Page 1

3776 en - 07.2007 / h

27

en

to

n

e

v

gi

be

to

s

i

l

T

h

is

m

a

nu

the

a

e

nd

us

e

r

VARMECA 30

Variable speed motor or geared motor

Installation and maintenance

Page 2

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

NOTE

LEROY-SOMER reserves the right to modify the characteristics of its products at any time in order to incorporate the latest

technological developments. The information contained in this document may therefore be changed without notice.

CAUTION

For the user’s own safety, this VARMECA 30 motor must be connected to an approved earth ( terminal).

If accidentally starting the installation is likely to cause a risk to p ersonnel or the machines being driven, it is essential to supply

the equipment via a circuit-breaking device (power contactor) which can be controlled via an external safety system (emergency

stop, detection of errors on the installation).

The VARMECA 30 motor is fitted with safety devices which, in the event of a fault, control stopping and thus stop the motor. The

motor itself can become jammed for mechanical reasons. Voltage fluctuations, and in particular power cuts, may al so cause the

motor to stop.

The removal of the causes of the shutdown can lead to restarting, which may be dangerous for certain machines or installations.

In such cases, it is essential that the user takes appropriate precautions against the motor restarting after an unscheduled stop.

The variable speed drive is designed to be able to supply a motor and the driven machine above its rated speed.

If the motor or the machine are not mechanically designed to withstand such speeds, the user may be exposed to serious danger

resulting from their mechanical deterioration. It is important that the user checks that the installation can withstand it, before

programming a high speed.

The variable speed drive which is the subject of this manual is designed to be integrated in an installation or an electrical machine,

and can under no circumstances be considered to be a safety device. It is therefore the responsibility of the machine manufacturer,

the designer of the installation or the user to take all necessary precautions to ensure that the system complies with current

standards, and to provide any devices required to ensure the safety of equipment and personnel.

LEROY-SOMER declines all responsibility in the event of th e above recommendations not being observed.

36

Page 3

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

SAFETY AND OPERATING INSTRUCTIONS FOR ELECTRICAL ACTUATORS

(In accordance with the low voltage directive 73/23/EEC modified by 93/68/EEC)

• Throughout the manual, this symbol warns of

consequences which may arise from inappropriate

use of the VARMECA 30, since electrical risks may lead

to material or physical damage as well as constituting a

fire hazard.

1 - General

Depending on their degree of protection, VARMECA 30

motors may contain moving parts, as well as hot surfaces,

during operation.

Unjustified removal of protection devices, incorrect use, faulty

installation or inappropriate operation could represent a

serious risk to personnel and equipment.

For further information, consult the manual.

All work relating to transportation, installation, commissioning

and maintenance must be performed by experienced,

qualified personnel (see IEC 364 or CENELEC HD 384, or

DIN VDE 0100 and national specifications for installation and

accident prevention).

In these basic safety instructions, qualified personnel means

persons competent to install, mount, commission and operate

the product and possessing the relevant qualifications.

2 - Use

VARMECA 30 motors are components designed for

integration in installations or electrical machines.

When integrated in a machine, commissioning must not take

place until it has been verified that the machine conforms with

directive 89/392/EEC (Machinery Directive).

It is also necessary to comply with standard EN 60204, which

stipulates in particular that electrical actuators (which include

VARMECA 30) cannot be regarded as circuit-breaking

devices and certainly not as isolating switches.

Commissioning can take place only if the requirements of the

Electromagnetic Compatibility Directive (89/336/EEC,

modified by 92/31/EEC) are met.

VARMECA 30 motors meet the requirements of the Low

Voltage Directive 73/23/EEC, modified by 93/68/EEC. The

harmonised standard of the DIN VDE 0160 series in

connection with standard VDE 0660, part 500 and EN 60146/

VDE 0558 are also applicable.

The technical characteristics and instructions concerning the

connection conditions specified on the nameplate and in the

documentation provided must be observed without fail.

4 - Installation

The installation and cooling of equipment must comply with

the specifications in the manual supplied with the product.

VARMECA 30 motors must be protected against excessive

stress. In particular, there must be no damage to parts and/or

modification of the clearance between components during

transportation and handling. Avoid touching the electronic

components and contact parts.

VARMECA 30 motors contain parts which are sensitive to

electrostatic stress and may be easily damaged if handled

incorrectly. Electrical components must not be exposed to

mechanical damage or destruction (risks to health!).

5 - Electrical connection

When work is performed on VARMECA 30 motors which are

powered up, national accident prevention specifications must

be respected.

The electrical installation must comply with the relevant

specifications (for example conductor cross-sections,

protection via fused circuit-breaker, connection of protective

conductor). More detailed information is given in the manual.

Instructions for an installation which meets the requirements

for electromagnetic compatibility, such as screening,

earthing, presence of filters and correct insertion of cabl es

and conductors, are given in the documentation supplied with

the VARMECA 30. These instructions must be followed in all

cases, even if the VARMECA 30 carries the CE mark.

Adherence to the limits given in the EMC legisl ation is the

responsibility of the manufacturer of the installation or the

machine.

6 - Operation

Installations incorporating VARMECA 30 motors must be

fitted with additional protection and monitoring devices as laid

down in the current relevant safety regulations: law on

technical equipment, accident prevention regulations, etc.

Modification of VARMECA 30 motors using control software

is permitted.

Active parts of the device and live power connections must

not be touched immediately after the VARMECA 30 is

powered down, as the capacitors may still be charged. In view

of this, the warnings fixed to VARMECA 30 motors must be

observed.

During operation, all protective covers must remain closed.

en

3 - Transportation, storage

All instructions concerning transportation, storage and correct

handling must be observed.

The climatic conditions sp ecified in the technica l manual must

be observed.

7 - Servicing and maintenance

Refer to the manufacturer’s documentation.

37

Page 4

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

Notes

3776 en - 07.2007 / h

38

Page 5

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

CONTENTS

1 - GENERAL INFORMATION.............................................................................................................................. 40

1.1 - General operating principle............................................................................................................................. 40

1.2 - Product name................................................................................................................................................. 40

1.3 - Characteristics............................................................................................................................................... 41

1.4 - Environmental characteristics........................................................................................................................ 43

1.5 - Radio-frequency interference......................................................................................................................... 43

1.6 - Description of cables and protection devices................................................................................................. 46

1.7 - UL conformity................................................................................................................................................. 47

1.8 - Weights and dimensions................................................................................................................................ 48

2 - INSTALLATION................................................................................................................................................ 49

2.1 - General.......................................................................................................................................................... 49

3 - CONNECTIONS ............................................................................................................................................... 49

3.1 - Wiring precautions......................................................................................................................................... 49

3.2 - Control terminal blocks .................................................................................................................................. 50

3.3 - Power terminal blocks.................................................................................................................................... 52

3.4 - Terminal blocks for options............................................................................................................................ 52

3.5 - Wiring diagrams............................................................................................................................................. 53

3.6 - Power supply and control for FCR brake motors........................................................................................... 57

3.7 - Brake rectified voltage depending on the mains supply................................................................................. 58

3.8 - Example of supplying 2 motors, with or without brake, in parallel, with a single VARMECA......................... 59

3.9 - Wiring diagrams for SO VMA and VMA ESFR options.................................................................................. 60

4 - COMMISSIONING............................................................................................................................................ 62

4.1 - Starting with the power supply....................................................................................................................... 62

4.2 - Starting with remote volt-free contact ............................................................................................................ 62

4.3 - Starting with local run/stop control (BMA 31/32, BMA 33/34 or BMAVAR 31/32,

BMAVAR 33/34 OPTION) ............................................................................................................................. 62

4.4 - Setting the speed........................................................................................................................................... 62

5 - FAULTS-DIAGNOSTICS.................................................................................................................................. 63

6 - MAINTENANCE ............................................................................................................................................... 63

6.1 - Care............................................................................................................................................................... 63

6.2 - Measurements............................................................................................................................................... 63

7 - OPERATING EXTENSIONS ............................................................................................................................ 64

7.1 - Speed control knob option (B 31/32 or B 33/34)............................................................................................ 64

7.2 - Control knob with integrated run-stop control option (BMA31/32 or BMA 33/34) .......................................... 64

7.3 - Control knob with forward/reverse/stop control option (BMAVAR 31/32

or BMAVAR 33/34)........................................................................................................................................ 64

7.4 - Internal speed control option (CVI VMA 31/32 or CVI VMA 33/34) ............................................................... 64

7.5 - IP 65 braking resistor option (RF100 – RF 200 – RF 600) ............................................................................ 65

7.6 - IP 20 external braking resistor option (RF – BRR – 800 – 200)..................................................................... 65

7.7 - Electromechanical brake power supply and control option (SO VMA 31/32) ................................................ 65

7.8 - Additional I/O interface and sequential brake control option (ESFR VMA 31/32).......................................... 6

7.9 - Addit

7.10 - Fieldbus options................................ ... ... ... .... ...................................... .... ... ... ... ........................................... 65

7.11 - Encoder feedback option (COD VMA 33/34).............................................................. ... ... .... ... ... ... .............. 65

7.12 - Parameter-setting console option (PX LCD)................................................................................................ 66

7.13 - Parameter-setting software option (SOFTVMA 30) ... .... ... ... ... ..................................................................... 66

7.14 - Operator display option (PAD VMA 30) ....................................................................................................... 66

7.15 - XPress Key.................................................................................................................................................. 66

7.16 - EMC filter (FLT VMA 33/FLT VMA34) ......................................................................................................... 67

7.17 - EMC filter option (FLT VMA 31M)................................................................................................................ 67

7.18 - EMC filter option (FLT VMA 31/32).............................................................................................................. 67

ional I/O interface and sequential brake control option (ESFR VMA 33/34).......................................... 65

en

5

39

Page 6

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

1 - GENERAL INFORMATION

• This manual describes the characteristics and installation of the VARMECA 31ML, 31M, 31TL, 31T, 32M, 32TL, 32T,

33TL, 33T, 34TL, 34T.

• The VARMECA 30 is designed to operate in an industrial environment. When used with an e xternal EMC filter,

the VARMECA 30 complies with standards for residential environment.

• If the run command has been enabled, the motor starts as soon as it is switched on.

1.1 - General operating principle

The VARMECA 30 is the physical association of a 3-phase

induction motor and an integrated variable speed drive.

The motor allows all kinds of mounting arrangement (foot or

flange) and can be combined with standard gearboxes from

the LEROY-SOMER range.

In the standard version, the drive with integrated control does

not require any connection other than the power supply.

The options may be used to broaden the application range of

the VARMECA 30.

Thanks to the advanced technology of the IGBT power

module, very high efficiency and reduced noise levels are

possible.

1.2 - Product name

Single-phase power supply

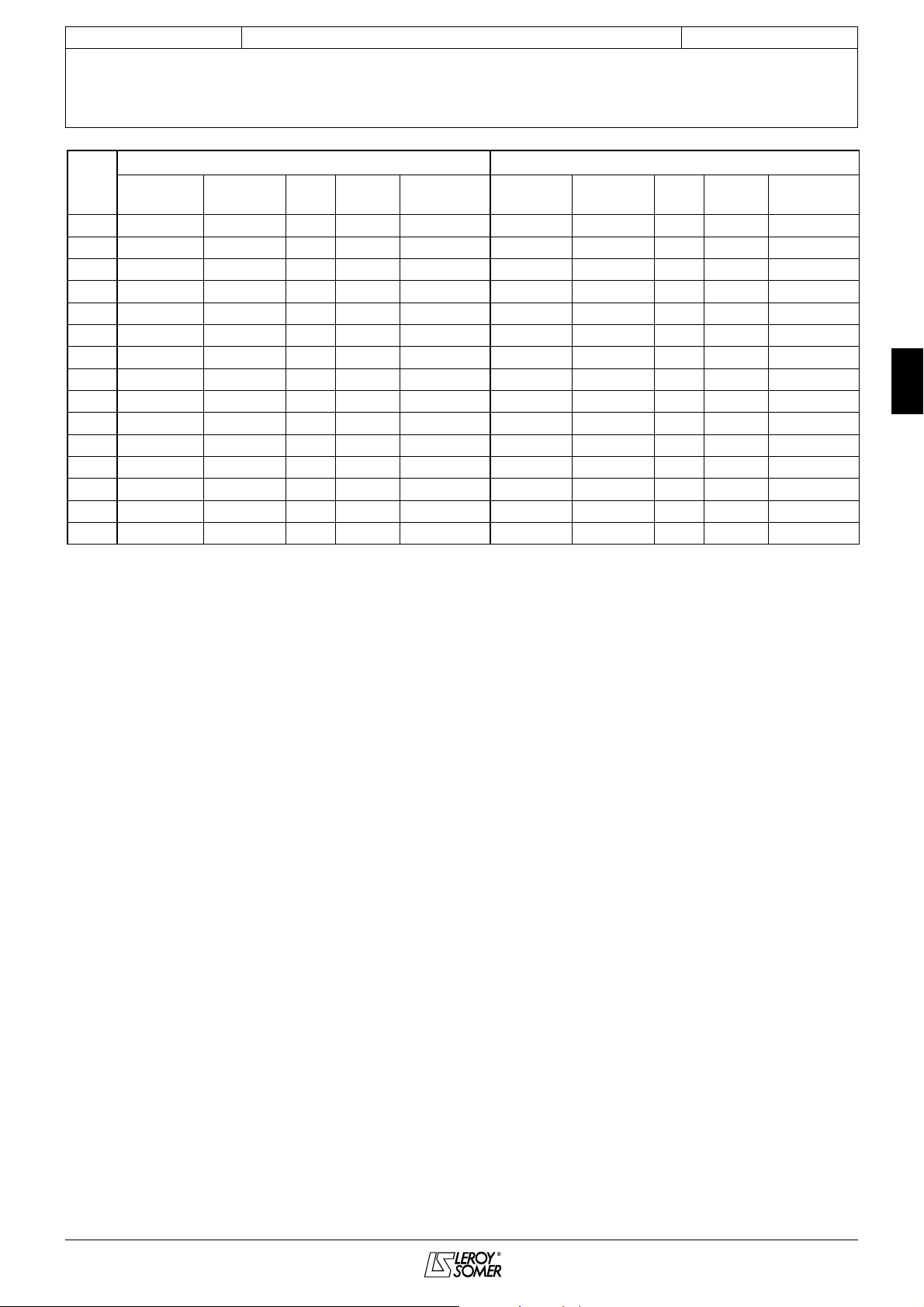

115 V ±10% - 50/60 Hz

Rating

31 ML 025 0.25 31 M 025 0.25 31 TL 025 0.25 31 T 025 0.25

31 ML 037 0.37 31 M 037 0.37 31 TL 037 0.37 31 T 037 0.37

Power (kW)

Single-phase power supply

200/240 V ±10% - 50/60 Hz

Rating Power (kW) Rating Power (kW) Rating Power (kW)

31 M 055 0.55 31 TL 055 0.55 31 T 055 0.55

31 M 075 0.75 31 TL 075 0.75 31 T 075 0.75

32 M 090 0.90 32 TL 090 0.90 31 T 090 0.90

32 M 110 1.1 32 TL 110 1.1 31 T 110 1.1

32 M 150 1.5 32 TL 150 1.5 32 T 150 1.5

3-phase power supply

200/240 V ±10% - 50/60 Hz

32 TL 180 1.8 32 T 180 1.8

32 TL 220 2.2 32 T 220 2.2

33 TL 300 3 32 T 300 3

33 TL 400 4 32 T 400 4

34 TL 550 5.5 33 T 550 5.5

34 TL 750 7.5 33 T 750 7.5

3-phase power supply

400/480 V ±10% - 50/60 Hz

34 T 900 9

34 T 111 11

40

Page 7

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

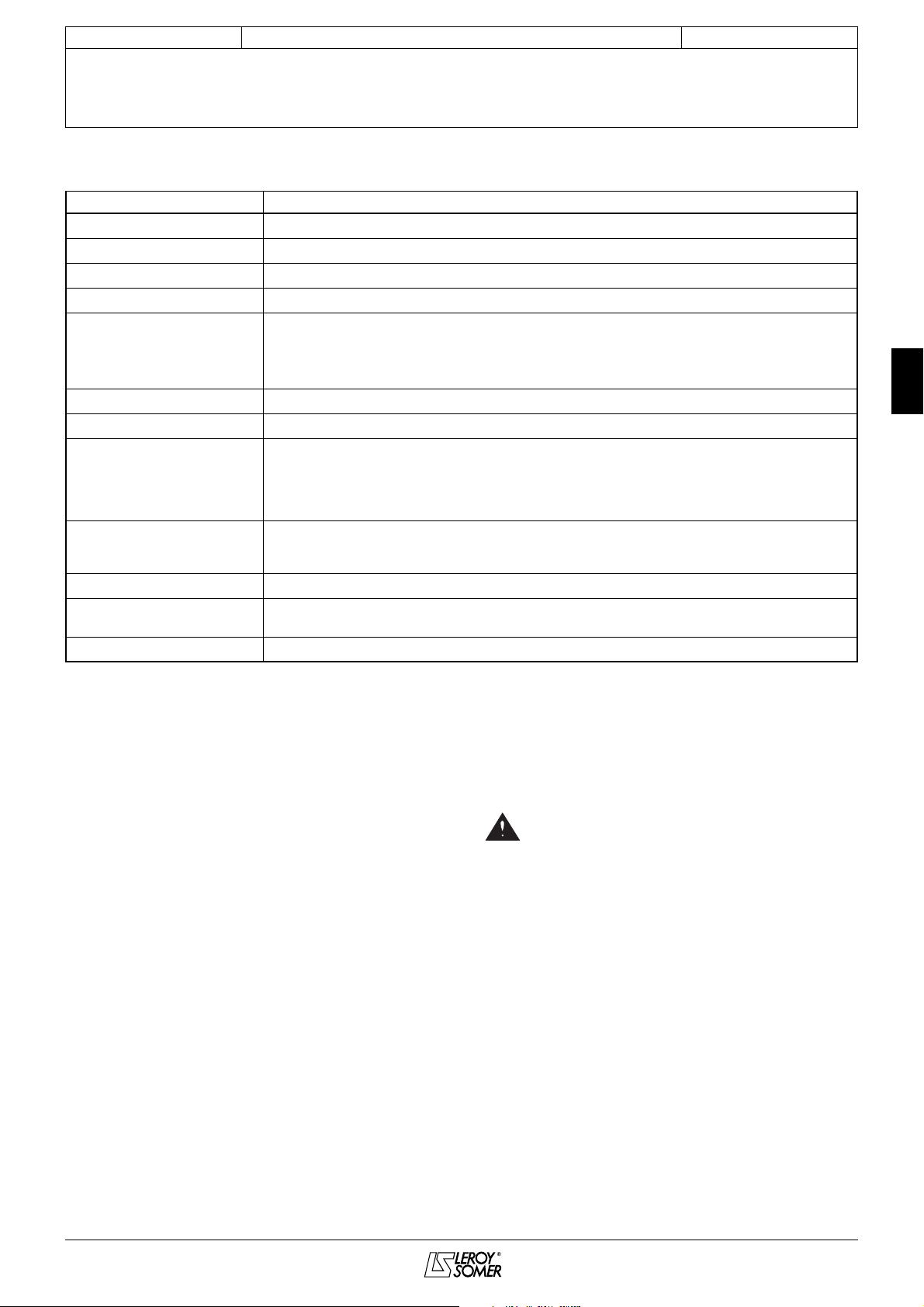

OPERA T ING EXTENSIONS

Designation Description

B 31/32 or B 33/34 Integrated speed control knob

BMA 31/32 or BMA 33/34 Speed control knob and integrated run-stop control knob

BMAVAR 31/32 or BMAVAR 33/34 Speed control knob and integrated stop forward/reverse control knob

CVI VMA 31/32 or CVI VMA 33/34 Integrated speed control

ESFR VMA 31/32 or ESFR VMA 33/34 Brake control

RF100 – RF200 – RF600 Braking resistor Power 100, 200 and 600 W

RF – BRR – 800 – 200 Braking resistor Power 800 W – External mounting

PX LCD Parameter-setting console

COD VMA 33/34 Encoder feedback

SOFTVMA 30 Parameter-setting software

PAD VMA 31/32 or PAD VMA 33/34 Local display unit

PX KEY Copy key

SO VMA 31/32 Fixed brake control and power supply (3-phase supply 400-480 V only)

VMA COM PB 31/32 or VMA COM PB 33/34 Fieldbus: PROFIBUS DP

VMA COM IS 31/32 or VMA COM IS 33/34 Fieldbus: INTERBUS S

VMA COM DT 31/32 or VMA COM DT 33/34 Fieldbus: DEVICENET

VMA COM CN 31/32 or VMA COM CN 33/34 Fieldbus: CAN OPEN

FLT VMA 31M EMC filter for residential environment – Internal mounting (for VMA 31M)

FLT VMA 31/32 EMC filter for residential environment – Internal mounting (for VMA 31TL/T 32/TL/T)

FLT VMA 33 EMC filter for industrial environment – Internal mounting (for VMA 33 TL/T)

FLT VMA 34 EMC filter for industrial environment – Internal mounting (for VMA 34 TL/T)

en

1.3 - Characteristics

1.3.1 - Electrical data

Power supply

Phase voltage imbalance - 3%

Output voltage From 0 V to input voltage From 0 V to input voltage

Power range (kW) 0.25 - 0.37* - 0.55 - 0.75 - 0.9 - 1.1 - 1.5

Maximum number of power-

ups per hour

*0.37 kW max. for 115 V supply (0,75 kW with 310M rating)

**7.5 kW max. for 230 V supply

Single-phase supply

110V -10 % to 120V +10 % 50-60Hz ± 2 %

208V -10 % to 240V +10 % 50-60Hz ± 2 %

10 100

1.3.2 - Characteristics and functions

Characteristics V ARMECA 30

- 10 to 80 Hz at constant torque (factory setting can be modified with parameter-setting

Motor frequency variation

range

Efficiency 97.5% motor efficiency

Overload

option)

- 10 to 50 Hz for general applications (factory setting can be modified with parameter-setting

option)

- 0 to Fmax depending on thermal and mechanical limits (Fmax = 400 Hz ; LEROY-SOMER to

be consulted anytime the applications requires the drive to run at more than 150 Hz)

150% of In for 60 s

10 times per hour

3-phase supply

208V -10 % to 240V +10 % 50-60Hz ± 2 %

380V -10 % to 480V +10 % 50-60Hz ± 2 %

0.25 - 0.37 - 0.55 - 0.75 - 0.9 -1.1 - 1.5 - 4 -

5.5 - 7.5** - 9 - 11

41

Page 8

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

Pilot control VARMECA 30

- Analogue reference (0 V or 4 mA) = Minimum speed

(10 V or 20 mA) = Maximum speed

- 0 to 10 V with integrated potentiometer (B31/32 – B33/34 option)

Speed reference

Speed regulation

Run/Stop

Forward/Reverse

Stop mode

Ramps - Ramps adjustable from 0 to 600s

Fieldbus - PROFIBUS DP, INTERBUS S, DEVICENET, CAN OPEN, MODBUS RTU, LS NET

- 0 to 10 V with remote potentiometer

- 4 to 20 mA with external reference

- Reference with internal potentiometer

- Digital references

- Fieldbus

- Speed regulation with encoder feedback option for VMA 33 or 34 only

- Regulation of a reference with integrated PI loop

- With power supply

- With remote volt-free contact

- With fieldbus

- With local run/stop control

- With internal connection on the terminal block

- With remote volt-free contact

- With fieldbus

- With local run/stop control

- On ramps (using volt-free contact or integrated control)

- Freewheel

- With electromechanical brake

Protection VARMECA 30

- Undervoltage (see notice 3847)

- Overvoltage (see notice 3847)

- Overloads (see notice 3847)

Power

Control - Short-circuit on 0-10 V/24 V inputs or outputs

Drive reset

.thermal, drive and motor

.protection against locked rotor

- Short-circuit

.motor windings

- Overspeed (see notice 3847)

- By switching off the VARMECA 30 or by opening/closing the connection between the 24V

and ENA (VMA 31/32) terminals or SDI 1 and SDI 2 (VMA 33/34) terminals

42

Page 9

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

1.4 - Environmental characteristics

Characteristics Level

Index of protection IP 65

Storage temperature - 40 °C to + 70 °C Conforming to standard IEC 68-2-1.

Transport temperature - 40 °C to + 70 °C

Operating temperature - 20 °C to + 50 °C (with power derated by 1% per °C, above 40 °C)

< 1000 m without derating.

Altitude

Ambient humidity 95% non condensing

Humidity during storage 93%, 40 °C, 4 days

Vibration

Shocks

Immunity Conforming to EN61000-6-2

Radiated and conducted

emissions

UL standards Conforming to UL 508 C (E211799)

The maximum authorised altitude is 4000 m, but above 1000 m, the continuous output current

should be derated by 1% per additional 100 m over 1000 m (eg: for an altitude of 3000 m,

derate by 20%).

- Exposed product: 0.01 g

- Sinusoidal vibration:

• VMA 31/32 : 2-9 Hz 3,5 ms

• VMA 33/34 : 2-6 Hz 3,5 ms-2 - 6-100 Hz 5 ms

in accordance with standard IEC 68-2-6.

Packaged product: 15 g, 6 ms, 500 times/direction in all 6 directions in accordance with

standard

IEC 68-2-29.

Conforming to EN50081-2 with internal filter

2

/Hz 1 hr in accordance with standard IEC 68-2-34.

-2

- 9-100 Hz 10 ms

-2

-2

3776 en - 07.2007 / h

en

1.5 - Radio-frequency interference

1.5.1 - General

Variable speed drives use high-speed switches (transistors,

semi-conductors) which switch high voltages (around

550VDC for 3-phase drives) at high frequencies (several

kHz). This provides better efficiency and a low level of motor

noise.

As a result, they generate radio-frequency signals which may

disturb operation of other equipment or distort measurements

taken by sensors:

- due to high-frequency leakage currents which escape to

earth via the stray capacity of the drive/motor cable and that

of the motor via the metal structures which support the motor

- by conduction or feedback of R.F. signals on the power

supply cable: conducted emissions

- by direct radiation near to the mains supply power cabl e or

the drive/motor cable: radiated emissions

These phenomena are of direct interest to the user.

The frequency range concerned (radio frequency) does not

affect the energy distribution company.

Conformity of the drive is only assured when the

mechanical and electrical installation instructions

described in this manual are adhered to.

43

Page 10

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

1.5.2 - Standards (Emission)

The maximum emission level is set by the generic industrial (EN 50081-2) and residential (EN 50081-1) standards.

VARMECA 30 conforms to the following standards:

EN 50081-2, EN 61000-6-4 - EN 61800-3, IEC 61800-3.

Emission

Conformity conditions according to the

switching frequency

Standard Description Application

Second environment with

unrestricted distribution (DENR)

Second environment with

EN 61800-3 Variable speed drive standards

EN 50081-1 Generic emission standards for

EN61000-6-3

EN 50081-2 Generic emission standards for

EN 61000-6-4

residential, commercial and light

industrial environments

the industrial environment A.C. supply

restricted distribution (DER)

First environment with

unrestricted distribution (R)

First environment with restricted

distribution (I)

A.C. supply -

VMA 31/32 ≤ 10kHz

VMA 33/34 ≤ 11kHz

VMA 31/32 ≤ 10kHz

VMA 33/34 ≤ 11kHz

VMA 31/32 ≤ 4kHz

VMA 33/34 ≤ 4,5kHz

VMA 31 ≤ 8kHz

VMA 32 ≤ 4kHz

VMA 33/34 ≤ 4,5kHz

With EMC filter

Internal External

VMA 31/32 ≤ 10kHz

VMA 33/34 ≤ 11kHz

VMA 31/32 ≤ 10kHz

VMA 33/34 ≤ 11kHz

-

VMA 31/32 ≤ 4kHz

VMA 33/34 ≤ 4,5kHz

VMA 31/32 ≤ 10kHz

VMA 33/34 ≤ 11kHz

VMA 31/32 ≤ 4kHz

VMA 33/34 ≤ 11kHz

VMA 31/32 ≤ 10kHz

VMA 33/34 ≤ 11kHz

The second environment includes industrial networks supplied with low voltage but which do not serve buildings

for domestic use. Operation of a dr iv e with out an EMC filte r in this ty pe of e nvironment may resu lt in inte rference

on certain electronic appliances located near the drive whose immun ity level might not be compatible with industrial

conditions. If it proves impossible to filter the disturbed element, add an external EMC filter.

44

Page 11

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

1.5.3 - Standards (Immunity)

The minimum immunity level is set by the generic industrial (EN 51000-6-2) and residential (EN 51000-6-1) standards.

VARMECA 30 conforms to the following standards:

EN 61000-4-2, IEC 61000-4-2 - EN 61000-4-3, IEC 61000-4-3 - EN 61000-4-5, IEC 61000-4-5 - EN 61000-4-6, IEC 61000-4-6 EN

61000-4-11, IEC 61000-4-11 - EN 61000-6-2, IEC 61000-6-2 - EN 61000-3, IEC 61000-3.

Immunity

Standard Description Application Conformity

IEC 61000-4-3 Immunity standards for radiated

EN 61000-4-3

IEC 61000-4-6 Generic immunity standards for

EN 61000-4-6

EN 50082-1 Generic immunity standards for

EN 61000-6-1

EN 50082-2

EN 61000-6-2

EN 61800-3

EN 61000-6-2

EN 61000-4-4 Bursts of fast transients Control cable Level 4 (hardened industrial)

EN 61000-4-5 Shock waves Phase-earth power supply cable Level 4

radio-frequency

conducted radio-frequency

residential, commercial and light

industrial environments

Generic immunity standards for the

industrial environment

Variable speed drive standards Conforms to the first and second environmentIEC 61000-6-2

shielded cables outside product

Product casing Level 3 (industrial)

Control and power cables

- ConformsIEC 61000-6-1

- ConformsIEC 61000-6-2

Power cable Level 3 (industrial)

Phase-to-phase power supply

cable

Earth signal circuits

(refer to section 1.5.5)

Level 3 (industrial)

Level 3

Level 2

en

1.5.4 - Earth leakage current

Earth leakage currents may depend on the type of EMC filter

used. The VARMECA 30 can be supplied with its filter

integrated and wired-up. The levels of leakage current also

depend on the voltage and/or the power supply frequency

and the size of the motor.

In all cases, for conformity with immunity standards, a voltage

limiting device is connected to earth. The shunt current is

negligible in normal circumstances.

1.5.4.1 - use of earth leakage detector (residual current

device)

1- Type AC: which detects AC faults. Not to be used with

variable speed drives.

2- Type A: which detects AC faults and pulsed DC faults

(provided that the DC is cancelled out at least once per cycle).

Only for use with single-phase drives.

3 - Type B: which detects AC faults, pulsed DC faults and

smoothed DC faults. Only this type is suitable for use with

all variable speed drives.

Note: If an external EMC filter is being used, a delay of 50 ms

should be incorporated to avoid spurious faults being taken

into account.

1.5.5 - Control cable immunity

Control cable immunity can be increased outside the

VARMECA 30 by one of the following 2 methods:

• Use of shielded twisted pair cable, with shielding connected

to earth around its circumference within 100 mm of the

VARMECA 30.

• Passing the cable through a ferrite ring at 100 mm maximum

distance from the VARMECA 30.

Note: Several control cables can pass through a single

ferrite.

1.5.6 - Control circuit immunity when

overvoltage occurs

Immunity to overvoltages in control circuits or in long cables

connected to the outside of a building.

The various drive input and output circuits conform to

standard EN61000-6-2 (1 kV) relating to overvoltages.

There are some exceptions, where the installation may be

exposed to overvoltage peaks which exceed the levels

determined by the standard. This may be the case in the

event of lightning strikes or earth faults associated with long

cable lengths (>30 m). To limit the risks of damage to the

drive, the following precautions could be taken:

45

Page 12

LEROY-SOMER

30 V Zener diode

(eg: 2xBZW50-15

Signal

0V 0V

to the drive

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

3776 en - 07.2007 / h

- Galvanic isolation of the I/O.

- Duplication of the cable shielding with an earth wire of

2

10 mm

must be linked at both ends and connected to earth with the

shortest possible connection. This stratagem enables high

currents to pass into the earth wire, rather than into the

shielding

- Reinforcement of the logic and analogue I/O protection by

adding a zener diode or a peak limiter.

Elimination of uni-directional logic and analogue I/O

overvoltages

minimum. The cable shielding and the earth wire

These circuits are available in modules (DIN rail mounting).

These circuits are not suitable for encoder signals or for highspeed logic data networks, because the diodes may affect the

signal. The majority of encoders have galvanic isolation

between the motor casing and the encoder circuit, and in this

case, no precautions are necessary. For data networks,

follow the specific network recommendations.

If a logic output is subjected to significant overvoltages, the

drive trips on an "Old1" fault.

1.6 - Description of cables and protection devices

• It is the responsibility of the user to connect and provide protection for the VARMECA 30 in accordance with the

legislation and regulations in force in the country of use. This is particularly important as regards the size of cables,

the type and rating of fuses, the earth or ground connection, powering down, acknowledging faults, insulation and

protection against overcurrents.

• These tables are given for information only, and must under no circumstances be used in place of the current standards.

• When using a circuit-breaker, it must be a motor circuit-brea ker (D curve).

• The residual current device must be type B. Too many devices connected to a single residual current device can cause

it to trip. Check that the circuit-breaker is only protecting the VARMECA.

• Comply with the size of protection fuses.

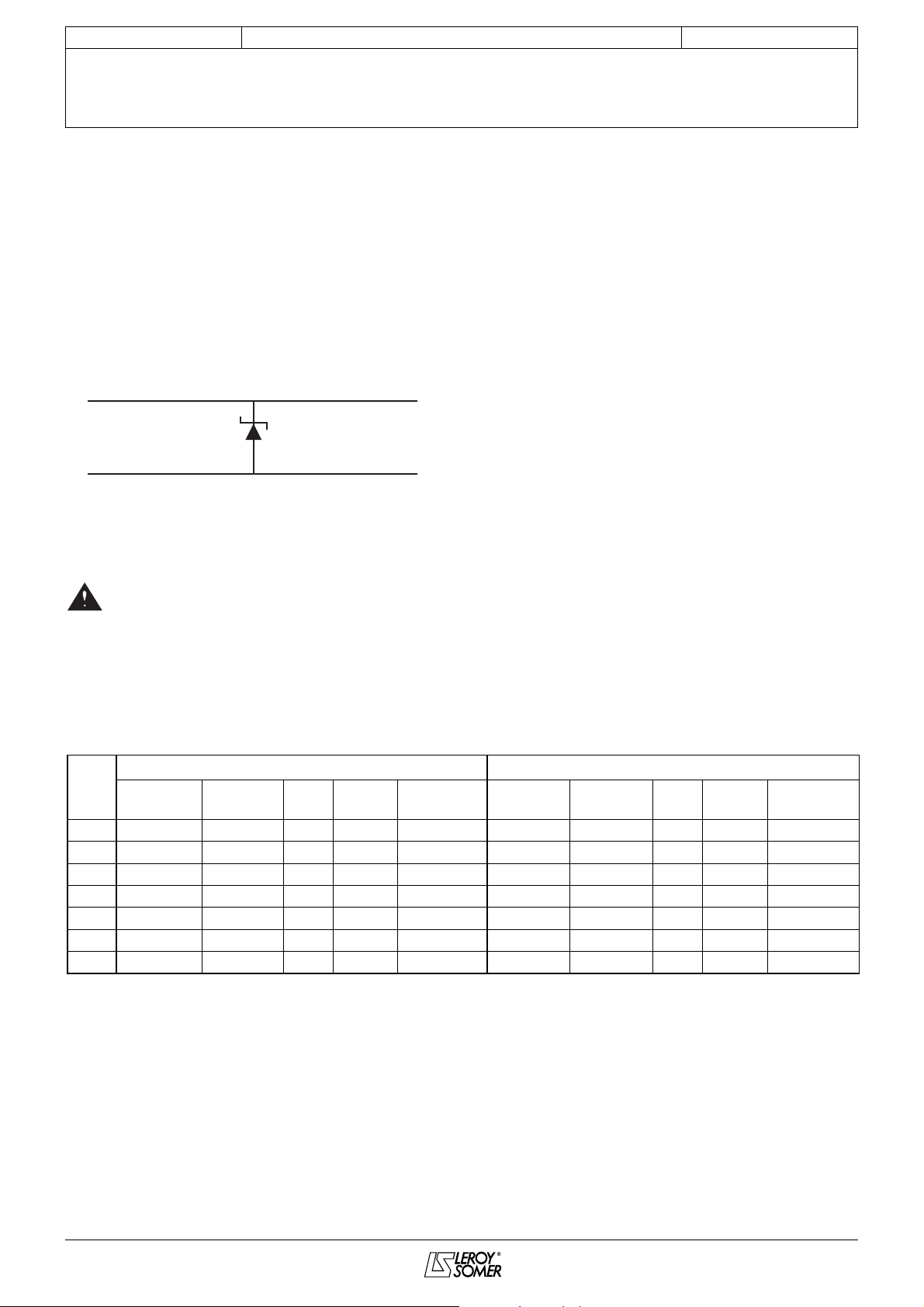

Single-phase power supply 110V - 10 % to 120 V + 10 % Single-phase power supply 208V - 10 % to 240V + 10 %

P

(kW)

0.25 31 ML 025 8 6.8 1.5 M16 + M20 31 M 025 8 3.5 1.5 M16 + M20

0.37 31 ML 037 10 8.5 1.5 M16 + M20 31 M 037 10 4 1.5 M16 + M20

0.55 31 M 055 10 4.5 1.5 M16 + M20

0.75 31 M 075 16 7 2.5 M16 + M20

0.9 32 M 090 16 9 2.5 M16 + M20

1.1 32 M 110 20 11 2.5 M16 + M20

1.5 32 M 150 25 14 2.5 M16 + M20

VMA

rating

Fuses

(gG)

I (A)

Cables

2

(mm

)

PE

VMA

rating

Fuses

(gG)

I (A)

Cables

(mm2)

PE

46

Page 13

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

Three-phase power supply 208V - 10 % to 240V + 10 % Three-phase power supply 380V - 10 % to 480V + 10 %

P

(kW)

0.25 31 TL 025 4 2 1.5 M16 + M20 3 1 T 025 4 1 1.5 M16 + M20

0.37 31 TL 037 6 3 1.5 M16 + M20 31 T 037 4 1.5 1.5 M16 + M20

0.55 31 TL 055 6 4 1.5 M16 + M20 3 1 T 055 6 2 1.5 M16 + M20

0.75 31 TL 075 8 5 1.5 M16 + M20 3 1 T 075 6 3 1.5 M16 + M20

0.9 32 TL 090 10 5.5 1.5 M16 + M20 31 T 090 8 3.5 1.5 M16 + M20

1.1 32 TL 110 10 6 2.5 M16 + M20 31 T 110 10 4 1.5 M16 + M20

1.5 32 TL 150 16 7 2.5 M16 + M20 32 T 150 10 5 1.5 M16 + M20

1.8 32 TL 180 16 7.5 2.5 M16 + M20 32 T 180 10 5.5 2.5 M16 + M20

2.2 32 TL 220 16 8 2.5 M16 + M20 32 T 220 10 6 2.5 M16 + M20

3 33 TL 300 16 12 2.5 M20 + M25 32 T 300 16 7 2.5 M16 + M20

4 33 TL 400 20 15 4 M20 + M25 32 T 400 16 8 2.5 M16 + M20

5.5 34 TL 550 25 20 4 M20 + M25 33 T 550 16 12 2.5 M20 + M25

7.5 34 TL 750 32 24 4 M20 + M25 33 T 750 20 16 4 M20 + M25

9 34 T 900 25 19 4 M20 + M25

11 34 T 111 3 2 22 4 M20 + M25

VMA

rating

Fuses

(gG)

I (A)

Cables

2

(mm

)

PE

VMA

rating

Fuses

(gG)

I (A)

Cables

(mm2)

PE

en

Note:

• The mains current value is a typical value which depends on t he source impedance. The high er the impedance, the lower the

current.

• The fuses (UL approved) are intended for installations capable of delivering 5000 A maximum at 480 V.

1.7 - UL conformity

1.7.1 - Specified mains supply

The drive can be incorporated in an installation which can deliver 5000 A rms maximum at a voltage of 264 VAC rms maximum

for 230 V (TL) drives or 528 VAC rms maximum for 400 V (T) drives.

1.7.2 - Cables

Only class 1 copper cables 60/75 °C (140/167 °F) should be used.

1.7.3 - Fuses

UL conformity is adhered to if the fuses used are UL-listed, fast-blow fuses (class CC up to 30 A) with a rating as indicated in the

above table, and if the short-circuit symmetrical current does not exceed 5 kA.

47

Page 14

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

GENERAL INFORMATION

1.8 - Weights and dimensions

Dimensions (mm)

Type VMA rating

LS 71 31ML-31M - 31TL - 31T 176 8 8 8 217 75 94 4.2

LS 80 L

LS 90 S/L

LS 100 L

LS 112 M

LS 112 MG

LS 132 S

LS 132 M 33T - 34TL - 34T 300 8 8 8 336 115 141 8.1

LS 160 M/MR 34T 309 38 38 38 336 115 141 8.1

31ML-31M - 31TL - 31T 190 12 12 12 217 75 94 4.2

32M - 32TL 190 12 12 12 232 75 94 4.2

31T 199 12 32 13 217 75 94 4.2

32M - 32 TL 199 12 32 13 232 75 94 4.2

32TL - 32T 205 12 12 12 232 75 94 4.2

33TL 270 4 4 4 336 115 141 8.1

32T 204 12 12 12 232 75 94 4.2

33TL 270 4 4 4 336 115 141 8.1

32T 213 21 21 21 232 75 94 4.2

33TL 280 13 13 13 336 115 141 8.1

32T 213 39 39 39 232 75 94 4.2

33TL - 33T 280 30 30 30 336 115 141 8.1

HJ

B3 B5 B14

LJ

J I II*

Weight (kg)

HJ

JLJ

III

48

Page 15

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

INSTALLATION

3776 en - 07.2007 / h

2 - INSTALLATION

• It is the responsibility of the owner or user to

ensure that the installation, operation and

maintenance of the drive and its options comply with

legislation relating to the safety of people and equipment

and with the regulations in force in the country of use.

• Before carrying out any work, disconnect and lock the

drive power supply. For the single-phase range, wait 2

minutes to make sure that the capacitors have

discharged.

• After connection, ensure that the seals are firmly in

place, and that the screws and cable glands are

watertight to ensure IP 65 protection.

• Holes are provided at the lowest points of the

enclosure, depending on the operating position, to drain

off any moisture that may have accumulated inside

during cooling of the machine. In conditions which

encourage the formation of con de nsation, it is advisable

to leave the drain holes permanently open.

3 - CONNECTIONS

• All connection work must be performed in

accordance with the laws in force in the country

where the drive is installed. This includes earthing to

ensure that no directly accessible part of the drive can be

at the mains voltage or any other v oltage which may be

dangerous.

• The voltages on the cables or connections of the mains

supply, the motor, the braking resistor or the filter may

cause fatal electric shocks. Contact must be avoided in

all circumstances.

• The drive must be supplied via a circuit-breaking device

so that it can be powered down safely.

• The drive contains capacitors which remain charged at

a fatal voltage even after the power supply has be en cut

off.

• Wait 2 minutes after powering down the drive before

removing the protection devices.

• The drive power supply must be protected against

overloads and short-circuits.

• It is vital to respect the rating of protection devices.

• Connection with copper conductor only.

• Check that the voltage and current of the drive, the

motor and the mains supply are compa t ible.

• After the drive has been operating, the hea tsink or the

braking resistors may be very hot (avoid touching them).

• When the cover is open, the VARMECA 30 degree of

protection is IP10. Any work should only be carried out

by experienced, qualified personnel.

2.1 - General

The VARMECA 30 motor is fitted to the machine like a

standard motor, with flange or foot mounting.

The motor ventilation cools the whole assembly. Make sure

that the ventilation air inlet is free of obstruction.

The positions of the potentiometer/cable gland supports are

specified at the time of ordering. However they may be

reversed if necessary.

en

• Check that the different earth points are actually at the same

voltage.

• Incorporate a bend where the cables enter the cable glands

so that water cannot penetrate the terminal box.

• Tighten the cable gland firmly.

• The VARMECA 30 has a positive logic

configuration.

Using a drive with a control system which has a different

control logic may cause unwanted starting of the motor.

• The control circuits in the drive are isolated from the

power circuits by single insulation (IEC 664-1). The

installer must ensure that the external control circuits are

isolated against any human contact.

• If the control circuits need to be connected to circuits

conforming to SELV safety requirements, additional

insulation must be inserted to maintain the SELV

classification.

3.1 - Wiring precautions

• When the VARMECA 30 is controlled remotely, avoid

parallel routing of power cables and control cables.

• All remote control cables must be shielded and have a

cross-section between 0.22 mm

should be connected to earth at both ends.

2

and 1 mm2. The shielding

49

Page 16

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3776 en - 07.2007 / h

3.2 - Control terminal blocks

• Check that the terminal block has been removed

from its fixed holder (unplugged) before making

any connections, so as to avoid putting pressure on the

card.

• The VARMECA has a positive logic configuration. Using

a drive with a control system which has a different

control logic may cause unwanted starting of the motor.

• Th e control circuits in the drive are isolated from the

power circuits by single insulation (IEC 664-1).

VMA

terminal

33/34

1 1 10V +10V analogue internal source

22ADI1

3 3 0V Logic circuit common 0V

44

5 NA 0V Logic circuit common 0V

VMA

terminal

31/32

Designation Function Characteristics

Analogue or logic

input 1

Assignment in standard

configuration: 0-10V speed

reference

Analogue or logic

input 2

ADI2

Assignment in standard

configuration: Motor PTC input

The installer must ensure that the external control

circuits are isolated against any human contact.

• If the control circuits need to be connected to circuits

conforming to SELV safety requirements, additional

insulation must be inserted to maintain the SELV

classification.

Removable screw terminal block:

- Tightening torque = 0.3 N.m

- Max. cross-section = 1.5 mm

Accuracy ± 2%

Maximum output current 30 mA

Voltage input

Full scale voltage 10 V ± 2%

Input impedance 95 k

Current input

Current range 0 to 20 mA ± 5%

Input impedance 500

Resolution 10 bits

Sampling 6 ms

Logic input (if connected to the +24V)

Thresholds "0": < 5 V – "1": > 10 V

Voltage range 0 to +24 V

Load 95 k

Input threshold 7.5 V

Voltage input

Full scale voltage 10 V ± 2%

Input impedance 95 k

Current input

Current range 0 to 20 mA ± 5%

Input impedance 500

Resolution 10 bits

Sampling 6 ms

Logic input (if connected to the +24V)

Thresholds "0": < 5 V – "1": > 10 V

Voltage range 0 to +24 V

Load 95 k

Input threshold 7.5 V

Input (PTC)

Trip

Cleared fault threshold < 1800

≥

3300

Ω

Ω

Ω

Ω

Ω

Ω

2

Ω

Ω

50

Page 17

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3776 en - 07.2007 / h

VMA

terminal

33/34

66ADIO3

77DIO1

85

11 11

98 DI2

10 9 DI3

12 10 DI4

13 NA SDI1 +24V dedicated to the safety input

14 12 SDI2/ENA Safety/unlocking input

15 13 COM/RL1

16 NA RL1C

17 14 RL1O/RL2 - 2 A, inductive load

18 NA SDO1

19 NA SDO2

VMA

terminal

31/32

Designation Function Characteristics

Characteristics Analogue voltage (common mode) or uni-directional

Voltage input

Full scale voltage 10 V ± 2%

Analogue or logic input or analogue

output 3

Assignment in standard

configuration: Analogue output

(LED control option for VMA31 up

to 34)

Digital input or output 1

Assignment in standard

configuration:

External fault management

24V +24V internal source

Logic input 2

Assignment in standard

configuration: Run forward

Logic input 3

Assignment in standard

configuration: Run reverse

Logic input 4

Assignment in standard

configuration: Selection of ADI1

Fault relay output

Safety contact

Input impedance 95 k

Current input

Current range 0 to 20 mA ± 5%

Input impedance 500

Resolution 10 bits

Sampling 6 ms

Logic input (if connected to the +24V)

Thresholds "0": < 5 V – "1": > 10 V

Voltage range 0 to +24 V

Load 95 k

Input threshold 7.5 V

Voltage output

Voltage range 0 to 10 V

Load resistor 2 k

Protection Short-circuit (40 mA max)

Current output

Current range 0 to 20 mA

Maximum voltage 10 V

Load resistor 500

Characteristics Digital input or output 1

Thresholds "0": < 5 V – "1": > 10 V

Voltage range 0 to +24 V

Sampling/refreshment 2 ms

Digital input

Absolute maximum voltage 0 to +35 V

Load 15 k

Input threshold 7.5 V

Logic output

Maximum output current 50 mA

Overload current 50 mA

Output current 10 mA in total

Overload current VMA 33/34: 150 mA - VMA 31/32: 50 mA

Accuracy ± 5%

Protection Current limiting and setting to fault mode

Characteristics Logic input (positive logic)

Thresholds "0": < 5 V – "1": > 10 V

Voltage range 0 to +24 V

Sampling/refreshment 2 ms

Absolute maximum voltage

range

Load

Input threshold 7.5 V

Characteristics Logic input (positive logic)

Thresholds "0": < 5 V – "1": > 18 V

Voltage range 9 to +33 V

Impedance 820

Characteristics

250 VAC maximum contact

current

Characteristics NO single-pole changeover contact

250 VAC maximum contact

current

(VMA 33/34 only)

Ω

Ω

Ω

Ω

Ω

Ω

0 to +35 V

Ω

15 k

Ω

VMA 33/34: NO_NC single-pole changeover contact

VMA 31/32: NO single-pole contact

- 4 A, resistive load

- 4 A, resistive load

- 2 A, inductive load

en

51

Page 18

LEROY-SOMER

PB1 & PB2

RJ 45

P2

VMA 31/32

VMA 33/34

SLOT 1

SLOT 2

RS 485

PB 1

PB 2

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3776 en - 07.2007 / h

3.3 - Power terminal blocks

3.3.1 - Terminal block for power supply PB1

(marked L1, L2 and L3)

This terminal block is used to connect the 3-phase power

supply when the EMC filter is not supplied with the

VARMECA 30. Otherwise, the EMC filter output is screwed

onto this connector and the power supply should be attached

to the terminals located on top of the filter.

Screw terminal block:VMA 33/34 VMA 31/32

Tightening torque 1.8 N.m 0.8 Nm

Max. cross-section 4 mm

3.3.2 - Terminal block for braking resistor PB2

(marked R+ and R-)

This terminal block is used to connect a braking resistor when

this option is required. The resistor is mounted on the outside

and/or the rear of the VARMECA 30 casing.

Screw terminal block:VMA 33/34 VMA 31/32

Tightening torque 1.8 N.m 0.8 Nm

Max. cross-section 4 mm

Note: For the VMA 31/32, PB1 and PB2 are both

located on the same terminal block.

The terminal block on the VARMECA 31/32 has a terminal

marked FI connected to the R- terminal which enables

use of the internal braking resistor. The jumper must be

removed when an external braking resistor is connected

or if the inertia is incompatible with the rated

deceleration ramp.

2

(AWG8) 2.5 mm

2

(AWG8) 2.5 mm

2

2

3.4 - Terminal blocks for options

3.4.1 - RS485 type serial link connector

This is an RJ 45 connector and is used to connect the PX LCD

console or a PC in order to use the PEGASE VMA 30

programming software.

For the VMA 31/32 it is also used to connect the fieldbus or the

PADVMA 31/32 option.

3.4.2 - Description of Slot 1

(VMA 33/34 only)

This slot is used to connect the encoder fee dback module

(option: COD VMA 30) when "closed loop" mode is selected.

3.4.3 - Description of Slot 2

(VMA 33/34 only)

This slot is used to connect one of the fieldbus modules

(protocols supported: PROFIBUS DP, INTERBUS S,

DEVICE NET and CAN OPEN).

3.4.4 - P2 connector (VMA 31/32 only)

This is used to connect the following options: Local

potentiometer (B 31/32), local potentiometer with integrated

Run/Stop (BMA 31/32), local potentiometer with integrated

Forward/Reverse/Stop (BMAVAR), Brake control

(ESFRVMA 30), etc.

52

Page 19

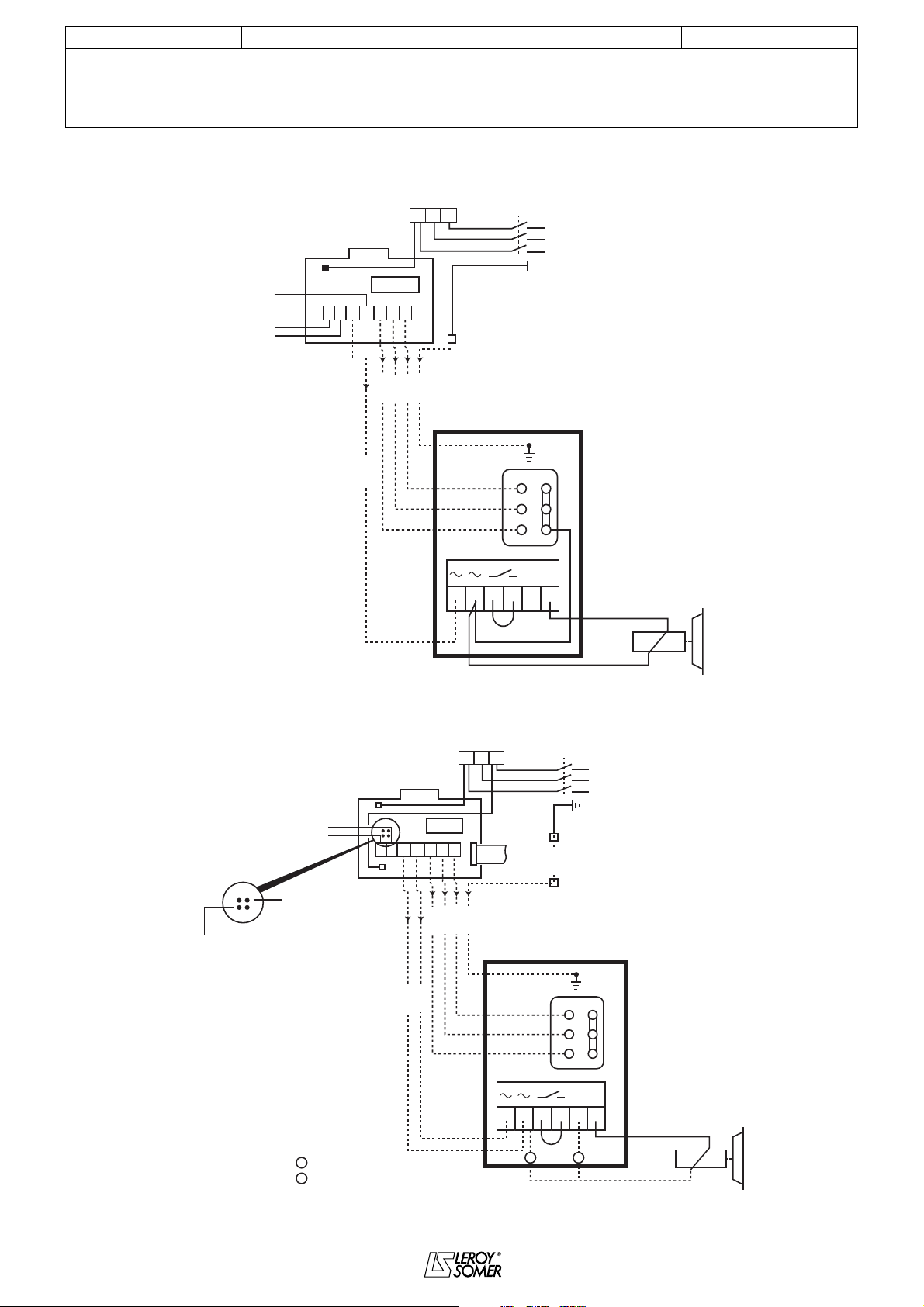

LEROY-SOMER

QS

Indicator relay

Locking input

0-10 V/4-20 mA

speed reference

(local options or external ref.)

Local option indication

External fault input

Forward/Stop

Reverse/Stop

Selection of 0-10 V/4-20 mA

speed reference

Motor PTC input

Braking resistor

(optional)

Jumper to be removed if

optional Braking resistor

connected

Mains supply

10V

ADI1

0V

ADI2

24V

ADIO3

DI01

DI2

DI3

Dl4

+24V

ENA

RL1

RL2

L1

L2

L3

R+

R-

Fi

PE

2

3

4

5

6

1

8

9

10

11

12

7

13

14

VARMECA 31/32

QS

Indicator relay

0-10 V/4-20 mA

speed reference

(local options or external ref.)

Local option indication

External fault input

Forward/Stop

Reverse/Stop

Locking input

Safety contact

Selection of 0-10 V/4-20 mA

speed reference

Motor PTC input

Braking resistor

(optional)

Mains supply

10V

ADI1

0V

ADI2

0V

ADIO3

DI01

+24V

DI2

DI3

+24V

DI4

SDI1

SDI2

COM

RL1C

RL10

SD01

SD02

L1

L2

L3

R+

R-

PE

2

3

4

5

6

1

8

9

10

11

12

13

14

7

15

16

17

18

19

VARMECA 33/34

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

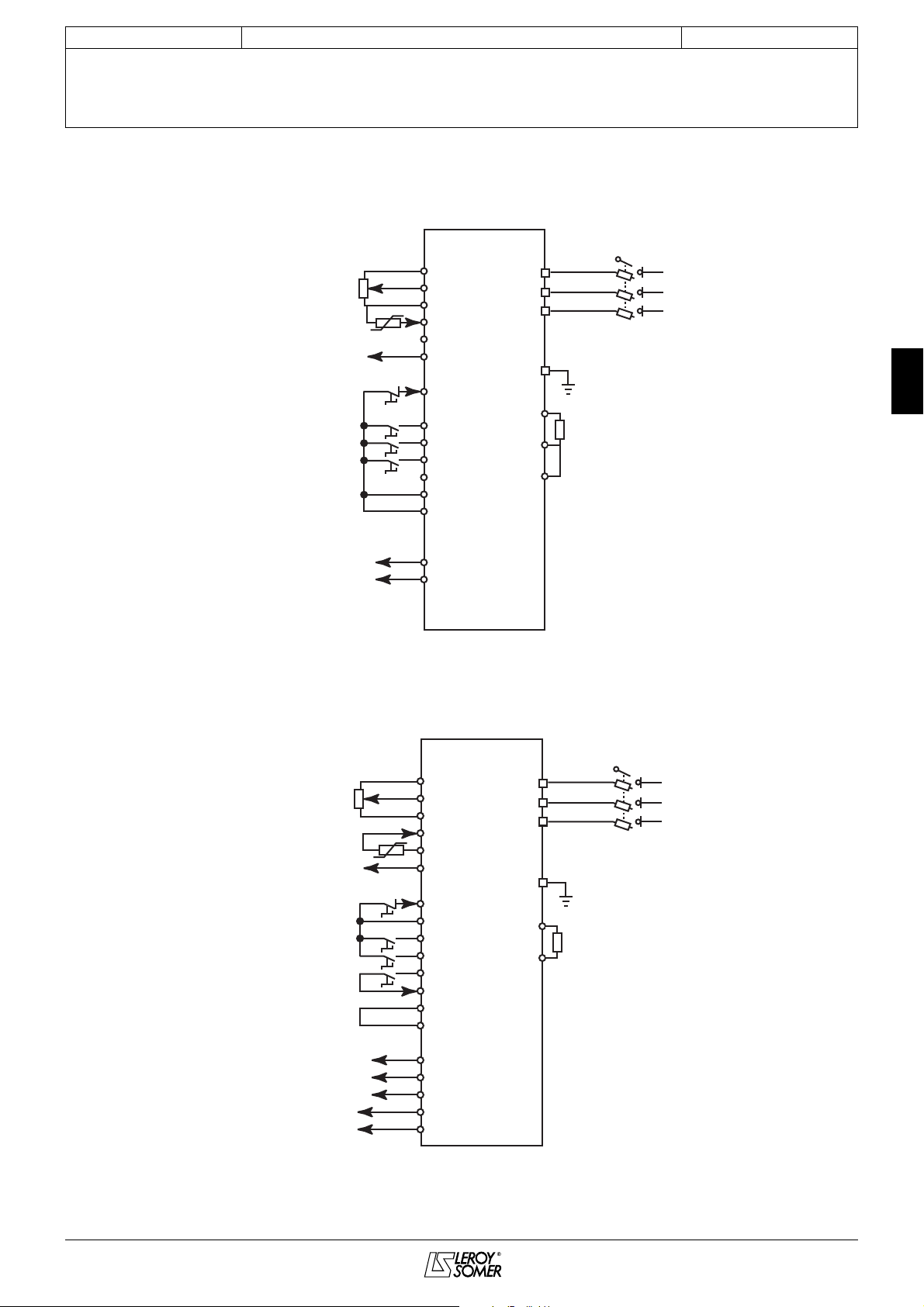

3.5 - Wiring diagrams

3.5.1 - Standard configuration connection diagram

3776 en - 07.2007 / h

en

Note:

For single-phase versions, the power supply is connected to terminals L and N.

53

Page 20

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3776 en - 07.2007 / h

3.5.2 - Connection diagram with safety input

3.5.2.1 - Safety input

This input, when opened, causes the drive to lock.

Independent of the microprocessor, it acts on several levels

of control from the power bridge. It is designed in such a way

that even if one or more circuit components were to fail, the

absence of torque on the motor shaft is guaranteed with a

very high level of integrity.

This input is used to create a safety function using the

principles of category 1 or 3 of standard EN954-1, depending

on the application diagram.

The design of the "freewheel stop" function using input SDI2

has been evaluated by CETIM.

The results of this examination are recorded in report no.

732773/47A.

This built-in functionality enables the drive to act as substitute

for a contactor in order to stop the motor in freewheel mode.

By using this safety input redundantly with another drive logic

input, a diagram can be used which is ca pable of resisting a

single fault. The drive will stop the motor in freewhee l mode

using two different control channels.

For correct use, the power connection diagrams described in

the following paragraphs must be adhered to.

To unlock the drive and provide the safety function , safety

input ENA (VMA 31/32) or SDI2 (VMA 33/34) must be

connected to the +24V source (SDI1 for VMA 33/34).

This +24V source should be reserved exclusively for the

safety input function (VMA33/34).

• The safety input is a safety component which

must be incorporated into the complete system

dedicated to machine safety. As for any installation, the

complete machine must be the subject of a risk analysis

by the integrator which will determine the safety category

with which the installation must comply.

• The safety input, when open, locks the drive, mean ing

the dynamic braking function i s no longer avai lable. If a

braking function is required before the drive safety lock

is applied, a time-delayed safety relay should be installed

to activate locking automatically after the end of braking.

If braking needs to be a machine safety function, it

should be provided by an electromechanical solution

since the dynamic braking by the drive function is not

considered to be a safety function.

• The safety input does not provide the electrical isolation

function. Before any work is carried out, the power

supply must be cut by an approved isolating device

(isolator, switch, etc).

• The safety function is not enabled when the drive is

controlled via the keypad or via a fieldbus.

54

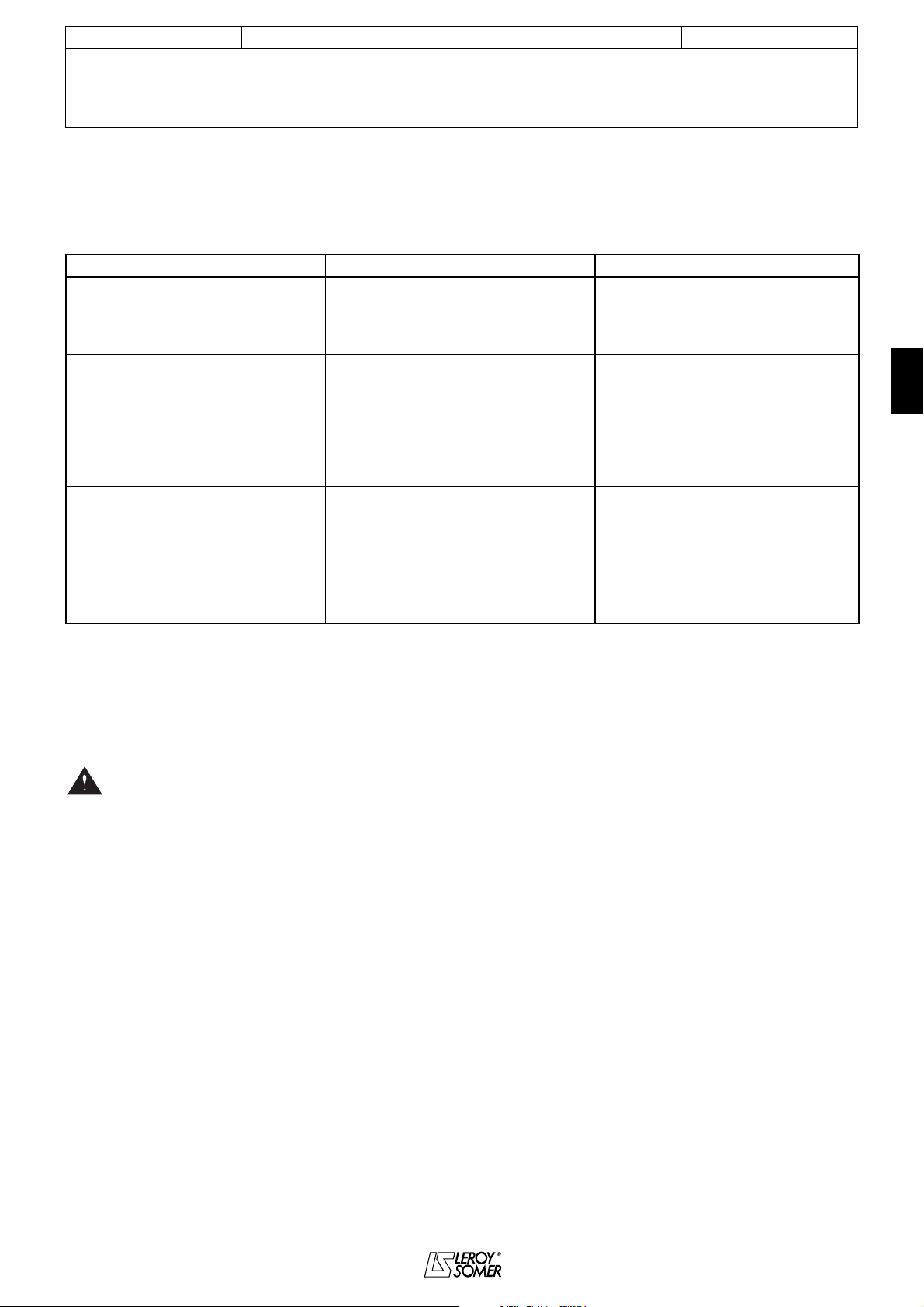

Page 21

LEROY-SOMER

AU

QS

QS

10V

ADI1

0V

ADI2

24V

ADIO3

DI01

DI2

DI3

DI4

+24V

ENA

RL1

RL2

L1

L2

L3

R+

R-

Fi

PE

2

3

4

5

6

1

8

9

10

11

12

7

13

14

Indicator relay

0-10 V/4-20 mA

speed reference

(local options or external ref.)

Local option indication

External fault input

Forward/Stop

Reverse/Stop

Selection of 0-10 V/4-20 mA

speed reference

Motor PTC input

Braking resistor

(optional)

Jumper to be removed if

optional Braking resistor

connected

Mains supply

VARMECA 31/32

QS

10V

ADI1

0V

ADI2

0V

ADIO3

DI01

+24V

DI2

DI3

+24V

DI4

SDI1

SDI2

COM

RL1C

RL10

SD01

SD02

L1

L2

L3

R+

R-

PE

2

3

4

5

6

1

8

9

10

11

12

13

14

7

15

16

17

18

19

AU

QS

Indicator relay

0-10 V/4-20 mA

speed reference

(local options or external ref.)

Local option indication

External fault input

Forward/Stop

Reverse/Stop

Safety contact

Selection of 0-10 V/4-20 mA

speed reference

Motor PTC input

Braking resistor

(optional)

Mains supply

VARMECA 33/34

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

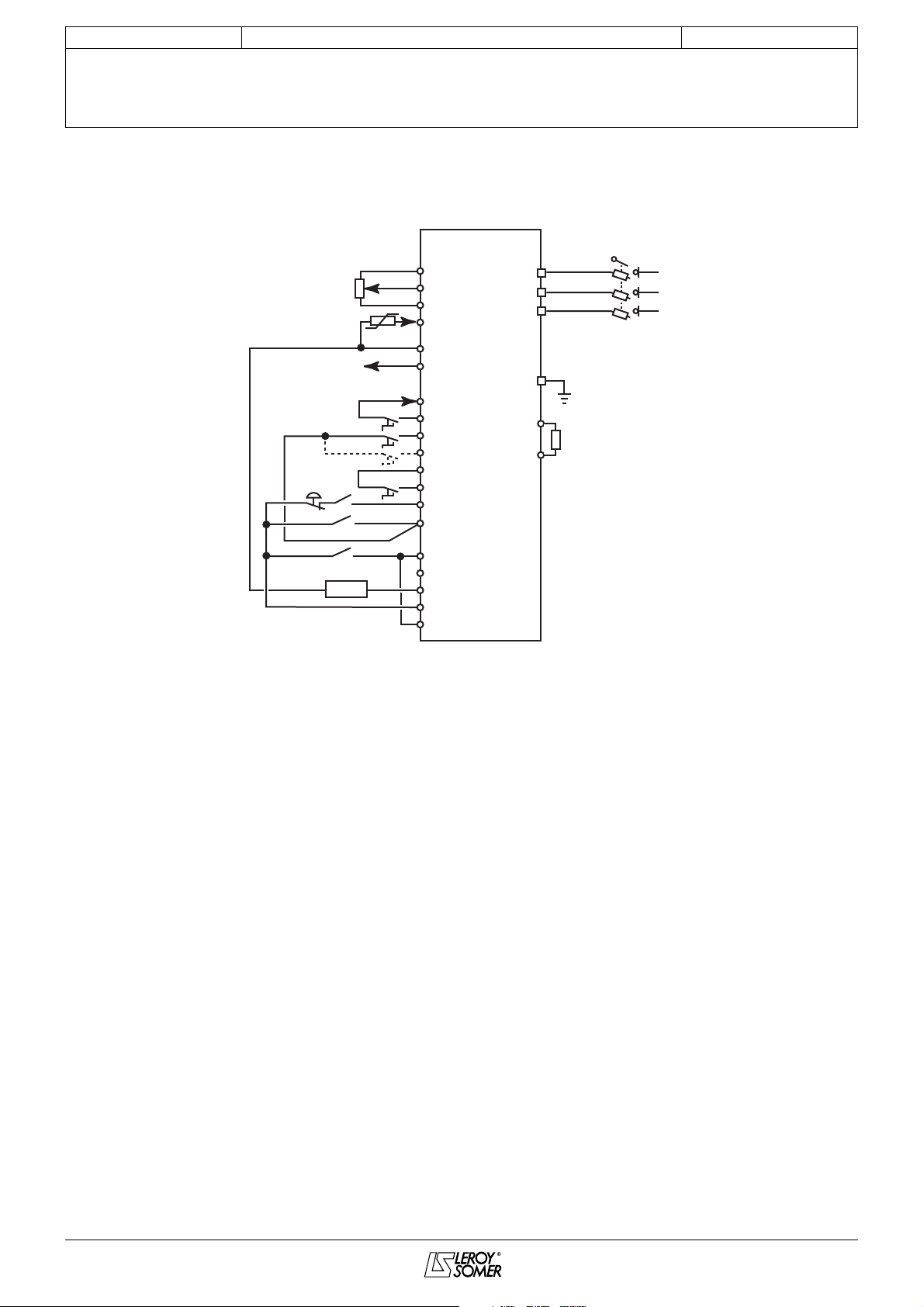

3.5.2.2 - 3-phase AC power supply in accordance with safety standard EN954-1 - category 1 with use of safety input

en

Note:

For single-phase standards, the power supply is connected to terminals L and N.

QS: Fused isolator: QS must be opened before any intervention on the electrical parts of the drive or motor.

AU: Emergency stop button.

Optional braking resistor. Dissipates the active power returned by the motor onto the drive DC bus in the event of a driving

machine.

Using the safety input means the motor can be stopped in freewheel mode without using a l ine contactor. The drive’s internal

principles are sufficiently safe to perform a stop using the safety input directly (category 1 of EN954-1).

55

Page 22

LEROY-SOMER

KA

KA

AU

QS

10V

ADI1

0V

ADIO3

0V

DI01

+24V

DI2

DI3

+24V

DI4

SDI1

SDI2

COM

RL10

SD01

SD02

L1

L2

L3

R+

R-

PE

KA

0-10 V/4-20 mA

speed reference

(local options or external ref.)

Motor PTC input

Local option

indication

External

fault input

Selection of

0-10 V/4-20 mA

speed reference

Forward/Stop

Reverse/Stop

Braking resistor

(optional)

Mains supply

VARMECA 33/34 (only)

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3.5.2.3 - 3-phase AC power supply in accordance with safety standard EN954-1 - category 2 or 3 with use of safety input

SDI2 redundantly with logic input DI2

QS: Fused isolator: QS must be opened before any intervention on the electrical parts of the drive or motor.

AU: Emergency stop button.

KA: Relays

Optional braking resistor. Dissipates the active power returned by the motor onto the drive DC bus in the event of a driving

machine.

Using the safety input means the motor can be stopped in freewheel mode without using a l ine contactor. The drive’s internal

principles are sufficiently safe to perform a stop using the safety input directly (category 1 of EN954-1).

Duplication of the stop command on a logic input enables use of the internal drive redunda ncy to perform a freewheel stop

(application of category 3 principles in accordance with EN954 for the part relating to the drive).

56

Page 23

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3776 en - 07.2007 / h

3.6 - Power supply and control for

FCR brake motors

3.6.1 - Power supply for the built-in fixed

control brake (SO VMA option) VMA 31/32 only

- The brake is supplied via the rectifier fixed o n the SO VMA

connection card. This connection is made at the factory.

- The rectifier is supplied by a mains phase and the motor star

point.

- No parameters need to be set on the VARMECA.

- The brake is released as soon as the VARMECA run

command is enabled. The brake is released after a stop

command, at the end of the deceleration ramp or on

disconnection of the power supply.

3.6.2 - Power supply for the built-in

sequential control brake (VMA ESFR option)

- The brake is supplied via the rectifier and a solid state relay

fixed on the VMA ESFR connection card. This connectio n is

made at the factory.

- The rectifier is supplied by two mains phases.

- The brake is controlled according to a sequence which can

be adjusted using the VARMECA parameters.

en

3.6.3 - Separate power supply

The brake is supplied and controlled by an external source.

57

Page 24

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3.7 - Rectified brake voltage according to the mains supply

3776 en - 07.2007 / h

Mains VMA rating Power (kW)

31M-025 0.25

Single-phase power

supply

208V -10%

to 240V +10%

3-phase power

supply

208V -10%

to 240V +10%

3-phase power

supply

380V -10%

to 480V +10%

3-phase power supply

208V -10%

to 240V +10%

3-phase power supply

380V -10%

to 480V +10%

NA: Not available, provide a separate power supply.

31M-037 0.37

31M-055 0.55

31M-075 0.75

32M-090 0.9

32M-110 1.1

32M-150 1.5

31TL-025 0.25

31TL-037 0.37

31TL-055 0.55

31TL-075 0.75

32TL-090 0.9

32TL-110 1.1

32TL-150 1.5

32TL-180 1.8

32TL-220 2.2

31T-025 0.25

31T-037 0.37

31T-055 0.55

31T-075 0.75

31T-090 0.9

31T-110 1.1

32T-150 1.5

32T-180 1.8

32T-220 2.2

32T-300 3

32T-400 4 100 VDC

33TL-300 3

33TL-400 4

34TL-550 5.5

34TL-750 7.5

33T-550 5.5

33T-750 7.5

34T-900 9

34T-111 11

FCR brake voltage

SO VMA option VMA ESFR option

NA 180 VDC

NA 180 VDC

120 VDC

NA

NA

180 VDC

100 VDC

180 VDC

58

Page 25

LEROY-SOMER

F1

F1

F2

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3776 en - 07.2007 / h

3.8 - Example of supplying 2 motors

with or without brake in parallel with a

single VARMECA

3.8.1 - The VARMECA must be sized to take

account of the total motor power rating

- The flange with 4 cable glands option must be used to make

it easier to wire up the 2nd motor.

3.8.2 - The 2nd motor is designed to connect to

the terminals marked U, V, W and PE on the SO

VMA and VMA ESFR options for VMA 31/32 or

on the 2nd motor option for VMA 33/34

3.8.3 - Connecting the brake on the 2nd motor

- With the SO VMA option, the rectifier is supplied between

the motor star point and a mains phase from the F1 terminal

of the SO VMA 31/32 option.

- With the VMA ESFR option, the rectifier is supplied

between 2 mains phases and the solid state relay; connect it

from the F1 and F2 terminals of the VMA ESFR 31/32 to the

VMA ESFR 33/34.

en

F1 and F2 terminals of the VMA ESFR 31/32 option

F1 terminal of the SO VMA 31/32 option

59

Page 26

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3.9 - Wiring diagrams for the SO VMA and VMA ESFR options

3.9.1 - Connection of the SO VMA 31/32 option

L1 L2 L3

3-phase

mains supply 400V

L1

Motor/star

point

Coil

brake

Power supply to 2nd brake

(mains voltage output)

SO VMA

U

VW+-F2

F1

CG

Power supply to 2nd motor

(variable frequency and voltage output)

U

V

W

3776 en - 07.2007 / h

3.9.2 - Connection of the VMA ESFR 31/32 option

L1

Full-wave

(208-240VAC

mains supply)

Coil

brake

Half-wave

(380-480VAC mains

supply)

Power supply to 2nd brake

(mains voltage output)

ESFR

VW+-F2

F1

L3

Power supply to 2nd motor

(variable frequency and voltage output)

L1 L2 L3

U

S06

+–

230/400V

mains supply*

CG

Flex trip to connector

for options

CG

U

V

W

Brake

100 - 120VDC

*NOTA : With single

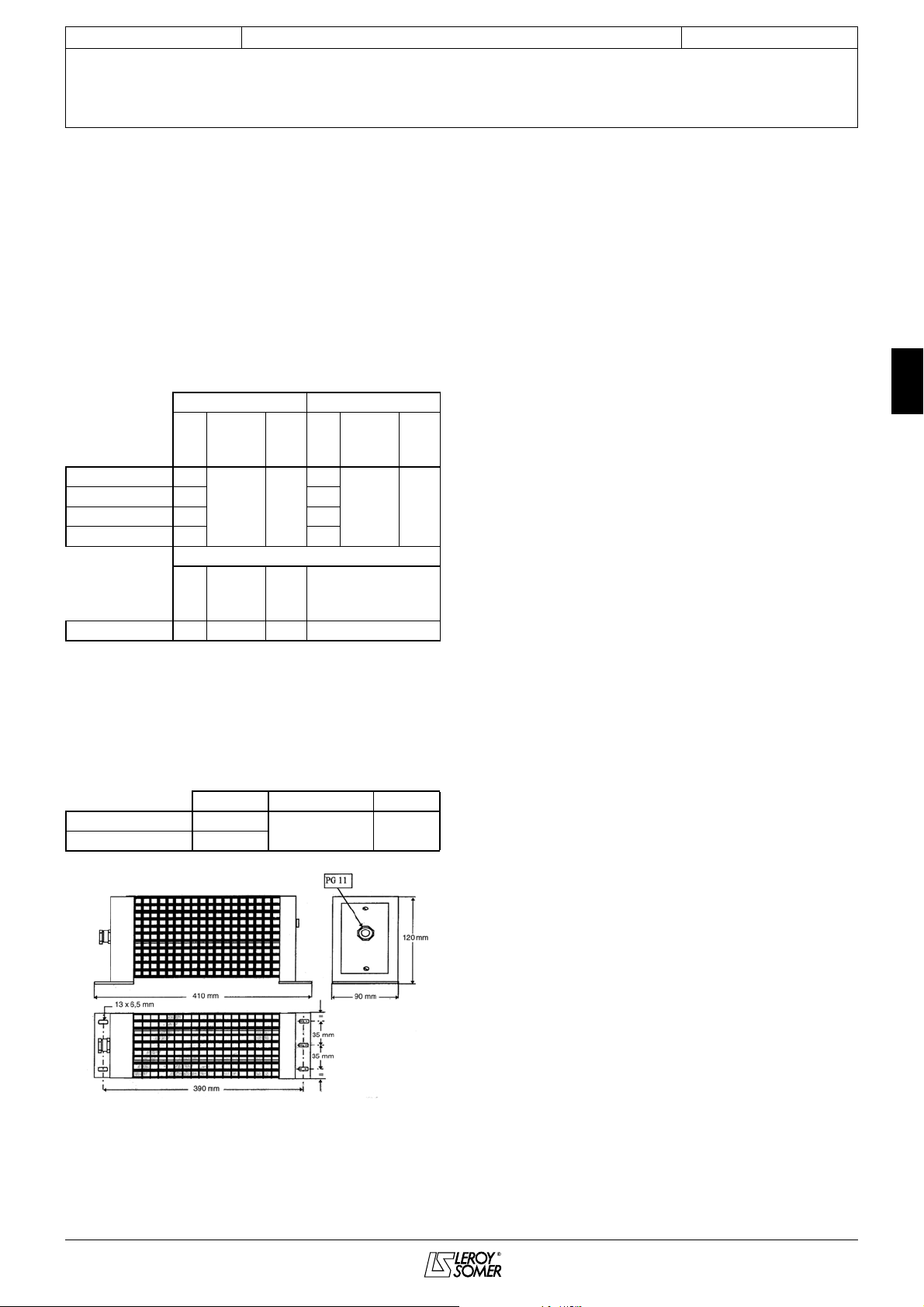

phase drive, connect

power supply

between L and N.

60

1

: 400/480V mains supply

2

: 230V mains supply

S06

1

+–

Brake

2

180VDC

Page 27

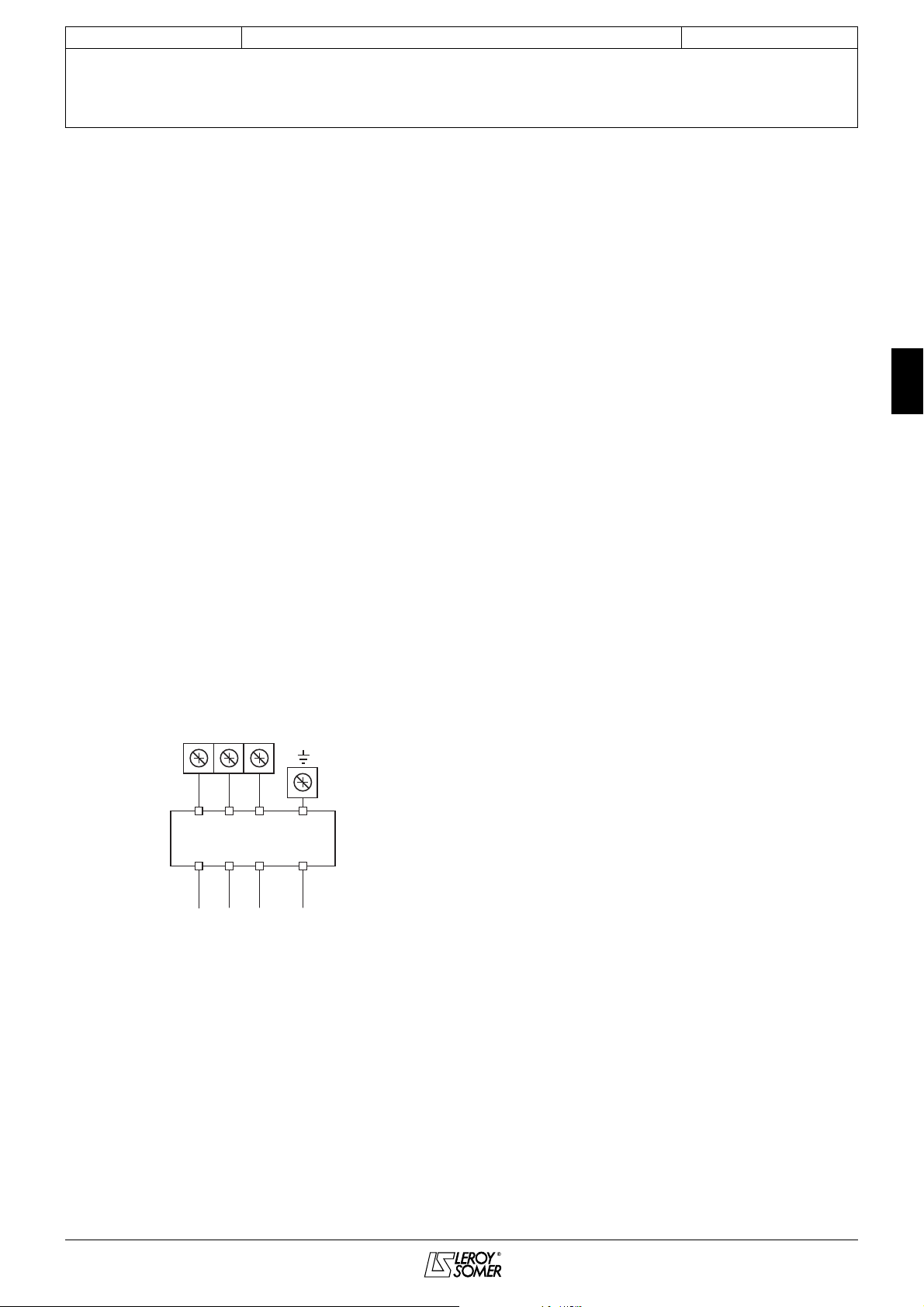

LEROY-SOMER

Opto Triac

Fu

Brake (p.58)

Dedicated logic output

AC power supply output

for a 2nd brake

1.25 A

600 V

L1

L3

F1

F2

Brake connection

on + and - terminals

Dedicated logic

output connection

Power supply on the

L1 and L3 terminals

F1 and F2 output

for a 2nd brake

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

CONNECTIONS

3.9.3 - Connection of the VMA ESFR 33/34 option

3776 en - 07.2007 / h

en

61

Page 28

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

COMMISSIONING

3776 en - 07.2007 / h

4 - COMMISSIONING

• Before switching on the VARMECA 30, check that

the electrical connections are correct, and that any

moving parts are mechanically protected.

• For the safety of personnel, the VARMECA 30 must not

be switched on with the protective cover removed.

4.1 - Starting with the power supply

Since the run command has been factory-enabled via a

jumper, the motor starts as soon as it is switched on.

The speed is adjusted with the local control knob (B 31/32 or

B 33/34 option) or a remote reference (0-10 V or 4-20 mA).

Power-up: the green indicator lamp is lit continuously.

The control terminals SDI1 and SDI2 (VMA 33/34) or 1 1 and

12 (VMA 31/32) are linked (unlocking).

4.1.1 - Automatic starting

By leaving the wire between control terminals 8 and 11 (VMA

31/32) or DI2 and +24V (VMA 33/34), the motor starts running

forward.

4.2 - Starting with remote volt-free

contact

Once it has been switched on, the motor starts in accordance

with the run command given by the closing of the vol t-free

contact corresponding to the desired direction of rotation.

The speed is adjusted with the local control knob (B 31/32 or

B 33/34 option) or a remote reference (0-10 V or 4-20 mA).

4.3 - Starting with local run/stop control

(BMA 31/32, BMA 33/34 or BMAVAR

31/32, BMAVAR 33/34 option)

Once it has been switched on, the motor starts after the

control knob corresponding to the desired direction of rotation

has been pressed for one second.

The speed is only adjusted with the local control knob.

4.4 - Setting the speed

4.4.1 - External reference

Adjust the speed reference using the chosen reference

(0/10 V or 4/20 mA).

4.4.2 - Control knob options (B 31/32 or B 33/34)

and remote potentiometer option

Adjust the speed reference using the control knob or the 10

kΩ remote potentiometer.

4.4.3 - Internal speed control option (CVI VMA

31/32 or CVI BMA 33/34)

Adjust the speed reference using the Int. Spd. potentiometer.

Adjust the Max. Spd. or Min. Spd. potentiometers if it is not

possible to reach the desired speed.

62

Page 29

LEROY-SOMER

INSTALLATION AND MAINTENANCE

3776 en - 07.2007 / h

VARMECA 30

Variable speed motor or geared motor

FAULTS-DIAGNOSTICS

5 - FAULTS-DIAGNOSTICS

Information relating to the status of the VARMECA 30 is provided by two indicator lamps located on the local control opti ons (B 31/

32 or B 33/34, BMA 31/32 or BMA 33/34, BMAVAR 31/32 or BMAVAR 33/34, CVI VMA 31/32 or CVI VMA 33/34 options), or by

the internal LED in VMA 31/32.

Colour and state of indic. lamp VARMECA status Checks to be performed

Steady green

Flashing green Current limiting

Flashing red

No trip

Mains present

IGBT temperature alarm

Motor overload

Braking resistor option overload

• Check that the motor is not

overloaded or stalled

• Check that air is able to circulate

around the motor fins and VARMECA

casing

• The motor is overloaded: check the

motor current using a clamp ammeter

• Check that the deceleration ramp is

long enough for applications with high

inertia

en

• Short-circuit of a motor winding

• Locked motor rotor

• Faulty insulation of a winding

Steady red

The fault is cleared by switching off the VARMECA 30 or by opening/closing the co nnection between terminals 12: ENA and 11: +24 V (VMA

31/32) or SDI1 and SDI2 (VMA 33/34).

6 - MAINTENANCE

• All work relating to installation, commissioning

and maintenance must be carried out by

experienced, qualified person nel.

• Before carrying out any work, disconnect an d lock the

VARMECA 30 power supply circuit and wait 2 minutes for

the capacitors to discharge.

6.1 - Care

No special care is required on the VARMECA 30, apart from the

regular removal of dust from the fan grille and the cooling fins

located at the bottom of the casing.

Do not dismantle the VARMECA 30 while it is still under

guarantee, as this would then imme diately become null and

void.

CAUTION:

Certain components which are sensitive to electrostatic

discharge may be destroyed simply by touching them.

Do not leave any metal object in the connection area, as this

could cause a short-circuit.

2

• I

t overheating

• Internal fault

• Undervoltage

• Overvoltage

The motor current IS NOT MEASURED ON THE VARMECA

30 POWER SUPPLY (L1, L2, L3).

It is measured using an ordinary clamp ammeter on one of the

wires which goes into the motor terminal block.

6.2.2 - Procedure for measuring the motor

current on VMA 31/32 (if the motor wire loop is

inaccessible)

- Open the VARMECA 30 power supply circuit and lock it.

- Wait 2 minutes for the capacitors to discharge (for the

single-phase range).

- Open the cover of the VARMECA 30.

- Open the connection between terminals SDI1 and SDI2

(VMA 33/34) or 11 and 12 (VMA 31/32).

- Remove the TORX + slot type screws from the protection

plate above the motor terminals.

- Pass the longest motor wire along the side of the protection

circuit.

- Replace the protection plate and fasten it.

- Pass the clamp ammeter through the motor wire loop.

- Remake the connection between terminals SDI1 and SDI2

(VMA 33/34) or 11 and 12 (VMA 31/32).

• Check that no incident has occurred

• Switch off and then on again to clear

the fault.

• Check the mains voltage

• Check that the deceleration ramp is

long enough for applications with high

inertia

• If the fault remains, consult LEROYSOMER

6.2 - Measurements

6.2.1 - General

The input voltages can be measured using ordinary

instruments.

63

Page 30

LEROY-SOMER

1

2

3

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

OPERATING EXTENSIONS

3776 en - 07.2007 / h

7 - OPERATING EXTENSIONS

7.1 - Speed control knob

option (B 31/32 or B 33/34)

The speed is set using a knob with graduations from 15 to

100%.

• With 2 indicator lamps.

• Connected on the P2 connector (VMA 31/32) or directly on

the control terminals (VMA 33/34)

7.2 - Control knob with integrated

run-stop control option

(BMA 31/32 or BMA 33/34)

In addition to speed control, a run button and a stop button

make it possible to control the VARMECA 30 locally, once it

has been switched on, as required. For a run command to be

taken into account, the button must be held down for one

second.

• With 2 indicator lamps.

• Connected on the P2 connector (VMA 31/32) or directly on

the control terminals (VMA 33/34).

• Do not wire the shunt between terminals 8-11 and/or 9-11

(VMA 31/32).

7.3 - Control knob with

forward/reverse/stop control option

(BMAVAR 31/32 or BMAVAR 33/34)

In addition to speed control, a forward button, a reverse

button and a stop button make it possible to control the

VARMECA 30 locally, once it has been switched on, as

required. For a run command to be taken into account, the

button must be held down for one second.

• With 2 indicator lamps.

• Connected on the P2 connector (VMA 31/32) or directly on

the control terminals (VMA 33/34).

• Do not wire the shunt between terminals 8-11 and/or 9-11

(VMA 31/32).

7.4 - Internal speed control option

(CVI VMA 31/32 or CVI VMA 33/34)

The speeds are set on potentiometers which are accessible

once the cover has been removed.

c Min.Spd potentiometer: calibration of the minimum speed.

d Int.Spd potentiometer: speed control which replaces

control via the control knob.

e Max.Spd potentiometer: calibration of the maximum speed.

There are also 2 indicator lamps.

Note: With this option, do not wire up terminal ADI1.

64

Page 31

LEROY-SOMER

INSTALLATION AND MAINTENANCE

VARMECA 30

Variable speed motor or geared motor

OPERATING EXTENSIONS

3776 en - 07.2007 / h

7.5 - IP 65 braking resistor option

(RF100 – RF200 – RF600)

For operation in 4 quadrants and energy dissipation, resistors

can be fixed directly onto the VARMECA casing. In this case,

the jumper between terminals FI and R- should be

removed (VMA 31 and 32).

RF 100 RF 200

P

P

peak

thermal

kW

VMA 31T/TL 3.2

VMA 31M 0.8 0.8

VMA 32T/TL 3.2 3.2

VMA 32M 0.8 0.8

RF 600

P

peak

thermal

kW

VMA 33/34T/TL

External resistors with greater thermal power can be used,

provided that the minimum ohmic value of 180 Ω (RF 100 –

RF 200) or 50 Ω (RF 600) is respected.

12.8 0.6 50

Value

kW

0.1 200

P

Value

kW

P

peak

Ω

kW

3.2

Ω

200 (2x100 in parallel)

P

thermal

kW

0.2

Value

Ω

200

(2x100

in

series)

7.7 - Power supply and

electromechanical brake control option

(SO VMA 31/32)

The motor must be fitted with an FCR brake adapted for the

VARMECA 31/32.

The brake has a built-in power supply. The brake is released

as soon as the run command is enabled. The brake is

engaged after a stop command, at the end of the deceleration

ramp or on disconnection of the power supply.

7.8 - Additional I/O interface and

sequential brake control option

(ESFR VMA 31/32)

The brake has a built-in power supply. The brake is controlled

according to a sequence which can be adjusted using the

VARMECA parameters.

7.9 - Additional I/O interface and

sequential brake control option

(ESFR VMA 33/34)

The brake has a built-in power supply. The brake is controlled

according to a sequence which can be adjusted using the

VARMECA parameters. See VARMECA 30 parametersetting manual.

en

7.6 - IP 20 external braking resistor

option (RF - BRR - 800 - 200)

P peak kW P thermal kW Ω value

VMA 31/32T-TL 3.2

VMA 31/32M 0.8

0.8 200

7.10 - Fieldbus options (not available

for VMA32 M)

The interface card is mounted inside the VARMECA casing.

Protocols supported:

PROFIBUS DP - INTERBUS S

DEVICENET - CAN OPEN

7.11 - Encoder feedback option

(COD VMA 33/34)

VMA33/34 only: Please contact Leroy-Somer.

65

Page 32

LEROY-SOMER

INSTALLATION AND MAINTENANCE