Warner Electric EM-50, EM-100, EM-180, EM-210, EM-215 User Manual

P-213

819-0303

Electro-Module EM-50,

EM-100, EM-180, EM-210, EM-215

Service & Installation Instructions

An Altra Industrial Motion Company

Contents

Pre-Installation Instructions

Pre-Installation Instructions . . . . . . . . . . . . . . . .2

Installation Instructions . . . . . . . . . . . . . . . . . . .4

Setting Airgap . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Coil Data . . . . . . . . . . . . . . . . . . . . . .8

Burnishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . .9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Overhung Load Data . . . . . . . . . . . . . . . . . . . .11

Dimensions and Specifications

EM-50-10 . . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-100-10 . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-180-10 . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-210-10 . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-50-20 . . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-100-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-180-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-210-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-215-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-50-30 . . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-100-30 . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-180-30 . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-210-30 . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-50-40 . . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-100-40 . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-180-40 . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-210-40 . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-10-20 . . . . . . . . . . . . . . . . . . . . . . . . . .16

EM-10-40 . . . . . . . . . . . . . . . . . . . . . . . . . .17

EM-20-30 . . . . . . . . . . . . . . . . . . . . . . . . . .18

EM-30-40 . . . . . . . . . . . . . . . . . . . . . . . . .19

NEMA Frame Standards . . . . . . . . . . . . . .20

Warranty . . . . . . . . . . . . . . . . . . . .Back Page

A. Before installing the Electro-Module to a

motor or reducer, make certain that the EM

size and NEMA frame dimensions match

according to Table 1.

Corresponding

EM NEMA Shaft C-Face

Size Frame Sizes Dia. Pilot Dia.

50 48Y/56C 5/8 4-1/2

100 48Y/56C 5/8 4-1/2

180 143TC/145TC 7/8 4-1/2

210 182TC/213TC 1-1/8 8-1/2

215 213TC/215TC 1-3/8 8 1/2

Table 1

B. Check the motor for shaft endplay. If the

shaft can be moved axially .030” or more, the

module should not be installed since excessive thrust may occur between the rotor and

field. The motor should not be used unless

the endplay can be reduced.

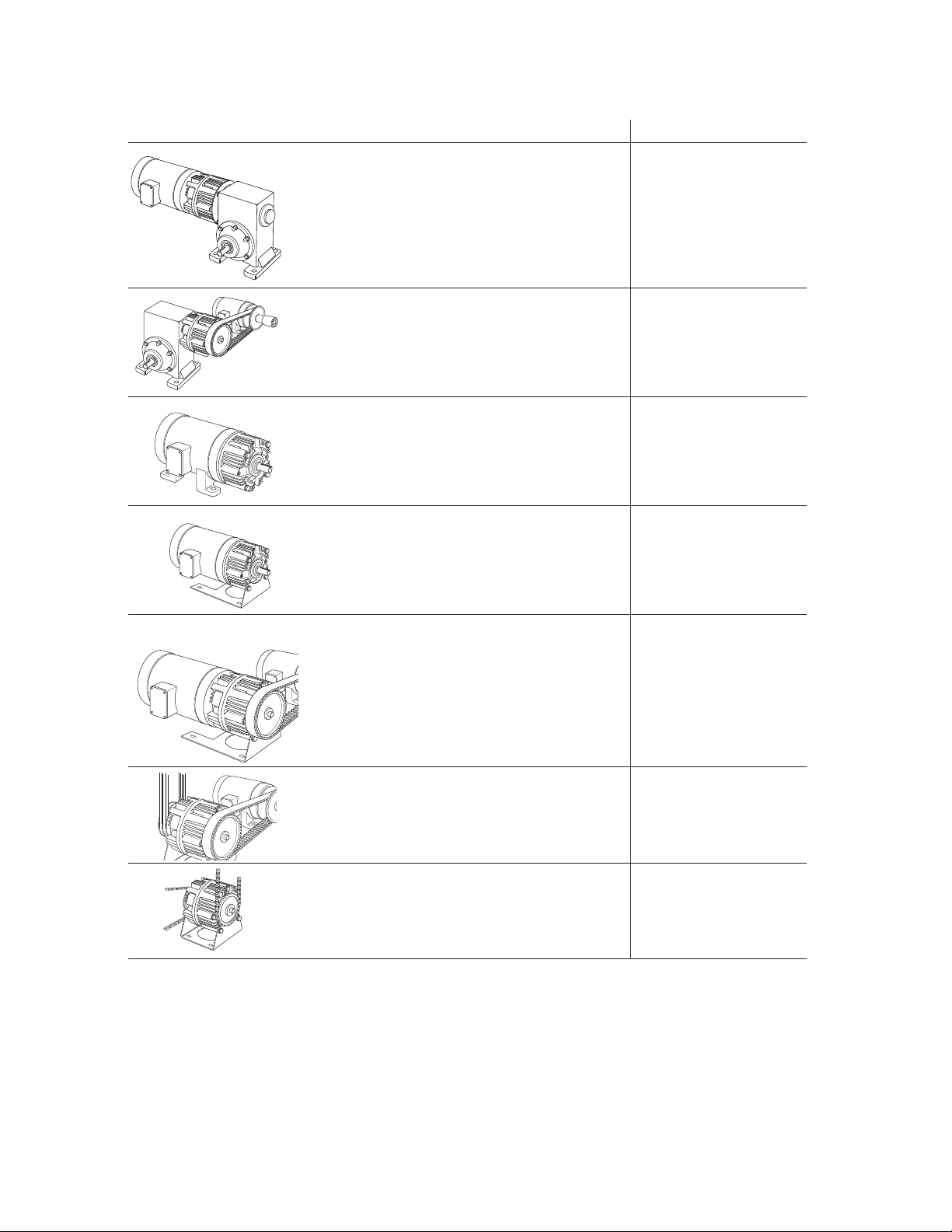

C. Install your specific modular combination

according to the installation steps specified

in Table 2. Use only those steps indicated for

each combination.

Failure to follow these instructions may result in product damage, equipment

damage, serious or fatal injury to personnel.

Warner Electric • 800-825-9050 P-213 • 819-0303

2

For these EM combinations: Use sections:

Electro Module Clutch-Brake Between A, B, C, G, H, I

C-Face Motor and Reducer – 10-20

Electro Module Clutch Between A, B, C, G, H, I

Motor and Reducer – 10-40

Electro Module Clutch Brake – 20-30 B, C, G, H, I

Electro Module Clutch – 30-40 B, C, G, H, I

Electro Module Brake D, C, G, H, I

on C-Face Motor – 20

Motor Mount Electro Module C, E, H, I

Clutch-Brake on C-Face Motor – 20-M

Motor Mount Electro Module ClutchBrake on C-Face Motor – 10-20-M A, B, C, E, H, I

Motor Mount Electro Module Clutch A, B, C, E, H, I

on C-Face Motor – 10-40-M

Base-Mounted B, C, F, H, I

Electro Module Clutch-Brake – 20-30-B

Base-Mounted B, C, F, H, I

Electro Module Clutch – 30-40-B

Table 2

Warner Electric • 800-825-9050 P-213 • 819-0303

3

Installation Instructions

Section A: Mounting the Motor Clutch Module

(10 Module)

1. Examine the clutch adapter. Note that there

are gaps between the housing fins on roughly

half of the circumference of the unit. Mount

the clutch adapter with the open gaps down.

This will keep contaminants from falling into

the unit. There are four screws and washers.

These will be bolted through the adapter onto

the four holes in the face of the motor (See

Figure 1).

3. Slide the rotor onto the motor shaft. (See

Figure 3) Make sure the rotor hub slides

easily onto the shaft. If the fit is too tight,

polish the shaft with emery paper so the hub

will slide on easily. Do not use a hammer or

force the rotor hub onto the shaft. Slide the

rotor back off the shaft.

Figure 1

2. Look at the back side of the rotor and note

there are cardboard spacer buttons as

depicted in figure 2.

Figure 2

Figure 3

4. Insert key onto the shaft. Prick punch the

motor shaft keyway at the end of the key to

prevent the key from sliding out. Slide the

rotor onto the motor shaft until it bottoms

against the field.

5. Using an Allen Wrench securely tighten the

two setscrews in the rotor hub. (See Figure 4)

When the motor is turned on, the spacer buttons will quickly wear away and provide the

proper gap between the field and rotor. The

setscrews are accessible from the front of the

rotor on sizes 100, 180, 210, and from behind

the rotor on size 50 units.

Figure 4

Warner Electric • 800-825-9050 P-213 • 819-0303

4

Section B: Bolting Two Modules Together

The brake module (20) and/or output clutch

module (40) may be assembled to the mounted

motor clutch module (10) or the input clutch (30).

1. Position the modules so that, in the usual

horizontal position, the ventilation holes are

down to prevent foreign matter from falling

into the units.

2. Bolt the modules together with the long hex

head bolts that are provided, see figure 5.

Mating pilot diameters assure proper alignment between module assemblies.

3. Proceed to Section C

Figure 6

Figure 5

Section C: Adjusting Airgap

For new installations it is necessary to adjust the

airgap between the friction faces of the clutch

and/or brake.

To set the airgap for an Electro-Module (EM) you

will need to access the armatures. On an EM

there are gaps between the fins on the housing

on 1/2 of the unit circumference. When looking

through this gap, you will see the fan on the

clutch rotor. In that fan there is a 1/2 x 1 inch

window. It is possible to look inside the unit and

see the armatures by looking through this window. When looking through this window you will

be looking between the two armatures of a

clutch/brake unit as shown in figures 6 and 7.

Figure 7

If the armature for either the clutch or the brake

is too far away from its mating friction surface, it

is possible to move this back into adjustment

using a flat blade screwdriver between the two

armatures. See figure 8.

Figure 8

Warner Electric • 800-825-9050 P-213 • 819-0303

5

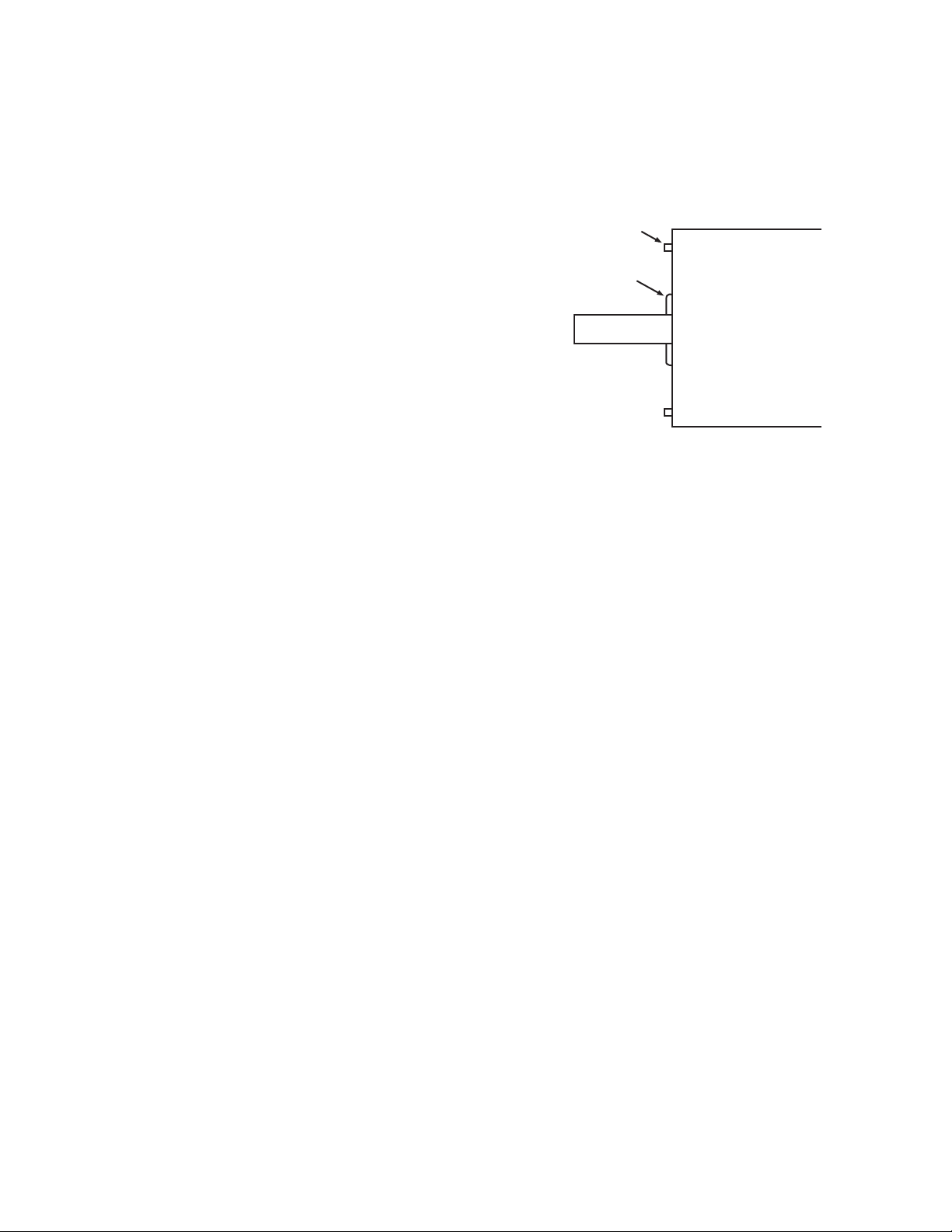

This is a three step process.

C-face mounting

If this boss extends

beyond the C-face

surface use the

spacer.

Do not use spacer

if boss is below the

C-face surface.

1. Simply slide the screwdriver through the

window and press the armature toward its mating friction surface.

2. Rotate the output of the unit. The rotor and the

window should stay in place when you do this.

Only the armatures will move. Rotating the

rotor will move the window.

3. Repeat steps 1 & 2 to ensure that the airgap

between armature and its mating friction surface is about 1/32” and that the armature is

kept square. (If the armature is cocked, it may

engage on one rim, giving the appearance of

engagement but failing to provide full torque.)

3. When using the EM-180-20 a possible interference may exist between the splined armature hub and some motors. (See Figure 10) A

spacer ring is provided with the EM-180

mounting accessory to provide the necessary

running clearance.

Section D: Mounting the Brake to a Motor

The brake module (20) can be mounted directly

to a motor.

1. Insert a key in the motor shaft keyway. Prick

punch the end of the (EM-50 and EM-100)

motor shaft keyway to prevent the key from

sliding out.

2. A set collar is provided in the EM-180 and

EM-210 mounting accessory to prevent the

key from sliding out. Slide the set collar up

against the motor bearing and tighten the

setscrew securely. (Figure 9)

Figure 10

Place the spacer ring between the brake

module housing and the C-face of the motor

when bolting the two units together.

4. Align the motor shaft and key with the mating

shaft hole and key slot in the brake module.

5. Secure brake module to the motor C-face with

the four (4) long 3/8-inch hex head capscrews.

Section E: Installing the Motor Mount (M)

A Motor Mount (M) can be installed to the brake

or output clutch module to provide a foot mounting for the complete assembly of module and

motor.

1. Remove the two (2) long hex head bolts from

the side of the module toward the ventilation

holes.

Warner Electric • 800-825-9050 P-213 • 819-0303

6

2. Mount the module on the Motor Mount so that

the base of the Motor Mount is underneath

the modules and motor. (See Figure 11) A pilot

diameter on the module mates with a pilot

diameter on the Motor Mount.

Figure 9

Figure 11

3. Secure the Motor Mount in place with two (2)

longer mounting bolts and the two shorter

bolts all provided in the kit.

Section F: Installing the Base Mount

Section G: Mounting to a Reducer

The output side of a brake (20) or output clutch

(40) module may be mounted directly to a reducer.

1. Align the output shaft and key of the modules

with the corresponding shaft hole and keyway

of the reducer. Slide the assembly together,

matching the pilot diameter on the module with

a pilot diameter on the reducer. (Figure 13)

Modules 20-30 and 30-40 can be base-mounted.

1. Mount the modules so that the base is located

below the ventilation holes. A pilot diameter

on the end of each module mates with pilot

diameters on the base.

2. Secure the base to the modules with the four

(4) bolts provided. (Figure 12)

Figure 12

Figure 13

2. Bolt the module to the reducer flange. The

four (4) bolts required (3/8 - 16 UNC-2A) are

normally furnished with the reducer.

Section H: Electrical Connections

The conduit connection hole in the motor clutch

module (10), brake (20), and input clutch (30) are

threaded for standard conduit connectors. The

wiring diagram, included with each Warner Electric

control shows the proper electrical connections

that must be made. (Control Service Manual P-239

includes complete information on all standard

control power supplies.)

For clutch/brake combinations, connect the red

wire from one module and the black wire from the

other module to the same terminal of the DC supply. With most basic Warner Electric controls, one

terminal is normally used for two connections –

one from the brake and one from the clutch.

For wiring of clutches, brakes, and clutch/brake

combinations consult manual P-239 for the wiring

diagram of the control being used. These

clutch/brakes are not polarity sensitive.

Warner Electric • 800-825-9050 P-213 • 819-0303

7

Loading...

Loading...