Page 1

●

Safety

Instructions

●

Assembly

●

Operation

●

Repair Parts

●

Consignes de

sécurité

●

Montage

●

Mode d’emploi

●

Pièces de

rechange

●

Instrucciones

de seguridad

●

Montaje

●

Manejo

●

Repuestos

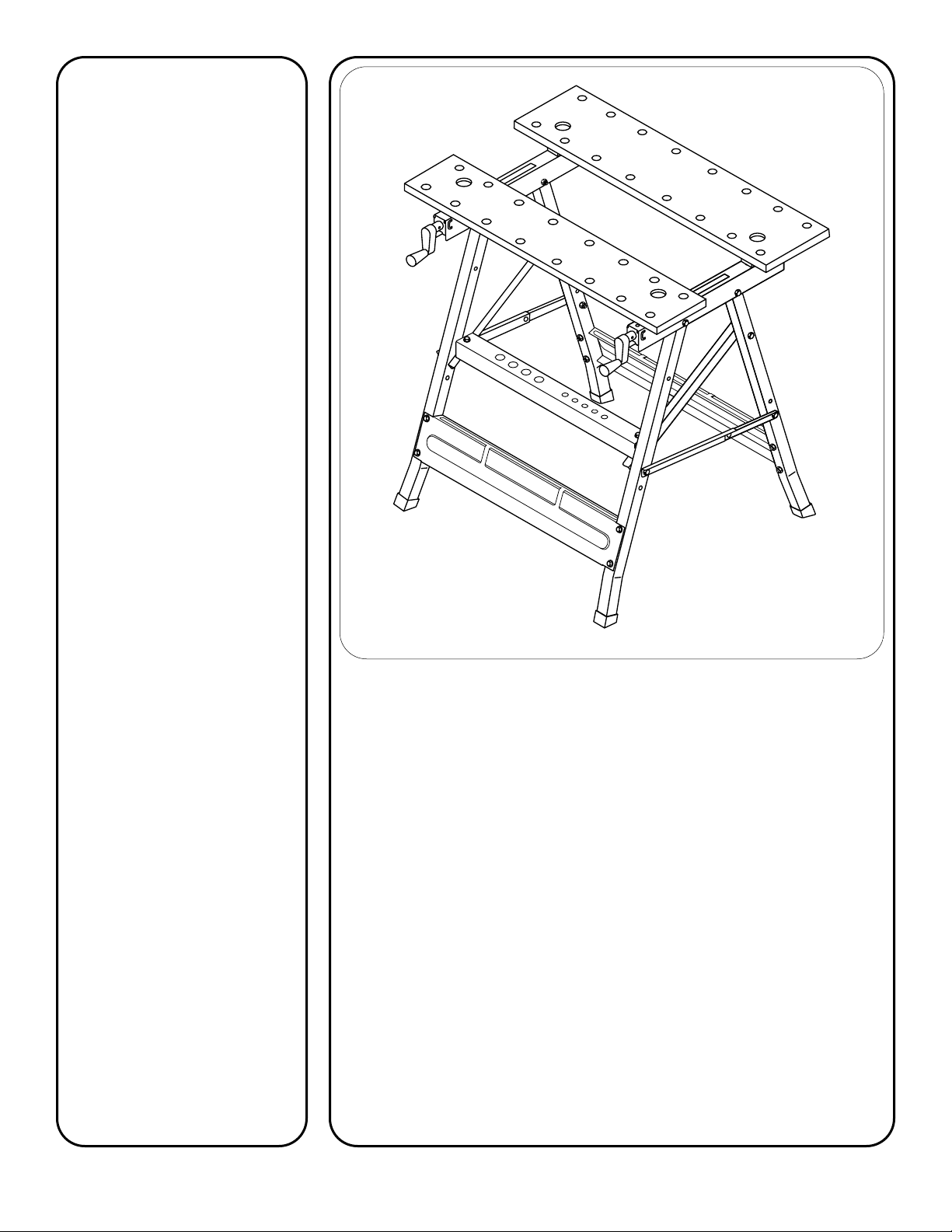

WOLF112-C

wolfcraft

®

Save this manual for

future reference.

Conservez ce guide pour

toute référence future.

Guarde este manual para

futuras referencias.

OWNER’S

MANUAL

MANUEL

D’UTILISATION

MANUAL DEL

USUARIO

MODEL NO. 6134

Modèle n°:6134

Modelo Nº 6134

Page 7-11:

Français et espagnol

Frances y Español

CAUTION:

Before using this

product, read this

manual and follow all its

Safety Rules and

Operating Instructions.

ATTENTION:

Avant d’utiliser cet établi,

lire attentivement ce

manuel et respecter toutes

les consignes de sécurité

et le mode d’emploi.

PRECAUCIÓN:

Antes de usar este

producto, lea este manual

y siga todas las

instrucciones de

seguridad y de manejo.

wolfcraft

®

QUICK JAW®WORKBENCH

ETABLI A BLOCAGE RAPIDE

BANCO DE TRABAJO DE

FIJACIÓN RÁPIDA

Page 2

2

DO NOT attempt to assemble or operate your

wolfcraft®Quick Jaw®Workbench until you have

read the safety instructions in this section.

DO NOT use this tool for

scaffolding or as a ladder. Make

sure to insert pin and fully tighten handles when

in use. Maximum capacity 250 lbs.

Read all instructions.

●

DO NOT attempt to use your portable

workbench unless the jaw is securely locked in

position.

●

DO NOT load tool stand with more than 250

pounds.

●

DO NOT apply an unbalanced load which could

result in the workbench tipping over.

●

DO NOT stand or climb on the workbench. It

could fall or tip over causing serious injury.

●

Be sure the workbench’s leg set frame

assembly is in the fully opened position before

using.

●

When operating a stationary power tool, such as

a miter saw , on your w orkbench, be sure the tool

is securely bolted to a separate piece of

plywood and the plywood is securely clamped to

the portable workbench. DO NOT clamp or

mount stationary power tools directly to table

top.This could cause serious bodily injury.

●

When operating a portable power tool such as a

drill, router, sander or planer: Always be sure

that the workpiece is securely clamped to your

workbench.This will avoid kickback which could

cause serious bodily injury.

●

When using a power tool with the workbench,

ALWAYS follow the safety instructions in the

power tool owner’s manual.

●

ALWAYS wear safety glasses or eye shields

when operating power tools.

●

To prevent personal injury while opening or

closing your workbench, always avoid

positioning hands or fingers where they could

get pinched.

●

Dress for safety. DO NOT wear loose clothing,

gloves, neckties or jewelry (rings, watches); they

can get caught and draw you into moving par ts.

ALWAYS wear non-slip footwear; tie back long

hair.

DO NOT store workbench

outdoors or in a damp location.

●

ALWAYS keep your work area clean,

uncluttered and well lit. DO NOT work on or

place workbench legs on floor surfaces that are

slippery from sawdust, oil, water or wax.

●

Keep visitors and children a safe distance away

from the work area, especially when you’re

operating a power tool.Visitors should wear the

same safety equipment as the operator.

●

SA VE THESE INSTRUCTIONS.

SAFETY INSTRUCTIONS

WARNING

WARNING

WARNING: FAILURE TO HEED ALL SAFETY AND OPERATING INSTRUCTIONS AND WARNINGS REGARDING USE OF THIS

PRODUCT CAN RESULT IN SERIOUS BODILY INJURY.

Safety items throughout this manual are labeled

with WARNING or CAUTION.

Means that failure to follow this

safety statement may result in

extensive product damage, serious personal

injury or death.

Means that failure to follow this

safety statement may result in

minor or moderate personal injury, proper ty or

equipment damage.

WARNING

CAUTION

CAUTION

Page 3

3

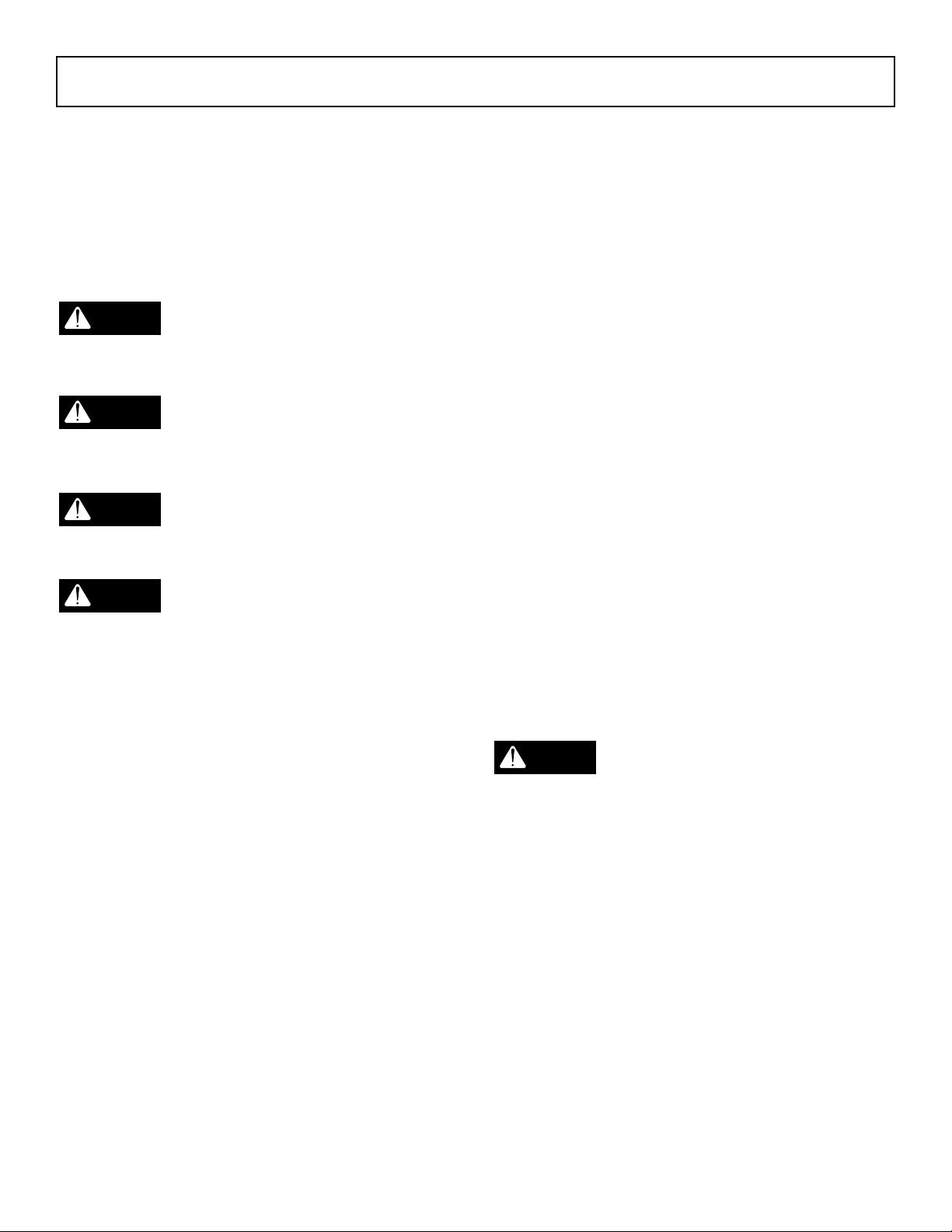

Packaging

Your wolfcraft®Workbench is shipped complete in

one carton.

Separate all parts from packing materials and check

each item with Figure 1 and “Table of Loose Par ts”.

Make sure all items are accounted for before

discarding any of the packing material.

ITEM DESCRIPTION QTY.

A Leg assembly – left.............................1

B Leg assembly – right ..........................1

D Hex Head Screw – M6 x 45 ................8

E Washer – medium...............................8

F Nut – M6............................................10

G Tool storage rack ................................1

H Hex Head Screw – M6 x 12 ................2

I Washer – small...................................4

ITEM DESCRIPTION QTY.

J Cross bar . . . . . . . . . . . . . . . . . . . . .2

K Foot pad . . . . . . . . . . . . . . . . . . . . . .4

L Support – table top . . . . . . . . . . . . . .4

M Table top – front . . . . . . . . . . . . . . . .1

N Screws – M8 x 55 . . . . . . . . . . . . . . .4

O Washer – large . . . . . . . . . . . . . . . . .6

P Table top – rear . . . . . . . . . . . . . . . .1

Q Nut – M8 . . . . . . . . . . . . . . . . . . . . .2

R Swivel peg . . . . . . . . . . . . . . . . . . . .4

TABLE OF LOOSE PARTS

Figure 1

TOOLS REQUIRED

#3 Phillips Screwdriver

Adjustable-Head Wrench

N

H

D

I

F

A

E

M

P

O

R

Q

L

J

L

G

J

B

K

K

WOLF112-1

Page 4

L

O

N

O

N

L

O

Q

4

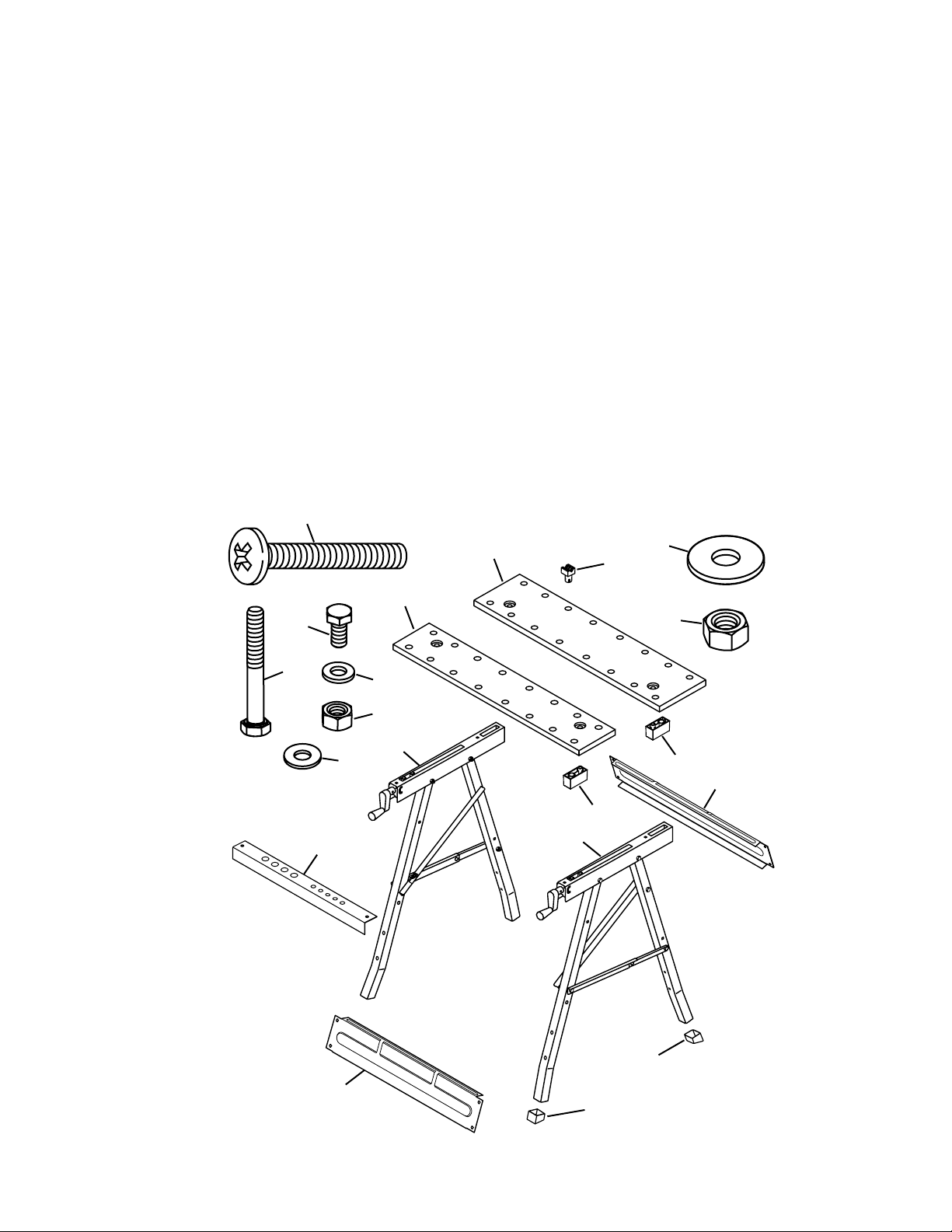

Assembly

Assembling the Workbench

Note: For correct assembly, the legs, [A] and [B],

must have hinges on the outside.

Refer to Figure 2 for steps 1 - 3

1. Attach the front cross bar [J] to the leg assemblies [A & B] with two screws, [D] (M6 x 45),

medium washers [E] and nuts [F] (M6) on each

side.Tighten securely.

2. Attach the tool storage rack [G] to the leg

assemblies [A & B] with a screw [H] (M6 x 12),

two small washers [I], and nut [F] (M6) on each

side.Tighten securely.

3. Attach the rear cross bar [J] to the leg

assemblies.Use two screws [D] (M6 x 45),

medium washers [E], and nuts [F] (M6) on each

side.Tighten securely.

Refer to Figure 3 for steps 4 - 8

4. Place the two top supports [L] on the front and top

of the leg assemblies [A & B] with the support’s

round knobs facing up and away from the front of

the table.The bottom round holes fit over the

threaded knobs of each screw arm assembly.

5. Place the front table top [M] on the supports [L],

aligning the table top holes over the round

support knobs and press into place.

6. Push on the threaded plastic traverse under

the channel and attach top using two screws

[N] (M8 x 55) and two large washers [O].

Tighten securely.

7. Place two table top supports [L] on rear and top

of the leg assemblies [A & B] with the round

knobs of the supports facing up and toward the

front of the table.The supports fit into the

rectangular cut-outs in the leg assemblies.

8. Place the rear table top [P] on the supports [L],

aligning the table top holes over the support

knobs and press into place. Install two screws [N]

(M8 x 55) and two large washers [O] in table top.

Move top and supports to the rear-most position

and install two large washers [O] and two nuts [Q]

(M8) in table bottom. Place the assembly in

position and tighten securely.

WOLF112-2

E

E

E

D

E

D

I

I

I

I

F

F

G

H

I

I

F

H

F

A

B

D

D

J

K

K

J

Figure 3Figure 2

Page 5

5

Folding Your Workbench

1. Remove any hand tools or parts from table top and

storage rack.

2. Carefully pull up on hinges, with fingers under

hinge flange, to unlock hinges.

3. Tilt Stand back slightly onto rear legs.

(See Figure 4.)

4. Reach down and push front legs backward.

Figure 4

Opening the Workbench

1. Standing at rear of workbench, grasp front edge of

table top and underside of rear cross brace.

2. Pull rear cross brace toward you while

simultaneously pulling up on table top.

3. When fully open, secure in locked position by

pushing on hinges until completely down.

T o Adjust T able T op Jaw

Turn the front table top jaw adjustment handles

counterclockwise to move front jaw toward you.Turn

adjustment handles clockwise to move front jaw

away.(See Figure 5.) The table top jaws open to

clamp a maximum 7-inch wide workpiece.

Adjusting Jaw to Angle

Workbench jaw adjusts to a maximum angle of 14

degrees for clamping irregular shaped workpieces.

To adjust jaw to angle, turn either the right or left

adjustment handle until desired angle is reached.

WOLF112-3

Figure 5

Using Adjustable Swivel Pegs – Figure 6

Your workbench is equipped with 4 swivel pegs

[R, page 3].The swivel pegs can be positioned into

any of the holes in the front and rear of top for

gripping irregular shaped workpieces, or to extend

gripping and clamping when the workpiece exceeds

the jaw capacity.

Swivel pegs are to be used to grip

workpiece only in cases where the workpiece DOES

NOT extend beyond the surface of the jaw.

Figure 6

WOLF112-5

WOLF112-4

CAUTION

Page 6

6

Specifications

Work Table Area: 30" x 13-1/4".

Maximum Weight Suppor t: 250 pounds.

Working Heights: 31-1/2"

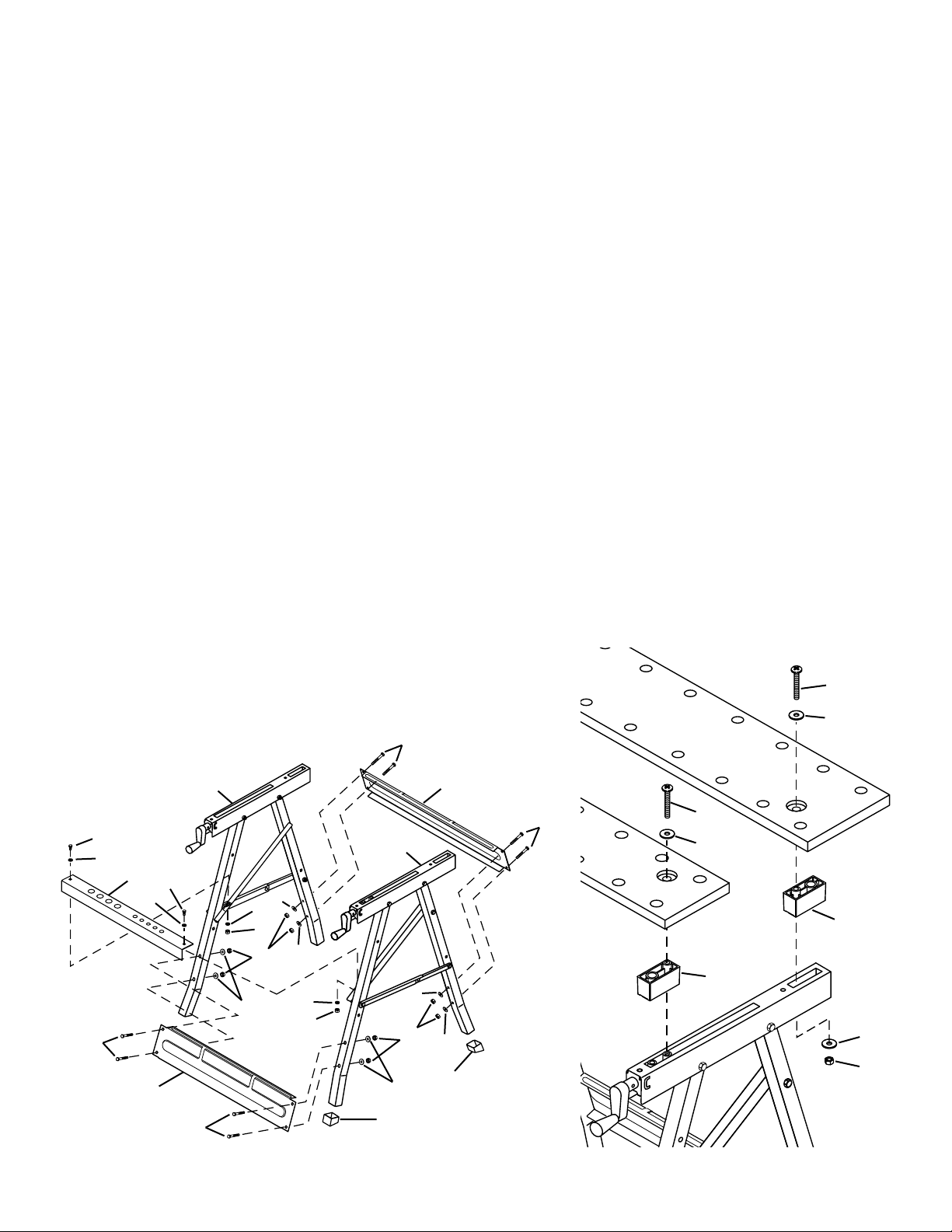

KEY

NO. PART NO. DESCRIPTION QTY.

A 119800360 Table Top - Front .........................1

B 119800361 Table Top - Rear..........................1

C 116610120 Handle.........................................2

E 116620265 Threaded Piece...........................2

F 117010204 Rail ..............................................2

G 117020205 Tool Rack.....................................1

I 117010193 Cross Bar ....................................2

J 117010206 L Bracket - Hinge - Rear.............2

K 117010207 L Bracket - Hinge - Front ............2

L 117010208 L Bracket - Left............................1

M 117010209 L Bracket - Right .........................1

N 117010210 L L - Bracket................................2

O 117010211 Leg ..............................................4

P 117220184 Spindle Threaded........................2

Parts List

Repair Parts

6134 W orkbench

KEY

NO. PART NO. DESCRIPTION QTY.

Q 116710002 Rivet............................................2

R 116720126 Rivet (4x20) .................................2

T 116700081 Hex Head Screw (M6x45) ........16

V 116710020 Lock Nut....................................10

W 116700026 Washer........................................8

X 116630199 Foot Pad ......................................4

Y 116610118 Connector Table Top Supports ...4

AA 116720040 Hex Head Screw (M6x12)..........2

BB 117710091 Screw (M8x55)............................4

CC 116720112 Nut (M8)......................................2

DD 116700023 Nut (M6)....................................10

EE 116700112 Washer........................................6

FF 116610722 Swivel Peg...................................4

T

F

FF

B

A

V

BB

EE

BB

EE

Y

T

K

Y

T

T

J

Q

O

W

W

O

V

M

W

V

DD

V

AA

W

V

I

T

N

E

C

G

V

L

O

P

R

V

W

DD

DD

W

X

W

T

F

T

O

K

WOLF112-6

EE

CC

I

T

W

T

J

Q

Page 7

7

ATENCIÓN: EL INCUMPLIMIENTO DE LAS INSTRUCCIONES DE SEGURIDAD / MANEJO Y DE LAS AD VERTENCIAS REFERENTES AL USO DE ESTE PRODUCTO

PODRÁ RESULTAR EN LESIONES PERSONALES GRAVES.

AVERTISSEMENT: LE NON RESPECT DES CONSIGNES DE SÉCURITÉ, DES INSTRUCTIONS DE FONCTIONNEMENT ET DES AVERTISSEMENTS CONCERNANT

L'UTILISATION DE CE PRODUIT RISQUE D'ENTRAÎNER DE GRAVES BLESSURES CORPORELLES.

NO trate de armar o manejar su Banco de Trabajo Wolfcraft® Quick Jaw® hasta

que haya leído todas las instrucciones de seguridad en esta sección.

En este manual, los aspectos de seguridad se indican con las palabras

A TENCIÓN o PRECAUCIÓN.

Esto significa que el incumplimiento de esta advertencia de

seguridad puede resultar en grandes daños para el producto,

así como en lesiones personales graves o incluso fatales.

Esto significa que el incumplimiento de esta advertencia de

seguridad puede resultar en lesiones personales pequeñas o

moderadas, así como en daños de la propiedad o equipos.

NO utilice este banco de trabajo como una escalerilla o

andamio. Cerciórese de que inserta el pasador y que apr ieta

del todo las manillas al usarlo. Capacidad máxima 250 libras.

Lea todas las instrucciones.

●

NO trate de usar su banco de trabajo portátil sin la mordaza bien trabada en

posición.

●

NO cargue el banco de trabajo con más de 250 libras.

●

NO aplique una carga desequilibrada que pudiera resultar en el vuelco del

banco de trabajo.

●

NO se suba al banco de trabajo ni se ponga de pie sobre el mismo, ya que

podría volcarse y resultar en lesiones graves.

●

Cerciórese de que las patas del banco de trabajo están totalmente abiertas

antes de usarlo.

●

Al trabajar con una herramienta eléctrica fija (tal como una sierra de ingletes)

en el banco de trabajo, cerciórese de que sujeta bien la herramienta a un troz o

de tablero aparte y sujete entonces el tablero al banco de trabajo portátil. NO

sujete o monte directamente una herramienta eléctrica fija a la superficie del

banco de trabajo, ya que podría resultar en lesiones personales graves.

●

Al manejar una herramienta eléctrica portátil (tal como un taladro, ranuradora,

lijadora o cepilladora), cerciórese siempre de que la pieza está bien sujeta al

banco de trabajo. Esto evitará las sacudidas que podrían resultar en lesiones

personales graves.

●

Al usar una herramienta eléctrica con el banco de trabajo, siga SIEMPRElas

instrucciones en el manual del usuario de dicha herramienta.

●

Al manejar herramientas eléctricas use SIEMPRE gafas de seguridad o una

pantalla para los ojos.

●

Para evitar lesiones personales al abrir o cerrar el banco de trabajo, evite

siempre colocar las manos o los dedos donde pudieran quedar atrapados.

●

Póngase la ropa apropiada. NO use ropa suelta, guantes, corbatas o joyas

(anillos y relojes de pulsera), ya que podrían engancharse y atraerle a las

partes móviles. Use SIEMPREun calzado antirresbaladizo. Recójase el pelo

largo.

NO guarde el banco de trabajo en el exterior o en un lugar

húmedo.

●

Mantenga SIEMPRE el área de trabajo limpia, ordenada y bien alumbrada.

NO trabaje ni coloque las patas del banco de trabajo sobre una superficie

resbaladiza a causa del serrín, aceite, agua o cera.

●

Mantenga a los visitantes o niños a una distancia de seguridad del área de

trabajo, particularmente al manejar una herramienta eléctrica. Los visitantes

deben llevar la misma ropa de seguridad que el operador.

●

GUARDE ESTAS INSTRUCCIONES.

INSTRUCCIONES DE SEGURIDAD

NE PAS tenter de monter ou d’utiliser votre établi Quick Jaw® wolfcraft® avant

d’avoir pris connaissance des consignes de sécurité qui suivent.

Les avis de sécurité contenus dans ce guide sont indiqués par les mentions

AVERTISSEMENT ou ATTENTION.

Cette indication signifie que le non respect des consignes

de sécurité risque d'endommager sérieusement le produit

et de provoquer des blessures corporelles graves voire mor telles.

Cette indication signifie que le non respect des consignes

de sécurité risque d'entraîner des blessures corporelles

légères ou modérées, et d'endommager légèrement le matériel ou les

équipements.

NE PAS utiliser cet établi comme échafaudage ou comme échelle.

Veiller à introduire la cheville et à serrer les poignées à f ond pendant

l’utilisation.Charge maximum: 250 livres.

Lire toutes les instructions.

●

NE PAS tenter d'utiliser l'établi portable si la mâchoire n'est pas solidement

bloquée.

●

NE PAS charger l'établi à plus de 250 livres.

●

NE PAS appliquer une charge non équilibrée qui pourrait provoquer le

renversement de l'établi.

●

NE PAS se tenir debout ou monter sur l'établi. Il pourrait tomber ou se

renverser, et provoquer des blessures graves.

●

S’assurer que le piétement de l'établi est en position

complètement ouverte avant l’utilisation.

●

En cas d'utilisation d'un outil motorisé fixe, tel qu'une scie à

onglets, sur l'établi, s'assurer que l'outil est solidement

boulonné à un morceau de contreplaqué séparé et que le

contreplaqué est solidement fixé à l'établi portable. NE PAS

fixer ou monter d'outil motorisé fixe directement sur le plateau

de l'établi. Ceci pourrait causer de graves blessures

corporelles.

●

En cas d'utilisation d'un outil motorisé portable, tel qu'une

perceuse, une défonceuse, une ponceuse ou un rabot,

toujours s'assurer que la pièce à usiner est solidement

bloquée sur l'établi, afin d'éviter toute secousse qui r isquerait

de provoquer de graves blessures corporelles.

●

Si l’on utilise un outil motorisé avec l'établi, TOUJOURS suivre les

consignes de sécurité figurant dans le manuel d’utilisation de l’outil

motorisé.

●

TOUJOURS porter des lunettes de protection ou des masques pour utiliser

des outils motorisés.

●

Afin d'éviter tout risque de blessures corporelles pendant l'ouverture et la

fermeture de l'établi, ne jamais mettre les mains ou les doigts là où ils

risquent d'être pincés.

●

Porter des vêtements de sécurité: NE PAS porter de vêtements amples,

gants, cravates ou bijoux (bagues, montres), qui risquent de s’accrocher et

de vous entraîner vers des parties en mouvement.TOUJOURS porter des

chaussures antidérapantes et attacher les cheveux longs.

NE PAS ranger l'établi dehors ou dans un endroit humide.

●

TOUJOURS maintenir la zone de travail propre, sans obstacles et bien

éclairée.NE PAS travailler et ne pas placer le piétement de l'établi sur des

sols glissants dus à la présence de sciure, d’huile, d’eau ou de cire.

●

Eloigner les visiteurs et les enfants de la zone de travail, sur tout lorsque

l’on travaille avec un outil motorisé. Les visiteurs doivent porter les mêmes

équipements de sécurité que l’opérateur.

●

CONSERVER CES INSTRUCTIONS.

CONSIGNES DE SECURITE

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

ATTENTION

PRECAUCIÓN

ATTENTION

ATTENTION

PRECAUCIÓN

Page 8

8

Contenu de l’emballage

Votre établi wolfcraft® est livré complet dans une boîte en

carton.

Extraire toutes les pièces de l’emballage et contrôler chaque

élément par rapport à la Figure 1 et à la ‘Liste des Pièces

détachées’.S’assurer que toutes les pièces sont comptabilisées

avant de mettre l’emballage au rebut.

Liste des Pieces Detachees

REPÈRE DESCRIPTION QUANTITÉ

APiétement gauche .........................................1

BPiétement droit..............................................1

D Vis tête 6 pans M6 x 45 ................................8

E Rondelle moyenne.........................................8

F Ecrou M6......................................................10

G Chevalet porte-outils .....................................1

H Vis tête 6 pans M6 x 12 ................................2

I Petite rondelle ..............................................4

J Traverse.........................................................2

K Patins.............................................................4

L Support du plateau ........................................4

M Plateau avant de l'établi ................................1

N Vis M8 x 55 ...................................................4

O Grande rondelle.............................................6

P Plateau arrière de l'établi...............................1

Q Ecrou M8.......................................................2

R Cheville orientable .........................................4

Contenido del Embalaje

El Banco de Trabajo wolfcraft® se envía completo en un cartón

de embalaje.

Separe todas las piezas de los materiales de embalaje y

contrástelas con la Figura 1 y con la “Tabla de Piezas Sueltas”.

Cerciórese de que identifica todas las piezas antes de desechar

los materiales de embalaje.

Tabla de Piezas Sueltas

REF. DESCRIPCIÓN .....................................CANTIDAD

A Juego de patas – izquierdo...........................1

B Juego de patas – derecho.............................1

D Tornillo cabeza hexagonal M6 x 45...............8

E Arandela mediana .........................................8

F Tuerca M6.....................................................10

G Estante de herramientas...............................1

H Tornillo cabeza hexagonal M6 x 12...............2

I Arandela pequeña.........................................4

J Travesaño......................................................2

K Tacos .............................................................4

L Soporte – superficie de trabajo.....................4

M Superficie de trabajo delantera .....................1

N Tornillos M8 x 55 ...........................................4

O Arandela grande............................................6

P Superficie de trabajo trasera.........................1

Q Tuerca M8......................................................2

R Clavijas giratorias..........................................4

Figure 1

Figura 1

OUTILS NECESSAIRES

Tournevis Phillips n° 3

Clé à molette

HERRAMIENTAS

REQUERIDAS

Destornillador Phillips N

o

3

Llave inglesa (ajustable)

N

P

O

R

M

H

Q

D

I

F

A

E

L

J

L

G

B

K

J

K

WOLF112-1

Page 9

9

WOLF112-2

E

E

E

D

E

D

I

I

I

I

F

F

G

H

I

I

F

H

F

A

B

D

D

J

K

K

J

Figure 3

Figura 3

MONTAGE

Assemblage de l'établi

Nota: Pour un assemblage correct, les charnières des

piétements [A] et [B] doivent se trouver à l'extérieur.

Pour les étapes de 1 à 3 se reporter à la Figure 2.

1. Fixer la barre transversale avant [J] aux piétements [A et B]

avec deux vis [D) (M6 x 45), des rondelles moyennes [E] et

des écrous [F] (M6) de chaque côté. Serrer à fond.

2. Fixer le chevalet porte-outils [G] aux piétements [A et B] avec

une vis [H] (M6 x 12), deux petites rondelles [I] et un écrou [F]

(M6) de chaque côté.Serrer à fond.

3. Fixer la barre transversale arrière [J] aux piétements.Utiliser

deux vis [D] (M6 x 45), des rondelles moyennes [E] et des

écrous [F] (M6) de chaque côté.Serrer à fond.

Pour les étapes de 4 à 8, se reporter à la Figure 3

4. Placer les deux supports de plateau [L] sur l'avant et le dessus

des piétements [A et B], avec les profilés ronds du support

dirigés vers le haut dans la direction opposée à l'avant de

l'établi.Les orifices du profilé rond inférieur s'adaptent aux

profilés filetés de chaque ensemble de bras à vis.

5. Installer le plateau avant de l'établi [M] sur les suppor ts [L],

en alignant les trous du plateau avec les moulages du

support rond et enfoncer pour le mettre en place.

6. Fixer le plateau avec deux vis [N] (M8 x 55) et deux

grandes rondelles [O]. Serrer à fond.

7. Installer les supports [L] du plateau arrière de l'établi sur

l'arrière et le dessus des piétements [A et B], avec les

profilés ronds du support dirigés vers le haut et vers l'avant

de l'établi. Les supports s'enclenchent dans les découpes

rectangulaires des piétements.

8. Placer le plateau arrière de l'établi [P] sur les supports [L], en

alignant les trous du plateau avec les profilés du support et

enfoncer pour le mettre en place.Fixer le plateau avec deux

vis [N] (M8 x 55) et deux grandes rondelles [O] sur l'établi et

avec deux grandes rondelles [O] et deux écrous [Q] (M8)

sous l'établi. Serrer à fond.

MONTAJE

Montaje del banco de trabajo

Nota: Para obtener el montaje correcto, las patas (A) y (B)

deben quedar con las bisagras hacia fuera. Véase la Figura 2

para los pasos 1 a 3.

1. Sujete el travesaño delantero (J) a los conjuntos de patas (A

y B) con dos tornillos (D) [M6 x 45], arandelas medianas (E) y

tuercas (F) [M6] a cada lado. Apriete bien.

2. Sujete el estante de herramientas (G) a los conjuntos de

patas (Ay B) con un tornillo (H) [M6 x 12], dos arandelas

pequeñas (I) y una tuerca (F) [M6] a cada lado. Apriete bien.

3. Sujete el travesaño trasero (J) a los conjuntos de patas, con

dos tornillos (D) [M6 x 45], arandelas medianas (E) y tuercas

(F) [M6] a cada lado. Apriete bien.

Véase la Figura 3 para los pasos 4 a 8.

4. Coloque los dos soportes (L) en el frente y parte superior de

los conjuntos de patas (A y B), con las extrusiones circulares

de los soportes hacia arriba y hacia la parte trasera del banco

de trabajo. Los agujeros inferiores de las extrusiones

circulares encajan sobre las extrusiones roscadas de cada

conjunto de pata.

5. Coloque la superficie de trabajo delantera (M) sobre los

soportes (L), alineando los agujeros en la superficie de trabajo

con las extrusiones circulares de los soportes y presiónela en

posición.

6. Sujete la superficie de trabajo con dos tornillos (N) [M8 x

55] y dos arandelas grandes. Apriete bien.

7. Coloque los dos soportes (L) en la parte trasera y en la parte

superior de los conjuntos de patas (A y B), con las

extrusiones circulares de los soportes hacia arriba y hacia el

frente del banco de trabajo. Los soportes encajan con las

aberturas rectangulares en los conjuntos de patas.

8. Coloque la superficie de trabajo trasera (P) sobre los soportes

(L), alineando los agujeros en la superficie de trabajo con las

extrusiones circulares de los soportes y presiónela en

posición. Sujete la superficie de trabajo con dos tornillos (N)

[M8 x 55] y dos arandelas grandes (O) en la superficie de

trabajo, y con dos arandelas grandes (O) y dos tuercas Q [M8]

en la parte inferior. Apriete bien.

Figure 2

Figura 2

N

O

N

O

L

L

O

Q

Page 10

3. Cuando esté totalmente abierto, sujételo en la posición

trabada empujando las bisagras hasta bajarlas del todo.

Ajuste de la mordaza en la superficie del banco de trabajo

Gire a izquierdas las dos manillas de ajuste de la mordaza en el

frente para mover hacia fuera la parte delantera de la mordaza

(a derechas para moverla hacia dentro). (Véase la Figura 5).

La mordaza en la superficie del banco se abre para sujetar una

pieza de 7" de ancho (máximo).

Ajuste angular de la mordaza

La mordaza puede ajustarse a un ángulo máximo de 14 grados

para sujetar piezas de forma irregular. Para ajustar el ángulo de

la mordaza, gire la manilla de ajuste izquierda o derecha hasta

obtener el ángulo deseado.

Empleo de las clavijas giratorias ajustables (Figura 6)

El banco de trabajo viene con 4 clavijas giratorias. Estas

clavijas giratorias pueden colocarse en cualquiera de los

agujeros en la parte delantera y trasera de la superficie del

banco de trabajo para facilitar el agarre de las piezas

irregulares, o para extender el agarre y fijación cuando la pieza

10

WOLF112-3

WOLF112-5

WOLF112-4

Figure 4

Figura 4

Figure 5

Figura 5

Figure 6

Figura 6

Pliage de l'établi

1. Enlever les éventuels outils manuels ou pièces se trouvant

sur l'établi et sur le chevalet.

2. Tirer doucement sur les charnières, en plaçant les doigts

sous la bride pour débloquer les charnières.

3. Faire légèrement basculer l'établi vers l'arrière sur le

piétement arrière (voir Figure 4).

4. Tendre le bras et pousser le piétement avant vers l'arrière.

Ouverture de l'établi

1. Debout derrière l'établi, saisir le bord avant du plateau et le

dessous de la traverse arrière.

2. Tirer la traverse arrière vers soi tout en tirant sur le plateau

simultanément.

3. Lorsque l'établi est entièrement ouvert, le bloquer en position

en poussant sur les charnières jusqu'à ce qu'elles soient

complètement abaissées.

Réglage de la mâchoire de l'établi

Tourner les poignées de réglage de la mâchoire dans le sens

inverse des aiguilles d'une montre pour déplacer la mâchoire

vers soi.Tourner les poignées de réglage dans le sens des

aiguilles d'une montre pour éloigner la mâchoire. (voir Figure 5).

La mâchoire de l'établi s'ouvre pour serrer des morceaux de

bois jusqu'à 7 pouces de large.

Réglage de l'angle de la mâchoire

La mâchoire de l'établi peut être réglée jusqu'à un maximum de

14 degrés pour serrer des morceaux de bois de forme

irrégulière. Pour régler l'angle de la mâchoire, tourner la poignée

de réglage vers la droite ou vers la gauche jusqu'à obtention de

l'angle désiré.

Utilisation des chevilles orientables réglables Figure 6

L'établi est équipé de quatre chevilles orientables.Ces chevilles

peuvent être placée dans n'importe quel trou du plateau avant

et arrière pour bloquer les pièces à usiner de formes

irrégulières, ou pour étendre la prise et le serrage lorsque la

pièce à usiner dépasse la capacité de la mâchoire.

Les chevilles orientables doivent être utilisées pour

maintenir la pièce à usiner uniquement lorsque la

pièce NE dépasse PAS de la surface de la mâchoire.

ATTENTION

Cómo plegar el banco de trabajo

1. Retire las herramientas manuales o piezas de la superficie

del banco y estante de almacenamiento.

2. Insertando los dedos bajo la brida de las bisagras, tire

cuidadosamente de las bisagras para destrabarlas.

3. Incline ligeramente hacia atrás el banco de trabajo contra las

patas traseras (véase la Figura 4).

4. Baje la mano y empuje las patas delanteras hacia atrás.

Cómo abrir el banco de trabajo

1. Colóquese detrás del banco y agárrelo por el borde superior

delantero de la superficie de trabajo y por debajo del

travesaño trasero.

2. Tire del travesaño trasero hacia usted y al mismo tiempo tire

hacia arriba de la superficie de trabajo del banco.

Page 11

Caracteristiques

Surface de l'établi:........................... 30" x 13-1/4"

Charge maximale:................................. 250 livres

Hauteur de travail:..................................... 31-1/2"

Pieces de Rechange

Etabli 6134

excede de la capacidad de la mordaza.

Las clavijas giratorias pueden

utilizarse para agarrar la pieza sólo en

los casos en que la pieza NO sobrepase la

superficie de la mordaza.

Especificaciones

Área de trabajo superior...................30" x 13-1/4"

Peso máximo soportado........................250 libras

Altura de trabajo........................................31-1/2"

PRECAUCIÓN

N° DE

REPERE PIECE DESCRIPTION QTE

A 119800360 Plateau avant......................................................1

B 119800361 Plateau arrière....................................................1

C 116610120 Poignée...............................................................2

E 116620265 Pièce filetée........................................................2

F 117010204 Rail......................................................................2

G 117020205 Chevalet porte-outils ..........................................1

I 117010193 Barre transversale..............................................2

J 117010206 Support L - charnière arrière.............................2

K 117010207 Support L - char nière avant ...............................2

L 117010208 Support L - gauche............................................1

M 117010209 Support L - droit.................................................1

N 117010210 LL - droit .............................................................2

O 117010211 Pied.....................................................................4

P 117220184 Tige filetée..........................................................2

N° DE

REPERE Piece DESCRIPTION QTE

Q 116710002 Rivet....................................................................2

R 116720126 Rivet (4 x 20) ......................................................2

T 116700081 Vis tête 6 pans (M6 x 45).................................16

V 116710020 Ecrou de blocage..............................................10

W 116700026 Rondelle..............................................................8

X 116630199 Patin....................................................................4

Y 116610118 Raccords pour support du plateau ...................4

AA 116720040 Vis tête 6 pans (M6 x 12)..................................2

BB 117710091 Vis (M8 x 55) ......................................................4

CC 116720112 Ecrou (M8)..........................................................2

DD 116700023 Ecrou (M6).........................................................10

EE 116700112 Rondelle..............................................................6

FF 116610722 Cheville orientable..............................................4

Liste des Pieces

N° DE

REF. PIEZA DESCRIPCIÓN CANTIDAD

A 119800360 T abla delantera 1

B 119800361 Ta bla t rasera 1

C 116610120 Manillas 2

E 116620265 Piezas de conexión2

F 117010204 Rieles 2

G 117020205 Estante de herramientas 1

I 117010193 Travesaño2

J 117010206 Soportes ‘L’– bisagra trasera 2

K 117010207 Soportes ‘L’– bisagra delantera 2

L 117010208 Soporte ‘L’ izquierdo 1

M 117010209 Soporte ‘L’derecho 2

N 117010210 Soportes ‘LL’ bisagra 2

O 117010211 Patas 4

P 117220184 Vástagos 2

N° DE

REF. PIEZA DESCRIPCIÓN CANTIDAD

Q 116710002 Remaches . . . . . . . . . . . . . . . . . . . . . . . . . . .2

R 116720126 Remaches (M4 x 20) . . . . . . . . . . . . . . . . . . . 2

T 116700081 Tornillo cabeza hexagonal (M6 x 45) . . . . . .16

V 116710020 T uercas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

W 116700026 Arandelas . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

X 116630199 T acos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Y 116610118 Conectores – sopor tes de

superficie de trabajo . . . . . . . . . . . . . . . . . . . .4

AA 116720040 T ornillo cabeza hexagonal (M6 x 12) . . . . . . . 2

BB 117710091 T ornillos (M8 x 55) . . . . . . . . . . . . . . . . . . . . . 4

CC 116720112 Tuercas (M8) . . . . . . . . . . . . . . . . . . . . . . . . . 2

DD 116700023

Tuercas

(M6) . . . . . . . . . . . . . . . . . . . . . . . . . 10

EE 116700112 Arandelas . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

FF 116610722 Clavijas giratoria . . . . . . . . . . . . . . . . . . . . . . .4

Lista de Piezas

11

FF

V

AA

B

BB

EE

Y

N

E

C

W

G

L

V

O

P

R

V

V

DD

BB

EE

Y

F

EE

CC

I

T

T

O

W

W

T

T

F

T

T

J

T

K

Q

O

W

V

O

V

W

V

A

M

W

DD

I

T

DD

W

W

T

X

WOLF112-6

Q

K

J

Page 12

wolfcraft

®

OWNER’S

MANUAL

MODEL NO.

6134

GUIDE DE

L’UTILISATEUR

MODÉLE NO.

6134

MANUAL DEL

USUARIO

NO. DE MODELO

6134

wolfcraft Inc., Itasca, IL 60143 U.S.A.

116, 310, 450/04, 01

Loading...

Loading...