Page 1

Operating instructions

Betriebsanleitung

Mode d´emploi

Manual de instrucciones

Pressure gauge with electrical output signal and

pressure gauge with electronic pressure switch

Druckmessgerät mit elektrischem Ausgangssignal und

Druckmessgerät mit elektronischem Druckschalter

Manomètre avec signal de sortie électrique et

manomètre avec pressostat électronique

Manómetro con señal eléctrica y

manómetro con presostato electrónico

PGT01 PGT21, PGS25PGT11, PGS07

PGT02, PGS05 PGT10, PGS06

GB

D

F

E

Page 2

Operating instructions

GB

intelliGAUGE / switchGAUGE

Betriebsanleitung

D

intelliGAUGE / switchGAUGE

Mode d´emploi

F

intelliGAUGE / switchGAUGE

Manual de instrucciones

E

intelliGAUGE / switchGAUGE

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

WIKA Operating instructions intelliGAUGE / switchGAUGE

2

Page 3-10

Seite 11-18

Page 19-26

Página 27-34

11349167.03 10/2011 GB/D/F/E

Page 3

Contents

Contents

1. Safety 4

2. Operating principle 4

3. Installation instruction 5

4. Installation and commissioning 6

5. Measuring arrangements 7

6. Electrical connection 8

7. Servicing / Maintenance / Cleaning / Repairing 9

8. Storage 9

9. Troubleshooting 10

10. Technical data 10

Information

This symbol provides you with information, notes and

tips.

Warning!

This symbol warns you against actions that can cause

11349167.03 10/2011 GB/D/F/E

injury to people or damage to the instrument.

WIKA operating instructions intelliGAUGE / switchGAUGE

GB

3

Page 4

1. Safety / 2. Operating principle

1. Safety

The appropriate national safety regulations (e.g. EN 837-2

GB

„Selection and installation recommendations for pressure

gauges“) must be ob-served when installing, commissioning and operating these devices.

■

Serious injuries and/or damage may occur should the appropriate

regulations not be observed.

■

Only appropriately qualied personnel should work on these

instruments.

■

The eective maximum surface temperature is not dependant upon

the device, but mainly on the temperature of the respective pressure medium! In the case of gaseous substances, the temperature

may increase due to compression warming. In these cases it may

be necessary to throttle the rate of change of pressure or reduce

the permissible temperature of the pressure medium.

2. Operating principle

Bourdon tubes are widely used as measuring elements for technical

pressure measurement due to their robustness and ease-of-use. Under

the inuence of pressure these measuring elements will deform within their

elastic range.

This movement is converted into a rotary motion by means of a mechanical

movement (gear). A magnet, xed to the pointer axle, turns with the

instrument´s pointer in direct proportion to the process pressure. The

electronics positioned facing the magnet detect the rotational motion of the

magnet.

The electronics’ non-contact sensor element (Hall sensor), aected by the

magnetic eld, detects any changes, free from any friction and wear to the

measuring element.

The sensor signal, which is in direct proportion to the angle of motion, is

transformed into an output signal. The span of the electrical output signal

corresponds to the measuring span of the dial.

An intelliGAUGE line pressure gauge with electrical output signal combines

all the advantages of an on-site display without the need for an external

power supply, with the demands of modern electronic measurement for

electrical signal transmission.

WIKA operating instructions intelliGAUGE / switchGAUGE

4

11349167.03 10/2011 GB/D/F/E

Page 5

3. Installation instructions

3. Installation instructions

Installation

■

Nominal position acc. EN 873-3 / 9.6.6 gure 7: 0° or 90°

■

Pressure connector bottom or rearside

Permissible vibration load at the mounting point

■

The instrument should always be installed in locations free of vibration.

■

If necessary, it is possible to isolate the instrument from the mounting

point by installing a exible connection line between the measuring

point and the pressure gauge and mounting the instrument on a suitable

bracket.

■

If this is not possible, the following limit values must not be exceeded:

Unlled devices: Frequency range 10 … 150 Hz

Accelaration < 0.5 g (5.0 m/s²)

Liquid lled devices: Frequency range 10 … 150 Hz

Accelaration < 4.0 g (39.2 m/s²)

The liquid lling has to be checked periodically.

The liquid level must not drop below 75 % of the instrument´s diameter.

Test connector

At certain use cases (e.g. steam vessels) isolating devices have to have a

test connector, so that the instrument can be checked without dismounting.

Mounting provisions

If the line for the pressure gauge is not rigid enough for vibration-free installation, fasten the instrument using appropriate fastening elements for wall

and / or pipe mounting, and, if necessary, by means of a capillary line.

Measuring system damping

If it is not possible to avoid vibration by means of appropriate mounting, use

pressure gauges with liquid lling.

Eects of temperature

The mounting of the pressure instrument has to be done in a way that the

operating temperature is neither exceeded nor falls below the permissible

operating temperature, even in consideration of thermal convection and

thermal radiation. Tailpipes of a suitable length or syphons may be used to

protect the pressure instrument and the isolating device.

The inuence of the temperature onto the accuracy of indication and of

measurement has to be noticed.

11349167.03 10/2011 GB/D/F/E

WIKA operating instructions intelliGAUGE / switchGAUGE

GB

5

Page 6

3. Installation instructions / 4. Installation and ...

Diaphragm seal / protective barrier

In case of aggressive, hot, highly viscous, contaminated or crystallizing

pressure media, which must not be allowed to intrude the measurign

element, diaphragm seals have to be used as separating barrier. A neutral

GB

transmission uid, used to transmit the pressure to the measuring element,

should be selected in consideration of the measuring range, the temperature and its compatibility with the pressure media.

The connection between the pressure gauge and the diaphragm seal must

not be released by no means.

Protection of the measuring element against overload

If the pressure media is subject to rapid pressure changes or pressure

impulses may be expected, these must not act directly upon the measuring

element. The eect of pressure impulses must be damped, e.g. by installing

an integrated restrictor screw (reduction of the cross section in the pressure

channel) or by connecting an adjustable throttle device in series.

Pressure test connection

The pressure test connection, with a suciently large bore size (≥ 6 mm

diameter), should be arranged, as far as possible, over a shut-o device,

in a position where the accuracy of the reading will not be aected by the

ow of the media being measured. The pipe between the pressure test

connection and the pressure instrument should have an inner diameter

large enough to avoid blockages or delays in pressure transmission. Also it

should not have any sharp bends. It is recommended that it is mounted with

a steep incline of approx. 1:15.

Piping

The piping should be arranged and tted so that it can withstand the

stresses caused by expansion, vibration and the inuence of heat. When

the media is gaseous, a water drain point should be provided at the lowest

point. For liquid pressure media, an air bleed should be provided at the

highest point.

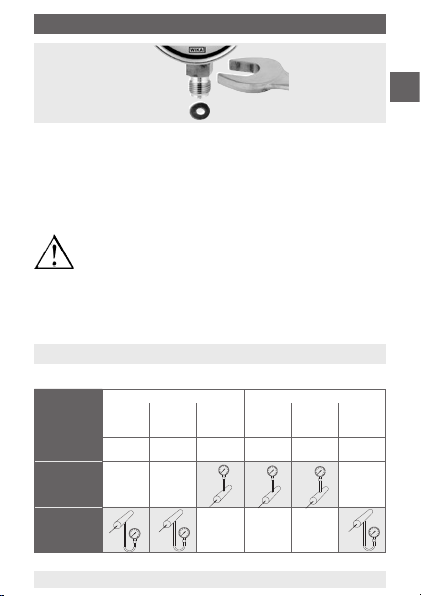

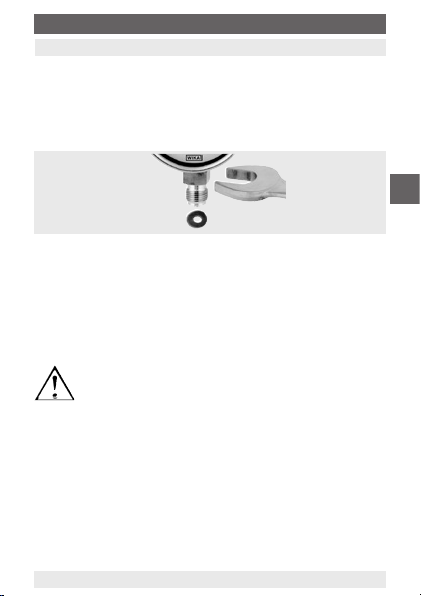

4. Installation and commissioning

To acchieve a correct sealing of pressure connections suitable sealing

rings, sealing washers or WIKA prole seals have to be used. In order to get

the pressure instrument into an orientation that allows to read the on-site

indicator the best, a connector with an adjusting nut or an union nut is

recommended. When mounting and dismounting it is not allowed to tighten

the pressure instruments by using the housing, but on the spanner ats of

the stem, only.

WIKA operating instructions intelliGAUGE / switchGAUGE

6

11349167.03 10/2011 GB/D/F/E

Page 7

4. Installation and commissioning / 5. Measuring arrangements

Installation using

a spanner

If the pressure transmitter is positioned lower than the pressure test

connection, the tailpipe has to be rinsed thoroughly prior to tting the gauge

to remove all foreign substances.

Once the pressure and electrical connections have been made, the trans-

mitter is ready for immediate use.

Before dismounting the pressure instrument the measuring element has to

be depressurized. Eventually the stress of the pipe has to be relieved.

Residual pressure medium remaining within the pressure

element may cause harm to men, facilities and environment.

Therefore sucient precautionary measures have to be

taken.

Pressure connector

In accordance with the general technical regulations for pressure gauges

(e.g. EN 837-2 „Selection and installation recommendations for pressure

gauges“).

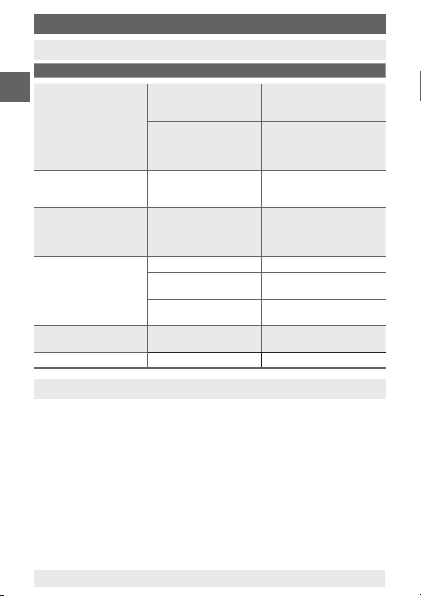

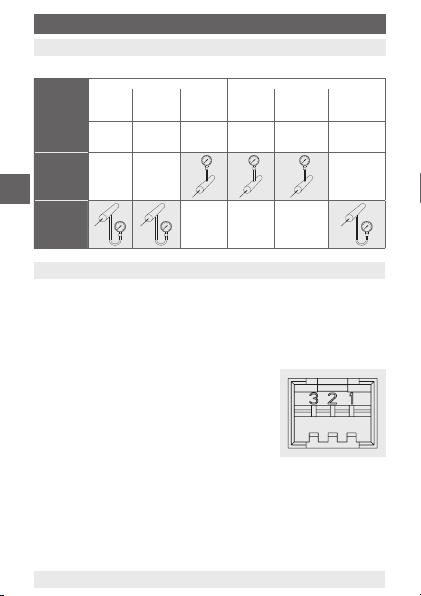

5. Measuring arrangements

Proven measuring arrangements for various types of media.

Liquid media Gaseous media

Contents of

tailpipe

Typically

Pressure

instrument

higher than

tapping point

Pressure instrument lower

than tapping

point

11349167.03 10/2011 GB/D/F/E

Liquid Liquid

Condensate

with

vapour

Boiling

liquid

Vapour

Gas only Wet gas Liquid

only

Liqueed

Dry air Moist air,

gas

Flue gas

gas condensate

Steam

WIKA operating instructions intelliGAUGE / switchGAUGE

GB

7

Page 8

6. Electrical connection

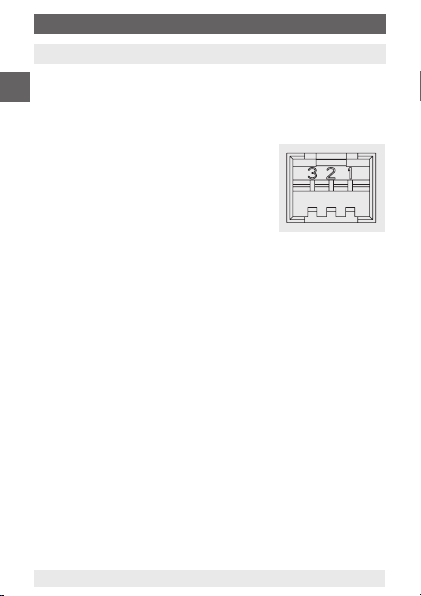

6. Electrical connection

The electrical connection of pressure gauges with an electrical output

/ electronic pressure switch is made via a plug or a cable. The correct

signal

GB

terminal connections can be seen in the table below.

Additionally the terminal assignment, output signal and necessary supply

voltage are written on the product label.

3-pin connector, model AMP Duoplug

Pin Signal

1 U

2 GND

3 U

Cable (2-wire)

Colour code Signal

black GND

red U

Cable (3-wire / 1 x NPN)

Colour code Signal

black GND

red U

orange U

Cable (4-wire / 2 x NPN)

Colour code Signal

black GND

red U

orange SP

brown SP

8

B+

SIG+

B+

B+

/ SP

SIG+

1

B+

1

2

WIKA operating instructions intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 9

7. Servicing, Maintenance, Cleaning, Repairing / 8. Storage

7. Servicing, Maintenance, Cleaning, Repairing

Always open isolating devices gently, never abruptly, since this may

generate sudden pressure surges that may damage the gauge.

Pressure instruments with an electrical output signal

require no maintenance and oer a long service life, if handled and

switch

operated properly. If the zero point drifts, it means that the instrument has

been overloaded.

Clean the instrument with a moistened cloth. If badly soiled, moisten the

cloth thoroughly with soapy water.

Repairs should be only be carried out by the manufacturer or by appropri-

ately trained sta.

8. Storage

Before the system is stored, all traces of any medium

residue must be removed. This is particularly important,

if the media is a health hazard such as corrosive, toxic,

carcinogenic, radioactice, etc.

Before installation, in order to prevent damage to the pressure

instrument, the following points should be observed:

■

The pressure instrument should be left in its original packaging until

installation.

■

After taking the instrument out (e.g. for test), reuse the original

packaging material.

■

The storage temperature should not be less than -40 °C or more

than +90 °C

Avoid the following inuences:

■

Direct sunlight or vicinity to hot objects

■

Mechanical vibration

■

Sot, steam, dust, humidity and corrosive gasses

■

Potentially explosive environment, inammable atmospheres

11349167.03 10/2011 GB/D/F/E

WIKA operating instructions intelliGAUGE / switchGAUGE

/ electronic pressure

GB

9

Page 10

9. Trouble shooting / 10. Technical data

9. Trouble shooting

Malfunction Possible cause Measure

GB

No output signal /

no switch signal

Steady signal despite

pressure changes

Excessively high,

steady signal despite

pressure changes

Full span reading

too low

Zero signal too low /

too high

Switch signal instable Supply voltage too low Adjust supply voltage

10. Technical data

For technical data please refer to the technical data sheets.

PV 11.01 intelliGAUGE, model PGT01, plug connector, NS 40

PV 11.02 intelliGAUGE, model PGT02, cable outlet, NS 40

PV 11.05 intelliGAUGE, model PGT10, plastic case, IP 41, NS 40, 50

PV 11.06 intelliGAUGE, model PGT11, stainless steel case, IP 41, NS 40, 50

PV 11.03 intelliGAUGE, model PGT21, stainless steel case, NS 50

PV 21.03 switchGAUGE, model PGS05, cable outlet, NS 40

PV 21.05 switchGAUGE, model PGS06, plastic case, IP 41, NS 40, 50

PV 21.06 switchGAUGE, model PGS07, stainless steel case, IP 41, NS 40, 50

PV 21.04 switchGAUGE, model PGS25, stainless steel case, NS 50

WIKA operating instructions intelliGAUGE / switchGAUGE

10

Failure of power supply

or wiring interrupted

Electronic defect

through incorrect

supply voltage or

external voltage

Pressure entry blocked Check tailpipes and

Electronic defect

through incorrect

supply voltage or

external voltage

Supply voltage too low Adjust supply voltage

Load impedance

too high

Zero point shifted Return instrument to

Zero point shifted Return instrument to

Check power supply and

wiring; replace defective

components

Return instrument to

manufacturer for repair

pressure entry bore, if necessary clean it carefully

Return instrument to

manufacturer for repair

Consider max. permissible

load

manufacturer for repair

manufacturer for repair

11349167.03 10/2011 GB/D/F/E

Page 11

Inhalt

Inhalt

1. Sicherheit 12

2. Funktionsprinzip 12

3. Montagehinweise 13

4. Montage und Inbetriebnahme 15

5. Messanordnung 15

6. Elektrischer Anschluss 16

7. Bedienung / Wartung / Reinigung / Reparatur 17

8. Lagerung 17

9. Maßnahmen bei Störungen 18

10. Technische Daten 18

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise oder

Tipps.

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

11349167.03 10/2011 GB/D/F/E

Personen oder am Gerät verursachen können.

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

D

11

Page 12

1. Sicherheit / 2. Funktionsprinzip

1. Sicherheit

Beachten Sie bitte unbedingt, bei Montage, Inbetriebnahme und Betrieb dieser Geräte die entsprechenden nationalen Sicherheitsvorschriften (z. B. EN 837-2 Auswahl- und

D

Einbauempfehlungen für Druckmessgeräte).

■

Bei Nichtbeachten der entsprechenden Vorschriften können

schwere Körperverletzungen und / oder Sachschäden auftreten.

■

Nur entsprechend qualiziertes Personal darf an diesen Geräten

arbeiten.

■

Die tatsächliche maximale Oberächentemperatur ist nicht von

diesen Geräten selbst abhängig, sondern hauptsächlich von

der jeweiligen Messstotemperatur! Bei gasförmigen Stoen

kann sich die Temperatur durch Kompressionswärme erhöhen.

In solchen Fällen muss ggf. die Geschwindigkeit der Änderung

des Drucks gedrosselt bzw. die zulässige Messstotemperatur

reduziert werden.

2. Funktionsprinzip

Als Messelement werden die in der technischen Druckmesstechnik wegen

ihrer Robustheit und einfachen Handhabung weit verbreiteten Rohrfeder-

messglieder verwendet. Unter dem Einuss des Drucks verformen sich diese

Messglieder im elastischen Bereich.

Diese Bewegung wird über ein mechanisches Messwerk (Zahnräder) in eine

Drehbewegung umgesetzt. Ein auf der Zeigerachse aufgesetzter Magnet

dreht sich proportional mit dem Instrumentenzeiger in direkter linearer

Abhängigkeit vom Prozessdruck. Die gegenüber dem Magneten positionierte

Elektronik erfasst die Drehbewegung des Magneten.

Ein magnetfeldabhängiger Sensor (Hall-Sensor) greift auf der elektronischen

Seite diese Veränderung berührungslos, verschleißfrei und ohne Rückwirkung

auf das Messglied ab.

Über einen Verstärker wird das der Drehbewegung proportionale Sensorsignal

in ein elektrisches Ausgangsignal umgewandelt. Die Spanne des elektrischen

Ausgangssignals entspricht der Messspanne auf dem Zierblatt. Mit entsprechender Transistorschaltung stehen auch Schaltausgänge zur Verfügung.

Ein Druckmessgerät mit elektrischem Ausgangssignal aus der Baureihe intelliGAUGE verbindet alle Vorteile einer fremdenergiefreien Vor-Ort-Anzeige mit

der Forderung nach einer elektrischen Signalübertragung für eine moderne

elektronische Messwerterfassung.

12

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 13

3. Montagehinweise

3. Montagehinweise

Installation

■

Nennlage nach EN 873-3 / 9.6.6 Bild 7: 0° oder 90°

■

Druckanschluss hinten oder unten

Zulässige Schwingungsbelastung am Einbauort

■

Die Geräte sollten grundsätzlich nur an Stellen ohne Schwingungsbelastung eingebaut werden.

■

Gegebenenfalls kann z. B. durch eine exible Verbindungsleitung von der

Messstelle zum Druckmessgerät und die Befestigung über eine Messgerätehalterung eine Entkopplung vom Einbauort erreicht werden.

■

Falls dies nicht der Fall ist, dürfen folgende Grenzwerte nicht über-

schritten werden:

Ungefüllte Geräte: Frequenzbereich 10 … 150 Hz

Beschleunigung < 0,5 g (5,0 m/s²)

Flüssigkeitsgefüllte Geräte: Frequenzbereich 10 … 150 Hz

Beschleunigung < 4,0 g (39,2 m/s²)

Die Flüssigkeitsfüllung ist regelmäßig zu überprüfen.

Der Flüssigkeitsspiegel darf nicht unter 75 % des Gerätedurchmessers

fallen.

Prüfanschluss

In bestimmten Anwendungsfällen (z. B. Dampfkessel) müssen die Absperrarmaturen einen Prüfanschluss besitzen, damit das Druckmess-gerät ohne

Ausbau überprüft werden kann.

Messgerätebefestigung

Ist die Leitung zum Druckmessgerät für eine erschütterungsfreie

Anbringung nicht stabil genug, so ist die Befestigung über entsprechende

Befestigungselemente für Wand- und / oder Rohrmontage, ggf. über eine

Kapillarleitung vorzunehmen.

Messsystemdämpfung

Können Erschütterungen nicht durch geeignete Installation vermieden

werden, dann sollten Druckmessgeräte mit Flüssigkeitsfüllung eingesetzt

werden.

11349167.03 10/2011 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

D

13

Page 14

3. Montagehinweise

Temperaturbelastung

Die Anbringung des Druckmessgerätes ist so auszuführen, dass die

zulässige Betriebstemperatur, auch unter Berücksichtigung des Einusses

von Konvektion und Wärmestrahlung, weder unter- noch überschritten wird.

Dazu sind Druckmessgerät und Absperrarmatur durch ausreichend lange

Messleitungen oder Wassersackrohre zu schützen.

D

Der Temperatureinuss auf die Anzeige- bzw. Messgenauigkeit ist zu

beachten.

Druckmittler / Schutzvorlagen

Bei aggressiven, heißen, hochviskosen, verunreinigten oder kristallisie-

renden Messstoen, die nicht in das Messglied eindringen dürfen, sind

Druckmittler als Trennvorlage vorzusehen. Zur Druckübertragung auf das

Messglied dient dann eine neutrale Mittlerüssigkeit, die entsprechend

dem Messbereich, der Temperatur und der Verträglichkeit mit dem

Messsto auszuwählen ist.

Die Verbindung zwischen Druckmessgerät und Druckmittler darf auf keinen

Fall gelöst werden.

Schutz der Messglieder vor Überlastung

Unterliegt der Messsto schnellen Druckänderungen oder ist mit Druckstößen zu rechnen, dürfen diese nicht direkt auf das Messglied einwirken. Die

Druckstöße müssen in ihrer Wirkung gedämpft werden, z. B. durch Einbau

einer Drosselstrecke (Verringerung des Querschnittes im Druckkanal) oder

durch Vorschaltung einer einstellbaren Drosselvorrichtung.

Druckentnahmestutzen

Der Druckentnahmestutzen soll mit einer genügend großen Bohrung

(≥≥ 6 mm) möglichst über ein Absperrorgan so angeordnet werden, dass

die Druckentnahme nicht durch eine Strömung des Messstoes verfälscht

wird. Die Messleitung zwischen Druckentnahmestutzen und Druckmessgerät soll zur Vermeidung von Verstopfung und Verzögerungen bei der

Druckübertragung einen genügend großen Innendurchmesser besitzen.

Sie soll auch ohne scharfe Krümmung sein. Ihre Verlegung mit einer steilen

Neigung von ca. 1:15 ist zu empfehlen.

Messleitung

Die Messleitung ist so auszuführen und zu montieren, dass sie die auftretenden Belastungen durch Dehnung, Schwingung und Wärmeeinwirkung

aufnehmen kann. Bei Gasen als Messsto ist an der tiefsten Stelle eine

Entwässerung, bei üssigen Messstoen an der höchsten Stelle eine

Entlüftung vorzusehen.

14

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 15

4. Montage und Inbetriebnahme

4. Montage und Inbetriebnahme

Zur Abdichtung der Anschlüsse sind Flachdichtungen, Dichtlinsen oder

WIKA-Proldichtungen einzusetzen. Um das Druckmessgerät in die

Stellung zu bringen, in der sich die örtliche Anzeige am besten ablesen

lässt, ist ein Anschluss mit Spannmue oder Überwurfmutter zu empfehlen.

Beim Ein- und Ausschrauben dürfen die Druckmessgeräte nicht am

Gehäuse angezogen werden, sondern nur an den Schlüsselächen des

Anschlussstutzens!

Montage mit

Gabelschlüssel

Ist das Druckmessgerät tiefer als der Druckentnahmestutzen angeordnet,

muss die Messleitung vor dem Anschließen gut durchgespült werden, um

Fremdkörper zu beseitigen.

Nach Herstellen der Druckverbindung und der elektrischen Anschlüsse sind

die Druckmessgeräte sofort betriebsbereit.

Vor dem Ausbau der Druckmessgeräte ist das Messglied drucklos zu

machen. Ggf. muss die Messleitung entspannt werden.

Messstoreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Menschen, Einrichtungen und Umwelt

führen. Ausreichende Vorsichtsmaßnahmen sind daher zu

ergreifen.

Druckanschluss

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte

(z. B. EN 837-2 „Auswahl- und Einbauempfehlungen für Druckmessgeräte“).

11349167.03 10/2011 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

D

15

Page 16

5. Messanordnung / 6. Elektrischer Anschluss

5. Messanordnung

Bewährte Messanordnungen für verschiedene Messstoarten.

Füllung der

Messleitung

D

Beispiele

Druckmessgerät

oberhalb des

Entnahmestutzens

Druckmessgerät

unterhalb

des Entnahmestutzens

6. Elektrischer Anschluss

Der elektrische Anschluss des Druckmessgerätes mit elektrischem

Ausgangssignal / elektronischem Druckschalter wird über einen Stecker

oder ein Kabel hergestellt. Die genauen Anschlussbelegungen können

der nachfolgenden Aufstellung entnommen werden. Zusätzlich sind die

Anschlussbelegung, Ausgangssignal und erforderliche Hilfsenergie auf dem

Typenschild vermerkt.

Stecker 3-polig, Typ AMP Duoplug

Pin Belegung

1 U

2 GND

3 U

Kabelausgang (2-Leiter)

Litzenfarbe Belegung

schwarz GND

rot U

Kabelausgang (3-Leiter / 1 x NPN) Kabelausgang (4-Leiter / 2 x NPN)

Litzenfarbe Belegung Litzenfarbe Belegung

schwarz GND schwarz GND

rot U

orange U

16

Flüssige Messstoe Gasförmige Messstoe

üssig zum Teil

Kondensat siedende

B+

SIG+

B+

B+

SIG+

/ SP

ausgasend

Flüssigkeiten

vollständig

gasförmig z. T. kon-

verdampft

„Flüssig-

trockene

gase“

Luft

rot U

orange SP

braun SP

1

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

densiert

(feucht)

feuchte Luft,

Rauchgase

B+

1

2

vollständig

kondensiert

Wasserdampf

11349167.03 10/2011 GB/D/F/E

Page 17

7. Bedienung, Wartung, Reinigung und Reparatur / 8. ...

7. Bedienung, Wartung, Reinigung und Reparatur

Zur Vermeidung von Druckstößen dürfen Absperreinrichtungen nur zur

langsam geönet werden.

Die Druckmessgeräte mit elektrischem Ausgangssignal

Druckschalter

Behandlung und Bedienung durch eine hohe Lebensdauer aus. Sollte sich

der Nullpunkt verschoben haben, wurde das Gerät überlastet.

Reinigen Sie das Gerät mit einem angefeuchteten Tuch. Bei starker

Verschmutzung das Tuch mit Seifenlauge durchfeuchten.

Reparaturen sind ausschließlich vom Hersteller oder entsprechend

geschultem Personal durchzuführen.

sind wartungsfrei und zeichnen sich bei sachgemäßer

8. Lagerung

Vor der Einlagerung des Gerätes müssen alle ggf. anhaftenden Mediumsreste entfernt werden. Dies ist besonders

wichtig, wenn das Medium gesundheitsgefährdend ist, wie

z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

Um Schäden zu vermeiden, sind für die Lagerung der Druckmessgeräte folgende Punkte zu beachten:

■

Druckmessgeräte in der Originalverpackung belassen.

■

Nach einer eventuellen Entnahme der Messgeräte für z. B. Prüfungen

sollte das Gerät wieder in der Originalverpackung eingelagert werden.

■

Lagertemperaturbereich -40 °C … +90 °C

Vermeiden Sie folgende Einüsse:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock

■

Ruß, Dampf, Staub, Feuchtigkeit und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

11349167.03 10/2011 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

/ elektronischem

D

17

Page 18

9. Maßnahmen bei Störungen / 10. Technische Daten

9. Maßnahmen bei Störungen

Störung Mögliche Ursache Maßnahme

Kein Ausgangssignal / kein

Schaltsignal

D

Gleich bleibendes

Ausgangssignal bei

Druckänderung

Zu hohes, bei

Druckänderung

gleich bleibendes

Ausgangssignal

Signalspanne zu

klein

Nullpunkt zu klein /

zu groß

Schaltsignal instabil

Keine Versorgungsspannung oder Leitungsbruch

Elektronik defekt durch

zu hohe Versorgungsspannung oder durch

Fremdspannung

Eingangskanal verstopft Eingangskanal bzw. Drossel-

Elektronik defekt durch

zu hohe Versorgungsspannung oder Fremdspannung

Versorgungsspannung

zu niedrig

Bürde zu hoch Max. zulässige Bürde

Nullpunkt verstellt Messgerät zur Instandset-

Nullpunkt verstellt Messgerät zur Instandset-

Versorgungsspannung

zu niedrig

10. Technische Daten

Technische Daten entnehmen Sie bitte den technischen Datenblättern.

PV 11.01 intelliGAUGE, Typ PGT01, Steckerausgang, NG 40

PV 11.02 intelliGAUGE, Typ PGT02, Kabelausgang, NG 40

PV 11.05 intelliGAUGE, Typ PGT10, Kunststogehäuse, IP 41, NG 40, 50

PV 11.06 intelliGAUGE, Typ PGT11, CrNi-Stahl-Gehäuse, IP 41, NG 40, 50

PV 11.03 intelliGAUGE, Typ PGT21, CrNi-Stahl-Gehäuse, NG 50

PV 21.03 switchGAUGE, Typ PGS05, Kabelausgang, NG 40

PV 21.05 switchGAUGE, Typ PGS06, Kunststogehäuse, IP 41, NG 40, 50

PV 21.06 switchGAUGE, Typ PGS07, CrNi-Stahl-Gehäuse, IP 41, NG 40, 50

PV 21.04 switchGAUGE, Typ PGS25, CrNi-Stahl-Gehäuse, NG 50

18

WIKA Betriebsanleitung intelliGAUGE / switchGAUGE

Spannungsversorgung und

Leitungen überprüfen; ggf.

defekte Teile austauschen

Messgerät zur Instandsetzung an Hersteller zurück

schraube reinigen

Messgerät zur Instandsetzung an Hersteller zurück

Versorgungsspannung

korrigieren

beachten

zung an Hersteller zurück

zung an Hersteller zurück

Versorgungsspannung

korrigieren

11349167.03 10/2011 GB/D/F/E

Page 19

Sommaire

Sommaire

1. Sécurité 20

2. Principe de fonctionnement 20

3. Instructions de montage 21

4. Installation et mise en service 22

5. Installation sur le point de mesure 23

6. Branchement électrique 24

Commande / Entretien / Nettoyage / Réparation

7.

8. Stockage 25

9. Mesures à prendre en cas de panne 26

10. Caractéristiques techniques 26

Informations

Ce signe vous donne des informations, des remarques ou

des conseils.

Avertissement !

Ce symbole vous avertit d'actions qui sont susceptibles

d'entraîner des dommages physiques ou matériels.

11349167.03 10/2011 GB/D/F/E

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

F

25

19

Page 20

1. Sécurité / 2. Principe de fonctionnement

1. Sécurité

Respectez impérativement les directives de sécurité

nationales correspondantes lors du montage, de la mise

en service et de l'exploitation de ces appareils (p. ex. EN

837-2 Choix et recommandations relatives à l'installation

de manomètres).

■

Le non-respect des instructions correspondantes est susceptible

d‘entraîner des risques de blessure et/ou des dégâts matériels.

F

■

Seul le personnel habilité et qualié est autorisé à manipuler les

instruments.

■

La température maximale réelle de surface n‘est pas fonction

de l'appareil lui-même, mais principalement de la température

du uide de mesure utilisé ! Dans le cas de uides gazeux, la

température peut augmenter en raison de la chaleur consécutive

à la compression. Dans un tel cas, il conviendra de chercher à

diminuer la vitesse d'évolution de la pression ou la température

admissible du uide

2. Principe de fonctionnement

Les tubes de Bourdon sont très largement utilisés comme élément de

mesure dans la technologie de mesure de pression en raison de leur solidi-

té et de leur facilité d‘emploi. Sous l‘inuence de la pression, ces éléments

de mesure se déforment dans la zone d‘élasticité.

Ce mouvement est transformé en mouvement rotatif au moyen d‘un

dispositif de mesure mécanique (secteur denté). Un aimant xé sur

l‘axe de l‘aiguille tourne proportionnellement à la rotation de l‘aiguille de

l‘instrument en fonction de la pression process. L‘électronique positionnée

en face de l‘aimant saisit le mouvement de rotation de l‘aimant.

Un capteur indépendant du champ magnétique (capteur à eet Hall) mesure du côté électronique cette modication sans le moindre contact, sans

usure et sans réaction sur l'organe de mesure.

Au moyen d‘un amplicateur, le signal du capteur proportionnel au

mouvement de rotation est transformé en signal de sortie électrique.

L’échelledu signal de sortie électrique correspond à l’échelle de mesure du

le cadran. Des sorties de commutation sont également disponibles avec un

montage à transistor correspondant.

Un manomètre avec signal de sortie électrique de la série intelliGAUGE allie

tous les avantages d‘un achage local ne nécessitant aucune alimentation

externe et la demande d‘une transmission de signal électrique permettant

une surveillance électronique moderne des valeurs de mesure.

20

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 21

3. Instructions de montage

3. Instructions de montage

Installation

■

Position nominale selon EN 837-3 / 9.6.6 gure 7 : 0 °C ou 90°

■

Raccord vertical ou arrière

Contrainte de vibration admissible au point de mesure

■

Par principe, les appareils doivent être installés à des emplacements qui

ne sont pas soumis à des vibrations.

■

Le cas échéant, il est possible d'isoler l'appareil du point de mesure en

utilisant par exemple un exible entre le point de mesure et le manomètre

et en installant celui-ci à l‘aide d‘un support adapté.

■

Dans le cas où cela n'est pas possible, les seuils suivants ne doivent pas

être dépassés :

Appareils non remplis : plage de fréquence 10 … 150 Hz

Accélération < 0,5 g (5,0 m/s

Appareils remplis : plage de fréquence 10 … 150 Hz

Accélération < 4,0 g (39,2 m/s

Le niveau de liquide doit être contrôlé régulièrement.

Le niveau de remplissage du liquide ne doit pas descendre au-dessous de

75 % du diamètre du boîtier.

Prise de contrôle

Les spécications locales de sécurité telles par exemple celles liées aux

chaudières vapeur peuvent rendre nécessaire des dispositifs d’isolement

permettant le test sur site de l'appareil.

Fixation des appareils

Si le raccordement au manomètre n'est pas assez robuste pour réaliser

une xation exempte de vibrations, la xation doit être réalisée au moyen

d'éléments de xation pour montage mural et/ou sur tube, le cas échéant

par l'intermédiaire d'un capillaire.

Amortissement du système de mesure

Si des vibrations ne peuvent pas être évitées au moyen d'installations

appropriées, il est recommandé d‘utiliser des manomètres remplis de liquide.

Contraintes thermiques

La position de montage de l’appareil est à choisir en fonction de la

température de service qui ne doit pas être dépassée, en tenant compte

également de l‘inuence de la conduction et du rayonnement thermique.

11349167.03 10/2011 GB/D/F/E

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

F

²

)

²

)

21

Page 22

3. Instructions de montage

Pour ce faire on utilisera des tuyaux-raccord susamments longs ou un

syphon placé avant le robinet d’isolement et l’appareil (prendre en considé-

ration l‘inuence de la température sur la précision de la mesure).

Séparateur / barrière de séparation

En cas de uide agressif, chaud, fortement visqueux, souillé ou cristallisant

qui ne doive pas pénétrer dans l'organe de mesure, on utilisera un sépara-

teur qui fera oce de barrière de protection pour l'instrument. Un liquide

de transmission qui servira à transmettre la pression à l'organe de mesure

F

devra être sélectionné en fonction de la plage de mesure, de la température

et de la compatibilité avec le uide de mesure.

L'assemblage du manomètre sur le séparateur ne devra en aucun cas être

démonté.

Protection de l'élément de mesure contre les surpressions

Si le uide de mesure est soumis à de brusques montées en pression

ou s'il faut s‘attendre à des coups de bélier, ceux-ci ne doivent pas agir

directement sur l‘organe de mesure. Les eets des coups de bélier doivent

être amortis, p. ex. par la pose d‘une vis frein (réduction de la section dans

le canal de pression) ou par l‘installation en amont d‘un

dispositif réglable d‘amortissement de la pression.

Raccord de la prise de pression

Le raccord de la prise de pression doit être pourvu d'un orice susamment

grand (≥ 6 mm), si possible posséder un robinet d'isolement et être installé

de façon à ce que le débit du uide ne perturbe pas la mesure. La tuyauterie

entre le raccord de mesure et le transmetteur de pression doit avoir un

diamètre susant an d'en éviter son bouchage ou de provoquer des

retards dans la transmission de la pression. On évitera également des

courbures trop importantes. Il est recommandé d'installer la tuyauterie avec

un rapport d'inclinaison de 1:15.

Tuyauterie

La tuyauterie est à concevoir et à installer de telle façon qu'elle supporte les

contraintes dues á des dilatations, vibrations et inuences thermiques. Pour

la mesure de gaz, il faut prévoir une purge de condensat au point le plus

bas de l'installation, et pour la mesure de liquides il faut une purge d'air au

point le plus èlevé.

22

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 23

4. Installation et mise en service

4. Installation et mise en service

Pour l'étanchéité des raccords, il faut utiliser des joints plats, des lentilles

d'étanchéité ou des joints prolés WIKA. Pour installer le manomètre dans

la position permettant la lecture la plus aisée de l'indication locale, il est

recommandé de réaliser le raccordement au moyen d'un écrou tournant ou

d'un écrou-chapeau. Lors du montage ou du démontage, les manomètres

ne doivent pas être serrés au niveau du boîtier, mais uniquement sur le

surplat au-dessus du letage du manomètre !

Montage avec

clé à fourche

En cas d'installation du transmetteur de pression au-dessous du point de

mesure, il faut nettoyer soigneusement la tuyauterie an d'éviter que des

particules ne pénètrent à l‘intérieur de l‘appareil.

Après raccordement du raccord process et branchement électrique de

l’appareil, celui-ci est prêt à fonctionner.

Le transmetteur de pression doit être démonté uniquement lorsqu'il est hors

pression. Si nécessaire vider la tuyauterie.

Les résidus de uide se trouvant à l'intérieur des

transmetteurs de pression démontés peuvent présenter

des dangers pour les personnes, l'environnement et

les installations. Il faut prendre toutes les précautions

nécessaires pour en assurer la sécurité.

Raccord process

Conformément aux règles techniques générales pour les manomètres

(par ex. EN 837-2 « Recommandations relatives au choix et à l'installation

des manomètres »).

11349167.03 10/2011 GB/D/F/E

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

F

23

Page 24

5. Installation sur le point de mesure / 6. Branchement ...

5. Installation sur le point de mesure

Types d’installations éprouvés selon diérents uides.

Remplissage

de la conduite

de mesure

Exemples

F

Manomètre

au-dessus

du point de

mesure

Manomètre

au-dessous

du point de

mesure

6. Branchement électrique

Le branchement électrique du manomètre avec signal de sortie électrique

/ pressostat eléctronique est eectué à l‘aide d‘un connecteur ou d‘un

câble. La disposition exacte des connexions est illustrée sur les dessins

présentés ci-après. En outre, la disposition des connexions, le signal

de sortie et l‘alimentation nécessaires sont notés sur la plaque

signalétique de l‘appareil.

Connecteur 3 plots, type AMP Duoplug

Plot Signal

1 U

2 GND

3 U

Câble (2 ls)

Code couleur Signal

noir GND

rouge U

Câble (3 ls / 1 x NPN)

Code couleur Signal Code couleur Signal

noir

GND noir GND

rouge U

orange U

24

Fluides liquides Fluides gazeux

liquides en partie

condensat liquides en

B+

SIG+

B+

gazeux

ébullition

complètement

évaporés

« gaz

liquides »

uide

gazeux

air sec air humide,

Câble (4 ls / 2 x NPN)

1

rouge U

orange SP

marron SP

B+

SIG+

/ SP

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

en partie

condensés

(humides)

gaz de combustion

B+

entièrement

condensé

vapeur

d‘eau

1

2

11349167.03 10/2011 GB/D/F/E

Page 25

7. Commande, Entretien, Nettoyage, Réparation / 8. ...

7. Commande, Entretien, Nettoyage, Réparation

Tout robinet d'isolement doit être ouvert progressivement et en aucun cas

brusquement an d'éviter les coups de bélier.

Les manomètres avec signal de sortie électrique

ne requièrent aucun entretien et se caractérisent par une longue durée de

vie s'ils sont traités et utilisés de manière appropriée. Un décalage du point

zéro signale une surpression subie par l‘appareil.

L'appareil se nettoie à l'aide d‘un chion humidié. S'il est fortement souillé,

humidier le chion avec de l'eau (et du savon de Marseille).

Les réparations ne doivent être eectuées que par le fabricant ou par du

personnel formé.

8. Stockage

Avant le stockage de l’appareil, tous les résidus du uide

doivent être éliminés. Ceci est particulièrement

important lorsque le produit est dangereux pour la santé,

ex. corrosif, toxique, cancérigène, radioactif, etc.

Avant l'installation, les points suivants doivent être respectés an de

d'éviter tout dommage sur l'appareil :

■

Laisser les transmetteurs de pression dans leur emballage d'origine

jusqu’à l'installation.

■

Après avoir démonté un transmetteur de pression (par exemple pour un

contrôle) le réemballer dans son emballage d'origine.

■

Température de stockage -40 °C … +90 °C

Évitez les conditions suivantes :

■

Lumière directe du soleil ou proximité avec des objets chauds

■

Vibrations mécaniques, chocs mécaniques (montage dicile)

■

Suie, vapeur, poussière, humidité et gaz corrosifs

■

Environnement explosif, atmosphères inammables

11349167.03 10/2011 GB/D/F/E

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

/ pressostat eléctronique

F

25

Page 26

9. Mesures à prendre en cas de panne / 10. Données ...

9. Mesures à prendre en cas de panne

Panne Cause possible Mesure à prendre

Aucun signal de

sortie/ pas de signal

de commutation

F

Signal de sortie

constant malgré des

variations de pression

Signal de sortie trop

élevé et constant

malgré des variations

de pression

Plage de signalisation

trop faible

Point zéro trop faible/

trop élevé

Signal de

commutation instable

10. Caractéristiques techniques

Vous trouverez des données techniques dans les ches techniques.

PV 11.01 intelliGAUGE, Type PGT01,

PV 11.02 intelliGAUGE, Type PGT02,

PV 11.05 intelliGAUGE, Type PGT10, boîtier plastique, IP 41, Diam. 40, 50

PV 11.06 intelliGAUGE, Type PGT11, boîtier en

PV 11.03 intelliGAUGE, Type PGT21, boîtier en

PV 21.03 switchGAUGE, Type PGS15,

PV 21.05 switchGAUGE, Type PGS06, boîtier plastique, IP 41, Diam. 40, 50

PV 21.06 switchGAUGE, Type PGS07, boîtier en

PV 21.04 switchGAUGE, Type PGS25, boîtier en

26

Aucune tension d'alimentation

Rupture de cable

Electronique défectueuse,

conséquence d'une tension

d'alimentation trop élevée ou d'une

tension d'origine étrangère

Canal d'entrée bouché Nettoyer le canal d'entrée et/

Electronique défectueuse,

conséquence d'une tension

d'alimentation trop élevée ou d'une

tension d'origine étrangère

Tension d'alimentation trop faible Corriger la tension

Charge ohmique trop élevée Respecter la charge ohmique

Zéro déréglé Renvoi du manomètre au

Zéro déréglé Renvoi du manomètre au

Tension d'alimentation trop faible Corriger la tension

sortie connecteur

sortie câble

sortie câble

Contrôler l'alimentat. et le

câblage ; le cas échéant

changer les pièces défectueuses

Envoyer le transmetteur au

fabricant pour réparation

ou la vis d'étranglement

Envoyer le transmetteur au

fabricant pour réparation

d'alimentation

max. admise

fabricant pour réparations

fabricant pour réparations

d'alimentation

, Diam. 40

, Diam. 40

acier inox

, IP 41, Diam. 40, 50

acier inox

, Diam. 50

, Diam. 40

acier inox

, IP 41, Diam. 40, 50

acier inox

, Diam. 50

WIKA Mode d´emploi intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 27

Contenido

Contenido

Seguridad

1.

Principio de funcionamiento

2.

Indicaciones de montaje

3.

Montaje y funcionamiento

4.

Disposición de medida

5.

Conexión eléctrica

6.

Servicio / Mantenimiento / Limpieza / Reparacion

7.

Almacenamiento

8.

Medidas en caso de fallos

9.

Datos técnicos

10.

Información

Este signo indica informaciones, notas o consejos.

¡Advertencia!

Este símbolo indica advertencias relativas a acciones que

puedan dañar personas o a la instalación.

11349167.03 10/2011 GB/D/F/E

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

28

28

29

30

E

31

32

33

33

34

34

27

Page 28

1. Seguridad / 2. Principio de funcionamiento

1. Seguridad

Es imprescindible observar las prescripciones nacionales

de seguridad (p. ej. EN 837-2 "Recomendaciones relativas

a la selección y montaje de manómetros") durante el montaje, la puesta en servicio y la utilización de estos aparatos.

■

Riesgo de lesiones graves y/o daños materiales en caso de no

observar las instrucciones correspondientes.

■

La manipulación de los instrumentos solamente la deben ejecutar

personal cualicado.

■

¡La temperatura máx. real de las supercies no depende de los

E

aparatos sino principalmente de la temperatura del medio! En el

caso de uidos gaseosos, la temperatura puede aumentar por

razón del calor consecuencia de la compresión. En estos casos,

hay que disminuir la hay que disminuir el ratio de presión o

reducir la temperatura admisible del medio, si fuera necesario.

2. Principio de funcionamiento

Los muelles de Bourdon son ampliamente empleados como elementos de

medida técnica debido a su robustez y su fácil utilización. Bajo la inuencia

de la presión estos elementos de medida se deforman dentro de su rango

elástico.

Este movimiento se convierte en un movimiento giratorio mediante un

mecanismo mecánico. El imán colocado en el eje de la aguja gira con

la aguja del instrumento, proporcionalmente a la presión de proceso. La

electrónica posicionada frente al imán detecta el movimiento giratorio del

imán.

Un sensor dependiente del campo magnético (sensor hall)

mide en el lado electrónico ese cambio sin fricción, sin desgaste y sin

reacción en el elemento de medición.

Un amplicador convierte la señal proporcional al movimiento giratorio

en una señal eléctrica de salida. El alcance de la señal eléctrica de

salida corresponde al alcance de medición en la esfera. Con circuito

de transistores correspondiente están disponibles también salidas de

conmutación.

La línea de manómetros intelliGAUGE con señal de salida eléctrica,

combina todas las ventajas de una visualización in –situ sin la necesidad de

28

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 29

3. Indicaciones de montaje

una fuente externa de alimentación con la demanda de la moderna medida

electrónica para señal de transmisión eléctrica.

3. Indicaciones de montaje

Instalación

■

Posición nominal según EN 837-3 / 9.6.6 ilustr. 7: 0° ó 90°

■

Conexión a presión en el lado posterior o en bajo

Carga de vibración admisible en el punto de montaje

■

Instalar los instrumentos sólo en lugares exentos de vibraciones.

■

Si es necesario, es posible aislar el instrumento del punto de montaje

mediante la instalación de una conexión exible entre el punto de medida

y el manómetro, mediante la jación del manómetro con un soporte de

jación.

■

Si esto no es posible, no sobrepasar los valores límite siguientes en

ningún caso:

Instrumentos vacíos: gama de frecuencias 10 … 150 Hz

aceleración < 0,5 g (5,0 m/s

Instrumentos llenados de líquido: gama de frecuencia 10 … 150 Hz

aceleración < 4,0 g (39,2 m/s

Comprobar el llenado de líquido a intervalos regulares.

El nivel de líquido no debe caer debajo del 75 % del diámetro del instrumento.

Toma de control

En ciertas aplicaciones (como por ejemplo, calderas de vapor) los órganos

de cierre deben de estar provistos de una toma de control con la nalidad

de poder controlar el transmisor de presión sin desmontarlo.

Fijación de los aparatos de medida

Si la línea al manómetro no es sucientemente estable para la jación

protegida contra vibraciones, hay que jar el manómetro mediante elementos de jación adecuados para el montaje en la pared y/o el tubo, si fuera

necesario, a través de un tubo capilar.

Amortiguación del sistema de medida

Si no es posible evitar vibraciones mediante una instalación adecuada, hay

que utilizar manómetros llenados con líquido.

11349167.03 10/2011 GB/D/F/E

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

E

²

)

²

)

29

Page 30

3. Indicaciones de montaje

Efectos de la temperatura

La temperatura operativa del transmisor de presión, que resulta de

los efectos del medio de presión, las temperaturas ambientes y, posiblemente, la radiación de calor, no deben superar el rango de temperatura

para el cual está diseñado el transmisor de presión. Puede utilizarse una

torre de refrigeración con la forma adecuada o sifones rellenos de agua

para separar el transmisor de presión. Tener en consideración la inuencia

de la temperatura respecto a la presión de la medida.

Sellos separadores / láminas de protección

Utilizar sellos separadores como membranas de protección en caso de

medios agresivos, calientes, de alta viscosidad o cristalizantes que no

deben penetrar en el elemento de medición. Para transmitir la presión al

E

elemento de medición se utiliza un líquido a seleccionar con respecto

al rango de medición, la temperatura y la compatibilidad con el medio.

En ningún caso aojar la conexión entre el manómetro y el sello

separador.

Protección de los elementos de medición contra una sobrecarga

Si el medio está sujeto a cambios rápidos de presión o si han de

esperarse golpes de ariete, no deben actuar directamente en el elemento

de medición. Hay que amortiguar los golpes de ariete, p. ej. instalando un

obturador de presión (reducción del corte transversal en el conducto

a presión) o preconectando un dispositivo de obturación ajustable.

Conexión del proceso

En la medida de lo posible, se deberá contar con una conexión del proceso

de un diámetro interior sucientemente grande (≥≥ 6 mm de diámetro)

sobre un dispositivo de cierre y en una posición en la que la exactitud de

la lectura no se vea afectada por el ujo de los medios que se miden. La

tubería entre la conexión del proceso y el transmisor de presión deberá

poseer un diámetro interno sucientemente grande para evitar bloqueos

o demoras en la transmisión de presión. Tampoco se deberá poseer

curvas pronunciadas. Se recomienda instalarlo con un declive continuo de

aproximadamente 1:15.

Tubería

La tubería debe montarse e instalarse de modo que pueda tolerar las

tensiones causadas por la expansión, la vibración y la inuencia del calor.

Cuando el medio es gaseoso, deberá proveerse un punto de drenaje de

agua en el punto más bajo. Debe proveerse una purga de aire en el punto

más alto en caso de medios de presión líquidos.

30

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 31

4. Montaje y funcionamiento

4. Montaje y funcionamiento

La correcta conexión de presión debe realizarse mediante una junta de

cierre o una arandela la de cierre o bien las juntas de perl WIKA adecuadas. Recomendamos conectar el manómetro mediante un manguito de

sujeción o un racor de unión para colocar el manómetro en la posición en

que pueda leerse lo mejor la indicación local. ¡Al montar y desmontar no

deben sujetarse los manómetros por la caja sino sólo en las supercies

provistas para la llave en el racor de conexión!

Montaje mediante

llave ja

En caso de que el transmisor de presión se posicione por debajo de punto

de conexión, el codo de trubería debe limpiarse integramente antes de

montar el transmisor

Una vez se ha efectuado las conexiones de presión y eléctrica, los transmisores están listos para su uso.

No debe intentarse retirar un transmisor presurizado. El sistema de presión

debe estar completamente ventilado, ya que el transmisor no podrá

aislarse.

El remanente del medio de presión contenido en el elemen-

to de presión puede ser peligroso o tóxico. Esto debe

considerarse cuando se manipula y almacena el transmisor

retirado.

Conexión a presión

Conforme a las reglas técnicas generales para manómetros (por ejemplo

EN 837-2 "Recomendaciones relativas a la selección y montaje de

manómetros").

11349167.03 10/2011 GB/D/F/E

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

E

31

Page 32

5. Disposición de medida / 6. Conexión eléctrica

5. Disposición de medida

Preparativos comprobados de medición para diversos tipos de medios.

Contenido

del tubo de

aspiración

Generalmente

Instrumento

por encima

del punto de

medica

E

Instrumento

por debajo

del punto de

medida

6. Conexión eléctrica

El manómetro con señal eléctrica de salida

conectado a la electricidad mediante una clavija o un cable. Los esquemas

exactos de la instalación eléctrica pueden observarse en los dibujos

siguientes. La señal de salida y la fuente de alimentación necesaria se

proporcionan en la placa de potencia de régimen, además de los detalles de

la instalación eléctrica.

Conector de 3 polos, modelo AMP Duoplug

Pin Ocupación

1 U

2 GND

3 U

Salida del cable (2 hilos)

Color del cordón Ocupación

negro GND

rojo U

Salida del cable (3 hilos / 1 x NPN) Salida del cable (4 hilos / 2 x NPN)

Color del cordón Ocupación Color del cordón Ocupación

negro GND negro GND

rojo U

naranja U

marrón

32

Medios líquidos Medios gaseosos

Líquido Líquido

Condensado

Vapor úni-

con vapor

camente

Líquido en

GLP Aire seco Aire húmedo

ebullición

Gas únicamente

Gas

húmedo

Gas de

combustión

/ presostato electrónico

B+

SIG+

B+

1

rojo U

naranja SP

SP

B+

SIG+

/ SP

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

Condensado

de gas

líquido

Vapor de agua

está

B+

1

2

11349167.03 10/2011 GB/D/F/E

Page 33

7. Servicio, Mantenimiento, Limpieza, Reparacion / 8. ...

7. Servicio, Mantenimiento, Limpieza, Reparacion

Para evitar golpes de ariete, hay que abrir lentamente los dispositivos de

cierre.

Los manómetros con señal eléctrica de salida

requieren mantenimiento y se distinguen por una vida útil elevada si se

utilizan y operan adecuadamente. Si se ha desplazado el punto cero, el

aparato ha sido sobrecargado.

Limpiar los instrumentos con un trapo húmedo. En caso de gran suciedad

mojar el trapo con lejía de jabón.

Todas las reparaciones solamente las debe efectuar el fabricante o personal especializado.

8. Almacenamiento

Antes del almacenamiento del aparato deben quitarse

todos los restos de medios eventualmente adheridos. Esto

es especialmente importante cuando el medio es nocivo

para la salud, como p. ej. cáustico, tóxico, cancerígeno,

radioactivo, etc.

Previo a la instalación, a n de evitar daños en los transmisores, siga

los puntos a continuación:

■

El transmisor de presión debe permanecer en su embalaje original hasta

la instalación.

■

Después de sacar el transmisor (por ejemplo, para pruebas) reutilice el

material de embalaje original.

■

La temperatura de almacenamiento no debe superar -40 °C … +90 °C

Evite las siguientes inuencias:

■

Luz solar directa o proximidad a objetos calientes

■

Vibración mecánica, impacto mecánico (apoyarlo de golpe)

■

Hollín, vapor, polvo, humedad y gases corrosivos

■

Entorno potencialmente explosivo, atmósferas inamables

11349167.03 10/2011 GB/D/F/E

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

/ presostato electrónico no

E

33

Page 34

9. Medidas en caso de fallos / 10. Datos técnicos

9. Medidas en caso de fallos

Falla Causa posible Solución

Sin señal de salida /

no señal de

conmutación

Señal estable a pesar de

la variación de presión

E

Señal estable y demasiado alta a pesar de la

variación de presión

Lectura del intervalo

total de medida

demasiado bajo

Señal de cero demasiado

baja / demasiado alta

Señal de conmutación

inestable

10. Datos técnicos

Consultar las hojas técnicas para los datos técnicos.

PV 11.01 intelliGAUGE, Modelo PGT01, Salida del Clavija, DN 40

PV 11.02 intelliGAUGE, Modelo PGT02, Salida del Cable, DN 40

PV 11.05 intelliGAUGE, Modelo PGT10, Caja de plástico, IP 41, DN 40, 50

PV 11.06 intelliGAUGE, Modelo PGT11, Caja de Acero CrNi, IP 41, DN 40, 50

PV 11.03 intelliGAUGE, Modelo PGT21, Caja de Acero CrNi, DN 50

PV 21.03 switchGAUGE, Modelo PGS15, Salida del Cable, DN 40

PV 21.05 switchGAUGE, Modelo PGS06, Caja de plástico, IP 41, DN 40, 50

PV 21.06 switchGAUGE, Modelo PGS07, Caja de Acero CrNi, IP 41, DN 40, 50

PV 21.04 switchGAUGE, Modelo PGS25, Caja de Acero CrNi, DN 50

34

Falla de la fuente de alimentación Instalación eléctrica

interrumpida

Falla electrónica por tensión

de alimentación o tensión

externa incorrectas

Entrada de presión

bloqueada

Falla electrónica por tensión

de alimentación o tensión

externa incorrectas

Tensión de alimentación

demasiado baja

Impedancia de carga

demasiado alta

Punto cero cambiado Para reparaciones, enviar el

Punto cero cambiado Para reparaciones, enviar el

Tensión de alimentación

demasiado baja

Controle la fuente de alimentación y la instalación eléctrica

y reemplace los componentes

defectuosos

Devuelva el transmisor al fabricante para su reparación

Controle el oricio de entrada y el

diámetro interior de la entrada de

presión; si es necesario, límpielo

cuidadosamente

Devuelva el transmisor al fabricante para su reparación

Ajuste la tensión de alimentación

Considere la carga máx.

admisible

manómetro al fabricante

manómetro al fabricante

Ajuste la tensión de alimentación

WIKA Manual de instrucciones intelliGAUGE / switchGAUGE

11349167.03 10/2011 GB/D/F/E

Page 35

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-Mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-Mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. „Al. Stamboliiski“ 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-Mail: info@wika.hr

www.wika.hr

11349167.03 10/2011 GB/D/F/E

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-Mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-Mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-Mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

35

Page 36

WIKA global

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-Mail: info@wikapolska.pl

www.wikapolska.pl

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-Mail: info@wika.ru

www.wika.ru

Weitere WIKA Niederlassungen weltweit nden Sie online unter www.wika.de.

Further WIKA subsidiaries worldwide can be found online at www.wika.de.

La liste des autres liales WIKA dans le monde se trouve sur www.wika.de

Otras sucursales WIKA en todo el mundo puede encontrar en www.wika.de.

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modications techniques.

Se reserva el derecho de modicaciones técnicas.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

36

Spain

Instrumentos WIKA, S.A.

08205 Sabadell (Barcelona)

Tel. (+34) 902 902577

Fax: (+34) 933 938666

E-Mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-Mail: info@manometer.ch

www.manometer.ch

11349167.03 10/2011 GB/D/F/E

Loading...

Loading...