Weller WTCPT User Manual

WTCPT SOLDERING STATION

A transformer powered soldering station, complete with a lightweight,

heat insulated, low voltage, temperature controlled soldering iron.

The special Weller® closed loop method of controlling maximum tip

temperature sensitive components. The soldering iron features a

stainless steel, plug in heating element construction, a non-burning

silicone rubber cord, and a large selection of tips in sizes from 1/64

diameter to 15/64 diameter with a choice of tip temperature of

600°F, 700°F and 800°F. The soldering iron is normally provided with

a PTA7 1/16 screwdriver 700°F.

The station features a housing of an impact resistant polycarbonate

plastic for durability and protection against accidental damage, a

quick disconnect plug for the soldering iron, a lighted on-off switch,

and a flexible 3 wire power cord.

The plastic soldering iron holder can be used attached to either side

of the transformer case, or separated as shown. The iron holder

incorporates a water reservoir with wick to keep the tip wiping

sponge moist.

The station housing and hand piece are grounded with a separate conductor that terminates at the third pin on the power cord.

The Weller® units are UL listed.

WARNING: This product, when used for soldering and similar applications, produces chemicals known to the State of

California to cause cancer and birth defects or other reproductive harm.

SPECIFICATIONS

POWER UNIT

1. Power input: 120 VAC, 60 Hz, (240VAC ±10%, 50/60 Hz) 60 watts.

2. Power unit output voltage: isolated 24 VAC @ 1.75 amperes.

3. Size: 4.5 x 5.875 x 3.625.

4. Line Cord: 3 wire U.L. recognized.

SOLDERING IRON

1. Wattage: 42 watts.

2. Iron weight: 2 ounces

3. Recovery time (from 100°F drop) with PTA7 tip: 11 seconds.

4. Cord: Silicone rubber, burn resistant, 4 feet.

PRINCIPLE OF OPERATION

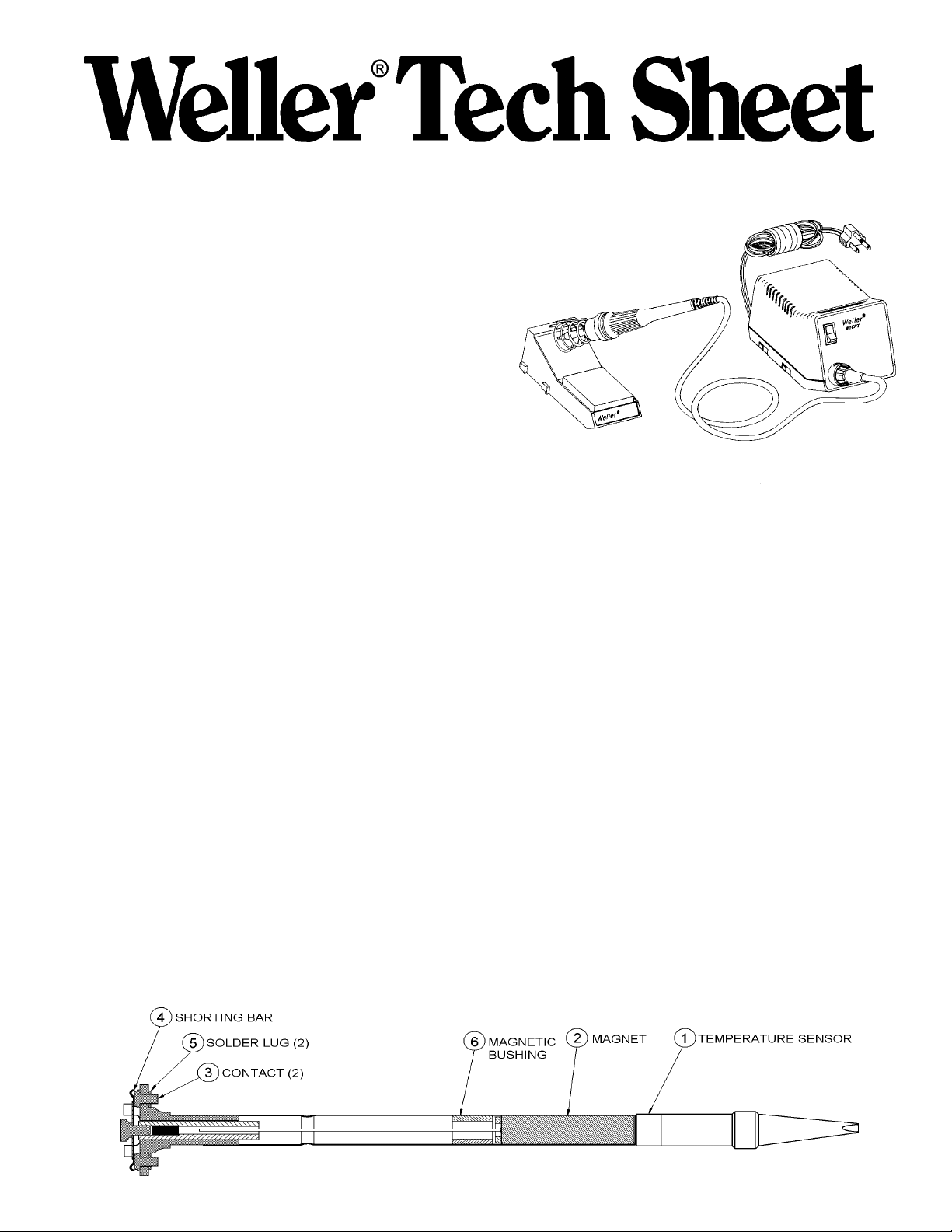

When the soldering tip is cold, a ferromagnetic temperature sensor (1) attached to the tip attracts a permanent magnet (2). The

magnet movement causes a shorting bar (4) to make contact with a set of isolated electrical contacts (3) thereby supplying

power to the heating element through the solder lugs (5). When the tip reaches its idle temperature, the sensor becomes

nonmagnetic and no longer attracts the magnet. Then a magnetic bushing (6) attracts the magnet causing the shorting bar to

break the circuit. In this manner, power to the heating element is turned on and off automatically.

CAUTION: Tip is grounded, do not solder an energized circuit.

WTCPT OPERATING INSTRUCTIONS

Unpack unit carefully. Place spring and funnel in slot in top of tool stand. Attach tool stand to either side of power unit, if desired.

Fill reservoir with water and wet sponge, distilled water is preferred. Insert tool in holder and connect tool plug to receptacle on

power unit; rotate plug housing to lock plug into receptacle. Insure correct tip is installed in iron, insert line cord plug into

properly grounded AC receptacle and turn unit on. Wait 30 seconds and tin tip with solder. Unit is not ready for use.

All Weller® PT series soldering iron tips are plated with an exclusive process that deposits three protective coatings. The high

conductivity copper tips are iron plated, nickel plated, then chromium plated on the non-working surfaces. The working surface

is then pre-tinned. The chromium and nickel plating of the tip prevents oxidation of the iron plating which can cause freezing of

the tip in the iron. Weller® temperature sensing tips have a small ferromagnet sensing element attached to the tip shank. The

sensing element is coded with a number to indicate the tip idle temperature in hundreds of degrees F. Thus a simple change of

tips is all that is necessary to adapt the tool to an entirely different temperature range. Use only original Weller® soldering

tips. The use of non-Weller components may void product warranty if the non-Weller component causes damage to the

unit.

SELECTION OF WELLER® PT SERIES TIPS

1. Select a tip configuration with the maximum working surface, thickest cross section, and shortest reach compatible with the

size, the accessibility, and the visual restrictions of the solder joint.

2. Select a tip temperature based on the size of the solder joint, the temperature sensitivity of the components, and the

production rate required. Please note that tip life is directly related to tip temperature, the lower the tip temperature the

longer the tip life.

600°F

PTA6

PTB6

PTC6

PTD6

PTH6

PTK6

PTO6

PTP6

PTQ6

PTR6

PTS6

PTX6

700°F

PTA7

PTAA7

PTB7

PTBB7

PTC7

PTCC7

PTD7

PTDD7

PTE7

PTF7

PTH7

PTJ7

PTK7

PTL7

PTM7

PTN7

PTO7

PTP7

PTR7

PTS7

PTX7

PTZ7

800°F

PTA8

PTAA8

PTB8

PTBB8

PTC8

PTCC8

PTD8

PTDD8

PTE8

PTF8

PTH8

PTJ8

PTK8

PTL8

PTM8

PTO8

PTP8

PTQ8

PTR8

PTS8

PTT8

PTZ8

DESCRIPTION

Screwdriver

Single Flat

Screwdriver

Single Flat

Screwdriver

Single Flat

Screwdriver

Single Flat

Screwdriver

Conical Flat

Screwdriver

Screwdriver

Long Screwdriver

Long Screwdriver

Long Screwdriver

Screwdriver

Long Conical

Conical

Single Flat

Narrow Screwdriver

Long Conical

Conical

Bent, Slotted

Bent, Slotted

TIP

1/16"

1/16"

3/32"

3/32"

1/8"

1/8"

3/16"

3/16"

15/64"

1/32"

1/32"

1/64"

3/64"

5/64"

1/8"

1/16"

1/32"

1/32"

1/32"

1/16"

1/64"

.025

1/32"

.020

REACH

5/8"

5/8"

5/8"

5/8"

5/8"

5/8"

3/4"

5/8"

5/8"

5/8"

5/8"

1"

1"

1"

1"

3/4"

1"

5/8"

5/8"

5/8"

1"

5/8"

CARE OF WELLER® PT SERIES TIPS

1. Keep tinned, wipe only before using.

2. Use rosin or activated rosin fluxes. Acid type flux will greatly reduce tip life.

3. Remove tip and clean with suitable cleaner for flux used. The frequency of cleaning will depend on the type of work and

usage. Tips in constant use should be cleaned at least once a week.

4. Dont try to clean tip with abrasive materials and never file tip, to do so will greatly reduce tip life. If the tip becomes

unwettable, it may be cleaned with a soft iron or brass brush using solder flux as a solvent; or the Weller® WPB1 Polishing

bar.

5. Dont remove excess solder from heated tip before sorting. The excess solder will prevent oxidation of the wettable surface

when tip is reheated.

6. Dont use anti-seize compounds on tips, the tips have been plated for oxidation protection.

Loading...

Loading...