Page 1

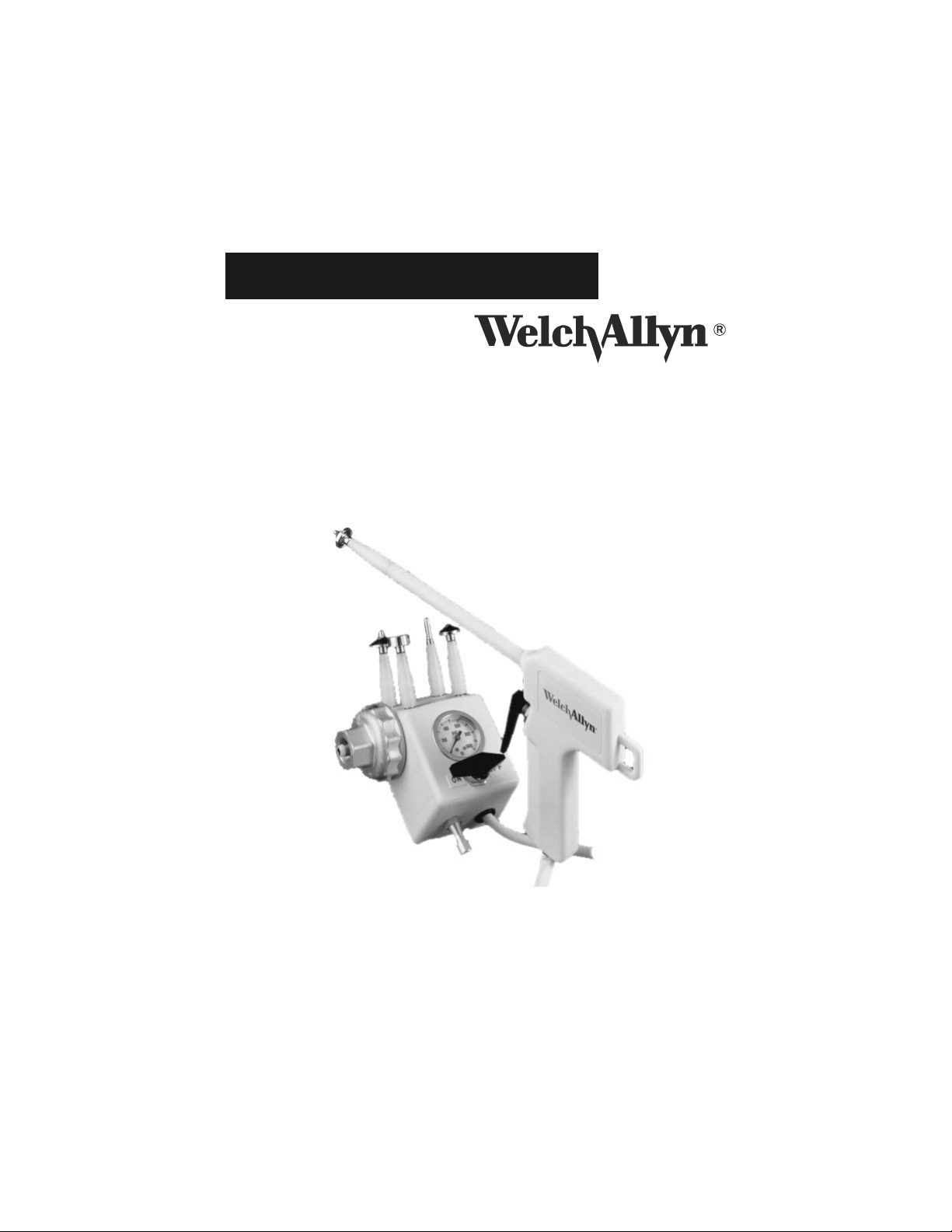

Cryosurgery System

REF 88372

Operating Manual

Page 2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The Cryosurgery System . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Scavenging Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Directions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Care and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sterilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page 3

Introduction

Thank you for purchasing the Welch Allyn, Inc. Cryosurgery System for

use in your clinic or private practice.

Each system is meticulously handcrafted and thoroughly tested prior to

shipment. Proper care and maintenance ensures a long and useful life.

This Operating Manual is intended to acquaint you with your new Cryosurgery System, its directions for use, cleaning and storage, and the

necessary safety precautions.

Precautions

Do not store gas cylinders above normal room temperatures.

Use only Medical Grade Nitrous Oxide (N

Do not crimp or tightly bend the gas hose. Coil the hose no tighter than

an 8-inch circle. If a hose is damaged, replace it.

Verify the O-ring is in place at the end of the cryogun prior to installing

a cryotip. Inspect O-ring and replace if cracked or damaged.

Hand tighten all connections. Tools are not necessary.

Turn the gas cylinder valve off before disconnecting the console from

the gas cylinder.

Verify the gas is off at the console before changing tips.

If a cryotip is dropped, inspect for damage and replace as necessary.

This manual is not meant to teach the proper technique or any of the

medical considerations regarding the use of this equipment. Welch

Allyn recommends that prospective users obtain appropriate training

before using this equipment as improper use is potentially hazardous

to the patient and the user. DO NOT use this device without proper

training.

1

O)/Carbon Dioxide (CO2) gas.

2

Page 4

CAUTION: FEDERAL LAW RESTRICTS THE SALE OF THIS DEVICE TO OR

ON THE ORDER OF A LICENSED MEDICAL PRACTITIONER OR DESIGNATED AGENT.

WARNING: EXPOSURE TO NITROUS OXIDE (N

O) MAY RESULT IN

2

IMPAIRMENT OF PERFORMANCE, COGNITION, OR DEXTERITY. VENTILATE WELL.

IT IS THE USER’S RESPONSIBILITY TO FIT THE EXHAUST HOSE

BETWEEN THE CRYOSURGERY UNIT EXHAUST AND DISPOSAL POINT

TO MINIMIZE NITROUS OXIDE (N

O)/CARBON DIOXIDE (CO2) EXPO-

2

SURE.

The Cryosurgery System

READ THIS ENTIRE MANUAL BEFORE OPERATING

YOUR NEW CRYOSURGERY INSTRUMENT.

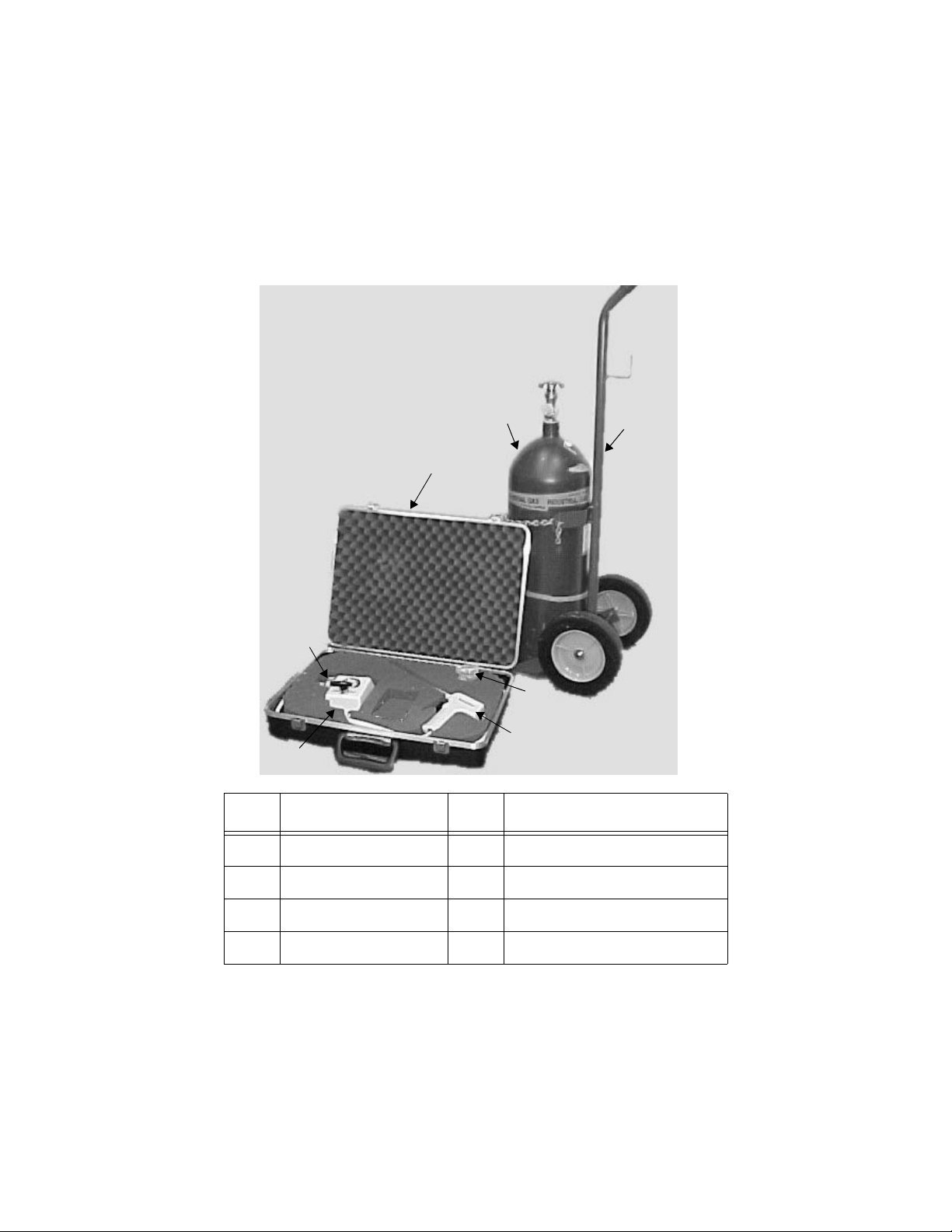

The Cryosurgery System is designed for easy assembly and operation.

No tools are necessary.

The system is delivered in an attaché carrying case along with cleaning plugs, a gas scavenging hose, and a package of replacement “O”

rings. On the end of the cryogun barrel is a tip protector, which is

removed when the cryotip is used and replaced when the cryogun is

not in use.

A 20# N

O (Nitrous Oxide) or CO2 (Carbon Dioxide) gas cylinder is

2

available for the Cryosurgery Unit. Nitrous Oxide/Carbon Dioxide is

used as the refrigerant for the cryogenic process. Use the N

O/CO2

2

only in a well-ventilated area. A 20-ft. scavenging hose is provided to

divert used gas away from the operator. Use the mobile hand cart for

cylinder movement. Do not drag, slide, or roll the cylinder. Store the

cylinders upright and firmly secured to prevent falling or accidentally

2

Page 5

getting knocked over. Refill the compressed gas cylinders only by qualified producers of compressed gases. Do not allow the storage cylinder

temperature to exceed normal room temperatures.

1

2

3

4

5

7

6

No. Description No. Description

1 20# Cylinder 5 Cleaning Plugs and “O” Rings

2 20# Mobile Cart 6 Console

3 Carrying Case 7 Cyrogun

4 Quick Connect

3

Page 6

General Instructions

Check the gas cylinder to verify that it contains adequate gas. The

pressure gauge should read between 600 and 800 PSI for proper freeze

to occur. A pressure below 600 PSI may not provide enough pressure

for sufficient freeze or defrost.

Securely seat the gas cylinder onto the mobile cart and hold it into

place with the safety chain provided.

Examine the tubing leading from the console to the gun by running the

line between the thumb and forefinger, checking for any kinks or abrupt

bends. A kink in the line can cause a weakness which can erupt under

pressure.

Inspect the “O” ring seal located between the tip and the gun barrel

prior to each use.

Scavenging Hose

A 20’ scavenging hose is provided with the unit to divert the N2O/CO2

gas away from the operator and patient to a remote, well-ventilated or

uninhabited area. Push one end of the scavenging hose over the

exhaust muffler on the console (a small amount of mild soapy water on

the inside diameter of the hose will ease this operation) of the cryo

unit and lead the other end o a remote, well-ventilated or uninhabited

area.

4

Page 7

Directions for Use

1. A 20# CO2 tank requries an adapter (supplied). Verify the plastic gasket (1) is in place (as shown) prior to fastening the adapter to the tank

valve.

(1)

2. Tighten the quick-connect

to medical grade N

gas supply as shown (or to

the adapter). (A)

O/CO2

2

3. Connect the gas scavenging

hose to the exhaust muffler

on console. Vent to remote

location. (B)

(A)

(B)

5

Page 8

4. Select the proper tip for the cryo procedure and unscrew the protective

shield (C) from the end of the cryogun. Hand tighten the cryo tip (D)

onto the gun.

NOTE: Verify the O-ring is in place at the end of the cryogun prior to

installing a cryotip. Inspect O-ring and replace if cracked or damaged.

(C)

5. Open the gas supply valve on cylinder.

6. Turn the arrow valve

to ON position.

Verify pressure is in

the working range.

(D)

NOTE: this manual is not meant to teach the proper technique or any

of the medical considerations regarding the use of this equipment.

Welch Allyn recommends that prospective users obtain appropriate

6

Page 9

training before using this equipment as improper use is potentially hazardous to the patient and the user. DO NOT use this device without

proper training.

7. Apply probe to surgical

site and squeeze the

trigger to freeze

(normal time is approx.

3 minutes).

8. Release trigger and remove the tip from the site and allow to stand for

approximately 3 minutes. Repeat steps 6 and 7 one time.

9. When the procedure is

complete, turn the

arrow valve to the OFF

position.

10. Close the gas supply valve on the cylinder.

7

Page 10

Care and Storage

Upon completion of the surgical procedure, shut off the system at both

the console and the tank. A squeeze of the trigger releases any residual gas in the console. Remove the cryo tip from the gun for cleaning

and place the tip protector onto the end of the gun. Wipe down the gun

barrel. The console can remain connected to the gas cylinder and the

gun can hang on the mobile cart hook. Or, disconnect the system and

return to the carrying case for storage.

Cleaning

WARNING: DO NOT USE BLEACH OR ANY PRODUCT CONTAINING

CHLORINE IN THE CLEANING OF THIS PRODUCT.

CAUTION: DO NOT RINSE OR SOAK TIPS WITHOUT FIRST INSTALLING

CLEANING PLUGS. VERIFY THE CLEANING PLUGS HAVE RUBBER ORINGS IN PLACE TO PREVENT LIQUID FROM ENTERING THE TIPS.

NOTE: NOT USING CLEANING PLUGS WILL CONTRIBUTE TO UNIT

MALFUNCTION.

Clean the cryogun and tips by wiping down with alcohol. Clean the tips

in a mild soap and water solution with cleaning plugs installed and Orings in place. After cleaning, remove the cleaning plugs and return to

the storage pouch. For storage, cleaning tips also fit on the metal studs

located on the console.

Disinfection

To disinfect the tips, soak in a cold disinfectant with cleaning plugs

installed and O-rings in place. Clean tips before disinfecting. Follow

the disinfectant manufacturer’s guidelines for disinfection.

8

Page 11

Sterilization

WARNING: DO NOT AUTOCLAVE THIS INSTRUMENT

NOTE: DO ALL CLEANING AND STERILIZATION WITH CLEANING

PLUGS AND O-RINGS IN PLACE ON TIPS.

COLD STERILIZATION: Sterilize the tips by soaking in a cold sterilant

with cleaning plugs installed and O-rings in place. Follow the sterilant

manufacturer’s guidelines for sterilization.

ETO STERILIZATION: Thoroughly clean and dry cryotips prior to ETO

Sterilization. Do not exceed 130° F or 100 PSI when sterilizing the tips.

Service

Customers with instruments requiring service should contact the

Welch Allyn Technical Service Department at (800) 535-6663, 315685-4100, or FAX: 315-685-4653.

Accessories

Contact Welch Allyn Customer Service for additional information on

the following accessories:

Part Number Description

88374 General Purpose Cryotip- Round End

88376 General Purpose Cryotip- Flat End

88378 Exocervical Cryotip

88380 Exo/Endocervical Cryotip - Short Top

88382 Exo/Endocervical Cryotip - Long Top

88384 Special Exo/Endocervical Cyrotip

88386 Large Exocervical Cryotip

9

Page 12

Part Number Description

88388 Jumbo Exo/Endocervical Cryotip

88390 Curved Anorectal Cryotip

88392 Condyloma Cryotip

88394 Derm Bevel Cryotip

88396 Berm Bevel Large Cryotip

88398 Maxiderm Cryotip

88400 Microderm Cryotip

88402 Soll Lash Epillating Cryotip

88404 “E” Cylinder Tank Adapter, CO

88406 “E” Cylinder Tank Adapter, N2O

88408 20 Lbs Cylinder N

88410 20 Lbs Cylinder CO

O

2

2

88412 20 Lbs Cylinder Cart

88414 7 Lbs E-Cylinder N

88416 7 Lbs E-Cylinder CO

O

2

2

88420 Carrying Case

88422 O-Rings (package of 10)

88424 Cleaning Plugs (package of 4)

10

2

Page 13

Warranty

One Year Limited Warranty On New Instruments

Instrumentation purchased new from Welch Allyn, Inc. (Welch Allyn) is

warranted to be free from original defects in the material and workmanship under normal use and service for a period of one year from

the date of first shipment from Welch Allyn. This warranty shall be fulfilled by Welch Allyn or its authorized representative repairing or

replacing at Welch Allyn’s discretion, any such defect, free of charge

for parts and labor.

Welch Allyn should be notified via telephone of any defective product

and the item should be immediately returned, securely packaged and

postage prepaid to Welch Allyn. Loss or damage in shipment shall be

at purchaser’s risk.

Welch Allyn will not be responsible for loss associated with the use of

any Welch Allyn product that (1) has had the serial number defaced, (2)

has been repaired by anyone other than an authorized Welch Allyn

Service Representative, (3) has been altered, or (4) has been used in a

manner other than in accordance with instructions.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE,

OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED OR

IMPLIED. WELCH ALLYN WILL NOT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES.

If you have questions regarding any Welch Allyn products, please call

Customer Service at (800) 535-6663, 315-685-4560, or FAX:315-685-

3361.

11

Page 14

4341 State Street Road

Skaneateles Falls, NY 13153, U.S.A.

Tel.: 1-315-685-4560 or 1-800-535-6663

Fax: 1-315-685-3361

Printed in the USA 883723 Rev. B

Loading...

Loading...