Whirlpool UXD8630DYS0, UXD8630DYS1, UXD8636DYS1, UXD8636DYS0 Owner’s Manual

30"(76.2 CM) AND 36"(91.4CM)

RETRACTABLE(POP-UP)DOWNDRAFTVENTSYSTEM

For questions about features, operation/performance, parts, accessories or service, call: 1-800-253-1301

or visit our website at www, whirlpool,com

In Canada, call 1-800-807-6777 or visit our website at www, whirlpool,ca

SYSTEMEDEVENTILATIONRI_TRACTABLE(CLAPET)

DE30"(76,2 CM) ET36"(91,4 CM)----ASPIRATION

PARLEBAS

Au Canada, pour assistance, installation ou service, composer

Table of Contents/Table des matieres ............................................................................. 2

le 1-800-807-6777 ou visiter notre site Web

www.whirlpool.ca

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

FOR RESIDENTIAL USE ONLY.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS.

POUR UTILISATION RC:SIDENTIELLE UNIQUEMENT.

LI3Z UB/W10342491 D

TABLEOFCONTENTS

VENT SYSTEM SAFETY ................................................................. 2

INSTALLATION REQUIREMENTS ................................................ 4

Tools and Parts ............................................................................ 4

Location Requirements ................................................................ 4

Electrical Requirements ............................................................... 7

Venting Requirements .................................................................. 7

INSTALLATION INSTRUCTIONS .................................................. 8

Venting Methods .......................................................................... 8

Install Vent System ....................................................................... 9

Rear Mounting - Blower Motor .................................................. 11

Complete Installation ................................................................. 12

Make Electrical Connections ..................................................... 13

Check Operation ........................................................................ 13

TABLEDESMATIERES

SECURITE DU SYSTEME DE VENTILATION ............................. 19

EXIGENCES D'INSTALLATION ................................................... 21

Outils et pieces ........................................................................... 21

Exigences d'emplacement ......................................................... 21

Specifications electriques .......................................................... 24

Exigences concernant I'evacuation ........................................... 24

INSTRUCTIONS D'INSTALLATION ............................................ 25

M6thodes d'evacuation ............................................................. 25

Installation du conduit d'evacuation .......................................... 26

Montage du ventilateur &I'arriere .............................................. 28

Achever I'installation .................................................................. 29

Raccordements electriques ....................................................... 30

Contr61e du fonctionnement ...................................................... 31

VENT SYSTEM USE ..................................................................... 14

Operating Downdraft Vent ......................................................... 14

VENT SYSTEM CARE ................................................................... 14

Surface of Downdraft Vent ......................................................... 14

Filters .......................................................................................... 14

WIRING DIAGRAM ....................................................................... 15

ASSISTANCE OR SERVICE ......................................................... 16

In the U.S.A ................................................................................ 16

In Canada ................................................................................... 16

Accessories ................................................................................ 16

WAR RANTY .................................................................................. 17

UTILISATION DU SYSTF:ME D'EXTRACTION ........................... 31

Utilisation du systeme d'extraction par le bas ........................... 31

ENTRETIEN DU SYSTEME D'E'VACUATION ............................. 32

Surface du systeme d'extraction par le bas .............................. 32

Filtres .......................................................................................... 32

SCHEMA DE CABLAGE ............................................................... 33

ASSISTANCE OU SERVICE ......................................................... 34

Au Canada .................................................................................. 34

Accessoires ................................................................................ 34

GARANTIE ..................................................................................... 35

VENTSYSTEMSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

2

iMPORTANT SAFETY iNSTRUCTiONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

[] Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

[] Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

[] Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

[] Do not operate any fan with a damaged cord or plug.

Discard fan or return to an authorized service facility for

examination and/or repair.

[] Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), the American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

[] When cutting or drilling into wall or ceiling; do not damage

electrical wiring and other utilities.

[] Ducted fans must always be vented outdoors.

CAUTION: For general ventilating use only. Do not use

to exhaust hazardous or explosive materials and vapors.

CAUTION: To reduce risk of fire and to properly exhaust

air, be sure to duct air outside - do not vent exhaust air into

spaces within walls or ceilings, attics or into crawl spaces,

or garages.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCTWORK.

WARNING: TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

[] Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

[] Always turn hood ON when cooking at high heat or when

flambeing food (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flamb6).

[] Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

[] Use proper pan size. Always use cookware appropriate for

the size of the surface element.

WARNING: TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING: a

[] SMOTHER FLAMES with a close fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. Ifthe flames do not go out

immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

[] NEVER PICK UP A FLAMING PAN - you may be burned.

[] DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

[] Use an extinguisher ONLY if:

- You know you have a class ABC extinguisher, and you

already know how to operate it.

- The fire is small and contained in the area where it

started.

- The fire department is being called.

- You can fight the fire with your back to an exit.

aBased on "Kitchen Fire Safety Tips" published by NFPA.

[] WARNING: To reduce the risk of fire or electrical shock,

do not use this fan with any solid-state speed control

device.

READ AND SAVE THESE INSTRUCTIONS

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

• Jigsaw or keyhole saw

• Drill

• 1/8"(3 mm) drill bit for pilot holes

• Pencil

• Tape measure or ruler

• Flat-blade screwdriver

• Phillips screwdriver

• 3/8"(9.5 mm) nut driver

• Level

• Pliers

• Metal snips

• Wire stripper or utility knife

• Caulking gun and weatherproof caulking compound

Parts Supplied

• Top trim - stainless

• End caps (2)

• Lower support legs (2)

• Undercounter mounting brackets (2)

• 4 x 8 mm screws (16)

• 3.5 x 9.5 mm screws (3)

• 31/4"x 10" (8.3 x 25.4 cm) rectangular damper

• 43/4"(12.0 cm) motor box

• 1¼.(6.4 mm) deep cover

• Flat vent cover plate

• 6" (15.2 cm) diameter vent transition with damper

Parts Needed

• UL listed or CSA approved 1/2"(12.7 mm) conduit connector

• Wall or roof cap with damper to match vent system

• Vent system

• Home power supply cable

• UL listed wire connectors (3)

• Vent clamps/duct tape as required

R; ccxt ion£equ

NOTI:: Downdraft vent is installed directly behind the cooktop.

Install the downdraft vent first, then install the cooktop.

IMPOFITANT: Observe all governing codes and ordinances.

• Have a qualified technician install the downdraft vent. It is the

installer's responsibility to comply with installation clearances

specified on the model/serial rating plate. The model/serial

rating plate is located on the front of the downdraft vent

above the terminal box cover.

Downdraft vent location should be away from strong draft

areas, such as windows, doors, and strong heating vents or

fans.

Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance.

Consult the cooktop manufacturer installation instructions

before making any cutouts.

Check that the downdraft vent and cooktop location will

clear the cabinet walls, backsplash, and rear wall studs

inside the cabinet.

Check for the minimum distance between the front edge

of the countertop and the front edge of the cooktop. The

minimum horizontal distance between the overhead

cabinets is the same as the width of the installed

downdraft vent.

All openings in ceiling and wall where the downdraft vent will

be installed must be sealed.

Grounded electrical outlet isrequired. See "Electrical

Requirements" section.

When installing the downdraft vent, the cabinet drawer will

need to be removed and the drawer front installed

permanently to the cabinet.

Cabinet Construction:

Downdraft vent is designed for use in a cabinet with a depth of

24" (61 cm). Some installations require a countertop deeper than

25" (63.5 cm). See the "Countertop Cutout Dimensions Chart."

The maximum depth of the overhead cabinet is 13" (33 cm).

Overhead cabinets installed at either side of the downdraft vent

must be 18" (45.7 cm) above the cooking surface.

For Mobile Home Installations

The installation of this downdraft vent must conform to

the Manufactured Home Construction Safety Standards,

Title 24 CFR, Part 328 (formerly the Federal Standard for

Mobile Home Construction and Safety, title 24, HUD, Part 280)

or when such standard is not applicable, the standard for

Manufactured Home Installation 1982 (Manufactured Home

Sites, Communities and Setups) ANSI A225.1/NFPA 501A, or

latest edition, or with local codes.

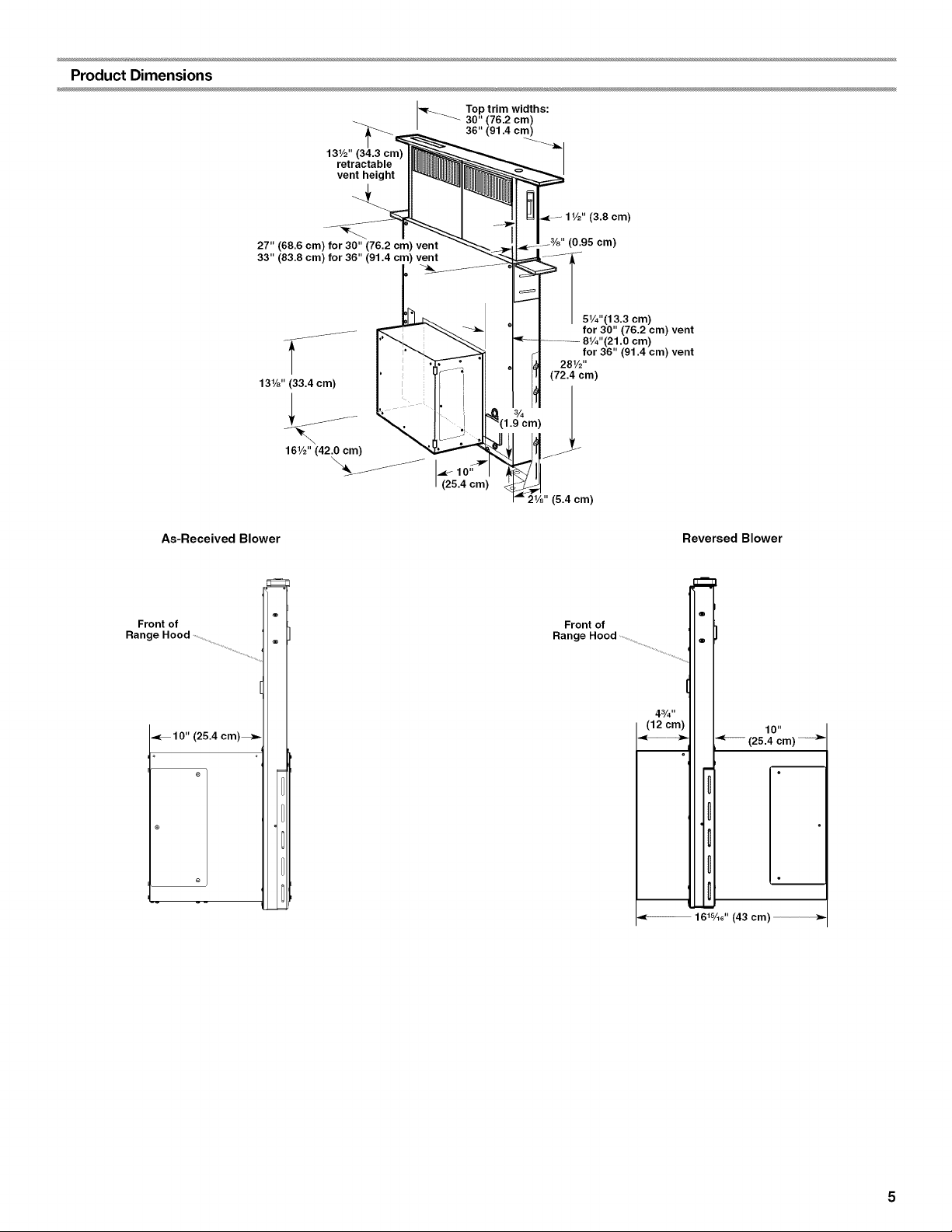

Product Dimensions

_Top trim widths:

131/2'` (34.3 cm)

retractable

vent height

27" (68.6 cm) for 30" (76.2 cm) vent (0.95 cm)

33" (83.8 cm) for 36" (91.4 cm) vent

As-Received Blower Reversed Blower

30" (76.2 cm)

36 (91.4 cm)

(3.8 cm)

Front of

_10" (25.4 cm)_

o

Front of [_

Range Hood I1® p

111

43/4,,II I 10"

(25.4 cm)

o

o

161%6'' (43 cm)

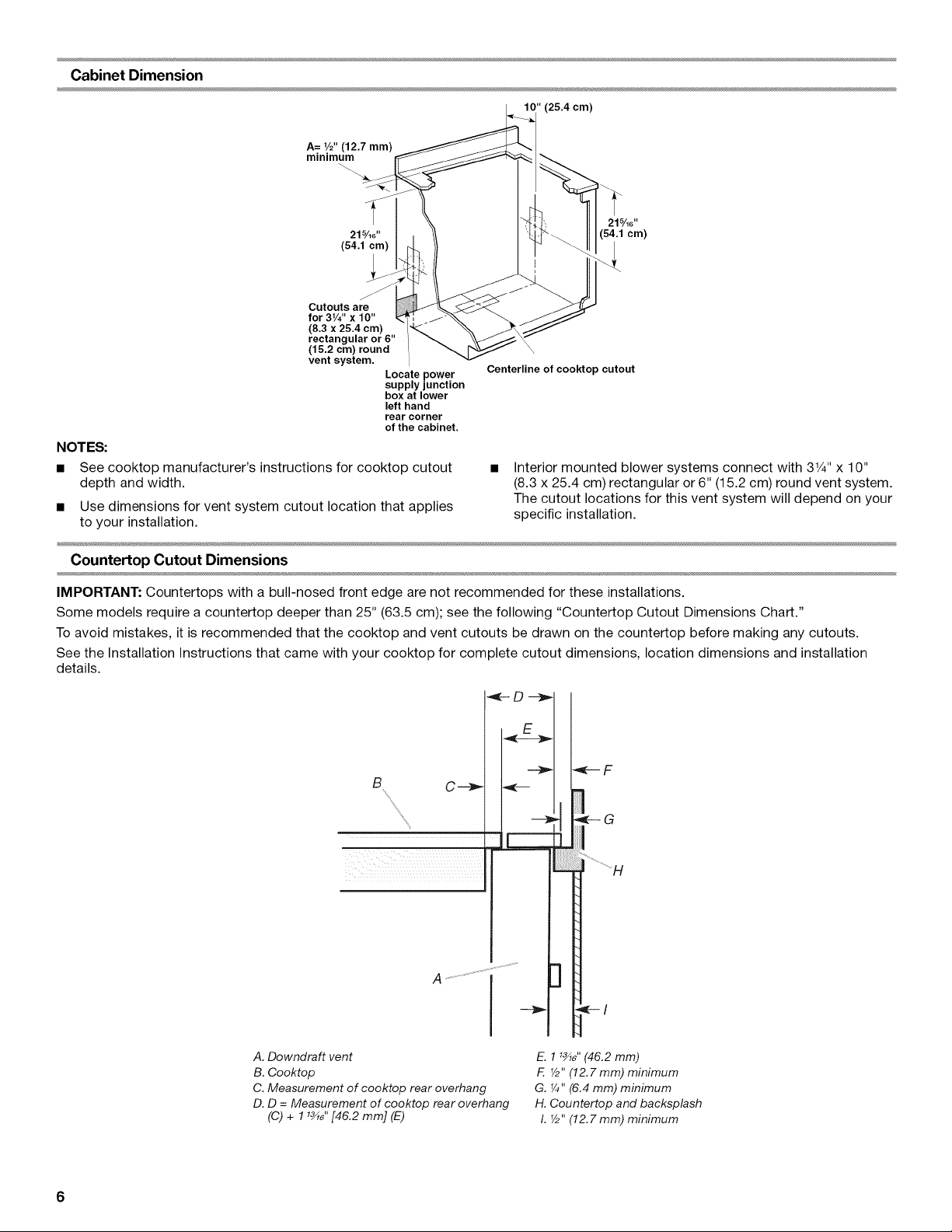

Cabinet Dimension

A= 1/2"(12.7 mm)

minimum

(25.4 cm)

21%6"

(54.1 cm)

Cutouts are

for 31/4"x 10"

(8.3 x 25.4 cm)

rectangular or 6"

(15.2 cm) round

vent system.

Locate power

supply junction

box at lower

left hand

rear corner

of the cabinet.

Centerline of cooktop cutout

21%6"

(54.1 cm)

NOTES:

See cooktop manufacturer's instructions for cooktop cutout

depth and width.

Use dimensions for vent system cutout location that applies

to your installation.

Interior mounted blower systems connect with 31/4"x 10"

(8.3 x 25.4 cm) rectangular or 6" (15.2 cm) round vent system.

The cutout locations for this vent system will depend on your

specific installation.

Countertop Cutout Dimensions

IMPORTANT: Countertops with a bull-nosed front edge are not recommended for these installations.

Some models require a countertop deeper than 25" (63.5 cm); see the following "Countertop Cutout Dimensions Chart."

To avoid mistakes, it is recommended that the cooktop and vent cutouts be drawn on the countertop before making any cutouts.

See the Installation Instructions that came with your cooktop for complete cutout dimensions, location dimensions and installation

details.

B C--e_

J1

A ...................................

A. Downdraft vent

B. Cooktop

C. Measurement of cooktop rear overhang

D. D = Measurement of eooktop rear overhang

(C) + 1'_" [46.2 mm] (E)

6

E. 11_,, (46.2 mm)

F. 7/2"(12.7 mm) minimum

G. ¼" (6.4 mm) minimum

H. Countertop and backsplash

I. 7/2"(12.7 mm) minimum

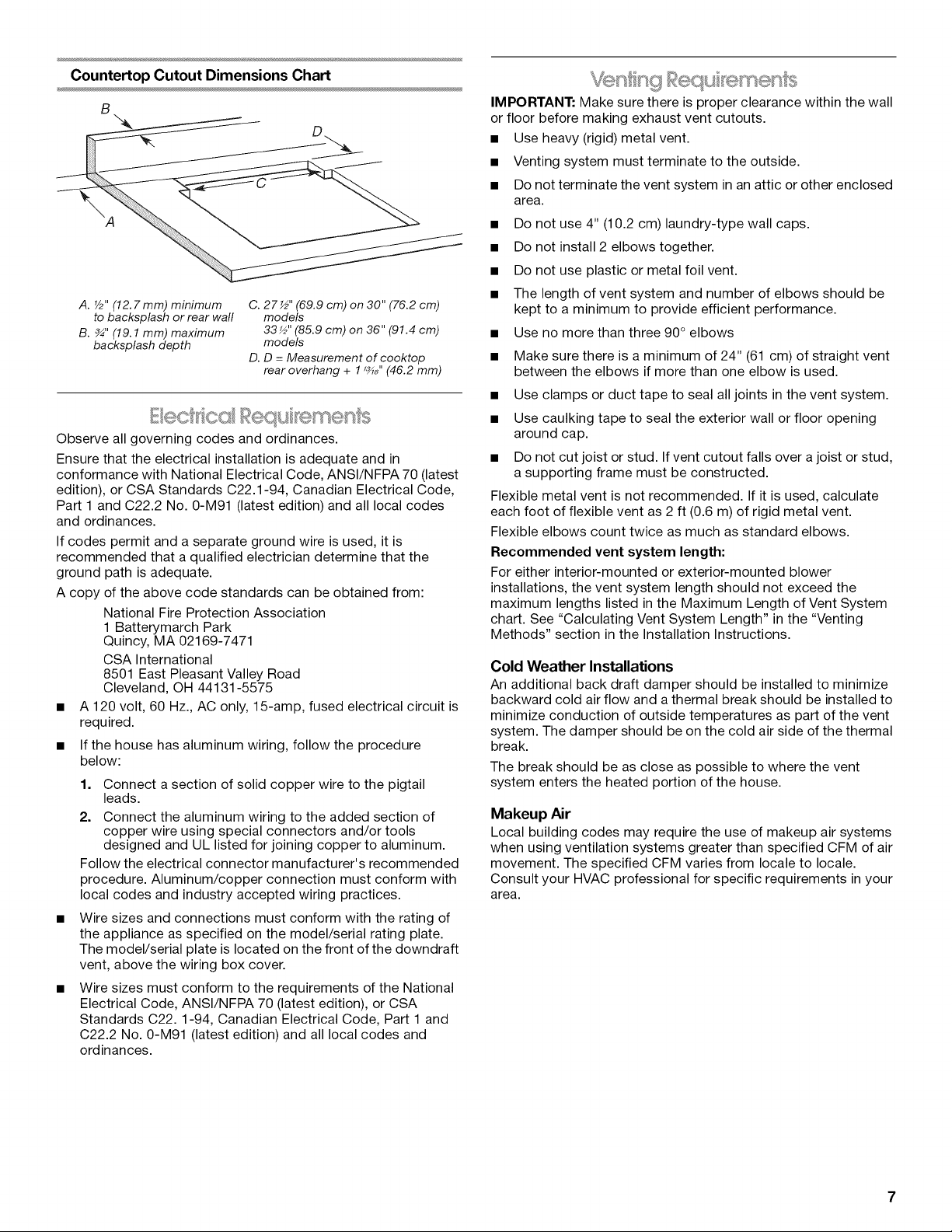

Countertop Cutout Dimensions Chart

B

A. 7/2"(12. 7mm) minimum

to backsplash or rear wall

B. ¾" (19.1 mm) maximum

backsplash depth

_'_f _1__'_,__''

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70 (latest

edition), or CSA Standards C22.1-94, Canadian Electrical Code,

Part 1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

• If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

Wire sizes and connections must conform with the rating of

the appliance as specified on the model/serial rating plate.

The model/serial plate is located on the front of the downdraft

vent, above the wiring box cover.

Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22.1-94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 (latest edition) and all local codes and

ordinances.

C. 27½" (69.9 cm) on 30" (76.2 cm)

models

33_" (85.9 cm) on 36" (91.4 cm)

models

D. D = Measurement of cooktop

rear overhang + 11_,, (46.2 mm)

IMPORTANT: Make sure there is proper clearance within the wall

or floor before making exhaust vent cutouts.

• Use heavy (rigid) metal vent.

• Venting system must terminate to the outside.

• Do not terminate the vent system in an attic or other enclosed

area.

• Do not use 4" (10.2 cm) laundry-type wall caps.

• Do not install 2 elbows together.

• Do not use plastic or metal foil vent.

• The length of vent system and number of elbows should be

kept to a minimum to provide efficient performance.

• Use no more than three 90° elbows

• Make sure there is a minimum of 24" (61 cm) of straight vent

between the elbows ifmore than one elbow is used.

• Use clamps or duct tape to seal all joints in the vent system.

• Use caulking tape to seal the exterior wall or floor opening

around cap.

• Do not cut joist or stud. If vent cutout falls over a joist or stud,

a supporting frame must be constructed.

Flexible metal vent is not recommended. If it is used, calculate

each foot of flexible vent as 2 ft (0.6 m) of rigid metal vent.

Flexible elbows count twice as much as standard elbows.

Recommended vent system length:

For either interior-mounted or exterior-mounted blower

installations, the vent system length should not exceed the

maximum lengths listed in the Maximum Length of Vent System

chart. See "Calculating Vent System Length" in the "Venting

Methods" section in the Installation Instructions.

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air flow and athermal break should be installed to

minimize conduction of outside temperatures as part of the vent

system. The damper should be on the cold air side of the thermal

break.

The break should be as close as possible to where the vent

system enters the heated portion of the house.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

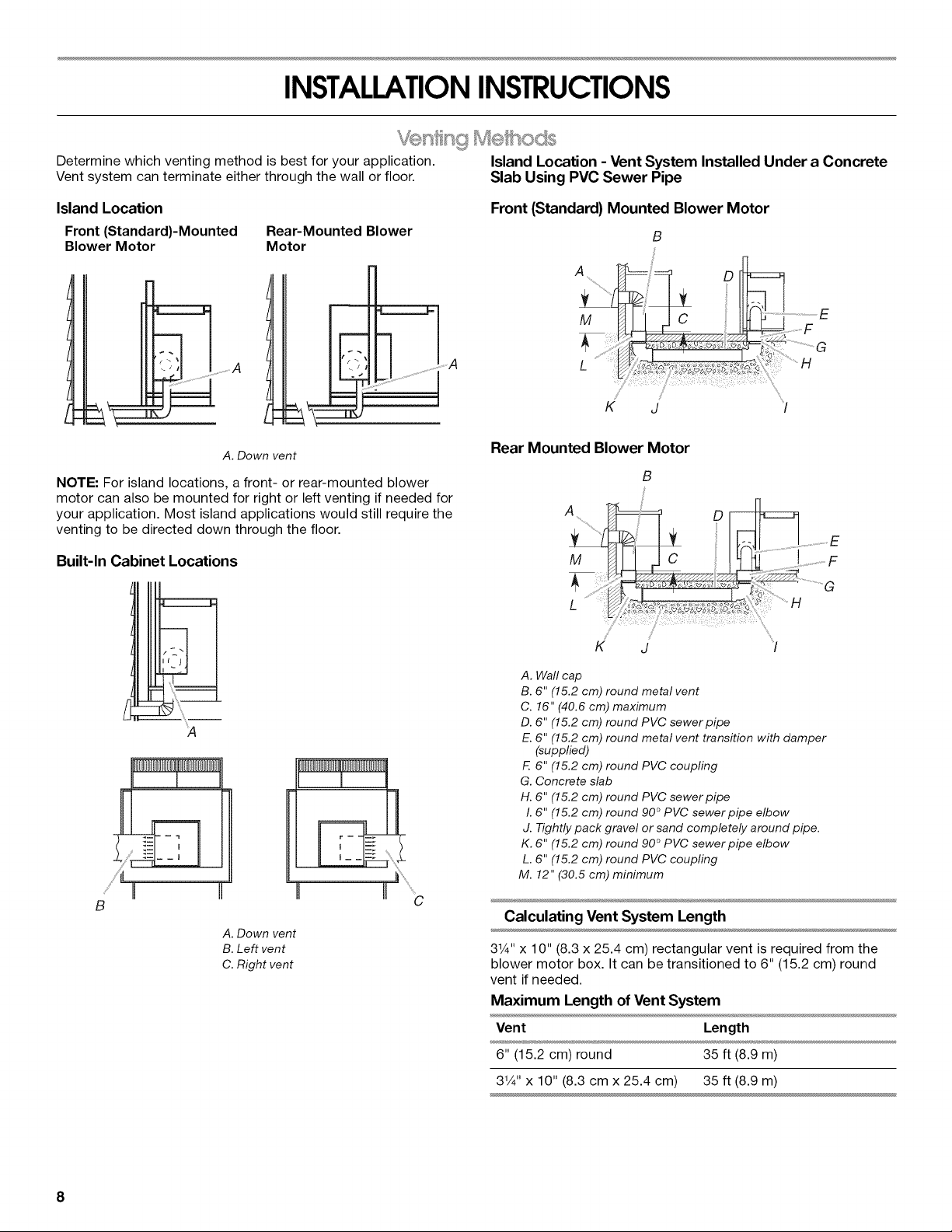

INSTALLATIONINSTRUCTIONS

Determine which venting method is best for your application. Island Location - Vent System Installed Under a Concrete

Vent system can terminate either through the wall or floor. Slab Using PVC Sewer Pipe

Island Location

Front (Standard)-Mounted

Blower Motor

NOTE: For island locations, a front- or rear-mounted blower

motor can also be mounted for right or left venting if needed for

your application. Most island applications would still require the

venting to be directed down through the floor.

Rear-Mounted Blower

Motor

]

A. Down vent

Built-In Cabinet Locations

Front (Standard) Mounted Blower Motor

B

K J

Rear Mounted Blower Motor

B

A _ D_

K d

E

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. 6" (15.2 cm) round metal vent transition with damper

(supplied)

F. 6" (15.2 cm) round PVC coupling

G. Concrete slab

H. 6" (15.2 cm) round PVC sewer pipe

I. 6" (15.2 cm) round 90° PVC sewer pipe elbow

J. Tightly pack gravel or sand completely around pipe.

K. 6" (15.2 cm) round 90° PVC sewer pipe elbow

L. 6" (15.2 cm) round PVC coupling

S

B

II II II .......

C

M. 12" (30.5 cm) minimum

Calculating Vent System Length

A. Down vent

B. Left vent

C. Right vent

3W' x 10" (8.3 x 25.4 cm) rectangular vent is required from the

blower motor box. It can be transitioned to 6" (15.2 cm) round

vent if needed.

Maximum Length of Vent System

Vent Length

6" (15.2 cm) round 35 ft (8.9 m)

31/4"x 10" (8.3 cm x 25.4 cm) 35 ft (8.9 m)

8

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

31/4'' x 10" (8.3 cm x 25.4 cm)

Vent Piece Rectangular

90° elbow (1.5 m)

3v4xlo<830mx acm o,t

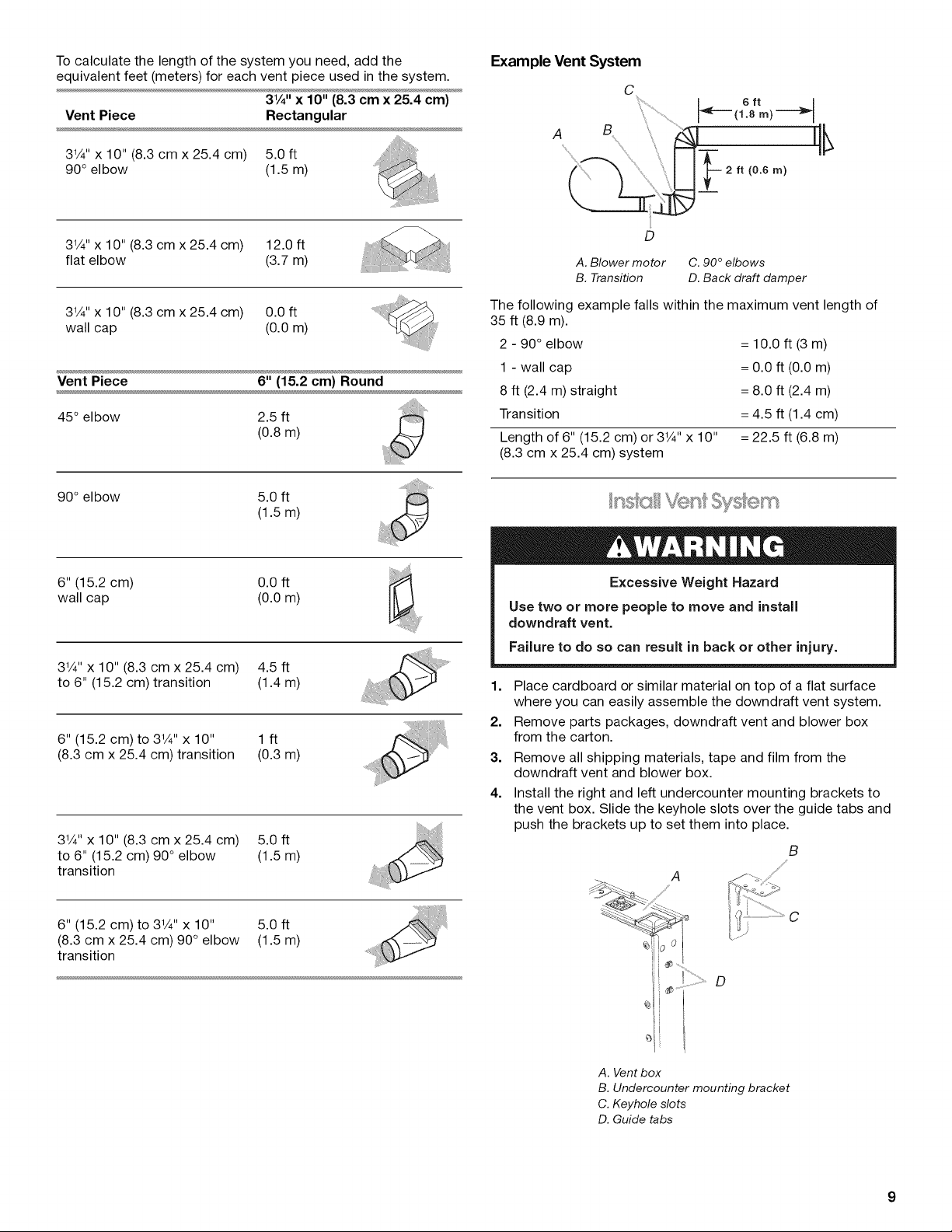

Example Vent System

A

2 ft (0.6 rn)

31A'' x 10" (8.3 cm x 25.4 cm) 12.0 ft

flat elbow (3.7 m)

3V4"x 10" (8.3 cm x 25.4 cm) 0.0 ft

wall cap (0.0 m)

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft

(0.8m)

90° elbow 5.0 ft

(1.5m)

6" (15.2 cm) 0.0 ft

wall cap (0.0 m)

3_A'' x 10" (8.3 cm x 25.4 cm) 4.5 ft

to 6" (15.2 cm) transition (1.4 m)

6" (15.2 cm) to 3_A'' x 10" 1 ft

(8.3 cm x 25.4 cm) transition (0.3 m)

3_A'' x 10" (8.3 cm x 25.4 cm) 5.0 ft

to 6" (15.2 cm) 90° elbow (1.5 m)

transition

D

A. Blower motor C. 90 ° elbows

B.Transition D. Back draft damper

The following example falls within the maximum vent length of

35 ft (8.9 m).

2 - 90 ° elbow

1 - wall cap

8 ft (2.4 m) straight

Transition

Length of 6" (15.2 cm) or 3V4" x 10"

(8.3 cm x 25.4 cm) system

Excessive Weight Hazard

Use two or more people to move and install

downdraft vent.

Failure to do so can result in back or other injury.

1. Place cardboard or similar material on top of a flat surface

where you can easily assemble the downdraft vent system.

2. Remove parts packages, downdraft vent and blower box

from the carton.

3. Remove all shipping materials, tape and film from the

downdraft vent and blower box.

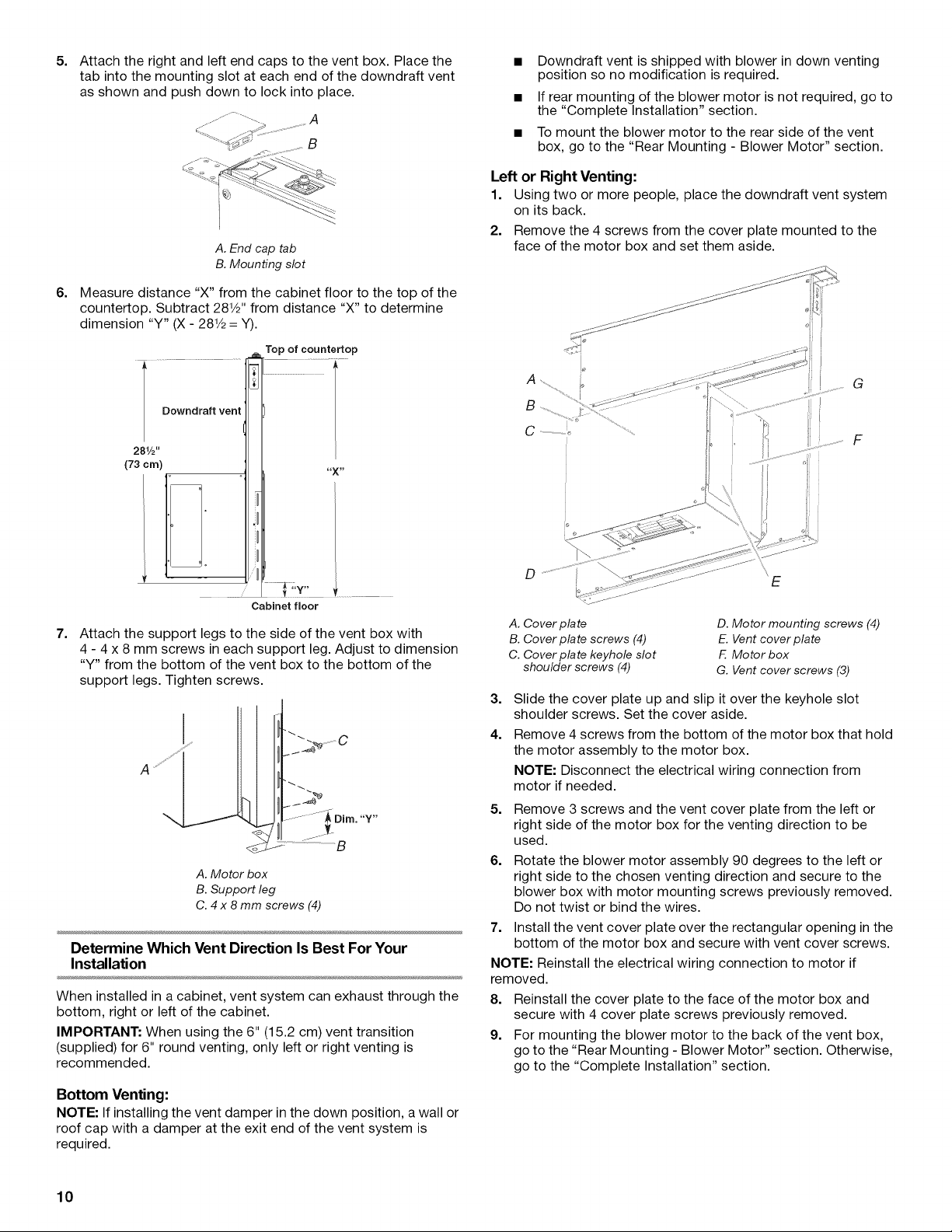

4. Install the right and left undercounter mounting brackets to

the vent box. Slide the keyhole slots over the guide tabs and

push the brackets up to set them into place.

A

= 10.0 ft (3 m)

= 0.0 ft (0.0 m)

= 8.0 ft (2.4 m)

= 4.5 ft (1.4 cm)

= 22.5 ft (6.8 m)

B

,//¢

6" (15.2 cm) to 31A'' x 10" 5.0 ft

(8.3 cm x 25.4 cm) 90° elbow (1.5 m)

transition

C

D

o

A. Vent box

B. Undercounter mounting bracket

C. Keyhole slots

D. Guide tabs

5. Attach the right and left end caps to the vent box. Place the

tab into the mounting slot at each end of the downdraft vent

as shown and push down to lock into place.

B

A. End cap tab

B. Mounting slot

6.

Measure distance "X" from the cabinet floor to the top of the

countertop. Subtract 281/2'' from distance "X" to determine

dimension "Y" (X - 281/2= Y).

,_ Top of countertop

Downdraft vent

281/2"

(73 cm)

Downdraft vent is shipped with blower in down venting

position so no modification is required.

If rear mounting of the blower motor is not required, go to

the "Complete Installation" section.

To mount the blower motor to the rear side of the vent

box, go to the "Rear Mounting - Blower Motor" section.

Left or Right Venting:

1. Using two or more people, place the downdraft vent system

on its back.

2. Remove the 4 screws from the cover plate mounted to the

face of the motor box and set them aside.

G

C ..................._

F

iiiit ............

Cabinet floor

7.

Attach the support legs to the side of the vent box with

4 - 4 x 8 mm screws in each support leg. Adjust to dimension

"Y" from the bottom of the vent box to the bottom of the

support legs. Tighten screws.

J

B

A. Motor box

B. Support leg

C. 4 x 8 mm screws (4)

Determine Which Vent Direction Is Best ForYour

Installation

When installed in a cabinet, vent system can exhaust through the

bottom, right or left of the cabinet.

IMPORTANT: When using the 6" (15.2 cm) vent transition

(supplied) for 6" round venting, only left or right venting is

recommended.

D

A. Cover plate

B. Cover plate screws (4)

C. Cover plate keyhole slot

shoulder screws (4)

3.

Slide the cover plate up and slip it over the keyhole slot

D. Motor mounting screws (4)

E. Vent cover plate

F. Motor box

G. Vent cover screws (3)

E

shoulder screws. Set the cover aside.

4.

Remove 4 screws from the bottom of the motor box that hold

the motor assembly to the motor box.

NOTE: Disconnect the electrical wiring connection from

motor if needed.

5. Remove 3 screws and the vent cover plate from the left or

right side of the motor box for the venting direction to be

used.

6. Rotate the blower motor assembly 90 degrees to the left or

right side to the chosen venting direction and secure to the

blower box with motor mounting screws previously removed.

Do not twist or bind the wires.

7. Install the vent cover plate over the rectangular opening in the

bottom of the motor box and secure with vent cover screws.

NOTE: Reinstall the electrical wiring connection to motor if

removed.

8. Reinstall the cover plate to the face of the motor box and

secure with 4 cover plate screws previously removed.

9. For mounting the blower motor to the back of the vent box,

go to the "Rear Mounting - Blower Motor" section. Otherwise,

go to the "Complete Installation" section.

Bottom Venting:

NOTE: If installing the vent damper in the down position, a wall or

roof cap with a damper at the exit end of the vent system is

required.

10

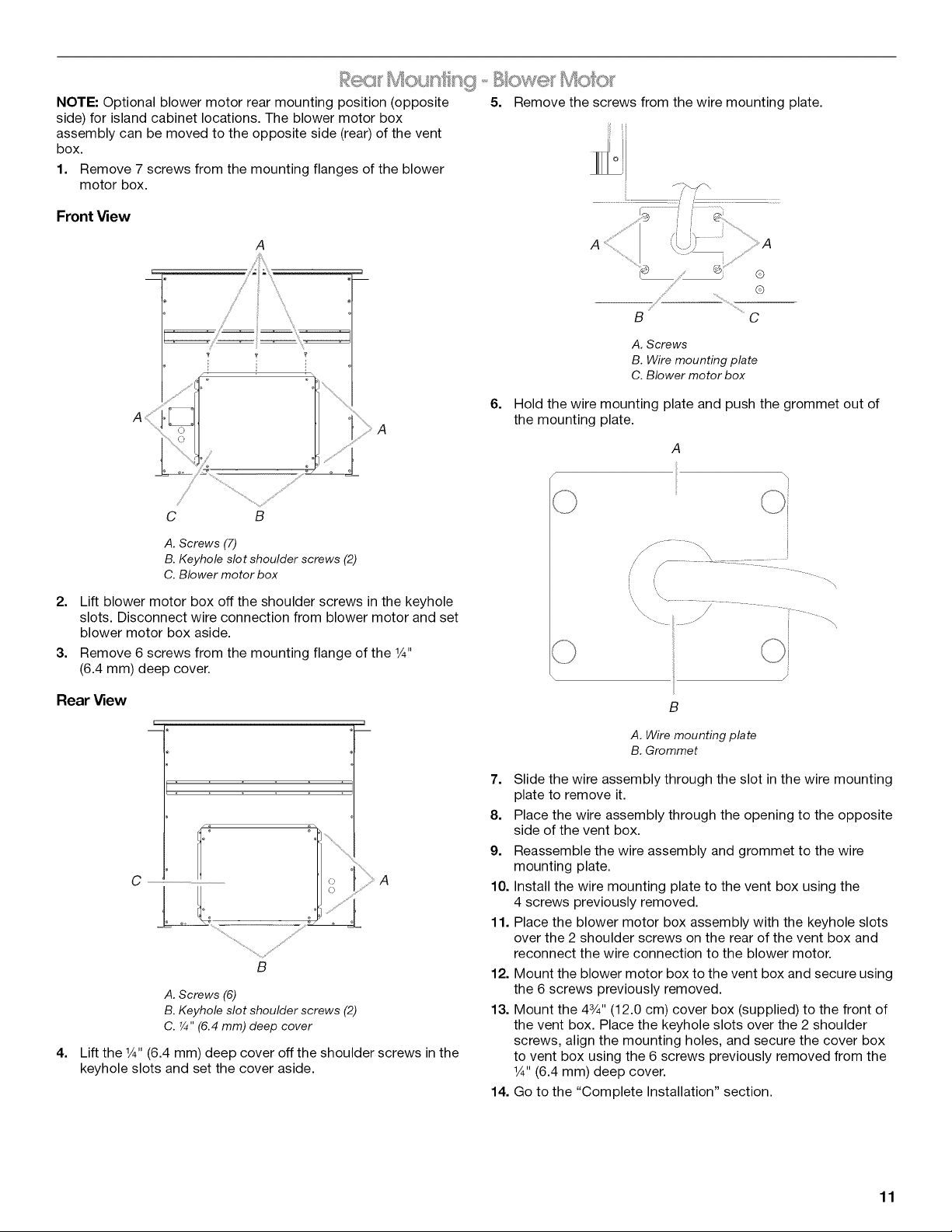

MousYrig Bow® Mo :x

NOTE: Optional blower motor rear mounting position (opposite 5. Remove the screws from the wire mounting plate.

side) for island cabinet locations. The blower motor box

assembly can be moved to the opposite side (rear) of the vent J

box.

1. Remove 7 screws from the mounting flanges of the blower

motor box. _\

Front View

A

B

A. Screws

B. Wire mounting plate

C. Blower motor box

6.

Hold the wire mounting plate and push the grommet out of

the mounting plate.

A

\

A. Screws (7)

B.Keyhole slot shoulder screws (2)

C. Blower motor box

2. Lift blower motor box off the shoulder screws in the keyhole

slots. Disconnect wire connection from blower motor and set

blower motor box aside.

3. Remove 6 screws from the mounting flange of the W'

(6.4 mm) deep cover.

Rear View

L

m

C

B

A. Screws (6)

B. Keyhole slot shoulder screws (2)

C. ¼" (6.4 mm) deep cover

4=

Lift the W' (6.4 mm) deep cover off the shoulder screws in the

keyhole slots and set the cover aside.

J

m

B

A. Wire mounting plate

B. Grommet

7. Slide the wire assembly through the slot in the wire mounting

plate to remove it.

8. Place the wire assembly through the opening to the opposite

side of the vent box.

9. Reassemble the wire assembly and grommet to the wire

mounting plate.

10. Install the wire mounting plate to the vent box using the

4 screws previously removed.

11. Place the blower motor box assembly with the keyhole slots

over the 2 shoulder screws on the rear of the vent box and

reconnect the wire connection to the blower motor.

12. Mount the blower motor box to the vent box and secure using

the 6 screws previously removed.

13. Mount the 43/4'' (12.0 cm) cover box (supplied) to the front of

the vent box. Place the keyhole slots over the 2 shoulder

screws, align the mounting holes, and secure the cover box

to vent box using the 6 screws previously removed from the

1_" (6.4 mm) deep cover.

14. Go to the "Complete Installation" section.

11

Loading...

Loading...