Page 1

wolfcraft

®

Save this manual for

future reference

Conservez ce manuel pour

toute référence future

Sírvase guardar este

manual para consultarlo

en el futuro

OWNER’S

MANUAL

MANUEL

D'UTILISATION

MANUAL DEL

USUARIO

MODEL NO.4525

MODÉLE N° 4525

N° DE MODELO 4525

Page 7:

Français et espagnol

Frances y Español

CAUTION:

Read, understand and

follow ALL instructions

before using this Drill

Guide.

ATTENTION:

Lisez, comprenez et

suivez T OUTES les

instructions avant d'utiliser

ce guide de perceuse.

PRECAUCIÓN:

Lea, comprenda y siga

TODAS las instrucciones

de seguridad antes de

usar esta Guía de

Taladrar.

wolfcraft

®

DRILL GUIDE

GUIDE DE PERCEUSE

GUÍA DE TALADRAR

OWNER’S MANUAL

GUIDE DE L’UTILISATEUR

MANUAL DEL USUARIO

Power tool NOT included.

Outil électrique non inclus.

No se incluye la herramienta eléctrica.

46441

RTD10000193AA

Page 2

1. KNOW YOUR POWER TOOL

Read the owner’s manual carefully. Learn its application and limitations as well as the specific potential hazards peculiar to this tool.

2. GROUND ALL TOOLS (UNLESS DOUBLE

INSULATED)

If tool is equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green conductor in the cord is the grounding wire. Never

connect the green wire to a live terminal.

3. KEEP GUARDS IN PLACE

In working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

Floor must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don’t use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from the

work area.

8. MAKE WORKSHOP KID-PROOF

— with padlocks, master switches, or by removing

the starter keys.

9. DON’T FORCE TOOL

It will do the job better and safer at the rate for

which it was designed.

10. USE THE RIGHT TOOL

Don’t force tool or attachment to do a job it was

not designed for.

11. WEAR RIGHT APPAREL

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) to get caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

Roll long sleeves above the elbow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANSI

Z87.1) at all times. Also, use face or dust mask if

cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods of operation.

13. SECURE WORK

Use clamps or a vise to hold work when practical.

It’s safer than using your hand, frees both hands

to operate tool.

14. DON’T OVERREACH

Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories such

as blades, bits, cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in “OFF” position before plugging in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner’s manual for recommended

accessories. Follow the instructions that accompany the accessories. The use of improper accessories may cause hazards.

19. NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

Do not store materials above or near the tool such

that it is necessary to stand on the tool to reach

them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or replaced.

21. NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don’t leave tool until it comes to a

complete stop.

2

WARNING: FAILURE TO HEED ALL SAFETY AND OPERATING INSTRUCTIONS AND WARNINGS REGARDING USE OF

THIS PRODUCT CAN RESULT IN SERIOUS BODILY INJURY.

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS

ADDITIONAL SAFETY INSTRUCTIONS FOR

wolfcraft

®

DRILL GUIDE

1. ALWAYS USE EYE PROTECTION

The operation of any power tool can result in foreign objects being thrown into the eyes, which can

result in severe eye damage. Always wear safety

goggles complying with ANSI Z87.1 before commencing power tool operation.

2. KEEP DRILL CLEAN

After every use, clean sawdust off the drill and

bits.

3. WARNING

Always turn “OFF” the drill and disconnect the

power cord when installing the cutter or bit

and/or adjusting the depth of cut.

Page 3

3

Introduction

Precision hole drilling and countersinking is a

skill that ordinarily takes years to acquire.Yet

the success of many projects depends on

drilling straight, accurate holes.

Your wolfcraft Drill Guide, when used with

your power drill, makes it easy to perform

many precision operations, including straight

and angled drilling, edge and round stock

drilling, countersinking and edge sanding. It

provides you with better control for a better

finished result.

You can use your wolfcraft Drill Guide anywhere you need a drill—even in masonry or

concrete using the proper bit.

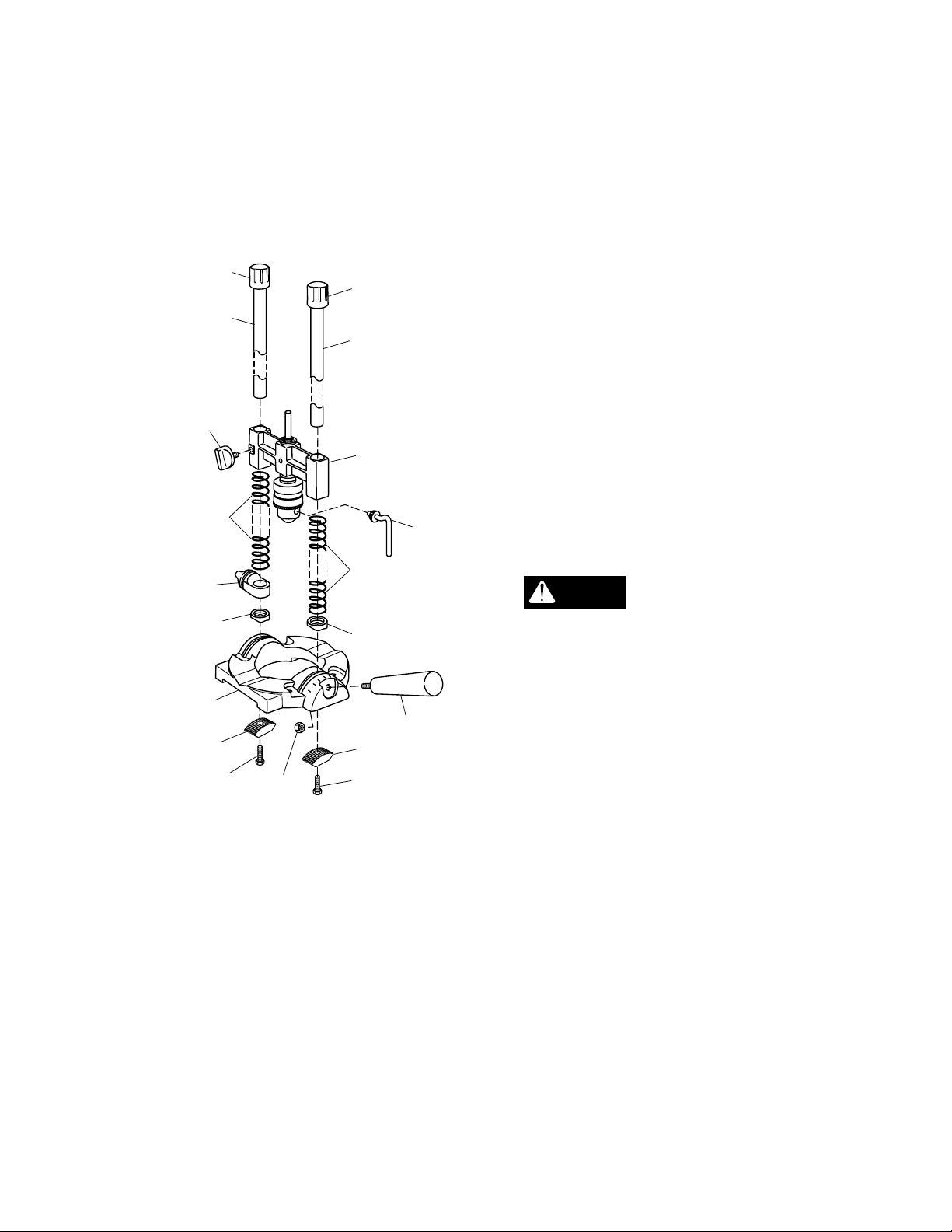

Unpacking and

Checking Contents

Separate all parts from the packing materials

and check them against the illustration and

the “Table of Parts.” Make sure all parts are

accounted for before discarding any of the

packing material.

FIG 1

A

L

K

A

L

K

D

C

E

F

I

I

J

J

E

M

G

H

B

Assembling Your Drill

Guide

(See Figure 1)

You must read and understand

all the instructions of your Drill

Guide as well as your drill owner’s manual

before attempting to assemble and oper ate this

product.

1. Secure handle (G) to base plate (F) with nut

(H).The ribs in base plate will hold nut in

position while tightening handle.

2. Remove springs (K) from both guide bars

(A).Slide guide bars into cross guide/chuck

assembly (B).Position springs back on

guide bars.

3. Thread thumb screw (C) into cross

guide/chuck assembly.

4. Slide depth stop (D) onto guide bar under

thumb screw in cross bar/chuck assemb ly.

Position thumb scre w on depth stop facing out.

5. Place bar holders (E) on guide bars. Rotate

bar holders so index marks are facing out.

6. Install hex screw (J) through each support

(I).Position guide bars on base plate with

tabs on bar holders passing through slots in

base plate.Hold guide bars vertical and

install supports. Rotate caps (L) clockwise

on top of guide bars to tighten screws.

Figure 1

TABLE OF PARTS

ITEM DESCRIPTION QTY.

A Guide Bar/Spring Assembly 2

B Cross Guide/Chuck Assembly 1

C Thumb Screw 1

D Depth Stop 1

E Bar Holder 2

F Base Plate 1

G Handle 1

H Nut 1

I Supports 2

J Hex Screw 2

K Springs 2

L Caps 2

M Chuck Key 1

WARNING

Page 4

4

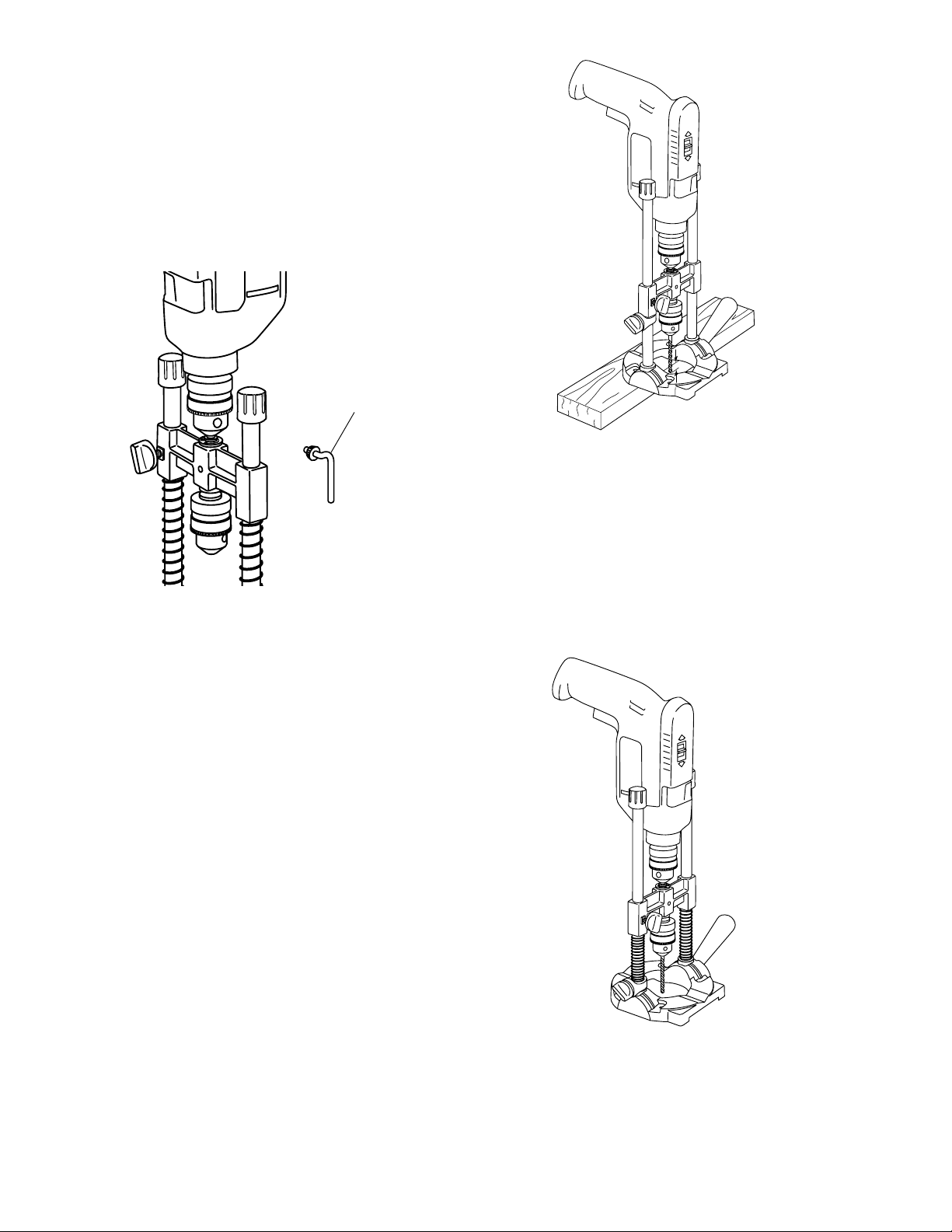

Operating Instructions

Do not use Drill Guide as a router.The base

plate must be secured when drilling round

stock and holes.

Setting Depth of Hole

The depth stop feature controls depth with

repeated accuracy. When operating your Drill

Guide using the depth stop feature, remove

springs from both guide rods.

1. Place the drill guide at the edge of your

workbench.

2. Press the drill down until the desired depth

of the hole is reached.(See Figure 3.)

Tighten the thumb screw in the cross

guide/chuck assembly.

3. Slide the depth stop against the cross bar/

chuck assembly.Tighten the depth stop thumb

screw. Release the thumb screw in cross

guide/chuck assembly.You are ready to drill.

Figure 3

90° Drilling

To dr ill a hole straight down, 90° angle to the

work piece, loosen both guide bars (See

Figures 4 and 5) and rotate them to align

index mark on both bar holders with 0 marks

on the base plate. Tighten guide bars in position. Place the Drill Guide flush with the work

piece before drilling.

Figure 4

Attaching and

Removing Your Drill

Before using, attach your drill to shaft using a

chuck ke y. (See Figure 2.) When completing a

drilling project, remove drill from the drill guide.

CHUCK KEY

Figure 2

Countersink

Install a countersink bit in the chuck.Adjust the

depth stop to desired countersink depth.

Page 5

5

Angle Drilling

Loosen caps on both guide bars (See Figure

5) and rotate guide bars to align the index

mark on both bar holders to the desired angle

(See Figure 6) reference marks on the base

plate. Tighten caps and drill the hole with the

Drill Guide flush with the work piece. (See

Figure 7.)

Figure 5

FIG 5

0˚ - 45˚

0˚ - 45˚

Figure 6

Figure 7

Edge Drilling

Place the Drill Guide on the edge of the work

piece to be drilled. (See Figure 8.) Rotate the

base plate clockwise until sides of work piece

contact the base plate. (See Figure 9.) The

drill is now centered on the edge.

A

A

A

A

Figure 8

Figure 9

Figure 10

Round Stock Drilling

V-blocks are provided to hold round stock for

90° drilling.(See Figure 10.)

A

Page 6

6

FIG 13

1

10

11

11

3

4

3

8

9

13

14

13

5

5

2

6

20

12

17

16

17

18

18

21

21

15

7

19

21

Figure 13

Repair Parts

KEY

NO. PART NO. DESCRIPTION QTY

1 116600036 Rod Cap 2

2 117220130 Shaft 1

3 116700029 Retaining Ring 2

4 116710120 Washer 1

5 117110002 Sleeve Bushing 2

6 116710067 Thumb Screw M6 x 16 1

7 116410022 Cross Guide 1

8 015100033 Chuck 1

9 116800011 Countersunk Screw 1

10 117200008 Guide Bar 2

11 117610002 Spring 2

12 116600085 Depth Stop 1

13 116600034 Bar Holder 2

14 116430120 Base Plate 1

15 116610051 Handle 1

16 116700023 Hex Nut 1

17 116600033 Support 2

18 116700055 Hex Screw 2

19 015100034 Chuck Key 1

20 116620052 Thumb Screw M6 x 10 1

21 117720017 Rubber Stop 4

Workbench Mounting Only for Edge Sanding

1. Use a hole saw to cut a hole no larger than

2 1/4" in the top of your workbench.

2. Center the Drill Guide base around the hole

on the underside of the bench.Push rubber

stopper pieces out.Secure base to the

bench using four 1/4" flat head screws

through holes provided in base (screws not

included).(See Figure 11.)

3. To keep the bit locked in place, adjust the bit

above the bench surf ace to the desired

position.Tighten the thumb screw in the

cross guide/chuck assembly.

NOTE: With this type of mounting, it is recom-

mended having a material guide or

straight edge secured to the top the

bench.

Figure 11

Edge Sanding

For edge sanding, the Drill Guide can either

be handheld or mounted under the

workbench. (See Figure 12.)

Figure 12

Page 7

7

1. CONNAISSEZ VOTRE OUTIL ELECTRIQUE

Lisez attentivement le manuel d'utilisation. Apprenez les

applications et les limites de l'outil ainsi que les dangers

potentiels qu'il présente.

2. METTEZ TOUS LES OUTILS A LA TERRE (SAUF

S'ILS ONT UNE DOUBLE ISOLATION)

Si l'outil est équipé d'un cordon à trois conducteurs

agréé et d'une fiche de mise à la terre à 3 broches,

branchez-le dans la prise de mise à la terre appropriée.

Le conducteur vert du cordon est le fil de terre. Ne

branchez jamais le fil vert à une borne sous tension.

3. LAISSEZ LES PROTECTIONS EN PLACE

En état de fonctionnement, en respectant le réglage et

l'alignement corrects.

4. ENLEVEZ LES CLES ET CLAVETTES DE REGLAGE

Prenez l'habitude de vérifier que les clés et clavettes

de réglage ont été retirées de l'outil avant de le mettre

en marche.

5. MAINTENEZ LA ZONE DE TRAVAIL BIEN PROPRE

Les zones de travail et les établis encombrés attirent les

accidents. Les sols ne doivent pas être rendus glissants

par de la cire ou de la sciure de bois.

6. EVITEZ LES ENVIRONNEMENTS DANGEREUX

N'utilisez pas d'outils électriques dans des endroits

humides ou mouillés et ne les exposez pas à la pluie.

Assurez un bon éclairage de la zone de travail.

L'espace autour de la zone de travail doit être approprié.

7. ELOIGNEZ LES ENFANTS

Tous les visiteurs doivent rester à une distance de

sécurité de la zone de travail.

8. ASSUREZ LA SECURITE DE L'ATELIER

— avec des cadenas, des interrupteurs généraux, ou

en enlevant les clés de contact.

9. NE FORCEZ PAS L'OUTIL

L'outil fonctionnera mieux et de façon plus sûre à la

vitesse pour laquelle il a été conçu.

10. UTILISEZ L'OUTIL APPROPRIE

Ne forcez pas l'outil ou l'accessoire à exécuter un travail pour lequel il n'a pas été conçu.

11. PORTEZ LES VETEMENTS APPROPRIES

Evitez de porter des vêtements lâches, des gants, des

cravates ou des bijoux (bagues, bracelets-montres) qui

pourraient se coincer dans les parties mobiles. Il est

recommandé de porter des chaussures antidérapantes.. Portez une coiffure protectrice pour retenir les

cheveux longs. Roulez les manches longues audessus du coude.

12. UTILISEZ DES LUNETTES DE SECURITE

(Protection pour la tête)

Portez des lunettes de sécurité (conformes aux normes

ANSI Z87.1) en toutes circonstances. Utilisez aussi un

masque de protection ou antipoussière si l'opération de

coupe risque de produire de la poussière. Portez des

protecteurs d'oreilles (bouchons ou casque antibruit)

pendant les périodes de travail prolongées.

13. FIXEZ LA PIECE

Utilisez des brides de serrage ou un étau pour maintenir la pièce en cas de besoin. Ils sont plus sûrs que

les mains et permettent d'avoir les deux mains libres

pour actionner l'outil.

14. NE VOUS ETENDEZ PAS TROP

Gardez les pieds au sol et un bon équilibre en toutes

circonstances.

15. ENTRETENEZ LES OUTILS AVEC SOIN

Maintenez les outils bien affûtés et propres pour

davantage de sécurité et un meilleur rendement.

Suivez les instructions concernant la lubrification et le

changement des accessoires.

16. DEBRANCHEZ LES OUTILS

avant de procéder à l'entretien ou au changement des

accessoires tels que les lames, les mèches, les

couteaux, etc.

17. EVITEZ UNE MISE EN MARCHE ACCIDENTELLE

Assurez-vous que l'interrupteur est en position d'arrêt

"OFF" avant de brancher l'appareil.

18. UTILISEZ LES ACCESSOIRES RECOMMANDES

Consultez le manuel d'utilisation pour connaître les

accessoires recommandés. Suivez les instructions qui

accompagnent les accessoires. L'utilisation d'accessoires non recommandés peut être la cause de dangers.

19. NE VOUS TENEZ JAMAIS DEBOUT SUR L'OUTIL

Des blessures graves peuvent se produire si l'outil

bascule ou si l'outil coupant est mis en marche

accidentellement.

N'entreposez pas de matériaux au-dessus ou à proximité de l'outil, qui ne seraient accessibles qu'en se

tenant debout sur l'outil.

20. VERIFIEZ LES PIECES ENDOMMAGEES

Avant d'utiliser l'outil, examinez avec soin toute protection ou autre pièce endommagée pour vous assurer

qu'elle fonctionnera correctement et qu'elle remplira la

fonction pour laquelle elle est prévue. Vérifiez l'alignement des pièces mobiles, la liaison des pièces

mobiles, les pièces cassées, le montage et toutes

autres conditions qui pourraient affecter le fonctionnement de l'outil. Toute protection ou autre pièce

endommagée doit être convenablement réparée ou

remplacée.

21. NE LAISSEZ JAMAIS L'OUTIL EN MARCHE SANS

SURVEILLANCE

Coupez le courant. Ne vous éloignez pas de l'outil

avant qu'il soit complètement arrêté.

ATTENTION: LE NON-RESPECT DE TOUTES LES CONSIGNES DE SECURITE, DES INSTRUCTIONS DE SERVICE ET DES AVERTISSEMENTS CONCERNANT L'UTILISATION DE CE PRODUIT PEUT ENTRAINER DE GRAVES DOMMAGES CORPORELS.

CONSIGNES DE SECURITE GENERALES

POUR LES OUTILS ELECTRIQUES

CONSIGNES DE SECURITE SUPPLEMENTAIRES

POUR LE GUIDE DE PERCEUSE wolfcraft

®

1. UTILISEZ TOUJOURS DES LUNETTES DE PROTECTION

Le fonctionnement des outils électriques risque de projeter des corps étrangers dans les yeux et de provoquer

de graves blessures aux yeux. Portez toujours des

lunettes de protection conformes à la norme ANSI Z87.1

avant de mettre en marche un outil électrique.

2. MAINTENEZ LA PERCEUSE PROPRE

Après chaque utilisation, éliminez la sciure de bois de la

perceuse et de la mèche.

3. AVERTISSEMENT

Désactivez toujours la perceuse et débranchez le cordon d'alimentation avant d'installer l'outil de coupe ou la

mèche et/ou de régler la profondeur de coupe.

Page 8

8

1. FAMILIARÍCESE CON SU HERRAMIENTA

ELÉCTRICA

Lea atentamente el manual del usuario de la

herramienta eléctrica. Aprenda cuál es su aplicación y

sus limitaciones, así como los riesgos potenciales

propios de la herramienta.

2. CONECTE A MASA (TIERRA) TODAS LAS

HERRAMIENTAS (A NO SER QUE TENGAN DOBLE

AISLAMIENTO).

Si la herramienta viene con un cable aprobado de 3

conductores y un enchufe del tipo de conexión a tierra

de 3 clavijas para una toma apropiada del tipo de

conexión a tierra, el conductor de color verde es el hilo

de tierra. Jamás conecte el hilo verde a un terminal

con corriente.

3. MANTENGA LAS PROTECCIONES COLOCADAS

Cerciórese de que las protecciones están en buenas

condiciones de funcionamiento, bien ajustadas y alineadas.

4. RETIRE LAS LLAVES DE AJUSTE Y DE APRIETE

Acostúmbrese a comprobar que se han retirado las

llaves de ajuste y de apriete de la herramienta antes

de arrancarla.

5. MANTENGA LIMPIA EL ÁREA DE TRABAJO

Las áreas y bancos de trabajo desordenados invitan

los accidentes. El piso no debe estar resbaladizo

debido a la cera y serrín.

6. EVITE LOS AMBIENTES PELIGROSOS

No utilice herramientas eléctricas en lugares húmedos

ni las exponga a la lluvia. Mantenga el área de trabajo

bien alumbrada y deje un espacio de trabajo adecuado

a su alrededor.

7. MANTENGA A LOS NIÑOS APARTADOS

Todos los visitantes deben mantenerse a una distancia

de seguridad del área de trabajo.

8. DEJE EL TALLER INACTIVADO

— con candados, interruptores maestros o extrayendo

las llaves de arranque.

9. NO FUERCE LA HERRAMIENTA

Desempeñará mejor el trabajo y con más seguridad

operando dentro de los límites para los que fue diseñada.

10. UTILICE LA HERRAMIENTA CORRECTA

No fuerce la herramienta o accesorio para hacer un

trabajo para el cual no han sido diseñados.

11. PÓNGASE LA ROPA APROPIADA

No use ropa suelta, guantes, collares o joyas (anillos y

relojes de pulsera) que puedan engancharse con

partes móviles. Se recomienda un calzado antirresbaladizo. Recójase y proteja el pelo largo. Enróllese las

mangas por encima del codo.

12. USE GAFAS DE SEGURIDAD (Protección para la

cabeza)

Use gafas de seguridad (conforme a la norma ANSI

Z87.1) en todo momento. Si se trata de trabajos de

corte que desprenden mucho polvo, póngase una

mascarilla o careta para el polvo, debiendo también

protegerse los oídos (con tapones u orejeras) al

efectuar trabajos de larga duración.

13. SUJETE BIEN LA PIEZA TRABAJADA

Utilice mordazas o un tornillo de banco para sujetar la

pieza trabajada cuando resulte práctico. Es más

seguro que usar la mano y además deja las dos

manos libres para manejar la herramienta.

14. NO SE ESTIRE

Mantenga un buen apoyo y equilibrio en todo

momento.

15. CUIDE DE LAS HERRAMIENTAS

Manténgalas afiladas y limpias para obtener óptimas

prestaciones con seguridad. Siga las instrucciones

para lubricar y cambiar los accesorios.

16. DESCONECTE LAS HERRAMIENTAS

— antes de hacer el mantenimiento y al cambiar

accesorios tales como cuchillas, barrenas, fresas, etc.

17. EVITE LOS ARRANQUES ACCIDENTALES

Cerciórese de que el interruptor está en la posición

OFF antes de enchufar la herramienta.

18. UTILICE LOS ACCESORIOS RECOMENDADOS

Consulte el manual del usuario para los accesorios

recomendados. Siga las instrucciones suministradas

con los accesorios. El uso de accesorios incorrectos

puede causar riesgos.

19. JAMÁS SE PONGA DE PIE SOBRE LA HERRAMIENTA

Podrán producirse lesiones graves si se vuelca la herramienta o si entra en contacto accidentalmente con la

herramienta de corte.

No coloque materiales sobre la herramienta o cerca de

la misma, que hagan necesario ponerse de pie sobre

la herramienta para alcanzarlos.

20. COMPRUEBE LAS PARTES DAÑADAS

Antes de continuar usando la herramienta, compruebe

cuidadosamente una protección u otra parte que esté

dañada para cerciorarse de que operará debidamente

y cumplirá con su cometido. Compruebe la alineación

de las partes móviles, agarrotamiento de partes

móviles, rotura de piezas, montaje y otras condiciones

que puedan afectar a su funcionamiento. Una protección u otra pieza que esté dañada debe repararse

debidamente o cambiarse.

21. JAMÁS DEJE LA HERRAMIENTA FUNCIONANDO

DESATENDIDA

Desconecte la corriente. No deje la herramienta hasta

que se haya parado del todo.

ATENCIÓN: DE NO SEGUIR TODAS LAS INSTRUCCIONES DE SEGURIDAD Y DE MANEJO, ASÍ COMO LAS ADVERTENCIAS

REFERENTES AL USO DE ESTE PRODUCTO, PODRÁ RESULTAR EN LESIONES GRAVES.

INSTRUCCIONES GENERALES DE SEGURIDAD

PARA HERRAMIENTAS ELÉCTRICAS

INSTRUCCIONES DE SEGURIDAD ADICIONALES

PARA LA GUÍA DE TALADRAR wolfcraft

®

1. UTILICE SIEMPRE PROTECCIÓN OCULAR

El manejo de cualquier herramienta eléctrica puede

resultar en materias extrañas que pueden introducirse

en los ojos, resultando en lesiones graves de los mismos. Use siempre gafas de seguridad conforme a la

norma ANSI Z87.1 antes de comenzar a trabajar con la

herramienta eléctrica.

2. MANTENGA EL TALADRO LIMPIO

Después de usarlo, limpie el serrín del taladro y las

brocas.

3. ATENCIÓN

Apague siempre el taladro y desconecte el cable de

corriente al instalar la fresa o broca y/o al ajustar la

profundidad de corte.

Page 9

9

fraisage et le ponçage de bordures. Il assure un meilleur contrôle et un meilleur travail fini.

Vous pouvez utiliser le guide de perceuse wolfcraft partout où

vous avez besoin d'une perceuse—même dans des

ouvrages en maçonnerie ou en béton, en utilisant la mèche

appropriée.

Montage du guide de perceuse

(Voir Figure 1)

Avant de procéder au montage du guide

de perceuse et à sa mise en marche,

vous devez lire et comprendre toutes les

instructions concernant le guide de perceuse ainsi que le

manuel d'utilisation de la perceuse.

1. Fixez la poignée (G) à la plaque de base (F) avec l'écrou

(H). Les rainures de la plaque de base maintiennent

l'écrou en position pendant que vous serrez la poignée.

2. Enlevez les ressorts (K) des deux glissières (A). Faites

coulisser les glissières dans le guide transversal/ensemble

de mandrin (B). Remontez les ressorts sur les glissières.

3. Enfilez la vis à ailettes (C) dans le guide

transversal/ensemble de mandrin.

4. Faites coulisser la butée de profondeur (D) sur la glissière,

sous la vis à ailettes de la barre transversale/ensemble

de mandrin. Montez la vis à ailettes sur la butée de

profondeur en la dirigeant vers l'extérieur.

5. Installez les porte-glissière (E) sur les glissières. Faire

tourner les porte-glissière de sorte que les repères soient

dirigés vers l'extérieur.

6. Montez une vis à 6 pans (J) dans chaque support (I).

Installez les glissières sur la plaque de base, en faisant

passer les languettes des porte-glissière à travers les

fentes pratiquées dans la plaque de base. Maintenez les

glissières verticalement et installez les supports. Tournez

les bouchons (L) situés au sommet des glissières dans

le sens des aiguilles pour serrer les vis.

Introducción

El taladrado y avellanado de agujeros con precisión es una

pericia que normalmente lleva años en adquirirse. Pero el

éxito de muchos proyectos depende de taladrar agujeros

rectos y con precisión.

Esta Guía de Taladrar Wolfcraft, utilizada junto con el taladro

eléctrico, permite efectuar con facilidad muchas operaciones

de precisión, incluyendo el taladrado recto y en ángulo,

taladrado de cantos y piezas redondas, avellanado y lijado de

cantos. Le ofrece un mejor control para unos mejores resultados finales.

Puede usar la Guía de Taladrar Wolfcraft en cualquier parte

en que requiera usar un taladro—incluso en hormigón y

piedra utilizando la broca correcta.

Armado de la Guía de Taladrar

(Véase la Figura 1)

Antes de armar y manejar este producto,

debe leer y comprender todas las instrucciones que vienen con la Guía de Taladrar

y las que aparecen en el manual del usuario del taladro.

1. Sujete la manilla (G) a la placa base (F) con la tuerca (H).

Las estrías en la placa base mantendrán la tuerca en

posición al apretar la manilla.

2. Retire los resortes (K) de las dos barras guía (A). Inserte

las barras guía en el conjunto de barra transversal/mandril

(B). Vuelva a colocar los resortes en las barras guía.

3. Enrosque el tornillo de apriete manual (C) en el conjunto

de barra transversal/mandril.

4. Deslice el tope de profundidad (D) sobre la barra guía bajo

el tornillo de apriete manual en el conjunto de barra transversal/mandril. Coloque el tornillo de apriete manual en el

tope de profundidad, mirando hacia fuera.

5. Coloque los portabarras (E) en las barras guía. Gire los

portabarras para dejar las marcas de referencia hacia

fuera.

6. Inserte un tornillo de cabeza hexagonal (J) en cada soporte

(I). Coloque las barras guía sobre la placa base, pasando

las aletas en los portabarras por las ranuras en la placa

base. Mantenga las barras guía en posición vertical e

instale los soportes. Gire a derechas las capuchas (L) en la

parte superior de las barras guía para apretar los tornillos.

ADVERTENCIA

AVERTISSEMENT

Déballage et vérification du contenu

Sortez toutes les pièces du matériel d'emballage et vérifiez

qu'elles correspondent à l'illustration et à la "Liste des

pièces". Assurez-vous que toutes les pièces sont bien là

avant de jeter le matériel d'emballage.

Desembalaje y comprobación del contenido

Separe todas las piezas de los materiales de embalaje y

contrástelas con ilustración y con la "Lista de Piezas".

Cerciórese de que identifica todas las piezas antes de

desechar los materiales de embalaje.

Figure 1 Figura 1

LISTE DES PIÈCES

REPÈRE DESCRIPTION QTÉ

A Glissière/Ensemble ressort 2

B Guide transversal/Ensemble mandrin 1

C Vis à ailettes 1

D Butée de profondeur 1

E Porte-glissière 2

F Plaque de base 1

G Poignée 1

H Ecrou 1

I Supports 2

J Vis 6 pans 2

K Ressorts 2

L Bouchons 2

M Clavette de mandrin 1

TABLA DE PIEZAS

REF. DESCRIPCIÓN CANTIDAD

A Conjunto de barra guía/resorte 2

B Conjunto barra transversal/mandril 1

C Tornillo de apriete manual 1

D Tope de profundidad 1

E Portabarra 2

F Placa base 1

G Manilla 1

H Tuerca 1

I Soportes 2

J Tornillo cabeza hexagonal 2

K Resortes 2

L Capuchas 2

M Llave del mandril 1

Introduction

Le perçage et le fraisage de précision sont des techniques

que l'on acquiert généralement après plusieurs années de

travail. Pourtant, la réussite de nombreux projets dépend du

perçage de trous droits et précis.

L'utilisation du guide de perceuse wolfcraft avec une

perceuse électrique permet d'effectuer facilement de nombreuses opérations de précision, y compris le perçage droit et

incliné, le perçage de bordures et de barres rondes, le

L

A

C

K

D

E

F

I

J

H

L

A

B

M

K

E

G

I

J

FIG 1

Page 10

10

Fixation et dépose de la perceuse

Avant l'utilisation, fixez la perceuse à l'axe à l'aide d'une clavette

de mandrin (voir Figure 2.) Lorsque le travail de perçage est

terminé, démontez la perceuse du guide de perceuse.

Cómo acoplar y desacoplar el taladro

Antes de efectuar el trabajo, acople el taladro al eje utilizando la

llave del mandril (véase la Figura 2). Después de terminar el

trabajo de taladrado, desacople el taladro de la guía de taladrar.

Figure 2 Figura 2

Mode d'emploi

N'utilisez pas le guide de perceuse comme une défonceuse. La

plaque de base doit être fixée lorsque l'on perce des barres rondes et des trous.

Réglage de la profondeur du trou

La butée de profondeur permet de régler la profondeur de

perçage avec une précision répétée. Lorsque vous utilisez le

guide de perçage avec la butée de profondeur, vous devez

enlever les ressorts des deux glissières.

1. Placez le guide de perceuse au bord de l'établi.

2. Enfoncez la perceuse jusqu'à la profondeur de perçage

désirée (voir Figure 3.) Serrez la vis à ailettes de la

glissière/ensemble de mandrin.

3. Faites coulissez la butée de profondeur jusqu'à la barre

transversale/ensemble de mandrin. Serrez la vis à ailettes

de la butée d'arrêt. Desserrez la vis à ailettes du guide

transversal/ensemble de mandrin. Vous êtes prêt à percer.

Instrucciones para el manejo

No utilice la Guía de Taladrar como una ranuradora. Sujete

bien la placa base al taladrar piezas redondas y agujeros.

Ajuste de profundidad del agujero

El tope de profundidad controla la profundidad con precisión

repetida. Al manejar la Guía de Taladrar usando el tope de profundidad, retire los resortes de las dos barras guía.

1. Coloque la Guía de Taladrar en el borde del banco de trabajo.

2. Presione hacia abajo el taladro hasta llegar a la profundidad

requerida del agujero (véase la Figura 3). Apriete el tornillo

de apriete manual en el conjunto de barra transversal/mandril.

3. Deslice el tope de profundidad contra el conjunto de barra

transversal/mandril. Apriete el tornillo de apriete manual del

tope de profundidad. Afloje el tornillo de apriete manual en

el conjunto de barra transversal/mandril. Estará ahora listo

para taladrar.

Figure 3

Figura 3

Figure 4

Figura 4

Perçage à 90°

Pour percer un trou droit, à un angle de 90° par rapport à la

pièce, desserrez les deux glissières (voir figures 4 et 5) et

tournez-les pour aligner le repère des deux porte-glissières

avec les repères 0 de la plaque de base. Serrez les glissières

en position. Installez le guide de perçage au niveau de la pièce

à usiner avant le perçage.

Taladrado a 90°

Para taladrar un agujero recto hacia abajo, a 90° con la pieza,

afloje las dos barras guía (véase las Figuras 4 y 5) y gírelas

para alinear la marca de referencia en los dos portabarras con

las marcas de ‘0’ en la placa base. Apriete las barras guía en

posición. Coloque la Guía de Taladrar a paño con la pieza

antes de taladrar.

Fraisage

Montez la mèche de fraisage dans le mandrin. Réglez la butée

de profondeur à la profondeur de fraisage désirée.

Avellanado

Coloque una broca de avellanar en el mandril. Ajuste el tope de

profundidad a la profundidad deseada de avellanado.

CLAVETTE DE MANDRIN

LLAVE DEL MANDRIL

Page 11

11

Perçage d'angle

Desserrez les chapeaux des deux glissières (voir Figure 5)

et tournez les glissières pour aligner le repère des deux

porte-barres à l'angle désiré (voir Figure 6) avec les repères

de la plaque de base. Serrez les bouchons et percez le trou

avec le guide de perceuse au niveau de la pièce à usiner

(voir Figure 7.)

Taladrado en ángulo

Afloje las capuchas en las dos barras guía (véase la Figura

5) y gire las barras guía para alinear la marca de referencia

en ambos portabarras al ángulo deseado (véase la Figura 6)

con las marcas de referencia en la placa base. Apriete las

capuchas y taladre el agujero manteniendo la Guía de

Taladrar a paño con la pieza (véase la Figura 7).

Figure 5

Figura 5

Perçage de bordure

Placez le guide de perceuse sur le bord de la pièce à percer

(voir Figure 8.). Faire tourner la plaque de base dans le

sens des aiguilles d'une montre jusqu'à ce que les côtés de

la pièce à usiner entrent en contact avec la plaque de base

(voir Figure 9.) La perceuse est maintenant centrée sur

le bord.

Taladrado de cantos

Coloque la Guía de Taladrar a paño con el canto de la pieza

que desea taladrar (véase la Figura 8). Gire la placa base a

derechas hasta dejar los costados de la pieza en contacto

con la placa base (véase la Figura 9). El taladro estará

ahora centrado en el canto.

Perçage de barres rondes

Des cales en V sont fournies pour maintenir les barres

rondes pour un perçage à 90°. (voir Figure 10.)

Figure 6

Figura 6

Taladrado de piezas redondas

Se proveen bloques en ‘V’ que permiten sujetar las piezas

redondas para taladrar a 90° (véase la Figura 10).

Montage sur établi uniquement pour le

ponçage de bordures

1. Utilisez une scie à trépan pour découper un trou ne

dépassant pas 2 1/4" dans la table de l'établi.

2. Centrez la base du guide de perceuse autour du trou,

sous l'établi. Poussez pour faire sortir les pièces de la

butée en caoutchouc. Fixez la base sur l'établi en

montant quatre vis à tête plate 1/4" dans les trous

pratiqués dans la base (vis non fournies). (voir Figure 11.)

3. Pour bloquer la mèche en position, régler la mèche

au-dessus de la surface de l'établi dans la position

désirée. Serrez la vis à ailettes dans le guide transversal/ensemble de mandrin.

NOTE: Avec ce type de montage, il est recommandé de

fixer un guide pour matériaux ou une règle droite à

la table de l'établi.

Montaje al banco de trabajo (sólo para

lijado de cantos)

1. Utilice una sierra de agujeros para cortar un agujero

que no exceda de 2 1/4" (57 mm) en la parte superior

del banco de trabajo.]

2. Centre la base de la Guía de Taladrar, respecto al

agujero, en la parte inferior del banco de trabajo.

Extraiga los tacos de goma. Sujete la base al banco de

trabajo con cuatro tornillos de cabeza plana de 1/4"

insertados en los agujeros provistos en la base (no se

incluyen los tornillos). (Véase la Figura 11).

3. Para mantener la broca en posición, ajuste la broca

sobre la superficie del banco de trabajo a la posición

deseada y apriete el tornillo de apriete manual en el

conjunto de barra transversal/mandril.

NOTA: Con este tipo de montaje se recomienda usar una

regla o una guía de material sujeta a la parte

superior del banco de trabajo.

Ponçage de bordures

Pour le ponçage de bordures, le guide de perceuse peut être

soit tenu à la main soit monté sous l'établi. (voir Figure 12.)

Lijado de cantos

Para lijar cantos, la Guía de Taladrar puede sostenerse con

la mano o montarse bajo el banco de trabajo (véase la

Figura 12).

Figure 7

Figura 7

Figure 8

Figura 8

Figure 9

Figura 9

Figure 11

Figura 11

Figure 12

Figura 12

Figure 10

Figura 10

0˚ - 45˚

0˚ - 45˚

FIG 5

A

A

A

A

A

FIG 8

Page 12

Pièces de rechange

Repuestos

FIG 13

1

10

11

11

3

4

3

8

9

13

14

13

5

5

2

6

20

12

17

16

17

18

18

21

21

15

7

19

21

Figure 13

Figura 13

REF. Nº PIEZA DESCRIPCIÓN CANTIDAD

1 116600036 Capucha de vástago 2

2 117220130 Eje 1

3 116700029 Anillo retención 2

4 116710120 Arandela 1

5 117110002 Buje liso 2

6 116710067 Tornillo manual M6 x 16 1

7 116410022 Barra transversal 1

8 015100033 Mandril 1

9 116800011 Tornillo cabeza embutida 1

10 117200008 Barra guía 2

11 117610002 Resorte 2

12 116600085 Tope de profundidad 1

13 116600034 Portabarra 2

14 116430120 Placa base 1

15 116610051 Manilla 1

16 116700023 Tuerca hexagonal 1

17 116600033 Soporte 2

18 116700055 Tornillo cabeza hexagonal 2

19 015100034 Llave del mandril 1

20 116620052 Tornillo manual M6 x 10 1

21 117720017 Tope de goma 4

REPERE

N° N° PIECE DESCRIPTION QTE

1 116600036 Bouchon à tige 2

2 117220130 Axe 1

3 116700029 Bague de retenue 2

4 116710120 Rondelle 1

5 117110002 Douille à manchon 2

6 116710067 Vis à ailettes M6 x 16 1

7 116410022 Guide transversal 1

8 015100033 Mandrin 1

9 116800011 Vis à tête noyée 1

10 117200008 Glissière 2

11 117610002 Ressort 2

12 116600085 Butée de profondeur 1

13 116600034 Porte-glissière 2

14 116430120 Plaque de base 1

15 116610051 Poignée 1

16 116700023 Ecrou 6 pans 1

17 116600033 Support 2

18 116700055 Vis 6 pans 2

19 015100034 Clavette de mandrin 1

20 116620052 Vis à ailettes M6 x 10 1

21 117720017 Butée en caoutchouc 4

OWNER’S

MANUAL

MODEL NO.

4525

GUIDE DE

L’UTILISATEUR

MODÉLE N°

4525

MANUAL DEL

USUARIO

N° DE MODELO

4525

116, 310, 114/05, 01 wolfcraft Inc., Itasca, IL 60143 U.S.A.

®

wolfcraft

Loading...

Loading...