Page 1

MASOSINE PROCESS PUMPS MANUALS

m-maso-sps-gb-04

MasoSine Process Pumps

SPS sinusoidal pumps

Contents

1 Declaration of conformity 2

2 Declaration of incorporation 2

3 Warranty and liability 3

4 When you unpack your pump 4

5 Information for returning pumps 5

6 Sinusoidal pumps—an overview 5

7 Safety notes 6

7.1 Obligation of the operating

organisation 6

7.2 Organisational measures 6

7.3 Obligation of the operators 7

7.4 Personnel training 7

7.5 Safety measures 7

7.6 Dangers when handling the

machine 7

7.7 Safety measures in normal

operation 8

7.8 Protective devices 8

7.9 Dangers due to hazardous

pumped material 8

7.10 Dangers due to electrical

energy 8

7.11 Dangers due to hydraulic

energy 9

7.12 Special danger points 9

7.13 Constructional changes to

the machine 9

7.14 Noise 9

7.15 Limit values for the pump 10

7.16 Maintenance and repair 10

7.17 Cleaning the pump 12

7.18 Faults 12

7.19 Use as intended 13

8 Safety notes (ATEX) 13

8.1 Safety signs 13

8.2 Earthing the pump 14

8.3 Material properties 14

8.4 Pressure conditions 14

8.5 Maintenance and repair 14

8.6 Cleaning the pump 15

8.7 Medium to be pumped 15

8.8 Coupling 15

8.9 Drive 15

9 Pump specifications 15

9.1 Dimensions (in millimetres) 16

10 Transport 22

11 Installation 22

12 Connection to the piping 23

12.1 Cavitation 24

13 Possible pump orientations 25

13.1 Changing pump orientation 25

13.2 Changing rotation direction 26

14 Connecting this product

to a power supply 27

15 Start-up and operation 27

16 Flushing the seal system 28

16.1 Static flushing device 28

17 Cleaning and sterilisation 29

18 Heating and cooling option 31

19 Oil change 32

20 Troubleshooting 33

21 SPS 200, SPS 300 and SPS 400:

Adjusting the shaft 35

21.1 Adjusting dimension X in

models with cast power

frame 35

21.2 Adjusting dimension X

in models with stainless

steel power frame 37

22 Dismantling and assembly 39

22.1 Dismantling all models 39

22.2 Dismantling and

assembling the SPS 100 39

22.2.1 Dismantling the SPS 100 39

22.2.2 Assembling the SPS 100 47

22.3 Dismantling and assembling

the SPS 200 53

22.3.1 Dismantling the SPS 200 53

22.3.2 Assembling the SPS 200 66

22.4 Dismantling and assembling

the SPS 250, SPS 300,

SPS 400 and SPS 500 79

22.4.1 Dismantling the SPS 300

and SPS 400 79

22.4.2 Assembling the SPS 250,

SPS 300, SPS 400 and SPS 500 88

23 The static flushing device 96

24 Tightening torques 102

25 Parts lists 104

25.1 Pumps 105

25.2 Seals 123

25.3 Front support versions 133

25.4 The flushing ring for tubing 138

25.5 The static flushing device 139

26 Decontamination certificate 142

27 Trademarks 143

28 Publication history 143

MasoSine SPS sinusoidal pumps User Manual 1

Page 2

1 Declaration of conformity

This pump complies with: Machinery Directive 2006/42/EC.

2 Declaration of incorporation

When this pump unit is to be installed into a machine or is to be assembled with

other machines for installations, it must not be put into service until the relevant

machinery has been declared in conformity with the Machinery Directive 2006/42/

EC. See 9 Pump specifications.

Responsible person: Ulrich Fromm, General Manager, MasoSine,

Postfach 100, 74358 Ilsfeld, Germany.

Telephone: +49 (0)7062 95600. Fax: +49 (0)7062 64593.

The information in this user guide is believed to be correct at the time

of publication. However, MasoSine Process Pumps accepts no liability for errors or

omissions. MasoSine Process Pumps has a policy of continuous product improvement,

and reserves the right to alter specifications without notice. This manual is intended

for use only with the pump it was issued with. Earlier or later models may differ. The

most up-to-date manuals appear on the MasoSine website:

http://www.masosine.de

MasoSine SPS sinusoidal pumps User Manual 2

Page 3

3 Warranty and liability

MasoSine warrants, subject to the conditions and exceptions below, through either

MasoSine, its subsidiaries, or its authorised distributors, to repair or replace free of

charge the pump housing or the pump front cover if it fails within 20 years of the

day of manufacture of the product. MasoSine warrants, subject to the conditions

and exceptions below, through either MasoSine, its subsidiaries, or its authorised

distributors, to repair or replace free of charge any other part of the product which

fails within three years of the day of manufacture of the product. Such failure must

have occurred because of defect in material or workmanship and not as a result of

operation of the product other than in normal operation as defined in this manual.

MasoSine will not be liable for any loss, damage, or expense directly or indirectly

related to or arising out of the use of its products, including damage or injury caused

to other products, machinery, buildings, or property, and MasoSine will not be liable

for consequential damages, including, without limitation, lost profits, loss of time,

inconvenience, loss of product being pumped, and loss of production. This warranty

does not obligate MasoSine to bear any costs of removal, installation, transportation, or other charges which may arise in connection with a warranty claim.

Specific exceptions to the above warranty are:

Exceptions

Warranty and liability claims for personal and material damage are excluded if

they are attributable to one or several of the following causes:

l

Use of the machine not as intended

l Incorrect installation, operation or maintenance of the machine

l Operating the machine with defective safety devices or safety and protective

devices not correctly attached or not functioning

l

Non-compliance with the operating instructions regarding transport, storage,

installation, start-up, operation, maintenance and setting of the machine.

l

Unauthorised constructional changes to the machine

l Insufficient monitoring of machine parts subject to wear

l Incorrectly performed repairs

l Catastrophe due to the effect of foreign bodies and acts of God

MasoSine grants no implicit warranties on the suitability of the products described

for a certain application. Watson-Marlow MasoSine accepts no liability for errors

contained in this documentation or consequential damage occurring due to the

design, performance and the use of this documentation.

MasoSine’s “General sales and delivery conditions” contain full details. These are

available to the purchaser at the latest when the purchase contract is finalised.

MasoSine SPS sinusoidal pumps User Manual 3

Page 4

4 When you unpack your pump

Unpack all parts carefully, retaining the packaging until you are sure all components

are present and in good order. Check against the components supplied lists, below.

Packaging disposal

Dispose of packaging materials safely, and in accordance with regulations in your

region.

Inspection

Check that all components are present. Inspect components for damage in transit.

If anything is missing or damaged, contact your distributor immediately.

Components supplied (SPS 100, SPS 200, SPS 250, SPS 300,

SPS 400 and SPS 500)

l SPS 100, SPS 200,

SPS 300 or SPS

400 sinusoidal

pump, bare-shaft,

with stainless steel

or cast iron power

frame

lThe technical data-

sheet identifying,

describing and

defining the pump

lOperating

instructions

SPS 100

SPS 200

SPS 250

SPS 300

stainless

power frame

cast iron

power frame

n/a

n/a

Optional items

l

Coupling

lCoupling guard

l

Drive

lBaseplate

SPS 400

Optional special

design

lFlush systems

l

Guard Master

lJacketing for heating

and cooling

MasoSine SPS sinusoidal pumps User Manual 4

SPS 500

n/a

Page 5

Storage

This product has an extended shelf life. However, plastic parts and elastomeric

parts should be stored in a cool, dry environment. The blue polyamide gate should

be stored in cool, clean water if it will be out of use for more than four weeks. Care

should be taken after storage to ensure that all parts function correctly.

5 Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic

chemicals or any other substance hazardous to health must be decontaminated

before it is returned to MasoSine or its distributor.

A certificate included at the rear of these operating instructions, or signed statement, must be attached to the outside of the shipping carton. This certificate is

required even if the pump is unused. See 28 Decontamination certificate.

If the pump has been used, the fluids that have been in contact with the pump and

the cleaning procedure must be specified along with a statement that the equipment

has been decontaminated.

If a returned pump requires cleaning, a charge will be made. Internal parts that have

not been decontaminated will be replaced and a charge will be made.

6 Sinusoidal pumps—an overview

The functioning principle of MasoSine pumps is ingeniously simple.

The pump consists of modular components.

The sinusoidal rotor creates a chamber within the pump body four times per revolu-

tion, in which the pumped fluid is displaced. As a filled chamber rotates, it contracts,

closes and discharges its contents. At the same time, the opposite chamber opens

by the same fraction of a millimetre to draw in more fluid. The result is a pump free

of pulsation.

The gate works as a seal between the pressure side and the suction side of the

pump. It prevents an equalization of the pressure created by the rotor, stopping it

escaping to the suction side.

MasoSine SPS sinusoidal pumps User Manual 5

Page 6

7 Safety notes

Knowledge of these safety instructions and of the safety regulations in your area is

a requirement for safe handling and trouble-free operation of this machine.

These operating instructions contain the most important instructions to operate the

machine safely. These operating instructions, especially the safety instructions, must

be observed by all persons who work on the machine. In addition, the rules and

regulations for accident prevention applicable at the place of use must be obeyed.

The following safety instructions must be observed absolutely. They are an essential and indispensable part of the user documentation. Non-compliance can result in

failure of warranty claims.

It is recommended in the interests of all involved to enter all installation measures,

maintenance, fault and repair cases, training courses, instructions and special occurrences in a logbook assigned to the machine.

This symbol highlights a safety instruction which must

be followed to avoid danger to people or to the pump.

This symbol means: Beware of high voltage.

7.1 Obligation of the operating

organisation

The operating organisation must ensure that people who work on the machine

are familiar with and comply with the regulations concerning working safety and

accident prevention.

7.2 Organisational measures

The personal protective equipment required must be provided by the operating

organisation. Safety devices must be checked regularly.

MasoSine SPS sinusoidal pumps User Manual 6

Page 7

7.3 Obligation of the operators

People who work on the machine must observe the relevant safety regulations concerning working safety and accident prevention before starting work; must read the

safety chapter and the warning notes in these operating instructions.

7.4 Personnel training

Only trained people may work on the machine. Their responsibilities must be defined

clearly for assembly, start-up, operation, setting, maintenance and repairing.

7.5 Safety measures

The operating instructions must be kept with the machine. General and local regulations for accident prevention and environmental protection, and the operating

instructions, must be observed. Safety and danger warnings on the machine must

be legible.

7.6 Dangers when handling the machine

The MasoSine pump is built according to state-of-the-art principles and the recognised safety engineering rules. Nevertheless, danger to life and limb of the user or

third persons, or impairments to the machine or to other assets, can arise in its use.

The machine must be used only:

l

for its intended use

l if it is in a safe engineering condition.

Faults which can impede safety must be rectified immediately.

MasoSine SPS sinusoidal pumps User Manual 7

Page 8

7.7 Safety measures in normal operation

Operate the machine only if all protective devices are functioning. Before switching

the machine on make sure that no one can be endangered when the machine starts.

At least once per shift inspect the machine for damage and for proper functioning

of the safety devices.

7.8 Protective devices

All protective devices must be attached correctly and functioning before every startup. Protective devices may be removed only after the machine has stopped and

protection measures against restarting the machine have been taken.

After spare parts have been fitted, protective devices must be attached according to

the operating organisation’s regulations.

If contact with hot or cold machine parts could be dangerous, protection must be

provided for the pump user.

7.9 Dangers due to hazardous pumped

material

If hazardous material is to be pumped, the appropriate regulations must be observed.

7.10 Dangers due to electrical energy

Work on the electrical supply must be performed only by an electrician.

Check the electrical equipment of the machine regularly. Rectify

loose connections and scorched cables immediately.

Keep the control cabinet locked closed or secured with a tool. Access is allowed only

to authorised personnel.

If work on parts conducting voltage must be done, call in a second person to switch

off the mains power if necessary.

Electrical connection of the pump must be made according to local regulations, by

skilled personnel only.

MasoSine SPS sinusoidal pumps User Manual 8

Page 9

7.11 Dangers due to hydraulic energy

Only personnel with special knowledge and experience in hydraulics may work on

hydraulic devices.

Relieve the pressure in the system sections and pressure lines to be opened before

starting repair work.

Replace hydraulic hose lines at appropriate intervals, even if no safety-relevant

defects are detectable.

7.12 Special danger points

The pump contains a rotating rotor,

which can crush or sever fingers and

hands. The pump must be guarded so

that it is not possible for people to hold the

pump by its inlet or delivery ports with the

rotor running. When the rotor is stationary,

the drive must be secured against unintentional start-up. Increased danger exists if

pipes are dismantled or the pump is open.

7

7.13 Constructional changes to the

machine

Make no changes, attachments or conversions to the machine without the manufacturer’s approval. All conversion measures require the written confirmation of

Watson-Marlow MasoSine.

Replace machine parts which are not in perfect condition immediately. Use only original spare and wearing parts. Parts not obtained from MasoSine are not guaranteed

to be designed and manufactured in compliance with load and safety requirements.

The warranty is invalid if genuine spare parts from MasoSine are not used.

7.14 Noise

The continuous sound pressure level proceeding from the machine should not

exceed 70 dB(A). Higher sound pressure levels that can cause deafness can arise,

depending upon local conditions. If this occurs, protect the operating personnel with

appropriate protective equipment / protective measures.

MasoSine SPS sinusoidal pumps User Manual 9

Page 10

7.15 Limit values for the pump

The pump’s maximum speed, maximum pressure and maximum temperature are

included in the technical data sheet supplied with each pump. These limit values

must not be exceeded in any circumstances. This applies in particular when using a

frequency converter.

If pump is supplied without a drive, the following values apply:

SPS 100 SPS 200 SPS 250 SPS 300 SPS 400 SPS 500

Maximum

pressure *

Maximum

speed *

Maximum

temperature *

10 bar 10 bar 15 bar 15 bar 15 bar 15 bar

1,000 rpm1,000 rpm 800 rpm 600 rpm 600 rpm 600 rpm

100°C 100°C 100°C 100°C 100°C 100°C

Ambient

temperature

* These limits may be lower, depending on the drive, the application and the rating

of the pump. (See your purchase order confirmation, or contact MasoSine and give

your pump’s serial number.) On customer request, higher pressures are possible.

-12°C to

+40°C

-12°C to

+40°C

-12°C to

+40°C

-12°C to

+40°C

-12°C to

+40°C

-12°C to

+40°C

7.16 Maintenance and repair

Inform operating personnel before starting maintenance and repair work. Protect all

plant parts and operating media connected before and after the machine, such as

compressed air and hydraulics, against unintentional start-up. In all maintenance,

inspection and repair work, switch the machine off and secure the main switch

against unintentional start-up.

Secure larger assemblies carefully to lifting gear. Check loosened screw connections

for firm seating. Use only original spare parts.

After maintenance work is finished, check the safety devices for

function.

MasoSine SPS sinusoidal pumps User Manual 10

Page 11

Bearings maintenance

l

The bearings of SPS 100 pumps must be renewed after running for the periods

shown in the table below.

200 rpm 400 rpm 600 rpm 800 rpm 1,000 rpm

5 bar 10,000 hours 10,000 hours 6,986 hours 5,239 hours 4,191 hours

10 bar 2,079 hours 1,040 hours 693 hours 520 hours 416 hours

l We recommend renewing the bearings of SPS 200 pumps with cast iron

power frames after running for 10,000 hours at any pressure.

l

We recommend renewing the bearings of SPS 200 pumps with stainless steel

power frames after running for the periods shown in the table below.

200 rpm 400 rpm 600 rpm 1,000 rpm

5 bar 10,000 hours 10,000 hours 10,000 hours 10,000 hours

10 bar 10,000 hours 10,000 hours 10,000 hours 6,260 hours

l We recommend renewing the bearings of SPS 250 pumps with stainless steel

power frames after running for the periods shown in the table below.

200 rpm 400 rpm 600 rpm 800 rpm

5 bar 10,000 hours 10,000 hours 10,000 hours 10,000 hours

10 bar 10,000 hours 10,000 hours 10,000 hours 10,000 hours

15 bar 10,000 hours 10,000 hours 10,000 hours 10,000 hours

l

We recommend renewing the bearings of SPS 300 pumps with cast iron or

stainless steel power frames after running for 10,000 hours at any pressure.

We recommend renewing the bearings of SPS 400 pumps’ with cast iron

l

power frames after running for the periods shown in the table below.

200 rpm 400 rpm 600 rpm

5 bar 10,000 hours 10,000 hours 10,000 hours

10 bar 10,000 hours 10,000 hours 10,000 hours

15 bar 10,000 hours 7 ,689 hours 5,126 hours

We recommend renewing the bearings of SPS 400 pumps with stainless steel

l

power frames after running for the periods shown in the table below.

200 rpm 400 rpm 600 rpm

5 bar 10,000 hours 10,000 hours 10,000 hours

10 bar 10,000 hours 10,000 hours 10,000 hours

15 bar 10,000 hours 7,210 hours 4,800 hours

l We recommend renewing the bearings of SPS 500 pumps with stainless steel

power frames after running for the periods shown in the table below.

200 rpm 400 rpm 600 rpm

5 bar 10,000 hours 10,000 hours 10,000 hours

10 bar 10,000 hours 10,000 hours 10,000 hours

15 bar 10,000 hours 10,000 hours 7,500 hours

MasoSine SPS sinusoidal pumps User Manual 11

Page 12

Note: Remove the bearing housing of SPS 200, SPS 300 and SPS 400 models

only to replace or adjust the shim ring (see 21 Adjusting the shaft). Do not

attempt to dismantle the power end of the pump or replace the bearings.

Pumps needing repair, servicing, new bearings or other work on the power

end must be returned to MasoSine for attention. Special training is available

for users of SPS 200, SPS 300 and SPS 400 models. Please contact MasoSine

for further information.

7.17 Cleaning the pump

Handle substances and materials used correctly, especially when working on

lubricating systems and when cleaning with solvents. For information on cleaning

the parts in contact with the pumped fluid, see 17 Cleaning.

7.18 Faults

If an operating fault occurs, switch off the machine and secure it against unintentional

start-up.

MasoSine SPS sinusoidal pumps User Manual 12

Page 13

7.19 Use as intended

The intended use of this product is listed in the order confirmation. The product

should not be put to a different use or a use going beyond the use described.

Consult MasoSine if you wish to change the product, its pressure, speed or operating temperature.

8 Safety notes (ATEX)

If your MasoSine pump is to be used in production machinery in potentially explosive

atmospheres, it will be equipped accordingly from the factory.

8.1 Safety signs

II 2 G c T4

Grounding symbol

Pump classification

MasoSine pumps are designed for continuous duty and are therefore assigned to the

Device Group II – Application field “dust – or gas – explosive areas”.

Zone classification

MasoSine pumps can be used in explosive areas of zone 1 / 21. This corresponds to

the category 2 G / D.

It is expressly forbidden to use the pumps in zone 0.

Classification of explosive atmospheres

A distinction is made between dust and gas explosive atmospheres. In the model

code, the atmosphere is abbreviated with G (Gas) and D (Dust). MasoSine pumps

are designed to be used in explosive atmospheres G (Gas) and D (Dust).

Ignition protection

II 2 D c T = 120C

MasoSine pumps pumps are subject to ignition protection “c” constructive safety,

according to the standard for non-electric appliances for use in explosion-risk areas,

EN 13463-5.

Temperature classes

l EX II 2 G c T4 ≥ 135C

l

EX II 2 D c T = 120C

MasoSine SPS sinusoidal pumps User Manual 13

Page 14

8.2 Earthing the pump

SPS pumps are equipped with an earthing point.

The pump must be earthed by an earthing cable

secured to the correct position. SPS 100 must

be earthed at the base of the rear foot. Other

models must be earthed as shown: with cast iron

power frame, right; with stainless steel power

frame, below right. This is particularly important in

potentially explosive atmospheres.

In addition to earthing the pump, the

drive motor must also be earthed. If the

drive is not earthed,

the pump unit may not

be operated.

8.3 Material properties

The plastic parts fitted inside the pump react more to temperature changes than

stainless steel parts. For this reason, the specified maximum fluid temperature for

which the pump is designed must not be exceeded. This temperature is included in

your purchase documents. If the specified temperature is exceeded, linear expansion may block the pump; this in turn could cause the pump to fail or could result

in damage to parts of the pump. In addition, excessive temperatures can accelerate

the wear of dynamic parts and reduce the life of plastic parts.

Corrosion may occur to a pump’s cast iron power frame if the paintwork is damaged.

Corrosion represents a hazard for the use of pumps in potentially explosive

atmospheres (for measures, see 20 Troubleshooting).

Pumps with a stainless steel power frame are not subject to power frame corrosion.

8.4 Pressure conditions

A pressure controller must be installed to avoid over-pressure in the pump as a

result of a closed pressure line.

8.5 Maintenance and repair

l Fill the pump with product before starting only outside the explosive atmos-

phere area. All tools used should comply with ATEX regulations.

l

The pump unit must be kept free of dust with a damp cloth: accumulated dust

can smoulder.

l

The flushing channels in the power frame must be free of blockages and, if

necessary, cleaned.

MasoSine SPS sinusoidal pumps User Manual 14

Page 15

8.6 Cleaning the pump

No solvent cleaning agents may be used to clean the pump as they

could create an uncontrollable explosive atmosphere.

8.7 Medium to be pumped

Carbon disulphide and chemicals that are combustible below 120C must not be

pumped.

8.8 Coupling

If the pump is used in potentially explosive atmospheres, it must be coupled to the

drive by means of an elastic, positive coupling with ATEX certification for use with

the pump. Chains, toothed belts, V-belts or similar equipment which may transmit

radial forces to the bearings should not be used.

8.9 Drive

Any reduction gears in the drive chain and control units must be ATEX-certified for

use with the pump. Combustion engines must never be used.

An inverter must be installed away from potentially explosive atmospheres, or have

the same ATEX certification as the pump. In any case the inverter must have the

properties required for operation in potentially explosive atmospheres: temperature

monitoring, speed limitation, etc.

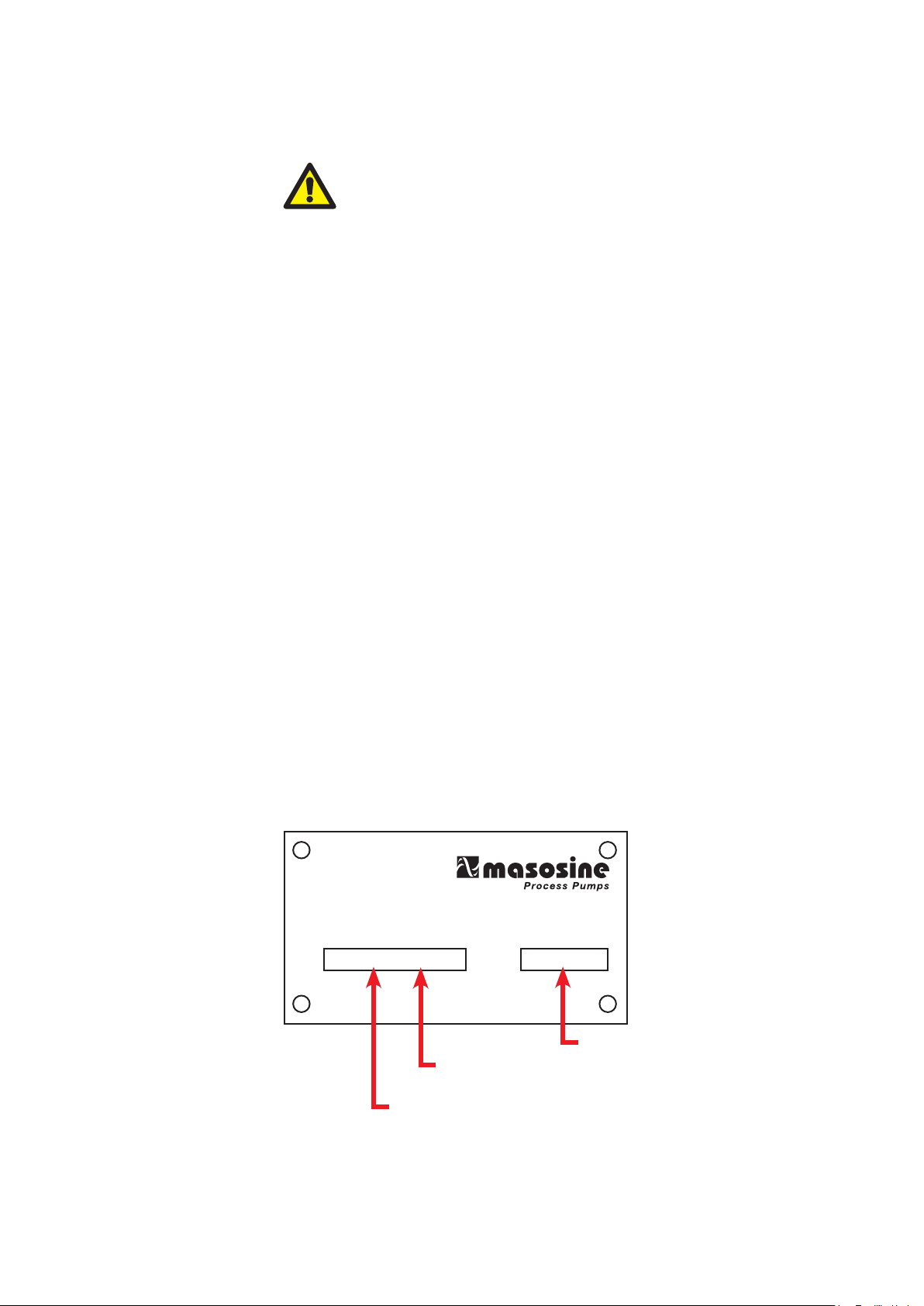

9 Pump specifications

Your pump carries a type plate on the bearing housing. It includes a serial

number, which identifies the features of the product. The serial number also

appears on the technical data sheet.

MasoSine Process Pumps, 74360 Ilsfeld, Germany

s/n.

133777 0807 SPS 200

month / year of manufacture

(eg August 2007)

serial number

Typ

model

MasoSine SPS sinusoidal pumps User Manual 15

Page 16

Standards

Relevant EC

directives

EC

harmonised

standards

2006/42/EC: EC Machinery Directive

73/23/EEC: EC Low Voltage Directive

2004/108/EC: EMC Directives

97/23/EG: Pressure Equipment Directive

Safety of machinery—electrical equipment of machines:

EN 60204-1

EN ISO 12100, 1-2 : Safety of machinery

For ATEX: EN 1127-1: Explosive atmospheres—

Explosion prevention and protection Part 1

For ATEX: EN 13463-1: Non-electrical equipment

for use in potentially explosive atmospheres Part 1

For ATEX: EN 13463-5: Non-electrical equipment

for use in potentially explosive atmospheres Part 5

EN 809: Pumps and pump units for liquids—

Common safety requirements

National technical standards,

guidelines and

specifications

DIN 31000/A1: General principles for the safe design of

technical products (Amendment 1)

DIN 11850: Pipes made of stainless steel for food and

DIN 11851: Stainless steel fittings for the food and chemical

industry - Screw pipe connections for expanding and welding

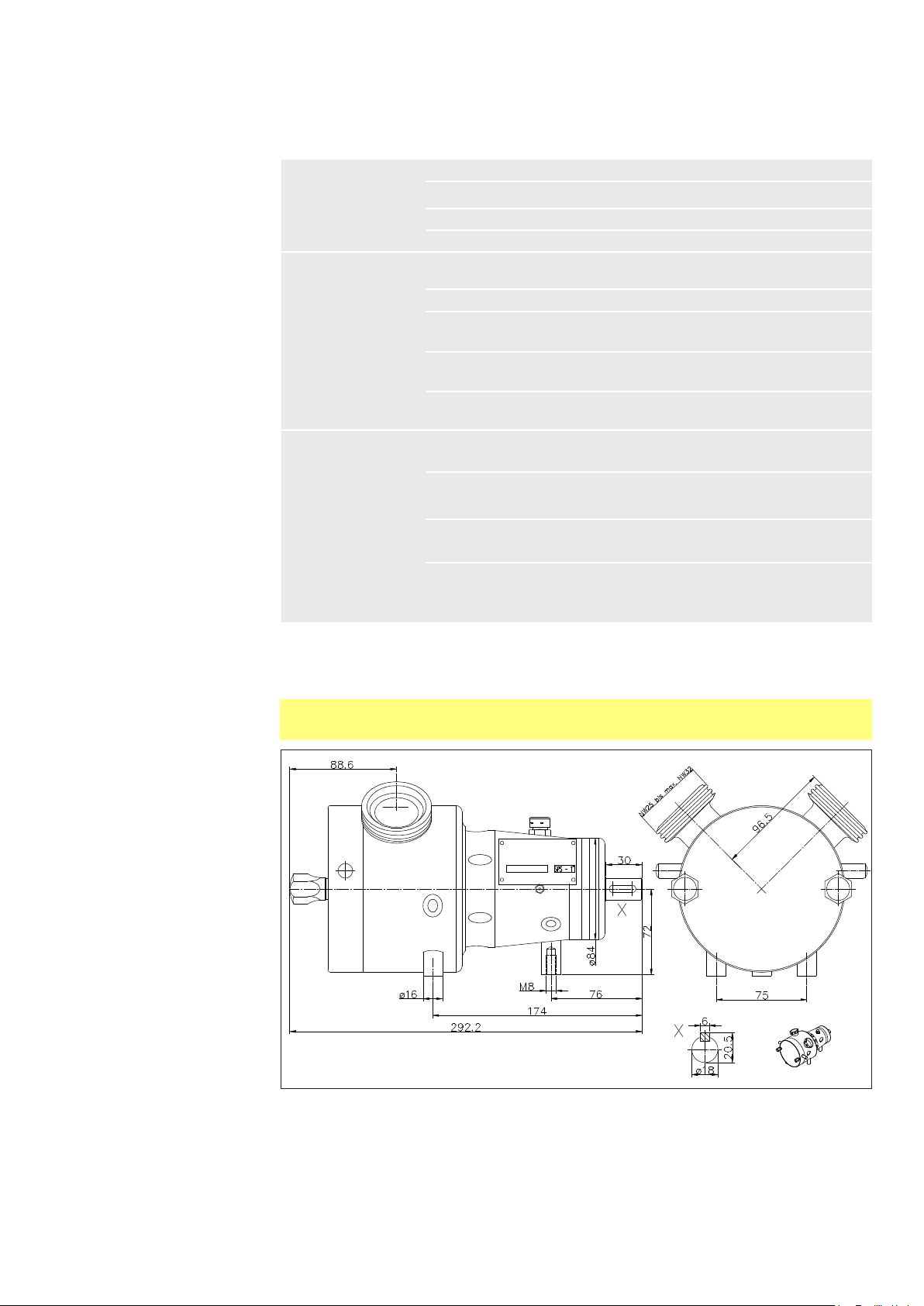

9.1 Dimensions (in millimetres)

SPS 100

chemical industries

MasoSine SPS sinusoidal pumps User Manual 16

Page 17

SPS 200 pumps, dimensions

Cast iron power frame

Stainless steel power frame

All critical dimensions of old and new power frame designs are the same,

including mounting bolt holes. Both designs are interchangeable

MasoSine SPS sinusoidal pumps User Manual 17

Page 18

SPS 250 pumps, dimensions

Stainless steel power frame

MasoSine SPS sinusoidal pumps User Manual 18

Page 19

SPS 300 pumps, dimensions

Cast iron power frame

Stainless steel power frame

All critical dimensions of old and new power frame designs are the same,

including mounting bolt holes. Both designs are interchangeable

MasoSine SPS sinusoidal pumps User Manual 19

Page 20

SPS 400 pumps, dimensions

Cast iron power frame

Stainless steel power frame

All critical dimensions of old and new power frame designs are the same,

including mounting bolt holes. Both designs are interchangeable

MasoSine SPS sinusoidal pumps User Manual 20

Page 21

SPS 500 pumps, dimensions

Stainless steel power frame

Unit weights

Pump weight,

cast power frame

SPS 100 17.00kg 37lb 8oz Part no: KK-... 13.00kg 28lb 11oz

SPS 200 23.00kg 50lb 11oz 20.00kg 44lb 1oz Part no: KK-... 13.00kg 28lb 11oz

SPS 250 39.00kg 86lb Part no: KK-... 13.00kg 28lb 11oz

SPS 300 80.00kg 176lb 6oz 68.00kg 149lb 15oz Part no: KM-... 19.00kg 41lb 14oz

SPS 400 160.00kg 352lb 12oz 125.00kg 275lb 9oz Part no: KG-... 31.00kg 68lb 5oz

SPS 500 171.00kg 377lb Part no: KG-... 31.00kg 68lb 5oz

Pump weight,

stainless steel

power frame

Weight of standard baseplate

MasoSine SPS sinusoidal pumps User Manual 21

Page 22

10 Transport

Choose the means of transport according to the size of the pump and the drive. The

pump must be suspended correctly for transport. If using a crane or a fork-lift truck,

the ropes or belts must be sufficiently dimensioned. If the pump is transported with

a lift truck or a fork-lift truck, note that the unit’s centre point is not necessarily the

centre of gravity.

7

11 Installation

The motor shaft and pump shaft connection must be guarded to protect the

user from contact.

7

7

3

3

7

l Place the pump on a level surface.

l Do not start the pump without a guard to protect the user from contact.

l The mounting surface should be strong enough to support the pump.

l There should be sufficient space for maintenance work around the pump.

l The motor must receive an adequate air supply.

l If the pump is used in potentially explosive atmospheres, an Ex-protected

motor must be used. Contact the manufacturers for assistance.

l

The unit must be protected against static charge.

MasoSine SPS sinusoidal pumps User Manual 22

3

Page 23

180°

7

l Align the pump shaft with the drive shaft.

12 Connection to the piping

Before connection, clean the piping and remove foreign bodies such as welding residues.

Fit elastic intermediate members (compensators) between pump and fixed

piping on the suction and pressure sides, to stop pump vibrations being

transmitted to the piping system.

Avoid forces and torques acting from the piping on the pump connections

(e.g. distortion, expansion due to temperatures etc.).

The piping on the pressure side of the pump should run upwards from the

pump, so that residual liquid can flow back into the pump when pumping

stops, and total dry running is avoided. Fluid left in the pump facilitates suction when pumping re-starts.

The user must ensure that a pressure rise above the pressure agreed in the

purchase order and listed in the technical data sheet is not possible.

3

MasoSine pumps normally run with such a low resonant frequency that no

damage results. However, particularly when running with inverters, certain

frequencies can cause inter ference vibrations which must be avoided. It is

important during commissioning to ascertain whether such vibrations exist

and to define them, so that the inverter can be programmed to avoid these frequencies. Similarly, interference from cavitation or rigid lines must be avoided. See 12.1

Cavitation.

MasoSine SPS sinusoidal pumps User Manual 23

Page 24

12.1 Cavitation

Cavitation is a problem in certain devices where fluid interacts with a moving surface. It can occasionally occur in sinusoidal pumps.

Where a surface moves through a fluid, low pressure areas are formed on the surface. The faster the surface moves, the lower the pressure around it can become.

If the static pressure of the liquid falls below its vapour pressure, vapour bubbles

form on the pressure side. These implode, causing very high, short-term pressure

peaks up to several thousand bar. These pressure peaks can cause material erosion

and are noisy.

To identify cavitation

If the pump is very noisy and vibrates vigorously, along with the pipe system

attached to the pump, cavitation is likely to be the cause.

To avoid or remove cavitation

Increasing the inlet pressure on the suction side, installing a larger diameter or

shorter inlet pipe or slowing the pump may solve the problem. Make sure that the

pump is not starved of duty fluid at all times.

Cavitation can destroy the pump. The operator must

ensure that the pump can work free of cavitation.

MasoSine SPS sinusoidal pumps User Manual 24

Page 25

13 Possible pump orientations

The pump can be positioned in three orientations, and rotate clockwise or counterclockwise.

9-12 12-910-2 12-3 3-122-10

Counter-clockwise rotation

of the rotor and motor

Unless ordered otherwise, the pump is delivered in position 2-10. Special

customised nozzle orientations are possible.

13.1 Changing the pump orientation

Disconnect the pump from the mains power, and secure it against

unintentional start-up.

SPS 100

Clockwise rotation

of the rotor and motor

l Turn the pump on to its side to

allow access to the baseplate securing

bolts.

l

Remove the three bolts and

washers using a 13mm spanner. As each

bolt is withdrawn, a spacer between the

baseplate and the pump will fall out.

l

Three sets of threaded fixing points

are provided on the pump; the central

set (pictured in use above) allows the

inlet and outlet ports to be positioned

at 10-2 or 2-10; the other sets (one fixing point arrowed) allow the pump to be

positioned with the inlet or outlet horizontal and the other port vertical.

l

Pass the bolts with washers through the baseplate and the spacers (Note: the

longer bolt and the longer spacer secure the baseplate to the bearing

housing at the rear of the pump). Screw the bolts into the set of fixing points

appropriate for the desired pump orientation. Tighten to 25Nm using a 13mm

spanner.

SPS 200, SPS 250 SPS 300, SPS 400, SPS 500

l

Follow the dismantling and assembly steps for your pump model. See 22

Dismantling and assembly

l

Remove the screws on the power frame. Turn the housing by an angle of 45°

to the left or right.

l

Refit the screws in their new position and tighten them to the correct torque:

SPS 200: 16 Nm SPS 250: 16 Nm SPS 300: 33 Nm SPS 400: 56 Nm SPS 500: 56 Nm

Note: If the direction of flow is also changed, the gate and gate guide must be

reversed. See 13.2 Changing rotation direction.

MasoSine SPS sinusoidal pumps User Manual 25

Page 26

Take care that fluid in the pressure line leaves the pump in an upward direction, so

that when pumping stops, some fluid remains in the pump. This will make it easier

for the pump to draw in viscous products when pumping restarts. This applies

particularly when the pressure connection is horizontal: positions 12-3 and 12-9.

Take care that the pressure line is run so that the pump rotor is always covered with

fluid, and dry running is avoided.

13.2 Changing rotation direction

When the direction of rotor rotation is reversed, the suction side and the pressure

side of the pump are exchanged. The orientation of the gate and the gate guide

must be changed, too, or the pump cannot pump efficiently. The pump can run for

only a short time with the gate and the gate guide wrongly oriented, and it

will not achieve more than 2 bar pressure. See 22 Dismantling and assembly.

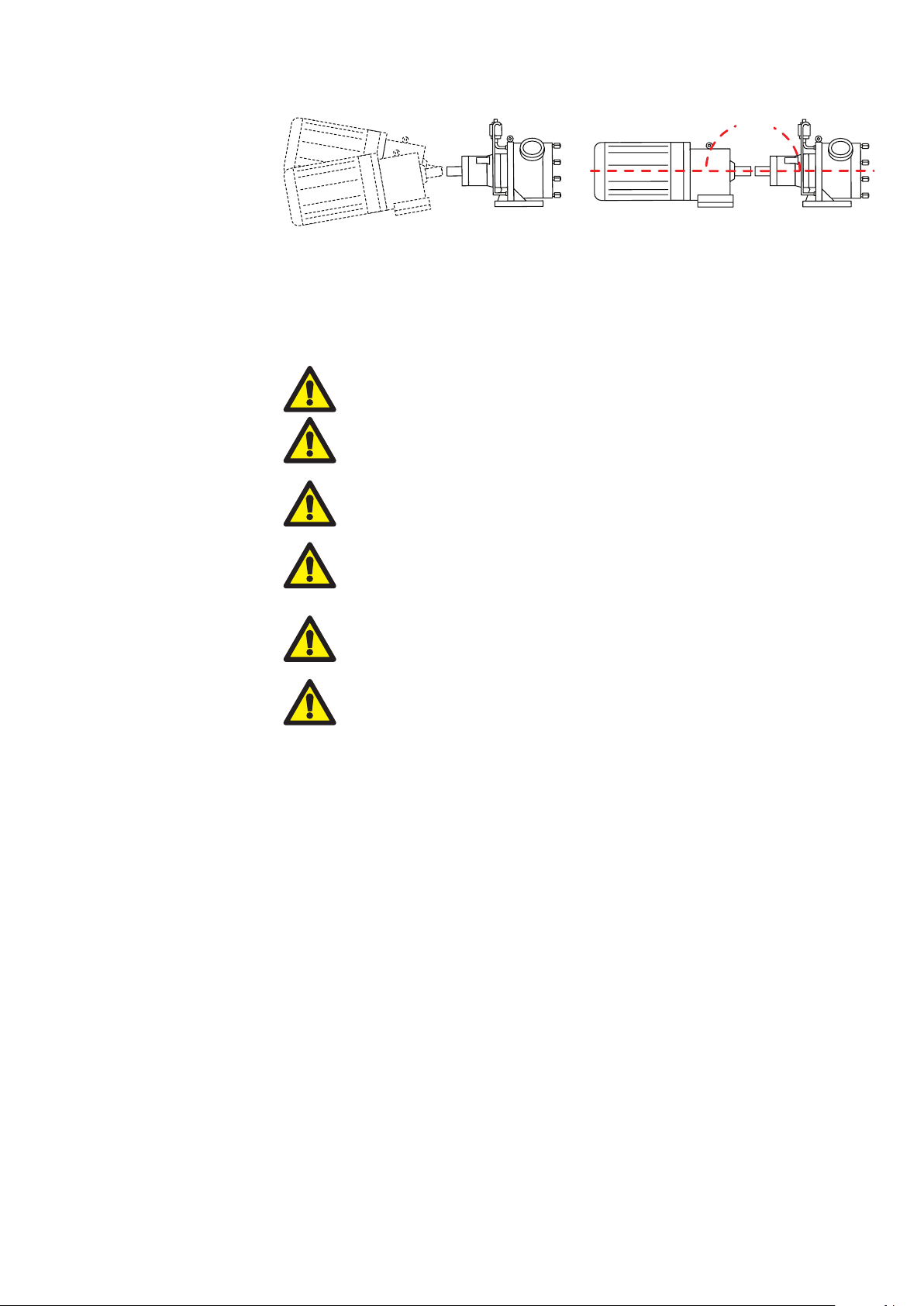

SPS 100 is shown here. All models are similar.

The gate and gate guide

shown inverted to make clear

the gate’s position within the

guide for counter- clockwise

rotor rotation

The gate and gate guide oriented

for clockwise rotor rotation

The gate and gate guide orient-

ed for counter- clockwise rotor

rotation

If the direction of rotation is reversed, change the rotation direction indicator arrows

and mark the suction and pressure ports correspondingly.

Disconnect the pump from the mains power, and secure it against

unintentional start-up. Ensure that the direction change is carried

out by a trained engineer.

l

Follow the dismantling and assembly steps for your pump model. See 22

Dismantling and assembly

l

Take special note of the instructions for fitting the rotor, the gate and the gate

guide

Take care that fluid in the pressure line leaves the pump in an upward direction, so

that when pumping stops, some fluid remains in the pump. This will make it easier

for the pump to draw in viscous products when pumping restarts. This applies

particularly when the pressure connection is horizontal: positions 12-3 and 12-9.

Take care that the pressure line is run so that the pump rotor is always covered with

fluid, and dry running is avoided.

MasoSine SPS sinusoidal pumps User Manual 26

Page 27

14 Connecting this product

to a power supply

The motor must be connected according to local regulations by a qualified

person. See the instruction manual supplied with your drive motor.

15 Start-up and operation

lIf you are starting the pump for the first time, or have performed cleaning or

repair work, check first that all screws are correctly and completely tightened.

lThe pump may have been contaminated during transport. Remove the pump

front cover and clean if necessary before start-up.

lBefore you start the pump, check that the gate and the gate guide are in the

correct orientation in relation to the suction side and the pressure side of the

pump. (See 13.2 Changing rotation direction).

Observe the appropriate regulations if hazardous fluid is

to be pumped.

Ensure that the pump is installed in an appropriate

position with all necessary safety guards and

precautions (sensors, switches, pressure gauges, etc).

MasoSine pumps must be primed before use.

Before commissioning and during operation, the

pump must be filled with fluid, with the fluid level

above the rotor (see diagram). This can be done

manually through a side channel of your system’s

pipework, or by using a vacuum device where very

viscous fluids are to be pumped; contact MasoSine

for further information. The need to prime can

be avoided by leaving product in the pump after

it is stopped; by leaving CIP or SIP fluid in the

pump after cleaning. For ATEX use, fill the pump

away from potentially explosive atmosphere, and

be aware that if the pump runs dry, the tem-

perature limit for the explosive area may be

exceeded.

Fluid

level

MasoSine SPS sinusoidal pumps User Manual 27

Page 28

Make sure before start-up that all valves on the

pressure and suction sides are open. The pump must

not pump against a closed valve without an overpressure valve.

If the pump leaks, stop pumping as quickly as possible

and replace the damaged sealing elements. See 22

Dismantling and assembly and 25.2 Seals.

The operator must ensure that the pump can work free

of cavitation. Cavitation can destroy the pump. See

12.1 Cavitation.

16 Flushing the seal system

Flushing fluid at atmospheric pressure—usually water—flushes the area behind the

seal system and prevents the product from hardening and damaging the seal system. If a static flushing device is fitted, the flushing fluid fills the area behind the

seal.

lCast iron power frame: If no static flushing device is fitted, adapt a fitting and

a tube to the threads of the intake and outlet in the power frame (see diagram

below; models differ) and circulate flushing fluid through the system.

lStainless steel power frame: Make sure that the correct flush ring is installed

with tube connections and circulate flushing fluid through the system.

lThe flushing medium must be at least suitable to the product being pumped. It

should not contain abrasive particles, which would damage the seals. We

recommend that transparent plastic tubes are used as flushing tubes.

lThe pump should be flushed without pressure: the flushing fluid should be

allowed to drain from the system without pressure.

lFill the pump with liquid to prevent it from running dry, possibly via a separate

intake valve connected to the suction or pressure pipe.

lIf your pump is set up for permanent flushing, always check the intake and

outlet (see diagram below).

16.1 Static flushing

device

Intake

Before commissioning, fill the

flushing device (if supplied) with a suitable flushing fluid, depending on the

product being pumped. Fill the sight glass

with flushing fluid until the fluid level is

just below the bend in the outlet pipe.

Outlet

Note: The diagram shows a flushing

device fitted to a pump with a cast iron frame. Pumps with stainless steel frames

are similar.

MasoSine SPS sinusoidal pumps User Manual 28

Page 29

17 Cleaning and sterilisation

MasoSine SPS pumps may be cleaned in place. Please follow our CIP cleaning

instructions—see below.

Maintaining a clean process line is vital to maintain a high level of hygiene and no

contamination of an end-product. Contamination costs time and money.

The heat or chemical reaction from clean-in-place (CIP) and steam-in-place (SIP)

cleaning processes damages a living cell’s essential structures, including the cytoplasmic membrane, rendering the cell no longer viable.

The process automatically re-circulates cleaning detergent and rinse solutions.

The benefits of clean-in-place (CIP) and steam-in-place (SIP)

l

Cleaning is faster

l Cleaning is less labour-intensive

l Cleaning is repeatable

l There is a reduced chance of operators being exposed to hazardous chemicals

Clean-in-place (CIP) for MasoSine products

Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes, vessels,

process equipment and associated fittings without disassembling.

The CIP procedure

l

Before the CIP process begins, a preliminary clean should be performed at

maximum speed with no back pressure. This will remove most of the residual

product.

l

Suitable cleaning fluids for the CIP process may include concentrations below

1% of additives. They may be:

l

Sodium hydroxide in distilled water

l Nitric acid in distilled water

l Phosphoric acid in distilled water

l CIP cleaning can be carried out between 80°C and 90°C as standard.

l Cleaning should be done at maximum pump speed to achieve a good cleaning

result.

l

It is very important that the differential pressure on the discharge side of the

pump is at least 3.0 bar / 43.5 psi higher than the pressure on the suction side

of the pump during the CIP process.

Attention: Keep a minimum distance of 50cm from the pump while

performing high-pressure cleaning.

MasoSine SPS sinusoidal pumps User Manual 29

Page 30

l A choke valve should be

installed in the discharge pipeline immediately after the

pump. Close the choke valve

slowly until the pressure differ-

flow of

cleaning

fluid

X

bar/psiY bar/psi

suction

side

discharge

side

choke

valve

ence is correct.

l The CIP time for the pump is

in accordance with the time

required for system cleaning:

usually 20-40 minutes.

Y-X ≥

3 bar / 43.5 psi

Steam-in-place (SIP) for MasoSine products

Steam sterilisation kills micro-organisms through the application of moist heat

(saturated steam) under pressure without disassembly.

l

Sterilising the pump with standard equipment is possible up to 120°C only at

standstill.

l

The pressure should be high enough to ensure that the steam reaches all parts

of the static pump through the existing clearances.

Class II SIP and CIP

procedure

CIP

Maximum

temperature

80-90°C / 176-194°F

Recommended

pressure differential

3 bar

SIP 120°C / 248°F -

Key CIP and SIP safety information

l A distance of one metre around the pump should be kept clear during SIP to

minimise danger in case of leakage.

l

CIP and SIP processes should be monitored continuously.

l If a leak occurs during CIP or SIP, the pumphead should not be touched until

system pressure has been relieved and the pumphead has been allowed to cool

down.

l

Ensure that an acclimatisation period is observed after SIP before the pump

process is started. The temperature inside a standard pump should not exceed

85C (176F) during operation.

MasoSine SPS sinusoidal pumps User Manual 30

Page 31

18 Heating and cooling option

Special versions of MasoSine

SPS 100, SPS 200, SPS 250, SPS 300,

SPS 400 and SPS 500 pumps can be

heated or cooled to provide the correct temperature for your process—

pumping chocolate or ice cream, for

example—by passing fluid at the temperature required through crescentshaped channels in the pump housing

and the front housing. The pump has

1/4in or 1/8in connections on two

sides through which the heating or

cooling agent flows. The position of

the connections varies depending on

the model. Counter pressure should

not exceed 1 bar.

Note: Most pumps can be retro–fitted

to allow heating and cooling.

Note: The connections on the front cover

may hinder some maintenance work at the

pump. In most cases, the heating / cooling of

the pump housing is sufficient. Maintenance is

not hindered by the connections.

Pump

housing

Front

cover

Note: If a heater is used to maintain a raised

temperature, that temperature must be approved

by MasoSine.

Part numbers for heating and cooling options

SPS 100 SPS 200 SPS 250 SPS 300 SPS 400 SPS 500

MP-HZG-G-

SPS10

MP-HZG-D-

SPS10

MP-HZG-G-

SPS20

MP-HZG-D-

SPS20

MP-HZG-G-

SPS21

MP-HZG-D-

SPS21

MP-HZG-G-

SPS25

MP-HZG-D-

SPS25

MP-HZG-G-

SPS40

MP-HZG-D-

SPS40

MP-HZG-G-

SPS50

MP-HZG-D-

SPS50

MasoSine SPS sinusoidal pumps User Manual 31

Page 32

19 Oil change

SPS 100

Every day before using your pump, check that there is enough grease in the storage

chamber. Remove the vent at A and insert grease through the nipple at B until

grease starts to come out at A. Refit the vent.

Standard first filling, for -10 to 60°C (14 to 140°F): MOLYDUVAL Soraja C532, DIN

51502.

Grease grades for Ex zones:

lAt temperature class T4 (60°C

(140°F) or less: MOLYDUVAL Soraja

C532, DIN 51502.

lAt temperature class T3 (61 to 120°C

(142 to 248°F) or less: MOLYDUVAL

Pegasus KD 460.

SPS 200, SPS 250, SPS 300, SPS

400, SPS 500

B

A

Cast iron

power frame

Stainless

steel power

frame

Every day before using your pump, check

the oil viewing glass at B (see 27 in the

parts list, section 25) in the bearing housing (see 11 in the parts list, section 25.1)

for damage and to confirm that enough oil is in the power frame. The oil should

reach the middle of the glass.

lCheck that the drain plug C is in place and fully tightened.

lOpen port A and fill the power frame with suitable oil (see Note, below) until it

is nearly full.

lClose port A.

lCheck the oil level in viewing glass at B. Do not allow the level to fall below the

viewing glass centre line.

Note: If the pump is intended to be used in an area where ATEX regulations apply,

the oil viewing glass is replaced by a screwed plug.

Note: When a new pump is supplied, it is filled as standard with Klüberoil 4 UH

1-220 N lubrication oil for the food and pharmaceutical industries, which is suitable

for process temperatures between –10°C and 60°C. If the pump is intended to be

used in an area where ATEX regulations apply, only this oil must be used.

C

Filling volumes

SPS 200 SPS 250 SPS 300 SPS 400 SPS 500

Approx 0.10

litre

Approx 0.10

litre

-

Approx 0.10

litre

Approx 0.18

litre

Approx 0.18

litre

Approx 0.38

litre

Approx 0.35

litre

-

Approx 0.45

litre

Dispose of used oil according to local regulations.

Oil or grease needs to be changed at least once a year.

MasoSine SPS sinusoidal pumps User Manual 32

Page 33

20 Troubleshooting

Error Cause Remedy

Direction of rotation not correct Check direction of rotation

No wetting liquid in pump Fill pump with liquid

Screw fastening not tight Check screw fastening

Suction pipe too long Adapt suction pipe

Pump does

not draw in

Pump does

not deliver

Suction pipe too narrow Adapt suction pipe

Shaft seal leaking Check all seals for damage

Wearing parts worn Replace wearing parts

Motor speed not correct Measure and regulate speed

Gate and gate guide wrongly

positioned

Direction of rotation not correct Check direction of rotation

Suction and pressure pipe

confused

Motor speed not correct

Wearing parts worn Replace wearing parts

Gate and gate guide wrongly

positioned

Inserted gate valve closed Check pipe system

Check position (see 13.2

Changing rotation direction)

Check pipe system

Check pump speed against

performance curves—see your

purchase order

Check position (see 13.2

Changing rotation direction)

Pump is

noisy

Pump leaks

Pump leaks

at front

housing

Pump is

blocked

Noises from the drive Consult manufacturer

Noises from the pump Consult manufacturer

Suction pipe too small

(cavitation)

Knocking noises from the

pumphead

Noises from power frame

Coupling not aligned

Sealing system is leaking

O-ring seal leaking Replace O-ring

Lip seal ring on the power

frame leaking, oil escapes

Housing seal not installed or

wrongly installed

Housing seal defective

Foreign body in the pump

Power supply interrupted

Defect in the drive

Shorten suction pipe or increase

diameter, reduce speed

Check for gate valve wear and

replace if necessary

Fill oil, change tapered roller

bearings

Align coupling correctly. See 11

Installation.

Change seal faces,

static / dynamic or lip seals

Dismantle power frame, replace

lip seals

Install housing O-ring correctly

or replace

Install housing O-ring correctly

or replace

Remove foreign body, examine

pump for damage

Check electrical installation and

fuses, check drive

Separate the coupling and turn

the pump by hand to confirm

MasoSine SPS sinusoidal pumps User Manual 33

Page 34

Error Cause Remedy

Severe wear

after short

operating

time

Rotor has

wear on one

side

Pump not

clean after

CIP cleaning

Solids in the pumped fluid

Pumped fluid is abrasive

Rotor not tightened correctly

on installation

Adjusting dimensions changed

after working on the bearing

housing

Cleaning regulation not

complied with. See 17

Cleaning

Change the wearing parts

frequently; check material

compatibility

Choose larger pump, reduce

speed

Tighten shaft nut firmly on

block

Check and correct dimension X:

SPS 200 = 17.5 mm +0.1~

SPS 250 = 17.4 mm +0.1

SPS 300 = 23.0 mm +0.1

SPS 400 = 15.0 mm +0.1

SPS 500 = 25.4 mm +0.1

See 21 Adjusting the shaft

Choke on the pressure side:

Check that the pressure

difference is 3-4 bar

Rotor has

seized on

liner

Flushing

material between

housing and

power frame

leaking

Water or

pumped

material in

the bearing

housing

Front

Support has

seized on

Rotor

Product is

leaking from

the bearing housing

openings

Rotor not correctly tightened Tighten shaft nut firmly on block

Temperature too high

(thermal expansion)

O-ring in the power frame

missing or defective

Flushing pressure too high

Leakage bores—bore holes

in the power frame where

pumped material can escape if

the seal system leaks—

blocked (see graphic on page

32)

O-ring in the front bearing

missing or worn

Front bearing wrongly installed

Sealing system in the pump is

leaking

Choose liner with larger

tolerances

Install or replace O-ring

Flushing must be pressureless (attach pressure reducer,

maximum 0.1 bar)

Check leakage bores for free

passage, replace shaft seals on

pump and power frame

Install or replace O-ring

Examine front bearing for

damage and install in correct

position

Inspect and if necessary

replace the sealing system and

clean the rinsing channels in

the power frame

Pump

assembly

subject to

vibrations

Smells

and smoke

coming from

the pump

Corrosion Corrosion occurs

MasoSine SPS sinusoidal pumps User Manual 34

Speed of the drive motor is

too high

Pump is running dry

Lower the speed of the drive

motor

Stop the pump immediately.

Check inner parts for damage

and replace if necessary

Eliminate corrosion;

lacquer or use spray oil

Page 35

SPS 200,

SPS 300,

SPS 400 pumps

21 SPS 200, SPS 300 and SPS 400:

Adjusting the shaft

It is important that dimension X is correct to achieve efficient pumping.

Note: Dimension X in all pumps may be measured as below. However, the structure

of the SPS 100 pump casing is different from other models (and not as shown here)

and SPS 100 dimension X is adjusted differently. SPS 100 pumps must be returned

to MasoSine for dimension X adjustment.

21.1 Adjusting dimension X in models

with cast power frame

Lip seals

Power frame

Shim ring

Bearing housing

Shaft

Bearing housing

retaining screw

Dimension X

Leakage bore

Dimension X

SPS 100 SPS 200 SPS 300 SPS 400

10.0mm +0.05 17.5mm +0.1 23.0mm +0.1 15.0mm +0.1

SPS 200, SPS 300 and SPS 400: adjusting dimension X

Note: SPS 100 pumps must be returned to MasoSine for dimension X adjustment.

Remove the front cover, the front support, the front liner, the rotor, the gate

l

and the gate guide. See 22 Dismantling and assembly.

lMeasure dimension X.

lCheck this dimension against the table above.

MasoSine SPS sinusoidal pumps User Manual 35

Page 36

SPS 200,

SPS 300,

SPS 400 pumps

lIf this dimension is not correct, continue disassembly (see 22 Dismantling and

assembly) until the face of the power frame is accessible (the SPS 300 and the

SPS 200 pumps are shown here; the SPS 400 is similar).

lUse a 6mm Allen key to loosen and remove the bearing housing retaining

screws and copper washers (arrowed; the number of screws varies with pump

model.)

lRemove the bearing housing and the pump shaft, being careful not to dam-

age the lip seals (arrowed). Note: lubricating oil will spill out as the bearing

housing is removed.

lRemove the shim ring (arrowed in the three lower pictures) and install a new

one. Reassamble, tightening the bearing housing retaining screws to 25Nm

(SPS 200) 50Nm (SPS 300) 35Nm (SPS 400), and measure dimension X again.

lIf this dimension is not correct (see table), disassemble and peel layers from

the shim ring equal in total thickness to the difference between the

re-measured distance and the correct distance, so that the correct dimension X

is achieved. One layer is 0.05mm thick.

lReassemble.

MasoSine SPS sinusoidal pumps User Manual 36

Page 37

21.2 Adjusting dimension X in models

with stainless steel power frame

Power frame

Power frame

Shim ring

Shim ring

Lip seals

Lip seals

Bearing housing

Bearing housing

Shaft

Shaft

Vernier

Vernier

Bearing housing

Bearing housing

retaining screw

retaining screw

Dimension X

Dimension X

Dimension X

SPS 100 SPS 200 SPS 250 SPS 300 SPS 400 SPS 500

10.0mm

+0.05

17.5mm

+0.1

17.4mm

+0.1

23.0mm

+0.1

15.0mm

+0.1

25.4mm

+0.1

SPS 200, SPS 250, SPS 300, SPS 400 and SPS 500: adjusting

dimension X

Note: SPS 100 pumps must be returned to MasoSine for dimension X adjustment.

Remove the front cover, the front support, the front liner, the rotor, the gate

l

and the gate guide. See 22 Dismantling and assembly.

lMeasure dimension X.

lCheck this dimension against the table above.

MasoSine SPS sinusoidal pumps User Manual 37

Page 38

SPS 200,

SPS 300,

SPS 400 pumps

l

If this dimension is not correct, use a wrench to loosen and remove the screws

securing the bearing housing to the power frame (arrowed; the number of screws

varies with pump model).

For SPS 200: 13mm wrench

For SPS 250: 13mm wrench

For SPS 300: 16mm wrench

For SPS 400: 18mm wrench

For SPS 500: 18mm wrench

lRemove the bearing housing and the pump shaft, being careful not to damage

lip seals (arrowed).

lRemove the shim ring (arrowed) and install a new one between the power

frame and the bearing housing. Reassamble, tightening the bearing housing

retaining screws as follows:

For SPS 200 M8: 16 Nm

For SPS 250 M8: 16 Nm

For SPS 300 M10: 33 Nm

For SPS 400 M12: 56 Nm

For SPS 500 M12: 56 Nm

and measure dimension X again.

lIf this dimension is not correct (see table), disassemble and peel layers from

the shim ring equal in total thickness to the difference between the re-meas-

ured distance and the correct distance, so that the correct dimension X is

achieved. One layer is 0.05mm thick.

lReassemble.

MasoSine SPS sinusoidal pumps User Manual 38

Page 39

22 Dismantling and assembly

22.1 Dismantling all models

Disconnect the pump from the mains power, and secure it against

unintentional start-up.

Removing the static flushing device (if supplied)

See 25.4 Parts: static flushing device

The flushing device must be emptied and removed before dismantling the pump.

See 23 The static flushing device.

SPS 100 pumps

22.2 Dismantling and assembling the

SPS 100

22.2.1 Dismantling the SPS 100

Removing the front cover

lUse a 22mm spanner to remove the cap nuts (right-hand thread) and

washers.

lLightly tap the two front cover pins if necessary and use them to pull off the

cover.

lYou can now access the front cover O-ring (arrowed in the first picture on the

next page) in its groove in the front cover.

MasoSine SPS sinusoidal pumps User Manual 39

Page 40

SPS 100 pumps

Removing the locking nut

It is important to ensure that the shaft cannot rotate while the shaft nut is removed.

If necessary, it may conveniently be secured using a well-padded wrench on the

shaft and the key or keyway. A blocking tool for the shaft is optionally available for

easy opening of the locking screw: (SPS 100: TL-SP10-010-31).

lUse a 17mm spanner to remove the locking nut from the end of the shaft

(right-hand thread).

The locking nut

MasoSine SPS sinusoidal pumps User Manual 40

Page 41

SPS 100 pumps

Removing the front liner and the front bushing

lPull the front liner to remove it.

Note: You may find it convenient to turn the pump shaft and rotor a little to create

space for your fingertips to grasp the top of the front liner.

lRemove the front bushing.

lYou can now access the rotor front O-ring (arrowed) in its groove in the rotor

front.

MasoSine SPS sinusoidal pumps User Manual 41

Page 42

SPS 100 pumps

Removing the rotor, the gate and the gate guide

lNote the orientation of the gate and the gate guide so that they can be refitted

in the same orientation. This is important because if the gate guide is refitted

in the wrong orientation the pump will not work properly and the gate guide

can be damaged. Use two hands to remove the rotor, the gate and the gate

guide together.

The gate and gate guide

shown inverted to make clear

the gate’s position within the

guide for counter- clockwise

rotor rotation

MasoSine SPS sinusoidal pumps User Manual 42

Page 43

SPS 100 pumps

Removing the rear liner

lPull the rear liner to remove it.

SPS 100 pumps

with a single

mechanical seal

Removing the mechanical seal and the static face

lRemove the mechanical seal. You can now access the mechanical seal O-rings.

lRemove the static face. You can now access the static face O-ring. Note: If

the static face cannot be removed by hand, it can be removed with the sealing

system (see Removing the sealing system).

The static face with its O-ring, left, the

mechanical seal with one of its O-rings

visible and the back bushing

MasoSine SPS sinusoidal pumps User Manual 43

Page 44

SPS 100 pumps

with a triple lip

seal

Removing the distance piece and the back bushing

lRemove the distance piece. You can now access the distance piece O-ring.

lRemove the back bushing.

The distance piece The front and back bushing.

They are identical

MasoSine SPS sinusoidal pumps User Manual 44

Page 45

SPS 100 pumps

Removing the sealing system

Note: If your SPS 100 pump is fitted with a static flushing system, this must be

removed before removing the sealing system. See 23 The static flushing device.

lUse the special tools supplied with the pump to remove the seal housing.

lPosition the pointed ends of the special tools to apply leverage to opposite

sides of the seal housing at once: first, to the castellations of the seal housing;

then to the end of the seal housing.

Direction of

movement

Second

leverage

point

First

leverage

point

Second

leverage

point

MasoSine SPS sinusoidal pumps User Manual 45

Page 46

SPS 100 pumps

lReverse the special tools and use the angled ends in the same way to apply

further leverage to the end of the seal housing, until it is accessible within the

pump chamber. Remove it.

The two versions of the SPS 100 pump

seal housing: left, where no static flushing system is fitted; right, where a static

flushing system is fitted

Disassembling the seals

lGraphics making clear how to disassemble and assemble the seals appear in

section 25.2.

MasoSine SPS sinusoidal pumps User Manual 46

Page 47

SPS 100 pumps

22.2.2 Assembling the SPS 100

During assembly, check that all O-rings are properly positioned before fitting each

component, and that all components are clean and lubricated.

Fitting the seal housing

The two versions of the SPS 100 pump

seal housing: left, where no static flushing system is fitted; right, where a static

flushing system is fitted

lPush the reassembled seal housing into position, castellations first. Make sure

it is pressed all the way home. This can be done using the special tools as

pushers, or using a special cylindrical tool which is available from MasoSine.

Note: If a static flushing device is to be fitted, align the threaded sockets on

both sides of the seal housing vertically, so they are central to the top hole in

the bearing housing. See 23 The static flushing device.

MasoSine SPS sinusoidal pumps User Manual 47

Page 48

SPS 100 pumps

with a single

mechanical seal

Fitting the static face and the mechanical seal

lCheck that the static face’s O-ring is properly positioned and that the O-rings

either side of the mechanical seal are properly positioned.

The static face with its O-ring, left,

and the mechanical seal with one of

its O-rings visible. The surfaces of the

two components seen here must come

together on reassembly. The back

bushing is seen, right

lPosition the static face in the mechanical seal, with the static face’s O-ring

facing the mechanical seal. The static face has two recesses (arrowed) which

must be correctly aligned with lugs (arrowed) either side of its seat

lUse a finger to retain the static face in position on the mechanical seal and

push them on to the pump shaft and all the way home into the pump housing.

Note: The mechanical seal has a lug on its inner surface which must be aligned

with the shaft splines.

MasoSine SPS sinusoidal pumps User Manual 48

Page 49

SPS 100 pumps

with a triple lip

seal

Pumps with a triple lip seal: fitting the distance piece

lCheck that the distance piece O-ring is in position.

lPush the distance piece into position, flanged end first.

Pumps with a triple lip seal: fitting the back bushing

SPS 100 pumps

lPush the back bushing into position, thick end (arrowed) first. (The two

bushings are identical.)

Fitting the rear liner

lPush the rear liner into position, pushing evenly at both ends so that it does

not jam. The anti-rotation pins within the pump housing (arrowed) guarantee

that the liner is properly positioned. The two liners are identical.

MasoSine SPS sinusoidal pumps User Manual 49

Page 50

SPS 100 pumps

Fitting the rotor, the gate and the gate guide

Note gate orienta-

tion

within the

guide

This end

in first

The gate and gate guide inverted to

show the gate’s position within the

guide for counter- clockwise rotor

rotation

Pressure

side

The gate and

gate guide oriented for

clockwise rotor rotation

lCheck that the rotor O-ring is in position.

lPosition the gate within the gate guide and hold as one unit.

Check that the gate and gate guide are correctly oriented for the

desired sense of rotor rotation. This is critical for

proper operation.

Suction

side

Suction

side

The gate and gate guide orient-

ed for counter- clockwise rotor

rotation

The rotor

Pressure

side

lHold the rotor vane in the slot of the gate, with the larger diameter end of

the rotor bush away from you. Position the rotor, the gate and the gate guide

together. Push the assembly into position. The gate and gate guide slide freely

into their channel; the splines within the rotor hub must be aligned with the

shaft splines.

lEnsure that the rotor is pushed all the way home.

MasoSine SPS sinusoidal pumps User Manual 50

Page 51

SPS 100 pumps

Fitting the front bushing and the front liner

lPush the front bushing into position, thick end (arrowed) first. (The two

bushings are identical.) Note

bushings.

lPush the front liner into position, pushing evenly at both ends so that it does

not jam. The anti-rotation pins within the pump housing (arrowed) guarantee

that the liner is properly positioned. The two liners are identical.

: Pumps are fitted with identical front and rear

MasoSine SPS sinusoidal pumps User Manual 51

Page 52

SPS 100 pumps

Fitting the locking nut

The locking nut

It is important to ensure that the shaft cannot rotate while the shaft nut is fitted. If

necessary, it may conveniently be secured using a well-padded wrench on the shaft

and the key or keyway. A blocking tool for the shaft is optionally available for easy

opening of the locking screw: (SPS 100: TL-SP10-010-31).

lUse a 17mm spanner to tighten the locking nut to 100Nm (right-hand

thread).

Fitting the front cover

lCheck that the front cover O-ring (arrowed above) is in its groove in the front

cover.

lFit the front cover over the shaft and the pump housing studs.

lFit the cap nuts (right-hand thread) and washers to the pump housing studs.

Use a 22mm spanner. Tighten them to 35Nm.

MasoSine SPS sinusoidal pumps User Manual 52

Page 53

SPS 200 pumps

22.3 Dismantling and assembling the

SPS 200

22.3.1 Dismantling the SPS 200

Note: The pictures show a pump with a cast iron power frame. Dismantling

models with stainless steel power frame is similar. For exceptions, see page 62.

Removing the front cover

lUse a 22mm spanner to remove the cap nuts (right-hand thread) and

washers.

lLightly tap the two front cover pins if necessary and use them to pull off the

cover.

Removing the front support, PEEK or stainless steel

The PEEK front support The stainless steel front support

MasoSine SPS sinusoidal pumps User Manual 53

Page 54

SPS 200 pumps

The front support may come off the shaft with the front cover, as pictured (PEEK

support: top pictures; stainless steel support: lower pictures), or it may remain on

the shaft. Note: the PEEK front support is breakable.

l

Remove the front support.

You can now access the front cover O-ring (arrowed) in its groove in the front cover.

MasoSine SPS sinusoidal pumps User Manual 54

Page 55

SPS 200 pumps

Removing the front liner

lPull the front liner to remove it.

Note: You may find it convenient to turn the pump shaft and rotor a little to create

space for your fingertips to grasp the top of the front liner.

Removing the shaft locking screw

It is important to ensure that the shaft cannot rotate while the shaft locking screw

is removed. It may be convenient to secure it using a tommy bar or a spanner

handle between the spider castellations on the drive shaft. Alternatively, a wellpadded wrench can be used on the shaft and the key or keyway. A blocking tool for

the shaft is optionally available for easy opening of the locking screw: (SPS 200:

TL-SP20-010-31).

lUse the 32mm ring spanner supplied with the pump to remove the locking

screw from the end of the shaft (left-hand thread).

lYou can now access the shaft nut O-ring in its groove in the shaft nut.

The shaft locking screw

MasoSine SPS sinusoidal pumps User Manual 55

Page 56

SPS 200 pumps

Removing the shaft nut

It is important to ensure that the shaft cannot rotate while the shaft nut is removed.

If the motor is fitted to the pump, its torque should be enough to secure the shaft.

If it is not secure, uncouple the pump from the motor and secure the shaft using a

tommy bar or a spanner handle between the spider castellations on the drive shaft.

Alternatively, a well-padded wrench can be used on the shaft and the key or keyway.

lUse the 32mm ring spanner supplied with the pump to remove the shaft nut

from the end of the shaft (right-hand thread).

lYou can now access the rotor front O-ring (arrowed) in its groove in the rotor

front.

The shaft nut

MasoSine SPS sinusoidal pumps User Manual 56

Page 57

SPS 200 pumps

Removing the rotor, the gate and the gate guide

lNote the orientation of the gate and the gate guide so that they can be refitted

in the same orientation. Use two hands to remove the rotor, the gate and the

gate guide together.

lYou can now access the rotor rear O-ring in its groove in the rotor rear.

The gate and gate guide

MasoSine SPS sinusoidal pumps User Manual 57

Page 58

SPS 200 pumps

with a single

mechanical seal

Pumps with a single mechanical seal: removing the rear liner and

the backing ring

lPull the rear liner to remove it.

lThe backing ring may remain on the shaft or it may come off the shaft with the

rear liner.

lRemove the backing ring.

The backing ring

MasoSine SPS sinusoidal pumps User Manual 58

Page 59

SPS 200 pumps

with a single

mechanical seal

Pumps with a single mechanical seal: removing the dynamic ring

holder

lPull the dynamic ring holder to remove it.

The dynamic ring holder

MasoSine SPS sinusoidal pumps User Manual 59

Page 60

SPS 200 pumps

with a single

mechanical seal

Pumps with a cast iron power frame and a single mechanical seal:

dismantling the pump housing

Note: See page 62 for dismantling the pump housing of a pump with a stainless

steel power frame.

lUse a 13mm spanner to loosen and remove the two screws (right-

hand thread) and washers which secure the pump housing to the

power frame.

lIf necessary, gently tap the pump housing with a soft hammer to free

it. Withdraw the pump housing carefully.

Note: the pump housing is heavy.

MasoSine SPS sinusoidal pumps User Manual 60

Page 61

SPS 200 pumps

with a single

mechanical seal

Pumps with a single mechanical seal: removing the seal and the

static face

lRemove the mechanical seal from the rear of the pump housing.

lRemove the static face from the mechanical seal.

lYou can now access the seal housing O-ring in its groove in the pump housing

(arrowed above), and the two O-rings in the mechanical seal (arrowed below).

Note: The mechanical seal is a tight push fit.

The mechanical sealThe static face

Pumps with a single mechanical seal: fitting the seal

lA graphic making clear how to disassemble and assemble the seal appears in

section 25.2.

MasoSine SPS sinusoidal pumps User Manual 61

Page 62

SPS 200 pumps

with a triple lip

seal

Pumps with a triple lip seal seal: removing the rear liner

lPull the rear liner to remove it.

Pumps with a triple lip seal: removing the sealing system

lPull the seal housing fitted with the shaft sleeve to remove it.

shaft sleeve

lip seals

seal housing

lRemove the shaft sleeve from the seal housing.

MasoSine SPS sinusoidal pumps User Manual 62

Page 63

SPS 200 pumps

with a triple lip

seal

Pumps with a triple lip seal: removing the pump housing

lUse a 13mm spanner to loosen and remove the two screws (right-