Page 1

Operator: Save these instructions for future use!

CAUTION

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY

AND/OR PROPERTY DAMAGE.

The compact zone valves are 2-way straight through, available

as a normally open or normally closed valve. The zone valves

come with or without a SPST normally open auxiliary switch and

feature a swing-type ball valve, which is designed to rotate which

causes the ball plug to seat on a different section of its surface

on each closing. They are available in several piping options,

sweat, NPT, inverted flare and flare fitting end connections for

standard copper tubing, for use with 2-wire thermostats. These

zone valves provide a low cost system of zoned temperature

control wherever hot water is the heating medium. In new

construction, the piping system can be laid out to produce any

number of independent temperature controlled zones by use of

these valves. In existing buildings, a variety of zone combinations can be obtained, depending on the particular piping layout.

Each zone requires one zone valve and one thermostat, but only

one circulator is normally required for the entire system.

This compact zone valve is intended for use with a low voltage

system; do not use this zone valve with a millivolt or line voltage

system. If in doubt about whether your wiring is millivolt, line or

low voltage, have it inspected by a qualified heating contractor

or electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

COMPACT ZONE VALVES

2-WIRE, 2-WAY

For use on systems up to 142 PSI

INST ALLA TION INSTRUCTIONS

DESCRIPTION

Flare Fittings

Available Separately

PRECAUTIONS

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box, until installation is complete.

CAUTION

To prevent injuries from scalding always drain system

before installing or removing valve. To avoid gear damage

operate lever slowly.

All guarantees are void if these specifications are exceeded.

Maximum System Pressure: 142 PSI

Differential Across Valve: 20 PSI

Maximum Water Temperature: 230°F

Minimum Water Temperature: 41°F

Maximum Ambiant Temperature: 140°F

Approx. Time Cycle: 10 seconds from full close to full open;

4 seconds from full open to full close.

Electrical Rating:

Valve motor – 0.35A @ 25VAC, 50/60 Hz., 6 W nominal

Auxiliary switch: 3.0A Max. @ 25VAC

Thermostat: Use two-wire heating thermostat, .35A heat

anticipation is required.

Flow Coefficient - Cv Rating:

1/2" valves – 3.5 Cv (3.0 Kv)

3/4" valves – 3.5 Cv (3.0 Kv)

1" valves – 3.5 Cv (3.0 Kv)

WHITE-RODGERS

EMERSON ELECTRIC CO.

9797 Reavis Road

St. Louis, MO 63123-5398

www.white-rodgers.com

WARNING

Do not use on circuits exceeding specified voltages.

Higher voltages will damage control and could cause

shock or fire hazard.

SPECIFICATIONS

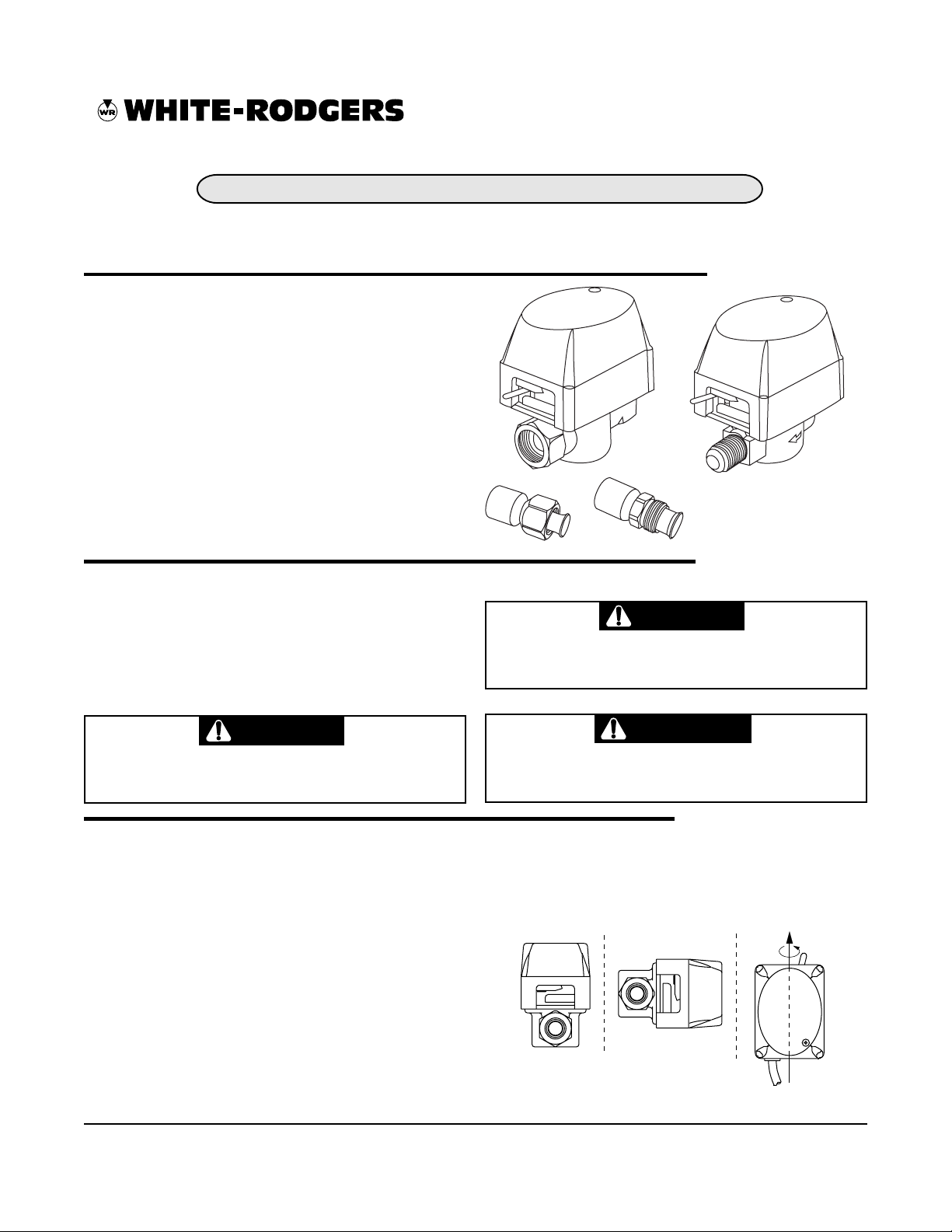

MOUNTING POSITIONS:

Upright or 0° to 90° from upright

UPRIGHT

Fig. 1 Zone valve mounting positions

LEFT OR RIGHT

INLET

UP OR DOWN

360°

MAN

AUTO

PART NO. 37-6334A

0142

Page 2

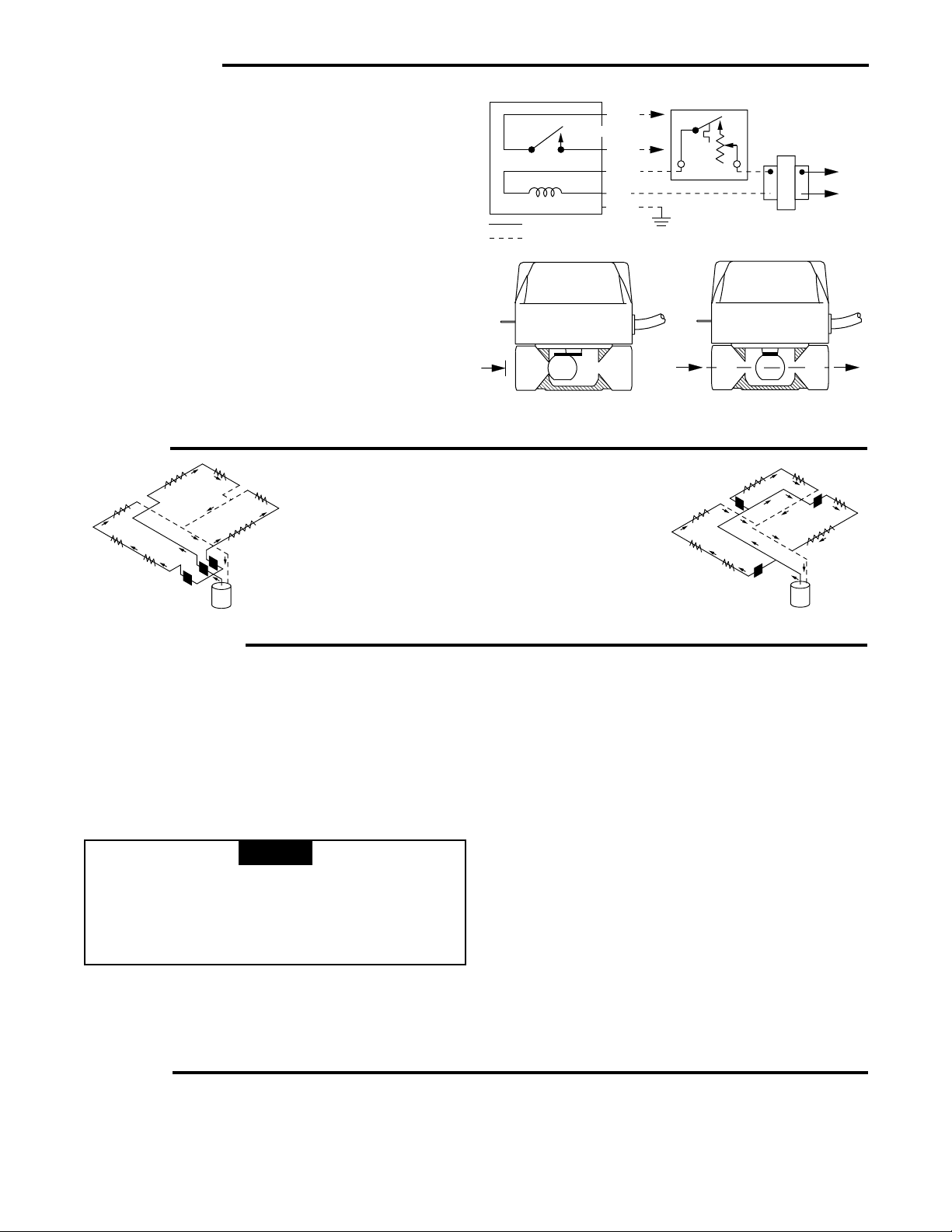

OPERATION

The schematic drawing Fig. 2 is for a normally closed valve.

As shown, the valve is closed and the thermostat is satisfied.

When the thermostat closes its contacts, the valve begins to

open as a circuit is made from the transformer to the motor and

thermostat, back to the transformer.

Shortly after the valve begins to open, the auxiliary switch

closes (providing a low voltage auxiliary circuit for starting

burner and/or circulator). After an elapsed time of about 10

seconds, the valve reaches the full open position. The valve

motor now remains energized to keep the valve in the open

position.

When the thermostat is satisfied, the circuit through the valve

motor is broken and a return spring begins to close the valve.

Just before the valve reaches the closed position, the auxiliary

switch opens to stop burner and/or circulator.

TYPE 'Z' ZONE VALVE

N.O. CONTACT

AUX. SWITCH

MOTOR

INTERNAL WIRING

EXTERNAL WIRING

A B

BLACK

BLACK

BROWN

BLUE

GREEN

2-WIRE HEATING

THERMOSTAT

Fig. 2

A

HOT

LINE

N

TRANSFORMER

B

VALVE CLOSED

VALVE OPEN

Fig. 3 Operation for normally close (N.C.) valve

PIPING

The two most commonly used piping systems are

shown below. Plan 1 is popular for new installations,

while plan 2 is frequently used when converting twopipe systems.

PLAN 2

A common main supplies all

zones, with a water valve installed

on the riser to each zone.

Fig. 4

PLAN 1

Water valves installed at the boiler

header to provide a separate

supply to each zone.

INSTALLATION

ALL GUARANTEES ARE VOID IF THE VALVE IS NOT ASSEMBLED ACCORDING TO THESE INSTRUCTIONS.

1. Disconnect electric power before connecting wiring to prevent

electrical shock or equipment damage.

2. Select suitable valve location. Valve may be installed in any

position, except upside down. The arrow on the side of the

body indicates direction of flow throught the valve. (“A” is

inlet, “B” is outlet)

3. Mount valve directly in the tube or pipe, as follows:

NOTE

For normally closed (N.C.) models, with sweat fittings,

set the manual lever to the "MAN" position before

applying heat to the fittings. This will protect the plug

ball inside the valve by removing it from the seat. After

installation, place manual lever in the "AUTO" position.

Flare fitting models

Use new, properly reamed pipe, free from chips. The valve

body is threaded for standard 5/8 in. OD copper, 45° SAE

flare-fitting nuts. These nuts are not furnished with the valve

and must be obtained separately.

Sweat copper models

Use new, properly reamed pipe, free from dents or corrosion.

Sweat the joints, keeping the outer surface free from solder.

DO NOT use silver solder because of the high melting

temperatures required.

NPT pipe models

Use new pipe that is properly chamfered, reamed and free of

burrs and chips. If using old pipe, be sure it is clean and free

of rust, scale, burrs, chips and old pipe joint compound.

Apply pipe joint compound or teflon tape, only to the male

threads of the pipe joint. DO NOT apply compound or teflon

tape to the first two threads. If using a vise or open-end

wrench to hold the valve while installing piping, do not tighten

excessively, as this may damage the valve.

4. Support piping with a pipe hanger on each side of valve.

Fig. 5

729

WIRING

All wiring should be done according to local and national electrical codes

Follow any specific wiring instructions provided by the boiler

manufacturer. If none are supplied, the following diagrams offer

typical wiring installations using 2-wire heating thermostats

(.35A Heat-Anticipation) and other related controls.

A 40VA Transformer will handle up to 4 zone valves. A 20VA will

handle up to 2 zone valves.

2

Page 3

WIRING CONT.

24 VAC

GAS VALVE

HIGH LIMIT

COMMON

G (BLK)

MUST BE N.E.C.

CLASS 1 WIRING

Fig. 7a Diagram for Gas-Fired System,

eliminate Oil Burner for Gas-Fired system

All wiring should be done according to local and national electrical codes

DIAGRAMS FOR SYSTEMS WHERE BURNER AND CIRCULATOR

OPERATION IS INDEPENDENT OF THERMOSTATS

TRANSFORMER

Fig. 6 Zone Valve (N.C.)

N

LINE

HOT

24 VAC

DIAGRAM FOR SYSTEMS WHERE INTERNAL TRANSFORMER OF RELAY CONTROL SUPPLIES POWER

FOR ZONE VALVES

TYPE 668

OIL BURNER CONTROL

IGNITION

TRANS.

BURNER MOTOR

N

LINE

HOT

ORANGE

WHITE

WHITE

BLACK

F

F

T

T

BLACK

HIGH

LIMIT

TYPE 956

FLAME

DETECTOR

RELAY/TRANSFORMER

TRANSFORMER

COM

W-R 2-WIRE HEATING THERMOSTATS

W

Y

STAT

R

BLUE

G

BLACK

BLACK

BLACK

BLUE

BROWN

ZONE VALVES (N.C.)

W-R 2-WIRE HEATING THERMOSTATS

BLUE

BROWN

ZONE VALVES (N.C.)

N.C.

RED

N.O.

CIRCULATOR

MOTOR

BROWN

RELAY COIL

TAPE

OFF

Fig. 7

Diagram for Oil-Fired system using Relay/

Transformer with Zone Valves (N.C.)

DIAGRAMS FOR SYSTEMS WHERE EXTERNAL TRANSFORMER REQUIRED FOR POWERING FOR ZONE

VALVES

W-R 2-WIRE HEATING THERMOSTATS

ADDITIONAL

ZONES

STAT

BLUE

BLACK

BLACK

LINE

HOT

N

TRANSFORMER

BLACK

BLACK

BLUE

BROWN

ZONE VALVES (N.C.)

LINE

HOT

N

BLUE

TRANSFORMER

BLACK

BROWN

BLACK

RELAY/TRANSFORMER

T1

CIRCULATOR

MOTOR

1

2

C1 C2

B1T2

B2

IGN.

TRANS.

BURNER

MOTOR

HOT

LINE

N

Fig. 8

Diagram for for System using Relay/transformer

with Zone Valves (N.C.)

3

Page 4

WIRING (Continued)

THERM

163

452

DIAGRAMS FOR SYSTEMS WHERE EXTERNAL TRANSFORMER REQUIRED FOR POWERING FOR ZONE

VALVES

TO ZONE

VALVES

N

LINE

HOT

BLACK

BLACK

RELAY/TRANSFORMER

TYPE 8B42A OR 8B43A

1

C1 C2

B1

TYPE 829A RELAY

TYPE 809A RELAY

T1T2

2

B2

IGN.

TRANS.

BLACK

BLACK

1 2 L L

HOT

LINE

N

BLACK

BLACK

HOT

LINE

N

TO GAS VALVE

CIRCULATOR

MOTOR

BURNER

MOTOR

Alternate Connections

For Relay/Transformer

AND TRANSFORMER

OR OIL BURNER

CONTROL

Alternate Connections

For Type 809A Relay

OPERATION

Automatic (AUTO) (N.C. valve) (Fig. 9)

On a call for by the thermostat, the valve opens and its auxiliary

contacts close, providing a low voltage auxiliary circuit for

starting the burner and/or circulator. After an elapsed time of

about 10 seconds, the valve reaches the full open position. The

valve motor now remains energized to keep the valve in the open

position. When the thermostat is satisfied, the valve closes by its

integral return spring. The auxiliary contacts open, de-energizing

the auxiliary circuit.

Manual (MAN)

Use manual lever in case of power failure or for servicing the

system. If power fails while valve is open, valve will return to the

closed position. To manually open the valve, move the manual

lever to the "MAN" position and lock in place. The valve will

return to the "AUTO" position when the valve is electrically

energized. The auxiliary contacts close in the "MAN" position.

The manual lever is not operational on normally open (N.O.)

valve models.

Normally open models (N.O.) (Fig. 11)

A normally open valve operates opposite to a normally closed

valve. It is open in the de-energized position and closes when

the valve is energized. A reverse-acting (close-on-rise) thermostat

is required to control a normally open (N.O.)valve.

CHECKING THE SYSTEM

Turn on the electricity. If gas fired, be sure pilot is lit. Then check

each zone separately as follows:

1. Turn thermostat to highest setting. Zone valve for that zone

will open and furnace burner will come on as auxiliary circuit

is made on valve motor.

2. Turn thermostat to lowest setting. Zone valve for that zone

will close and furnace burner will shut off as auxiliary circuit

is broken on zone valve.

(Fig. 10)

CIRCULATOR

MOTOR

OIL BURNER

CONTROL

CIRCULATOR

MOTOR

TO GAS VALVE AND

TRANSFORMER OR

Alternate Connections

For Type 829A Relay

AUXILIARY

SWITCH

N.O.

A B

VALVE CLOSED

POWER 'OFF'

AUXILIARY

SWITCH

CLOSED

A

VALVE OPEN

POWER 'ON'

B

Fig. 9 Normally close (N.C.) zone valve

AUTO MAN

AUXILIARY

SWITCH

CLOSED

A B

VALVE OPEN, MANUAL POSITION

POWER 'OFF'

Fig. 10 Manual operation of normally close (N.C.) valve

AUXILIARY

SWITCH

N.O.

A

VALVE OPEN

POWER 'OFF'

B

AUXILIARY

SWITCH

CLOSED

A B

VALVE CLOSED

POWER 'ON'

Fig. 11 Normally open (N.O.) zone valve

4

Loading...

Loading...