Page 1

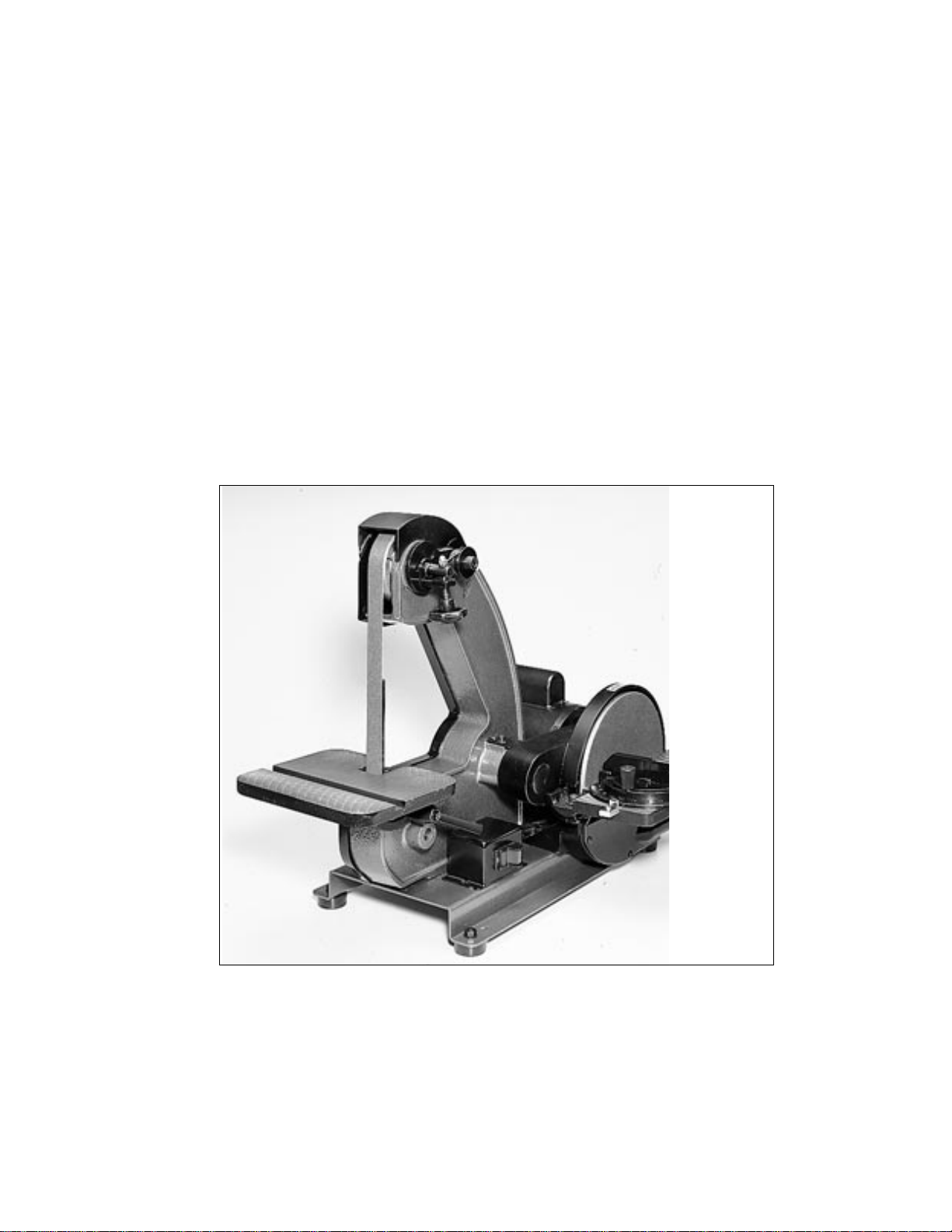

Operating Instructions — Parts Manual

1-Inch Belt / 8-Inch Disc Sander

Model 4002

Part No. 9078321

Revision A1

Page 2

Table of Contents

Cover.................................................................................................................................... 1

General specifications ..........................................................................................................3

Machine general safety warning ........................................................................................... 4

Safe operation precautions................................................................................................... 5

Setting up the sander............................................................................................................ 6

Operating instructions ........................................................................................................... 9

Adjustments ........................................................................................................................ 10

Typical operations............................................................................................................... 13

Replacement parts ............................................................................................................. 15

Belt Sander Parts - Exploded View ................................................................................. 16

Belt Sander Parts - Parts List.......................................................................................... 17

Disc Sander Parts - Exploded View................................................................................. 18

Disc Sander Parts - Parts List......................................................................................... 19

2

Page 3

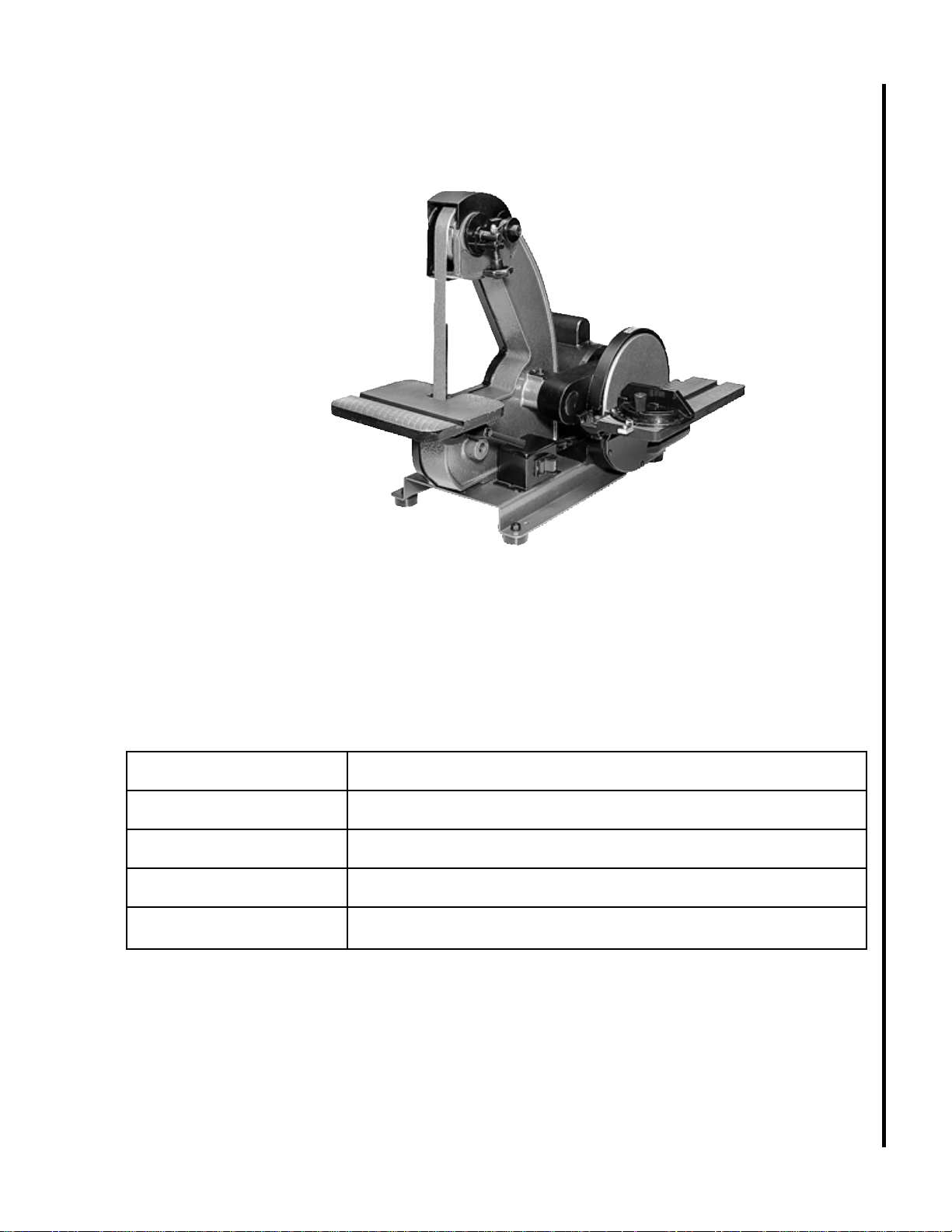

General Specifications

The Wilton Model 4002 sander is designed to serve the varying sanding needs of the professional or the

home hobbyist. The sander features both a belt and a disc sanding surface.

Specifications

Belt 1-inch wide x 42-inches long

Disc 8-inches diameter

Motor 1/3 horsepower, 1725 rpm

Power requirements 1 15 volts

Dimensions: Sander (LWH) 25.50 x 15.50 x 19.50 inches

3

Page 4

WARNING

- Misuse of this machine can cause serious injury .

- For safety, machine must be set up, used and

serviced properly .

- Read, understand and follow instructions in the

Operating Instructions and Parts Manual which

was shipped with your machine.

When setting up machine:

- Always avoid using machine in damp or poorly

lighted work areas.

- Always be sure the machine support is securely

anchored to the floor or the work bench.

When using machine:

- Always wear safety glasses with side shields (See

ANSI Z87.1)

- Never wear loose clothing or jewelry .

- Never overreach - you may slip and fall.

When servicing machine:

- Always disconnect the machine from its electrical

supply while servicing.

- Always follow instructions in Operating Instructions

and Parts Manual when changing accessory tools

or parts.

- Never modify the machine without consulting

Wilton Corporation.

You—the stationary power tool user—

hold the key to safety.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly ,

Wilton’s machinery is among the best in design and

safety . However , any machine used improperly can

be rendered inefficient and unsafe. It is absolutely

mandatory that those who use our products be

properly trained in how to use them correctly . They

should read and understand the Operating Instructions and Parts Manual as well as all labels affixed to

the machine. Failure in following all of these warnings can cause serious injuries.

Machinery general safety warnings

4

1. Always wear protective eye wear when operating

machinery . Eye wear shall be impact resist ant,

protective safety glasses with side shields which

comply with ANSI Z87.1 specifications. Use of

eye wear which does not comply with ANSI Z87.1

specifications could result in severe injury from

breakage of eye protection.

2. Wear proper apparel. No loose clothing or

jewelry which can get caught in moving parts.

Rubber soled footwear is recommended for best

footing.

3. Do not overreach. Failure to maintain proper

working position can cause you to fall into the

machine or cause your clothing to get caught

pulling you into the machine.

4. Keep guards in place and in proper working

order. Do not operate the machine with guards

removed.

5. Avoid dangerous working environments. Do not

use stationary machine tools in wet or damp

locations. Keep work areas clean and well lit.

6. Avoid accidental starts by being sure the start

switch is “OFF” before plugging in the machine.

7. Never leave the machine running while unattended. Machine shall be shut off whenever it is

not in operation.

8. Disconnect electrical power before servicing.

Whenever changing accessories or general

maintenance is done on the machine, electrical

power to the machine must be disconnected

before work is done.

9. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the

changing of accessories. No attempt shall be

made to modify or have makeshift repairs done to

the machine. This not only voids the warranty but

also renders the machine unsafe.

10. Machinery must be anchored to the floor.

1 1. Secure work. Use clamps or a vise to hold work,

when practical. It is safer than using your hands

and it frees both hands to operate the machine.

12. Never brush away chips while the machine is in

operation.

13. Keep work area clean. Cluttered areas invite

accidents.

14. Remove adjusting keys and wrenches before

turning machine on.

15. Use the right tool. Don’t force a tool or attachment to do a job it was not designed for.

16. Use only recommended accessories and follow

manufacturers instructions pertaining to them.

17. Keep hands in sight and clear of all moving parts

and cutting surfaces.

Page 5

18. All visitors should be kept at a safe distance from

the work area. Make workshop completely safe

by using padlocks, master switches, or by

General electrical cautions

removing starter keys.

19. Know the tool you are using its application,

limitations, and potential hazards.

This sander should be grounded in accordance

with the National Electrical Code and local codes

and ordinances. This work should be done by a

qualified electrician. The sander should be

grounded to protect the user from electrical shock.

WARNING: Do not connect the sander to a

240 volt power source. The sander motor requires

120 volts alternating current.

AWG (American wire gauge) number

Conductor length 240 volt lines 120 volt lines

0-50 feet NOT APPLICABLE No. 14

50-100 feet NOT APPLICABLE No. 12

Over 100 feet NOT APPLICABLE No.8

Wire sizes

Caution: For circuits which are far away from the

electrical service box, the wire size must be increased in order to deliver ample voltage to the motor.

T o minimize power losses and to prevent motor

overheating and burnout, the use of wire sizes for

branch circuits or electrical extension cords according to the following table is recommended.

Safety instructions for the 1-Inch belt / 8-Inch disc sander

WARNING: Do not operate your machine until it is

completely assembled and installed according to the

instructions.

WARNING: The dust generated by cert ain woods

and wood products can be injurious to your health.

Always operate machinery in well ventilated areas and

provide for proper dust removal. Use wood dust

collection systems whenever possible.

WARNING: This machine can be use for processing wood or metal products. However , combining

wood dust and metal filings can create a fire hazard.

Make sure that the dust collector is free of wood dust

deposits before processing metal products.

1. If you are not thoroughly familiar with the opera-

tion of belt and disc sanders, obtain advice from

your supervisor, instructor or other qualified

person.

2. If there is a tendency for the machine to tip over

or move during operation such as when sanding

long or heavy boards, the machine must be

securely fastened to a supporting surface.

3. Make sure the sanding belt is running in the

proper direction. The sanding belt must travel

downward when viewed from the front of the

machine.

4. Make sure the sanding belt is tracking correctly

in order that it does not run off the pulleys.

5. Make sure the sanding belt or disc is not torn or

loose.

6. Hold the work firmly when sanding.

7. Always hold the work firmly on the table when

sanding on the belt or disc. The only exception is

curved work performed on the top wheel of the

belt.

8. Always sand on the downward side of the disc

when using the disc portion of the machine, so

that the work is held securely on the table.

Sanding on the upward side of the disc could

cause the workpiece to fly up which could be

hazardous.

9. Always maintain a minimum clearance of 1/16inch or less between the table and the sanding

belt or disc.

10. Never wear gloves or hold the work with a rag

when sanding.

1 1. Sand with the grain of the wood.

12. Do not sand pieces of material that are too small

to be safely supported.

13. Avoid awkward hand positions where a sudden

slip could cause a hand to move into the sanding

belt or disc.

14. When sanding a large workpiece, provide

additional support at table height.

15. Never force the work. Slowing or stalling the

motor will cause overheating.

16. When sanding metal, never use a steady stream

of water on the work piece. Dip the workpiece in

water to cool it.

5

Page 6

17. Do not sand or polish magnesium. It could catch

fire.

18. Always remove scrap pieces and other objects

from the belt and disc tables before turning the

machine ON.

19. Never perform layout, assembly or set-up work

on the tables while the sander is operating.

20. Always turn the machine OFF and disconnect the

cord from the power source before installing or

removing accessories.

21. Never leave the machine work area when the

power is ON or before the machine has come to

a complete stop.

Setting up the sander

WARNING: For your own safety, do not connect the sander to the

power source until the machine is completely assembled and you

have read and understood the entire Operating Instructions and Parts

Manual.

Unpacking

The sander is shipped complete in one carton. Carefully unpack the

machine and all loose items from the carton. If any parts are missing,

do not attempt to operate your sander until the missing parts are

obtained and installed correctly .

Cleaning

6

Remove the protective coating from the surfaces of the sander and

from any loose parts. This coating may be removed with a soft cloth

moistened with kerosene (do not use acetone, gasoline or lacquer

thinner for this purpose). After cleaning, cover the table surfaces with

a good quality paste wax.

Assembly

Assembly of the sander is limited to the installation of the disc table

and the belt table. Proceed as described in the following paragraphs.

Assembling sanding disc table

WARNING: When assembling the sanding disc table, make certain

the motor is disconnected from the power source.

1. The sanding disc table is secured with two cap screws and nuts.

A hex wrench is required to tighten the screws.

2. Set the table on the rounded pockets in the support casting.

Install the nuts in the channel on the back side of the pockets.

3. Install the screws through the table and base casting into the nuts.

Tighten the screws.

4. Check for 1/16-inch clearance between the edge of the table and

the face of the disc. Adjust the clearance if required

Removal/Installation of the Disc)

.

Installing belt sander table

WARNING: When assembling the belt sander table, make cert ain the

motor is disconnected from the power source.

1. The belt table is secured with a spring-loaded locking handle

assembly . The handle assembly is disassembled for ease of

installation.

(see

Figure 1. Installing the disc sander

table

Figure 2. Securing the disc sander

table

Page 7

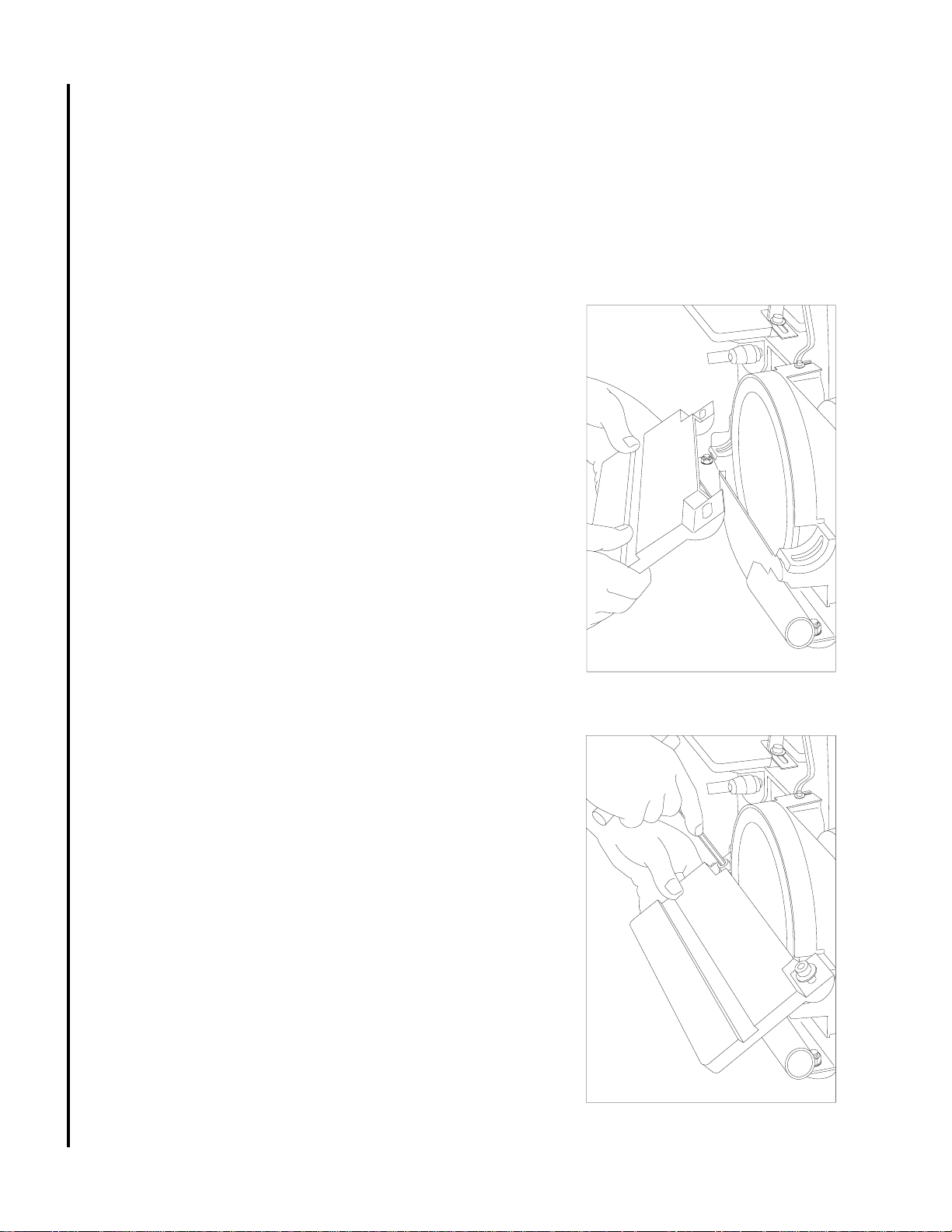

2. Remove the screw and spring from the handle assembly . Separate

the handle and stud.

3. Set the table in place against the sander.

4. Put the flat washer provided in the sander carton on the stud.

5. Install the stud through the belt table bracket and into the sander

housing. Tighten the stud finger tight.

6. Install the handle over the stud. Install the spring and screw into the

stud.

7. T o tighten the handle (and secure the table), pull out on the handle.

While holding the handle out, turn the handle counterclockwise.

Release the handle and tighten in a clockwise direction. Repeat as

required to secure the table.

Figure 3. Installing stud in table

bracket

Setup

Fastening sander to supporting surface

During operation the sander may have a tendency to slide or move about on the bench or table. It is recommended that the sander be fastened to the bench or table. T wo holes are supplied in the sander base plate for

easy mounting.

Dust chutes

The sander has two 1-1/4 inch diameter dust chutes (see Figure 5). The disc sander chute is at the rear of the

sander under the disc sander table. The belt sander chute is in the cover on the left side of the sander. The

chutes can be connected to a vacuum system to collect dust particles during use.

Figure 4. Belt table installed and handle in place Figure 5. Dust chutes

7

Page 8

Connecting sander to power source

The motor supplied with your sander is wired for operation at 1 15 V olts. IT MUST NEVER BE CONVERTED TO

OPERA TE A T 230 VOL TS !

Before connecting the motor cord to the power source, make certain the switch is in the OFF position and

be sure that the electric current is of the same characteristics as stamped on the motor nameplate.

Grounding instructions

WARNING: The sander must be grounded while in

use to protect the operator from electric shock. Make

sure that the receptacle is properly grounded. If you

are not sure the receptacle is grounded, have a

certified electrician check for proper grounding

• In the event of a malfunction or breakdown,

grounding provides a path of least resistance

for electric current to reduce the risk of

electric shock. This tool is equipped with an

electric cord having an equipment-grounding

conductor and a grounding plug. The plug

must be plugged into a matching outlet that is

properly installed and grounded in accordance

with all local codes and ordinances.

• Do not modify the plug provided—if it will not

fit have a new outlet installed by a qualified

electrician.

• Improper connection of the equipmentgrounding conductor can result in risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipment ground-

ing conductor. If repair or replacement of the

electric cord or plug is necessary do not

connect the equipment grounding conductor to

a live terminal.

• Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded. Use

only 3-wire extension cords that have 3-prong

grounding type plugs and 3-hole receptacles

that accept the plug, as shown in Figure 6.

• Repair or replace damaged or worn cord

immediately .

• This tool is intended for use on a circuit that

has an outlet and a plug that looks like the one

shown in Figure 6.

• A temporary adapter , which looks like the

adapter illustrated in Figure 7, may be used to

connect this plug to a 2-pole receptacle, as

shown in Figure 7, if a properly grounded

outlet is not available.

8

Figure 6. Grounded plug in grounded receptacle Figure 7. Grounded adapter connection

Page 9

Operating instructions

Starting and stopping sander

The on/off switch (see Figure 8) is mounted in a switch box on the right

side of the sander base. Move the switch to the forward (ON) position to

start the sander. Move the switch to the rear (OFF) position to stop the

sander.

Locking switch in the OFF position

We recommend that the switch be locked in the OFF position when the

sander is not in use. The switch can be locked by pulling the switch

locking tab out of the switch toggle (see Figure 9). The switch will not

operate with the locking tab removed. If the switch toggle is removed

when the sander is running, it can be turned OFF once, but it cannot be

restarted without inserting the switch tab.

Tracking the sanding belt

The belt tracking adjustment is set at the factory so the belt runs true on

the pulleys. However, if the belt tracks to one side of the pulleys, tracking

can be adjusted by turning the tracking knob . Turning the knob clockwise

moves the belt to the right when facing the sander. T urning the knob

counterclockwise will move the belt to the left. A VOID TURNING THE

KNOB TOO F AR. THE AMOUNT OF ADJUSTMENT REQUIRED IS

USUALL Y VERY SLIGHT !

Figure 8. ON/OFF switch

Platen

WARNING: When making adjustments, make sure the motor is disconnected from the power source.

The platen (see Figure 11) is used to properly support the work when

sanding. The platen is constructed of heavy steel to provide adequate

support.

The platen should be adjusted so it is almost touching the back of the

sanding belt. Loosen the cap screw and adjust the platen to the desired

position. Tighten the screw to secure the platen.

The platen can be removed for operations such as stripping, contour

sanding, polishing or other special operations. To remove the platen,

remove the cap screw. Be sure to reinstall the platen before performing

operations where support of the belt is required.

Figure 9. Switch locking tab

9

Figure 10. Adjusting belt tracking Figure 11. Platen

Page 10

Belt table adjustments

The belt sander table can be tilted or moved in or out to accommodate the operation being performed. Loosen

the locking handle to change the position of the table. Move the table to the desired position and tighten the

locking handle.

NOTE: The lock handle is spring loaded. Reposition the handle by pulling out on the handle and turning the

handle on the serrated locking stud. Release the handle and turn the locking handle to tighten or loosen the

table.

WARNING: T o avoid trapping the work or fingers between the t able and sanding belt, the table edge should

be positioned a maximum of 1/16-inch from the sanding belt.

Setting the belt table 90-degree stop

WARNING: When making adjustments, make sure the motor is disconnected from the power source.

For most sanding operations the table is set at a 90-degree angle to the sanding belt. A positive stop is

provided to insure fast positioning of the table at 90 degrees to the belt. Loosen the table locking handle (see

Figure 12) and tilt the table to the rear as far as possible.

Use a combination square. Put one end of the square on the table with the other end against the sanding

belt. Check to see if the table is 90 degrees to the belt. If the table is not at 90 degrees to the belt, turn adjusting screw with a hex wrench. T urn the adjusting screw until the screw bottoms out against the frame. Recheck

the angle and readjust if required.

Setting the belt table at a 45-degree angle

WARNING: When making adjustments, make sure the motor is disconnected from the power source.

WARNING: T o avoid trapping the work or fingers between the t able and sanding belt, the table edge should

be positioned a maximum of 1/16-inch from the sanding belt when the table is tilted.

The table can be tilted to a 45-degree angle (see Figure 13). To change the angle, loosen the locking

handle. Use a combination square to set the table to 45 degrees to the belt. T ighten the locking lever to secure

the table.

10

Figure 13. Setting belt table to 45-degree angleFigure 12. Setting belt table 90-degree stop

Page 11

Disc table adjustments

Adjusting the table angle

WARNING: When making adjustments, make sure the motor is discon-

nected from the power source.

WARNING: To avoid trapping the work or fingers between the table

and sanding disc, the table edge should be positioned a maximum of 1/16inch from the sanding disc.

The disc table is positioned at 90 degrees to the sanding disc for most

operations (see Figure 14). To check and see if the table is at 90 degrees, place a square, on the table with one end of the square against the

sanding disc. If an adjustment is necessary, loosen the cap screws and

move table until it is at 90 degrees to the sanding disc. Tighten the screws

to secure the table.

The disc table (see Figure 15) can be tilted downward 45 degrees.

Loosen the two cap screws, tilt the table to the desired angle, and tighten

the cap screws.

Adjusting the disc-to-table gap

WARNING: When changing abrasive belts, make sure the motor is

disconnected from the power source.

Adjust the sanding disc to leave a maximum of 1/16-inch gap between

the table and the disc. This can be accomplished by moving the sanding

disc in or out on the motor shaft (see Figure 16).

Use a T-handle type hex wrench. Put the wrench through the hole in

the top of the disc guard. Loosen the setscrew in the hub of the disc.

Move the disc in or out as needed to establish a 1/16-inch gap. When the

gap is established, tighten the setscrew .

Figure 14. Disc table at 90

degrees

Changing abrasive belts

WARNING: When changing abrasive belts, make sure the motor is

disconnected from the power source.

Remove the upper belt cover by removing the screw and nut (see

Figure 17). Remove the two knobs from the side cover. Remove the side

cover.

11

Figure 15. Disc table at 45

degrees

Figure 17. Removal of coversFigure 16. Adjusting disc-to-table gap

Page 12

Changing abrasive belts (continued)

Press down on the tracking knob to release belt tension (see Figure 18).

Remove the belt from the three pulleys. Install the replacement belt.

Replace side cover; secure the cover with two knobs.

IMPORT ANT: Some belt s have a directional arrow printed on the

inside of the belt. In these cases the belt must be installed so the directional arrow is in the same direction that the machine is running. The

sanding belt travels down the front of the machine.

Before installing the upper belt cover , start the sander and check belt

tracking. Adjust tracking if needed (refer to Tracking the Sanding Belt).

Changing abrasive discs

WARNING: When removing and installing abrasive discs, make cert ain

the motor is disconnected from the power source.

Remove the screws and nuts from the sanding disc table. Remove the

disc table.

Remove the lower disc guard (see Figure 19).

Loosen the setscrew in the hub of the disc. Remove the disc from

the motor shaft (see Figure 20).

Remove the old abrasive disc by peeling it from the sanding disc

plate.

Clean the disc plate thoroughly . Spray the face of the disc with 3M

Super 77 adhesive (or equivalent).

Remove the backing from the new abrasive disc and press the

abrasive disc firmly onto the disc plate (see Figure 21).

Figure 18. Removing the belt

12

Figure 19. Removal of lower disc

guard

Figure 21. Attaching sanding discFigure 20. Removal of sanding disc

Page 13

Changing abrasive discs

(continued)

Align the keyway in the disc hub with the key on the motor shaft

(see Figure 22). Install the disc plate on the shaft. Position the

disc so the face of the disc is even with the edge of the upper

disc guard. Tighten the setscrew in the hub of the disc plate.

If necessary, adjust the position of the upper disc guard.

Loosen the screws and adjust the position of the upper disc

guard.

Replace the lower disc guard and the sanding disc table.

Miter gauge

A miter gage (see Figure 23) is supplied with the sander. The

miter gauge can be used on the disc table or the belt table. The

miter gauge can be set anywhere up to 45 degrees right or left.

Adjust the angle by loosening the knob, rotating the miter

gauge to the desired angle and retightening the knob.

Motor Belt

If the motor belt becomes loose, the belt can be tightened by

loosening the motor hold down nuts (see Figure 24). Slide to the

rear of the sander to tighten the belt. Hold the motor in position

and tighten the four motor hold down nuts.

T ypical operations

The following are just some of the many operations that can be

performed with your Wilton Sander:

Sharpening a wood chisel on the sanding belt using a block of

wood. Use the block of wood to support the chisel and provide

clearance for the chisel handle (see Figure 25).

Sand a bevel in the block of wood in order to position the

wood as close as possible to the sanding belt and clamp the wood

to the table, as shown.

A cold chisel can also be sharpened on the belt table with the table tilted.

Figure 22. Installation of the disc

Figure 23. Miter gauge (shown on disc

table)

13

Figure 25. Sharpening a wood chiselFigure 24. Tightening motor belt

Page 14

T ypical operations

(continued)

Sanding aluminum on the disc unit with the table tilted and using the

miter gauge as a guide (see Figure 26).

NOTE: Always sand on the left (downward) side of the sanding

disc, as shown. Sanding on the right (upward) side of the sanding

disc could cause the workpiece to fly up which could be hazardous.

Sanding outside curves on the belt unit with the platen removed

(see Figure 27).

Polishing using the accessory felt belt in place of the sanding

belt (see Figure 28).

NOTE: Most polishing operations are performed with the platen

removed.

Sanding in tight areas with the sanding belt (see Figure 29).

Figure 26. Sanding aluminum

14

Figure 27. Sanding outside curves Figure 28. Polishing using a felt belt

Figure 29. Sanding in tight areas

Page 15

T ypical operations (continued)

Inside curves can be sanded on the upper sanding belt idler wheel (see

Figure 30). The upper cover can either be hinged back or removed.

Figure 30. Sanding inside curves

Replacement parts

This section provides exploded view illustrations that show the replacement parts for the 1-Inch Belt / 8-Inch

Disc Sander. Also provided are p arts listings that provide part number and description. The item numbers

shown on the illustrations relate to the item number in the facing parts listing.

Order replacement parts from:

Wilton Corporation

300 South Hicks Road

Palatine, IL 60067

708/934-6000

FAX: 708\934-7813 or 1-800-626-9676

Identify the replacement part by the part number shown in the parts listing. Be sure to include the model

number and serial number of your machine when ordering replacement parts to assure that you will receive the

correct part.

15

Page 16

16

Exploded View of Sander (Belt Sander Parts)

Page 17

Item Part

No. Number Description

1 564003-1 Hex. Socket Head Screw (M10 x 40 MM)

2 564004-1 Flat Washer (12 MM)

3 564005-1 Spring

4 564006-1 Spacer

5 564007-1 Tracking Adjustment Screw

6 564008-1 Spring

7 564009-1 Support

8 564015-1 Spring Pin (M3 x 20 MM)

9 564016-1 Idler Shaft

10 564017-1 Idler Shaft

1 1 564018-1 Hex. Soc. Set Screw (M5 x 5 MM)

12 564019-1 Hex. Soc. Set Screw (M5 x 12 MM)

13 564025-1 Drive Pulley

14 564026-1 Retaining Plate

15 564027-1 Slot Hd. Mach. Screw (M4 x 12 MM)

16 564028-1 Lock Washer (4.1 MM)

17 564029-1 Ball Bearing

18 564033-1 Key

19 564034-1 Main Drive Shaft

20 564035-1 Ball Bearing

21 564036-1 Frame

22 564029-1 Ball Bearing

23 564037-1 Idler

24 564038-1 Flat Washer (6.4 MM)

25 564039-1 Upper Cover

26 564043-1 Hex. Socket Head Screw (M6 x 10MM)

27 564044-1 Hex. Socket Head Screw (M10 x 20MM)

28 564045-1 Lock Washer (10 MM)

29 564046-1 Flat Washer (10 MM)

30 564047-1 Platen

31 564048-1 Spacer

32 564029-1 Ball Bearing

33 564037-1 Idler

34 564049-1 Retaining Ring

35 564051-1 Hex. Socket Setscrew (M5 x 16 MM)

36 564052-1 Drive Wheel

37 564010-1 Sanding Belt - 50 Grit

564011-1 Sanding Belt - 80 Grit

564012-1 Sanding Belt - 120 Grit

564013-1 Sanding Belt - 220 Grit

564014-1 Sanding Belt - 320 Grit

564030-1 Abrasive Belt, Non-woven - Fine

564031-1 Abrasive Belt, Non-woven - Medium

564032-1 Abrasive Belt, Non-woven - Coarse

38 564054-1 Nut

39 564055-1 Washer

40 564058-1 Bolt

41 564057-1 Knob

42 564063-1 Washer

43 564059-1 Cover

44 564068-1 Lockwasher

45 564062-1 T able

46 564061-1 Knob

47 564064-1 Clamp Assembly

48 564065-1 Special Washer

49 564066-1 Bracket

50 564067-1 Flat Washer (8,4 MM)

52 564069-1 Screw (M8 x 15 MM)

70 564046-1 Flat Washer (10 MM)

71 564045-1 Lock Washer (10 MM)

72 564044-1 Hex. Socket Head Screw (M10 x 20MM)

103 564056-1 Rotation Label

17

Page 18

18

Exploded View of Sander (Disc Sander Parts)

Page 19

Item Part

No. Number Description

53 5640711 Hex. Socket Head Screw (M5 x 12 MM)

54 5640721 Drive Pulley

55 5640731 Key

56 5640741 Motor

57 5640751 Hex Nut (M10)

59 5640461 Flat Washer (10 MM)

60 5640761 Carriage Head Screw (M10 x 12MM)

61 5640771 Base

62 5640781 Pan Head Screw (M4 x 20 MM)

63 5640791 External Tooth Washer (4 MM)

64 5640811 Hex. Head Screw (M8 x 20 MM)

66 5640671 Flat Washer (8.4 MM)

67 5640821 Rubber Foot

68 5640671 Flat Washer (8.4 MM)

69 5640831 Hex. Nut (M 8)

80 5640841 Allen Wrench (2.5 MM)

81 5628791 Allen Wrench (8 MM)

99 5640201 Sanding Disc - 50 Grit

5640211 Sanding Disc - 80 Grit

5640221 Sanding Disc - 120 Grit

100 5640871 Disc Plate

101 5640181 Soc. Hd. Mach. Screw (M5 x 5 MM)

102 5640881 Screw

103 5640561 Rotation Label

106 5640921 pulley cover - belt/disc

5640922 pulley cover - belt only

107 5640931 V-Belt

- - - 5640941 Miter Gauge Assembly

110 5640961 • Hand Knob (1/4-Inch)

111 5640971 • Flat Washer (3/16-Inch)

112 5640981 • Miter Gauge Body

113 5640991 • Spring Pin (M4 x 10 MM)

114 5641011 • Guide Bar

120 5641021 Table

121 5632851 Cap Screw

122 5641041 Washer

123 5641051 Nut

124 5641241 Cap Screw

125 5640461 Washer

130 5641121 Side Guard

131 5641131 Pan Hd. Screw (M4 x 6 MM)

132 5641141 Support

137 5641161 Switch

138 5641171 Switch Key

139 5641181 Switch Cover

140 5640781 Pan Head Screw (M4 x 12 MM)

141 5641191 Cord

142 5641211 Heyco Bushing (5/8-Inch)

143 5640781 Pan Head Screw (M4 x 12 MM)

144 5641221 Cable Clamp

145 5641231 Connector

19

Page 20

20

Wilton Corporation

300 South Hicks Road

Palatine, IL 60067

708/934-6000

FAX 1-800-626-9676

Industrial Products Group: Wilton Tool Wilton Machinery Anderson Products Anderlex Abrasives

Loading...

Loading...