Weidmuller UR67, UR67-PN-HP-8IOL-12-30M, UR67-PN-HP-8IOL-12-60M Series Manual

Remote-I/O-System u-remote UR67

I/O-Module IP67 for PROFINET IO-Link

Manual

Letʼs connect.

UR67-PN-HP-8IOL-12-30M 2426250000 UR67-PN-HP-8IOL-12-60M 2426260000

Content

1 About this documentation 3

1.1 Symbols and notes 3

1.2 Complete documentation 3

1.3 Standard data structure 3

2 Safety 4

2.1 General safety notice 4

2.2 Intended use 4

2.3 Legal notice 5

3 System overview 6

3.1 Port characteristics 6

3.2 Fieldbus characteristics 6

3.3 IO-Link functions 7

3.4 Web server 7

3.5 Accessories 7

4 Module descriptions 8

4.1 UR67-PN-HP-8IOL-12-30M 8

4.2 UR67-PN-HP-8IOL-12-60M 9

4.3 Connector pin assignment 10

4.4 Technical data 11

5 Installation and wiring 14

5.1 Preparations for installation 14

5.2 Installing the module and earth connection 14

5.3 Attaching markers 17

5.4 Wiring 17

5.5 Insulation test 17

6 Earthing and shielding 18

6.1 Earthing of shielded cables 18

6.2 Potential ratios 20

6.3 Electromagnetic compatibility (EMC) 20

6.4 Shielding of cables 21

7.5 Conguring IO-Link channels 27

7.6 Parameterising the IO-Link channels 28

7.7 Parameterising the status/control module 30

7.8 Parameterising the IO-Link device 32

7.9 Simple Network Management Protocol (SNMP) 33

7.10 Media Redundancy Protocol (MRP) 33

7.11 Identication & Maintenance functions (I&M) 34

8 Bit allocation 36

8.1 Process data of status/control module, slot1/subslot 1 36

8.2 Process data of IO-Link ports, slot1/subslots2–9 37

9 Diagnostics 38

9.1 System/sensor power supply 38

9.2 Auxiliary/actuator power supply 38

9.3 I/O port sensor power supply outputs 38

9.4 Digital 500mA outputs 38

9.5 Digital 2.0 A outputs 38

9.6 Type-B port aux. power supply 39

9.7 IO-Link C/Q 39

9.8 IO-Link device diagnoses 39

10 Web server 40

10.1 Connecting and starting up the web server 40

10.2 Getting to know and arranging the web server 40

10.3 Module settings and diagnostics 42

10.4 Web server in Force mode 44

10.5 Updating rmware 45

11 Disassembly and disposal 46

11.1 Disassembling the u-remote module 46

11.2 Disposing of the u-remote module 46

12 LED indicators 47

7 Commissioning 23

7.1 Requirements and factory settings 23

7.2 Installing the GSDML le 23

7.3 Connecting the module to the PROFINET network 24

7.4 Assiging device names 26

Manufacturer

Weidmüller Interface GmbH & Co. KG

Klingenbergstraße 16

D-32758 Detmold

T +49 5231 14-0

F +49 5231 14-292083

info@weidmueller.com

www.weidmueller.com

Dokument-No. 2492410000

Revision 00/January 2017

22492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

1 About this documentation

1 About this documentation | Symbols and notes

1.1 Symbols and notes

The safety notices in this documentation are designed according to the severity of the danger.

DANGER

Imminent danger to life!

Notes with the signal word “Danger” warn

you of situations that will result in serious

injury or death if you do not follow the

instructions given in this manual.

WARNING

Possible danger to life!

Notes with the signal word “Warning” warn

you of situations that may result in serious

injury or death if you do not follow the

instructions given in this manual.

CAUTION

Risk of injury!

Notes with the signal word “Caution” warn

you of situations that may result in injury if

you do not follow the instructions given in

this manual.

The situation-dependent safety notices may contain the following warning symbols:

Symbol Meaning

Warning against dangerous electrical voltage

Warning against electrostatically charged

components

Warning against automatic startup

Observe the documentation

▶ All instructions can be identified by the black triangles

next to the text.

– Lists are marked with a tick.

21

Female connections with sockets are illustrated

4

1

using empty circles.

3

Male connections with pins are illustrated using

34

lled circles.

2

ATTENTION

Material damage!

Notes with the signal word “Attention” warn you of

hazards that may result in material damage.

Text next to this arrow are notes that are not relevant to safety, but provide important information

about proper and effective work procedures.

1.2 Complete documentation

The documentation is intended for trained electricians who are familiar with national and international laws, provisions and standards.

All documents can also be downloaded from the

Weidmüller website.

1.3 Standard data structure

All information about the structure of data

(e.g.process data and parameters) refers to the

standard data format settings in the module parameters. These are shown in the Motorola format.

32492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

2 Safety

2 Safety | General safety notice

This chapter includes general safety instructions on handling

the UR67 modules. Specic safety instructions for specic

tasks and situations are given at the appropriate places in

the documentation.

All work may only be carried out by trained

electricians who are familiar with the

safety standards that apply to automation

technology.

The documentation must be stored in such a

way that it is accessible to operating staff at all

times.

2.1 General safety notice

When working during ongoing operations, the emergency

stop mechanisms must not be made ineffective.

If faults connected to a u-remote product cannot be rectied,

the product in question must be sent to Weidmüller. Weidmüller assumes no liability if the module is tampered with!

Fusing

The operator must set up the equipment so that it is protected against overloading. The upstream fuse must be designed so that it does not exceed the maximum load current.

The maximum permissible load current can be found in the

technical data. The operator must decide whether additi-

onal surge protection is required according to IEC62305.

Voltages that exceed +/-30V may cause the destruction of

the modules. A power supply with secure isolation must be

used.

Earthing (functional earth FE)

Every UR67-IO-Link module is equipped with an earth connection, with the connection point labelled “XE”. Further

information is available in chapters 5 and 6.

Shielding

Shielded lines are to be connected with shielded plugs in

compliance with the relevant standard (see chapter 6).

2.2 Intended use

All connected devices must comply with the requirements

set out in EN61558-2-4 and EN61558-2-6. Only cables

and accessories that meet the requirements and provisions

regarding safety, electromagnetic compatibility and, if necessary, telecommunications terminal equipment, as well as the

specications, may be installed. Information on the specic

cables and accessories that are permitted to be installed is

provided in this manual or can be requested from Weidmüller.

Electrostatic discharge

u-remote products can be damaged or destroyed by electrostatic discharge. When handling the products, the neces-

sary safety measures against electrostatic discharge (ESD)

according to IEC61340-5-1 and IEC61340-5-2 must be

observed. The packing and unpacking as well as the installation and disassembly of a device may only be carried out by

qualied personnel.

The UR67-IO-Link modules are decentral input and output

devices in a PROFINET network that can be used as an IOLink master. The products are designed for use in industrial

automation and may only be used within the scope of the

stated technical specications. The devices to be connected

must comply with the requirements set out in EN61558-2-4

and EN61558-2-6.

The industrial environment is labelled as such to ensure that

consumers are not directly connected to the public low-voltage network. Additional measures must be taken for use in

the home, and in the business and commercial sectors.

Any intervention in the products hardware or software other

than described in this manual may only be realised by Weidmüller.

Malfunction-free operation is only guaranteed if the housing

is fully assembled. Observance of the documentation is also

part of the intended use.

42492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

2.3 Legal notice

The UR67-series products comply with the EU Directive

2014/30/EU (EMC Directive).

Components of the following free software products are integrated into the modules:

Componente License Link

jQuery MIT

jQuery-custom-

Select

jQuery-i18n MIT

jQuery-overs-

croll

jQuery-ui MIT

JSZip MIT

md5 (as part

of CryptoJS)

snap-svg

underscore MIT

MIT

MIT

MIT

Apache

license 2.0

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/Stuk/jszip/blob/master/

LICENSE.markdown

https://code.google.com/archive/p/crypto-js/

wikis/License.wiki

https://github.com/adobe-webplatform/Snap.

svg/blob/master/LICENSE

https://github.com/jashkenas/underscore/blob/

master/LICENSE

2 Safety | Legal notice

52492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

3 System overview

3 System overview | Port characteristics

The UR67-IO-Link modules are IO-Link master modules that

are based on PROFINET. The metal housing (zinc diecast,

completely encapsulated) ensures that they conform to the

IP67 protection class. The UR67-IO-Link modules come in

two designs:

– UR67-PN-HP-8IOL-12-30M: 30-mm width, 8I/O ports

– UR67-PN-HP-8IOL-12-60M: 60-mm width, 8I/O ports

The UR67-IO-Link modules support the IO-Link standard

V1.1. The output current is a maximum of 2A per port. Four

ports have output circuits that are electrically isolated from

the rest of the network and from the sensor electronics.

The modules support a fail-safe function, which can be used

to set how a channel congured as an output is to respond

to an impaired or interrupted PROFINET communication.

All of the module interfaces are equipped with protection

against inverse polarity, short circuits and overloads.

3.1 Port characteristics

All ports are colour-coded and therefore cannot be mixed up:

– PROFINET network (green): D-coded, 4-pole M12 plug-in

connector (IN and OUT). The maximum transmission rate

is 100Mbps.

– I/O ports (black): 8 A-coded, 5-pole M12 plug-in connec-

tors

– Power supply connections (grey): L-coded, 5-pole M12

connector (IN and OUT).

Characteristics of the I/O ports

Each module features 8I/O ports:

– 4type-A ports (IO-Link specification classA) with an addi-

tional, hard-wired digital input at pin2.

– 4type-B ports (IO-Link specification classB) with different

designs depending on the type of module:

– UR67-PN-HP-8IOL-12-30M:

with an electrically isolated auxiliary power supply connected to pins 2 and 5, respectively, and a total current

of 4A

– UR67-PN-HP-8IOL-12-60M:

with an electrically isolated auxiliary power supply connected to pins 2 and 5, respectively, each with a max.

current of 2A (8A total current). The auxiliary power

supply can be congured as a digital output.

LED

Each I/O port is assigned two status LEDs which change co-

lour and the frequency at which they ash according to the

status of the respective port (seechapter 12).

3.2 Fieldbus characteristics

PROFINET product characteristics

The UR67-IO-Link modules support PROFINET IO device IRT

(Isochronous Real-Time). This allows time-critical process

data to be transmitted between the network components

in real time. The modules conform to the PROFINET specication V2.3 as well as to the requirements of Conformance

ClassC (CC-C).

The integrated Ethernet switch with two PROFINET ports allows for the PROFINET network to be set up in a line or ring

topology A highly available network infrastructure can be set

up by also implementing the Media Redundancy Protocol

(MRP).

Supported protocols

The UR67-IO-Link modules use the following protocols:

– DCP: for the automatic allocation of IP addresses

– LLDP: for device detection in the immediate surroundings

(neighbourhood detection)

– SNMP: for monitoring network components and the

communication between the master and the device

I&M functions

Identication and maintenance data (I&M) is information saved in the module.

– The identification data is read-only manufacturer informa-

tion on the module.

– The maintenance data is system-independent information

created during the project planning process.

Modules can be easily identied online using the I&M data.

The following are supported:

– Module-specific I&M functions I&M 0–4 for the network

interfaces (slot0)

– The I&M functions specifically for IO-Link master I&M0

and I&M99 (IO-Link master directory) for the IO-Link

ports (slot1)

Alarm and diagnostic messages

The modules offer expanded PROFINET alarm and diagnostic messages.

Conguration and parameterisation

A GSDML le is needed to congure and parameterise the

module in the engineering tool.

The current GSDML le can be downloaded from

the Weidmüller website.

62492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

3 System overview | IO-Link functions

3.3 IO-Link functions

Parameter storage

This function saves and monitors the IO-Link device and

IO-Link master parameters so that it is easier to exchange in-

dividual components (IO-Link device or IO-Link master). The

function can only be used if it is supported by the IO-Link

device and IO-Link master (IO-Link specication V1.1 and

higher).

Device validation

After being enabled, this function checks whether the iden-

tication data for the connected IO-Link device matches the

values set in the IO-Link master. The transfer of the process

data will only start once all of the checked values match.

Parameterisation of IO-Link devices

The IO-Link devices can be parameterised in PROFINET using

the control unit with the Siemens function components

IO_LINK_CALL (STEP 7) and IO_LINK_DEVICE (TIA Portal).

3.4 Web server

The web server can be used to display the UR67-IO-Link module on a connected PC. This allows you to execute the following functions for test purposes or during commissioning

or service work:

– Query the module status

– Display and change the module parameters

– Access diagnostic information

– Operate the module in Force mode for testing purposes

3.5 Accessories

Protective caps

Protection class IP67 is only realised with a completely connected module. This means that all of the ports not being

used must be sealed off using protective caps.

Size Usage Protective cap Order No.

M12 Sensor connection SAI-SK M12 9456050000

M12 Bus-out and power-out SAI-SK-M12-UNI 2330260000

M12 Bus-in and power-in SAI-SK M12 connector 1781520000

Markers

Module and port markers are available to label equipment. All

of the markers can be printed using the Weidmüller PrintJet

ADVANCED (Order No. 1324380000).

Module Markers Order No.

UR67-PN-HP-8IOL-12-30M MF 5/10 MC NE WS 1954050000

UR67-PN-HP-8IOL-12-60M ESG-M8/20 MC NE WS 1027290000

Conductors and connections

In order to select suitable cables, we recommend referring to

Weidmüller Catalogue8 or the Product Congurator on the

Weidmüller website.

72492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

4 Module descriptions

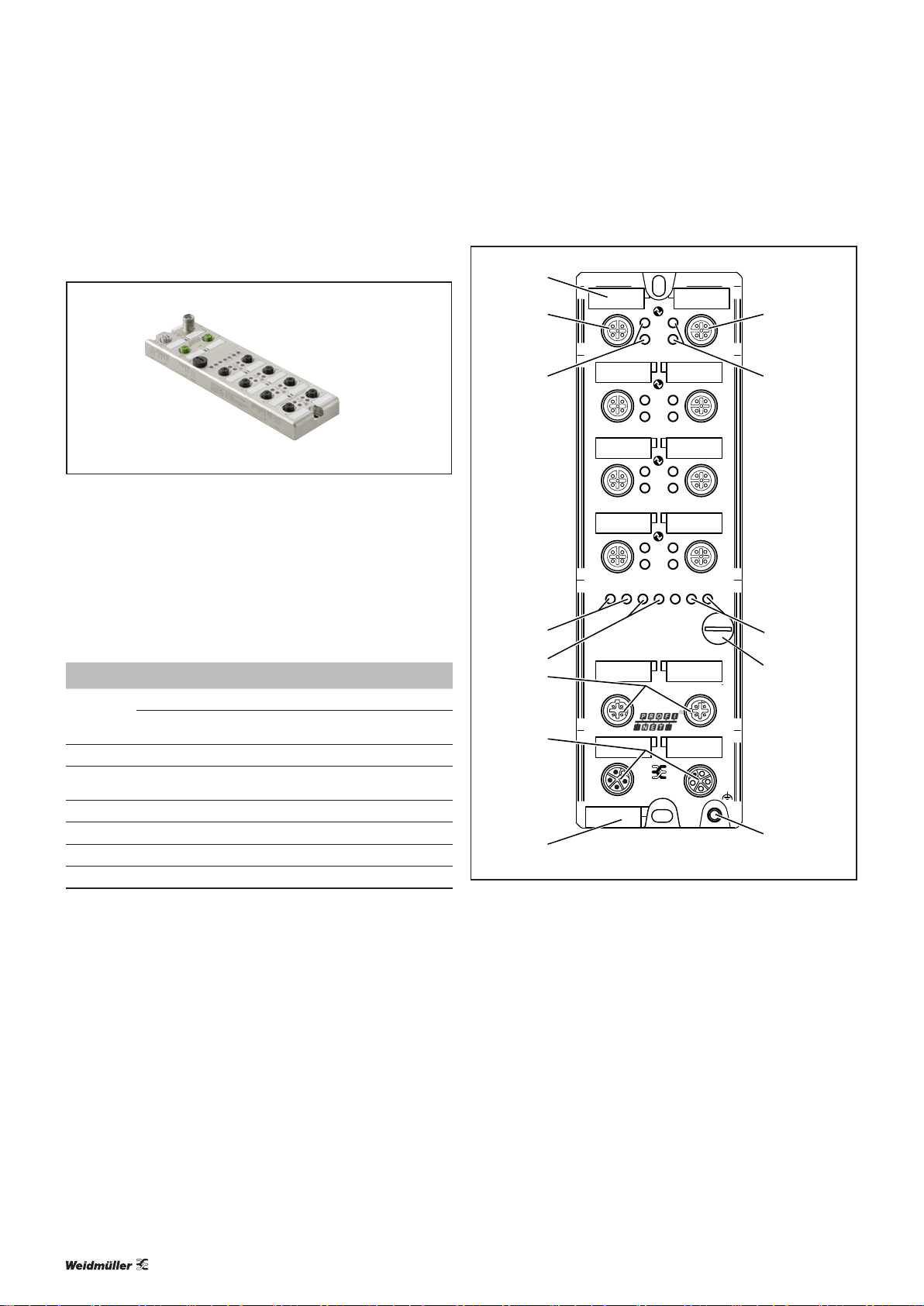

4 Module descriptions | UR67-PN-HP-8IOL-12-30M

4.1 UR67-PN-HP-8IOL-12-30M

Digital IO-Link module UR67-PN-HP-8IOL-12-30M (Order No. 2426250000)

The digital IO-Link module UR67-PN-HP-8IOL-12-30M is intended for the decentralised control in a PROFINET-network.

The module has 8 slots (M12, 5-pole, A-coded, 4 of typeA

and 4 of typeB) for connecting signal lines as well as connections for the eldbus (M12, 4-pole, D-coded) and for the

power supply (M12, 5-pole, L-coded).

Diagnostic and status LEDs

LED Colour Meaning

1 ... 8 A Green

Yellow Standard I/O mode: status of the digital input or output at

1 ... 8 B

Lnk/Act

White

Green Ethernet connection to another participant available, link

P1, P2

U

U

BF

DIA

Aux

S

Green

Green

Off

Off

LED displays (normal operation), error messages see chapter 12

IO-Link COM mode: IO-Link communication

C/Q (pin 4), cable “on”

Status of the digital input at pin 2, cable “on”

detected

Auxiliary sensor/actuator power supply > 18V

System/sensor power supply > 18V

Connection to the PROFINET controller active

No diagnosis available

1

2

1

A B

A B

5

3

2

3

4

4

5

6

7

X01

IN

IN

8

A B

A B

A B

Link/Act

P2P1

BF

DIA

A B

6

A B

7

A B

8

U

SUAux

BUS

OUT

AUX

OUT

XE

UR67-PN-HP-8IOL-12-30M

1 I/O port typeA (1–4)

2 Status LED port 1

3 Marker port 1

4 Ethernet connection LED (Link/Act)

5 Fieldbus (BF) and diagnostics (DIA) LED

6 Micro-USB port (not to be used by the customer)

7 Fieldbus ports (IN, OUT)

8 Module markers

9 Status LED port 5

10 Marker port 5

11 I/O port typeB (5–8)

12 Status LED power supply

= system/sensor power supply, U

(U

S

= auxiliary sensor/actuator power

Aux

supply)

13 Supply voltage connections (IN, OUT)

14 Earth connection

9

10

11

12

13

14

82492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

4.2 UR67-PN-HP-8IOL-12-60M

4 Module descriptions | UR67-PN-HP-8IOL-12-60M

1

Digital IO-Link module UR67-PN-HP-8IOL-12-60M ( Order No. 2426260000)

The digital IO-Link module UR67-PN-HP-8IOL-12-60M is intended for the decentralised control in a PROFINET-network.

The module has 8 slots (M12, 5-pole, A-coded, 4 of typeA

and 4 of typeB) for connecting signal lines as well as connections for the eldbus (M12, 4-pole, D-coded) and for the

power supply (M12, 5-pole, L-coded).

Diagnostic and status LEDs

LED Colour Meaning

1 ... 8 A Green

Yellow Standard I/O mode: status of the digital input or output at

1 ... 8 B

Lnk/Act

White

Green Ethernet connection to another participant available, link

P1, P2

U

U

BF

DIA

Aux

S

Green

Green

Off

Off

LED displays (normal operation), error messages see chapter 12

IO-Link COM mode: IO-Link communication

C/Q (pin 4), cable “on”

Status of the digital input at pin 2, cable “on”

detected

Auxiliary sensor/actuator power supply > 18V

System/sensor power supply > 18V

Connection to the PROFINET controller active

No diagnosis available

2

3

1

2

3

4 8

A

DIA

B

UR67-PN-HP-8IOL-12-60M

A

DIA

B

A

DIA

B

A

DIA

B

BF DIA

Lnk/Act

P2P1

U

U

Aux

S

4

5

6

IN

BUS

7

IN

AUX

8

UR67-PN-HP-8IOL-12-60M

1 Marker port 1

2 I/O port typeA (1–4)

3 Status LED port 1

4 Ethernet connection LED (Link/Act)

5 Fieldbus (BF) and diagnostics (DIA) LED

6 Fieldbus ports (IN, OUT)

7 Supply voltage connections (IN, OUT)

8 Module markers

9 I/O port typeB (5–8)

10 Status LED port 5

11 Status LED power supply

= system/sensor power supply, U

(U

S

= auxiliary sensor/actuator power

Aux

supply)

12 Micro-USB port (not to be used by the customer)

13 Earth connection

9

5

10

6

7

11

X01

12

OUT

OUT

XE

13

92492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

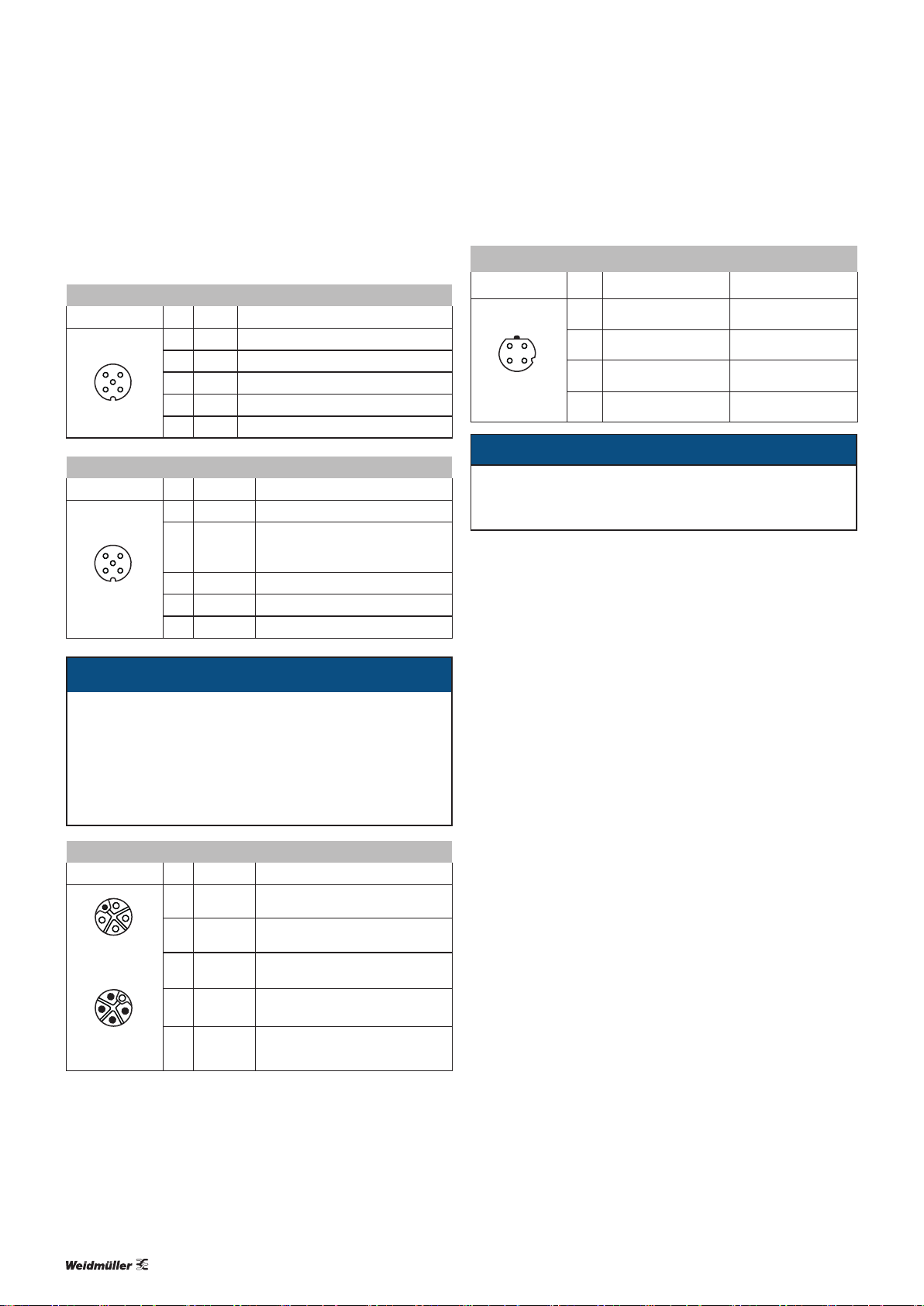

4 Module descriptions | Connector pin assignment

5

4.3 Connector pin assignment

I/O port typeA

M12, 5-pole Pin Signal Function

1 L+ IO-Link +24 V power supply

3

2

5

M12, 5-pole Pin Signal Function

3

2

2 IN-x Ch. B: Digital input (type 1)

4

3 L– IO-Link GND_U

1

4 C/Q Ch. A: IO-Link data communication

5 n. c. Not connected

I/O port typeB

1 L+ IO-Link +24 V power supply

Ch. B auxiliary power supply

2 U

(+24V)

4

1

Aux

(electrically isolated from the system/sensor

power supply)

3 L– IO-Link GND_US power supply

4 C/Q Ch. A: IO-Link data communication

5 GND_U

Earth/reference potential U

Aux

ATTENTION

power supply

S

PROFINET port

M12, 4-pole, D-coded Pin Signal Function

1 TD+ Transmission data +

21

4

3

2 RD+ Receive data +

3 TD– Transmission data –

4 RD– Receive data –

ATTENTION

The product can be destroyed!

▶ Never place the power supply (24VDC) on the signal

or data lines.

Aux

For the system/sensor power supply and the actuator

power supply, please only use power supplies that con-

form to PELV (Protective Extra Low Voltage) or SELV

(Safety Extra Low Voltage) requirements. Power supplies in accordance with EN61558-2-6 (transformer) or

EN60950-1 (switched-mode power supply) meet these

requirements.

Power supply connection

M12, 5-pole, L-coded Pin Signal Func tion

1

5

2

4

3

OUT

1

5

2

4

3

IN

(+24V) System/sensor power supply

1 U

S

2 GND_U

Earth/reference potential U

Aux

3 GND_USEarth/reference potential U

(+24V)

Auxiliary power supply

(electrically isolated)

4 U

Aux

5 FE (PE) Functional earth

Aux

S

102492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

4 Module descriptions | Technical data

4.4 Technical data

Technical data UR67-PN-HP-8IOL-12-30M (2426250000) UR67-PN-HP-8IOL-12-60M (2426260000)

Bus system

Protocol

Device identification (DeviceID)

Vendor identification (VendorID)

GSDML file

Update cycle

Data transmission rate

Auto-negotiation

Supported Ethernet protocols

SNMPv1 (network diagnosis): Read community: public; Write community: private

Switch functionality

Connection

Electrical isolation of the Ethernet ports/FE

I/O ports 1–8

Number

Connection

Ch.A / C/Q / pin 4 configured as a digital input

Number

Input type

Input wiring

Rated input voltage

Input current at 24VDC

Short-circuit-proof

Status indicator

Diagnosis indicator

Ch.A / C/Q / pin 4 configured as a digital output

Number

Output type

Rated output current per channel

1)

Signal status “1”

Signal status “0”

Signal level of the outputs

Signal status “1”

Signal status “0”

Max. output current

Short-circuit-proof

1) In the case of inductive loads in utilisation category DC13 (in acc. withEN60947-5-1), the outputs can operate with currents of 0.5A and a frequency of 1Hz..

2) Technically possible and approved on the following conditions: looped sensor/system power supply – max. 2.5 A; STL 204 power supply cable (5 x 1.0 mm²);

max. ambient temperature – 40°C; max. current-carrying capacity – 12 A

PROFINET IO device, Conformance Class C (CC-C)

0x0134hex

0x18C6hex

GSDML-Vx.x-WI-UR67-yyyymmdd.xml

1ms

100Mbps full duplex

Supported

Ping, ARP, LLDP, DCP, HTTP, TCP/IP, MRP Client,

integrated, IRT supported

M12, 4-pole, D-coded

2,000VDC

4 typeA and 4 typeB

M12, 5-pole, A-coded

max. 8 congurable

NO contact, P-switching

Type 1 in acc. with IEC 61131-2

24VDC

typically 3mA

yes

Yellow LED

Red LED for each port

max. 8 congurable

NO contact, P-switching

max. 500mA

max. 1mA

min. (US – 1V)

max. 2V

9 A/module

2)

yes

112492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

4 Module descriptions | Technical data

Technical data UR67-PN-HP-8IOL-12-30M (2426250000) UR67-PN-HP-8IOL-12-60M (2426260000)

Overload-proof

Short circuit or overload behaviour

Status indicator

Diagnosis indicator

Switch off, automatic switch on

Yellow LED for each output

yes

Red LED for each port

Ch.A / C/Q / pin 4 as IO-Link channel in COM mode

IO-Link master specification

Transfer rates

Cable lengths for the IO-Link device

Number of IO-Link ports

4.8 kbaud (COM 1), 38.4 kbaud (COM 2) and 230.4 kbaud (COM 3)

v1.1, IEC 61131-9

max. 20m

max. 8 congurable

Ports 1– 4, type B, ch. B / pin 2 as digital inputs

Number

Input type

Input wiring

Rated input voltage

Input current at 24 V DC

Status indicator

Diagnosis indicator

NO contact, P-switching

Type 1 in acc. with IEC 61131-2

4

24VDC

typically 3mA

White LED

Red LED for each port

Ports 5–8, type B, ch. B / pin 2 configured as digital 2-A output

Number

Output type

Rated output current per channel

Signal status “1”

Signal status “0”

Signal level of the outputs

Signal status “1”

Signal status “0”

Max. output current

Short-circuit-proof

Overload-proof

Short circuit or overload behaviour

Filter period in the event of a signal

1)

– 4

– NO contact, P-switching

– 2A

– max. 2A

– max. 1mA

–

– min. (U

– max. 2V

– 16A/module

– yes

– yes

– Switch off, no automatic switch on

– 0–255ms; default 80ms

Aux

– 1V)

2)

change

Status indicator

Diagnosis indicator

– White LED for each output

– Red LED for each port

Module electronics/sensor power supply

Rated voltage U

S

Voltage range

Electronics current consumption

typically 160 mA (± 20% with rated voltage US)

24VDC (SELV/PELV)

24VDC ± 25%

1) In the case of inductive loads in utilisation category DC13 (in acc. withEN60947-5-1), the outputs can operate with currents of 0.5A and a frequency of 1Hz..

2) Technically possible and approved on the following conditions: looped sensor/system power supply – max. 2.5 A; STL 204 power supply cable (5 x 1.0 mm²);

max. ambient temperature – 40°C; max. current-carrying capacity – 12 A

122492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

4 Module descriptions | Technical data

Technical data UR67-PN-HP-8IOL-12-30M (2426250000) UR67-PN-HP-8IOL-12-60M (2426260000)

Sensor voltage

Sensor current consumption (L+/pin 1)

min. (US–1.5 V)

max. 500mA per port (at Tu 30°C)

Short-circuit protection/

overload-protection for the sensor power

yes, for each port

supply

Polarity protection

Status indicator (US)

Connection

M12-Power, 5-pole, L-coded, pin 1

yes

Green LED

Power supply for type-B ports (auxiliary power supply)

Rated voltage U

Aux

Voltage range

Polarity protection

Status indicator (U

Connection

)

Aux

24 V DC (SELV/PELV)

24VDC ± 25%

yes

Green LED

M12-Power, 5-pole, L-coded, pin 4

General data

Protection class

Ambient temperature

Weight

480 g 500 g

IP 67 (when screwed in only)

–20°C to +70°C (–4°F to +158°F)

Dimensions

Housing material

Vibration resistance – vibration

Zinc diecast, nickel matt surface nish

15g/5–500Hz

(DIN EN 60068-2-6 (2008-11))

Vibration resistance – impact

50g/11ms, ±X,Y,Z

(DIN EN 60068-2-27 (2010-02))

Tightening torques

M12 plug-in connector

0.5Nm

1) In the case of inductive loads in utilisation category DC13 (in acc. withEN60947-5-1), the outputs can operate with currents of 0.5A and a frequency of 1Hz..

2) Technically possible and approved on the following conditions: looped sensor/system power supply – max. 2.5 A; STL 204 power supply cable (5 x 1.0 mm²);

max. ambient temperature – 40°C; max. current-carrying capacity – 12 A

132492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

5 Installation and wiring

5 Installation and wiring | Preparations for installation

WARNING

Dangerous contact voltage!

▶ All installation and wiring work must be

carried out with the power supply disconnected.

▶ Make sure that the place of installation

has been disconnected from the power

supply!

5.1 Preparations for installation

Make sure that the permitted environmental conditions for

installation and operation are observed (see Technical data).

Installation position and dimensions

The modules must be installed on a level surface. The instal-

lation dimensions and tightening torques for the xings are

provided in the installation drawings on the following pages.

Unpacking the delivery

▶ Please check the delivery for completeness and transport

damage.

▶ Please report any transport damage immediately to the

respective transport company.

5.2 Installing the module and earth connection

▶ Drill the holes for the fixings (for the drilling dimensions,

see the installation drawings on the following pages).

▶ Affix each module with two screws and a washer (as per

DINEN ISO 7089).

▶ Observe the screw dimension and tightening torques indi-

cated.

Element Torque

M12 plug-in connector 0.5Nm

M12 protective cap 0.5Nm

The modules have an earth connection (“XE”) with an M4

thread for discharging interference currents and for EMC

stability.

▶ Connect the earth connection to the reference earth via a

low-impedance connection.

If the mounting surface is earthed, the connection can be

made directly via the mounting screws.

If the mounting surface is not earthed, use an earthing strap

or a suitable cable!

▶ Connect the earthing strap or the FE cable to the earth

connection (“XE”) using an M4 screw.

ATTENTION

The product can be destroyed by electrostatic discharge!

u-remote products can be destroyed by electrostatic discharge.

▶ Please make sure that personnel and work

equipment are adequately earthed!

▶ Unpack the parts.

▶ Dispose of all packaging in accordance with the local dis-

posal guidelines. The cardboard packaging can be sent

for paper recycling.

142492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

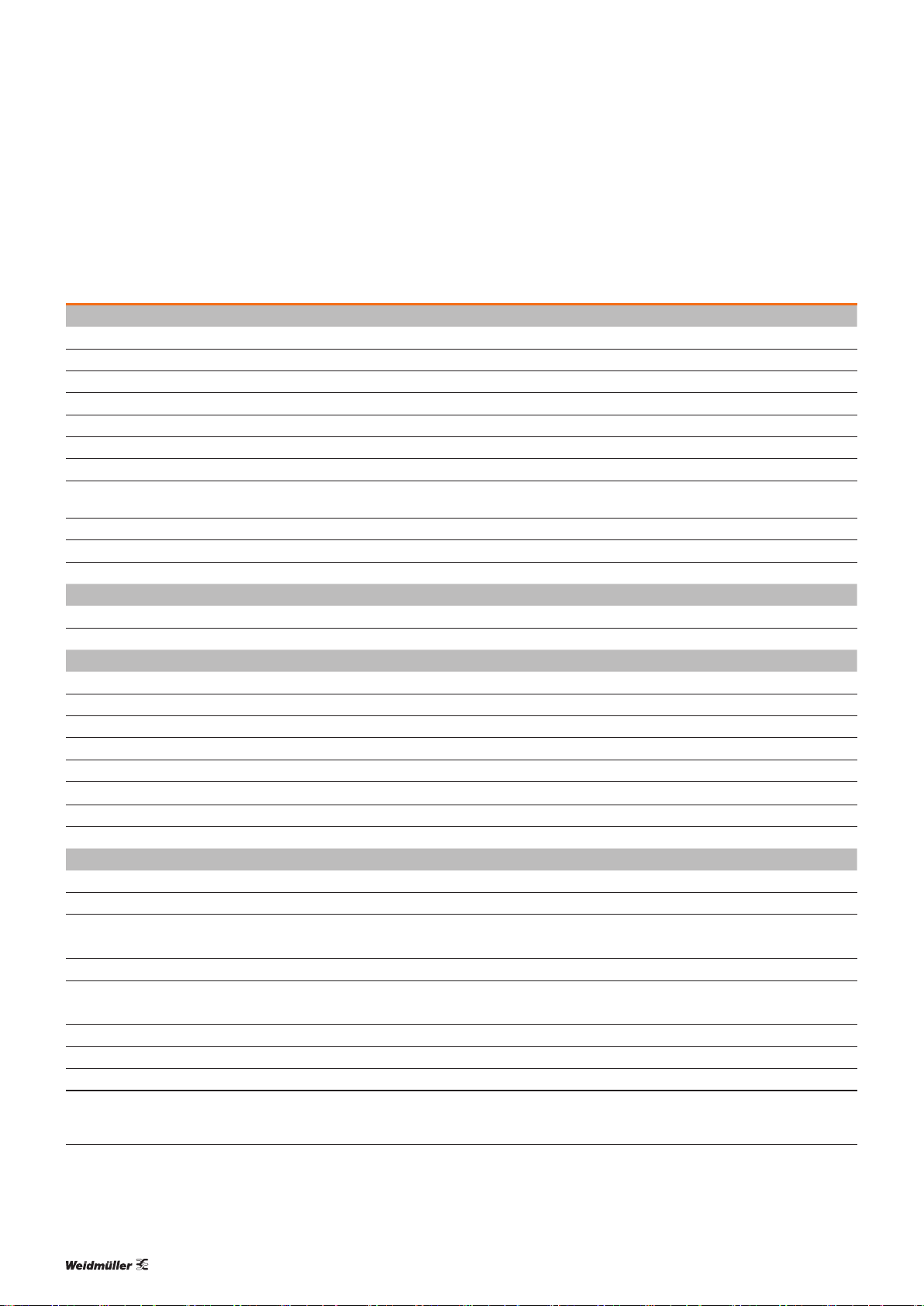

5 Installation and wiring | Installing the module and earth connection

M12

33.4

3

4

female

2

1

5

M12 IO-L Type B

(5-8)

Function Pin

1

+24V

2

+24V

Aux/Out

3

GND

4

C/Q

5

GND Aux

Max. Amblent Temp.: -20° ... +70 °C / -4° ... +158 °F

System Power Supply: 24V +25% / -25%; 200mA

UR67-PN-HP-8IOL-12-30M

Input Power Supply: 24V 200mA

Output Power Supply: 24V 0,5A per Port / PD max.9A

225

1

A B

2

A B

3

A B

4

A B

215.7 ... 217

Link/Act

P2P1

30

15

A B

A B

A B

A B

U

SUAux

M4x 30/35

5

6

7

8

M12

PROFINET

M12

AUX

Installation dimensions UR67-PN-HP-8IOL-12-30M

3

2

BUS

(IN-OUT)

Function Pin

TD +

RD+

TDRD-

FE

POWER

(IN-OUT)

Function Pin

+24V

GND Aux

GND

+24V Aux

FE

43.1

1

4

30

BF

DIA

4

female

1

1

2

3

4

2

female

3

1

2

3

4

5

X01

IN

IN

BUS

OUT

AUX

OUT

XE

M4

XE

M4x 30/35

152492410000/00/01.2017 UR67-IO-Link Manual UR67 for PROFINET IO-Link

Loading...

Loading...