Page 1

Service

Manual

CL 300 Surgical llluminator

SolarTec Source 270

CL

100

Surgical

llluminator

SolarTec Source

100

PN: LB-MAN

CLSERV

Rev. A

Welch Allyn Lighting Products

4619

Skaneateles Falls, NY 131

Jordan

Road

53-0187

Page 2

Table

of Contents

GENERAL INFoRMATToN

TECHNTCAL HELP INFoRMATToN

SERVICE CENTERS

WARRANTY

SYSTEM SYMBoL DESCRIPTIoNS

WARNINGS AND PRECAUTIoNS

Warning

Caution-

OPERATING INSTRUCTIoNS

Conlrols

PowER

F|BER

MULTI LINKTM EXPANSIoN

LicHT A]-TENUATToN

LAMP LIFE lNDrcAToR

Principles Of Operation

LIGHT SoURcE

REPLACEMENT LAMPS

PowER Supply wrrH CoNTRoL ELEcrRoNrcs

MULT| LiNKTM PoRTAND MULTr LTNKTM ExpANsroN PoRT

-----

-- - ---

ON/OFF

PoRr

-----

SwrrcH.

PoRT-

CoNTRoL

-

-

INSTALLATIoN

-----

AND USE

(oPTIONAL)

--

------1-1

- -

1-1

-----

-.----.1-3

-------

----

-'----

------

. - - -- -...- -1-7

---------1-7

-----. ---1-8

----

---------1-8

---

---

-

---1-8

1-2

1-4

1-5

1-5

1-5

1-6

1'6

16

16

-'l-7

1-8

-1-8

SERVTCE

TooLS REoUIRED

TRoUBLESHooTNG

-

CLEANTNG

SURGTCAL ILLUMTNAToR

MULT|

CL 100 SuRGrcAr ILLUMTNAToR

CL 1OO SURGICAL ILLUI\,IINAToR DISASSEMBLY

TEST

TEST

TEST#3: CooLrNG FAN

TEST

------

LTNKTM

#1: BLoWN

#2:

#4:

ExpANsroN PoRT

-----

FUsEs

1OO WATT

LED/OVEBTEMP SWITCH

--------

- -

POWER SUPPTY

---

- - - -

---------

.-

------1-9

--

---

- - - - ... -'I-12

- -

--------

.

- - - -'

1-9

1-9

--1-9

1-10

1-11

1-11

1-12

1-13

.1-13

1.13

Page 3

TEsr#s: MrcRo LINK@ FTBER TEsr

TEST#6: PowER SuppLy CALTBRAIoN

CL 1OO SURGICAL ILLUMINAToR DISASSEMBLY

PoWER SUPPLY REMoVAL

PLATFoRM REMoVAL

FRoNT BEZEL REMoVAL

DEFLECToR REMoVAL 1 16

FAN

CHASSIS

LED/OVERTEMP HARNESS REMoVAL

LAMP CABLE REMoVAL

INTERLoCK

PoWER ENTRY MODULE REMoVAL

CL

CL300

CL 3OO SURGICAL ILLUMINAToR DISASSEMBLY

TEsr#1:BLowN FusEs

TEST #2: AuxrLrARy BoARD lNpur TERMTNALS

TEsr#3:

TEsr

TEST

FAN REMoVAL

SwrrcH

100 SURGTCAL ILLUMTNAToR REPATF

SURGTCAL ILLUMTNAToR

CooLrNG

LED

#4:

MIcRo LINK@ FTBER TEST

#5:

RENtovAL

----

FAN

OPERAToN

- - - - ---

PARTS Lrsr

---

--

----- -

- - -

- -

--------

--------

'- -------

-..

-.

-- - ----'l

- ---

- - -

-.

-----

- - -

----

- - - -

-----

- - -

-

-'

- _

1-13

1-14

1.15

1-15

1-16

1-16

1-17

1-17

1-17

1-18

1-18

1-19

25

1-27

1-21

'l-27

127

1-27

1-2A

CL 3OO

SURGICAL

INTERNAL MoDULE REMoVAL

PoWER

PCBA

lGNrroR

L|NE

CHASSIS FAN REMoVAL

PowER ENTRY MoDULE REMoVAL

PLATFoRM REMoVAL

FRoNT BEZEL REMoVAL

BLowER FAN REMoVAL

LAMP CABLE REMoVAL

300 SURGTCAL ILLUMTNAToR REPATR PARTS Lrsr

CL

IIIUMINAToR

SUPPLY REMoVAL

(pARr

No. A4-10670)

REMoVAL

FTLTER

REMoVAL

DISASSEMBLY

------

REMoVAL

.-

-- - -

---

.. -

1-29

------129

129

------.---

-

--------

------

-----

--------1-34

-----

--

--

. -

----

---

1,30

1-31

1-31

1-32

1-33

1-34

1-34

1 35

1-36

Page 4

GLoSSARY oFTERN4S

------

1-42

FINAL INSPECTIoN

CL 1OO SURGICAL ILLUMINAToR

CL 3OO SURGICAL ILLUMINAToR

SPEcrFlcAroNS

THEoRYoF OPERATIoN

LrGHr SouRcE

REPLACEMENT LAMPS

PowER

MULTI

CL 1OO SURGICAL ILLUMINAToR

CL 3OO

SURGICAL

SuppLy wrrH CoNTRoL ELEcrRoNrcs

LINKTM PoRTAND MULTr LTNKTM ExpANStoN PoRT

ILLUMINAToR

- -------1-46

CIRCUIT

CIRCUIT

.. .

DIAGRAM

DIAGRAM

--

1-43

-..

-

1-43

-

1-43

---

1-45

-----

------1-46

--- - --

- - ---------1-46

--- ----

-. - - - -

.

1-46

1-46

,I-47

1-48

Page 5

GENERAL

The Welch

illumination for the

sunlight.

of

f iber

INFoRMATToN

Allyn CL

Special

bundle.

'100

Surgical

physician

and

features include

TECHNTCAL HELP lNFoRrvrATroN

llluminator

and the Welch Allyn CL 300 Surgical llluminator

surgeon. The lamps

produce

high intensity light nearly identical

provide

brilliant

to the spectrum

the ability to use either a Cogent Optics Micro Link@ Fiber or a conventional

fully

Only

replacement

trained and

parts

properly

and

correct

equipped

procedures.

compromise instrument saf ety and

personnel

Failure

performance.

should

to do so

perform

Read and understand all safety warnings and service notes

Manuals,

help. or to

part

number

LB-IVAN-100W270W.

lf

there is any doubt about any

order additional copies of the Operating Manual, contact:

Customer Service

Welch Allyn, Inc.

4619 Jordan

Road.

PO

Box 187

Skaneateles Falls, NY 13153-0187 USA

Telephone: 1-315-685-2993o1

1-866-801-8428

FAX: 1-315-685-2999

Techncial Assistance

Telephone:

When calling, refer to the model number shown

Technical assistance is

1-315-685-4233,7:00am-3:00pm(EST)

the data label, found on the

on

"Troubleshooting "

contained

in

on

page

all service and reparrs, usrng

will invalidate

printed

11

the

in this Service Manualand the

this manual.

of

product

precaution

warranty

back of

or

your

qenurne

and could

Operating

procedure,

for

phone

Surgical llluminator.

PN: LB-MAN

CLSERV

Bev. A

Page 6

Welc$11ytt'

SeRvrce

you

lf

you

numbers listed

schedule the

BEFORE

ALLYN. AN RMA

SERVICE PERSONNEL.

RETURNS WITHOUT

USA

Welch Allyn, Inc.,

4619

Skaneateles

Tel: 1-315-685-2993

Fax:

INTERNATIONAL

Welch

Zollerstrasse 2 4

72417

fel:

Fax.011-49-7477-9271-93

CENTERS

have an equipment

for

assistance.

below. lf

reDair

RETURNING A PRODUCT

(RETURN

CUSTOMERS

U.S.A.

Jordan Road

Falls,

NY 13153-0187

315-685-2999

CUSTOMERS

Allyn, GmbH

JunEngen, Germany,

011-49-7

-9211-73

477

problem

Technical

you

with

the servrce cente. nearesl

BE

AN RMA NUMBER

you

that

service support rs

are advised to return a

FOR REPAIR YOU

MERCHANDISE

TO

SURE

cannot resolve,

available by telephone on norma

AUTHORIZATION} NUMBER WILL

NOTE THIS NUMBER ON THE

WILL NOT BE ACCEPTED FOR DELIVERY.

you

may

call the

product

you.

CANADA

Welch Allyn, Ltd.,

'160

Mississauga,

Tel:

Fax:

Welch Allyn,

300 Beach Road, #25-08

The

Singapore 199589

Tel: 01 1 65-291-0882

Fax:

to Welch Allyn for repair

MUST OBTAIN AUTHORIZATION FROM WELCH

CUSTOMERS

Matheson Blvd. E., Unit #2

Canada L4Z 1V4

905-890-0004

905-890-0008

Ltd., Singapole

Concourse

011-65-291-5780

Welch

OUTSIDE OF YOUR SHIPPING BOX.

Canada

Allyn Service Center nearest

routine

or

days

at the

marntenance,

business

BE GIVEN TO YOU BY OUR

phone

Welch Allyn, Ltd.,

Metro Center

Unit 5 38 South Street

Rydalmere, NSW

Tel:

01 1-61-294-183-155

Fax:

01 1-61-294-183-650

Welch

Bon Marusan

Jinbo-Cho, Chiyoda-Ku

Tokyo

Japan

Tel:

f ax. 0 1 1

LATIN AMERICAN

MD Intemational

Miami,

Tel:

Fax: 1-305-669-1971

Allyn, Japan

101-0051

01 1-813-521 2 7391

-81

3-3261

1

1 300 N.W. 41

FL 33178 USA

l-305-669-9003

Australia

2116, Australia

8F, 3-5-1 Kanda

-7

37 2

CUSTOMERS

st Street

Welch Allyn,

Room

708, 22'/ lluang Pi Road, North

Central

Shanghai 200003

PR. China

Tel:

011-86-21-63279631

F ax. O 1 1'86-2 1

Plaza

China

-6327

9632

12

WELCH

ALLYN

Page 7

WARRANTY

Welch

workmanship

service for

either

within

aurhorized distnbJtor, agent.

Welch Allyn

the

neglect, accidents, improper installation, modification,

cleaning

Thrs

warranty requirements. No

Allyn warrants the CL 300 or CL 100

and to

period

a

repair

or replace any components found to be defective or

this time at

pertorm

of one

no

cost to the customer. lt shall be the

in

accordance with

year

from

or service

warrants the lamp to be free of defects in materials and workmanship tor a

date of

purchase.

This warranty does not cover the lamp for breakage or failure due to tampering, misuse,

procedures.

warranty is void if the instrument is not

required

service is

performed

by other than Welch Allyn or an authorized agent. Purchase date

other express or implied warranty rs

Surgical

manufacturer's

date of

purchase

representatrve.

in

used

llluminator when new to

trom Welch Allyn or an authorized agent. Welch Allyn will

shipping, or from improper maintenance, servrce, or

accordance

specificatrons when subject to normal use and

variance from manufacturer's

at

purchaser's

responsibility to return the instrument to the

with manufacturer's recommendations

grven.

be

free

of defects

period

in material

and

speclfications

months from

of 6

if

or

determrnes

PN: LB MAN

CLSERV Fev.

A

Page 8

Velc$1yt

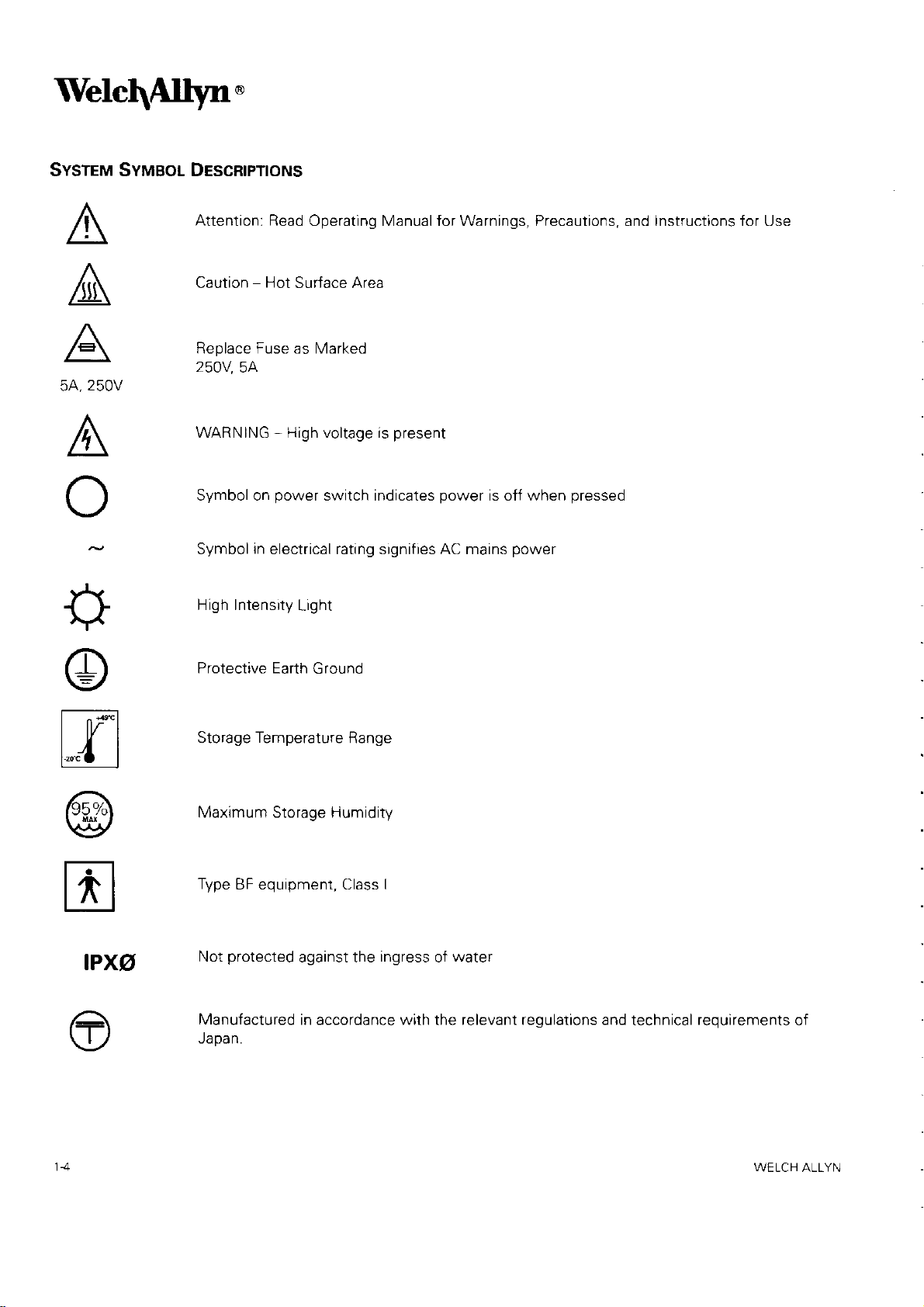

SYSTEM SYMBoL DEscRtPTtoNs

'

A

A

A

5A,250V

A

I

+

@

Attention: Read

Caution

Ra^la^a tr,,c6 ec lr,4ert orl

250V

WARNING - High voltage is

Symbol on

Symbol

High Intensity

Protective Earth G round

-

5A

in

Operating Manual for Warnings, Precautions, and Instructions for Use

Hot

Surface Area

power

electrical rating signifies AC mains

switch indicates

Light

present

power

is off when

power

pressed

|- ^.*l

| |f l

t4__l

@

tr

aPxg

Storage

Maximum Storage Humidity

Type

Not

Manufactured

Japan.

Temperature

BF equrpment, Class I

protected

against the

in accordance with the relevant regulations and

Range

ingress

of

water

technical

requirements

of

WELCH ALLYN

Page 9

WARNINGS AND PRECAUTIoNS

WARNING

e

/-\

l\

.

Keeo

.

Not suitable tor use in

nitrous

.

Disconnect from the

.

ELECTRICAL

.

Routinely examine the

with approved hospital

.

Do not olace the exoosed distal end of the

headlight

clothing,

.

High

energy

light

the

.

Use care

The

brilliant

Values {or Chemical Substances and Physical

3,1995).

.

Applied

42/EEC)

a Standards Council of Canada accredited

The

use of

.

During li{e

reolacement lamo.

.

The light source lamps are highly

failure or explosion of the

.

The light

operation.

powered

reach

out ol

oxide.

SHOCK

or other accessory.

or other

radiated light

outlet and to the tip

not

to

light

parts

attached to this equipment

(Europe),

non-approved

threatening

source

Temperatures

off.

patient.

of

the

patient

HAZARD. Do not remove the too cover

power

grade

material inadvertently

point

the distal end of the

output f

2) approved by a Nationally

procedures,

lamps

are

presence

before the discharge of a cardiac defibrillator.

guided

ot the instrument.

rom

components

lamp.

hot immediately

peak

of a flammable anesthetic mixture with air or

piug.

cord and

power

Failure

the unit can cause eye

cord and

to observe these

through endoscopes

it is recommended to have a backup Light source and an additional

pressurized,

in the light Sources approximately 60 seconds after the Light Source is

Do not

plug

Micro

Link@

placed

may compromise safety.

in front of the Micro Link@ Fiber or

fiber

or

Agent

should

be

Recognized Testing

laboratory

any damage or

after use,

if inspection reveals

use

with appropriate electrical

Fiber

precautions

may

headliqht

injury

Biological Exposure Indices, Final

and

approved 1) to the Medical Device Directive

(Canada)

allow the lamp to cool for five

fiber

or

give

directly

per

to the appropriate

improper handling may

bundle attached to either

may result in burns to skin,

rise to high temperatures in front

at the eye when unit is operating.

RP 27 .1

('1994

Laboratory

with

oxygen or

damage.

rating.

1995 Threshold Limit

(United

Replace only

fiber

bundle.

States),

medical standards.

cause

(5)

minutes after

a

of

March

dratt

(93/

and

3) by

premature

CAUTION

r

lA

PN: LB-MAN

.

.

.

Do not

Clogged or blocked vents

Keep

Fully

CLSERV

place

anythrng on top of the Light Source. Do

the Light Source clear

close the attenuator

Rev. A

not

may

cause Light Source overheating and

of any

obstructions.

before turning on the Light Source or when operational but not

liquid

store

above the

will result in thermal

Light Source.

shutdown.

in

use.

Page 10

Welc$11yn.

OPERATTNG lNsrRucloNs

CONTROLS

PowER ON/OFF swrrcH

Plug hospital

grounding

Press

Main Power

grade

Power

reliability.

Switch ON

Cord into

(l

pressed

grounded

a

in).

"Hospital

Grade" or

"Hospital

Use"

receptacle

to ensure

The lamp will

cannot

NOTE:

F|BER PoRT

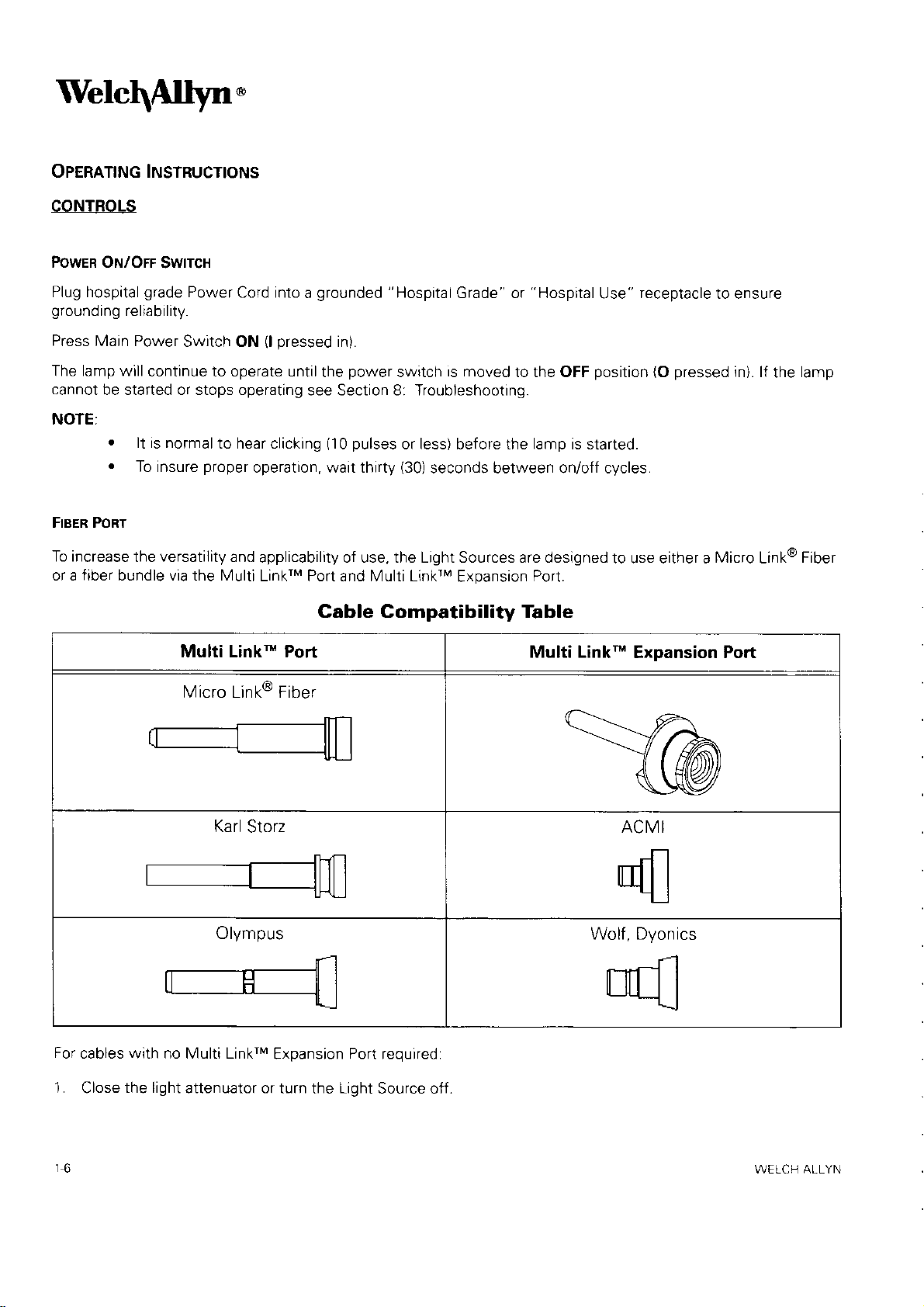

To increase

or a tiber bundle via the Multi

continue to operate untilthe

be started or stops operating

.

lt is normal

.

To insure

the

versatility

to hear clicking

proper

and

Multi Linkn Port

Micro Link@ Fiber

power

see Section 8: Troubleshooting.

(10

operation, wait thirty

applicability of use, the Light Sources are designed

LinkrM Port and Multi LinkrM

switch

pulses

is moved

or less) bef ore the lamp is started.

(30)

seconds between on/off cycles.

Expansion

to the OFF

Port.

position

Cable Gompatibility Table

Multi Link-

(O

pressed

to use either a

Expansion Port

in). lf

Micro

lamp

the

Fiber

Link@

Karl

Olympus

For

cables with no Multi LinkrM

1.

r6

Close

the light

attenuator or turn

Storz ACMI

Wolf , Dyonics

Expansion Port required:

Light

the

Source off.

WELCH ALLYN

Page 11

2.

Connect the

lnstrument

end of the

Micro Link@ Fiber or fiber bundle to the instrument.

Insert,

3.

4. Turn on Light

until fully engaged

Source.

MULT| L|NK'" ExpANsroN PoRT - lNsrALLATroN aNo

CAUTION: The Multi LinkrM Expansion Port contains

aouseo.

or

NOTE: The Multi

(snap

sound), the Lrght Source end

Adjust the light

LinkrM Expansion

attenuator to

Port must

the required illumination level.

(oproNAL)

UsE

optical

fully

be

Bundle.

Fiber

Port,

Light

perform

fiber

or

press

Source

the following operations:

bundle

from

and turn clockwise until

end

the fiber bundle into the Multi LinkrM Expansion Port.

of

To

use the

1.

Close the light attenuator or turn the Light Source off.

2. Remove, if

3. Insert the Multi LinkrM

4.

Connect the fiber bundle to the instrument.

5. Insert, until fully engaged,

l\4ulti

LinkrM Expansion Port

Micro

any,

Link@

Expansion

the

into

elements that

engaged

Multi

the

Multi

the

into

LinkrM

LinkrM

become

can

the Light Source before

Port.

it locks into

place.

Port.

damaged

if

inserting Fiber

dropped

6. Turn on Light

To remove

1. Turn

the Light Source off.

2. Remove

3. Turn

l\,4ulti

Source.

the Multi LinkrM Expansion Port

fiber

the

LinkrM Expansion

LrcHT ATTENUATToN

Adjust

bundle.

CoNTRoL

Moving the illumination wheel

LAMP LrFE lNDrcAToR

yellow

A

remaining

remaining

indicator light located on the console will light when there is approximately 50 hours

on the

hours have been exhausted the lamp will turn otf.

lamp. A

new

light

the

Port

* in"r"ur". light output. Moving the wheel down

up

Replacement Lamp

attenuator to the

perform

the following operations:

counter-clockwise until unlocked and remove.

should be available at this

required illumination level.

point.

-

reduces rrgnt output.

Once the

PN:

LB-MAN CLSERV

REV. A

Page 12

Welc\Allyn.

PRINCIPLES OF OPERATION

LtcHT SouRcE

The

Surgical

controls

event

that the

exceeds the engineering

power

REPLAcEMENT LAMPs

The lamps are high

fixture

to the optrcal

PowER

All

the electricity to the Light Source is

lamp, tans, and control

The

operational

MuLr

Internal,

designed to

reduce

Fiber and f iber bundles.

llluminators

indicators,

and

fan(s)

to the

which is designed to

LtNxn PoRT AND MULT| L|NK* ExpANsroN PoRT

lamp. After

platform.

Supply

temperatures at the optical

wrrx

life

to both the Multi LinkrM Port

produce

consist

power

and a

malfunctions

specifications, an internal thermal

cooling, the Light

pressure,

CoNTRoL ELEcrRoNtcs

of the lamp

the highest

high

allow both easy and rapid exchange

circuitry is

of an enclosure housing a high

supply

if adequate

or

intensity and long life Light Sources. They are mounted into a

provided

lamp life indicator

and

output

coupling

with

control electronics. Cooling

flow is

air

Sources

controlled through the ON/OFF switch.

by a custom designed, wattage regulated, switching

Multi

and

powers.

joints

may

be

are controlled

LinkrM Expansion

Internal

thereby

intensity lamp,

blocked

protection

to the

minimizing

and/or the internal temperature

restarted.

in

the

Port,

Light

mechanism will automatically shut off

field

by a lamp voltage monatoring

are

Sources are

the

proprietary

provided

is

well

as

patented

possibility

as ensuring

Power

coupling optics and

fans

of damage to

via internal fans. In

to energize and

and

optical

platform,

of

patented

precise

power

circuit.

heatsinks

Micro Lrnk@

user

the

the

device

lamp

alignment

operate

mechanics

designed to

the

supply.

1B

WELCH

ALLYN

Page 13

SERVTCE

CLEANTNG

1. Prior

to cleaning, turn the

power

switch OFE and disconnect

power

the wall outlet.

2.

Clean the external surfaces by wiping wrth a cloth dampened with 10%

r

Routinely inspect

.

Follow the manufacturer's instructions when Cleaning

and clean allair

intakes

/

out flows at the rear

fiber

the

source.

the

power

plug

the

cord with a cloth dampened with 107o

WET.

power

source into a wall outlet until it is thoroughly

bleach solution and

Wipe

3.

NOT RECONNECT

4.

DO NOT wipe down any lenses or windows.

DO NOT

5.

SURGtcAL ILLUMtNAToR

The

console may be cleaned using a clean soft cloth with

Enzymatic Solution

lsopropyl

Hydrogen

Alcohol

Peroxide

2% G lutaraldehyde

(Enzol)

3% USP

Solution

following

the

Soap and Water

'lOo/o

bleach sotutton

and

water

source

of the chassis

from

both the Light Source and

bleach solution. DO NOT

for lint

or other debris.

IMMERSE.

bundles or accessories used with the light

water.

NOT IIVIMERSE.

DO

DO

dry.

cleaning agents:

CAUTION: Do not splash cleaning agents into

MULT| L|NK* ExPANsroN PoRT

The outside surfaces may

be cleaned

with

a soft cloth using the

isopropyl Alcohol

Soap

glass

The

A

cotton swab

Blow with

NOTE: Use care in

Water

and

surfaces may be cieaned by the following methods:

moistened

with lsopropyl Alcohol

dry compressed air

cleaning the optical

surfaces

PN: LB-MAN CLSERV Rev. A

openings,

any

of the

seams or electrical components.

following:

Multi

LinkrM Expansion

Port

prevent

to

scratches.

1-9

Page 14

'IVelc$;1*.

TooLs REoUIRED

.

Slotted screwdriver, less

.

#1 Phillips

.

#2 Phillips

.

Open

.

Needle nose

.

Nut Driver Set - English

.

Nut Driver

.

Deep well

.

Non-conductive

.

Light output

100

.

Laght output meter - Labsphere Model FIMS-400P

Screwdriver, less than

Screwdriver, less than

wrench

end

Set

socket set and

Surgical

set- English or 5/16"

pliers

-

Metric

pot

adjusting tool - CL

power

llluminator

meter with head.

or 3/16", 114",5116"

or 1 Omm

"

than 6

wrench

long

long

6"

long

6"

-

(2)

100

CL

100

Surgical llluminator

Coherent Lasermate 1 D or equivalent

minator

Surgical llluminator

(meter),

or equivalent that measures in lumens

Head Model 1d10

-

CL 300 Surgical

-

CL

lllu-

o

CaIbrateo

RMS

Drgital Multimeter

(DMM)

1,10

WELCH ALLYN

Page 15

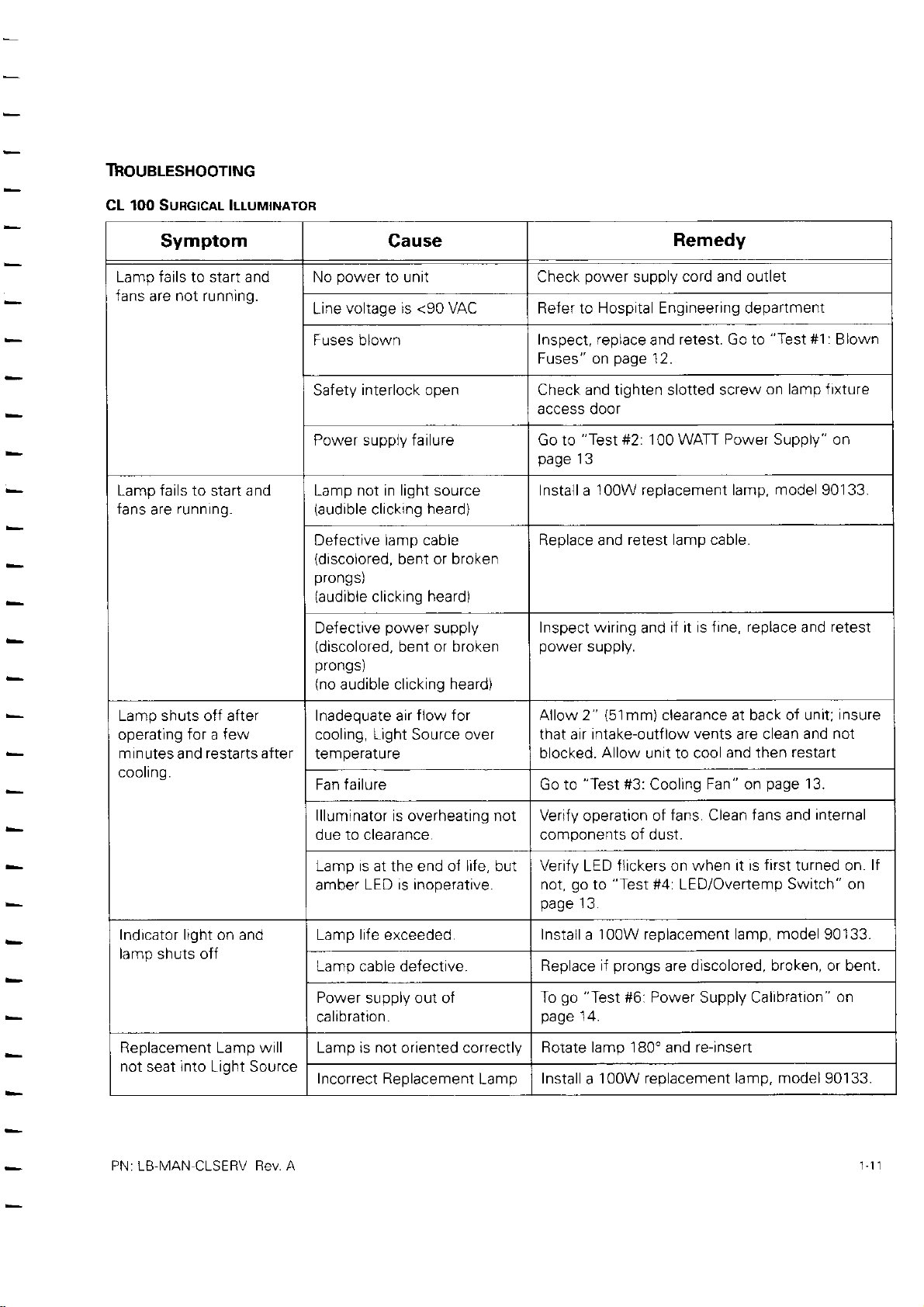

ThouBLESHoorNG

CL 1o0 SURGTCAL ILLUMTNAToR

Symptom Cause

Lamp fails to start and

fans are not ru nning.

Lamp fails to

fans

| ^'n^ ^h' '+^ ^al ^t.^.

Lo, r,P r,,urr u, I o, rel

operating

m in

running.

are

for a few

utes and

and

start

restarts after

coolrng.

power

No

voltage is <90 VAC Refer to Hospital Engineering department

Line

Fuses blown

Safety

Power supply failure Go to

Lamp not in light source

(audible

Defective lamp cable

(discolored,

prongs)

(audrble

Defective

(discolored,

prongs)

(no

audible clicking

Inadequate air

cooling,

lemperalUre

Fan failure Go to

Remedy

to unit Check

power

supply

Inspect, replace

Fuses" on

page

interlock open Check and tighten slotted screw

access door

"Test

#2: 100 WATT Power Supply" on

page

13

100W repiacement lamp, model 90133.

retest lamo cable.

clicking

heard)

Install a

Reolace and

bent or broken

power

bent or

heard)

supply

broken

Inspect wiring

power

supply.

clicking

heard)

(51mm)

Allow

"Test

#3:

Light

flow for

Source over

Ailow 2"

that air intake-outflow

blocked.

cord and outlet

retest. Go to

and

12.

if it is fine,

and

replace

clearance at back of unit;

vents

are clean

unit to cool

Cooling

and then restart

Fan " on

"Test

#1 :

Blown

on lamp f ixture

retest

and

insure

and not

'l

page

3.

Ind icator light on and

lamp shuts off

Replacement Lamp will

not

PN:

into

seat

LB-MAN CLSERV

Light Source

Bev. A

llluminator is overheating not

due to clearance.

Lamp rs at the end oi life, but

amber

LED is inoperative.

Lamp life exceeded.

Lamp cable defectrve.

Power

supply out of

calibration.

Lamp is not oriented correctly

Incorrect Replacement

Lamp

Verify operation of

fans. Clean fans and

components of dust.

Verify

go

not,

page

LED

to

13.

flickers

"Test

when it is

on

#4: LED/Overtemp

first

Install a 100W replacement lamp,

go

i'prongs

"Test

#6: Power Supply Calibration"

discolored. broken. or bent

are

14.

re-insert

and

lamp, model

Replace

To

page

Rotate lamp 180'

Install a 100W replacement

internal

turned on.

Switch" on

model

90'133.

90133.

lf

on

Page 16

Velc$11yn.

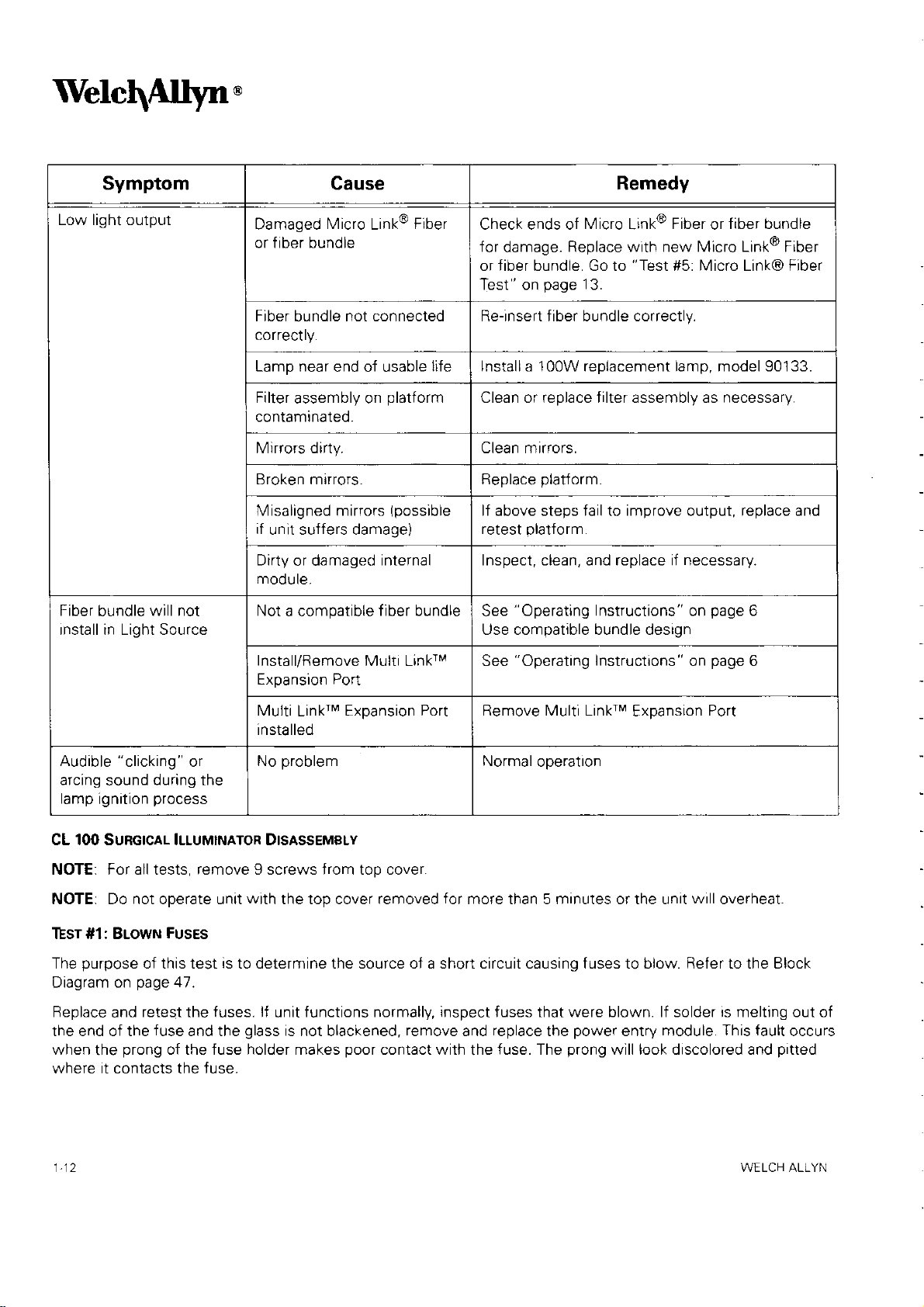

Symptom Cause Remedy

Lowlig ht oulpul

Fiber

bundle

Install in Light Source

will not

Damaged

or f iber bundle

Fiber

correctly.

Lamp near

Filter

contamrnated.

Minors dirty. Clean mirrors.

Broken mirrors. Replace

Misaligned mirrors

if

unit suffers damage)

Dirty

mooute.

Not

Micro

bundle

assembly on

or damaged

a compatible

not connected

end of usable

Fiber

Link@

life

platform

(possible

internal

f iber bundle

Check ends of

for

damage.

or fiber bundle. Go to

Test" on

Re-insert f iber bundle correctly.

lnstalla 100W replacement lamp, model 90133.

Clean or replace filter assembly as necessary.

lf above steps fail to improve output, replace and

retest

Inspect, clean, and replace if necessary.

"Operating

See

Replace with new Micro Link@ Fiber

page

platform.

platform.

Use compatible bundle design

Install/Femove

Expansion Port

Multi LinkrM

"Operatrng

See

Micro

'13.

Fiber

Link@

"Test

#5: Micro Link@ Fiber

Instructions" on

Instructrons"

fiber bundle

or

page

page

on

6

6

Multi

installed

Audible

arcing

lamp

CL lOO SURGICAL ILLUMINAToR DISASSEMBLY

NOTE: For all tests, remove 9 screws from top cover.

NOTE: Do not operate unit

TEST #1: BLowN

The

Diagram on

Replace

the end of the

when

where it contacts the fuse.

"

clicking " or

sound

ignition

purpose

page

and

prong

the

No

during

of this test is to determine the source of a short circuit causing fuses to blow. Refer to the Block

retest the fuses. lf

the

process

with

FUsEs

47.

fuse

and the

of the fuse holder makes

glass

krM Expansion Port

Lin

problem

the top cover removed

functions normally, inspect fuses that were blown. lf solder is melting out of

unit

is not blackened,

poor

remove

contact with

Remove Multi LinkrM

Normal

for

more than 5 minutes or the unit

and

the

operation

replace

fuse. The

the

power

prong

Fxpansion

entry

will look discolored and

Port

will

overheat.

module. This fault

pitted

occurs

WELCH ALLYN

Page 17

lf

fuse

the

replace

blows agarn, Inspect

visually

any

defective components.

the

power

supply and the wiring tor

damaged or burnt components. Remove

and

lf visual

Inspection

does

not

yield

any evidence

IEST #2: lOO WATT PowER SUPPTY

Verify operating voltage is

J2 terminals. When

Verify the lamp

lf voltage is

lf voltage is not

access door is closed.

present,

present,

present

power

reprace

inspect the f

on

is

applied to the unit, verify the

and retest

TEST #3: CooLING FAN

purpose

The

Visually

cover and inspect fan.

lf fan is inoperative

.

lf

voltage is

.

lf voltage is not

of this test ls to verify

inspect for a broken tan.

Replace any

and not broken, measure

present,

replace and retest fan.

present,

replace

When the unit is

IEST #4: LED/OVERTEMP SwITcH

purpose

The

of

this

test

is

to veriiy

of damage, remove and replace

power

supply input

terminals. Connect meter and

operating

power

uses,

supply.

wiring,

power

entry module, line filter,

the operatton of the lamp

broken

powered

fans.

up,

using DMM set for Volts DC for 12VDC

power

retest

and

proper

operation

supply.

of the LED.

cooling

look for

voltage

is displayed on the meter. NOTE:

power

and

supply

interlock

and retest.

to volts AC

set

switch.

tan.

a fan not turning. lf found, remove

fan

on

connector.

to J1 and

top

Visually inspect

and LED with DMM

.

lf

the DMM reading does not

r

lf

DMM reading matches

TEST #5: MIcRo

purpose

The

With

the

dramete'

.

lf

the intensity of light is not

not

cause the shape to change,

.

lf

the intensity is not

that LED/overtemp

set to the Diode

LINK@

FIBER lEsT

of this test is to verify

illuminator

to the

on, connect the fiber and

largest

stze.

consistent with alternating light

above, replace and retest

Over the same distance, adjust

focused.

lt any spot irregularities

connector.

switch harness is connected

Scale.

match,

DMM

replace

and retest

should read = .7VDC.

the

to the

LED harness

the

power

the operation of the Micro Link@ Fiber.

headlight.

the

consistent throughout the light

headlight

the

is the most likely

Over a distance of at least five teet,

spot and rotating the distal end connector does

and dark

headlight

the

are

present,

to the smallest

hold

the

diameter spot. At this adjustment, the headlight is

headlight

steady while rotating

power

suppty.

cause of the

present,

rings

supply. Verify continuity of wiring

adjust the spot

fault

the fiber is broken

distal

the

at the distal

(black)

end

PN:

LB-MAN-CLSEBV Rev. A

1,13

Page 18

Welc\Allyn'

.

lf

location

the

test. Replace

.

lf

the

location

of the

the fiber if

of the

defects move, remove the fiber,

detects are still

defects remain stationary,

present.

the

fault

clean the

is within the headlight.

end

with

distilled water, reconnect

the unit, and

TEST #6: PowER

purpose

The

power

Apply

power

DMM to

turning the

DMM. Monitor

and 18.00v.

'

lf the voltage

o

supply. The

the Lamp Return

lf the voltage is less

lt the voltage is more

1-31

5-685-2993 or 1

SUPPLY CAL|BRAT|oN

of this test is

to unit, once

unit on. When the lamp ignites,

the voltage

is between 17.00VDC

verify

to

the

positive

lead

-

terminal on the

displayed on the f luke when

than 17.00VDC, remove

than 18.00DC,

31 5-685-4233, 7:00am-3:00pm(EST).

the operation

lamp

lights, connect

of DMM

to the

power

there is

and 18VDC, remove

contact the Welch Allyn Technical

of the

the DIVIV

HV+

supply. WARNING: Do not

approximately 25kV on the

and replace

power

terminal on

the LED first turns

and

supply.

(set

to volts DC)

the

power

the

replace

to the lamp

power

supply and the negative lead

connect DIVM to wires

terminals which could damage

on. Verify the voltage is

supply

the lamp fixture.

Services Department

return

or

wires

cable

the unit for recalibration.

on the

of the

prior

between

at

to

the

17.00

WELCH ALLYN

Page 19

100

CL

PowER SUPPLY REMoVAL

'l

. Bemove the 9 screws securinq the

SURGTCAL

ILLUMTNAToR

DrsAssEMBLy

cover

toD

and

remove

the

cover.

2. Remove the 3 screws from the

3. Disconnect

4. Remove

wires from

the 2 screws

Screws

securing center

baffle to bottom

chass rs

J1 and J2 on the

from

the bottom chassis, securing the center baffle

w

Remove

5.

the

nut that

secures the center baffle to the back

bottom

side

of the back

power

supplv.

pane.

Disconnect

fan

(see

from

figure

connector

J4.

below).

lC"

oo

panel.

6.

PN:

Pull

supply.

LB

panel

back

MAN'CLSERV Rev.

out and move to the

A

platform

of the chassis to

side

garn

access to the back of the

power

115

Page 20

Welc$;1yt

7.

Remove the two white lamp cable wires and disconnect

'

the

4 wire

connector.

Remove

the supply and baff

le.

Remove the 4

8.

Reinstallation is the reverse

9.

of the two

return. Refer to " Photo 8"

PLATFoR'U REMovAL

'L

Remove

the bottom chassis and

2. Remove the 2 screws from

3. Remove the 4 screws f

4. As necessary, remove the 2

5. Remove the

movement

FRONT BEZEL REMoVAL

1.

Remove 9 screws securing top cover and remove the

the bottom chassis and

screws

lamp

9 screws securing top cover and remove the cover. Remove the 5 screws securing the front bezel to

platform.

of attenuator. Loosen

from

the corners of the

process

wires

cable

attaches to the

on

pull

front

the

rom

the corners of

screws

Reinstallation is the reverse

pull

front

with

page

24

panel

fan deflector

from

platform

panel

the

(+)

to connect the

from

out

the

the

screws and repositron as necessary.

out from chassis.

power

brown wire

assemblv.

f ilter

supply. Remove supply.

lamp

HV terminal and the shorter wire attaches to the

HV+

chassis.

platf

orm.

assembly.

process.

cover.

going

to J1 and the blue

lamp return

and

Remove

the

Installthe front

Remove

going

wire

-

terminals as shown.

lamp from

bezel and check

the 5 screws securing the

platform.

the

to J2.

for

The longer

(-)

proper

front

bezel to

lamp

from

the

the

power

remove

reverse

heat

the

reverse

switch noting wire localions. Push on

the black Rry from the LED wires where it mounts

process.

the

passing

process

through.

cover

top

shrink tubing

remove it

2. Remove

from

3. Using a sharp knife,

removed,

front bezel.

4. Installation is

superglue, loctite 430 to mount

light from the illuminator

FAN DEFLECTOR REMOVAL

1.

Remove 9 screws securing

2.

Remove

3.

Remove the overtemp switch f rom the fan

4.

Carefully

5.

Disconnect

Installation is

6.

wires

the bezel.

apply acetone to the LED and the front bezel to weaken the

the 5 screws securing the

remove

the connector and

switch

To

attach the LED, ensure both

LED.

and

front

with

installing new heat shrink tubing over fan connector.

RTV

Use

remove

bezel to the bottom chassis and

def

from

from the

sealant Dow Corning 737 to seal the LED,

the cover.

lector.

fan

the

wiring harness.

power

supply.

from

the

to

glue

bond

and

panel

and LED surfaces are clean. Use

pullfront panel

inside

the tront

remove the

to

bezel.

remove the LED from the

preventing

out from chassis.

switch

Once

any

WELCH ALLYN

Page 21

CHAssrs

FAN REMovAL

T. Remove

9 screws securing top cover

pane.

2. Remove heat

platform

the

3. Installation is the reverse

shrink tubing from the fan

mounts. Remove

process.

LED/OVERTEMP HARNESS REMovAL

1. Remove 9

the bottom chassis and

Remove

2.

harness at

Using a sharp

removed,

screws securing top cover and remove the

pulltront panel

the overtemp switch from the fan

platf

the

orm.

knife, remove

the black RTV from the LED wires where it mounts

apply acetone to the LED and

front bezel.

4.

Remove the 3 wire

lnstallation is

5.

Use superglue

light from

any

ties and

the reverse

(loctite

the illuminator to

process.

430)

to

remove

mount

remove

and

the cover.

connector.

the fan.

out from chassis.

lector

def

front

the

bezel to

the harness.

To attach

the

LED,

the LED. Use RTV sealant

pass

through.

See

figure

Remove 4

Disconnect

cover.

assembly.

and

Remove

Remove

weaken

ensure both the

(Dow

for routing

below

screws securing the

remove

the 5 screws

the wire tie

glue

the

panel

wire

the

to

bond and

and the

from the harness

ties

securing the front

f rom

the overtemp switch

the front bezel. Once

remove

LED

surfaces

Corning 737) to seal the LED

wires.

of

fan to

LED from

the

the back

at

bezel to

the

are

clean.

preventing

LAMP

CABLE

1. Remove I screws securing

back

PN:

LB-MAN-CLSERV Rev. A 1 17

REMovAL

panel.

Remove the nut securing

the top cover and

center baffle to the back

remove

the cover. Remove the 3 screws

panel.

Slide back

panel

from

the bottom of the

to

the side.

Page 22

Welc\ffiytt.

Remove

2.

from

cable

Installation is

3.

and connecting the shorter wire to the Lamp Return - terminal.

HV+

and the

INTERLoCK SwtrcH REMovAL

1. Remove the 9 screws securino the toD cover and

2. Disconnect the wires trom the interlock switch.

3. Remove the two nuts from the interlock switch and remove.

4. Instaliation is

PowER ENTRY MoDULE REMoVAI

Remove

1.

panel.

back

Remove

2.

3.

Remove the two nuts securing the PElvl to the back

nut from

the

power

the

the

Lamp Return - are

the reverse

9 screws securing the top cover and

Bemove

the 4 screws securing the chassis

the wire tie clamp secunng the

supply and remove the cable.

reverse

process

process,

nut securing center baffle to the back

the

with the

connected as shown

connecting the

longer

fan. Remove

cable wrre

remove

wires

remove

panel.

lamp

cable to the bottom chassis.

"Photo

in

the cover.

to the terminals

the cover.

the

Remove the

going

View

8" on

Remove

panel.

wires from PEM.

to the

the unit

page

marked

the 3 screws

PEM.

HV+

24.

terminal on

from

rear

the

COM and

from

Remove the lamp

power

the

and compare

NO.

the

supply

the

bottom of the

4.

lnstallation is the reverse

.

The

The

Rotate the screw

The

terminal marked as N on the PEN/]. The

nal on the

washer is located

star

washer is installed

flat

brown

wire is

PEM.

process

between the

on the other side of the

you

that

so

connected to

with the tollowing requirements:

PEM flange

later install the

can

the terminal marked

green

wire from the back

and the

panel

power

as

painted

is

and

cord retainer.

P on the PEM. The blue wire is connected to the

surface side

secured

panel

is connected to the

with

of the back

nut.

the

panel.

ground

termi-

r 1B WELCH ALLYN

Page 23

CL

100

SuRGrcAr ILLUMTNAToR REpAtR

Part

Number

PARTS Ltsr

Description

Photo #

Bubble

#

Ouantity

90133 l

LB-MAN.1OOW27OW MANUAL,

A0-10756

A0-10768

A0-1

101

4

071

0033 SCREW, #8-32

101-0022

016-0005 XLS,

-0068

1

01

A0-10683

A0-107

21 KAPTON TAPE,

A0-t

0828 PANEL,

u50087

u50081

u50085

u50075 l

A0-1071 1

A0-10856

213-0017

102-0012

44-10650

A4-10647

A0-10746

A0-10712

OOW R EPLACEM ENT LAMP

PANEL, BOTTOIV,

LABEL, WARNING, ILLUIVINATORS

SCREW,

scREW,

BUIV PER, RUBBER,

SEMS,

COVER,

FRONT,

l OOW INTERNAL

l OOW FAN DEFLECTOR

l OOW FILTE R

OOW ALIGNED PLATFORM

FAN,

PANEL,

POWER ENTRY MODULE/LINE

KE PS,

#6.32, W/CONICAL

WtRE

HARNESS,

POWER

OVERTEMP/LED

BAFFLE,

A0-'r0843 FOAM,

101-0062

-0007

207

105-0008

r06-0011

208-0016

44-10465

101-0073

010-0016 TUBING,

I01

0061

101 0038

SEMS, #6

GUARD,

CORD, RETAINING

STANDOFF, #8,.751

FUSE,

WIRE, PEM

SCREW, #8-32

HEAT SHRINK

SCREW,

1 OOW2TOW

SOLARTEC

27OW 1 1

PAINTED,

XLS

X 3/8, PHPS 1 4

#6-32

PHSS

X 1/4,

5/8 1 6 4

#6-32

TOE

CHASSIS, XLS

16

X

XLS

IOP

SOLARTEC

MODULE ASSEMBLY

PHPS

5i

CHASSIS 2 8 1

COVER, XLS 2 9 1

,]OOW

ASSEMBLY

ASSEMBLY

BACK WAVE PATTERN

FILTE R,

FUSED

WASHEB

ON/OFF, l OOW

SUPPLY XLS

SW]TCH ASSEMBLY 4

CENTER,

IGN

32 X 9/16

FAN,

5A SHEET III

XLS

TOR

PHPS

92MM

CLAMP

TO DIN

X 3/4", PHPS

BLACK

3/4"

#4-40X114, PHPS

PLUG,6/25

'l

'l

1

1 3 12

1 5

1 1

3 10 1

3

2 1

1t

4

2

I

1

3 12 1

3

3 14

3 15 1

3

3

3

3

4 20 1

4

4 40

5

5 24 1

5 25 I

5 26 4

6 27 2

6 28 1

6 29 4

6 30 z.za

6 31 4

7

13 1

to

17

18 4

'19

21 1

22 1

23

32 1

1

1

'l

1

1

4

PN:

LB-MAN.CLSERV ReV. A

Page 24

Welc$11*.

Number

Part

1 04

0006 WASHEH, COLOH

1

04-0008 WASHER,

104-0007

102-0001

104-0019

A0-10864

1 1 2-0001

Description Photo # Bubble

COAI II) 7 33 1

SEFRATED 7 1

WASHER, FLAT 7

NUT, H EX 7

WASHER, #4 tXItRNAI

CABLE,

CABLE

LAMP,

TIE,

SMALL

3OK

TOOTH

4"

# Ouantity

35 1

36 1

7 31 2

8 38

8 39 8

1

124

WELCH ALLYN

Page 25

PHoro 1

PHOTO 2

c

,,

=---|'

5

-/).

e

('

<-;-2

--.

lc"

"t-.......-o

a.--.-r

PN: LB MAN

CLSERV

BEv. A

1-21

Page 26

Welc$;1*'

PHoTo 3

19

12

10

11

PHoTo 4

14 18 17 15

21

WELCH ALLYN

Page 27

PHoTo

PHoTo 6

5

23

?4

31

30

PN: LB-MAN-CLSERV Rev. A

Page 28

Welc\ffi*'

PHoro 7

PHoTo 8

WELCH ALLYN

Page 29

CL 300 SuRGrcAr ILLUMTNAToR

Symptom Cause

Lamp fails

fans are not running.

Lamp fails to start and

tans are

to start and

running.

power

No

Line voltage is

Fuses

Satety interlock open Check and tighten slotted screw on lamp fixture

Power

board tailure

Lamp not in light source

(audible

Defective lamp cable

(discolored,

prongs)

(audible

Defective

(discolored,

prongs)

(no

audible

to unit Checf

<90

VAC Refer

blown

supply or auxiliary

clicking heard)

or

bent

clicking heard)

power

bent

clicking

broken

supply

or

broken

heard)

Remedy

power

to

Inspect, replace

"

Fuses

access door

"Test

Go to

page

an

Install a 270W replacement lamp, model 90125.

Replace and retest lamp cable.

Inspect wiring

power

supply.

supply cord a1d outlel

Hospital Engineering department

retest.

and

page

on

27

27.

#2:Auxiliary Board

if it is fine, replace and retest

and

"Test

Go to

Input Terminals

#1 :

Blown

Lamp shuts off after

seat

for a few

on and

Lamp

into

Light Source

operating

m In utes and restarts

Indicator lrght

lamp shuts off

Replacement

not

will

lnadequate air flow for

cooling, Light Source over

IemperaTUre

Fan failure

llluminator is overheating not

due to clearance.

Lamp is

amber LED is inoperative.

Lamp life exceeded. Install a 270W replacement lamp,

Lamp cable delective. Beplace

Lamp is not oriented correctly Rotate

lncorrect Replacement Lamp Install a 270W replacement lamp, model 90125.

at the end of

liie,

Allow 2"

that air

blocked.

Go to

Verify operation of

components of dust.

Verify LED flickers on when it is first turned on. lf

but

not, go

(51mm)

intake-outflow vents

Allow

"Test

"Test

to

prongs

if

lamp 180"

clearance at back of unit, insure

to cool and then restart

unit

#3.

Cooling

f4

Fan"

fans.

Clean

L ED Operatron " on

are discolored, broken, or bent.

re-insert

and

are clean and

page

on

fans

27.

and internal

page

model

90125.

not

27

.

PN. LB-MAN-CLSERV Rev. A

Page 30

Welc\ffiyr..

Symptom

Low light output Filter

contamrnated.

Mirrors are dirty. Clean

Broken mirrors. Replace

Misaligned mirrors

if

unit suffers damage)

Damaged Micro

or f iber bundle

Fiber

correctly.

Lamp

Fiber

bundle

install

will not

in Light Source

Not

a compatrble

Install/Remove

Expansion Port

Cause

assembly on

Link@

ndle

bu

near

not connected

end of usable

Multi LinkrM

platform

(possible

Fiber

life

fiber

bundle See

Remedy

Clean or replace filters as necessary.

mrrrors.

tne

platform.

lf above

platform.

retest

Check ends of Micro Link@

f or damage. Replace with new Micro Link@

fiber

or

Test"

Be-insert f iber bundle

Install a 270W replacement lamp, model 90125.

Use compatible bundle design

See

bundle. Go to

on

"Operating

"Operatrng

failto improve output, replace and

steps

Fiber

or

"Test

#5:

Micro Link@

page

28.

correctly.

on

page

page

Instructions" on

Instructrons"

fiber

6

6

bundle

Fiber

Fiber

Audible " clicking

"

or

arcrng sound during the

lamp ignition

process

Multi LinklM Expansion Port Bemove Multi LinkrM

problem

No

Normal operation

Expansion

Port

WELCH ALLYN

Page 31

CL

300

SURGTGAL ILLUMTNAToR DrsAssEMBLy

NOTE:

NOTE: Do not

lEsT #1:

The

Diagram on

Replace

the end of

when

where it contacts

lf visual inspection

wires

For

all tests, remove 9

operate unit with the top cover removed for more

BLowN FUsEs

purpose

of this test is to determine the source of a short

page

48.

and retest the fuses. lf unit functions normally, inspect fuses

fuse

the

the

prong

and the

of the fuse holder makes

the fuse.

does not

that connect

PCBA

and inspect fuses

.

lf

fuses

.

TEsr #2:

the

lf fuses are tine, remove

AuxtLtARy BoARD lNpur TERM|NALS

are blown,

Verity operating voltage is

termrnals.

J4

When

Verifv the lamo

power

access door

screws

glass

from

top cover.

is

not blackened, remove and replace

poor

yield

any evidence of damage,

auxi iary

remove

and

present

to the

board

replace

and

replace

on auxiliary board input termrnals. Connect meter

is applied to the unit

is

closed.

contact

power

with

supply. Replace

the PCBA

power

the

suppty.

the operating

than 5

circuit

causing fuses

that were blown. lf solder is melting

tuse.

the

remove

The

J2 and J3 from auxiliary board

fuses

auxiliary board

voltage, verify

minutes

power

the

prong

or the unrt

to blow.

entry

will look discolored

will

Refer

module. This

and turn system on. Remove

(part

no. A4-10670).

and set

is

it

displayed on the meter. NOTE:

to volts

overheat.

to the Block

out of

fault occurs

pitted

and

(blue

and brown

power

AC to J1 and

lf voltage is

lf voltage is

NOTE: lf

lEsr #3:

purpose

The

Visually inspect for

present,

not

lamp is not

replace

present,

on and

inspect the fuses, wiring,

CooUNG FAN

of this test is to verity

a broken fan. When the unit is

and retest auxiliary

voltage is

cover and inspect fan. Replace any

lf fan is inoperative

the lamp fan

.

lf voltage is

.

lf vo tage is not

#4:

IEST

The

LED OPERATIoN

purpose

Visually inspect that J1 is

Diode

the

Scale. DMM should read = .7VDC.

and not broken, measure

(exhaust)

this

of

and J101or the

present,

present,

test is to

replace and retest fan.

replace

verify

connected to the auxiliary board. Verify contrnuitv

board.

power

present,

check

if

the operation of the

powered

broken

fans

usrng DMM set

power

re-test

and

proper

supply

operation of the LED.

(intake).

auxilrary board.

entry

power

the

lamp

up,

module,

line filter, and interlock switch.

supply is defective.

cooling

fan.

look tor a fan not

for Volts

DC for

turning.

'l2VDC

wiring

of

lf found,

on fan connectors,

LED with

and

remove top

Jl

DMM set to

T is {or

PN: LB MAN-CLSERV

Rev. A

Page 32

Welc$1yn.

.

lf the DMM reading

.

f

TEST #5: MIcRo LINK@ FIBER TEST

purpose

The

reading matches

DMM

of this test is to verify the

not match, replace

does

above, replace and retest

and retest the LED

operation of the

auxiliary

the

Micro

board.

Link@

harness.

Fiber.

With

diameter to the largest

.

.

Over the same distance,

focused. lf

connector.

.

.

illuminator

the

intensity

lf the

not

cause the shape to change, the headlight is

lf the intensity is not consistent with

rstal

the d

any spot irregularities are

lf the location of the defects move, remove

Replace

test.

lf

location

the

on, connect the fiber and the headlight. Over a distance oi at least five feet, adjust the spot

size.

light

of

end.

the fiber if defects are still

of the defects remain

is not consistent

adjust the

headlight

present,

throughout the

the

hold

the

light

the

fiber,

alternating

to the smallest diameter spot.

present.

stationary, the

light

spot and

most likely

and dark

headlight

clean the end

fault is within the headlight.

steady

rotating

oJ the fault.

cause

rings

present,

are

At

while rotating the

with

distilled

the distal end connector does

the broken

this adlustment, the

water, reconnect

fiber is

headlight is

distalend

broken

(black)

the unit, and

at

WELCH ALLYN

Page 33

CL 300 SURGICAL

ILLUMTNAToR

DrsAssEMBLy

NOTE: All servicing requires removal

INTERNAL MODULE REMovAL

1. Remove

2. Remove the front bezel

3. Pull the internal module out of the

Installation

4.

will f t into

PowER SUPPLY REMovAL

1. Bemove

2. Remove the front bezel

3. Remove the air duct strap and air duct.

4.

Remove the 5 wires from the PCBA

Remove

5.

NOTE: Pull

termlnal's solder

the top cover.

is the reverse

recessed

the

the top cover.

wires f

the 7

or

pry

rom the

the wires straight up.

joint

on the

removing

by

process

area of the

by

of the

platform

with the

front

removing

auxiliary

power

power

supply board.

Puli or

Do

the

the

supply.

not rock

top cover. Remove the 9 screws and

5 screws securing the front bezel to the bottom chassis.

assembly.

portion

flat

edges on the

panel

and the

5 screws securing the front bezel to the bottom chassis.

(part

board

Rocking

pry

wire terminal straight up.

wire to remove it f rom the

the

remove.

to

gray

black dot in the

no. A4-10670).

remove

internal module

of the

gray plastic

to the bottom right.

power

the cover.

supply may damage the

aligned so

rt

Use bent tiD needle nose

PN: LB-MAN-CLSERV ReV. A

to

oliers

the terminal off.

orv

The handle

of a screwdriver

is

used as the f ulcrum.

Page 34

TVelc$1*.

6. Remove

7.

Installation is

.

P1

on

.

P2A- Used

.

P2

on

.

P3

on

.

P4

on

o

P5 on

.

P11 on

.

P12

on

(PARr

PCBA

'1.

Remove

2. Not

No. 44-10670)

location

the

the 4

screws

the reverse

power

power

power

power

power

power

power

power

from

supply to Jb

to confrgure

supply to J4

supplytoJl

supply

supply - red

as noted

and

-

supply - red

supply - black wire from red/black

REMovaL

remove

power

the

process

on

to 230v operation only

on

on PCBA

black wire from red/black

wire f rom red/black

or

above.

connectors

supply and

with

PCBA

PCBA

white

wires located

the

(part

no. A4-10670) - red

(parr

no. 44-10670)

(part

no. 44

wire from red/black

from J6, J7,

pullthe

-

pair

supply out of the front

as forrows:

NOT USED

-

brown wire

10670) bluewire

-

pair

housed

-

housed in

(thtn

pair

(thin

parr

J9, J

wire

10, J 1

1 , and J 12.

wire

in tubing

tubing

wire

pair)

pair)

remove.

to

3. Using a short #1

PCBA.

4.

Installation is

for

below

the reverse

proper

screwdriver, remove

process.

wire routing.

Use

the 4 screws from

the block diagrams as necessary

the corners of PCBA

(part

reconnect

to

no. A4-10670)

the wires.

and remove

See

figure

WELCH ALLYN

Page 35

IGNIToR REMovAL

1. Remove

Disconnect

2.

Remove 4

3.

center

Installation is

4.

baff

Installing

Reconnect

5.

.

Red wire to the lower center most terminal.

.

Black wire

-

lamp cable wire to the top left terminal

+ lamp cable wire to the top right terminal

the top cover.

lamp

the 2

cable wires and the

screws, securing rgnitor

module

red

and black

wires f rom

to the center baffle. Screws are

le.

the

reverse

process.

NOTE:

because

the screwdriver will not

and removing the screws lnto the ignitor to tap the

the

wires

to the

follows

as

lower

{see

outermost termina

figure for

(shorter

orientation).

.

wire).

llonger

wire).

holes

ignitor.

the

located

directly

prior

to installing the

Note the

wire locations.

on the other side of the

reach the lower screws,

ignitor

in the unit will

LINE FILTER REMOVAL

1. Remove the

PN: LB MAN

top cover.

CLSERV

REv. A

Page 36

Welc$1ytt'

2. Remove the screws

Hex head

secu

ring

screw

center

batfle to side of

securing the center baffle to the back

a

bottom cnassts

3. Remove the wires from both ends

panel

and the

XLS Rubber Bumper

rentdr baffle to

bottom chassis

a

Screw securing

center baffle to

panel

back

the line filter. Note location of wires.

of

bottom

chassis

(see

figure below).

4. Remove the 2 screws

Installation is the reverse

5.

.

The

end of the filter with 3 terminals is on the

.

The

.

The blue wires

termrnals.

CHAssrs

'1

. Remove

2.

3. Disconnect the

FAN REMovAL

Remove

unit, remove the fan on the

center baffle, then

(ground)

green

go

the top cover.

the 4 screws securing the fan and the wire

pull

fan

connector from the PCBA Auxiliary board

securing the

process

goes

wire

to the terminals

power

wires

the

line filter

with the

to the terminal directly

supply

out of

remove.

and

following requirements:

platform

nearest

side. To remove the lamp

grommet.

the

the

fans

guard.

side of the center baffle.

mounted to the metalsurtace.

on both ends.

NOTE: to

(part

The brown wires

remove

fan,

no.

the

push

the split

A4-10670) and

go

to the center most

fan from the lamp side of the

grommet

remove.

through the

WELCH

ALLYN

Page 37

4. InstalatlonisthereverseprocesswithJ11forthefanonthelampsrdeandJl0forthefanonthepower

supply side. Route

Wire Bouting

(part

the wires as shown in figures

on lgnitor and PCBA

no.

44- 10670)

below.

Chassis

Fan Wrre Routing

The label

on the lamp

POWER ENTRY

T. Remove

2. Remove

the top

the 3 screws securing the

baff le.

fan faces

side

MoDULE REMoVAL

cover.

out, the label on the

back

panel

to the

bottom

power

supply

side

faces in

chassis and the 1 screw back

(see

figure

panel

below).

to center

Remove

3.

Move

4.

Remove nuts from

5.

PN:

LB-MAN.CLSERV ReV. A

the 3 wire terminals from

panel

back

as necessary

to

power

gain

entry module.

access to

the PEM and remove module.

nuts

securing the

PEM

(power

entry module).

Page 38

Welc$11yr..

6. Installation is

.

.

o

PLATFoRM REMoVAL

'1

.

Remove the top cover

2. Remove

mooute.

3. Remove the two screws from

4. Remove the 4

5. Remove the lamp shroud f rom

Remove

6.

7. Installation is

internal module

lock

The

The flat

green

The

is connected

the front bezel by removing

the

reverse

the

washer is inserted

washer is inserted between

(ground)

to the terminal labeled N

screws securing the

platform

reverse

the

are

process

wire is

remove

and

and

the thermistor assembly from J12.

process.

installed.

Reattach the front bezel

with the following requirements.

between the

connected to the terminalsoldered directly to the metal surface. The blue wire

the lamp.

the 5 screws that secure it to the bottom chassis. Remove the internal

the air duct strap and remove the

plat{orm.

platform.

the

When installing

PEIV1

and the

non-painted

the

and the brown

the

painted

side of the back

wire

platform,

and check

side of the back

to the terminal marked P

duct.

verify that the shroud duct, the strap, and the

for

panel

attenuator

panel.

and the nut.

wheel

alignment.

.

Botate

freely,

FRoNT

1.

2. Remove

3. Noting the wire locations,

4.

5. Installation is the reverse

BLowER FAN REMovAL

2. Remove

3. Remove the air duct strap

BEZEL REMoVAL

Remove the top cover.

Using a sharp knife, remove

the LED and

set, apply opaque

the illuminator

1. Remove

wheel

the

loosen the

the 5 screws,

the

passing

the top cover.

front

the

across its adjustment range and if

platform

panel

front

sealant, Dow Corning 737 or equivalent, to the

bezel as

securing the

process

through

screws and

front

remove the wires from

the black

to loosen the

with

the LED.

described oreviouslv.

and duct as described above.

reposition

bezel to the bottom chassis.

RW from

qlue

the LED

the

power

the

the LED. Once removed, apply acetone to the area between

bond. Remove the LED.

glued

to the front

wheel moves freely,

the

platform

switch.

the wheel rotates freely.

so

Push

panel

using Loctite 430

around

area

continue, if

out the

the

power

LED to

it

does

switch.

equivalent.

or

prevent

not

move

Once

light from

I

-34

WELCH

ALLYN

Page 39

4.

Remove electrical connector

from PCBA

Jg

(part

no. 44-10670).

5. Remove the 2 nuts,

installation

6.

.

Spacers are installed

LAMP

CABLE

I Remove the

2. Open the lamp

3. Disconnect

4 Pull

lamo

5. Installation is

.

Bemove the nylon wire

is the reverse

REMoVAL

top cover.

access door, open the

the lamp cable wires from the ignitor.

cdble

out

reverse

the

througl-

Feed the wires through

Connect the shorter wire to the top left terminal on the ignitor.

terminal. Install the terminals between

screws, and spacers that

process

with

the

mount

the blower fan to the

following requirements:

on the screws between the bracket and the fan.

latch,

and disconnect cable.

la'np

the

process

tie

the space between the

with

from

the

access door.

following

the

lamp

cable.

two flat washers

the

requirements.

line filter

and the center chassis.

Connect the

(see

figure for

blower bracket.

longer wire

routing).

wire

to the top, right

Wire Routing

(part

no. 44-10670)

on lgnrtor and PCBA

PN: LB MAN CLSERV Rev. A

Page 40

Welc$11*'

CL 300 SURGTCAL ILLUMTNAToR REPATR PARTS Lrsr

Part Number Description

901 25 27W R EPLACEM tN I LAMP

tB-MAN-1OOW27OW MANUAL, 1

RM-LBL-023 LABEL, PROTECTIVE EARTH

A0-10755 BETEL

A0-10880

A0- 1 0797 EXTERNAL MODULE HOLDER, 27OW

A0-10714

A0-10768 LABEL, WARNING. ILLUMINATOFS 2 5

TOP

OOW2TOW

R,

COVE

SCREW,

PAINTED, XLS

LENGTHENED

SOLARTEC

GROUND

27A

Photo # Bubble # 0uantity

101-0033 SCREW, #8 32 X 3/8, PHPS 2

101-0022

SCBEW,

A0-10907

1

01-0068 SEMS,

016-0005 XLS, BUMPER, RUBBER, 5/8

#6-32 X 1/4,

CHASSIS BASE

#6-32 X

101,0062 SEMS, #6.32 X 9/16 PHPS

207-0007 GUARD,

FAN,

1 05-0008 CORD, RETAINING CLAMP

208-0016

A0-10904 BACK PANEL 2

213-0019 ROCKEB SWITCH,

A0-10906

A0- 1 0905

44 1 0670 PCBA, AUXILIARY 3

FUSE,

5A SHEET

BLOWER BRACI..ET

CENTER

BAFFLE 3

PHSS

2

2 8

PHPS 2 9 8

5/16,

2 10

2 11 I

92MM

2 12 2

2 13

III 1 2

ON/OFF,

WHITE 3

3

218 0003 IGNITOF, 270 WPI 3

A0-10864

105-0010 TENSION

101-0078

44-10680 WIRE HARNESS, LED/AU)?PS 3

112 0001 CABLE TIE, SMALL

A0-1 081 2 DUCI NOZZLE BLOWER, 27OW

A0-10814 STRAE AIR DUCT

17

u501

SCREW,4-40

27OW LAMP SHROUD SUB-ASSEN/ BLY

CABLE, LAMP, 3OK

RETAINER 3 22

WIRE

X 1/4, FHD,

StT 82DG

4"

u50111 27OW ADJUSTED POWER SUPPLY

213-0018 SWITCH,

1A2 0012 KEPS, #6_32,

21

0-0001

INTERLOCK,

WCONICAL

LIN E FILTER,

6.04,

POLE 4 30

SNGL

WASHER

FLANGE 4 32

3 21

3 23

3

4 26 1

4 27

4 28

4 29

4 31 3

2

3

4

6

7 8

15

16 1

17 1

Itt

18 1

19 1

20

24 1

25

'l

'I

1

1

1

1

4

4

1

1

4

1

,l

'1

1

,l

1

I

WELCH

ALLYN

Page 41

Part

Number Description Photo # Bubble # 0uantity

101-0059

213-0017

101-0084

POWER

SIMS,

ENIRY

SCREW,

u50123 27OW INTERNAL MODULE SUB ASSMB 4

u501 25 27OW FILTE R ASSEMBLY

-0061

1 01

SCREW, #4-40 X 1/4, PHPS

#6-32 X 1i4 PHPS 4

MODULE

FUS ED

#6 THD FRMG, PHPS

/

LINE

FILTER,

33

4

4 35

34

36

5 31

5

38 2

u501 1 5 27OOW ALIGNED PLATFORM 5 39

101-0073

44-10655 FAN,

A4-1067

44-10673 WIRE HARN ESS,

A4-1Q67 4 WIRE HARN ESS, AC/FILTER

1

09-0006

44 10675 WIRE HARNESS, AC/SWITCH

44 1

44-10676 WIRE HARN ESS, FILTER/PS

44-10678 WIRE HARNESS, AUXTPS

A4-10677 WIRE HARN ESS,

2 WIRE HARN ESS, FILTEF/GFOUND 6

0465

101-0085

44-10683 FAN, BLOWER, TEFLON WIRE 7

101 0083 SCEEW, 4.40 X 1 1/4",PHPS, SS 7

106-001 5 SPACER,

1

02-0008 NUT,

106-001 1

SCREW,

BUSHING,