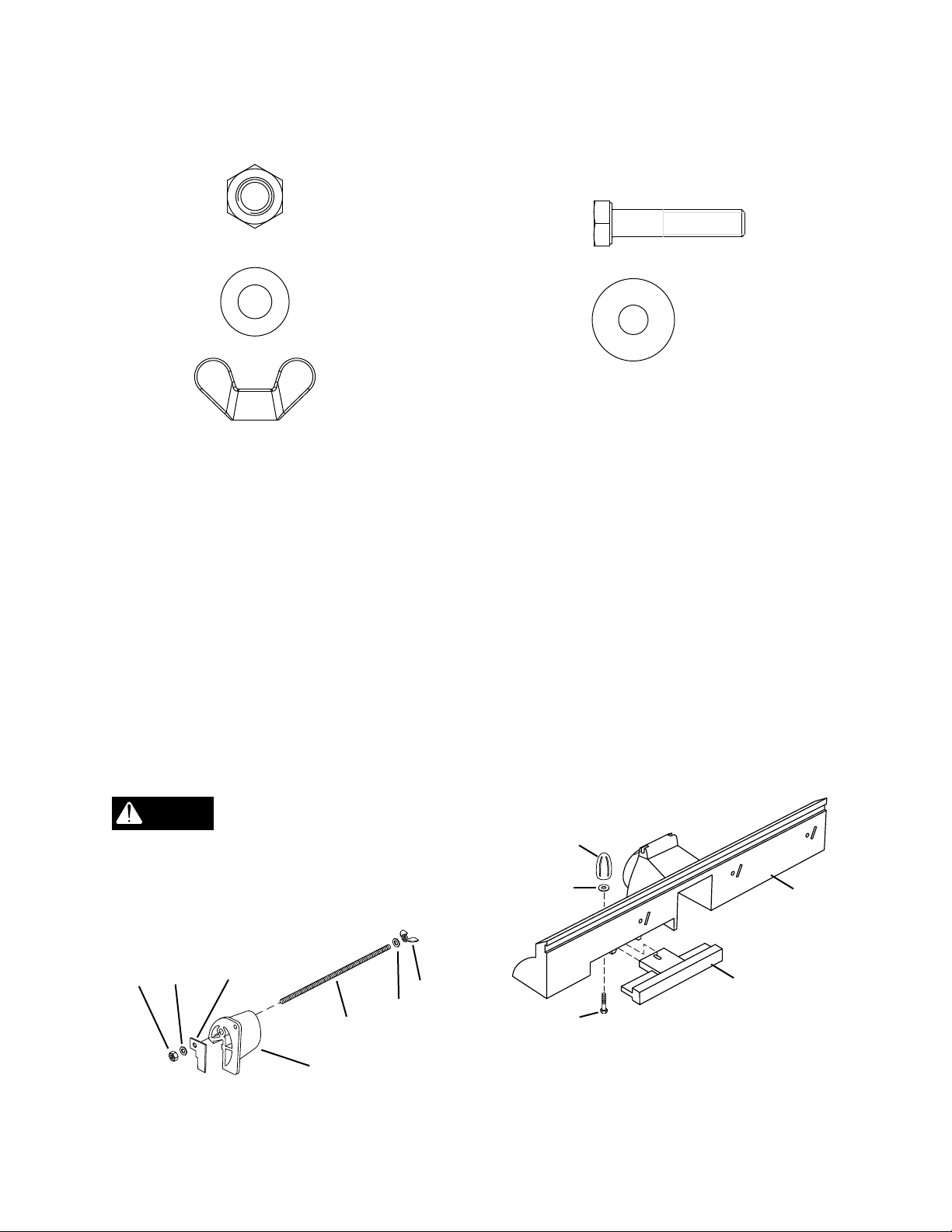

Page 19

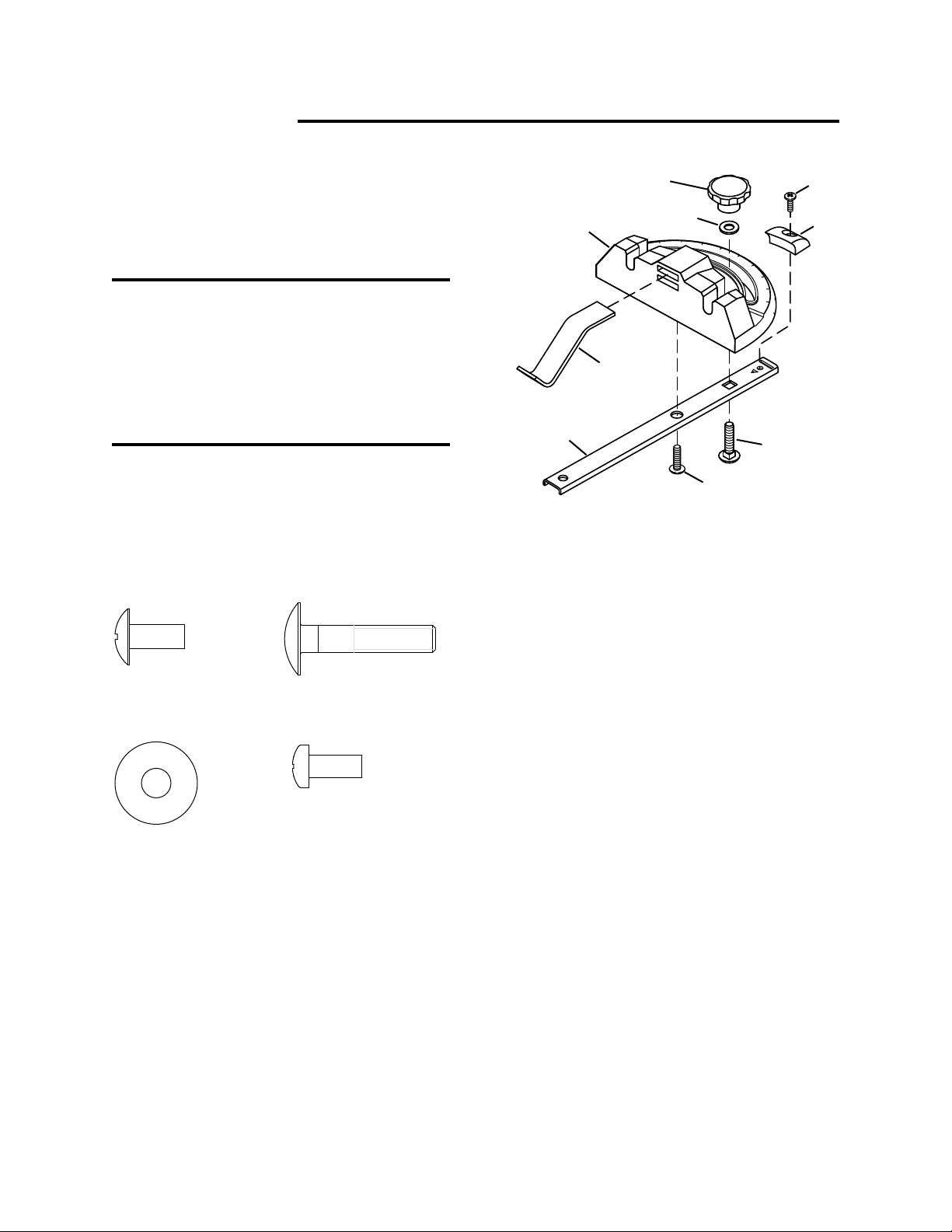

Assemble Push Shoe

AU (1)

black

AV (2)

black

AW (1)

black

1. On one end of the threaded clamp

rod (S), thread the clamp plate (T)

about 1/2".

Assemble Jointing Fence to

Router Table Fence

AX (1)

zinc

AH (1)

black

1. Using the slots on the fence as

guides, slide the jointing fence (W)

into the router table fence (V).

(Jointing fence may be taped into

place at the factory.)

2. On same end of rod, add washer (AV)

and nut (AU).

3. Slide the clamp rod (S) through push

shoe (R) so the end with the clamp

plate, washer, and nut is on the large

end of the push shoe. See Figure 14.

4. Add washer (AV) and wing nut (AW)

to end of threaded rod.

Vibrations from normal

WARNING

routing may loosen the

washer and bolt that hold the rod to the

plate. Occasionally check these

components to make sure they are tight.

AU

AV

T

AW

AV

S

2. Slide hex head bolt (AX) into bottom

of jointing fence (W) and through hole

in fence (V). Add washer (AH) and

jointing fence knob (X). See Figure

15.

3. Slide the jointing fence into the router

table fence as far as you can.

Remove factory tape if necesssary.

X

AH

W

AX

V

R

Figure 15

Figure 14

19

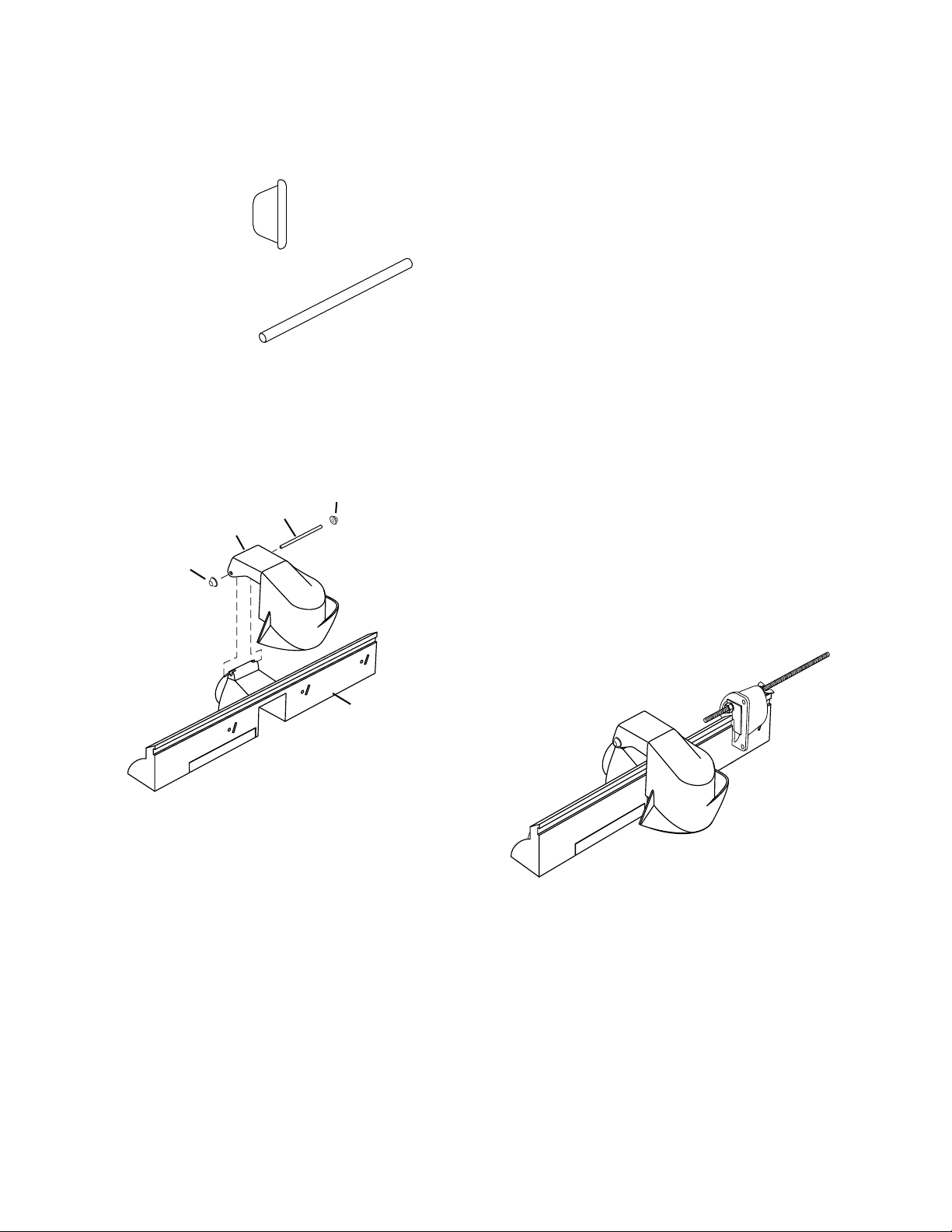

Page 20

Attach Security Guard Fence

AY, zinc (2)

Assemble Push Shoe to Fence

1. Place push shoe assembly onto

fence so the slot in the push shoe

aligns with rail on fence. See Figure

17.

AZ, black (1)

1. Position the two holes on the security

guard (Y) so that they align with the

two holes on the fence (V). See

Figure 16.

AY

AZ

Y

AY

V

2. With safety shield in the up position,

test moveability of push shoe by

sliding it along fence. It should slide

with ease.

NOTE: It is recommended that you

occasionally lightly lubricate the push

shoe and fence sliding surfaces with

furniture wax.

NOTE: For best performance,

periodically remove any wood chips that

accumulate inside the push shoe slot

and rail.

Figure 16

2. Position one cap nut (AY) on one end

of pivot pin (AZ). Using a hammer,

lightly tap pivot pin until it seats in cap

nut.

3. Slide pivot pin (AZ) through holes in

fence and security guard. Add

second cap nut (AY) and secure on

end of pin.

3. Test moveability by moving security

guard up and down.

Figure 17

20

Page 21

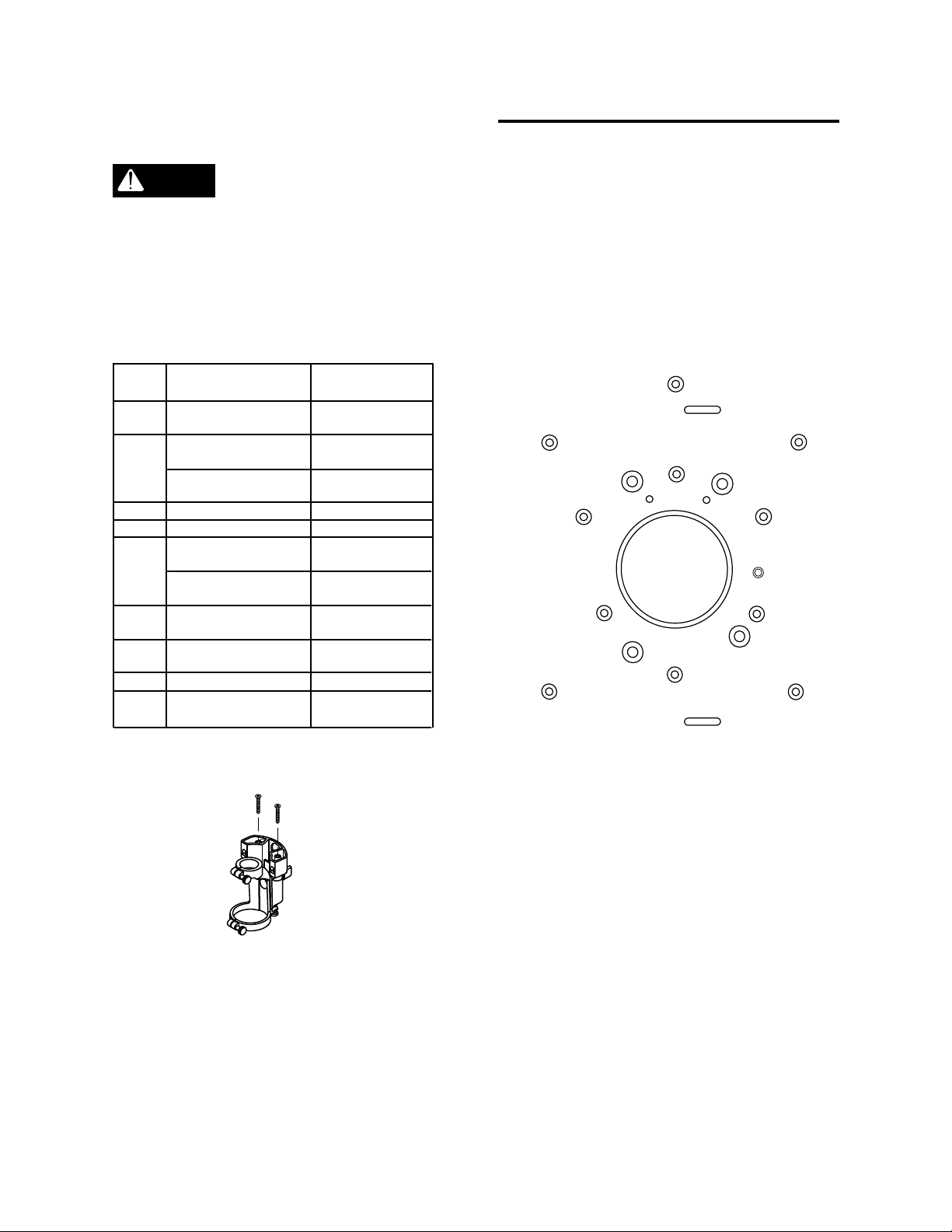

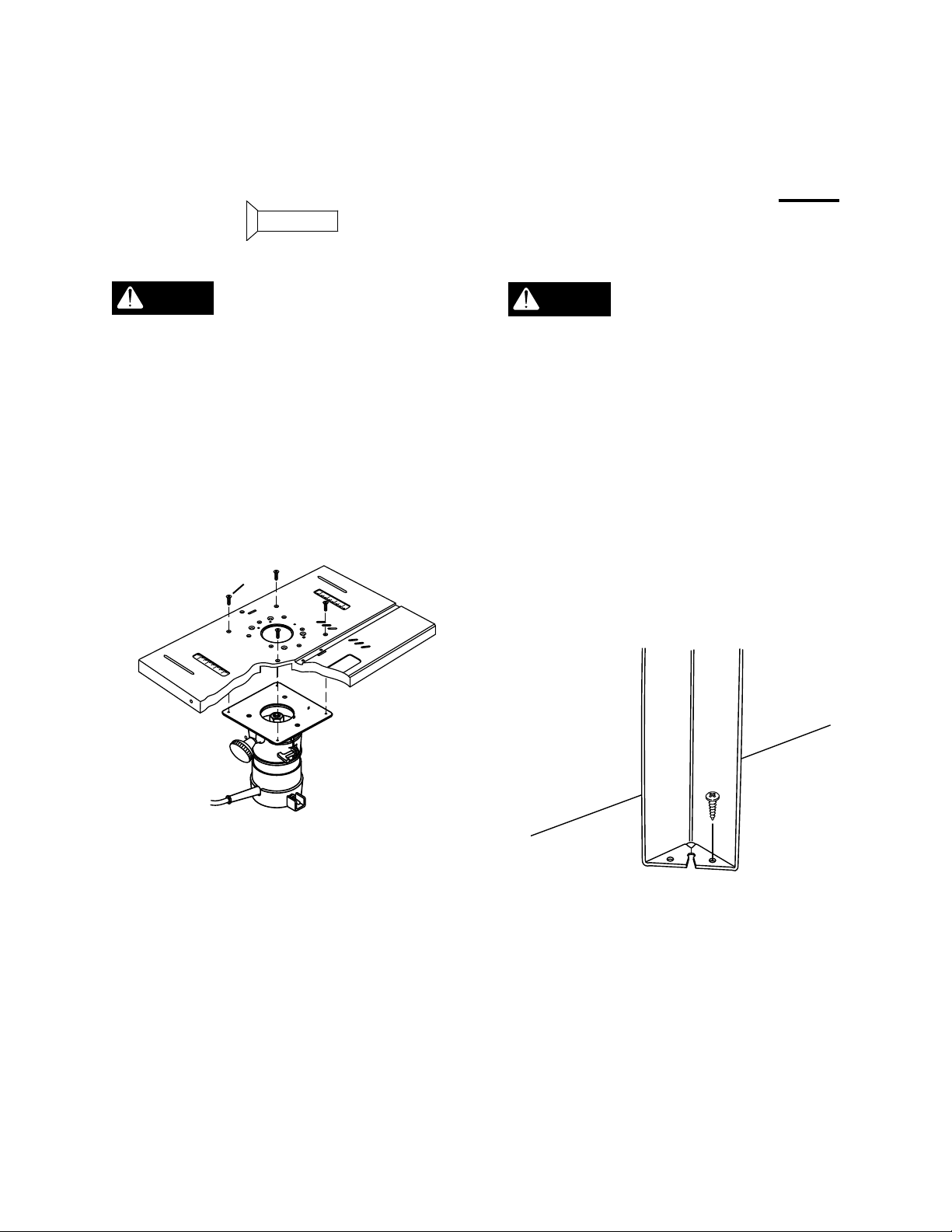

MOUNTING THE ROUTER

Always remove router bits

WARNING

and unplug router before

mounting to router table.

The table will accept routers with bases

up to 7" in diameter. There are two

methods for attaching routers to router

table.

Hole

Pattern

A

B

C

D

E

F*

G

H

J

Dremel™ is a registered trademark of S-B Power Tool

Company.

*Mounts with Dremel™ #330 Router Attachment Kit (not

included, see below).

Router Brand/

Hole Use

Square Adaptor Plate

Mounting Holes

Ryobi

Craftsman

Ryobi

Porter Cable

Skil

Craftsman

Dremel™ Rotary

Hobby Tools

Threaded Hole for

Pilot Pin

Pilot Pin Storage Hole

Dovetail/Box Joint

Fixture Mounting Slots

Specific Model

Numbers

Most routers

mount with plate

#R160K, #R160V,

#R165, #R180

#27500, #27510,

#27511

#R174, #RE175

#690, #6931

#1823, #1835,

#1845-02,

#17504, #17505,

#17506

All

n/a

n/a

n/a

At least three holes should be aligned

for proper support of the router. If fewer

than three holes line up, follow

instructions on how to mount your router

with the square adaptor base plate (Z)

on the next page.

H

J

A

B/C

E

D

B

F

F

D

E

A

B

J

A

E

G

D

B/C

A

Figure 18

If your router is not one of those listed

in the chart, place the router base plate

on top of the router table and rotate the

base plate until the holes are aligned.

When the two hole patterns line up,

your mounting pattern has been

identified. See Figure 18.

21

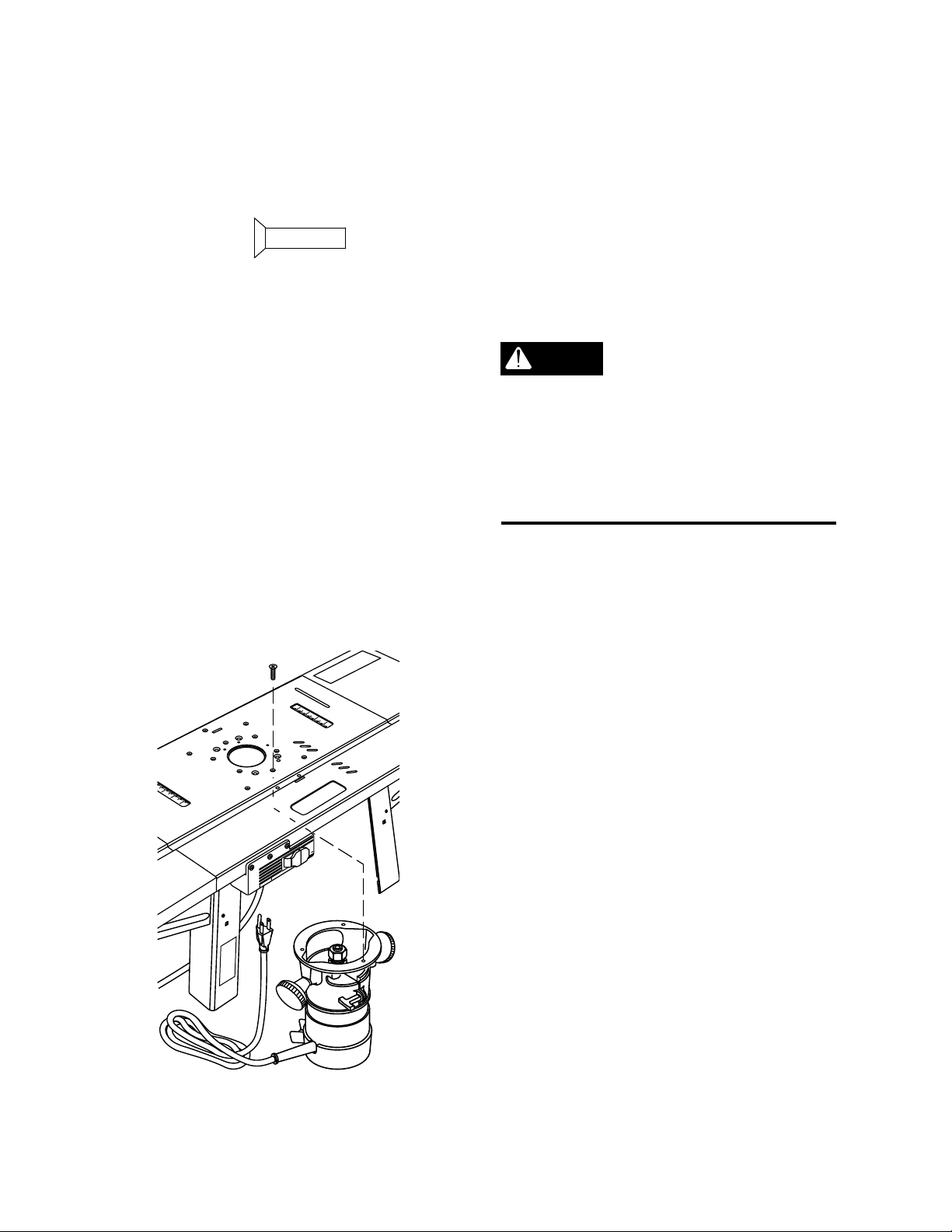

Page 22

Mount Router Directly to the

P

U

L

L

O

N

P

U

S

H

O

F

F

R

E

S

E

T

O

U

T

L

E

T

S

Table

BA, black (4)

1. Remove router base plate from

router by removing screws.

2. Loosen knobs and slide fence so that

it clears mounting holes.

3. While holding router upside down,

position it underneath the table so

that the center of the router is within

the center ring of the table top.

NOTE: For ease of use, position the

router so the ON-OFF switch is

accessible from the front of the table.

5. Insert router base plate screws

previously removed through holes in

table top and into router mounting

holes. Tighten securely. See Figure

19.

Make sure the screws

WARNING

from your router base

plate match the countersinks in the table

and are long enough to mount the router

to the table. If necessary repace with

screws that are 1/8 to 1/4 inch longer.

4. Rotate router until mounting holes in

router base line up with the holes in

the table top.

G

N

I

N

R

WA

NG

I

RN

A

W

Figure 19

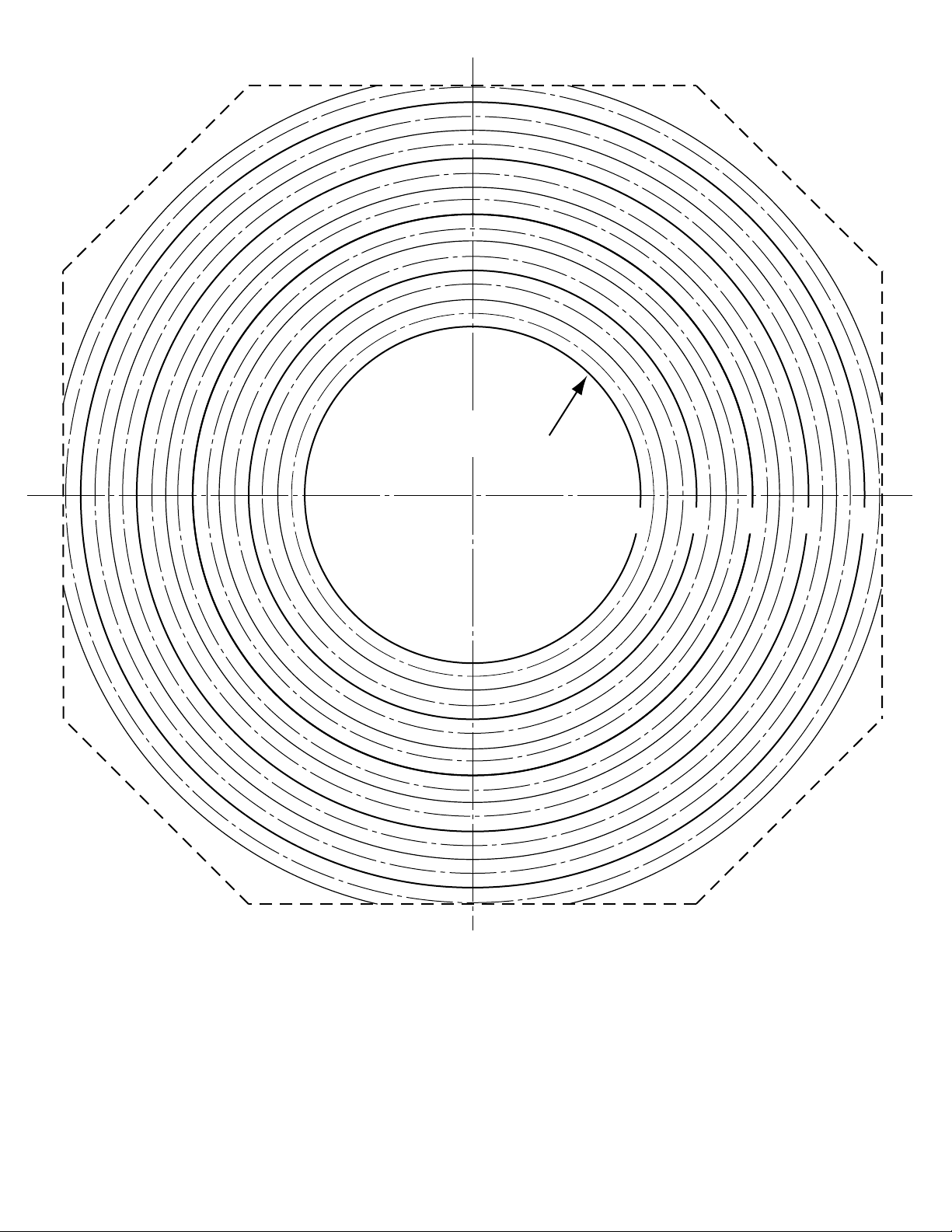

Mounting Routers with Square

Adaptor Plate

Some router models will not mount

directly to this router table. For these

routers, a square adapator base plate is

provided. It will need to be modified to

fit your particular router. Once modified,

and attached to your router, it will mount

directly to the router table.

1. Cut out template on page 23. Also

cut out inner circle of template.

2. Position template on the side of

square adaptor base plate with

welded nuts.

3. Accurately line up the edges of the

template with the edges of the adaptor

base plate. Make sure inner circle

also precisely matches hole in plate.

22

Page 23

LINE UP WITH HOLE

IN ADAPTER PLATE

ALIGNER AVEC LE TROU DE

LA PLAQUE INTERMEDIAIRE

ALINEE CON EL AGUJERO

EN LA PLACA ADAPTADORA

3" 4" 5" 6" 7"

SQUARE ADAPTER PLATE TEMPLATE

GABARIT DE LA PLAQUE INTERMEDIAIRE

PLANTILLA PARA LA PLACA ADAPTADORA

23

Figure 20

Figura 20

Page 24

This page intentionally left blank.

Cette page part intentionnellement le vide.

Esta página intensionalmente blanco de

izquierda.

24

Page 25

ROUTER

BASE PLATE

TEMPLATE

SQUARE

ADAPTOR

BASE

PLATE (Z)

Make sure edges of

CAUTION

template align with edges

WELDNUT

Figure 21

of square adaptor base plate, and inner

circle accurately lines up with hole in

plate. Routing accuracy will suffer if

alignments are not true.

8. Using a pen or pencil, mark the

positions of the mounting holes in the

base plate on the paper template.

9. Take the base plate off the square

adaptor base plate and put it aside.

10. Using a drill bit that matches the

diameter of the holes in the router

base plate, bore into the square

adaptor base plate in the locations

previously marked. (To reduce drill

breakout, use a back-up board.)

11. Remove the paper template from the

square adaptor base plate.

12. Flip the square adaptor base plate

over. With the welded nuts now

facing downward, position the adaptor

plate on the router. (The welded nuts

and the router must be on the same

side of the adapter plate.) See Figure

22.

4. Use tape to attach template to the

square adaptor base plate (Z).

5. Lay the square adaptor base plate on

a flat surface with template and

weldnuts facing up.

6. Unscrew the fasteners that hold the

router base plate to the router and set

them aside.

7. Turn the router base plate over and

position it face down on the template,

which is still taped to the square

adaptor base plate. The position of

the base plate must line up with one

of the circles on the template. See

Figure 21.

13. With the square adaptor base plate

holes and router holes aligned, insert

appropriate screws and tighten.

Make sure the screws

WARNING

from your router base plate

are long enough to mount the square

adaptor base plate securely. If

necessary, replace with screws that are

1/8" to 1/4" longer.

WELDNUT

Figure 22

25

Page 26

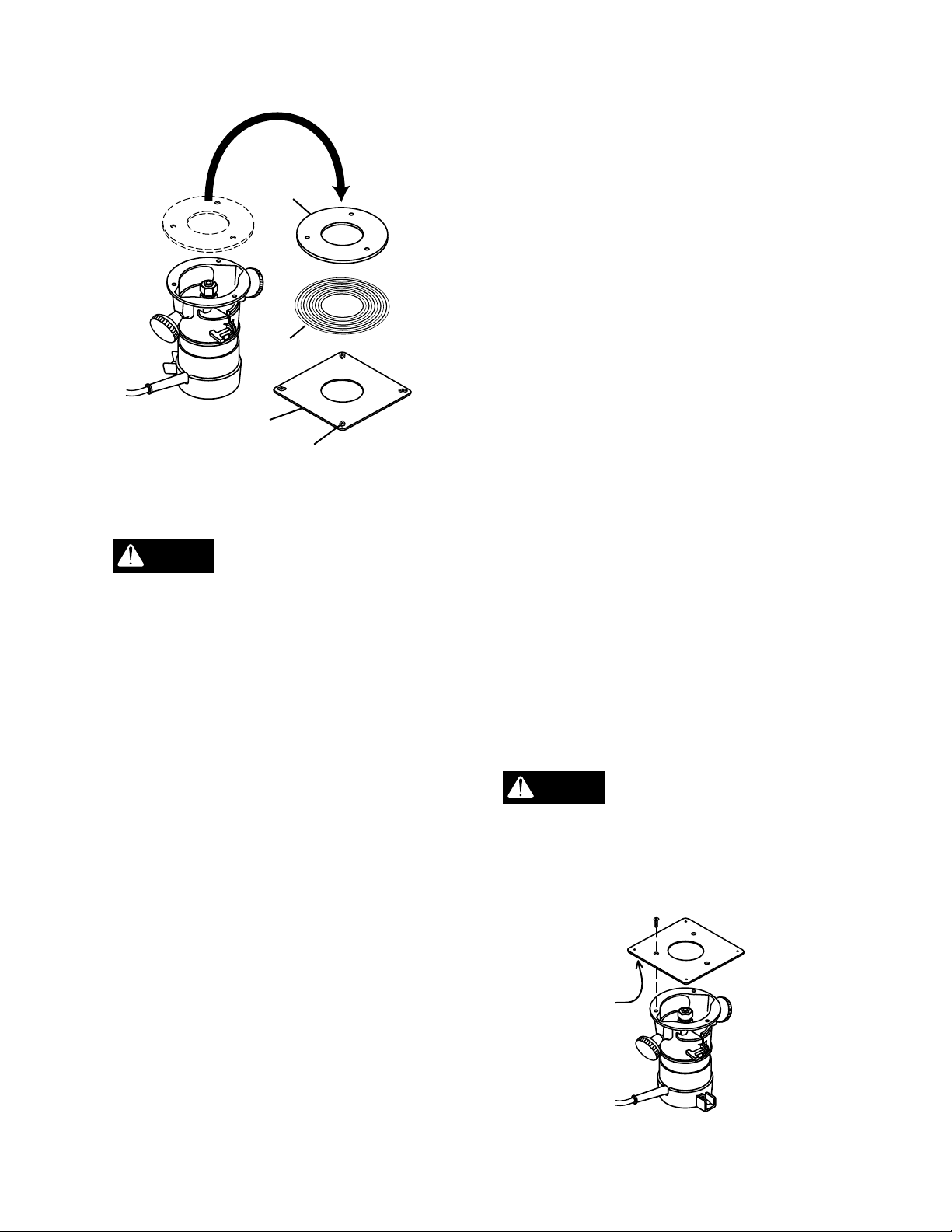

Mount Router (with Square

Adaptor Base Plate) to Table

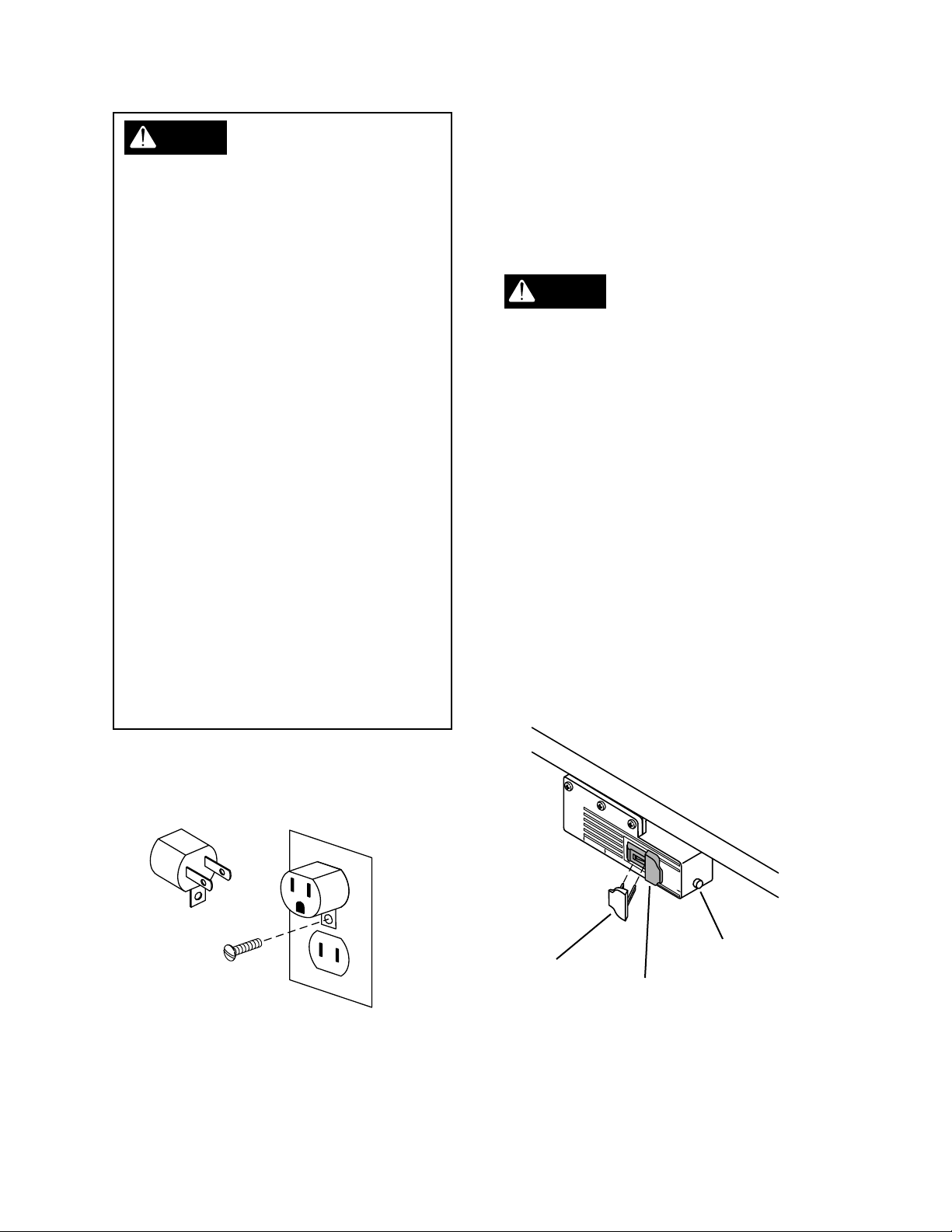

SECURING THE

ROUTER TABLE

BA, black (4)

Only assemble the router

CAUTION

to the table after you

have attached it to the square adaptor

base plate. Do not attempt to attach

the square adapter plate and then the

router to the table.

1. With router attached, place the

square adaptor base plate

underneath the router table inside the

area provided and against the metal

bosses.

AL

(Model 6156 Only)

DO NOT use the router

WARNING

table unless it is firmly

mounted to a stable work surface.

Failure to securely mount the router

table could lead to serious personal

injury and/or property damage.

Secure router table to the work surface

using wood screws or sheet metal

screws and washers (not provided)

through the holes provided. There are 8

mounting holes. See Figure 24.

Figure 23

2. If your router has a on/off switch,

make sure it faces toward the front of

the table for easy access, if needed.

3. Align the holes in the welded nuts on

the adaptor base plate to the holes in

the bosses.

4. Insert 4 flathead sink screws (BA)

through the holes and tighten them

securely. See Figure 23.

Figure 24

26

Page 27

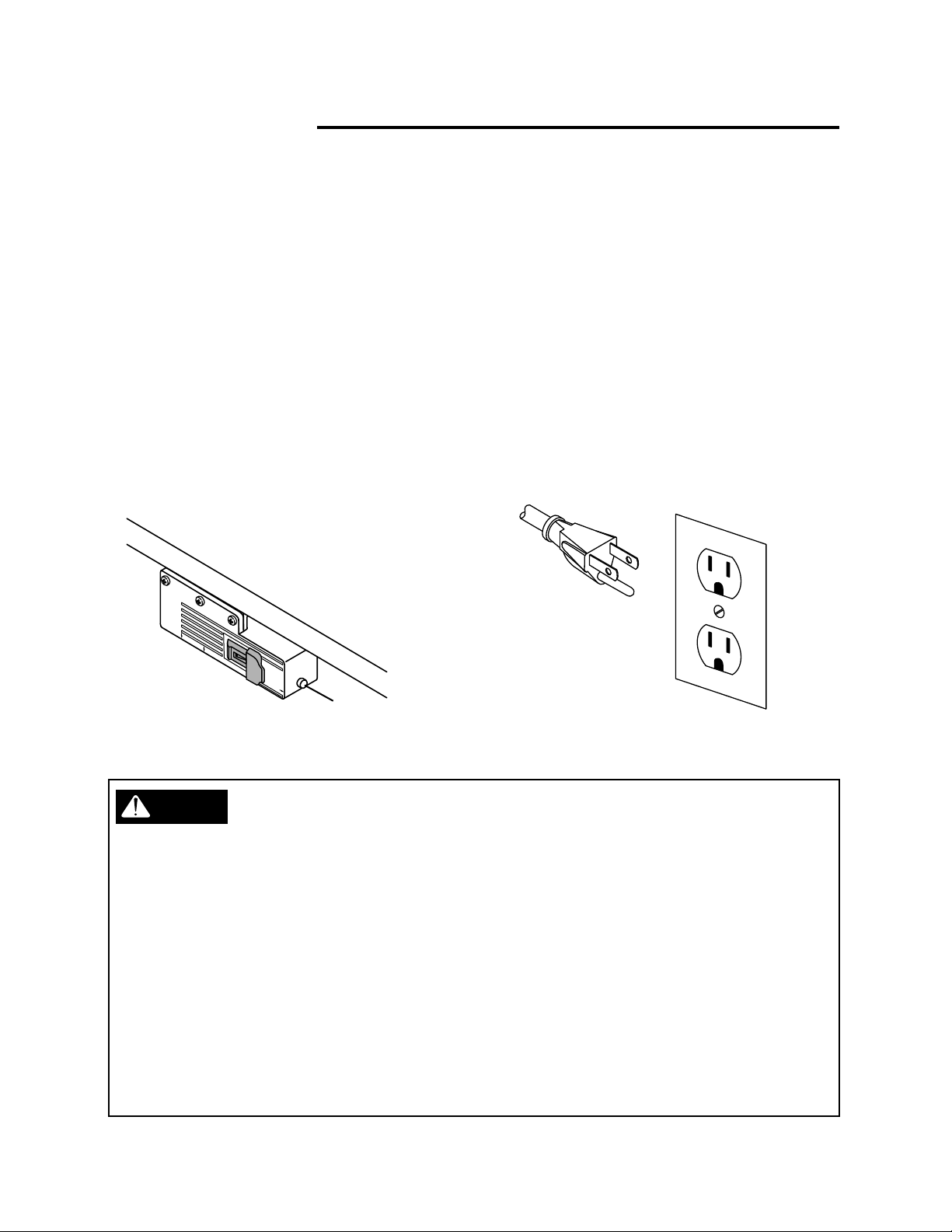

SWITCH BOX

Introduction

A conveniently located Switch Box

allows the operator to:

• turn the router ON and OFF from the

front of the table

• simultaneously operate other devices

such as a light or a vacuum

It also features a resettable, internal

circuit breaker that protects your

equipment against overloads. See

Figure 25.

O

U

T

L

ET

S

P

U

L

L

O

N

P

U

S

H

O

F

R

F

E

S

E

T

Electrical Hookup

Proper grounding diverts potentially

dangerous electricity away from the

operator. The switch box is intended for

use with a three-prong, grounded outlet.

(See Figure 26, below.) The switch

box's electrical cord features an

equipment-grounding connector and a

grounding plug. Insert the plug into an

accommodating outlet that conforms to

the National Electric Code (NEC) and all

local electrical codes.

reset button

Figure 25

WARNING

DO NOT MODIFY THE PLUG

If it does not fit correctly, a qualified electrician

must install a compatible outlet.

AVOID THE RISK OF ELECTRICAL SHOCK

NEVER connect the equipment grounding

connector (green wire) to a "hot" electrical

terminal. When repairing or replacing the

electric plug or cord, DO NOT connect the

grounding connector to a "hot" electrical

terminal.

Consult a qualified electrician if you do not

understand the grounding procedures, or if you

are not sure whether the switch box is correctly

grounded.

Figure 26

REPLACE DAMAGED CORDS

Damaged and/or worn cords must be repaired

or replaced immediately.

Extension cords must be three-wire, 14 gauge

or larger, with three-prong "male" plugs, and

three hole "female" receptacles fabricated to

accept the tool's plug.

The electrical outlets on the bottom of the

switch box accept three-prong grounded plugs

and the two-prong plugs of double insulated

tools.

27

Page 28

WARNING

Switch Box Familiarization

The electrical outlets on the bottom of the

switch box accept three-prong grounded

plugs and the two-prong plugs of double

insulated tools. If a correctly grounded

outlet is unavailable, use a temporary

adaptor to connect the switch box's threeprong plug to a two-hole receptacle. Make

use of the temporary adaptor only until a

qualified electrician installs a correctly

grounded, three-prong outlet. The green

rigid lug or grounding wire MUST connect to

the ground on the outlet. See Figure 27.

RISK OF ELECTRIC SHOCK

DO NOT touch prongs when inserting or

removing plug from outlet. Improper

grounding can produce potentially

hazardous electrical discharges that can

cause serious injury or death - especially in

wet conditions such as a basement, outside,

or near plumbing.

DO NOT attach a 3-way plug or any other

adaptor to outlets on bottom of switch box.

Only use the switch box when it is properly

assembled to the router table AND when the

router is properly attached to the router

table.

The purpose of this section is to

familiarize the user with the operation of

the switch box BEFORE the router is

plugged in.

DO NOT plug the

WARNING

router in at this time. An

ON switch will start the router and an

unprepared user could possibly be

seriously injured.

The Switch Box also features a safety

key that prevents tools plugged into the

switch box from being turned ON

inadvertently. Removal of the safety

key disables the switch box by locking

the switch in the OFF position. Strike

the switch paddle with your hand to turn

the router OFF in an emergency

situation. Please note paddle switch

positions and reset button at this time.

See Figure 28.

Figure 27

28

OU

T

L

E

T

S

safety key

P

U

L

L

O

N

P

U

S

H

O

F

R

F

E

SET

reset button

paddle switch

Figure 28

Page 29

Operation of Switch Box and

Router

Make sure router switch

WARNING

is OFF and switch box is

OFF BEFORE proceeding.

1. Insert the yellow safety key into the

switch box.

2. Position router power switch to ON.

NOTE: If your router requires the use of

the switch trigger and "Lock-On" button,

refer to your Router Owner's Manual for

operating instructions.

3. Insert finger under paddle and pull out

switch to ON position.

4. To turn router OFF push paddle in.

2. To start router, depress trigger on

router switch and engage "LOCK-ON"

button. Router should start.

NOTE: Typically, a router will not start if

the router switch is already in the

"LOCK-ON" position. In this case,

unlock the trigger, depress the trigger to

start the router, then re-engage the

"LOCK-ON" button.

3. To turn router OFF, push switch

paddle in.

Circuit Breaker

If an overload occurs, the circuit breaker

inside the Switch Box trips and interrupts

power to the router and any accessories.

If this happens:

Router bit must come to a

WARNING

complete stop before

leaving router table unattended.

5. Lock switch to OFF position by

removing key from switch box.

For Routers With "LOCK-ON"

Feature

The "LOCK-ON" feature on some

routers will not permit the router to be

turned ON by the switch box, but it can

be turned OFF by the switch box.

1. Place the switch box to ON as

previously described. The router

should NOT start even though the

trigger lock is in the "LOCK-ON"

position. Refer to your router table

Owner's Manual.

1. Unplug the power cord.

2. Remove the workpiece from the router

bit and table.

3. Find the cause of the overload and

correct.

4. Push the reset button to reset it. See

Figure 29.

5. Plug in power cord.

6. Follow instructions under Operation of

Switch Box and Router to reset router.

O

UT

L

E

T

S

P

U

L

L

O

N

P

U

S

H

O

F

R

F

E

S

E

T

reset button

Figure 29

29

Page 30

When router table is

WARNING

not in use, always:

5. Make sure router collet assembly is

below router table.

1. Place the switch box in OFF position

and remove the safety key.

6. Remove and place safety key in a

secure location. Remember where you

place the safety key.

2. Place router power switch in OFF

position.

3. Unplug switch box from wall outlet.

If the breaker trips, the

WARNING

router stalls, or the power

fails for any other reason, place the

switch box in the OFF position, remove

4. Remove router bit.

the safety key, and unplug the switch box

from the wall outlet.

ASSEMBLING FENCE TO THE ROUTER TABLE

1. Place the fence on the router table

with the front of the fence (flat side)

facing the front of the router table.

See Figure 30.

2. Insert knob screw into the hole in the

tabletop and through the nut (AM) in

the fence guide mounted to the

underside of the table. Repeat for

other knob.

3. Turn knobs clockwise to secure fence

in desired position.

AM

G

IN

N

R

A

W

N

O

L

UL

F

P

F

O

H

US

P

T

E

S

RE

S

T

E

L

T

U

O

G

IN

N

AR

W

Figure 30

30

Page 31

Assemble Inserts

Inserts help reduce the amount of

wood chips and dust that can

accumulate on the router table. They

can also lend stability to the work

piece.

Four inserts come with your router

table. Three of the inserts are for use

with a specific size bit; one can be

custom drilled. Refer to Figure 31 and

to the chart, above right. A center

marking is on the back of the blank

insert for drilling.

Diameter of

Diameter

of Insert

1-1/4"

1-7/8"

2-1/8"

1/4 to 2-3/8"

Do not use a router bit

WARNING

Router Bit

To Be Used

1-1/8"

1-3/4"

2"

drill out no more

than 2-3/8"

for 2-1/4" bits

Figure 31

Reference

AA

AB

AC

AD

with a diameter of more

than 2-3/4" on this router table.

Insert Use

1. Select correct insert for the router

bit and your application.

T

U

V

W

Figure 31

2. To assemble to router table, press

the insert into the hole in the table,

applying pressure to all sides

equally. This assures that insert

snaps into place.

Before removing insert,

WARNING

switch box must be in

OFF position, router switch must be in

OFF position, and power cord must

be unplugged from outlet.

3. Remove the insert by placing your

finger into the hole in the center.

With light pressure, pull up the

insert.

NOTE: Remove the router bit from the

router before attempting to remove

the insert.

31

Page 32

OPERATION

Connecting a Vacuum

In the fence, a port is provided that will

accept standard 2-1/2" vacuum hose

connections. If plugged into the switch

box, the vacuum will turn ON and OFF

simultaneously with the router.

Using your router/router table

Setting Depth/Height of the Cut

Make sure router is

WARNING

unplugged before starting

depth/height adjustments.

PENCIL LINE #1 PENCIL LINE #2

NOTE: Using scrap board that is

smooth and true is recommended for

making this adjustment.

1. At the end of the board, use a soft

pencil to mark line #1. This indicates

the depth of the cut. See Figure 32.

2. Mark line #2, indicating the height of

the cut.

3. Place your board so that it is snuggly

against the face of the fence. The

end with lines #1 and #2 should be

near the bit.

4. Loosen fence clamping knobs

enough so you can move the fence

easily. Move fence and board so that

the board contacts the outer edge of

the router bit at line #1.

Figure 32

5. Tighten fence clamping knobs.

6. Adjust router height so the cutting

edge of the bit contacts line #2.

7. Make sure bit is securely tightened in

router chuck.

When standing in front of

CAUTION

router table, feed work

from right to left.

32

Page 33

Using the Router for Beading

and Edge Cutting

Using Ball-Bearing-Guided Bits;

Veining, Fluting, and Grooving

1. Loosen the knobs that hold the fence

in place.

2. Position the fence for the desired

cutting depth. See item 3 in Figure

33.

3

2

4

1

1. Tabletop

2. Fence

3. Cutting depth

4. Workpiece

5

7

5. Successive cut

6. Depth of cut

7. Router bit

Figure 33

6

3. Tighten the knobs securing the fence

in place.

4. Swing the safety shield over the

router bit.

5. Your router/router table is now ready

for use.

NOTE: Remember to always feed the

workpiece against router bit's direction

of rotation. Test on scrap wood before

making final cuts.

To help reduce the

WARNING

chance of injury, make

sure the fence is as close as possible to

the ball-bearing-guided bit. Move the

fence back ONLY enough to permit the

ball-bearing-guide to control the depth

of cut.

Figure 34

The edge of the workpiece that slides

along fence must be straight and true

for best results. (Use scrap to test

settings.) See Figures 33 and 34.

1. With the router bit set at the required

depth, position and secure the fence

behind the bit at a distance

determined by the previous cut.

Lower safety shield.

2. Slide the workpiece against the

fence. Adjust fence for subsequent

cuts.

NOTE: For deep work, make successive

cuts until you reach the correct depth.

To avoid overloading router, remove

waste material as you go.

33

Page 34

Using the Fence and Push

P

U

LL

O

N

P

U

S

H

O

F

F

R

E

S

E

T

Shoe for End Cutting

1. Place correct insert into hole in table.

See Figure 35.

This operation is done

WARNING

without the safety shield

in place. Use extreme caution. Do not

allow any body part to contact the

router bit at any time. Doing so could

lead to serious personal injury.

Unplug router while

WARNING

making adjustments.

Routing to make tongue and groove

joints, tenons, and sliding dovetails

requires that the workpiece edges and

ends be true and smooth, with all sides

at 90° angles to one another. Use

scrap wood to test adjustments before

making final cuts.

PUSH SHOE

CLAMP PLATE

2. Lock the jointing fence in the fully

retracted position.

3. At the end of the board where the cut

will occur, use a soft pencil to mark

line #1. This indicates the depth of

the cut (how much wood to be

removed). Then mark another line

#2, indicating the height of the tenon.

See Figure 32, page 32.

4. Place your board so that it is snug

against the push shoe and clamp

plate, with its side against the face of

the fence. Lines #1 and #2 should be

near the bit; the end of the workpiece

should be on the edge of the insert

hole.

5. Making sure the clamp plate

continues to hold the workpiece.

Tighten the wing nut on the clamp

rod.

JOINTING

FENCE

INSERT

Figure 35

Do not overtighten wing

CAUTION

nut. Overtightening may

cause binding in the push shoe's

motion, which in turn may produce

"steps" or other variations in the tenon.

NOTE: For deep work, make

successive cuts until you reach the

correct depth. To avoid overloading

router, remove waste material as you

go.

6. Move fence and board, and adjust

the router, so the board contacts the

outer edge of the router bit at line #1

and the cutting edge of the bit

contacts line #2. Clamp down fence

and secure router.

34

Page 35

7. Move push shoe with workpiece

slightly back from the router bit.

8. Use switch to turn on router.

Holding push shoe/workpiece with

both hands at a safe distance from

rotating bit, slide workpiece toward

and across bit. Make a complete

pass of workpiece without stopping.

9. Turn off router at switch box.

10. Declamp workpiece, returning push

shoe to other side of router bit.

11. Clamp and position the opposite

side of workpiece (see Step 4).

Repeat Steps 7, 8, and 9.

12. When cutting ends of tenon, clamp

and position workpiece as

described in Step 4, except hold

edge of workpiece flush on face of

fence, and rest end to be cut on top

of the router table. Repeat Steps 7,

8, and 9.

Using the Router as a Jointer

JOINTER OFFSET

FENCE KNOBS

1. Position the fence for the desired

depth of cut. Tighten the fence knobs.

2. Place a straight edge against the

jointer offset.

3. Loosen the knob holding the jointer

offset in place.

DEPTH OF CUT

Figure 36

NOTE: For all four sides of tenon,

make just one pass, cutting complete

depth of tenon.

NOTE: Clamping workpiece with the

end to be cut laying on the tabletop can

help to minimize any variation in

tenon's finished surface that may be

caused by irregularities in tabletop

flatness.

When standing in front of

CAUTION

router table, feed work

from right to left.

4. Slide jointer offset out until the

straight edge touches the outside

diameter of the router bit.

See Figure 36.

5. Tighten the jointer offset knob.

6. Swing the safety shield over the

router bit.

7. Your router/router table is ready to

use.

NOTE: Try a piece of scrap wood to

check for correct adjustment.

35

Page 36

Using the Fence with Board for

P

U

L

L

O

N

P

U

S

H

O

F

F

R

E

S

E

T

P

U

L

L

O

N

P

U

S

H

O

F

F

R

E

S

E

T

O

U

T

L

E

T

S

Larger Workpieces

Routing Without Push Shoe,

Safety Shield, and/or Fence

NG

Figure 37

Three holes in the fence allow for

mounting of a 8-inch high (maximum)

board for safe and secure routing of

larger workpieces.

1. Remove push shoe from fence.

For many jobs you must remove the

fence from the router table.

Using the router without

WARNING

the safety shield and

fence in place can lead to serious

personal injury. Use extreme caution.

Operate the router without safety

shields and fence ONLY when

absolutely necessary, and always with

ball-bearing-guided router bits.

Feed workpiece against

WARNING

the router bit's direction of

rotation. Unplug router prior to changing

the bit, modifying settings, or making

any other adjustments.

Inside Routing

2. Attach board to fence with 4

woodscrews (not provided). See

Figure 37.

3. Board can be notched out prior to

routing or router bit profile can be

made in board by driving board

through router bit.

4. Position the fence to the desired depth

of the cut. Tighten the fence knobs.

5. Securely tighten the router bit, and

make sure the router is properly

assembled to the router table as

previously detailed in this manual.

6. Your router/router table is ready to

rout large workpieces.

1. Place your workpiece on the table

relative to the router bit as shown in

Figure 38.

N

I

N

R

A

W

Figure 38

G

2. Feed your workpiece through the bit

in the direction of the arrow. Always

feed against the router bit's direction

of rotation.

36

Page 37

Outside Routing

STARTING PIN IN

MOUNTING HOLE

HOLE

P

UL

L

O

N

P

US

H

OF

F

RE

S

E

T

O

U

T

L

E

T

S

1. Place your workpiece on the table

relative to the router bit as shown in

Figure 39.

ING

WARN

Figure 39

2. Feed your workpiece through the bit

in the direction of the arrow. Always

feed against the router bit's direction

of rotation.

Routing Irregular Workpieces

PIN STORAGE

Figure 40

3. Drawing the workpiece along the

starting pin (from right to left, in front

of the router), feed it through the bit,

at the same time pressing it against

the ball-bearing guide until the cut is

complete. See Figure 41.

BB, black (1)

Use starting pin. Use only ball-bearingguided router bits.

1. With fence removed, remove starting

pin from storage hole and thread into

mounting hole.

2. Position the workpiece against the

starting pin, but clear of the router bit.

Turn on router and slowly advance

the workpiece toward the bit until it

touches the ball-bearing guide and

the bit begins to cut wood. Feed

workpiece against the rotation of the

bit. See Figure 40.

Figure 41

4. When the cut is complete, move the

workpiece away from the bit, at the

same time keeping it in contact with

the starting pin, until it clears the

router bit completely. See Figure 41.

5. Using the switch box, turn off router.

37

Page 38

Using the Miter Guage and

6

0

4

5

3

0

1

5

0

15

3

0

45

6

0

P

UL

L

O

N

P

US

H

O

FF

RE

S

E

T

Fence

The miter gauge can serve as extra

support for routing small workpieces

ends of long workpieces.

You must use the

WARNING

security guard when

making cuts using the miter guide.

NOTE: Make sure fence and miter

guide slot are parallel before cutting.

To cut miters, unclamp knob that

secures the miter guide head. Turn

head up to 60° in either direction.

Retighten knob.

Do not allow any body

WARNING

part to be in line with the

router bit at any time when the miter

guide is in use. Doing so could lead to

serious personal injury.

When making cuts using

WARNING

the miter guide, hold the

workpiece firmly against the fence, the

miter guide, and the table.

Using the Dovetail/Box Joint

Bars (for Model 6155 Only)

BC, black (1)

BD, black (1)

BE, zinc (2)

BF, zinc (2)

This operation is done

WARNING

without the safety shield

and fence in place. Use extreme

caution. Do not allow any body part to

contact the router bit at any time.

Doing so could lead to serious

personal injury.

Use the dovetail/box bars to make box

joints, combination joints, and dovetail

(Miter guide for Router Table 6155

shown in Figure 42.)

G

N

I

N

Figure 42

38

BOX JOINT

DOVETAIL JOINT

COMBINATION

JOINT

JOINING

STRAIGHT BOARDS

Figure 43

Page 39

BD

BE

Mounting the Bar

Use spacer bar (either 3/8" or 1/4") to

position dovetail/boxjoint bar. Position

dovetail/boxjoint bar so that the space

between the bar and the bit is equal to

the bit and bar width (either 3/8" or

1/4"). For easiest measuring, use the

spacer bars provided as a measuring

device.

Figure 45

SPACER

BAR

BIT

DOVETAIL/

BOXJOINT

BAR

Figure 44

1. Place spacer bar on router table with

edge touching outside diameter of

(3/8" or 1/4") router bit. See Figure

44.

Making Standard Dovetail

Joints and Box Joints

1. Assemble dovetail/box joint bar to

table as instructed above.

2. Select two pieces of wood of the

same thickness.

3. Adjust router so that the bit height

exactly matches the height of one

piece of wood laid horizontally. If you

wish to sand joint flush after

assembly, set cutter slightly deeper.

Securely tighten the router bit.

4. Offset the two pieces of wood 1/2"

and clamp them together. See Figure

46.

2. Line up dovetail/box joint bar edge on

opposite side of spacer bar.

3. Secure each end of dovetail/box joint

bar by inserting a pan head screw

(BD) through hole and securing with a

hex nut (BE). See Figure 45.

CLAMP

1/2" OFFSET

Figure 46

39

Page 40

NOTE: Dovetail joint is used to connect

PUSH

BLOCK

PUSH

BLOCK

(lengthen) two straight boards in this

application.

5. Stand them vertically on the router

table near the router bit, making sure

the bottom of the two wood pieces are

flush with the tabletop.

6. With the fence removed and using a

block of wood as a push shoe so that

the tail is not torn out, run the pieces

through the router. This makes your

first cut and leaves a tail on piece that

was offset. See Figure 47.

Figure 48

9. Assemble joint and test for fit.

NOTE: Move the dovetail/box joint bar

slightly towards the bit to make the joint

slightly looser; move the bar away from

the bit to make the joint slightly tighter.

Figure 47

7. Place clamped wood pieces over

dovetail/box joint bar with cut

straddling bar. Using your first cut

as a guide, make the next cut.

8. Continue making your cuts across

the entire width of the pieces of

wood, using each previous cut as a

guide. See Figure 48.

Making Combination Joints

A combination joint is comprised of a

dado cut and a rabbet cut.

1. Set up router with same 3/8" bit

height and the same spacing as for

dovetail or box joints.

2. Lay a 3/4" piece of wood on the

tabletop. With it snuggly against the

dovetail bar, run it over the bit. This

makes the dado cut. See Figure 49.

40

Figure 49

Page 41

3. Use the first piece of wood as an

PUSH

BLOCK

offset to make the next cut. Lay the

first piece on the table with the dado

cut straddling the dovetail bar. Lay

another 3/4" piece of wood on its

edge next to the first piece and run it

through router bit. This makes the

rabbet cut. See Figure 50.

4 SIDES

DADO CUTS

CLAMP

SCRAP WOOD

Figure 51

Figure 50

4. Assemble the two pieces of wood to

make joint.

Box Construction

In constructing a box shape, for a

drawer, for example, you will want to

make sure all four sides are even in

height; that is, the joints are located in

exactly the same location on each piece

of wood.

1. Use a piece of scrap wood to make a

3/8" or 1/4" dado cut along length of

piece.

2. Place the 4 pieces of wood you will

be using for the sides of the box on

the piece of wood on which you just

made the dado cut: two in the slots

and two in the spaces between the

slots. This places the offset on each

piece exactly in the same location.

See Figure 51.

3. Set up router, bar and bit in the

same configuration as for

dovetail/box joints (see page 39).

4. Clamp pieces of wood together.

Run through router on each side.

Sides come out even every time.

See Figure 52.

Figure 52

41

Page 42

Using the Featherboard Flaps

The featherboard flaps (AE) provide

support for workpieces by holding the

pieces securely to help minimize

chatter and kickback.

Insert the featherboard flaps into the

fence or router table to hold down

workpieces.

Holding pressure can be varied by

putting long or short end of flaps in

fence or table, or by varying the

distance of flap end from the fence.

See Figure 53.

AE

N

O

L

L

U

F

P

F

O

H

S

U

P

T

E

S

E

R

S

ET

L

T

U

O

G

NIN

AR

W

Figure 53

42

Page 43

REPAIR PARTS 6155/6156 Router Table

15

18

20

36

32

46

47

33

22

49

35

21

48

50

29

47

23

O

54*

T

E

L

T

U

43

S

17

44

20

55/56*

N

O

LL

PU

FF

O

SH

PU

SET

E

R

14

34

18

44

45

53*

16

24

25

26

27

28

12

32

13*

10

30*

*Model 6155 only

32

9**

10

**Model 6156 only

0

12

33

4

5

6

30

11

15

0

5

1

0

3

5

4

60

8*

31

51*

52*

33

4

5

60

0

3

5

1

11

0

5

1

0

3

5

4

0

6

31

40*

40*

41*

42*

39

38

19

33

38

7*

6*

37

2.1*/2.2**

43

37

37

38

39

5.1

38

39

5.1

38

33

5.1

1

5.1*/5.2**

4

W

A

R

N

IN

3

G

2.1

Page 44

REPAIR PARTS 6155/6156 Router Table

All Parts

KEY

NO.

1

2.1

2.2

3

4

5.1

5.2

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

ITEM

A

B-1

B-2

C

D

E-1

E-2

F

G

H

J

K

L

M

N

P

Q

R

S

T

U

V

W

X

Y

Z

AA

AB

AC

AD

AE

AF

AG

AH

AJ

AK

AL

AM

AN

AP

AQ

AR

AS

AT

AU

AV

AW

AX

AY

AZ

BA

BB

BC

BD

BE

BF

BG

BH

PART NO.

116 420 214

117 020 208

119 900 010

117 020 209

117 020 210

117 020 211

119 900 012

117 020 212

117 020 213

116 420 215

116 600 134

117 040 133

116 680 221

116 670 012

116 600 136

117 920 107

116 600 135

116 620 249

117 220 180

117 040 134

116 680 223

116 620 247

116 620 248

116 670 011

116 680 216

115 980 005

116 680 217

116 680 218

116 680 219

116 680 220

116 680 222

116 700 071

116 700 066

116 730 132

116 710 068

116 700 078

116 730 128

116 750 135

116 700 070

116 730 134

116 730 126

116 700 065

116 730 133

116 730 125

116 730 129

116 730 130

116 730 124

116 700 068

116 730 135

117 220 182

116 700 080

117 220 181

117 040 139

117 040 140

116 730 072

116 730 127

117 040 136

117 040 137

DESCRIPTION

Tabletop

Extension

Extenstion, right**

Leg support, left

Leg support, right

Leg, short

Leg, short front left**

Leg, long*

Tool tray*

Miter guide head, aluminum*

Miter guide head, plastic**

Miter bar

Miter pointer

Miter guide knob

Miter guide clamp*

Switch box

Retainer

Push shoe

Clamp rod

Clamp plate

Rubber shoe*

Fence

Jointing fence

Jointing fence knob

Safety shield

Square adaptor base plate

Tabletop insert, small hole

Tabletop insert, medium hole

Tabletop insert, large hole

Tabletop insert, solid

Feather flap

Pan head screw (M5x12)*

Carriage bolt (M6x30)

Washer (M6)

Phillips head screw, self-tapping (M5x12)

Pan head screw (10-32x1/2)

Hex nut (10-32)

Square nut (M6)

Pan head screw (M5x16)

Toothed washer (M5)

Hex nut (M5)

Carriage bolt (M6x16)*

Toothed washer (M6)*

Hex nut (M6)*

Hex nut (M8)

Washer (M8)

Wing nut (M8)

Hex head bolt (M6x30)

Cap nut (M6)

Pivot pin

Flat head countersink screw (10-32x7/8)

Starter pin

Spacer bar (1/4)*

Spacer bar (3/8)*

Pan head screw (5-40x3/4)*

Hex nut (5-40)*

Dovetail/box joint bar (1/4)*

Dovetail/box joint bar (3/8)*

QTY.

1

1

2

2

1

4

1

1

1

1

1

1

1

1

2

1

1

1

4

1

1

1

1

1

1

1

1

1

3

1

1

2

21

3

3

2

18

34

18

24

24

24

1

2

1

1

2

1

4

1

1

1

2

2

1

1

6155: 2

6156: 1

6155: 4

6156: 3

* Model 6155 only ** Model 6156 only

44

Page 45

REPAIR PARTS 6155 Router Table

Hardware Bags

KEY

NO.

11

12

13

15

19

22

25

26

Hardware Bag 1

Part # 119 900 879

27

28

29

ITEM

L

M

N

Q

U

X

AA

AB

AC

AD

AE

PART NO.

116 680 221

116 670 012

116 600 136

116 600 135

116 680 223

116 670 011

116 680 217

116 680 218

116 680 219

116 680 220

116 680 222

DESCRIPTION

Miter pointer

Miter guide knob

Miter guide clamp

Retainer

Rubber shoe

Jointing fence knob

Tabletop insert, small hole

Tabletop insert, medium hole

Tabletop insert, large hole

Tabletop insert, solid

Feather flap

QTY.

1

1

1

2

4

1

1

1

1

1

3

33

34

35

36

38

39

Hardware Bag 2

Part # 119 900 864

18

31

32

37

43

44

45

46

47

Hardware Bag 3

Part # 119 900 865

48

49

50

30

40

41

42

51

52

53

Hardware Bag 4

Part #119 900 866

54

AJ

AK

AL

AM

AP

AQ

T

AG

AH

AN

SU

AV

AW

AX

AY

AZ

BA

BB

AF

AR

AS

AT

BC

BD

BE

BF

116 710 068

116 700 078

116 730 128

116 750 135

116 730 134

116 730 126

117 040 134

116 700 066

116 730 132

116 700 070

116 730 129

116 730 130

116 730 124

116 700 068

116 730 135

117 220 182

116 700 080

117 220 181

116 700 071

116 700 065

116 730 133

116 730 125

117 040 139

117 040 140

116 730 072

116 730 127

Phillips head screw, self-tapping (M5x12)

Pan head screw (10-32x1/2)

Hex nut (10-32)

Square nut (M6)

Toothed washer (M5)

Hex nut (M5)

Clamp plate

Carriage bolt (M6x30)

Washer (M6)

Pan head screw (M5x16)

Hex nut (M8)

Washer (M8)

Wing nut (M8)

Hex head bolt (M6x30)

Cap nut (M6)

Pivot pin

Flat head countersink screw (10-32x7/8)

Starter pin

Pan head screw (M5x12)

Carriage bolt (M6x16)

Toothed washer (M6)

Pan head screw (5-40x3/4)

Spacer bar, 1/4"

Spacer bar, 3/8"

Hex nut (M6)

Hex nut (5-40)

21

3

3

2

34

18

1

1

2

18

1

2

1

1

2

1

4

1

1

24

24

24

1

1

2

2

45

Page 46

REPAIR PARTS 6156 Router Table

Hardware Bags

KEY

NO.

11

12

15

22

25

26

27

Hardware Bag 1

Part # 119 900 880

28

29

ITEM

L

M

Q

X

AA

AB

AC

AD

AE

PART NO.

116 680 221

116 670 012

116 600 135

116 670 011

116 680 217

116 680 218

116 680 219

116 680 220

116 680 222

DESCRIPTION

Miter pointer

Miter guide knob

Retainer

Jointing fence knob

Tabletop insert, small hole

Tabletop insert, medium hole

Tabletop insert, large hole

Tabletop insert, solid

Feather flap

QTY.

1

1

2

1

1

1

1

1

3

33

34

35

36

38

39

Hardware Bag 2

Part # 119 900 864

18

31

32

37

43

44

45

46

47

Hardware Bag 3

Part # 119 900 865

48

49

50

AJ

AK

AL

AM

AP

AQ

T

AG

AH

AN

SU

AV

AW

AX

AY

AZ

BA

BB

116 710 068

116 700 078

116 750 128

116 730 135

116 730 134

116 730 126

117 040 134

116 700 066

116 730 132

116 700 070

116 730 129

116 730 130

116 730 124

116 700 068

116 730 135

117 220 182

116 700 080

117 220 181

Phillips head screw, self-tapping (M5x12)

Pan head screw (10-32x1/2)

Hex nut (10-32)

Square nut (M6)

Toothed washer (M5)

Hex nut (M5)

Clamp plate

Carriage bolt (M6x30)

Washer (M6)

Pan head screw (M5x16)

Hex nut (M8)

Washer (M8)

Wing nut (M8)

Hex head bolt (M6x30)