Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

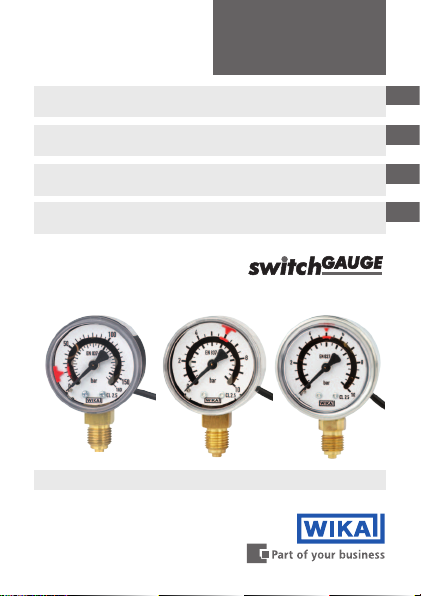

Pressure gauges with switch contacts

Models PGS10, PGS11 and PGS21

Druckmessgeräte mit Schaltkontakten

Typen PGS10, PGS11 und PGS21

Manomètres à contacts électriques

Types PGS10, PGS11 et PGS21

Manómetros con contactos eléctricos

Modelos PGS10, PGS11 y PGS21

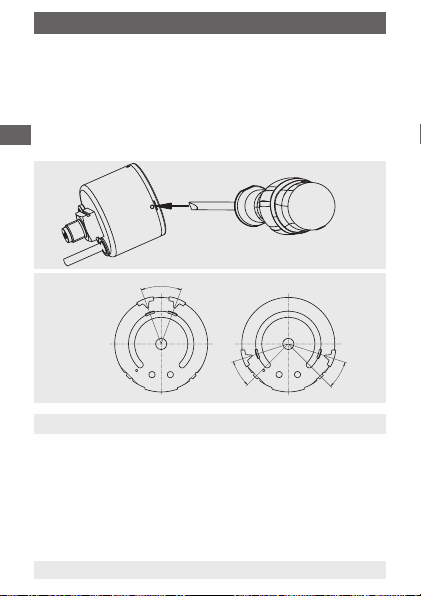

Model PGS10 Model PGS11 Model PGS21

GB

D

F

E

Page 2

Operating instructions

GB

Models PGS10, PGS11 and PGS21

Betriebsanleitung

D

Typen PGS10, PGS11 und PGS21

Mode d’emploi

F

Types PGS10, PGS11 et PGS21

Manual de instrucciones

E

Modelos PGS10, PGS11 y PGS21

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions models PGS10, PGS11 and PGS21

Page 3-18

Seite 19-34

Page 35-50

Página 51-57

11581752.02 09/2013 GB/D/F/E

Page 3

Contents

Contents

GB

1. General information

2. Safety

3. Specications

4. Design and function

5. Electrical switch contacts

6. Transport, packaging and storage

7. Commissioning, operation

8. Maintenance and cleaning

9. Dismounting and disposal

Appendix 1: Declaration of performance model PGS11.040

Appendix 2: Declaration of performance model PGS21.050

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

4

5

8

9

9

12

13

15

16

17

18

3

Page 4

1. General information

1. General information

■

The pressure gauge described in the operating instructions has been

GB

designed and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental

criteria during production. Our management systems are certied to

ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling

the instrument. Working safely requires that all safety instructions and

work instructions are observed.

■

Observe the relevant local accident prevention regulations and general

safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in

the immediate vicinity of the instrument and readily accessible to skilled

personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused

by using the product contrary to its intended use, non-compliance with

these operating instructions, assignment of insuciently qualied skilled

personnel or unauthorised modications to the instrument.

■

The general terms and conditions, contained in the sales

documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PV 20.01, PV 21.01, PV 21.02,

4

WIKA operating instructions models PGS10, PGS11 and PGS21

SP 21.01 and SP 21.03

11581752.02 09/2013 GB/D/F/E

Page 5

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result

in serious injury or death, if not avoided.

Information

… points out useful tips, recommendations and information

for ecient and trouble-free operation.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure

that the appropriate pressure gauge has been selected in

terms of measuring range, design and specic measuring

conditions.

In order to guarantee the measuring accuracy and long-term

stability specied, the corresponding load limits must be

observed.

Only work on the gauge with the voltage disconnected.

Non-observance can result in serious injury and/or damage

to equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

2.1 Intended use

The pressure gauges with switch contacts, switchGAUGE models PGS10,

PGS11 and PGS21, are used for controlling industrial processes for plant

monitoring and for the switching of circuits.

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

GB

5

Page 6

2. Safety

The instrument has been designed and built solely for the intended use

described here, and may only be used accordingly.

GB

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury to

personnel and damage to equipment.

■ The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their

technical training, knowledge of measurement and control technology and

on their experience and knowledge of country-specic regulations, current

standards and directives, are capable of carrying out the work described

and independently recognising potential hazards.

2.3 Special hazards

WARNING!

Dangerous pressure media such as oxygen, acetylene,

ammable gases or liquids, toxic gases or liquids as well

as for refrigeration plants or compressors require attention

above the standard regulations. Here the specic safety

codes or regulations must be considered.

WARNING!

Residual media in dismounted pressure gauges may result

in a risk to people, the environment and the system. Take

sucient precautionary measures.

6

WIKA operating instructions models PGS10, PGS11 and PGS21

11581752.02 09/2013 GB/D/F/E

Page 7

2. Safety

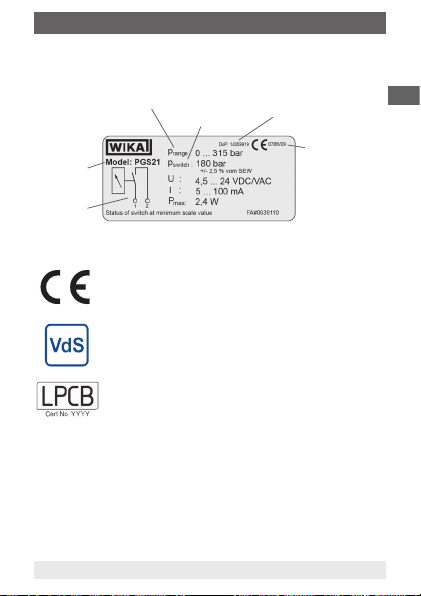

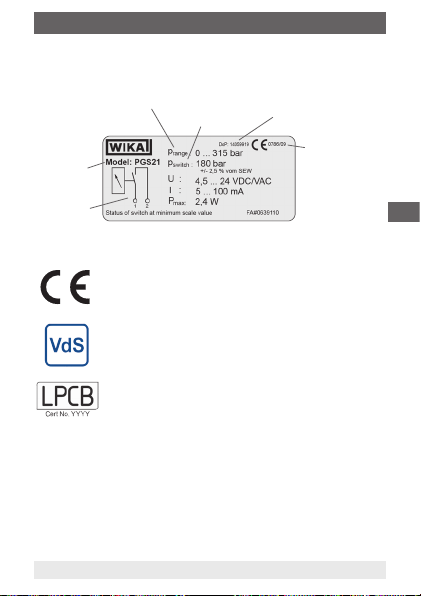

2.4 Labelling / safety marks

Product label

Prange ... scale range

Model

Pin

assignment

Explanation of symbols

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant

European directives.

Instruments bearing this mark are recognised by the VdS.

Instruments bearing this mark are recognised by the LPCB.

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

P

switch ... switch point

Reference number of the

declaration of performance

Identication number

of the product

certication body

including year of the

rst CE marking

GB

7

Page 8

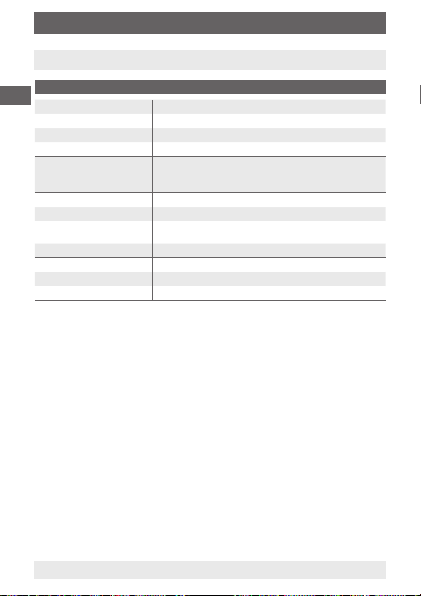

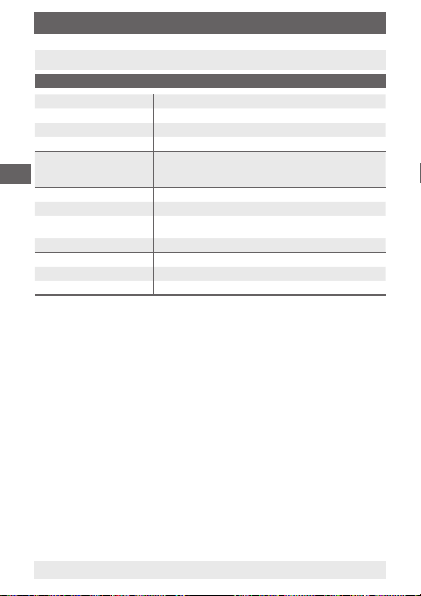

3. Specications

3. Specications

Models PGS10, PGS11 and PGS21

GB

Pressure limitation

- Steady 3/4 x full scale value

- Fluctuating 2/3 x full scale value

- Short time Full scale value

Temperature eect When the temperature of the measuring system

Ingress protection

- Enclosing case per EN 60529 / IEC 529

Operating temperature

- Ambient -20 ... +60 °C

- Medium Maximum +60 °C

For further specications see data sheet PV 20.01, PV 21.01, PV 21.02,

SP 21.01, SP 21.03 and the order documentation.

8

deviates from the reference temperature (+20 °C):

max. ±0.4 %/10 K of the span

Model PGS10 and PGS11: IP 41

(for PGS11.040 with VdS: IP 54)

Model PGS21: IP 65

WIKA operating instructions models PGS10, PGS11 and PGS21

11581752.02 09/2013 GB/D/F/E

Page 9

4. Design and function / 5. Electrical switch contacts

4. Design and function

Description

Bourdon tube measuring elements are widely used in technical pressure

measurement due to their robustness and ease-of-use. Under the inuence

of pressure, these measuring elements deform within their elastic limits.

This motion is converted, via a mechanical movement (toothed gear), into

a rotational motion. To this, an electrical limit switch is connected - the

magnetic snap-action contact. The contact closes or opens the connected

electrical circuits when the settable limit values are exceeded.

Scope of delivery

Cross-check scope of delivery with delivery note.

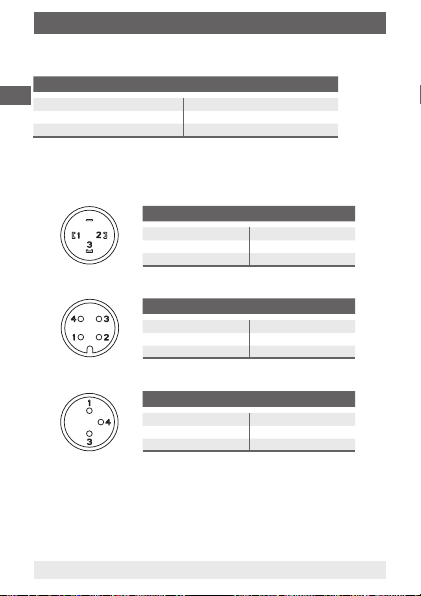

5. Electrical switch contacts

Electrical connection

■

The electrical connection must only be made by qualied skilled

personnel

■

Connection of the switches via cable or via screw terminals in the

terminal box (L-connector)

■

The terminal assignment is stated on the product label of the pressure

gauge

■

The gauges must be connected to the equipotential bonding of the plant

Electromagnetic compatibility

EMC per EN 60947-5-2.

The instruments are to be protected against strong electromagnetic elds.

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

GB

9

Page 10

5. Electrical switch contacts

Flying leads

Single contact Double contact

GB

red: U

black: SP 1 orange: SP 1

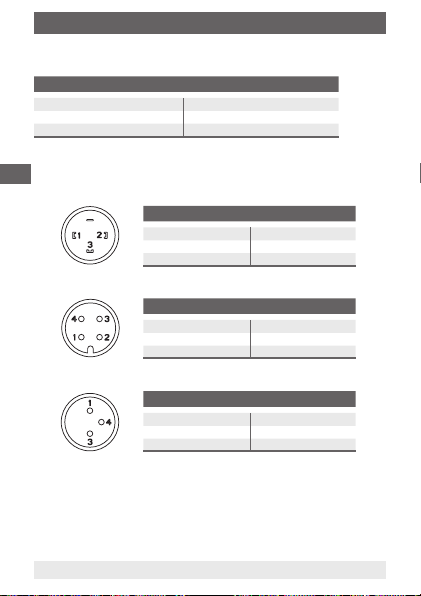

Electrical connection via connector (NS 50, 63)

If the IP ingress protection of the connector is lower than that of the

pressure gauge, then this determines the overall ingress protection of the

instrument.

10

+ red: UB+ (common)

B

black: SP 2

Angular connector EN 175301-803-C

Single contact Double contact

1: U

+ 1: UB+ (common)

B

2: SP 1 2: SP 1

3: SP 2

Circular connector M12 x 1

Single contact Double contact

1: U

+ 1: UB+ (common)

B

4: SP 1 4: SP 1

2: SP 2

Circular connector M8 x 1

Single contact Double contact

1: U

+ 1: UB+ (common)

B

4: SP 1 4: SP 1

WIKA operating instructions models PGS10, PGS11 and PGS21

3: SP 2

11581752.02 09/2013 GB/D/F/E

Page 11

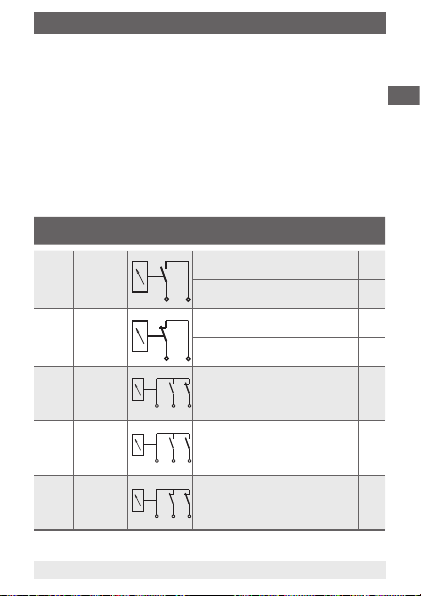

5. Electrical switch contacts

Magnetic snap-action contact (normally closed or normally open)

The instruments are delivered with a single or double contact (normally

closed or normally open).

With 'normally closed', the contact ag is engaged with the limit switch and,

on rising pressure, disengages from the contact via the actuator attached to

the pointer. The circuit will be interrupted.

With 'normally open' the contact ag follows the pointer until the limit value

is reached. Once the limit value has been exceeded, the contact ag

engages and the circuit is closed.

The switching function of the switch is indicated by the index 1, 2, 12, 11

or 22.

Index Designa-

1 Normally

2 Normally

12 Normally

11 Normally

22 Normally

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

Symbol Switching function / setting

tion

open

(NO)

closed

(NC)

open /

closed

(NO-NC)

open /

open

(NO-NO)

closed /

closed

(NC-NC)

direction

Contact makes with rising pressure or

clockwise pointer motion (standard)

Contact breaks with falling pressure or

anticlockwise pointer motion

Contact breaks with rising pressure or

clockwise pointer motion (standard)

Contact makes with falling pressure or

anticlockwise pointer motion

See switching function or setting

direction for single contact

See switching function or setting

direction for single contact

See switching function or setting

direction for single contact

GB

Code

1

5

2

4

11

Page 12

5. Electrical switch contacts / 6. Transport, packaging ...

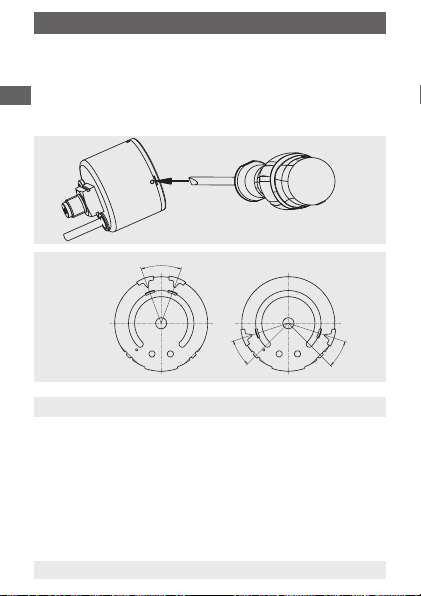

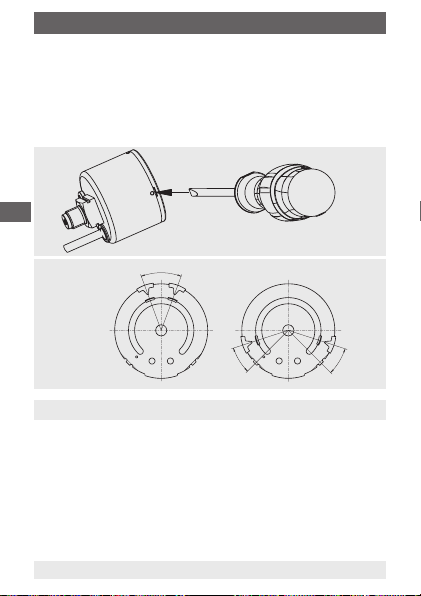

Switch point adjustment (models PGS10 and PGS11)

To adjust the switch point, carefully loosen the window using a screwdriver.

The contact (red mark pointer) can then be set to the desired position by

GB

hand. It can be set between 10 % and 90 % of the full scale value.

Afterwards, lightly push the window back into the case.

If the switch point of the instruments approved by VdS is changed

by the customer, the customer will lose the VdS approval.

Adjustability of

contacts

15 % FSV

10 % FSV

6. Transport, packaging and storage

6.1 Transport

Check pressure gauge for any damage that may have been caused by

transport.

Obvious damage must be reported immediately.

6.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport

(e.g. change in installation site, sending for repair).

12

WIKA operating instructions models PGS10, PGS11 and PGS21

31023461.01

10 % FSV

11581752.02 09/2013 GB/D/F/E

Page 13

6. Transport, packaging ... / 7. Commissioning, operation

6.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +70 °C

7. Commissioning, operation

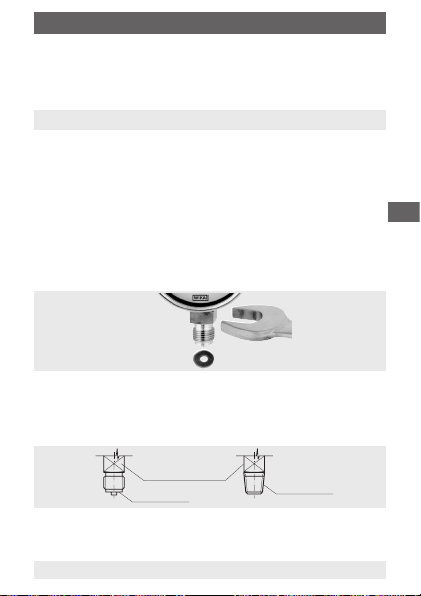

Mechanical connection

In accordance with the general technical regulations for pressure gauges

(e.g. EN 837-2 "Selection and installation recommendations for pressure

gauges").

If the pressure gauge is mounted lower than the pressure tapping, the

capillary must be ushed thoroughly before connection in order to clear out

any foreign matter.

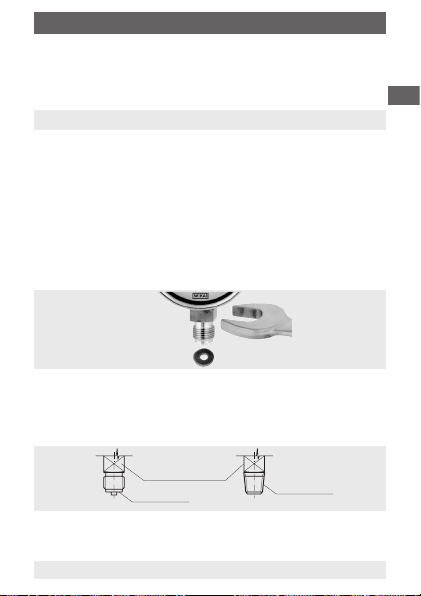

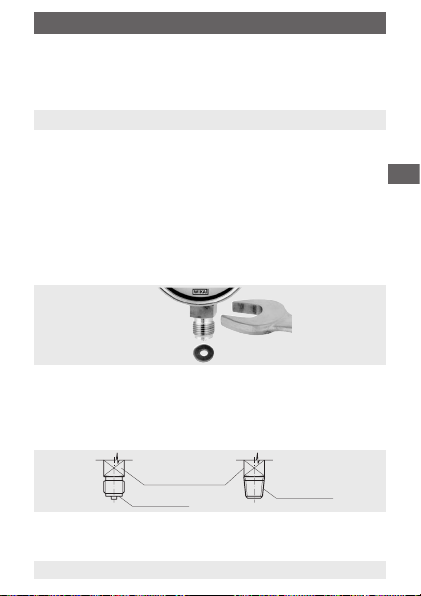

When screwing gauges in, the force required for this must not be applied

through the case, but rather through the spanner ats (using a suitable tool)

provided for this purpose on the square shaft of standard connections.

Installation with

spanner

Correct sealing of pressure gauge connections with parallel threads must

be made using suitable sealing rings, sealing washers or WIKA prole seals.

The sealing of tapered threads (e.g. NPT threads) is made by providing the

thread

, with additional sealing material such as, for example, PTFE tape

(EN 837-2).

GB

Wrench surface

Sealing face

The torque depends on the seal used. Connecting the gauge using a clamp

socket or a union nut is recommended, so that it is easier to orientate the

11581752.02 09/2013 GB/D/F/E

gauge correctly.

WIKA operating instructions models PGS10, PGS11 and PGS21

Sealing in the

thread

13

Page 14

7. Commissioning, operation

Requirements for the installation point

If the measuring point is not adequately stable a measuring instrument

support such as a bracket or ange should be used for fastening (and

GB

possibly via a exible capillary line). If the pressure gauge is exposed to

vibration or pulsating pressure or both, then a liquid lled pressure gauge

may provide considerably better performance and readability. Instruments

should be protected against coarse dirt and wide uctuations in ambient

temperature.

Installation

■

Nominal position per EN 837-1 / 9.6.7 Figure 9: 90° ( ⊥ )

■

Process connection bottom or rear!

■

In order to avoid any additional heating, the instruments must not be

exposed to direct solar irradiation while in operation!

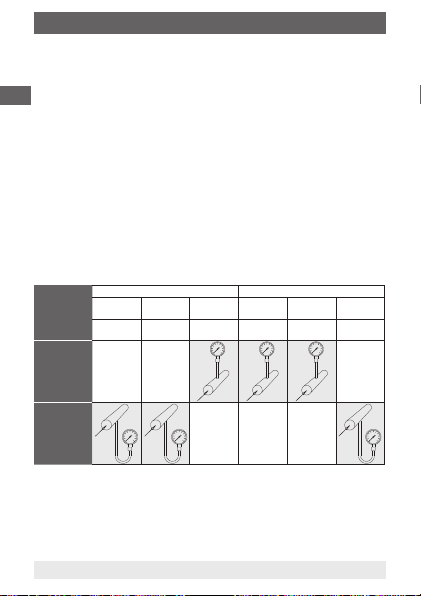

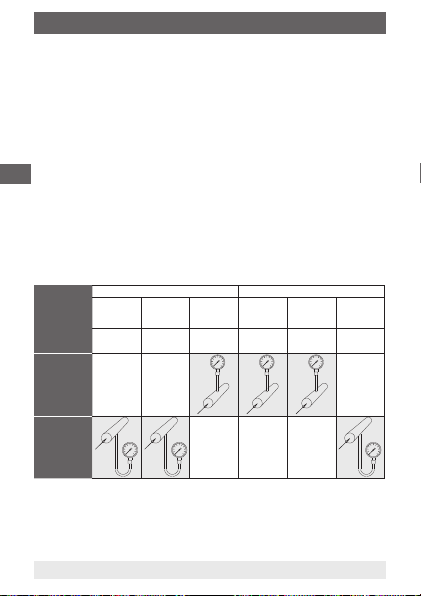

Measuring assemblies

Proven measuring assemblies for various types of media.

liquid media gaseous media

Filling of the

capillary

Examples

Pressure

gauge above

the tapping

point

Pressure

gauge below

the tapping

point

Admissible ambient and working temperatures

When mounting the pressure gauge it must be ensured that, taking into

consideration the inuence of convection and heat radiation, no deviation

above or below the permissible ambient and medium temperatures can

occur. The inuence of temperature on the display accuracy must be

observed.

14

liquid with

liquid

condensate boiling liquid

vapour only gaseous wet gas

vapour

"liqueed

gases"

dry air

moist air, ue

gases

WIKA operating instructions models PGS10, PGS11 and PGS21

liquid gas

condensate

Steam

11581752.02 09/2013 GB/D/F/E

Page 15

7. Commissioning, operation / 8. Maintenance and cleaning

Permissible vibration load at the installation site

■

The instruments should always be installed in locations free from

vibration.

■

If the pipe to the gauge is not rigid enough for a vibration-free

installation, the gauge should be mounted by means of mounting

devices for surface or pipe mounting, and, if necessary, with a capillary.

■

If necessary, it is possible to isolate the instrument from the mounting

point by installing a exible connection line between the measuring

point and the pressure gauge and mounting the instrument on a suitable

bracket.

■

If this is not possible, the following limit values must not be exceeded:

Frequency range < 150 Hz

Acceleration < 0.5 g (5 m/s

2

)

Commissioning

During the commissioning process pressure surges must be avoided at all

costs. Open the shut-o valves slowly.

8. Maintenance and cleaning

8.1 Maintenance

■

The instruments are maintenance-free.

■

The indicator and switching function should be checked once or twice

every year. The gauge must be disconnected from the process to check

with a pressure testing device.

■

Repairs are only to be carried out by the manufacturer or appropriately

trained skilled personnel.

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

GB

15

Page 16

8. Maintenance and cleaning / 9. Dismounting and disposal

8.2 Cleaning

CAUTION!

GB

■

Before cleaning, correctly disconnect the pressure gauge

from the pressure supply, switch it o and disconnect it

from the mains.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with

moisture.

■

Wash or clean the dismounted instrument before

returning it, in order to protect persons and the

environment from exposure to residual media.

9. Dismounting and disposal

WARNING!

Residual media in dismounted pressure gauges may result

in a risk to people, the environment and the system. Take

sucient precautionary measures.

9.1 Dismounting

Only disconnect the pressure gauge once the system has been depressurised!

9.2 Disposal

Incorrect disposal may endanger the environment.

Dispose of instrument components and packaging materials in an environ-

mentally compatible way and in accordance with the country-specic waste

disposal regulations.

16

WIKA operating instructions models PGS10, PGS11 and PGS21

11581752.02 09/2013 GB/D/F/E

Page 17

WIKA Alexander Wiegand SE & Co. KG

Germany

Peter Koll

Daniel Kotlewski

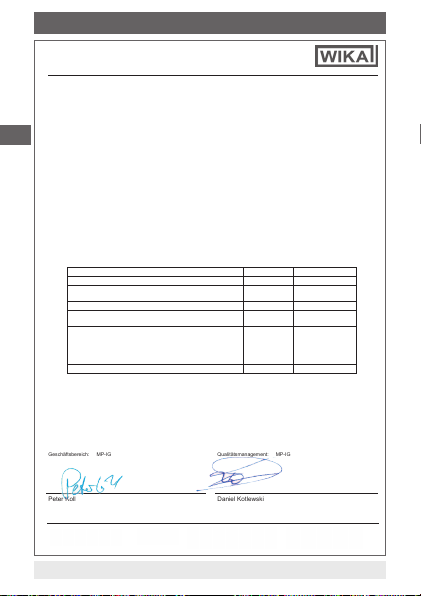

Appendix 1: Declaration of performance model PGS11.040

DECLARATION OF PERFORMANCE

according Construction Performance Regulation EU Nr. 305/2011

Tel. +49 9372 132-0

Fax +49 9372 132-406

E-Mail info@wika.de

www.wika.de

Document No.: 14059917.02

Kommanditgesellschaft: Sitz Klingenberg –

Amtsgericht Aschaffenburg HRA 1819

Komplementärin: WIKA Verwaltungs SE & Co. KG –

Sitz Klingenberg –Amtsgericht Aschaffenburg

HRA 4685

as part of e complete operating system.

ued following certificate of certificate of

pass

pass

pass

pass

1. Identification: pressure gauge with switch

2. Model: PGS11.040 according to data sheet SP 21.01

3. Intended use according EN 12094-10: 2003

Components for use in gas extinguishing systems in buildings

4. Manufacturer:

WIKA Alexander Wiegand SE & Co.KG

Alexander-Wiegand-Str. 30, DE 63911 Klingenberg

5. Representative: Not applicable

6. Assessment: System 1

7. Notified body:

VdS Schadenverhütung GmbH, 0786 has performed type testing of the product, initial inspection of the

manufacturing plant and of factory production control with continuous surveillance, assessment and

evaluation of factory production control under system 1 and iss

conformity 0786-CPD-30089.

8. European Technical Assessment: Not applicable

9. Declared performance:

Essential Characteristics Performance EN 12094-10:2003

Operational reliability -- general pass 4.1.1

Nominal activation conditions/sensitivity

- accuracy class and nominal size pass 4.1.2

Durability of operational reliability against - corrosion pass 4.1.3

Nominal activation conditions/sensitivity

- accuracy class and nominal size pass 4.2.1

Operational reliability

- Design

- Internal pressure

- Operational reliability

- Temperature

Durability of operational reliability against - corrosion pass 4.2.6

10. The performance of the product identified in points 1 and 2 is in conformity with the declared performance in point

9. This declaration of performance is issued under the sole responsibility of the manufacturer identified in point 4.

Signed for and on behalf of

WIKA Alexander Wiegand SE & Co. KG

Klingenberg, 2013-08-02

Company devision: MP-IG Quality management: MP-IG

Signature authorized by the company

Alexander-Wiegand-Straße 30

63911 Klingenberg

11581752.02 09/2013 GB/D/F/E

WIKA operating instructions models PGS10, PGS11 and PGS21

4.2.2

4.2.3

4.2.4

4.2.5

Komplementärin:

WIKA International SE -Sitz Klingenberg Amtsgericht Aschaffenburg HRB 10505

Vorstand: Alexander Wiegand

Vorsitzender des Aufsichtsrats: Dr. Max Egli

GB

17

Page 18

Tel. +49 9372 132-0

www.wika.de

Vorsitzender des Aufsichtsrats: Dr. Max Egli

Appendix 2: Declaration of performance model PGS21.050

GB

1. Identification: pressure gauge with switch

2. Model: PGS21.050 according to data sheet SP 21.03

3. Intended use according EN 12094-10: 2003

Components for use in gas extinguishing systems in buildings as part of e complete operating system.

4. Manufacturer:

WIKA Alexander Wiegand SE & Co.KG

Alexander-Wiegand-Str. 30, DE 63911 Klingenberg

5. Representative: N

6. Assessment: System 1

7. Notified body:

VdS Schadenverhütung GmbH, 0786 has performed type testing of the product, initial inspection of the

manufacturing plant and of factory production control with continuous surveillance, assessment and

evaluation of factory production control under system 1 and issued following certificate of certificate of

conformity 0786-CPD-30095.

8. European Technical Assessment: Not applicable

9. Declared performance:

Essential Char

Operational reliability -- general pass 4.1.1

Nominal activation conditions/sensitivity

- accuracy class and nominal size pass 4.1.2

Durability of operational reliability against - corrosion pass 4.1.3

Nominal activation conditions/sensitivity

- accuracy class and nominal size pass 4.2.1

Operational reliability

- Design

- Internal pressure

- Operational reliability

- Temperature

Durability of operational reliability against - corrosion pass 4.2.6

10. The performance of the product identified in points 1 and 2 is in conformity with the declared performance in point

9. This declaration of performance is issued under the sole responsibility of the manufacturer identified in point 4.

Signed for and on behalf of

WIKA Alexander Wiegand SE & Co. KG

Klingenberg, 2013-08-02

Company devision: MP-IG Quality management: MP-IG

Peter Koll Daniel Kotlewski

Signature authorized by the company

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

Germany

18

DECLARATION OF PERFORMANCE

according Construction Performance Regulation EU Nr. 305/2011

Document No.: 14059919.02

ot applicable

acteristics Performance EN 12094-10:2003

pass

pass

pass

pass

Kommanditgesellschaft: Sitz Klingenberg –

Amtsgericht Aschaffenburg HRA 1819

Fax +49 9372 132-406

Komplementärin: WIKA Verwaltungs SE & Co. KG –

E-Mail info@wika.de

Sitz Klingenberg –Amtsgericht Aschaffenburg

HRA 4685

WIKA operating instructions models PGS10, PGS11 and PGS21

4.2.2

4.2.3

4.2.4

4.2.5

Komplementärin:

WIKA International SE -Sitz Klingenberg Amtsgericht Aschaffenburg HRB 10505

Vorstand: Alexander Wiegand

11581752.02 09/2013 GB/D/F/E

Page 19

Inhalt

Inhalt

1. Allgemeines

2. Sicherheit

3. Technische Daten

4. Aufbau und Funktion

5. Elektrische Schaltkontakte

6. Transport, Verpackung und Lagerung

7. Inbetriebnahme, Betrieb

8. Wartung und Reinigung

9. Demontage und Entsorgung

Anlage 1: Leistungserklärung Typ PGS11.040

Anlage 2: Leistungserklärung Typ PGS21.050

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

20

D

21

24

25

25

28

29

31

32

33

34

19

Page 20

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Druckmessgerät wird nach

dem aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen

Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach

D

ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem

Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller

angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer

Nähe des Gerätes für das Fachpersonal jederzeit zugänglich

aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten

sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz

ungenügend qualizierten Fachpersonals sowie eigenmächtiger

Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den

Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: PV 20.01, PV 21.01, PV 21.02,

20

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

SP 21.01 und SP 21.03

11581752.02 09/2013 GB/D/F/E

Page 21

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie

Informationen für einen ezienten und störungsfreien Betrieb

hervor.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen,

dass das richtige Druckmessgerät hinsichtlich Messbereich,

Ausführung und spezischen Messbedingungen ausgewählt

wurde.

Die Belastungsgrenzen sind einzuhalten, um die

Messgenauigkeit und die Lebensdauer zu gewährleisten.

Alle Arbeiten dürfen nur im spannungslosen Zustand

erfolgen.

Bei Nichtbeachten können schwere Körperverletzungen und/

oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Die Druckmessgeräte mit Schaltkontakten switchGAUGE Typen

PGS10, PGS11 und PGS21 dienen zum Steuern und Regeln von

Industrieprozessen, zur Anlagenüberwachung und zum Schalten von

Stromkreisen.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungs-

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

D

21

Page 22

2. Sicherheit

gemäßen Verwendungszweck konzipiert und konstruiert und darf nur

dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

D

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■ Die in dieser Betriebsanleitung beschriebenen Tätigkeiten

nur durch Fachpersonal nachfolgend beschriebener

Qualikation durchführen lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen

sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen

und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen und

mögliche Gefahren selbstständig zu erkennen.

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen,

brennbaren oder giftigen Stoen, sowie bei Kälteanlagen,

Kompressoren etc. müssen über die gesamten allgemeinen

Regeln hinaus die jeweils bestehenden einschlägigen

Vorschriften beachtet werden.

WARNUNG!

Messstoreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Personen, Umwelt und Einrichtung

führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

22

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

11581752.02 09/2013 GB/D/F/E

Page 23

2. Sicherheit

2.4 Beschilderung / Sicherheitskennzeichnungen

Typenschild

Prange ... Anzeigebereich

Typ

Anschlussbelegung

Symbolerklärung

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

Geräte mit dieser Kennzeichnung sind vom VdS

anerkannt.

Geräte mit dieser Kennzeichnung sind vom LPCB

anerkannt.

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

P

switch ... Schaltpunkt

Bezugsnummer der

Leistungserklärung

Kennnummer der

Produktzertizierungsstelle mit Jahr

der ersten CEKennzeichnung

D

23

Page 24

3. Technische Daten

3. Technische Daten

Typen PGS10, PGS11 und PGS21

Druckbelastbarkeit

- Ruhebelastung 3/4 x Skalenendwert

- Wechselbelastung 2/3 x Skalenendwert

D

- Kurzzeitig Skalenendwert

Temperatureinuss Bei Abweichung von der Referenztemperatur am Messsy-

Schutzart

- Umhüllendes Gehäuse nach EN 60529 / IEC 529

Zulässige Temperatur

- Umgebung -20 ... +60 °C

- Messsto Maximal +60 °C

Weitere technische Daten siehe Datenblatt PV 20.01, PV 21.01, PV 21.02,

SP 21.01, SP 21.03 und Bestellunterlagen.

24

stem (+20 °C): max. ± 0,4 %/10 K von der Anzeigespanne

Typ PGS10 und PGS11: IP 41

(bei PGS11.040 mit VdS: IP 54)

Typ PGS21: IP 65

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

11581752.02 09/2013 GB/D/F/E

Page 25

4. Aufbau und Funktion / 5. Elektrische Schaltkontakte

4. Aufbau und Funktion

Beschreibung

Als Messelement werden die in der technischen Druckmesstechnik wegen

ihrer Robustheit und einfachen Handhabung weit verbreiteten Rohrfeder-

Messglieder verwendet. Unter dem Einuss des Drucks verformen sich

diese Messglieder im elastischen Bereich.

Diese Bewegung wird über ein mechanisches Messwerk (Zahnräder) in

eine Drehbewegung umgesetzt. Zu dem ist ein elektrischer Grenzwertschalter eingebaut, der sogenannte Magnetspringkontakt. Der Kontakt

schließt oder önet die angeschlossenen Stromkreise bei Überschreiten

der einstellbaren Grenzwerte.

Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Elektrische Schaltkontakte

Elektrischer Anschluss

■

Der elektrische Anschluss darf nur durch qualiziertes Fachpersonal

erfolgen

■

Anschluss der Schalter über Kabel oder über Schraubklemmen in der

Kabeldose (Winkelstecker)

■

Klemmenbelegung auf Typenschild am Druckmessgerät

■

Die Geräte sind in den Potenzialausgleich der Anlage mit einzubeziehen

Elektromagnetische Verträglichkeit

EMV gemäß EN 60947-5-2.

Die Geräte sind vor starken elektromagnetischen Feldern zu schützen.

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

D

25

Page 26

5. Elektrische Schaltkontakte

Kabelausgang

Einzelkontakt Doppelkontakt

rot: U

schwarz: SP 1 orange: SP 1

D

Elektrischer Anschluss über Stecker (NG 50, 63)

Wenn die IP-Schutzart des Steckverbinders kleiner ist als die des Druckmessgerätes, bestimmt diese die Gesamtschutzart des Gerätes.

26

+ rot: UB+ (common)

B

schwarz: SP 2

Winkelstecker EN 175301-803-C

Einzelkontakt Doppelkontakt

1: U

+ 1: UB+ (common)

B

2: SP 1 2: SP 1

Rundsteckverbinder M12 x 1

Einzelkontakt Doppelkontakt

1: U

+ 1: UB+ (common)

B

4: SP 1 4: SP 1

Rundsteckverbinder M8 x 1

Einzelkontakt Doppelkontakt

1: U

+ 1: UB+ (common)

B

4: SP 1 4: SP 1

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

3: SP 2

2: SP 2

3: SP 2

11581752.02 09/2013 GB/D/F/E

Page 27

5. Elektrische Schaltkontakte

Magnetspringkontakt (Öner oder Schließer)

Die Geräte werden mit einem Einfach- oder Doppelkontakt (Öner oder

Schließer) ausgeliefert.

Bei einem Öner liegt die Kontaktfahne an dem Grenzwertschalter an und

wird durch den am Zeiger angebrachten Mitnehmer, bei steigendem Druck,

vom Kontakt gelöst. Der Stromkreis wird unterbrochen.

Bei einem Schließer folgt die Kontaktfahne dem Zeiger nach, bis der Grenz-

wertschalter erreicht ist. Nach Überschreiten des Grenzwertschalters liegt

die Kontaktfahne an und der Stromkreis ist geschlossen.

Die Schaltfunktion des Schalters wird durch die Kennzahl 1, 2, 12, 11 oder

22 angegeben.

Kenn-

Bezeich-

zahl

1 Schließer

2 Öner

12 Schließer-

11 Schließer-

22 Öner-

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

Symbol Schaltfunktion / Einstellrichtung Code

nung

Kontakt schließt bei steigendem Druck

(NO)

(NC)

Öner

(NO-NC)

Schließer

(NO-NO)

Öner

(NC-NC)

bzw. Zeigerbewegung im Uhrzeigersinn

(Standard)

Kontakt önet bei fallendem Druck

bzw. Zeigerbewegung gegen den

Uhrzeigersinn

Kontakt önet bei steigendem Druck

bzw. Zeigerbewegung im Uhrzeigersinn

(Standard)

Kontakt schließt bei fallendem Druck

bzw. Zeigerbewegung gegen den

Uhrzeigersinn

Siehe Schaltfunktion bzw.

Einstellrichtung bei Einzelkontakt

Siehe Schaltfunktion bzw.

Einstellrichtung bei Einzelkontakt

Siehe Schaltfunktion bzw.

Einstellrichtung bei Einzelkontakt

D

1

5

2

4

27

Page 28

5. Elektrische Schaltkontakte / 6. Transport, Verpackung ...

Schaltpunktverstellung (Typen PGS10 und PGS11)

Zur Verstellung des Schaltpunktes die Sichtscheibe mit einem Schraubendreher vorsichtig lösen. Der Kontakt (roter Markenzeiger) kann daraufhin

per Hand auf die gewünschte Position gestellt werden. Er ist zwischen 10 %

und 90 % vom Skalenendwert verstellbar.

Sichtscheibe anschließend unter leichtem Druck wieder ins Gehäuse

D

drücken.

Wird bei VdS zugelassenen Geräten der Schaltpunkt vom

Kunden verstellt, so geht die VdS-Zulassung verloren.

Einstellbarkeit

der Kontakte

15 % SEW

10 % SEW

6. Transport, Verpackung und Lagerung

6.1 Transport

Druckmessgerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

6.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

28

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

31023461.01

10 % SEW

11581752.02 09/2013 GB/D/F/E

Page 29

6. Transport, Verpackung ... / 7. Inbetriebnahme, Betrieb

6.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -20 ... +70 °C

7. Inbetriebnahme, Betrieb

Mechanischer Anschluss

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte

(z. B. EN 837-2 "Auswahl- und Einbauempfehlungen für Druckmessgeräte").

Ist das Druckmessgerät tiefer als der Druckentnahmestutzen angeordnet,

muss die Messleitung vor dem Anschließen gut durchgespült werden, um

Fremdkörper zu beseitigen.

Beim Einschrauben der Geräte darf die zum Abdichten erforderliche Kraft

nicht über das Gehäuse oder die Kabelanschlussdose aufgebracht werden,

sondern mit geeignetem Werkzeug nur über die dafür vorgesehenen

Schlüsselächen am Vierkant des Anschlusszapfens.

Montage mit

Gabelschlüssel

D

Zur Abdichtung der Druckmessgeräteanschlüsse mit zylindrischem

Gewinde an der Dichtäche

WIKA-Proldichtungen einzusetzen. Bei kegeligem Gewinde (z. B.

NPT-Gewinde) erfolgt die Abdichtung im Gewinde

Dichtwerkstoen, wie z. B. PTFE-Band (EN 837-2).

Das Anzugsmoment ist von der eingesetzten Dichtung abhängig. Um das

Messgerät in die Stellung zu bringen, in der es sich am besten ablesen

11581752.02 09/2013 GB/D/F/E

lässt, ist ein Anschluss mit Spannmue oder Überwurfmutter zu empfehlen.

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

sind Flachdichtungen, Dichtlinsen oder

Schlüsseläche

Dichtäche

, mit zusätzlichen

Abdichtung im

Gewinde

29

Page 30

7. Inbetriebnahme, Betrieb

Anforderungen an die Einbaustelle

Ist die Leitung zum Messgerät für eine erschütterungsfreie Anbringung nicht

stabil genug, sollte (evtl. über eine exible Kapillarleitung) die Befestigung

mittels Messgerätehalterung erfolgen. Können Erschütterungen nicht durch

geeignete Installationen vermieden werden, sollten Geräte mit Flüssigkeitsfüllung eingesetzt werden. Die Geräte sind vor grober Verschmutzung und

D

starken Schwankungen der Umgebungstemperatur zu schützen.

Installation

■

Nennlage nach EN 837-1 / 9.6.7 Bild 9: 90° ( ⊥ )

■

Prozessanschluss unten bzw. rückseitig!

■

Um zusätzliche Aufheizung zu vermeiden, dürfen die Geräte im Betrieb

keiner direkten Sonneneinstrahlung ausgesetzt werden!

Messanordnungen

Bewährte Messanordnungen für verschiedene Messstoarten.

üssige Messstoe gasförmige Messstoe

Füllung der

Messleitung

Beispiele

Druckmessgerät

oberhalb des

Entnahmestutzens

Druckmessgerät

unterhalb des

Entnahmestutzens

üssig

Kondensat

zum Teil

ausgasend

siedende

Flüssigkeiten

vollständig

verdampft

„Flüssiggase“ trockene Luft

Zulässige Umgebungs- und Betriebstemperaturen

Die Anbringung des Druckmessgerätes ist so auszuführen, dass die

zulässigen Umgebungs- und Messstotemperaturgrenzen, auch unter

Berücksichtigung des Einusses von Konvektion und Wärmestrahlung,

weder unter- noch überschritten werden. Der Temperatureinuss auf die

Anzeigegenauigkeit ist zu beachten.

30

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

gasförmig

z. T. kondensiert feucht)

feuchte Luft,

Rauchgase

vollständig

kondensiert

Wasserdampf

11581752.02 09/2013 GB/D/F/E

Page 31

7. Inbetriebnahme, Betrieb / 8. Wartung und Reinigung

Zulässige Schwingungsbelastung am Einbauort

■

Die Geräte sollten grundsätzlich nur an Stellen ohne

Schwingungsbelastung eingebaut werden

■

Ist die Leitung zum Druckmessgerät für eine erschütterungsfreie

Anbringung nicht stabil genug, so ist die Befestigung über

entsprechende Befestigungselemente für Wand- und/oder

Rohrmontage, ggf. über eine Kapillarleitung vorzunehmen.

■

Gegebenenfalls kann z. B. durch eine exible Verbindungsleitung von

der Messstelle zum Druckmessgerät und die Befestigung über eine

Messgerätehalterung eine Entkopplung vom Einbauort erreicht werden.

■

Falls dies nicht möglich ist, dürfen folgende Grenzwerte nicht

überschritten werden:

Frequenzbereich < 150 Hz

Beschleunigung < 0,5 g (5 m/s

2

)

Inbetriebnahme

Bei Inbetriebnahme Druckstöße unbedingt vermeiden, Absperrventile

langsam önen.

8. Wartung und Reinigung

8.1 Wartung

■

Die Geräte sind wartungsfrei.

■

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis

2 Mal pro Jahr erfolgen. Dazu ist das Gerät vom Prozess zu trennen und

mit einer Druckprüfvorrichtung zu kontrollieren.

■

Reparaturen sind ausschließlich vom Hersteller oder entsprechend

qualiziertem Fachpersonal durchzuführen.

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

D

31

Page 32

8. Wartung und Reinigung / 9. Demontage und Entsorgung

8.2 Reinigung

VORSICHT!

■

Vor der Reinigung das Druckmessgerät ordnungsgemäß

von der Druckversorgung trennen, ausschalten und vom

D

Netz trennen.

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in

Berührung bringen.

■

Ausgebautes Gerät vor der Rücksendung spülen bzw.

säubern, um Personen und Umwelt vor Gefährdung

durch anhaftende Messstoreste zu schützen.

9. Demontage und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Personen, Umwelt und Einrichtung

führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

Druckmessgerät nur im drucklosen Zustand demontieren!

9.2 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

32

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

11581752.02 09/2013 GB/D/F/E

Page 33

Kommanditgesellschaft: Sitz Klingenberg –

HRA 4685

Geschäftsbereich: MP-IG

Qualitätsmanagement: MP-IG

Peter Koll

Daniel Kotlewski

Anlage 1: Leistungserklärung Typ PGS11.040

LEISTUNGSERKLÄRUNG

gemäß Bauprodukteverordnung EU Nr. 305/2011

installiert ist.

Dokument Nr.: 14059917.02

bestanden

bestanden

bestanden

bestanden

4.2.2

4.2.3

4.2.4

4.2.5

1. Beschreibung: Druckmessgerät mit Grenzsignalgeber

2. Typ: PGS11.040 nach Datenblatt SP 21.01

3. Verwendungszweck gemäß EN 12094-10: 2003

Bauteil für die Verwendung in Löschanlagen mit gasförmigen Löschmitteln, das in Gebäuden

als Teil einer Anlage

4. Hersteller:

WIKA Alexander Wiegand SE & Co.KG

Alexander-Wiegand-Str. 30, DE 63911 Klingenberg

5. Bevollmächtigter: Nicht zutreffend

6. Bewertung: System 1

7. Notifizierte Stelle:

VdS Schadenverhütung GmbH, 0786 hat die Typprüfung des Produkts, die Erstinspektion des Werks und

der werkseigenen Produktionskontrolle mit laufender Überwachung, Bewertung und Evaluierung der

werkseigenen Produktionskontrolle unter System 1 durchgeführt und das EG-Konformitätszertifikat 0786C

PD-30089 ausgestellt.

8. Europäische Technische Bewertung: Nicht zutreffend

9. Erklärte Leistung

Wesentliche Merkmale Leistung EN 12094-10:2003

Betriebszuverlässigkeit - Allgemeines bestanden 4.1.1

Nennansprechbedingungen/Annsprechempfindlichkeit

- Genauigkeitsklasse und Nenngröße bestanden 4.1.2

Stabilität der Betriebszuverlässigkeit gegen - Korrosion bestanden 4.1.3

Nennansprechbedingungen/Ansprechempfindlichkeit

- Genauigkeitsklasse und Nenngröße bestanden 4.2.1

Betriebszuverlässigkeit

- Konstruktion

- Innendruck

- Betriebssicherheit

- Temperatur

Stabilität der Betriebszuverlässigkeit gegen -Korrosion bestanden 4.2.6

10. Die Leistung des Produkts gemäß den Nummern 1 und 2 entspricht der erklärten Leistung nach Nummer 9.

Verantwortlich für die Erstellung dieser Leistungserklärung ist allein der Hersteller gemäß Nummer 4.

Unterzeichnet für und im Namen von

WIKA Alexander Wiegand SE & Co. KG

Klingenberg, 2013-08-02

D

Unterschrift, autorisiert durch das Unternehmen

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

Germany

11581752.02 09/2013 GB/D/F/E

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

Tel. +49 9372 132-0

Fax +49 9372 132-406

E-Mail info@wika.de

www.wika.de

Amtsgericht Aschaffenburg HRA 1819

Komplementärin: WIKA Verwaltungs SE & Co. KG –

Sitz Klingenberg –Amtsgericht Aschaffenburg

Komplementärin:

WIKA International SE -Sitz Klingenberg Amtsgericht Aschaffenburg HRB 10505

Vorstand: Alexander Wiegand

Vorsitzender des Aufsichtsrats: Dr. Max Egli

33

Page 34

HRA 4685

Komplementärin:

Geschäftsbereich: MP-IG

Qualitätsmanagement: MP-IG

Peter Koll

Daniel Kotlewski

Anlage 2: Leistungserklärung Typ PGS21.050

LEISTUNGSERKLÄRUNG

gemäß Bauprodukteverordnung EU Nr. 305/2011

stellt.

Dokument Nr.: 14059919.02

bestanden

bestanden

bestanden

bestanden

1. Beschreibung: Druckmessgerät mit Grenzsignalgeber

D

2. Typ: PGS21.050 nach Datenblatt SP 21.03

3. Verwendungszweck gemäß EN 12094-10: 2003

Bauteil für die Verwendung in Löschanlagen mit gasförmigen Löschmitteln, das in Gebäuden

als Teil einer Anlage installiert ist.

4

. Hersteller:

WIKA Alexander Wiegand SE & Co.KG

Alexander-Wiegand-Str. 30, DE 63911 Klingenberg

5. Bevollmächtigter: Nicht zutreffend

6. Bewertung: System 1

7. Notifizierte Stelle:

VdS Schadenverhütung GmbH, 0786 hat die Typprüfung des Produkts, die Erstinspektion des Werks und

der werkseigenen Produktionskontrolle mit laufender Überwachung, Bewertung und Evaluierung der

werkseigenen Produktionskontrolle unter System 1 durchgeführt und das EG-Konformitätszertifikat 0786CPD-30095 ausge

8. Europäische Technische Bewertung: Nicht zutreffend

9. Erklärte Leistung

Wesentliche Merkmale Leistung EN 12094-10:2003

Betriebszuverlässigkeit - Allgemeines bestanden 4.1.1

Nennansprechbedingungen/Annsprechempfindlichkeit

- Genauigkeitsklasse und Nenngröße bestanden 4.1.2

Stabilität der Betriebszuverlässigkeit gegen - Korrosion bestanden 4.1.3

Nennansprechbedingungen/Ansprechempfindlichkeit

- Genauigkeitsklasse und Nenngröße bestanden 4.2.1

Betriebszuverlässigkeit

- Konstruktion

- Innendruck

- Betriebssicherheit

- Temperatur

Stabilität der Betriebszuverlässigkeit gegen - Korrosion bestanden 4.2.6

10. Die Leistung des Produkts gemäß den Nummern 1 und 2 entspricht der erklärten Leistung nach Nummer 9.

Verantwortlich für die Erstellung dieser Leistungserklärung ist allein der Hersteller gemäß Nummer 4.

Unterzeichnet für und im Namen von

WIKA Alexander Wiegand SE & Co. KG

Klingenberg, 2013-08-02

4.2.2

4.2.3

4.2.4

4.2.5

Unterschrift, autorisiet durch das Unternehmen

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

Germany

34

Kommanditgesellschaft: Sitz Klingenberg –

Tel. +49 9372 132-0

Fax +49 9372 132-406

E-Mail info@wika.de

www.wika.de

Amtsgericht Aschaffenburg HRA 1819

Komplementärin: WIKA Verwaltungs SE & Co. KG –

Sitz Klingenberg –Amtsgericht Aschaffenburg

WIKA International SE -Sitz Klingenberg Amtsgericht Aschaffenburg HRB 10505

Vorstand: Alexander Wiegand

Vorsitzender des Aufsichtsrats: Dr. Max Egli

WIKA Betriebsanleitung Typen PGS10, PGS11 und PGS21

11581752.02 09/2013 GB/D/F/E

Page 35

Sommaire

Sommaire

1. Généralités

2. Sécurité

3. Caractéristiques techniques

4. Conception et fonction

5. Contacts électriques

6. Transport, emballage et stockage

7. Mise en service, exploitation

8. Entretien et nettoyage

9. Démontage et mise au rebut

Appendix 1 : Declaration de performance type PGS11.040

Appendix 2 : Declaration de performance type PGS21.050

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

36

37

F

40

41

41

44

45

47

48

49

50

35

Page 36

1. Généralités

1. Généralités

■

Le manomètre décrit dans le présent mode d’emploi est conçu

et fabriqué selon les dernières technologies en vigueur. Tous les

composants sont soumis à des critères de qualité et d’environnement

stricts durant la fabrication. Nos systèmes de gestion sont certiés selon

ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant

l'utilisation de l'instrument. Il est possible de travailler en toute sécurité

F

avec ce produit en respectant toutes les consignes de sécurité et

d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents

et les prescriptions générales de sécurité en vigueur pour le domaine

d'application de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à

proximité immédiate de l'instrument et accessible à tout moment pour

le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu

soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages

provoqués par une utilisation non conforme à l'usage prévu, de non

respect de ce mode d'emploi, d'utilisation de personnel peu qualié

de même qu'en cas de modications de l'instrument eectuées par

l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de

vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site internet : www.wika.de / www.wika.com

- Fiche technique

correspondante :

36

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

PV 20.01, PV 21.01, PV 21.02,

SP 21.01 et SP 21.03

11581752.02 09/2013 GB/D/F/E

Page 37

1. Généralités / 2. Sécurité

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est

pas évitée.

Information

… met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s‘assurer que le manomètre a été choisi de façon adéquate,

en ce qui concerne la plage de mesure, la version et les

conditions de mesure spéciques.

Les limites de surpression admissible sont à respecter an

d'assurer la précision et la durée de vie.

Toutes les interventions doivent être eectuées hors tension.

Un non respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d'emploi.

2.1 Utilisation conforme à l'emploi prévu

Les manomètres à contacts électriques«switchGAUGE» des types PGS10,

PGS11 et PGS21 servent aux contrôle des processus industriels, à la

surveillance des installations et à la mise en marche de circuits électriques.

L'instrument est conçu et construit exclusivement pour une utilisation

conforme à l'usage prévu décrit ici et ne doit être utilisé qu'en conséquence.

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

F

37

Page 38

2. Sécurité

Aucune réclamation ne peut être recevable en cas d‘utilisation non

conforme à l‘usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication

insusante !

F

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses

connaissances dans le domaine de la technique de mesure et de régulation

et de ses expériences de même que de sa connaissance des prescriptions

nationales des normes et directives en vigueur, en mesure d'eectuer les

travaux décrits et de reconnaître automatiquement les dangers potentiels.

2.3 Dangers particuliers

38

Une utilisation non conforme peut entraîner d‘importants

dommages corporels et matériels.

■ Les opérations décrites dans ce mode d‘emploi ne

doivent être eectuées que par un personnel ayant la

qualication décrite ci-après.

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l‘oxygène, l‘acétylène, des substances combustibles

ou toxiques, ainsi que dans le cas d‘installations de réfrigération, de compresseurs etc., les directives appropriées

existantes doivent être observées en plus de l‘ensemble des

règles générales.

AVERTISSEMENT !

Les restes de uides se trouvant dans des manomètres

démontés peuvent mettre en danger les personnes,

l‘environnement ainsi que l‘installation.

Prendre des mesures de sécurité susantes.

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

11581752.02 09/2013 GB/D/F/E

Page 39

2. Sécurité

2.4 Etiquetage / Marquages de sécurité

Plaque signalétique

Prange ... Echelle de mesure

Type

Raccordement

électrique

Explication des symboles

CE, Communauté Européenne

Les appareils avec ce marquage sont conformes aux

directives européennes pertinentes.

Les instruments avec ce marquage sont homologués

par VdS.

Les instruments avec ce marquage sont homologués

par LPCB.

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

P

switch ... Point de seuil

Numéro de référence de la

déclaration de performance

Numéro

d‘identication

de l‘organisme

de certication

du produit et

l‘année du premier

marquage CE

F

39

Page 40

3. Caractéristiques techniques

3. Caractéristiques techniques

Types PGS10, PGS11 et PGS21

Limitations en pression

- Charge statique 3/4 x n d'échelle

- Charge dynamique 2/3 x n d'échelle

- Temporaire Fin d'échelle

Inuence de la

température

F

Degré de protection

- Boîtier enveloppant selon EN 60529 / IEC 529

Température admissible

- Ambiant -20 ... +60 °C

- Fluide de mesure max +60 °C

Pour les autres caractéristiques techniques, voir che technique PV 20.01,

PV 21.01, PV 21.02, SP 21.01, SP 21.03 et documents de commande.

40

Erreur d’achage en cas de divergence de la

température de référence (+20 °C) sur l’organe

moteur : max. ±0,4 %/10 K de l‘étendue de mesure

Type PGS10 et PGS11 : IP 41

(pour PGS11.040 agréés VdS : IP 54)

Type PGS21: IP 65

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

11581752.02 09/2013 GB/D/F/E

Page 41

4. Conception et fonction / 5. Contacts électriques

4. Conception et fonction

Description

Les tubes de Bourdon sont très largement utilisés comme élément de

mesure dans la technologie de mesure de pression en raison de leur

solidité et de leur facilité d‘emploi. Sous l‘inuence de la pression, ces

éléments de mesure se déforment dans la zone d‘élasticité.

Ce mouvement est transformé en mouvement rotatif au moyen d‘un

dispositif de mesure mécanique (secteur denté). Cet instrument integre

un seuil d’alarme électrique. Ce seuil d’alarme est généré par un contact

électrique sec à aimant. Le contact ouvre ou ferme les circuits électriques

raccordés en cas de dépassement des seuils réglables.

Détail de la livraison

Le matériel doit être en accord avec le descriptif du bordereau de livraison.

5. Contacts électriques

Raccordement électrique

■

Le raccordement électrique ne doit être eectué que par du personnel

qualié.

■

Le branchement des contacts se fait par câble ou par borniers à vis

dans la boîte de jonction (che coudée).

■

Le plan du borniers se trouve sur la plaque signalétique du manomètre

■

Les appareils sont à inclure dans la compensation de potentiel de

l’installation

Compatibilité électromagnétique

CEM selon EN 60947-5-2.

Les appareils sont à protéger contre de forts champs électromagnétiques.

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

F

41

Page 42

5. Contacts électriques

Sortie de câble

Contact individuel Double contact

rouge : U

noir : SP 1 orange : SP 1

Raccordement électrique par connecteur (diamètre 50, 63)

F

Si l‘indice de protection du connecteur est plus faible que celui du

manomètre, alors c‘est lui qui détermine l‘indice de protection global de

l‘instrument.

42

+ rouge : UB+ (commun)

B

noir : SP 2

Connecteur coudé EN 175301-803 C

Contact individuel Double contact

1 : U

+ 1 : UB+ (commun)

B

2 : SP 1 2 : SP 1

Connecteur circulaire M12 x 1

Contact individuel Double contact

1 : U

+ 1 : UB+ (commun)

B

4 : SP 1 4 : SP 1

Connecteur circulaire M8 x 1

Contact individuel Double contact

1 : U

+ 1 : UB+ (commun)

B

4 : SP 1 4 : SP 1

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

3 : SP 2

2 : SP 2

3 : SP 2

11581752.02 09/2013 GB/D/F/E

Page 43

5. Contacts électriques

Contact électrique sec à aimant (contact à ouverture ou contact à

fermeture)

Les appareils sont livrés avec un simple contact ou un double contact

(contact à ouverture ou contact à fermeture).

Pour un contact à ouverture, au repos la lamelle de contact du seuil d‘alarme

est active. Le circuit électrique est fermé à pression croissante lorsque l’aiguille

atteint le point de seuil, cette dernière entraine avec elle la lamelle de contact. Le

contact est interrompu.

Le circuit électrique est ouvert pour un contact à fermeture, la lamelle de contact

suit l‘aiguille jusqu‘à ce que seuil d‘alarme soit atteint. Lorsque le seuil d‘alarme

est atteint, la lamelle de contact est active et le circuit électrique est fermé.

La fonction de commutation du seuil est indiquée par le chire d'identication

1, 2, 12, 11 ou 22.

Chire Désigna-

1 Contact à

2 Contact à

12

11

22

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

Symbole Fonction de commutation / sens

tion

fermeture

(NO)

ouverture

(NC)

Contact à

fermeture /

ouverture

(NO-NC)

Contact à

fermeturecontact à

fermeture

(NO-NO)

Contact à

ouverture

- contact à

ouverture

(NC-NC)

de réglage

Le contact se ferme lorsque à pression croissante

le point de seuil réglé est dépassé. (Rotation dans

le sens des aiguilles d’une montre) (standard)

Le contact s’ouvre à pression décroissante lorsque

l’aiguille indique une pression inférieure à celle

du seuil réglé (rotation dans le sens inverse des

aiguilles d’une montre)

Le contact s’ouvre lorsque à pression croissante le

point de seuil réglé est dépassé. (Rotation dans le

sens des aiguilles d’une montre) (standard)

Le contact se ferme à pression décroissante

lorsque l’aiguille indique une pression inférieure à

celle du seuil réglé (rotation dans le sens inverse

des aiguilles d’une montre)

Voir la fonction de commutation ou

le sens de réglage pour le contact

individuel

Voir la fonction de commutation ou

le sens de réglage pour le contact

individuel

Voir la fonction de commutation ou

le sens de réglage pour le contact

individuel

F

Code

1

5

2

4

43

Page 44

5. Contacts électriques / 6. Transport, emballage ...

Réglage des points de commutation (types PGS10 et PGS11)

Pour le réglage du point de commutation, desserrer avec précaution le

voyant à l'aide d'un tournevis. Le point de seuil (l‘indicateur de marque

rouge) peut être ensuite réglé manuellement à la position souhaitée. Il peut

être réglé entre 10 % et 90 % de valeur nale de l'échelle.

Ensuite remonter le voyant en le clipsant sur le boîtier.

F

La modication du point de commutation des dispositifs homologués

VdS par le client entraîne une perte de l‘homologation VdS.

Capacité de

réglage des

contacts

6. Transport, emballage et stockage

6.1 Transport

Vérier s‘il existe des dégâts sur l‘appareil liés au transport. Communiquer

immédiatement les dégâts constatés.

6.2 Emballage

N‘enlever l‘emballage qu‘avant le montage.

Conserver l‘emballage, celui-ci ore, lors d‘un transport, une protection

optimale (par ex. changement de lieu d‘utilisation, renvoi pour réparation).

44

15 % de n d‘échelle

10 % de

n d‘échelle

10 % de

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

31023461.01

n d‘échelle

11581752.02 09/2013 GB/D/F/E

Page 45

6. Transport, emballage ... / 7. Mise en service, exploitation

6.3 Stockage

Conditions admissibles sur le lieu de stockage

Température de stockage : -20 ... +70 °C

7. Mise en service, exploitation

Raccordement mécanique

Conformément aux règles techniques générales pour les manomètres

(par exemple EN 837-2 Recommandations sur le choix et l‘installation des

manomètres).

Si le manomètre est placé à un niveau inférieur à celui du raccord de la

prise de pression, la conduite de mesure doit être bien nettoyée avant le

montage an d'éliminer les corps étrangers.

Lors du vissage des appareils, la force nécessaire ne doit pas être

appliquée sur le boîtier ou la prise câblée, mais seulement sur les surfaces

prévues à l'aide d'un outil approprié sur le carré du raccord.

Montage avec clé

à fourche

Pour assurer l’étanchéité du raccord avec letage cylindrique du

manomètre sur la surface d‘étanchéité

des joints forme lentille ou les joints à écrasement WIKA. Pour les letages

coniques (par exemple letage NPT) l‘étanchéité sur le letage

en utilisant en plus un matériau d‘étanchéité comme par exemple la bande

PTFE (selon EN 837-2).

il faut utiliser des joints plats,

se fait

F

Clef plate

Surface d‘étanchéité

Le couple de serrage dépend du joint utilisé. An de positionner l‘appareil

de mesure de façon à ce qu‘il soit facilement lisible, il est recommandé

11581752.02 09/2013 GB/D/F/E

d‘utiliser un manchon de serrage ou un écrou-chapeau.

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

Etanchéité

sur letage

45

Page 46

7. Mise en service, exploitation

Exigences particulières sur le point de montage

Si la conduite à l‘appareil de mesure n‘est pas susamment stable pour

un montage sans vibrations il faut prévoir la xation par l‘intermédiaire

d‘un support d‘appareil de mesure (et éventuellement par un capillaire

exible). S‘il n‘est pas possible de supprimer les vibrations par un montage

approprié, il faut utiliser des manomètres à remplissage de liquide. Les

instruments doivent être protégés contre un encrassement important et

contre les uctuations de la température ambiante.

Installation

F

■

Position de base selon EN 837-1 / 9.6.7. image 9: 90° ( ⊥ )

■

Raccord process vertical ou arrière !

■

Les instruments ne doivent pas être exposés directement aux rayons

solaires en cours d’utilisation pour ne pas provoquer d’échauement

additionnel !

Installation sur le point de mesure

Types d’installations éprouvés selon diérents uides.

Fluides liquides Fluides gazeux

Remplissage

liquides

de la conduite

de mesure

condensat

Exemples

Manomètre

au-dessus

du point de

mesure

Manomètre

au-dessous

du point de

mesure

Températures ambiantes et de service autorisées

Le montage du manomètre est à réaliser de façon que la température de

service autorisée (ambiante et uide à mesurer), même sous l‘inuence

de la chaleur de convection et de radiation, ne doit pas être dépassée en

augmentation ou en diminution. Il faut prendre en considération l‘inuence

de la température pour la précision de la pression indiquée.

46

comp-

en partie

lètement

gazeux

évaporés

liquides en

"gaz liquides" air sec

ébullition

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

uide

gazeux

en partie

condensés

(humides)

air humide,

gaz de

combustion

entièrement

condensé

vapeur d‘eau

11581752.02 09/2013 GB/D/F/E

Page 47

7. Mise en service, exploitation / 8. Entretien et nettoyage

Contrainte de vibration admissible sur le point de montage

■

Les appareils ne devraient en principe être installés que sur des

applications exemptes de vibrations.

■

Si le raccordement au manomètre n'est pas assez robuste pour réaliser

une xation exempte de vibrations, la xation doit être réalisée au

moyen d'éléments de xation pour montage mural et/ou sur tube, le cas

échéant par l'intermédiaire d'un capillaire.

■

Le cas échéant, on peut atteindre un isolement du point de mesure en

utilisant une liaison exible au manomètre et en le xant à l’aide d’un

support mural.

■

Dans le cas où cela n‘est pas possible, les valeurs suivantes ne doivent

pas être dépassées :

Plage de fréquence < 150 Hz

Accélération < 0,5 g (5 m/s

2

)

Mise en Service

Lors de la mise en service il faut absolument éviter les coups de bélier.

Ouvrir lentement lesrobinets d’isolement.

8. Entretien et nettoyage

8.1 Entretien

■

Les instruments ne requièrent aucun entretien.

■

Un contrôle de l’achage et des fonctions de commande est recom-

mandé 1 à 2 fois/an. Pour le contrôle de l’achage et des fonctions de

commande, il faut isoler l’appareil du process et le contrôler avec un

dispositif de contrôle de pression.

■

Toute réparation doit être exclusivement conée au fabricant ou au

personnel qualié correspondant.

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

F

47

Page 48

8. Entretien et nettoyage / 9. Démontage et mise au rebut

8.2 Nettoyage

ATTENTION !

■

Avant le nettoyage, il est impératif de mettre le

manomètre hors pression, de le mettre hors circuit et

de le séparer du secteur.

■

Nettoyer l‘instrument avec un chion humide.

■

F

Eviter tout contact des raccords électriques avec

l‘humidité.

■

Laver ou nettoyer l‘instrument démonté avant de

le retourner an de protéger les personnes et

l‘environnement contre le danger lié aux restes de uides

adhérents.

9. Démontage et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des manomètres

démontés peuvent mettre en danger les personnes,

l‘environnement ainsi que l‘installation.

Prendre des mesures de sécurité susantes.

9.1 Démontage

Démonter le manomètre uniquement qu‘en état exempt de pression !

9.2 Élimination des déchets

Une mise au rebut inadéquate peut entraîner des dangers pour

l'environnement.

Éliminer les composants des appareils et les matériaux d'emballage

conformément aux prescriptions nationales pour le traitement et

l'élimination des déchets et aux lois de protection de l'environnement en

vigueur.

48

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

11581752.02 09/2013 GB/D/F/E

Page 49

WIKA Alexander Wiegand SE & Co. KG

Germany

Peter Koll

Daniel Kotlewski

Appendix 1: Declaration de performance type PGS11.040

DECLARATION DE PERFORMANCE

Selon Réglementation de Performance de Construction EU Nr. 305/2011

1. Identification: manomètre à contact

2. Type: PGS11.040 selon la fiche technique SP 21.01

3. Usage prévu selon EN 12094-10: 2003

Composants pour utilisation sur systèmes d’extinction gazeux dans

système de fonctionnement complet.

4. Fabricant:

WIKA Alexander Wiegand SE & Co.KG

Alexander-Wiegand-Str. 30, DE 63911 Klingenberg

5. Représentant: Non applicable

6. Evaluation: Système 1

7. Organisme notificateur:

VdS Schadenverhütung GmbH, 0786 a réalisé un test type du produit, une inspection initiale du site de

production et du contrôle de production de l’usine avec surveillance continue, une évaluation de contrôle de

production de l’usine

30089.

8. Evaluation Tecnique Europénne: Non applicable

9. Performance déclarée:

Caractéristiques essentielles Performance EN 1209 4-10:2003

Fiabilité opérationelle -- général réussi 4.1.1

Conditions d’activation nominale/sensibilité

- classe de precision et diamètre réussi 4.1.2

Durabilité de la fiabilité opérationnelle contre la corrosion réussi 4.1.3

Conditions d’activation nominale/sensibilité

- classe de precision et diamètre réussi 4.2.1

Fiabilité opérationnelle

- Conception

- Pression interne

- Fiabilité opérationnelle

- Température

Durabilité de la fiabilité opérationnelle contre la corrosion réussi 4.2.6

10. La performance du produit identifié aux points 1 et 2 est en conformité avec la performance déclarée au point 9.

Cette déclaration de performance est émise sous la seule responsabilité du fabricant identifié au point 4.

Signé pour et de la part de

WIKA Alexander Wiegand SE & Co. KG

Klingenberg, 2013-08-02

Division de la société:: MP-IG Management dela qualité: MP-IG

Signature autorisée par la société

Alexander-Wiegand-Straße 30

63911 Klingenberg

11581752.02 09/2013 GB/D/F/E

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

Document No.: 14059917.02

des bâtiments en tant que partie d’un

sous le système 1 et émis le certificat suivant de certificat de conformité 0786-CPD-

réussi

réussi

réussi

réussi

Kommanditgesellschaft: Sitz Klingenberg –

Tel. +49 9372 132-0

Amtsgericht Aschaffenburg HRA 1819

Fax +49 9372 132-406

Komplementärin: WIKA Verwaltungs SE & Co. KG –

E-Mail info@wika.de

Sitz Klingenberg –Amtsgericht Aschaffenburg

www.wika.de

HRA 4685

4.2.2

4.2.3

4.2.4

4.2.5

Komplementärin:

WIKA International SE -Sitz Klingenberg Amtsgericht Aschaffenburg HRB 10505

Vorstand: Alexander Wiegand

Vorsitzender des Aufsichtsrats: Dr. Max Egli

F

49

Page 50

Kommanditgesellschaft: Sitz Klingenberg –

Appendix 2: Declaration de performance type PGS21.050

DECLARATION DE PERFORMANCE

Selon Réglementation de Performance de Construction EU Nr. 305/2011

1. Identification: manomètre à contact

2. Type: PGS21.050 selon la fiche technique SP 21.03

3. Usage prévu selon EN 12094-10: 2003

Composants pour utilisation sur systèmes d’extinction gazeux dans d

système de fonctionnement complet.

4. Fabricant:

F

WIKA Alexander Wiegand SE & Co.KG

Alexander-Wiegand-Str. 30, DE 63911 Klingenberg

5. Représentant: Non applicable

6. Evaluation: Système 1

7. Organisme notificateur:

VdS Schadenverhütung GmbH, 0786 a réalisé un test type du produit, une inspection initiale du site de

production et du contrôle de production de l’usine avec surveillance continue, une évaluation de contrôle de

production de l’usine

30095.

8. Evaluation Tecnique Europénne: Non applicable

9. Performance déclarée:

Caractéristiques essentielles Performance EN 12094-10:2003

Fiabilité opérationelle -- général réussi 4.1.1

Conditions d’activation nominale/sensibilité

- classe de precision et diamètre réussi 4.1.2

Durabilité de la fiabilité opérationnelle contre la corrosion réussi 4.1.3

Conditions d’activation nominale/sensibilité

- classe de precision et diamètre réussi 4.2.1

Fiabilité opérationnelle

- Conception

- Pression interne

- Fiabilité opérationnelle

- Température

Durabilité de la fiabilité opérationnelle contre la corrosion réussi 4.2.6

10. La performance du produit identifié aux points 1 et 2 est en conformité avec la performance déclarée au point 9.

Cette déclaration de performance est émise sous la seule responsabilité du fabricant identifié au point 4.

Signé pour et de la part de

WIKA Alexander Wiegand SE & Co. KG

Klingenberg, 2013-08-02

Division de la société: MP-IG Management dela qualité: MP-IG

Peter Koll Daniel Kotlewski

Signature autorisée par la société

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

Germany

50

Document No.: 14059919.02

es bâtiments en tant que partie d’un

sous le système 1 et émis le certificat suivant de certificat de conformité 0786-CPD-

réussi

réussi

réussi

réussi

Tel. +49 9372 132-0

Amtsgericht Aschaffenburg HRA 1819

Fax +49 9372 132-406

Komplementärin: WIKA Verwaltungs SE & Co. KG –

E-Mail info@wika.de

Sitz Klingenberg –Amtsgericht Aschaffenburg

www.wika.de

HRA 4685

WIKA mode d‘emploi types PGS10, PGS11 et PGS21

4.2.2

4.2.3

4.2.4

4.2.5

Komplementärin:

WIKA International SE -Sitz Klingenberg Amtsgericht Aschaffenburg HRB 10505

Vorstand: Alexander Wiegand