Page 1

1F84-51

Programmable Electronic Digital

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

Heat Pump Thermostat

INSTALLATION AND

OPERATION INSTRUCTIONS

DESCRIPTION

Your new White-Rodgers 7-Day Digital Heat Pump Thermostat

uses the technology of a solid-state microcomputer to provide

precise time/temperature control. This thermostat offers you the

flexibility to design heating and cooling programs that fit your

needs.

Features:

• Separate program for each day of the week

• Simultaneous heat and cool program storage

• Preprogrammed temperature control

• Four separate time/temperature settings per 24 hour period

This thermostat is intended for use with a 24 volt system; do not

use this thermostat with a millivolt or line voltage system. If in

doubt about whether your wiring is millivolt, line, or low voltage,

have it inspected by a qualified heating and air conditioning

contractor or electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

• LCD continuously displays set point, and alternately displays time and room temperature

• Temperature override until next program period

• Manual program override (HOLD temperature)

• °F/°C convertibility

• Temperature range 45° to 90°F

• Eight terminals for single or two-transformer systems

• O/B terminal for heat pump systems

• Armchair Programming Capability

PRECAUTIONS

CAUTION

!

To prevent electrical shock and/or equipment damage

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

WARNING

!

Do not use on circuits exceeding specified voltage.

Higher voltage will damage control and could cause

shock or fire hazard.

Do not short out terminals on gas valve or primary

control to test. Short or incorrect wiring will damage

thermostat and could cause personal injury and/or

property damage.

ELECTRICAL DATA

Electrical Rating:

20 to 30 VAC 50/60 Hz. or D.C.

0.05 to 1.5 Amps (Load per terminal)

1.5 Amps Maximum Total Load (All terminals combined)

THERMAL DATA

Setpoint Temperature Range:

45°F to 90°F (7°C to 32°C)

Operating Ambient Temperature Range:

32°F to 105°F

Operating Humidity Range:

0 to 90% RH (non-condensing)

Shipping Temperature Range:

-40°F to 150°F

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS ROAD

ST. LOUIS, MISSOURI 63123-5398

APPLICATIONS

For use with:

• Heat pump systems with up to two stages heat, one stage

cool

DO NOT USE WITH:

• Millivolt systems

• Systems exceeding 30 VAC and 1.5 amps

• 3-wire zoned hydronic heating systems

Printed in U.S.A.

SPECIFICATIONS

PART NO. 37-5739A

Replaces 37-5613C

9637

Page 2

INSTALLATION

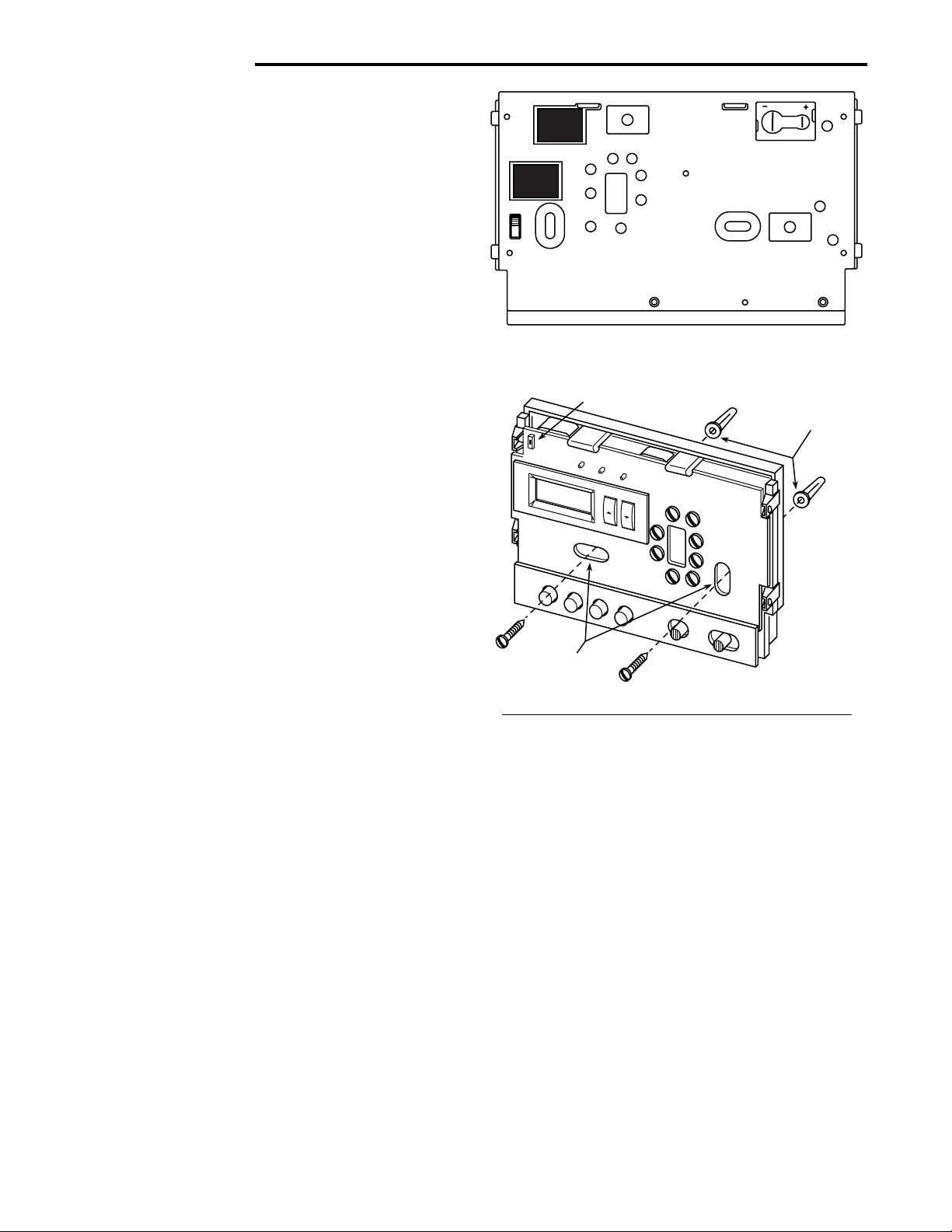

Figure 1. Back of thermostat base

W904

CUT FOR

NON-ELECTRIC

AUX.

O

B

W903

CUT TO DEFEAT EMR

BATTERY CUTOUT FOR

ARMCHAIR PROGRAMMING

Figure 2. Thermostat base

SET TIME

RUN PRGM

VIEW PRGM

HOLD TEMP

AUTO

FAN ON

COOL

OFF

HEAT

EMER

Reset Button

Mounting

holes

Screw anchors

L

E

Y

W2

O/B

R

G

C

REMOVE OLD THERMOSTAT

1. Shut off electricity at the main fuse box until installation is

complete. Ensure that electrical power is disconnected.

2. Remove the front cover of the old thermostat. With wires

still attached, remove wall plate from the wall. If the old

thermostat has a wall mounting plate, remove the thermostat

and the wall mounting plate as an assembly.

3. Identify each wire attached to the old thermostat using

the labels enclosed with the new thermostat.

4. Disconnect the wires from old thermostat one at a time. DO

NOT LET WIRES FALL BACK INTO THE WALL.

5. Install new thermostat using the following procedures.

ATTACH THERMOSTAT BASE TO WALL

1. Remove the packing material from the thermostat.

2. If necessary, cut the non-electric heat jumper (see NON-

ELECTRIC HEAT SYSTEMS) and/or the EMR jumper (see

ENERGY MANAGEMENT RECOVERY). Check the set-

ting of the O/B switch (see O/B TERMINAL SWITCH

SELECTION).

3. If you want to program the thermostat before mounting the

thermostat on the wall, see ARMCHAIR PROGRAMMING.

4. Gently pull the thermostat cover straight off the base. Forcing

or prying on the thermostat will cause damage to the unit.

5. Check that the SYSTEM switch is in the OFF position.

Connect wires beneath terminal screws on base using

appropriate wiring schematic (see figs. 3 through 5).

6. Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

7. Move base out of the way. Drill mounting holes.

8. Fasten base loosely to wall, as shown in fig. 2, using two

mounting screws. Place a level against bottom of base,

adjust until level, and then tighten screws. (Leveling is for

appearance only and will not affect thermostat operation.) If

you are using existing mounting holes, or if holes drilled are

too large and do not allow you to tighten base snugly, use

plastic screw anchors to secure subbase.

9. Push excess wire into wall and plug hole with a fire-resistant

material (such as fiberglass insulation) to prevent drafts from

affecting thermostat operation.

NON-ELECTRIC HEAT SYSTEMS

Read the following information before clipping the non-electric

heat jumper. If you are unsure of your application, contact a

qualified serviceperson.

If your emergency or auxiliary system is non-electric (gas, oil,

etc.) and will energize the blower, then jumper, W904, on the

back of the thermostat base must be cut (see fig. 1).

If your emergency or auxiliary heat system is electric and

requires that the thermostat energize the fan circuit, do not cut

jumper W904.

ENERGY MANAGEMENT RECOVERY

When the EMR feature is activated, the thermostat's microcomputer automatically calculates the time it will take to change the

room temperature to the next program setting. Then the thermostat will start the heating or cooling system before the next

2

programmed period so that the desired temperature is reached

at or near the beginning of the next program period (the

thermostat calculates 30 minutes for every 2°F temperature

change).

For example, assume that the thermostat is programmed to

provide an overnight heating temperature of 66°F, and during

the next program period, beginning at 6:00 AM, the programmed

temperature is 70°F. With EMR activated, the thermostat will

automatically start the heating system at 5:00 AM, so that the

programmed temperature of 70°F is reached by about 6:00 AM.

If the overnight room temperature drops only to 68°, the thermostat will start the system at 5:30 to reach the programmed

temperature of 70° at 6:00.

The thermostat is shipped with the EMR feature active, which

(EMR)

means that the thermostat will start the system before the

beginning of the next program period. This feature provides

better efficiency by allowing gradual temperature changes using

only the first stage of heat and cooling.

To de-activate the EMR function, clip wire W903 on the back

of the thermostat (see fig. 1). The thermostat will then wait until

the programmed time to start the system for a temperature

change. This may cause the more costly electric second stage

of heating to be used.

Page 3

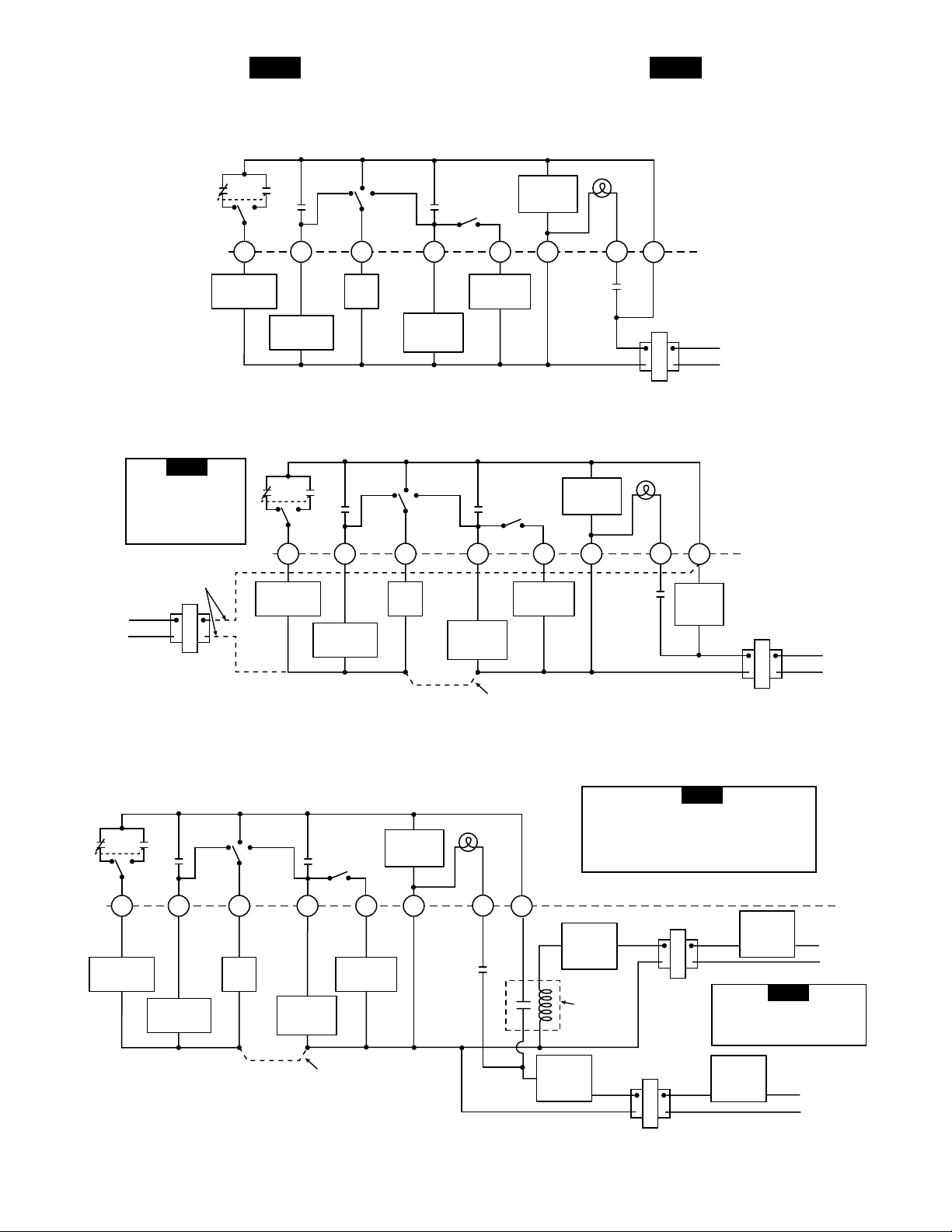

tion and wiring. For proper installation, refer to the original

manufacturer's instructions.

NOTENOTE

Relay contacts shown are thermostatically operated.The following wiring diagrams show typical terminal identifica-

FAN ON

FAN

AUTO

Heat

or Cool

Changeover

Relay*

Compressor

Contactor

* Changeover Relay is energized in COOL when O/B switch is in the “O” position

Changeover Relay is energized in HEAT when O/B switch is in the “B” position

FAN

AUTO

Emer

G W2

Fan

Relay

Aux/Emer

Relay

(Stage 2)

Figure 3. Typical wiring diagram for single transformer systems

NOTE

If safety circuits are in

only one of the systems,

remove the transformer

of the system with NO

safety circuits.

CUT AND

TAPE OFF!

HOT

120 VAC

NEUTRAL

* Changeover Relay is energized in COOL when O/B switch is in the “O” position

Changeover Relay is energized in HEAT when O/B switch is in the “B” position

24 VAC

Changeover

Relay*

Compressor

Contactor

FAN

AUTO

Heat

or Cool

Fan

Relay

FAN ON

FAN

AUTO

Emer

G W2

EMERGENCY

E

Emergency

Relay

EMERGENCY

Emergency

Aux/Emer

Relay

(Stage 2)

TWO COMMONS MUST

BE JUMPERED TOGETHER!

Thermostat

Control

Circuit

CYO/B

E

Relay

MALF

SYSTEM

MONITOR

SWITCH

24 VAC

Thermostat

Control

Circuit

CYO/B

L

R

TRANSFORMER

MALF

SYSTEM

MONITOR

SWITCH

THERMOSTAT

SYSTEM

Hot

120 VAC

Neutral

R

Limit or

Safety

Switches

24 VAC

THERMOSTAT

L

SYSTEM

Hot

120 VAC

Neutral

TRANSFORMER

Figure 4. Typical wiring diagram for two transformer systems with NO safety circuits

FAN ON

FAN

AUTO

Heat

or Cool

Changeover

Relay*

Compressor

Contactor

* Changeover Relay is energized in COOL when O/B switch is in the “O” position

Changeover Relay is energized in HEAT when O/B switch is in the “B” position

FAN

AUTO

Emer

G W2

Fan

Relay

EMERGENCY

Emergency

Aux/Emer

Relay

(Stage 2)

TWO COMMONS MUST

BE JUMPERED TOGETHER!

E

Relay

Thermostat

Control

Circuit

Figure 5. Typical wiring diagram for two transformer systems with safety circuits in BOTH systems

CYO/B

MALF

SYSTEM

MONITOR

SWITCH

L

R

COMMON

Limit or

Switches

Limit or

Safety

Switches

Polarity must be observed. If the HOT side of

NOTE

the second transformer is jumpered to the

COMMON side of the first transformer a short

will be made. Damage to equipment will occur

when power is restored.

THERMOSTAT

Safety

ACCESSORY

RELAY N.O.

24 VAC

24 VAC

CONTACT

COMMON

24 VAC 120 VAC

Heat Pump Transformer

SYSTEM

Auxiliary

Heating

Transformer

120 VAC

Limit or

Safety

Switches

NOTE

The accessory relay scheme

is required when safety

circuits exist in both systems.

Limit or

Safety

Switches

HOT

NEUTRAL

HOT

NEUTRAL

3

Page 4

O/B TERMINAL SWITCH SELECTION

The O/B switch on this thermostat is factory set to the “O”

position. This will accommodate the majority of heat pump

applications, which require the changeover relay to be energized in COOL. If the thermostat you are replacing or the heat

pump being installed with this thermostat require the “B” terminal, to energize the changeover relay in HEAT, the O/B switch

must be moved to the “B” position.

ARMCHAIR PROGRAMMING

Armchair Programming is a unique feature that allows your

thermostat to be programmed before being mounted on the wall.

If you do not want to Armchair Program, the thermostat can be

programmed after being mounted on the wall and system power

turned on.

If you wish to Armchair Program your thermostat, temporarily

hold a new 9-volt battery against the wires in the battery cutout

on the back of the thermostat base for approximately 45 seconds. This will provide a charge that will last approximately 30

to 45 minutes to allow the thermostat to be programmed. After

programming, the thermostat must be mounted on the wall,

wires connected and system power turned on.

Heating System

1. Move SYSTEM switch to HEAT position. If the auxiliary

heating system has a standing pilot, be sure to light it.

2. Press to adjust thermostat setting to 90° and hold for five

seconds. Both stages of the heating system should begin to

operate. However, if the word HEAT is flashing, the compressor lockout feature is operating (see Lockout Bypass

Option to temporarily override the compressor lockout feature during testing).

3. Press to adjust temperature setting below room temperature. The auxiliary heating system will stop immedi-

ately, and the first stage will stop within three to four

minutes.

Cooling System

CAUTION

!

To prevent compressor and/or property damage, if the

outdoor temperature is below 50°F, DO NOT operate

the cooling system.

1. Move SYSTEM switch to COOL position.

NOTE

To have sufficient time to complete the installation without losing

the programming, hold the 9-volt battery to the terminals on the

back of the base for 30 to 45 seconds again after programming

the thermostat. The battery must be removed before mounting

the thermostat on the wall.

ADJUSTABLE ANTICIPATION

The first stage has anticipation that can be set to 2.5 or 4 cycles

per hour for heating or cooling. The second stage heat has a

fixed anticipation. To change the first stage anticipation in the

HEAT or COOL mode, press SET TIME and VIEW PRGM

buttons at the same time until the desired setting is displayed

(S for slow (factory setting) or F for fast).

CHECK THERMOSTAT OPERATION

If at any time during testing your system does not operate

properly, contact a qualified serviceperson.

Fan Operation

1. Turn on power to the system.

2. Move SYSTEM switch to OFF position.

3. Move FAN switch to ON. The blower should begin to operate.

4. Move FAN switch to AUTO position. The blower should stop

within a short period of time.

2. Press to adjust thermostat setting below room temperature. The blower should come on immediately on high speed,

followed by cold air circulation. However, if the fan is running

but the compressor is not running and the word COOL is

flashing, the compressor lockout feature is operating (see

Lockout Bypass Option to temporarily override the compressor lockout feature during testing).

3. Press

perature. The cooling system should stop operating.

to adjust temperature setting above room tem-

LOCKOUT BYPASS OPTION

FOR QUALIFIED SERVICE TECHNICIANS’ USE

ONLY. OPERATORS SHOULD NOT USE THIS FEATURE DUE TO POSSIBILITY OF EQUIPMENT OR

PROPERTY DAMAGE, OR PERSONAL INJURY.

COMPRESSOR SHORT TERM

CYCLE PROTECTION

This thermostat has a built-in short term (5-minute)

time delay. During this 5-minute period, the thermostat will lock out the compressor to allow head pressure to stabilize. If you want to override this feature

while testing thermostat operation, simply press

and at the same time.

DO NOT USE THE LOCKOUT BYPASS OPTION

UNLESS THE COMPRESSOR OIL HEATERS HAVE

BEEN OPERATIONAL FOR 6 HOURS AND THE

SYSTEM HAS NOT BEEN OPERATIONAL FOR AT

LEAST 5 MINUTES.

4

Page 5

Before you begin programming your thermostat, you should be

familiar with its features and with the display and the location and

operation of the thermostat buttons. Your thermostat consists of

two parts: the thermostat cover and the base. To remove the

cover, gently pull it straight out from the base. To replace the

cover, line up the cover with the base and press gently until the

cover snaps onto the base.

OPERATION

EMER MALF AUX

1

2

THE THERMOSTAT BASE

Other than and , the following buttons and switches are

located behind the door on the bottom of the thermostat cover

(see fig. 6). Pull the door down to open it.

The Thermostat Buttons and Switches

(Red arrow) Raises temperature setting.

1

(Blue arrow) Lowers temperature setting.

2

SET TIME/SET TEMP button.

3

VIEW PRGM (program) button.

4

RUN PRGM (program) button.

5

HOLD TEMP/ADV DAY button.

6

FAN switch (ON, AUTO).

7

SYSTEM switch (COOL, OFF, HEAT, EMER).

8

The Display

Indicates day of the week.

9

HEAT is displayed when the SYSTEM switch is in the

10

HEAT position. COOL is displayed when the SYSTEM

switch is in the COOL position. COOL or HEAT is displayed

(flashing) when the compressor is in lockout mode.

Alternately displays current time and temperature.

11

EMERGENCY is displayed when the SYSTEM switch is in

12

the EMER position.

Displays currently programmed set temperature (this is

13

blank when SYSTEM switch is in the OFF position).

The word HOLD is displayed when the thermostat is in the

14

HOLD mode.

OPERATING FEATURES

Now that you are familiar with the thermostat buttons and

display, read the following information to learn about the many

features of the thermostat.

• SIMULTANEOUS HEATING/COOLING PROGRAM

STORAGE — When programming, you can enter both your

heating and cooling programs at the same time. There is no

need to reprogram the thermostat at the beginning of each

season.

• TEMPERATURE OVERRIDE — Press or until the

display shows the temperature you want. The thermostat

will override current programming and keep the room

OFF HEAT

AUTOSET TIME VIEW PRGM RUN PRGM HOLD TEMP FAN ON

SET TEMP

3

4 5 6 7 8

ADV DAY

COOL EMER

9 910

SU

SA

HOLD

COOL

11

MO TU WE TH FR

EMERGENCY

HEAT

AM

1012 1113 14

Figure 6. Thermostat display, buttons, and switches

temperature at the selected temperature until the next

program period begins. Then the thermostat will automatically revert to the program.

• HOLD TEMPERATURE — The thermostat can hold any

temperature within its range for an indefinite period, without

reverting to the programmed temperature. Press HOLD

TEMP/ADV DAY button. HOLD will be displayed. Then

choose the desired hold temperature by pressing or .

The thermostat will hold the room temperature at the

selected setting until you press RUN PRGM button to start

program operation again.

• °F/°C CONVERTIBILITY — Press SET TIME/SET TEMP

and HOLD TEMP/ADV DAY buttons until the temperature

display is in Celsius (°C). To display Fahrenheit (°F), repeat

the process.

• TEMPERATURE DISPLAY ADJUSTMENT — Your new

thermostat has been accurately set in our factory. However,

if you wish, you may adjust your new thermostat temperature display to match your old thermostat. This can be

accomplished (within a ±4° range) as follows:

1. Press VIEW PRGM and HOLD TEMP/ADV DAY buttons

at the same time.

2. Press or to adjust the displayed temperature to

your desired setting.

3. Press RUN PRGM to resume normal program operation.

• COPY DAY FUNCTION — This feature allows Monday’s

program to be copied into the rest of the week’s programming. This feature is only available the first time you

program your thermostat. To use this feature, simply

enter the program for Monday as described in PROGRAMMING YOUR THERMOSTAT, and then press RUN PRGM.

5

Page 6

• RESET BUTTON - (see fig. 2) resets the thermostat pro-

PM

HEAT

gram to the factory setting. This button can be used if you

do not like the program you have entered or if you wish to

start over in the programming procedure. The reset button

can also be used to reset the program if the thermostat has

been subjected to a voltage spike and the program has

become scrambled or frozen.

example, heating/cooling period 1 on Monday may begin at

5:00 AM, but heating/cooling period 1 on Saturday may

begin at 9:00 AM). Use the table on the following page to plan

your program time periods, and the temperatures you want

during each period. You may also want to look at the sample

program table to get an idea of how the thermostat can be

programmed.

PROGRAMMING YOUR THERMOSTAT

Now you are ready to program your thermostat. This section will

help you plan your thermostat’s program to meet your needs.

For maximum comfort and efficiency, keep the following guidelines in mind when planning your program.

• When heating (cooling) your building, program the temperatures to be cooler (warmer) when the building is vacant

or during periods of low activity.

• During early morning hours, the need for cooling is usually

minimal.

Look at the factory preprogrammed times and temperatures

shown below. If this program will suit your needs, simply press

the RUN PRGM button to begin running the factory preset

program.

Heating Program for

ALL days of the Week:

PERIOD TIME TEMP PERIOD TIME

1st

2nd

3rd

4th

FACTORY PREPROGRAMMING

6:00 AM

8:00 AM

5:00 PM

10:00 PM

70°F

62°F

70°F

62°F

If you want to change the preprogrammed times and temperatures, follow these steps.

1. Determine the heating and cooling temperatures you want to

use. You may select up to four heating temperatures (HEAT

1, HEAT 2, HEAT 3, and HEAT 4), and up to four cooling

temperatures (COOL 1, COOL 2, COOL 3, and COOL 4).

Use the table below to write down the temperatures you have

selected.

Heat Temperatures Cool Temperatures

12341234

Your selected

temperatures*

Factory

pre-programmed

70°F62°F70°F62°F78°F85°F78°F82°F

temperatures*

* You may only program heating temperatures you have selected into the heating

program and cooling temperatures into the cooling program (for example, you

cannot program the COOL 1 temperature into your heating program). You may

program the temperatures you choose in any order, and you may use the same

temperature in consecutive program periods (for example, you may program

period 1 with temperature 1 and periods 2, 3, and 4 with temperature 2). You do

not have to use all possible temperature choices (for example, you may want to

select temperatures for HEAT 1 and HEAT 2 only – in this case, the HEAT 3 and

HEAT 4 temperatures would stay the same as previously programmed).

2. Determine the time periods during which you will program

the temperatures you have just selected. You must program

four periods for each day (periods 1, 2, 3, and 4). However,

you may use the same heating and cooling temperatures for

consecutive time periods. Also keep in mind that, for any

given day, you can only program one set of times for both

heating and cooling (for example, if you select 5:00 AM to

begin heating period 1 on Monday, then your cooling period

1 for Monday will also begin at 5:00 AM). However, you may

select different time periods for each day separately (for

6

Cooling Program for

ALL Days of the Week:

1st

6:00 AM

2nd

8:00 AM

3rd

5:00 PM

4th

10:00 PM

TEMP

78°F

85°F

78°F

82°F

ENTERING YOUR PROGRAM

Set Current Time and Day

1. Press SET TIME/SET TEMP button once. The display will

show the hour only.

EXAMPLE:

2. Press and hold either or until you reach the correct

hour and AM/PM designation (AM begins at midnight; PM

begins at noon).

3. Press SET TIME/SET TEMP once. The display window will

show the minutes only.

EXAMPLE:

4. Press and hold either or until you reach the correct

minutes.

5. Press SET TIME/SET TEMP once. The display will show the

day of the week.

6. Press or until you reach the current day of the week.

7. Press RUN PRGM once. The display will show the correct

time and room temperature alternately.

Select Heating Temperatures

1. If you want to change the display from Fahrenheit to Celsius

(or vice-versa), press SET TIME/SET TEMP and HOLD

TEMP/ADV DAY at the same time.

2. Move the SYSTEM switch to HEAT.

3. Press SET TIME/SET TEMP four times. The display will

show the number 1, along with the currently programmed

HEAT 1 temperature.

EXAMPLE:

4. Press or to change the displayed temperature to your

selected HEAT 1 setting (if you only want to program a

temperature for HEAT 1, skip to step 8).

5. Press SET TIME/SET TEMP once. The number 1 will

change to the number 2, representing HEAT 2.

6. Press

temperature.

7. Repeat steps 5 and 6 to select HEAT 3 and HEAT 4

temperature settings, if desired.

8. Press RUN PRGM.

or until you reach your selected HEAT 2

Page 7

THIS THERMOSTAT ALLOWS ONE SET OF TIMES FOR BOTH HEATING AND COOLING

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Time

Heat

Temp.

Heating/Cooling Schedule Plan

Cool

Temp. Time

Heat

Temp.

Cool

Temp. Time

Heat

Temp.

Cool

Temp. Time

Period 4Period 3Period 2Period 1

Temp.

Heat

Cool

Temp.

SAMPLE

Heating/Cooling Schedule Plan

THIS THERMOSTAT ALLOWS ONE SET OF TIMES FOR BOTH HEATING AND COOLING

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Time

5:00 AM

6:00 AM

5:00 AM

5:00 AM

5:00 AM

8:00 AM

8:00 AM

Heat

Temp.

65° (1)

65° (1)

65° (1)

65° (1)

65° (1)

65° (1)

70° (3)

Cool

Temp. Time

80° (1)

80° (1)

80° (1)

80° (1)

80° (1)

80° (1)

78° (2)

9:00 AM

8:00 AM

9:00 AM

9:00 AM

9:00 AM

10:00 AM

9:00 AM

Heat

Temp.

65° (1)

70° (3)

70° (3)

70° (3)

70° (3)

70° (3)

70° (3)

Enter Heating/Cooling Times and Heating

Temperatures

1. Move the SYSTEM switch to HEAT.

2. Press VIEW PRGM once. MO, the abbreviation for Monday,

will be displayed. Also displayed are the currently programmed start time for the 1st heating/cooling period and the

currently programmed HEAT 1, 2, 3, or 4 temperature for the

1st heating/cooling period (flashing).

MO

EXAMPLE:

This example display shows that for the 1st Monday heating/

cooling period, the start time is 6:00 AM, and 70° is the

programmed temperature (this example reflects factory preprogramming).

AM

HEAT 1 = 65° COOL 1 = 80°

HEAT 2 = 68° COOL 2 = 78°

HEAT 3 = 70° COOL 3 = 76°

HEAT 4 = 72° COOL 4 = 74°

Period 4Period 3Period 2Period 1

Cool

Temp. Time

80° (1)

76° (3)

76° (3)

76° (3)

76° (3)

76° (3)

76° (3)

3:30 PM

4:30 PM

3:30 PM

5:30 PM

3:30 PM

3:30 PM

3:30 PM

Heat

Temp.

65° (1)

72° (4)

72° (4)

72° (4)

72° (4)

72° (4)

68° (2)

Cool

Temp. Time

80° (1)

11:30 PM

74° (4)

10:30 PM

74° (4)

11:30 PM

74° (4)

11:30 PM

74° (4)

10:30 PM

74° (4)

11:30 PM

76° (3)

9:30 PM

Heat

Temp.

65° (1)

65° (1)

65° (1)

65° (1)

65° (1)

65° (1)

65° (1)

Cool

Temp.

80° (1)

80° (1)

80° (1)

80° (1)

80° (1)

80° (1)

80° (1)

3. If the temperature displayed is not the HEAT 1, 2, 3, or 4

temperature you want for Monday’s period 1, press or

until the correct temperature is displayed (if you keep pressing or , the HEAT 1, 2, 3, and 4 temperatures you

previously programmed will be alternately displayed).

4. To change the displayed start time to the time you have

selected for Monday’s heating/cooling period 1, press SET

TIME/SET TEMP once (the programmed time will flash).

Press or until your selected time is displayed. The

time will change in 30-minute increments. The time that you

program will be the start time of Monday’s period 1 for

both heating and cooling. After selecting the correct period

1 start time, press SET TIME/SET TEMP again to return to

the change temperature mode.

5. Press VIEW PRGM once. The currently programmed start

time and heating setpoint temperature for Monday’s heating/

cooling period 2 will be displayed.

(Programming instructions continue on next page.)

7

Page 8

6. Repeat steps 3 and 4 to select the start time and heating

temperature for Monday’s 2nd heating/cooling period.

7. Repeat steps 3 through 5 for Monday’s 3rd and 4th heating/

cooling period. Monday’s heating program is now complete.

NOTE

If you are programming your thermostat for the first time, and you

want programming for all days of the week to be the same as

Monday’s program, press RUN PRGM at this point, and proceed

to the SELECT COOLING TEMPERATURES section (this

COPY DAY feature only works the first time you program your

thermostat; if you are changing your thermostat’s programming,

you must program each day separately).

8. Press HOLD TEMP/ADV DAY once. TU (indicating Tuesday’s

program) will be displayed, along with the start time for the

1st heating/cooling period and the currently programmed

heating setpoint temperature.

9. Repeat steps 3 through 7 to complete Tuesday’s heating

program.

10.Continue entering each day’s programming until all heating/

cooling periods and heating temperatures have been selected.

11.Press RUN PRGM to end heating programming. Proceed to

the SELECT COOLING TEMPERATURES section.

Select Cooling Temperatures

1. Move the SYSTEM switch to COOL.

2. Press SET TIME/SET TEMP four times. The display will

show the number 1, along with the currently programmed

COOL 1 temperature.

3. Press

selected COOL 1 setting (if you only want to program a

temperature for COOL 1, skip to step 7).

4. Press SET TIME/SET TEMP once. The number 1 will

change to the number 2, representing COOL 2.

5. Press or until you reach your selected COOL 2

temperature.

6. Repeat steps 4 and 5 to select COOL 3 and COOL 4

temperature settings, if desired.

7. Press RUN PRGM.

or to change the displayed temperature to your

Enter Cooling Temperatures

CAUTION

!

If the outside temperature is below 50°F, disconnect

power to the cooling system before programming.

Energizing the air conditioner compressor during

cold weather may cause personal injury or property

damage.

1. Move SYSTEM switch to COOL position.

2. Press VIEW PRGM once. MO, the abbreviation for Monday,

will be displayed. Also displayed are the start time you

previously programmed for the 1st heating/cooling period

and the currently programmed COOL 1, 2, 3, or 4 temperature for the 1st heating/cooling period (flashing). Remember

that the time you previously selected is for both heating

and cooling periods. If you change a programmed start

time now, it will also change the start time for the heating

program.

3. If the temperature displayed is not the COOL 1, 2, 3, or 4

temperature you want for Monday’s period 1, press

until the correct temperature is displayed (if you keep pressing or , the COOL 1, 2, 3, and 4 temperatures you

previously programmed will be alternately displayed).

4. Press VIEW PRGM once. The currently programmed start

time and cooling setpoint temperature for Monday’s heating/

cooling period 2 will be displayed.

5. Repeat step 3 to select the cooling temperature for Monday’s

2nd heating/cooling period.

6. Repeat steps 3 and 4 for Monday’s 3rd and 4th heating/

cooling period. Monday’s cooling program is now complete.

or

NOTE

If you are programming your thermostat for the first time, and you

want programming for all days of the week to be the same as

Monday’s program, press RUN PRGM to begin program operation (this COPY DAY feature only works the first time you

program your thermostat; if you are changing your thermostat’s

programming, you must program each day separately).

7. Press HOLD TEMP/ADV DAY once. TU (indicating Tuesday’s

program) will be displayed, along with the start time for the

1st heating/cooling period and the currently programmed

cooling setpoint temperature.

8. Repeat steps 3 through 6 to complete Tuesday’s cooling

program.

10.Continue entering each day’s programming until all cooling

temperatures have been selected.

11.Press RUN PRGM to end programming and begin program

operation.

CHECK YOUR PROGRAMMING

Follow these steps to check your thermostat programming one

final time before beginning thermostat operation.

1. Move SYSTEM switch to HEAT position.

2. Press VIEW PRGM to view the 1st Monday heating period

time and temperature. Each time you press VIEW PRGM,

the next heating period time and temperature for Monday will

be displayed in sequence. Press HOLD/ADV DAY to display

Tuesday’s 1st heating period program. Press VIEW PRGM

to check the remaining Tuesday heating period times and

temperatures. To check each day’s heating program, press

HOLD TEMP/ADV DAY to change days, then press VIEW

PRGM to look at each programming period for the day (you

may change any time or temperature during this procedure;

remember that if you change the start time, it changes for

both heating and cooling).

3. Press RUN PRGM.

4. Move SYSTEM switch to COOL position.

5. Repeat step 2 to check cooling temperatures.

6. Press RUN PRGM to begin program operation.

YOUR THERMOSTAT IS NOW COMPLETELY PROGRAMMED AND READY TO AUTOMATICALLY PROVIDE

MAXIMUM COMFORT AND EFFICIENCY!

Loading...

Loading...