Page 1

Operating instructions

Betriebsanleitung

Mode d´emploi

Manual de instrucciones

Pressure gauge model PGS with reed contacts

Druckmessgerät Typ PGS mit Reed-Kontakten

Manomètre du type PGS avec contacts Reed

Manómetro modelo PGS con contactos Reed

Example: Pressure gauge model PGS23.100 with 851.33

GB

D

F

E

Page 2

GB

Operating instructions model PGS Page 3-15

D

Betriebsanleitung Typ PGS Seite 17-29

F

Mode d´emploi type PGS Page 31-43

E

Manual de instrucciones modelo PGS Página 45-57

© 2011 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta posterior!

WIKA operating instructions pressure gauge model PGS with reed contacts

2

14000322.01 03/2011 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

Design and function

4.

5. Transport, packaging and storage 9

6. Commissioning, operation 10

7. Contact protection measures 12

8. Maintenance and cleaning 15

9. Dismounting and disposal 15

9

GB

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

3

Page 4

1. General information

1. General information

■

The pressure gauge described in the operating instructions has been

designed and manufactured using state-of-the-art technology.

GB

All components are subject to stringent quality and environmental

criteria during production. Our management systems are certied to

ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the pressure gauge. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the pressure gauge's range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the pressure gauge and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused

by using the product contrary to its intended use, non-compliance

with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the pressure

gauge.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Application consultant: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

WIKA operating instructions pressure gauge model PGS with reed contacts

4

14000322.01 03/2011 GB/D/F/E

Page 5

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation which can

result in serious injury or death if not avoided.

Information

… points out useful tips, recommendations and information

for ecient and trouble-free operation.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure

that the appropriate pressure gauge has been selected in

terms of measuring range, design and specic measuring

conditions.

Check the compatibility with the medium of the materials

subjected to pressure!

In order to guarantee the measuring accuracy and long-

term stability specied, the corresponding load limits must

be observed.

GB

The instruments are no safety accessories as dened by

the pressure equipment directive 97 / 23 / EC.

Non-observance can result in serious injury and/or damage

to the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

5

Page 6

2. Safety

2.1 Intended use

These pressure gauges are used for measuring pressure and for the

switching of switching currents in industrial applications.

GB

The pressure gauge has been designed and built solely for the intended

use described here and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury if qualication is insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have

the qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their

technical training, knowledge of measurement and control technology

and on their experience and knowledge of country-specic regulations,

current standards and directives, are capable of carrying out the work

described and of independently recognising potential hazards.

2.3 Special hazards

WARNING!

When installing, commissioning and operating these instruments, observe the appropriate national safety regulations

(e.g. VDE 0100).

WIKA operating instructions pressure gauge model PGS with reed contacts

6

14000322.01 03/2011 GB/D/F/E

Page 7

2. Safety

WARNING!

Only work on the gauge with the voltage disconnected.

WARNING!

Residual media in dismounted instruments can result in a

risk to persons, the environment and equipment.

Take sucient precautionary measures.

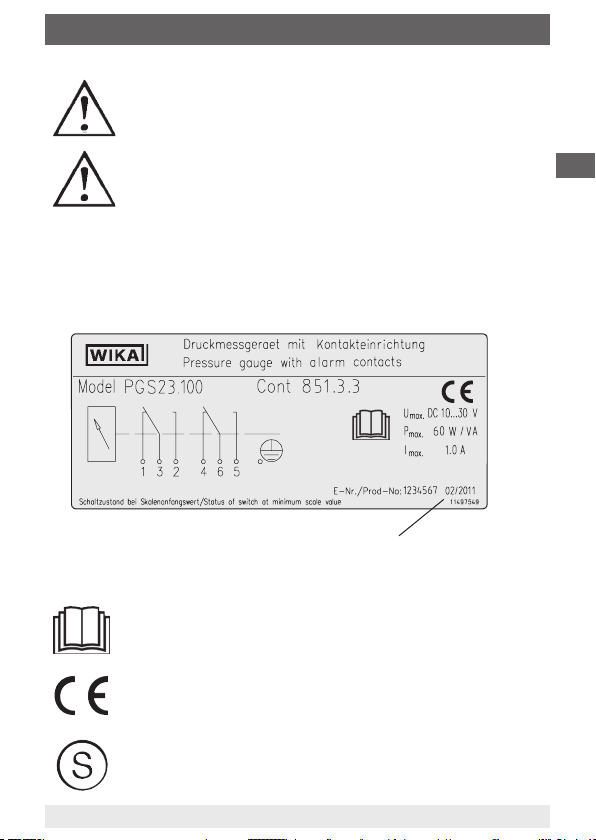

2.4 Labelling / safety marks

Product label

Explanation of symbols

Before mounting and commissioning the pressure gauge,

ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant

European directives.

GB

Date of manufacture

Instruments bearing this mark on the dial are safety

pressure gauges with solid bae wall per EN 837 (S3).

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

7

Page 8

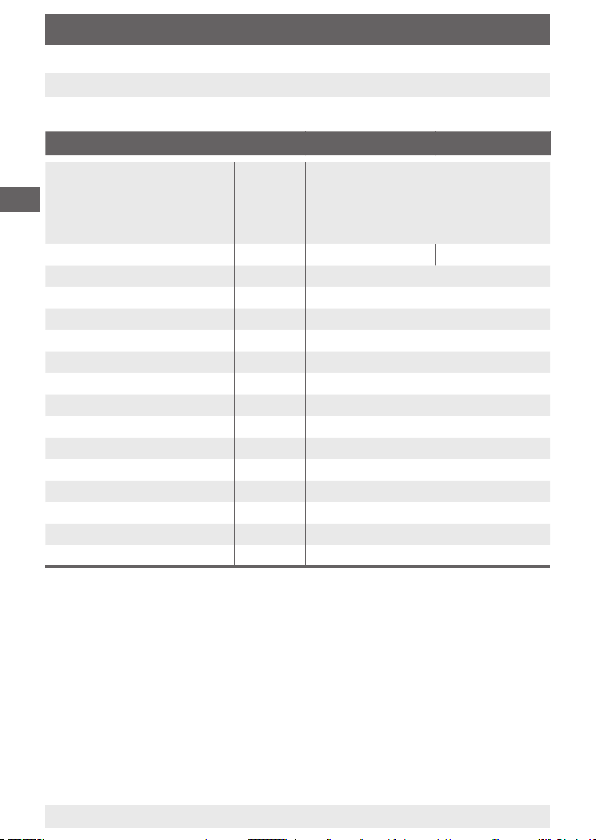

3. Specications

3. Specications

Limits for the contact rating with resistive load

Specications Model 851.3 Model 851.33

GB

Used for instrument type PGS21.1x0, PGS23.1x0, PGS43.1x0,

Contact design

Type of contact bistable

Max. switching voltage AC/DC V 250

Min. switching voltage V not required

Max. switching current AC/DC A 1

Min. switching current mA not required

Max. carry current AC/DC A 2

cos ϕ 1

Contact rating W/ VA 60

Contact resistance (static) mΩ 100

Insulation resistance Ω 10

Breakdown voltage DC V 1000

Switching time incl.

contact chatter

Contact material Rhodium

Switch hysteresis % 3 ... 5

ms 4.5

PGS43HP.1x0, PGS63HP.1x0,

DPGS43.1x0, DPGS43HP.1x0,

APGS43.1x0

1 change-over

contact

9

2 change-over

contacts

The ingress protection to EN 60529 against external inuences depends

on the basic instrument and is found in the respective data sheet.

The limit switches can be used in the range from -20 to +70 °C. Where

the permissible temperatures for the basic instrument (see data sheet)

deviate from this range, the lower values are valid.

For further specications see the corresponding WIKA data sheet and

the order documentation.

WIKA operating instructions pressure gauge model PGS with reed contacts

8

14000322.01 03/2011 GB/D/F/E

Page 9

4. Design and function / 5. Transport, packaging ...

4. Design and function

4.1 Description

The built-in electrical switch contacts (reed contacts) are auxiliary

current switches which open or close (change-over contacts) connected

electric circuits at the set limits via the permanent magnet which is

moved by the instrument pointer. The reed contacts used are bistable

switches, which keep their condition after a signal change up to the next

actuation.

4.2 Scope of delivery

Cross-check the scope of delivery with the delivery note.

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused during transportation.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: In accordance with measuring instrument

GB

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

9

Page 10

6. Commissioning, operation

6. Commissioning, operation

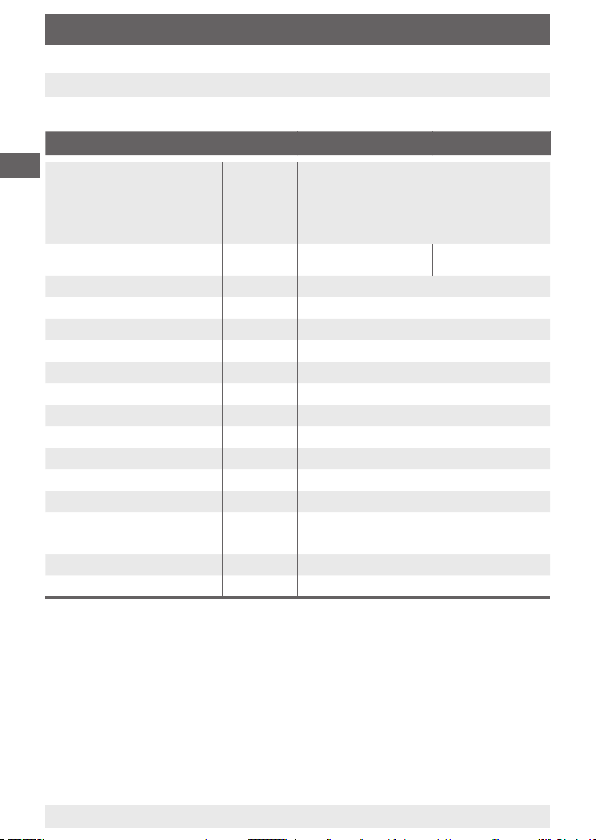

6.1 Mechanical connection

In accordance with the general technical regulations for pressure

GB

gauges (e.g. EN 837-2 "Selection and installation recommendations for

pressure gauges").

When screwing gauges in, the force required for this must not be

applied through the case or the cable terminal box, but rather through

the spanner ats (using a suitable tool) provided for this purpose on the

square shaft of standard connections.

Installation with

open-ended spanner

Correct sealing of pressure gauge connections with parallel threads

must be made using suitable sealing rings, sealing washers or WIKA

prole seals. The sealing of tapered threads (e.g. NPT threads) is made

by providing the thread , with additional sealing material such as, for

example, PTFE tape (EN 837-2).

Spanner ats

Sealing face

Sealing in the

thread

The torque depends on the seal used. Connecting the gauge using

a clamp socket or a union nut is recommended, so that it is easier to

orientate the gauge correctly. When a blow-out device is tted to a

pressure gauge, it must be protected against being blocked by debris

and dirt.

WIKA operating instructions pressure gauge model PGS with reed contacts

10

14000322.01 03/2011 GB/D/F/E

Page 11

6. Commissioning, operation

With safety pressure gauges (see dial symbol k) ensure that the free

space behind the blow-out back is at least 15 mm.

6.2 Special requirements for the installation point

If the line to the measuring instrument is not adequately stable, a measuring

instrument holder should be used for fastening (and possibly via a exible

capillary). If vibrations cannot be avoided by means of suitable instal-

lation, instruments with liquid lling should be used. The instruments

should be protected against coarse dirt and wide uctuations in ambient

temperature.

In rare cases an actuation of the reed switches can occur due to an

impermissibly high shock or vibration. In this case these reed switches

have to be reset after installation of the instrument in the measuring

point by moving the instrument pointer once over the set switch point

(reed switch).

6.3 Electrical connection

The electrical connection must only be made by qualied skilled personnel. Connection details and switching functions are given on the product

label. Connection terminals and earth terminal are appropriately marked.

The mains connection lines to be provided must be dimensioned for

maximum instrument power consumption and comply with IEC 227 or

IEC 245. For power ratings (see "Specifications") and protective circuits

with inductive and capacitive loads see chapter "7. Contact protection

measures".

GB

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

11

Page 12

6. Commissioning, operation / 7. Contact protection ...

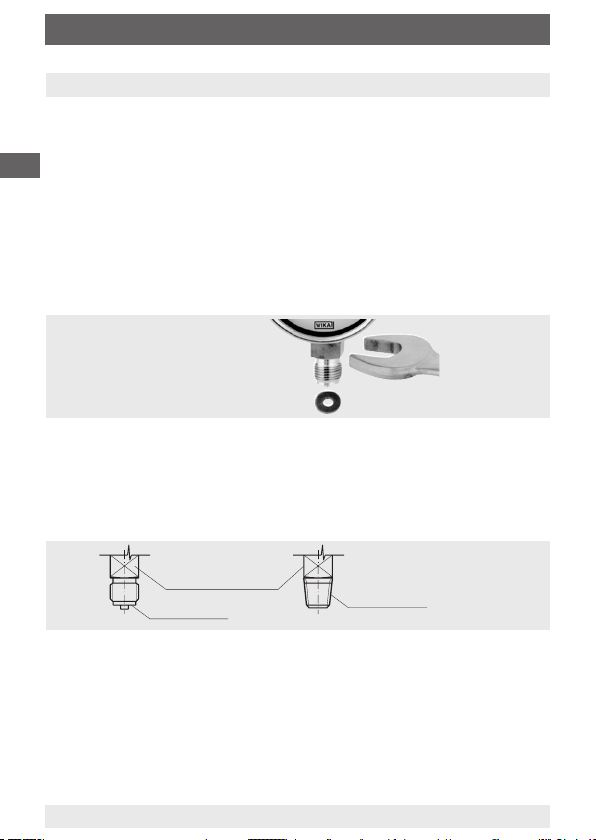

6.4 Adjusting the set pointers

The setting of the set points is achieved using the adjustment lock in the

window with the aid of the adjustment key (part of the scope of delivery;

found in standard instruments on the side of the terminal box).

GB

With nominal size 160 measuring instruments it has to be ensured that

the adjusting arm is pushed down exclusively in the area of the set

pointer to be adjusted. Otherwise damage to the instrument pointer or a

misadjustment of the zero point cannot be excluded.

Set pointer

Adjustment lock

Adjusting arm

Removable

adjustment key

The set pointers of the limit switches are freely adjustable between 10 %

and 90 % of the scale range; the distance between the two set pointers

is approx. 10 % of the scale range (corresponds to approx. 30 ∢°).

Commissioning

During the commissioning process pressure surges must be avoided at

all costs. Open the shut-o valves slowly.

7. Contact protection measures

Mechanical contacts must not exceed the specied electrical values for

switching current and switching voltage independent of each other, not

even for a short time only.

For capacitive or inductive loads we recommend one of the following

protective circuits:

WIKA operating instructions pressure gauge model PGS with reed contacts

12

14000322.01 03/2011 GB/D/F/E

Page 13

7. Contact protection measures

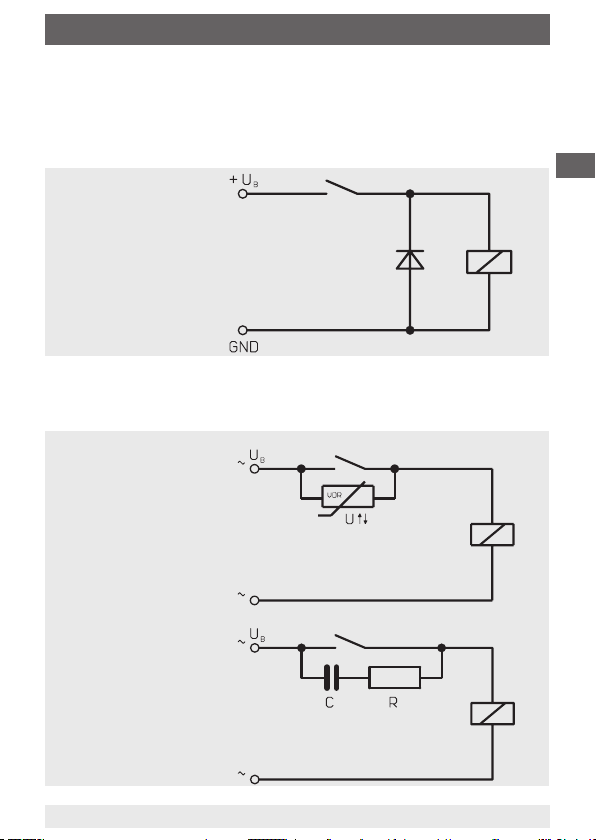

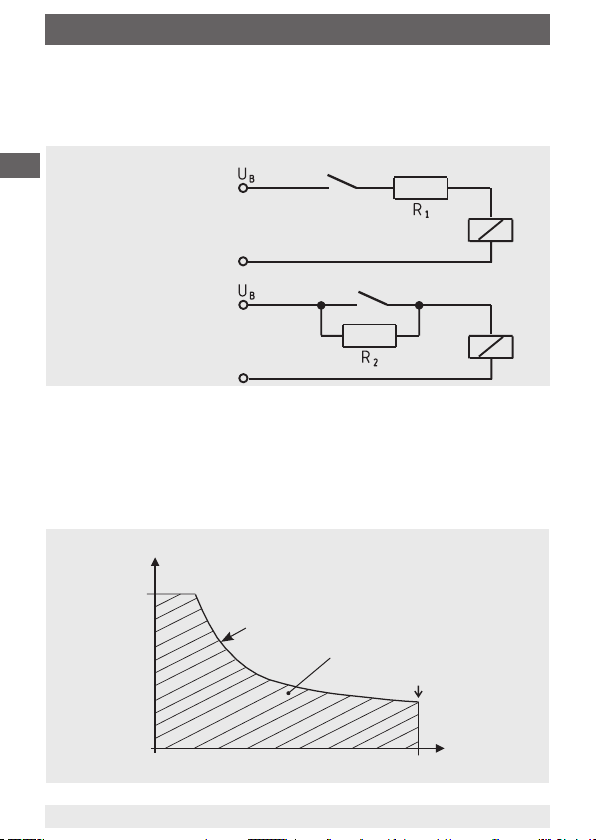

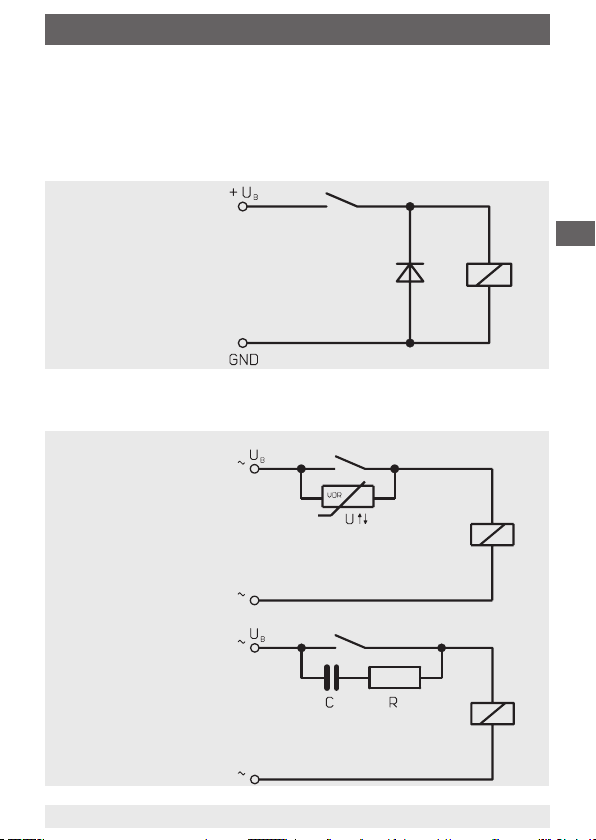

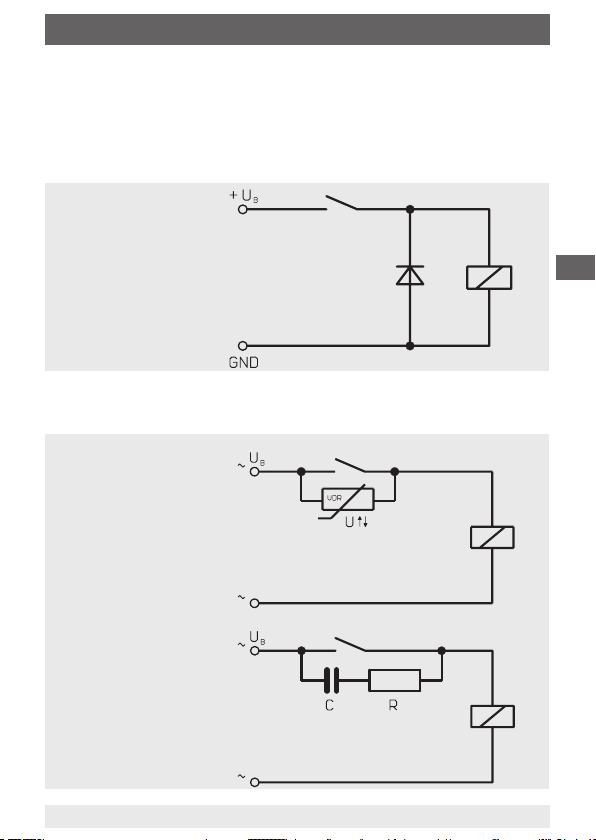

7.1. Inductive load with DC voltage

With DC voltage the contact protection can be achieved via a freewheeling diode, connected in parallel to the load. The polarity of the

diode must be arranged so that it closes when the operating voltag

e is on.

Example:

Contact protection

Contact

measure with freewheeling diode

Diode

7.2. Inductive load with AC voltage

With AC voltage two protection measures are possible:

Example:

Contact

Contact protection measure with

voltage-dependent resistor VDR

GB

Example:

Contact

Contact protection

measure with RC

element

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

13

Page 14

7. Contact protection measures

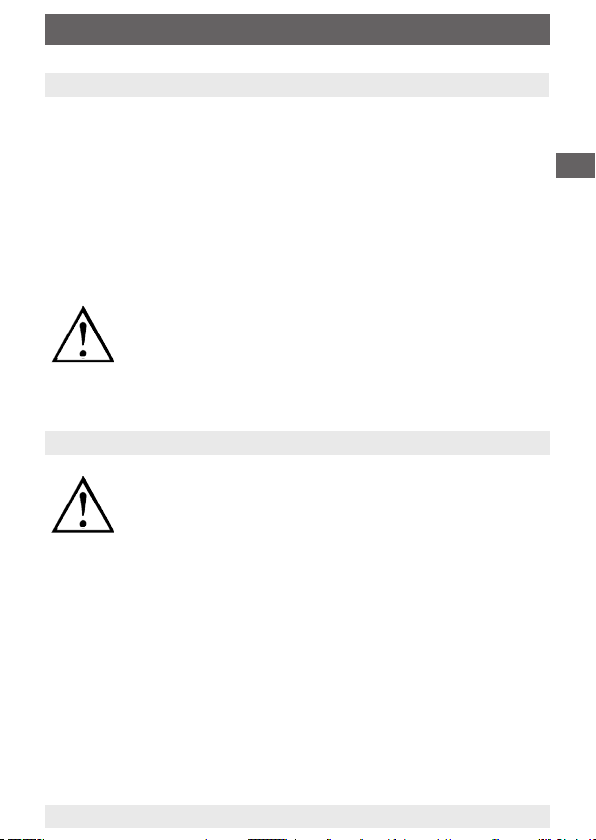

7.3. Capacitive load

With capacitive loads elevated switch-on currents arise. These can be

reduced by series-connecting resistors in the supply line.

GB

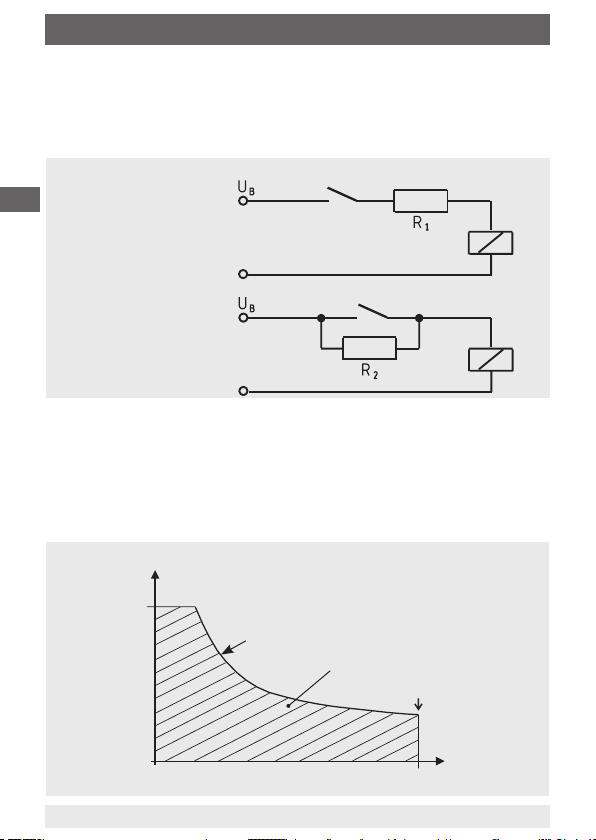

Examples:

Contact

Contact protection measure with

current-limiting

resistor

Contact

Contact curve

The hatched area of the contact curve shows the permissible electrical

values for the respective contact.

Accordingly the voltage and/or current to be switched must not exceed

the respective maximum values.

The power to be switched may only lie below the limit curve.

V

Vmax

max. voltage

Switching voltage

limit curve

Switching current

allowed working

range

max. current

A

Amax

WIKA operating instructions pressure gauge model PGS with reed contacts

14

14000322.01 03/2011 GB/D/F/E

Page 15

8. Maintenance and cleaning / 9. Dismounting and disposal

8. Maintenance and cleaning

8.1 Maintenance

The instruments are maintenance-free. The indicator and switching

function should be checked once or twice every year. For this the

instrument must be disconnected from the process to check with a

pressure testing device.

Repairs must only be carried out by the manufacturer or appropriately

qualied skilled personnel.

8.2 Cleaning

CAUTION!

■

Clean the pressure gauge with a moist cloth.

■

Wash or clean the dismounted pressure gauge before

returning it, in order to protect sta and the environment

from exposure to residual media.

9. Dismounting and disposal

WARNING!

Residual media in dismounted pressure gauges can result

in a risk to persons, the environment and equipment. Take

sucient precautionary measures.

9.1 Dismounting

Only disconnect the pressure gauge once the system has been

depressurised!

When dismounting, close the compensating valve (if available).

GB

9.2 Disposal

Incorrect disposal can put the environment at risk. Dispose of instrument

components and packaging materials in an environmentally compatible

way and in accordance with the country-specic waste disposal

regulations.

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

15

Page 16

GB

WIKA operating instructions pressure gauge model PGS with reed contacts

16

14000322.01 03/2011 GB/D/F/E

Page 17

Inhalt

Inhalt

1. Allgemeines 18

2. Sicherheit 19

3. Technische Daten 22

Aufbau und Funktion

4.

5. Transport, Verpackung und Lagerung 23

6. Inbetriebnahme, Betrieb 24

7. Kontaktschutzmaßnahmen 26

8. Wartung und Reinigung 29

9. Demontage und Entsorgung 29

23

D

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

17

Page 18

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Druckmessgerät wird

nach den neuesten Erkenntnissen konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen

Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind

D

nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Druckmessgerät. Voraussetzung für sicheres Arbeiten ist die

Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Druckmessgerätes geltenden

örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Druckmessgerätes für das Fachpersonal jederzeit

zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung,

Einsatz ungenügend qualizierten Fachpersonals sowie eigenmächtiger Veränderung am Druckmessgerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Anwendungsberater: Tel.: (+49) 9372/132-0

18

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

14000322.01 03/2011 GB/D/F/E

Page 19

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informati-

onen für einen ezienten und störungsfreien Betrieb hervor.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen,

dass das richtige Druckmessgerät hinsichtlich Messbe-

reich, Ausführung und spezischen Messbedingungen

ausgewählt wurde.

Verträglichkeit der druckbelasteten Werkstoe mit dem

Messsto prüfen!

Die Belastungsgrenzen sind einzuhalten, um die

Messgenauigkeit und die Lebensdauer zu gewährleisten.

D

Die Geräte sind keine Ausrüstungsteile mit Sicherheitsfunktion im Sinne der Druckgeräterichtlinie 97 / 23 / EG.

Bei Nichtbeachten können schwere Körperverletzungen

und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

19

Page 20

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Diese Druckmessgeräte dienen zum Messen von Druck und Schalten

von Schaltströmen bei industriellen Anwendungen.

Das Druckmessgerät ist ausschließlich für den hier beschriebenen

bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert

D

und darf nur dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen

Tätigkeiten nur durch Fachpersonal nachfolgend

beschriebener Qualikation durchführen lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen

sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen

und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen

und mögliche Gefahren selbstständig zu erkennen.

2.3 Besondere Gefahren

WARNUNG!

Bei Montage, Inbetriebnahme und Betrieb dieser Geräte

unbedingt die entsprechenden nationalen Sicherheitsvorschriften (z. B. VDE 0100) beachten.

20

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

14000322.01 03/2011 GB/D/F/E

Page 21

2. Sicherheit

WARNUNG!

Alle Arbeiten dürfen nur im spannungslosen Zustand

erfolgen.

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

2.4 Beschilderung / Sicherheitskennzeichnungen

Typenschild

D

Symbolerklärung

Herstellungsdatum

Vor Montage und Inbetriebnahme des Druckmessgerätes

unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

Geräte mit dieser Kennzeichnung auf dem Zierblatt sind

Sicherheitsdruckmessgeräte mit bruchsicherer Trennwand

nach EN 837 (S3).

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

21

Page 22

3. Technische Daten

3. Technische Daten

Grenzwerte für die Kontaktbelastung bei ohmscher Belastung

Technische Daten Typ 851.3 Typ 851.33

Verwendet für Gerätetyp PGS21.1x0, PGS23.1x0, PGS43.1x0,

D

Kontaktausführung 1 Wechsler 2 Wechsler

Kontaktart bistabil

Max. Schaltspannung AC/DC V 250

Min. Schaltspannung V nicht erforderlich

Max. Schaltstrom AC/DC A 1

Min. Schaltstrom mA nicht erforderlich

Max. Transportstrom AC/DC A 2

cos ϕ 1

Schaltleistung W/ VA 60

Kontaktwiderstand (statisch) mΩ 100

Isolationswiderstand Ω 10

Durchschlagspannung DC V 1000

Schaltzeit inkl. Prellen ms 4,5

Kontaktwerksto Rhodium

Schalthysterese % 3 ... 5

PGS43HP.1x0, PGS63HP.1x0,

DPGS43.1x0, DPGS43HP.1x0,

APGS43.1x0

9

Die Schutzart nach EN 60529 gegen äußere Einüsse hängt vom

Grundgerät ab und ist dem entsprechenden Datenblatt zu entnehmen.

Die Grenzwertschalter können im Umgebungstemperaturbereich von

-20 bis +70 °C eingesetzt werden. Falls die für das Grundgerät zugelassenen Temperaturen (siehe Datenblatt) diesen Bereich eingrenzen,

gelten die eingeschränkten Werte.

Weitere technische Daten siehe jeweiliges WIKA Datenblatt und

Bestellunterlagen.

22

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

14000322.01 03/2011 GB/D/F/E

Page 23

4. Aufbau und Funktion / 5. Transport, Verpackung ...

4. Aufbau und Funktion

4.1 Beschreibung

Die eingebauten elektrischen Schaltkontakte (Reed-Kontakte) sind

Hilfsstromschalter, die angeschlossene elektrische Stromkreise über

den vom Gerätezeiger bewegten Permanentmagnet bei den eingestellten Grenzwerten önen bzw. schließen (Wechsler). Bei den verwendeten Reedkontakten handelt es sich um bistabile Schalter, die nach einer

Signaländerung ihren Zustand bis zur nächsten Betätigung beibehalten.

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport

einen optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

Lagertemperatur: entsprechend Messgerät

D

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

23

Page 24

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

6.1 Mechanischer Anschluss

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte (z. B. EN 837-2 „Auswahl- und Einbauempfehlungen für Druckmessgeräte“).

D

Beim Einschrauben der Geräte darf die zum Abdichten erforderliche

Kraft nicht über das Gehäuse oder die Kabelanschlussdose aufgebracht

werden, sondern mit geeignetem Werkzeug nur über die dafür vorgese-

henen Schlüsselächen am Vierkant des Anschlusszapfens.

Montage mit

Gabelschlüssel

Zur Abdichtung der Druckmessgeräteanschlüsse mit zylindrischen

Gewinde an der Dichtäche sind Flachdichtungen, Dichtlinsen oder

WIKA-Proldichtungen einzusetzen. Bei kegeligen Gewinde (z. B.

NPT-Gewinde) erfolgt die Abdichtung im Gewinde , mit zusätzlichen

Dichtwerkstoen, wie z. B. PTFE-Band (EN 837-2).

Schlüsseläche

Dichtäche

Abdichtung im

Gewinde

Das Anzugsmoment ist von der eingesetzten Dichtung abhängig. Um

das Messgerät in die Stellung zu bringen, in der es sich am besten

ablesen lässt, ist ein Anschluss mit Spannmue oder Überwurfmutter zu

empfehlen. Sofern ein Druckmessgerät eine Ausblasvorrichtung besitzt,

muss diese vor Blockierung durch Geräteteile oder Schmutz geschützt

sein.

24

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

14000322.01 03/2011 GB/D/F/E

Page 25

6. Inbetriebnahme, Betrieb

Bei Sicherheitsdruckmessgeräten (zu erkennen am k) ist darauf zu

achten, dass der Freiraum hinter der ausblasbaren Rückwand mindestens 15 mm beträgt.

6.2 Besondere Anforderungen an die Einbaustelle

Ist die Leitung zum Messgerät für eine erschütterungsfreie Anbringung

nicht stabil genug, sollte (evtl. über eine exible Kapillarleitung) die

Befestigung mittels Messgerätehalterung erfolgen. Können Erschütterungen nicht durch geeignete Installationen vermieden werden,

dann sollten Geräte mit Flüssigkeitsfüllung eingesetzt werden. Die

Geräte sind vor grober Verschmutzung und starken Schwankungen der

Umgebungstemperatur zu schützen.

In seltenen Fällen kann es vorkommen, dass die Reedschalter durch

die Einwirkung eines unzulässig hohen Schocks oder einer Vibration

betätigt worden sind. In diesem Fall sind diese Reedschalter nach

dem Einbau des Gerätes in der Messstelle durch einmaliges Bewegen

des Gerätezeigers über den eingestellten Schaltpunkt (Reedschalter)

zurückzusetzen.

6.3 Elektrischer Anschluss

Der elektrische Anschluss darf nur durch qualiziertes Fachpersonal

erfolgen. Die Belegung der Anschlüsse und die Schaltfunktionen sind

auf dem Typenschild am Gerät angegeben und die Anschlussklemmen

sowie die Erdungsklemme sind entsprechend gekennzeichnet.

Die vorgesehenen Netzanschlussleitungen müssen für die größte

Stromaufnahme des Gerätes bemessen sein und IEC 227 oder IEC

245 entsprechen. Leistungsdaten (siehe "Technische Daten") und

Schutzschaltungen bei induktiven und kapazitiven Lasten siehe Kapitel

"7. Kontaktschutzmaßnahmen".

D

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

25

Page 26

6. Inbetriebnahme, Betrieb / 7. Kontaktschutzmaßnahmen

6.4 Einstellen der Sollwertzeiger

Das Einstellen der Sollwerte erfolgt über das Verstellschloss in der

Sichtscheibe mit Hilfe des Verstellschlüssels (gehört zum Lieferumfang;

bendet sich bei Standardgeräten seitlich an der Kabeldose).

Bei Messgeräten der Nenngröße 160 ist darauf zu achten, dass der

Verstellarm ausschließlich im Bereich der zu verstellenden Sollwertzei-

D

ger niedergedrückt wird. Andernfalls ist eine Beschädigung des Gerätezeigers bzw. eine Verstellung des Nullpunktes nicht auszuschließen.

Sollwertzeiger

Verstellschloss

Verstellarm

abnehmbarer

Verstellschlüssel

Die Sollwertzeiger der Grenzwertschalter sind zwischen 10 % und 90 %

des Skalenbereiches frei einstellbar, wobei der Abstand zwischen den

beiden Sollwertzeigern mindestens ca. 10 % des Skalenbereiches

(entspricht ca. 30 ∢°) beträgt.

Inbetriebnahme

Bei Inbetriebnahme Druckstöße unbedingt vermeiden, Absperrventile

langsam önen.

7. Kontaktschutzmaßnahmen

Mechanische Kontakte dürfen die angegebenen elektrischen Werte

für Schaltstrom und Schaltspannung unabhängig voneinander, auch

kurzzeitig, nicht überschreiten.

Für kapazitive oder induktive Lasten empfehlen wir eine der folgenden

Schutzbeschaltungen:

26

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

14000322.01 03/2011 GB/D/F/E

Page 27

7. Kontaktschutzmaßnahmen

7.1 Induktive Last bei Gleichspannung

Bei Gleichspannung kann der Kontaktschutz durch eine parallel zur Last

geschalteten Freilaufdiode erzielt werden. Die Polung der Diode muss

so erfolgen, dass sie bei angelegter Betriebsspannung sperrt.

Beispiel:

Kontaktschutz-

Kontakt

maßnahme mit

Freilaufdiode

Diode

7.2 Induktive Last bei Wechselspannung

Bei Wechselspannung gibt es zwei mögliche Schutzmaßnahmen:

Beispiel:

Kontakt

Kontaktschutzmaßnahme mit

Spannungsabhängigem Widerstand VDR

Beispiel:

Kontakt

Kontaktschutzmaßnahme mit

RC-Glied

D

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

27

Page 28

7. Kontaktschutzmaßnahmen

7.3 Kapazitive Last

Bei kapazitiven Lasten treten erhöhte Einschaltströme auf. Diese

können durch Reihenschalten von Widerständen in der Zuleitung

verringert werden.

Beispiele:

Kontaktschutz-

D

Kontakt

maßnahme mit

Widerstand zur

Strombegrenzung

Kontakt

Kontaktkurve

Die Kontaktkurve zeigt mit dem schraerten Bereich die elektrischen

Werte, die für den jeweiligen Kontakt zulässig sind.

Demnach dürfen die zu schaltende Spannung und/oder der zu schaltende Strom ihre maximalen Werte nicht überschreiten.

Die zu schaltende Leistung darf nur unterhalb der Grenzkurve liegen.

V

28

V

max. Spannung

max

Grenzkurve

Schaltspannung

Schaltstrom

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

erlaubter

Arbeitsbereich

max. Strom

A

A

max

14000322.01 03/2011 GB/D/F/E

Page 29

8. Wartung und Reinigung / 9. Demontage und Entsorgung

8. Wartung und Reinigung

8.1 Wartung

Die Geräte sind wartungsfrei.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis

2 mal pro Jahr erfolgen. Dazu ist das Gerät vom Prozess zu trennen und

mit einer Druckprüfvorrichtung zu kontrollieren.

Reparaturen sind ausschließlich vom Hersteller oder entsprechend

qualiziertem Fachpersonal durchzuführen.

8.2 Reinigung

VORSICHT!

■

Das Druckmessgerät mit einem feuchten Tuch reinigen.

■

Ausgebautes Druckmessgerät vor der Rücksendung

spülen bzw. säubern, um Mitarbeiter und Umwelt

vor Gefährdung durch anhaftende Messstoreste zu

schützen.

9. Demontage und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Personen, Umwelt und Einrichtung

führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

D

9.1 Demontage

Druckmessgerät nur im drucklosen Zustand demontieren!

Bei Demontage Belüftungsventil (falls vorhanden) schließen.

9.2 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

14000322.01 03/2011 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

29

Page 30

D

30

WIKA Betriebsanleitung Druckmessgerät Typ PGS mit Reed-Kontakten

14000322.01 03/2011 GB/D/F/E

Page 31

Sommaire

Sommaire

1. Généralités 32

2. Sécurité 33

3. Caractéristiques techniques 36

Conception et fonction

4.

5. Transport, emballage et stockage 37

6. Mise en service, exploitation 38

7. Dispositifs de protection 40

8. Entretien et nettoyage 43

9. Démontage et mise au rebut 43

37

F

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

31

Page 32

1. Généralités

1. Généralités

■

Le manomètre décrit dans le mode d'emploi est conçu et fabriqué

selon les dernières technologies en vigueur. Tous les composants

sont soumis à des critères de qualité et d'environnement stricts

durant la fabrication. Nos systèmes de gestion sont certiés selon

ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concern-

F

ant l'utilisation du manomètre. Il est possible de travailler en toute

sécurité avec ce produit en respectant toutes les consignes de

sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur pour

le domaine d‘application du manomètre.

■

Le mode d'emploi fait partie de l'appareil et doit être conservé à

proximité immédiate du manomètre et accessible à tout moment

pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération,

avoir lu soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de

dommages provoqués par une utilisation non conforme à l'usage

prévu, de non respect de ce mode d'emploi, d'utilisation de person-

nel peu qualié de même qu'en cas de modications du manomètre

eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents

de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site internet : www.wika.fr

- Conseiller applications : Tel. : (+33) 1 343084-84

32

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

Fax : (+33) 1 343084-94

E-Mail: info@wika.fr

14000322.01 03/2011 GB/D/F/E

Page 33

1. Généralités / 2. Sécurité

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer la mort ou des blessures

graves si elle n'est pas évitée.

Information

… met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le manomètre a été choisi de façon adéquate,

en ce qui concerne la plage de mesure, la version et les

conditions de mesure spéciques.

Vérier si les matériaux soumis à la pression sont

compatibles avec le uide de mesure !

Les limites de surpression admissible sont à respecter an

d'assurer la précision et la durée de vie.

Les instruments ne sont pas des équipements avec fonction

de sécurité dans l'esprit de la directive sur les équipements

sous pression 97 / 23 / CE.

F

Un non-respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d'emploi.

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

33

Page 34

2. Sécurité

2.1 Utilisation conforme à l'usage prévu

Ces manomètres sont utilisés pour la mesure de pression et la commutation de courants de commutation dans les applications industrielles.

Le manomètre est conçu et construit exclusivement pour une utilisation conforme à l'usage prévu décrit ici et ne doit être utilisé qu'en

conséquence.

F

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne

doivent être eectuées que par un personnel ayant la

qualication décrite ci-après.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de

ses connaissances dans le domaine de la technique de mesure et de

régulation et de ses expériences de même que de sa connaissance des

prescriptions nationales des normes et directives en vigueur, en mesure

d'eectuer les travaux décrits et de reconnaître automatiquement les

dangers potentiels.

2.3 Dangers particuliers

AVERTISSEMENT !

Lors du montage, de la mise en service et du fonctionnement de ces instruments, respectez impérativement les

consignes de sécurité nationales pertinentes (p. ex. VDE

0100).

34

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

14000322.01 03/2011 GB/D/F/E

Page 35

2. Sécurité

AVERTISSEMENT !

Toutes les interventions doivent être eectuées hors

tension.

AVERTISSEMENT !

Les restes de uides se trouvant dans des appareils

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

2.4 Etiquetage / Marquages de sécurité

Plaque signalétique

F

Explication des symboles

Date de fabrication

Avant de monter et mettre le manomètre en service, lire

impérativement le mode d'emploi !

CE, Communauté Européenne

Les appareils avec ce marquage sont conformes aux directives européennes pertinentes.

Les appareils avec ce marquage sur le cadran sont des

manomètres de sécurité dotés d‘une cloison de sécurité

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

incassable selon EN 837 (S3).

35

Page 36

3. Caractéristiques techniques

3. Caractéristiques techniques

Valeurs limites pour la charge sur le contact en cas de charge ohmique

Caractéristiques techniques Type 851.3 Type 851.33

Utilisé pour le type d'instrument PGS21.1x0, PGS23.1x0,

F

Exécution des contacts 1 inverseur 2 inverseurs

Type de contact bistable

Tension de commutation maxi. AC/DC V 250

Tension de commutation mini. V pas nécessaire

Courant de commutation maxi. AC/DC A 1

Courant de commutation mini. mA pas nécessaire

Courant de transport maxi. AC/DC A 2

cos ϕ 1

Puissance de commutation W/ VA 60

Résistance du contact (statique) mΩ 100

Résistance d'isolement Ω 10

Tension de claquage DC V 1000

Temps de commutation

y compr. rebondissement

Matériau du contact Rhodium

Hystérésis de commutation % 3 ... 5

ms 4,5

PGS43.1x0, PGS43HP.1x0,

PGS63HP.1x0, DPGS43.1x0,

DPGS43HP.1x0, APGS43.1x0

9

L'indice de protection selon EN 60529 contre les inuences extérieures

dépend de l'instrument de base et est indiqué dans la che technique

respective.

Les interrupteurs de n de course peuvent être utilisés sur une plage de

-20 à +70 °C. Si les températures admissibles pour l'instrument de base

(voir che technique) limitent cette plage de température, les valeurs

limites s'appliquent.

Pour de plus amples spécications, voir la che technique WIKA corre-

spondante et la documentation de commande.

36

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

14000322.01 03/2011 GB/D/F/E

Page 37

4. Conception et fonction / 5. Transport, emballage et ...

4. Conception et fonction

4.1 Description

Les contacts de commutation électriques intégrés (contacts Reed)

sont des interrupteurs auxiliaires qui ouvrent ou ferment des circuits

électriques raccordés via l'aimant permanent déplacé par l'aiguille de

l'instrument aux valeurs limites réglées (inverseur). Les contacts reed

sont utilisés en commutateur bistable ce qui leurs permet de garder leur

état après un changement de signal jusqu'à la prochaine commutation.

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur l'appareil liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection

optimale (par ex. changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

Température de stockage: selon l'instrument de mesure

F

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

37

Page 38

6. Mise en service, exploitation

6. Mise en service, exploitation

6.1 Raccordement mécanique

Conformément aux règles techniques générales pour les manomètres

(par ex. EN 837-2 "Recommandations sur le choix et l'installation des

manomètres").

F

Lors du vissage des appareils, la force nécessaire ne doit pas être appliquée sur le boîtier ou sur le boîtier de raccordement mais seulement sur

les surfaces prévues par un outil approprié sur le carré du raccord.

Montage avec

clé à fourche

Pour assurer l’étanchéité du raccord avec letage cylindrique du

manomètre sur la surface d‘étanchéité il faut utiliser des joints plats,

des joints forme lentille ou les joints à écrasement WIKA. Pour les

letages coniques (par exemple letage NPT) l‘étanchéité sur le letage

se fait en utilisant en plus un matériau d‘étanchéité comme par

exemple la bande PTFE (selon EN 837-2).

Clef plate

Surface d‘étanchéité

Etanchéité sur

letage

Le couple de serrage dépend du joint utilisé. An de positionner

l‘appareil de mesure de façon à ce qu‘il soit facilement lisible, il est

recommandé d‘utiliser un manchon de serrage ou un écrou-chapeau.

Au cas où un manomètre est équipé d‘une paroi arrière éjectable, celleci doit être protégée contre un blocage par des pièces d‘appareil et

contre la crasse.

38

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

14000322.01 03/2011 GB/D/F/E

Page 39

6. Mise en service, exploitation

Pour les manomètres de sécurité (reconnaissables au symbole k sur

le cadran), il convient de veiller à ce que l‘espace libre à l‘arrière de

l‘instrument soit au minimum de 15 mm.

Exigences particulières relative au point de montage

Si la conduite au point de mesure n'est pas assez stable, il est recommandé

(éventuellement via un capillaire exible) de xer l'instrument au moyen d'un

support approprié. S‘il n‘est pas possible de supprimer les vibrations par un

montage approprié, il convient d'utiliser des manomètres remplis de liquide

amortisseur. Les instruments doivent être protégés contre un encrassement

important et contre les uctuations de la température ambiante.

Dans de rares cas, un actionnement des commutateurs Reed peut

survenir en raison d'un choc ou de vibrations important(es) non

autorisé(es). Dans ce cas, ces contacts Reed doivent être réinitialisés

après l'installation de l'instrument dans le point de mesure en déplaçant

l'aiguille de l'instrument une fois au-dessus du point de commutation

déni (commutateur Reed).

6.3 Branchement électrique

Les travaux de raccordement électrique ne doivent être eectués que

par des personnels qualiés. L'aectation des branchements et les

fonctions de commutation sont indiquées sur la plaque signalétique

de l'instrument et les bornes de raccordement ainsi que la borne de

terre sont marquées en conséquence. Les câbles de raccordement

au réseau prévus doivent être dimensionnés pour la plus grande

alimentation de l'instrument et correspondre à IEC 227 ou IEC 245. Pour

les caractéristiques (voir "Caractéristiques techniques") et les circuits

de protection en cas de charges inductives et capacitives, voir chapitre

"7. Dispositifs de protection".

F

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

39

Page 40

6. Mise en service, exploitation / 7. Dispositifs de protection

6.4 Réglage de la valeur de consigne

Le réglage des valeurs de consigne s‘eectue via l'orice de réglage

dans le cadran à l‘aide de la clef de réglage (fournie avec l‘instrument,

elle se trouve, sur les modèles standard, sur le côté du boîtier de

raccordement).

Avec la taille nominale 160 des instruments de mesure, s'assurer que

le bras de réglage est poussé vers le bas exclusivement dans la zone

de l'indicateur de valeur de consigne devant être réglé. Dans le cas

F

contraire, des dommages sur l'aiguille de l'instrument ou un réglage

erroné du point zéro ne peut/peuvent être exclu(s).

Indicateur de

la valeur de

consigne

Orice de réglage

Bras de réglage

Clef de réglage

amovible

Les indicateurs de valeur de consigne des interrupteurs de n de

course peuvent être réglés librement entre 10 % et 90 % de la plage de

l'échelle, la distance entre les deux indicateurs devant être au moins

10 % de la plage de l'échelle (ce qui correspond env. à 30 ∢°).

Mise en service

Lors de la mise en service il faut absolument éviter les coups de bélier.

Ouvrir lentement les robinets d'isolement.

7. Dispositifs de protection

Les contacts mécaniques ne doivent pas dépasser les valeurs

électriques indiquées pour le courant de commutation et la tension de

commutation, même pour une durée brève.

Pour les charges capacitives ou inductives, nous recommandons l'un

des circuits de protection suivants :

40

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

14000322.01 03/2011 GB/D/F/E

Page 41

7. Dispositifs de protection

7.1 Charge inductive sous tension continue

En cas de tension continue, la protection par contact peut être

obtenue par une diode de récupération de self-induction commutée

parallèlement à la charge. La polarité de la diode doit garantir qu'elle

bloque lorsque la tension de service est appliquée.

Exemple :

dispositif de

Contact

protection

avec diode de

récupération de

Diode

self-induction

7.2 Charge inductive sous tension alternative

En cas de tension alternative, il existe deux dispositifs de protection :

Exemple :

Contact

dispositif de

protection avec

une varistance

VDR

F

Exemple :

Contact

dispositif de

protection avec

élément RC

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

41

Page 42

7. Dispositifs de protection

7.3 Charge capacitive

En cas de charges capacitives, des courants de démarrage plus

importants apparaissent. Ils peuvent être réduits par la commutation en

série de résistances dans le câble d'alimentation.

Exemples :

Contact

dispositif de

protection avec

F

résistance pour

limiter le courant

Contact

Courbe de contact

La partie hachurée de la courbe de contact montre les valeurs

électriques qui sont admissibles pour le contact respectif.

En conséquence, la tension et/ou le courant devant être commuté(e)

ne doit pas excéder les valeurs maximales respectives.

La puissance à commuter doit impérativement être inférieure à la

courbe limite

V

42

Vmax

Tension maxi.

Courbe limite

Tension de commutation

Courant de commutation

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

Plage de travail

autorisée

Courant maxi.

Amax

A

14000322.01 03/2011 GB/D/F/E

Page 43

8. Entretien et nettoyage / 9. Démontage et mise au rebut

8. Entretien et nettoyage

8.1 Entretien

Les instruments ne requièrent aucun entretien. Un contrôle de

l’achage et de la fonction de commutation est recommandé 1 à 2 fois/

an. Pour contrôler l'achage et la fonction de commutation, l'appareil

doit être isolé du processus de mesure et contrôlé à l'aide d'un dispositif

de contrôle de la pression.

Toute réparation doit être exclusivement conée au fabricant ou au

personnel qualié correspondant.

8.2 Nettoyage

ATTENTION !

■

Nettoyer le manomètre avec un chion humide.

■

Laver ou nettoyer le manomètre démonté avant de

le retourner an de protéger les collaborateurs et

l‘environnement contre le danger lié aux restes de

uides adhérents.

9. Démontage et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des manomètres

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

9.1 Démontage

Démonter le manomètre uniquement qu‘en état exempt de pression !

Lors du démontage, fermer le levier de mise à l’atmosphère (si

disponible).

9.2 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour

l'environnement. Éliminer les composants des appareils et les matériaux

d'emballage conformément aux prescriptions nationales pour le

traitement et l'élimination des déchets et aux lois de protection de

l'environnement en vigueur.

14000322.01 03/2011 GB/D/F/E

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

F

43

Page 44

F

44

WIKA mode d´emploi manomètre du type PGS avec contacts Reed

14000322.01 03/2011 GB/D/F/E

Page 45

Contenido

Contenido

1. Información general 46

2. Seguridad 47

3. Datos técnicos 50

Diseño y función

4.

5. Transporte, embalaje y almacenamiento 51

6. Puesta en servicio, funcionamiento 52

7. Medidas de protección del contacto 54

8. Mantenimiento y limpieza 57

9. Desmontaje y eliminación 57

51

E

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

45

Page 46

1. Información general

1. Información general

■

El manómetro descrito en el manual de instrucciones está

construido y fabricado según los conocimientos actuales. Todos los

componentes están sujetos a criterios rígidos de calidad y medio

ambiente durante la producción. Nuestros sistemas de gestión están

certicados según ISO 9001 e ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes

acerca del manejo del manómetro. Para un trabajo seguro es

E

imprescindible cumplir con todas las instrucciones de seguridad y

manejo indicadas.

■

Cumplir siempre las normativas sobre la prevención de accidentes

y las normas de seguridad en vigor en el lugar de utilización del

manómetro.

■

El manual de instrucciones es una parte integrante del manómetro

y debe guardarse en la proximidad del mismo para que el personal

especializado pueda consultarlo en cualquier momento.

■

El personal especializado debe haber leído y entendido el manual

de instrucciones antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso de

daños causados por un uso no conforme a la nalidad prevista, la

inobservancia del presente manual de instrucciones, un manejo por

personal insucientemente cualicado así como una modicación no

autorizada del manómetro.

■

Se aplican las condiciones generales de venta incluidas en la

documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Servicio técnico: Tel.: (+34) 933 938 630

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

46

Fax: (+34) 933 938 666

E-Mail: info@wika.de

14000322.01 03/2011 GB/D/F/E

Page 47

1. Información general / 2. Seguridad

Explicación de símbolos

¡ADVERTENCIA!

… indica una situación probablemente peligrosa que pueda

causar la muerte o lesiones graves si no se evita.

Información

... marca consejos y recomendaciones útiles así como infor-

maciones para una utilización ecaz y libre de fallos.

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta en servicio y el funcionamiento

asegurarse de que se haya seleccionado el manómetro

adecuado con respecto a rango de medida, versión y

condiciones de medición especícas.

¡Asegúrese de que los productos bajo presión sean aptos

para el material de medición!

Para garantizar la precisión de medición y la durabilidad del

instrumento, se deberán respetar los límites de carga.

Los instrumentos no son componentes de equipo con

función de seguridad en el sentido de la Directiva de

Equipos a Presión 97/23/CE.

E

El no respetar las instrucciones puede generar lesiones

graves y/o daños materiales.

Los distintos capítulos de este manual de instrucciones

contienen otras importantes indicaciones de seguridad.

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

47

Page 48

2. Seguridad

2.1 Uso conforme a lo previsto

Estos manómetros se utilizan para medir presiones y realizar

conmutaciones de corrientes eléctricas en aplicaciones industriales.

El manómetro ha sido diseñado y construido únicamente para la

nalidad aquí descrita y debe utilizarse en conformidad a la misma.

No se admite ninguna reclamación debido a un manejo no adecuado.

E

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente cualicación!

Un manejo no adecuado puede causar considerables

daños personales y materiales.

■

Las actividades descritas en este manual de

instrucciones deben realizarse únicamente por personal

especializado con la consiguiente cualicación.

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica

de regulación y medición así como a su experiencia y su conocimiento

de las normativas, normas y directivas vigentes en el país de utilización

el personal especializado es capaz de ejecutar los trabajos descritos y

reconocer posibles peligros por sí solo.

2.3 Riesgos especícos

¡ADVERTENCIA!

Es imprescindible observar las prescripciones nacionales de seguridad (p. ej. VDE 0100). durante el montaje, la

puesta en servicio y la operación de estos aparatos.

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

48

14000322.01 03/2011 GB/D/F/E

Page 49

2. Seguridad

¡ADVERTENCIA!

Todos los trabajos que se ejecuten en los instrumentos han

de hacerse sin someter el instrumento a presión.

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados

pueden causar riesgos para personas, medio ambiente e

instalación.

Tomar adecuadas medidas de precaución.

2.4 Rótulos / Marcajes de seguridad

Placa indicadora de modelo

E

Explicación de símbolos

Fecha de fabricación

¡Es absolutamente necesario leer el manual de

instrucciones antes del montaje y la puesta en servicio del

manómetro!

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas

europeas aplicables.

Los instrumentos con este marcaje en la esfera son

manómetros de seguridad con una pared divisora

resistente a la fractura conforme a EN 837 (S3).

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

49

Page 50

3. Datos técnicos

3. Datos técnicos

Valores límite para la carga del contacto con carga óhmica

Datos técnicos

Se utiliza para los modelos PGS21.1x0, PGS23.1x0,

Contactos 1 conmutador

E

Tipo de contacto biestable

Tensión de conmutación máx. AC/DC V 250

Tensión de conmutación mín. V no aplicable

Max. corriente de conmutación AC/DC A 1

Mín. corriente de conmutación mA no aplicable

Máx. corriente de transporte AC/DC A 2

cos ϕ 1

Potencia de ruptura W/ VA 60

Resistencia de contacto (estática) mΩ 100

Resistencia al aislamiento Ω 10

Tensión disruptiva DC V 1000

Tiempo de conmutación incl. rebote ms 4,5

Material de los contactos Rodio

Histéresis de conmutación % 3 ... 5

Mod. 851.3 Mod. 851.33

PGS43.1x0, PGS43HP.1x0,

PGS63HP.1x0, DPGS43.1x0,

DPGS43HP.1x0, APGS43.1x0

2 conmutadores

9

El tipo de protección según EN 60529, protección frente a inuencias

externas, depende del instrumento básico; consulte la hoja técnica

correspondiente.

Los contactos de alarma pueden utilizarse dentro del rango de

temperaturas ambientales de -20 a +70 °C. Si las temperaturas

permitidas para el instrumento básico (véase la hoja técnica) limitan

este rango, son válidos los valores restringidos.

Para consultar más datos técnicos véase la hoja técnica

correspondiente de WIKA y la documentación de pedido.

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

50

14000322.01 03/2011 GB/D/F/E

Page 51

4. Diseño y función / 5. Transporte, embalaje ...

4. Diseño y función

4.1 Descripción

Los contactos eléctricos incorporados (contactos Reed) son

interruptores secundarios que abren o cierran los circuitos eléctricos en

el límite de valor previamente ajustado mediante el imán permanente.

Este imán se desplaza en función del movimiento del indicador del

instrumento (conmutador). Los contactos Reed son interruptores

biestables que mantienen su estado tras el cambio hasta la siguiente

activación.

4.2 Volumen de suministro

Comprobar mediante el albarán si se ha entregado la totalidad de las

piezas.

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el instrumento presenta eventuales daños causados en el

transporte.

Noticar de inmediato cualquier daño evidente.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje porque es la protección ideal durante el transporte

(por ejemplo si el lugar de instalación cambia o si se envía

el instrumento para posibles reparaciones).

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento:

Temperatura de almacenamiento: en función del instrumento de

medición

E

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

51

Page 52

6. Puesta en servicio, funcionamiento

6. Puesta en servicio, funcionamiento

6.1 La conexión mecánica

Conforme a las reglas técnicas generales para manómetros (por

ejemplo EN 837-2 "Recomendaciones relativas a la selección y montaje

de manómetros").

Para atornillar el instrumento, se debe utilizar la fuerza mediante el uso

de herramientas adecuadas sobre las supercies planas de ajuste

E

-previstas y no sobre la caja o la caja de conexiones.

Montaje mediante

llave de boca

Para el cierre de las conexiones de los manómetros con roscas

cilíndricas en la supercie de cierre se debe instalar juntas planas,

arandelas o juntas perladas WIKA. Para roscas cónicas (por ejemplo,

roscas NPT) se realiza el cierre en la rosca con material de cierre

complementario, como por ejemplo, cinta PTFE (EN 837-2).

Supercie plana

de ajuste

Supercie de cierre

Junta en

la rosca

El momento de arranque depende del tipo de cierre utilizado. Para

poner el manómetro en la posición que proporcionará la mejor lectura,

se recomienda una conexión con un manguito tensor o tuerca tapón.

Si un manómetro está bloqueo de un dispositivo de ventilación es

necesario protegerlo contra blocaje por piezas de aparatos o suciedad.

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

52

14000322.01 03/2011 GB/D/F/E

Page 53

6. Puesta en servicio, funcionamiento

En caso de manómetros de seguridad (reconocibles por la inscripción

k

) se debe vigilar que el espacio detrás de la pared trasera de escape

es de 15 mm como mínimo.

6.2 Requerimientos especiales en el lugar de instalación

Si el tubo que conecta al instrumento no fuera sucientemente estable

para asegurar una conexión exenta de vibraciones, se debería efectuar la

sujeción mediante un soporte (si es necesario, mediante un tubo capilar

En el caso de no poder evitar las vibraciones mediante las

exible).

instalaciones apropiadas, deben instalarse instrumentos con relleno

de líquido. Los instrumentos deben protegerse contra contaminación y

fuertes oscilaciones de la temperatura ambiental.

Pocas veces puede suceder que el contacto Reed se active por la

inuencia de un choque o de vibraciones fuertes. En tal caso se debe

recolocar el contacto tras el montaje en el punto de medida mediante un desplazamiento del indicador por encima del punto de ruptura

previamente ajustado.

6.3 Conexión eléctrica

La conexión eléctrica sólo la puede realizar personal especializado

y cualicado. Las conexiones y las funciones de conmutación están

indicadas en la placa indicadora del instrumento, y los bornes de

conexión y de puesta a tierra están marcados. Las líneas de conexión

de red deben estar diseñadas para soportar el consumo máximo de

corriente del instrumento y deben cumplir IEC 227 o IEC 245.

Véase el dorso para los datos de rendimiento (véase "Datos técnicos")

y circuitos protectores con cargas inductivas y capacitativas véase el

capítulo "7. Medidas de protección del contacto".

E

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

53

Page 54

6. Puesta en servicio, funcionamiento

6.4 Ajuste de los indicadores de valor nominal

El ajuste de los valores nominales se hace a través del cierre de ajuste

en la mirilla, utilizando la llave de ajuste (incluido en el suministro; se

encuentra en un lado de la caja de cable para versiones estándar).

En las versiones de diámetro 160 se debe apretar la palanca

únicamente dentro del rango del indicador de valor nominal. En caso

contrario no se puede descartar daños del indicador o cambios del

punto cero.

E

Indicador de

valor nominal

Cierre de ajuste

Palanca de ajuste

Llave de ajuste

desmontable

Los indicadores de valor nominal de los contactos de alarma pueden

ajustarse libremente entre 10 % y 90 % de la escala siendo la distancia

entre los dos indicadores de valor nominal mínimo aprox. 10 % de la

escala (aprox. 30 ∢°).

Puesta en servicio

Evitar golpes de ariete en todo caso durante la puesta en servicio, abrir

las válvulas de cierre despacio.

7. Medidas de protección del contacto

Los contactos mecánicos, independientemente uno de otro, no deben

exceder ni puntualmente los valores eléctricos de corriente y tensión de

conmutación.

Para cargas capacitativas o inductivas recomendamos uno de los

siguientes circuitos protectores:

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

54

14000322.01 03/2011 GB/D/F/E

Page 55

7. Medidas de protección del contacto

7.1 Carga inductiva sobre tensión continua

Con tensión continua puede garantizarse la protección del contacto por

un diodo de rueda libre conmutado en paralelo a la carga. La polaridad

del diodo debe seleccionarse de modo que cierra cuando se aplica la

tensión de servicio.

Ejemplo:

Protección del

Contacto

contacto mediante

diodo de rueda libre

Diodo

7.2 Carga inductiva sobre tensión alternante

Con tensión alterna hay dos posibles medidas de protección:

Ejemplo:

Contacto

Protección del

contacto con

resistor alineal

VDR

E

Ejemplo:

Contacto

Protección del

contacto con

elemento RC

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

55

Page 56

7. Medidas de protección del contacto

7.3 Carga capacitativa

Con cargas capacitativas se producen corrientes de conexión elevadas.

Estas pueden reducirse utilizando resistores conectados en serie en la

línea de alimentación.

Ejemplos:

Contacto

Protección del

contacto con

resistor para

limitación de

E

corriente

Contacto

Curva característica de los contactos

La curva característica de los contactos muestra, en el área sombreado,

los valores eléctricos que son admisibles para el contacto en cuestión.

La tensión y/o la corriente a conmutar no debe exceder los valores

máximos.

La potencia a conmutar no debe estar por debajo de la curva límite.

V

Vmax

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

56

Tensión máx.

Curva límite

Tensión de conmutación

Corriente de conmutación

Rango de

funcionamiento

admisible

Corriente máx.

Amax

A

14000322.01 03/2011 GB/D/F/E

Page 57

8. Mantenimiento y limpieza / 9. Desmontaje y eliminación

8. Mantenimiento y limpieza

8.1 Mantenimiento

Los instrumentos no requieren mantenimiento. Controlar el instrumento

y la función de conmutación una o dos veces al año. Para eso, separar

el instrumento del proceso y controlarlo con un dispositivo de control de

presión.

Todas las reparaciones solamente las debe efectuar el fabricante o

personal especializado e instruido.

8.2 Limpieza

¡CUIDADO!

■

Limpiar el manómetro con un trapo húmedo.

■

Lavar o limpiar el manómetro desmontado antes de

devolverlo para proteger a los empleados y el medio

ambiente de los peligros causados por restos de

medios.

9. Desmontaje y eliminación

¡ADVERTENCIA!

Restos de medios en manómetros desmontados pueden

crear riesgos para personas, medio ambiente e instalación.

Tomar adecuadas medidas de precaución.

9.1 Desmontaje

¡Desmontar el manómetro sólo si no está sometido a presión!

Para realizar el desmontaje se debe cerrar la válvula de ventilación (si

existe).

E

9.2 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio

ambiente. Eliminar los componentes de los instrumentos y los materiales de embalaje conforme a los reglamentos relativos al tratamiento de

residuos y eliminación vigentes en el país de utilización.

14000322.01 03/2011 GB/D/F/E

WIKA manual de instrucciones manómetro modelo PGS con contactos Reed

57

Page 58

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-Mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-Mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. „Al. Stamboliiski“ 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19, 10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-Mail: info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-Mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-Mail: info@wika.fr

www.wika.fr

WIKA operating instructions pressure gauge model PGS with reed contacts

58

Germany

WIKA Alexander Wiegand SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-Mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. Sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-Mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania S.R.L.

Bucuresti, Sector 5, Calea Rahovei

Nr. 266-268, Corp 61, Etaj 1

78202 Bucharest

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-Mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-Mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763722

Fax: (+381) 11 753674

E-Mail: info@wika.co.yu

www.wika.co.yu

14000322.01 03/2011 GB/D/F/E

Page 59

WIKA global

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Tel. (+34) 933 938630

Fax: (+34) 933 938666

E-Mail: info@wika.es

www.wika.es

Switzerland

MANOMETER AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-Mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 21

34775 Yukari Dudullu - Istanbul

Tel. (+90) 216 41590-66

Fax: (+90) 216 41590-97

E-Mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Tel. (+38) 062 34534-16

Fax: (+38) 062 34534-17

E-Mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. (+44) 1737 644-008

Fax: (+44) 1737 644-403

E-Mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Oce

Edmonton, Alberta, T6N 1C8

Tel. (+1) 780 46370-35

Fax: (+1) 780 46200-17

E-Mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.

01210 Mexico D.F.

Tel. (+52) 55 55466329

E-Mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Tel. (+1) 770 5138200

Fax: (+1) 770 3385118

E-Mail: info@wika.com

www.wika.com

WIKA Instrument Corporation

Houston Facility

950 Hall Court

Deer Park, TX 77536

Tel. (+1) 713-475 0022

Fax (+1) 713-475 0011

E-mail: info@wikahouston.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. (+1) 512 3964200-15

Fax (+1) 512 3961820

E-Mail: sales@mensor.com

www.mensor.com

14000322.01 03/2011 GB/D/F/E

WIKA operating instructions pressure gauge model PGS with reed contacts

59

Page 60

WIKA global

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Tel. (+54) 11 47301800

Fax: (+54) 11 47610050

E-Mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Tel. (+55) 15 34599700

Fax: (+55) 15 32661650

E-Mail: marketing@wika.com.br

www.wika.com.br

Further WIKA subsidiaries worldwide can be found online at www.wika.de.

Weitere WIKA Niederlassungen weltweit nden Sie online unter www.wika.de.

La liste des autres liales WIKA dans le monde se trouve sur www.wika.de

Otras sucursales WIKA en todo el mundo puede encontrar en www.wika.de.

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modications techniques.

Se reserva el derecho de modicaciones técnicas.

Chile

WIKA Chile S.P.A.

Av. Coronel Pereira, 101, Ocina 101

Las Condes, Santiago de Chile

Tel. (+56) 9 66084258

Fax (+56) 2 3346219

E-Mail: info@wika.cl

www.wika.cl

Asia

China

WIKA Shanghai Oce

A2615, NO.100, Zuyi Road

Changning District, 200051 Shanghai

Tel. (+86) 21 538525-72

Fax: (+86) 21 538525-75

E-Mail: info@wika.com.cn

www. wika.com.cn

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel (+49) 93 72/132-0

Fax (+49) 93 72/132-406

E-Mail info@wika.de

www.wika.de

WIKA operating instructions pressure gauge model PGS with reed contacts

60

14000322.01 03/2011 GB/D/F/E

Loading...

Loading...