Whirlpool 4GWTW4950YW Installation Instructions

WASHER INSTALLATION INSTRUCTIONS

INSTRUCTIONS POUR L’INSTALLATION DU LAVE-LINGE

INSTRUCCIONES DE INSTALACIÓN DE LA LAVADORA

Table of Contents

WASHER SAFETY ...................................................................... 2

INSTALLATION REQUIREMENTS ............................................. 2

Tools and Parts ................................................................... 2

Location Requirements ..................................................... 3

Drain System ...................................................................... 3

Electrical Requirements .................................................... 4

Table des matières

SÉCURITÉ DU LAVE-LINGE ....................................................10

EXIGENCES D’INSTALLATION ...............................................10

Outillage et pièces ...........................................................10

Exigences d’emplacement ..............................................11

Système de vidange .........................................................11

Spécications électriques ...............................................12

INSTALLATION INSTRUCTIONS ............................................... 5

Connect Drain Hose ........................................................... 6

Connect Inlet Hoses ........................................................... 6

Level Washer ...................................................................... 8

Power Cord Installation ..................................................... 9

Complete Installation Checklist ........................................ 9

INSTRUCTIONS D’INSTALLATION .........................................13

Raccordement du tuyau de vidange...............................14

Raccordement des tuyaux d’arrivée d’eau ....................15

Établissement de l’aplomb du lave-linge .......................16

Installation du cordon d’alimentation .............................17

Liste de vérication pour l’achèvement

de l’installation .................................................................18

SEGURIDAD DE LA LAVADORA ............................................. 19

REQUISITOS DE INSTALACIÓN ............................................. 19

Herramientas y piezas ..................................................... 19

Requisitos de ubicación .................................................. 20

Sistema de desagüe. ........................................................ 20

Requisitos eléctricos ....................................................... 21

W10549313A

Índice

INSTRUCCIONES DE INSTALACIÓN ..................................... 22

Conexión de la manguera de desagüe ........................... 23

Conexión de las mangueras de entrada ........................ 24

Nivelación de la lavadora ................................................ 25

Instalación del cable eléctrico ........................................ 26

Lista de control de la instalación terminada .................27

4GWTW4740

4GWTW4800

4GMVWC100

4GMVWC300

4GWTW5550

4GWTW4950

4GMVWX500

4GMVWC400

4GNTW4400

4GNTW4600

4GATW4900

WASHER SAFETY

INSTALLATION REQUIREMENTS

Tools and Parts

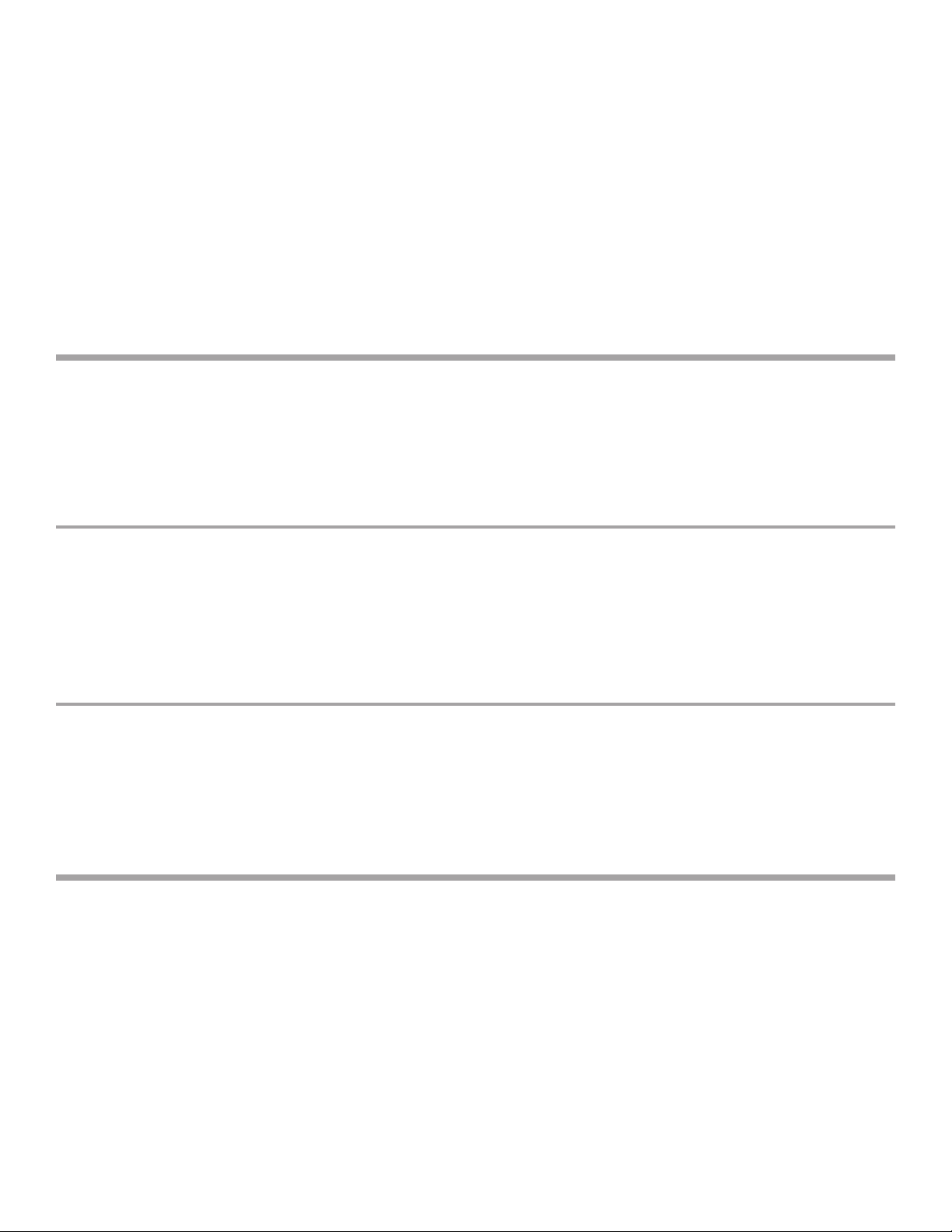

Gather required tools and parts before starting installation.

Tools needed:

Adjustable or open end

wrench 9/16" (14 mm)

4" min

(102 mm)

Wood block

Level

Ruler or measuring tape

Parts supplied:

NOTE: All parts supplied for installation are in cardboard

insert in the top of the washer.

Cable tie

Inlet hoses with flat

washers

Drain hose with clamp

“Y” connector

Pliers that open to

13⁄4" (44.5 mm)

Optional tools:

Flashlight Bucket

2

Plugs and cord lock cover

Alternate parts: (Not supplied with washer)

3"

Your installation may require additional parts. To order, please

contact the dealer from whom you purchased your washer or an

authorized service company.

If you have: You will need:

Overhead sewer Standard 20 gal. (76 L) 39" (990 mm)

tall drain tub or utility sink, sump

pump and connectors (available from

local plumbing suppliers)

1" (25 mm) standpipe 2" (51 mm) diameter to 1" (25 mm)

diameter Standpipe Adapter

Part Number 3363920

Connector Kit Part Number 285835

Drain hose too short Extension Drain Hose Part

Number 285863

Connector Kit Part Number 285835

Lint clogged drain Drain Protector Part Number 367031

Connector Kit Part Number 285835

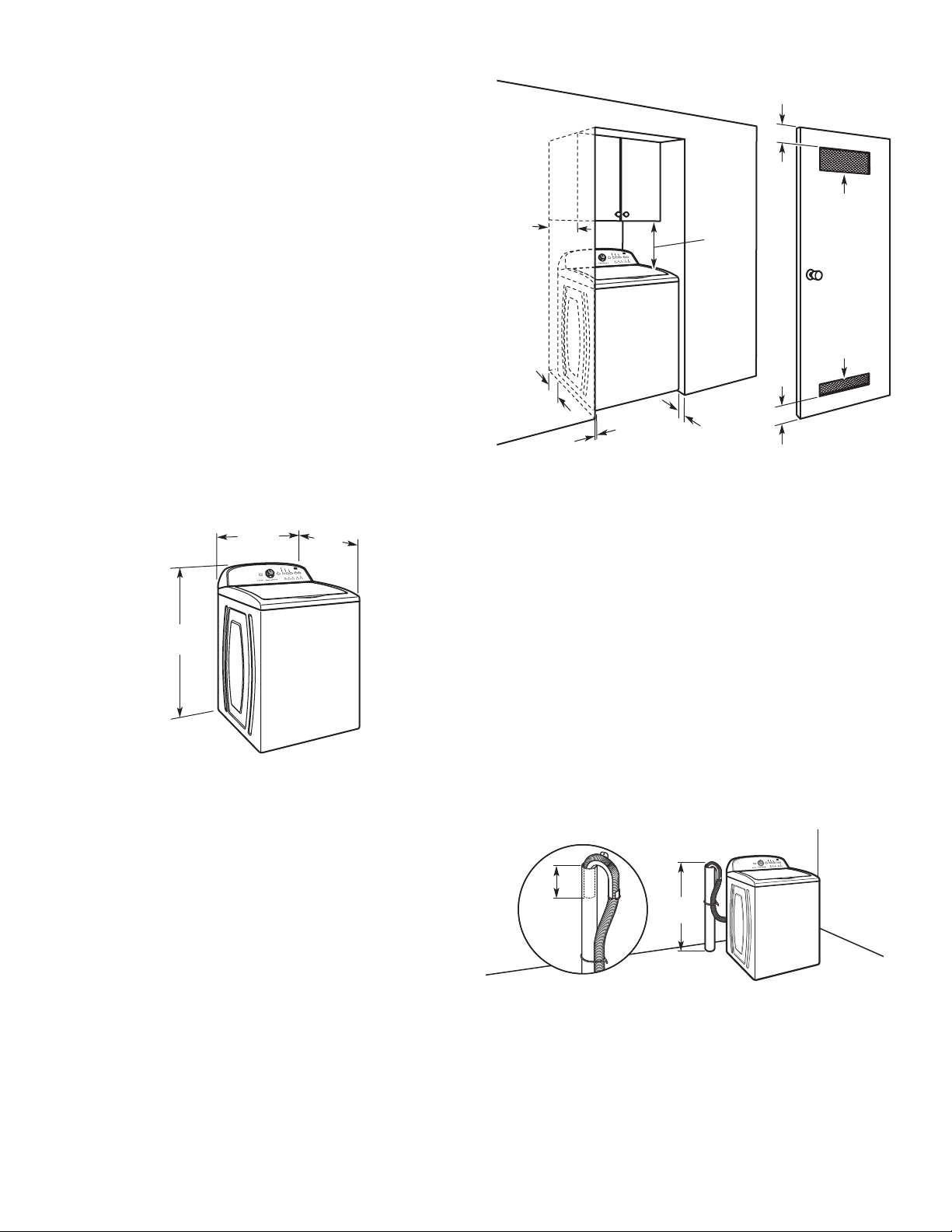

Recessed area or closet installation

14" max.

(356 mm)

17"

(432 mm)

5"

(126 mm)

(76 mm)

2

48 in.

(310 cm2)

2

24 in.

(155 cm2)

LOCATION REQUIREMENTS

Select proper location for your washer to improve performance

and minimize noise and possible “washer walk”. Install your

washer in a basement, laundry room, closet, or recessed area.

1

/2"

27

(699 mm)

42"

(1067 mm)

You will need:

n

A water heater set to 120° F (49° C).

n

A grounded electrical outlet located within 4 ft (1.2 m) of

power cord on back of washer.

n

Hot and cold water faucets located within 3 ft (0.9 m) of hot

and cold water ll valves on washer, and water pressure

of 20-100 psi (138-690 kPa).

n

A level oor with maximum slope of 1" (25 mm) under entire

washer. Installing on carpet is not recommended.

n

Floor must support washer’s total weight (with water and load)

of 315 lbs (143 kgs).

IMPORTANT: Do not install, store, or operate washer where it

will be exposed to weather or in temperatures below 32° F (0° C).

Water remaining in washer after use may cause damage in low

temperatures. See “Washer Care” in your Use and Care Guide

for winterizing information.

Proper installation is your responsibility.

27"

(686 mm)

1"

1"

(25 mm)

(25 mm)

3"

(76 mm)

Dimensions show recommended spacing allowed, except for

closet door ventilation openings which are minimum required.

This washer has been tested for installation with spacing of

0" (0 mm) clearance on the sides. Consider allowing more space

for ease of installation and servicing, and spacing for companion

appliances and clearances for walls, doors, and oor moldings.

Add spacing of 1" (25 mm) on all sides of washer to reduce

noise transfer. If a closet door or louvered door is installed,

top and bottom air openings in door are required.

DRAIN SYSTEM

Drain system can be installed using a oor drain, wall standpipe,

oor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

39"

4.5"

(114 mm)

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum

carry-away capacity: 17 gal. (64 L) per minute. Top of standpipe

must be at least 39" (990 mm) high; install no higher than

48" (1.22 m) from bottom of washer. If you must install higher

than 48" (1.22 m), you will need a sump pump system.

(990 mm)

3

Wall standpipe drain system

4.5"

(114 mm)

4.5"

(114 mm)

See requirements for oor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number

285834), 2 Connector Kits (Part Number 285835), and an

Extension Drain Hose (Part Number 285863) that may be

purchased separately.

whom you purchased your washer or an authorized service

company.

of washer. (Additional hoses may be needed.)

Minimum siphon break: 28" (710 mm) from bottom

To order, please contact the dealer from

Laundry tub drain system

39"

(990 mm)

Minimum capacity: 20 gal. (76 L). Top of laundry tub must be at

least 39" (990 mm) above oor; install no higher than 48" (1.22 m)

from bottom of washer.

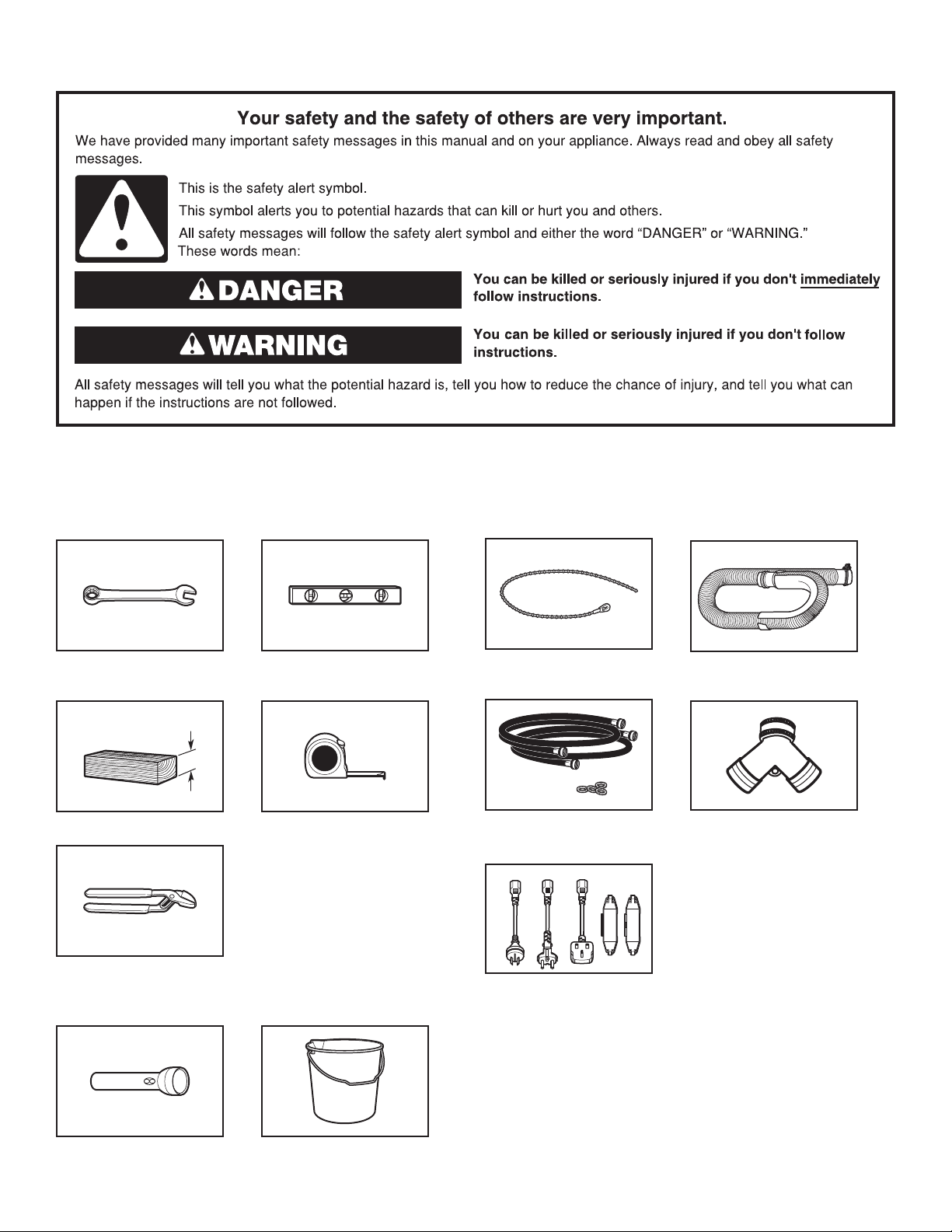

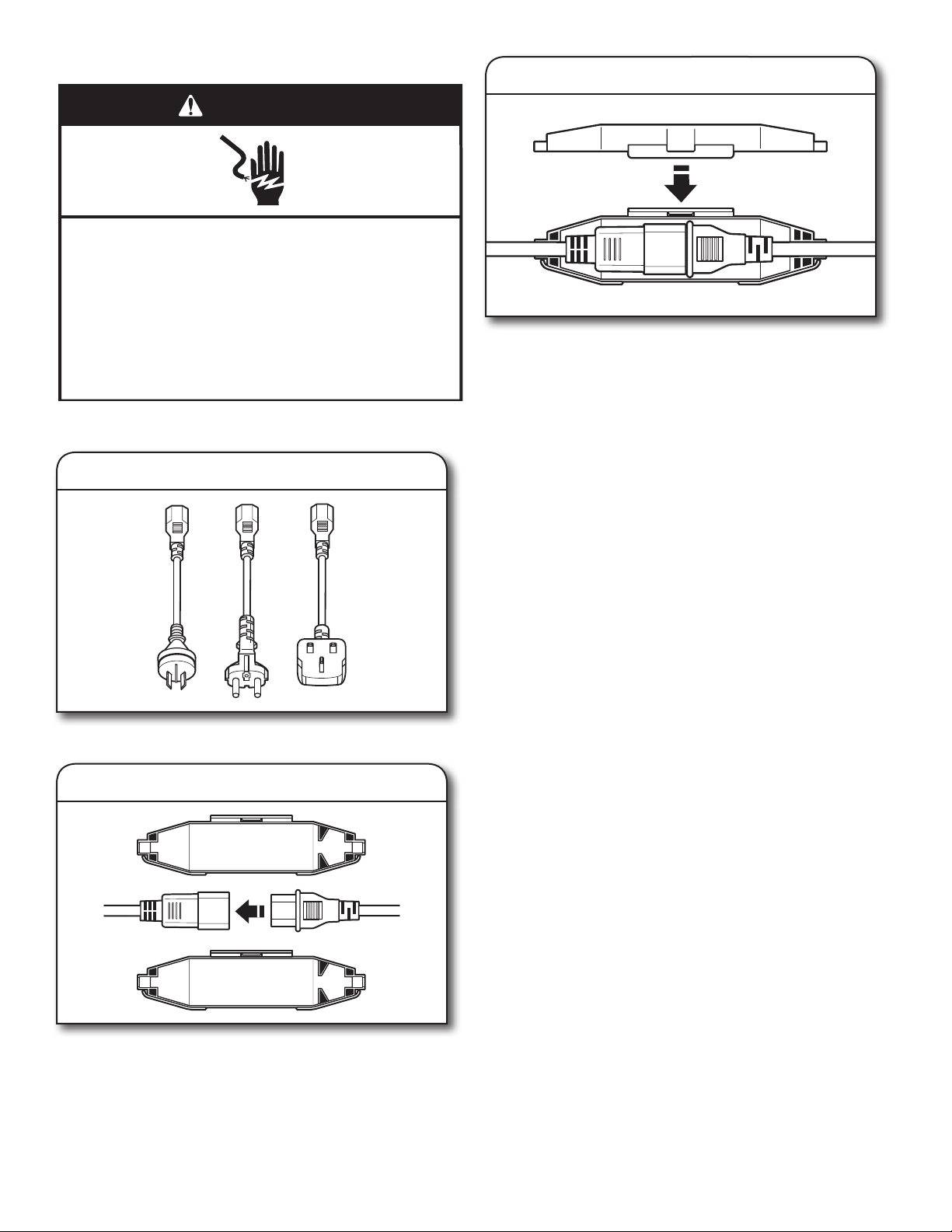

ELECTRICAL REQUIREMENTS

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

re, or electrical shock.

n

A 220-240 volt, 60 Hz., AC only, 10-amp, fused electrical supply

is required. A time-delay fuse or circuit breaker is recommended.

It is recommended that a separate circuit breaker serving only this

appliance be provided.

n

This washer is equipped with a power supply cord having

a 3 prong grounding plug.

n

To minimize possible shock hazard, the cord must be plugged

into a mating, 3 prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating outlet

is not available, it is the personal responsibility and obligation

of the customer to have the properly grounded outlet installed

by a qualied electrician.

n

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

n

Do not ground to a gas pipe.

n

Check with a qualied electrician if you are not sure the

washer is properly grounded.

n

Do not have a fuse in the neutral or ground circuit.

IMPORTANT: To avoid siphoning, no more than 4.5" (114 mm)

of drain hose should be inside standpipe or below the top of

wash tub. Secure drain hose with cable tie.

4

INSTALLATION INSTRUCTIONS

Before you start: remove shipping materials

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

3. Remove packing tray from tub

1. Move washer

48"

(1.2 m)

Move washer to within 4 ft (1.2 m) of its nal location; it must

be in a fully upright position.

NOTE: To avoid oor damage, set washer onto cardboard

before moving it and make sure lid is taped shut.

2. Remove shipping base

Remove tape from washer lid, open lid and remove cardboard

packing tray from tub. Be sure to remove all parts from tray.

NOTE: Keep tray in case you need to move washer later.

4. Free power cord

Firmly grasp power cord plug and pull to free from rear panel.

Gently place power cord over console to allow free access

to back of washer.

To avoid damaging oor, place cardboard supports from

shipping carton on oor behind washer. Tip washer back and

place on cardboard supports. Remove shipping base. Set

washer upright.

IMPORTANT: Removing shipping base is necessary for proper

operation. If your washer includes a sound shield, please refer

to the instructions included with the sound shield to install it at

this time.

5

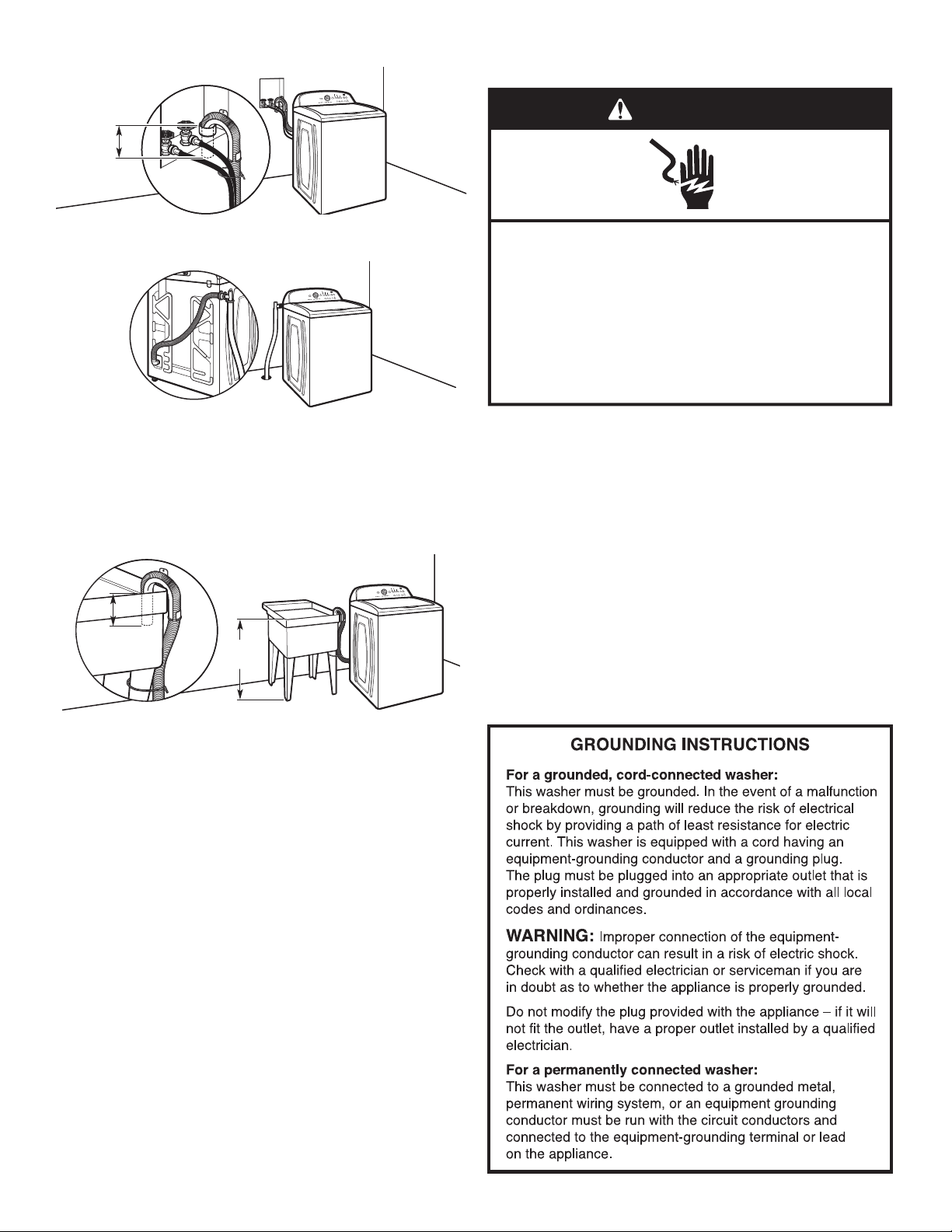

CONNECT DRAIN HOSE

5. Attach drain hose to drain port

7. Remove drain hose form

(oor drain installations only)

Remove the red plastic plug from the black drain port on the

back of the washer.

If clamp is not already in place on elbow end of drain hose,

slide it over end as shown. Squeeze clamp with pliers and

slide black elbow end of drain hose onto black drain port

and secure with clamp.

For a laundry tub or standpipe drain, go to step 6.

For a oor drain, remove the preinstalled drain hose form as

shown in Step 7. You may need additional parts with separate

directions. See “Tools and Parts”.

6. Place drain hose in standpipe

Drain

hose form

4.5"

(114 mm)

For oor drain installations, you will need to remove the drain

hose form from the end of the drain hose. You may need

additional parts with separate directions. See “Tools and Parts”.

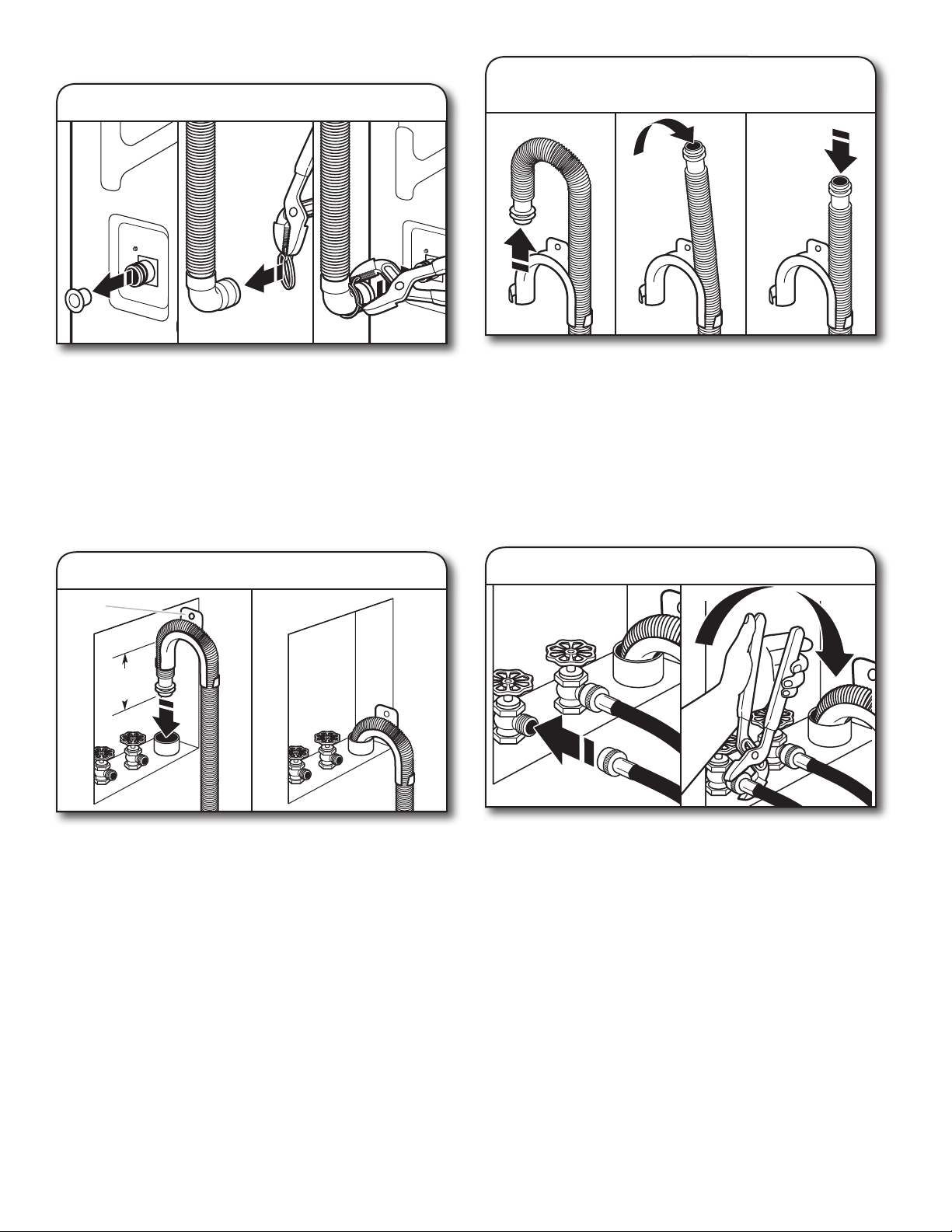

CONNECT INLET HOSES

Washer must be connected to water faucets with new inlet

hoses with at washers (provided). Do not use old hoses.

NOTE: Both hoses must be attached and have water owing

to inlet valves. If you are only connecting to a cold water

faucet, you must use a Y-adapter (provided).

8a. Connect inlet hoses to water faucets

Place hose into standpipe (shown in picture) or over side of

laundry tub.

IMPORTANT: 4.5" (114 mm) of drain hose should be inside

standpipe; do not force excess hose into standpipe or lay on

bottom of laundry tub. Drain hose form must be used.

6

Attach hose to hot water faucet. Screw on coupling by hand

until it is seated on washer. Use pliers to tighten couplings an

additional two-thirds turn. Repeat this step with second hose

for cold water faucet.

IMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

8b.

Attach the brass female end of the “Y”

connector to the cold water faucet. Use pliers

to tighten couplings an additional two-thirds turn. One end of

the long hose has a wire mesh strainer inside the coupling.

Attach this end to the “Y” connector. Attach washer cold inlet

hose to other side of “Y” connector. Screw on coupling by

hand until it is seated on connector. Using pliers, tighten the

couplings an additional two-thirds turn.

IMPORTANT: Do not overtighten or use tape or sealants

on valve when attaching to faucets or washer. Damage

can result.

Connect inlet hoses to “Y” connector

9. Clear water lines

10. Connect inlet hoses to washer

Attach hot water hose to hot water inlet valve marked with a

red ring. Screw coupling by hand until it is snug. Use pliers to

tighten couplings an additional two-thirds turn. Repeat with

cold water inlet valve.

IMPORTANT: To reduce risk of hose failure, replace the hoses

every 5 years. Record hose installation or replacement dates

for future reference.

n

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

11. Check for leaks

Run water for a few seconds through hoses into a laundry tub,

drainpipe, or bucket to avoid clogs. Water should run until clear.

Make note of which hose is connected to hot water to help in

attaching hoses to washer correctly.

Turn on water faucets to check for leaks. A small amount of

water may enter washer. It will drain later.

12. Secure drain hose

Laundry Tub Standpipe Wall

4.5"

4.5"

4.5"

(114 mm)

(113 mm)

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with cable tie.

4.5"

(114 mm)

4.5"

(113 mm)

(114 mm)

7

LEVEL WASHER

IMPORTANT: Level washer properly to reduce excess noise

and vibration.

13. Check levelness of washer

Place level here

Place level here

14.

Jam nut

Adjust leveling feet

Models with

metal feet

or

Move the washer to its nal location. Place a level on top

edges of washer. Use side seam as a guide to check levelness

of sides. Check levelness of front using lid, as shown. Rock

washer back and forth to make sure all four feet make solid

contact with oor. If washer is level, skip to step 15, (on

models with metal feet) or step 16 (on models with plastic

feet).

Not Level LEVEL Not Level

Models with

plastic feet

If washer is not level:

On models with metal feet, use a 9/16" or 14 mm open-end or

adjustable wrench to turn jam nuts clockwise on feet until they

are about 1/2" (13 mm) from the washer cabinet. Then turn the

leveling foot clockwise to lower the washer or counterclockwise

to raise the washer.

On models with plastic feet, use adjustable pliers to turn the

plastic leveling foot counterclockwise to lower the washer or

clockwise to raise the washer. On all models, recheck levelness

of washer and repeat as needed.

HELPFUL TIP: You may want to prop up front of washer

about 4" (102 mm) with a wood block or similar object that

will support weight of washer.

15. Tighten leveling feet

Jam nut

On models with metal feet, when washer is level, use a

9/16" or 14 mm open-end or adjustable wrench to turn jam

nuts counterclockwise on leveling feet tightly against washer

cabinet.

HELPFUL TIP: You may want to prop washer with

wooden block.

8

POWER CORD INSTALLATION

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

re, or electrical shock.

Plug power supply cord into an grounded outlet. Turn power

supply on.

16. Select plug

Select the plug that ts with the electric receptacle.

17. Assemble plug

18. Secure power cord

Secure the power cord by seating the connection on the cord

lock. Place the cord lock cover and push until it snaps. Make

sure the power cord connection is seated on the cord lock and

that the cord lock clamps correctly.

COMPLETE INSTALLATION

CHECKLIST

Check electrical requirements. Be sure you have correct

q

electrical supply and recommended grounding method.

Check that all parts are now installed. If there is an extra

q

part, go back through steps to see what was skipped.

Check that you have all of your tools.

q

Check that shipping materials were completely

q

removed from washer.

Check that water faucets are on.

q

Check for leaks around faucets and inlet hoses.

q

Remove lm from console and any tape remaining on washer.

q

Check that washer is plugged into a grounded

q

outlet.

Dispose of/recycle all packaging materials.

q

Read “Washer Care” in your Use and Care Guide.

q

To test and clean your washer, measure 1/2 of normal

q

recommended amount of powdered or liquid detergent

and pour it into washer basket or detergent dispenser

(on some models). Close lid. Select any cycle. Start washer

and allow to complete full cycle.

Assemble the plug into the end of the power cord.

9

SÉCURITÉ DU LAVE-LINGE

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et piéces nécessaires avant de commancer

l’installation.

Outillage nécessaire :

Pièces fournies :

REMARQUE : Toutes les pièces fournies pour l’installation se

trouvent dans l’insert en carton dans le panier du lave-linge.

Clé à molette ou clé

hexagonale de 14 mm (9/16")

102 mm

min

(4")

Cale en bois

Pince avec ouverture

jusqu’à 44,5 mm (1¾")

Optional tools:

Niveau

Règle ou mètre ruban

Attache-câble

Tuyaux d’arrivée d’eau

avec rondelles plates

Prises et boîtier de

protection du branchement

Tuyau d’évacuation avec

bride

Raccord en “Y”

Autres pièces : (Non fournies avec le lave-linge)

Il se peut que l’installation nécessite des pièces supplémentaires.

Pour commander, contacter soit le marchand auprès duquel la

sécheuse a été achetée, soit un service d’entretien autorisé.

Lampe de poche Seau

10

Si vous avez : Si vous avez :

Un égout surélevé Tuyau de vidange standard de 76 L

(20 gal.) de 990 mm (39") de haut ou

évier de décharge, pompe de puisard

et connecteurs (disponibles chez les

vendeurs de matériel de plomberie

locaux)

Tuyau de rejet à Adaptateur pour tuyau rigide de rejet

l’égout rigide à l’égout rigide de diamètre 51 mm (2")

à 25 mm (1") Pièce numéro 3363920

Ensemble de connexion, pièce

numéro 285835

Un tuyau de vidange Tuyau de vidange supplémentaire,

trop court pièce numéro 285863

Ensemble de connexion pièce

numéro 285835

Le système d’évacuation Protecteur de canalisation,

obstrué par de la charpie pièce numéro 367031

Ensemble de connexion, pièce

numéro 285835

Installation dans un encastrement ou un placard

76 mm

(3")

356 mm

(14" max.)

126 mm

(5")

432 mm

(17")

310 cm

(48 in.2)

155 cm

(24 in.2)

2

2

EXIGENCES D’EMPLACEMENT

Le choix d’un emplacement approprié pour le lave-linge en

améliore le rendement et réduit au minimum le bruit et le

“déplacement” possible du lave-linge. Le lave-linge peut être

installée dans un sous-sol, une salle de buanderie, un placard

ou un encastrement.

699 mm

1

(27

1067 mm

(42")

Il vous faudra :

n

Un chauffe-eau réglé à 49° C (120°F).

n

Une prise électrique reliée à la terre et située à moins de

1,2 m (4 pi) du cordon d’alimentation situé à l’arrière du

lave-linge.

n

Des robinets d’eau chaude et d’eau froide situés à moins

de 0,9 m (3 pi) des électrovannes de remplissage d’eau

chaude et d’eau froide situées sur le lave-linge et une pression

d’eau de 138 à 690 kPa (20-100 lb/po2).

n

Un plancher de niveau avec une pente maximale de 25 mm

(1") sous l’ensemble du lave-linge. L’installation sur de la

moquette n’est pas recommandée.

n

Un plancher capable de supporter le poids total de 143 kg

(315 lb) du lave-linge (eau et charge comprises).

IMPORTANT : Ne pas installer, remiser ou faire fonctionner

le lave-linge à un emplacement où il sera exposé aux

intempéries ou à des températures inférieures à 0°C (32°F). De

l’eau restée dans le lave-linge après utilisation peut causer des

dommages à basse température. Voir “Entretien du lave-linge”

dans les Instructions d’utilisation du lave-linge pour des

renseignements sur l’hivérisation.

C’est à l’utilisateur qu’incombe la responsabilité de réaliser

une installation correcte.

/2")

686 mm

(27")

25 mm

25 mm

(1")

(1")

76 mm

(3")

Les dimensions représentent les dégagements recommandés

permis, hormis pour les ouvertures de ventilation de la porte

du placard qui correspondent aux dimensions minimales

nécessaires. Ce lave-linge a été testé pour une installation

avec des dégagements de 0 mm (0") sur les côtés. On peut

éventuellement laisser davantage de dégagement pour faciliter

l’installation et l’entretien, et des distances de séparation pour

les appareils ménagers voisins et des dégagements pour les

murs, portes et plinthes. Ajouter un espace supplémentaire de

25 mm (1") de tous les côtés du lave-linge pour réduire le

transfert de bruit. Si l’on installe une porte de placard ou une

porte à persiennes, des ouvertures d’aération au sommet et au

bas de la porte sont nécessaires.

SYSTÈME DE VIDANGE

Le système de vidange du lave-linge peut être installé à

l’aide d’un conduit d’évacuation au plancher, un tuyau de

rejet à l’égout au plancher ou mural ou un évier de buanderie.

Sélectionner la méthode à utiliser.

Système de vidange avec tuyau de rejet à l’égout

au plancher

114 mm

(4,5")

Diamètre minimal pour un tuyau de rejet à l’égout : 51 mm (2")

Capacité minimale d’acheminement : 64 L (17 gal.) par minute.

Le sommet du tuyau de rejet à l’égout doit avoir une hauteur d’au

moins 990 mm (39"); ne pas l’installer à plus de 1,22 m (48") du

bas du lave-linge. Si l’on doit l’installer à plus de 1,22 m (48") de

hauteur, un système de pompe de puisard est nécessaire.

990 mm

(39")

11

Loading...

Loading...