Watts TK-9A User Manual

IS-TK-9A

Instructions

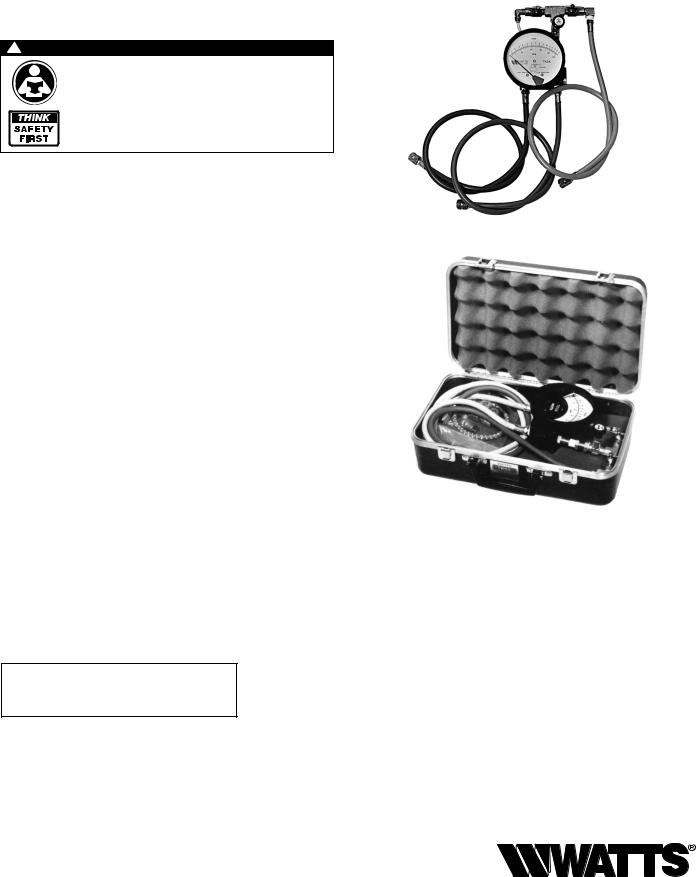

Watts TK-9A

Backflow Preventer Test Kit

! WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can result in death, serious personal injury, property damage, or damage to the equipment.

Keep this Manual for future reference.

The Watts No. TK-9 Model “A” Backflow Preventer Test Kit is a compact portable testing device made for testing all Reduced Pressure Zone Backflow Prevention Assemblies and Double Check Valve Assemblies. The TK-9A is easily connected to any RPZ device enabling accurate testing of zone differential

pressure, relief valve opening differential, fouled check valves or similar problems that visual inspections cannot locate. The unit is supplied with a rugged carrying case for easy handling and accessibility.

Specifications

•Maximum working pressure – 175 psi (12.1 bar).

•Maximum working temperature – 210°F (99°C).

•Gauge - 41⁄2" diameter face dual scale 0 – 15 psid and 0-1 kg/cm2, ±2% accuracy full scale.

•Test Valves – (2) ball valves and (1) needle valve.

•Hoses – (3) 3' with female threaded swivel couplings.

•Adaptors – (3) 1⁄4" threaded coupling adaptors

(3)1⁄2" x 1⁄4" bushings

(3) 3⁄4" x 1⁄4" bushings

•1 – 16" securing strap.

•1 – Moisture resistant instruction guide.

•Case – light weight, shock resistant molded plastic with foam inserts.

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

No. TK-9 Model “A” Test Kit

Reduced Pressure Zone Backflow Preventers must be inspected and tested periodically,

in accordance with local codes, to ensure proper operation of check valves within the unit. A differential pressure gauge is recommended for Test No. 1 rather than a manometer for the following reasons: It utilizes minimum time to perform the test. It eliminates the necessity of closing the inlet ball valve which could release pipe scale and foreign matter into the backflow preventer. Only a slight amount of water is ‘spilled’ in test. A mercury manometer could cause a pollution hazard.

Test Set Up

Reduced Pressure Zone Assembly

Close Valves A, B and C on Test Kit.

Connect high side hose to test cock #2

Connect low side hose to test cock #3. Close shutoff #2. Open test cocks #2 and #3.

Open vent valve C.

Open ‘high’ valve A and bleed to atmosphere until all the air is expelled.

Close valve A. Open ‘low’ valve B and bleed to atmosphere until all air is expelled. Close ‘low’ valve B. Close ‘vent’ valve C.

Connect vent hose to test cock #4.

Test Procedure

Reduced Pressure Zone Assembly

Field Test Equipment Required

Reduced Pressure Zone Backflow Preventer Test Kit

Test No. 1

Purpose: To test check valve No. 2 for tightness against reverse flow.

Requirements: Valve must be tight against reverse flow under all pressure differentials. Slowly open the high valve A and

the vent valve C, and keep the low valve B closed. Open test cock #4. Indicated pressure differential will decrease slightly. If pressure differential continues to decrease (until the vent opens) check valve #2 is reported as leaking.

Test No. 2

Purpose: To test shutoff #2 for tightness.

Requirements: After passing Test No. 1, continue to Test No. 2 by closing test cock #2. The indicated pressure differential will decrease slightly. If pressure differential continues to decrease

(approaching “zero”), shutoff #2 is reported to be “leaking”.

Test No. 3

Purpose: To test Check Valve No. 1 for tightness.

Requirements: Valve must be tight against reverse flow under all pressure differentials. Close high valve A and open test cock

#2. Close test cock #4. Disconnect vent hose at test cock #4.

Open valves B and C, bleeding to atmosphere. Then closing valve B restores the system to a normal static condition. Observe the pressure differential gauge. If there is a decrease in the indicated value, Check Valve No. 1 is reported as “leaking”.

Test No. 4

Purpose: To test operation of pressure differential relief valve.

Requirements: The pressure differential relief valve must operate to maintain the “zone” between the two check valves at least 2 psi less than the supply pressure. Close vent valve C. Open high valve A. Open the low valve B very slowly until the differential gauge needle starts to drop. Hold the valve at this position and observe the gauge reading at the moment the first discharge is noted from the relief valve. Record this as the opening differential pressure of the relief valve.

NOTICE

It is important that the differential gauge needle drops slowly.

Close test cocks #2 and #3. Use vent hose to relieve pressure from test kit by opening valves A, B and C. Remove all test equipment and open shutoff #2.

|

Ball Type |

|

Test Valves |

(A) |

(C) |

|

(B) |

|

Needle |

|

Valve |

Auxiliary |

|

Test Cock |

Low Hose |

|

|

|

(Color - White or Red) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vent Hose |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

(Color - Blue) |

|

|

|

|||

|

|

|

High Hose |

|

|

|||||||||||||

|

|

|

(Color - Yellow) |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Test Cock |

|

|

||||||||

|

|

|

|

|

|

|

|

No. 3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

Test Cock |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Test Cock |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

No. 2 |

|

|

|

|

|

No. 4 |

|

|

|

|||

|

Test Cock |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

No. 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

Check Valve |

|

|

|||||||

|

|

|

|

|

|

|

|

|

No. 1 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shutoff |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shutoff |

||||

|

|

|

No. 1 |

|

|

|

|

|

|

|

|

|

|

|

|

No. 2 |

||

|

|

|

|

|

|

|

|

|

|

Check Valve |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. 2 |

|

|

||

909QT shown |

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

! CAUTION

|

To prevent freezing, hold Test Kit vertically to drain |

2 |

differential gauge and hoses prior to placing in case. |

|

Loading...

Loading...