Page 1

U

SER'S HANDBOOK

Model 9100

Universal Calibration System

Volume 2 — Performance

W

Final Width = 215mm

Page 2

User's Handbook

For

The Model 9100

Universal Calibration System

Volume 2 — Performance

(for Introduction, Installation, Controls (with Tutorial), Manual Mode and Procedure Mode

refer to Volume 1 — Operation)

(for Options 250 and 600 refer to Volume 3 — Operation and Performance)

W

ISO 9002

Wavetek Ltd

CERTIFICATE

No. FM 29700

For any assistance contact your nearest Wavetek Sales and Service Center.

Addresses can be found at the back of this handbook.

Due to our policy of continuously updating our products, this handbook may contain minor

differences in specification, components and circuit design to the instrument actually supplied.

Amendment sheets precisely matched to your instrument serial number are available on request.

W

is a US registered trademark of Wavetek Corporation.

Page 3

Wavetek Corporation

Standard Warranty Policy

Wavetek warrants that all Products manufactured or procured by Wavetek conform to Wavetek's published specifications and are free from

defects in materials and workmanship for a period of one (1) year from the date of delivery to the original Buyer, when used under normal

operating conditions and within the service conditions for which they were designed. This warranty is not transferrable and does not apply

to used or demonstration products.

The obligation of Wavetek arising from a Warranty claim shall be limited to repairing, or at its option, replacing without charge, any assembly

or component (except batteries) which in Wavetek's sole opinion proves to be defective within the scope of the Warranty. In the event Wavetek

is not able to modify, repair or replace nonconforming defective parts or components to a condition as warranted within a reasonable time

after receipt thereof, Buyers shall receive credit in the amount of the original invoiced price of the product.

Wavetek must be notified in writing of the defect or nonconformity within the Warranty period and the affected Product returned to Wavetek's

factory, designated Service Provider, or Authorized Service Center within thirty (30) days after discovery of such defect or nonconformity.

Buyer shall prepay shipping charges and insurance for Products returned to Wavetek or its designated Service Provider for warranty service.

Wavetek or its designated Service Provider shall pay costs for return of Products to Buyer.

Wavetek shall have no responsibility for any defect or damage caused by improper storage, improper installation, unauthorized modification,

misuse, neglect, inadequate maintenance, accident or for any Product which has been repaired or altered by anyone other than Wavetek or

its authorized representative or not in accordance with instructions furnished by Wavetek.

The Warranty described above is Buyer's sole and exclusive remedy and no other warranty, whether written or oral, expressed or implied by

statute or course of dealing shall apply. Wavetek specifically disclaims the implied warranties of merchantability and fitness for a particular

purpose. No statement, representation, agreement, or understanding, oral or written, made by an agent, distributor, or employee of Wavetek,

which is not contained in the foregoing Warranty will be binding upon Wavetek, unless made in writing and executed by an authorized

representative of Wavetek. Under no circumstances shall Wavetek be liable for any direct, indirect, special, incidental, or consequential

damages, expenses, or losses, including loss of profits, based on contract, tort, or any other legal theory.

April 1, 1994

SAFETY WARNING!

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

This product complies with the requirements of the following European Community Directives:

However, noisy or intense electromagnetic fields in the vicinity of the equipment can disturb the measurement

circuit. Users should exercise caution and use appropriate connection and cabling configurations to avoid

misleading results when making precision measurements in the presence of electromagnetic interference.

© 1998 Wavetek Ltd 850301 Issue 8.0 (June 1998)

89/336/EEC (Electromagnetic Compatibility) and 73/23/EEC (Low Voltage)

as amended by 93/68/EEC (CE Marking).

Page 4

Contents

Page

Section 1 The Model 9100 Multifunction Calibrator See Volume 1 - Operation

Section 2 Installing the Model 9100 See Volume 1 - Operation

Section 3 Model 9100 Controls See Volume 1 - Operation

Section 4 Using the Model 9100 — Manual Mode See Volume 1 - Operation

Section 5 Using the Model 9100 — Procedure Mode See Volume 1 - Operatio

Final Width = 215mm

Volume 2 — Performance (

Section 6 Remote Interfaces

6.1 About Section 6 ................................................................................................ 6-1

6.2 Index of IEEE-488.2 and SCPI Codes used in the Model 9100 ....................... 6-2

6.3 Introduction....................................................................................................... 6-4

6.4 Using the Model 9100 in a System................................................................... 6-8

6.5 Retrieval of Device Status Information ............................................................. 6-15

6.6 Model 9100 SCPI Language - Commands and Syntax.................................... 6-24

6.7 The IEEE Bus Interface for the Power Option .................................................. 6-58

Section 6 Appendix A: IEEE 488.2 Device Documentation Requirements............... 6-A1

Section 6 Appendix B: SCPI Conformance Information ........................................... 6-B1

Section 6 Appendix C: IEEE 488.2 Common Commands and Queries

Section 6 Appendix D: Model 9100 — Device Settings after *RST .......................... 6-D1

Section 6 Appendix E: Model 9100 — Device Settings at Power On ....................... 6-E1

Section 7 Model 9100 Specifications

7.1 General............................................................................................................. 7-1

7.2 Options and Associated Products .................................................................... 7-2

7.3 DC Voltage Specifications ................................................................................ 7-3

7.4 AC Voltage Specifications ................................................................................ 7-4

7.5 DC Current Specifications ................................................................................ 7-8

7.6 AC Current Specifications ................................................................................ 7-9

7.7 Resistance Specifications ................................................................................ 7-14

7.8 Conductance Specifications ............................................................................. 7-15

7.9 Frequency Function Specifications .................................................................. 7-16

7.10 Mark/Period Function Specifications ................................................................ 7-17

7.11 % Duty Cycle Function Specifications .............................................................. 7-18

7.12 Auxiliary Functions - Specifications .................................................................. 7-19

7-13 Capacitance Specifications .............................................................................. 7-20

7.14 Thermocouple Temperature Specifications...................................................... 7-21

7.15 RTD Temperature Specifications ..................................................................... 7-22

7.16 Logic-Pulses Function Specifications ............................................................... 7-23

7.17 Logic-Levels Function Specifications ............................................................... 7-24

7.18 Insulation/Continuity Specifications .................................................................. 7-25

7.19 Power Specifications ........................................................................................ 7.27

This Volume

Implemented in the Model 9100 ........................................... 6-C1

)

0-2 Model 9100 User's Handbook — Contents List

Page 5

Section 8 Model 9100 — Routine Maintenance and Test

8.1 About Section 8 ................................................................................................ 8-1

8.2 Routine Maintenance ....................................................................................... 8-2

8.3 Model 9100 Test and Selftest........................................................................... 8-10

8.4 Printing Selftest Results ................................................................................... 8-26

Section 8 Appendix A Error Reporting Subsystem .................................................. 8-A1

Section 9 Model 9100 — Specification Verification

9.1 About Section 9 ................................................................................................ 9-1

9.2 The Need for Verification.................................................................................. 9-1

9.3 Equipment Requirements ................................................................................. 9-2

9.4 Interconnections ............................................................................................... 9-2

9.5 Verification Points............................................................................................. 9-3

9.6 Calculating Absolute Specification Limits ......................................................... 9-4

Section 10 Model 9100 — Calibration

10.1 About Section 10 .............................................................................................. 10.1-1

10.2 The Model 9100 Calibration Mode ................................................................... 10.2-1

10.2.1 Introduction ....................................................................................... 10.2-1

10.2.2 Mode Selection ................................................................................. 10.2-2

10.2.3 Selection of Calibration Mode ........................................................... 10.2-2

10.2.4 Special Calibration ............................................................................ 10.2-5

10.2.5 Cold Junction Calibration .................................................................. 10.2-8

10.2.6 Standard Calibration ......................................................................... 10.2-12

10.2.7 Overview of Calibration Operations .................................................. 10.2-14

10.3 Standard Calibration — Basic Sequences ....................................................... 10.3-1

10.3.1 Introduction ....................................................................................... 10.3-2

10.3.2 Selecting Hardware Configurations................................................... 10.3-4

10.3.3 Selecting Target Calibration Values .................................................. 10.3-5

10.3.4 Calibrating the Model 9100 at Target Values .................................... 10.3-9

10.3.5 Standard Calibration of AC Functions ............................................... 10.3-13

10.4 Front Panel Calibration by Functions ............................................................... 10.4-1

10.4.1 Introduction ....................................................................................... 10.4-1

10.4.2 Summary of Calibration Process....................................................... 10.4-2

10.4.3 DC Voltage Calibration...................................................................... 10.4-6

10.4.4 AC Voltage Calibration ...................................................................... 10.4-14

10.4.5 DC Current Calibration ...................................................................... 10.4-20

10.4.6 AC Current Calibration ...................................................................... 10.4-28

10.4.7 Resistance Calibration ...................................................................... 10.4-36

10.4.8 Capacitance Calibration .................................................................... 10.4-45

10.4.9 Insulation Resistance Calibration ...................................................... 10.4-51

10.4.10 Continuity Calibration ........................................................................ 10.4-57

10.5 Remote Calibration of the Model 9100 via the IEEE 488 Interface .................. 10.5-1

10.5.1 The Model 4950 MTS System........................................................... 10.5-1

Page

Final Width = 215mm

Model 9100 User's Handbook — Contents List 0-3

Page 6

DANGER

HIGH VOLTAGE

THIS INSTRUMENT IS CAPABLE OF DELIVERING

A LETHAL ELECTRIC SHOCK !

Model 9100: I+, I-, Hi, Lo, sHi and sLo Terminals

!

Final Width = 215mm

Model 9105: H (Red), sH (Red), sL (Black) L

I+20 (Yellow) Leads carry the Full Output Voltage

and

I- (Black)

THIS CAN KILL !

Avoid damage to your instrument !

!

Unless

Refer to User's Handbook, Volume 2, Section 7; for

Maximum Output Voltages and Currents.

you are sure that it is safe to do so,

DO NOT TOUCH ANY of the following:

Model 9100: I+ I- Hi Lo sHi or SLo leads and terminals

Model 9105: H sH

sL LI- or I+20 leads

DANGER

Page 7

Section 6: 9100 System Application via IEEE-488 Interface

6.1 About Section 6

Section 6 describes the environment in which the Model 9100 will operate in remote

applications, using the SCPI (Standard Commands for Programmable Instruments)

language, within the IEEE-488.1 remote interface. In Section 6 we shall show how the

9100 adopts the IEEE-488.2 message-exchange model and reporting structure, and

define the SCPI commands and syntax used to control the 9100. Section 6 is divided into

the following sub-sections:

page:

6.2 Index of IEEE-488.2 and SCPI Codes used in the 9100...............................6-2/3

6.3 Introduction

9100 System Operational Parameters.

6.3.1 Interface Capability.........................................................................6-4

6.3.2 Interconnections. ............................................................................. 6-6

6.3.3 SCPI Programming Language. ....................................................... 6-7

6.4 Using the 9100 in a System

9100 System — Infrastructure.

6.4.1 Addressing the 9100. ...................................................................... 6-8

6.4.2 Operation via the IEEE-488 Interface. ........................................... 6-10

6.4.3 Message Exchange.......................................................................... 6-12

6.4.4 Request Service (RQS). .................................................................. 6-14

6.5 Retrieval of Device Status Information.

9100 'SCPI' Status Reporting Structure, based on IEEE-488.2.

6.5.1 General. ........................................................................................... 6-15

6.5.2 IEEE-488 and SCPI Standard-Defined Features. ........................... 6-17

6.5.3 9100 Status Reporting — IEEE-488.2 Basics. ............................... 6-18

6.5.4 9100 Status Reporting — SCPI Elements. ..................................... 6-23

6.6 9100 SCPI Language — Commands and Syntax.

Detailed treatment of the 9100 SCPI Command Set

6.6.1 Introduction..................................................................................... 6-24

6.6.2 CALibration Subsystem.................................................................. 6-25

6.6.3 OUTPut Subsystem.........................................................................6-28

6.6.4 SOURce Subsystem. ....................................................................... 6-30

6.6.5 STATus Subsystem.........................................................................6-49

6.6.6 SYSTem Subsystem. ...................................................................... 6-53

Final Width = 215mm

Appendix A: IEEE 488.2 Device Documentation Requirements. ................. 6-A1

Appendix B: SCPI Command Set & Conformance Information. .................. 6-B1

Appendix C: IEEE 488.2 Common Commands and Queries. ....................... 6-C1

Appendix D:

Appendix E: Power-on Conditions. .............................................................. 6-E1

∗

RST (Reset) Conditions. ......................................................... 6-D1

Section 6: 9100 System Operation — SCPI Language 6-1

Page 8

Final Width = 215mm

6.2 Index of IEEE 488.2 and SCPI Codes used in the 9100

6.2.1 Common IEEE 488.2 Commands and Queries

Program Coding Description Appendix C, Page:

∗CLS Clears event registers and queues (not O/P queue) 6-C1

∗ESE Nrf Enables standard-defined event bits 6-C2

∗ESE? Returns ESE register mask value 6-C2

∗ESR? Reads Event Status register 6-C3

∗IDN? Reports manufacturer, model, etc. 6-C4

∗OPC Sets the 9100 to monitor the 'No-Operations-Pending' flag. 6-C5

∗OPC? For 'No-Operations-Pending' flag 'TRUE', places a 1 in the Output Queue. 6-C5

∗OPT? Recalls the instrument's option configuration. 6-C6

∗PSC 0/1 Sets/resets power-on status clear flag 6-C7

∗PSC? Recalls power-on status clear flag 6-C8

∗PUD Allows entry of user data to protected store 6-C9

∗PUD? Recalls user-entered data 6-C10

∗RST Resets instrument to power on condition 6-C11 / App D, p6-D1

∗SRE Nrf Enables Service Request Byte bits 6-C11

∗SRE? Returns Service Request Byte mask value 6-C12

∗STB? Non-destructively reads Service Request Byte 6-C12

∗TST? Perform Full Test 6-C13

∗WAI Conforms, but little relevance to 9100 application 6-C14

6-2 Section 6: 9100 System Operation — SCPI Language

Page 9

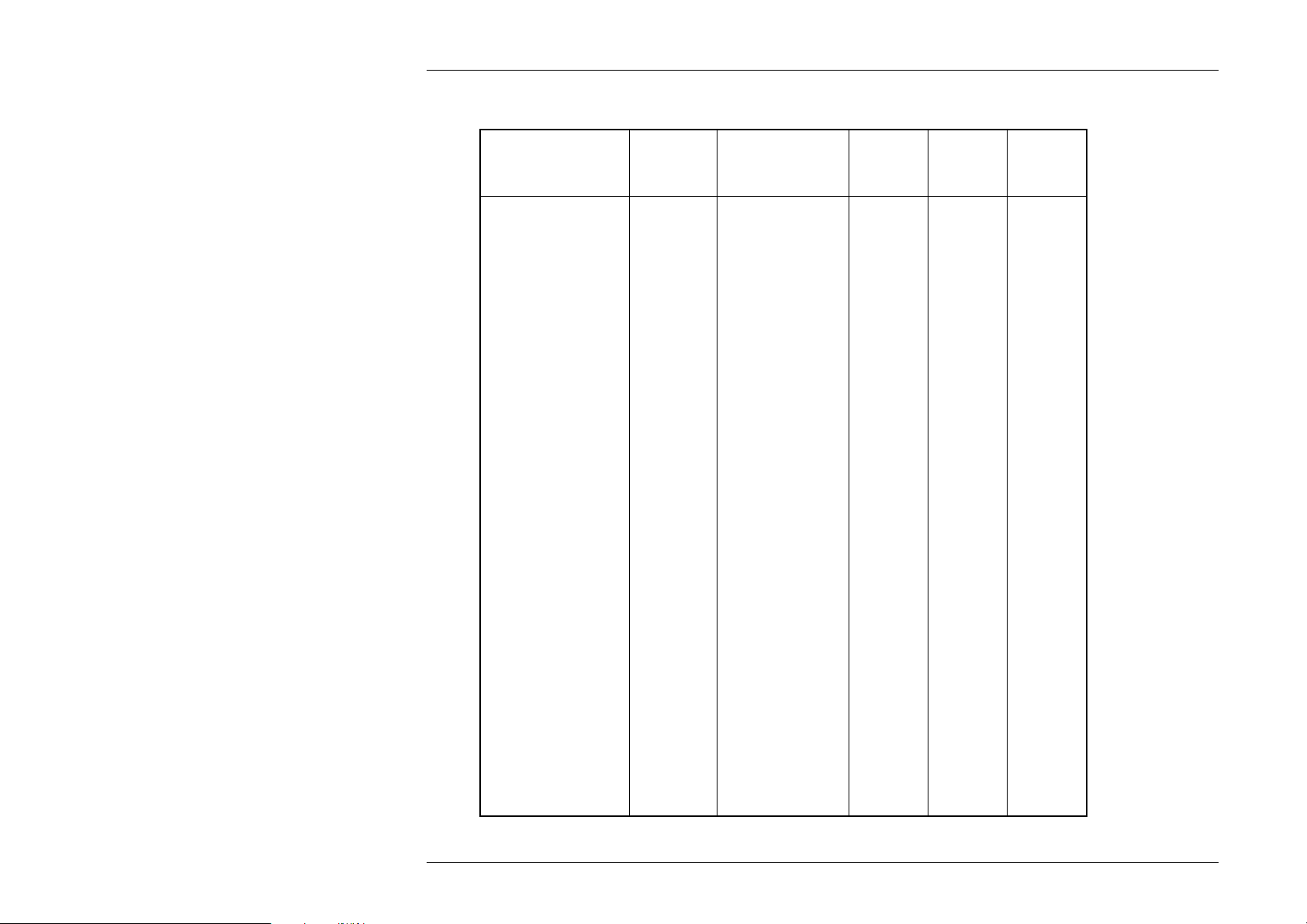

6.2.2 9100 SCPI Subsystems

CALibration Used to calibrate the functions and hardware ranges of the 9100, correcting for system errors which have

accumulated due to drift and ageing effects:........................................................................................................................6-25

SECure :PASSword. Gains access to Calibration operations, using 'Cal Enable' switch and Password.

:EXIT. Permits clean exit from calibration operation ..................................................................... 6-25

TARGet Sets up the calibration target point, hardware range (and frequency, where required). ................ 6-26

TRIGger? Initiates the calibration at a single point, once the target and levels have been set up,

and returns '0' for pass, and '1' for fail............................................................................................6-27

SPECial? Runs the DAC characterization and returns '0' for pass, and '1' for fail ......................................... 6-27

CJUNction? Runs the reference thermocouple junction temperature measurement

and returns '0' for pass, and '1' for fail............................................................................................6-27

OUTPut Used to control parameters associated with output connections: ........................................................................................ 6-28

[STATe] (?) Controls output on/off switching ..................................................................................................... 6-28

COMPensation (?) Switches the output connections for 4-wire/2-wire in impedance functions ................................... 6-28

ISELection (?) For Current outputs, selects between front panel terminals (High currents, Current coils), and

front panel D-type Socket (Low currents).......................................................................................6-29

[SOURce] Used to select the main 9100 Function (Voltage, Current etc.), to be output:...................................................................... 6-30

FUNCtion Selects the Waveshape of output signals ...................................................................................... 6-32

VOLTage Selects the Voltage source for output ............................................................................................ 6-34

CURRent Selects the Current source for output ............................................................................................ 6-36

RESistance Selects the Resistance source for output.......................................................................................6-37

CONDuctance Selects the Conductance source for output ................................................................................... 6-38

CAPacitance Selects the Capacitance source for output .................................................................................... 6-39

FREQuency Controls the Output Frequency value for AC functions .................................................................. 6-40

PHASe Selects and controls the Phase-shifting facility .............................................................................. 6-41

PULSe Selects and controls the Pulse source for output...........................................................................6-43

TEMPerature Selects and controls the Temperature sources for output ............................................................. 6-44

Final Width = 215mm

STATus Gives access to the 9100 SCPI-defined Status Reporting Structure: ..................................................................................6-49

OPERation Reads from, or writes to, the OPERation Status Register ............................................................. 6-49

QUEStionable Reads from, or writes to, the QUEStionable Status Register.........................................................6-51

PRESet Presets a default status reporting condition ................................................................................... 6-52

SYSTem Collects general functions that are not related to 9100 performance: .................................................................................. 6-53

ERRor? Requests the next entry from the 9100 error queue. ..................................................................... 6-53

DATE(?) Reads or writes the present date ................................................................................................... 6-54

TIME(?) Reads or writes the present time ................................................................................................... 6-55

SVOLtage(?) Reads or writes the Safety Threshold Voltage in DC or AC Voltage function................................6-56

VERSion? Returns a numeric value corresponding to the SCPI version for which the instrument complies .. 6-56

Section 6: 9100 System Operation — SCPI Language 6-3

Page 10

Final Width = 215mm

IEEE

488.1 Interface Function

Subset

SH1 Source Handshake Capability

AH1 Acceptor Handshake

Capability

T6 Talker (basic talker, serial

poll, unaddressed to talk if

addressed to listen)

L4 Listener (basic listener,

unaddressed to listen if

addressed to talk)

SR1 Service Request Capability

RL1 Remote/Local Capability (incl.

Local Lockout)

PP0 No Parallel Poll Capability

DC1 Device Clear Capability

DT0 No Device Trigger Capability

C0 No Controller Capability

E2 Open-Collector and Three-

State Drivers

Table 6.1

IEEE 488.1 Interface Capability

6.3 Introduction

This first part of Section 5 gives the information necessary to put the 9100 into operation

on the IEEE 488 bus. For more detailed information, refer to the standard specification

in the publications ANSI/IEEE Std. 488.1-1987 and IEEE Std. 488.2-1988.

6.3.1 Interface Capability

6.3.1.1 IEEE Standards 488.1 and 488.2

The 9100 conforms to the Standard Specification IEEE 488.1-1987: ‘IEEE Standard

Digital Interface for Programmable Instrumentation’, and to IEEE 488.2-1988: ‘Codes,

Formats, Protocols and Common Commands’.

6.3.1.2 The 9100 in IEEE 488.2 Terminology

In IEEE 488.2 terminology the 9100 is a device containing a system interface. It can be

connected to a system via its system bus and set into programmed communication with

other bus-connected devices under the direction of a system controller.

6.3.1.3 Programming Options

The instrument can be programmed via the IEEE Interface, to:

• Change its operating state (Function, Range, etc).

• Transmit its own status data over the bus.

• Request service from the system controller.

6.3.1.4 Capability Codes

To conform to the IEEE 488.1 standard specification, it is not essential for a device to

encompass the full range of bus capabilities. For IEEE 488.2, the device must conform

exactly to a specific subset of IEEE 488.1, with a minimal choice of optional capabilities.

The IEEE 488.1 document describes and codes the standard bus features, for manufacturers

to give brief coded descriptions of their own interfaces’ overall capability. For IEEE

488.2, this description is required to be part of the device documentation. A code string

is often printed on the product itself.

The codes which apply to the 9100 are given in table 6.1, together with short descriptions.

They also appear on the rear of the instrument next to the interface connector. These codes

conform to the capabilities required by IEEE 488.2.

Appendix C of the IEEE 488.1 document contains a fuller description of each code.

6-4 Section 6: 9100 System Operation — SCPI Language

Page 11

6.3.1.5 Bus Addresses

When an IEEE 488 system comprises several instruments, a unique ‘Address’ is assigned

to each to enable the controller to communicate with them individually.

Only one address is required for the 9100. The application program adds information to

it to define ‘talk’ or ‘listen’. The method of setting the address, and the point at which the

user-initiated address is recognized by the 9100, is given in Sub-Section 6.4.1.

The 9100 has a single primary address, which can be set by the user to any value within

the range from 0 to 30 inclusive. It cannot be made to respond to any address outside this

range. Secondary addressing is not available.

6.3.1.6 Limited Access

The 9100 has five main modes, which are described briefly in Volume 1 of this Handbook,

Section 1, Sub-section 1.2.2. Remote operation is available only subject to the following

limitations:

• Procedure Mode

When the 9100 is in Procedure Mode, it is driven essentially from the front panel.

Remote Operation will not be allowed in this mode.

N.B. The 9100 can be powered up in either Manual mode or Procedure mode, as set

locally in Configuration mode.

• Manual Mode

Remote operation is available for each Manual mode function, but for ease of

programming, some remote commands do not mirror front panel operations exactly.

• Configuration Mode

Remote operation is not available, and configuration commands have not been

included in the SCPI command set for the 9100.

• Calibration Mode

Remote operation is available, but refer to Sub-section 6.6.2 for details of entry

protection.

• Test Mode

Remote operation is not available, but the 'Full' selftest can be initiated by a SCPI

command. The 9100 will give a straight Pass/Fail response, but to investigate further,

it will be necessary to re-run the test in Test mode from the front panel.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-5

Page 12

Final Width = 215mm

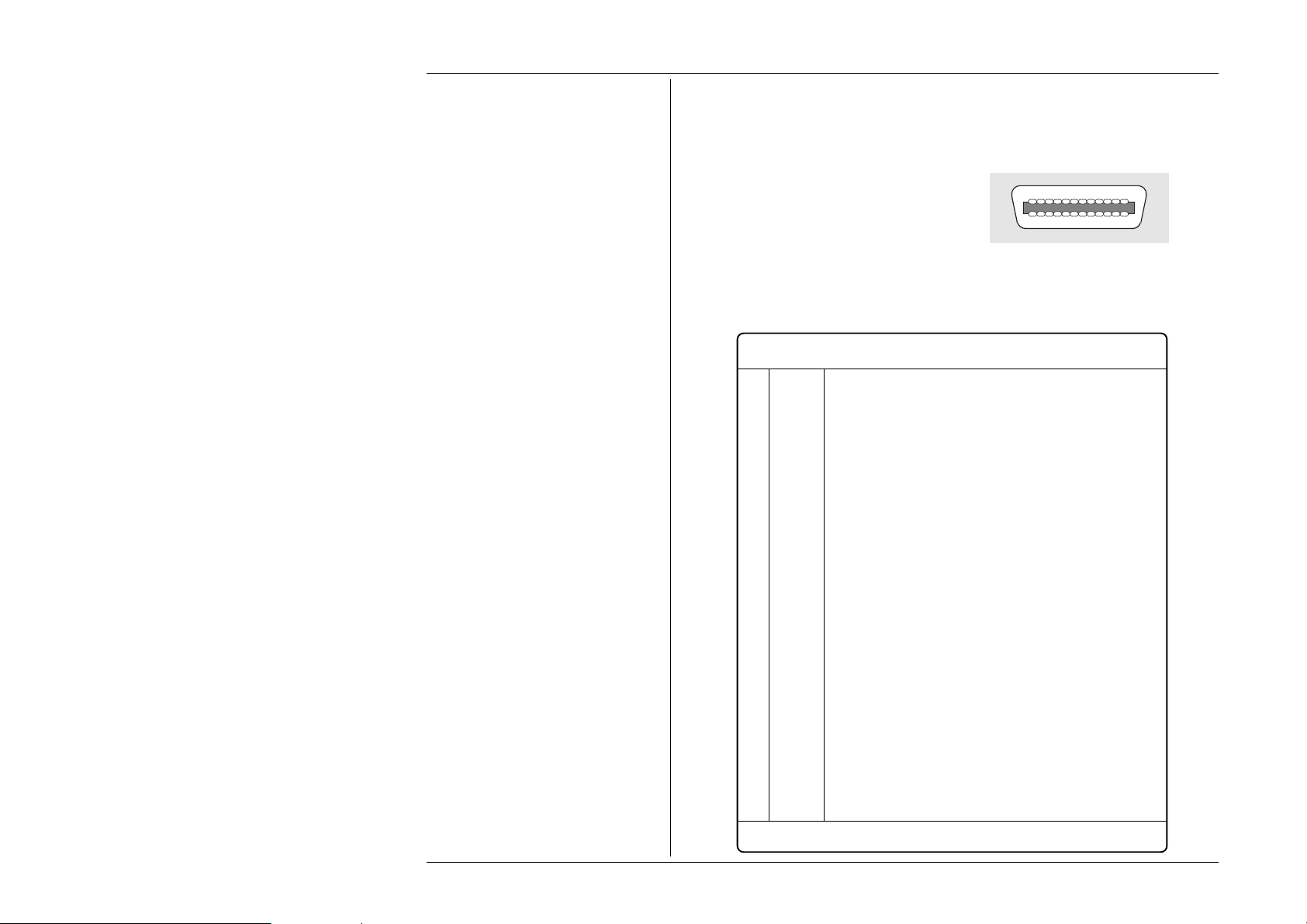

6.3.2 Interconnections

Instruments fitted with an IEEE 488

interface communicate with each other

through a standard set of interconnecting

cables, as specified in the IEEE 488.1

Standard document.

The IEEE-488 interface socket, J101, is

fitted on the rear panel. It accommodates

the specified connector, whose pin

designations are also standardized as

shown in Table 6.2

Pin

No. Name Description

1 DIO 1 Data Input/Output Line 1

2 DIO 2 Data Input/Output Line 2

3 DIO 3 Data Input/Output Line 3

4 DIO 4 Data Input/Output Line 4

5 EOI End or Identify

6 DAV Data Valid

7 NRFD Not Ready For Data

8 NDAC Not Data Accepted

9 IFC Interface Clear

10 SRQ Service Request

11 ATN Attention

12 SHIELD Screening on cable (connected to 9100 safety ground)

13 DIO 5 Data Input/Output Line 5

14 DIO 6 Data Input/Output Line 6

15 DIO 7 Data Input/Output Line 7

16 DIO 8 Data Input/Output Line 8

17 REN Remote Enable

18 GND 6 Gnd wire of DAV twisted pair

19 GND 7 Gnd wire of NRFD twisted pair

20 GND 8 Gnd wire of NDAC twisted pair

21 GND 9 Gnd wire of IFC twisted pair

22 GND 10 Gnd wire of SRQ twisted pair

23 GND 11 Gnd wire of ATN twisted pair

24 GND 9100 Logic Ground (internally connected to Safety Ground)

112

1324

Connector J101 - Pin Layout

Table 6.2 Connector J101 - Pin Designations

6-6 Section 6: 9100 System Operation — SCPI Language

Page 13

6.3.3 SCPI Programming Language

Standard Commands for Programmable Instruments (SCPI) is an instrument command

language which goes beyond IEEE 488.2 to address a wide variety of instrument

functions in a standard manner.

IEEE 488.2 defines sets of Mandatory Common Commands and Optional Common

Commands along with a method of Standard Status Reporting. The 9100 implementation

of SCPI language conforms with all IEEE-488.2 Mandatory Commands but not all

Optional Commands. It conforms with the SCPI-approved Status Reporting method.

Note: Commands in SCPI language, prefaced by an asterisk (eg: ∗CLS), are IEEE-488.2

standard-defined ‘Common’ commands.

Conformance of the 9100 remote programming commands to SCPI ensures that the 9100

has a high degree of consistency with other conforming instruments. For most specific

commands, such as those relating to frequency and voltage, the SCPI approved command

structure already exists and has been used wherever possible.

SCPI commands are easy to learn, self-explanatory and account for a wide variety of

usage skills. A summary of the 9100 commands is given on pages 6-2 and 6-3. The full

range of 9100 commands, with their actions and meanings in the 9100, is detailed in

alphabetical order in Sub-Section 6-6.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-7

Page 14

Final Width = 215mm

6.4 Using the 9100 in a System

6.4.1 Addressing the 9100

6.4.1.1 Accessing the Bus Address

The instrument address can only be set manually; using the Bus Address menu, which

is accessed via the Configuration menus.

N.B. A password is required for access to change the bus address.

6.4.1.2 Select 'Configuration' Mode

1. Press the Mode key on the right of the

front panel to obtain the 'Mode

Selection' menu screen:

2. Press the CONFIG screen key at the

center of the bottom row to progress

into 'Configuration' mode. The 9100

will transfer to the open 'Configuration'

menu screen:

Mode Selection

Select required mode using softkeys

TODAYS DATE TIME

PROC MANUAL CONFIG CALIB TEST

Configuration

Ser. No. XXXXXX Rev. XXX

Present Settings:

Language English

Power-up mode Manual

Bus Address 1

Printer NONE

Results Card Disabled

Safety Voltage . V

Border Line 7 . %

Scope option Option 600

Crystal option High acc

TODAYS DATE TIME

MOREVIEW

6.4.1.3 Select 'MORE' Parameters

The bus address is one of the 'MORE' parameters. By trying to select 'MORE', the

'Configuration' password will be required.

Press the MORE screen key on the right of the bottom row. The 9100 will transfer

to the 'Password Entry' screen.

6-8 Section 6: 9100 System Operation — SCPI Language

Page 15

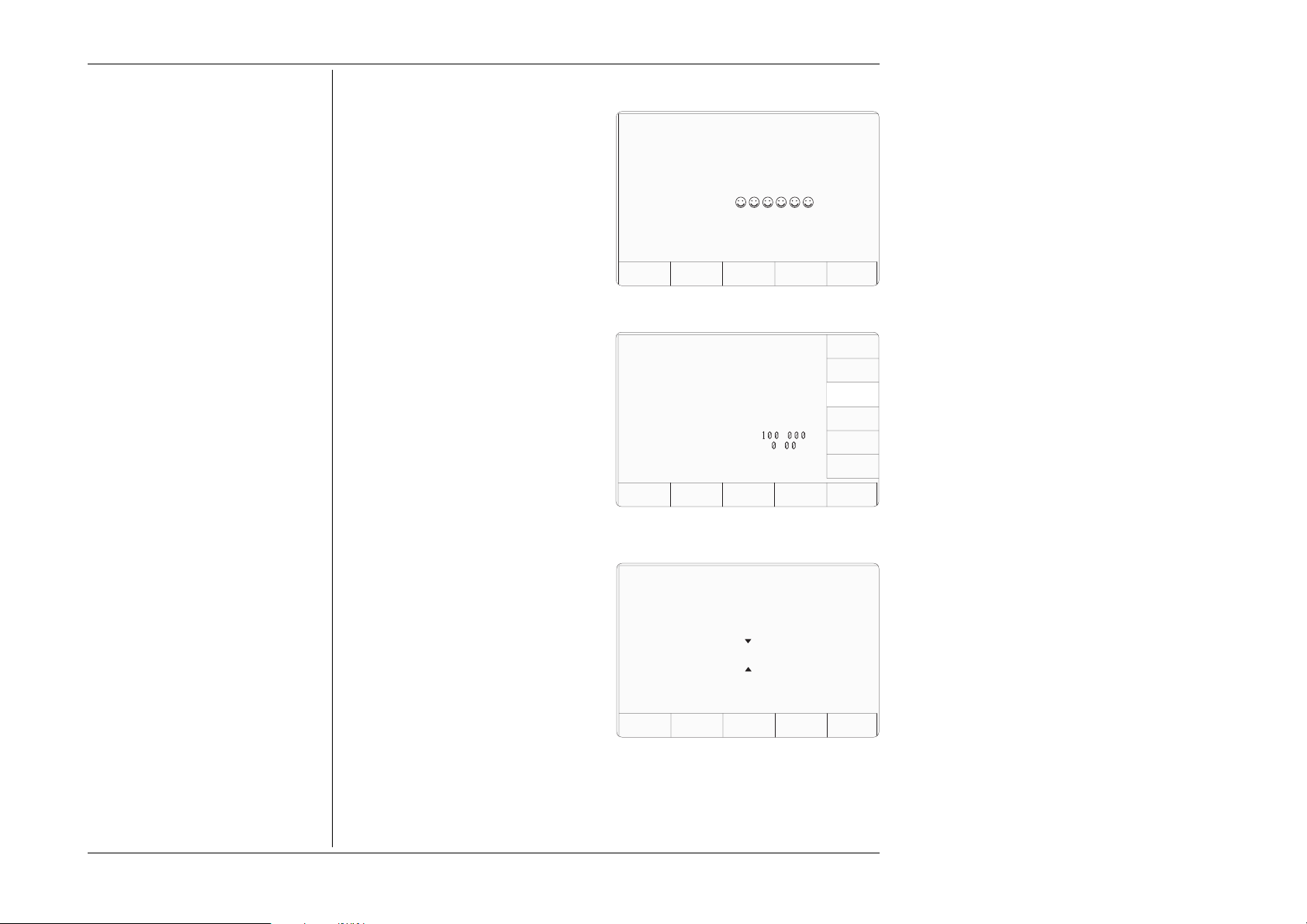

6.4.1.4 Enter Your Password

1. When you enter your password using

the alpha-numeric keyboard, security

icons will appear on the screen as you

type. Finally press the ↵ (return) key.

If the password is incorrect: an error

message will be given and the security

icons will be removed, enabling a new

attempt to enter the password.

The 'EXIT' screen key acts to escape,

back to the previous screen.

2. The correct password, followed by ↵,

will provide entry to the main

'Configuration' menu screen, which

shows the present settings of the

parameters which can be changed using

screen keys on this display:

3. In this case we are interested in 'BUS

ADDRESS'.

6.4.1.5 Change the Bus Address

Password Entry

For Configuration

Enter password :

TODAYS DATE TIME

EXIT

Configuration

Ser. No. XXXXXX Rev. XXX

Present Settings:

Language English

Power-up mode Manual

Bus Address 1

Printer NONE

Results Card Disabled

Safety Voltage . V

Border Line 7 . %

Scope option Option 600

Crystal option High acc

TODAYS DATE TIME

VOLTAGE

LIMIT

DATE

TIME

BORDER

LINE

SELECT

LANG

POWER

UP MODE

BUS

ADDRESS

PRINTER

RESULTS

CARD

CLEAR

USER

LIST

MORE

Final Width = 215mm

Note: Address Recognition

With an address selected in the range 0

to 30; control may be manual, or remote

as part of a system on the Bus. The

address must be the same as that used

in the controller program to activate

the 9100. The 9100 is always aware of

its stored address, responding to Talk

or Listen commands from the controller

at that address. When the address is

changed by the user, the 9100

recognizes its new address and ignores

its old address, as soon as it is stored by

the user pressing the EXIT key in the

Configuration — Bus Address menu.

1. For access from the 'Present Settings'

screen, press the BUS ADDRESS

screen key on the right. This action will

transfer to the 'Change the address'

screen:

The 9100 IEEE-488 bus address can be set

to any number within the range 0 to 30.

2. Use Digit edit or Direct edit to set the

required bus address number. If using

Direct edit, after typing the number

press the ↵ key.

3. Press EXIT to return to the 'Present

Settings' screen.

Section 6: 9100 System Operation — SCPI Language 6-9

Configuration

Change the address by using

digit or direct editing.

Bus address =

TODAYS DATE TIME

EXIT

22

Page 16

Final Width = 215mm

6.4.2 Operation via the IEEE-488 Interface

6.4.2.1 General

The power-up sequence is performed as in local operation. The 9100 can be programmed

to generate an SRQ at power-up, also preparing a status response for transmission to the

controller when interrogated by a subsequent serial poll.

6.4.2.2 Operating Conditions

When the 9100 is operating under the direction of the application program, there are two

main conditions, depending on whether the application program has set the 'REN'

management line 'true' or 'false':

1. REN True ('REN' line low):

The 9100 can be addressed and commanded if in either 'Manual' or 'Calibration' mode.

All access to front panel control will be removed, except for the bottom right screen

key, labelled 'Enable Local Usage'. The cursor controls will not be present.

If LLO (Local Lockout) has been sent with REN true, then the 'Enable Local Usage'

screen key will be inoperative. If LLO has not been sent, the 'Enable Local Usage'

screen key will return to local control as if REN were false (see 2 below).

The 9100 will act in response to valid commands, performing any changes in output,

etc. The display presentation will track the changes.

Remote control cannot command 'Configuration' mode or 'Procedure' mode. These

are Local Modes only. Remote control cannot break into locally-entered 'Configuration'

mode, 'Procedure' mode or 'Test' mode. However, 'Test' can be run remotely.

2. REN False ('REN' line high):

The 9100 will remain in Local Operation, but can be addressed and commanded,

while full access to front panel control is also retained.

The 9100 will act in response to the commands, performing any changes in output, etc.

These changes will occur rapidly enough for the only noticeable effect to be the

display presentation tracking the changes.

6.4.2.3 Programmed Transfer to Local Control (GTL or REN False)

The application program can switch the 9100 into ‘Local’ Control (by sending Command

GTL, or by setting the REN line false), permitting a user to take manual control from the

front panel.

The application program can regain ‘Remote’ control by sending the overriding command:

Listen Address with REN true (addressing the 9100 as a listener with the Remote Enable

management line true {Low}). This will re-impose remote control, unless the 9100 is in

Configuration, Procedure or Test Mode.

6-10 Section 6: 9100 System Operation — SCPI Language

Page 17

6.4.2.4 ‘Device Clear’

Either of the commands DCL or SDC will force the following instrument states:

• all IEEE 488 input and output buffers cleared;

• with 'IFC' (Interface Clear), any device-dependent message bus holdoffs cleared.

• the status byte is changed by clearing the MAV bit.

These commands will not:

• change any settings or stored data within the device except as listed above;

• interrupt analog output;

• interrupt or affect any functions of the device not associated with the IEEE 488

system;

6.4.2.5 Levels of Reset

Three levels of reset are defined for IEEE 488.2 application programs, a complete system

reset being accomplished by resetting at all three levels, in order, to every device. In other

circumstances they may be used individually or in combination:

IFC Bus initialization;

DCL Message exchange initialization;

∗RST Device initialization.

The effects of the ∗RST command are described in Appendix C to this section.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-11

Page 18

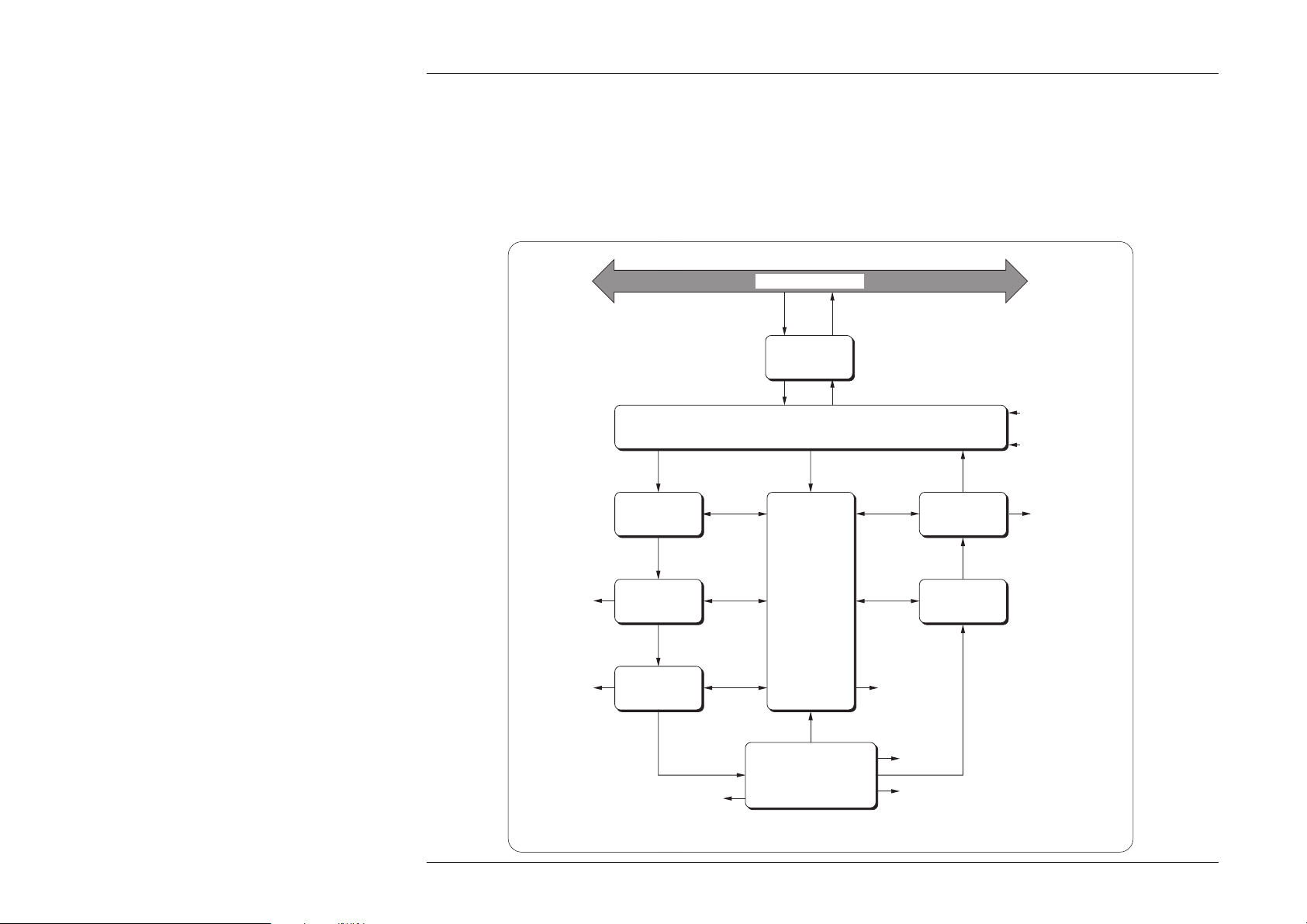

6.4.3 Message Exchange

6.4.3.1 IEEE 488.2 Model

The IEEE 488.2 Standard document illustrates its Message Exchange Control Interface model at the detail level required by the

device designer. Much of the information at this level of interpretation (such as the details of the internal signal paths etc.) is

transparent to the application programmer. However, because each of the types of errors flagged in the Event Status Register is

related to a particular stage in the process, a simplified 9100 interface model can provide helpful background. This is shown below

in Fig. 6.1, together with brief descriptions of the actions of its functional blocks.

IEEE 488.1 bus

Bus

Messages

9100 Bus

Transmissions

Final Width = 215mm

General and Addressed

Bus Messages

Received

Message

Elements

Command

Errors

(CME bit)

Parsed

Message

Elements

Execution

Errors

(EXE bit)

Execution

Control

Executable

Message

Elements

Device-Dependent

Errors (DDE bit)

Input

Buffer

Parser

IEEE-488-1

Bus Interface

Input/Output Control

Message

Exchange

Control

9100 Functions

and Facilities

Filter out bus management and

configuration commands

Requested

Bus Messages

Output

Queue

Response

Message

Elements

Response

Formatter

Query Errors

(QYE bit)

Power On

(PON bit)

(URQ bit)

Response

Data

Status Byte

(STB)

RQS bit state

for Status Byte

Message

Available

(MAV bit)

Fig. 6.1 9100 Message Exchange Model

6-12 Section 6: 9100 System Operation — SCPI Language

Page 19

Note: Coupled Commands

Coupled commands are best described by

an example:

In Section 7, on pages 7-5 and 7-10, the

'Volt-Hz' and 'Amp-Hz' profiles are given.

In the 9100, no AC output can be generated

whose product of amplitude and frequency

occurs outside the relevant profile.

With sequential execution of commands a

change in amplitude and frequency

(e.g.:VOLT 121;:FREQ 10E3 - a setting

within the profile) would cause an execution

error if the present frequency was 50kHz,

as the combination of 121V and 50kHz is

outside the profile

Such anomalies are overcome by defining

a coupling between commands which

allows the execution of the individual

components to be deferred until all

contiguous coupled commands in the same

group have been parsed and the validity of

the combination checked

Note that this does not require that all the

coupled components in a group must be

supplied for each new signal but that those

programmed will be correctly parsed.

Individual commands may be a member of

several coupled command groups. Refer to

Appendix A to this Section, page 6-A1, for

details of coupled groups.

6.4.3.2 9100 STATUS Subsystem

Input/Output Control transfers messages from the 9100 output queue to the system bus;

and conversely from the bus to either the input buffer, or other predetermined destinations

within the device interface. It receives the Status Byte from the status reporting system,

as well as the state of the Request Service bit which it imposes on bit 6 of the Status Byte

response. Bit 6 reflects the ‘Request Service state true’ condition of the interface.

6.4.3.3 Incoming Commands and Queries

The Input Buffer is a first in - first out queue, which has a maximum capacity of 128 bytes

(characters). Each incoming character in the I/O Control generates an interrupt to the

instrument processor which places it in the Input Buffer for examination by the Parser.

The characters are removed from the buffer and translated with appropriate levels of

syntax checking. If the rate of programming is too fast for the Parser or Execution

Control, the buffer will progressively fill up. When the buffer is full, the handshake is

held.

The Parser checks each incoming character and its message context for correct Standard-

defined generic syntax, and correct device-defined syntax. Offending syntax is reported

as a Command Error, by setting true bit 5 (CME) of the Standard-defined Event Status

register (refer to Sub-Section 6.5 ‘Retrieval of Device Status Information’).

Execution Control receives successfully parsed messages, and assesses whether they

can be executed, given the currently-programmed state of the 9100 functions and

facilities. If a message is not viable then an Execution Error is reported, by setting true

bit 4 (EXE) of the Standard-defined Event Status register. Viable messages are executed

in order, altering the 9100 functions, facilities etc. Execution does not ‘overlap’

commands; instead, the 9100 Execution Control processes all commands or coupled

groups of commands (see Note in left column) ‘sequentially’ (ie. waits for actions

resulting from the previous command to complete before executing the next).

6.4.3.4 9100 Functions and Facilities

The 9100 Functions and Facilities block contains all the device-specific functions and

features of the 9100, accepting Executable Message Elements from Execution Control

and performing the associated operations. It responds to any of the elements which are

valid Query Requests (both IEEE 488.2 Common Query Commands and 9100 Devicespecific Commands) by sending any required Response Data to the Response Formatter

(after carrying out the assigned internal operations).

Device-dependent errors are detected in this block. Bit 3 (DDE) of the Standard Event

Status register is set true when an internal operating fault is detected. Each reportable

error number is appended to the Error Queue as the error occurs.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-13

Page 20

Final Width = 215mm

6.4.3.5 Outgoing Responses

The Response Formatter derives its information from Response Data (being supplied

by the Functions and Facilities block) and valid Query Requests. From these it builds

Response Message Elements, which are placed as a Response Message into the Output

Queue.

The Output Queue acts as a store for outgoing messages until they are read over the

system bus by the application program. For as long as the output queue holds one or more

bytes, it reports the fact by setting true bit 4 (Message Available - MAV) of the Status Byte

register. Bit 4 is set false when the output queue is empty (refer to Sub-Section 6.5

‘Retrieval of Device Status Information’).

6.4.3.6 ‘Query Error’

This is an indication that the application program is following an inappropriate message

exchange protocol, resulting in the Interrupted, Unterminated or Deadlocked condition:

Refer to 'Bit 2' in paras 6.5.3.5.

The Standard document defines the 9100’s response, part of which is to set true bit 2

(QYE) of the Standard-defined Event Status register.

6.4.4 Request Service (RQS)

6.4.4.1 Reasons for Requesting Service

There are two main reasons for the application program to request service from the

controller:

• When the 9100 message exchange interface is programmed to report a system

programming error;

• When the 9100 is programmed to report significant events by RQS.

The significant events vary between types of devices; thus there is a class of events which

are known as ‘Device-Specific’. These are determined by the device designer.

6.4.4.2 RQS in the IEEE 488.2 Model

The application programmer can enable or disable the event(s) which are required to

originate an RQS at particular stages of the application program. The IEEE 488.2 model

is extended to incorporate a flexible SCPI status reporting structure in which the

requirements of the device designer and application programmer are both met.

This structure is described in Sub-Section 6.5, dealing with ‘Retrieval of Device Status

Information’.

6-14 Section 6: 9100 System Operation — SCPI Language

Page 21

6.5 Retrieval of Device Status Information

6.5.1 General

For any remotely-operated system, the provision of up-to-date information about the

performance of the system is of major importance. In the case of systems which operate

under automatic control, the controller requires the necessary feedback to enable it to

progress the task; any break in the continuity of the process can have serious results.

When developing an application program, the programmer needs to test and revise it,

knowing its effects. Confidence that the program elements are couched in the correct

grammar and syntax (and that the program commands and queries are thus being accepted

and acted upon), helps to reduce the number of iterations needed to confirm and develop

the viability of the whole program. So any assistance which can be given in closing the

information loop must benefit both program compilation and subsequent use.

Such information is given in the following pages.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-15

Page 22

Final Width = 215mm

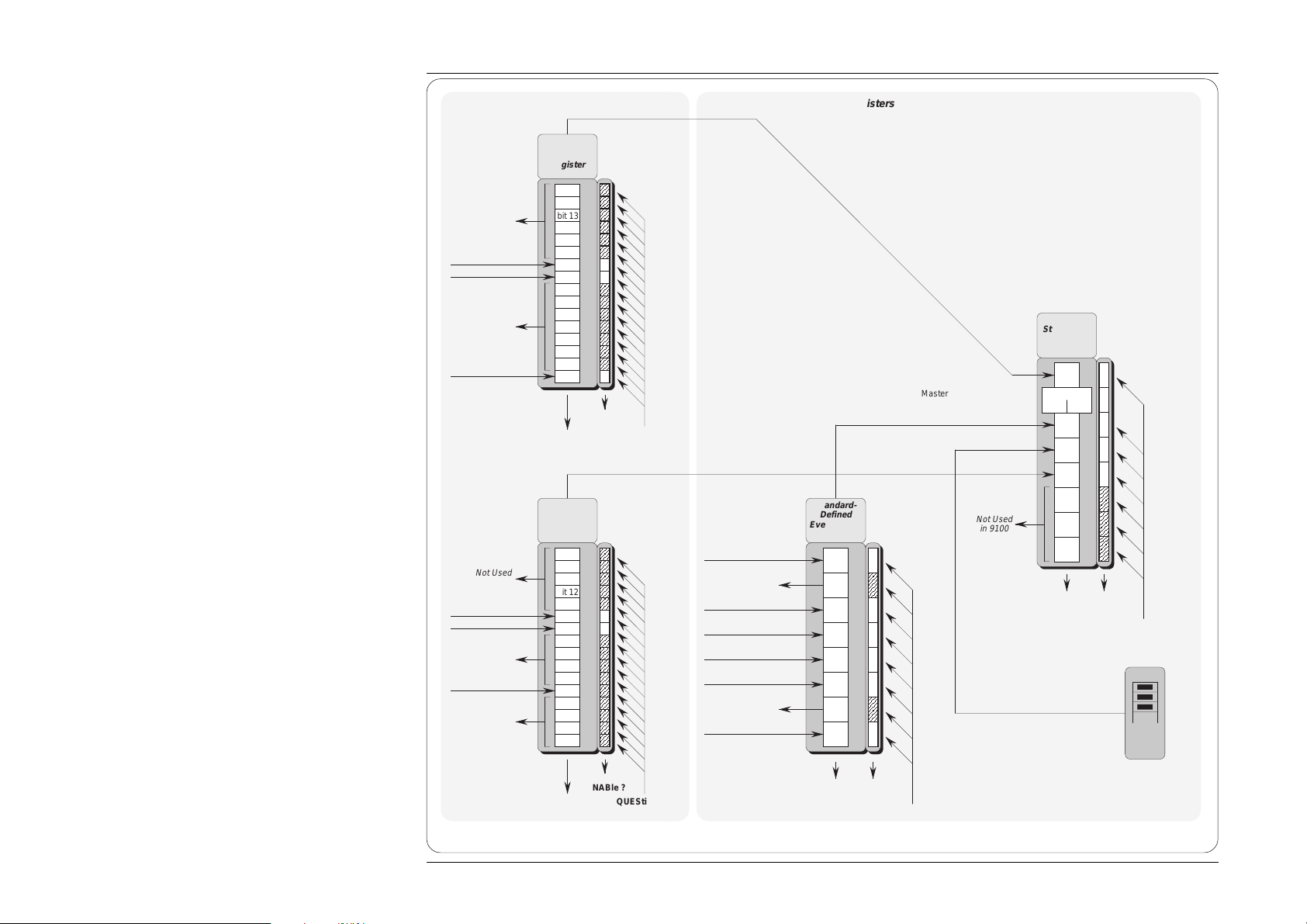

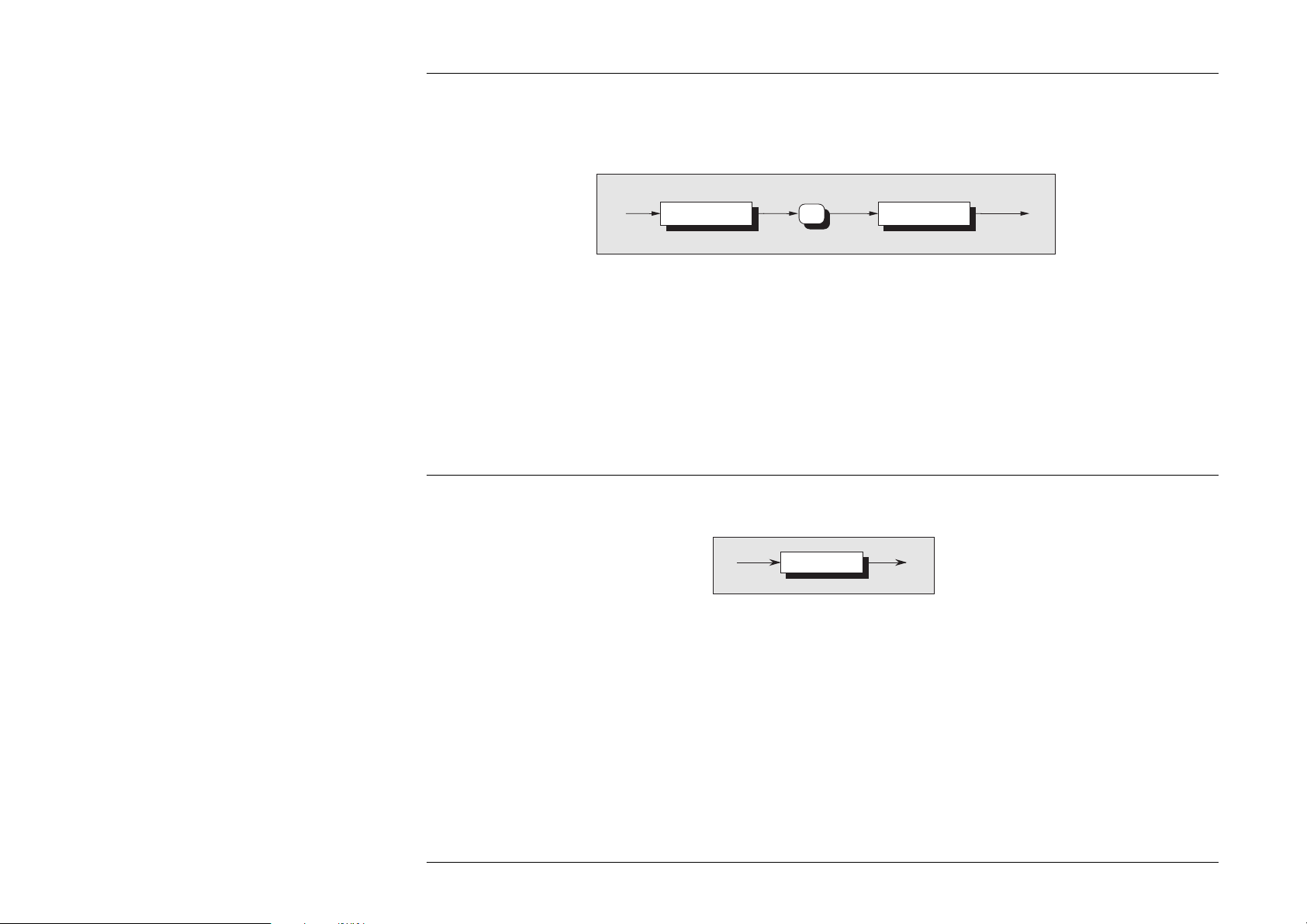

SCPI Status Structure Registers

Summary Bit — OSS

Operation

Status

Register

bit 15

bit 14

Not Used

in 9100

PRETESTING

TESTING

Not Used

in 9100

CALIBRATING

Not Used

in 9100

INV OHM CURR2

INV OHM CURR1

Not Used

in 9100

TEMPerature

Not Used

in 9100

bit 13

bit 12

bit 11

bit 10

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

OPERation:

OPERation:

EVENt ?

Summary Bit — QSS

Questionable

Status

Register

bit 15

bit 14

bit 13

bit 12

bit 11

bit 10

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

ENABle ?

Operation Status

Enable Register

OPERation:

ENABle <DNPD>

Questionable

Status

Enable Register

IEEE 488.2 Status Structure Registers

Summary Bit — ESB

Standard-

Defined

Event Status

Power On

Not Used

in 9100

Command Error

Execution Error

Device-Dependent Error

Query Error

Not Used

in 9100

Operation Complete

Register

bit 7

PON

bit 6

URQ

bit 5

CME

bit 4

EXE

bit 3

DDE

bit 2

QYE

bit 1

RQC

bit 0

OPC

Enable Register

Master Status Summary Bit

Event Status

Request for Service Bit

Not Used

in 9100

Message Available Bit — MAV

(True if one or more

messages are present in

the Output Queue)

Status Byte

Register

bit 7

OSS

bit 6

MSS RQS

bit 5

ESB

bit 4

MAV

bit 3

QSS

bit 2

bit 1

bit 0

∗ STB? ∗ SRE?

Service Request

Enable Register

∗ SRE

phs Nrf

FIFO

Output

Queue

QUEStionable:

QUEStionable:

EVENt ?

ENABle ?

QUEStionable:

ENABle <DNPD>

∗ ESR? ∗ ESE?

Fig. 6.2 9100 Status Reporting Structure

6-16 Section 6: 9100 System Operation — SCPI Language

∗ ESE

phs Nrf

Page 23

6.5.2 IEEE-488 and SCPI Standard-Defined Features (Fig. 6.2)

Two main categories of information are provided: 'Status Summary' information, and 'Event Register' conditions.

6.5.2.1 Status Summary Information and SRQ

The Status Byte consists of four 'summary' bits which notify

events in the 8-bit latched IEEE-488.2-defined ‘Event Status

Register’ (ESB), the two 16-bit latched SCPI-defined registers

(OSS & QSS), and the Output Queue (MAV). Whenever one of

these summary bits is enabled and set true, the Status Byte

summary bit (MSS) is also set true. The buffered bit 'RQS'

follows true when MSS goes true, and will set the IEEE-488

SRQ line true (Note that in Fig 6.2 no arrow points at bit 6 of the

Service Request Enable Register — bit 6 is always enabled).

A subsequent serial poll by the Application Program will

discover that the 9100 was the requesting device (while resetting

RQS false again, MSS remaining true), and which of the

summary bits is true. The ∗STB? command is an equivalent

command to serial poll, where serial poll is not available.

6.5.2.2 Event Register Conditions

The Status Byte summary bits direct the application program

down the structure towards causal events.

ESB and MAV are standard IEEE-488 features, described in

detail in Sub-Section 6.5.3.

OSS and QSS are features of the SCPI structure, described in

Sub-Section 6.5.4.

6.5.2.3 Access via the Application Program

Referring to Fig. 6.2, take as an example the main Event Status

register:

Enabling the Events

The main Standard-Defined Event Status Register' has a

second 'Event Status Enable Register'. A program command

(∗ESE phs Nrf) can be used to set the state of the bits in the

Enable register. This enables or disables the events which

will set the main register's summary bit true.

Reading the Enable Register

A 'query' command (*ESE?) permits the application program

to read the state of the Enable register, and hence find out

which events are enabled to be reported.

Reading the Main Register

Another 'query' command (*ESR?) reads the state of the

main Standard-Defined register, to discover which event

has occurred (i.e. has caused the summary bit to be set true).

Reading this register clears all its bits.

Reporting the Event

If an event is to be reported via the SRQ, its corresponding

enable bit will have been set true, (using the number Nrf).

Each bit in the Standard-Defined register remains in false

condition unless its assigned event occurs, when its condition

changes to true and remains true until cleared by ∗ESR? or

∗CLS. This causes the register's summary bit in the Status

Byte also to be set true. If this bit is enabled, then the Status

Byte bit 6 (MSS/RQS) will be set true, and the 9100 will set

the IEEE-488 bus SRQ line true.

SCPI Status Registers

The two SCPI Status registers operate in the same way, using

the appropriate program commands to set the enable registers,

and query commands to discover the condition of the registers.

Subsequent Action

Thus the application programmer can enable any assigned event

to cause an SRQ, or not. The controller can be programmed to

read the Status Byte, using a serial poll to read the Status Byte

register and the true summary bit (ESB, OSS, QSS or MAV).

The application program then investigates the appropriate event

structure until the causal event is discovered. The detail for each

register is expanded in the following paragraphs, and in the

command descriptions.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-17

Page 24

Final Width = 215mm

6.5.3 9100 Status Reporting - IEEE-488.2 Basics

6.5.3.1 IEEE 488.2 Model

This develops the IEEE 488.1 model into an extended structure with more definite rules.

These rules invoke the use of standard ‘Common’ messages and provide for devicedependent messages. A feature of the structure is the use of ‘Event’ registers, each with

its own enabling register as shown in Fig. 6.2.

6.5.3.2 9100 Model Structure

The IEEE 488.2 Standard provides for an extensive hierarchical structure with the Status

Byte at the apex, defining its bits 4, 5 and 6 and their use as summaries of a Standarddefined event structure, which must be included if the device is to claim conformance with

the Standard. The 9100 employs these bits as defined in the Standard.

Bits 0, 1, 2 and 3 and 7 are available to the device designer; only bits 3 and 7 are used in

the 9100, and these are as defined by the SCPI standard.

It must be recognized by the application programmer that whenever the application

program reads the Status Byte, it can only receive summaries of types of events, and

further query messages will be needed to probe the details relating to the events

themselves. For example: a further byte is used to expand on the summary at bit 5 of the

Status Byte.

6.5.3.3 Status Byte Register

In this structure the Status Byte is held in the ‘Status Byte Register’; the bits being

allocated as follows:

Bits: 0 (DIO1), 1 (DIO2) and 2 (DIO3) are not used in the 9100 status byte. They are

always false.

Bit 3 (DIO4) SCPI-defined Questionable Status Summary Bit (QSS)

Summarizes the state of the ‘Questionable Status data’, held in the ‘Questionable Status

register’ (QSR), whose bits represent SCPI-defined and device-dependent conditions in

the 9100. The QSS bit is true when the data in the QSR contains one or more enabled bits

which are true; or false when all the enabled bits in the byte are false. The QSR and its

data are defined by the SCPI Standard; they are described in Sub-Section 6.5.4.

Bit 4 (DIO5) IEEE 488.2-defined Message Available Bit (MAV)

The MAV bit helps to synchronize information exchange with the controller. It is true

when a message is placed in the Output Queue; or false when the Output Queue is empty.

The common command ∗CLS can clear the Output Queue, and the MAV bit 4 of the Status

Byte Register; providing it is sent immediately following a ‘Program Message Terminator’.

6-18 Section 6: 9100 System Operation — SCPI Language

Page 25

Bit 5 (DIO6) IEEE 488.2-defined Standard Event Summary Bit (ESB)

Summarizes the state of the ‘Event Status byte’, held in the ‘Event Status register’ (ESR),

whose bits represent IEEE 488.2-defined conditions in the device. The ESB bit is true

when the byte in the ESR contains one or more enabled bits which are true; or false when

all the enabled bits in the byte are false.

Bit 6 (DIO7) is the Master Status Summary Message (MSS bit), and is set true if one

of the bits 0 to 5 or bit 7 is true (bits 0, 1 and 2 are always false in the 9100).

Bit 7 (DIO4) SCPI-defined Operation Status Summary Bit (QSS)

Summarizes the state of the ‘Operation Status data’, held in the ‘Operation Status register’

(OSR), whose bits represent processes in progress in the 9100. The OSS bit is true when

the data in the OSR contains one or more enabled bits which are true; or false when all

the enabled bits in the byte are false. The OSR is described in Sub-Section 6.5.4.

Reading the Status Byte Register

∗STB?

The common query: ∗STB? reads the binary number in the Status Byte register. The

response is in the form of a decimal number which is the sum of the binary weighted values

in the enabled bits of the register. In the 9100, the binary-weighted values of bits 0, 1 and

2 are always zero.

6.5.3.4 Service Request Enable Register

The SRE register is a means for the application program to select, by enabling individual

Status Byte summary bits, those types of events which are to cause the 9100 to originate

an RQS. It contains a user-modifiable image of the Status Byte, whereby each true bit

acts to enable its corresponding bit in the Status Byte.

Bit Selector: ∗SRE phs Nrf

The common program command: ∗SRE phs Nrf performs the selection, where Nrf is a

decimal numeric, whose binary decode is the required bit-pattern in the enabling byte.

For example:

If an RQS is required only when a Standard-defined event occurs and when a message

is available in the output queue, then Nrf should be set to 48. The binary decode is

00110000 so bit 4 or bit 5, when true, will generate an RQS; but with this decode, even

if bit 3 is true, no RQS will result. The 9100 always sets false the Status Byte bits 0,

1 and 2, so they can never originate an RQS whether enabled or not.

Reading the Service Request Enable Register

The common query: ∗SRE? reads the binary number in the SRE register. The response

is in the form of a decimal number which is the sum of the binary-weighted values in the

register. The binary-weighted values of bits 0, 1 and 2 will always be zero.

Final Width = 215mm

Section 6: 9100 System Operation — SCPI Language 6-19

Page 26

Final Width = 215mm

Note about the ERROR Queue

The Error Queue is a sequential

memory stack. Each reportable error

has been given a listed number and

explanatory message, which are entered

into the error queue as the error occurs.

The queue is read destructively as a

First-In/First-Out stack, using the query

command SYSTem ERRor? to obtain

a code number and message.

Repeated use of the query SYSTem

ERRor? will read successive DeviceDependent, Command and Execution

errors until the queue is empty, when

the 'Empty' message (0,"No error")

will be returned.

It would be good practice to repeatedly

read the Error Queue until the 'Empty'

message is returned.

The common command ∗CLS clears

the queue.

6.5.3.5 IEEE 488.2-defined Event Status Register

The ‘Event Status Register’ holds the Event Status Byte, consisting of event bits, each of

which directs attention to particular information. All bits are ‘sticky’; ie. once true,

cannot return to false until the register is cleared. This occurs automatically when it is read

by the query: ∗ESR?. The common command ∗CLS clears the Event Status Register and

associated error queue, but not the Event Status Enable Register.

Note that because the bits are 'sticky', it is necessary to read the appropriate subordinate

register of the status structure in order to clear its bits and allow a new event from the same

source to be reported.

The ‘Event Status Register’ bits are named in mnemonic form as follows:

Bit 0 Operation Complete (OPC)

This bit is true only if ∗OPC has been programmed and all selected pending operations

are complete. As the 9100 operates in serial mode, its usefulness is limited to registering

the completion of long operations, such as self-test.

Bit 1 Request Control (RQC)

This bit is not used in the 9100. It is always set false.

Bit 2 Query Error (QYE)

QYE true indicates that the application program is following an inappropriate message

exchange protocol, resulting in the following situations:

• Interrupted Condition. When the 9100 has not finished outputting its Response

Message to a Program Query, and is interrupted by a new Program Message.

• Unterminated Condition. When the application program attempts to read a Response

Message from the 9100 without having first sent the complete Query Message

(including the Program Message Terminator) to the instrument.

• Deadlocked Condition. When the input and output buffers are filled, with the parser

and the execution control blocked.

Bit 3 Device Dependent Error (DDE)

DDE is set true when an internal operating fault is detected, and the appropriate error

message is added to the Error Queue. See the 'Note about the Error Queue' in the previous

column.

Bit 4 Execution Error (EXE)

An execution error is generated if the received command cannot be executed, owing to

the device state or the command parameter being out of bounds. The appropriate error

message is added to the Error Queue. See the 'Note about the Error Queue' in the previous

column.

6-20 Section 6: 9100 System Operation — SCPI Language

Page 27

Bit 5 Command Error (CME)

CME occurs when a received bus command does not satisfy the IEEE 488.2 generic

syntax or the device command syntax programmed into the instrument interface’s parser,

and so is not recognized as a valid command. The appropriate error message is added to

the Error Queue. See the 'Note about the Error Queue' on the previous page.

Bit 6 User Request (URQ)

This bit is not used in the 9100. It is always set false.

Bit 7 9100 Power Supply On (PON)

This bit is set true only when the Line Power has just been switched on to the 9100, the

subsequent Power-up Selftest has been completed successfully, and the 9100 defaults

into Manual mode at Power-on. (If the Power-on default is Procedure mode, remote

operation is not available. If the selftest is unsuccessful, the 9100 will report the fact in

Test mode, which also does not permit remote operation).

Whether or not an SRQ is generated by setting bit 7 true, depends on the previouslyprogrammed ‘Power On Status Clear’ message ∗PSC phs Nrf:

• For an Nrf of 1, the Event Status Enable register would have been cleared at power on,

so PON would not generate the ESB bit in the Status Byte register, and no SRQ would

occur at power on.

• If Nrf was zero, and the Event Status Enabling register bit 7 true, and the Service

Request Enabling register bit 5 true; a change from Power Off to Power On will

generate an SRQ. This is only possible because the enabling register conditions are

held in non-volatile memory, and restored at power on.

This facility is included to allow the application program to set up conditions so that a

momentary Power Off followed by reversion to Power On (which could upset the 9100

programming) will be reported by SRQ. To achieve this, the Event Status register bit 7

must be permanently true (by ∗ESE phs Nrf, where Nrf ≥ 128); the Status Byte Enable

register bit 5 must be set permanently true (by command ∗SRE phs Nrf, where Nrf lies

in one of the ranges 32-63, 96-127, 160-191, or 224-255); Power On Status Clear must

be disabled (by ∗PSC phs Nrf, where Nrf = 0); and the Event Status register must be read

destructively immediately following the Power On SRQ (by the common query ∗ESR?).

Final Width = 215mm

Continued Overleaf

Section 6: 9100 System Operation — SCPI Language 6-21

Page 28

Final Width = 215mm

6.5.3.6 Standard Event Status Enable Register

The ESE register is a means for the application program to select, from the positions of

the bits in the standard-defined Event Status Byte, those events which when true will set

the ESB bit true in the Status Byte. It contains a user-modifiable image of the standard

Event Status Byte, whereby each true bit acts to enable its corresponding bit in the

standard Event Status Byte.

Bit Selector: ∗ESE phs Nrf

The program command: ∗ESE phs Nrf performs the selection, where Nrf is a decimal

numeric, which when decoded into binary, produces the required bit-pattern in the

enabling byte.

For example:

If the ESB bit is required to be set true only when an execution or device-dependent

error occurs, then Nrf should be set to 24. The binary decode is 00011000 so bit 3 or

bit 4, when true, will set the ESB bit true; but when bits 0-2, or 5-7 are true, the ESB

bit will remain false.

Reading the Standard Event Enable Register

The common query: ∗ESE? reads the binary number in the ESE register. The response

is a decimal number which is the sum of the binary-weighted values in the register.

6.5.3.7 The Error Queue

As errors in the 9100 are detected, they are placed in a 'first in, first out' queue, called the

'Error Queue'. This queue conforms to the format described in the SCPI Command

Reference (Volume 2) Chapter 19, para 19.7, although errors only are detected. Three

kinds of errors are reported in the Error Queue, in the sequence that they are detected:

Command Errors, Execution Errors and Device-Specific errors

Reading the Error Queue

The queue is read destructively as described in the SCPI Command Reference, using the

query command SYSTem ERRor? to obtain a code number and error message. The query

SYSTem ERRor? can be used to read errors in the queue until it is empty, when the

message '0, No Error' will be returned.

6-22 Section 6: 9100 System Operation — SCPI Language

Page 29

6.5.4 9100 Status Reporting — SCPI Elements

6.5.4.1 General

In addition to IEEE 488.2 status reporting the 9100 implements the Operation and

Questionable Status registers with associated 'Condition', 'Event' and 'Enable' commands.

The extra status deals with current operation of the instrument and the quality of

operations.

The structure of these two registers is detailed in Fig. 6.2, together with the nature of the

reported events. Access to the registers is detailed in the STATus subsystem of Sub-

Section 6.6 of this handbook.

6.5.4.2 SCPI Status Registers

The SCPI states are divided into two groups, reporting from the Operation or Questionable

Status event register. Each Status register has its own 'Enable' register, which can be used

as a mask to enable bits in the event register itself, in a similar way to that set by the ∗ESE

command for the Standard Event status Register (ESR).

Each Status Register is associated with its own third 'Condition' register (not illustrated

in Fig. 6.2), in which the bits are not 'sticky', but are set and reset as the internal conditions

change.

Each Enable Register can be commanded to set its mask to enable selected bits in the

corresponding Event Register. All registers (Event, Enable and Condition) can be

interrogated by appropriate 'Queries' to divulge their bits' states.

Final Width = 215mm

6.5.4.3 Reportable SCPI States

Operation Status Event Register

The following 'sticky' bits are set by their associated conditions:

bit 0 CALIBRATING: a capacitance self-calibration operation is in progress.

bit 8 TESTING: the instrument is performing a self test.

bit 9 PRETESTING: the instrument is performing a power-up self test.

Questionable Status Event Register

The following 'sticky' bits are set by their associated conditions:

bit 4 TEMPerature: Thermocouple Reference Junction conditions doubtful

bit 9 INV OHM CURR 1: High/Low Current warning — outside specification

bit 10 INV OHM CURR 2: High/Low Current warning — change setting

Section 6: 9100 System Operation — SCPI Language 6-23

Page 30

Final Width = 215mm

6.6 9100 SCPI Language - Commands and Syntax

The command subsystems are placed in alphabetical order.

6.6.1 Introduction

This Sub-Section lists and describes the set of SCPI-compatible remote commands used to operate the 9100.

To provide familiar formatting for users who have previously used the SCPI reference documentation, the command descriptions

are dealt with in a similar manner. In particular, each sub-system's documentation starts with a short description, followed by a table

showing the complete set of commands in the sub-system; finally the effects of individual keywords and parameters are described.

Some extra identification of style and syntax is detailed in paras 6.6.1.1 and 6.6.1.2 to clarify shorthand meanings.

6.6.1.1 SCPI Syntax and Styles

Where possible the syntax and styles used in this section follow those defined by the SCPI consortium. The commands on the

following pages are broken into three columns; the KEYWORD, the PARAMETER FORM, and any NOTES.

The KEYWORD column provides the name of the command. The actual command consists of one or more keywords since SCPI

commands are based on a hierarchical structure, also known as the tree system.

Square brackets ( [ ] ) are used to enclose a keyword that is optional when programming the command; that is, the 9100 will process

the command to have the same effect whether the optional node is omitted by the programmer or not.

Letter case in tables is used to differentiate between the accepted shortform (upper case) and the long form (upper and lower case).

The PARAMETER FORM column indicates the number and order of parameter in a command and their legal value. Parameter

types are distinguished by enclosing the type in angle brackets ( < > ). If parameter form is enclosed by square brackets ( [ ] ) these

are then optional (care must be taken to ensure that optional parameters are consistent with the intention of the associated keywords).

The vertical bar ( | ) can be read as "or" and is used to separate alternative parameter options.

6.6.1.2 Legend

<DNPD> = Decimal Numeric Program Data, used to identify numerical information needed to set controls to required

values. The numbers should be in 'Nrf' form as described in the IEEE 488.2 Standard Specification.

<CPD> = Character Program Data. This normally represents alternative groups of unique 'literate' parameter names,

available for the same keyword. In the notation the set of alternatives will follow the <CPD> in the Parameter

Form column of the Sub-System table, enclosed in a pair of braces. For example, in the OUTPut sub-system,

the compound command header (keyword): OUTPut:COMPensation is followed by the parameter form

<CPD>{ON|OFF|0|1}. The <CPD> gives the denomination of 'Character' program data, and

{ON|OFF|0|1} gives the actual characters to be used to command each unique parameter.

<SPD> = String Program Data. This is a string of variable literate characters which will be recognized by the internal

9100 software. They are used for such inputs as passwords, serial numbers and date/time.

? = Indicate query commands with no associated command form, and no attached parameters.

(for example: CALibration:TRIGger?).

(?) = All commands which may include parameters in the command form, but also have an additional query form

without parameters.

(for example: OUTPut:COMPensation(?) <CPD>{HIGHi|LOWi})

The response from this query will be one of the parameters listed in association with the command.

6-24 Section 6: 9100 System Operation — SCPI Language

Page 31

6.6.2 CALibration Subsystem

This subsystem is used to calibrate the functions and hardware ranges of the 9100. This will correct for any system errors due to

drift or ageing effects.

Before any calibration can take place, two security levels must be set. First, there is a switch on the 9100 itself that must be set to

CAL ENABLE. Having done this, the calibration password command must be sent.

Once entered into Calibration mode, the commands present in the table at 6.6.2.1 are enabled.

6.6.2.1 CALibration Subsystem Table

Keyword Parameter Form Notes

CALibration

:SECure

:PASSword <SPD>

:EXIT [<SPD>,<CPD>{PRD7|PRD14|PRD30|PRD60}]

:TARGet <DNPD>,<DNPD>[,<DNPD>]

:TRIGger? [query only]

:SPECial? [query only]

:CJUNction? <DNPD>

6.6.2.2 CAL:SEC:PASS <SPD>

Purpose

This command is used to gain access to Calibration mode. The <SPD> must be the correct 'Calibration' password registered in the

9100 software. The calibration password can be changed only in Configuration mode from the 9100 front panel.

(Refer to Volume 1 of this User's Handbook, Section 3, Paras 3.3.2.11 and 3.2.2.22).

Final Width = 215mm

6.6.2.3 CAL:SEC:EXIT [<SPD>,<CPD>{PRD7|PRD14|PRD30|PRD60}]

Purpose

This command is used to switch off Calibration mode, cancelling any set CAL:TARG command and protecting the calibration by

positively disabling the calibration commands. Parameters in the command permit a user optionally to date-stamp the calibration,

record the next-due calibration date, and set up an advance warning for that calibration. Certain Functions are not available in

Calibration Mode (such as Conductance and Logic Pulses/Levels, for which calibration is not required). When finishing a

calibration procedure, it is necessary to exit from Calibration mode in order to access these functions.

• The <SPD> must be the due date of the next calibration for the 9100. It must conform to the format decided by the SYStem

FORmat <spd> command.

• In the <CPD>, PRDXX gives the required number of days advance warning of the cal due date.

(Refer to Section 10, Paras 10.3.6).

Section 6: 9100 System Operation — SCPI Language 6-25

Page 32

Final Width = 215mm

6.6.2 CALibration Subsystem (Contd.)

6.6.2.4 CAL:TARG <DNPD>,<DNPD>[,<DNPD>]

Purpose

For each calibration operation, the required calibration point (factor) must be targetted (Refer to Section 10, Paras 10.3.4). This

command permits the user to define three parameters associated with the calibration point in the current operation:

• The first <DNPD> is an integer from 1 to 6, allocated to the calibration point at which calibration is intended. This will be one

of those listed on the Calibration mode screen, in 'Target State', for the corresponding function and hardware range.

• The second <DNPD> is a value which will determine the required hardware range (amplitude) of the 9100 for that calibration

point.

• The third, optional, <DNPD> is a value which will determine the required hardware range (frequency) of the 9100 for that

calibration point.