Whirlpool 4GWED4750, 4GWED4900, 4GWGD4900, 4GMEDC100, 4GMEDC300 Installation Instructions

...

ELECTRIC OR GAS DRYER

INSTALLATION INSTRUCTIONS - 29" WIDE MODELS

INSTRUCTIONS D’INSTALLATION DU SECHE-LINGE

ELECTRIQUE OU A GAZ - MODELES DE LARGEUR 29'' (74 CM)

SECADORA A GAS O ELÉCTRICA INSTRUCCIONES DE

INSTALACIÓN - MODELOS DE 29" DE ANCHO

Table of Contents

DRYER SAFETY .........................................................................2

INSTALLATION REQUIREMENTS ............................................. 3

Tools and Parts .................................................................. 3

Location Requirements .....................................................4

Electrical Requirements....................................................5

Gas Requirements ............................................................. 5

Install Leveling Legs .......................................................... 6

Electrical Connection ........................................................ 7

Table des matières

SECURITE DU SECHE-LINGE ................................................ 19

EXIGENCES D’INSTALLATION ...............................................20

Outillage et pièces ........................................................... 20

Exigences d’emplacement ............................................. 21

Spécications électriques .............................................. 22

Exigences concernant l’alimentation en gaz ................ 23

Installation des pieds de nivellement ............................ 24

Raccordement électrique ............................................... 25

Índice

SEGURIDAD DE LA SECADORA ............................................ 38

REQUISITOS DE INSTALACIÓN ............................................. 39

Piezas y herramientas ..................................................... 39

Requisitos de ubicación ................................................. 40

Requisitos eléctricos ...................................................... 41

Requisitos de gas ............................................................ 42

Instalación de las patas niveladoras ............................. 42

Conexión eléctrica .......................................................... 43

VENTING ................................................................................... 10

Venting Requirements .....................................................10

Plan Vent System ............................................................. 11

Install Vent System .......................................................... 12

Make Gas Connection ..................................................... 13

Connect Vent ...................................................................13

Level Dryer ....................................................................... 14

COMPLETE INSTALLATION CHECKLIST .............................. 14

REVERSE DOOR SWING (OPTIONAL) ................................... 15

TROUBLESHOOTING .............................................................. 18

EVACUATION ...........................................................................29

Exigences concernant l’evacuation ............................... 29

Planication du système d’evacuation .......................... 30

Installation du circuit d’evacuation ................................31

Raccordement au gaz ..................................................... 31

Raccordement du conduit d’evacuation ....................... 32

Réglage de l’aplomb du sèche-linge ............................. 33

ACHEVER L’INSTALLATION - LISTE DE VERIFICATION ...... 33

INVERSION DU SENS DE L’OUVERTURE

DE LA PORTE (FACULTATIF) ................................................... 34

DEPANNAGE ............................................................................37

VENTILACIÓN .......................................................................... 46

Requisitos de ventilación................................................ 46

Planicación del sistema de ventilación ....................... 47

Instalación del sistema de ventilación .......................... 48

Conexión del suministro de gas .....................................49

Conexión del ducto de escape ....................................... 50

Nivelación de la secadora .............................................. 50

LISTA DE CONTROL DE LA INSTALACIÓN TERMINADA ....51

CAMBIO DEL SENTIDO DE ABERTURA

DE LA PUERTA (OPCIONAL)................................................... 51

SOLUCIÓN DE PROBLEMAS .................................................. 55

W10454274C

4GWED4750

4GWED4900

4GWGD4900

4GMEDC100

4GMEDC300

4GNED4400

4GNED4600

4GAED4900

DRYER SAFETY

2

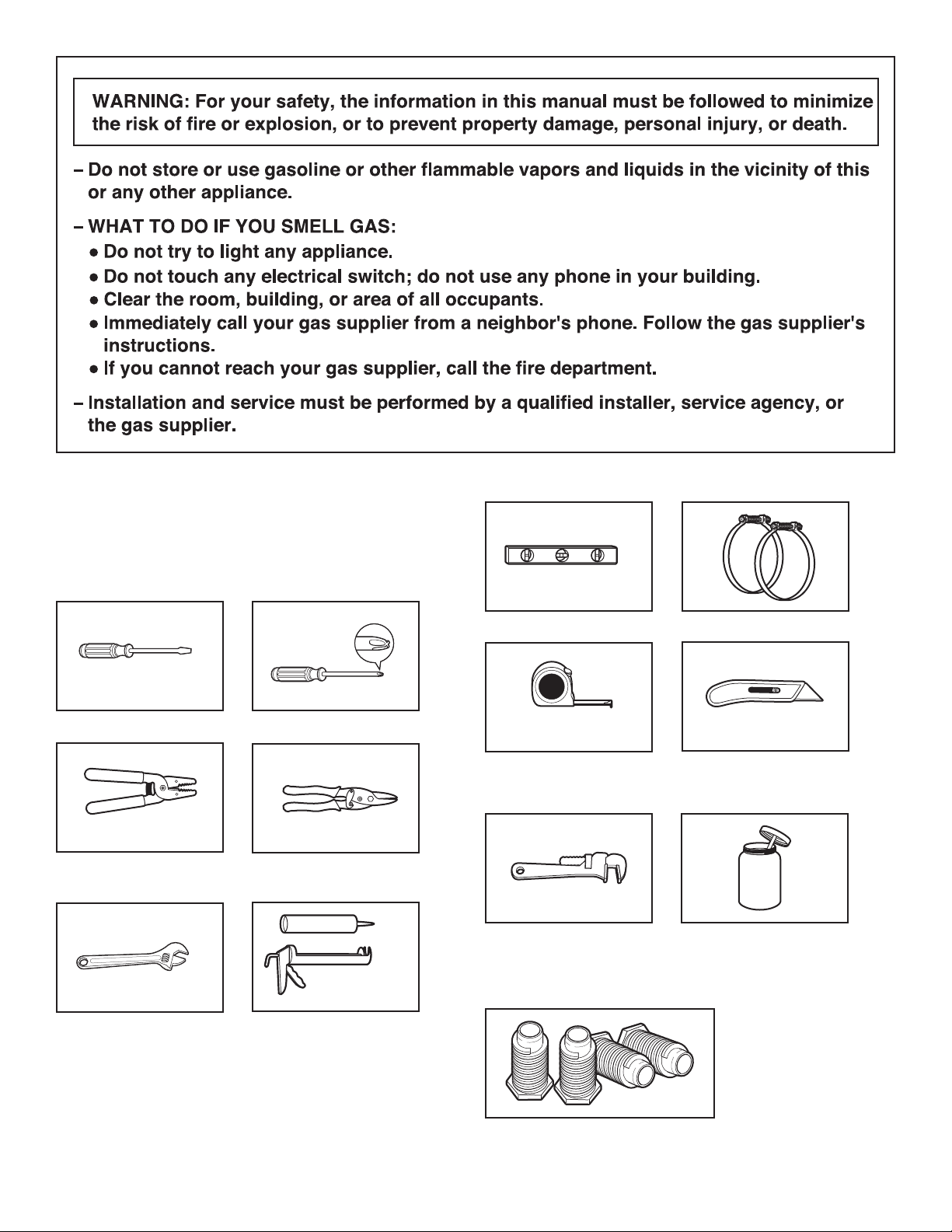

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed for all installations:

Flat-blade screwdriver

Wire stripper

(direct wire installations)

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

#2 Phillips screwdriver

Tin snips

(new vent installations)

Caulking gun and

compound (for installing

new exhaust vent)

Level

Tape measure

Vent clamps

Utility knife

Tools needed for gas installations:

Adjustable pipe wrench

that opens to 8" (204 mm)

or 10" (254 mm)

Pipe joint compound

resistant to LP gas

Parts supplied (all models):

Leveling legs (4)

Parts package is located in dryer drum. Check that all parts

are included.

3

AB

CD

mm)

Parts needed:

Check local codes. Check existing electrical supply and venting,

and read “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL listed 30-amp power supply cord, rated 230 volt

minimum. The cord should be type SRD or SRDT and be

at least 4 ft (1.22 m) long. The wires that connect to the

dryer must end in ring terminals or spade terminals with

upturned ends.

■ A UL listed strain relief.

For gas installation:

Check local codes and gas supplier, and read electrical, gas,

and venting requirements before purchasing parts.

Gas supply line must have:

■ Shutoff valve.

Rigid gas supply line must be:

■ Minimum 1/2" (12.5 mm) ID pipe.

Flexible gas supply line must be:

■ Minimum 3/8" (10 mm) ID approved exible hose.

■ Level oor with maximum slope of 1" (25 mm) under entire

dryer. (If slope is greater than 1" [25 mm], install Extended

Dryer Feet Kit, Part Number 279810.) If not level, clothes

may not tumble properly and automatic sensor cycles may

not operate correctly.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, or sleeping quarters.

Contact your local building inspector.

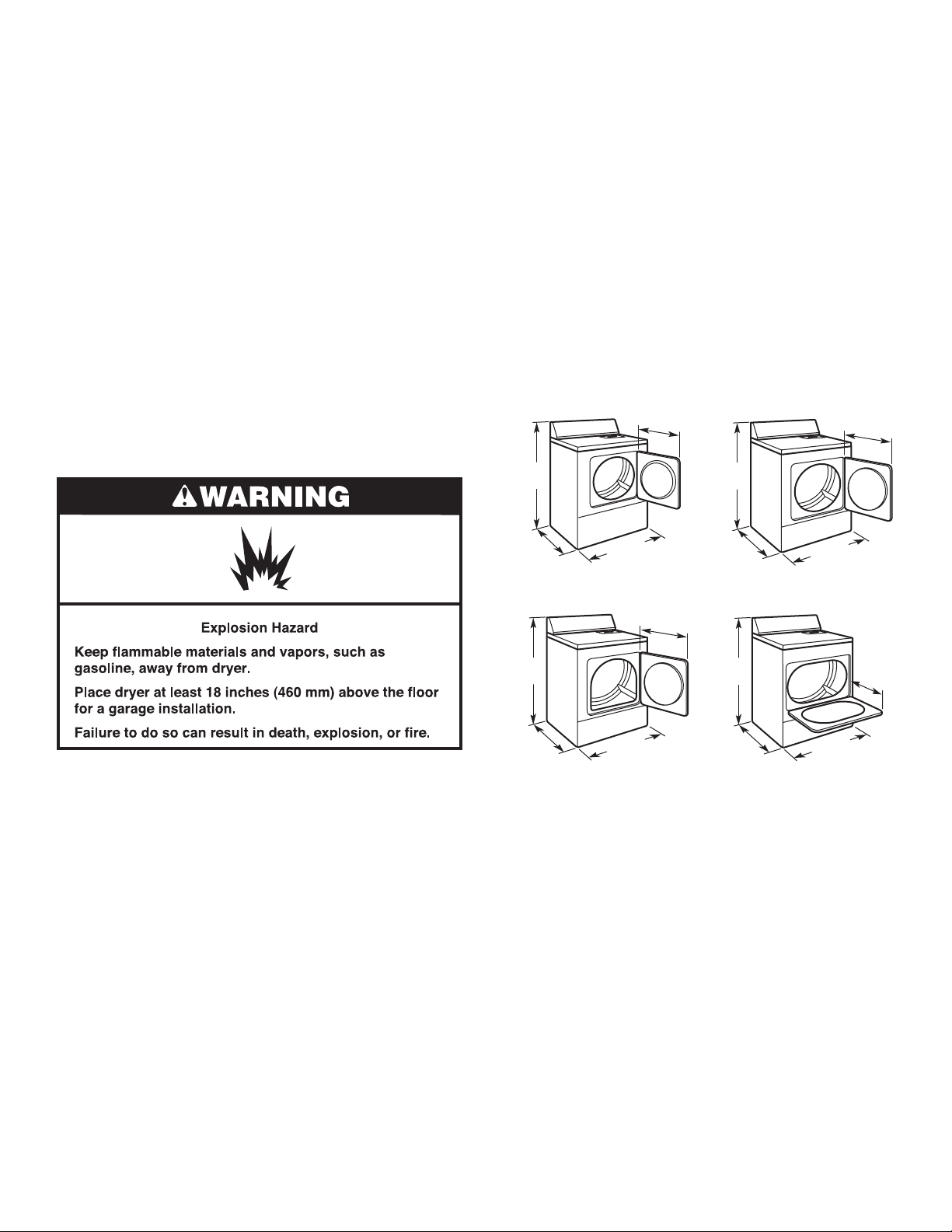

Installation clearances:

The location must be large enough to allow the dryer door to

open fully.

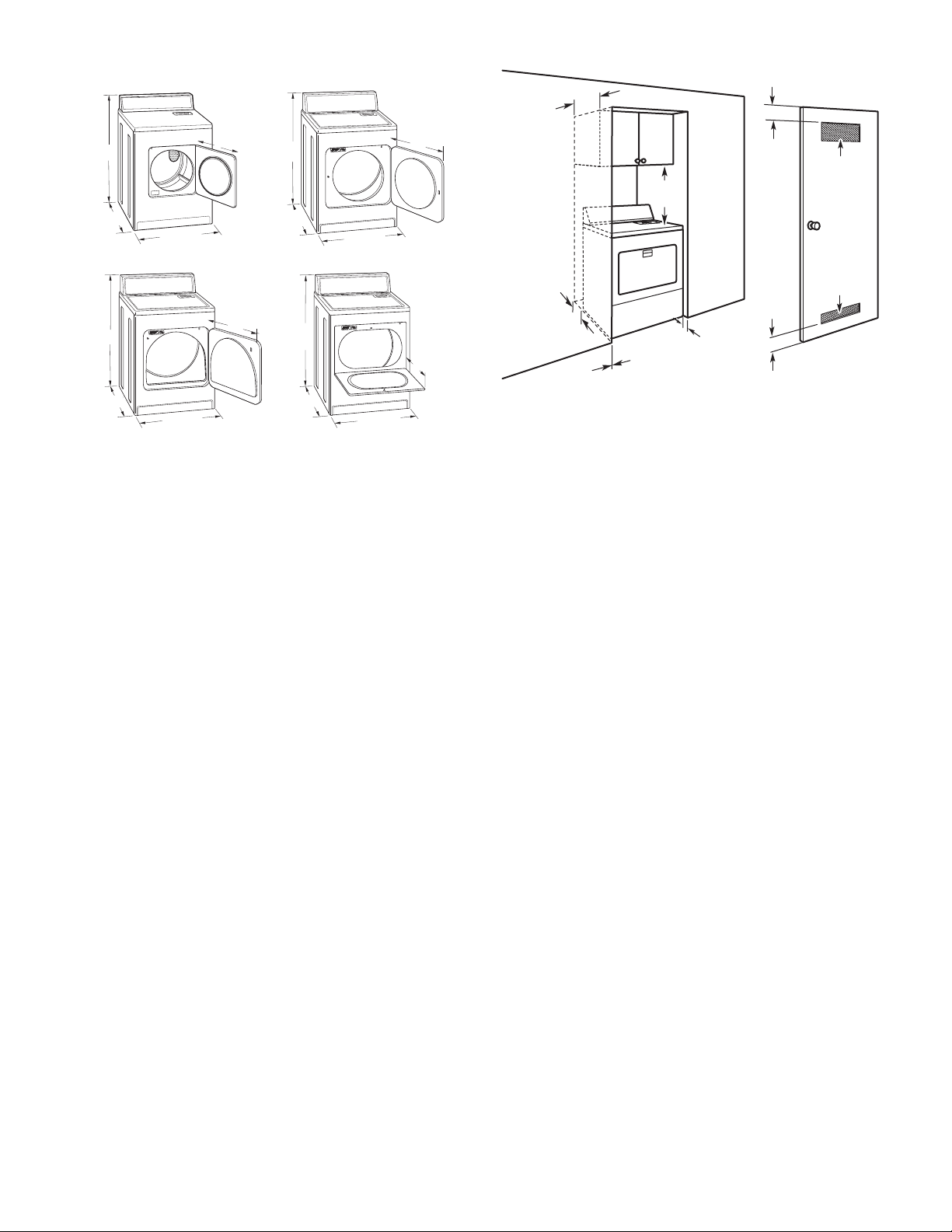

Dryer Dimensions

433/8"

(1102 mm)

151/4"

(387 mm)

433/8"

(1102 mm)

223/4"

(578 mm)

L.P. Gas Conversion:

A gas conversion kit, is available for purchase from your dealer.

Full instructions are supplied with the kit. Conversion must be

made by a competent technician.

Additional parts may be required, depending on your installation.

Check local codes. Check existing venting and electrical and gas

supply. Read “Electrical Requirements,” “Gas Requirements,”

and “Venting Requirements” before purchasing parts.

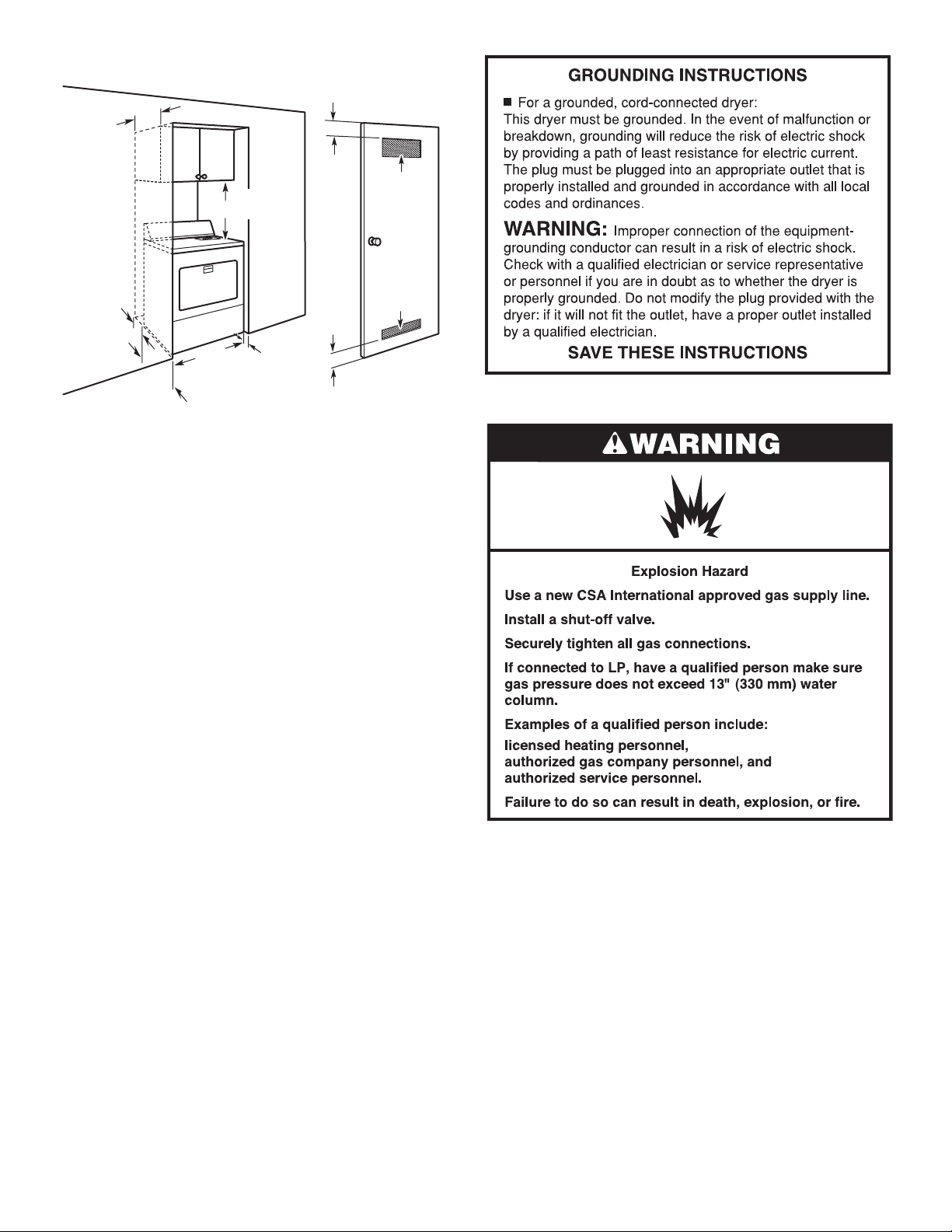

LOCATION REQUIREMENTS

You will need:

■ A location allowing for proper exhaust installation.

See “Venting Requirements.”

■ A separate 30 amp circuit.

■ If you are using power supply cord, a grounded electrical

outlet located within 2 ft (610 mm) of either side of dryer.

See “Electrical Requirements.”

■ A sturdy oor to support the total weight (dryer and load)

of 200 lbs. (90.7 kg). The combined weight of a companion

appliance should also be considered.

4

*26"

(660 mm)

433/8"

(1102 mm)

*273/4"

(705 mm)

29"

(737 mm)

223/4"

(578 mm)

29"

(737 mm)

A. Small opening side-swing door

B. Large opening side-swing door

C. Wide opening side-swing door

D. Wide opening hamper door

*273/4"

(705 mm)

433/8"

(1102 mm)

*273/4"

(705 mm)

29"

(737 mm)

133/4"

(349

29"

(737 mm)

*Most installations require a minimum 5" (127 mm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

Minimum spacing for recessed area or closet

installation

The dimensions shown are for the minimum spacing allowed.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

oor moldings.

■ Additional spacing of 1" (25 mm) on all sides of the dryer

is recommended to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings

are acceptable.

■ Companion appliance spacing should also be considered.

14"max.

(356 mm)

3"

5"

(127 mm)

(457 mm)

(457 mm)

29"

(737 mm)

18"

18"

(25 mm)

(76 mm)

3"

(76 mm)

1"

2

48 in.

(310 cm2)

2

24 in.

(155 cm2)

27¾"

(705 mm)

A. Recessed area

B. Side view - closet or conned area

C. Closet door with vents

*Additional spacing recommended

ELECTRICAL REQUIREMENTS

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with all local codes and ordinances.

■ To supply the required 3, single phase, 230 volt, 60 Hz, AC

only electrical supply on a separate 30-amp circuit (15 or 20

amp circuit for gas dryers), fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL listed 30-amp power supply cord, rated 230 volt

minimum. The cord should be type SRD or SRDT and be

at least 4 ft (1.22 m) long. The wires that connect to the

dryer must end in ring terminals or spade terminals with

upturned ends.

■ A UL listed strain relief.

Connecting by direct wire:

Power supply cable must match power supply and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with exible metallic conduit. All

current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft (1.52 m) long.

GAS REQUIREMENTS

OBSERVE ALL GOVERNING CODES AND

ORDINANCES.

Gas supply:

Check that dryer is equipped with the correct burner for the

particular type of gas supply. Burner information will be found

on the model/serial rating plate in the door well of the dryer. If

this information does not agree with the type of gas available,

see your dealer.

5

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certied for use with L.P. (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specied on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a qualied service technican.

Gas conversion kits are available for purchase from your dealer.

Full instructions are supplied with the kit.

Supply Line Requirements

Provide a rigid gas supply line to the dryer location. It should be

minimum 1/2" (12.5 mm) ID. When acceptable to the gas supplier

and local codes, 3/8" (10 mm) ID rigid supply line may be used

for lengths under 20 ft (6.1 m). Pipe-joint compounds resistant to

the action of L.P. gas must be used.

Gas connection to the dryer itself should be made by means of

a exible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 3/8" (10 mm) ID.

A means of restraint should be used between the appliance and

the wall to prevent straining of the rigid gas supply when the

appliance is moved. An appropriate length of chain and a wall

hook is recommended.

The dryer gas inlet connection is a 3/8" (10 mm) NPT thread. An

adapter is supplied for conversion to standard ISO.228-1 thread

3/8" BSP (10 mm).

Check for leaks by using an approved noncorrosive leak

detection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the gas

valve within the dryer, accessible after removal of the lower front

panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

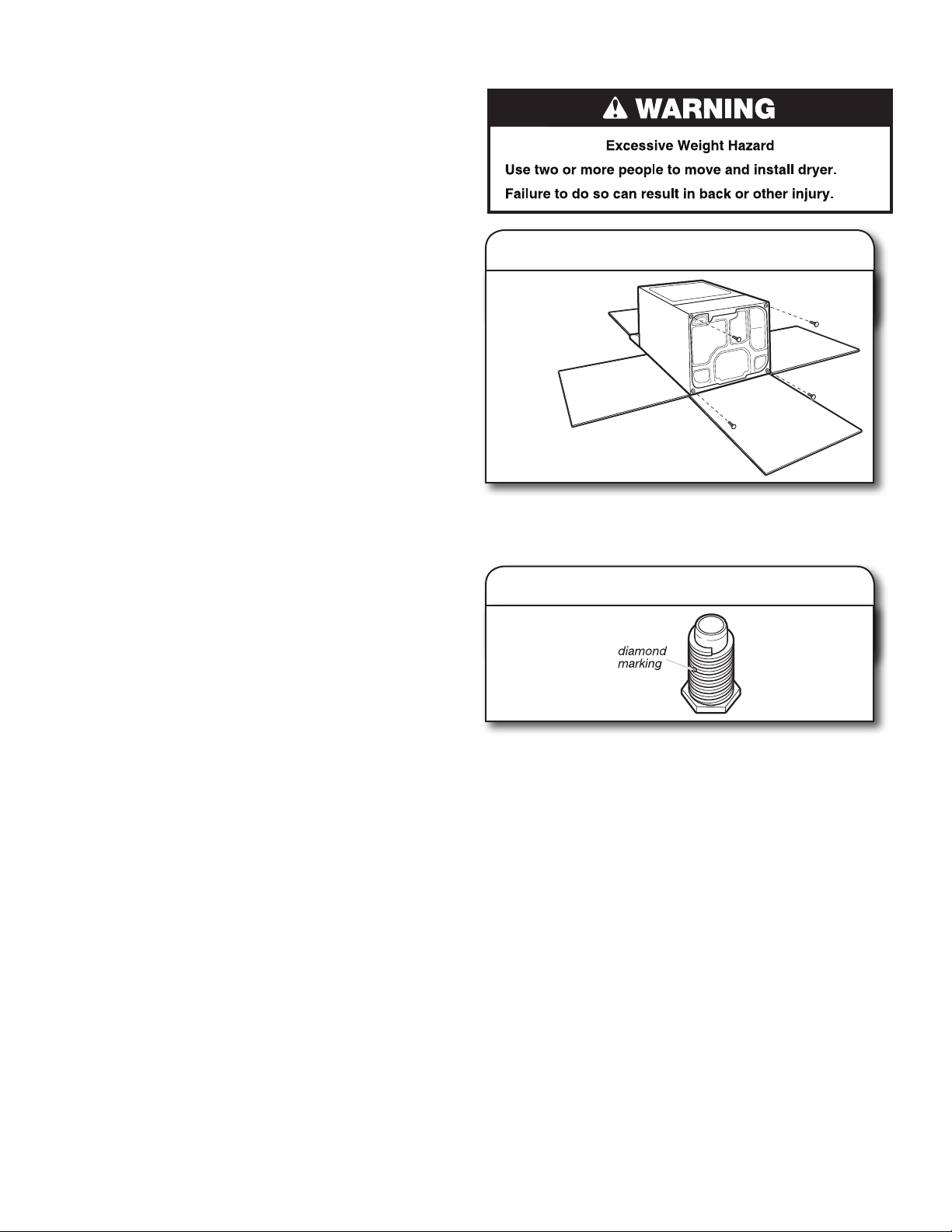

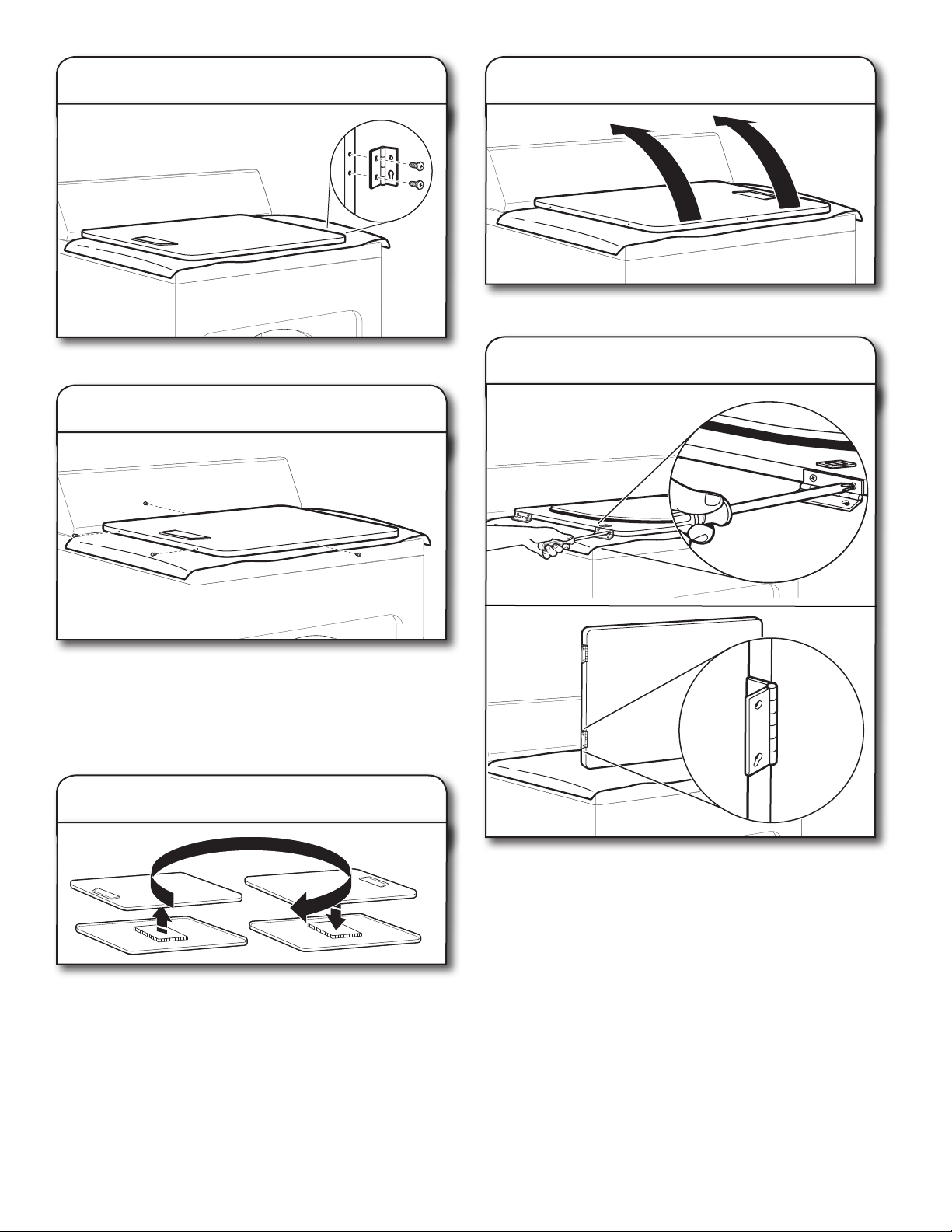

INSTALL LEVELING LEGS

Prepare dryer for leveling legs

1.

To avoid damaging oor, use a large at piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

Screw in leveling legs

2.

Examine leveling legs, nd diamond marking. Screw legs into

leg holes by hand, use a wrench to nish turning legs until

diamond marking is no longer visible.

Now stand the dryer on its feet. Slide the dryer until it is

close to its nal location. Leave enough room for electrical

connection and to connect the exhaust vent.

6

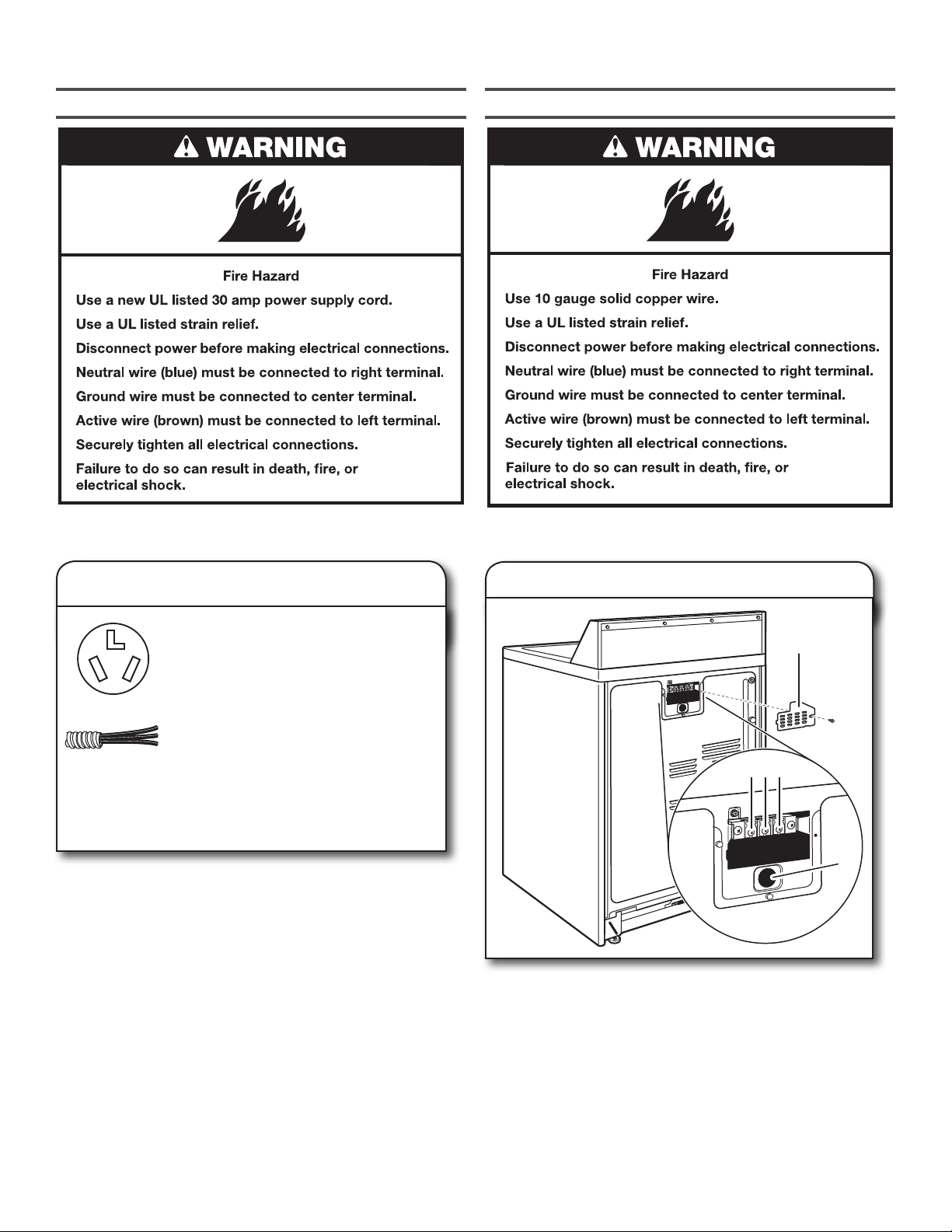

ELECTRICAL CONNECTION

Power Supply Cord Direct Wire

Electrical Connection Options

1. Choose electrical connection type

Power supply cord (NEMA Type 10-30R):

Go to steps 1-2 on page 8 for power supply

cord strain relief: then steps 3-5 for “Power

Supply Cord Connection” section. Then go

to “Venting Requirements.”

Direct wire connection: Go to steps 1-2

on page 8 for direct wire strain relief: then

steps 3-7 for “Direct Wire Connection”

section. Then go to “Venting Requirements.”

NOTE: If local codes do not permit connection of a

cabinet-ground conductor to neutral wire, go to “Direct

Wire” section. This connection may be used with either

a power supply cord or a direct wire connection.

2. Remove terminal block cover

A

BCD

E

Before you start, disconnect power. Remove terminal block

cover (A).

A. Terminal block cover

B. Active screw

C. Ground screw

D. Neutral screw

E. Strain relief hole

7

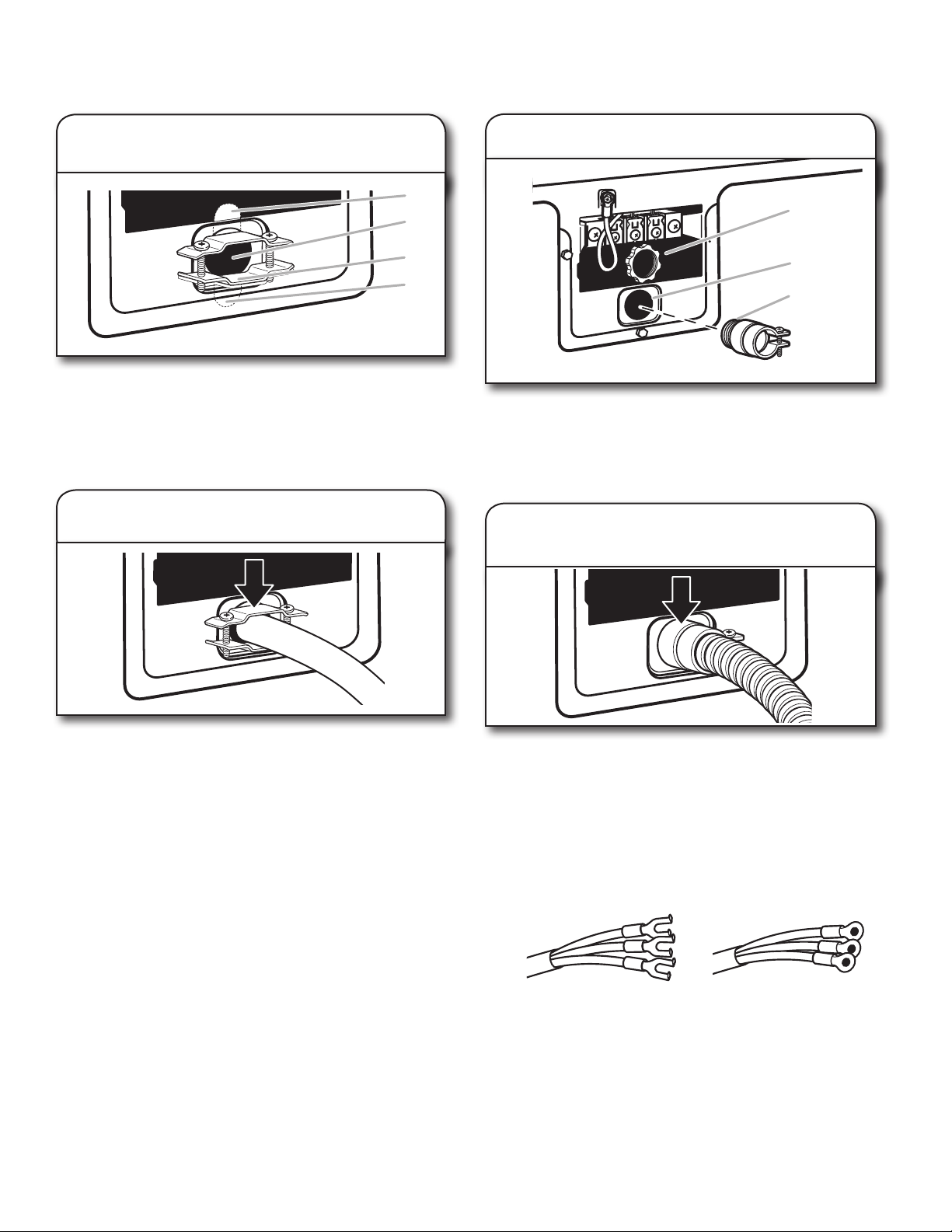

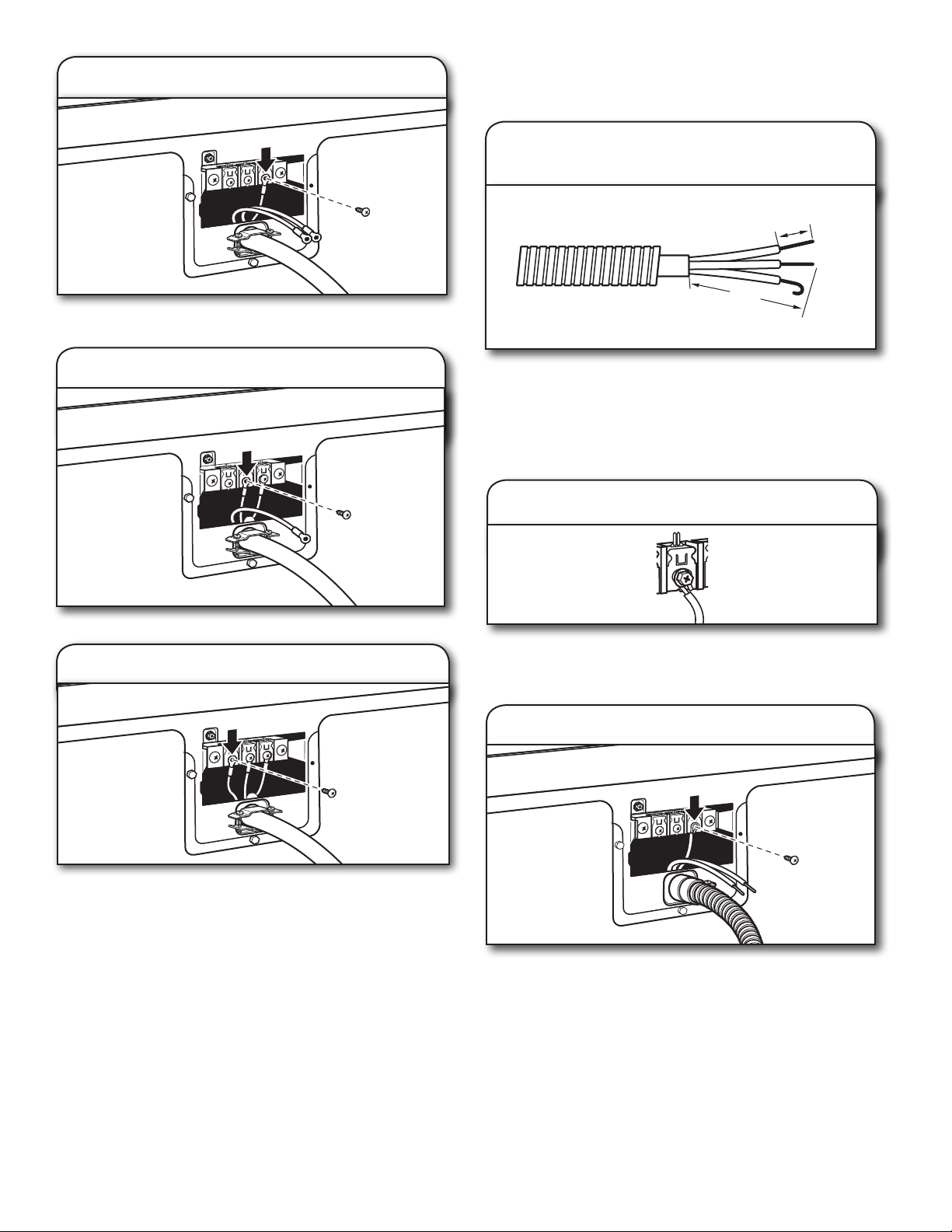

Install Strain Relief

Power supply cord strain relief

Direct wire strain relief

Attach power supply cord

1.

strain relief

A

B

C

D

Remove the screws from a 3/4" (19 mm) UL listed strain relief

(UL marking on strain relief). Put the tabs of the two clamp

sections (C) into the hole (B) below the terminal block opening

so that one tab is pointing up (A) and the other is pointing

down (D), and hold in place. Tighten strain relief screws just

enough to hold the two clamp sections (C) together.

Attach power supply cord

2.

to strain relief

1. Attach direct wire strain relief

A

B

C

Unscrew the removable conduit connector (A) and any screws

from a 3/4" (19 mm) UL listed strain relief (UL marking on strain

relief). Put the threaded section of the strain relief through the

hole (B) below the terminal block opening. Reaching inside

the terminal block opening, screw the removable conduit

connector onto the strain relief threads (C).

2. Attach direct wire cable

to strain relief

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the

strain relief. The strain relief should have a tight t with the

dryer cabinet and be in a horizontal position. Do not further

tighten strain relief screws at this point.

Go to “Power Supply Cord Connection”.

8

Put direct wire cable through the strain relief. The strain relief

should have a tight t with the dryer cabinet and be in a

horizontal position. Tighten strain relief screws.

Go to “Direct Wire Connection”.

Power Supply Cord Connection

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

A B

A. Spade terminal with up turned ends

B. 3/4" (19 mm) UL listed strain relief with ring terminals

3. Connect neutral wire

Connect neutral wire (blue) of power supply cord to the right

terminal screw of the terminal block. Tighten screw.

Connect ground wire

4.

Direct Wire Connection

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

3. Prepare your 3-wire cable for

direct connection

1"

(25 mm)

3½"

(89 mm)

Direct wire cable must have 5 ft (1.52 m) of extra length so

dryer may be moved if needed.

Strip 31/2" (89 mm) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape wire ends

into hooks.

4. Connect wires to terminal block

Connect ground wire to the center terminal. Tighten screw.

5. Connect active wire

Connect active wire (brown) to the left terminal. Tighten screw

and strain relief screws.

Finally, reinsert tab of terminal block cover into slot of dryer

rear panel. Secure cover with hold-down screw. Now, go to

“Venting Requirements”.

To connect wires to terminal block, place hooked end of wire

under terminal block screw, facing to the right, squeeze

hooked end together and tighten screw.

5. Connect neutral wire

Place hooked end of neutral wire (blue) of power supply

cable under the right screw of terminal block (hook facing

right). Squeeze hooked end together. Tighten screw.

9

Connect ground wire

6.

Place hooked end of ground wire power supply cable

under the center terminal block screw (hook facing right).

Squeeze hooked end together and tighten screw.

Connect active wire

7.

VENTING

VENTING REQUIREMENTS

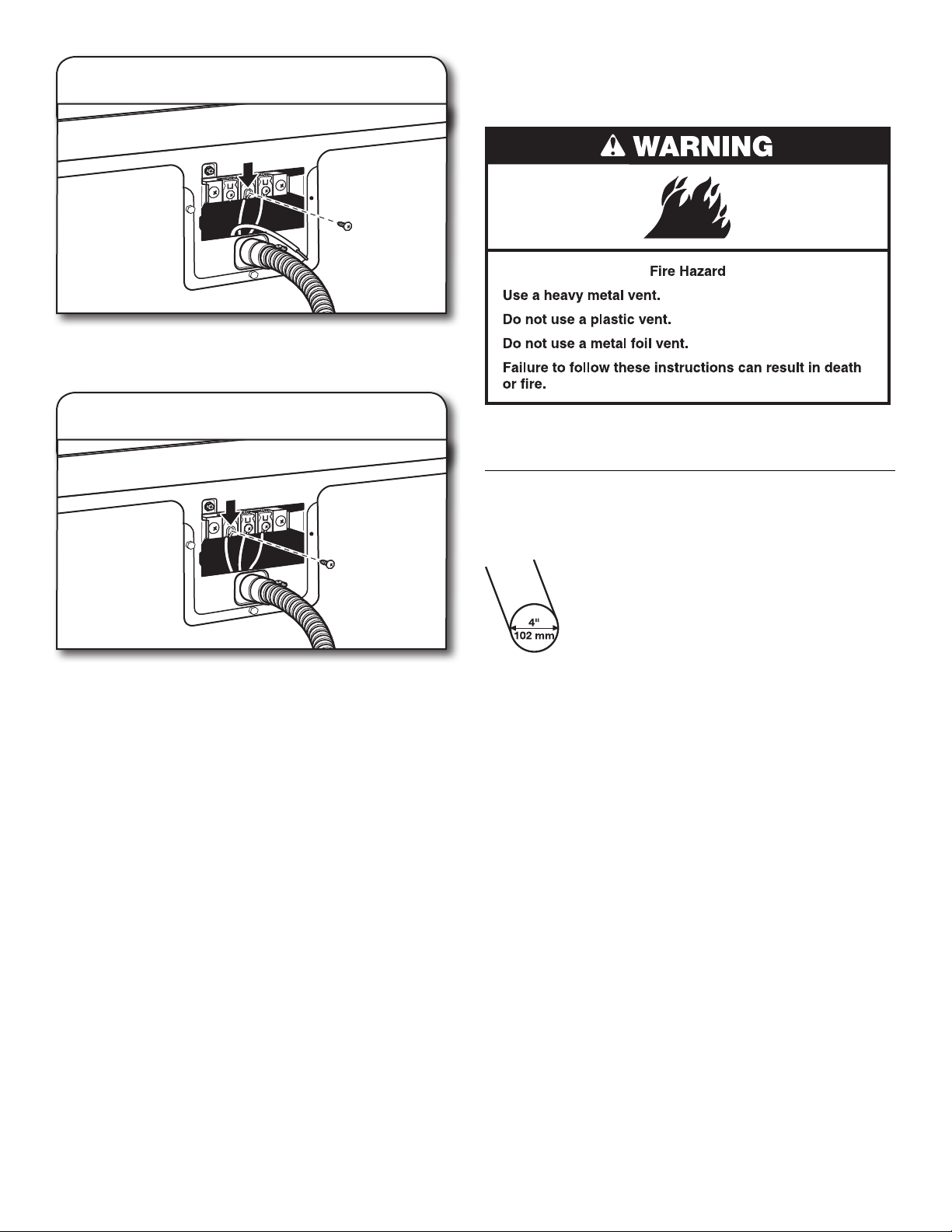

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used for

exhausting.

Place hooked end of the active wire (brown) power supply cable

under the left terminal block screw (hook facing right). Squeeze

hooked end together. Tighten screw and strain relief screw.

Finally, reinsert tab of terminal block cover into slot of dryer rear

panel. Secure cover with hold-down screw. Now, go to

“Venting Requirements”.

■ Only a 4" (102 mm) heavy metal exhaust

vent and clamps may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 7

3

/4 ft (2.4 m).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not plugged

with lint. Replace plastic or metal foil vents with rigid metal or

exible metal vents. Review Vent system chart and if necessary,

modify existing vent system to achieve best drying performance.

10

Exhaust hoods:

B

4"

■ Must be at least 12" (305 mm) from ground or any object that

may obstruct exhaust (such as owers, rocks, bushes, or

snow).

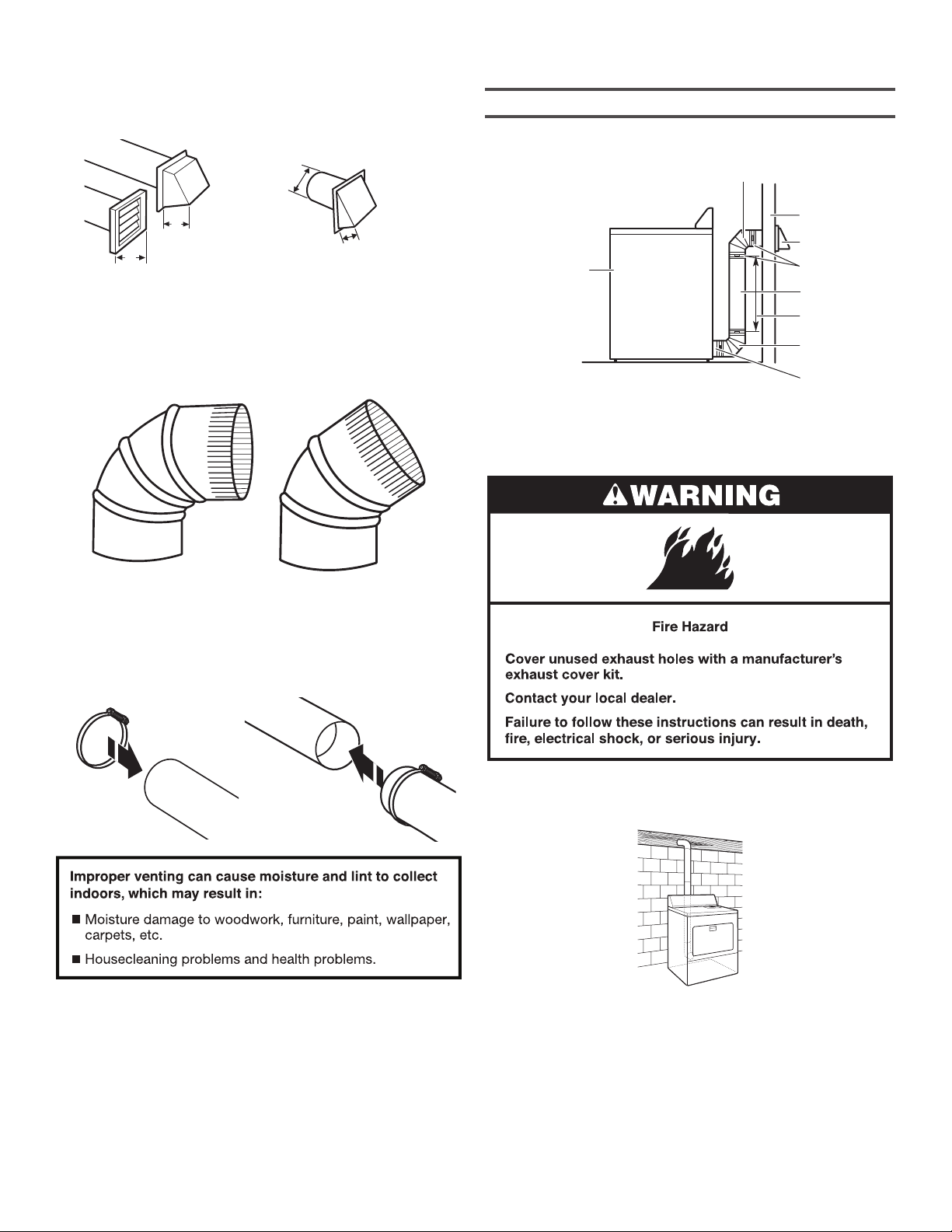

PLAN VENT SYSTEM

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

A

4"

(102 mm)

4"

(102 mm)

Recommended styles:

A. Louvered hood

B. Box hood

(102 mm)

2½"

(64 mm)

Acceptable styles:

C. Angled hood

Elbows:

■ 45° elbows provide better airow than 90° elbows.

Good Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

A

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

B

C

D

E

F

G

B

H

E. Clamps

F. Rigid metal or exible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Standard exhaust installation with rigid or exible

metal vent

11

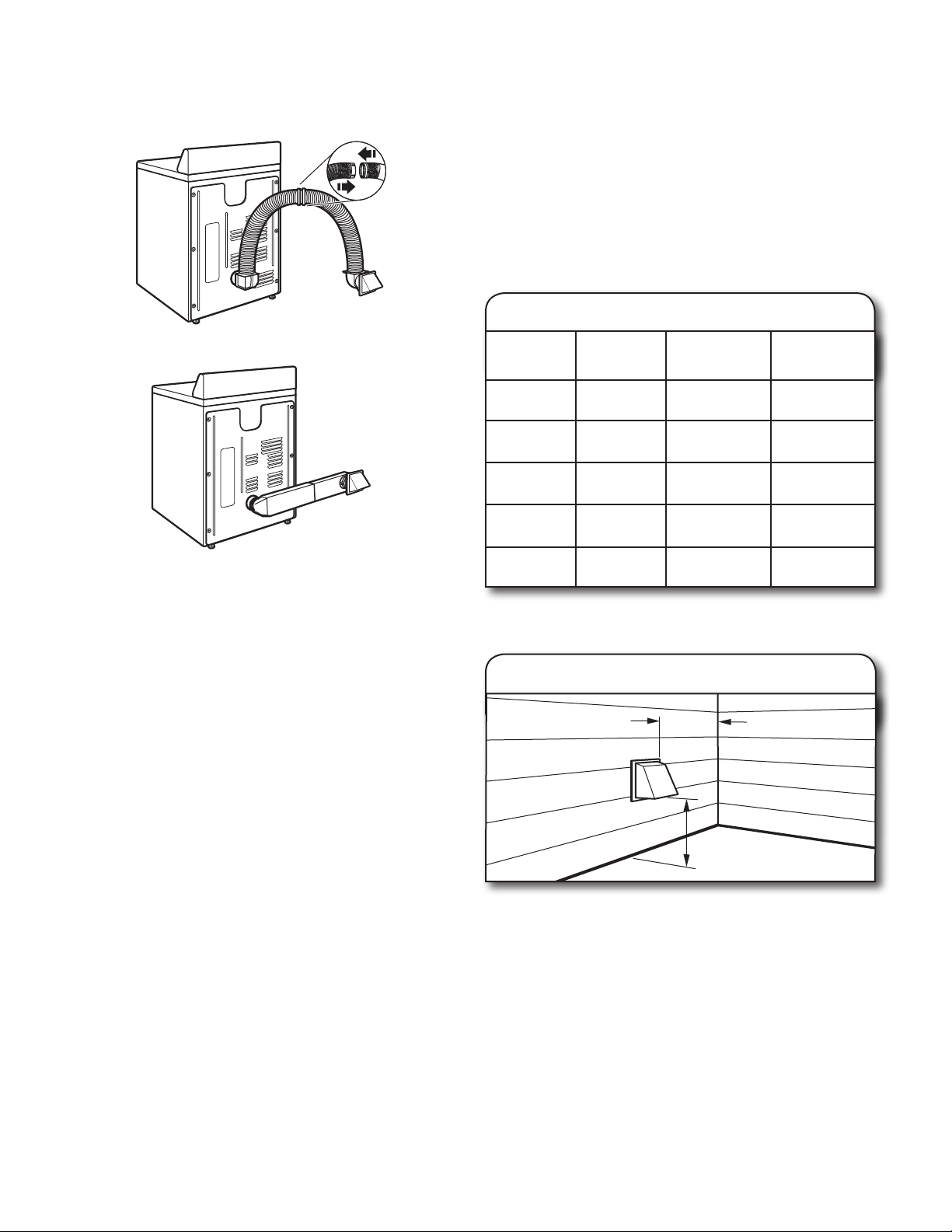

Alternate installations for close clearances

12" min.

(305 mm)

12" min.

(305 mm)

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

Determine vent length and elbows needed for best

drying performance:

■ Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specied

in Vent System Chart. Exhaust systems longer than those

specied will:

■ Shorten life of dryer.

■ Reduce performance, resulting in longer drying times

and increased energy usage.

The Vent System Chart provides venting requirements that

will help achieve best drying performance.

Vent System Chart

Over-The-Top installation (also available with one offset elbow)

Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. To order, please

contact the dealer from whom you purchased your dryer

or an authorized service company.

■ Over-the-Top Installation:

Part Number 4396028

■ Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 4396037 - 0" (0 mm) to 18" (457.2 mm)

mismatch

Number of

90° turns

or elbows

0

1

2

3

4

Type

of vent

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Box/louvered

hoods

64 ft (20 m)

54 ft (16.5 m)

44 ft (13.4 m)

35 ft (10.7 m)

27 ft (8.2 m)

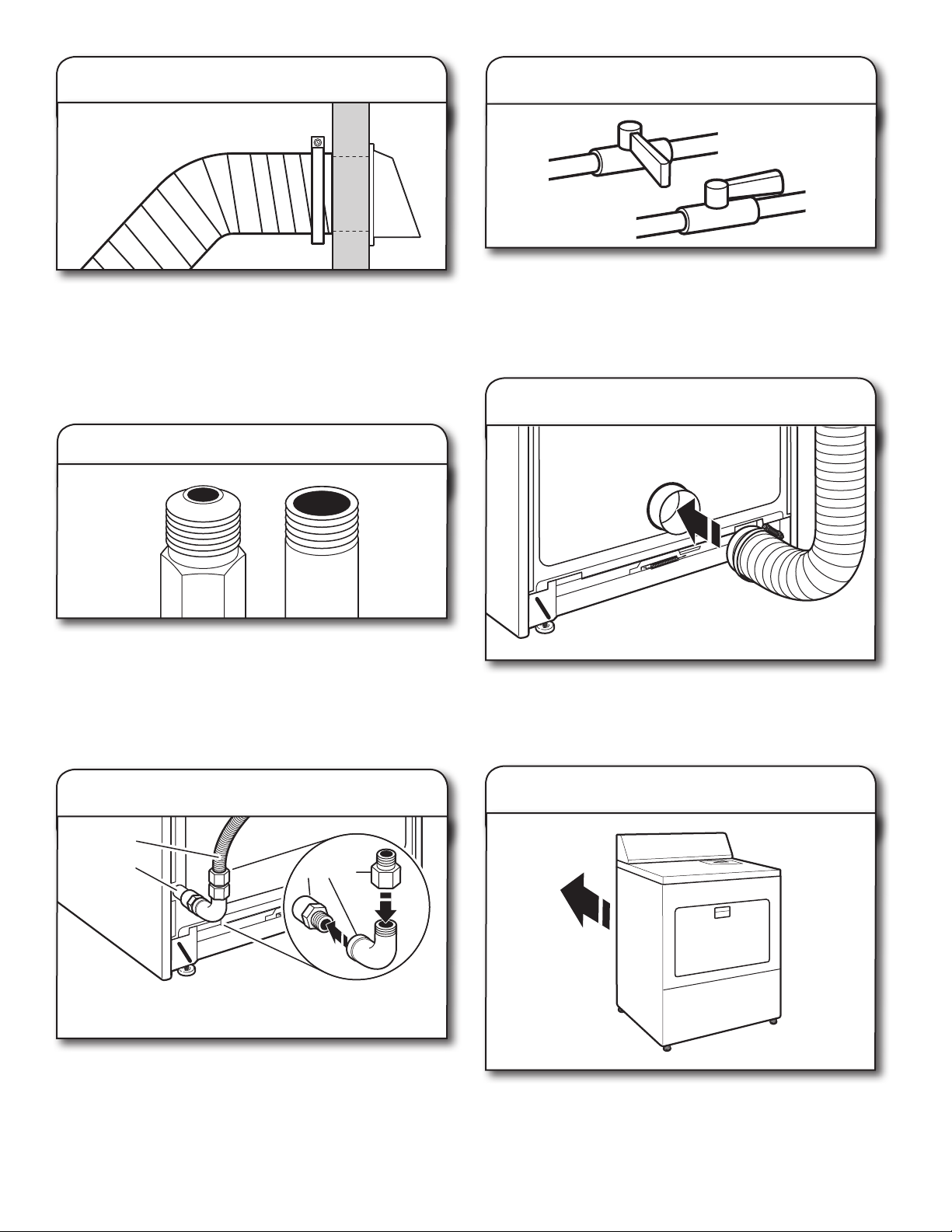

INSTALL VENT SYSTEM

Install exhaust hood

1.

Angled

hoods

58 ft (17.7 m)

48 ft (14.6 m)

38 ft (11.6 m)

29 ft (8.8 m)

21 ft (6.4 m)

Part Number 4396011 - 18" (457.2 mm) to 29" (736.6 mm)

mismatch

Part Number 4396014 - 29" (736.6 mm) to 50" (1270 mm)

mismatch

Determine vent path:

■ Select route that will provide straightest and most direct

path outdoors.

■ Plan installation to use fewest number of elbows and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use as few 90° turns as possible.

12

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

Connect vent to exhaust hood

A

B

CD

E

A

B

2.

Vent must t over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

MAKE GAS CONNECTION

Connect gas supply to dryer

1.

Open shut-off valve

3.

Closed valve

A

Open valve

B

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

CONNECT VENT

Connect vent to exhaust outlet

1.

Flared

male tting

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-ared male ttings. If exible metal

tubing is used, be sure there are no kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON®† tape.

Plan pipe tting connection

2.

A. 3/8" exible gas connector

B. 3/8" dryer pipe

C. 3/8" to ISO thread adapter tting.

D. 3/8" to 3/8" pipe elbow

E. 3/8" pipe-to-are adapter

tting

Non-ared

male tting

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must t over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

Move dryer to nal location

2.

A combination of pipe ttings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

†®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

Move dryer to nal location. Avoid crushing or kinking vent.

After dryer is in place, remove corner posts and cardboard

from under the dryer.

13

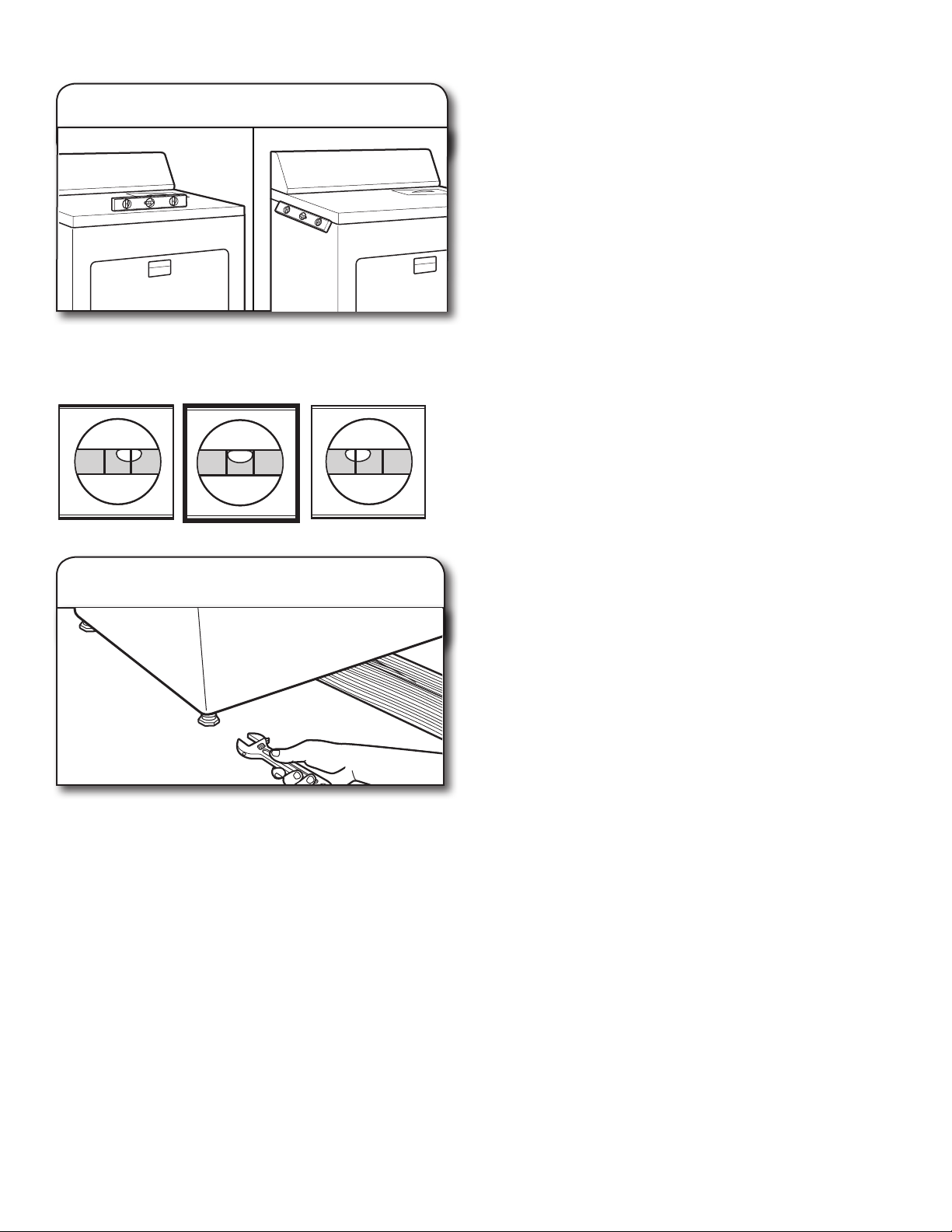

LEVEL DRYER

Level Dryer

1.

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level for the moisture sensing system

to operate correctly.

Not Level LEVEL Not Level

Tighten and adjust leveling legs

2.

If dryer is not level, prop up using a wood block, use wrench

to adjust legs up or down, and check again for levelness.

Once legs are level, make sure all four legs are snug against

the ground before tightening them.

COMPLETE INSTALLATION

CHECKLIST

Check that all parts are now installed. If there is an extra

q

part, go back through steps to see what was skipped.

Check that you have all of your tools.

q

Dispose of/recycle all packaging materials.

q

Check dryer’s nal location. Be sure vent is not crushed

q

or kinked.

For power supply cord installation, plug into an outlet.

q

For direct wire installation, turn on power.

Check that dryer is level. See “Level Dryer”.

q

Remove lm on console and any tape remaining on dryer.

q

Wipe dryer drum interior thoroughly with a damp cloth to

q

remove any dust.

Read “Dryer Use” in your Use and Care Guide.

q

Set the dryer on a full heat cycle (not an air cycle) for

q

20 minutes and start the dryer. (If you have a gas dryer, it is

equipped with an electronic ignition system for the burner

which is fully automatic; no action is needed by the user

(there is no pilot light).

If the dryer will not start, check the following:

■ Controls are set in a running or “On” position.

■ Start button has been pushed rmly.

■ Dryer is plugged into an outlet and/or electrical supply

is on.

■ Household fuse is intact and tight, or circuit breaker has

not tripped.

■ Dryer door is closed.

When the dryer has been running for 5 minutes, open the

q

dryer door and feel for heat. If you feel heat, cancel cycle and

close the door.

If you do not feel heat, turn off dryer, and check the

following:

■ There may be 2 household fuses or circuit breakers for

the dryer. Check that both fuses are intact and tight, or

that both circuit breakers have not tripped. If there is still

no heat, contact a qualied technician.

NOTE: You may notice an odor when the dryer is rst heated.

This odor is common when the heating element is rst used.

The odor will go away.

14

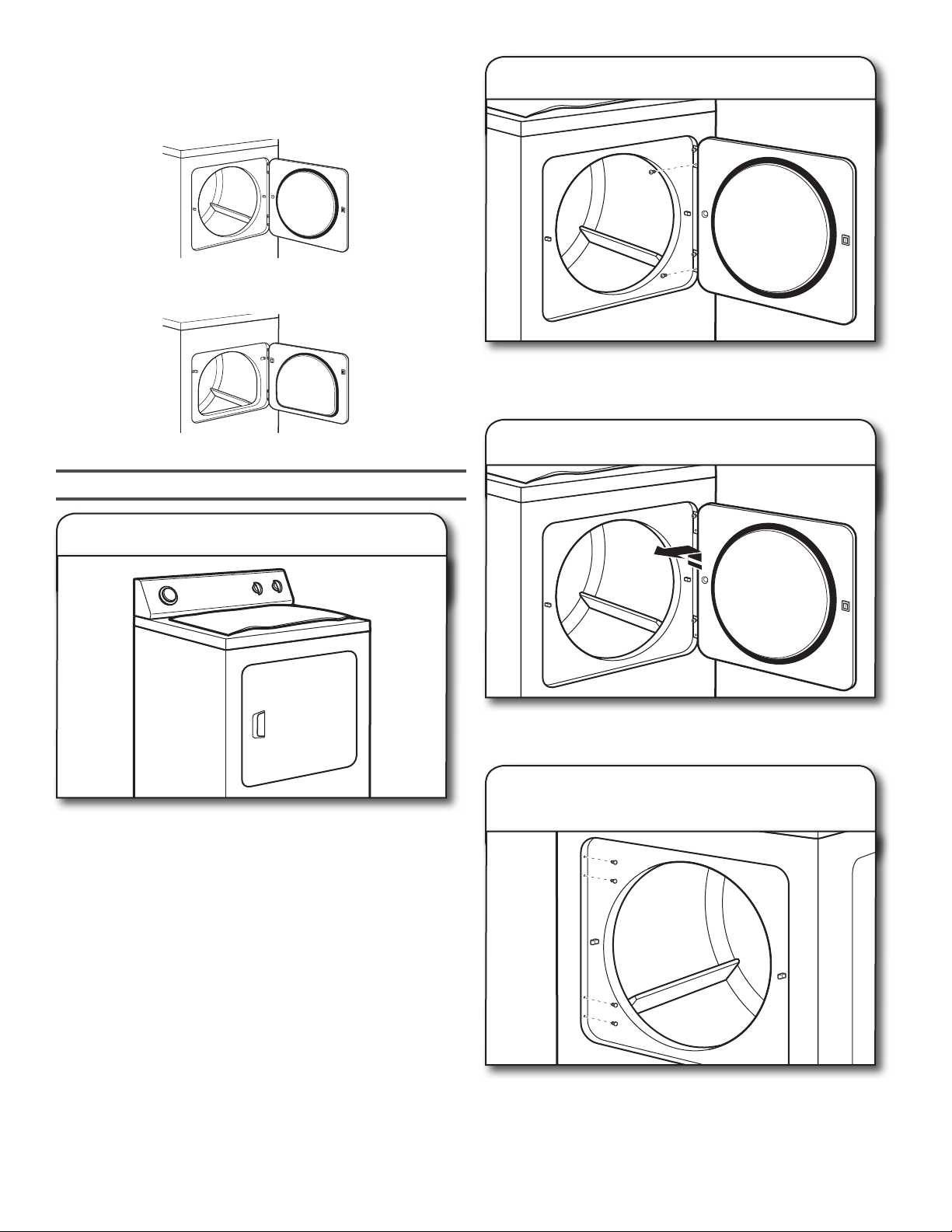

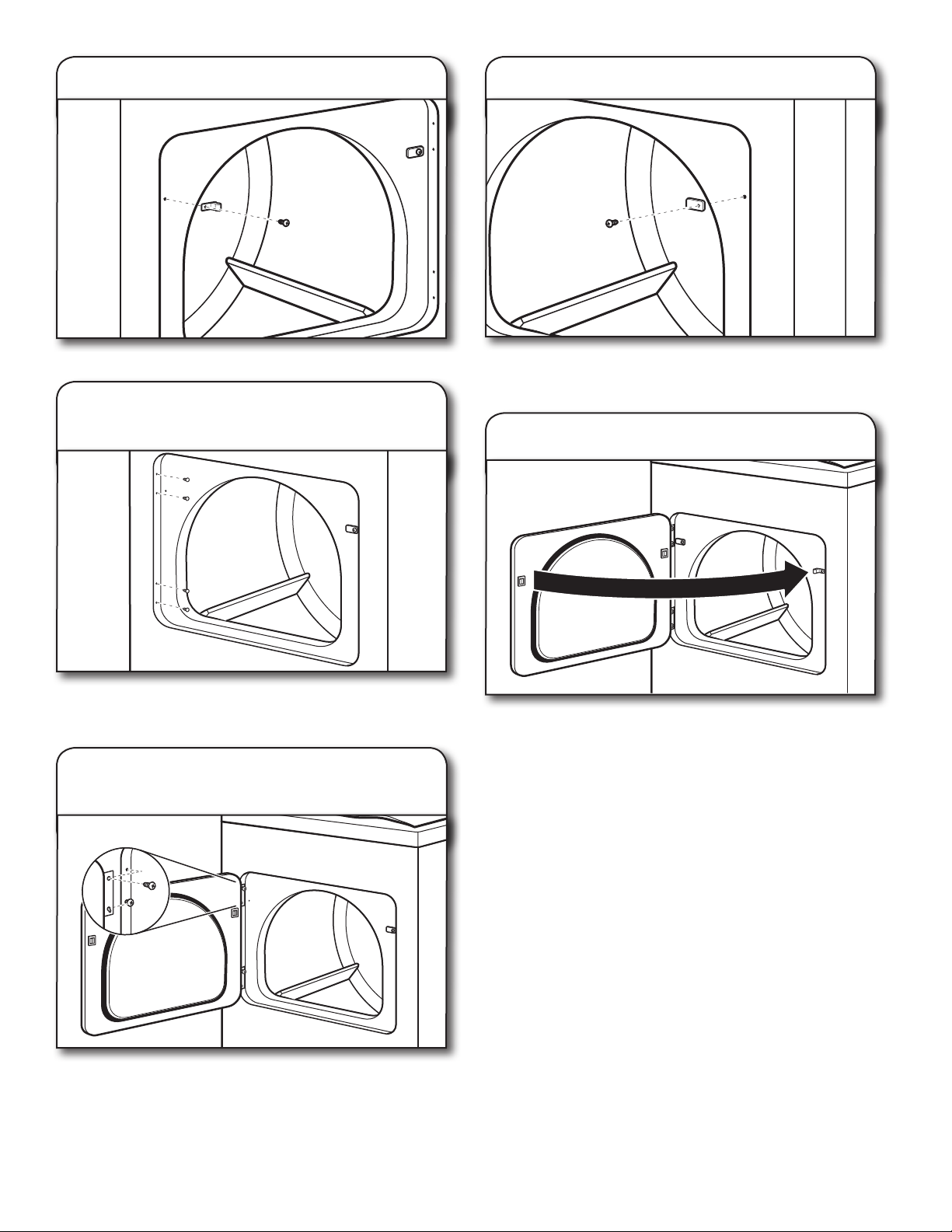

REVERSE DOOR SWING

(OPTIONAL)

If your door is the 29" Large Side-Swing Door,

follow steps 1-6.

If your door is the 29" Super Wide Side-Swing Door,

follow steps 1-13 on page 16.

NOTE: Magnetized screw driver is helpful.

Large Side-Swing Door

Remove bottom screws

2.

Open dryer door. Remove bottom screws from dryer cabinet

side of hinges. Loosen (do not remove) top screws from dryer

cabinet side of hinges.

Lift door off top screws

3.

Place towel on dryer

1.

Place towel on top of dryer to avoid damaging the surface.

Lift door until top screws in cabinet are in large part of hinge

slot. Pull door forward off screws. Set door on top of dryer.

Remove top screws from dryer cabinet.

Remove and transfer hinge

4.

hole plugs

Use a small, at-blade screwdriver to gently remove 4 hinge

hole plugs on left side of dryer cabinet. Insert plugs into hinge

holes on opposite side of dryer cabinet.

15

Insert screws in hinge holes on

5.

dryer cabinet

NOTE: Two people maybe needed to reinstall door.

Insert screws into bottom holes on left side of dryer cabinet.

Tighten screws halfway. Position door so large end of door

hinge slot is over screws. Slide door up so screws are in

bottom of slots. Tighten screws. Insert and tighten top

screws in hinges.

Check door strike alignment

6.

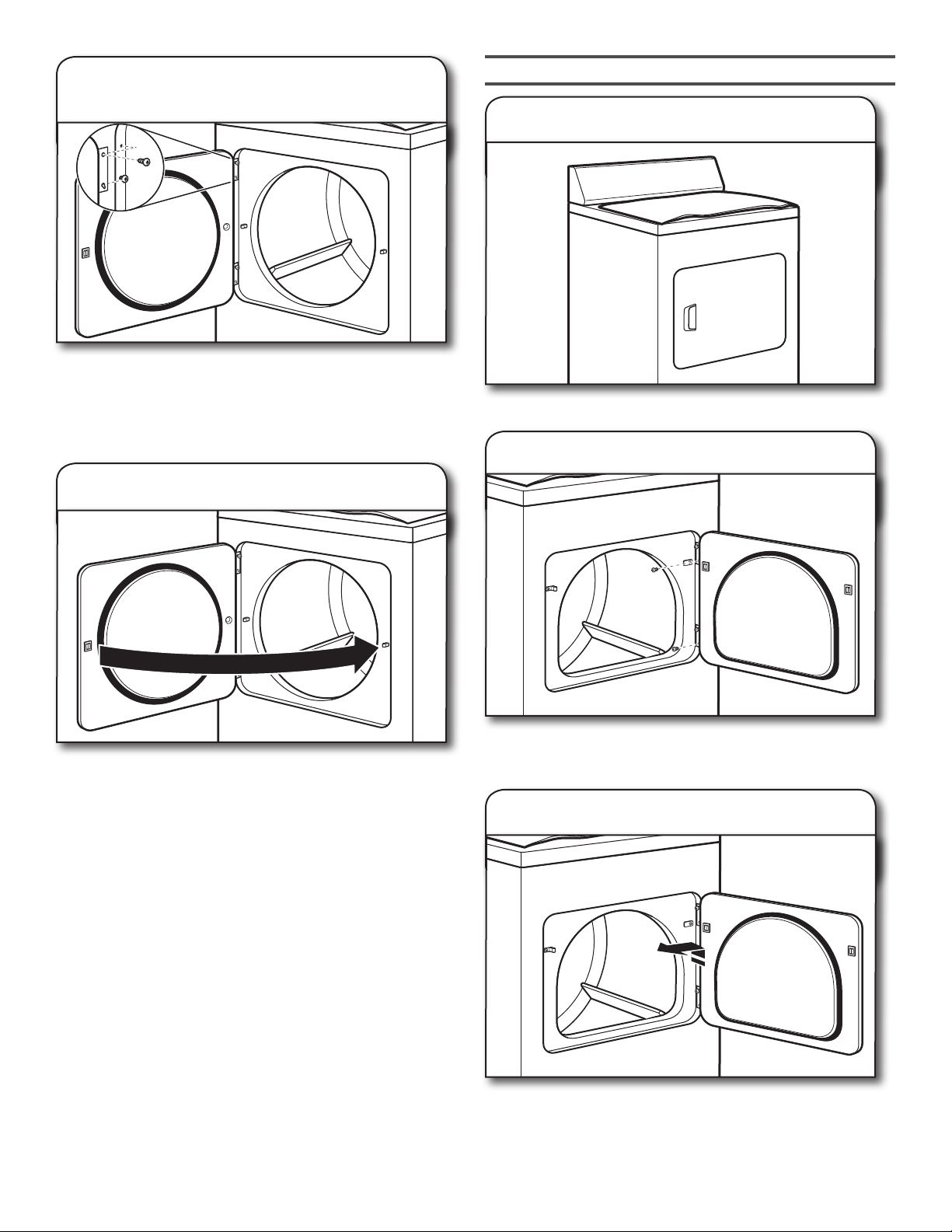

Super Wide Side-Swing Door

Place towel on dryer

1.

Place towel on top of dryer to avoid damaging the surface.

Remove bottom screws

2.

Close door and check that door strike aligns with door

catch. If needed, slide door catch left or right within slot

to adjust alignment.

16

Open dryer door. Remove bottom screws from dryer cabinet

side of hinges. Loosen (do not remove) top screws from

dryer cabinet side of hinges.

Lift door off top screws

3.

Lift door until top screws in dryer cabinet are in large part of

hinge slot. Pull door forward off screws. Set door (handle side

up) on top of dryer. Remove top screws from dryer cabinet.

Remove screws from hinges

4.

Remove screws attaching hinges to door.

Remove screws from door

5.

Flip door over

7.

Flip door over so handle side is down.

Attach door hinges

8.

Remove screws at top, bottom, and side of door (4 screws).

Keep door screws separate from hinge screws as they are

diferent sizes. Holding door over towel on dryer, grasp sides

of outer door and lift to separate it from inner door.

NOTE: Do not pry apart with putty knife or screwdriver.

Do not pull on door seal or plastic door catches.

Rotate outer door

6.

Take outer door and rotate in 180º and set it back down on

inner door. Be certain to keep cardboard spacer centered

between doors. Reattach outer door panel to inner door

panel so handle is on the side where hinges were just

removed. Insert 4 door screws.

Reattach door hinges to dryer door so that the larger hole is

at the bottom of the hinge.

17

Remove door strike

9.

Remove door strike plug

12.

Remove door strike from dryer cabinet and set aside.

10.

Remove and transfer hinge

hole plugs

Use a small, at-blade screwdriver to gently remove 4 hinge

hole plugs on left side of dryer cabinet. Transfer plugs into

hinge holes on opposite side of dryer cabinet.

11.

Insert screws in hinge holes

on dryer cabinet

Remove door strike plug. Insert the door strike removed in

Step 9 into hole and secure with screw. Insert door strike

plug into original door strike hole and secure with screw.

Check door strike alignment

13.

Close door and check that door strike aligns with door

catch. If it is needed, slide door catch left or right within slot

to adjust alignment.

Troubleshooting

See the Use and Care Guide to possibly avoid the cost of

a service call.

NOTE: Two people maybe needed to reinstall door.

Insert screws into the bottom holes on left side of dryer

cabinet. Tighten screws halfway. Position door so large end

of door hinge slot is over screws. Slide door up so screws

are in bottom of slots. Tighten screws. Insert and tighten top

screws in hinges.

18

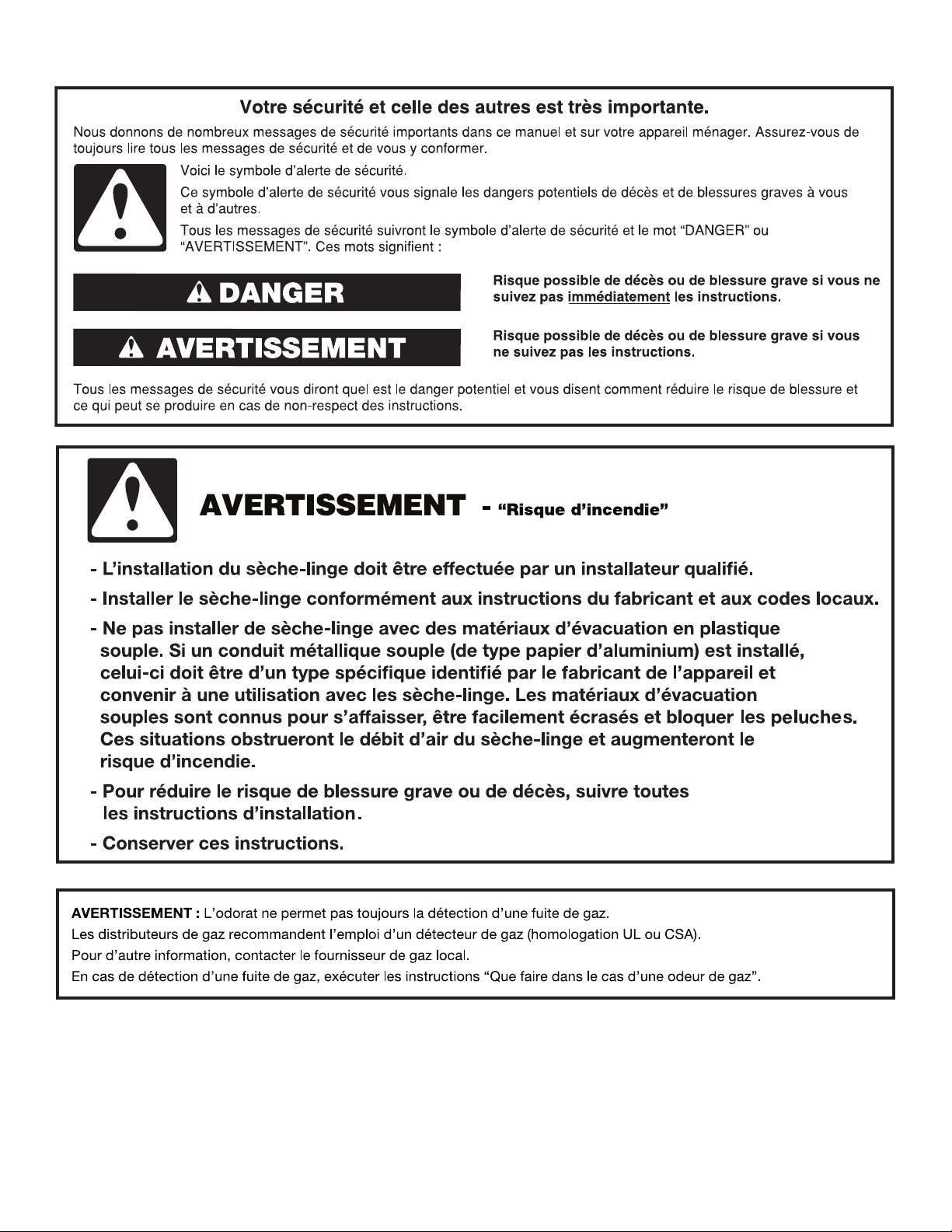

SECURITE DU SECHE-LINGE

19

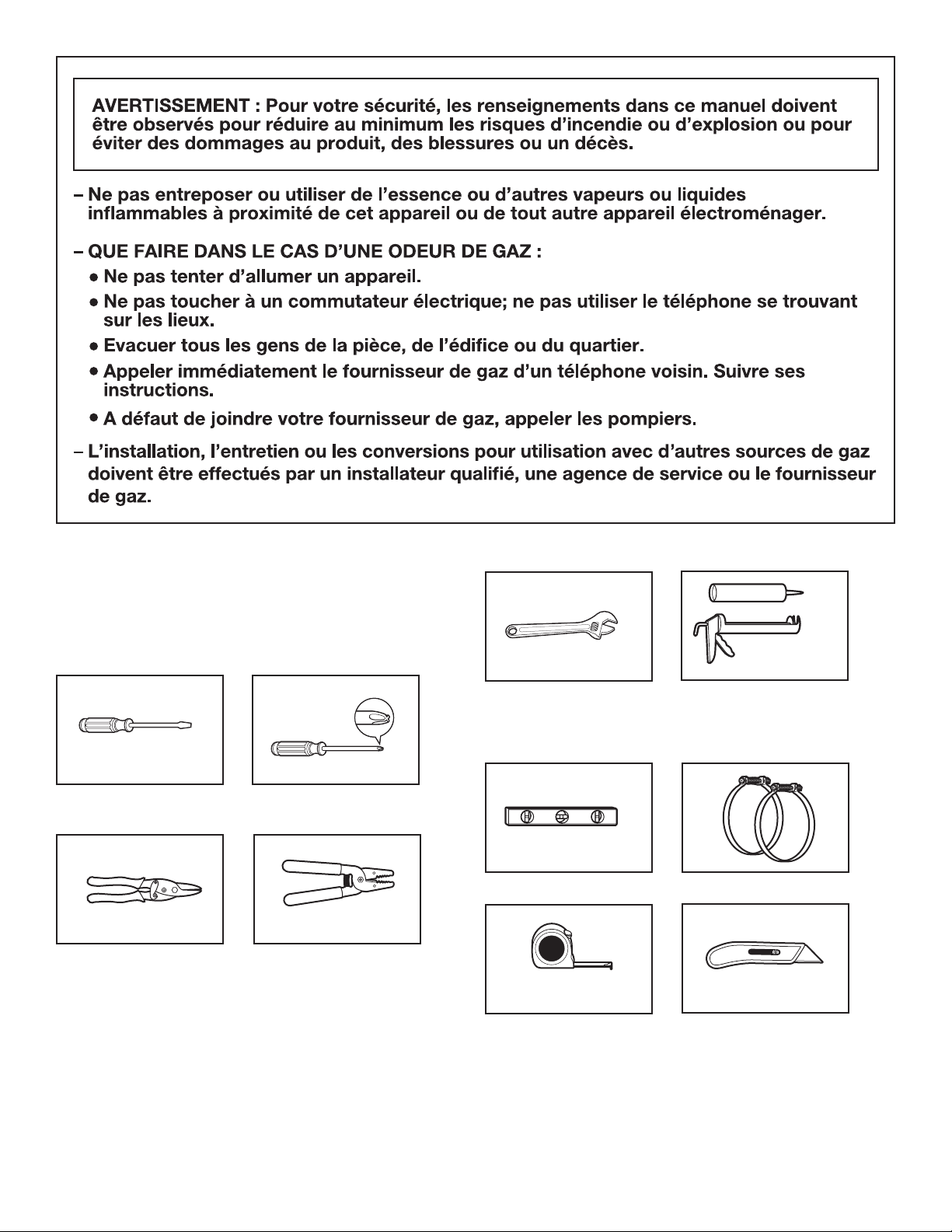

EXIGENCES D’INSTALLATION

OUTILLAGE ET PIECES

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et suivre les instructions fournies avec les outils

indiqués ici.

Outils nécessaires pour toutes les installations :

Tournevis à lame plate

Cisaille de ferblantier

(pour l’installation d’un

nouveau conduit)

Tournevis Phillips no 2

Pince à dénuder les ls

(pour les installations à

raccordement direct)

Clé à molette avec

ouverture jusqu’à 25mm

(1") ou clé à douille à tête

hexagonale

Niveau

Mètre ruban

Pistolet à calfeutrage et

composé de calfeutrage (pour

l’installation d’un nouveau circuit

d’évacuation)

Clapets d’évacuation

Couteau utilitaire

20

Outils nécessaires aux installations au gaz :

Clé à tuyau réglable qui

s’ouvre jusqu’à 204 mm

(8") ou 254 mm (10")

Composé d’étanchéité

des raccords letés –

résistant au gaz propane

Pièces fournies (tous les modèles) :

Pieds de nivellement (4)

Le sachet de pièces se trouve dans le tambour du sèche-linge.

Vérier que toutes les pièces sont présentes.

Pièces nécessaires :

Consulter les codes locaux. Vérier l’alimentation électrique et

le circuit d’évacuation existants. Voir “Spécications électriques”

et “Exigences concernant l’évacuation” avant d’acheter les

pièces.

En cas d’utilisation d’un câble d’alimentation électrique :

Utiliser un ensemble de câble d’alimentation électrique

homologué UL marqué compatible avec les sèche-linge.

L’ensemble doit contenir :

■ Un câble d’alimentation électrique homologué UL de 30

ampères, 230 volts minimum. Le cordon doit être de type

SRD ou SRDT et mesurer au moins 1,22 m (4 ft) de long.

Les fils raccordés au sèche-linge doivent se terminer par

des cosses rondes ou à fourche à pointes relevées.

■ Un serre-câble (homologation UL).

Pour une installation au gaz :

Consulter la réglementation locale et le fournisseur de gaz, et lire

les exigences relatives au branchement électrique, au gaz et à

l’évacuation avant d’acheter des pièces.

La conduite d’alimentation en gaz doit comprendre :

■ Un robinet d’arrêt

La conduite rigide d’alimentation en gaz doit respecter les

exigences suivantes :

■ Un tuyau de 12,5 mm (1/2") de diamètre intérieur minimum

La conduite exible d’alimentation en gaz doit respecter les

exigences suivantes :

■ Conduite flexible homologuée de 10 mm (3/8") de diamètre

intérieur minimum

Conversion au gaz butane/propane :

Un ensemble de conversion de gaz est disponible à l’achat chez

votre marchand. Toutes les instructions sont fournies dans cet

ensemble. Un technicien qualifié doit effectuer la conversion.

Des pièces supplémentaires seront peut-être nécessaires, selon

l’installation. Consulter les codes locaux. Vérifier la ventilation et

les alimentations en gaz et électrique existantes. Voir “Exigences

concernant l’installation électrique”, “Exigences concernant

l’alimentation en gaz” et “Exigences concernant l’évacuation”

avant d’acheter les pièces.

EXIGENCES D’EMPLACEMENT

On a besoin de :

■ Un emplacement permettant une évacuation appropriée.

Voir “Exigences concernant l’évacuation”.

■ Un circuit séparé de 30 ampères.

■ Si on utilise un cordon d’alimentation, une prise électrique

avec liaison à la terre située à moins de 610 mm (2 ft) de l’un

des côtés du sèche-linge. Voir “Spécications électriques”.

■ Un plancher robuste capable de supporter le poids du sèche-

linge (sèche-linge et charge) de 90,7 kg (200 lb). Il faut aussi

prendre en compte le poids combiné d’un appareil ménager

voisin.

■ Un plancher de niveau ayant une pente maximale de 25 mm

(1") sous l’ensemble du sèche-linge. Si la pente est supérieure

à 25 mm (1"), installer un ensemble de pieds d’extension

pour sèche-linge, pièce n° 279810. Si le sèche-linge n’est

pas d’aplomb, le linge peut ne pas culbuter convenablement,

et les programmes automatiques commandés par détecteur

peuvent ne pas fonctionner correctement.

Ne pas faire fonctionner le sèche-linge à une température

inférieure à 7°C (45°F). A des températures inférieures, le

sèche-linge risque de ne plus s’arrêter à la n d’un programme

automatique. Les temps de séchage risquent alors d’augmenter.

Le sèche-linge ne doit pas être installé ou remisé dans un endroit

où il sera exposé à l’eau et/ou aux intempéries.

Vérier les règlements locaux. Certains codes limitent ou

n’autorisent pas l’installation des sèche-linge dans un garage,

un placard ou une chambre à coucher. Communiquer avec

l’inspecteur des bâtiments local.

Espacements d’installation :

L’emplacement doit être assez grand pour permettre d’ouvrir

complètement la porte du sèche-linge.

21

Dimensions du sèche-linge

387 mm

15¼")

1102 mm

433/8")

(

*660 mm

(26")

737 mm

(29")

(

1102 mm

3

/8")

(43

705 mm

(*27¾")

737 mm

(29")

A

578 mm

1102 mm

433/8")

(

705 mm

(*27¾")

737 mm

(29")

(22¾")

1102 mm

433/8")

(

705 mm

(*27¾")

737 mm

C

A. Porte à pivotement latéral à petite ouverture

B. Porte à pivotement latéral à grande ouverture

C. Porte à pivotement latéral à large ouverture

D. Porte rabattable à large ouverture

*La plupart des installations requièrent un espace minimum de

127 mm (5") derrière le sèche-linge pour le conduit d’évacuation

avec coude. Voir “Exigences concernant l’évacuation”.

B

(29")

578 mm

(22¾")

349 mm

(13¾")

D

Dégagement minimal pour une installation dans un

encastrement ou un placard

Les dimensions correspondent à l’espacement minimum permis.

■ Prévoir davantage d’espace pour faciliter l’installation et

l’entretien.

■ Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

■ Un espace supplémentaire de 25 mm (1") doit être envisagé

de chaque côté du sèche-linge an de réduire le transfert

de bruit.

■ Pour installation dans un placard avec porte, on doit prévoir

des ouvertures minimums d’entrée d’air en haut et en bas

de la porte. Les portes à claire-voie offrant des ouvertures

équivalentes de passage de l’air sont acceptables.

■ Il faut aussi prendre en compte l’espace requis entre les

appareils voisins.

356 mm

(14"max.)

76 mm

(3")

457 mm

310 cm

(48 in.2)

2

(18")

2

155 cm

102 mm

(4")

76 mm

(3")

(24 in.2)

25 mm

0 mm

(1")

(0")

A. Encastrement

B. Vue latérale - placard ou endroit exigu

C. Porte du placard avec orices d’entrée d’air

*Espace supplémentaire recommandé

SPECIFICATIONS ELECTRIQUES

C’est à l’utilisateur qu’incombe la responsabilité de :

■ Contacter un électricien qualié.

■ Veiller à ce que le branchement électrique soit correctement

effectué et conforme aux prescriptions de tous les codes et

règlements locaux en vigueur.

■ Fournir une alimentation de 230 VCA, 60 Hz monophasée à

3 ls, sur un circuit séparé de 30 ampères (15 ou 20 ampères

pour les sèche-linge à gaz) protégé par fusible aux deux

extrémités de la ligne. On recommande d’utiliser un fusible ou

un disjoncteur temporisé. On recommande également que cet

appareil soit alimenté par un circuit indépendant. Ne pas avoir

de fusible dans le circuit neutre ou de liaison à la terre.

■ Ne pas utiliser de câble de rallonge.

■ Si les codes le permettent et si l’on utilise un conducteur

distinct de liaison à la terre, il est recommandé qu’un

électricien qualié vérie la qualité de la liaison à la terre.

Raccordement électrique

Pour installer le sèche-linge de façon appropriée, il faut

déterminer le type de raccordement électrique à utiliser et suivre

les présentes instructions.

En cas d’utilisation d’un câble d’alimentation électrique :

Utiliser un ensemble de câble d’alimentation électrique

homologué UL marqué compatible avec les sèche-linge.

L’ensemble doit contenir :

■ Un câble d’alimentation électrique homologué UL de 30

ampères, 230 volts minimum. Le cordon doit être de type

SRD ou SRDT et mesurer au moins 1,22 m (4 ft) de long. Les

ls raccordés au sèche-linge doivent se terminer par des

cosses rondes ou à fourche à pointes relevées.

■ Un serre-câble (homologation UL).

22

Raccordement direct :

Le câble doit correspondre à l’alimentation électrique et présenter

les caractéristiques suivantes :

■ Un câble en cuivre à gaine non métallique ou blindé souple

(avec l de liaison à la terre), avec conduit métallique souple.

Tous les ls sous tension doivent être isolés.

■ Fil en cuivre plein de calibre 10 (ne pas utiliser d’aluminium).

■ Longueur d’au moins 1,52 m (5 ft).

INSTRUCTIONS DE LIAISON À LA TERRE

■

Pour un sèche-linge relié à la terre et connecté par un

cordon :

Ce sèche-linge doit être relié à la terre. En cas de mauvais

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courant électrique

un acheminement d’évacuation de moindre résistance. La

che doit être branchée sur une prise appropriée qui est

bien installée et reliée à la terre conformément à tous les

codes et règlements locaux.

AVERTISSEMENT : Le raccordement incorrect de

cet appareil au conducteur de liaison à la terre peut susciter

un risque de choc électrique. En cas de doute quant à la

qualité de liaison à la terre du sèche-linge, consulter un

électricien ou un technicien ou un personnel qualié. Ne

pas modier la che de branchement fournie avec le

sèche-linge; si la che ne correspond pas à la conguration

de la prise de courant, demander à un électricien qualié

d’installer une prise de courant appropriée.

EXIGENCES CONCERNANT

L’ALIMENTATION EN GAZ

CONSERVEZ CES INSTRUCTIONS

RESPECTER LES DISPOSITIONS DE TOUS LES CODES

ET REGLEMENTS EN VIGUEUR.

Alimentation en gaz :

Vérier que le sèche-linge est équipé du brûleur approprié

correspondant au type de gaz utilisé. Les informations

concernant le brûleur se trouvent sur la plaque signalétique

située sur la paroi interne de la porte du sèche-linge. Si

l’information ne correspond pas au type de gaz disponible,

consulter votre revendeur.

Gaz naturel :

Ce sèche-linge est conguré en usine pour l’utilisation au

GAZ NATUREL (G20) et aucun réglage supplémentaire n’est

nécessaire lors de l’installation.

Gaz butane/propane :

Ce sèche-linge est également homologué pour une utilisation

avec des gaz de pétrole liquéés (propane ou butane) avec

la conversion appropriée. Ne pas entreprendre de convertir

l’appareil pour une utilisation avec un gaz différent de celui

indiqué sur la plaque signalétique sans d’abord consulter le

fournisseur de gaz.

La conversion doit être effectuée par un technicien qualié.

Des ensembles de conversion de gaz sont disponibles à l’achat

chez votre revendeur. Toutes les instructions sont fournies dans

cet ensemble.

Exigences concernant la conduite d’alimentation

Installer une conduite rigide d’alimentation en gaz à

l’emplacement du sèche-linge. Le diamètre interne minimal de la

conduite doit être de 12,5 mm (1/2"). Lorsque les codes locaux

et votre fournisseur de gaz l’autorisent, une conduite rigide de

diamètre intérieur de 10 mm (3/8") peut être utilisée pour des

longueurs inférieures à 6,1 m (20 ft). Un produit d’étanchéité

résistant à l’action du gaz propane/butane doit être utilisé pour

les joints des conduites.

23