Weller WTL1000S User Manual

MODEL WTL1000S ELECTRONIC SOLDERING STATION

WARNING: This product, when used for soldering and similar applications, produces chemicals known to the

State of California to cause cancer and birth defects or other reproductive harm.

OPERATING INSTRUCTIONS

Unpack unit carefully. Place spring and funnel in slot in top of tool stand. Attach tool stand to either side of

power unit, if desired. Fill reservoir with water and wet sponge, distilled water is preferred. Insert tool in holder

and connect tool plug to receptacle on power unit; rotate plug housing to lock plug in receptacle. Insert line cord

plug into properly grounded AC receptacle and turn station on. If the desired temperature key is not installed,

the key may be changed while power is on. Wait 30 seconds. Remove tool from holder and tin tip with solder.

Unit is now ready for use.

Always use the lowest temperature that will handle the load you are soldering. The Weller

provides maximum power to the heated load even when set to the lowest temperature; therefore, there is no

need to use high temperature to handle heavy soldering loads. By using lower temperatures and properly

selecting tip styles, sensitive components will be protected from heat damage.

A WCM1 Calibration Unit is available that interfaces directly with the WTL1000Ss microprocessor through the

iron receptacle and provides the ability to enable a timed setback mode, a temperature lock out feature, digital

calibration of the unit to an outside temperature reference, and reset the unit to its original factory calibration.

When the unit enters Setback mode, turn the unit off and back on to return to normal operation.

®

electronic control

WARNING: Do not remove ground prong from line cord plug. Removal may cause tip temperature

control to be erractic.

AVAILABLE MODELS AND HAND PIECES

PRODUCT DESCRIPTION

WTL1000S-0 Power unit only, 120V 60 Hz, °F dial markings

WTL1000S-0D Power unit only, 240V 50/60 Hz, °C dial markings

WTL1000S-1 Power unit, 120V 60Hz, °F dial markings, EC1201A tool with ETA tip and tool stand

WTL1000S-1D Power unit, 240V 50/60Hz, °C dial markings, EC1201A tool with ETA tip and tool stand

WTL1000S-2 Power unit, 120V 60Hz, °F dial markings, EC1302B tool with EPH101 tip and tool stand

WTL1000S-2D Power unit, 240V 50/60Hz, °C dial markings, EC1302B tool with EPH101 tip and tool stand

WTL1000S-3 Power unit, 120V 60Hz, °F dial markings, EC1503B tool with EMA tip and tool stand

WTL1000S-3D Power unit, 240V 50/60Hz, °C dial markings, EC1503B tool with EMA tip and tool stand

EC1201A 40 Watt soldering tool w/ETA tip

EC1302B 20 Watt soldering tool w/EPH101 tip

EC1503B 42 Watt high capacity soldering tool w/EMA tip

SPECIFICATIONS

1. Power Input: 120VAC ±10%, 60Hz, (240VAC ± 10%, 50/60 Hz), 60 watts

2. Power unit output voltage: isolated 24VAC @ 2.1 amperes.

3. Size: 4.5" x 5.9" x 3.6"

4. Line Cord: 3 wire, UL recognized.

5. Tip temperature control range: 350°F to 850°F (175°C to 455°C).

6. Control setting resolution: 10°F (5°C).

7. Stability: ±10°F (±6°C) per MIL-STD-2000.

8. Absolute accuracy: Average tip temperature is calibrated to ±9°F (±5°C) at idle with no load.

9. Ambient temperature range: 60°F to 110°F (16°C to 44°C).

10. Housing made with Electrostatic Protective Material as required in MIL-B-81705.

11. Housing passes Static Decay test per Federal Test Method Standard No. 101, method 4046.

12. Weller

®

ESD tools comply with DOD-HDBK-263.

13. WTL1000S units are UL listed and meet DOD-STD-2000, MIL-STD-2000, MIL-S-45743, W-S-6536,

W-S-570, DOD-STD-1686.

TROUBLESHOOTING GUIDE

WARNING: AC line voltage is present inside power unit even when power

switch is off. Refer service to qualified personnel.

NOTE: Access to internal parts may be gained by removing four rubber feet,

four screws under feet and top case.

TOOL DOES NOT HEAT

With line cord unplugged and power switch on, check for approximately 21 ohms at line cord blades for

120VAC units (55 ohms for 240VAC units).

Check fuse, located on bottom of case - replace if required. Use slow blow fuse - 0.6A for 120VAC

(0.3A for 240VAC).

Check power switch - replace if defective.

Check line cord - repair or replace if defective.

Check transformer primary - replace transformer if defective.

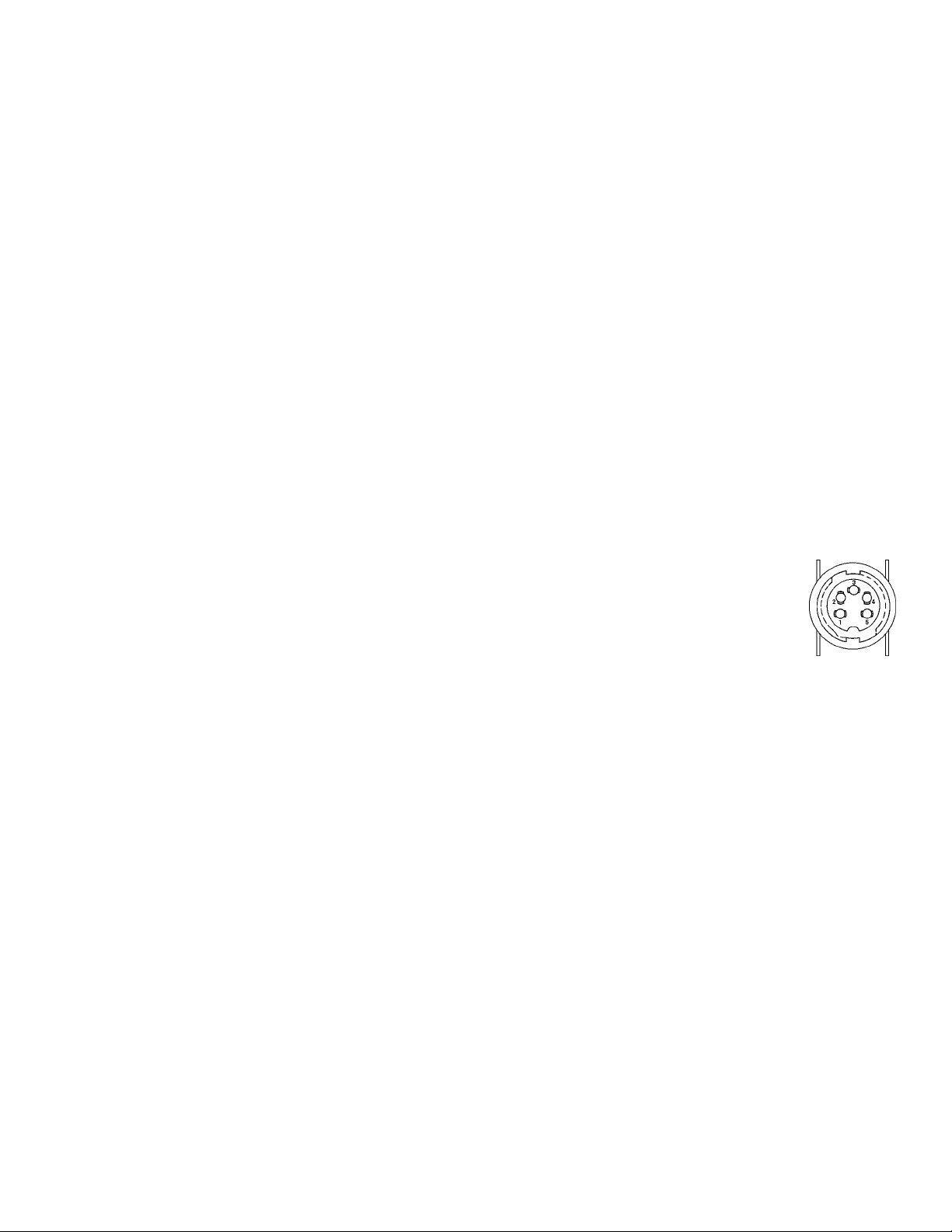

With line cord plugged in and power switch on, check for 24VAC ±10% between pins #1 and #4 of tool

receptacle.

Check transformer secondary for 24VAC ±10% - replace transformer if defective.

Check wiring to printed circuit board assembly - repair or replace if defective.

Replace printed circuit board assembly.

With line cord plugged in and power switch on, check for 5 VDC ±1 VDC, between pins #3 and #4 of tool

receptacle

.

Replace printed circuit board assembly.

Check wiring from tool receptacle to printed circuit board.

Repair or replace if defective.

Replace soldering tool with known good tool and recheck.

Troubleshoot soldering tool using guide in soldering iron tech sheet.

Loading...

Loading...