Page 1

MEDUCORE Easy

Automatic external defibrillator

Device nos. 1000 to 1340 from device no. 1341 with ILCOR 2005

MEDUCORE Easy

MEDUCORE Easy

Service and Repair instructions

with Battery-Pack

with Rechargeable Battery-Pack

Page 2

Contents

Introduction

1.

Overview

2.

Description of Equipment

2.1

2.2

2.3

2.4

3.

Cleaning and disinfecting instructions

4.

Checking the device

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

5.

Maintenance

5.1

5.2

5.3

5.4

6.

Safety related check according to

§6 Medicinal products and Users ordinance .

6.1

6.2

6.3

6.4

6.5

. . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . 5

Intended use

Scope of application

User qualification

Functional description

Testing parts needed

Preparations for testing

Entering the device data

Checking the devices self testing

Checking the volume levels

Testing the ECG detection, current input,

shock button and shock output

Checking the procedure display

and capacitor discharge

Checking the info-button

and reading contact

Checking the status LEDs

Checking the condition of the exterior,

the equipment and the accessories

Checking the IRDA interface and the

software version

Checking the maintenance and safety

related check (SRC) stickers

Preparing a device for dispatch

following repair

Documentation

Intervals

Check the Battery/Rechargeable Battery.

Renew maintenance sticker

Disposal

General

Execution

Testing devices

Replace SRC sticker

Documentation

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . .

. . . . .

. . . . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . 8

10

10

10

11

11

12

13

13

. . . .

14

15

15

15

17

18

18

19

20

21

21

21

21

21

21

7.

Malfunctions and Rectification

8.

Repair information and repair instructions

8.1

General

8.2

5

5

5

6

9

9.

10.

11.

12.

13. Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Tools and facilities

8.3

Discharge high voltage capacitor

and open up device

8.4

Opening the device

8.5

Exchange the device lids

8.6

Close the device

8.7

Exchanging the capacitor

8.8

Replace the Real Time Clock batteries

8.9

Replacing the main circuit board

8.10

Exchanging pad plug cable

8.11

Exchanging the speaker

8.12

Exchange encasing, upper part

8.13

Exchanging encasing, lower part

Replacement parts

Tools and testing devices

10.1

General tools

10.2

Special tools

10.3

Software

10.4

Testing devices

Technical data

Technical Changes

12.1 Device: MEDUCORE Easy . . . . . . . . 43

12.2 Software . . . . . . . . . . . . . . . . . . . . 43

13.1 Repairs and maintenance protocol . . . . 44

13.2 Test record "Safety related check in

accordance with §6 of the MP BetreibV

(German Medicinal Products and Users

Ordinance)". . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . 22

. . 24

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. .

. . . . .

. . . . . . . .

. . . . . . . . . . .

. . . . . .

. . . . .

. . . . . . . . . . . . . . . 38

24

24

25

27

27

28

29

29

30

32

32

33

33

38

38

38

38

© Copyright WEINMANN GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised WEINMANN Service Partners in

the course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with WEINMANN.

2

Page 3

Introduction

WEINMANN has been developing,

manufacturing and marketing emergency medical

devices for oxygen and inhalation therapy for

decades.

The aim of this service and repair manual is to

bring you to an expert level on the

MEDUCORE Easy, allowing you to understand the

operation, technology and repairs of the device. In

combination with the training, that you have already

completed for WEINMANN, you now belong to

the “trained, informed, experts”, thereby allowing

you to give your customers professional help and

repair malfunctions independently and in

accordance with the operation manual illustrated

you have the possibility of making functional

checks and if necessary carrying out repairs as

shown in the service and repair manual.

In case of warranty claims all devices are to be sent

to WEINMANN.

In order to handle warranty or goodwill requests

we will require you to submit proof of purchase

(invoice) of the customer.

Repair and maintenance work must be performed

by WEINMANN or knowledgeable, well trained

specialists.

They are responsible for all repairs carried out and all

associated warranties!

When performing maintenance, only genuine

WEINMANN replacement parts ought to be used.

Please consider:

Your customers puts trust in your capabilities just as

much as you trust in WEINMANN.

Note:

Please use the operation manual for the following information about MEDUCORE Easy:

• Safety instructions

• Preparing the device for use

• Operation

• Cleaning and disinfecting while in use

• Warranty

Please note that the operation of devices with and without ILCOR 2005 is different.

Introduction 3

Page 4

1. Overview

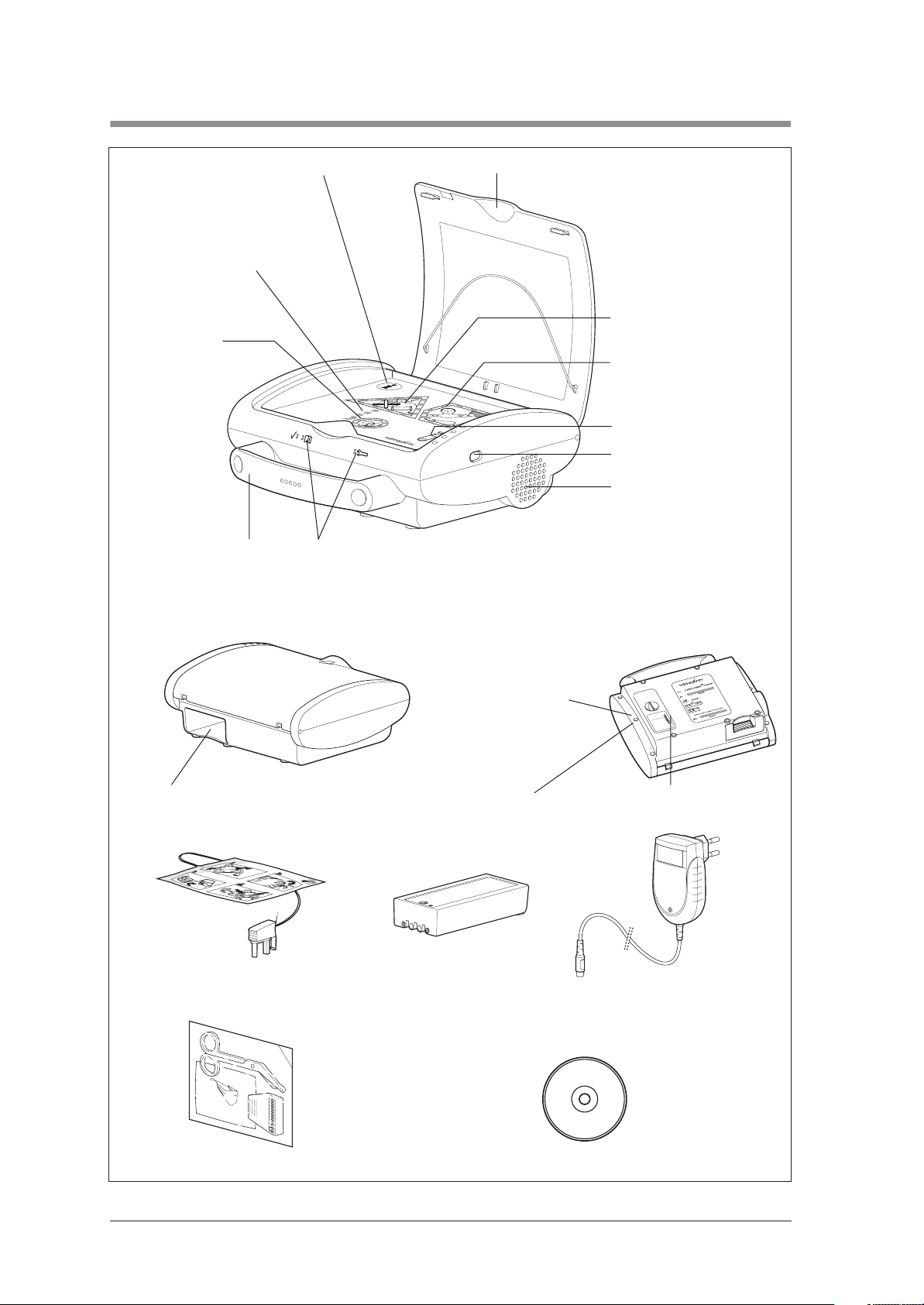

1 Info-button

11 Display:

Shock preperation

10 Shock key

9 Carrying handle

8 LEDs

2 Device lid

3 Display field: “Stand clear of

the patient!”

4 Display field: “You can now

touch the patient“

5 Socket for electrode plug

6 Infra red interface

7 Loudspeaker

Underside of device:

12 Battery compartment

16 Self sticking

defibrillation electrodes

Underside of device:

13 Maintenance sticker

14 SRC sticker

(only in Germany)

17 Battery-Pack/

Rechargeable

Battery-Pack

(optional)

18 Battery charger

15 Device plaque

(only in Rechargeable-Pack model)

4 Overview

19 Emergency set 20 CD-ROM with software EasyView

Page 5

2. Description of Equipment

2.1 Intended use

The MEDUCORE Easy is an automatic external

defibrillator (AED). It has been devised to assist the

user in the resuscitation of patients who show

symptoms of acute cardiovascular arrest (pulseless

ventricular tachycardia pVT or ventricular fibrillation

VF).

The MEDUCORE Easy guides the user through the

resuscitation process with the help of acoustic and

optical instructions. The device conducts an ECG

analysis on patients and, if necessary, makes

preparations for the delivery of an electric shock. The

delivery of a shock is carried out directly by the user,

after the device has prompted to do so.

Only use the device MEDUCORE Easy for the

purposes described below.

2.2 Scope of application

2.3 User qualification

The MEDUCORE Easy has been devised for

application in the heart/lung resuscitation (HLR) of

patients from upwards of 20 kg body weight at the

emergency’s location.

The MEDUCORE Easy may only be used by persons

who hold documented proof of the following

qualifications:

• Training in fundamental, life saving emergency

care including the application of automatic

defibrillators.

• Instructions for the application of the

MEDUCORE Easy carried out by an

WEINMANN authorized person.

Description of Equipment 5

Page 6

2.4 Functional description

The MEDUCORE Easy is compact, light and

ergonomic. The acoustic and optical user instructions

make the operation of the device, to a great extent,

self explanatory.

Persons with a nominal medical knowledge, after a

short instruction, can therefore be in the position to

operate a defibrillator in the case of a heart lung

resuscitation.

Optical and acoustic userguide The acoustic and optical user instructions are made up

of display fields and spoken orders.

After opening the device lid the user is led by

MEDUCORE Easy with the help of detailed spoken

orders through a step by step resuscitation process.

During this process a green and red display field light

up, indicating in which phase of the resuscitation the

patient may be touched or not touched (traffic light

principle).

Metronome function

(only for devices with ILCOR 2005)

An activated metronome function gives off an acoustic

metronome signal at a frequency of 100 beats per

minute during the HLR-pause. Carry out the cardiac

massage in rhythm with audible signal tone.

After 30 signal tones a spoken announcement is

issued “Give 2 breaths now” You will now have time

to carry out 2 respiratory sequences, before “Give 30

chest compressions now” is announced and 30 signal

tones are given.

This ordered sequence repeats itself, until the HLR

pause comes to an end and the red display field

(“Stand clear of the patient”) lights up.

If the info button is pressed during the HLR pause, the

info announcement is made. The metronome continues

to run in the background but without an audible tone.

ECG-recording and analysis As soon as the electrodes are placed on the bare

upper body of the patient, the device will

automatically begin with the recording and analysis of

the ECG. The ECG recording and analysis will

continue until the electrodes are removed from the

patient or as soon as the lid of the MEDUCORE Easy

is closed, which results in the device being switched

off.

6 Description of Equipment

Page 7

Defibrillation If the ECG analysis indicates defibrillation (pulseless

ventricular tachycardia pVT or ventricular fibrillation

VF), the MEDUCORE Easy prepares to deliver a

shock. Afterwards the device instructs the user to

administer a shock.

For other heart rhythms, the device informs the user that

they should carry out a heart-lung revival.

Application documentation The MEDUCORE Easy saves ECG and event data.

The data could later be used e.g. in the follow-up of

treatment. For this, use the documentation and

configurations software EasyView.

Self testing The MEDUCORE Easy initiates a self test at regular

intervals and after every time it is switched on. The

device status is shown via light diodes on its front side.

Self test results can be requested via the documentation

and configuration software EasyView and saved onto

a PC.

Description of Equipment 7

Page 8

3. Cleaning and disinfecting instructions

Warning!

• The Battery/Rechargeable Battery Pack must be

removed from MEDUCORE Easy before

cleaning.

• Never immerse the MEDUCORE Easy in any

disinfectant or any other liquid. Only carry out

disinfection by wiping over the surface. This can

otherwise lead to damage of the device and

consequently endanger users and patients.

The MEDUCORE Easy can be kept properly clean by

simply wiping to disinfect. Please observe the users

instruction for the disinfectant selected. We

recommend that you wear suitable gloves when

disinfecting the equipment (e.g. household or

disposable gloves).

We recommend that you use TERRALIN disinfectant,

which is available from the Schülke & Mayr

Company, Robert-Koch-Str. 2, D-22851 Norderstedt

(Internet: www.schuelkemayr.de).

8 Cleaning and disinfecting instructions

Page 9

4. Checking the device

Important!

The device must undergo the following tests after every

repair and every maintenance according to WM 40006,

and the results must be entered into the test records.

Additionally the test can be used for fault finding in the

device.

If you detect errors or deviations from defined values

in the course of your final testing you must not redeploy

MEDUCORE Easy before these errors have been

eliminated.

You can determine possible causes of such errors and

recommended countermeasures by referring to

chapter "7. Malfunctions and Rectification" on

page 22.

We recommend that you generally keep the following

ready for use:

• Emergency-Set WM 15460

• Battery-Pack WM 40155

• Rechargeable Battery-Pack WM 40150

4.1 Testing parts needed

• Electrodes, packed WM 40116

Important!

The electrodes have a limited shelf life. Please make a

note of the expiry date on the packaging.

• Fully charged Rechargeable battery Pack or

Battery-Pack

• Defibrillator-Tester (see also 10.4, page 38)

• IR-Adapter WM 22498

• PC with installed software EasyView WM 40192

• Multimeter, Measuring range up to 20 A

• Battery adapter WM 40008

• Test line MEDUCORE Easy WM 40454

Checking the device 9

Page 10

4.2 Preparations for testing

EasyView

EasyView-Service

1. Boot up PC.

2. Start the PC software.

Overview of software versions:

• EasyView

Reading, editing and saving usage data,

modifying device settings.

• EasyView-Service

Works like EasyView, facility for programming the

serial number.

• EasyView-Light

Works like EasyView; device settings cannot be

modified.

EasyView-Light

4.3 Entering the device data

Enter the serial number of the device (Device-No.) and

the manufacturing date into the test records.

4.4 Checking the devices self testing

1. Insert rechargeable or Battery-Pack.

2. Open the device lid.

3. Close the device lid.

Request:

– The device is giving off a short double peeping

tone.

– All LEDs light up briefly.

– The device announces clearly and completely

the spoken order “This device will assist you.”.

– The green status LED lights up.

10 Checking the device

Page 11

4.5 Checking the volume levels

1. Ensure that the volume setting is on "automatic". To

do so, connect the device to EasyView and cor-

Microphone

rect the setting if necessary.

2. Open the device lid.

3. Create a sound directly over the microphone of

the MEDUCORE Easy, by scratching on the encasing for example.

The microphone in the MEDUCORE Easy can be

found between the analysis triangle and pentagon.

Request:

– The volume of the repeated and clearly spoken

order increases.

4.6 Testing the ECG detection, current input, shock button and shock output

Preparation of the MEDUCORE Easy

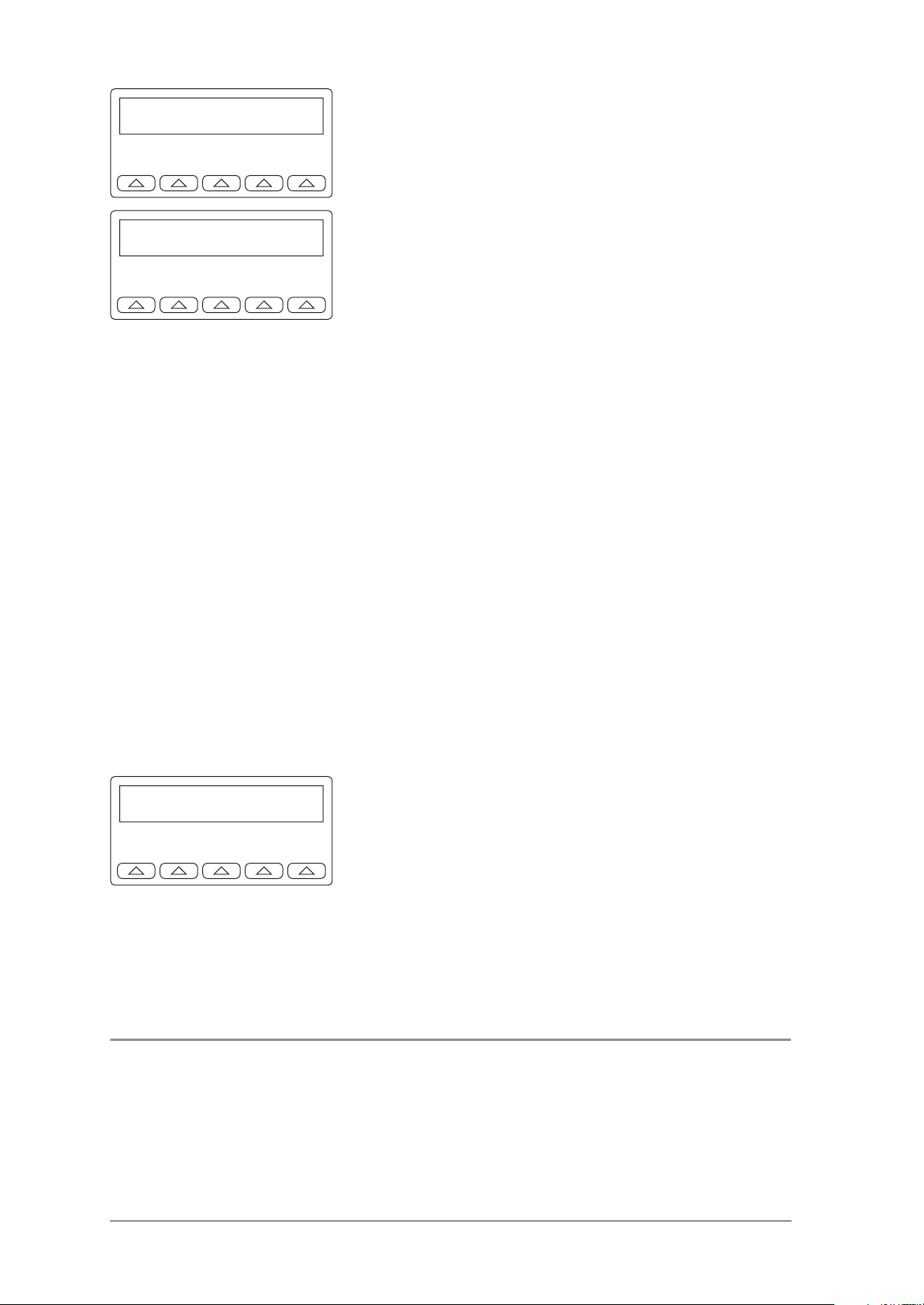

1. Connect the rechargeable battery adapter, current measuring device and rechargeable battery

or battery pack as illustrated.

2. Install the rechargeable battery adapter in the

MEDUCORE Easy.

Preparation of the defibrillator tester The defibrillator tester emulates a patient impedance

of 50 Ω.

1. Connect MEDUCORE Easy test line WM 40454

to the defibrillator tester as illustrated.

2. Connect the defibrillator tester to a power supply

(battery or mains plug).

3. Switch on the defibrillator tester (sliding switch

POWER in position I).

ENRG SYNC PEAK WAVE more

Main Menu 1

A self-test is performed. The main menu appears

in the display (Main Menu 1).

Checking the device 11

Page 12

Energy --- J

WAV> ECG90 PLAY HDR esc

4. Press the arrow button under ENERG.

The indicator for the Energy Modus appears in the

display.

Energy --- J

WAV> VFIB PLAY HDR esc

button under WAV until VFIB appears in the

display.

Performing the test 1. Open the lid of the device.

2. Plug the defibrillator tester electrode plug into the

device.

Requirement:

– The device detects ventricular fibrillation and

after a maximum of 10 sec clearly gives the

spoken message "Shock required".

3. The device prepares to give the shock.

Requirement:

– The current consumption of the device is be-

tween 6 A and 12 A.

4. Note the current consumption in the test report.

5. After the spoken message: "Press the flashing

shock key", activate this.

Requirement:

– The shock is triggered by activation of the

shock button.

– The shock is given. The device clearly gives the

spoken message "Shock was delivered".

5. To simulate venticular fibrillation: Press the arrow

Energy 162 J

WAV> VFIB PLAY HDR esc

– The energy discharged is between

168 J ± 10 % (Low Energy). The value is

shown in the display of the defibrillator tester.

Note:

Only the testing of the "Low Energy" shock is necessary.

If it is also required to test the "High Energy", the energy

must be 298 J ± 10 %.

In this case, ventricular fibrillation must be set on the

defibrillator tester as described above. Return to the main

menu via esc.

4.7 Checking the procedure display and capacitor discharge

Note:

Do not press the shock key during this test!

1. Simulate ventricular fibrillation with the defibrillator-tester (Signal Vfib).

12 Checking the device

Page 13

2. The device makes a clear spoken order “Stand

clear of the patient” and “Analyzing”.

Request:

– All of the LEDs in the red triangle light up.

– The device continues to give spoken orders,

during which all the LEDs on the shock key

arrow are lit up in red.

– All of the LEDs around the shock key flash red.

3. After approx. 15 seconds it is announced that

“Shock was not delivered”.

Request:

– The capacitor is discharged with an audible

sound.

4. Simulate f = 60 bpm with the defibrillator-tester

Sinus EKG.

Request:

– All of the LEDs in the green pentagon light up.

4.8 Checking the info-button and reading contact

Info-button

4.9 Checking the status LEDs

1. While the green pentagon is lit up, press the infobutton.

Request:

– The device announces a spoken order similar

to “Device has been in use for…in total

1 shock since device startup”.

2. Pull the electrode plug out of the device.

3. Close the device lid.

Request:

– The device cuts short any spoken order,

extinguishes all process LED lights and leaves

only the green status LED blinking.

– No new spoken order is made.

Open the device lid to turn the device on.

Request:

– All of the three Status-LEDs, (red, green, yellow)

light up.

Checking the device 13

Page 14

4.10 Checking the condition of the exterior, the equipment and the accessories

1. Firstly, carry out a visual test of everything.

Requests:

• Encasing

– Encasing not scratched and without blemishes

– Encasing completely screwed on

– Front film and sticker stuck down firmly and

correctly on the lid

– Labelling OK?

– The loudspeaker opening is free from dirt.

• Electrode connection

– Undamaged

– In working order

• Push buttons

– Undamaged

– Working correctly

• Lid

– Lid not scratched and without blemishes

– Lid is correctly attached, easy to open and

closes firmly

– Functions open, close, switch on are ok.

• Inner part

– The socket for the electrode plug is free from

dirt.

• Rechargeable Battery-Pack

– Completely charged

• Battery-Pack

– Check expiry date (see device sign Battery-

Pack). Insert new Battery-Pack if necessary.

– If the expiry date is not yet reached, then check

the level of charging. Insert battery, open and

close device lid. The green LED must flash; the

yellow LED should not flash.

If these parts have been delivered, check:

14 Checking the device

• Defibrillation electrodes WM 40116 available.

Check expiry date, if necessary replace.

• Rechargeable Battery-Pack WM 40150

available.

• Battery-Pack WM 40155 available.

• Emergency set WM 15460 available.

Page 15

4.11 Checking the IRDA interface and the software version

1. Check that the interface is working correctly by

retrieving the device data.

Request:

All the device data are displayed.

2. Ensure that a PCB with the latest device software

is installed in the device. This can be done by

comparing the software version displayed with

table (see "12.2 Software" on page 43).

If the software version is no longer current, replace

the PCB with an up-to-date one as described in

section 8.9 and enter the device number as

described.

4.12 Checking the maintenance and safety related check (SRC) stickers

Check that the maintenance and SRC stickers are

affixed correctly (SRC sticker applies only to

Germany). If repairs have been carried out, then you

should replace the stickers with new ones.

4.13 Preparing a device for dispatch following repair

Conditions The Programme EasyView must be started up and

the PC infrared interface or the infrared adapter

must be aligned with the infrared interface of the

MEDUCORE Easy (see chapter “Operation” in

the PC-software operating instructions EasyView

WM 16880).

Execution 1. Insert Rechargeable Battery or Battery-Pack.

2. Open the device lid.

3. Read off the charge status of the battery pack and

compare it with the value specified in the test

record.

Depending on the Battery-Pack capacity

displayed proceed as follows:

• Capacity is > 50%:

– The Battery-Pack is OK.

• Capacity is < 50%:

– Inform your customer about the charging

level.

Checking the device 15

Page 16

– Recommend that your customer regularly

checks the charging level.

– Recommend that your customer replaces the

Battery-Pack in good time.

• Capacity is < 15%:

– Inform your customer about the charging

level.

– Recommend that your customer regularly

checks the charging level.

– Offer your customer a new Battery-Pack.

– Recommend that your customer replaces the

Battery-Pack as soon as possible.

• Capacity is < 8%:

– Inform your customer about the charging

level.

– Offer your customer a new Battery-Pack.

– Point out to your customer that the Battery-

Pack should be replaced immediately for

safety reasons.

4. Set the date and time with the help of the

EasyView (see chapter “Operation“ in the operating instructions for the PC-Software EasyView

WM 16880).

After exchanging the printed circuit

board, if no customer parameter are

known 1. Delete the memory.

2. Enter serial number (Device-No.) (see "4.3 Entering the device data" on page 10).

After exchanging the printed circuit

board, if customer parameter are

known 1. Programme customer parameter.

2. Delete the memory.

3. Check the selected language version.

Request:

– EasyView-Service must display the selected

language version without any error messages.

Note:

To continue testing, the volume must be set to

"automatic".

Completion 1. Close the device lid.

2. Remove Rechargeable Battery or Battery-Pack

16 Checking the device

3. To unload the internal remaining charge, open

and close the device lid again.

Page 17

4.14 Documentation

Note down the points 4.3 to 4.12 as well as the test

date and tester number in the test records.

Checking the device 17

Page 18

5. Maintenance

5.1 Intervals

Note:

After all maintenance and repair work the device must be

tested, as described in chapter „4. Checking the

device“on page 9.

As a preventative maintenance measure every 6 years

the device must be fully checked:

The points of maintenance are as follows:

• Testing for completeness (see chapter 4.10,

page 14)

• Visual test (see chapter 4.10, page 14)

– Mechanical damage

– Electrode connections

– Labelling

• Check the charge levels on the Battery/

Rechargeable Battery (see chapter 5.2, page 18)

• Replace internal battery (see chapter 8.8,

page 29)

• Final check in accordance with test directive

WM 40006 (see chapter 4., page 9)

• Renew maintenance sticker

In Germany a safety related check (SRC) must be

conducted within a statutory limit of 2 years in

accordance with §6 Medicinal Products and Users

Ordinance.

5.2 Check the Battery/Rechargeable Battery.

Conditions The Programme EasyView must be started up and

the PC infrared interface or the infrared adapter

must be aligned with the infrared interface of the

MEDUCORE Easy (see chapter ”Operation“ in

the PC-software operating instructions EasyView

WM 16880).

18 Maintenance

Page 19

Execution 1. Insert Rechargeable Battery or Battery-Pack

2. Open the device lid.

3. Read off the level of charge of the Battery-Pack

and note in the test records.

Depending on the Battery-Pack capacity

displayed proceed as follows:

• Capacity is > 50%:

– The Battery-Pack is OK.

• Capacity is < 50%:

– Inform your customer about the charging

level.

– Recommend that your customer regularly

checks the charging level.

– Recommend that your customer replaces the

Battery-Pack in good time.

• Capacity is < 15%:

– Inform your customer about the charging

level.

– Recommend that your customer regularly

checks the charging level.

– Offer your customer a new Battery-Pack.

– Recommend that your customer replaces the

Battery-Pack as soon as possible.

5.3 Renew maintenance sticker

Maintenance sticker

• Capacity is < 8%:

– Inform your customer about the charging

level.

– Offer your customer a new Battery-Pack.

– Point out to your customer that the Battery-

Pack should be replaced immediately for

safety reasons.

If required, replace the Battery or charge

Rechargeable Battery

Renew the maintenance sticker (current year

+ 6 years) sticking it to the underside of the device.

• Replace the old maintenance sticker with one

carrying the newly entered data. Cut out the

correct month using a ticket puncher or the point

of some nail scissors. Stick the new maintenance

sticker on the underside of the device.

Maintenance 19

Page 20

5.4 Disposal

Device

Do not dispose of the device as domestic waste. To

dispose of the device properly, please contact a

licensed and certified electronic waste recycler.

Names and addresses can be obtained from your

Environmental Officer or municipal authorities.

Disposal of batteries

Do not dispose of spent batteries in the domestic

waste. Please either contact WEINMANN or or your

official local public disposal authorities.

20 Maintenance

Page 21

6. Safety related check according to §6 Medicinal products and Users ordinance

6.1 General

Important!

Performance of a safety related check [SRC] in

accordance with §6 of the German Medicinal products

and Users ordinance [MedizinprodukteBetreiberverordnung] is only mandatory in Germany.

6.2 Execution

Safety related checks follow the same steps as

described in chapter "4. Checking the device" on

page 9.

The following is only an additional description of the

required steps to be taken.

6.3 Testing devices

6.4 Replace SRC sticker

SRC sticker

6.5 Documentation

Additional to the named testing devices described in

chapter 4.1 you will need:

• SRC protocol (see " WM 40007f, page 2" on

page 46)

If you have carried out a safety related check, a new

SRC sticker (current year + 2 years) has to be stuck to

the underside of the device.

• Replace the SRC sticker with a new one with the

correct dates. Cut out the correct month using a

hole puncher or the point of some nail scissors.

Stick the new SRC sticker next to the maintenance

sticker on the underside of the device.

• Fill out the SRC protocol.

• Prepare an SRC certificate for the customer.

Safety related check according to §6 Medicinal products and Users ordinance 21

Page 22

7. Malfunctions and Rectification

Malfunctions Cause Rectification

In stand by mode (lid closed) a

signal tone is set off every four

minutes.

A malfunction has been

established while the device

underwent the monthly/daily self

tests.

Battery capacity is exhausted.

Check which LED blinks and the

procedure, according to the

respective LED described in the

following table.

Insert new Battery/Rechargeable

Battery Pack (see chapter „Energy

Supply“ in the operating

instructions MEDUCORE Easy).

When the lid is open the device

can not turn on.

Upon opening the lid the

following message can be heard:

“Device is not ready for use”

Upon opening the lid the

following message can be heard:

“Battery is low”

The red LED will light up (flashing

when on stand by and constant

when in operation).

Damaged connection between the

energy supply contacts and main

circuit board

Main circuit board defective.

Battery power levels are low.

If the battery power levels are low

then fewer than 3 shocks can be

delivered.

Device is not ready for operation,

self test has detected a

malfunction.

Opening device and checking

connections (Chapter 8.3,

Page 25).

Open up device and replace the

main circuit board (Chapter 8.9,

Page 30).

Device messages with EasyView

voice prompting. If EasyView

“Malfunction in the main circuit

board” is displayed, then replace

the main circuit board

(Chapter 8.9, Page 30).

Finish off current treatment and

then replace batteries (see

Chapter “Energy Supply” in the

operating instructions

MEDUCORE Easy).

Replace battery (see Chapter

“Energy Supply” in the operating

instructions of the

MEDUCORE Easy), to enable

continued treatment.

Finish off current treatment. Then

read out malfunction protocol via

the EasyView. If EasyView

“Malfunction in the main circuit

board” is displayed, then

exchange main circuit board

(Chapter 8.9, Page 30).

The green and yellow LEDs light

up (flashing when on stand by

and constant when in operation).

The yellow LEDs light up (flashing

when on stand by and constant

when in operation).

22 Malfunctions and Rectification

The battery/rechargeable battery

power levels are low and barely

10/6 shocks can still be

delivered.

A less critical malfunction has

been detected, e.g. time is

incorrect.

Finish off current treatment and

then replace batteries (see

Chapter “Energy Supply” in the

operating instructions

MEDUCORE Easy).

Finish off current treatment. Then

read out malfunction protocol via

the EasyView and if necessary

correct malfunction e.g. reset

clock.

Page 23

Malfunctions Cause Rectification

After switching device on, one or

more LEDs/display fields do not

light up briefly.

Spoken command: “Attach

electrodes to bare chest!“ repeats

itself even though electrodes have

been stuck down.

Shocks can not be delivered, in

spite of flashing shock key.

Spoken command “Movement

detected. Stand clear of the

patient!” is made.

One or more of the status LEDs/

display fields is defective.

RTC battery empty.

Electrode plug is not correctly

plugged in.

Electrodes not correctly stuck

down.

Electrodes touching each other.

Electrodes defective

Wrong electrodes

Damaged connection between the

electrode contacts and main

circuit board

Main circuit board defective.

Main circuit board defective.

MEDUCORE Easy recognises

artefact and carries out a new

analysis.

Finish off current treatment, and

then replace the main circuit

board (Chapter 8.9, Page 30).

Replace Real Time Clock batteries

(Chapter 8.8, Page 29).

Insert plug correctly.

Press the electrodes directly down

onto dry, and if necessary shaved

skin.

Check the positioning of the

electrodes.

Replace electrodes, otherwise do

not attempt to operate device.

Only use genuine WEINMANNelectrodes.

Open device and check

connections (Chapter 8.3,

Page 25).

Open up device and exchange

the main circuit board

(Chapter 8.9, Page 30).

Open up device and exchange

the main circuit board

(Chapter 8.9, Page 30).

Do not touch or move the patient

during the analysis.

Green status LED does not flash

when the lid has been closed.

No automatic self test is carried

out.

Time and date entries, after

switching the device off and on

again, display a default value.

Rechargeable Battery or BatteryPack is drained.

LED is defective

RTC battery empty.

RTC battery empty.

Insert new Battery/Rechargeable

Battery Pack (see Chapter “Energy

Supply” in the operating

instructions MEDUCORE Easy).

Open up device and replace the

main circuit board (Chapter 8.9,

Page 30).

Replace Real Time Clock batteries

(Chapter 8.8, Page 29).

Replace Real Time Clock batteries

(Chapter 8.8, Page 29).

Malfunctions and Rectification 23

Page 24

8. Repair information and repair instructions

8.1 General

• Please perform repairs on MEDUCORE Easy only on

an ESD work station!

• Refer to the safety instructions in the operating

manuals for MEDUCORE Easy.

• Any handling of this device requires in-depth

knowledge of and adherence to the operating

manual and the maintenance and repair manual.

• Perform only the repairs as described in this

maintenance and repair manual. This is the only

way to ensure that the MEDUCORE Easy

operates properly.

• Make sure that your hands and your workspace

are clean when performing repairs.

• After every repair a maintenance check must be

performed (see "4. Checking the device" on

page 9).

• When replacing components or single parts, use

only genuine WEINMANN Parts.

• When ordering the device’s lower encasing 25

you have to state the device type, year of

manufacture and serial number.

Note:

The item numbers stated in the following text are identical

to the item numbers of the spare part list on page 34 and

the overview on page 4.

8.2 Tools and facilities

24 Repair information and repair instructions

In order to perform the repairs described in this

chapter, you will need the following tools and

facilities:

• Phillips screwdriver size: PZ 2

• Nail scissors or ticket-punch to mark the

maintenance plaque

• Pincers

• High-voltage protected needle nose pliers

• ESD Workstation

• Discharging device WM 40009

or:

protected high-voltage workstation

Page 25

Danger of death! Danger of electric shock! If no discharging unit is available, work on the MEDUCORE Easy must

be carried out at a protected high-voltage workstation.

Before carrying out any repair, it is essential to discharge

the capacitor as described in Section “8.3 Discharge high

voltage capacitor and open up device” on page 25, otherwise fatal injuries may be sustained.

8.3 Discharge high voltage capacitor and open up device

Preparation

Danger! Risk of electric shock!

If a malfunction occurs in the device during a functional

check, then it may not be used.

1. Remove the Battery-Pack/Rechargeable Battery

Pack from the battery compartment

MEDUCORE Easy.

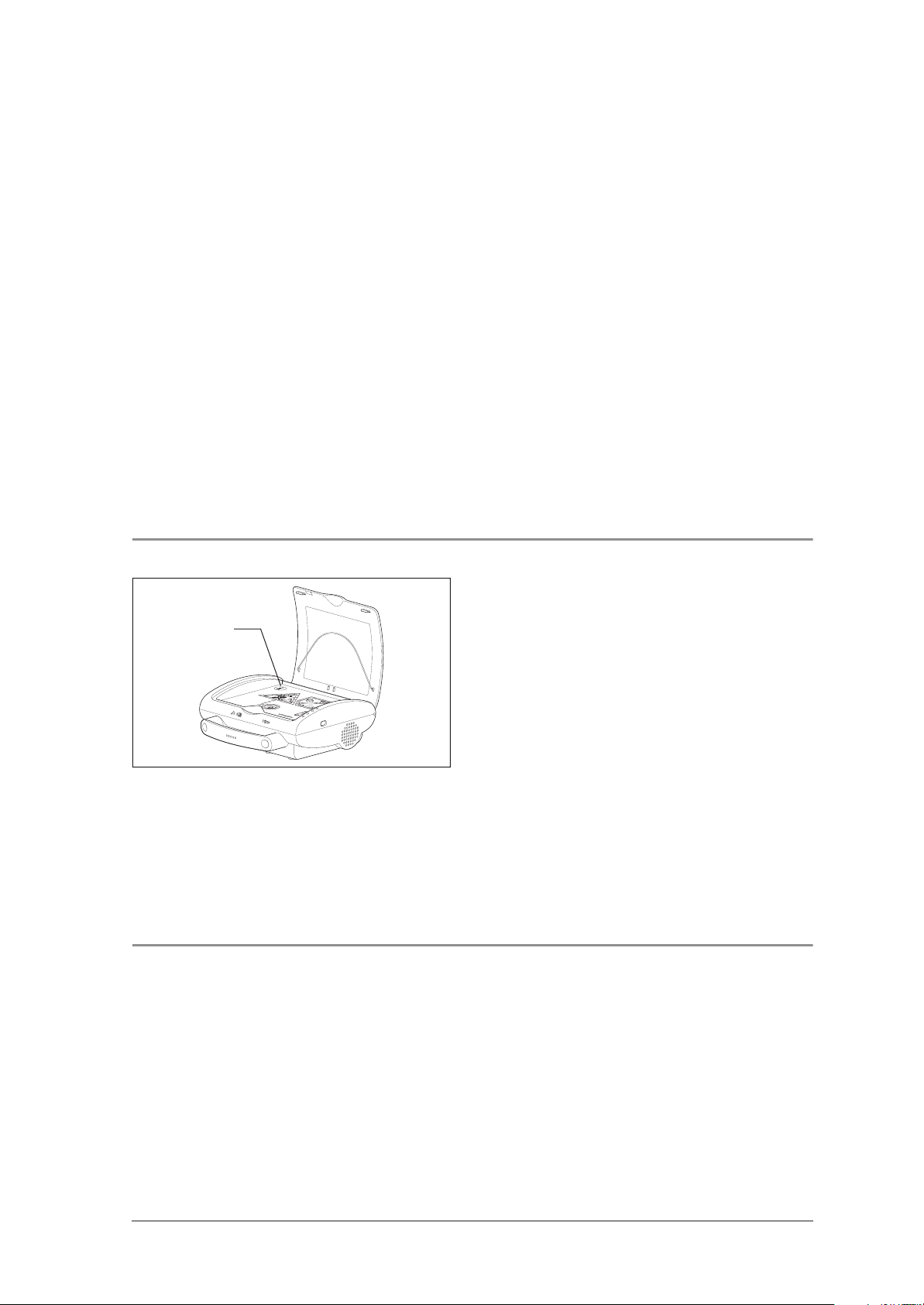

2. Lie the MEDUCORE Easy with the red lid facing

down on a non-slip surface.

30 33

3. Remove the sealing plugs 33.

4. Loosen and remove the ten screws 30.

5. Take the MEDUCORE Easy in both hands and

hold both encasing elements together. Lie the

MEDUCORE Easy with the red lid facing upward

in the discharging device.

6. Close the discharging device lid.

7. Pull back the contact rocker of the discharge device and swing it upwards.

Discharging process 1. Slide the locking element back to release the

lifting aid.

2. Press the bellows together and place the suction

pad far left of the middle on the red lid of the

MEDUCORE Easy.

3. Release the bellows. The suction pad will fasten

itself.

4. Pull the lifting aid upwards. This serves to lift the

upper part of the encasing.

5. Slide the locking element forwards to hold the

lifting aid up and in so doing also the upper part

of the encasing.

Repair information and repair instructions 25

Page 26

6. Slide the contact rocker into its resting position.

7. Check to see that the contact pin is directly above

the capacitor contacts.

If necessary, make some fine settings using the

black screw on the front of the carriage.

8. Flip down the contact rocker. The contact pin must

now be touching the capacitor contacts on the

printed circuit board.

The capacitor is then completely discharged. The

discharging process lasts approx. 4 seconds. It is

completed when -0.00 is displayed.

To be certain that the capacitor is discharged, carry

out the following tests:

9. Press the red button on the front of the device.

– The capacitor is very slightly charged. The

display will now show for example 0.07.

– Upon releasing the button the display must

slowly return to -0.00 .

Danger! Risk of electric shock!

If the display returns immediately to -0.00 then the

contact pin is no longer in contact with the capacitor

contact on the printed circuit board. The capacitor has in

this case not been discharged. Adjust the position of the

contact pin and check it again.

Completion 1. Pull the contact rocker back.

2. Slide the locking element back to release the

lifting aid.

3. Lower the upper part of the encasing.

4. Rotate the lifting aid to release the suction pad

from the lid.

5. Open the protective cover of the device and

remove the MEDUCORE Easy.

6. Switch the discharging device via the rocker

switch off.

7. Close the device (8.6, page 28).

26 Repair information and repair instructions

Page 27

8.4 Opening the device

21

22

24

25

Danger of death! Danger of electric shock! If no discharging unit is available, work on the MEDUCORE Easy must

be carried out at a protected high-voltage workstation.

1. Take the red device lid 2 off.

2

2. Remove the pins 21 and springs 22 and store them

in a safe place.

3. Lie the MEDUCORE Easy with the upper

encasing 24 facing down on a non-slip surface.

4. Carefully open the lower encasing device 25.

5. Pull the loudspeaker cable from the printed circuit

board.

6. Pull the red cable plug out of the printed circuit

board.

7. Pull the capacitor out of the lower encasing part

and place it carefully on the main circuit board.

8. Pull the plug belonging to the pad cable 40 and

40

41 out of the printed circuit board.

9. Pull the blue and black cable plugs out of printed

circuit board.

10. Now you can set aside the lower encasing part 25.

40

24

8.5 Exchange the device lids

Remove lid 1. Open the red device lid 2.

2. Slide the pins 21 out to one side and remove

21

2

22

them.

3. Pull the springs 22 out and store them in a safe

place.

4. Take the device lid 2 off.

Repair information and repair instructions 27

Page 28

Fitting lid 1. Place the ends of the springs 22 into the prepared

holes of a new device lid.

2. Slide the pins 21 from the side far enough into the

lid, so that the springs 22 are held in place.

3. Replace the lid 2, so that the other end of the

springs are situated between the encasing halves.

4. Slide the pins 21right in.

5. Close the device lid.

8.6 Close the device

30 33

1. Hold the lower encasing part 25 up to the upper

encasing part 24.

2. Plug the blue cable into the printed circuit board

(Labelled HDQ).

3. Plug the black cable into the printed circuit board

(Labelled ACCU -).

4. Take the pad plug cable 40 and 41 and plug it

into the printed circuit board.

5. Press the capacitor into the compartment of the

lower encasing part. Guide the cable in through

the slit.

6. Plug the cables for capacitor 27 onto the board.

Ensure that polarity +/- is correct (see labeling on the

board and on the capacitor)! If the cables are the

wrong way round, the top and bottom parts of the

device will not fit together properly.

7. Plug the red cable into the printed circuit board

(Labelled ACCU + ).

8. Plug the speaker cable into the printed circuit

board.

9. Place the lower encasing part 25 onto the upper

encasing part 24.

Please make sure that the cables do not get clamped.

10. Now screw the upper encasing part tightly with

the ten screws 30 .

11. Set the sealing plugs 33 in place.

12. Turn the device around the right way again and

fit the lid (see "8.5 Exchange the device lids" on

page 27).

13. Check the device (see "4. Checking the device"

on page 9).

28 Repair information and repair instructions

Page 29

8.7 Exchanging the capacitor

27

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge the capacitor and open the device (see

Chapter "8.3", Page 25).

2. Pull the capacitor cable 27 out of the printed

circuit board with the aid of high-voltage

protected needle nose pliers.

3. Remove the capacitor 27 and dispose of it (see

Chapter "5.4", Page 20).

4. Place a new capacitor onto the printed circuit

board. Make sure that insulation mats 28 are lying

between the capacitor and the main circuit board.

5. Plug the capacitor cable 27 into the printed circuit

board. Make sure that the polarity is correct +/- (see the

labelling on the printed circuit board and on the

capacitor)! If the cables are mixed up then the upper and

lower device parts will not fit to each other correctly.

6. Close the device (see Chapter "8.6", Page 28).

8.8 Replace the Real Time Clock batteries

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge the capacitor and open the device (see

Chapter "8.3", Page 25).

34

2. Push the springs slightly backwards and remove

the battery 34.

3. Replace with new (button cell CR2032) battery.

Make sure that the polarity is correct!

4. Close the device (see Chapter "8.6", Page 28).

5. Set the date and time with the help of EasyView

(see chapter “Operation” in the operations

manual for PC software EasyView WM 16880).

Repair information and repair instructions 29

Page 30

8.9 Replacing the main circuit board

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge the capacitor and open up the device

(see "8.3 Discharge high voltage capacitor

and open up device" on page 25).

Remove the main circuit board 1. Pull the capacitor cable 27 out of the circuit

board.

26

27

2. Remove the capacitor 27.

3. Lever the main circuit board 26 out.

Inserting the main circuit board 1. Insert a new main printed circuit board 26 in

place. Make sure that the capacitor buffer 29 is

jutting out of the main circuit board.

2. Place the capacitor onto the printed circuit board.

Make sure that insulation mats 28 are lying between

the capacitor and the main circuit board.

3. Plug the capacitor cable 27 into the printed circuit

board. Make sure that the polarity is correct +/- (see

the labelling on the printed circuit board and on the

capacitor)! If the cables are mixed up then the upper

and lower device parts will not fit to each other

correctly.

4. Close the device (see Chapter "8.6", Page 28).

Program the serial number on new main

circuit board To change the serial number on the main circuit board

in MEDUCORE Easy you will require the EasyViewService software (see Chapter "4.2", Page 10).

Note:

Remember that the serial number entered can be 4

or 5 characters, and can only consist of the numbers

0 to 9!

30 Repair information and repair instructions

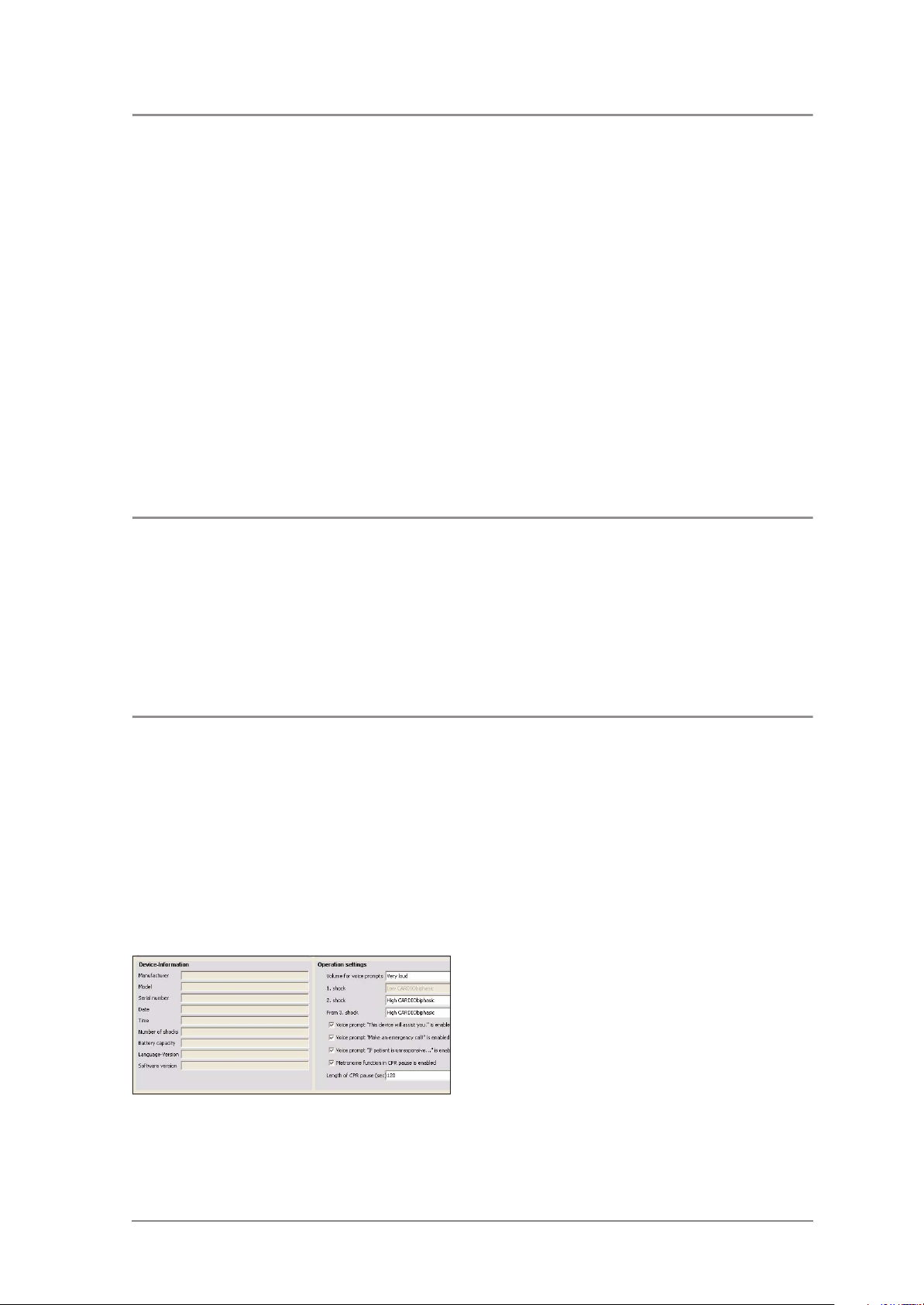

1. Start the EasyView-Service software and choose

the "Device settings" tab.

Page 31

Click the "Get device settings" button.

The device configuration will be displayed.

2. Enter the device's 5-digit serial number. Then click

the "Print settings" button.

3. Next, confirm the change to the device

configuration. The number will now be stored in

MEDUCORE Easy.

If a 4-digit serial number is entered, the system will

automatically pad it out to 5 digits by adding a

leading "0".

If the serial number was entered successfully, the

following message will appear: "Communication

successful".

If you have entered a serial number with less than 4

(or more than 5) digits, the following message will

appear: "Serial number must have 4 or 5 digits".

Repair information and repair instructions 31

Page 32

8.10 Exchanging pad plug cable

41

40

43 42

Repeat the process with a number of the correct

length.

This concludes the programming of the serial number.

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge capacitor and open up the device (see

"8.3 Discharge high voltage capacitor

and open up device" on page 25).

2. Loosen the nuts 43 and take the spring washer 42

off.

3. Pull the plug belonging to the cable 40 and 41 out

of the printed circuit board.

4. Plug the new cable in its place.

5. Place the cable lug and spring washer onto the

screw and screw the nut onto it. Make sure that the

order is correct!

6. Close the device (see Chapter "8.6", Page 28).

8.11 Exchanging the speaker

Removing the speaker

47

46

44

45

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge capacitor and open up the device (see

"8.3 Discharge high voltage capacitor

and open up device" on page 25).

2. In the lower encasing part: Rotate the screw out of

the wedge 47 .

3. Pull the wedge 46 out.

4. Remove the loudspeaker 44 together with the

seal 45.

Dispose of the old seal and the old wedge,

together with the defective loudspeaker.

32 Repair information and repair instructions

Page 33

Fitting speaker 1. Use only parts from spare parts set WM 15705.

2. Take new seal 45 from the spare parts set and put

it on the new loudspeaker.

3. Place the new speaker into the device. Make

certain the seal is well fitted and flush.

4. Put the wedge into its position and screw it in

tightly.

5. Close the device (see Chapter "8.6", Page 28).

8.12 Exchange encasing, upper part

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge capacitor and open up the device (see

Chapter "8.3", Page 25).

2. Remove the main circuit board (see Chapter

"8.9", Page 30).

3. Install the main circuit board into a new upper

encasing part 24 (see Chapter "8.9", Page 30).

4. Close the device (see Chapter "8.6", Page 28).

8.13 Exchanging encasing, lower part

Danger of death! Danger of electric shock! The condenser

must be completely discharged (see Chapter "8.3",

Page 25).

1. Discharge capacitor and open up the device (see

Chapter "8.3", Page 25).

2. Remove the handle from the old lower encasing

part and fit it to the new lower encasing part 25

(see operating instructions “Fitting accessories“).

3. Close the device (see Chapter "8.6", Page 28).

Repair information and repair instructions 33

Page 34

9. Replacement parts

Note:

The item numbers of the following table are identical to the numbers used in the body of text of this service

and maintenance manual.

Item-No. Name Ordering-No.

Lid, complete DE

Lid, complete GB

Lid, complete FR

Lid, complete IT

Lid, complete TH

Lid, complete JP

Lid, complete NO

Lid, complete SE

Lid, complete DK

Lid, complete RU

Lid, complete PL

Lid, complete NL

2

Lid, complete ES

Lid, complete PT

Lid, complete FI

Lid, complete IS

Lid, complete TR

Lid, complete CZ

Lid, complete GR

Lid, complete SI

Lid, complete SK

Lid, complete HR

Lid, complete ID

Lid, complete CN

Lid, complete IR

WM 40125

WM 40337

WM 40347

WM 40357

WM 40367

WM 40377

WM 40387

WM 40397

WM 40407

WM 40417

WM 40427

WM 40437

WM 40447

WM 40457

WM 40467

WM 40477

WM 40487

WM 40497

WM 40507

WM 40517

WM 40527

WM 40667

WM 40677

WM 40687

WM 40558

16

Defibrillation electrodes DE GB

Defibrillation electrodes FR

Defibrillation electrodes IT

Defibrillation electrodes TH

Defibrillation electrodes JP

Defibrillation electrodes NO

Defibrillation electrodes SE

Defibrillation electrodes DK

Defibrillation electrodes RU

Defibrillation electrodes PL

Defibrillation electrodes NL

Defibrillation electrodes ES

Defibrillation electrodes PT

Defibrillation electrodes FI

Defibrillation electrodes IS

Defibrillation electrodes TR

Defibrillation electrodes CZ

Defibrillation electrodes GR

Defibrillation electrodes SI

Defibrillation electrodes SK

Defibrillation electrodes HR

Defibrillation electrodes ID

Defibrillation electrodes CN

Defibrillation electrodes IR

WM 40116

WM 40349

WM 40359

WM 40369

WM 40379

WM 40389

WM 40399

WM 40409

WM 40419

WM 40429

WM 40439

WM 40449

WM 40459

WM 40469

WM 40479

WM 40489

WM 40499

WM 40509

WM 40519

WM 40529

WM 40439

WM 40019

WM 40069

WM 40468

34 Replacement parts

Page 35

Item-No. Name Ordering-No.

17

18 Battery charger WM 40003

19 Set, Emergency MEDUCORE Easy WM 15460

20 PC-Software EasyView WM 40192

Battery-Pack

Rechargeable Battery-Pack

WM 40155

WM 40150

21 Hinge pin WM 40123

22 Spring for lid WM 40124

23 Retaining bracket WM 40024

24 Encasing, upper part, preassembled WM 40076

25 Encasing, lower part, assembled* WM 40002

26

Main circuit board DE, new

Main circuit board DE, replacement

Main circuit board GB, new

Main circuit board GB, replacement

Main circuit board FR, new

Main circuit board FR, replacement

Main circuit board IT, new

Main circuit board IT, replacement

Main circuit board TH, new

Main circuit board TH, replacement

Main circuit board JP, new

Main circuit board JP, replacement

Main circuit board NO, new

Main circuit board NO, replacement

Main circuit board SE, new

Main circuit board SE, replacement

Main circuit board DK, new

Main circuit board DK, replacement

Main circuit board RU, new

Main circuit board RU, replacement

Main circuit board PL, new

Main circuit board PL, replacement

Main circuit board NL, new

Main circuit board NL, replacement

Main circuit board ES, new

Main circuit board ES, replacement

Main circuit board PT, new

Main circuit board PT, replacement

Main circuit board FI, new

Main circuit board FI, replacement

Main circuit board, IS, new

Main circuit board, IS, replacement

Main circuit board TR, new

Main circuit board TR, replacement

Main circuit board CZ, new

Main circuit board CZ, replacement

Main circuit board GR, new

Main circuit board GR, replacement

Main circuit board SI, new

Main circuit board SI, replacement

Main circuit board SK, new

Main circuit board SK, replacement

WM 40130

WM 40063

WM 40330

WM 40313

WM 40340

WM 40343

WM 40350

WM 40353

WM 40360

WM 40363

WM 40370

WM 40373

WM 40380

WM 40383

WM 40390

WM 40393

WM 40400

WM 40403

WM 40410

WM 40413

WM 40420

WM 40423

WM 40430

WM 40433

WM 40440

WM 40443

WM 40450

WM 40453

WM 40228

WM 40483

WM 40368

WM 40023

WM 40244

WM 40493

WM 40258

WM 40503

WM 40375

WM 40193

WM 40268

WM 40203

WM 40378

WM 40243

Replacement parts 35

Page 36

Item-No. Name Ordering-No.

26

Main circuit board HR, new

Main circuit board HR, replacement

Main circuit board ID, new

Main circuit board ID, replacement

Main circuit board CN, new

Main circuit board CN, replacement

Main circuit board IR, new

Main circuit board IR, replacement

WM 40277

WM 40303

WM 40294

WM 40463

WM 40295

WM 40473

WM 40435

WM 40464

27 High voltage capacitor WM 40078

28 Insulation mat for capacitor, bottom WM 40137

29 Capacitor buffer WM 40106

30 Fillister head screw KB 40x25 WM 40143

31 Shock button, printed WM 40168

32 Info button WM 40167

33 Sealing plug WM 40158

34 Battery 3 V WM 40089

35 Handle WM 40103

36 Handle sealing WM 40186

37 Cylinder head screw M8x30; DIN EN ISO 4762 ST-ZN WM 50607

38 Flexible handle including attaching brackets WM 40164

39 Protective and carrying bag WM 40100

40 Cable, long WM 40282

41 Cable, short WM 40283

42 Serrated lock washer J3,2 DIN 6798-V2A; WNR.1.4310 WM 51850

43 Hexagonal nut M3 DIN 934 MS-NI WM 50910

Set Speaker,

WM 15705

consisting of:

44

45

46

Speaker with wiring

Speaker sealing

Wedge

WM 40266

WM 40113

WM 40178

47 Fillister head screw KB 40x8 WM 40141

48 Cable, blue WM 40281

49 Cable, red WM 40284

50 Cable, black WM 40285

51 Contact, rechargeable battery compartment WM 40139

52 Sealing plate WM 40138

36 Replacement parts

Page 37

Item-No. Name Ordering-No.

Instructions for use MEDUCORE Easy DE

Instructions for use MEDUCORE Easy FR; NL; IT

Instructions for use MEDUCORE Easy GB; ES; PT

Instructions for use MEDUCORE Easy DK; NO; SE

Instructions for use MEDUCORE Easy JA; TH

Instructions for use MEDUCORE Easy PL; RU

Instructions for use MEDUCORE Easy IS; FI

Instructions for use MEDUCORE Easy TR; GR

Instructions for use MEDUCORE Easy ID; CN

Instructions for use MEDUCORE Easy CZ; SL

Instructions for use MEDUCORE Easy HR; SK

Instructions for use MEDUCORE Easy IR

WM 16799

WM 16912

WM 16913

WM 16920

WM 16921

WM 16922

WM 66450

WM 66451

WM 66452

WM 66453

WM 66454

WM 66455

Fitting instructions MEDUCORE Wall bracket DE; GB; FR WM 16264

* When placing an order please make sure to include type, unit serial no. and year built.

Replacement parts 37

Page 38

10. Tools and testing devices

The following is a list of all tools and testing devices mentioned in this maintenance- and repair manual.

Special tools can be obtained from WEINMANN, the manufacturer.

10.1 General tools

• Phillips screwdriver size:PZ 2

• Nail scissors or ticket-punch to mark the maintenance plaque

• ESD Workstation

• High-voltage protected needle nose pliers

10.2 Special tools

• Discharging unit WM 40009 (obtainable from WEINMANN)

• IR-Adapter WM 22498

• Rechargeable Battery Adapter WM 40008

• Test line MEDUCORE Easy WM 40454

10.3 Software

• EasyView-Service PC software

10.4 Testing devices

• Multimeter, measuring range up to 20 A

• Defi-tester

ECG graphs: Sinusoidal rhythm and arrhythmias

(VT/VF), as described under 201.102.3 in

EN 60601-2-4.

Discharge resistance: 50 ohms ±1% (noninductive)

Maximum energy: up to at least 350 joules

Maximum voltage: > 2500 V

Maximum current: > 50 A

Precision of energy measurement: < ±2% of

measured value

The tester should be calibrated by the

manufacturer.

e.g. Defi-tester from the Fluke Company, Type:

QED6H

Fluke Deutschland GmbH

Heinrich-Hertz-Straße 11

D-34123 Kassel

Germany

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

USA

www.fluke.com

38 Tools and testing devices

Page 39

11. Technical data

Device

Dimensions/Environment/Norms

Dimensions L x B x H (in mm incl. handle) 240 x 240 x 93

Weight, empty:

With Rechargeable Battery/Battery-Pack and electrodes:

Device class according to MPG and Guidelines 93/42/EEC: IIb

Operation:

Temperature range:

Without Rechargeable Battery/Battery-Pack and electrodes:

Air humidity:

Air pressure:

Transport/Storage: 0 °C to +50 °C

Temperature range:

max. 2 weeks

Without Rechargeable Battery and electrodes: -30 °C to +70 °C

Air humidity:

Air pressure:

Protective class IEC 529: IPX4 (protected against sprayed water)

Vibration and knock DIN-EN 1789:1999

Free fall EN 60601-1: 1996

Electromagnetic compatibility:

Norms:

Resuscitation protocol ERC, AHA; 2005

2.1 kg

2.6 kg

0 °C to +50 °C

0 °C to +50 °C

0 % to 95 %

700 to 1060 hPa

-20 °C to +60 °C

0 % to 95 %

500 to 1060 hPa

EN 60601-1-2:2001

EN 55011:1998/A1

EN 55014 -1: 2000/A1

EN 61000-4-2:1995/A1/A2

EN 61000--4-3: 1996/A1

EN 61000--4-4.5: 1995

EN 61000--4-6: 1996/A1

EN 61000--4-8: 1993

EN 1789, AAMI ANSI DF 39, EN 60601-2-4: 2003, rarely

used

Self testing

Interval daily, monthly, when switched on

Time programmable

Range

Defibrillation electrodes

Condition upon delivery

Polarisation not polarized (exchange allowed)

Cable length 125 cm

Electrodes upper surface every 125 cm

service life 30 Months from date of manufacture

battery, electronic, software, charge, shock button, environmental

temperature

self sticking once-only electrodes, packed with connecting plug

extruding

2

Technical data 39

Page 40

Power supply

Version Battery-Pack Rechargeable Battery-Pack (optional)

Type LiSO

Dimensions LxBxH (in mm) 148.6 x 71.6 x 32.6

Weight: 400 g

Shock capacity*,**: up to 200 shocks up to 100 shocks

Minimum capacity 100 shocks –

Monitoring capacity*,***: up to 18 hours up to 9 hours

Rated capacitance: 3800 mAh

Rated voltage: 11.2 V 12.4 V

Fuse – 16 A

Stand-by-Time*:

Minimum Stand-by-Time:

Maximum charging time – < 4 h

Maximum charging power – 1,2 A

Transport/Storage:

Temperature range:

Air humidity:

Service life – > 300 full charges

* For new Rechargeable Battery or Battery-Pack, 20 C.

** At Low-Energy settings

*** At the lowest volume

2

up to 5 years

4 years

– - 40˚C to +85˚C

Li-Ion

0% to 90%

Battery charger (optional)

Dimensions LxBxH (in mm) 108 x 65 x 77

Mains voltage 100-240 ~V

Mains frequency 50/60 Hz

Output voltage 15 V

Weight 230g

Ambient temperature

Operation

Transport/Storage

Fuse T2A 250 V

Short circuit proof Durable

Protective function Voltage surge protection

Charger plug

Mains plug Exchangeable, for different countries

Electromagnetic compatibility see “Dimensions/Environment/Norms”

0˚C to 40˚C

-20˚C to +85˚C

Quadripolar

Secured against incorrect polarity

40 Technical data

Page 41

Defibrillation/Analysis

Defibrillation system CARDIObiphasic

Operational mode Automated (1-button operation)

Wave form Biphasic, current limited

Energy levels

level of energy at 50 ΩΩ

Max. patient imp.

Max. patient imp.

Shock sequence programmable: constant or rising

HLR pause adjustable 60-300 s

Energy levels adjustable

* For new Rechargeable Battery/Battery-Pack, 20˚C.

ECG analysis system CARDIOlogic

Analysis time < 10 s

Conduction II

Impedance measurement checked electrode contact, matches energy to the impedance

Movement and object detection

Reacts to implanted pacemakers

Asystoly threshold < 0.08 mV

Sensitivity VF/pVT* > 93 %

Specificity NSR/Asystoly* > 99 %

ΩΩ

Low Energy (max. 200 J at 75 ΩΩΩΩ)

High Energy (max 310 J at 75 ΩΩΩΩ)

Low Energy:

High Energy:

200 ΩΩ

ΩΩ

5 ΩΩ

Low

High

Constant checking of signal quality, acoustic warning when

patient moves

Pulses from implanted pacemakers may affect or prevent the

proper identification of arrhythmias. It is thus possible that not all

defibrillatable rhythms will be identified, and shock output from the

device is not recommended under certain circumstances.

168 J ±10%

298 J ±10%

ΩΩ

* The test report on the analysis system is available upon request from the manufacturer WEINMANN.

Operation/Data management

Operation

– automatic switch on when lid is opened

Control element

Info-mode

Display elements

Acoustic signals

Data management

Utilisation documentation automatic registration of ECG and event data.

Storage capacity

Data recall, data evaluation, device configuration via infrared interface and and PC software EasyView

– flashing shock button (1-button operation)

– Info-button

Announcement of elapsed time and total shocks delivered since

device was started with start button

– Lighting symbols (traffic light principle)

– Device LEDs (Stand by, Change batteries, Self test results/

Maintenance display)

– Spoken instructions

– Signal tones (during operation)

– Signal tones (in stand-by mode for device malfunction or low

battery levels)

– Metronome function in resuscitation pause

up to 4 data records with a total of a max. 2 hrs. complete ECG

and event data

Technical data 41

Page 42

Data management

– Volume (Level 1 - 4, automatic)

– Self test times

– Pause time period

Configurable parameter

– Selected messages on/off

– Energy level low/high

– Energy protocol constant/rising

– Metronome function on/off

Distance from HF telecommunications equipment

Recommended safe distance between mobile HF telecommunications devices

(e.g. mobile telephones) and the MEDUCORE Easy

Nominal output of HF

equipment

in W

0.01 0.04 0.04 0.07

0.1 0.11 0.11 0.22

1 0.35 0.35 0.70

10 1.11 1.11 2.21

100 3.50 3.50 7.00

150kHz - 80MHz 80MHz - 800MHz 800MHz – 2.5GHz

Subject to design modifications.

Safety distance dependent on transmission frequency

in m

42 Technical data

Page 43

12. Technical Changes

12.1 Device: MEDUCORE Easy

Technical Changes From Device No. Date

ILCOR 2005 1342 13.12.2006

12.2 Software

Technical Changes Software version Date

Adjustment for ILCOR 2005 reanimation procedure

Adjusting the EasyView software for the extended flash

memory erase time on the WM 40130 PCB (revision by

the manufacturer)

Adjusting the EasyView software for the new languages

offered (10 new languages)

Adjusting the EasyView software for the new language

editions (1 new language + dummy entry for "other,

unknown" languages)

V1.2.2

WM 40192a

V.1.2.3.

WM 40192b

V1.2.4

WM 40192c

V1.2.5

WM 40192d

08.12.2006

21.02.2007

03.07.2007

11.12.2007

Technical Changes 43

Page 44

13. Protocol

13.1 Repairs and maintenance protocol

Date Signature

Service performed in accordance

with MEDUCORE service instructions

Company

_____________ __________________

Company

Measures / Comments

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

22525 Hamburg

Device master data Service and repair work carried out in accordance with service instructions

Manufacturer: WEINMANN GmbH +

Co.

44 Protocol

Device type: MEDUCORE Easy

Order No.: ________________________

Date of manufacture: ________________

Safety check - 2 years _______________

Safety check - 4 years _______________

Safety check - 6 years _______________

Safety check - 8 years _______________

Safety check - 10 years _______________

Page 45

13.2 Test record "Safety related check in accordance with §6 of the MP BetreibV (German Medicinal Products and Users Ordinance)"

WM 40007f, page 1

Certificate

to verify that a safety related check has been carried out

in accordance with §6 of the Medicinal Products and Users Ordinance

Type of device: Defibrillator

Serial-No: __________________________________________________

Manufacturer: WEINMANN GmbH & Co. KG

Device type: MEDUCORE Easy WM 40000 WM 40005

(Manufacturer's designation)

Operator: .................................................................................................

.................................................................................................

.................................................................................................

Safety related check:

Due date: 2 years

Scope: Verify that the equipment is complete

Visual inspection for mechanical damage

Test of system components

Safety related check as specified in manufacturer's test instructions

WM 40006

Note: The safety related check is no substitute for necessary maintenance or the

preventative replacement of wearing parts.

Test result: The device meets the requirements of § 6 of the German Medicinal Products

and Users Ordinance.

Date: QM tester:

_________________ ____________________________

Geräte für Medizin GmbH+Co. KG, P.O. Box 54 02 68, D-22502 Hamburg, Fax +49 40/54 70 24 61, Phone +49 40/54 70 2-0

Protocol 45

Page 46

WM 40007f, page 2

Test record for safety related check in accordance with § 6 Medicinal Products and Users Ordinance,

based on test instructions WM 40006

Unit: MEDUCORE Easy WM-No.: 40000 40005 Serial-No.: .......………... Date of manufacture:…...................

1. Testing devices

• Defi-Tester Type Fluke QED6H, PC with IrDE interface, Software EasyView, Rechargeable Battery Adapter WM 40008,

Rechargeable Battery Pack WM 40150 (completely charged), tool for removing the safety check (STK) sticker

2. Preparations for testing

• Connect MEDUCORE Easy to the testing device

3. Entering the device data

• Entering the above mentioned device data Value OK not OK

4. Checking the device’s self testing

• Device self test is carried out

5. Checking the volume levels

• The speech is clear and with a gradual increase in volume

6. Testing the ECG detection, current input, shock button and shock output

• The ECG ventricular fibrillation is recognized

• The middle charging current is 9 ± 3 A

• The shock button is operational, the shock meets the requirements

7. Checking the procedure display and capacitor discharge

• LEDs belonging to the progress displays: pentagon, triangle, charge and shock

button are all lighting correctly

• The capacitor is discharged if the shock is not delivered

8. Check the info button and the reed contact

• The info button is correctly recognised

• The reed contact is switching the device correctly

9. Checking the Status-LEDs

• The status LEDs red, green, and yellow are all lighting correctly

10.Test IrDE interface and the software version

• The interface is functioning correctly

• The software version corresponds to the current release

11.Check maintenance sticker and safety check (STK) sticker

• Maintenance executed

• Maintenance sticker stuck down correctly

• STK sticker stuck down correctly

12.Check the equipment and the accessories (system components)

• Defibrillation electrodes undamaged

Attention! The customer should be notified if the minimum durability falls below

6 months.

• Set, Emergency Meducore Easy WM 15460 complete

• Undamaged rechargeable Battery Pack

• Undamaged Battery Pack

• Capacity (mark wth a cross) ≥ 8 ≤ 15 % > 15 ≤ 50 % >50 %

• Medicinal products book

• Instruction manual

yes no

available yes no

A

Maintenance executed: yes no Final test executed: ______ _______ __________________

Date Tester-No. Signature

46 Protocol

Page 47

Page 48

Weinmann

Geräte für Medizin GmbH+Co. KG

P.O. Box 540268 • D-22502 Hamburg

Kronsaalsweg 40 • D-22525 Hamburg

T: +49-(0)40-5 47 02-0

F: +49-(0)40-5 47 02-461

E: info@weinmann.de

www.weinmann.de

Center for

Production, Logistics, Service

Weinmann

Geräte für Medizin GmbH+Co. KG

Siebenstücken 14

D-24558 Henstedt-Ulzburg

T: +49-(0)4193-88 91-0

F: +49-(0)4193-88 91-450

WM 16941b- 01.09

Loading...

Loading...