Whirlpool AWM 215, AWM 246/3, AWM 310, AWM 246/5 INSTRUCTION FOR USE

INSTALLATION INSTRUCTIONS

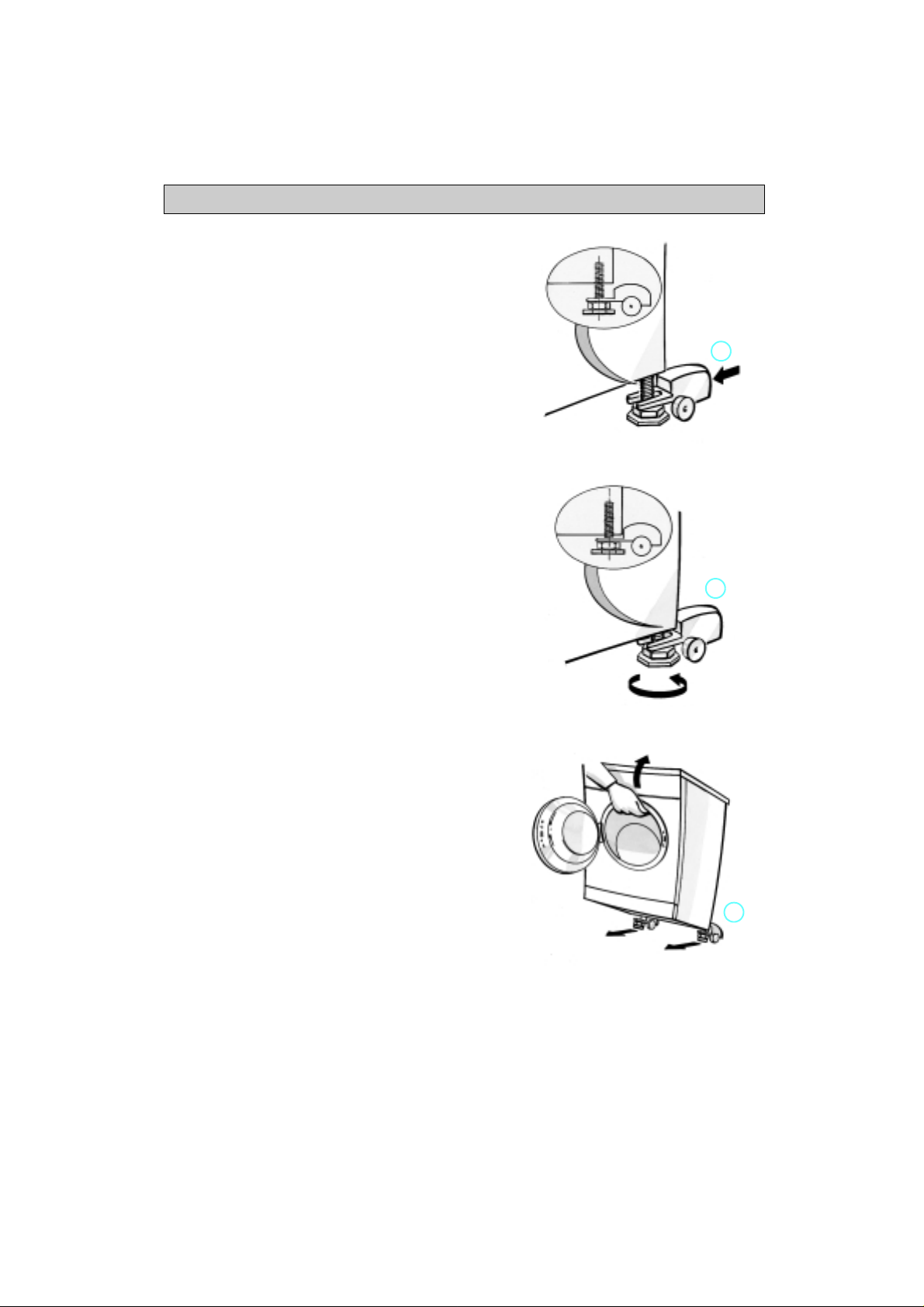

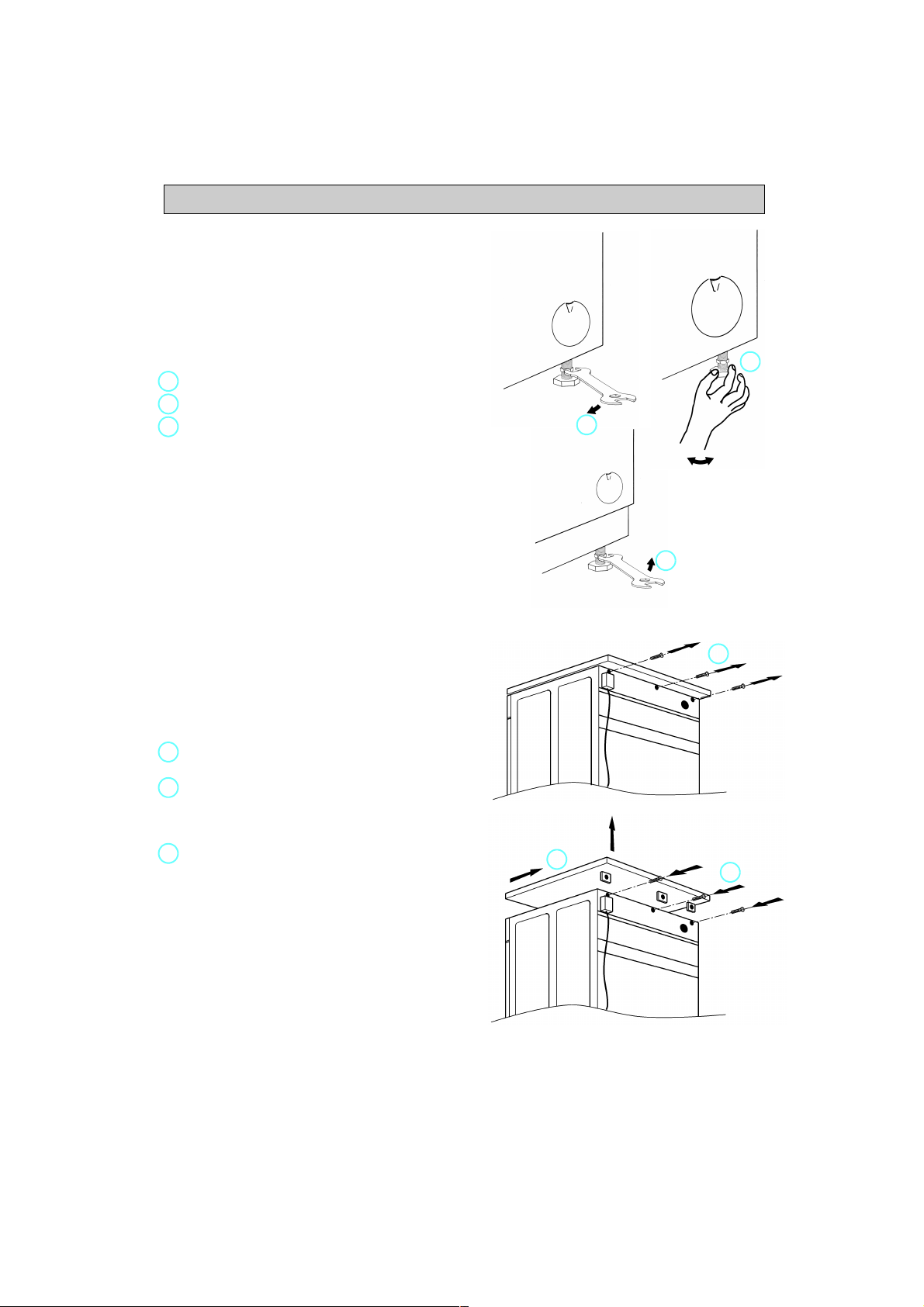

MOBILITY WHEELS

(for UK only)

Depending on model, your washing machine is

provided with mobility wheels.

You will find these wheels in the accessory kit supplied

with the machine, or you can order them from our

After-Sales Service.

MOUNTING INSTRUCTIONS

Tilt the machine forward.

1.

Loosen the two rear feet.

2.

Insert the wheels as close as possible to the

3.

screw (1).

Tighten the screw completely (2).

4.

Put the machine in an upright position.

5.

Adjust the front feet making sure that the machine

6.

is completely level with the floor.

: Levelling is extremely important to avoid any

Note

risk of instability and vibrations.

1

2

MOVING THE MACHINE

Open the door of the machine.

1.

Lift the machine by 1 or 2 cm (3).

2.

Push or pull the machine according to your need.

3.

3

79

INSTALLATION INSTRUCTIONS

1) ELECTRICAL CONNECTIONS

“Warning - this appliance must be earthed”

This appliance is normally supplied with a mains

lead having a plug fitted in the factory which has

been checked for correct earth continuity.

If the fitted plug is not suitable for your socket

outlet, or if the machine’s mains lead is not fitted

with a plug, you should fit a suitable new, good

quality plug by following the instructions in (2)

below.

Any unsuitable plug should be cut off and

disposed of in order to avoid a possible shock

hazard should it be inserted into a socket.

2) CONNECTION TO A REWIRABLE PLUG - to be

carried out only by a qualified electrician

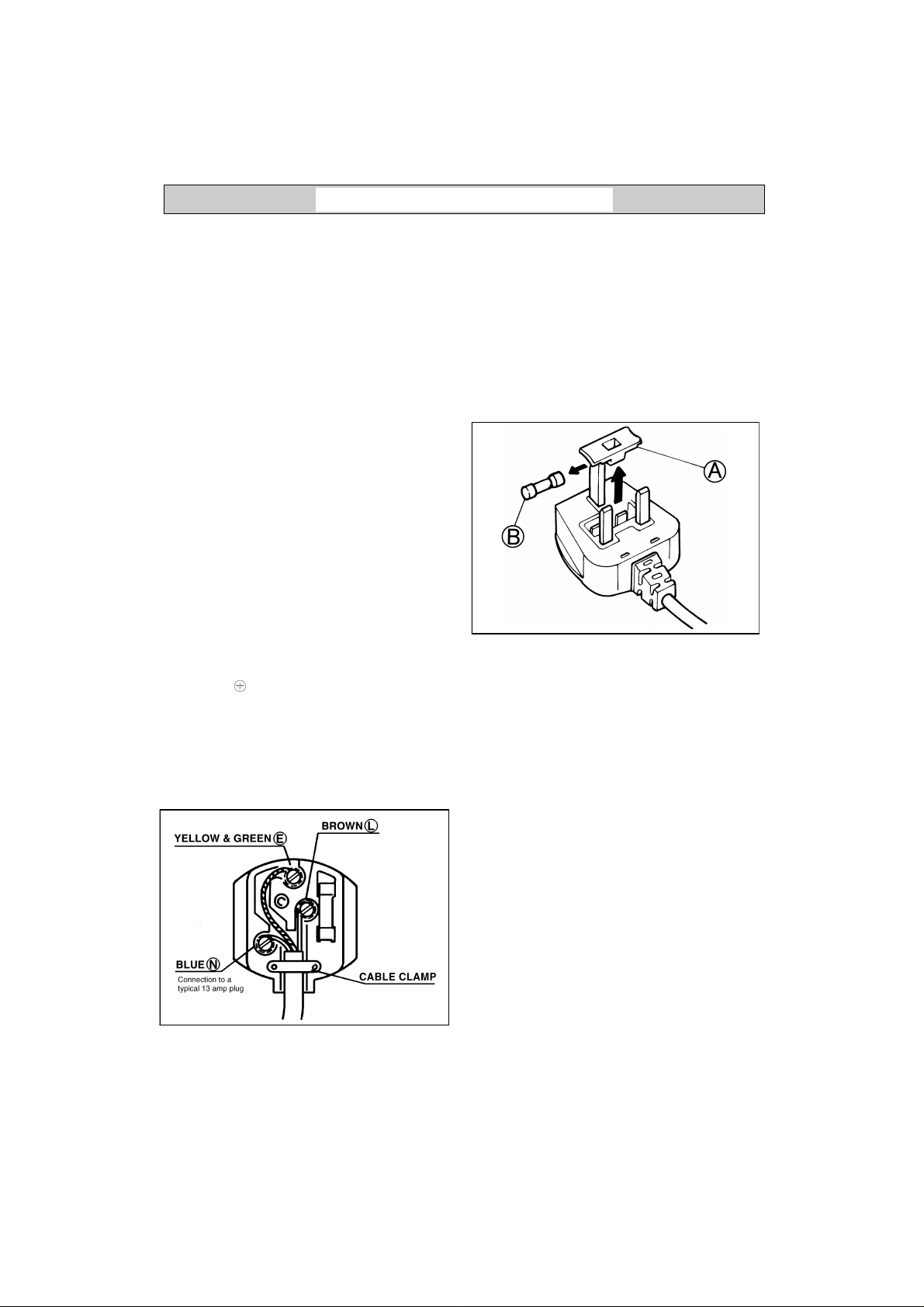

The wires in the mains lead are coloured in

accordance with the following code:

BLUE - “NEUTRAL” (“N”)

BROWN - “LIVE” (“L”)

GREEN AND YELLOW - “EARTH” (“E”)

To fit a new plug, proceed as follows:

2.1Polarized Plugs (e.g. 3 pin, 13 amp plug

conforming to BS 1363A)

a.

The GREEN AND YELLOW wire must be

connected to the terminal in the plug which is

marked with the letter “E” or by the Earth

symbol or coloured yellow or green and

yellow.

b.

The BLUE wire must be connected to the

terminal which is marked with the letter “N” or

coloured black.

c.

The BROWN wire must be connected to the

terminal which is marked with the letter “L” or

coloured red.

2.2Non-polarized plugs (e.g. 2 pin with side

earth contact)

The wire which is coloured GREEN AND

YELLOW must be connected to the earth

contact. The other two wires should be

connected to the two pins, irrespective of colour.

3) FUSE REPLACEMENT

If the mains lead of this appliance is fitted with a

BS 1363A 13 amp fused plug, replace the fuse

only with an A.S.T.A. approved type conforming

to BS 1362 and proceed as follows:

1.

Remove the fuse cover (A) and the fuse (B).

2.

Fit the replacement 13 A fuse into the fuse

cover.

3.

Refit both into the plug.

For all other types of plug, the supply socket

should be protected by a 16 A fuse or circuit

breaker at the distribution board.

78

INSTALLATION INSTRUCTIONS

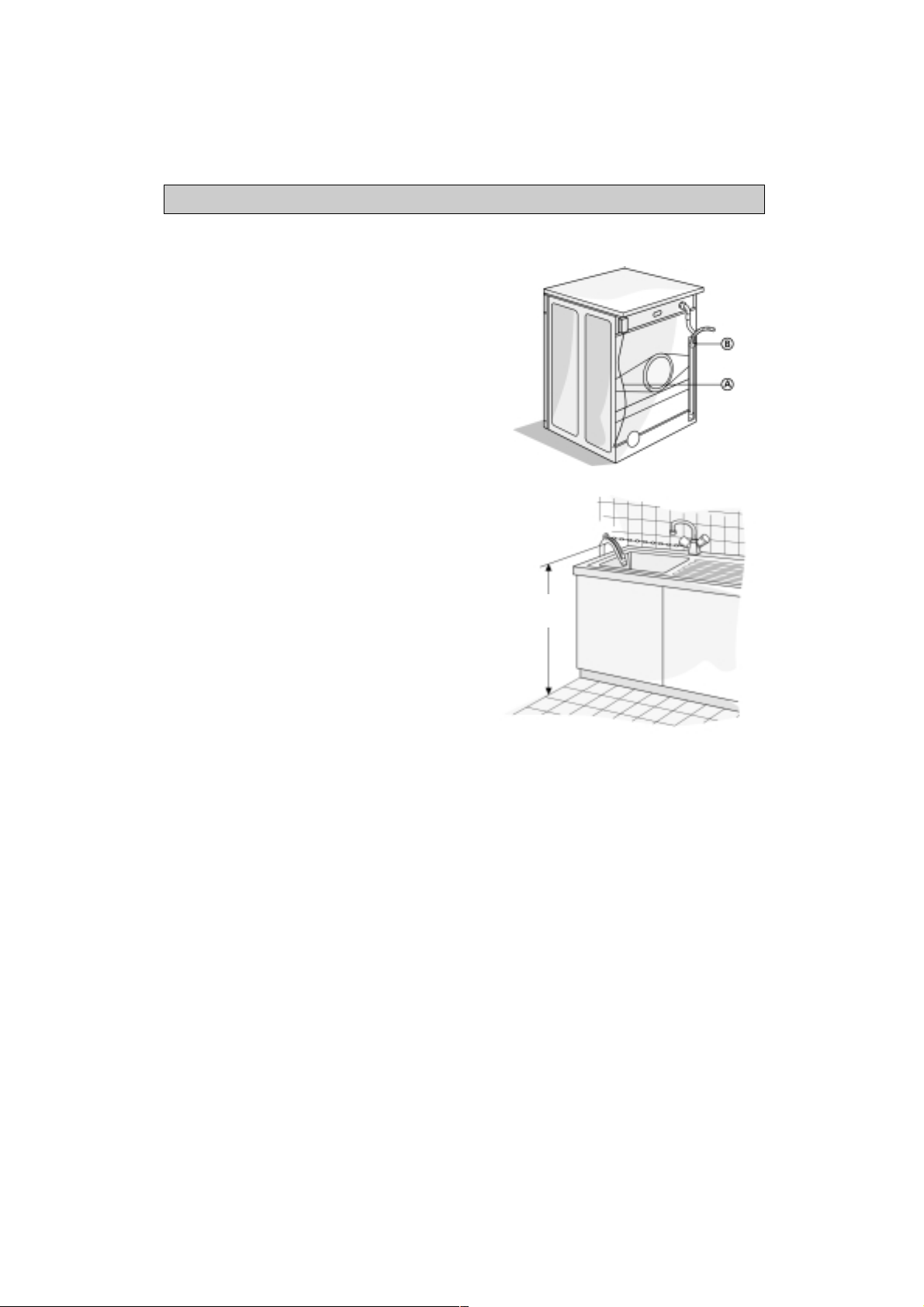

DRAIN HOSE

Drain hose connection to water outlet.

•

Unhook the drain hose from the left clip;

1.

see arrow A in Fig. 1.

Important:

Do NOT loosen the drain hose connection;

see arrow B in Fig. 1, otherwise there is the risk of

leakage (danger of scalding with hot water).

Fit the drain hose either to the siphon or hook it

2.

over the edge of a sink or bath tub with the “U”

bend (Fig. 1). Small hand basins are not suitable.

Minimum drain height: 70 cm.

3.

Maximum U-bend drain height: 125 cm.

If you need to add an extension, use a flexible

4.

hose of the same type and secure the union with

screw-on hose clips. Maximum overall drain hose

length 2.5 m.

Important

Make sure that there are no kinks in the drain hose run

and take precautions against it falling while the

appliance is running (Fig. 2).

Fig. 1

CONNECTION TO THE MAINS

Observe local utility company regulations.

•

The connection must be made with a correctly

•

installed, earthed and insulated socket.

The system must be earthed.

•

The manufacturer declines all responsibility for

injury to persons or pets and damage to property

caused by disregarding the above instructions.

The data concerning voltage, consumption and

•

necessary fuse are supplied on the inside of the

appliance door.

The mains connection cable may only be replaced

•

by a qualified electrician.

The appliance conforms to European safety

•

regulations, EC directive 93/68/EWG and

EN 60555.

Do not use extension leads or multiplugs.

•

Min 70 cm

Max 125 cm

Fig. 2

77

INSTALLATION INSTRUCTIONS

WATER SUPPLY

Water supply: only cold water.

•

Tap: 3/4” threaded hose connector.

•

Water pressure (mains pressure):

•

10-100 N/cm2 (1-10 bar).

For Great Britain and Ireland only

Water inlet: hot and cold fill. The warm water inlet

•

temperature must not exceed 60°C.

INLET HOSE(S)

If the inlet hose is already fitted to the rear panel

Note:

on the appliance, ignore points 1 and 4.

Remove the inlet hose from the drum.

1.

Fit the mesh filter supplied in the thread between

2.

the straight end of the inlet hose(s) and the tap(s).

Carefully screw the straight end of the inlet hose(s)

3.

to the tap(s) by hand.

Screw the curved end of the hose to the appliance

4.

taking care that the hose is not kinked.

Turn the tap(s) on fully and check that the joints at

5.

the washing machine and the tap(s) are watertight.

If the hose is not long enough, replace it with a

•

suitable length of pressure-resistant hose

(approved under EN 500 65 to withstand a

minimum of 10 bar).

Check the hose regularly for brittleness and cracks

•

and replace if necessary.

The washing machine may be connected without a

•

non-return valve.

Observe any special local regulations regarding

•

connection to the water supply.

76

INSTALLATION INSTRUCTIONS

INSTALLATION

Install the appliance on a solid and level floor

•

surface, preferably in a corner of the room.

Make sure that all four feet are resting firmly on

•

the floor and check that the appliance is perfectly

level (use a spirit level).

If the floor is uneven, adjust the levelling feet as

•

required (do not insert pieces of wood, cardboard

etc. under the feet).

Slacken the locknut using the spanner supplied.

1.

Adjust the height of the foot, turning it by hand.

2.

Tighten the locknut anticlockwise towards the

3.

washing machine.

If the appliance is to be installed on a wooden floor,

•

distribute the weight by placing it on a 60 x60 cm

sheet of plywood at least 3 cm in thickness. Secure

the plywood sheet to the floor.

2

1

3

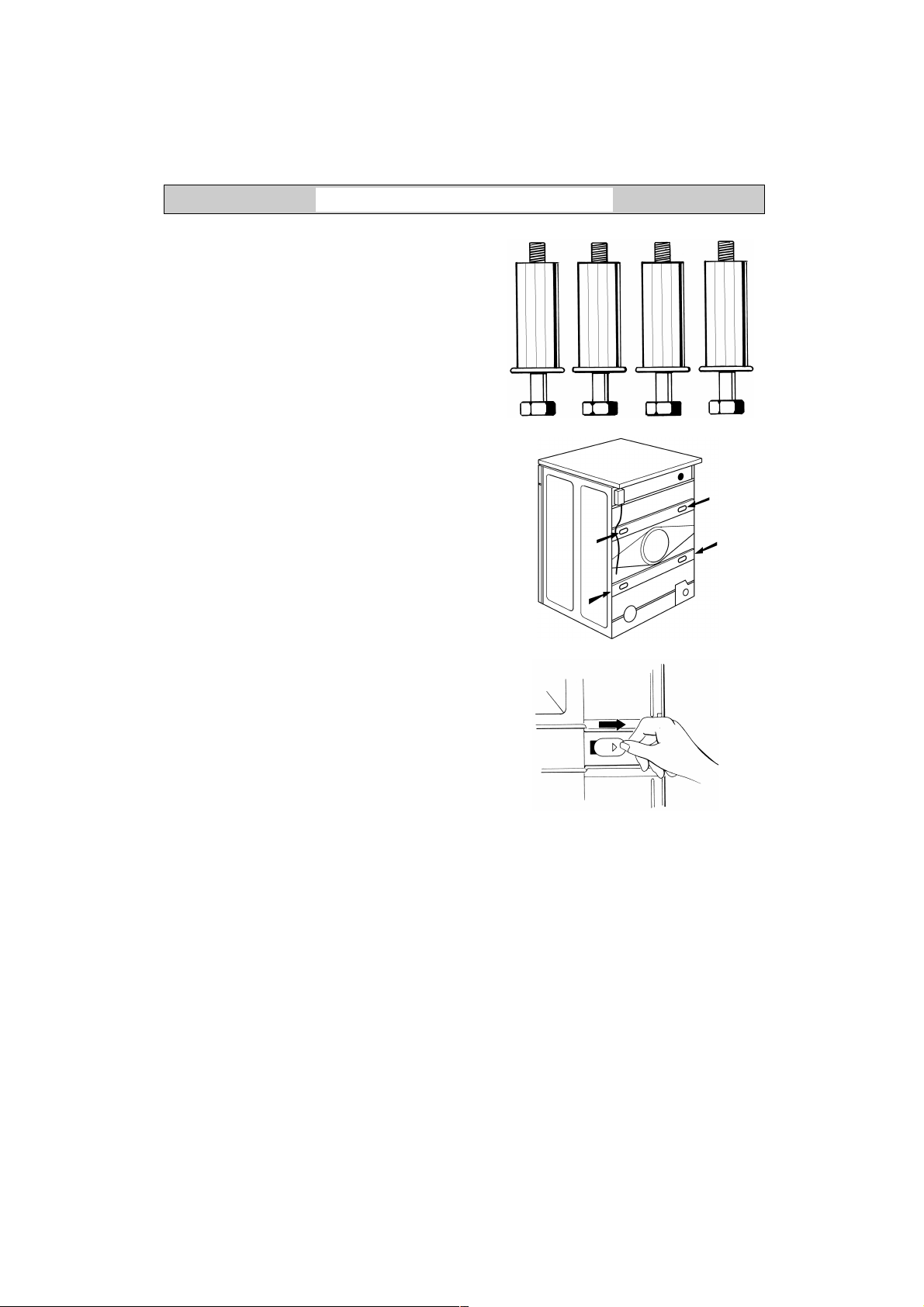

BUILD-UNDER / WORKTOP

The appliance must be installed only under a

fitted, continuous kitchen worktop.

The appliance must only be built under using the

built under set UBS.

Unplug the appliance from the mains.

•

Unscrew the worktop fixing screws from the rear

1.

of the appliance.

Slide the worktop fully backward and lift it

2.

upwards to remove.

Install the cover panel following the relative

instructions.

Refit the fixing screws and tighten them.

3.

BUILD-UNDER OPENING DIMENSIONS

Width 600 mm

Height 825 mm

Depth 600 mm

WARNING:

Only plug the machine into the mains power socket

after you have fitted the cover panel or the machine

worktop.

1

2

3

75

INSTALLATION INSTRUCTIONS

TRANSIT BOLTS

The appliance is fitted with transit bolts to prevent

internal damage while it is being moved.

Before using the appliance the transit bolts MUST

be removed (Fig. 1).

Slacken the bolts with the spanner supplied (Fig. 2).

1.

Unscrew the bolts by hand.

2.

Hold each bolt head and pull the bolts complete

3.

with red plastic spacer through the wide part of the

holes.

Close the holes with the provided plastic caps.

4.

Fit the caps in the direction indicated by the arrow

in the large opening and slide them into the narrow

slot until they sit properly (Fig. 3).

Keep the transit bolts for future use.

5.

Note

Fit the transit bolts before transporting the appliance as

follows:

Pry up the plastic caps with a screwdriver, slide

1.

them out against the direction indicated with the

arrow and remove them.

Fit the transit bolts by following the above

2.

procedure in reverse order.

Fig. 1

Fig. 2

74

Fig. 3

Loading...

Loading...