Page 1

Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS

CAREFULLY BEFORE INSTALLING OR OPERATING

THIS CONTROL COULD CAUSE PERSONAL INJURY

AND/OR PROPERTY DAMAGE.

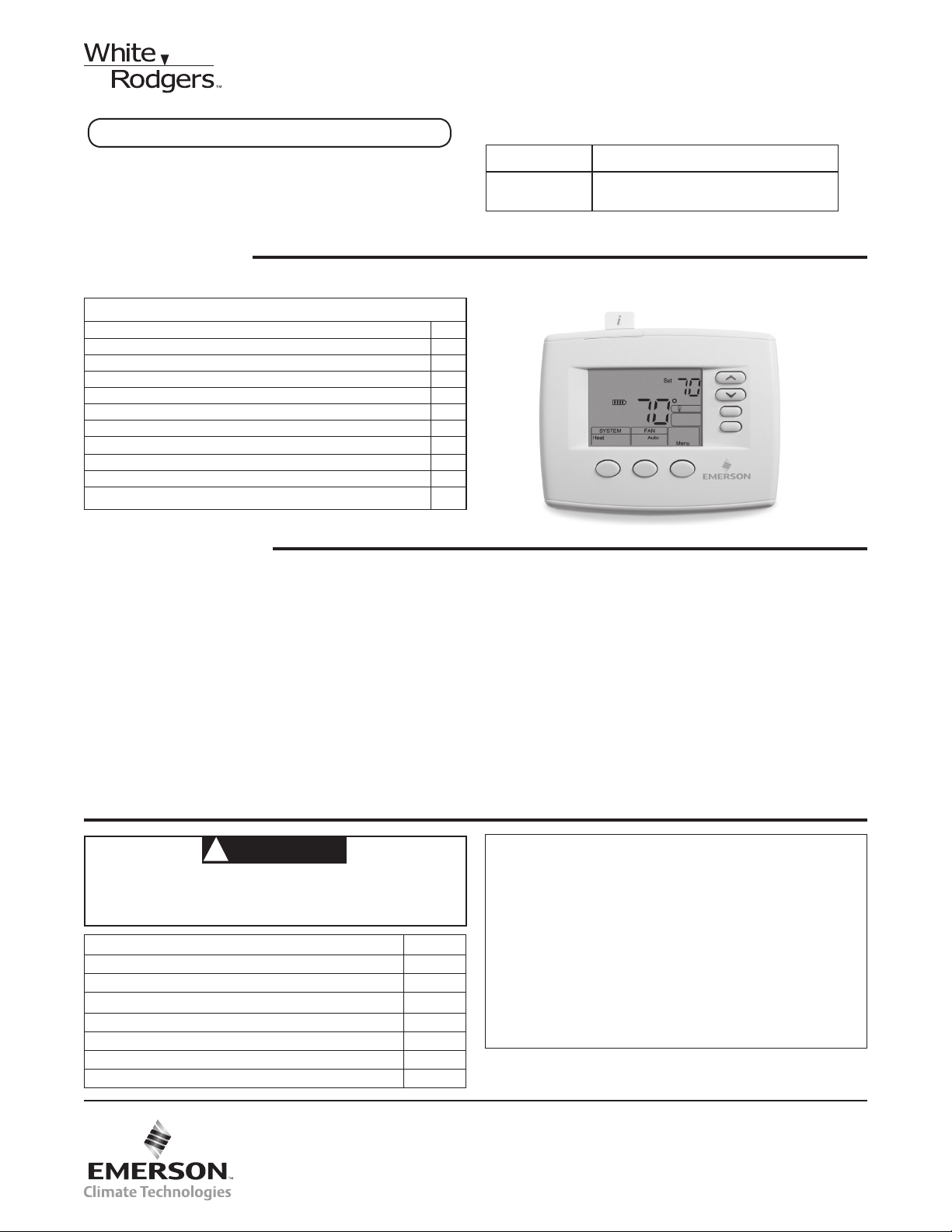

APPLICATIONS

Blue 4” Universal Thermostat with

Automatic Heat/Cool Changeover Option

Single Stage, Multi-Stage or Heat Pump

Installation and Operating Instructions for Model:

Model Programming Choice

1F83-0471

Non-Programmable

THERMOSTAT APPLICATION GUIDE

Description

Heat Pump (No Aux. or Emergency Heat) Yes

Heat Pump (with Aux. or Emergency Heat) Yes

Systems with up to 2 Stages Heat, 2 Stages Cool Yes

Heat Only Systems (with optional fan switch) Yes

Millivolt Heat Only Systems – Floor or Wall Furnaces Yes

Cool Only Systems Yes

Gas or Oil Heat Yes

Electric Furnace

Hydronic (Hot Water) Zone Heat – 2 Wires Ye s

Hydronic (Hot Water) Zone Heat – 3 Wires Ye s

Compressor with Comfort Alert II Module (1F85CA only) Yes

Yes

1F83-0471 Thermostat

SPECIFICATIONS

Electrical Rating:

Battery Power .................................................... mV to 30 VAC, NEC Class II, 50/60 Hz or DC

Input-Hardwire ................................................... 20 to 30 VAC

Terminal Load ........................................................... 1.5 A per terminal, 2.5A maximum all terminals combined

Setpoint Range ......................................................... 45° to 90°F (7° to 32°C)

Rated Differentials: Fast Med. Slow

Heat (Single Stage/Multi Stage) ........................ 0.4 °F 0.6 °F 1.7 °F

Cool (Single Stage/Multi Stage) ........................ 0.9 °F 1.2 °F 1.7 °F

Heat Pump ......................................................... 0.9 °F 1.2 °F 1.7 °F

Aux. Heat ........................................................... 0.6 °F – 1.7 °F

Operating Ambient .................................................... 32° to +105°F (0° to +41°C)

Operating Humidity ................................................... 90% non-condensing max.

Shipping Temperature Range ................................... -40° to +150°F (-40° to +65°C)

Dimensions Thermostat ............................................ 3-7/8”H x 5-1/8”W x 1-1/4”D

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Index Page

Installation 2

Wiring Connections 2

Wiring Diagrams 3

Thermostat Quick Reference 4

Installer Configuration Menu 5

Operating Your Thermostat 7

Troubleshooting 7

www.white-rodgers.com

www.emersonclimate.com

ATTENTION: MERCURY NOTICE

This product does not contain mercury. However, this product

may replace a product that contains mercury.

Mercury and products containing mercury must not be

discarded in household trash. Do not touch any spilled

mercury. Wearing non-absorbent gloves, clean up any

spilled mercury and place in a sealed container. For proper

disposal of a product containing mercury or a sealed

container of spilled mercury, place it in a suitable shipping

container. Refer to www.white-rodgers.com for location to

send product containing mercury.

PART NO. 37-7237A

1117

1

Page 2

INSTALLATION

Mounting

Hole

Mounting

Hole

Place Level

across

Mounting Tabs

(for appearance only)

Place Level

across

Mounting Tabs

(for appearance only)

WARNING

!

Thermostat installation and all components of the

control system shall conform to Class II circuits per

the NEC code.

Remove Old Thermostat

A standard heat/cool thermostat consists of three basic parts:

1. The cover, which may be either a snap-on or hinge type.

2. The base, which is removed by loosening all captive

screws.

3. The switching subbase, which is removed by unscrewing

the mounting screws that hold it on the wall or adapter

plate. Before removing wires from old thermostat,

label each wire with the terminal designation from

which it was attached. Disconnect the wires from the

old thermostat one at a time. Do not let wires fall back

into the wall.

Installing New Thermostat

1. Pull the thermostat body off the thermostat base. Forcing

or prying on the thermostat will cause damage to the unit.

2. Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

3. Move base out of the way. Drill mounting holes. If you

are using existing mounting holes and the holes drilled

are too large and do not allow you to tighten base snug ly, use plastic screw anchors to secure the base.

4. Fasten base snugly to wall using mounting holes shown

in Figure 2 and two mounting screws. Leveling is for

appearance only and will not affect thermostat operation.

5. Connect wires to terminal block on base.

6. Push excess wire into wall and plug hole with a fire re-

sistant material (such as fiberglass insulation) to prevent

drafts from affecting thermostat operation.

7. Carefully line the thermostat up with the base and snap

into place.

Figure 1 – Battery door shown open

“AA” Alkaline Batteries

Thermostat can be powered by system AC power or Battery.

If

is displayed, the thermostat is battery powered. If

is not displayed, thermostat is system powered with optional

battery back-up. When battery power remaining is approximately half, the

will be displayed. When “Change ”

is displayed, install fresh “AA” alkaline batteries immediately.

For best results, replace all batteries with new premium brand

alkaline batteries such as Duracell

®

or Energizer®. We recom-

mend replacing batteries every 2 years. If the home is going

to be unoccupied for an extended period (over 3 months) and

is displayed, the batteries should be replaced before

leaving. When less than two months of battery life remain, the

setpoint temperature will offset by 10 degrees (10 degrees

cooler in Heat mode / 10 degrees warmer in Cool mode). If

offset occurs, the normal setpoint can be manually reset with

or . Another offset will occur within two days if batter-

ies are not replaced.

Figure 2 – Thermostat base and rear view of thermostat

Batteries

2 “AA” alkaline batteries are included with the thermostat.

To install the batteries, pull the battery door as shown by the

arrow and lift open. Using the polarity indicated inside the battery door, insert the batteries. To close the battery door, swing

the door down while pulling in the direction of arrow. Once

fully down, snap the door back into position. To replace the

batteries, set system to OFF.

WIRING CONNECTIONS

Refer to equipment manufacturers’ instructions for specific

system wiring information. After wiring, see CONFIGURATION

section for proper thermostat configuration.

2

TERMINAL DESIGNATION DESCRIPTIONS

Terminal

Designation Description

L .............. Heat pump malfunction indicator for systems

with malfunction connection or Comfort Alert signal

O .............. Changeover valve for heat pump energized

constantly in cooling

B .............. Changeover valve for heat pump energized

constantly in heating

Y .............. Compressor Relay

Y2 ............. 2nd Stage Compressor

Refer to figure 3 through 6 for wiring diagram specifications.

Terminal

Designation Description

W/E ............Heat Relay/Emergency Heat Relay (Stage 1)

W2 .............2nd Stage Heat (3rd Stage Heat in HP 2)

G ..............Fan Relay

RH .............Power for Heating

RC .............Power for Cooling

C ..............Common wire from secondary side of cooling system

transformer or heat only system transformer

6...............3 Wire Zone Valve – Energized when no call for Heat

Page 3

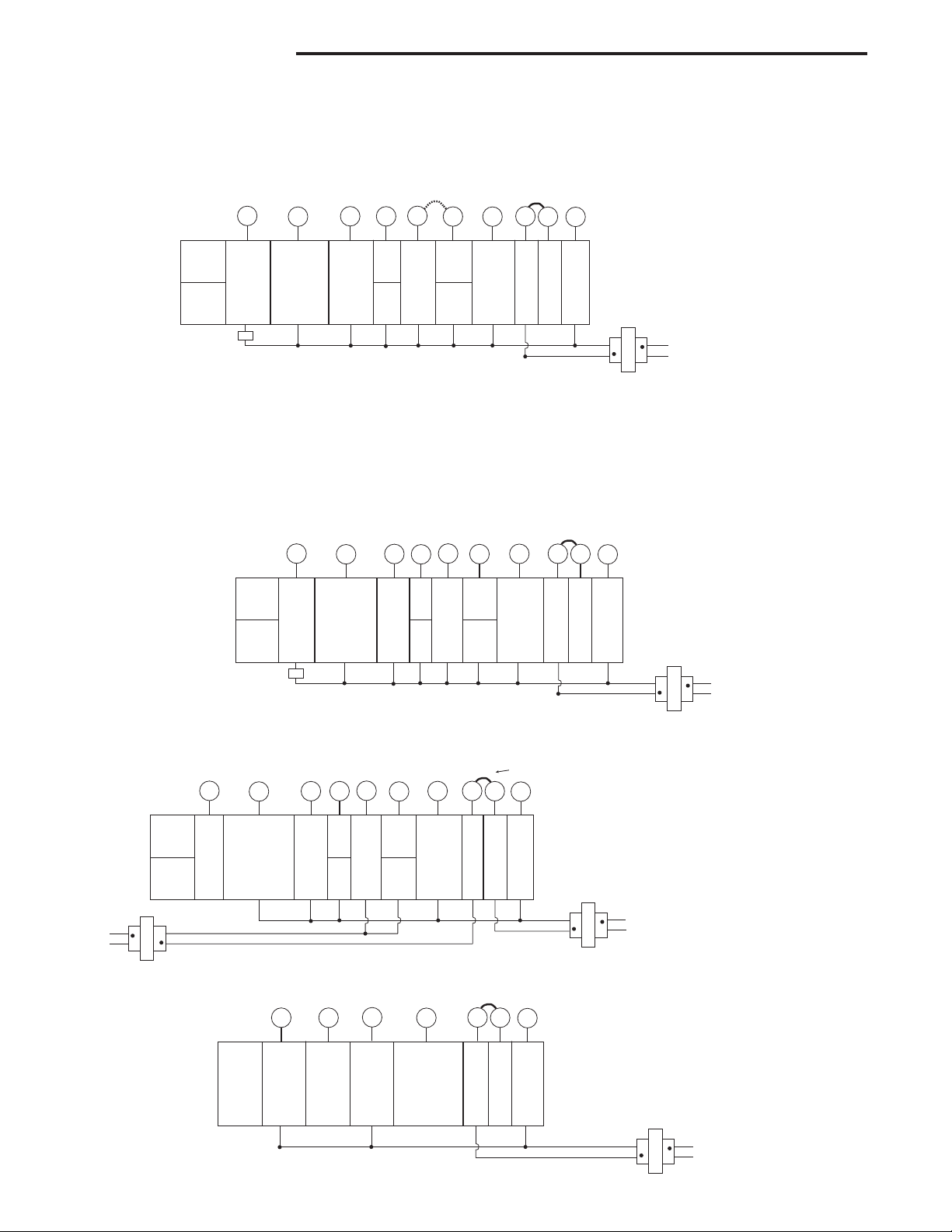

WIRING DIAGRAMS

Heat Pump Connections

If you do not have a heat pump system, refer to figures 4-6.

Refer to equipment manufacturers’ instructions for specific

system wiring information.

You can configure the thermostat for use with the following

heat pump systems.

System

Heat Pump 1

(HP1)

Heat Pump 2

(HP2)

Comfort Alert II Module

or Similar System

Malfunction Module

Figure 3 – Heat Pump Systems

L

Fault Indicator

or System

Malfunction

Switch

O/B

O

Energized in

Cool Mode

B

Energized in

Heat, Off,

Emergency

Mode

Y

Heat and

Cool Mode

1st Stage

(Compressor)

Y2

No

Output

2nd

Stage

(Com-

pressor)

W/E

Emergency

Mode

1st Stage

Jumper

Heat Mode

2nd Stage.

Emergency

Mode 2nd

Heat Mode

3rd Stage.

Emergency

Mode 2nd

Single Stage and Multi-Stage Connections

Refer to equipment manufacturers’ instructions for specific

system wiring information.

This thermostat is designed to operate a single-transformer

or two-transformer system.

You can configure the thermostat for use with the following

fossil fuel systems:

Figure 4 – Single Stage or Multi-Stage System (No Heat Pump) with Single Transformer

L

System

Single

Stage 1

(SS1)

Multi-

Stage 2

(MS2)

Comfort Alert II Module

or Similar System

Malfunction Module

Fault

Indicator

or

System

Malfunction

Switch

O/B

O

Energized Constantly

in Cool Mode

B

Energized Constantly

in Heat, Off,

Emergency

Mode

Y

Cool Mode

1st Stage

Y2

No

Output

Cool

Mode

2nd

Stage

Heat

Mode

1st Stage

HEAT PUMP TYPE 1 (HP 1). Single stage compressor

system; gas or electric backup.

HEAT PUMP TYPE 2 (HP 2). Multi-stage compressor or two

compressor system with gas or electric backup.

After wiring, see INSTALLER CONFIGURATION section for

proper thermostat configuration.

Jumper

C

W2

G

RC

RH

NOTE: If your system does

not provide an E connection,

jumper W2 to W/E to use

the Auxiliary Heat in the

Emergency Mode.

* Common connection

required for fault or

malfunction indication.

120VAC

Stage

Stage

Blower/

Circulator

Fan Energized

on Call for

Heat or Cool.

Set Elect/Gas

Option for

Emergency

Mode

24 Volt

(Hot)

Heat

24 Volt

(Hot)

Cool

Optional*

24 Volt

(Com-

mon)

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

SINGLE STAGE (SS 1) gas, oil or electric.

MULTI-STAGE (MS 2) gas, oil or electric.

After wiring, see INSTALLER CONFIGURATION section for

proper thermostat configuration.

Jumper

W/E

No Output

Heat Mode

2nd Stage

W2

G

Blower/

Circulator

Fan Energized

on Call for

Cool (and

Heat if

configured

for Electric

Heat)

RH

24 Volt

(Hot)

Heat

RC

24 Volt

(Hot)

Cool

C

Optional*

24 Volt

(Com-

mon)

NEUTRAL

24VAC

HOT

* Common connection

required for fault or

malfunction indication.

120VAC

CLASS II

TRANSFORMER

120VAC

HEATING

CLASS II

TRANSFORMER

Figure 5 – Single Stage or Multi-Stage System (No Heat Pump) with Two Transformers

Remove Jumper Wire

Jumper

between RH & RC

System

Single

Stage 1

(SS1)

Multi-

Stage 2

(MS2)

NEUTRAL

24VAC

HOT

L

Fault

Indicator

(NOT

USED)

O/B

O

Energized Constantly

in Cool Mode

B

Energized Constantly

in Heat, Off,

Emergency

Mode

Y

Cool Mode

1st Stage

Y2

No

Output

Cool

Mode

2nd

Stage

W/E

Heat

Mode

1st Stage

W2

No Output

Heat Mode

2nd Stage

Fan Energized

G

Blower/

Circulator

on Call for

Cool (and

Heat if

configured

for Electric

Heat)

RH

24 Volt

(Hot)

Heat

RC

24 Volt

(Hot)

Cool

C

Optional

24 Volt

(Com-

mon)

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

COOLING

Figure 6 – 3-Wire (SPDT) Heat Only Zone Valve Wiring

Jumper

W

Y

Opens

Valve

(4)

G

Blower/Circulator

Fan Energized

RH

24 Volt

(Hot)

Heat

(5)

RC

24 Volt

(Hot)

Cool

C

Constant

24 Volt

(Common)

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

System

Single Stage

3-wire

Zone Valve

application

6

Closes

Valve

(6)

NOTE: If continuous backlight or

hardwired power input are desired but

do not function in both HEAT and COOL

modes, cut the heating transformer 24V

wires and tape off. Connect the neutral

circuit disconnected from the heating

transformer to the neutral circuit of the

cooling transformer. Disconnect the wire

to the RH terminal and install a jumper

between RH and RC. Depending on

the system requirements, replace the

cooling transformer with a 75VA class II

transformer if needed.

120VAC

3

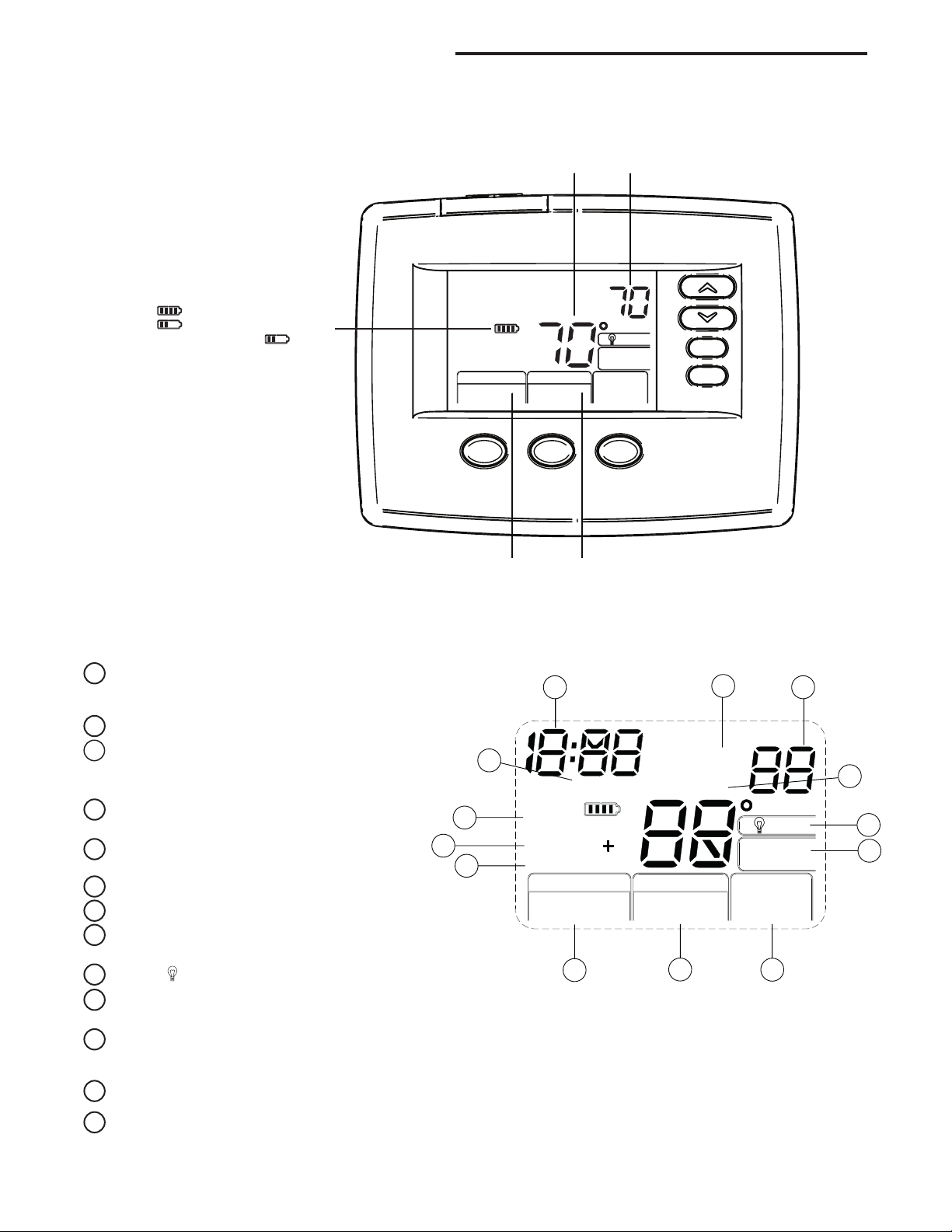

Page 4

Room

Setting

THERMOSTAT QUICK REFERENCE

Home Screen Description

Figure 7 – Home Screen Display

Displays the power level of

the 2 “AA” batteries:

indicates good power level

indicates batteries at about

half power. “Change ” indicates

batteries are low and should be

replaced with 2 new premium brand

“AA” Alkaline batteries.

(See page 2 for more details)

Heat

SYSTEM

System

Indicator

Temperature

Set

FAN

Auto

Fan

Indicator

Temperature

Menu

Programming and Configuration Items

“System On” indicates when heating or cooling stage

1

is energized. “+2” flashing indicates when a second

stage is energized, +2 not flashing when “Aux” is energized.

2

The word “Set” indicates the setpoint temperature.

Displays “Change Filter” when the system has run

3

for the programmed filter time period as a reminder to

change or clean your filter.

Displays System Mode (Heat, Emer, Auto, Cool, Off)

4

in Menu Mode.

5

Displays Fan Mode (On, Auto) or “Run Sched” in

Menu Mode.

6

Displays “Menu”.

7

Displays “Save” when Cool Savings

Displays “Heat Pump” to indicate thermostat is config-

8

TM

is working.

ured for Heat Pump.

9

Displays

“Cool Savings” when in the Cool Mode if Cool Savings

10

(light bulb) in non-programmable mode.

has been enabled in the menu.

“Call For Service” indicates a fault in the heating/

11

cooling system, it does not indicate a fault in the

thermostat.

12

Flashes “LOC” when keypad lockout is enabled.

In Configuration Menu, shows screen number. If blank,

13

thermostat is earlier model and requires instruction sheet

37-7149B.

Figure 8 – Programming & Configuration Items

12 13

2

Mo Tu We Th Fr Sa Su

11

3

1

8

Month Call For Service

Change

Filter

System On 2

Heat Pump

SYSTEM

Heat Emer Auto

Cool O Time

P Date

Temp

On Auto

Run Sched

4

FAN

5

Save

Set

Cool Savings

Schedule

Year

Hold

Auto Sched

Run

Menu

6

7

9

10

4

Page 5

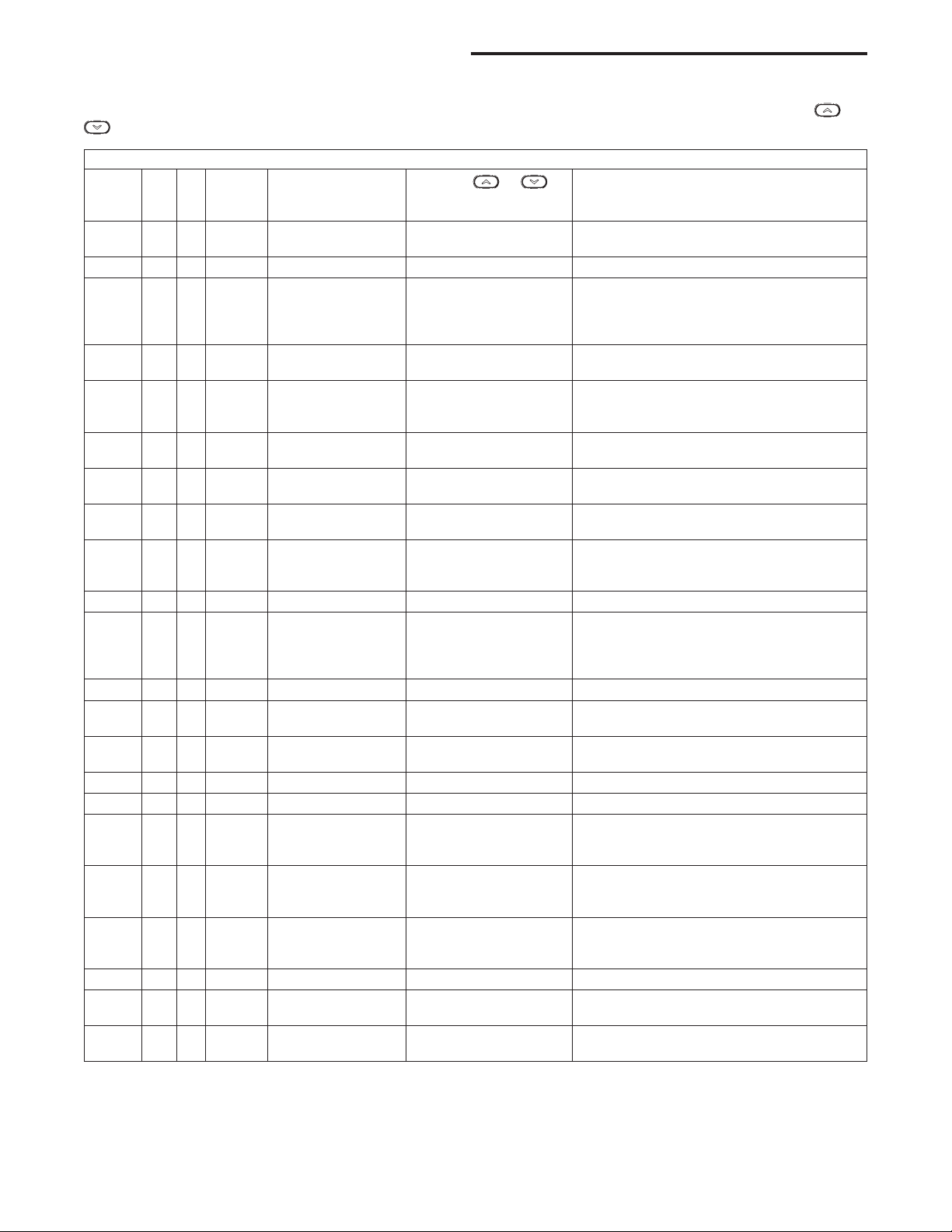

INSTALLER/CONFIGURATION MENU

To enter the Configuration Menu, SYSTEM must be set to HEAT, COOL or EMER. Press the Menu button for at least 5

seconds. The display will show item #1 in the table below. Press Menu button to advance to the next menu item. Press

to change a menu item.

INSTALLER/CONFIGURATION MENU

MENU

SCREEN

NUMBER

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18 HP2

19

20

21

22

MS/SSPRESS

HP

BUTTON

MENU (Off)

MENU (000) Lk 001 to 999 Selects Keypad lockout combination number

MENU (MS 2) HP 1, HP 2, SS 1 Selects Multi-Stage (MS 2 No Heat Pump),

MENU (GAS) for SS or MS

MENU (0) CS 1, 2, 3, 4, 5, 6 Selects Cool Savings

MENU (ME)

MENU (ME)

MENU (ME)

MENU (FA)

MENU (OFF) CL CL On Compressor Lockout Time Delay

MENU Heat Auto

MENU (On) dL dL OFF Selects Display Light On or OFF

MENU 0

MENU

MENU (90) L Heat L 62 to L 89 Selects Limited HEAT Range

MENU (45) L Cool L 46 to L 82 Selects Limited COOL Range

MS MENU (On) Heat FA OFF Fast Heat option may be disabled by

MENU (On) Cool FA OFF Fast Cool option may be disabled by

MENU (OFF) CA On Selects active Comfort Alert On or OFF.

MENU (OFF) Change Filter On Selects Filter Change-out Indicator On or OFF.

MENU (200 h) Change Filter 25-1975 h Change Filter time in 25 hour increments. This

MENU (o) Cool On (b) Heat On Selects operation of the reversing valve termi-

DISPLAYED

(FACTORY DEFAULT)

Lk

(ELE) for HP

CR Heat

CR Cool

CR Heat Pump

CR Emer

Cool Off

(current temperature)

°F °C

Press

to select from listed

or

options

L Total Keypad lockout

ELE or

GAS

SL, FA Adjustable Anticipation:

SL, FA

SL, FA Adjustable Anticipation (Heat Pump) (only

SL, FA

SL

Heat Cool Off,

Heat Off with Fan icon,

Heat Off without Fan icon,

Cool Off, Auto Off

1 HI, 2 HI, 3 HI, 4 HI,

1 LO, 2 LO, 3 LO, 4 LO

COMMENTS

(Not available on earlier models)

Heat Pump 1 (HP 1, 1 compressor), or

Single Stage (SS 1), Heat Pump 2 (HP 2,

2 compressor or 2 speed compressor)

GAS setting: furnace controls the blower

ELE setting: thermostat controls the blower

Value 1 (low) to 6 (high),

Value 0 Disables Feature

Selects heating cycle rate for MS or SS

Adjustable Anticipation:

Selects cool cycle rate

when heat pump selected in #1)

Selects the cycle rate for Emergency

mode and Auxiliary stage if Heat Pump

is selected in item 1.

Select System Switch Conguration

with Automatic Changeover capability.

Adjustable Ambient Temperature Display

Selects Fahrenheit/Celsius

Temperature Display

selecting OFF. NA to SS cong.

NA to Cool only system.

selecting OFF. NA to SS cong.

NA to Heat only system.

Requires CA II Module.

(Not available on earlier models)

menu only appears if On is selected in above.

nal (O/B) output as an O or B terminal.

or

5

Page 6

INSTALLER/CONFIGURATION MENU

1 & 2)Keypad Lockout – This menu selection will display

“Lk” and “OFF” (default, keypad not locked out). The

and are used to toggle the selection between

“OFF” and “L” (keypad locked out). When the keypad

lockout selection is enabled “L”, and the MENU button

is pressed again, the display will indicate the number

“0” (default, still disabled) in the time digits. The

and

to 999. If a combination of 0 is selected and the MENU

button is pressed, the menu will be exited and keypad

will not be locked. If 1 to 999 is selected and the MENU

button is pressed, the combination is stored into memory

and the menu is exited. The “Loc” will display designating keypad locked with a valid combination. The SYSTEM

button will operate for 10 seconds after the menu mode

is exited to allow the user to change the mode from OFF

to the desired SYSTEM mode.

While the keypad is locked out, a press of MENU will en-

ter the configuration menu. The first menu item displayed

is the combination code “0”. The

used to set the combination unlock number from 0 to

999. If the unlock number matches exactly with the combination lock number stored in memory when the MENU

button is pressed, the keypad is unlocked and the “Loc”

is removed. If the unlock number does not match when

the MENU button is pressed, the combination returns to

“0” for another attempt to set the unlock code. To exit the

menu, without unlocking the keypad, press RUN SCHED.

To reset the combination code and unlock the keypad if

the code is forgotten, see troubleshooting section.

3) This control can be configured for:

MS 2 – Multi-Stage System (no heat pump)

HP 1 – Heat Pump with one stage of compressor

HP 2 – Heat Pump with two stage compressor or two

compressor system, Gas or Electric backup

SS 1 – Single Stage System

4) GAS or Electric (ELE) fan operation. If the heating system requires the thermostat to energize the fan, select

ELE. Select GAS if the heating system energizes the fan

on a call for heat.

5) Select Cool Savings™ value – Selects the amount

of adjustment for the Cool Savings™ feature in Cool

mode with 1 (1°) being the least amount of adjustment

and 6 (6°) being the most amount of adjustment. Default

value is 0 which disables this feature. Selecting a value

greater than 0 will display Cool Savings on the screen

and enable the key for Cool Savings feature. Cool Savings is an optional energy saving feature that can reduce

your cooling costs. It is based on the principal that lower

indoor humidity makes a slightly higher temperature

feel more comfortable. Cool Savings operates during

periods of high demand which normally occur on the

hottest summer days when a cooling system may run

for hours to reach the thermostat setting. Long cooling

run times also lower the indoor humidity. Cool Savings,

very slowly, adjusts the setpoint temperature to make the

setpoint closer to the displayed room temperature, to a

maximum of the number of degrees you select. Adjusting the setpoint temperature over a long cooling run time

allows the system to reach your set temperature and turn

off. The room temperature will actually be higher than

the thermostat displays but the reduction in humidity will

allow comfort at the slightly higher temperature.

To turn this feature on in the Cool mode press Cool

Savings. The display will show “Save” next to the

setpoint temperature. When Cool Savings is making adjustments to the room temperature display “Save” will be

flashing and the displayed room temperature may vary

within the adjustment range you selected.

are used to set the combination number from 0

or keys are

If “Save” is not displayed and this feature is OFF, no

change will occur when the cooling system is continuously running during periods of high demand.

6, 7, 8 & 9) Cycle Rate Selection – The factory default set-

ting for Heat and Cool modes, SS1, MS2, is medium

cycle (ME). For Heat Pump, HP1, HP2, the default setting is medium (ME). For Emer (Aux) the default setting

is fast cycle (FA). To change cycle rate, press the

key.

Cycle rate differentials for different settings are:

Fast Medium Slow

MODE FA ME SL

Heat (SS1, MS2) 0.4°F 0.6°F 1.7°F

Cool (SS1, MS2) 0.9°F 1.2°F 1.7°F

Heat Pump (HP1, HP2) 0.9°F 1.2°F 1.7°F

Emer (HP1, HP2) 0.6°F - 1.7°F

10) Select Compressor Lockout CL OFF or ON – Select-

ing CL ON will cause the thermostat to wait 5 minutes

between cooling cycles. This is intended to help protect

the compressor from short cycling. Some newer com-

pressors already have a time delay built in and do not

require this feature. Your compressor manufacturer can

tell you if the lockout feature is already present in their

system. When the thermostat compressor time delay oc-

curs, it will flash the setpoint for up to five minutes.

11) System Mode Configuration – This thermostat is

configured for Heat and Cool (SYSTEM switch with Cool,

Off, Heat) default. It can also be configured for Heat and

Cool with Auto changeover (Heat, Auto, Cool, Off), Heat

only with fan (Off, Heat), Heat only without fan, Auto only

(Auto, Off), and Cool only (Cool, Off).

12) Select Backlight Display – The display backlight im-

proves display contrast in low lighting conditions. When

the “C” terminal is powered, selecting backlight CdL ON

will keep the light on continuously. Select backlight OFF

will turn the light on momentarily after any key is pressed.

When the “C” terminal is not powered, the light will be on

momentarily after any key is pressed no matter whether

the backlight is selected ON or OFF.

13) Select Temperature Display Adjustment 4 LO to 4 HI

– Allows you to adjust the room temperature display up

to 4° higher or lower. Your thermostat was accurately cali-

brated at the factory, but you have the option to change

the display temperature to match your previous thermo-

stat. The current or adjusted room temperature will be

displayed.

14) Select F° or C° Readout – Changes the display readout

to Celsius or Fahrenheit as required.

15 & 16) Temperature Limit Range Heat or Cool – This

selection sets the maximum HEAT (13) or minimum

COOL (14) temperature for the setpoint range. Select the

limit temperature using the

Schedule mode, the setpoint temperature will not adjust

past the limit temperature selected. When the limit tem-

perature is reached, trying to raise or lower the setpoint

past the limit will cause “L” to be displayed in the times

digits for about 6 seconds. This feature is not available on

earlier models.

17 & 18) Select Fast Second Stage ON or OFF – Heat

pump or Multi-stage only, in the run mode, with the fast

Heat feature enabled (FA Heat On), if the Heat setpoint

temperature is manually raised by 3°F (2°C) or more

above the actual temperature using

stage will energize immediately. With FA OFF, second

stage will not energize until the setpoint temperature is

1°F or more above actual temperature for more than ten

minutes. The Fast Cool feature (FA Cool) provides the

same controls when the setpoint temperature is lowered.

or keys. In the Run

the second

or

6

Page 7

INSTALLER/CONFIGURATION MENU

19) Comfort Alert with Active Protection – Turn this

feature ON to enable active protection. This allows the

thermostat to identify fault codes sent by the Comfort

Alert module when compressor damage is possible and

react to those codes by turning the compressor off. Fault

codes from the Comfort Alert module will flash on the

thermostat. (Refer to Comfort Alert Yellow Alert Codes

in Troubleshooting section.) If a Comfort Alert module is

not connected, or to disable active protection, turn this

feature OFF. If a Comfort Alert module is connected and

this feature is turned OFF, the thermostat will still receive

and flash the fault codes from the Comfort Alert module,

but the active protection will not be enabled to protect the

compressor.

20 & 21) Select Filter Replacement Reminder and Set

Run Time – Select the “Change Filter” reminder On

or OFF. If selected On, press MENU to select the time

OPERATING YOUR THERMOSTAT

Choose the Fan Setting (Auto or On)

Press the FAN button to Auto or On.

Fan Auto is the most commonly selected setting and runs the

fan only when the heating or cooling system is on.

Fan On runs the fan continuously for increased air circulation

or to allow additional air cleaning.

Choose the System Setting

(Heat, Off, Cool, Auto, Emer)

Press the SYSTEM button to select:

Heat: Thermostat controls only the heating system.

Off: Heating and Cooling systems are off.

Cool: Thermostat controls only the cooling system.

Auto: Auto Changeover is used in areas where both heating

and cooling may be required on the same day. AUTO allows

the thermostat to automatically select heating or cooling

depending on the indoor temperature and the selected heat

and cool temperatures. When using AUTO, be sure to set the

Cooling temperatures more than 1° Fahrenheit higher than

the heating temperature.

Emer: (Heat Pump models) Thermostat controls only backup

heating system.

period from 25 to 1975 hours in 25 hours increments.

In a typical system, 200 hours (default) of run time is

approximately 30 days. After the selected time of blower

operation, the thermostat will display “Change Filter”

as a reminder to change or clean your air filter. When

“Change Filter” is displayed, press MENU or RUN

SCHED button to clear the display and restart the time to

the next filter change.

22) Select Reversing Valve Output – The O/B option is

factory set at “O” position. This will accommodate the

majority of heat pump applications, which require the

changeover relay to be energized in COOL. If the

thermostat you are replacing or the heat pump being

installed with this thermostat requires a “B” terminal, to

energize the changeover relay in HEAT, the O/B option

should be set at “B” position.

IMPORTANT!

Second Stage Time Delay

Your thermostat is designed to determine the optimum time

to activate the second stage. Simply raising the temperature

in heating or lowering it in cooling will not always force the

thermostat to bring the second stage on quickly. There is a

time delay from 0-30 minutes depending on the performance

of the first stage of the system.

EXAMPLE: For the last 2 hours the thermostat is set on 70°

and the room temperature is 70° with the equipment using

only the first stage of heat. Since the equipment is keeping

the temperature within 1° of setpoint, the thermostat will

delay second stage for a longer time if you manually raise the

temperature or if the room temperature quickly changes. Once

the second stage comes on, it will come on sooner the next

time there is a difference between the setpoint and the room

temperature. The net effect of the staging program is that when

the first stage is capable of making temperature the second

stage will delay longer. When the thermostat calculates that

first stage cannot make temperature in a reasonable time,

the second stage will come on sooner. This built in function

automatically optimizes the use of additional stages of heat

or cool.

Manual Operation for Non-Programmable Mode

Press the SYSTEM button to select Heat or Cool and use

the

desired setting. After selecting your desired settings you can

also press the SYSTEM button to select AUTO to allow the

thermostat to automatically change between Heat and Cool.

or buttons to adjust the temperature to your

TROUBLESHOOTING

Comfort Alert Codes

The Comfort Alert diagnostics product monitors the air conditioning outdoor systems with single phase Copeland Scroll

compressors. Abnormal system and electrical conditions are

indicated by flashing ALERT codes on the yellow LED on the

Comfort Alert module. The flash codes are transmitted to the

thermostat by the Comfort Alert Thermostat interface module.

The Comfort Alert compatible thermostat displays “Call For

Service” that flashes at the same rate as the yellow LED on

the Comfort Alert module.

Comfort Alert Yellow Alert Codes

1 Flash Long run time

2 Flashs System pressure trip

3 Flashs Short cycling

4 Flashs Locked rotor

5 Flashs Open circuit

6 Flashs Open start circuit

7 Flashs Open run circuit

8 Flashs Welded Contactor

9 Flashs Low voltage

7

Page 8

TROUBLESHOOTING

Reset Operation

Note: When thermostat is reset, installer configuration menu

settings and programming will reset to factory settings.

If a voltage spike or static discharge blanks out the display

or causes erratic thermostat operation, you can reset the

thermostat by removing the wires from terminals R and C

(do not short them together) and removing batteries for 2

minutes. After resetting the thermostat, replace the wires and

batteries. If the thermostat has been reset and still does not

function correctly contact your heating/cooling service person

or place of purchase.

Note: Be sure to review the installer configuration menu

settings.

To reset the programming, clock and configuration settings,

press

and and the FAN button simultaneously. The

thermostat should go blank and then all segments will be

displayed momentarily.

Symptom Possible Cause Correction Action

No Heat/No Cool/No Fan

(common problems)

No Heat

No Cool

Heat, Cool or Fan

Runs Constantly

Thermostat Setting &

Thermostat Thermometer

Disagree

Furnace (Air Conditioner)

Cycles Too Fast or Too

Slow (narrow or wide

temperature swing)

Forgot Keypad

Lockout Code

Thermostat does not have

Menu Screen Numbers

1. Blown fuse or tripped circuit breaker.

2. Furnace power switch to OFF.

3. Furnace blower compartment door or panel

loose or not properly installed.

4. Loose connection to thermostat or system.

1. Pilot light not lit.

2. Furnace Lock-Out Condition. Heat

may also be intermittent.

3. Heating system requires service or

thermostat requires replacement.

1. Cooling system requires service or

thermostat requires replacement.

1. Possible short in wiring.

2. Possible short in thermostat.

3. Possible short in heat/cool/fan system.

4. FAN Switch set to Fan ON.

1. Thermostat thermometer setting

requires adjustment.

1. The location of the thermostat and/or

the size of the Heating System may

be influencing the cycle rate.

1. Earlier version of thermostat. Refer to Instruction Sheet 37-7149B

Replace fuse or reset breaker.

Turn switch to ON.

Replace door panel in proper position to engage safety

interlock or door switch.

Tighten connections.

Re-light pilot.

Many furnaces have safety devices that shut down when

a lock-out condition occurs. If the heat works intermittently

contact the furnace manufacturer or local HVAC service

person for assistance.

Diagnostic: Set SYSTEM Switch to HEAT and raise the

setpoint above room temperature. Within a few seconds

the thermostat should make a soft click sound. This sound

usually indicates the thermostat is operating properly. If the

thermostat does not click, try the reset operation listed above.

If the thermostat does not click after being reset contact your

heating and cooling service person or place of purchase for

a replacement. If the thermostat clicks, contact the furnace

manufacturer or a HVAC service person to verify the heating

is operating correctly.

Same as diagnostic for No Heat condition except set the

thermostat to COOL and lower the setpoint below the room

temperature. There may be up to a five minute delay before

the thermostat clicks in Cooling.

Check each wire connection to verify they are not shorted or

touching together. No bare wire should stick out from under

terminal block. Try resetting the thermostat as described

above. If the condition persists the manufacturer of your

system or service person can instruct you on how to test

the Heat/Cool system for correct operation. If the system

operates correctly, replace the thermostat.

The thermometer can be adjusted +/- 4 degrees. See

Temperature Display Adjustment in the Configuration Menu

section.

Digital thermostats provide precise control and cycle faster

than older mechanical models. The system turns on and off

more frequently but runs for a shorter time so there is no

increase in energy use. If you would like an increased cycle

time, choose SL for slow cycle in the Configuration menu,

step 6 (heat), 7 (cool) or 8 (heat pump). If an acceptable cycle

rate is not achieved, contact a local HVAC service person for

additional suggestions.

Hold MENU key for 20 seconds and the lockout will reset.

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

HOMEOWNER HELP LINE: 1-800-284-2925

www.white-rodgers.com

www.emersonclimate.com

Page 9

www.emersonclimate.com

www.white-rodgers.com

LÍNEA DE AYUDA PARA EL USUARIO: 1-800-284-2925

1. Version anterior del termostato. Refiérase al manual 37-7149B.

se restablecerá.

Presione el botón MENU durante 20 segundos y el bloqueo

especializado para obtener sugerencias adicionales.

aceptable, póngase en contacto con personal técnico

u 8 (bomba de calor). Si no alcanza una velocidad de ciclo

ciclo lento en el menú de configuración, paso 6 (calor), 7 (frío)

Si desea aumentar el tiempo de un ciclo, seleccione SL para un

más corto por lo que no hay aumento en el consumo de energía.

apaga con más frecuencia pero funciona durante un período

modelos mecánicos más antiguos. El sistema se enciende y se

preciso y pueden reiniciar el ciclo más rápidamente que algunos

Los termostatos digitales proporcionan un control de temperatura

la temperatura visualizada en la sección Menú de configuración.

El termómetro puede ajustarse en +/- 4 grados. Vea el Ajuste de

correctamente, cambie el termostato.

frío/calor está funcionando correctamente. Si el sistema funciona

personal técnico podrá indicarle cómo probar si el sistema de

abajo. Si la condición persiste, el fabricante de su sistema o el

terminales. Intente reajustar el termostato como se describe más

sobresalir ningún cable pelado por debajo de los tornillos

de que no estén en cortocircuito o tocándose entre sí. No debe

Verifique todas las conexiones de los cables para asegurarse

minutos en pasar al modo de enfriamiento.

temperatura ambiente. El termostato puede tardar hasta cinco

y coloque la temperatura de referencia por debajo de la

el sistema no calienta pero coloque el termostato en COOL

Siga el mismo procedimiento de diagnóstico que Cuando

para verificar que la calefacción esté funcionando correctamente.

contacto con el fabricante del calefactor o con el personal técnico

un reemplazo. Si el termostato hace un chasquido, póngase en

calefacción y enfriamiento o con el lugar de compra para obtener

póngase en contacto con su personal de servicio técnico de

Si el termostato no hace un chasquido después de reajustarlo,

chasquido, intente la operación de reajuste arriba indicada.

termostato está funcionando correctamente. Si no se oye un

suave del termostato. Por lo general, este sonido indica que el

ambiente. En cuestión de segundos, debería oírse un chasquido

la temperatura de referencia por encima de la temperatura

Diagnostico: Ajuste el interruptor SYSTEM en HEAT y suba

solicitar ayuda.

fabricante de la caldera o con el personal técnico local para

funciona de manera intermitente, póngase en contacto con el

cuando se produce una condición de bloqueo. Si la calefacción

Muchas calderas tienen dispositivos de seguridad que se cierran

Vuelva a encender el piloto.

Ajuste las conexiones.

o de la puerta.

que se enganche con el interruptor de interbloqueo de seguridad

Vuelva a colocar el panel de la puerta en el lugar correcto para

Coloque el interruptor en ON.

Cambie el fusible o vuelva a activar el disyuntor.

en la duración de los ciclos.

del sistema de calefacción pueden influir

1. La ubicación del termostato y/o el tamaño

requiere ajuste.

1. El valor del termómetro del termostato

4. El interruptor FAN está en Fan ON.

de calor/frío/ ventilador.

3. Posible cortocircuito en el sistema

2. Posible cortocircuito en el termostato.

1. Posible cortocircuito en los cables.

técnico o debe cambiarse el termostato.

1. El sistema de enfriamiento requiere servicio

técnico o debe cambiarse el termostato.

3. El sistema de calefacción requiere servicio

El calor también puede ser intermitente.

2. Condición de bloqueo del calefactor.

1. La luz piloto no está encendida.

está suelta.

4. La conexión al termostato o al sistema

están debidamente instalados.

soplador del calefactor están sueltos o no

3. La puerta o el panel del compartimento del

está en OFF.

2. El interruptor de alimentación del calefactor

1. Se quemó el fusible o se disparó el disyuntor.

servicio de Emerson Electric Co.

marca comercial y una marca de

El logotipo de Emerson es una

de Emerson Electric Co.

White-Rodgers es una división

del menu

numerous de la pantalla

El termostato no tiene los

bloqueo del teclado

Olvidó el código de

amplia de la temperatura)

(oscilación reducida o

o demasiado cortos

son demasiado largos

aire acondicionado

Los ciclos del calefactor/

coincide con el termómetro

El ajuste del termostato no

manera constante

ventilador funciona de

El modo de calor, frío o

El sistema no enfría

El sistema no calienta

(problemas comunes)

No funciona el ventilador

El sistema no enfría/

El sistema no calienta/

Síntoma Causa posible Acción correctiva

se iluminarán durante unos instantes.

termostato debería ponerse en blanco y luego, todos los segmentos

y el botón FAN simultáneamente. La pantalla del

Para reajustar la programación, el reloj y la configuración, presione

de configuración.

Nota: asegúrese de revisar los ajustes del menú instalador/

de calefacción/enfriamiento o con el lugar donde realizó la compra.

funciona correctamente, póngase en contacto con su servicio técnico

cables y las pilas. Si el termostato se ha reajustado pero aún no

2 minutos. Después de reajustar el termostato, vuelva a colocar los

terminales R y C (no los cortocircuite) y retirando las pilas durante

errática, puede reajustar el termostato retirando los cables de las

blanco la pantalla o hace que el termostato funcione de manera

de fábrica. Si un pico de voltaje o una descarga estática pone en

instalador/de configuración y la programación volverán a los ajustes

Nota: una vez reajustado el termostato, la configuración del menú

Operación de reajuste

SOLUCIÓN DE PROBLEMAS

Page 10

7

9 parpadeos Bajo voltaje

8 parpadeos Contactor soldado

7 parpadeos Circuito de funcionamiento abierto

6 parpadeos Circuito de inicio abierto

5 parpadeos Circuito abierto

4 parpadeos Rotor bloqueado

3 parpadeos Ciclo corto

2 parpadeos Disparo de presión del sistema

Tiempo de funcionamiento prolongado

1 parpadeo

Códigos de alerta amarilla del alerta de comodidad

el uso de etapas adicionales de calor o frío.

activará antes. Esta función incorporada optimiza automáticamente

temperatura dentro de un tiempo razonable, la segunda etapa se

el termostato calcula que la primera etapa no puede llegar a la

temperatura, la segunda etapa se demorará más tiempo. Cuando

por etapas es que cuando la primera etapa es capaz de alcanzar la

de referencia y la temperatura ambiente. El efecto neto del programa

antes la próxima vez que haya una diferencia entre la temperatura

rápidamente. Una vez que se activa la segunda etapa, se activará

manualmente la temperatura o si la temperatura ambiente cambia

el termostato demorará la segunda etapa un tiempo más si sube

temperatura dentro de 1 grado de la temperatura de referencia,

la primera etapa de calor. Como el equipo está manteniendo la

y suba la temperatura ambiente es de 70°, y el equipo utiliza sólo

EJEMPLO: Durante las últimas 2 horas el termostato está en 70°

minutos según el rendimiento de la primera etapa del sistema.

entre rápidamente en la segunda etapa. Hay una demora de 0–30

la temperatura de refrigeración no siempre hará que el termostato

activar la segunda etapa. Subir la temperatura de calefacción o bajar

Su termostato está diseñado para determinar el tiempo óptimo para

Demora de tiempo de la segunda etapa

termostato cambie automáticamente entre calor y frío.

el botón SYSTEM para seleccionar AUTO para permitir que el

de seleccionar los valores deseados también puede presionar

o para ajustar la temperatura al valor deseado. Después

Presione el botón SYSTEM para seleccionar Heat o Cool y utilice los

Operación manual para Modo no programable

módulo de alerta de comodidad.

al servicio técnico), que parpadea junto con el LED amarillo del

alerta de comodidad muestra el mensaje “Call For Service” (Llamar

termostato-alerta de comodidad. El termostato compatible con el

intermitentes son transmitidos al termostato por el módulo de interfaz

el LED amarillo del módulo de alerta de comodidad. Los códigos

en el sistema se indican con códigos de ALERTA intermitentes en

Scroll de una sola fase. Las condiciones anormales eléctricas y

sistemas de aire acondicionado externos con compresores Copeland

El producto de diagnóstico de alerta de comodidad monitorea los

Códigos de alerta de comodidad

SOLUCIÓN DE PROBLEMAS

sistema de calefacción auxiliar.

Emer: (modelos de bomba de calor) El termostato sólo controla el

la temperatura de calefacción.

temperaturas de enfriamiento a más de 1° Fahrenheit por encima de

seleccionadas. Cuando utilice AUTO, asegúrese de ajustar las

según la temperatura interior y las temperaturas de calor y frío

termostato seleccionar automáticamente calefacción o enfriamiento

calefacción y enfriamiento en el mismo día. AUTO permite al

Auto: Auto changeover, se usa en lugares donde se requiere

Cool: el termostato controla únicamente el sistema de enfriamiento.

Off: los sistemas de calefacción y enfriamiento están apagados.

Heat:

el termostato controla únicamente el sistema de calefacción.

Presione el botón SYSTEM para seleccionar:

(Heat, Off, Cool, Auto, Emer)

Elija la configuración del sistema

mayor circulación de aire o para permitir la limpieza adicional del aire.

Fan On hace funcionar el ventilador de forma continua para una

o enfriamiento está encendido.

funcionar el ventilador únicamente cuando el sistema de calefacción

Fan Auto es la configuración más comúnmente seleccionada y hace

Coloque el botón FAN en Auto o en On.

Elija la configuración del ventilador (Auto u On)

en HEAT, el interruptor O/B debe colocarse en la posición “B”.

requiere una terminal “B”, para energizar el relé de conmutación

o la bomba de calor que está instalando con este termostato

esté energizado en COOL. Si el termostato que está cambiando

de bomba de calor, que requieren que el relé de conmutación

posición “O”. Esta opción admite la mayoría de las aplicaciones

inversora) – La opción O/B viene ajustada de fábrica en la

22) Selección de Reversing Valve Output (salida de válvula

pantalla y reiniciar la hora para el siguiente cambio de filtro.

Filter” presione el botón MENU O RUN SCHED para borrar la

cambiar o limpiar su filtro de aire. Cuando aparezca “Change

termostato mostrará “Change Filter” como recordatorio para

vez seleccionado el tiempo de funcionamiento del soplador, el

predeterminado) equivalen a aproximadamente 30 días. Una

aplicación típica, 200 horas de tiempo de funcionamiento (valor

25 hasta 1975 horas en incrementos de 25 horas. En una

presione MENU para seleccionar la cantidad de tiempo desde

CÓMO USAR SU TERMOSTATO ¡IMPORTANTE!

en On (activado) u OFF (desactivado). Si selecciona On,

tiempo de funcionamiento – Coloque “Change Filter”

20 y 21)Selección de aviso de cambio de filtro y ajuste de

activará la protección activa del compresor.

códigos de falla del módulo de alerta de comodidad pero no se

el termostato recibirá y mostrará de forma intermitente los

módulo de alerta de comodidad y esta función está desactivada,

la protección activa, desactive esta función. Si se conecta un

conecta un módulo de alerta de comodidad, o para desactivar

de comodidad en la sección Solución de problemas.) Si no se

termostato. (Refiérase a los códigos de alerta amarilla del alerta

alerta de comodidad aparecerán de forma intermitente en el

apagando el compresor. Los códigos de falla del módulo de

de que el compresor se dañe y reaccionar a dichos códigos

módulo de Alerta de Comodidad cuando existe el peligro

al termostato identificar los códigos de falla enviados por el

función en ON para activar la protección activa. Esto permite

19) Alerta de comodidad con protección activa – Coloque esta

MENÚ INSTALADOR/DE CONFIGURACIÓN

Page 11

mismos controles cuando la temperatura de referencia disminuye.

minutos. La función de frío rápido (FA Cool) proporciona los

o más por encima de la temperatura real durante más de diez

energizará hasta que la temperatura de referencia esté a 1° F

inmediatamente. Con FA en OFF, la segunda etapa no se

la temperatura real con el la segunda etapa se energizará

se aumenta manualmente en 3° F (2° C) o más por encima de

activada (FA Heat On), si la temperatura de referencia de calor

o multietapa, en el modo Run, con la función de calor rápido

OFF (desactivada) – Sólo en sistemas de bomba de calor

17 y 18) Selección de segunda etapa rápida ON (activada) u

Esta función no está disponible en los modelos anteriores.

en los dígitos de horas durante aproximadamente 6 segundos.

de referencia más allá del límite aparecerá una “L” en la pantalla

alcanzar la temperatura límite, si se intenta subir o bajar el valor

se ajustará más allá de la temperatura límite seleccionada. Al

En el modo Run Schedule, la temperatura de referencia no

Seleccione la temperatura límite usando las teclas o .

temperatura mínima de COOL (14) para el rango de referencia.

Esta opción ajusta la temperatura máxima de HEAT (13) o la

15 y 16) Rango de límite de temperatura de calor o frío –

según su preferencia.

temperatura en la pantalla a grados centígrados o Fahrenheit

14) Seleccione F° o C° – Cambia la unidad en que aparece la

la temperatura ambiente actual o ajustada.

coincida con el de su termostato anterior. La pantalla mostrará

el valor de temperatura que aparece en la pantalla para que

con precisión de fábrica pero usted tiene la opción de cambiar

de 4° más arriba o más abajo. El termostato viene calibrado

ajustar la visualización de la temperatura ambiente en el rango

(4 más abajo) o 4 HI (4 más arriba) – Este control le permite

13) Seleccione el ajuste de la temperatura visualizada de 4 LO

esté en ON o en OFF.

botón, independientemente de que la luz de fondo de la pantalla

momentáneamente encendida después de presionar cualquier

de la selección de la luz de fondo, la luz se mantendrá

la terminal “C” no está conectada, independientemente

encendida después de presionar cualquier botón. Cuando

Al seleccionar OFF, la luz se mantendrá momentáneamente

ON mantendrá la luz de fondo encendida de forma continua.

Cuando la terminal “C” está conectada, la selección de CdL

mejora el contraste de la pantalla en condiciones de poca luz.

12) Seleccione luz de fondo de la pantalla – La luz de fondo

Off) y sólo frío (Cool, Off).

ventilador (Off, Heat), sólo calor sin ventilador, sólo auto (Auto,

conmutación automática (Heat, Auto, Cool, Off), sólo calor con

Off, Heat). También puede configurarse para calor y frío con

configurado para calor y frío (interruptor del SISTEMA con Cool,

11) Configuración del modo del sistema – Este termostato está

durante un máximo de cinco minutos.

mostrará la temperatura de referencia de forma intermitente

la demora de tiempo del compresor del termostato, la pantalla

si su modelo incluye la función de bloqueo. Cuando se activa

termostato. Consulte al fabricante de su compresor para saber

de tiempo y no requieren que esta función esté activada en el

compresores más nuevos ya tienen incorporada una demora

realice ciclos de encendido y apagado cortos. Algunos de los

entre ciclos de enfriamiento para evitar que el compresor

Si se selecciona CL ON, el termostato esperará 5 minutos

10) Selección de bloqueo del compresor (CL) en OFF u ON –

Emer (HP1, HP2) 0.6°F - 1.7°F

Heat Pump (HP1, HP2) 0.9°F 1.2°F 1.7°F

Cool (SS1, MS2) 0.9°F 1.2°F 1.7°F

Heat (SS1, MS2) 0.4°F 0.6°F 1.7°F

MODO FA ME SL

Rápido Medio Lento

ajustes son:

Los diferenciales de la velocidad del ciclo para los diferentes

velocidad del ciclo, presione el o .

el ajuste predeterminado es el ciclo rápido (FA). Para cambiar la

ajuste predeterminado es el ciclo medio (ME). Para Emer (Aux),

MS2 es el ciclo medio (ME). Para bomba de calor, HP1, HP2 el

predeterminado de fábrica para los modos Heat y Cool, SS1,

6, 7, 8 y 9) Selección de la velocidad del ciclo – El ajuste

6

funcionando de forma continua durante períodos de alta demanda.

se realizarán cambios cuando el sistema de enfriamiento esté

Si no aparece la palabra “Save” y esta función está en OFF, no

dentro del rango de ajuste seleccionado.

intermitente y la temperatura ambiente visualizada podrá variar

ambiente, aparecerá la palabra “Save” en la pantalla de forma

referencia. Cuando Cool Savings está ajustando la temperatura

La pantalla mostrará “Save” (ahorro) junto a la temperatura de

Para activar esta función en el modo Cool, presione Cool Savings.

comodidad a la temperatura ligeramente superior.

termostato, pero la reducción de la humedad proporcionará

la temperatura ambiente será más alta que la indicada en el

podrá alcanzar la temperatura definida y apagarse. En realidad,

durante un tiempo de enfriamiento prolongado, el sistema

grados seleccionado. Si se ajusta la temperatura de referencia

temperatura ambiente en pantalla, hasta el número máximo de

la temperatura de referencia para que se acerque más a la

la humedad interior. Cool Savings ajusta muy lentamente

de funcionamiento de enfriamiento largos también reducen

horas para alcanzar el ajuste del termostato. Los tiempos

el sistema de enfriamiento puede estar funcionando durante

suelen producirse en los días de verano más calurosos cuando

Cool Savings funciona durante períodos de alta demanda que

una temperatura ligeramente mayor se sienta más cómoda.

en el principio de que una humedad interior menor hace que

opcional que puede reducir sus costos de enfriamiento. Se basa

Cool Savings. Cool Savings es una función de ahorro de energía

mostrará Cool Savings y se activará la clave para la función

función. Si se selecciona un valor superior a 0, la pantalla

La opción predeterminada de fábrica es 0, que desactiva esta

Cool, donde 1 (1°) es el ajuste mínimo y 6 (6°) el ajuste máximo.

cantidad de ajuste para la función Cool Savings™ en el modo

5) Selección de valor de Cool Savings™ – Selecciona la

calefacción energiza el ventilador en una llamada de calor.

el ventilador, seleccione ELE. Seleccione GAS si el sistema de

Si el sistema de calefacción requiere que el termostato energice

4) Funcionamiento del ventilador con GAS o electricidad (ELE).

SS 1 – Sistema de una sola etapa

sistema de dos compresores, sistema auxiliar de gas o eléctrico

HP 2 – Bomba de calor con compressor de dos etapas o

HP 1 – Bomba de calor con compresor de una etapa

MS 2 – Sistema multietapa (sin bomba de calor)

3) Este control puede configurarse para:

teclado si olvida el código, vea la sección Solución de problemas.

Para reajustar el código de combinación y desbloquear el

presione RUN SCHED.

desbloqueo. Para salir del menú sin desbloquear el teclado,

vuelve a “0” para realizar otro intento de ajuste del código de

no coincide al presionar el botón MENU, la combinación

y desaparecerá el icono “Loc”. Si el número de desbloqueo

al presionar el botón MENU, el teclado quedará desbloqueado

de bloqueo de la combinación que se almacenó en la memoria

el número de desbloqueo coincide exactamente con el número

ajustar el número de desbloqueo de combinación de 0 a 999. Si

de combinación 0. Las teclas o se utilizan para

menú la primera opción del menú que aparecerá es el código

ingresar en el menú de configuración. Cuando ingrese en el

Mientras el teclado está bloqueado, al presionar MENU podrá

modo de OFF al modo del SISTEMA deseado.

de salir del modo de menú para permitir al usuario cambiar el

El botón SYSTEM funcionará durante 10 segundos después

que el teclado está bloqueado con una combinación válida.

memoria y el menú se cerrará. Aparecerá “Loc” para indicar

presionar el botón MENU, la combinación se almacenará en la

no se bloqueará. Si se selecciona de 1 a 999 y se vuelve a

0 y se presiona el botón MENU, se cerrará el menú y el teclado

combinación de 0 a 999. Si se selecciona una combinación de

hora. El y el se utilizan para ajustar el número de

(opción predeterminada, aún desactivado) en los dígitos de la

presionar el botón MENU, la pantalla mostrará el número “0”

bloqueo del teclado se encuentra activada “L” y se vuelve a

bloqueado) y “ L” (teclado bloqueado). Cuando la función de

se utilizan para cambiar la selección entre OFF (teclado no

predeterminada, teclado no bloqueado). Los y

del menú, la pantalla muestra “Lk” y “OFF” (opción

1 y 2)Bloqueo de teclado – Cuando se selecciona esta opción

MENÚ INSTALADOR/DE CONFIGURACIÓN

Page 12

5

como terminal O o B.

opción anterior.

la

u OFF (desactivado).

en On u OFF

automática

para MS o SS

OBSERVACIONES

de la terminal de válvula inversora (O/B)

Selecciona el funcionamiento de la salida

aparece si se ha seleccionado On (activado) en

incrementos de 25 horas. Este menú sólo

(indicador de Cambio de ltro) en On (activado)

(No disponible en modelos anteriores)

Requiere el módulo CA II.

On (activada) u OFF (desactivada).

NA a sistemas de sólo calor.

seleccionando OFF. NA a conguración SS.

NA a sistemas de sólo frío.

seleccionando OFF. NA a conguración SS.

grados Fahrenheit o Celsius

Temperatura ambiente ajustable en pantalla

del sistema con capacidad de conmutación

Selecciona Conguración de interruptor

bomba de calor en la opción 1.

Emergency y etapa auxiliar si se ha seleccionado

Selecciona la velocidad del ciclo para el modo

seleccionado bomba de calor en la opción Nº 1)

ajustable – bomba de calor) (sólo cuando se ha

Selecciona la velocidad del ciclo de FRÍO

Selecciona la velocidad del ciclo de calefacción

6 (máximo); un valor de 0 desactiva la función

Opción ELE: el termostato controla el soplador.

2 compresores o compresor de 2 velocidades)

una sola etapa (SS 1), bomba de calor 2 (HP 2,

calor), bomba de calor 1 (HP 1, 1 compresor), o

(No disponible en modelos anteriores)

Heat On

(b)

25-1975 h Ajusta la frecuencia de cambio del ltro en

On Selecciona Filter Change-out Indicator

OFF La opción Fast Cool puede desactivarse

OFF La opción Fast Heat puede desactivarse

SL

SL, FA

SL, FA Adjustable Anticipation (Heat Pump) (anticipación

SL, FA Adjustable Anticipation (anticipación ajustable):

SL, FA Adjustable Anticipation (anticipación ajustable):

L Bloqueo del teclado total.

L 46 a L 82 Selecciona el rango de FRÍO limitado

L 62 a L 89 Selecciona el rango de CALOR limitado

1 LO, 2 LO, 3 LO, 4 LO

1 HI, 2 HI, 3 HI, 4 HI,

Cool Off, Auto Off

Off sin icono de ventilador,

icono de ventilador, Heat

Heat Cool Off, Heat Off con

ELE o GAS Opción GAS: el calefactor controla el soplador.

opciones indicadas

seleccionar unas de las

Presione o para

Cool On

Cambiar ltro

Cambiar ltro

Cool FA

Heat FA

L Cool

L Heat

Cool Off

CR Emer

CR Cool

CR Heat

Lk

PANTALLA

MENÚ (o)

MENÚ (200 h)

MENÚ (OFF)

MENÚ (OFF) CA On Selecciona alerta de comodidad activa en

MENÚ (On)

MENÚ (45)

MENÚ (90)

MENÚ °F °C Selecciona visualización de temperatura en

(temperatura actual)

CR Heat Pump

(ELE) para HP

(AJUSTE DE FÁBRICA)

MENÚ 0

MENÚ (On) dL dL OFF Selecciona la luz de fondo de la pantalla

MENÚ Heat Auto

MENÚ (OFF) CL CL On Tiempo del bloqueo del compresor

MENÚ (FA)

MENÚ (ME)

MENÚ (ME)

MENÚ (ME)

MENÚ (0) CS 1, 2, 3, 4, 5, 6 Selecciona Cool Savings valor 1 (mínimo) a

MENÚ (GAS) para SS o MS

MENÚ (MS 2) HP 1, HP 2, SS 1 Selecciona multietapa (MS 2, sin bomba de

MENÚ (000) Lk 001 a 999 Selecciona la combinación de bloqueo del teclado

MENÚ (Off)

EL BOTÓN

PRESIONE

MENÚ INSTALADOR/DE CONFIGURACIÓN

MS MENÚ (On)

22

21

20

19

18 HP2

17

16

15

14

13

12

11

10

9

8

7

6

05

04

03

02

01

DE MENÚ HP SS

LA PANTALLA

NÚMERO DE

Menú para avanzar a la siguiente opción del menú. Presione o para cambiar una opción del menú.

Presione el botón Menú durante 5 segundos. Aparecerá la opción Nº 1 del menú tal como se describe en la siguiente tabla. Presione el botón

MENÚ INSTALADOR/DE CONFIGURACIÓN

Page 13

4

Temperatura

Configuración

9

10

manual 37-7149B.

Si es blanco, el termostato es un modelo anterior y require el

13

En el menu de la configuracion, indica el numero de la pantalla.

Parpadea "LOC" cuando el teclado esta bloqueado.

12

6

Menu

Schedule

Run

Cool Savings

Auto Sched

5

Run Sched

On Auto

FAN

Hold

Year

7

Save

Temp

Set

P Date

4

Cool O Time

Heat Emer Auto

SYSTEM

Heat Pump

System On 2

Filter

Change

Month Call For Service

11

está

TM

8

1

3

Mo Tu We Th Fr Sa Su

212 13

Figura 8 – Elementos de programación y configuración

del termostato.

en el sistema de calefacción/enfriamiento. No indica una falla

11

“Call For Service” (llamar al servicio técnico) indica una falla

en el menú.

en el modo Cool si se ha activado la opción Cool Savings

10

“Cool Savings” (ahorro en enfriamiento) cuando está

Muestra (bombilla) en el modo no programmable.

9

como termostato de bomba de calor.

8

Muestra “Heat Pump” cuando el sistema está configurado

en funcionamiento.

Muestra “Save” cuando Cool Savings

7

Muestra “Menu”.

6

en el modo de menú.

Muestra el modo Fan (On, Auto) o “Run Sched”

5

Cool, Off) en el modo de menú.

4

Muestra el modo del sistema (Heat, Emer, Auto,

recordarle que debe cambiar o limpiar el filtro de aire.

por la cantidad de tiempo selecionada en el filtro para

3

Muestra “Change Filter” cuando el sistema se ha utilizado

Muestra “Set” para ajustar la temperatura de referencia.

2

parpadear cuando “Aux” está energizado.

indica que está energizada una segunda etapa ;+2 sin

calefacción o enfriamiento está energizada. “+2” intermitente

1

“System On” (sistema encendido) indica que la etapa de

Elementos de programación y configuración

del ventilador

Indicador

Menu

de temperatura

Auto

FAN

Set

ambiente

del sistema

Indicador

Heat

SYSTEM

más detalles)

(Consulte la página 2 para ver

nuevas de marca de alta calidad.

zarse con 2 pilas alcalinas “AA”

poca carga y deben reempla ” indica que las pilas tienen

están a media carga. “Cambiar

carga indica que las pilas

2 “AA”: indica buen nivel de

Exhibe el nivel de carga de las

Figura 7 – Descripción de la pantalla

Descripción de la pantalla

GUÍA DE REFERENCIA RÁPIDA DEL TERMOSTATO

Page 14

3

120 VCA

CLASE II

TRANSFORMADOR

VIVO

24 VCA

NEUTRO

Válvula

Cierra la

B

O

O/B

modo Cool

constante en

sola etapa

de una

de 3 cables

zonificadas

a válvulas

Aplicación

Sistema

Figura 6 – Cableado de válvulas zonificadas de calor solamente de 3 cables (SPDT)

Heat, Off, Emergency

constante en modo

Energizado de forma

UTILIZA)

(NO SE

de fallas

Indicador

Energizado de forma

L

VIVO

24 VCA

NEUTRO

(MS2)

(SS1)

Multietapa 2

etapa 1

Una sola

Sistema

CLASE II

TRANSFORMADOR

CALEFACCIÓN

120 VCA

75 VA clase II si es necesario.

enfriamiento por un transformador de

sistema, cambie el transformador de

RH y RC. Según los requisitos del

120 VCA

terminal RH e instale un puente entre

CLASE II

TRANSFORMADOR

ENFRIAMIENTO

VIVO

24 VCA

NEUTRO

Desconecte el cable que va a la

del transformador de enfriamiento.

de calefacción al circuito neutro

desconectado del transformador

encíntelos. Conecte el circuito neutro

del transformador de calefacción y

y COOL, corte los cables de 24 V

no funciona en los modos HEAT

alimentación interna continua pero

NOTA: si desea luz de fondo o

frío

(neutro)

(vivo)

24 voltios

voltios

Constante

24

RC

C

frío

(vivo)

(nuetro)

24 voltios

voltios

Opcional*

24

C

RC

entre RH y RC

Retire el cable puente

(5)

24

Puente

Puente

calor

RH

24

(vivo)

voltios

calor

(vivo)

RH

(4)

circulador energizado

Válvula

Soplador/Ventilador

Abre la

G

eléctrico)

para calor

configurado

(y calor si está

de frío

voltios

en llamada

energizado

circulador

Ventilador

Soplador/

G

2º etapa

Modo Heat

No salida

W2

W

2º etapa

Cool

Modo

1º etapa

Heat

Modo

salida

No

Y2

W/E

(6)

Y

1º etapa

Modo Cool

6

Y

Figura 5 – Sistema de una sola etapa o multietapa (sin bomba de calor) con dos transformadores

CLASE II

TRANSFORMADOR

VIVO

120 VCA

de falla o desperfecto.

neutra para indicación

24 VCA

NEUTRO

1º etapa

Heat

Modo

W/E

2º

No

Y2

etapa

Cool

Modo

salida

Y

1º etapa

Modo Cool

eléctrico)

2º etapa

para calor

Heat

configurado

calor

frío

(vivo)

(vivo)

(nuetro)

voltios

24

Opcional*

voltios

voltios

24

24

* Se requiere una conexión

RC

C

RH

Puente

circulador

Soplador/

G

Ventilador

(y calor si está

llamada de frío

energizadoen

Modo

No salida

W2

B

O

O/B

Off, Emergency

en modo Heat,

forma constante

Energizado de

en modo Cool

forma constante

Energizado de

L

del sistema

de desperfecto

interruptor

falla o

Indicador de

Módulo de alerta

(MS2)

Multietapa 2

(SS1)

etapa 1

Una sola

Sistema

de desperfecto similar

de confort II o módulo

Figura 4 – Sistema de una sola etapa o multietapa (sin bomba de calor) con un solo transformador

sistemas de combustible fósil:

Puede configurar el termostato para utilizarlo con los siguientes

transformador o de dos transformadores.

DE CLASE II

120 VCA

falla o desperfecto.

neutra para indicación de

* Se requiere una conexión

modo Emergency.

utilizar el calor auxiliar en el

puente W2 con W/E para

cuenta con una conexión E,

NOTA: Si su sistema no

configurarlo correctamente.

MENÚ INSTALADOR/DE CONFIGURACIÓN cómo

Después de conectar el termostato, vea en la sección

MULTIETAPA (MS 2) gas, aceite o eléctrico.

UNA SOLA ETAPA (SS1) gas, aceite o eléctrico.

TRANSFORMADOR

VIVO

21 VCA

NEUTRO

2º etapa

C

(neutro)

voltios

24

Opcional*

frío

24

(vivo)

voltios

RC

calor

(vivo)

24

RH

Puente

Emergency

Emergency

para modo

Modo

Elect/Gas

3º etapa.

Ajustar opción

Modo Heat

calor o frío.

en llamada de

circulador

Soplador/

G

energizado

Ventilador

2º tapa

Emergency

Modo

2º Etapa.

Modo Heat

W2

W/E

Puente

voltios

1º Etapa

Emergency

Modo

(compressor)

2°

etapa

salida

No

Y2

1° etapa

Y

(compresor)

Calor/ Frío

B

O

O/B

Emergency

modo Heat, Off,

Energizado en el

modo Cool

Energizado en el

L

del sistema

de desperfecto

falla o interruptor

Indicador de

de desperfecto similar

de confort II o módulo

Módulo de alerta

(HP2)

calor 2

Bomba de

(HP1)

calor 1

Bomba de

Sistema

Este termostato está diseñado para operar un sistema de un solo

del sistema.

información más específica sobre las conexiones eléctricas

Refiérase a las instrucciones del fabricante del equipo para ver

Conexiones de una sola etapa y multietapa

Figura 3 – Sistemas de bomba de calor

INSTALADOR/DE CONFIGURACIÓN cómo configurarlo correctamente.

Después de conectar el termostato, vea en la sección MENÚ

o de dos compresores con sistema de gas o eléctrico auxiliar.

BOMBA DE CALOR TIPO 2 (HP 2). Sistema de compresor multietapa

sola etapa; sistema auxiliar de gas o eléctrico.

BOMBA DE CALOR TIPO 1 (HP 1). Sistema de compresor de una

sistemas de bombas de calor.

Puede configurar el termostato para utilizarlo con los siguientes

información más específica sobre las conexiones eléctricas del sistema.

Refiérase a las instrucciones del fabricante del equipo para ver

Si no tiene un sistema de bomba de calor, refiérase a las figuras 4 y 6.

Conexiones de la bomba de calor

DIAGRAMA DE CONEXIONES

Page 15

2

Orificio de

montaje

Orificio de

montaje

Coloque

nivelado en los

apéndices de

soporte de forma

transversal

(por razones

estéticas

solamente)

Coloque

nivelado en los

apéndices de

soporte de forma

transversal

(por razones

estéticas

solamente)

hay llamada de calor

de sólo calor

sistema de enfriamiento o del transformador del sistema

6............... Válvula zonificada de 3 cables – Energizada cuando no

C .............. Cable neutro del lado secundario del transformador del

RC .............Alimentación para enfriamiento

RH .............Alimentación para calefacción

G ..............Relé del ventilador

W2 .............Calor 2° etapa (calor 3° etapa en HP 2)

W/E ............Relé de calor/Relé de calor de emergencia (etapa 1)

de la terminal Descripción

Designación

de conexiones.

Refiérase a las figuras 3 a 6 para ver las especificaciones del diagrama

Y2 ............. Compresor de segunda etapa

Y .............. Relé del compresor

constantemente en calefacción

B .............. Válvula inversora para bomba de calor energizada

constantemente en enfriamiento

O .............. Válvula inversora para bomba de calor energizada

alerta de confort

sistemas con conexión de desperfectos o señal de

L .............. Indicador de desperfecto de la bomba de calor para

de la terminal Descripción

Designación

DESCRIPCIÓN DE LAS DESIGNACIONES DE LAS TERMINALES

cómo configurar correctamente el termostato.

sistema. Después de conectarlo, vea en la sección CONFIGURACIÓN

información más específica sobre las conexiones eléctricas del

Refiérase a las instrucciones del fabricante del equipo para ver

CONEXIONES ELÉCTRICAS

pilas, coloque el sistema en OFF.

totalmente abajo, enganche la puerta en su lugar. Para cambiar las

abajo mientras tira en el sentido indicado por la flecha. Cuando esté

Para cerrar la puerta del compartimiento de las pilas, gírela hacia

según la polaridad indicada dentro de la puerta del compartimiento.

tire de la puerta como muestra la flecha y levántela. Coloque las pilas

El termostato incluye dos pilas alcalinas “AA”. Para instalar las pilas,

Pilas

en su lugar.

7. Alinee con cuidado el termostato con la base y engánchelo

el funcionamiento del termostato.

fibra de vidrio) para evitar que las corrientes de aire afecten

tape el orificio con un material ignífugo (como aislamiento de

6. Empuje el cable que sobresale hacia el interior de la pared y

5. Conecte los cables al bloque de terminales en la base.

funcionamiento del termostato.

Nivelar es por razones estéticas solamente y no afectará el

Figura 2 – Base del termostato y vista trasera del termostato

muestra en la figura 2, usando dos tornillos de montaje.

4. Fije la base a la pared sin ajustarla demasiado como se

tendrá lugar otra compensación dentro de los dos días.

referencia normal con los o . Si no se cambian las pilas,

produce esta compensación, puede reajustarse la temperatura de

menos en el modo Heat y 10 grados más en el modo Cool). Si se

temperatura de referencia se compensará en 10 grados (10 grados

Cuando a las pilas les quedan menos de dos meses de vida útil, la

aparece el símbolo , las pilas deben cambiarse antes de partir.

estar desocupada durante un tiempo prolongado (más de 3 meses) y

Recomendamos cambiar las pilas cada 2 años. Si la vivienda va a

o Energizer®.

®